Page 1

IDS1000 Container Data Center

Single-Zone Fire Extinguishing System

User Manual

Issue

01

Date

2014-3-15

HUAWEI TECHNOLOGIES CO., LTD.

Page 2

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

i

Copyright © Huawei Technologies Co., Ltd. 2014. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior

written consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective

holders.

Notice

The purchased products, services and features are stipulated by the contract made between Huawei and

the customer. All or part of the products, services and features described in this document may not be

within the purchase scope or the usage scope. Unless otherwise specified in the contract, all statements,

information, and recommendations in this document are provided "AS IS" without warranties, guarantees or

representations of any kind, either express or implied.

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute a warranty of any kind, express or implied.

Huawei Technologies Co., Ltd.

Address:

Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website:

http://www.huawei.com

Email:

support@huawei.com

Page 3

IDS1000 Container Data Center

User Manual

About This Document

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

ii

Purpose

Symbol

Description

Indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in equipment damage, data loss,

performance deterioration, or unanticipated results.

NOTICE is used to address practices not related to

This document describes the operation methods and precautions for the fire extinguishing

system in the IDS1000 container data center in terms of configurations, power-on

commissioning, maintenance, alarm references, troubleshooting, and parts replacement. It

provides you a quick grasp of the operations of the fire extinguishing system in the container

data center.

Intended Audience

About This Document

This document is intended for:

Maintenance engineers

Technical support engineers

System engineers

Hardware installation engineers

Commissioning engineers

Symbol Conventions

The symbols that may be found in this document are defined as follows.

Page 4

IDS1000 Container Data Center

User Manual

About This Document

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

iii

Symbol

Description

personal injury.

Calls attention to important information, best practices

and tips.

NOTE is used to address information not related to

personal injury, equipment damage, and environment

deterioration.

Change History

Changes between document issues are cumulative. The latest document issue contains all the

changes made in earlier issues.

Issue 01 (2014-03-15)

This issue is the first official release.

Page 5

IDS1000 Container Data Center

User Manual

Contents

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

iv

Contents

About This Document .................................................................................................................... ii

1 Configuration Description .......................................................................................................... 1

1.1 System Introduction ...................................................................................................................................................... 1

1.2 Components .................................................................................................................................................................. 4

1.3 Configuration Principles ............................................................................................................................................... 6

2 Operation Description ................................................................................................................. 8

2.1 Precautions .................................................................................................................................................................... 8

2.2 Emergency Operation Overview ................................................................................................................................... 8

2.3 Preparations .................................................................................................................................................................. 9

2.3.1 Obtaining Tools .......................................................................................................................................................... 9

2.3.2 Obtaining Technical Documents .............................................................................................................................. 10

2.3.3 Personnel Skill Requirements .................................................................................................................................. 11

3 Power-On Commissioning ........................................................................................................ 12

3.1 Initial Configuration ................................................................................................................................................... 12

3.2 Checking Before Power-On ........................................................................................................................................ 17

3.3 Hardware Power-On Commissioning ......................................................................................................................... 19

3.4 Fire Extinguishing System Commissioning ................................................................................................................ 20

4 Routine Maintenance ................................................................................................................. 29

4.1 Routine Maintenance Overview ................................................................................................................................. 29

4.2 Daily Maintenance ...................................................................................................................................................... 29

4.3 Weekly Maintenance ................................................................................................................................................... 30

4.4 Monthly Maintenance ................................................................................................................................................. 30

4.5 Quarterly Maintenance ............................................................................................................................................... 31

4.6 Semi-Yearly Maintenance ........................................................................................................................................... 32

4.7 Yearly Maintenance .................................................................................................................................................... 33

5 Alarm Reference .......................................................................................................................... 34

6 Troubleshooting .......................................................................................................................... 36

6.1 Smoke Detector Fault ................................................................................................................................................. 36

6.2 Heat Detector Fault ..................................................................................................................................................... 37

6.3 Gas Release Indicator Fault ........................................................................................................................................ 39

Page 6

IDS1000 Container Data Center

User Manual

Contents

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

v

6.4 Audible and Visual Alarm Fault .................................................................................................................................. 40

6.5 Fire Alarm Bell Fault .................................................................................................................................................. 42

6.6 Failed to Drive the Fire Cylinder ................................................................................................................................ 43

6.7 VESDA Fault .............................................................................................................................................................. 43

6.8 Gas Extinguishing Controller Fault ............................................................................................................................ 43

7 Parts Replacement ....................................................................................................................... 45

7.1 Replacing a Smoke Detector ....................................................................................................................................... 45

7.2 Replacing a Heat Detector .......................................................................................................................................... 47

7.3 Replacing a Gas Release Indicator ............................................................................................................................. 49

7.4 Replacing an Audible and Visual Alarm ..................................................................................................................... 50

7.5 Replacing a Fire Alarm Bell ....................................................................................................................................... 51

7.6 Replacing a Fire Cylinder ........................................................................................................................................... 52

7.7 Replacing a Gas Extinguisher ..................................................................................................................................... 52

7.8 Replacing the Emergency Start/Abort Switch ............................................................................................................ 53

7.9 Replacing a VESDA ................................................................................................................................................... 54

7.10 Replacing a Gas Extinguishing Controller................................................................................................................ 55

8 Emergency Operation ................................................................................................................. 56

8.1 Early Fire Alarm ......................................................................................................................................................... 56

8.2 Single Fire Alarm ........................................................................................................................................................ 58

8.3 Composite Fire Alarm ................................................................................................................................................. 59

A Acronyms and Abbreviations .................................................................................................. 61

Page 7

IDS1000 Container Data Center

User Manual

1 Configuration Description

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

1

1 Configuration Description

1.1 System Introduction

System Composition

The container data center fire extinguishing system consists of the automatic fire alarm

system, gas extinguishing equipment, and the control system.

The automatic fire alarm system consists of components including the heat detector, smoke

detector, audible and visual alarm, alarm bell, gas release indicator, and the very early smoke

detection apparatus (VESDA for short, able to detect and report fire alarms at an early stage).

The gas extinguishing equipment uses heptafluropropane as the extinguishing agent. It

consists of components such as the extinguishing agent vessel, gas supply pipe, pressure

annunciator, and solenoid valve driver.

The control system consists of the gas extinguishing controller and emergency start/abort

switch.

Working Principles

When a fire occurs and generates smoke and heat, the smoke detector and the heat detector

will be triggered and send fire alarm signals to the fire controller. Then the controller will

generate a startup current to start the solenoid valve to open the storage valve, which will

release the extinguishing agent to the protected zone. The automatic alarm system will send

alarm signals at the same time.

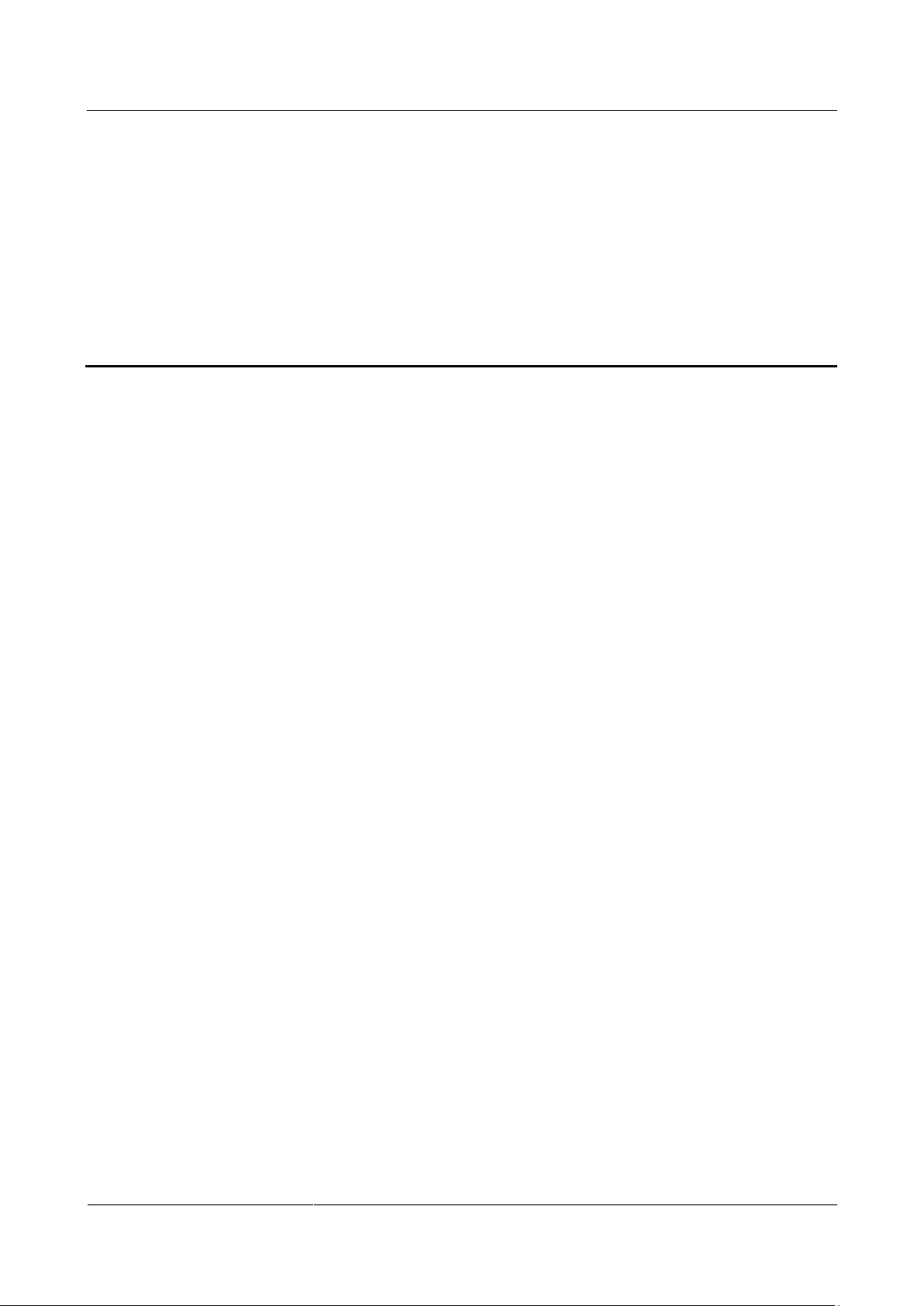

Figure 1-1 shows the network diagram of the container data center fire extinguishing system.

Table 1-1 lists the functions of the components in the fire extinguishing system.

