Page 1

Demolition Hammer

Martillo

日立牌電動鎚

H 90SB

HANDLING INSTRUCTIONS

INSTRUCCIONES DE MANEJO

使用說明書

Read through carefully and understand these instructions before use.

Leer cuidadosamente y comprender estas instrucciones antes del uso.

使用前務請詳加閱讀-

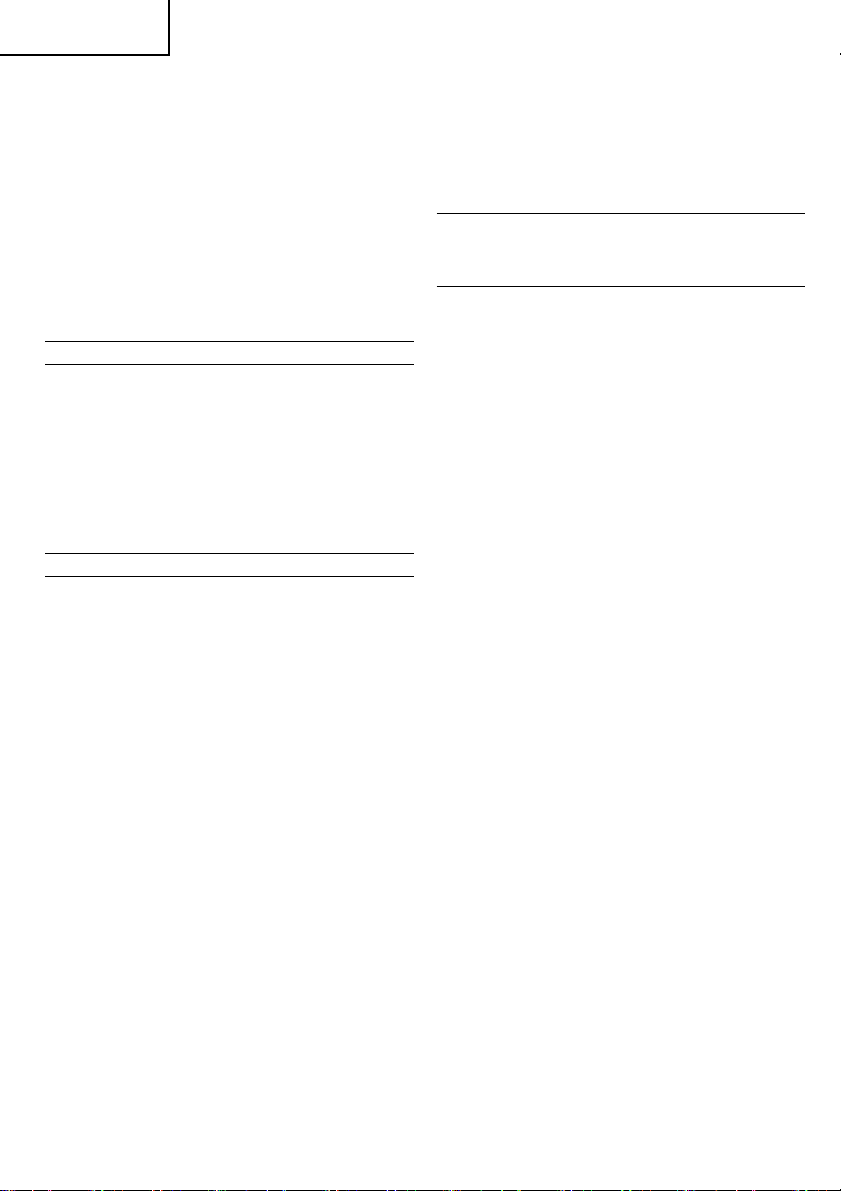

Page 2

12

2

3

1

1

3

4

4

86

7 mm

17 mm

English Español

1 Front cover Cubierta delantera

2 Retainer Retenedor

3 Tool shank Barrena

4 Wear limit Límite de desgaste

5 No. of carbon brush No. de escobilla de carbón

6 Tail cover Cubiertra posterior

7 Hexagon socket hd. bolt M5 × 10

5

Perno de cabeza hexagonal

M5 × 10

7

6

中國語

前罩

夾持器

工具柄

磨損極限

碳刷號

後罩

六角型螺拴 M5 × 10

1

Page 3

English

GENERAL OPERATIONAL PRECAUTIONS

WARNING! When using electric tools, basic safety pre-

cautions should always be followed to reduce the risk of

fire, electric shock and personal injury, including the

following.

Read all these instructions before operating this product

and save these instructions.

For safe operations:

1. Keep work area clean. Cluttered areas and benches

invite injuries.

2. Consider work area environment. Do not expose

power tools to rain. Do not use power tools in

damp or wet locations. Keep work area well lit.

Do not use power tools where there is risk to

cause fire or explosion.

3. Guard against electric shock. Avoid body contact

with earthed or grounded surfaces. (e.g. pipes,

radiators, ranges, refrigerators).

4. Keep children away. Do not let visitors touch the

tool or extension cord. All visitors should be kept

away from work area.

5. Store idle tools. When not in use, tools should

be stored in a dry, high or locked up place, out

of reach of children.

6. Do not force the tool. It will do the job better and

safer at the rate for which it was intended.

7. Use the right tool. Do not force small tools or

attachments to do the job of a heavy duty tool.

Do not use tools for purposes not intended; for

example, do not use circular saw to cut tree limbs

or logs.

8. Dress properly. Do not wear loose clothing or

jewellery, they can be caught in moving parts.

Rubber gloves and non-skid footwear are recommended when working outdoors. Wear protecting

hair covering to contain long hair.

9. Use eye protection. Also use face or dust mask

if the cutting operation is dusty.

10. Connect dust extraction equipment.

If devices are provided for the connection of dust

extraction and collection facilities ensure these

are connected and properly used.

11. Do not abuse the cord. Never carry the tool by

the cord or yank it to disconnect it from the

receptacle. Keep the cord away from heat, oil and

sharp edges.

