Page 1

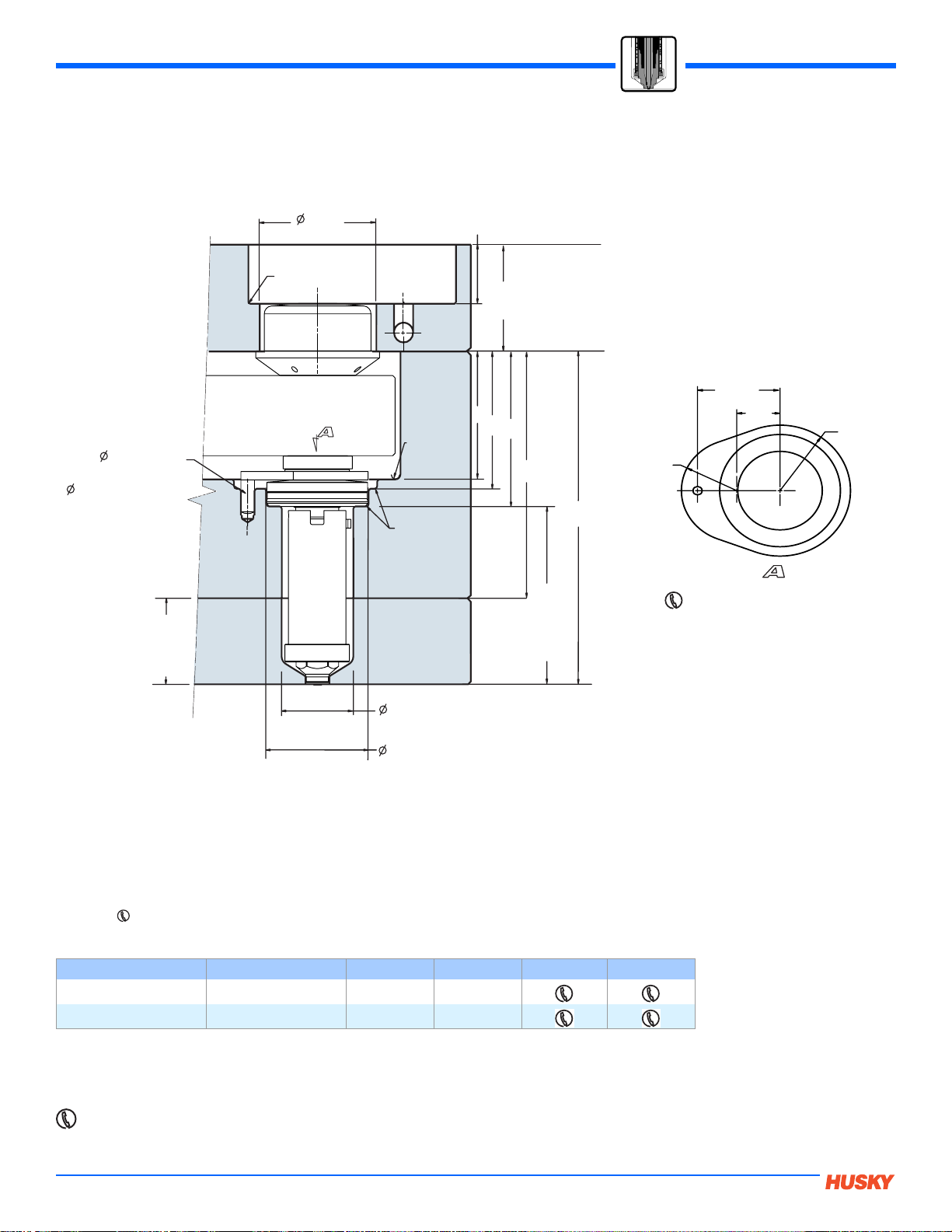

Nozzle Selection Ultra 1000

ULTRA 1000 DESIGN INFORMATION

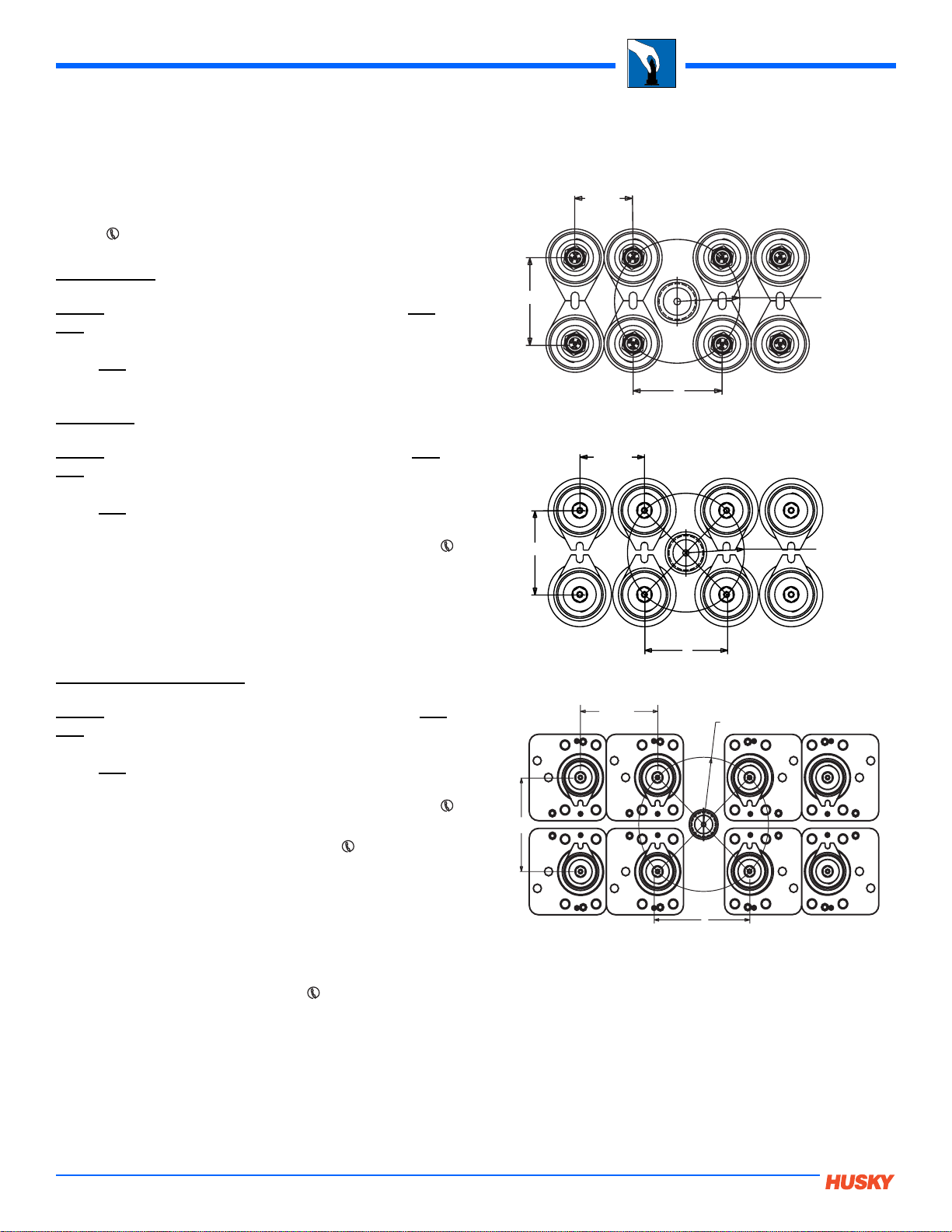

Ultra 1000 Nozzle Pitch

Minimum nozzle pitch dimensions for the Ultra 1000 nozzle are

provided on the right and below. For applications that exceed 8

drops, .

Thermal Gate

NOTE:The sprue minimum radius 50.0 mm (1.97") and the X

and

Y minimum distances must all be satisfied.

•X and

Valve Gate

NOTE: The sprue minimum radius 72.0 mm (2.83") and the X

and

•X and

• For VG/VX pitches greater than 500.0 mm (19.69")

Y must be greater than 70.7 mm (2.78").