Page 8

IDS1000 Container Data Center

User Manual

1 Configuration Description

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

2

Figure 1-1 Fire extinguishing system network diagram

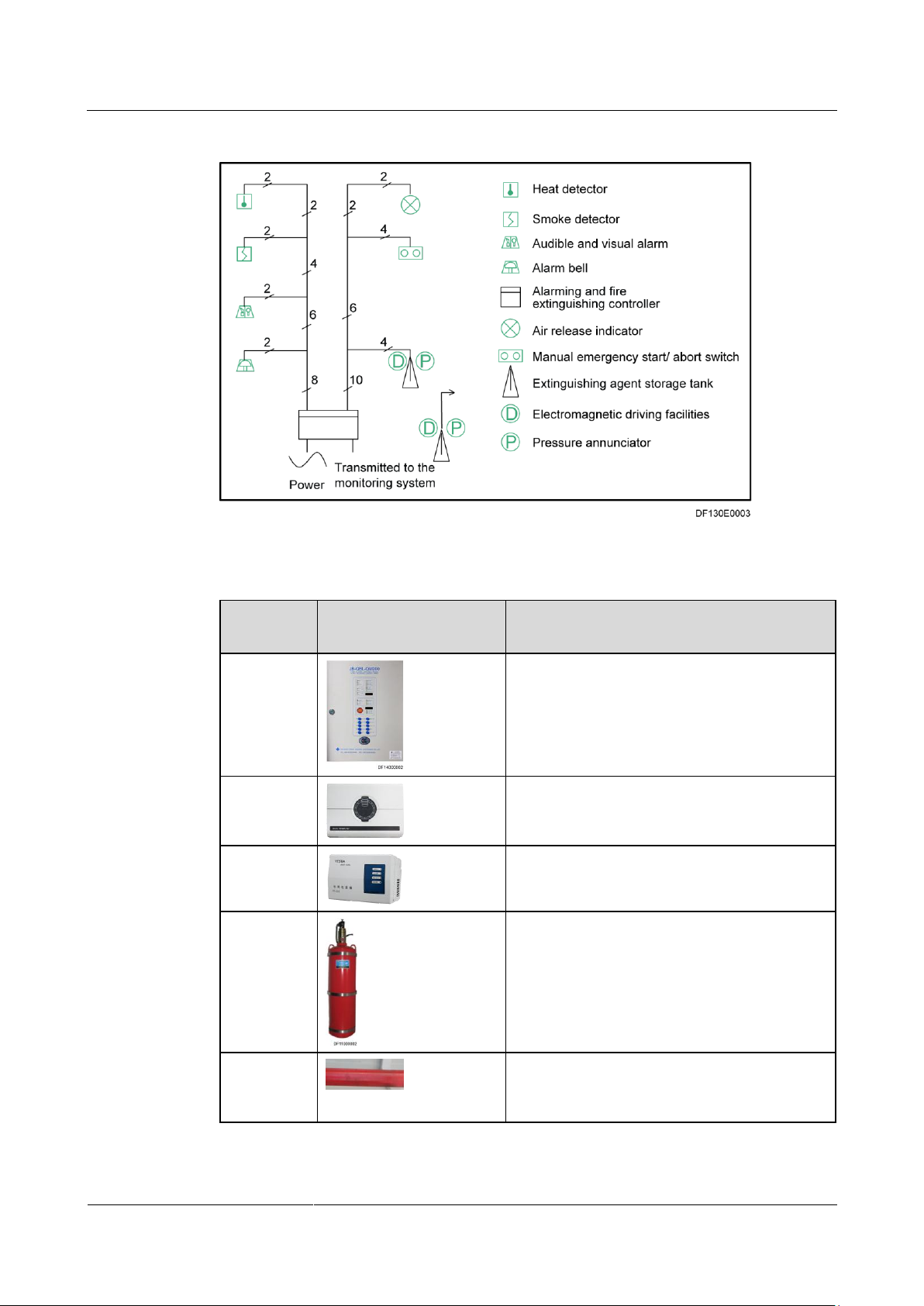

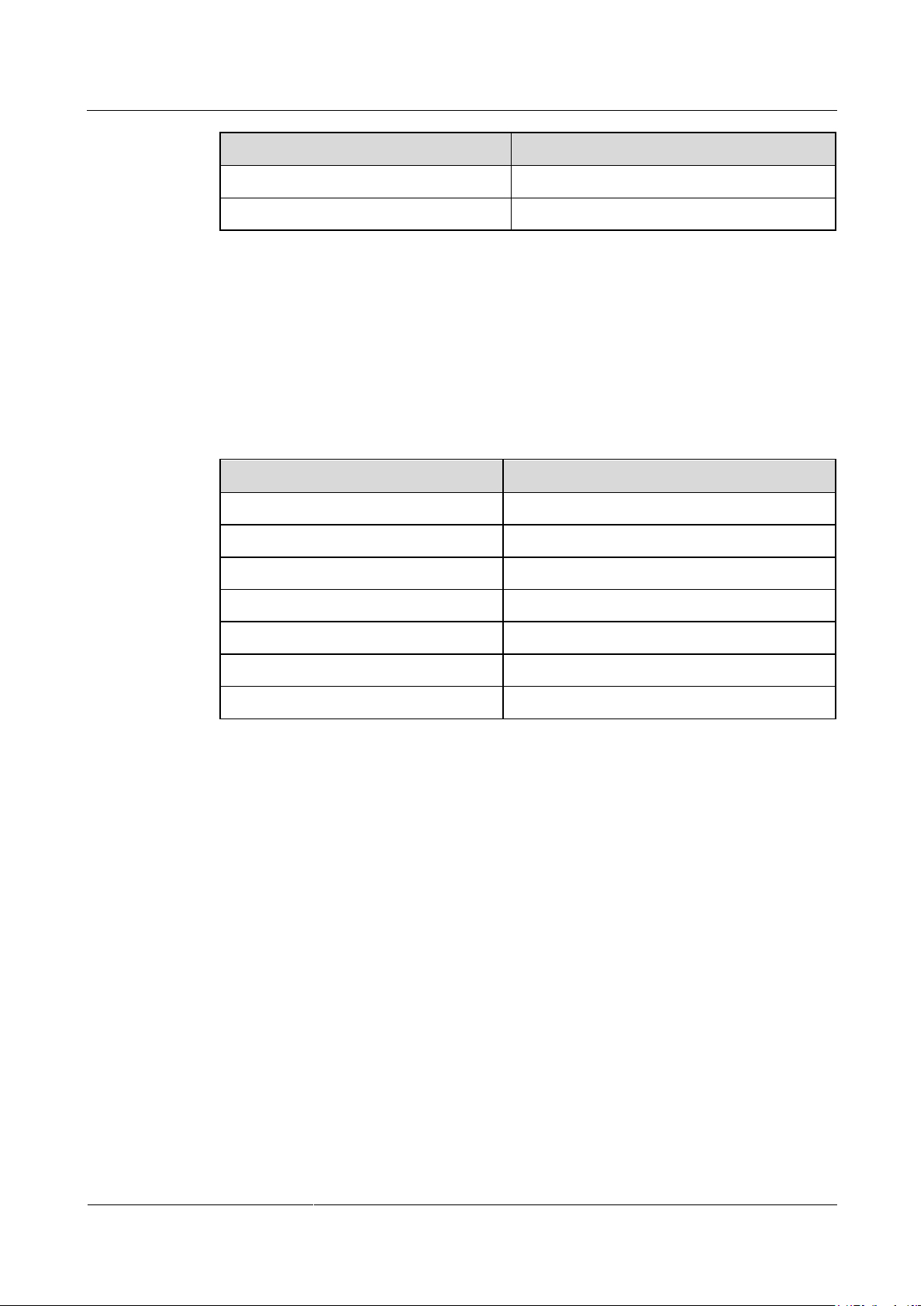

Compone

nt Name

Appearance

Function

Gas

extinguishin

g controller

Controls the fire extinguishing system and

reports fire alarm signals.

VESDA

Detects smoke at an early stage, displays the

smoke density and alarm severities, and reports

these information to the monitoring system.

VESDA

power box

Supplies power to the VESDA.

Gas

extinguishin

g

equipment

Stores and releases an extinguishing agent.

Fire

extinguishin

g pipe

Transports an extinguishing agent swiftly and

evenly to the entire protected zone to

extinguish fire in total flooding mode.

Table 1-1 Functions of the components in the fire extinguishing system

Page 9

IDS1000 Container Data Center

User Manual

1 Configuration Description

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

3

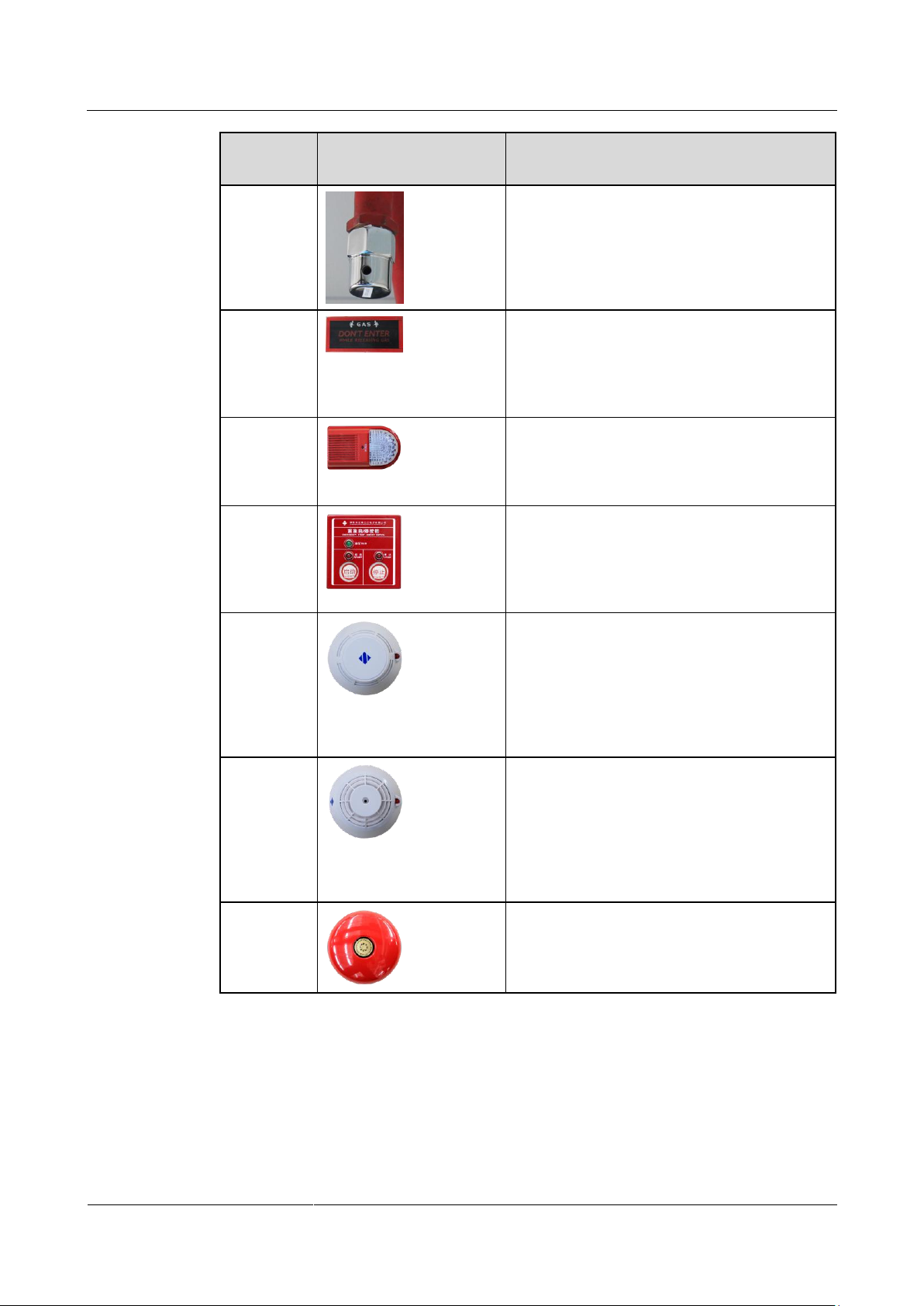

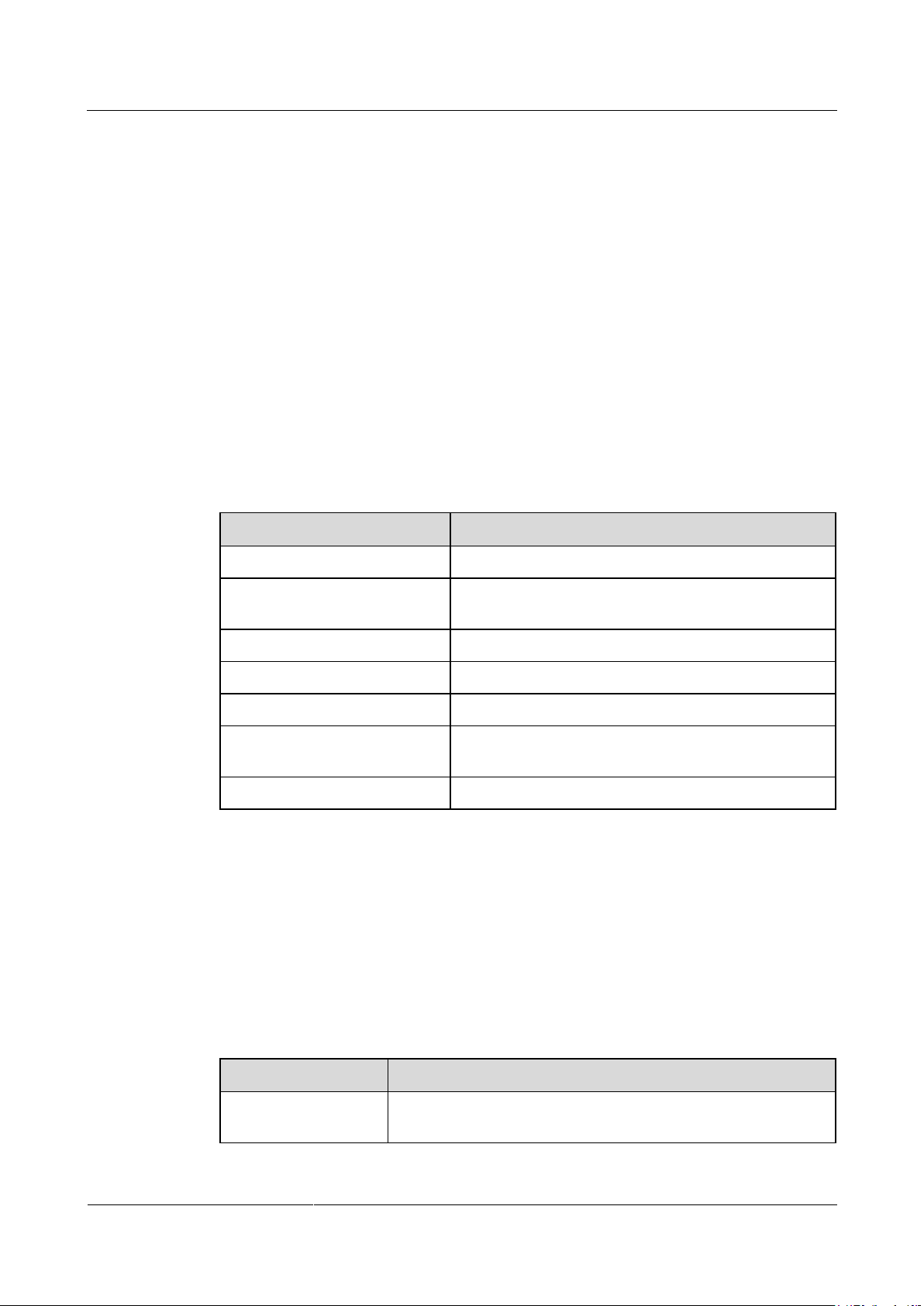

Compone

nt Name

Appearance

Function

Atomizer

nozzle

Sprays an extinguishing agent to aisles in case

of a fire.

