Page 1

AP7052DN

Hardware Installation and

Maintenance Guide

Issue

01

Date

2017-12-29

HUAWEI TECHNOLOGIES CO., LTD.

Page 2

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

i

Copyright © Huawei Technologies Co., Ltd. 2017. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior

written consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective

holders.

Notice

The purchased products, services and features are stipulated by the contract made between Huawei and

the customer. All or part of the products, services and features described in this document may not be

within the purchase scope or the usage scope. Unless otherwise specified in the contract, all statements,

information, and recommendations in this document are provided "AS IS" without warranties, guarantees or

representations of any kind, either express or implied.

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute a warranty of any kind, express or implied.

Huawei Technologies Co., Ltd.

Address:

Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website:

http://e.huawei.com

Page 3

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

About This Document

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

ii

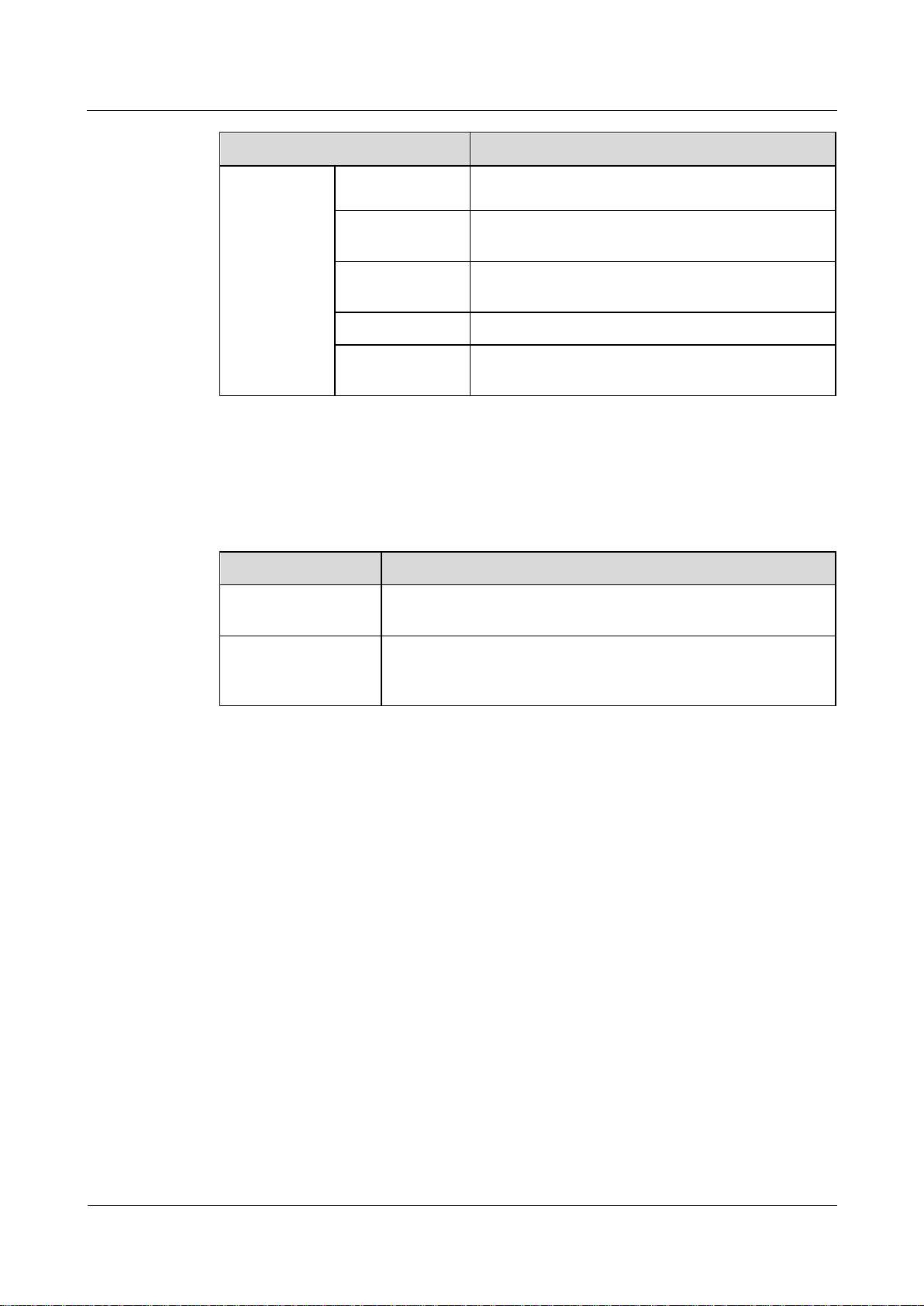

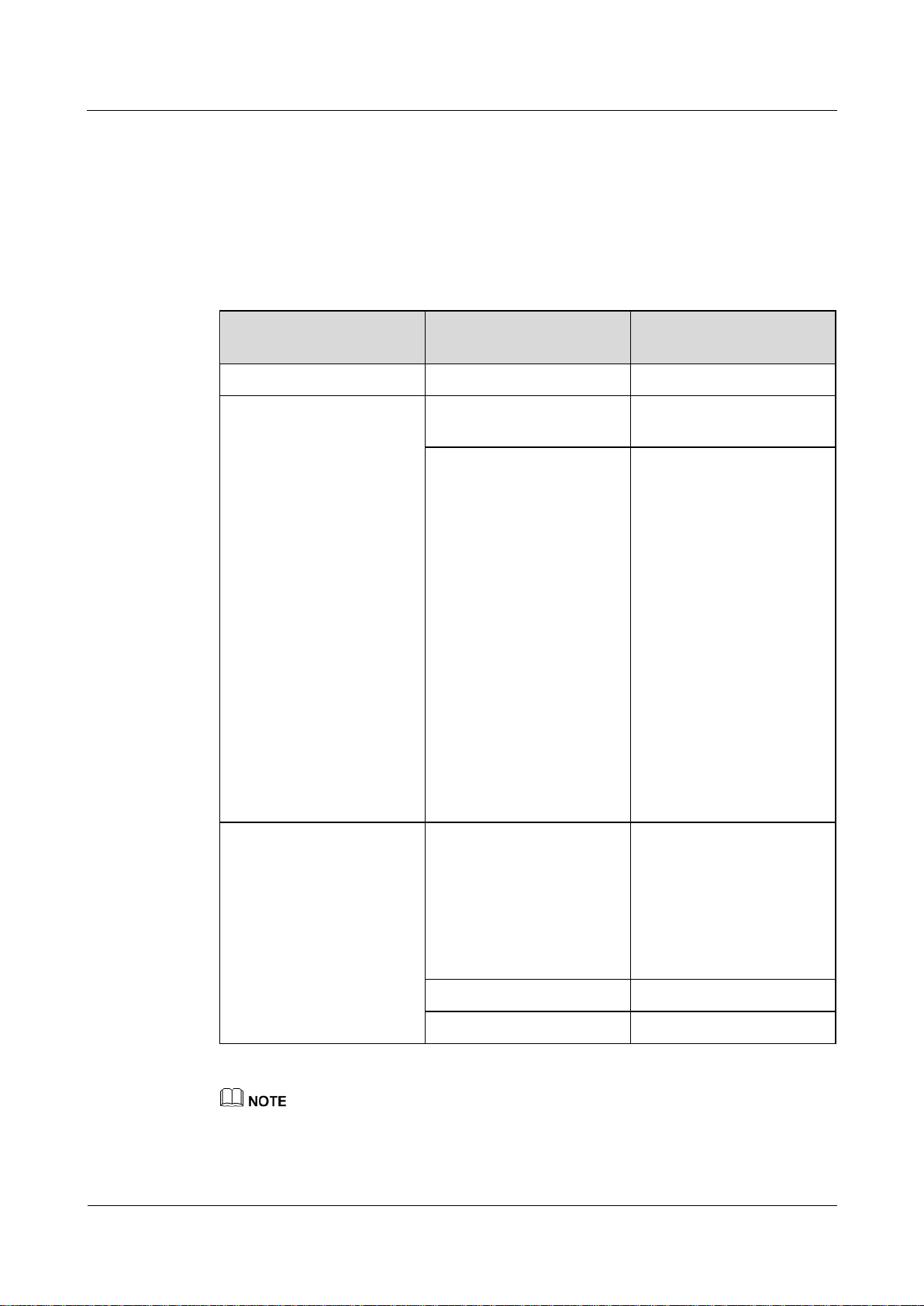

Overview

Symbol

Description

Indicates an imminently hazardous situation

which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation

which, if not avoided, could result in death

or serious injury.

Indicates a potentially hazardous situation

which, if not avoided, may result in minor

or moderate injury.

Indicates a potentially hazardous situation

which, if not avoided, could result in

equipment damage, data loss, performance

deterioration, or unanticipated results.

NOTICE is used to address practices not

related to personal injury.

