Humminbird 196cxi, 196ci, 195c, 165, 175 Owner's Manual

...

PiranhaMAX 165, 175, 176i, 195c, & 196ci

PiranhaMAX 165, 175, 176i, 195c, & 196ci

Installation and Operations Manual

Installation and Operations Manual

532030-1_A

Thank You!

Thank you for choosing Humminbird®, the #1 name in Fishfinders.

Humminbird® has built its reputation by designing and manufacturing

top-quality, thoroughly reliable marine equipment. Your Humminbird®

accessory is designed for trouble-free use in even the harshest marine

environment. In the unlikely event that your Humminbird® accessory does

require repairs, we offer an exclusive Service Policy - free of charge during the

first year after purchase, and available at a reasonable rate after the

one-year period. For complete details, see the separate warranty card included

with your accessory. We encourage you to read this operations manual

carefully in order to get full benefit from all the features and applications of

your Humminbird® product.

Contact our Customer Resource Center at 1-800-633-1468 or visit our

Web site at humminbird.com.

The following models are covered in this manual:

• PiranhaMAX 165 - Single Beam, 240 V x 160 H Monochrome Display

• PiranhaMAX 175 - Dual Beam, 240 V x 160 H Monochrome Display

• PiranhaMAX 176i - Dual Beam, 240 V x 160 H Monochrome Display

• PiranhaMAX 195c - DualBeam,320V x 240 H Transmissive ColorDisplay

• PiranhaMAX 196ci - DualBeam,320V x 240 H Transmissive ColorDisplay

WARNING! This device should not be used as a navigational aid to prevent collision,

grounding, boat damage, or personal injury. When the boat is moving, water depth

may change too quickly to allow time for you to react. Always operate the boat at very

slow speeds if you suspect shallow water or submerged objects.

WARNING! Disassembly and repair of this electronic unit should only be performed by

authorized service personnel.Any modification of the serial number or attempt to repair

the original equipment or accessories by unauthorized individuals will void the warranty.

WARNING! Do not travel at high speed with the unit cover installed. Remove the unit

cover before traveling at speeds above 20 mph.

WARNING! This product contains chemicals known to the State of California to cause

cancer and/or reproductive harm.

i

NOTE: Some features discussed in this manual require a separate purchase, and some

features are only available on international models. Every effort has been made to clearly

identify those features. Please read the manual carefully in order to understand the full

capabilities of your model.

NOTE: The illustrations in thismanual may notlook the same as your product,but your unit

will function in the same way.

NOTE: To purchase accessories for your control head, visit our web site at

humminbird.com or contact our Customer Resource Center at 1-800-633-1468.

NOTE: The procedures and features described in this manual are subject to change

without notice. This manual was written in English and may have been translated to

another language. Humminbird® is not responsible for incorrect translations or

discrepancies between documents.

ROHS STATEMENT: Product designed and intended as a fixed installation or part of a

system in a vessel may be considered beyond the scope of Directive 2002/95/EC of the

European Parliament and of the Council of 27 January 2003 on the restriction of the use of

certain hazardous substances in electrical and electronic equipment.

ATTENTION INTERNATIONAL CUSTOMERS: Products sold in the U.S. are not

intended for use in the international market. Humminbird® international units provide

international features and are designed to meet country and regional regulations.

Languages, maps, time zones, units of measurement, and warranty are examples of

features that are customized for Humminbird® international units purchased through

our authorized international distributors.

To obtain a list of authorized international distributors, please visit our Web site at

humminbird.com or contact our Customer Resource Center at (334) 687-6613.

Humminbird®, Fish ID+™, Structure ID®, and WhiteLine™ are trademarked by or registered

trademarks of Johnson Outdoors Marine Electronics, Inc.

Baekmuk Batang, Baekmuk Dotum, Baekmuk Gulim, and Baekmuk Headline are registered

trademarks owned by Kim Jeong-Hwan.

© 2012 Johnson Outdoors Marine Electronics, Inc. All rights reserved.

ii

Table of Contents

Installation Overview 1

Fixed Control Head Installation 2

Determine Where to Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Connect the Power Cable to the Boat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Assemble the Control Head Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Route the Control Head Cables Under the Deck . . . . . . . . . . . . . . . . . . . . . . . . . 5

Attach the Control Head to the Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Attach the Cables to the Control Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Transom Transducer Installation Overview 8

Transom Transducer Installation 9

Locate the Transducer Mounting Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Prepare the Mounting Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Assemble and Mount the Transducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Route the Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Test and Finish the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

PiranhaMAX Portable Case Assembly 20

Assemble the Control Head Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Assemble the Base and Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Attach the Control Head to the Base and Handle . . . . . . . . . . . . . . . . . . . . . . . 23

Route the Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Assemble the Portable Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Charge and Install the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Assemble the Transducer Mounting Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Stow the Portable Transducer and Battery Charger into the Portable Case. . . 29

Installing the Portable Case on the Boat 30

Connect the Transducer and Power Cables to the Portable Case. . . . . . . . . . . 30

Attach the Portable Case to the Boat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Mounting the Portable Transducer 32

Test the Transducer Prior to Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Mount the Portable Transducer on the Boat . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

iii

Table of Contents

Moving the Portable Fishfinder 34

Power ON and OFF 35

PiranhaMAX Sonar Technology 36

Single Beam Sonar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Dual Beam Sonar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

What You See on the Display 38

How GPS Works 39

The PiranhaMAX Control Head 40

Key Functions 41

POWER/MENU Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

UP and DOWN Arrow Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

CHECK/ENTER Key. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

How to Use the Menu System 43

Set Up the Control Head 45

Contrast (PiranhaMAX 165, 175, and 176i models only) . . . . . . . . . . . . . . .. . . . . . . . . . . . . 46

Fish ID+™

Bottom View

Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Language

Units - Distance

Units - Speed

Units - Temp

Units - Depth

(Sonar View only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

(Sonar View only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

(International Models only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

(Units submenu) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

(Units submenu) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

(International Models only, Units submenu) . . . . . . . . . . . . . . . . . . . . . . 48

(International Models only, Units submenu) . . . . . . . . . . . . . . . . . . . . . 48

Views 49

Display a View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Status View 50

Sonar View 51

iv

Table of Contents

Sonar Menu 52

View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Depth Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Sensitivity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Zoom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Chart Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Beam Select. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Track View (PiranhaMAX 176i and 196ci only) 56

Track Menu (PiranhaMAX 176i and 196ci only) 57

View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Zoom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

COG Vector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Clear Track . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Delete. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Delete All . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Alarms 60

Maintenance 62

Troubleshooting 64

PiranhaMAX 165 Specifications 66

PiranhaMAX 175/176i/195c/196ci Specifications 67

Contact Humminbird® 69

NOTE: Entries in this Table of Contents which list (International Only) are only available

on products sold outside of the U.S. by our authorized International Distributors. It is

important to note that products sold in the U.S. are not intended for resale in the

international market. To obtain a list of authorized International Distributors, please visit

our Web site at humminbird.com or contact our Customer Resource Center at

1-800-633-1468 to locate the distributor nearest you.

v

Installation Overview

Before you start installation, we encourage you to read these instructions

carefully in order to get the full benefit from your PiranhaMAX.