Gas release

indicator

Displays "DON'T ENTER WHILE

RELEASING GAS" to warn onsite personnel

in case of a fire and the fire extinguishing

equipment releases the extinguishing agent into

the protected zone.

Audible and

visual alarm

Generates dazzling flash signals and shrill

audible signals in case of a fire, reminding

onsite personnel to evacuate from the site

immediately, thereby avoiding major accident.

Emergency

start/abort

switch

Starts or stops the gas extinguishing equipment

in case of a fire. The device is installed outside

the door of the protected zone. If you press the

glass plate to start extinguishing in emergency,

the red indicator lights up.

Heat

detector

Evenly deployed in the aisles inside containers

to detect the temperature inside the containers

in real time. When it works in monitoring

mode, the red indicator blinks. When the

ambient temperature exceeds the alarm

threshold, it enters alarm mode and the red

indicator is steady on.

Smoke

detector

Evenly deployed in the aisles inside containers

to detect the smoke density inside the

containers in real time. When it works in

monitoring mode, the red indicator blinks.

When the onsite smoke density exceeds the

alarm threshold, it enters alarm mode and the

red indicator is steady on.

Alarm bell

Produces clear and consistent sounds in case of

a fire, reminding onsite personnel to evacuate

from the site immediately, thereby avoiding

major accident.

System Features

All surface-mounted fire control cables are routed through metal hoses. The hose ends

are protected with grommets to prevent damage in case of a fire. Fire control cables are

routed and used separately which ensures secure and reliable power supplies to the fire

extinguishing system.

Page 10

IDS1000 Container Data Center

User Manual

1 Configuration Description

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

4

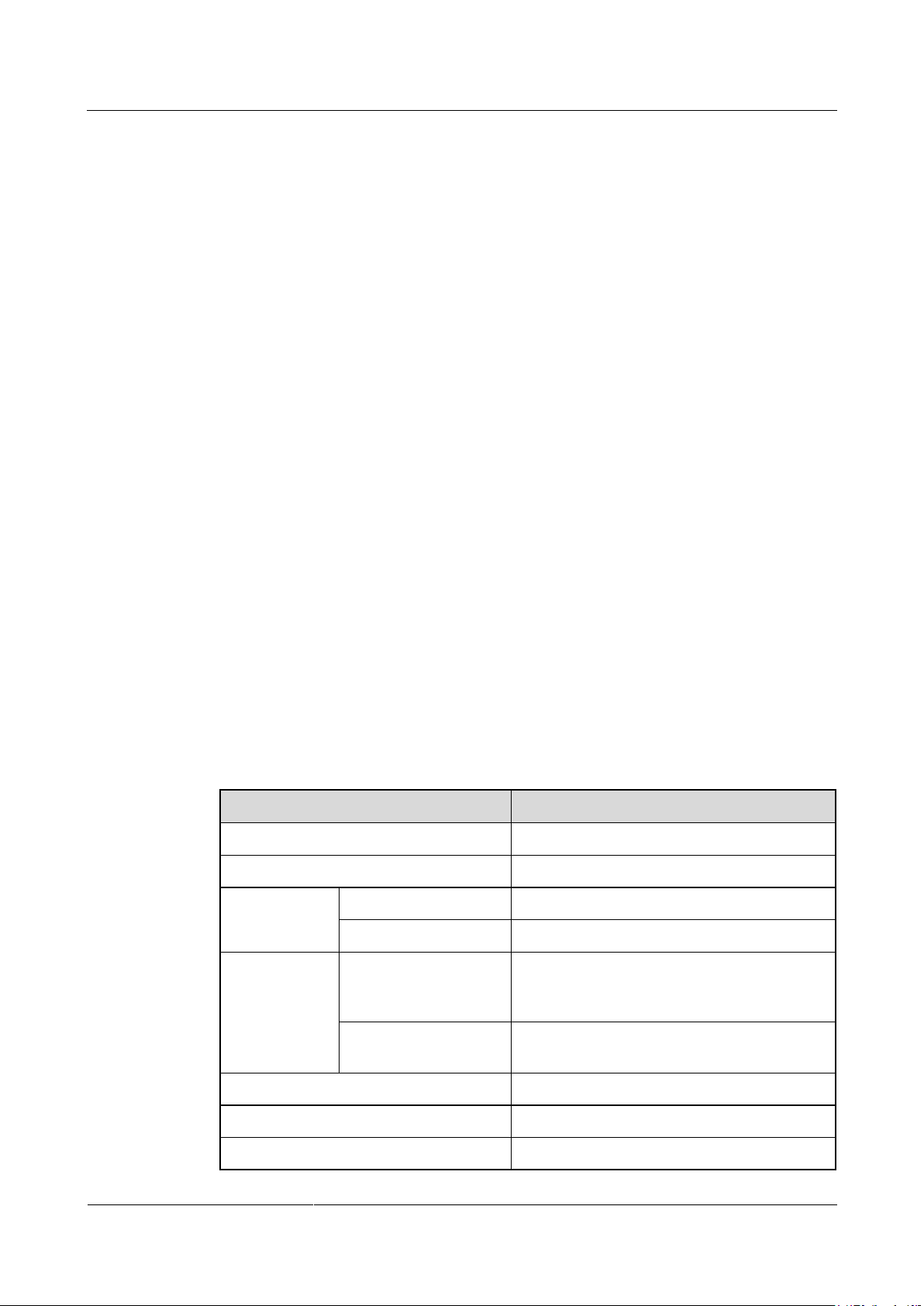

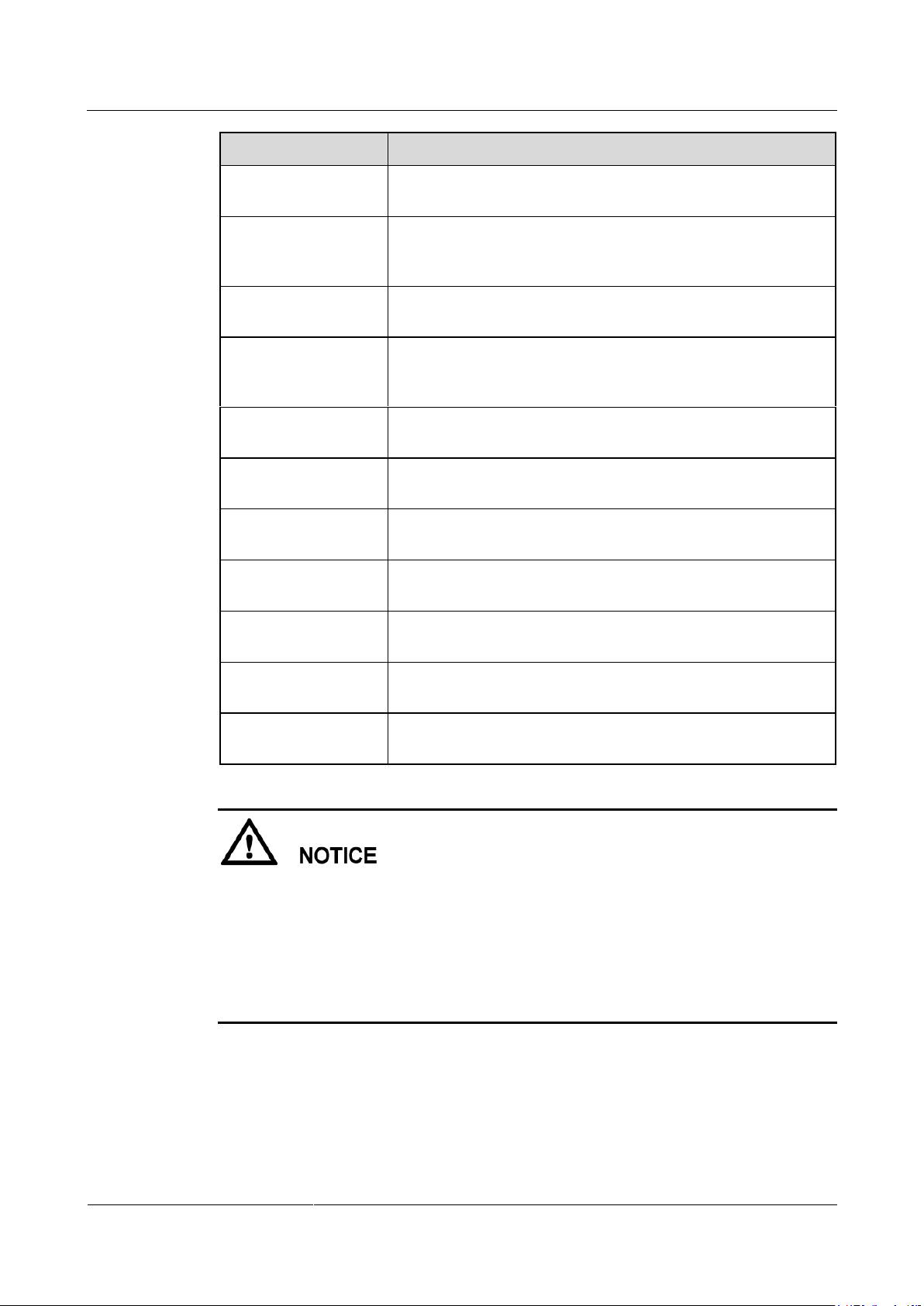

Item

Specifications

AC input frequency

≤ 120 W

AC input voltage

220 V AC ± 20%

DC backup

power

Voltage

24 V DC

Electricity

7.0 Ah

Capacity

Number of detector

loops

Two loops: one loop connected to the common

heat detector and the other connected to the

smoke detector

Number of detectors

connected to each loop

≤ 20 (common detectors)

Wire system of the detector loop

Two-wire system

Length of the detector loop

≤ 1000 m

Relay contact capacity

7 A, 24 V DC for all relays

Each core component in the fire extinguishing system can be flexibly matched with each

other to create a system that meets the fire extinguishing requirements of different levels

in a single container or combined containers.

1.2 Components

Gas Extinguishing Controller

A gas extinguishing controller provides the following functions:

Detects and reports composite fire alarm signals in dual loops. It can be connected to the

emergency startup button, which ensures that the system operation is under control in

case of an emergency or during onsite equipment maintenance.

Restarts automatically after a fault is rectified.

Provides a port for the gas release confirmation signal (reporting pressure values).

Generates single and composite fire alarms, drives gas release indicators and audible and

visual alarms, and controls alarm bells.

Provides an independent output port for the solenoid valve driver and supports 3 A, 24 V

solenoid valve (electric detonator) startup current.

Detects the open circuit fault of the input loop and the short circuit and open circuit of

the output loop (in active output mode).

Provides the intelligent monitoring, and overcharge and overdischarge protection for

standby batteries.

Adopts the low-power consumption design, and supports at least 48-hour consecutive

operation for the backup power.

Provides password lock protection for the keypad to prevent misoperations.

Table 1-2 lists the specifications for the gas extinguishing controller.