Calls attention to important information,

best practices and tips.

NOTE is used to address information not

related to personal injury, equipment

This document describes hardware features of the AP7052DN and AP7152DN and provides

basic installation methods.

Intended Audience

This document is intended for network engineers responsible for WLAN installation and

maintenance. You should have experience in network device installation and maintenance.

About This Document

Symbol Conventions

The symbols that may be found in this document are defined as follows.

Page 4

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

About This Document

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

iii

Symbol

Description

damage, and environment deterioration.

Change History

Changes between document issues are cumulative. The latest document issue contains all

changes made in previous issues.

Issue 01 (2017-12-29)

Initial commercial release

Page 5

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

Contents

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

iv

Contents

About This Document ............................................................................................................... ii

1 Product Overview..................................................................................................................... 1

1.1 Device Structure .................................................................................................................................................... 1

1.2 Indicator Description ............................................................................................................................................. 3

1.3 Basic Specifications ............................................................................................................................................... 4

1.4 Ordering Information ............................................................................................................................................. 5

2 AP Installation .......................................................................................................................... 6

2.1 Preparing for Installation ....................................................................................................................................... 6

2.2 Installation Flowchart ............................................................................................................................................ 8

2.3 Unpacking the Equipment ...................................................................................................................................... 8

2.4 Determining the Installation Position ..................................................................................................................... 9

2.5 Installing an IoT Card ................................ ................................................................................................ ...........10

2.6 Installing the AP ...................................................................................................................................................12

2.6.1 Installing the Device on a Wall ...........................................................................................................................12

2.6.2 Installing the Device on a Ceiling.......................................................................................................................14

2.6.3 Installing the Device on a T-rail..........................................................................................................................15

2.6.4 Installing an AP into a Ceiling ............................................................................................................................16

2.6.5 Removing an AP ................................................................................................................................................18

2.7 Cable Connection .................................................................................................................................................19

2.8 Connecting the Security Lock ...............................................................................................................................22

2.9 Checking the Device After Installation .................................................................................................................. 23

2.10 Powering on the AP ............................................................................................................................................24

3 Logging In to the Device ....................................................................................................... 25

3.1 Logging In to the Device Using STelnet/Telnet .....................................................................................................25

3.2 Logging In to the Device Through the Web System ...............................................................................................27

3.3 Logging In to the Device Through the Console Port ..............................................................................................29

4 Hardware Failures .................................................................................................................. 32

4.1 A Device Fails to Be Powered On .........................................................................................................................32

5 Appendix ................................................................................................................................. 35

5.1 On-site Cable Assembly and Installation ...............................................................................................................35

5.1.1 Cable Assembly Precautions ..............................................................................................................................35

Page 6

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

Contents

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

v

5.1.2 Assembling Power Cables ................................................................................................................................ ..36

5.1.2.1 Assembling a DC 2-Pin Round Connector (A) .................................................................................................36

5.1.2.2 Assembling a DC 2-Pin Round Connector (B) .................................................................................................41

5.1.2.3 Assembling the OT Terminal and Power Cable ................................................................................................48

5.1.2.4 Assembling the JG Terminal and Power Cable .................................................................................................51

5.1.2.5 Assembling the Cord End Terminal and the Power Cable .................................................................................53

5.1.3 Assembling Ethernet Cables ...............................................................................................................................57

5.1.3.1 Assembling the Shielded RJ45 Connector and Ethernet Cable ..........................................................................57

5.1.3.2 Assembling an Optimized Shielded RJ45 Connector and SFTP Network Cables ..............................................62

5.1.3.3 Assembling an Integrated Shielded RJ45 Connector and SFTP Network Cables ................................ ...............67

5.1.3.4 Assembling a Shielded RJ45 Connector and an FTP Network Cable ................................................................71

5.1.3.5 Assembling an Unshielded RJ45 Connector and Ethernet Cable .......................................................................76

5.1.3.6 Checking the Appearance of Contact Strips .....................................................................................................78

5.1.3.7 Testing the Connection of Assembled Cables ...................................................................................................81

5.1.3.8 Common Network Cable Faults and Preventive Measures ...............................................................................84

5.1.4 Assembling Feeders ...........................................................................................................................................85

5.1.4.1 Assembling the Straight Male Coaxial N Connector and the 1/2'' Feeder ..........................................................85

5.1.4.2 Assembling a Straight Male Coaxial N Connector and an RG8U Feeder ..........................................................88

5.1.5 Installing Cable Accessories ...............................................................................................................................94

5.1.5.1 Precautions for Installing Cable Accessories ....................................................................................................94

5.1.5.2 Installing Power Adapters ...............................................................................................................................95

5.1.5.2.1 Installing the OT Terminal............................................................................................................................95

5.1.5.2.2 Installing the Cord End Terminal ..................................................................................................................98

5.1.5.2.3 Installing a 2-Pin Round Connector and a DC Power Cable ..........................................................................99

5.1.5.3 Installing Ethernet Adapters .......................................................................................................................... 103

5.1.5.3.1 Installing a Shielded Ethernet Connector .................................................................................................... 103

5.1.5.3.2 Installing an Unshielded Ethernet Connector .............................................................................................. 104

5.1.5.4 Installing Fiber Connectors ................................ ........................................................................................... 106

5.1.5.4.1 Cleaning Fiber Connectors ......................................................................................................................... 106

5.1.5.4.2 Installing an FC Fiber Connector ................................................................................................................ 107

5.1.5.4.3 Installing an LC Fiber Connector ................................................................................................................ 108

5.1.5.4.4 Installing the SC Fiber Connector ................................ ............................................................................... 110

5.1.5.4.5 Installing an MPO Connector ..................................................................................................................... 111

5.1.6 Replacing the Mold of the Crimping Tool......................................................................................................... 113

5.2 Environmental Requirements for Device Operation ............................................................................................. 116

5.2.1 Environmental Requirements for an Equipment Room ..................................................................................... 116

5.2.1.1 Requirements for Selecting a Site for an Equipment Room ............................................................................ 116

5.2.1.2 Equipment Room Layout .............................................................................................................................. 117

5.2.1.3 Construction Requirements for the Equipment Room .................................................................................... 118

5.2.1.4 Equipment Room Environment ..................................................................................................................... 119

5.2.1.5 Requirements for Corrosive Gases ................................................................................................................ 120

5.2.1.6 Requirements for ESD Prevention ................................................................................................................. 121

Page 7

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

Contents

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

vi

5.2.1.7 Electromagnetism Requirements for the Equipment Room ............................................................................ 121

5.2.1.8 Requirements for Lightning Proof Grounding ................................................................................................ 121

5.2.2 Requirements for Power Supply ....................................................................................................................... 123

5.2.2.1 Requirements for AC Power Supply .............................................................................................................. 123

5.2.2.2 Recommendations for AC Power Supply ....................................................................................................... 124

5.2.2.3 Requirements for DC Power Supply .............................................................................................................. 124

5.2.2.4 Recommendations for DC Power Supply ....................................................................................................... 125

5.3 Equipment Grounding Specifications .................................................................................................................. 126

5.3.1 General Grounding Specifications .................................................................................................................... 126

5.3.2 Grounding Specifications for an Equipment Room ........................................................................................... 126

5.3.3 Grounding Specifications for Devices .............................................................................................................. 126

5.3.4 Grounding Specifications for Communications Power Supply .......................................................................... 127

5.3.5 Grounding Specifications for Signal Cables...................................................................................................... 127

5.3.6 Specifications for Laying Out Grounding Cables .............................................................................................. 128

5.4 Engineering Labels for Cables ............................................................................................................................ 128

5.4.1 Introduction to Labels ...................................................................................................................................... 129

5.4.1.1 Label Materials ............................................................................................................................................. 129

5.4.1.2 Type and Structure ........................................................................................................................................ 129

5.4.1.3 Label Printing ............................................................................................................................................... 131

5.4.1.4 Writing Labels .............................................................................................................................................. 133

5.4.1.5 Attaching Labels ........................................................................................................................................... 134

5.4.1.6 Contents of Engineering Labels ..................................................................................................................... 136

5.4.1.7 Precautions for Using Engineering Labels ..................................................................................................... 137

5.4.2 Engineering Labels for Optical Fibers .............................................................................................................. 137

5.4.2.1 Labels for the Optical Fibers Connecting Devices .......................................................................................... 137

5.4.2.2 Labels for the Optical Fibers Connecting the Device and an ODF .................................................................. 138

5.4.3 Engineering Labels for Network Cables ........................................................................................................... 140

5.4.4 Engineering Labels for User Cables ................................................................................................................. 141

5.4.5 Engineering Labels for Power Cables ............................................................................................................... 142

5.4.5.1 Engineering Labels for DC Power Cables ...................................................................................................... 142

5.4.5.2 Engineering Labels for AC Power Cables ...................................................................................................... 144

5.5 Guide to Using Optical Modules ................................................................................................ ......................... 145

5.6 Fault Tag ............................................................................................................................................................ 148

5.7 Installation Checklist .......................................................................................................................................... 149

5.8 Guide to Making Drip Loops .............................................................................................................................. 156

5.9 Power Adaptation Solution ................................................................................................................................. 158

Page 8

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

1 Product Overview

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

1

About This Chapter

Model

Appearance

The AP7052DN and AP7152DN have the following advantages:

4x4 MU-MIMO

Good service support capabilities

High reliability

High security

Simple network deployment

Automatic AC discovery and configuration

Real-time management and maintenance

1 Product Overview

In compliance with IEEE 802.11ac, the AP7052DN and AP7152DN support a theoretical rate

of up to 3.46 Gbit/s, greatly improving wireless user experience.