There are three basic installation tasks that you must perform for the

PiranhaMAX:

• Installing the Control Head

• Installing the Transducer

• Testing the complete installation and locking the transducer position.

NOTE: In addition to the hardware supplied with your transducer, you will need a

powered hand drill and various drill bits, various hand tools, including a ruler or

straightedge, a level, a 12" plumb line (weighted string or monofilament line), marker or

pencil, safety glasses and dust mask, and marine-grade silicone sealant.

NOTE: If you have purchased a PiranhaMAX Portable unit, proceed to

PiranhaMAX Portable Case Assembly for installation instructions. If you are

planning a fixed installation, proceed to Fixed Control Head Installation.

1

Installation Overview

Fixed Control Head Installation

1. Determine Where to Mount

Begin the installation by determining where to mount the control head.

Consider the following to determine the best location:

• To check the location planned for the control

head, test run the cables for the power and

transducer. See Transom Transducer Installation

in order to plan the location of the transducer

and cable route.

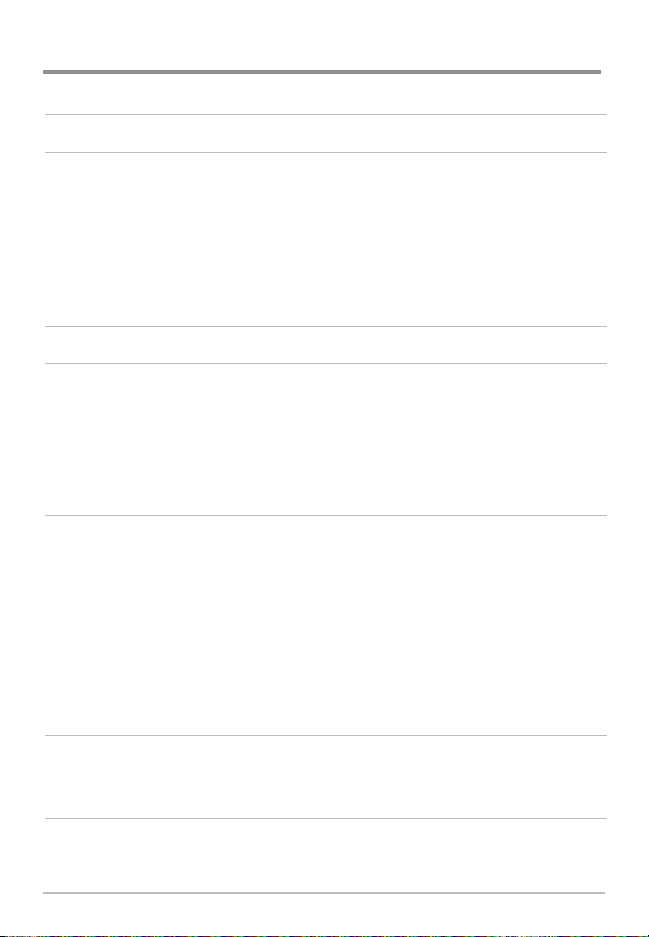

Figure 1

• The mounting surface should be stable enough

to protect the control head from excessive wave

shock and vibration, and should provide visibility

while in operation.

• Your PiranhaMAX uses a tilt and swivel

mounting base. The mounting area should allow

sufficient room for the unit to pivot and swivel

Figure 2

freely, and for easy removal and installation

(Figures 1 and 2).

2. Connect the Power Cable to the Boat

A 6' long power cable is included to supply power to the control head. You may

shorten or lengthen the cable using 18 gauge multi-stranded copper wire.

CAUTION! Some boats have 24 or 36 Volt electric systems, but the control head MUST

be connected to a 12 VDC power supply.

The control head power cable can be connected to the electrical system of the

boat at two places: a fuse panel usually located near the console, or directly to

the battery.

NOTE: Make sure that the power cable is not connected to the control head at the

beginning of this procedure.

Fixed Control Head Installation

2

NOTE: Humminbird® is not responsible for over-voltage or over-current failures. The

GROUNDGROUND

POSITIVEPOSITIVE

control head must have adequate protection throughthe proper selectionand installation

of a 1 amp fuse.

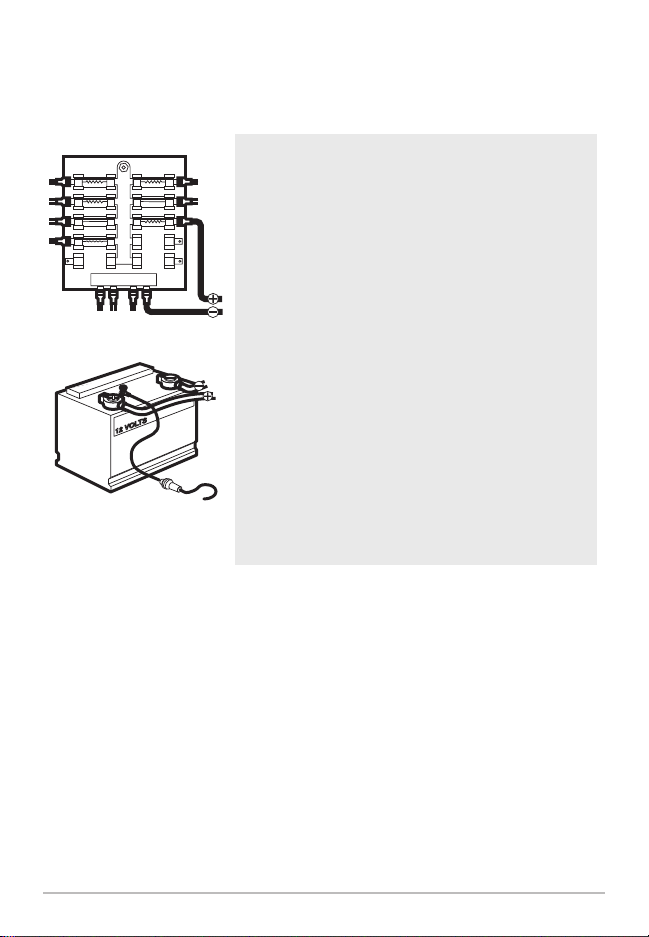

1a. If a fuse terminal is available, use crimp-on

type electrical connectors (not included)

that match the terminal on the fuse panel.