Table 1-2 Specifications for the gas extinguishing controller

Page 11

IDS1000 Container Data Center

User Manual

1 Configuration Description

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

5

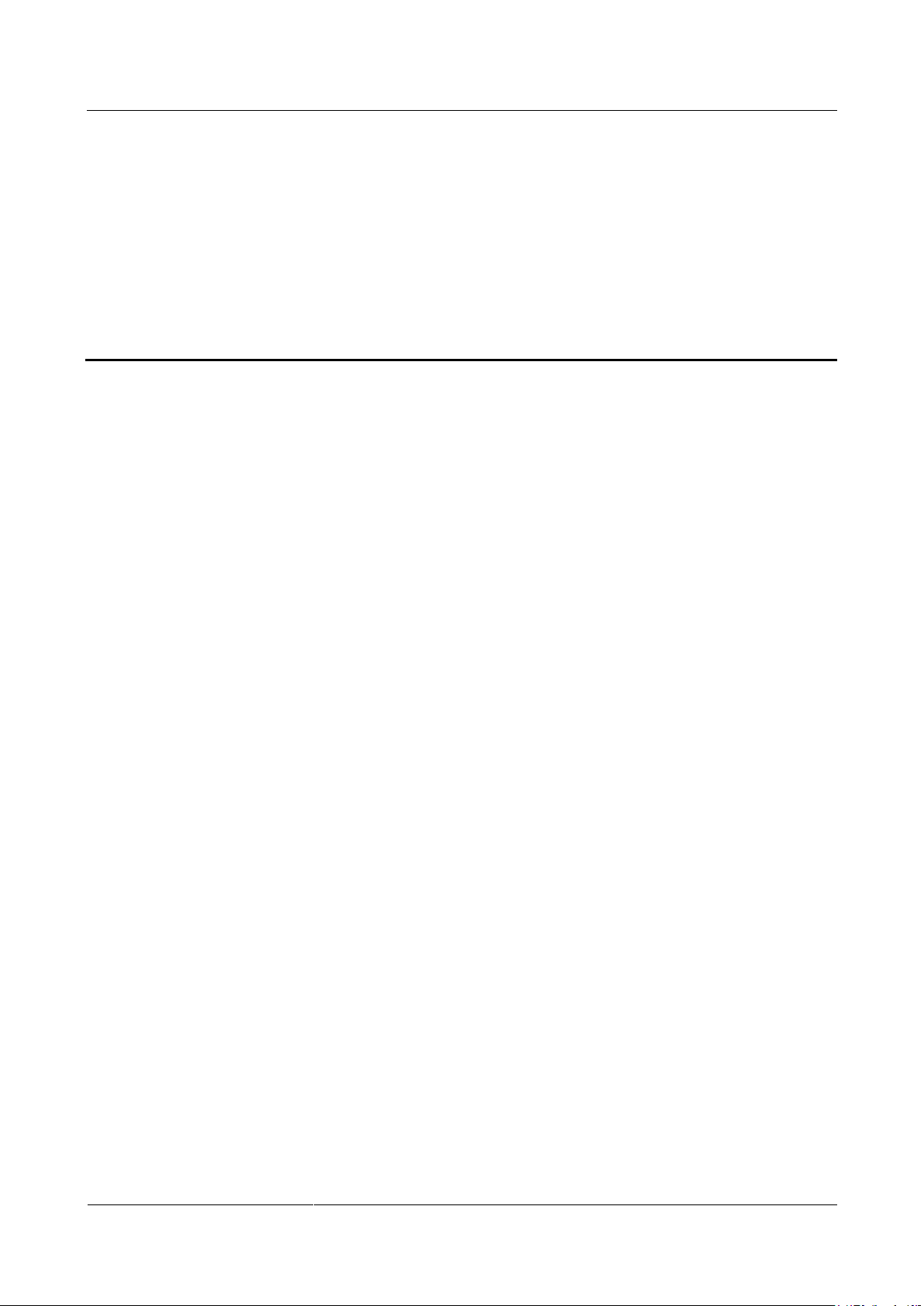

Item

Specifications

Solenoid valve output loop

≤ 3 A

Output loop current limit for other drivers

≤ 1 A

Item

Specifications

Dimensions

Outer diameter of the steel vessel: 364 mm

Maximum operating pressure

50°C: 3.4 MPa

Storage pressure

20°C: 4.2 MPa

Storage container volume

70 L

Heptafluropropane filling density

≤ 1120 kg/m3

Startup current

1.2 A

Startup voltage

24 V DC

Gas Extinguishing Equipment

The gas extinguishing equipment uses heptafluropropane as the extinguishing agent. It

consists of components such as the extinguishing agent vessel, gas supply pipe, pressure

annunciator, and solenoid valve driver.

Table 1-3 lists the specifications for the gas extinguishing equipment.

Table 1-3 Specifications for the heptafluropropane gas extinguishing equipment

VESDA

A VESDA consists of the host, power box, and sampling pipe. The VESDA host includes two

types: VLS and VLP. The VLS is a four-pipe scanning detector that can monitor each pipe and

generate alarms. The VLP is a standard detector that can only conduct general monitoring but

not for each pipe. The host should be configured based on practical requirements.

The detector host consists of a suction pump, filter, high-sensitivity smoke detector, and

precision electrical analyzer. The fan sucks air samples from the monitored environment

through the air sampling pipe to the smoke detector, which will analyze and process the

samples and calculate the amount of smoke in the air. If the smoke density exceeds the preset

alarm threshold, the system blinks and sends alarm signals to the ECC.

A dedicated PPS-004 power box should be configured for the VESDA. The PPS-004 power

box should be supplied by a 220 V AC main input and supplies 24 V DC power to the

VESDA host. Backup batteries should be deployed for the PPS-004 power box.

The features of the VESDA are as follows:

High sensitivity and wide sensitivity adjustment range (0.005–20% obs/m), able to detect

regular fires at an early stage as well as the particles generated by the softened insulation

layer of an overloaded power cable

Page 12

IDS1000 Container Data Center

User Manual

1 Configuration Description

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

6

Item

Specifications

Dimensions (H x W x D)

175 mm x 90 mm x 245 mm

Power supply voltage

24 V DC, powered by a dedicated power box (The

power box is powered by 220 V external AC input.)

Power backup duration

DC, 24 V, 7 Ah, ≥ 8 h

Temperature of the sampled air

0–40°C

IP level

IP30

Maintenance port

Real-time fault detector, air filter, and programming

port

Coverage area

500 m2

Component Name

Configuration Principle

Gas extinguishing

controller

Configure one single-zone gas extinguishing controller for each

single-zone fire extinguishing system.

Active air sampling which uses the high-efficient air suction pump to continuously suck

the air samples from the protected zone to the detection cell; detecting results less

influenced by air flow compared with the traditional fire detection method

Small-sized and easy for installation; able to be deployed based on onsite requirements,

adopting polyvinyl chloride (PVC) pipes that enable flexible installation such as on the

ceiling, under the floor, at the air conditioner air return vents, and in the positions that

require special protection, for example, inside the equipment cabinet through the

capillary air sampling pipes to monitor the equipment in the cabinet.

Using a dedicated filter to process the air that will be used to clean the laser measuring

cell, which prolongs the life span of the detector. The filter can be easily maintained and

replaced, and cleaned by blowing the air sampling pipe. Therefore, you do not have to

replace other components.

Improved self-diagnostic system that enables the monitoring of the VESDA system,

network, and sampling pipe status in real-time; generating alarm signals and able to

locate the faulty areas if a fault occurs

Table 1-4 lists the specifications for the VESDA.

Table 1-4 VESDA specifications

1.3 Configuration Principles

Each independent protected zone in the container data center can be configured with one

single-zone fire extinguishing system, as described in 1.1 System Introduction. Table 1-5

describes the quantity configuration principle for each component in the fire extinguishing

system.

Table 1-5 Quantity configuration principle for each component in the fire extinguishing system

Page 13

IDS1000 Container Data Center

User Manual

1 Configuration Description

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

7

Component Name

Configuration Principle

VESDA

Determine the model and quantity of VESDAs based on the size

of the protected zone.

VESDA power box

Determine the quantity of VESDA power boxes based on the

quantity of VESDAs. Each VESDA is configured with one power

box.

Gas extinguishing

equipment

Determine the quantity of gas extinguishing equipment based on

the size of the protected zone.

Fire extinguishing

pipe

After ensuring that extinguishing agents can be transported to the

entire protected zone swiftly and evenly, deploy the pipes flexibly

based on the layout of the protected zone.

Atomizer nozzle

Installed on fire extinguishing pipes based on the size of the

protected zone.

Gas release indicator

Configured at the entrance or exit of the protected zone (one to

two in general).

Audible and visual

alarm

Configured based on the size of the protected zone (one to two in

general).

Emergency start/abort

switch

Configured at the entrance or exit of the protected zone (one in

general).

Heat detector

Configured in couple with a smoke detector based on the size of

the protected zone.

Smoke detector

Configured in couple with a heat detector based on the size of the

protected zone.

Alarm bell

Configured based on the size of the protected zone (one to two in

general).

For details about how to configure the container data center fire extinguishing system, see

the corresponding descriptions in the Container Data Center Initial Configuration Guide.

A VESDA is optional in the fire extinguishing system. If it is not configured in the

practical solution, ignore the relevant VESDA descriptions in this document.

A gas extinguisher is an auxiliary device in the fire extinguishing system. If it is not

configured in the practical solution, ignore the relevant gas extinguishing equipment

descriptions in this document.

Page 14

IDS1000 Container Data Center

User Manual

2 Operation Description

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

8

2.1 Precautions

Before commissioning the fire extinguishing system, ensure that all control cables to fire

cylinder solenoid valves have been disconnected. This prevents the fire extinguishing

equipment from malfunctioning due to improper manual operations or incorrect cable

connections, and further prevents accidental damage. After the commissioning is

complete, reconnect the solenoid valves.

To ensure the normal operation of the fire extinguishing system, the dowel tightening the

solenoid valve and the container valve must be removed. To prevent the fire

extinguishing system from spraying falsely when installing the IT equipment and

commissioning the system, remove the dowel tightening the solenoid valve and the

container valve on the fire cylinder only after you have commissioned the IT equipment

and fire extinguishing system.

Before commissioning the system, perform the jumper operation for the passive output.

Otherwise, the 6 A fuse (5D) on the main board will be damaged.

The main task involves commissioning of fire extinguishing association, which can be

operated only by professionals in this field.

Only qualified personnel are allowed to perform the operation and maintenance (O&M)

on the fire extinguishing system of the container data center.

Before performing routine maintenance of the fire extinguishing system, inform the

related departments of the temporary downtime due to maintenance. In addition, disable

the logical control function of the area or system to prevent false alarms. Inform the

related departments of the system recovery after the maintenance is complete.

Take ESD measures before removing the front panel from the VESDA.

The following contents in this document describe the operation of a single-zone fire

extinguishing system. If the container data center is configured with multiple single-zone

fire extinguishing systems, perform the operation based on corresponding introductions

in this document.

2 Operation Description

2.2 Emergency Operation Overview

Precautions

Only qualified personnel are allowed to perform emergency operations.

Page 15

IDS1000 Container Data Center

User Manual

2 Operation Description

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

9

Alarm or

Fault

Find Through

Possible

Causes

Possible

Impact

Emergency

Operation

Early fire alarm

System and

equipment

alarms or

maintenance

There is slight

smouldering in

the data center.

A fire is caused.

8.1 Early Fire

Alarm

Single fire

alarm

System and

equipment

alarms or

maintenance

A smoke alarm

or heat alarm is

generated.

A fire is caused.

8.2 Single Fire

Alarm

Composite fire

alarm

System and

equipment

alarms or

maintenance

A fire is caused

in the data

center.

The data center

is destroyed.

8.3 Composite

Fire Alarm

Tools and Materials

Phillips screwdriver

Flat-head screwdriver

Box cutter

Emergency operations are performed only when a critical alarm or fault occurs in the

container data center.

Emergency operations are basic measures taken to prevent or reduce the loss or

destruction of the container data center. When performing emergency operations during

the O&M process, also take the actual situation into consideration.

This document provides only common emergency operations for the container data

center. It does not cover all emergency operations. If the symptom is different from the

symptom described in this document, do not use the method provided in this document

to rectify the fault.

For more information about emergency operations, contact Huawei technical support.

Common Critical Alarms and Faults

Table 2-1 describes the common critical alarms and faults of the container data center.

Table 2-1 Common critical alarms and faults

2.3 Preparations

2.3.1 Obtaining Tools

Table 2-2 lists the tools required for the container data center.

Table 2-2 Tools and materials

Page 16

IDS1000 Container Data Center

User Manual

2 Operation Description

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

10

Tools and Materials

Multimeter

Electroprobe

Wire stripper

Cable ties

PVC insulation tape

Marker

Electrostatic discharge

(ESD) gloves

Ladder (2 m)

ESD wrist strap

Technical Manual

Function

Obtaining Method

(Remarks)

Container Data Center

Installation Parameter

Description

Provides guide for the

container data center initial

configurations. You can

obtain fire extinguishing

system initial

configurations and the

reported alarm information

in the management system.

Downloaded from

http://support.huawei.com.

Container Data Center

Power-On Commissioning

Guide

Provides guide for the

power-on commissioning,

and shutdown and

power-off for the container

data center. You can obtain

the power control

information of the fire

extinguishing system.