The AP7052DN and AP7152DN provide highest-quality wireless services for mobile office,

high-density scenarios, elementary education, and higher education. They can be flexibly

deployed in different environments.

A cloud AP must be used together with a cloud server.

1.1 Device Structure

1.2 Indicator Description

1.3 Basic Specifications

1.4 Ordering Information

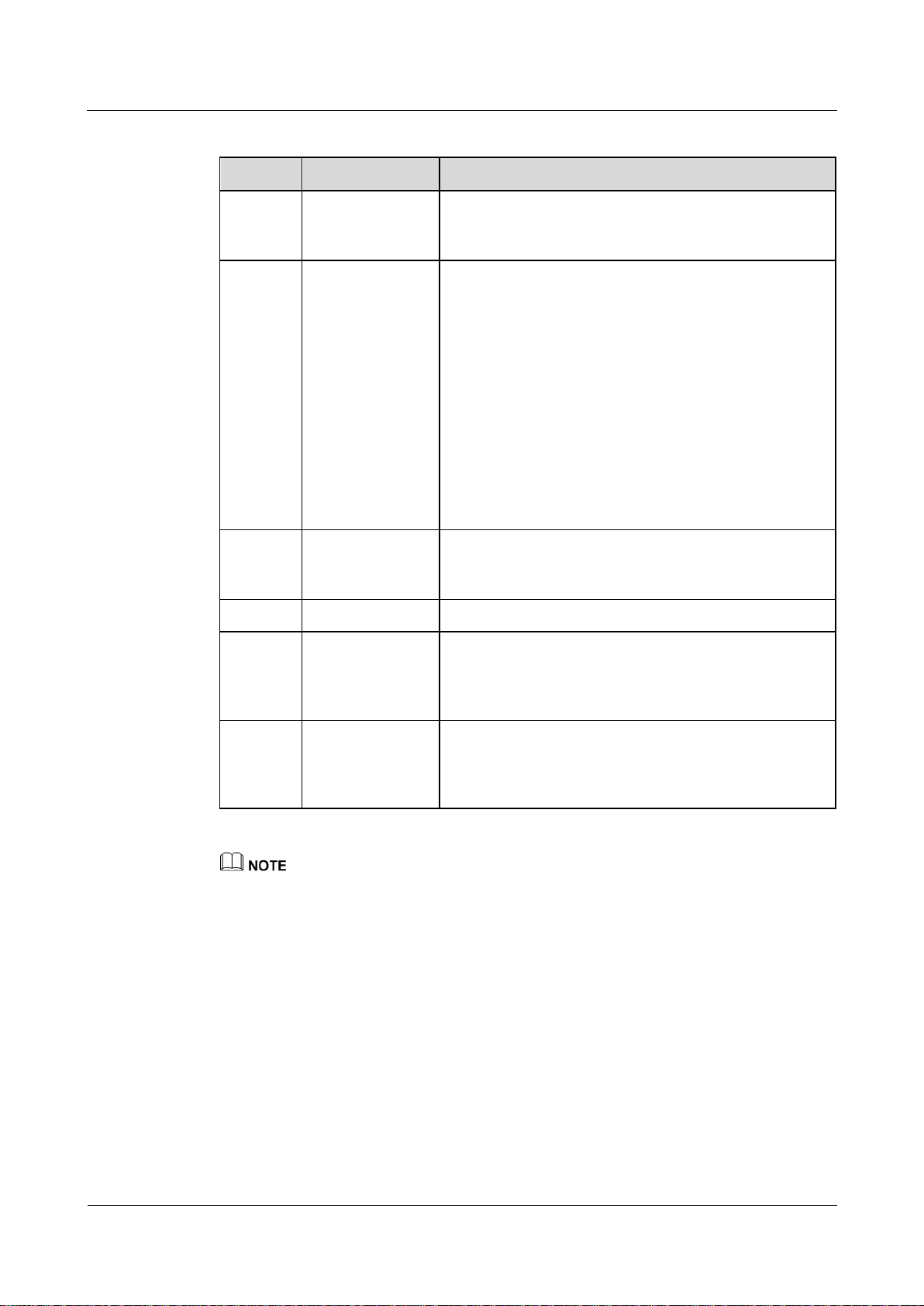

1.1 Device Structure

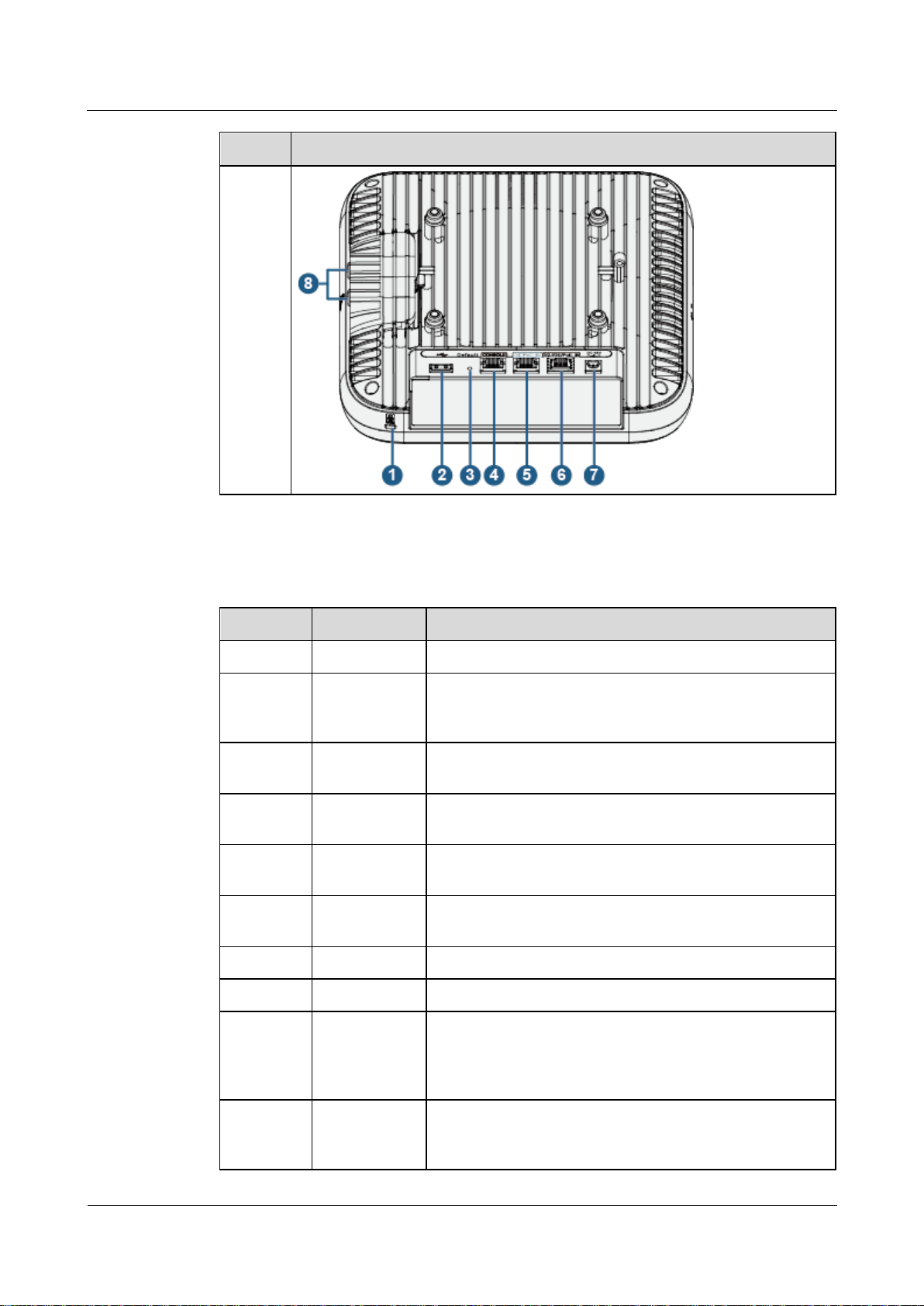

Table 1-1 shows the appearance of the AP7052DN and AP7152DN.