Y minimum distances must all be satisfied.

Y must be greater than 101.8 mm (4.01").

Thermal Gate

61.00

[2.40]

Y

R 50.0

[1.97]

X

Valve Gate

75.0

[2.95]

Y

R 72.0

[2.83]

Valve Gate (With Airplate)

NOTE: The sprue minimum radius 115.0 mm (4.53") and the X

and

Y minimum distances must all be satisfied.

•X and

• For VG/VX pitches greater than 500.0 mm (19.69")

• For applications that exceed 8 drops

NOTE: Minimum distance between outermost nozzle drop center

to outer edge of the manifold plate is 1 25mm (4.921”). If reduced

distance is required, contact Husky.

Y must be greater than 162.6 mm (6.40").

X

Valve Gate (With Airplate)

121.0

[4.76]

Y

R 115.0

[4.53]

X

2006.08

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

114

Page 2

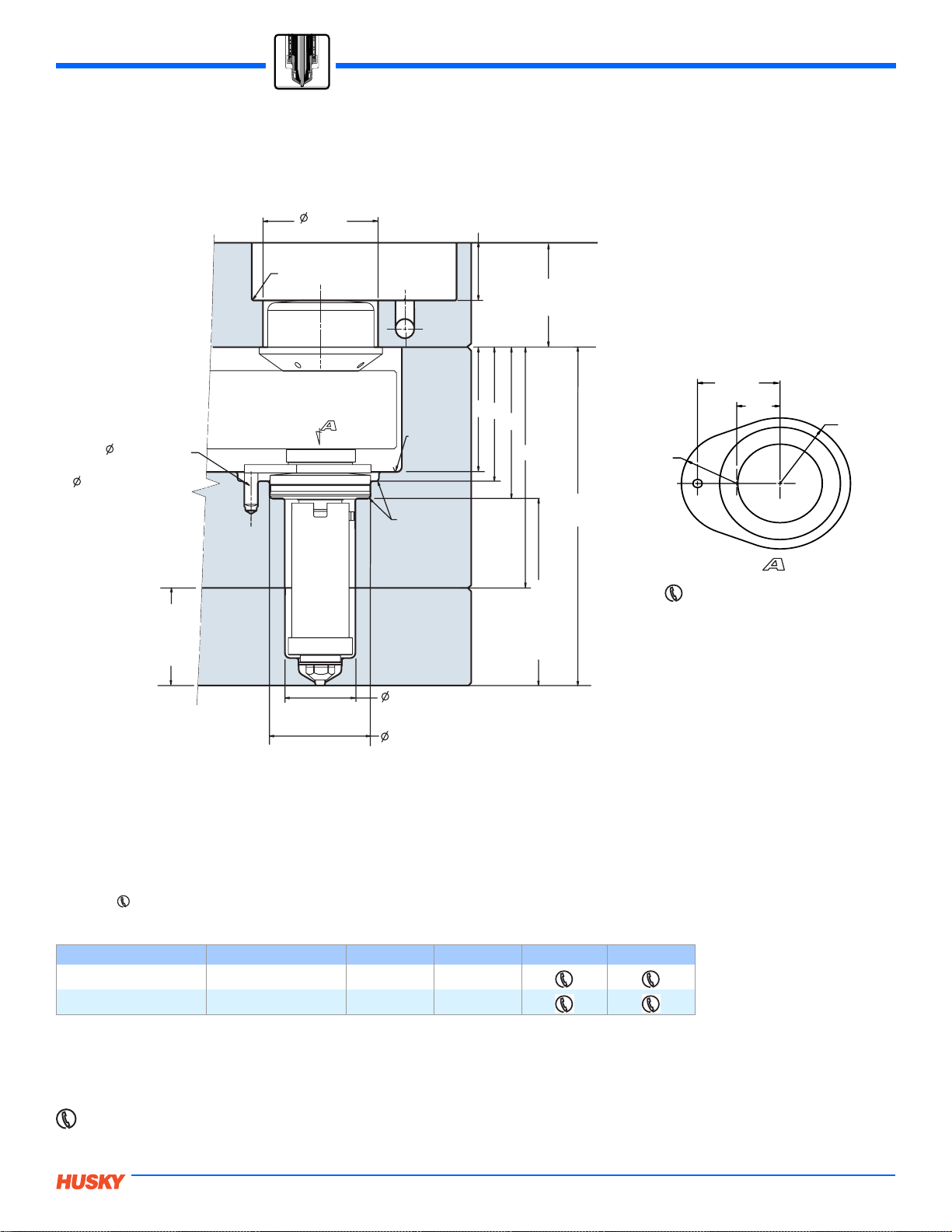

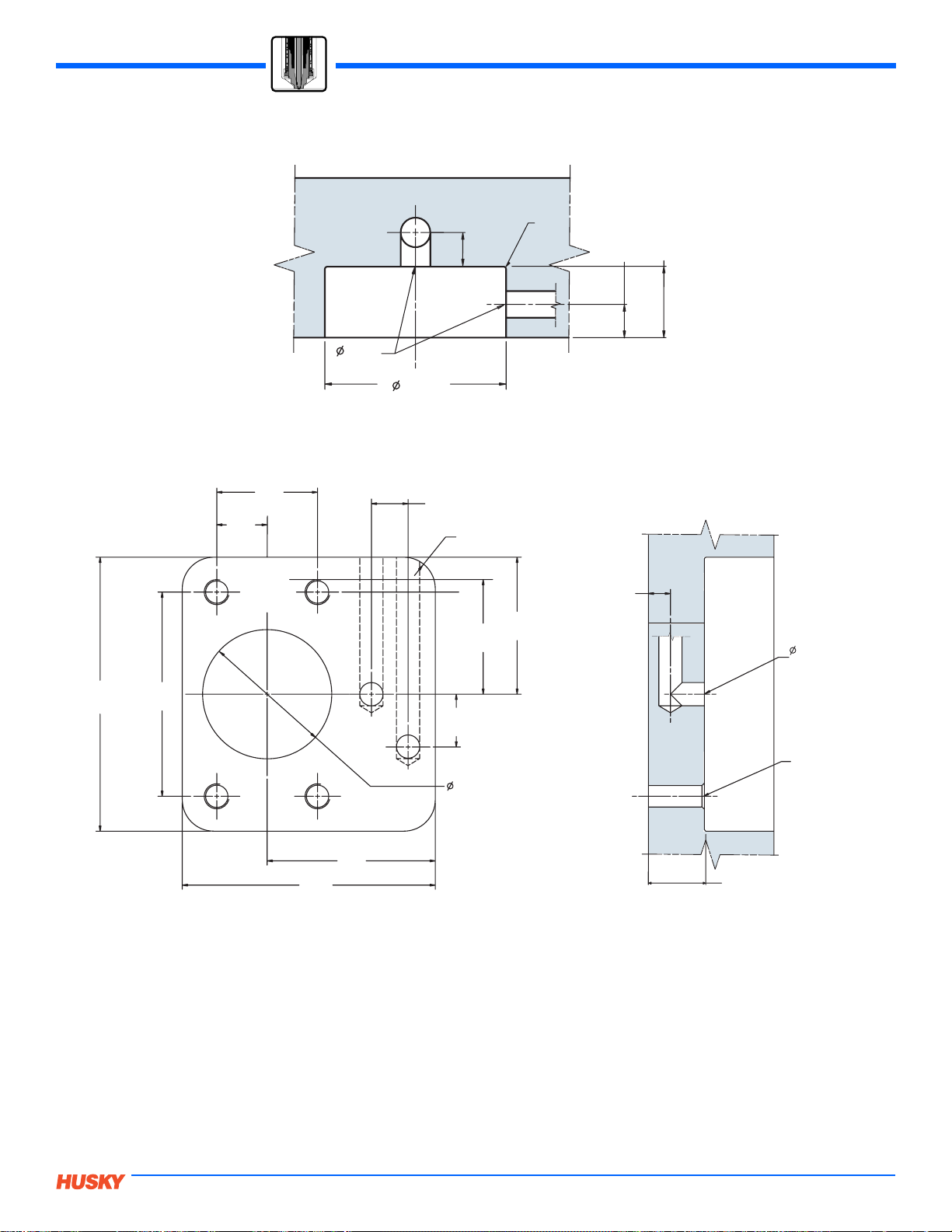

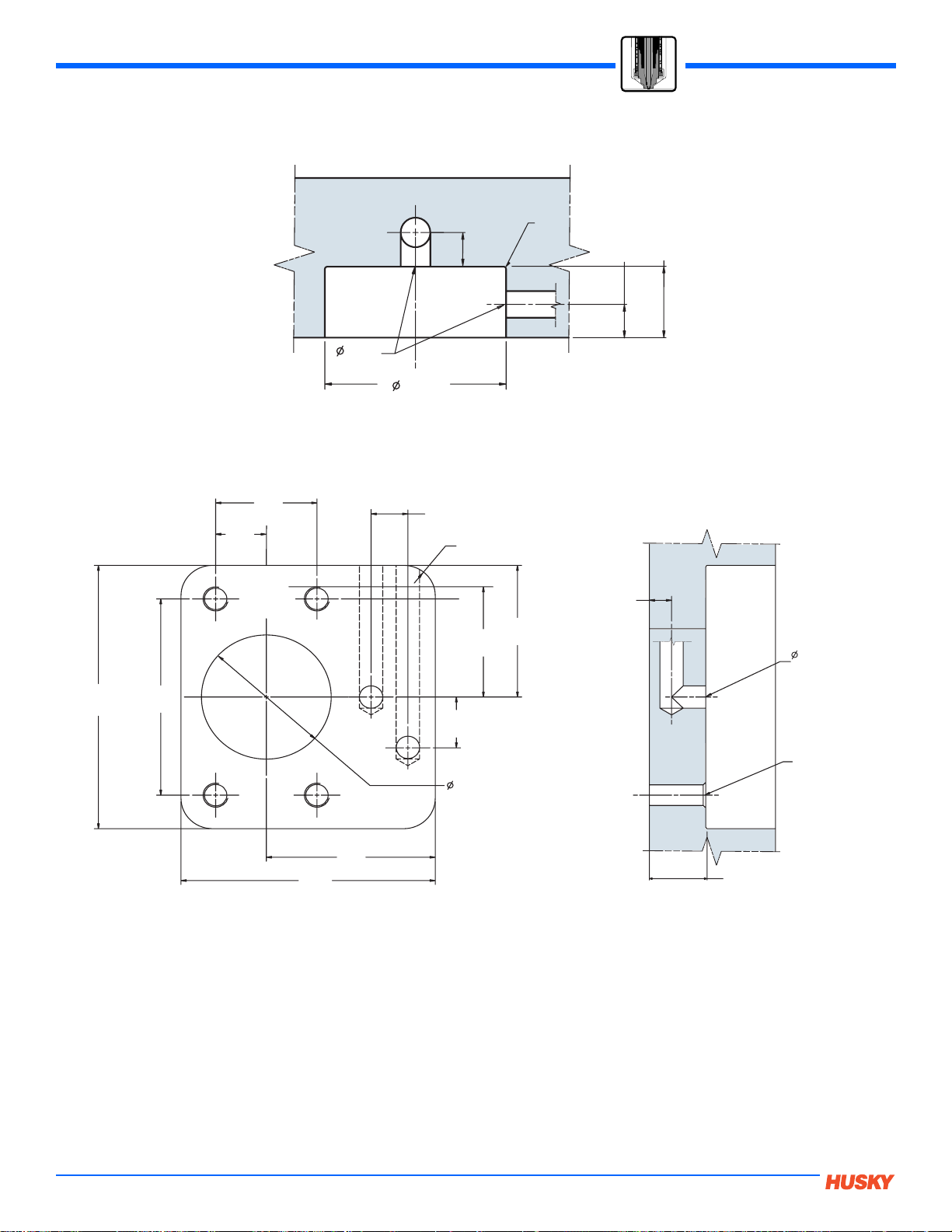

Plate Sizing - Pocket Detail