Downloaded from

http://support.huawei.com.

iManager NetEco 6000

Product Documentation

Provides guide for

installing, configuring, and

commissioning the

management system. You

can obtain the methods for

Downloaded from

http://support.huawei.com.

The listed tools are for routine maintenance only. Prepare other tools as required.

2.3.2 Obtaining Technical Documents

Table 2-3 lists the documents required for the operation and maintenance (O&M) of the

container data center fire extinguishing system.

Table 2-3 O&M document list

Page 17

IDS1000 Container Data Center

User Manual

2 Operation Description

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

11

Technical Manual

Function

Obtaining Method

(Remarks)

configuring the fire

extinguishing controller

and VESDA in the

management system.

Container Data Center

Installation Guide

Provides guide for

installing the container data

center. You can obtain the

methods for installing the

container data center

hardware devices.

Downloaded from

http://support.huawei.com.

Container Data Center O&M

Parameter Description

Provides guide for

operating and maintaining

the container data center.

You can obtain the

relationship between the

fire extinguishing system

and other systems in the

container data center.

Downloaded from

http://support.huawei.com.

Container Data Center Core

Component Document

Package

Provides guide for the

power-on commissioning,

configuration, and O&M of

core components.

Provided by Huawei for the

customer during project

delivery.

Field

Personnel Skill Requirement

Remarks

Fire

extinguishing

system

Familiar with the configurations of

the fire extinguishing system and

the operations of each core

component

Familiar with the overall

configurations and layout of the

container data center

Experienced in maintaining the fire

extinguishing system

None

2.3.3 Personnel Skill Requirements

Table 2-4 describes the skills required for the container data center fire extinguishing system

O&M personnel.

Table 2-4 Requirements for the O&M personnel

Page 18

IDS1000 Container Data Center

User Manual

3 Power-On Commissioning

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

12

3 Power-On Commissioning

3.1 Initial Configuration

Prerequisites

The container data center has been installed and passed installation tests.

You have obtained the Container Data Center Initial Configuration Guide for the

corresponding solution.

Procedure

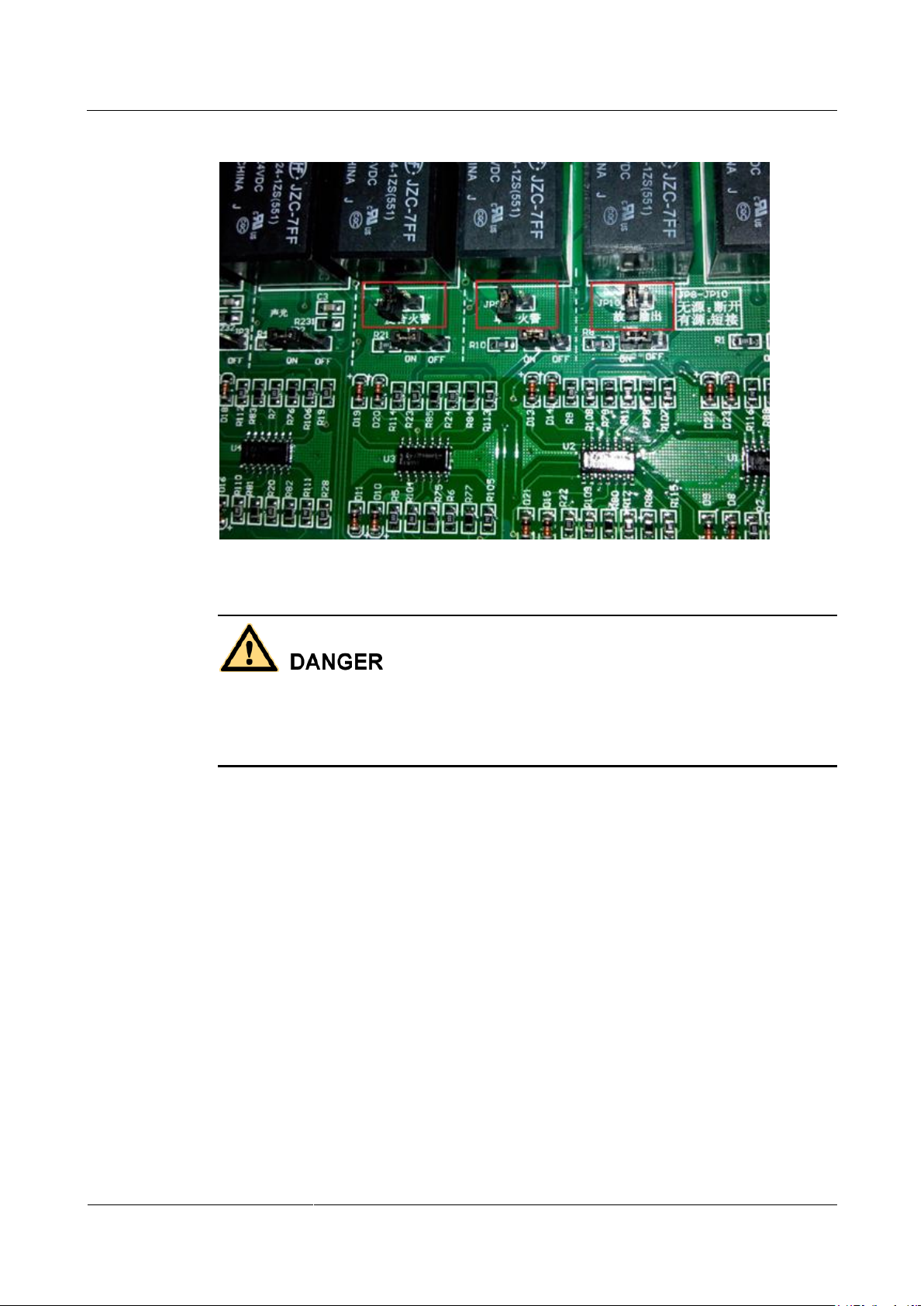

Step 1 Set the output jumper mode of the single alarm (JP8), composite alarm (JP9), and general

Before commissioning the fire extinguishing system, familiarize yourself with the

configurations of the fire extinguishing system and the layout of each component in the

corresponding solution. For details, see the Container Data Center Initial Configuration

Guide for corresponding solutions.

fault (JP10) to passive output, as shown in Figure 3-1.

Page 19

IDS1000 Container Data Center

User Manual

3 Power-On Commissioning

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

13

Figure 3-1 Setting passive output for alarms

You must perform the jumper operation. Otherwise, the 6 A fuse (5D) on the main board will

be damaged.

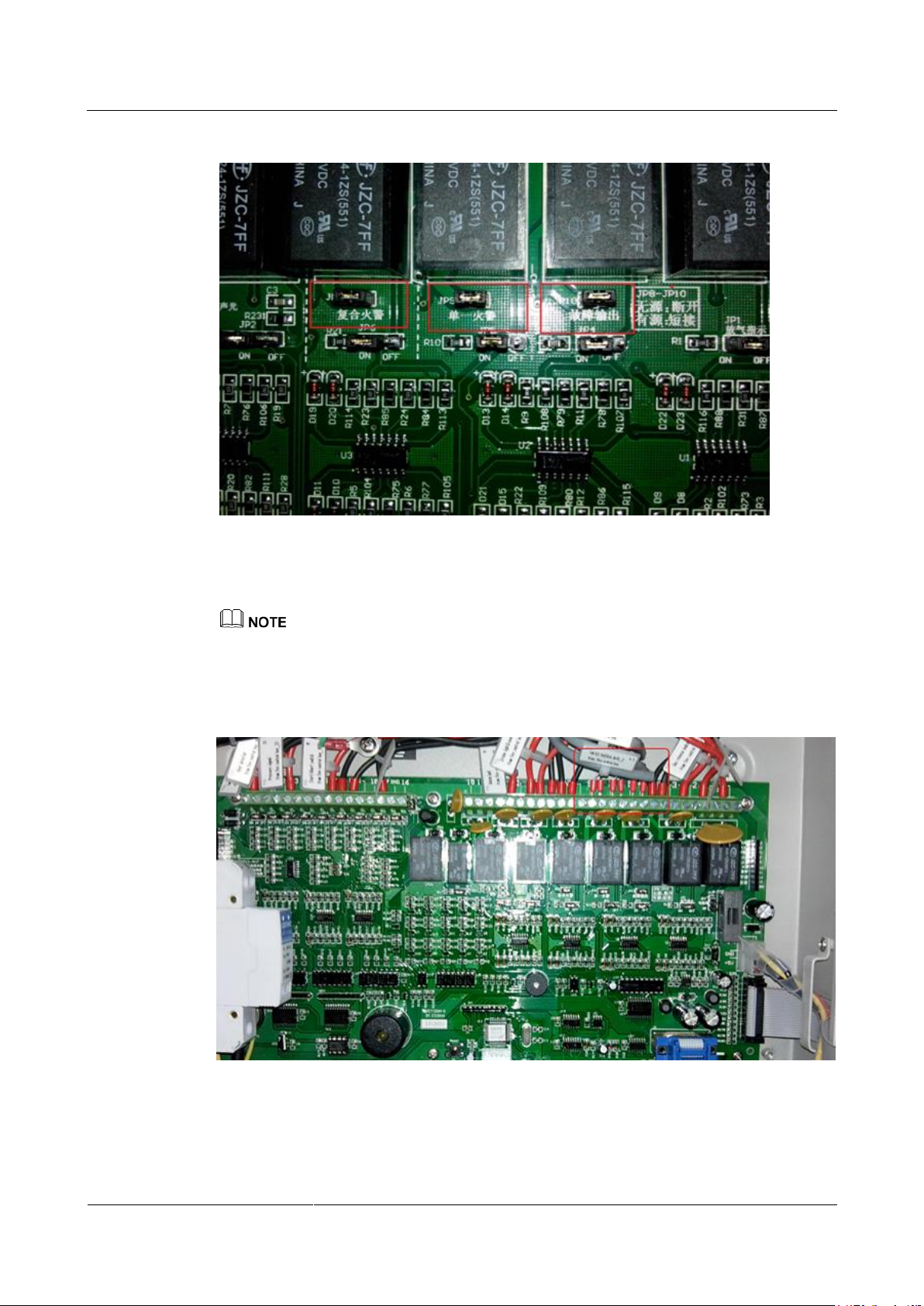

The factory setting of the jumper mode on the fire extinguishing controller for the single

alarm, composite alarm, and general fault is active output, as shown in Figure 3-2.

Page 20

IDS1000 Container Data Center

User Manual

3 Power-On Commissioning

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

14

Figure 3-2 Setting active output for alarms

Step 2 Check the connections of the monitoring cables for reporting the single alarm, composite

alarm, and general fault.

The gas extinguishing controller adopts the passive output to report the alarms, and reports alarm signals

to the management system through the network cable. Figure 3-3 shows the correct cable connections.

Figure 3-3 Correct cable connections for the general fault cables (4, 5), single alarm cables (6, 7),

and composite alarm cables (8, 9)

Step 3 Set the solenoid valve test mode.

Page 21

IDS1000 Container Data Center

User Manual

3 Power-On Commissioning

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

15

For details about how to set the solenoid valve test mode, see the Container Data Center

Initial Configuration Guide.