Table 1-1 Appearance of the AP

Page 9

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

1 Product Overview

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

2

Model

Appearance

AP7052

DN

No.

Name

Description

1

Security slot

Connects to a security lock.

2

USB port

Connects to a USB flash drive or other storage devices to

extend the storage space of the AP. The USB2.0 standard is

supported.

3

Default

Restores factory settings and restarts the device when you

hold down the button more than 3 seconds.

4

CONSOLE

Connects to a maintenance terminal for AP configuration

and management.

5

GE/PoE_IN

10/100/1000M port that connects to the wired Ethernet and

supports PoE input.

6

5/2.5GE/PoE_

IN

100M/1000M/2.5G/5G port that connects to the wired

Ethernet and supports PoE input.

7

DC 48V

Connects a power adapter to the AP.

8

Radio port

Connects an antenna to an IoT card through a radio cable.

9

2.4G/5G

Connects a 2.4 GHz or 5 GHz antenna to the AP to send

and receive wireless signals.The port type is

RP-SMA-K.The port is applicable only to an AP that

supports external antennas.

10

5G

Connects a 5 GHz antenna to the AP to send and receive

wireless signals.The port type is RP-SMA-K.The port is

applicable only to an AP that supports external antennas.

Table 1-2 describes ports on the AP7052DN

Table 1-2 Interface description

Page 10

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

1 Product Overview

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

3

Type

Color

Status

Description

Default

status

after

power-on

Green

Steady on

The AP is just powered on and the software is not

started yet.

Software

startup

status

Green

Steady on

after

blinking

once

After the system is reset and starts uploading the

software, the indicator blinks green once. Until the

software is uploaded and started, the indicator

remains steady green.

Running

status

Green

Blinking

once

every 2s

(0.5 Hz)

The system is running properly, the Ethernet

connection is normal, and STAs are associated

with the AP.

The system enters the Uboot CLI.

Blinking

The system is running properly, the Ethernet

The AP supports the following power supply modes: PoE power supply and DC power supply.

When the AP uses the DC power supply, use a power adapter for power supply; otherwise, the AP

may be damaged.

For power adapter models, see 5.9 Power Adaptation Solution.

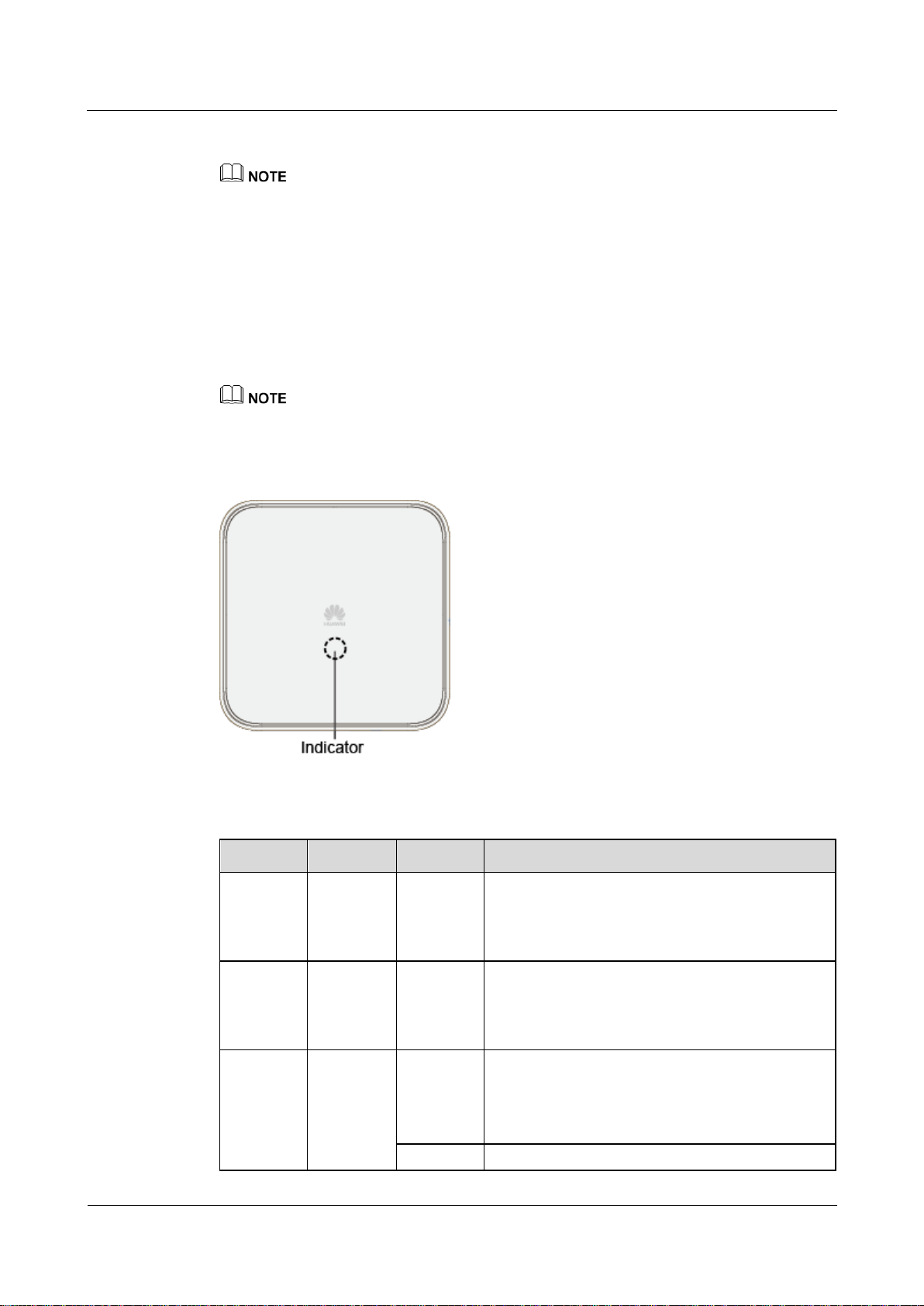

1.2 Indicator Description

The AP7052DN and AP7152DN provide only a single indicator, as shown in Figure 1-1.

The indicator is located inside the panel, which turns on after the AP is powered on.

Indicator colors may vary slightly at different temperature.

Figure 1-1 Indicator

Table 1-3 Description about the single indicator

Page 11

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

1 Product Overview

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

4

Type

Color

Status

Description

once

every 5s

(0.2 Hz)

connection is normal, and no STA is associated

with the AP. The system is in low power

consumption state.

Alarm

Green

Blinking

once

every

0.25s (4

Hz)

The software is being upgraded.

After the software is loaded and started, the AP

requests to go online if it works in Fit AP or

cloud-based management mode. The indicator

remains in this state before the AP successfully

goes online.

The AP works in Fit AP or cloud-based

management mode and fails to go online.

Fault

Red

Steady on

A fault that affects services has occurred, such as a

DRAM detection failure or system software

loading failure. The fault cannot be automatically

rectified and must be rectified manually.