12. Secure work. Use clamps or a vise to hold the

work. It is safer than using your hand and it frees

both hands to operate tool.

13. Do not overreach. Keep proper footing and balance at all times.

14. Maintain tools with care. Keep cutting tools sharp

and clean for better and safer performance. Follow instructions for lubrication and changing

accessories. Inspect tool cords periodically and if

damaged, have it repaired by authorized service

center. Inspect extension cords periodically and

replace, if damaged. Keep handles dry, clean, and

free from oil and grease.

15. Disconnect tools. When not in use, before servicing, and when changing accessories such as

blades, bits and cutters.

16. Remove adjusting keys and wrenches. Form the

habit of checking to see that keys and adjusting

wrenches are removed from the tool before turning it on.

17. Avoid unintentional starting. Do not carry a

plugged-in tool with a finger on the switch. Ensure

switch is off when plugging in.

18. Use outdoor extension leads. When tool is used

outdoors, use only extension cords intended for

outdoor use.

19. Stay alert. Watch what you are doing. Use common sense. Do not operate tool when you are

tired.

20. Check damaged parts. Before further use of the

tool, a guard or other part that is damaged should

be carefully checked to determine that it will

operate properly and perform its intended function. Check for alignment of moving parts, free

running of moving parts, breakage of parts,

mounting and any other conditions that may affect

its operation. A guard or other part that is damaged should be properly repaired or replaced by

an authorized service center unless otherwise

indicated in this handling instructions. Have defective switches replaced by an authorized service

center. Do not use the tool if the switch does not

turn it on and off.

21. Warning

The use of any accessory or attachment, other

than those recommended in this handling instructions, may present a risk of personal injury.

22. Have your tool repaired by a qualified person.

This electric tool is in accordance with the relevant

safety requirements. Repairs should only be carried out by qualified persons using original spare

parts. Otherwise this may result in considerable

danger to the user.

PARTICULAR PRECAUTIONS ON USING

DEMOLITION HAMMER

In addition to the precautions mentioned above, following

particular precautions for this demolition hammer should

be followed.

1. Wear earplugs to protect your ears during opera-

tions.

2. Do not touch the bit during or immediately after

operation. The bit becomes very hot during operation and could cause serious burns.

3. Before starting to break, chip or drill into a wall,

floor or ceiling, thoroughly confirm that such items

as electric cables or conduits are not buried inside.

4. Properly set the bit holder.

5. At the start of work, confirm screw tightening.

6. When working at a highly elevated location, pay

attention to articles and persons below.

7. Wear protective shoes to protect your feet.

2

Page 4

SPECIFICATIONS

Voltage (by areas)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Power input* 1450W

Full-load impact rate 850/min.

Weight (without cord) 32 kg

*Be sure to check the nameplate on this demolition hammer as it is subject to change by areas.

STANDARD ACCESSORIES

(1) Hexagon Bar Wrench for M12 .............................. 1

(2) Hexagon Bar Wrench for M8 ................................ 1

(3) Hexagon Bar Wrench for M5 ................................ 1

(4) Side Handle ............................................................... 1

(5) Bolt .............................................................................. 4

(6) Spring Lock Washer ................................................4

Standard accessories are subject to change without notice.

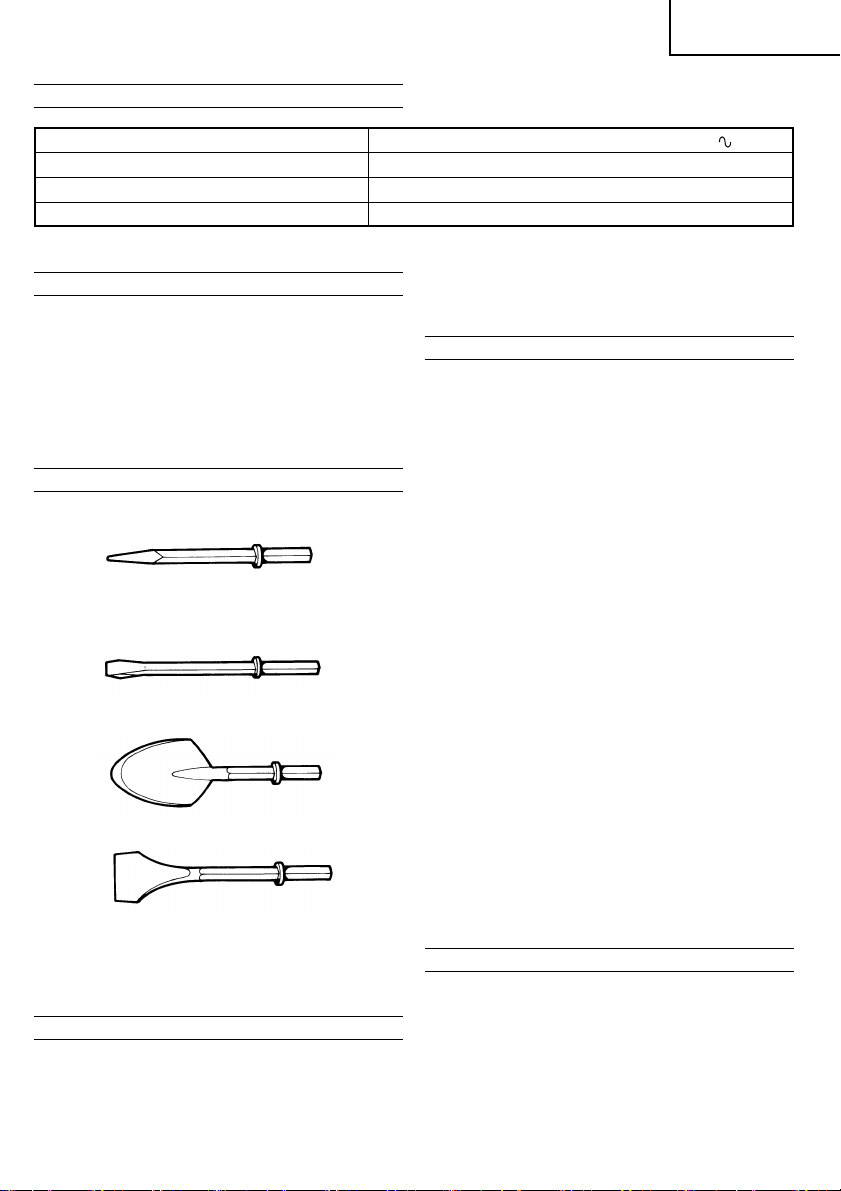

OPTIONAL ACCESSORIES (sold separately)

1. Bull point

Overall length: 520 mm

2. Cold chisel

3. Scoop

4. Cutter

5. Hammer grease 500 g (in a can)

Optional accessories are subject to change without notice.