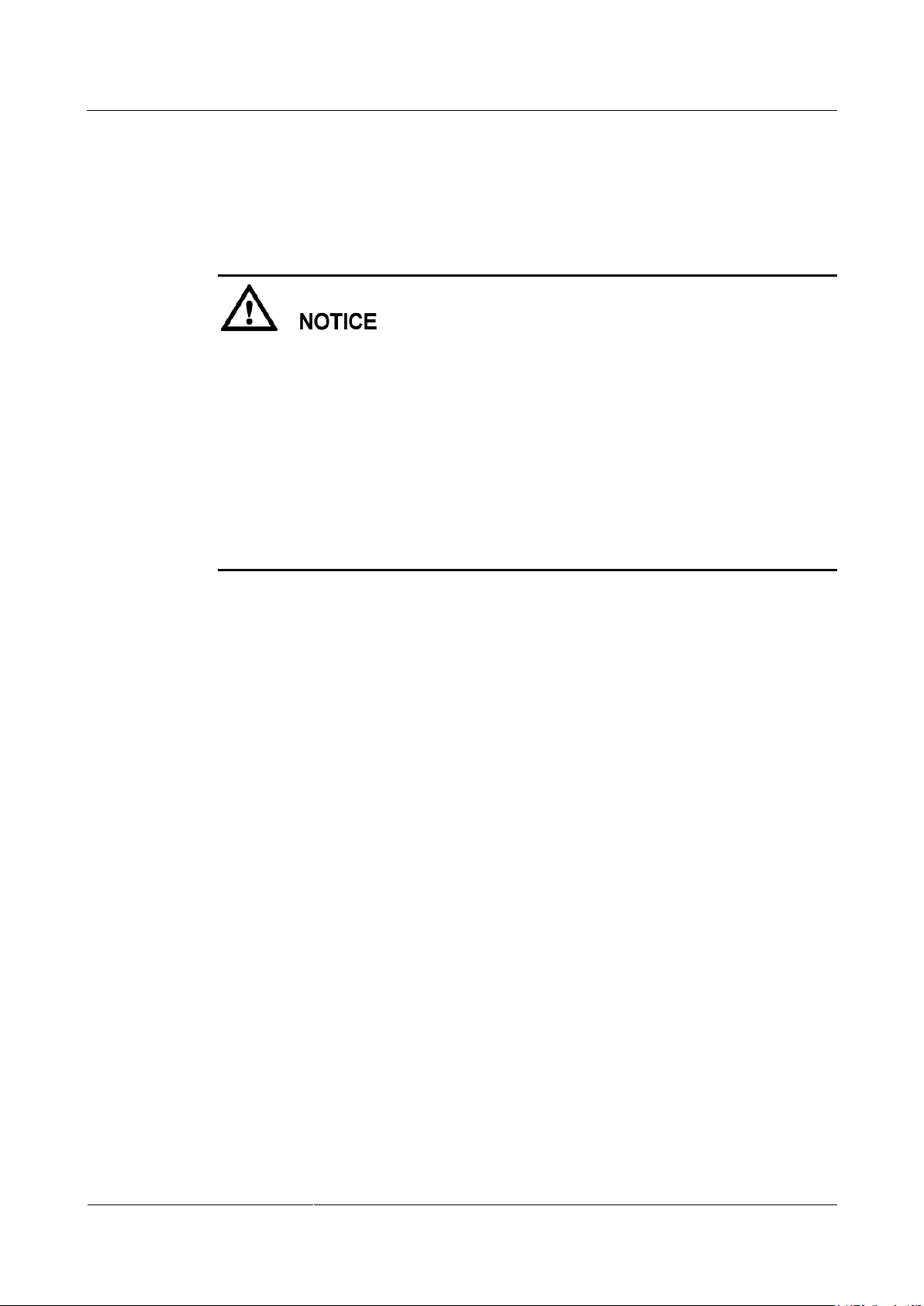

1. If the system is configured with one fire extinguishing cylinder and no fire extinguishing

power box is configured (fire extinguishing power module SJ-DYX-0607, with relays

and batteries). Ensure that the jumper state for JP7 is OFF (detecting faults). If the

jumper state is not OFF, adjust it to OFF. Figure 3-4 shows the position to be set.

Figure 3-4 Setting the test mode for the solenoid valve

2. If the system is configured with two or more fire extinguishing cylinders and no fire

extinguishing power box is configured (mode of the fire extinguishing power module

SJ-DYX-0607, with relays and batteries). Ensure that the jumper state of JP7 is ON (not

detecting faults). If the jumper state is not ON, adjust it to ON Figure 3-5 shows the

position to be set.

Figure 3-5 Setting the test mode for the solenoid valve

Step 4 Set the power-on delay for the solenoid valve.

Set the power-on delay for the solenoid valve from 25s to 30s, as shown in Figure 3-6.

Page 22

IDS1000 Container Data Center

User Manual

3 Power-On Commissioning

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

16

Figure 3-6 Setting the power-on delay for the solenoid valve from 25s to 30s

The factory setting for the solenoid valve power-on delay is 30s, as shown in Figure 3-7.

Figure 3-7 Setting the initial power-on delay for the solenoid valve

Step 5 Set the gas extinguishing controller time display.

Open the controller panel and calibrate time from the rear of the display panel.

There are three buttons and one light emitting diode on the rear of the panel. The three buttons are

Switchover S12, Former plus S11, and Later plus S10, respectively, which are used to calibrate time.

Former plus means plus 1 for the first two values of the nixie tube, and Later plus means

plus 1 for the last two values of the nixie tube. The adjustment methods are as follows:

1. Press Switchover S12, and the H11 indicator lights up, indicating that the time is being

calibrated. The nixie tube displays the year in the format of ??. Press Later plus S10 to

add the value, which ranges from 1 to 60.

2. Then press Switchover S12, and the nixie tube displays the month and day in the format

of ??.??.

Press Former plus S11 to adjust the month, which ranges from 1 to 12, and then press

Later plus S10 to adjust the date, which ranges from 1 to 31.

3. Press Switchover S12 again to display hour and minute, which is in the format of ??:??.

Press Former plus S11 to adjust the month, which ranges from 1 to 23. Then press

Later plus S10 to adjust the day, which ranges from 0 to 59.

4. Press Switchover S12 again to finish the time setting. The indicator H11 lights off. The

nixie tube displays the hour and minute.

Page 23

IDS1000 Container Data Center

User Manual

3 Power-On Commissioning

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

17

----End

3.2 Checking Before Power-On

Prerequisites

You have completed the power-on for the Power Supply and Distribution System and the

fire extinguishing power distribution box (PDB) in the container data center.

Before the power-on, ensure that you have been familiarized with the function and control

relationship of each circuit breaker in the Power Supply and Distribution System. For details

about the function and control relationship of each circuit breaker in the Power Supply and

Distribution System, see the corresponding descriptions in the Container Data Center Initial

Configuration Guide.

Procedure

Step 1 Configure and check the initial parameter settings of the fire extinguishing system by

referring to the Container Data Center Initial Configuration Guide.

For details about how to configure and check the parameters, see 3.1 Initial Configuration.

Step 2 Check the cable connections of solenoid valves. Disconnect the control cables to solenoid

valves to prevent the fire extinguishing equipment from malfunctioning due to improper

manual operations. Figure 3-8 shows the solenoid valve.

Figure 3-8 Solenoid valve

Page 24

IDS1000 Container Data Center

User Manual

3 Power-On Commissioning

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

18

Step 3 Check whether the emergency shutdown button short-circuit cable (between terminals 19 and

GND) is disconnected. If not, disconnect the cable and do not reconnect it after that. Ensure

that the cable to terminal 19 is red and that to GNT is black. Ensure that the short-circuit cable

between terminals 20 and GND is properly connected (in the manual switchover state), as

shown in Figure 3-9.

Figure 3-9 Cable to the emergency start/abort switch

Step 4 Check the battery cable connection. Figure 3-10 shows the correct cable connections.

Figure 3-10 Connecting battery cables

Step 5 Check the cable connections between other components and the gas extinguishing controller

in the fire extinguishing system.

Step 6 Ensure that cable labels are correct, intact, and clearly legible.

Step 7 Ensure that the input circuit breaker for the gas extinguishing controller is OFF.

Step 8 Ensure that the input circuit breaker for the VESDA power box is OFF.

Step 9 Ensure that the cable connections for the VESDA power box batteries are correct and the

power box is correctly connected to the host.

Step 10 Ensure that the power for the gas extinguishing controller and VESDA power box circuit

breakers meets rated voltage and current requirements.

Page 25

IDS1000 Container Data Center

User Manual

3 Power-On Commissioning

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

19

Before the power-on of the container data center fire extinguishing system, check all the fire

extinguishing components one by one by following the preceding check methods and items.

----End

3.3 Hardware Power-On Commissioning

Prerequisites

You have completed the power-on check.

You have obtained the Container Data Center Initial Configuration Guide and Container

Data Center Power-On Commissioning Guide.

You have obtained the documents delivered with the fire extinguishing devices.

Procedure

Step 1 Switch on the input circuit breaker for the VESDA power box in the corresponding protected

zone. For details, see the Container Data Center Initial Configuration Guide and Container

Data Center Power-On Commissioning Guide.

Step 2 Complete the power-on commissioning for the VESDA. For details, see the delivered

VESDA documents.

If multiple VESDAs are configured in the protected zone, follow the preceding power-on

operations to power on their hardware.

Step 3 Switch on the input circuit breaker for the gas extinguishing controller in the corresponding

protected zone. For details, see the Container Data Center Initial Configuration Guide and

Container Data Center Power-On Commissioning Guide.

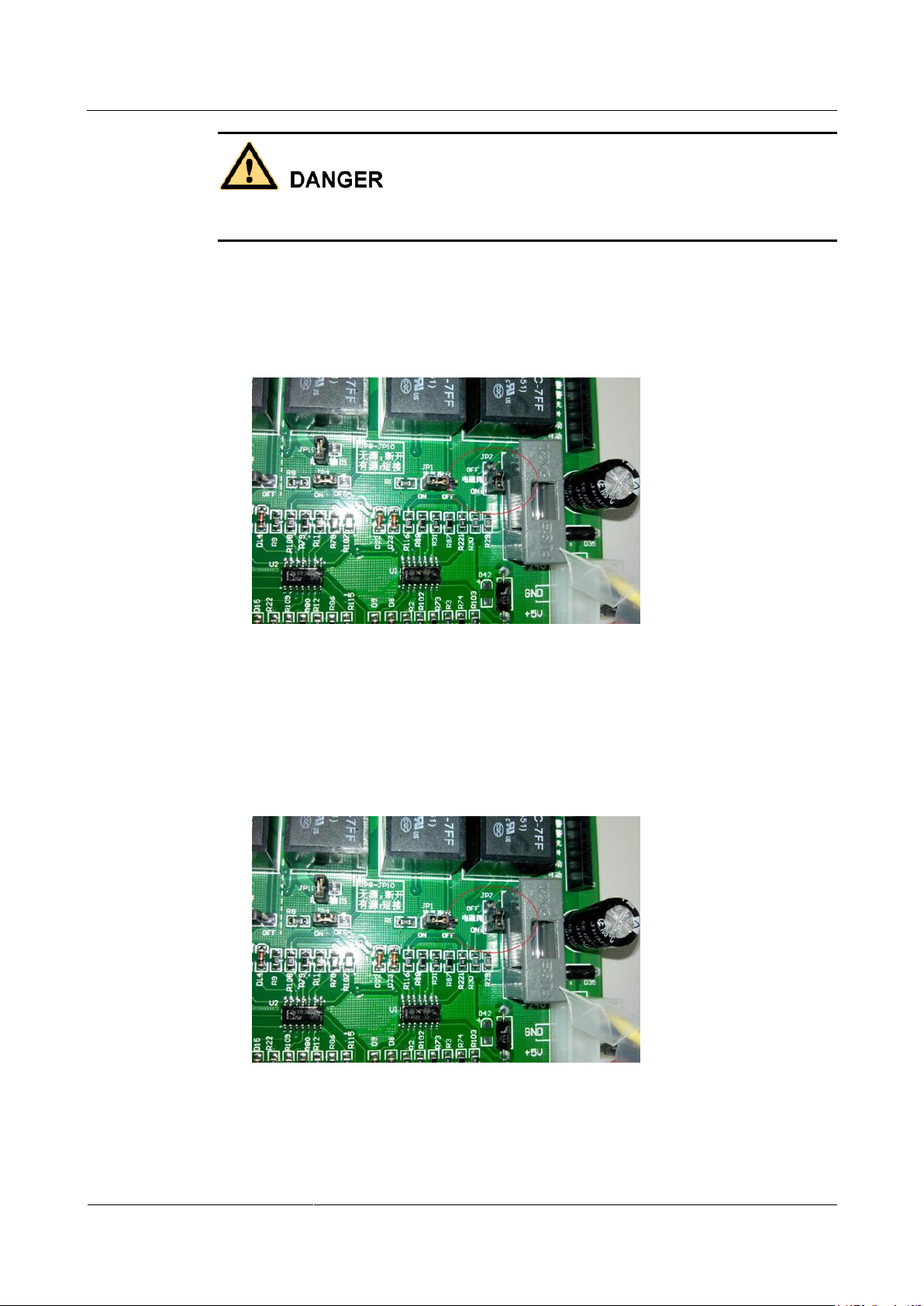

Step 4 Turn on the main power and backup power switches for the controller to power on the gas

extinguishing controller. Figure 3-11 shows the positions of the switches.

Page 26

IDS1000 Container Data Center

User Manual

3 Power-On Commissioning

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

20

Figure 3-11 Power switches

Step 5 Unlock the keypad.

The keypad is locked to prevent misoperation. To unlock the keypad, press /KEY ON/OFF

and then press /QUERY TIME. The keypad is unlocked and the keypad indicator is on. To

lock the keypad, press /KEYON/OFF. The keypad indicator is off. The key will be locked if

no operation is performed in 4 minutes.

Step 6 Start or stop the audible and visual alarm.

When the keypad is unlocked, press /HORN/STROBE to start or stop the audible and visual

alarm. After the audible and visual alarm is started, the indicator beside the button is on.

Step 7 Start or stop the alarm bell.

When the keypad is unlocked, press /ALARM BELL to start or stop the alarm bell. After the

alarm bell is started, the indicator beside the button is on.