Nozzle SelectionUltra 1000 VG

6.8 x 17.0 DP

[0.27 x 0.67]

8.03 + 0.03 x 14.0 DP

[0.32 + 0.001 x 0.55]

L

29.3 - 182.2

[1.15 - 7.17]

R 0.8

[0.03]

68.00

[2.677]

R 3.0

[.12]

R 1.5

[.06]

33.20 - 0.03

[1.31 - 0.001]

J

S

K

60.00

[2.362]

N

BL

[4.05 - 7.99]

102.9 - 202.9

SL

R 27.5

[1.08]

41.00

[1.614]

21.5

[0.83]

For more than 8 drops.

R 35.0

[1.38]

42.0

[1.65]

60.01 + 0.03

[2.36 + 0.001]

Nominal dimensions shown for layout purpose only.

Actual dimensions dependent on operating temperatures.

Thermal Calculations

BL / K / L / ML / N / SL - Refer to the plate calculator at http://www.husky.ca/hotrunners/content-316-219.html

- OR -

Contact Husky for plate thickness and critical bore depths.

Ultra 1000 VG Plate Sizing

Number of Drops Manifold Height J S K N

2 - 4 45.00 (1.772") 64.1 (2.52") 77.6 (3.06")

6 - 8 60.00 (2.362") 79.1 (3.11") 92.6 (3.65")