Overall length: 520 mm

Overall length: 546 mm

Overall length: 520 mm

Width: 75 mm

APPLICATIONS

This demolition hammer should be applied to breaking

concrete, chipping off concrete, grooving, bar cutting and

driving piles in installation of piping and wiring, sanitary

facility installation, machinery installation, water supply

and drainage work, interior jobs, harbor facilities and

other civil engineering work.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specified on the

nameplate of this demolition hammer.

2. Power switch

Ensure that the power switch is in the OFF position.

If the plug is connected to a receptacle while the

power switch is in the ON position, this demolition

hammer will start operating immediately, inviting

serious accident.

3. Extension cord

When the work area is remote from the power

source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be

kept as short as practicable.

4. Mounting an accessory, such as a bull point, a

cutter, etc.

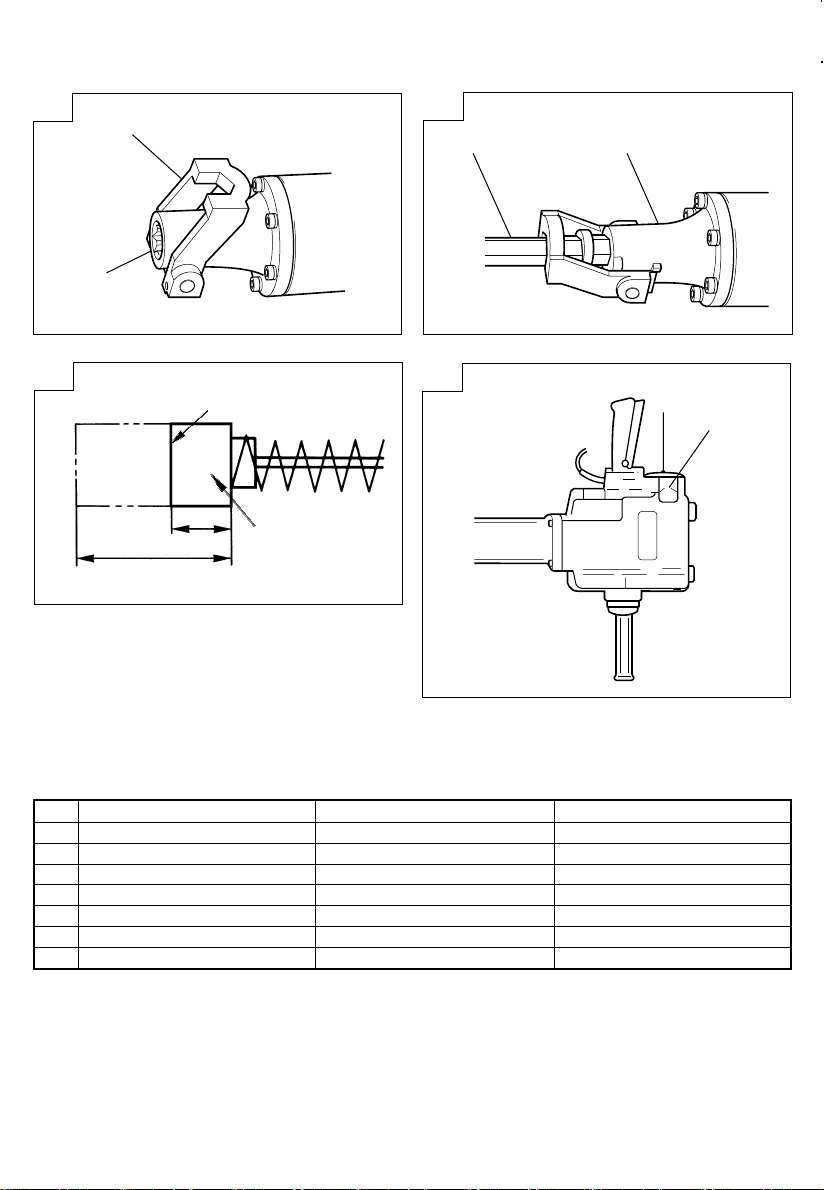

(1) With the retainer directed backward, insert the

accessory shank point into the hole on the front

cover. (Fig. 1)

(2) Swing the retainer back into place so that it engages

the accessory shank point and prevents the

accessory, such as a bull point, a cutter, etc. from

coming all the way out of front cover. (Fig. 2)

NOTE

Use a manual hammer to open/close the retainer,

as it is too heavy to move by hand.

When removing the accessory, such as a bull point,

a cutter, etc., follow the above procedure in reverse

order.

5. Always hold the body handle and side handle of

this demolition hammer firmly.

Otherwise the counterforce produced may result in

inaccurate and even dangerous operation.

OPERATION

1. Pull the trigger switch after applying the tip of the

bit to the crushing position.

In some cases, it is necessary to punch the tip of

the bit against the crushing position forcibly in

order to begin the striking stroke.

This is not due to malfunction of the power tool.

It means that the safe guard mechanism against

no-load striking is working.

English

3

Page 5

English

2. Operate this demolition hammer by utilizing its

own weight.

The performance will not be better even if it is

pressed or thrust forcibly against the work surface.