Step 8 Check that all smoke detector and heat detector indicators work properly.

Normally, the indicators blink once every 6 seconds.

Step 9 Check that emergency startup/abort switch indicators work properly.

Normally, the Run indicator is steady on.

When powering on and commissioning the hardware of the fire extinguishing system, commission all

the fire extinguishing devices in the container data center. For details about the positions of each fire

extinguishing device, see the Container Data Center Initial Configuration Guide.

----End

3.4 Fire Extinguishing System Commissioning

Commission the fire extinguishing system before using the container data center to ensure that

the system works properly.

Page 27

IDS1000 Container Data Center

User Manual

3 Power-On Commissioning

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

21

Prerequisites

You have completed the power-on for the fire extinguishing system.

The monitoring system is working properly.

Smoke and heat generators have been prepared.

The main task involves commissioning of fire extinguishing association, which can be

operated only by professionals in this field.

Before commissioning the system, ensure that all control cables to solenoid valve drivers

have been disconnected. This prevents the fire extinguishing equipment from

malfunctioning due to improper manual operations or incorrect cable connections, and

further prevents accidental damage. After the commissioning is complete, reconnect the

solenoid valves.

Before commissioning the system, perform the jumper operation for the passive output.

Otherwise, the 6 A fuse (5D) on the main board will be damaged.

If a blow drier is used to simulate the high-temperature scenario, do not get too close to the

detector to avoid the damage of the detector probe caused by high temperature.

Procedure

Step 1 Commission the VESDA.

Step 2 Check whether the gas extinguishing controller is in the automatic mode (the controller has

Release some smoke to the protected zone using a smoke pistol and observe the reaction of

the VESDA.

two modes: automatic and manual).

The AUTO indicator lights up when the controller enters automatic mode, and the MANUAL

indicator lights up when the controller enters manual mode. The positions of the indicators are

as shown in Figure 3-12.

Page 28

IDS1000 Container Data Center

User Manual

3 Power-On Commissioning

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

22

Figure 3-12 AUTO and MANUAL indicators on the gas extinguishing controller panel

If the status is manual, no solenoid valve driving signals will be generated from the controller when the

dual fire alarms from the smoke detector and heat detector are triggered.

Step 3 Simulate to trigger the smoke detector and heat detector.

When the gas extinguishing controller is tested and the first and second fire alarms are

triggered in sequence, the first loop indicator on the panel turns from off to blinking, and the

second loop indicator turns from off to steady on, which are normal reactions.

1. Use a conductor to short-circuit terminals 26 and GND to simulate to trigger the smoke

detector, as shown in Figure 3-13.

Figure 3-13 Short-circuiting terminals 26 and GND

Page 29

IDS1000 Container Data Center

User Manual

3 Power-On Commissioning

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

23

After the short-circuiting, a smoke detector loop alarm is triggered, and the loop 1

indicator on the gas extinguishing controller panel blinks in red, as shown in Figure 3-14.

The controller reports a single loop alarm and the fire extinguishing alarm bell alarms.

Figure 3-14 Loop 1 indicator on the gas extinguishing controller panel

You can also use a smoke pistol to release smoke near the smoke detector until the detector is

triggered.

Do not clear the alarm. Proceed to the alarm simulation for the heat detector.

2. Use a conductor to short-circuit terminals 25 and GND to simulate to trigger the heat

detector, as shown in Figure 3-15.

Figure 3-15 Short-circuiting terminals 25 and GND

Page 30

IDS1000 Container Data Center

User Manual

3 Power-On Commissioning

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

24

After the short-circuiting, a heat detector loop alarm is triggered, and the loop 2 indicator

on the gas extinguishing controller panel is steady red, as shown in Figure 3-16.

The controller generates another loop fire alarm. The audible and visual alarm begins to

operate and enter the 30s countdown mode.

Figure 3-16 Loop 2 indicator on the gas extinguishing controller panel

You can also use a blow drier or heat gun to blow hot air near the heat detector until the detector is

triggered.

3. Measure the output voltage of the solenoid valve.

After the countdown is completed, use a multimeter to measure the output voltage for the

solenoid valve, and ensure that the voltage ranges from 24 V to 27.5 V, as shown in

Figure 3-17. The gas release indicator turns on at the same time.

Figure 3-17 Measuring the voltages for the two terminals of the solenoid valve

Page 31

IDS1000 Container Data Center

User Manual

3 Power-On Commissioning

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

25

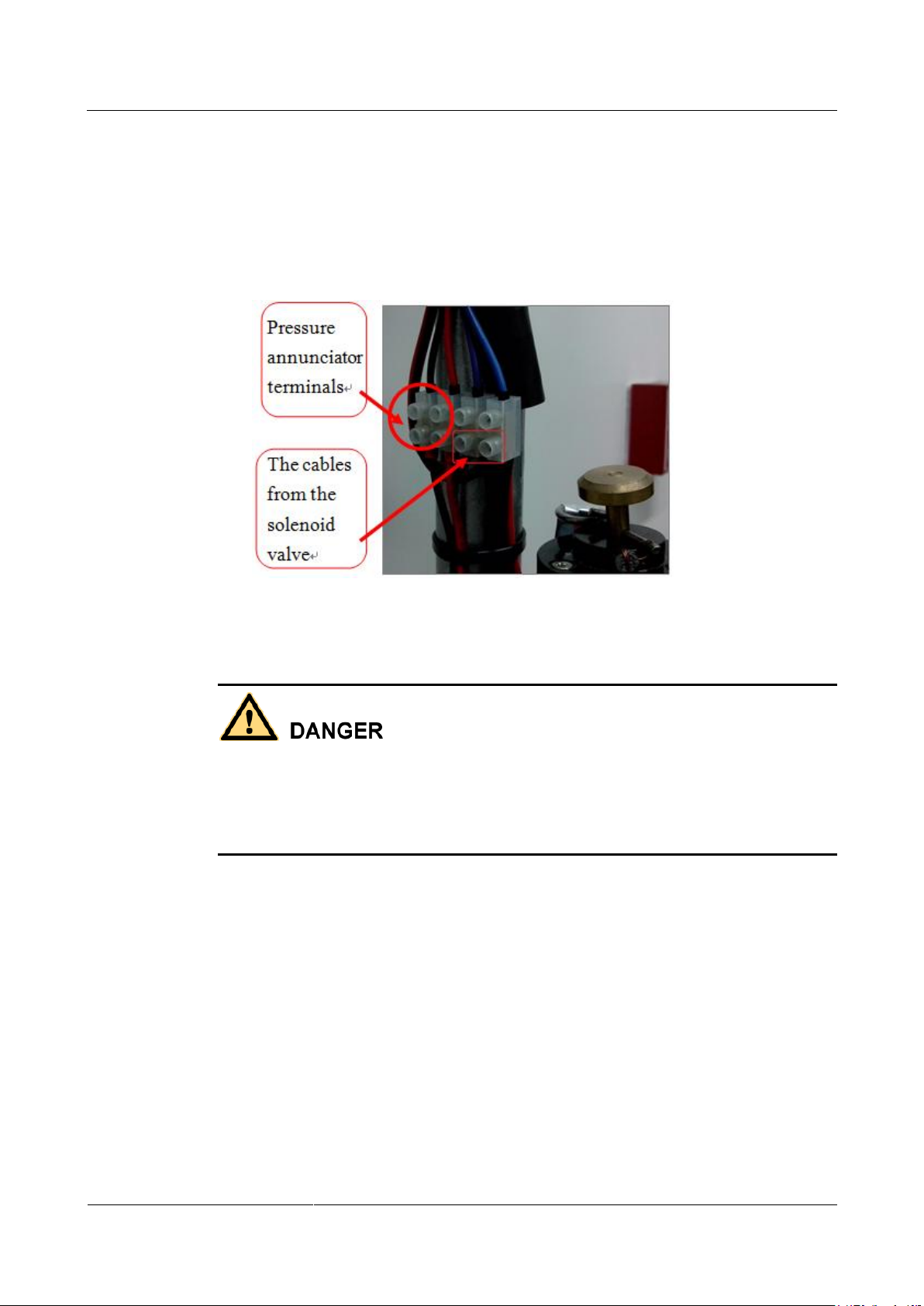

Step 4 Commission the pressure annunciator.

1. Reset the gas extinguishing controller to automatic and disconnect the cables from the

solenoid valve.

2. Short-circuit the pressure annunciator cables (red and black), as shown in Figure 3-18.

The gas release indicator should light up.

Figure 3-18 Short-circuiting the pressure annunciator terminals

Step 5 Commission the emergency startup/abort switch.

The panel of the emergency startup/abort switch is for one-time use only. Before the

commissioning, remove the panel to perform an operation on the emergency startup/abort

switch directly, as shown in Figure 3-19.

Reset the emergency startup/abort switch after the commissioning (the switch is bounced up

and not pressed).

Page 32

IDS1000 Container Data Center

User Manual

3 Power-On Commissioning

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

26

Figure 3-19 Emergency startup/abort switch (panel not removed on the left, panel removed on the

right)

Press the startup button, the system enters the gas releasing delay mode, and the audible and

visual alarm begins to operate. After the countdown is complete, solenoid valve driving

signals are generated and the gas release indicator lights up. If you press the shutdown button

during the delay, the system will stop generating the solenoid valve driving signals.

Step 6 Test the functions of detectors.

Remove the smoke detector or heat detector from the base, as shown in Figure 3-20. Simulate

a network failure for the smoke detector or heat detector in this loop. The gas extinguishing

controller should report relevant loop faults, as shown in Figure 3-21. Reinstall the smoke

detector or heat detector, and the fault is rectified.

Figure 3-20 Removing detectors

Page 33

IDS1000 Container Data Center

User Manual

3 Power-On Commissioning

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

27

Figure 3-21 Loop fault alarm indicators for the smoke detector and heat detector (Zone 1 for the

smoke detector, and Zone 2 for the heat detector).

Step 7 After the test is complete, reset the gas extinguishing controller.

Step 8 (Optional) Check that the fire control signals are reported to the monitoring center.

Page 34

IDS1000 Container Data Center

User Manual

3 Power-On Commissioning

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

28

The fire extinguishing system meets requirements if operations during the commissioning

have expected results and corresponding alarms are generated in the iManager NetEco

management system.

The system can be put into use if operations during the commissioning have expected

results.

To ensure the normal operation of the fire extinguishing system, the dowel tightening the

fire cylinder solenoid valve and the container valve must be removed. Figure 3-22 shows

the dowel.

Figure 3-22 Dowel tightening the fire cylinder solenoid valve

----End

Page 35

IDS1000 Container Data Center

User Manual

4 Routine Maintenance

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

29

4 Routine Maintenance

Maintenan

ce Item

Operation

Expected

Result

Troubleshooting

Fire alarm

Check gas fire

extinguishing

No fire

alarms are

If an alarm is generated, take

actions immediately. For details,

4.1 Routine Maintenance Overview

Routine Maintenance

Routine maintenance is scheduled maintenance carried out to ensure proper system operating

and to therefore avoid any unscheduled breakdown and downtime.

Routine maintenance helps the O&M personnel to:

Find and handle alarms related to equipment operating in a timely manner.

Discover potential risks in a timely manner, preventing faults that could possibly cause

economic losses and reduce customer satisfaction.

Analyze the system operating trend based on collected information and take measures to

improve operating efficiency.

Emergency maintenance is a process of rectifying a fault occurred during the system operation. For

details, see 1 Configuration Description.

Routine Maintenance Interval

The routine maintenance interval specifies how often a maintenance task is performed. A

maintenance task can be performed on a daily, weekly, monthly, quarterly, semi-annual, or

annual basis. For example, if the maintenance interval for a task is daily, the task is performed

every day.

In this document, if a maintenance task is not given a fixed maintenance interval, determine the

maintenance interval based on actual situation of the container data center.

4.2 Daily Maintenance

Page 36

IDS1000 Container Data Center

User Manual

4 Routine Maintenance

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

30

Maintenan

ce Item

Operation

Expected

Result

Troubleshooting

controllers for alarms.

generated.

see the emergency operations for

the fire extinguishing system.

Maintenan

ce Item

Operation

Expected

Result

Troubleshooting

Fire

extinguisher

s

Check whether the fire

extinguishers are in

good condition.

Check the validity

period of fire

extinguishers.

The fire

extinguishers

are in good

condition and

within the

validity

period.

If a fire extinguisher is not in

good condition or has expired,

replace the fire extinguisher.

Maintena

nce Item

Operation

Expected Result

Troubleshooting

Appearance

of

cabinet-type

gas

extinguisher

components

, including

the

extinguishin

g agent

vessel,

solenoid

valve

driver,

pipes, and

nozzles

Check all

components of

the cabinet-type

gas

extinguishers.