Attach the black wire to ground (-), and the

red wire to positive (+) 12 VDC power

(Figure 3). Install a 1 amp fuse (not

included) for protection of the unit.

Figure 3

Humminbird® is not responsible for overvoltage or over-current failures.

or...

1b. If you need to wire the control head

directly to a battery, obtain and install an

inline fuse holder and a 1 amp fuse (not

included) for the protection of the unit

Figure 4

(Figure 4). Humminbird® is not responsible

for over-voltage or over-current failures.

NOTE: In order to minimize the potential for interference with other marine electronics,

a separate power source (such as a second battery) may be necessary.

3

Fixed Control Head Installation

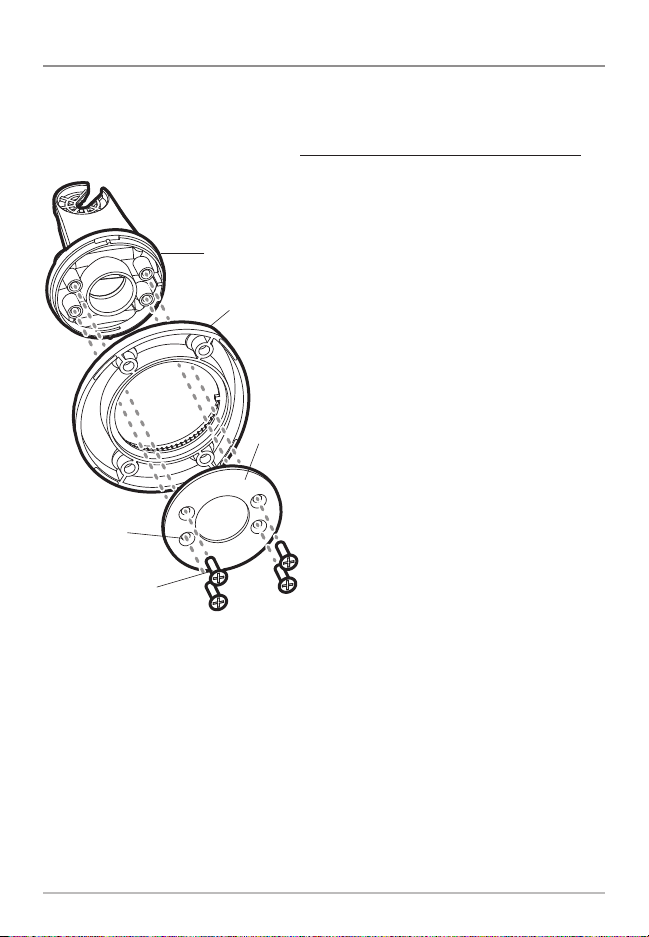

3. Assemble the Control Head Base

Your control head base will have a tilt and swivel mount. See the instructions

below to assemble and mount the control head base.

Figure 5

Tilt and Swivel Mount

Control Head Base Assembly

Countersink

Side Out

Arm Screws,

4 #6 x7/16"

Mount Arms

Base

To assemble a tilt and swivel mount:

1. Insert the mount arms into the

base. Then, hold the mount arms in

place as you turn the base upside

down.

2. Insert the swivel ring into the base,

with the countersink holes for the

arm screws facing out.

3. Secure the mount arms with the

four #6 screws provided (Figure 5).

Swivel

Ring

Hand tighten only!

4. Set the assembled control head

base in place on the mounting

surface. Mark the four mounting

screw locations with a pencil or

punch.

5. Set the base aside, and drill the

four mounting screw holes using a

9/64" bit.

6. Proceed to Route the Control Head

Cables Under the Deck.

Fixed Control Head Installation

4

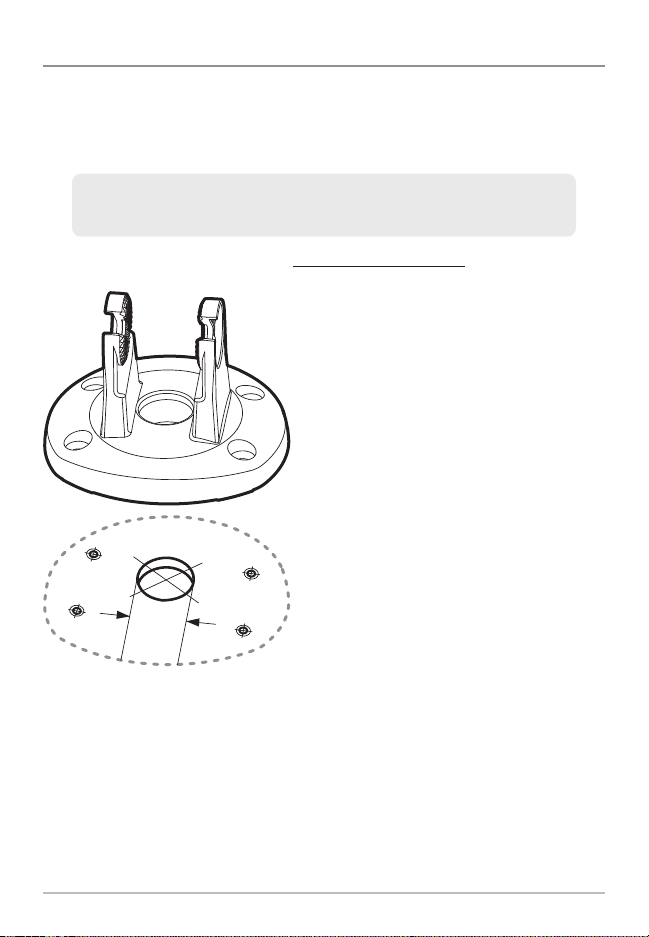

4. Route the Control Head Cables Under the Deck

3

/

4

”

1

9

m

m

Use the following steps to route the control head cables under the deck.

NOTE: Under the deck cable routing is not always possible. If this is not an option, the

cables should be routed and secured above deck.

NOTE: See Transom Transducer Installation in order to plan the location of the

transducer and cable route.

Figure 6

Tilt and Swivel Mount

Control Head Base

Tilt and Swivel Mount:

1a. Mark and drill a 3/4" hole as shown

in Figure 6. Route the cables

through the hole. The cables will

exit through the center hole on the

control head base.

1b. If the cables cannot be routed

directly beneath the control head

base, mark and drill a 3/4" hole that

will allow you to run the cables

close to the control head base.