Hold this demolition hammer with a force just

sufficient to counteract the reaction.

CAUTION

Sometimes the power tool does not begin the

striking stroke even when the motor rotates because

the oil has become thick.

If the power tool is used at low temperatures or

if it is used after a long idle time, this demolition

hammer should be kept running in for about five

minutes in order to warm it up.

HOW TO REPLACE GREASE

This demolition hammer is full air-tight construction

to protect against dust and to prevent lubricant leakage.

Therefore, this demolition hammer can be used without

lubrication for long periods. Replace the grease as

described below.

Grease replacement period

After purchase, replace grease after every 6 months

of usage. Ask for grease replacement at the nearest

authorized service center.

MAINTENANCE AND INSPECTION

1. Inspecting this demolition hammer

Use of a dull accessory, such as a bull point, a

cutter, etc., will cause motor malfunctioning and

degraded efficiently. Replace with a new one without

delay when abrasion is noted.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

3. Inspecting the retainer (Fig. 1, Fig. 2)

The retainer may become loose due to excessive

use. Always, pay attention to its proper functioning

to securely hold the accessory shank portion. If any

wear and tear is found, bring this demolition

hammer to an authorized service center for

maintenance service.

4. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool. Exercise due care to ensure the winding

does not become damaged and/or wet with oil or

water.

5. Inspecting the carbon brushes (Fig. 3)

The motor employs carbon brushes which are

consumable parts. When they become worn to or

near “wear limit”, it results in motor trouble. When

an auto-stop carbon brush is equipped, the motor

will stop automatically. At that time, replace both

carbon brushes with new ones which have the

same carbon brush Nos. shown in the figure 3. In

addition, always keep carbon brushes clean and

ensure that they slide freely within the brush holders.

6. Replacement procedure

Loosen the screw (Hexagon socket hd. bolt M5 ×

10) of the tail cover, then remove the tail cover

(Fig. 4). After removing the brush cap, the carbon

brush can be removed.

After replacing the carbon brush, tighten the brush

cap, then mount the tail cover securely.

NOTE

Due to HITACHI’s continuing program of research and

development, the specifications herein are subject to

change without prior notice.

4

Page 6

Español

PRECAUCIONES GENERALES PARA

OPERACIÓN

¡ADVERTENCIA! Cuando utilice herramientas eléctricas,

tome las medidas de seguridad básicas para reducir

el riesgo de incendios, descargas eléctricas, y lesiones,

incluyendo lo siguiente. Lea todas todas estas

instrucciones antes de utilizar este producto y guárdelas.

Para realiza roperaciones seguras:

1. Mantener el área de trabajo limpia, áreas y bancos

de trabajo desordenados son causa de da ños

personales.

2. Considerar el medio ambiente del área de trabajo.

No exponer las herramientas eléctricas a la lluvia.

No usar herramientas eléctricas en lugares mojados o húmedos. Mantener el área de trabajo bien

iluminada.

No utilice herramientas eléctricas cuando exista

el riesgo de incendios o de explosión.

3. Protegerse contra descargas eléctricas. Evitar el

contacto del cuerpo con las superficies puestas

a tierra. (p. ej., tubos, radiadores, hornos de

microondas, o refrigeradores.)

4. Mantener a los ni ños alejados. No dejar que los

visitantes toquen las herramientas ni los cables

de extensión. Todos los visitantes deberán

mantenerse alejados del área de trabajo.

5. Guardar las herramientas que no se usen y

ponerlos en lugares secos, altos o cerrados, fuera

del alcance de los ni ños.

6. No forzar las herramientas, éstas trabajarán más

y con mayor seguridad cuando cumplan con las

especificaciones para las cuales fueron diseñadas.

7. Usar las herramientas apropiadas. No forzar

pequeñas herramientas o accesorios a realizar el

trabajo de herramientas de mayor potencia. No

utilizar herramientas para otros propósitos para

los cuales no fueron dise ñadas, por ejemplo, no

utilizar sierras circulares para cortar ramas de

árboles o troncos.

8. Vestir apropiadamente. No ponerse ropas que

queden flojas ni tampoco joyas. Estas podrian

quedar atrapadas en las partes móviles de las

herramientas. Cuando se trabaje en exteriores, se

recomienda el uso de guantes de goma y calzado

que no resbale.

9. Usar gafas de protección. Usar también mascarillas

contra el polvo si las condiciones de corte fuesen

polvorientas.

10. Conecte un equipo colector de polvo.

Si existen dispositivos para la conexión de equipos

de extracción y recolección de polvo, cerciórese

de queéstos estén conectados adecuadamente, y

de utilizarlos en la forma correcta.

11. Cuidar del cable. Nunca lleve las herramientas

colgando del cable, tampoco tire del cable para

efectuar la desconexión de las herramientas.

Mantener el cable alejado del calor, aceite y bordes

agudos.

12. Asegurar la pieza de trabajo usando para ello

abrazaderas o un tornillo. Esto es más seguro que

usar las manos, ademas, ambas manos quedan

libres para operar la herramienta.

13. No extenderse excesivamente para efectuar un

trabajo. Mantener en todo momento un buen

balance y base de apoyo.

14. Mantener cuidadosamente las herramientas.Tener

las siempre limpias y afiladas para obtener un

mejor rendimiento y un funcionamiento más

seguro. Seguir siempre las instrucciones para la

lubricación y el cambio de accesorios. Inspeccionar

periódicamente los cables de las herramientas y

si estuviesen da nãdos, hacer que los reparen

técnicos ó expertos. Inspeccionar periodicamente

los cables de extensión y cambiarlos si estuviesen

da ñados. Mantener los mangos secos, limpios,

y libres de aceite y grasa.

15. Desconectar las herramientas cuando no se usen,

antes de repararlas, y cuando se cambien

accesorios como por ejemplo, cuchillas, brocas,

cortadores, etc.