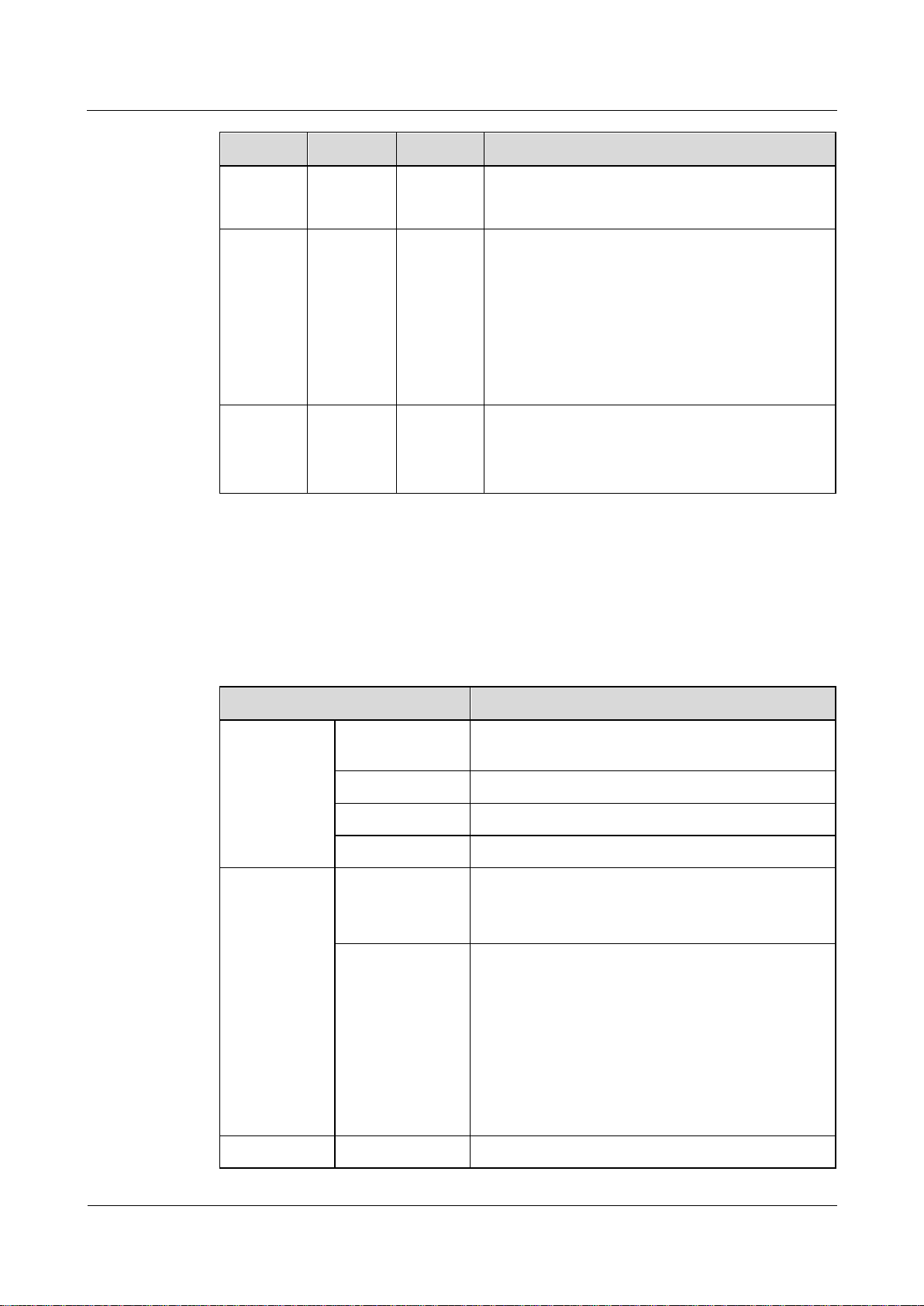

Item

Description

Physical

specifications

Dimensions (H x

W x D)

52 mm × 220 mm × 220 mm

Weight AP7052DN: 1.68 kg

System memory

512 MB DDR3L

FLASH

16 MB NOR FLASH + 128 MB NAND FLASH

Power

specifications

Power input

DC: 42.5 V to 57 V

PoE power supply: in compliance with IEEE

802.3at/bt

Maximum power

consumption

DC/802.3bt power supply: 33 W (excluding the

output power of the USB port)

802.3at power supply: 25.5 W (The USB function

is unavailable. The port rate of 5/2.5GE/PoE_IN

decreases to 2.5 Gbit/s. The IoT card power is

lower than 0.5 W.)

NOTE

The actual maximum power consumption depends on local

laws and regulations.

Environment

Operating

-60 m to +1800 m: -10°C to +50°C

1.3 Basic Specifications

Table 1-4 provides basic specifications of the AP7052DN and AP7152DN.

Table 1-4 Basic specifications

Page 12

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

1 Product Overview

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

5

Item

Description

specifications

temperature

1800 m to 5000 m: Temperature decreases by

1°C every time the altitude increases 300 m.

Storage

temperature

-40°C to +70°C

Operating

humidity

5% to 95% (non-condensing)

IP rating

IP41

Atmospheric

pressure

53 kPa to 106 kPa

Part Number

Description

02351KDV

AP7052DN Mainframe(11ac Wave2,Indoor,4X4 Dual-Band,IoT

Expansion,Built-in Antenna)

02351KEA

AP7052DN-USA Mainframe(11ac Wave2,Indoor,4X4

Dual-Band,IoT Expansion,Built-in Antenna,United States

dedicated)

1.4 Ordering Information

To place an order, contact technical support personnel.

Page 13

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

2 AP Installation

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

6

About This Chapter

2.1 Preparing for Installation

2.2 Installation Flowchart

2.3 Unpacking the Equipment

2 AP Installation

2.4 Determining the Installation Position

2.5 Installing an IoT Card

2.6 Installing the AP

2.7 Cable Connection

2.8 Connecting the Security Lock

2.9 Checking the Device After Installation

2.10 Powering on the AP

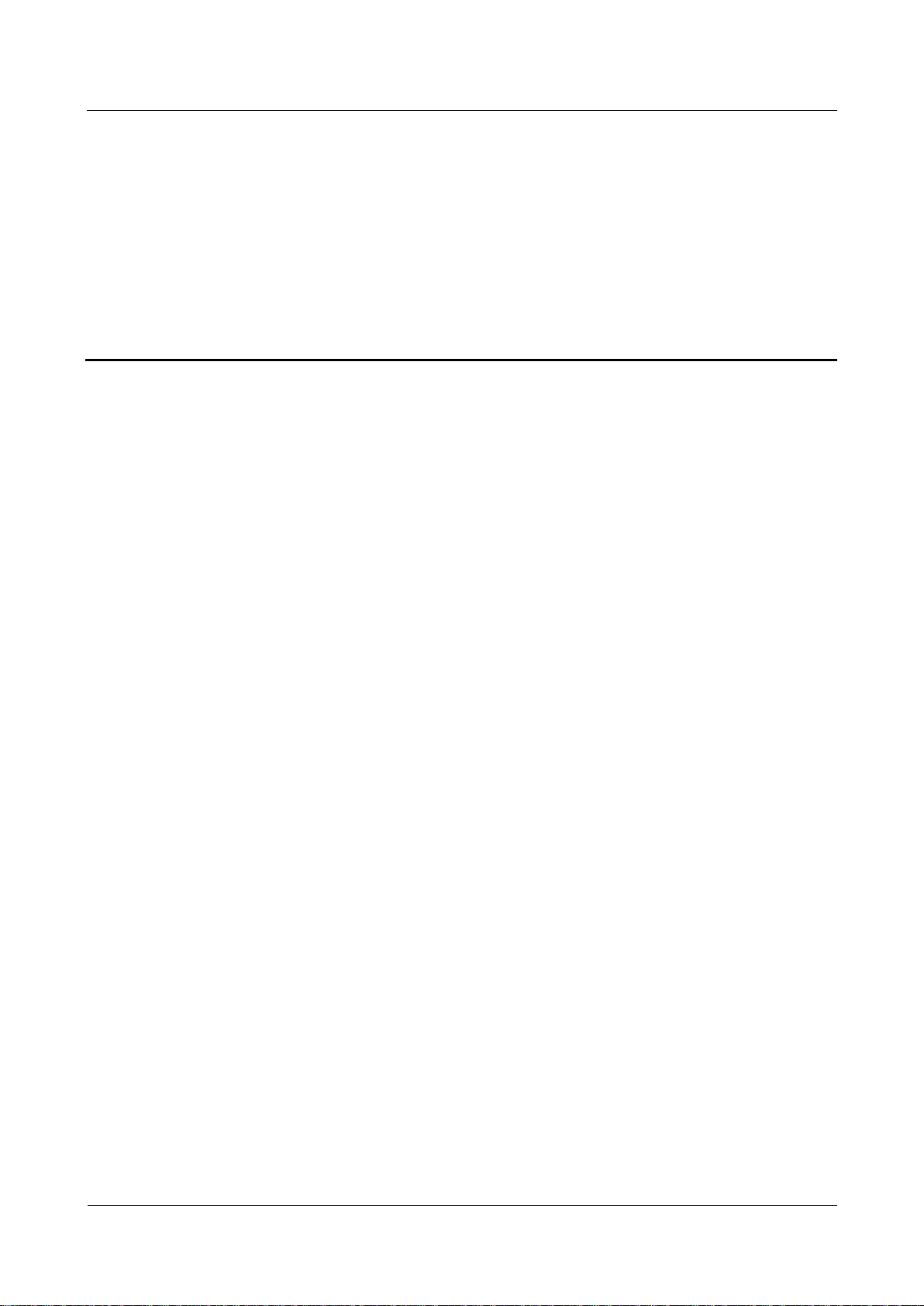

2.1 Preparing for Installation

This section describes safety precautions and tool preparations for AP installation.

Safety Precautions

Take proper measures to prevent injuries and device damage.

Place the device in a dry and flat position away from any liquid and prevent the device

from slipping.

Keep the device clean.

Do not put the device and tools in the aisles.

Page 14

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

2 AP Installation

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

7

Only the qualified personnel are permitted to install and remove the device and its accessories.

Phillips screwdriver

Protective gloves

ESD gloves

Slip-proof glove

Marker

Hammer drill

Claw hammer

Diagonal pliers

Wire stripper

RJ45 crimping tool

Cable cutter

Network cable tester

Jig saw

Multimeter

Ladder

Safety helmet

Safety belt

Anti-skid shoes

Before installation and operation, read the safety precautions carefully.

Tool Preparation

To install APs, prepare tools listed in Table 2-1.