5

Fixed Control Head Installation

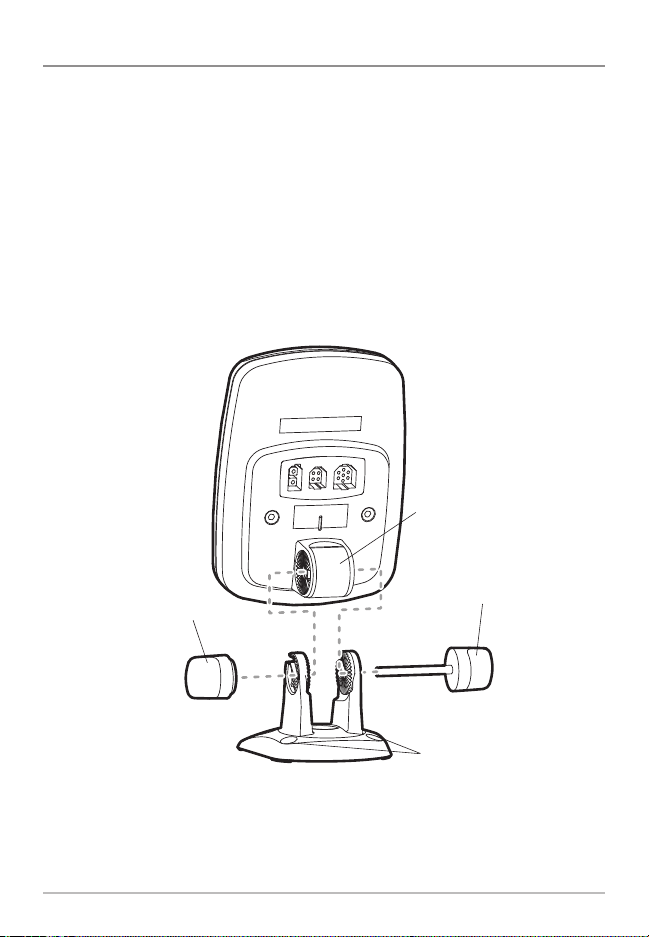

5. Attach the Control Head to the Base

Follow these steps to attach the control head to the already-assembled base:

NOTE: The transducer cable and power cable should be routed prior to securing the

mounting bracket to the deck.

1. Apply marine-grade silicone sealant to the drilled holes for the

mounting bracket.

2. Place the mounting bracket on the mounting surface, aligning with the

drilled holes.

3. Insert the four #8 Phillips countersink wood screws into the mounting

holes. Hand tighten only!

Pivot Knuckle

Gimbal Knob

Figure 7

Thumbknob Bolt

Mounting Holes

4. Insert the thumbknob bolt through the pivot knuckle on the control

head (Figure 7).

Fixed Control Head Installation

6

5. Align the pivot knuckle with the mount base arms and slide into place,

twisting slightly if necessary, until the unit is firmly seated.

6. Rotate the control head to the desired angle and hand tighten the

thumbknob bolt.

7. Thread the gimbal knob onto the pivot bolt and tighten.

6. Attach the Cables to the Control Head

Follow these steps to attach the power and transducer cables to the control

head:

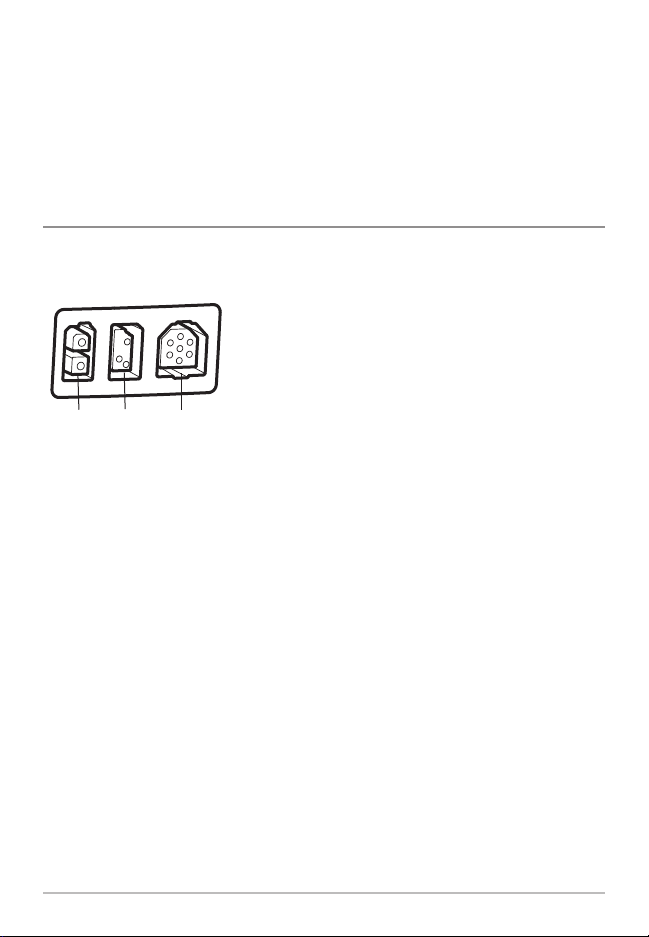

1. Matching the cable plugs to the shape and

orientation of the sockets, insert the

transducer and power cables into the correct

sockets on the control head (Figure 8).

Power Serial Transducer

Figure 8

NOTE: The serial port is for authorized service personnel

use only. Do not connect a cable to this port. The serial

port does not require a port cover.

2. With the control head in place, tilt and/or

swivel the unit through its full range to make

sure there is enough cable slack for the unit to

move freely. Hand tighten the thumbknob bolt

when you achieve the desired position for the

control head.

You are now ready to install the transducer. Proceed

to Transom Transducer Installation Overview.

7

Fixed Control Head Installation

Transom Transducer Installation Overview

Following are instructions for transom mount installation. The transom mount

installation provides the least loss of signal since the transducer is mounted

outside the hull. This installation also allows adjustment of both running angle

and depth after the transducer is mounted, which enables you to tune the

installation for best results.

NOTE: Due to the wide variety of hulls, only general instructions are presented in

this installation guide. Each boat hull represents a unique set of requirements that

should be evaluated prior to installation. It is important to read the instructions

completely and understand the mounting guidelines before beginning installation.

NOTE: When drilling holes in fiberglass hulls, itis best to start with a smallerbit and use

progressively larger drill bits to reduce the chanceof chippingor flakingthe outer coating.

NOTE: If you cannot find a transom mount location that will work for your boat hull, a

different mounting technique or transducer type should be considered. See the FAQ

(Frequently Asked Questions) section of our Web site at humminbird.com or call our

Customer Resource Center at 1-800-633-1468 .