16. Quitar las cuñas y las llaves de tuercas.

Acostumbrarse a comprobar si se han quitado las

cu ñas y las llaves de tuercas antes de poner las

harramientas en funcionamiento.

17. Evitar puestas en funcionamiento sin fin alguno.

No llevar las herramientas con los dedos en los

inerruptores mientras que éstas cstán conectadas.

Cuando se conecten las herramientas, cerciorarse

de que los interruptores esten en la posición de

desconectados.

18. Para usos en exteriores usar cables de extensión.

Cuando las herramientas vayan a ser usadas en

exteriores, usar solamente cables de extensión

diseñados para tal propósito.

19. Estar siempre alerta y poner atención a lo que

se está haciendo, usar el sentido común y no

operar con la herramienta cuando se esté cansado.

20. Comprobar las piezas dañadas. Antes de seguir

con el funcionamiento de las herramientas, las

piezas que estén dañadas deberán comprobarse

cuidadosamente para determinar si pueden

funcionar apropiadamente y cumplir con la función

para las que fueron dise ñadas. Comprobar el

alineamiento y agarrotamiento de piezas móviles,

rotura de piezas, montura, y cualiquier otra

anomalia que pudiese afectar al rendimiento de

la herramienta. Cualquier pieza que estuviese da

ñada deberá repararse apropiadamente o

cambiarse en un centro de reparaciones autorizado,

al menos que se indique, lo contrario en este

manual de instrucciones. Procurar que los

interruptores defectuosos los cambie un centro de

reparaciones autorizado.

No usar las herramientas si sus interruptores no

funcionasen apropiadamente.

21. Advertencia

La utilización de cualquier accesorio o aditivo no

recomendado en este manual de instrucciones

puede conducir al riesgo de lesiones.

22. En caso de avería, haga que su herramienta sea

reparada por un técnico cualificado.

Esta herramienta eléctrica está de acuerfdo con

los requisitos de seguridad pertinentes. Las

reparaciones solamente deberán realizarlas

técnicos cualificadosutilizando piezas de repuesto

originales. De lo contrario, el usuario podría

lesionarse.

5

Page 7

Español

PRECAUCIONES ESPECIALES AL USAR EL

MARTILLO

Además de las precauciones que se han indicado, se

deben seguir las precauciones especiales de este

martillo.

1. Usar protectores de oídos durante el trabajo.

2. No tocar la broca durante ni inmediatamente

después de trabajar, puesto que se pone ardiente

y puede causar quemaduras serias.

3. Antes de empezar a romper, picar o perforar en

una pared, suelo o techo, comprobar cuidadosamente

que no hayan objetos empotrados, tales como cables

o conductos eléctricos.

4. Coloque correctamente el portabrocas.

5. Al comenzar el trabajo, compruebe si los tornillos

están apretados.

6. Cuando tenga que trabajar en un lugar elevado,

tenga cuidado con las cosas y personas que haya

debajo.

7. Utilice botas de seguridad para proteger sus pies.

ESPECIFICACIONES

Voltaje (por áreas)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Acometida* 1450 W

Impacto a carga plena 850/min.

Peso (sin cable) 32 kg

* Verifique los datos de la placa del martillo, pues varían de acuerdo con el país de destino.

ACCESORIOS ESTANDAR

(1) Llave de barra hexagonal para M12 ................... 1

(2) Llave de barra hexagonal para M8 ..................... 1

(3) Llave de barra hexagonal para M5 ..................... 1

(4) Mango lateral ........................................................... 1

(5) Perno .......................................................................... 4

(6) Arandela de seguridad ........................................... 4

Los accessorios estándar están sujetos a cambios sin

previo aviso.

ACCESORIOS FACULTATIVOS

(de venta por separado)

1. Punta

Longitud total: 520 mm

2. Cincel frío

Longitud total: 520 mm

3. Pala

Longitud total: 546 mm

4. Cargadora

Longitud total: 520 mm

Antura: 75 mm

6

5. Grasa para martillo 500 (en una lata)

Los accesorios facultativos están sujetos a cambios sin

previo aviso.

APLICACIONES

Este martillo se debe utilizar para romper hormigón

armado, cortar o picar hormigón, hacer ranuras, cortes

y colocar pilotes en las obras de instalación de tuberías

y artículos sanitarios, instalación de maquinarias,

trabajos de suministro de agua y de drenaje, trabajos

en interiores, instalaciones portuarias y demás trabajos

propios de ingeniería civil.

ANTES DE LA PUESTA EN MARCHA

1. Alimentación

Asegúrese de que la alimentación de red que se

debe utilizar responde a las exigencias de corriente

especificadas en la placa de características del

martillo.

2. Conmutador de alimentación

Asegúrese de que el conmutador de alimentación

esté en la posición OFF (desconectado).

Si la clavija está conectada a la caja del enchufe

mientras el conmutador de alimentación esté en

posición ON (conectado), el martillo empezará a

trabajar inmediatamente, pudiendo provocar

accidentes graves.

3. Cable de prolongación

Cuando el área de trabajo está lejos de la red de

alimentación, utilice un cable de prolongación de

un grosor suficiente y de potencia nominal.

El cable de prolongación debe ser lo más corto

posible.

4. Montaje de un accesorio como, por ejemplo, una

punta maestra, una cuchilla, etc.

(1) Con el retenedor dirigido hacia atrás, inserte la

punta del vástago del accesorio en el orificio de

la cubierta frontal. (Fig. 1)

Page 8

Español

(2) Deslice el retenedor hasta su posición de forma que

enganche la punta del vástago del accesorio para evitar

que el accesorio (la punta maestra, la cuchilla, etc.) se

salga a través de la cubierta frontal. (Fig. 2)

NOTA

Para abrir y cerrar el retenedor, utilice un martillo,

ya que es demasiado pesado para moverlo

manualmente.

Para extraer el accesorio (por ejemplo, la punta

maestra, la cuchilla, etc.), siga el procedimiento

inverso.

5. Sujete siempre firmemente el asidero del cuerpo

y el asidero lateral del martillo.