Contact Husky for more information

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

115

2006.08

Page 3

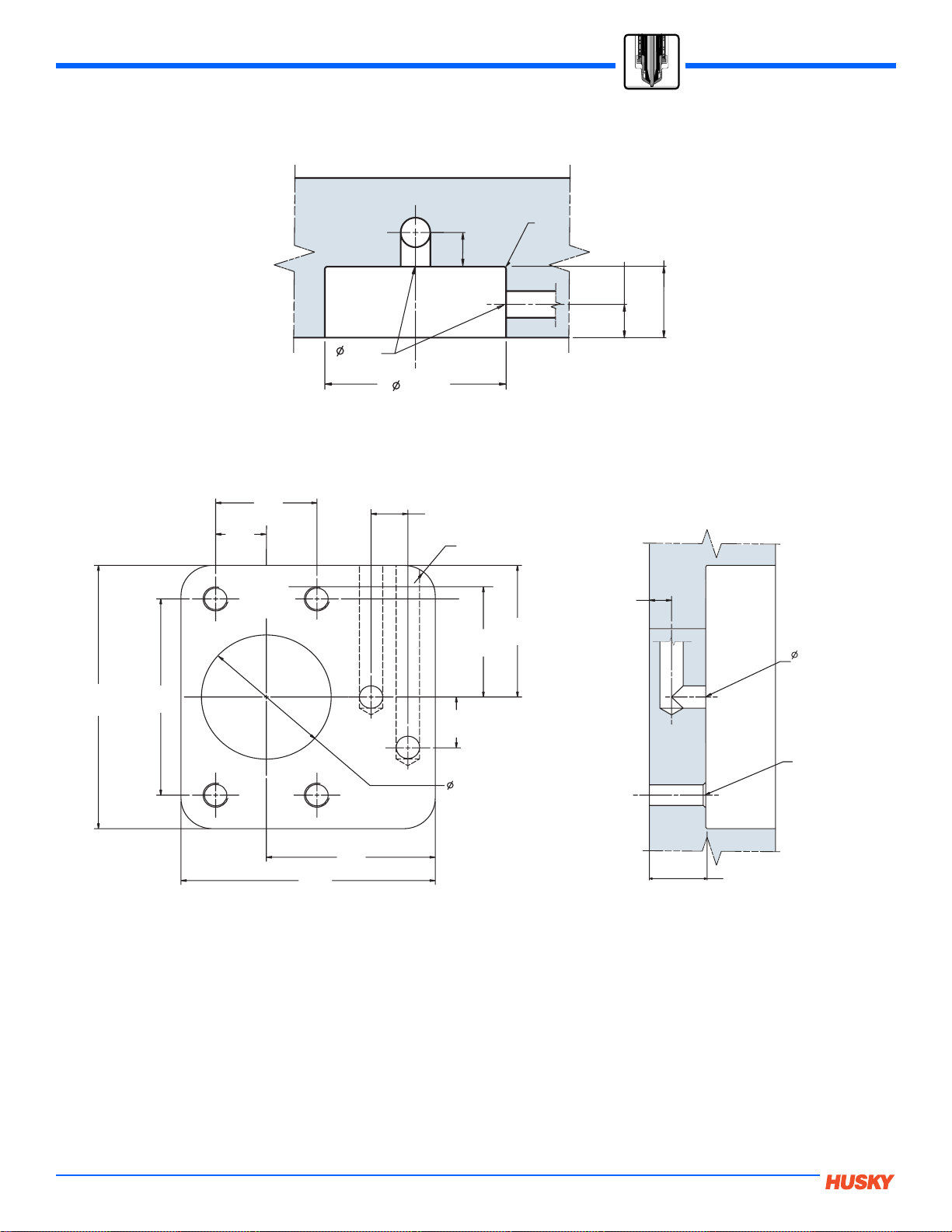

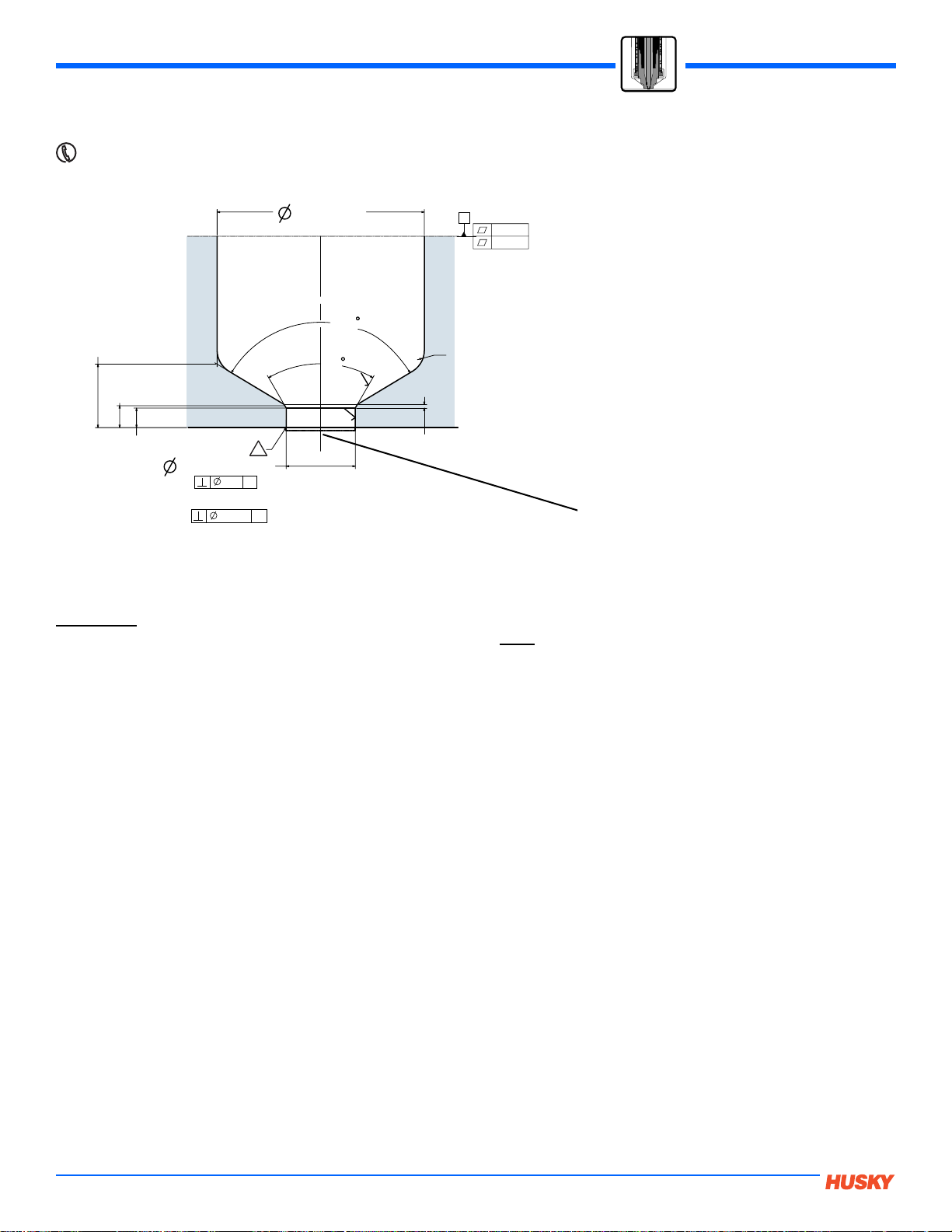

Nozzle Selection Ultra 1000 VG

Backing Plate Installation (Without Airplate)

[0.39]

11.11

[0.437]

68.0

[2.68]

Backing Plate Installation (With Airplate)

48.20

[1.898]

24.10

[.949]

17.50

[0.689]

>10.0

R 15.0 [0.59]

R 1.5

[0.06]

[0.39]

>10.0

31.8 + 0.03

[1.252 + 0.001]

[5.16]

131.0

[3.84]

97.62

121.0

[4.76]

80.40

[3.17]

25.25

68.0

[2.68]

[0.99]

48.81

[1.922]

65.5

[2.578]

10.6

[0.42]

31.8 + 0.03

[1.252 .001]

11.1 x 16.2 DP

[0.44 x 0.64]

M12 THRU (4)