Transom Transducer Installation Overview

8

Transom Transducer Installation

1. Locate the Transducer Mounting Position

Turbulence: You must first determine the best location on the transom to

install the transducer. It is very important to locate the transducer in an area

that is relatively free of turbulent water.

Consider the following to find the best location with the least amount of

turbulence:

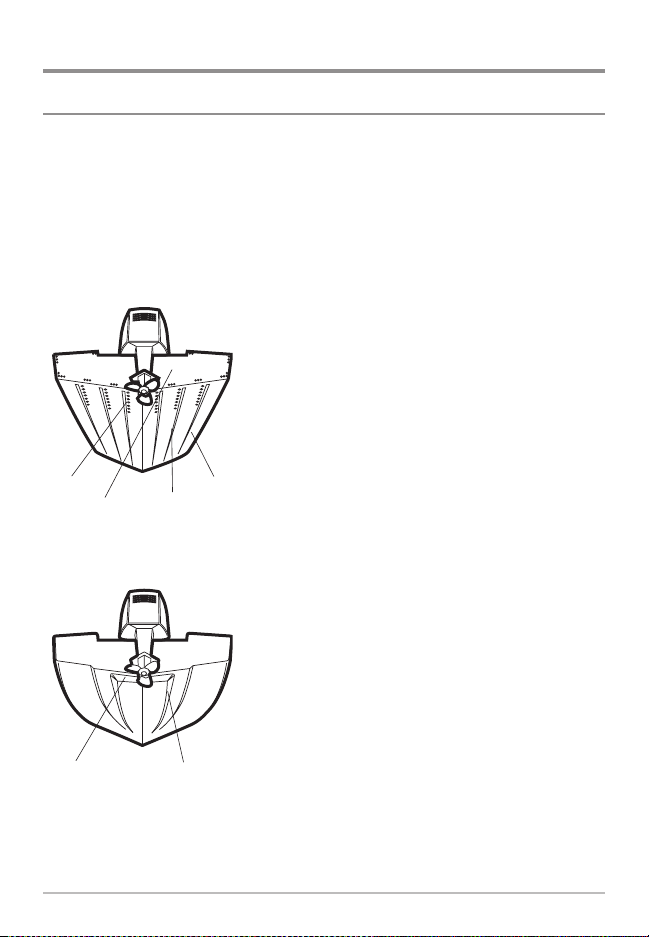

Areas of Possible Turbulence

Rivets

Transom

Figure 9

Stepped Hull

Step

Figure 10

Strakes

• As the boat moves through the water,

turbulence is generated by the weight of the

boat and the thrust of the propeller(s) - either

clockwise or counter-clockwise. This turbulent

water is normally confined to areas

immediately aft of ribs, strakes or rows of

rivets on the bottom of the boat, and in the

immediate area of the propeller(s). Clockwise

Hull

propellers create more turbulence on the port

side. On outboard or inboard/outboard boats,

it is best to locate the transducer at least 15"

to the side of the propeller(s) (Figure 11).

• The best way to locate turbulence-free

water is to view the transom while the boat

is moving. This method is recommended if

maximum high-speed operation is a high

priority. If this is not possible, select a

location on the transom where the hull

forward of this location is smooth, flat and

Rib

free of protrusions or ribs (Figure 9).

• On boats with stepped hulls, it may be

possible to mount the transducer on the

step. Do not mount the transducer on the

transom behind a step to avoid popping the

9

Transom Transducer Installation

transducer out of the water at higher speeds. The transducer must

15”

remain in the water for the control head to maintain the sonar signal

(Figure 10).

• If the transom is behind the propeller(s), it may be impossible to find an

area clear from turbulence, and a different mounting technique or

transducer type should be considered, such as an Inside the Hull

Transducer.

• If you plan to trailer your boat, do not mount the transducer too close

to trailer bunks or rollers to avoid moving or damaging the transducer

during loading and unloading of the boat.

• If high speed operation is critical, you may want to consider using an

In-Hull transducer instead of this Transom Mount transducer.

Level

Deadrise Angle

Find a turbulence-free location at least 15” from the propeller(s)

and not in line with trailer bunks or rollers. (Figure 11).

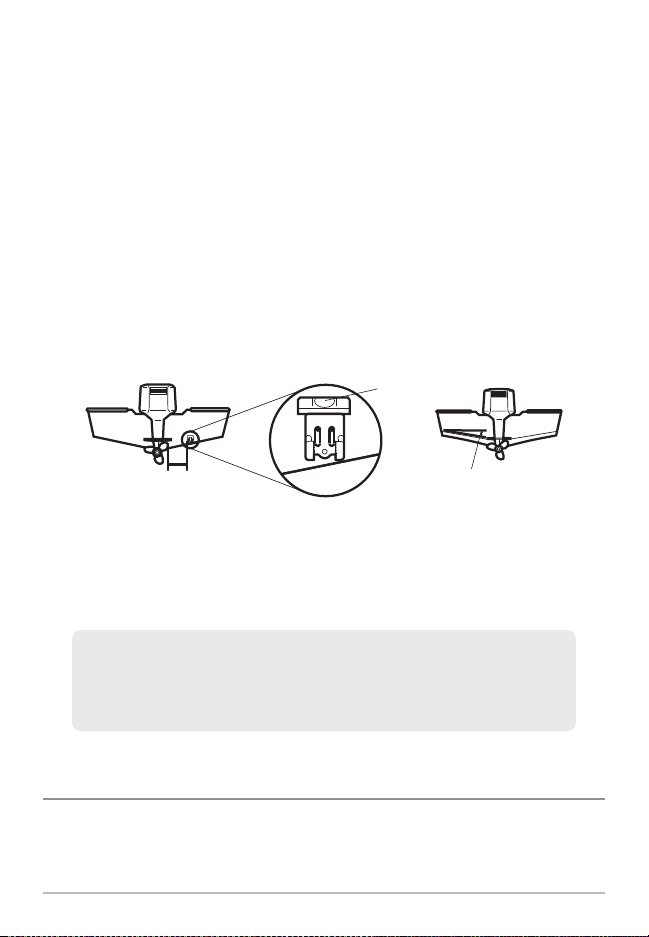

NOTE: The hydrodynamic shape of your transducer allows it to point straight down

without deadrise adjustment (Figure 12).

Figure 12

NOTE: If you cannot find a transom mount location that will work for your

high-speed application, please visit the FAQ (FrequentlyAsked Questions) section

of our Web site at humminbird.com or call our Customer Resource Center at

1-800-633-1468.

2. Prepare the Mounting Location

After determining the mounting location for the transducer, follow the steps

below to position and mount the transducer bracket.