Table 2-1 Tools

Page 15

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

2 AP Installation

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

8

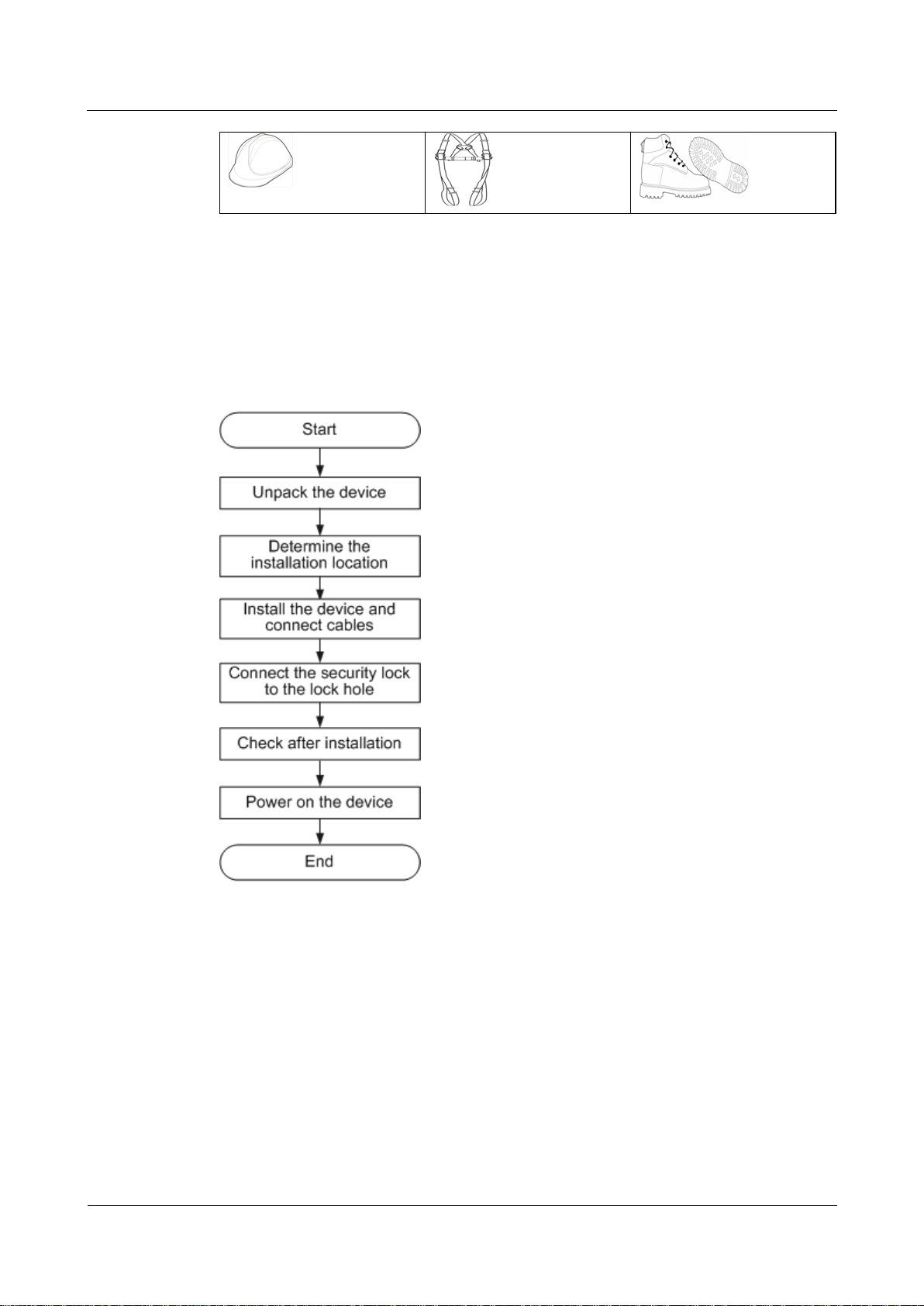

2.2 Installation Flowchart

The following figure shows the process for installing an AP.

Figure 2-1 Installation flowchart

2.3 Unpacking the Equipment

Before unpacking the carton, ensure that the packing carton is intact and not damaged or

soaked. Stop unpacking if the equipment is rusted or soggy. Then, investigate causes and

contact the supplier.

After unpacking, check items in the carton against the packing list. If any item is missing,

contact the supplier or agent.

Usually, the packing list contains the following items.

AP device

Page 16

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

2 AP Installation

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

9

Sheet metal mounting bracket

Screws

Adjustable buckle

Expansion screws

Quick start guide

Warranty card

MAC address label

SN label

If a PoE adapter or a DC power adapter is required, you need to purchase it separately. For DC power

adapter models, see 5.9 Power Adaptation Solution.

2.4 Determining the Installation Position

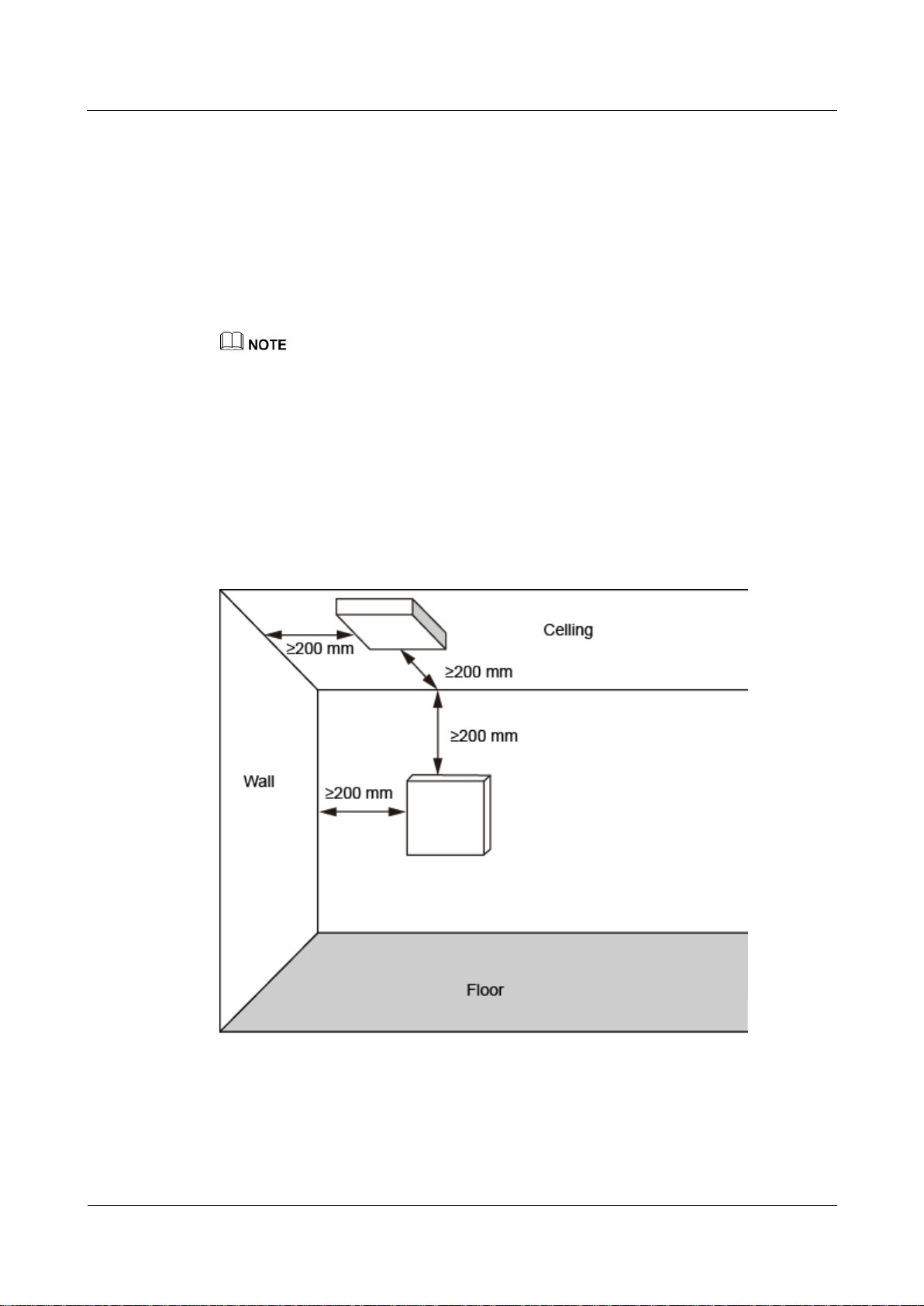

Indoor APs are usually mounted on a wall or ceiling using sheet metal mounting brackets. The

installation position is determined by the site survey. There must be at least 200 mm clearance

between the cabling end of the AP and the wall. Figure 2-2 shows space requirements.

Figure 2-2 Mounting an AP

When determining the AP installation position, comply with the following rules:

Try to reduce the number of obstacles, such as walls, between the AP and user terminals.

