Page 1

Introduction

OVERVIEW

Welcome to the Husky Hot Runner Design Center . This information is intended to simplify the hot runn er selection process.

Each section has been organized using easy to follow icon s.

Introduction

The primary hot runner system types offered by Husky are

identified within this section. Components that make up each

system are labeled for easy identification.

Nozzle Selection

This section guides the designer through the decisions and steps

for determining the gating method and nozzle size that best

satisfies the specific application.

Design Guidelines

In this section guidelines are offered to integrate Husky hot runner

systems into the mold.

Accessories

NOTE:

Sp are components and installation information are provided within

this section.

CAD Library

Mold designers are provided with all standard gating methods,

nozzles and generic hot runner view installations to be merged into

their CAD file. Available formats include:.dxf,.igs, and .prt.

Please refer to www.hotrunners.com for the most current design information.

2006.08

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

1

Page 2

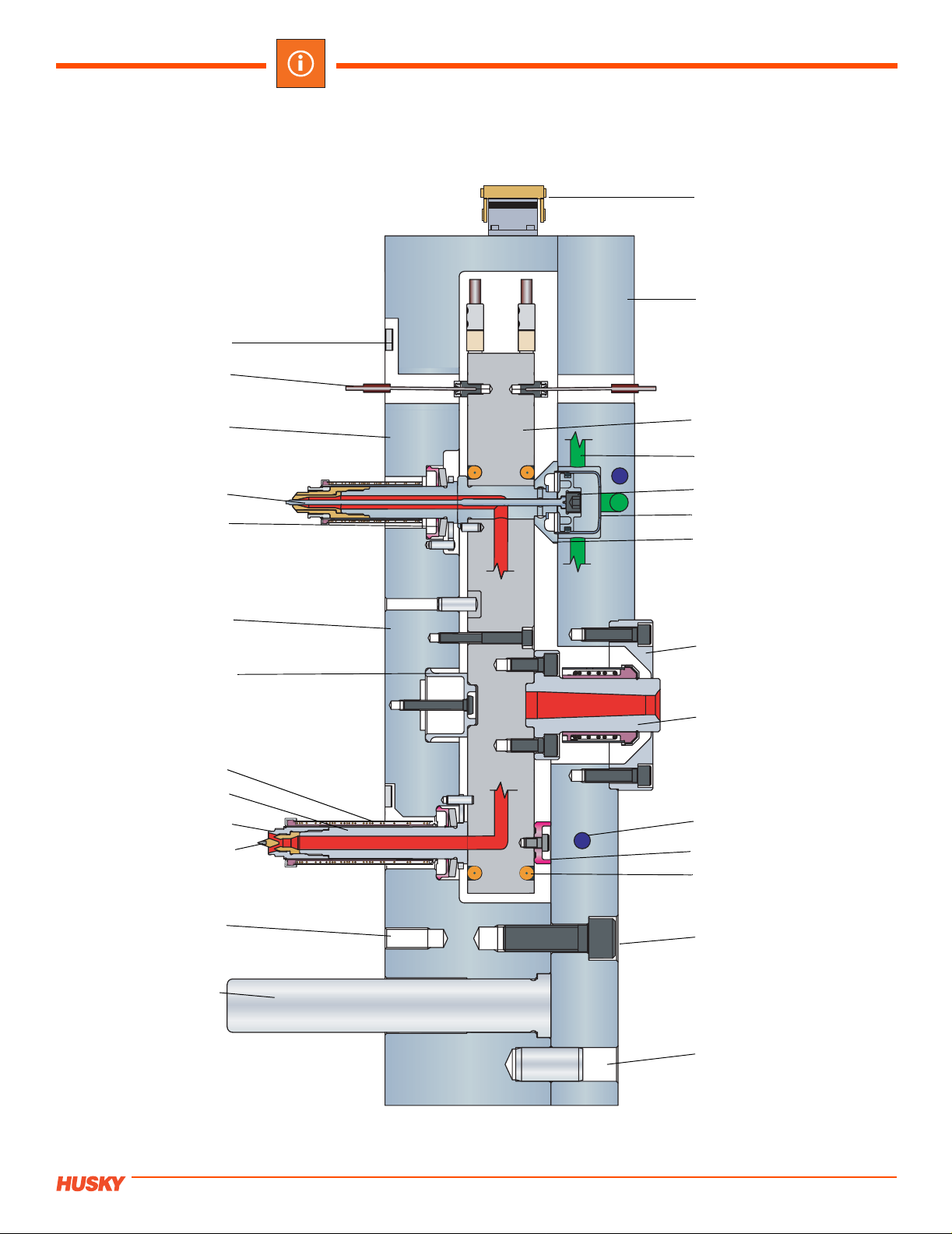

COMPLETE HOT RUNNER SYSTEM

Ultra 750 HT/VG Shown

Wire Clip

Manifold Thermocouple

Introduction

Electrical Connector

Backing Plate

Manifold Bushing

Valve Stem

UltraSeal

Manifold Plate

Center Locating

Insulator

Nozzle Heater

Nozzle Housing

Tip Retainer

Tip Insert

Manifold

Air Line

Piston

Cylinder

Backup Pad

Locating Ring

Sprue Bushin g

Plate Cooling

Backup Insulator Pad

Manifold Heater

Cavity Interface Tap

Guide Pin

Plate Bolt

Plate Alignment Dowel

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

2

2006.08

Page 3

Introduction

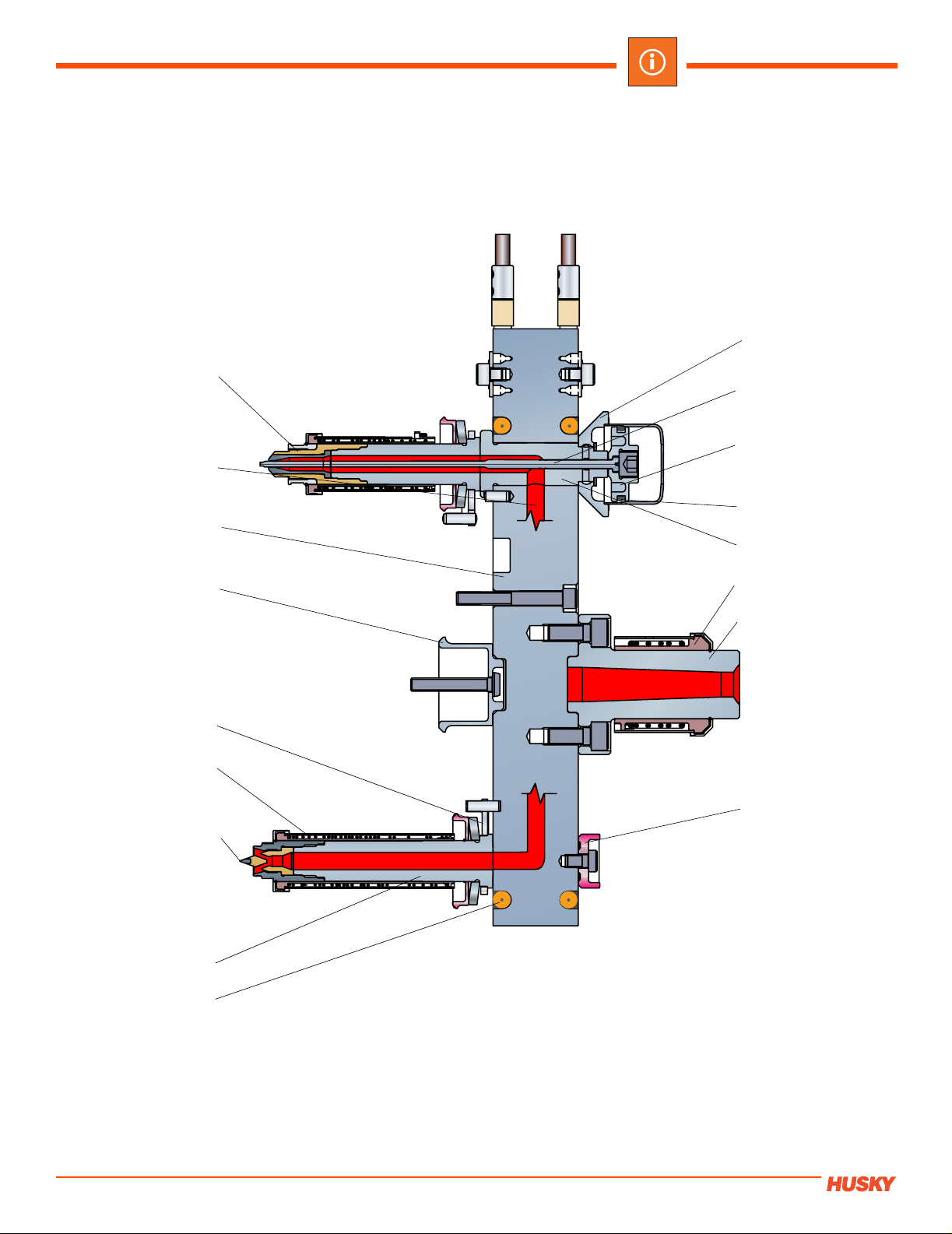

MANIFOLD SYSTEM

Ultra 750 HT/VG Shown

Nozzle Tip

Melt Channel

Backup Pad

Va lve Stem

Piston

Manifold

Center Insulator