Transom Transducer Installation

10

Positioning the Mounting Bracket

Level

Figure 13

Boat Hull Types Require

Different Mounting Positions

1/8” for aluminum

1/4” for fiberglass

Figure 14

Using the Mounting Bracket to

Mark the Initial Drill Holes

Mark Initial

Drill Holes

3rd hole

Figure 15

1. Make sure that the boat is level on the trailer, both

from port to starboard and from bow to stern, by

placing your level on the deck of the boat, first in

one direction, then in the other.

Level

2. Hold the mounting bracket against the transom of

the boat in the location you have selected (Figure

13). Align the bracket horizontally, using the level.

Make sure that the lower screw hole protrusion

does not protrude past the bottom of the hull, and

there is at least 1/4" clearance between the

bottom of the bracket and the bottom of the

transom for fiberglass boats, and 1/8" clearance

for aluminum boats (Figure 14).

NOTE: If you have a flat-bottomed aluminum boat, some

additional adjustment may be needed to accommodate the

rivets on the bottom of the boat (i.e. the gap may need to be

a little smaller than 1/8"). This will help you to avoid excessive

turbulence at high speeds.

NOTE: If your propeller moves clockwise as the boat moves

forward (as you're facing the stern of the boat from behind),

mount the transducer on the starboard side, and align the

bottom right corner of the mounting bracket with the bottom

of the boat. If your propeller moves counterclockwise as the

boat moves forward (as you're facing the stern of the boat

from behind), mount the transducer onthe port side, and align

the bottom left corner of the mounting bracket with the

bottom of the boat.

3. Continue to hold the bracket on the transom of the

boat, and use a pencil or marker to mark where to

drill the two mounting holes. Mark the drill holes

near the top of each slot, making sure that your

mark is centered in the slot (Figure 15).

NOTE: The third hole should not be drilled until the angle

and height of the transducer is finalized, which you will

not do until a later procedure.

11

Transom Transducer Installation

4. Make sure that the drill bit is perpendicular to the actual surface of the

-2 -1 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Transom Angle (°)

Bead Alignment

Number

142531425

25 26 27328 29 30

1

Measured Distance (x)

1.1cm

1/2“

0.0 cm

0“

2.5 cm1“4.3 cm

1 5/8“

5.9 cm

2 3/8“

7.6 cm3“9.3cm

3 5/8“

11.1cm

4 3/8“

12.9cm5“14.9cm

5 7/8“

16.9cm

6 5/8“

transom, NOT parallel to the ground, before you drill. Using a 5/32” bit,

drill the two holes only to a depth of approximately 1”.

NOTE: On fiberglass hulls, it is best to use progressively larger drill bits to reduce the

chance of chipping or flaking the outer coating.

3. Assemble and Mount the Transducer

In this procedure, you will assemble the transducer using the hardware

provided, then mount it and make adjustments to its position without locking

it in place.

NOTE: You will initially assemble the transducer and the mounting bracket by matching

the two ratchets to a numbered position on the transducer knuckle. Further adjustments

may be necessary.

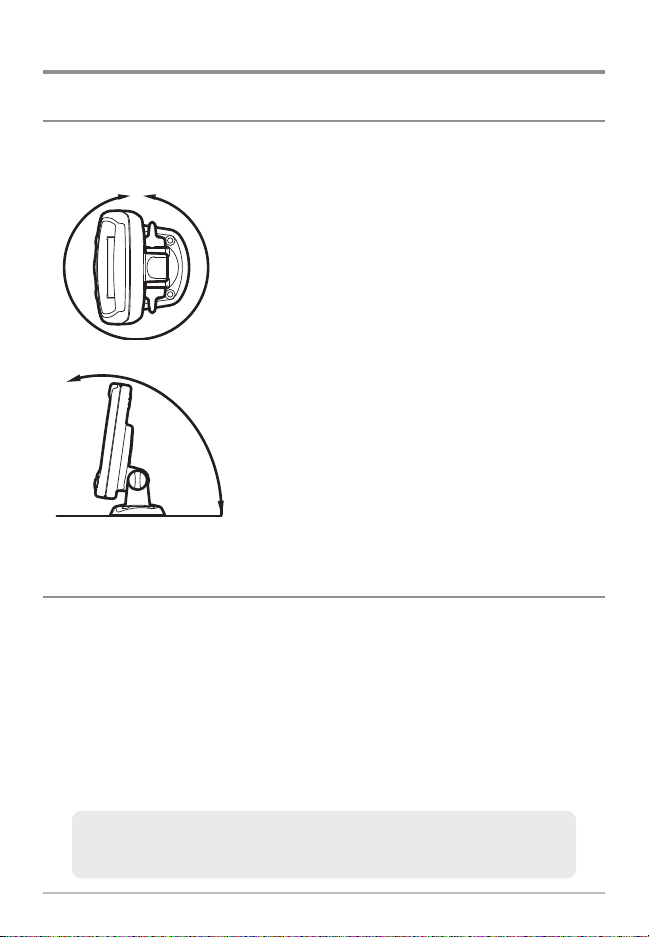

1a. If you already know your transom angle, refer to the chart below for

the initial position to use to set the ratchets (Figure 16). If your transom

is angled at 14 degrees (a common transom angle for many boats) use

position 1 for the ratchets. In either case, go to step 2.

Figure 16

or...

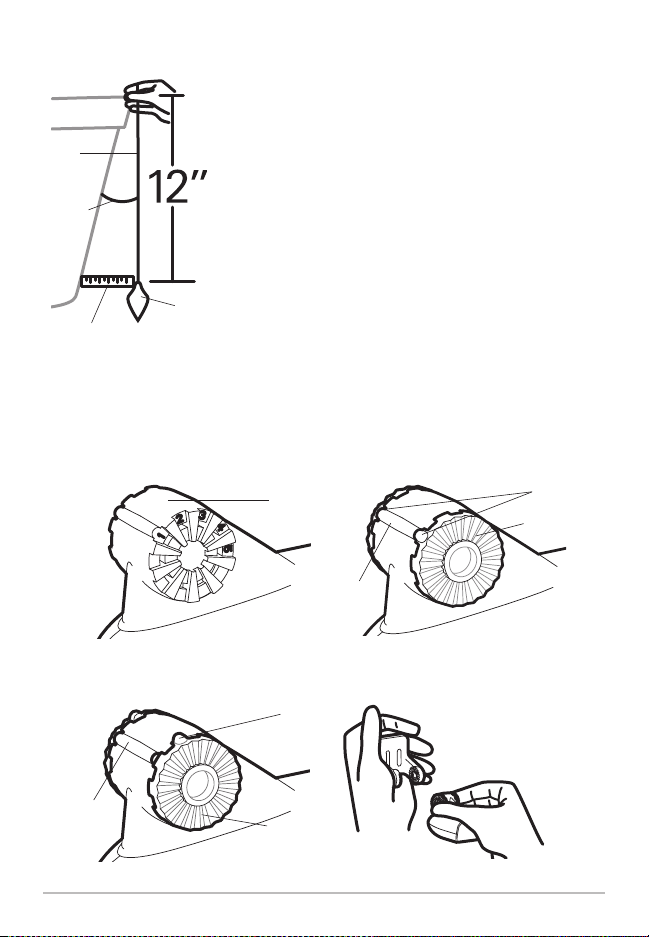

1b. If you do not know your transom angle, measure it using a plumb line

(weighted nylon string or monofilament line) exactly 12 inches long.