Page 17

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

2 AP Installation

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

10

Scenario

Deployment Distance Requirement

Indoor

installation

There should be at least a 7 m distance between antennas.

The antennas should be placed at least 2 m from the 4G antennas of

the carrier.

The antennas should be placed far away from electronic devices that

may produce interference, such as microwave ovens.

Place the AP far away from electronic devices that may produce radio interference, such

as microwave ovens, other APs, antennas, and other radio communication devices. For

details, see Table 2-2.

Install the AP in a hidden position that does not affect daily lives and work of residents.

Install the AP in a site that is free from leaking or dripping water, heavy dew, and

humidity, and take protective measures to prevent water from flowing into the equipment

along the cable.

Do not install the AP in an environment with high temperature, dust, poisonous gases,

flammable or explosive objects, electromagnetic interference (from a radar station, radio

station, or substation), unstable voltage, violent shakes, or strong noise.

Table 2-2 General anti-interference requirements

If antennas are embedded into APs, the deployment distance requirements on the antennas are those on

APs.

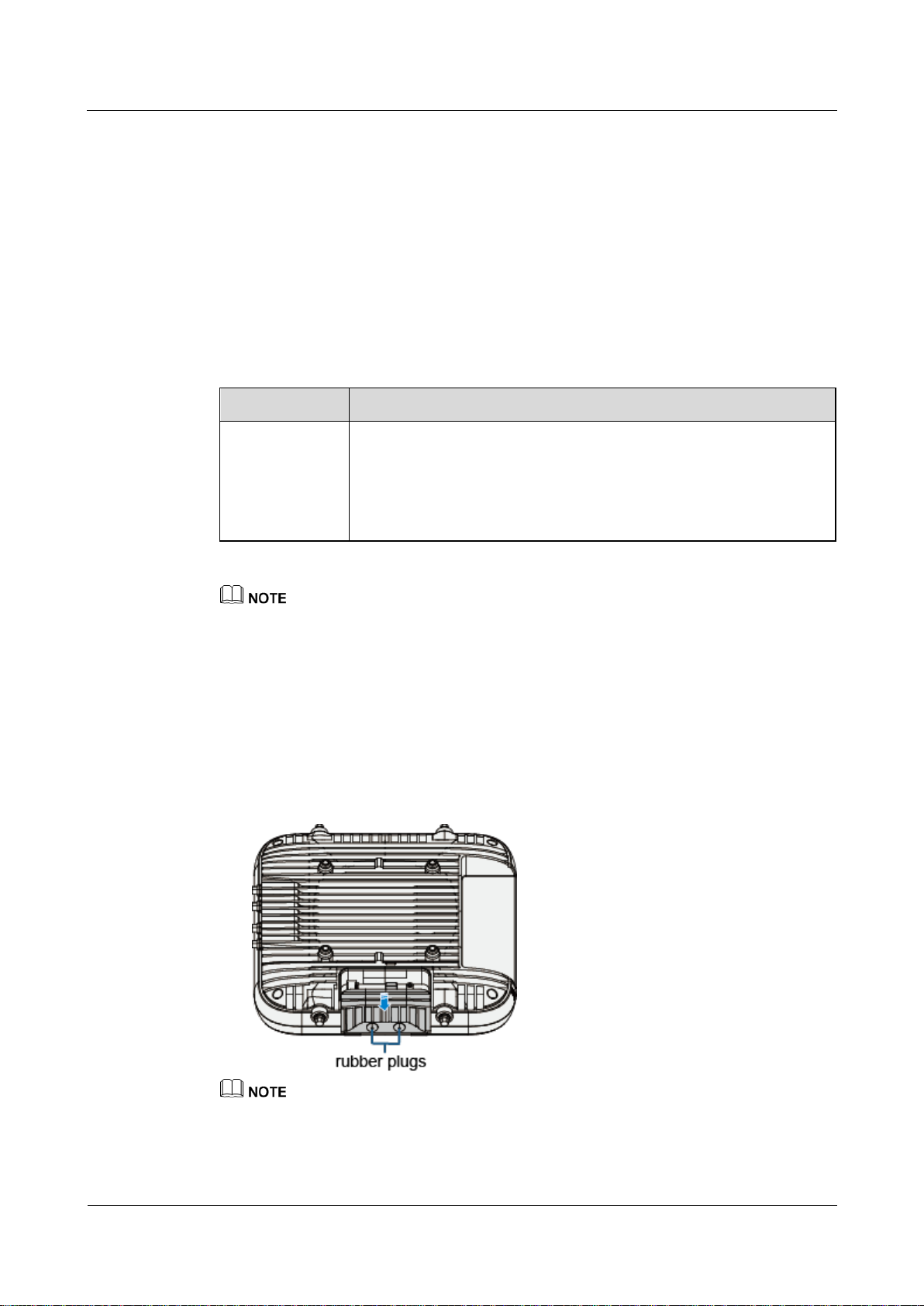

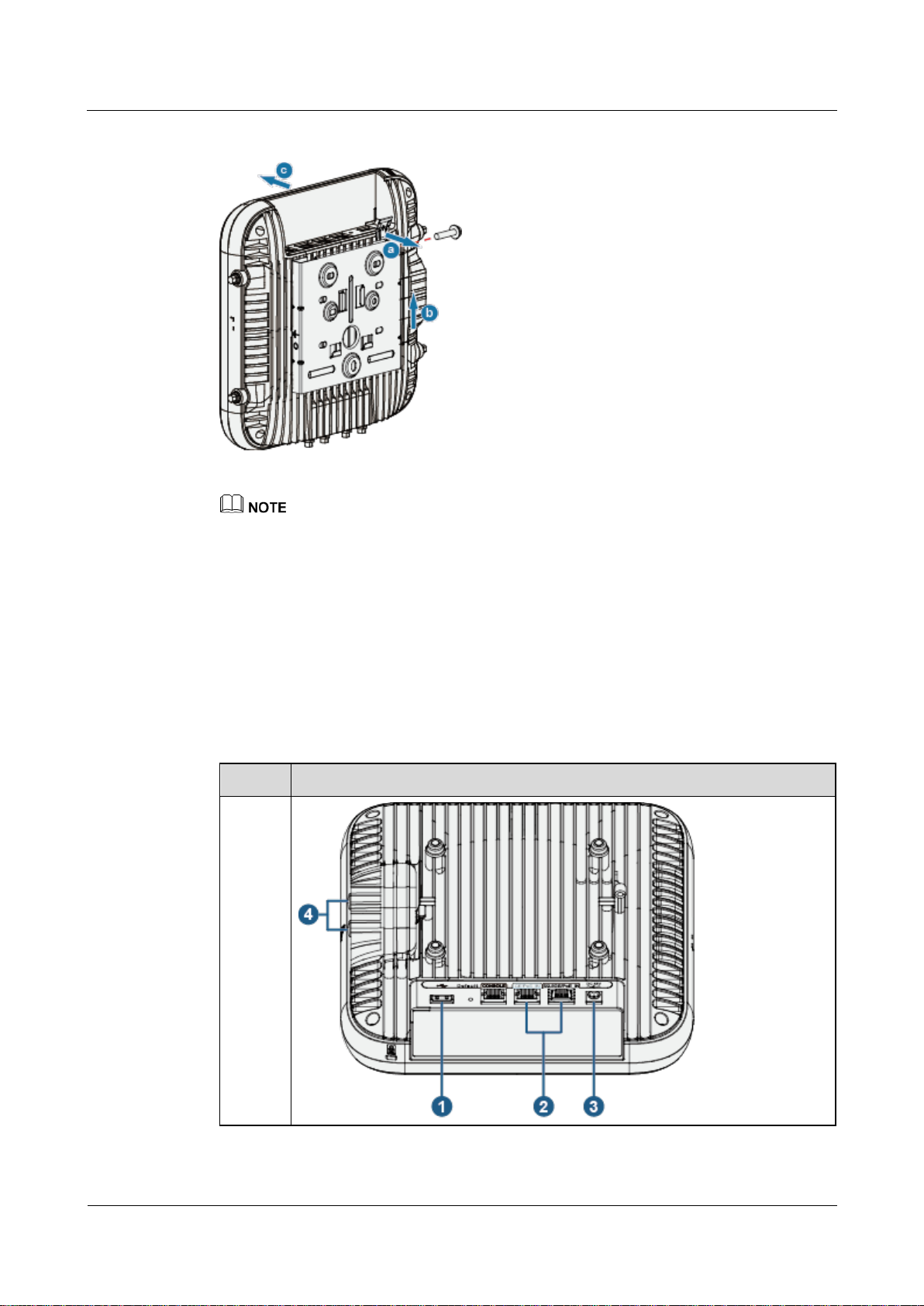

2.5 Installing an IoT Card

The AP provides an IoT slot for installing an ANT or RFID card based on customer

requirements.