2006.08

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

116

Page 4

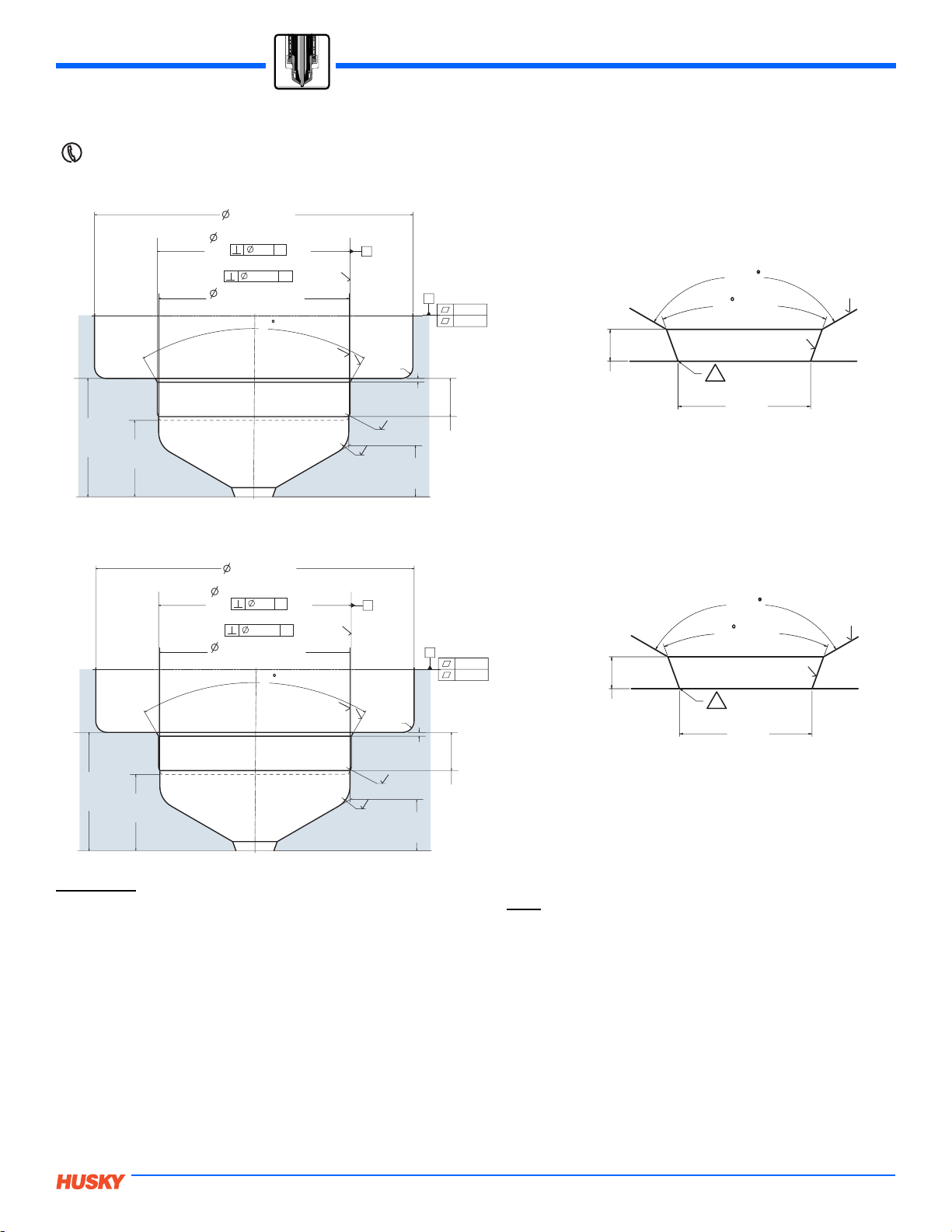

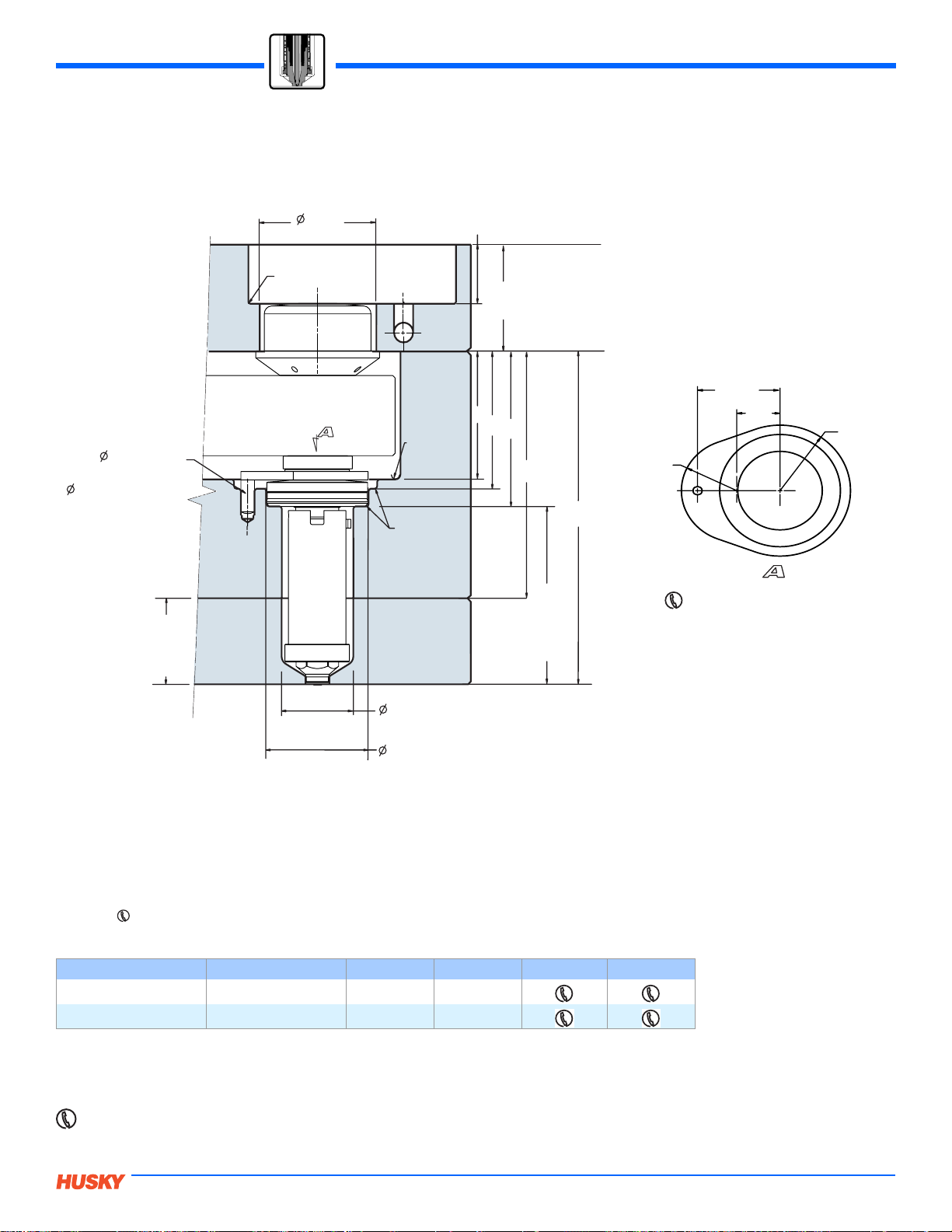

Gate Detail (Taper)

L

L

Contact Husky with any gate insert back-up concerns.

3mm Gate Diameter

42.0 [1.65]

15.61

[0.615]

8.95

[0.352]

25.415 + 0.005

[1.0006 +0.0004]

25.085 + 0.100

[0.9876 +0.0004]

0.01

0.0004

60

A

A

0.4

0.8

0.8

0.8

R 3.0

[0.12]

B

R 1.5

0.8

[.06]

R 0.8

[0.03]

1.5

7.32

A

[0.06]

[.288]

METRIC

0.005

0.0002

IMPERIA

[0.249]

6.35 REF

1.20

[0.047]

Nozzle SelectionUltra 1000 VG

120

40 +0 -15'

S

3.00

[.118]

0.8

0.4

5mm Gate Diameter

[1.0006 +0.0004]

25.085 + 0.100

[0.9876 +0.0004]

15.61

[0.615]

8.95

[0.352]

Gate Steel:

Hardened tool steels such as 49 - 51 Rc AISI H13 / DIN 1.2344

provide a good combination of strength and ductility. Note

These steels may not offer the desired resistance to abrasive

and/or corrosive resins, fillers and/or additives.

42.0 [1.65]

25.415 + 0.005

0.01

0.0004

A

A

60

0.4

0.8

0.8

0.8

R 3.0

[0.12]

B

R 1.5

0.8

[.06]

[0.03]

R 0.8

1.5

6.75

A

[0.06]

[.266]

METRIC

0.005

0.0002

IMPERIA

[0.249]

6.35 REF

120

40 +0 -15'

0.4

S

1.20

[0.047]

5.00

[.197]

5.00 (.197") and 3.00 (.118”) gate diameters are

standard, other sizes require custom parts.

Obtain gate diameter for the specific application

from Husky prior to machining.

:

0.8

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

117

2006.08

Page 5

Nozzle Selection Ultra 1000 VX

Plate Sizing - Pocket Detail

6.8 x 17.0 DP

[0.27 x 0.67]

8.03 + 0.03 x 14.0 DP

[0.32 + 0.001 x 0.55]

L

29.3 - 182.2

[1.15 - 7.17]

R .80

[.03]

68.00

[2.68]

R 3.0

[0.12]

R 1.5

[0.06]

33.20 - 0.03

[1.31 - 0.001]

60.00

[2.362]

J

S

K

N

BL

[4.05 - 7.99]

102.9 - 202.9

SL

R 27.5

[1.08]

41.00

[1.614]

21.5

[0.83]

For more than 8 drops.

R 35.0

[1.38]

42.0

[1.65]

60.01 + 0.03

[2.36 + 0.001]

Nominal dimensions shown for layout purpose only.

Actual dimensions dependent on operating temperatures.

Thermal Calculations

BL / K / L / ML / N / SL - Refer to the plate calculator at http://www.husky.ca/hotrunners/content-316-219.html

- OR -

Contact Husky for plate thickness and critical bore depths.