De lo contrario, la contrafuerza producida podría

causar un funcionamiento impreciso e incluso

peligroso.

OPERACIÓN

1. Después de aplicar con fuerza la punta de la

herramienta contra la superficie de trabajo, apriete

el interruptor disparador para comenzar la percusión.

Esto no se debe a una avería de la herramienta

eléctrica.

Esto significa que está trabajando el mecanismo de

protección contra la percusión sin carga.

2. Emplee el martillo utilizando su propio peso.

El rendimiento no mejorará aunque presione con

mayor fuerza la heramienta contra la superficie de

trabajo.

Emplee la fuerza suficiente en el martillo para

controlar la reacción.

PRECAUCIÓN

Puede ser que algunas veces la herramienta eléctrica

no comience a percutir, aunque el motor esté en

funcionamiento, debido a que el aceite se ha vuelto

espeso.

Cuando utilice la herramienta eléctrica a bajas

temperaturas, o cuando no la haya utilizado durante

mucho tiempo, deje el martillo en funcionamiento

durante cinco minutos aproximadamente para que

se caliente.

CAMBIO DE GRASA

La construcción de este martillo completamente estanca,

para evitar que entre polvo y haya fugas de lubricante.

Por ello, el martillo puede usarse sin lubricante durante

largos períodos. Cuando haya que cambiar la grasa,

proceda como sigue:

Período de cambio de grasa

Tras la adquisición de la herramienta, cambie la grasa

cada 6 meses de uso. Consultar para ello al centro de

servicio autorizado.

MANTENIMIENTO E INSPECCION

1. Inspección del martillo

La utilización de un accesorio mellado (por ejemplo,

una punta maestra, una cuchilla, etc.) puede causar

la avería del motor y degradar la eficacia. Cuando

note abrasión, reemplácela lo antes posible por

otra nueva.

2. Inspección de los tornillosde montaje

Inspeccionar regularmente todos los tornillos de

montaje y asegurarse de que estén apretados

firmemente. Si cualquier tornillo estuviera suelto,

volver a apretarlo inmediatamente. El no hacer esto

provocaría un riesgo serio.

3. Inspección del retenedor (Fig. 1, Fig. 2)

Es posible que el retenedor se afloje debido a un

uso excesivo. Fíjese siempre si funciona

correctamente para sujetar bien el vástago del

accesorio. Si descubre algún desgaste o rotura,

lleve el martillo a un centro de servicio autorizado

para que lo reparen.

4. Mantenimiento del motor

La unidad de bobinado del motor es el verdadero

“corazón” de las herrantientas eléctricas.

Prestar el mayor cuidado a asegurarse de que el

bobinado no se dañe y/o se humedezca con aceite

o agua.

5. Inspección de las escobillas de carbón (Fig. 3)

El motor emplea escobillas de carbón que son

partes consumibles. Cuando se gasten o estén cerca

del “límite de uso”, causan problemas al motor.

Al equiparse la escobilla de carbón de parada

automática, el motor se detendrá automáticamente.

En ese momento hay que proceder a cambiar ambas

escobillas de carbón por las nuevas, que tienen los

mismos números de escobillas de carbón que se

muestran en la figura 3. Adicionalmente, debe

mantener siempre limpias las escobillas de carbón

y asegurarse de que se deslicen libremente dentro

de los portaescobillas.

6. Procedimiento de reemplazo

Afloje el tornillo (perno de cabeza hexagonal M5

× 10) de la cubierta posterior, y extraiga ésta

(Fig. 4).

Después de reemplazar las escobillas, apriete las

tapas de las mismas y, por último, monte

firmemente la cubierta posterior.

NOTA

Debido al programa continuo de investigación y

desarollo de HITACHI estas especificaciones están

sujetas a combios sin previo aviso.

7

Page 9

中國語

作業上的一般注意事項

警告﹗當使用電動工具時-為了減少造成火災﹑電擊

和人身傷害-必須時刻遵守基本注意事項-以及

下述操作注意事項在操作本機之前-請通讀本說明書-並予以妥善

保管-

安全操作注意事項︰

1. 工作場所應打掃乾淨-清理妥當-雜亂無章將導

致事故-

2. 確保妥適的作業環境-電動工具不可任其風吹雨

打-不得在潮濕的地方作業-工作場所需保持充

分的亮度-請勿在有可能造成火災或爆炸的地方

使用電動工具-

3. 謹防觸電事故-應避免身體同大地或接地表面不

可讓訪客觸摸電動工具或延伸線纜接觸(例如︰

管道﹑散熱器﹑爐灶﹑冰箱等)

4. 不可讓孩童靠近工作場所-與作業無關的訪客也

必須保持安全距離-

5. 不使用的電動工具應存放到乾燥而孩童伸手不及

的高處-並加鎖保管-

6. 不得使勁用力推壓-電動工具需按設計條件才能

有效而安全地工作-絕不可勉強-

7. 妥選使用工具- 不可用小型工具或附件去幹重

活-不可用於規定外的作業-舉例說-用圓鋸進

行伐木打枝或原木鋸切作業-

8. 工作時衣服穿戴要合適-不要讓松散的衣角和寶

石類卷入轉動部份-屋外作業時-最好手戴橡膠

手套-腳穿防滑膠鞋-同時要戴上能夠罩籠長髮

的工作帽-

9. 絕大多數的電動工具作業時-均需戴安全眼鏡進行粉塵飛揚的切削作業時-需戴防塵面罩-

10. 連接除塵設備

如果提供連擊除塵和集塵的設備-請確認是否已

經連接好並且使用正常-

11. 不要拿電線提起電動工具-也不得拉扯電線從電

源插座拆除插頭-電線需從熱源和油液隔開-並

避免與銳利的邊緣接觸-

12. 作業以安全第一為原則-工件要用夾具或臺鉗卡

緊-這樣做-比用手按壓更為可靠-也能夠讓雙

手專心操作-

13. 作業時腳步要站穩-身體姿勢要保持平衡-

14. 工具應維護妥善-經常保持鋒利﹑清潔才能充分

發揮性能-落實作業安全的要求-應按規定加注

潤滑脂﹑更換附件-線纜應定期檢查-如發現損

傷應即委託專業性的服務單位加以修復-延伸電

纜如有損傷應予更換-手柄要保持乾燥-並防止

沾附油脂類-

15. 不使用時-維修前以及更換附件(如:刀具﹑鑽

頭﹑鋸具等)之前-都必須拆卸電源插頭才行-

16. 開動前務必把調整用鍵和扳手類拆除下來-這一

點與安全有關-應養成習慣-嚴格遵守-

17. 謹防誤開動-插頭一插上電源插座-指頭就不可

隨便接觸電源開關-插接電源之前-應先確認:

開關是否切斷-

18. 屋外延伸線纜的使用-屋外作業時-必須使用專

用的延伸線纜-

19. 保持高度警覺-充分掌握情況-以正常的判斷力

從事作業-疲憊時切不可開動電動工具-

20. 檢查損壞部件-在繼續使用電動工具之前-應詳

細檢查各部零件以及防護裝置有無損壞-以便決

定能否正常工作-能否發揮正常效能-檢查轉動

部份的對準﹑空轉﹑各零件有無異常-安裝是否

妥善以及其它足以給工作帶來不良影響的情況如防護以及其它零件損傷了-除非本說明書中已

有記載否則應即委託服務中心進行修理或更換開關一發現缺陷-應即委託服務中心加以更換如開關不能正常地接通或切斷-絕不可使用該電

動工具-

21. 警告

為了防止人身傷害-不得使用電動工具去進行規

定外的作業-並祇能使用本說明書目錄中所指定

的附件-

22. 本工具必須委托有資格的維修人員進行維修本電動工具滿足相關的安全要求-維修必須由專

業人員使用純正配件來進行-否則有可能會給用

戶造成人身損害-

8

Page 10

中國語

使用電動鎚時的特別注意事項

除上述注意事項外﹐使用電動鎚時﹐還應遵守下列特

別注意事項-

1. 作業時戴上耳塞保護您的耳朵-

2. 不要在作業時或作業之後馬上就觸摸鑽頭-在作業

時鑽頭變得非常熱﹐可能引起嚴重的燒傷-

3. 鑽鑿牆壁﹑天花板﹑地板時﹐應先確認有無埋設電

纜﹑管道等-

4. 正確固定好鑽頭套-

5. 開始作業時﹐要先確認螺釘類是否妥善扭緊-

6. 在高處作業時﹐應充分注意下面的東西和行人安

全-

7. 穿上保護鞋以保護足部-

規 格

電 壓(按地區)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

輸入功率* 1450W

滿載衝擊率 850 次/分

重 量(不含線纜) 32 kg

*當須改變地區時﹐應檢查該電動鎚上的銘牌-

4. 刀具

標準附件

(1) 六角頭棒形扳手 用於 M12 ............................. 1

(2) 六角頭棒形扳手 用於 M8 ............................... 1

(3) 六角頭棒形扳手 用於 M5 ............................... 1

(4) 側柄................................................................. 1

(5) 螺栓................................................................. 4

(6) 彈簧鎖墊圈 ...................................................... 4

標準附件可能不預先通告而徑予更改-

5. 電動鎚潤滑油 500g(在油罐內)

選購附件可能不預先通告而徑予更改-

用 途

全長:520 mm

寬 :75 mm

選購附件(分開銷售)

1. 尖鑽頭

全長:520 mm

2. 冷鑿

全長:520 mm

3. 鏟子

全長:546 mm

本電動鎚適用於混凝土破碎﹑混凝土切削﹑開槽﹑棒

切割與打椿及裝配管道﹑敷設線纜﹑衛生記備安裝﹑

機械安裝﹑給排水設施建設﹑室內裝修﹑港口設施建

設﹑其他土木工程施工中的混凝土破碎﹑混凝土切

削﹑開槽﹑棒切割與打椿-

作業之前

1. 電源

確認所使用的電源與本電動鎚銘牌上標示的規格是

否相符-

2. 電源開關

確認電源開關是否切斷-若電源開關接通-則插頭

插入電源插座時﹐電動鎚將出其不意地立刻轉動﹐

從而招致嚴重事故-

9

Page 11

中國語

3. 延伸線纜

若作業場所遠離電源﹐應使用容量足夠﹑鎧裝合適

的延伸線纜﹐並且要盡可能地短些-

4. 裝上附件﹐如尖鑽頭﹑鋸具等-

(1) 把擋板向後拉-在前蓋的孔內插入附件杆頭-

(圖 1)

(2) 放回擋板-使它與附件杆頭接合-並使附件﹐如尖

鑽頭﹑鋸具等不會從前蓋中出來-(圖 2)

註

使用榔頭打開/關閉擋板﹐擋板太重﹐用手無法移

動拆下附件﹐如尖鑽頭﹑鋸具時﹐按上面的順序相

反的步驟-

5. 一定要握緊機身上的把手和電動鎚的把手-

否則﹐反作用力會導致不準確甚至危險的操作-

操作

1. 把鑽頭對準擊碎的位置後-再扣動開關在某些情況下-要用力把鑽頭擊打要擊碎的位置以

開始粉碎這不是電動工具故障-而是在無負載沖擊時的保護

機製-

2. 用電動鎚本身的重量來操作用力按壓鎚不會有更好的操作性能應只用能抗拒反作用力大小的力來握住鎚-

註

有時因為机油變渾濁﹐即便是馬達旋轉電動工

具也不會開始擊碎如果在低溫下使用電動工具或閑置長時間後再

使用時﹐為了預熱﹐電動鎚需運行約 5 分鐘-

如何換機油

維護和檢查

1. 電動鎚的檢修

使用磨損的附件﹐如尖鑽頭﹑鋸具等﹐會造成馬達

故障和降低效率-有磨損時應立即更換新的-

2. 檢查安裝螺釘

要經常檢查安裝螺釘是否緊固妥善-若發現螺釘鬆

了﹐應立即重新扭緊﹐否則會導致嚴重的事故-

3. 檔板的檢修(圖 1、圖 2)