Hold the top of the plumb line against the top of the transom with your

finger, and wait until the line hangs straight down (Figure 17). Using a

ruler, measure the distance from the bottom of the plumb line to the

back of the transom, then use the chart (Figure 16).

NOTE: It is important to take your measurement in the location shown in Figure 17,

from exactly 12 inches down from the top of the transom.

Transom Transducer Installation

12

Measuring the Transom Angle

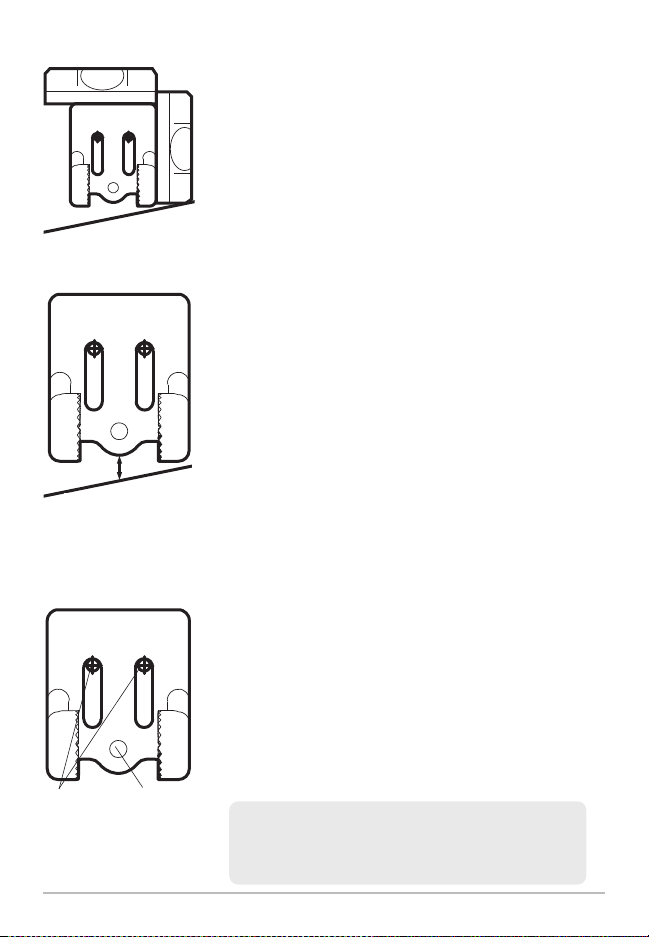

2. Place the two ratchets, one on either side of

the transducer knuckle, so that the beads on

each ratchet line up with the desired position

number on the knuckle (Figure 18a). If you are

Plumb

Line

Transom

Angle in

degrees

(°)

Measured Distance (X)

Weight

Figure 17

setting the ratchets at position 1, the beads

on each ratchet will line up with the rib on the

transducer knuckle to form one continuous

line on the assembly (Figure 18b).

NOTE: The ratchetsare keyed. Make surethat the square

teeth on each ratchet face the square teeth on the

transducer knuckle, and the triangular teeth face

outward.

Hold the ratchets on the transducer knuckle with one hand and fit the

mounting bracket over them until it snaps into place with the other hand. Refer

to the illustration (Figure 18d).

Transducer Knuckle Positions

Ratchets Placed in Position 2

Rib

Knuckle

Figure 18a

Bead

Ratchet

Figure 18c

Ratchets Placed in Position 1

Rib at

position 1

Fitting the Mounting Bracket Over the Ratchet

13

Transom Transducer Installation

Beads

Ratchet

Figure 18b

Figure 18d

Inserting the Pivot Bolt

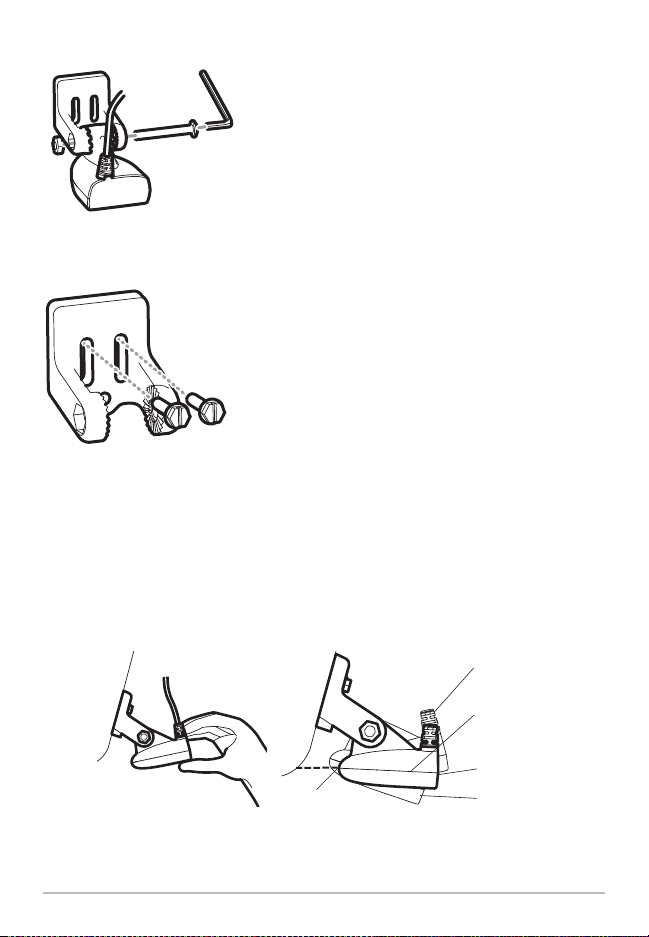

3. Put the pivot bolt through the assembly to

hold it in position and loosely install the nut,

but do NOT tighten the nut at this time (Figure

19).

CAUTION! Do not use a high speed driver on this

combination of fasteners. Hand tighten only.

Figure 19

Mounting the Assembly

to the Transom

4. Align the mounting bracket transducer

assembly with the drilled holes in the

transom. With a 5/16" socket driver, mount

the assembly to the transom using the two

#10 - 1" long screws provided (Figure 20).