Ultra 1000 VX Plate Sizing

Number of Drops Manifold Height J S K N

2 - 4 45.00 (1.772") 64.1 (2.52") 77.6 (3.06")

6 - 8 60.00 (2.362") 79.1 (3.11") 92.6 (3.65")

Contact Husky for more information

2006.08

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

118

Page 6

Backing Plate Installation (Without Airplate)

11.11

[0.437]

68.0

[2.68]

Backing Plate Installation (With Airplate)

48.20

24.10

[.949]

[1.898]

17.50

[0.689]

[0.39]

>10.0

R 15.0 [0.59]

R 1.5

[0.06]

[0.39]

>10.0

31.8 + 0.03

[1.252 + 0.001]

Nozzle SelectionUltra 1000 VX

[5.16]

131.0

[3.84]

97.62

121.0

[4.76]

80.40

[3.17]

25.25

68.0

[2.68]

[0.99]

48.81

[1.922]

65.5

[2.578]

10.6

[0.42]

31.8 + 0.03

[1.252 .001]

11.1 x 16.2 DP

[0.44 x 0.64]

M12 THRU (4)

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

119

2006.08

Page 7

Nozzle Selection Ultra 1000 VX

Gate Detail

Contact Husky with any gate insert back-up concerns.

14mm Gate Diameter

42.0 [1.65]

A

0.005

0.0002

METRIC

IMPERIAL

118

12.85

[0.506]

4.44

[0.175]

3.95 [0.156]

14.000 + 0.005

Land

0.01

[0.5512 +0.0002]

0.0004

60

0.8

0.4

S

A

A

0.75

R 5.0

[0.20]

[0.030]

5.00 (.197") dia. gate is standard, other sizes require customized parts. Obt ain

gate diameter for the specific application from Husky prior to machining

Gate Steel:

Hardened tool steels such as 49 - 51 Rc AISI H13 / DIN 1.2344

provide a good combination of strength and ductility . Note

: These

steels may not offer the desired resistance to abrasive and/or

corrosive resins, fillers and/or additives.

Clearance required in this area >.50 (.020").

Front face of nozzle tip cannot make

contact.

2006.08

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

120

Page 8

Plate Sizing - Pocket Detail

Nozzle SelectionUltra 1000 VX-X

6.8 x 17.0 DP

[0.27 x 0.67]

8.03 + 0.03 x 14.0 DP

[0.32 + 0.001 x 0.55]

L

29.3 - 182.2

[1.15 - 7.17]

R .80

[.03]

68.00

[2.68]

R 3.0

[0.12]

R 1.5

[0.06]

33.20 - 0.03

[1.31 - 0.001]

60.00

[2.362]

J

S

K

N

BL

[4.05 - 7.99]

102.9 - 202.9

SL

R 27.5

[1.08]

41.00

[1.614]

21.5

[0.83]

For more than 8 drops.

R 35.0

[1.38]

42.0

[1.65]

60.01 + 0.03

[2.36 + 0.001]

Nominal dimensions shown for layout purpose only.

Actual dimensions dependent on operating temperatures.

Thermal Calculations

BL / K / L / N / SL - Refer to the plate calculator at http://www.husky.ca/hotrunners/content-316-219.html

- OR -

Contact Husky for plate thickness and critical bore depths.

Ultra 1000 VX Plate Sizing

Number of Drops Manifold Height J S K N

2 - 4 45.00 (1.772") 64.1 (2.52") 77.6 (3.06")

6 - 8 60.00 (2.362") 79.1 (3.11") 92.6 (3.65")

Contact Husky for more information

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

121

2006.08

Page 9

Nozzle Selection Ultra 1000 VX-X

Backing Plate Installation (Without Airplate)

[0.39]

11.11

[0.437]

68.0

[2.68]

Backing Plate Installation (With Airplate)

48.20

[1.898]

24.10

[.949]

17.50

[0.689]

>10.0

R 15.0 [0.59]

R 1.5

[0.06]

[0.39]

>10.0

31.8 + 0.03

[1.252 + 0.001]

[5.16]

131.0

[3.84]

97.62

121.0

[4.76]

80.40

[3.17]

25.25

68.0

[2.68]

[0.99]

48.81

[1.922]

65.5

[2.578]

10.6

[0.42]

31.8 + 0.03

[1.252 .001]

11.1 x 16.2 DP

[0.44 x 0.64]

M12 THRU (4)

2006.08

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

122

Page 10

Gate Detail

Contact Husky with any gate insert back-up concerns.

Nozzle SelectionUltra 1000 VX-X

19.05

[0.750] REF

12.44

[0.490]

11.95

REF

20.000 + 0.005

0.01

[0.787 + 0.0002]

[0.470] LAND

0.0004

42.0 [1.65]

118

60

0.8

0.4

S

A

A

0.75

A

R 5.0

[0.20]

[0.030]

0.005

0.0002

METRIC

IMPERIAL

5.00 (.197") dia. gate is standard, other sizes require customized parts. Obt ain

gate diameter for the specific application from Husky prior to machining

Gate Steel:

Hardened tool steels such as 49 - 51 Rc AISI H13 / DIN 1.2344

provide a good combination of strength and ductility . Note

: These

steels may not offer the desired resistance to abrasive and/or

corrosive resins, fillers and/or additives.

Clearance required in this area >.50 (.020").

Front face of nozzle tip cannot make

contact.

Contact Husky for more information

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

123

2006.08

Page 11

Plate Sizing - Pocket Detail

6.8 x 17.0 DP

[0.27 x 0.67]

8.03 + 0.03 x 14.0 DP

[0.32 + 0.001 x 0.55]

R 3.0

[0.12]

R 1.5

[0.06]

J

40.00

[1.574]

S

Nozzle SelectionUltra 1000 HT-D

K

N

R 27.5

SL

[1.08]

41.00

[1.614]

21.5

[0.83]

R 35.0

[1.38]

BL

L

28.0 - 180.0

[1.10 - 7.09]

42.0

[1.65]

60.01 + 0.03

[2.36 + 0.001]

[4.00 - 7.94]

101.6 - 201.6

For more than 8 drops.

Nominal dimensions shown for layout purpose only.

Actual dimensions dependent on operating temperatures.

Thermal Calculations

BL / K / L / ML / N / SL - Refer to the plate calculator at http://www.husky.ca/hotrunners/content-316-219.html

- OR -

Contact Husky for plate thickness and critical bore depths.

Ultra 1000 HT-D Plate Sizing

Number of Drops Manifold Height J S K N

2 - 4 45.00 (1.772") 60.1 (2.37") 65.9 (2.60")

6 - 8 60.00 (2.362") 75.1 (2.96") 80.9 (3.19")

Contact Husky for more information

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

124

2006.08

Page 12

Nozzle Selection Ultra 1000 HT-D

Gate Detail

Contact Husky with any gate insert back-up concerns.

6.30

Gate Steel:

42.0 [1.65]

0.4

0.8

B

0.8

R 1.0

[0.04]

R 1.5

[0.06]

A

1.50

[0.059]

METRIC

0.005

0.0002

IMPERIAL

13.0 [0.51]

Int Pts

[0.248]

18.010 + 0.005

0.01

A

[0.7091 + 0.0002]

A

0.0004

60

Hardened tool steels such as 49 - 51 Rc AISI H13 / DIN 1.2344

provide a good combination of strength and ductility . Note

: These

steels may not offer the desired resistance to abrasive and/or

corrosive resins, fillers and/or additives.

110

0.8

0.4

80

V

0.4

G

[0.005]

0.13

G

is application specific, contact Husky prior

to machining.

V

is variable according to gate diameter.

2006.08

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

125

Page 13

Plate Sizing - Pocket Detail

40.00

[1.574]

Nozzle SelectionUltra 1000 HT-T

6.8 x 17.0 DP

[0.27 x 0.67]

8.03 + 0.03 x 14.0 DP

[0.32 + 0.001 x 0.55]

L

28.0 - 180.0

[1.10 - 7.09]

R 3.0

[0.12]

R 1.5

[0.06]

42.0

[1.65]

60.01 + 0.03

[2.36 + 0.001]

J

S

K

N

R 27.5

SL

BL

[4.00 - 7.94]

101.6 - 201.6

[1.08]

41.00

[1.614]

21.5

[0.83]

For more than 8 drops.