UltraSeal

Nozzle Heater

Carbide Insert Tip

Piston Seal

Manifold Bushing

Sprue Heater

Sprue Bushin g

Backup Insulator Pad

2006.08

Nozzle Housing

Manifold Heater

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

3

Page 4

SINGLE CAVITY VALVE GATE SYSTEM

Ultra 750 SCVG Shown

Sprue Body Inser t

Introduction

Sprue Body Heater

Nozzle Heater

Nozzle Tip

Valve Stem

Locating Ring

Air Line

Tip Insulator

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

4

2006.08

Page 5

Introduction

HOT SPRUE

Ultra 750 HS Shown

Insulator Body

Nozzle Heater

Band Heater

Nozzle Tip Retainer

Nozzle Tip

Locating Ring

2006.08

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

5

Page 6

Introduction

INTRODUCTION

HOT RUNNER SYSTEMS

The objective of a hot runner system is to distribute the material from the machine nozzle to each gate, while minimizing

adverse effects to the material’s properties. Husky offers two hot runner system types:

• Complete hot runner system with plates

• Manifold system

Complete Hot Runner System

A complete hot runner system is supplied to the customer as a fully assembled unit, ready to be fastened to the cavity plate

and installed into the machine press.

Manifold System

A manifold system includes all components that make up the heated flow path except the hot runner plates. Drawings that

outline the necessary plate machining to accommodate the manifold and related components are include d with every

shipped manifold system.

Benefits of Ordering Complete Hot Runner System vs. Manifold System

Customer benefits when ordering a complete hot runner system:

• Husky's extensive design experience

• With a complete system, plate features such as: cooling circuits, air circuits, wire channels, and plate bolts are optimally positioned to maximize performanc e.

• 3-Year Leak-Proof Guarantee for UltraSeal