檔板使用時間較長時會鬆弛-應時刻注意其能否正

常發揮作用﹐牢牢固持附件桿部分-若發現電動鎚

有任何磨損或損壞﹐請送至授權的維修中心進行維

修-

4. 電動機的維護

電動機繞線是電動工具的心臟部-應仔細檢查有無

損傷﹐是否被油液或水沾濕-

5. 檢查碳刷(圖 3)

電動機所用的碳刷是一種消耗品-碳刷一旦使用到

磨損極限﹐電動機就會出現各種障礙; 如果所使用

的碳刷是"自停式"﹐電動機將自動地停止轉動-遇

到上述情況﹐應立即換上與圖3上代號一致的新碳

刷此外﹐碳刷應經常保持乾淨狀態﹐以保証能在刷握

中自由滑動-

6. 更換步驟

松開後蓋的螺絲(M 5 × 10六角型螺栓)

(圖 4)-然後取下後蓋-取掉碳刷蓋後-可取下

碳刷更換碳刷後-擰緊碳刷蓋-然後確實地裝上後蓋-

註

為求改進﹐本手冊所載規格可能不預先通告而徑予更

改-

本電動鎚是密封的-以防止灰塵進入和潤滑油流出所以本電動鎚可以不加潤滑油而使用很長的時間-按

下列方法更換機油-

機油更換時間

購買本機後-每使用 6 個月可更換機油-在離您最

近的授權維修中心更換機油-

10

Page 12

中國語

11

Page 13

中國語

12

Page 14

中國語

Item

No.

1 Roll Piin D6✕36

2 Lever Pin

3 Seal Lock Bolt M12✕40

4 Retainer

5 Front Cover

6O-Ring (S-90)

7 O-Ring

8 Second Hammer

9 O-Ring (D)

10 O-Ring (A)

11 Hammer Holder

12 Seal Lock Hex. Socket Hd.Bolt M6✕16

13 Stopper Washer

14 Handle (A)

15 Rubber Leg

16 Cord Clip

17 Tapping Screw (W/Washer) D4✕20

18 Handle Rubber

19 Handle (B)

20 Switch

21A Support (E)

22 Seal Lock Hex. Socket Hd. Bolt M6✕16

23 Retaining Ring For D4 Shaft

24 Switch Lever

25 Pin

26 Internal Wire Holder

27 Brush Cap

28C Carbon Brush

29 Brush Holder

30 Stop Plate

31 Damper

32 Damper Plate

33 Mouth

34 Mouth Washer

35 Urethane Ring

36 Cylinder Case

37 Seal Lock Bolt M10✕45

38 Washer M10

39 O-Ring

40 Striker

41 O-Ring (B)

42 Piston Pin

43 Piston

44 Oil Seal (A)

45 Connecting Rod Ass’y

46 Needle Bearing (NSK RLM2220)

47 Cord

48 Tube (D)

49 Cord Armor

50 Vinyl Tube (A) I.D.7✕T0.5✕50

51 Terminal M4

52 Ball Bearing (6305VVCMPS2S)

53 Oil Seal

54 O-ring (A)

55 Bearing Boss

56 Spring Washer M6

57 Seal Lock Hex. Socket Hd. Bolt M6✕20

58 Crank Washer

59 Seal Lock Hex. Socket Hd. Bolt M10✕16

60 Support (B)

Part Name

Item

No.

61 Noise Suppressor

62 Pillar Terminal

63 Connector (50091)

64 Connector (50092)

65 Internal Wire

66 Seal Lock Hex. Socket Hd. Bolt M10✕60

67 Seal Lock Hex. Socket Hd. Bolt M8✕30

68 Spring Washer M8

69 Side Hanle

70 Ball Bearing (6204VVCMPS2S)

71 Distance Washer

72 Final Gear

73 Distance Ring (B)

74A Inner Cover

75 Housing Ass’y

76 O-ring (S-38)

77A Oil Cap Ass’y

78A Tail Cover Ass’y

79 Spring Washer M5

80 Seal Lock Hex. Socket Hd. Bolt M5✕10

81 Rivet D2.5✕4.8

82 Name Plate

83 Seal Lock Hex. Socket Hd. Bolt M10✕55

84 Gear Cover

85 Ball Bearing (6201VVCMPS2S)

86 Counter Gear

87 Seal Lock Hex. Socket Hd. Bolt M5✕14

88 Bearing Cover (A)

89 Needle Bearing (BK1312V1)

90 Ball Bearing (6203VVCMPS2S)

91 Bearing Washer

92 Pin D8✕14

93 Feather Key 4✕4✕15

94 Crank Shaft

95 Friction Piece

96 Hex. Socket Set Screw M5✕8

97 Fan

98 Armature Ass’y

99 Hex. Hd. Tappimg Screw D5✕85

100 Special Washer

101 Internal Wire

102 Stator Ass’y

103 Brush Terminal

104 Vinyl Tube (B) I.D.4✕T0.4✕80

105 Bearing Washer

106 Ball Bearing (6201VVCMPS2S)

107 HITACHI Label

108 Housing Cover

109 Collar

110 Bolt Washer M6

111 Spring Washer M6

112 Seal Lock Hex. Socket Hd. Bolt M6✕20

113 Cap Rubber

501 Hex. Bar Wrench 4MM

502 Hex. Bar Wrench 6MM

503 Hex. Bar Wrench 10MM

Parts are subject to change without any obligation on the part

of the HITACHI due to improvements.

Part Name

13

Page 15

中國語

14

Page 16

15

Page 17

Hitachi Koki Co., Ltd.

Code No. C99006732 N

Printed in Japan

407

Loading...

Loading...