Nominal dimensions shown for layout purpose only.

Actual dimensions dependent on operating temperatures.

Thermal Calculations

BL / K / L / ML / N / SL - Refer to the plate calculator at http://www.husky.ca/hotrunners/content-316-219.html

- OR -

Contact Husky for plate thickness and critical bore depths.

R 35.0

[1.38]

Ultra 1000 HT-T Plate Sizing

Number of Drops Manifold Height J S K N

2 - 4 45.00 (1.772") 60.1 (2.37") 65.9 (2.60")

6 - 8 60.00 (2.362") 75.1 (2.96") 80.9 (3.19")

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

126

2006.08

Page 14

Nozzle Selection Ultra 1000 HT-T

Gate Detail

Contact Husky with any gate insert back-up concerns.

6.30

Gate Steel:

42.0 [1.65]

0.4

0.8

B

0.8

R 1.0

[0.04]

R 1.5

[0.06]

A

1.50

[0.059]

METRIC

0.005

0.0002

IMPERIAL

13.0 [0.51]

Int Pts

[0.248]

18.010 + 0.005

0.01

A

[0.7091 + 0.0002]

A

0.0004

60

Hardened tool steels such as 49 - 51 Rc AISI H13 / DIN 1.2344

provide a good combination of strength and ductility . Note

: These

steels may not offer the desired resistance to abrasive and/or

corrosive resins, fillers and/or additives.

110

0.8

0.4

80

V

0.4

G

[0.005]

0.13

G

is application specific, contact Husky prior

to machining.

V

is variable according to gate diameter.

2006.08

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

127

Page 15

Plate Sizing - Pocket Detail

6.8 x 17.0 DP

[0.27 x 0.67]

8.03 + 0.03 x 14.0 DP

[0.32 + 0.001 x 0

.55]

R 3.0

[0.12]

R 1.5

[0.06]

40.00

J

[1.574]

S

K

Nozzle SelectionUltra 1000 TS

41.00

[1.614]

21.5

N

R 27.5

SL

[1.08]

[0.83]

R 35.0

[1.38]

BL

[4.00 - 7.94]

L

28.0 - 180.0

[1.10 - 7.09]

42.0

[1.65]

60.01 + 0.03

[2.36 + 0.001]

101.6 - 201.6

For more than 8 drops.

Nominal dimensions shown for layout purpose only.

Actual dimensions dependent on operating temperatures.

Thermal Calculations

BL / K / L / ML / N / SL - Refer to the plate calculator at http://www.husky.ca/hotrunners/content-316-219.html

- OR -

Contact Husky for plate thickness and critical bore depths.

Ultra 1000 TS Plate Sizing

Number of Drops Manifold Height J S K N

2 - 4 45.00 (1.772") 60.1 (2.37") 65.9 (2.60")

6 - 8 60.00 (2.362") 75.1 (2.96") 80.9 (3.19")

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

128

2006.08

Page 16

Nozzle Selection Ultra 1000 TS

Gate Detail

Contact Husky with any gate insert back-up concerns.

42.0 [1.65]

A

0.005

METRIC

0.0002

IMPERIAL

120

14.70

[0.579]

60

R 5.0

[0.20]

5.75

[0.226]

Land

5.25 [0.207]

11.000 +0.005

0.01

A

[0.4331 +0.0002]

A

0.0004

0.4

0.8

0.75

[0.030]

Clearance required in this area >.50 (.020"). Front face of nozzle tip cannot make contact.

Gate Steel:

Hardened tool steels such as 49 - 51 Rc AISI H13 / DIN 1.2344 provide a good combination of strength and

ductility. Note

: These steels may not offer the desired resistance to abrasive and/or corrosive resins, fillers

and/or additives.

2006.08

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

129

Page 17

Plate Sizing - Pocket Detail

6.8 x 17.0 DP

[0.27 x 0.67]

8.03 + 0.03 x 14.0 DP

[0.32 + 0.001 x 0.55]

R 3.0

[0.12]

R 1.5

[0.06]

J

40.00

[1.574]

S

Nozzle SelectionUltra 1000 HT-DC

K

N

R 27.5

SL

[1.08]

41.00

[1.614]

21.5

[0.83]

R 35.0

[1.38]

BL

L

28.0 - 180.0

[1.10 - 7.09]

42.0

[1.65]

60.01 + 0.03

[2.36 + 0.001]

[4.00 - 7.94]

101.6 - 201.6

For more than 8 drops.

Nominal dimensions shown for layout purpose only.

Actual dimensions dependent on operating temperatures.

Thermal Calculations

BL / K / L / ML / N / SL - Refer to the plate calculator at http://www.husky.ca/hotrunners/content-316-219.html

- OR -

Contact Husky for plate thickness and critical bore depths.

Ultra 1000 HT-DC Plate Sizing

Number of Drops Manifold Height J S K N

2 - 4 45.00 (1.772") 60.1 (2.37") 65.9 (2.60")

6 - 8 60.00 (2.362") 75.1 (2.96") 80.9 (3.19")

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

130

2006.08

Page 18

Nozzle Selection Ultra 1000 HT-DC

Gate Detail

Contact Husky with any gate insert back-up concerns.

42.0 [1.66]

A

0.01

A

0.0004

[

]

A

0.005

0.0002

120

60

R 5.0

[0.20]

0.75

[0.030]

5.75 [0.226]

12.60 [0.496]

0.8

0.4

S

20.008 + 0.005

0.01

A

[0.7877+0.0002]

A

0.0004

Clearance required in this area >.50 (.020"). Front face of nozzle tip cannot make contact.

Gate Steel:

Hardened tool steels such as 49 - 51 Rc AISI H13 / DIN 1.2344 provide a good combination of strength

and ductility. Note

: These steels may not offer the desired resistance to abrasive and/or corrosive resins,

fillers and/or additives.

METRIC

IMPERIAL

2006.08

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

131

Page 19

Plate Sizing - Pocket Detail

-

-

Nozzle SelectionUltra 1000 HS

87.2 [3.43]

60.6 [2.39]

WIRE GROOVE

-

+

-

+

20.93 0.01 [0.824 0.0004]

45

5.00 [0.197]

-

+

-

+

25.93 0.01

[1.021 0.0004]

BL +

PL -

[0.39]

10.0

WIRE GROOVE

SR

15.00 [0.591]

(X4)

7.50

[0.295]

(X4)

REF19.08 [0.751]

LOC. RING RELIEF

+0.02

97.01

0.00

58

REF30.64 [1.206]

LR DIA.

3.819

70.00 [2.756]

(X2)

40

+0.001

-0.000

(X2)

58

(X2)

40

(X2)

WIRE GROOVE

12.7 [0.50]

80.0 [3.15]

M8 X 16.0 DP. (X4)

M6 X 12.0 DP. (X4)

72.0 [2.83]

REF25.71 [1.012]

REF30.53 [1.202]

58.02

Orifice

+0.02

0.00

2.284

+0.001

-0.000

0.0004]

-

PL

+

BL

-

+

17.93 0.010 [0.706

*Refer to following page for definitions. Ultra 1000 HS

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

132

1.5 [0.06]R

0.5 [0.02]R

1.5 [0.06]R

0.5 (0.02)X 30

0.5 [0.02]R

2006.08

Page 20

Nozzle Selection Ultra 1000 HS

Dimensions

Ultra 1000 HS “A” Dimension Chart (Thermal Gate)

PL (Plate Length) LR DIA LR Relief Dia. RAD ORIFICE

HT-D: 116.45 (4.585”) - 216.71 (8.532”)

HT-T 116.45 (4.585”) - 216.71 (8.532”)

HT-U 116.45 (4.585”) - 216.71 (8.532”)

HT-DC 116.45 (4.585”) - 216.71 (8.532”)

TS 116.45 (4.585”) - 216.71 (8.532”)

101.31 (3.99")

101.57 (4")

100 (3.94")

120 (4.72")

125 (4.92")

160 (6.30")

105 (4.13")

105 (4.13")

105 (4.13")

124 (4.88")

129 (5.08")

163.71 (6.45")

Design Criteria

• Ultra 1000 hot sprues are designed using customer specified PL, LR, RAD, orifice, melt operating temperature, and

mold temperature.