Hand tighten only!

NOTE: Make sure that the mounting screws are snug, but

do not fully tighten the mounting screws at this time to

allow the transducer assembly to slide for adjustment

Figure 20

purposes.

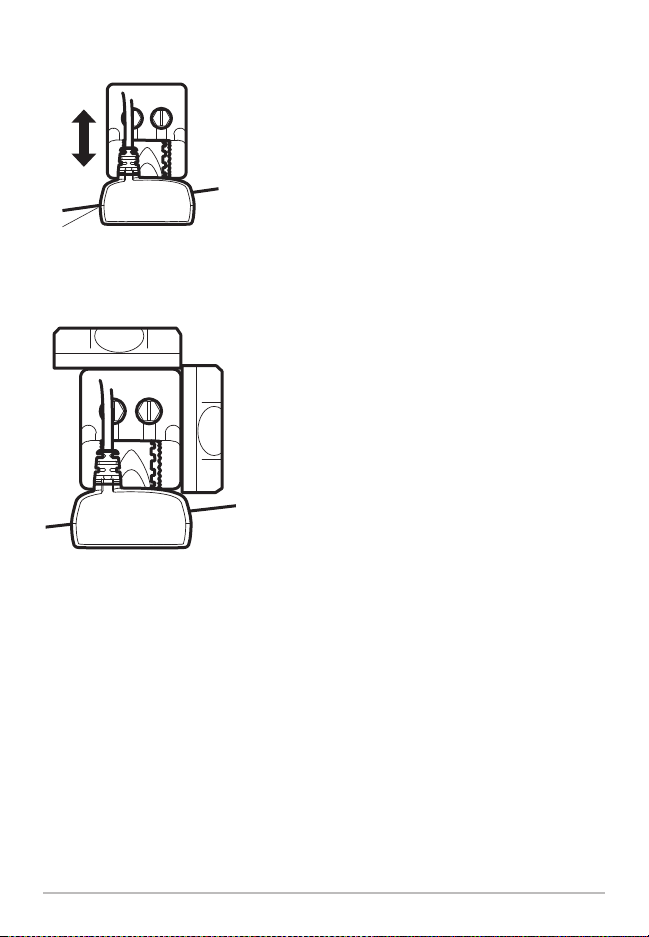

5. Adjust the initial angle of the transducer from back to front by rotating

the transducer until the side seam on the transducer is almost parallel

with the bottom of the boat, one click at a time in either direction

(Figure 21 and 22).

Adjusting the Initial Transducer Angle

One click too high

Correctly aligned

(transducer side

seam aligned

with boat bottom)

Trailing edge

Leading edge One click too low

Figure 21

Figure 22

Transom Transducer Installation

14

Adjusting the Transducer

Mounting Position

Seam aligned with boat hull

Figure 23

Leveling the Mounting

Assembly Horizontally

Level

Figure 24

6. Adjust the transducer assembly vertically,

until the seam on the leading edge of the

transducer (the edge closest to the transom of

the boat) is level and just slightly below the

hull (Figure 23).

NOTE: The transducer has a natural downward slant of 4-5

degrees from leading edge (closest to the boat transom) to

trailing edge (farthest away from the boat). Looking at the

back of the transducer, the seam should be slightly below

the bottom of the hull.

7. Continue to adjust until the bracket is also

level from port to starboard (horizontally level

as you look at the transducer from behind the

boat [Figure 24]).

8. Mark the correct position on the transom by

Level

tracing the silhouette of the transducer

mounting bracket with a pencil or marker.

9. Tighten the pivot bolt, using the pivot screw

and nut to lock the assembly. Hand tighten

only!

CAUTION! Do not use a high speed driver on this

combination of fasteners. Hand tighten only.

10. Hand-tighten the two mounting screws.

NOTE: You will drill the third mounting hole and finalize the

installation after you route the cable and test and finish the

installation in the following procedures.

15

Transom Transducer Installation

4. Route the Cable

The transducer cable has a low profile connector, which must be routed to the

point where the control head is mounted. There are several ways to route the

transducer cable to the area where the control head is installed. The most

common procedure routes the cable through the transom into the boat.

NOTE: Your boat may have a pre-existing wiring channel or conduit that you can use for

the transducer cable.

1. Unplug the other end of the transducer cable from the control head.

(The transducer cable was connected in the earlier section Attach the

Cables to the Control Head

to accommodate the planned route by running the cable over the

transom.

CAUTION! Do not cut or shorten the transducer cable, and try not to damage the cable

insulation. Route the cable as far as possible from any VHF radio antenna cables or

tachometer cables to reduce the possibility of interference. If the cable is too short,

extension cables are available to extend the transducer cable up to a total of 50'. For

assistance, contact the Customer Resource Center at humminbird.com or call

1-800-633-1468 for more information.

NOTE: Allow enough slack in the cable for slight movement at the pivot point. It is best

to route the cable to the side of the transducer so the transducer will not damage the

cable during movement.

2a. If you are routing the cable over the transom of the boat, secure the

cable by attaching the cable clamp to the transom, drilling 9/64"

diameter holes for the #8 x 5/8" wood screws, then skip directly to step

5 to connect the cable.

2b. If you will be routing the cable through a hole in the transom, drill a

5/8" diameter hole above the waterline. Route the cable through this

hole, then fill the hole with marine-grade silicone sealant and proceed

to the next step immediately.

). Make sure that the cable is long enough

or...

Transom Transducer Installation

16

Figure 25

Figure 26

Routing the Cable

Storing Excess Cable

3. Place the escutcheon plate over the cable

hole and use it as a guide to mark the two

escutcheon plate mounting holes. Remove

the plate, drill two 9/64" diameter x 5/8" deep

holes, and then fill both holes with marinegrade silicone sealant. Place the escutcheon

plate over the cable hole and attach with two

#8 x 5/8" wood screws. Hand tighten only!

4. Route and secure the cable by attaching the

cable clamp to the transom. Drill one 9/64"

diameter x 5/8" deep hole, then fill hole with

marine-grade silicone sealant, then attach the

cable clamp using a #8 x 5/8" screw. Hand

tighten only!

NOTE: If there is excess cable that needs to be

gathered at one location (as shown in the illustration),

dress the cable routed from both directions so that a

single loop is left extending from the storage location.

Doubling the cable up from this point, form the cable

into a coil. Storing excess cable using this method can

reduce electronic interference (Figure 26).

5. Plug the cable connector back into the control

head. The slots are keyed to prevent reversed

installation, so be careful not to force the

connector into the holder.

Your control head is now ready for operation.

17

Transom Transducer Installation

Loading...

Loading...