• Complete hot runner is ready to be fastened to the cavity plate and begin production.

• Simplified communication by providing one source responsibility.

™ systems.

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

6

2006.08

Page 7

Introduction

Single Drop Assemblies

Single drop assemblies are well-suited for single cavity molds and prototype applications. Two single drop system types

are available:

• Single Cavity Valve Gate (SCVG).

• Hot Sprue (HS).

SCVG

The SCVG is ideal for applications that require negligible gate vestige . R es in flow is mechanically regulated. Ultra 500,

Ultra 750 and Ultra 1000 SCVG’s are available for fast delivery.

HS

The HS is best suited for applications where a small gate mark is acceptable. Resin flow is thermally regulated. Ultra 500,

Ultra 750 and Ultra 1000 HS are available for fast delivery.

2006.08

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

7

Page 8

Introduction

TOLERANCE AND DIMENSION STANDARDS

All drawings within this section use imperial units of measurement. To simplify the drawing, the standard dimension

tolerancing, surface finishes, parallelism, and concentricity requirements are listed below and followed throughout the

manual. In situations where special tolerances or finishes are used, these are indicated on the drawing.

Tolerances

1 decimal place (.1)

2 decimal places (.01)

3 decimal places (.001)

4 decimal places (.0001)

Surface Finish

16µin

32µin

64µin

Definitions

To reduce the amount of text, the following symbols/abbreviations are used on the drawings:

Ø Full Diameter

Imperial

+/-.02

+/-.008

+/-.004

N/A

SR Spheric al Radius

BK-PLT Backing Plate

MF-PLT Manifold Plate

FR Full Radius

R, RAD Radius

B Nozzle Bore Depth

Gate Land

Sharp

XX Value

YY Value

T/C Thermocouple

G

Gate

> Minimum, greater than

< Maximum, less than

Contact Husky

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

8

2006.08

Loading...

Loading...