• If required PL is outside published range, extended lead times may apply. Please contact Husky.

• Actual BL dimension is a function of PL, tip selection, nozzle housing selection and operating conditions.

FLAT

10.00 (.394")

12.70 (.500")

15.50 (.610")

19.05 (.750")

20.00 (.787")

40.00 (1.575")

N/A

11.50 (.453")

• Actual BL dimension will be provided after system design. If a specific BL is required please contact Husky .

Contact Husky for more information

2006.08

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

133

Page 21

Gate Detail HT-D / HT-T / HT-U

Contact Husky with any gate insert back-up concerns.

Nozzle SelectionUltra 1000 HS

6.30

Gate Steel:

42.0 [1.65]

0.4

0.8

B

0.8

R 1.0

[0.04]

R 1.5

[0.06]

A

1.50

[0.059]

METRIC

0.005

0.0002

IMPERIAL

13.0 [0.51]

Int Pts

[0.248]

18.010 + 0.005

0.01

A

[0.7091 + 0.0002]

A

0.0004

60

Hardened tool steels such as 49 - 51 Rc AISI H13 / DIN 1.2344

provide a good combination of strength and ductility . Note

: These

steels may not offer the desired resistance to abrasive and/or

corrosive resins, fillers and/or additives.

110

0.8

0.4

80

V

0.4

G

[0.005]

0.13

G

is application specific, contact Husky prior

to machining.

V

is variable according to gate diameter.

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

134

2006.08

Page 22

Nozzle Selection Ultra 1000 HS

Gate Detail HT-DC

Contact Husky with any gate insert back-up concerns.

42.0 [1.66]

A

0.01

A

0.0004

[

]

A

0.005

0.0002

120

60

R 5.0

[0.20]

0.75

[0.030]

5.75 [0.226]

12.60 [0.496]

0.8

0.4

S

20.008 + 0.005

0.01

A

[0.7877+0.0002]

A

0.0004

Clearance required in this area >.50 (.020"). Front face of nozzle tip cannot make contact.

Gate Steel:

Hardened tool steels such as 49 - 51 Rc AISI H13 / DIN 1.2344 provide a good combination of strength

and ductility. Note

: These steels may not offer the desired resistance to abrasive and/or corrosive resins,

fillers and/or additives.

METRIC

IMPERIAL

2006.08

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

135

Page 23

Gate Detail TS

Contact Husky with any gate insert back-up concerns.

14.70

[0.579]

42.0 [1.65]

120

Nozzle SelectionUltra 1000 HS

A

0.005

METRIC

0.0002

IMPERIAL

60

R 5.0

[0.20]

5.75

[0.226]

Land

5.25 [0.207]

11.000 +0.005

0.01

A

[0.4331 +0.0002]

A

0.0004

0.4

0.8

0.75

[0.030]

Clearance required in this area >.50 (.020"). Front face of nozzle tip cannot make contact.

Gate Steel:

Hardened tool steels such as 49 - 51 Rc AISI H13 / DIN 1.2344 provide a good combination of strength and

ductility. Note

: These steels may not offer the desired resistance to abrasive and/or corrosive resins, fillers

and/or additives.

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

136

2006.08

Page 24

Nozzle Selection Ultra 1000 SCVG

Plate Sizing - Pocket Detail

12.7 [.50]

36.00 + 0.03

[1.417 + .001]

(4)

65.00 [ 2.559]

+ 0.03

[+ .001]

PL*

37.0

[1.46]

10.0

75.0 - 0.1

[2.95 - .001]

+ 0.03

[+ .001]

BL

[.39]

5.0

[.20]

[.39]

10.0

50.8

[2.00]

150.00 + 0.03

[5.906 + .001]

105.0 [4.13]

88.0 [3.47]

5.0 [.20] x 45

(3)

45 (4)

LOCATING RING DIAMETER

RADIUS

ORIFICE

5.03 + 0.03 x 8.0 DP

[.198 + .001 x .31]

5

/

M8 [ - 18]

16

(4)

R 0.80

[.031]

R 0.80

[.031]

87.02 + 0.03

[3.426 + .001]

*Refer to following page for definitions.

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

2006.08

137

Page 25

Nozzle Selection Ultra 1000 SCVG

Dimensions

Ultra 1000 SCVG Dimension Chart (Valve Gate)

Nozzle

70 - 190

(2.76 - 7.48”)

Design Criteria

• Refer to Ultra 1000 VG/VX for resin selection guidelines.

• Ultra 1000 single cavity valve gates are designed using customer specified PL, LR, RAD, orifice, melt operating temperature, and mold temperature parameters.

• Actual BL dimension is based on application specific parameters supplied to Husky prior to design. Husky provides all

manufacturing dimensions with customer drawings.

BL Nominal

±.5 (0.02")

37.3 - 157.5

(1.47 - 6.20”)

PL Range LR DIA RAD ORIFICE GATE DIA.

FLAT

125 - 245

(4.92 - 9.65")

Available in

20mm incre-

ments

101.35 (3.99")

101.57 (4")

100 (3.93")

125 (4.92")

12.70 (.500")

15.50 (.610")

19.05 (.750")

10.00 (.394")

20.00 (.787")

40.00 (1.575")

11.50

(0.45")

3.0 (0.12")

5.0 (0.20”)

• Maximum operating temperature is 375

• Maximum operating injection pressure is 1793 bar (26000 psi).

• Taper style stem only available.

• If required PL or BL is outside published range, extended lead times ma y apply. Please contact Husky.

° C (710° F).

2006.08

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

138

Page 26

Nozzle Selection Ultra 1000 SCVG

Gate Detail - VG (Taper)

Contact Husky with any gate insert back-up concerns.

42.0 [1.65]

15.61

[0.615]

8.95

[0.352]

25.415 + 0.005

[1.0006 +0.0004]

25.085 + 0.100

[0.9876 +0.0004]

0.01

0.0004

60

A

A

0.4

0.8

0.8

0.8

R 3.0

[0.12]

B

R 1.5

0.8

[.06]

R 0.8

[0.03]

1.5

A

[0.06]

V

METRIC

0.005

0.0002

IMPERIAL

[0.249]

6.35 REF

120

40 +0 -15'

S

1.20

[0.047]

5.00 (.197") dia. gate is standard, other

sizes require customized parts. Obtain gate

diameter for the specific application from

Husky prior to machining.

G

0.8

0.4

Gate Steel:

Hardened tool steels such as 49 - 51 Rc AISI H13 / DIN 1.2344

provide a good combination of strength and ductility . Note

: These

steels may not offer the desired resistance to abrasive and/or

corrosive resins, fillers and/or additives.

2006.08

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

139

Page 27

Nozzle Selection Ultra 1000 SCVG

Gate Detail - VX

Contact Husky with any gate insert back-up concerns.

42.0 [1.65]

A

0.005

0.0002

METRIC

IMPERIAL

118

12.85

[0.506]

4.44

[0.175]

3.95 [0.156]

14.000 + 0.005

Land

0.01

[0.5512 +0.0002]

0.0004

60

0.8

0.4

S

A

A

0.75

R 5.0

[0.20]

[0.030]

5.00 (.197") dia. gate is standard, other sizes require customized parts.

Obtain gate diameter for the specific application from Husky prior to

machining

Gate Steel:

Hardened tool steels such as 49 - 51 Rc AISI H13 / DIN 1.2344

provide a good combination of strength and ductility. Note

These steels may not offer the desired resistance to abrasive

and/or corrosive resins, fillers and/or additives.

Clearance required in this area >.50 (.020").

Front face of nozzle tip cannot make

contact.

:

2006.08

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

140

Loading...

Loading...