The components are

free from mechanical

damage.

The components are

free from rust and

corrosion, the

protective coating is

intact, and the

nameplate is clear.

The protective cover,

lead seal, and safety

signs on

hand-operated

devices are intact.

Devices, pipes,

supports, and

hangers in the

extinguishing agent

If components are bent due to

collision, contact Huawei

technical support.

4.3 Weekly Maintenance

Gas extinguishers are optional for the container data center. The weekly maintenance tasks may vary

with the fire extinguishers you use.

4.4 Monthly Maintenance

Page 37

IDS1000 Container Data Center

User Manual

4 Routine Maintenance

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

31

Maintena

nce Item

Operation

Expected Result

Troubleshooting

vessel are installed

securely.

All nozzle openings

are not blocked.

Gas

pressure of

the fire

cylinder

Observe the

pointer on the

barometer of

the fire

cylinder.

The pointer is in the

green area.

If the pointer is not in the

green area, contact Huawei

technical support.

Maintena

nce Item

Operation

Expected

Result

Troubleshooting

Alarm

indicator on

smoke

detectors

Observe the

alarm indicator

on each smoke

detector.

The alarm

indicator blinks

once every six

seconds.

If an alarm indicator blinks twice

every six seconds or does not blink,

the smoke detector is faulty or the

cables are not properly connected.

Connect the cables or replace the

smoke detector. For details, see the

operations described in 6.1 Smoke

Detector Fault.

Alarm

indicator on

heat

detectors

Observe the

alarm indicator

on each heat

detector.

The alarm

indicator blinks

once every six

seconds.

If an alarm indicator blinks twice

every six seconds or does not blink,

the heat detector is faulty or the cable

is not properly connected. Connect

the cables or replace the heat

detector. For details, see the

operations described in 6.2 Heat

Detector Fault.

Audible and

visual alarm

Trigger a

smoke detector

and a heat

detector.

Audible and

visual alarms are

generated.

If no alarm is generated, the audible

and visual alarm is faulty or the cable

is not properly connected. Rectify the

fault by following the instructions in

6.4 Audible and Visual Alarm Fault.

Fire alarm

bell

Trigger a

smoke detector

or a heat

detector.

The fire alarm

bell rings.

If the fire alarm bell does not ring,

the alarm bell is faulty or the cable is

not properly connected. Connect the

cable or replace the alarm bell. For

details, see the operations described

in 6.5 Fire Alarm Bell Fault.

4.5 Quarterly Maintenance

Page 38

IDS1000 Container Data Center

User Manual

4 Routine Maintenance

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

32

4.6 Semi-Yearly Maintenance

Maintena

nce Item

Operation

Expected

Result

Troubleshooting

VESDA air

detector

network

Check the connection of

air detectors.

The air detectors

are securely

connected.

Connect the air detectors

securely.

Smoke

detectors

Use a dedicated test

instrument or a smoke

generator to blow

smoke to a smoke

detector and check the

indicator status on the

smoke detector.

If the smoke

density is

below the

alarm

threshold, the

alarm

indicator

blinks once

every six

seconds.

If the smoke

density

exceeds the

alarm

threshold, the

alarm

indicator is

steady on.

If the smoke density is

below the alarm threshold

but the alarm indicator

blinks twice every six

seconds, the smoke

detector is faulty. Replace

the smoke detector.

If the smoke density

exceeds the alarm

threshold but the alarm

indicator is not steady on,

replace the smoke

detector.

For details about how to

replace a smoke detector, see

7.1 Replacing a Smoke

Detector.

NOTE

You are advised to clean smoke

detectors every two years.

Heat

detectors

Use a dedicated test

instrument or a blow

drier to check the heat

detectors. Observe the

alarm indicator.

NOTICE

To prevent damage to the

heat detector probe, keep

a proper distance between

the sensor probe and the

blower drier.

If the

temperature

is below the

alarm

threshold, the

alarm

indicator is

blinking.

If the

temperature

exceeds the

alarm

threshold, the

alarm

indicator is

steady on.

If the temperature is

below the alarm threshold

but the alarm indicator is

steady on, replace the

heat detector.

If the temperature

exceeds the alarm

threshold but the alarm

indicator is not steady on

(that is, no alarm is

generated), replace the

heat detector.

For details about how to

replace a heat detector, see

7.2 Replacing a Heat

Detector.

Page 39

IDS1000 Container Data Center

User Manual

4 Routine Maintenance

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

33

4.7 Yearly Maintenance

Maintena

nce Item

Operation

Expected Result

Troubleshooting

Other

maintenanc

e tasks of

the VESDA

For details, see the documents delivered with the VESDA.

Fire

extinguishin

g system

commission

ing

For details, see the 3.4 Fire Extinguishing

System Commissioning.

See the troubleshooting and

alarm handling procedure of

the fire extinguishing system.

Page 40

IDS1000 Container Data Center

User Manual

5 Alarm Reference

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

34

5 Alarm Reference

Alarm

Alarm

Severit

y

Alarm

Type

Impact on the

System

Solution

Gas

extinguish

ing

controller

communic

ation

failure

Critical

Event

The fire

extinguishing

system cannot

be monitored.

See the documents delivered with the

gas extinguishing controller.

Fire

extinguish

ing

hardware

fault

Critical

Event

The fire

extinguishing

system does not

work.

1. Check whether the fire

extinguishing components are in

good condition and properly

connected.

If yes, contact Huawei

technical support.

If no, go to 2.

2. Rectify the fault and check

whether the alarm is cleared.

If yes, no further action is

required.

If no, contact Huawei technical

support.

Fire

extinguish

ing

triggered

Critical

Alarm

The fire

extinguishing

equipment has

released

extinguishing

agents into the

protected zone

of the container.

Check whether a fire is present in the

container.

If yes, fire extinguishing cylinders are

triggered. Wait for the fire

extinguishing system to respond.

If no, check whether fire

extinguishing cylinders are triggered.

If the fire extinguishing cylinders

are triggered, press the shutdown

button on the emergency

startup/abort switch to stop fire

Page 41

IDS1000 Container Data Center

User Manual

5 Alarm Reference

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

35

Alarm

Alarm

Severit

y

Alarm

Type

Impact on the

System

Solution

extinguishing actions. Then see

6.6 Failed to Drive the Fire

Cylinder.

If the fire extinguishing cylinders

are not triggered, see 6.6 Failed to

Drive the Fire Cylinder.

Page 42

IDS1000 Container Data Center

User Manual

6 Troubleshooting

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

36

6.1 Smoke Detector Fault

Possible Causes

The power supply to the smoke detector is abnormal.

The smoke detector is faulty.

The cable connection of the smoke detector is abnormal.

6 Troubleshooting

Tools and Materials

Multimeter

Screwdriver

Step ladder

Spare smoke detectors

Procedure

Step 1 Check whether the power supply to the smoke detector is abnormal.

In normal conditions, use a multimeter to measure the common terminal (base terminal 1) and

the signal terminal (base terminal 3) and check whether the voltage is about 24 V.

Y => The voltage is normal. Go to Step 2.

N => Regulate the voltage to a normal value.

Check whether the fault is rectified.

If yes, no further action is required.

If no, go to Step 2.

Step 2 Replace the smoke detector.

Check whether the fault is rectified.

If yes, no further action is required.

If no, go to Step 3.

Step 3 Check the cable connection of the sensor base.

Page 43

IDS1000 Container Data Center

User Manual

6 Troubleshooting

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

37

Figure 6-1 shows the positions and functions of terminals on the sensor base.

Figure 6-1 Terminals on the sensor base

Terminals (no polarity, two-wire)

1: L2 (connected to the common terminal)

2: L1 (connected to a lower-level device)

3: L1 (connected to an upper-level device)

4: reserved

Use a multimeter to check whether there is any short circuit or open circuit.

Y => Rectify the connection fault.

Check whether the fault is rectified.

If yes, no further action is required.

If no, contact Huawei technical support.

N => Contact Huawei technical support.

----End

6.2 Heat Detector Fault

Possible Causes

The power supply to the heat detector is abnormal.

The heat detector is faulty.

The cable connection of the heat detector is abnormal.

Tools and Materials

Multimeter

Page 44

IDS1000 Container Data Center

User Manual

6 Troubleshooting

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

38

Procedure

Step 1 Check whether the power supply to the heat detector is abnormal.

Step 2 Y=> Replace the heat detector.

Screwdriver

Step ladder

Spare heat detector

In normal conditions, use a multimeter to measure the common terminal (base terminal 1) and

the signal terminal (base terminal 3) and check whether the voltage is about 24 V.

Y => Go to Step 2.

N => Regulate the voltage to a normal value.

Check whether the fault is rectified.

If yes, no further action is required.

If no, go to Step 2.

Check whether the fault is rectified.

If yes, no further action is required.

If no, go to Step 3.

Step 3 Check the cable connection of the sensor base.

Figure 6-2 shows the positions and functions of terminals on the sensor base.

Figure 6-2 Terminals on the sensor base

Terminals (no polarity, two-wire)

Page 45

IDS1000 Container Data Center

User Manual

6 Troubleshooting

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

39

1: L2 (connected to the common terminal)

2: L1 (connected to a lower-level device)

3: L1 (connected to an upper-level device)

4: reserved

Use a multimeter to check whether there is any short circuit or open circuit.

Y => Rectify the connection fault.

Check whether the fault is rectified.

If yes, no further action is required.

If no, contact Huawei technical support.

N => Contact Huawei technical support.

----End

6.3 Gas Release Indicator Fault

Possible Causes

The power supply to the gas release indicator is abnormal.

The gas release indicator is faulty.

The cable connection of the gas release indicator is abnormal.

Tools and Materials

Multimeter

Gloves

Screwdriver

Step ladder

Procedure

Step 1 Check the power supply to the gas release indicator.

Short circuit the pressure annunciator after the cable is removed from the solenoid valve.

When the gas release indicator is off, use a multimeter to measure the two terminals (24 V+

and GND) of the gas release indicator. Check whether the voltage is within the normal range.

Y => Go to Step 2.

N => Regulate the voltage to a normal value.

Check whether the fault is rectified.

If yes, no further action is required.

If no, go to Step 2.

Step 2 Replace the gas release indicator.

Check whether the fault is rectified.

If yes, no further action is required.

Page 46

IDS1000 Container Data Center

User Manual

6 Troubleshooting

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

40

If no, go to Step 3.

Step 3 Check the connection between the gas release indicator and the controller.

Use a multimeter to check whether there is any short circuit or open circuit.

Y => Rectify the connection fault.

Check whether the fault is rectified.

If yes, no further action is required.

If no, contact Huawei technical support.

N => Contact Huawei technical support.

----End

6.4 Audible and Visual Alarm Fault

Possible Causes

The power supply to the audible and visual alarm is abnormal.

The audible and visual alarm is faulty.

The cable connection of the audible and visual alarm is abnormal.

Tools and Materials

Multimeter

Screwdriver

Step ladder

Procedure

Step 1 Check the power supply to the audible and visual alarm.

Trigger a smoke alarm and a temperature alarm when the cable is removed from the solenoid

valve, and observe whether audible and visual alarms are generated. Use a multimeter to

measure the DC24V+ and GND terminals of the audible and visual alarm, and check whether

the voltage is within normal range.

Y => Go to Step 2.

N => Regulate the voltage to a normal value.

Check whether the fault is rectified.

If yes, no further action is required.

If no, go to Step 2.

Step 2 Replace the audible and visual alarm.

Check whether the fault is rectified.

If yes, no further action is required.

If no, go to Step 3.

Page 47

IDS1000 Container Data Center

User Manual

6 Troubleshooting

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

41

Step 3 Check the connection between the audible and visual alarm and the controller.

Figure 6-3 shows the terminals on the audible and visual alarm.

Figure 6-3 Terminals on the audible and visual alarm

Terminals (two-wire):

1: reserved

2: +24 V positive

3: GND negative

4: reserved

Use a multimeter to check whether there is any short circuit or open circuit.

Y => Rectify the connection fault.

Check whether the fault is rectified.

Check whether the fault is rectified.

If yes, no further action is required.

If no, contact Huawei technical support.

N => Contact Huawei technical support.

----End

Page 48

IDS1000 Container Data Center

User Manual

6 Troubleshooting

Issue 01 (2014-3-15)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

42

6.5 Fire Alarm Bell Fault

Possible Causes

The power supply to the fire alarm bell is abnormal.

The fire alarm bell is faulty.

The cable connection of the fire alarm bell is abnormal.

Tools and Materials

Multimeter

Gloves

Step ladder

Screwdriver

Procedure

Step 1 Check whether the power supply to the fire alarm bell is abnormal.

Trigger a smoke alarm and a temperature alarm when the cable is removed from the solenoid