1. Hold the buckle on the bottom cover of the AP, and remove the cover and plastic plugs.

The number of rubber plugs to be removed depends on the number of radio cables.

Use a flat-head screwdriver to remove the cover. Insert the flat-head screwdriver under the cover buckle

and lever the buckle.

Page 18

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

2 AP Installation

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

11

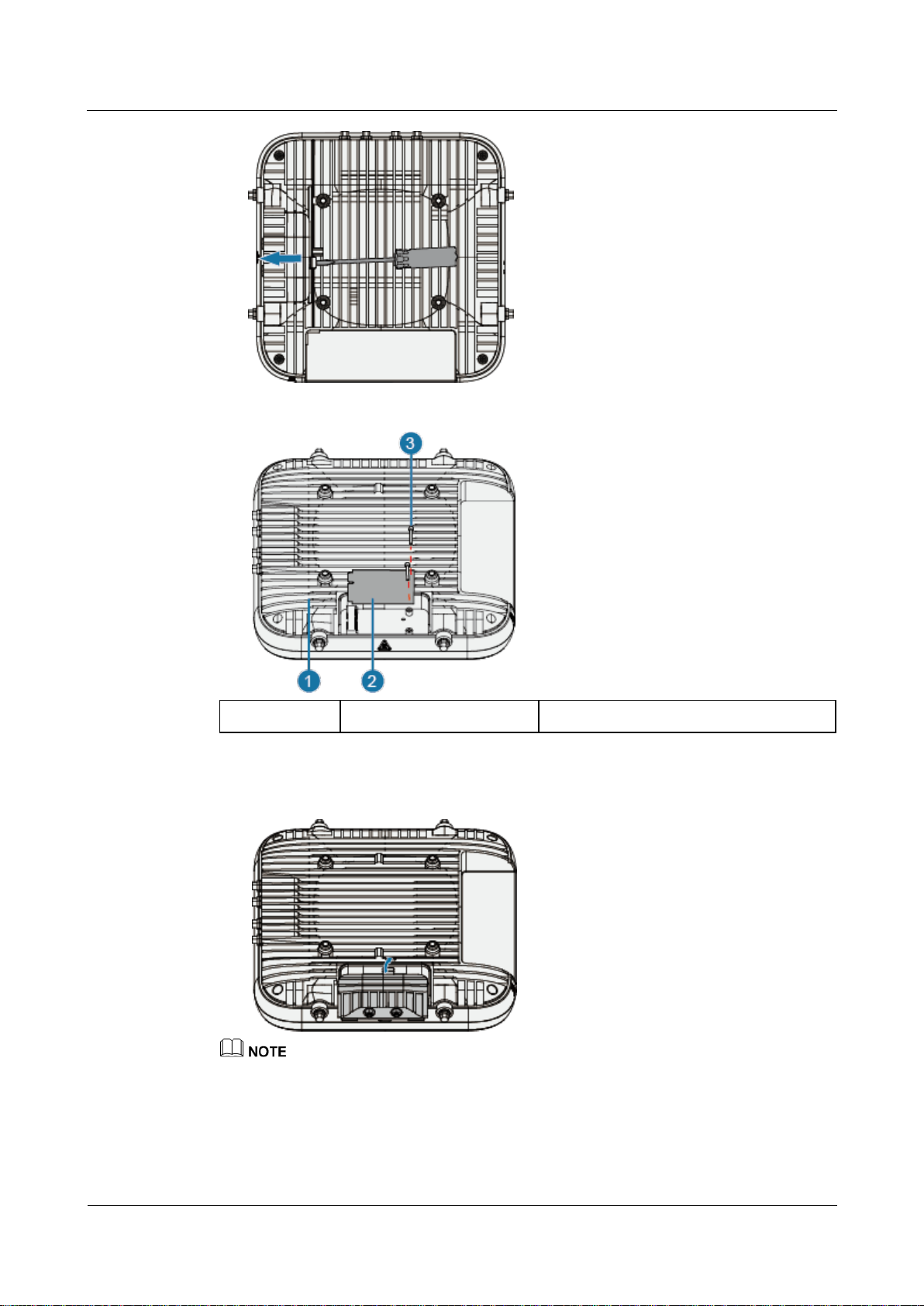

1. AP

2. IoT card

3. M2.5x6 screws

2. Place an IoT card in the slot and tighten the card using M2.5x6 screws (with a tightening

torque of 0.3 Nm).

3. Connect an IoT antenna with the MMCX connector of an IoT card, and slide the IoT

card cover to secure the IoT card. When installing the IoT card cover, insert the

protrusion on the cover into the opening on the AP. Then press the protrusion until you

hear a click sound.

The diagonal size of a hexagon SMA connector must be less than or equal to 8 mm; otherwise, the

cable cannot be installed.

The ANT card has one radio port, and the RFID card has two.

Page 19

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

2 AP Installation

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

12

2.6 Installing the AP

2.6.1 Installing the Device on a Wall

A wall for installing the device needs to meet the following requirements:

The wall can bear the weight of four times the total weight of the device and mounting bracket

without damage.

When the tightening torx of a screw reaches 5 N•m, the screw still properly works, without crack or

damage on the wall.

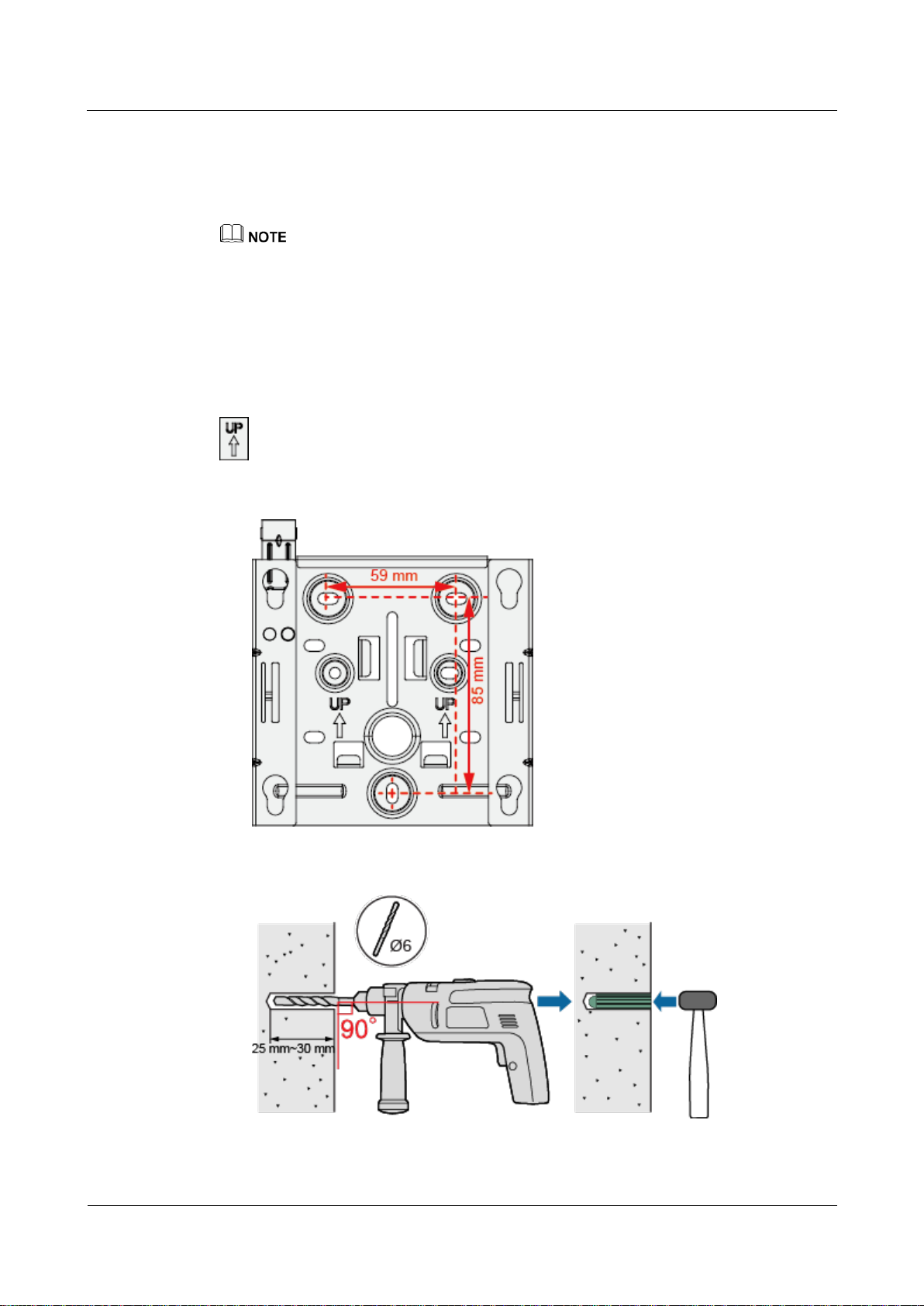

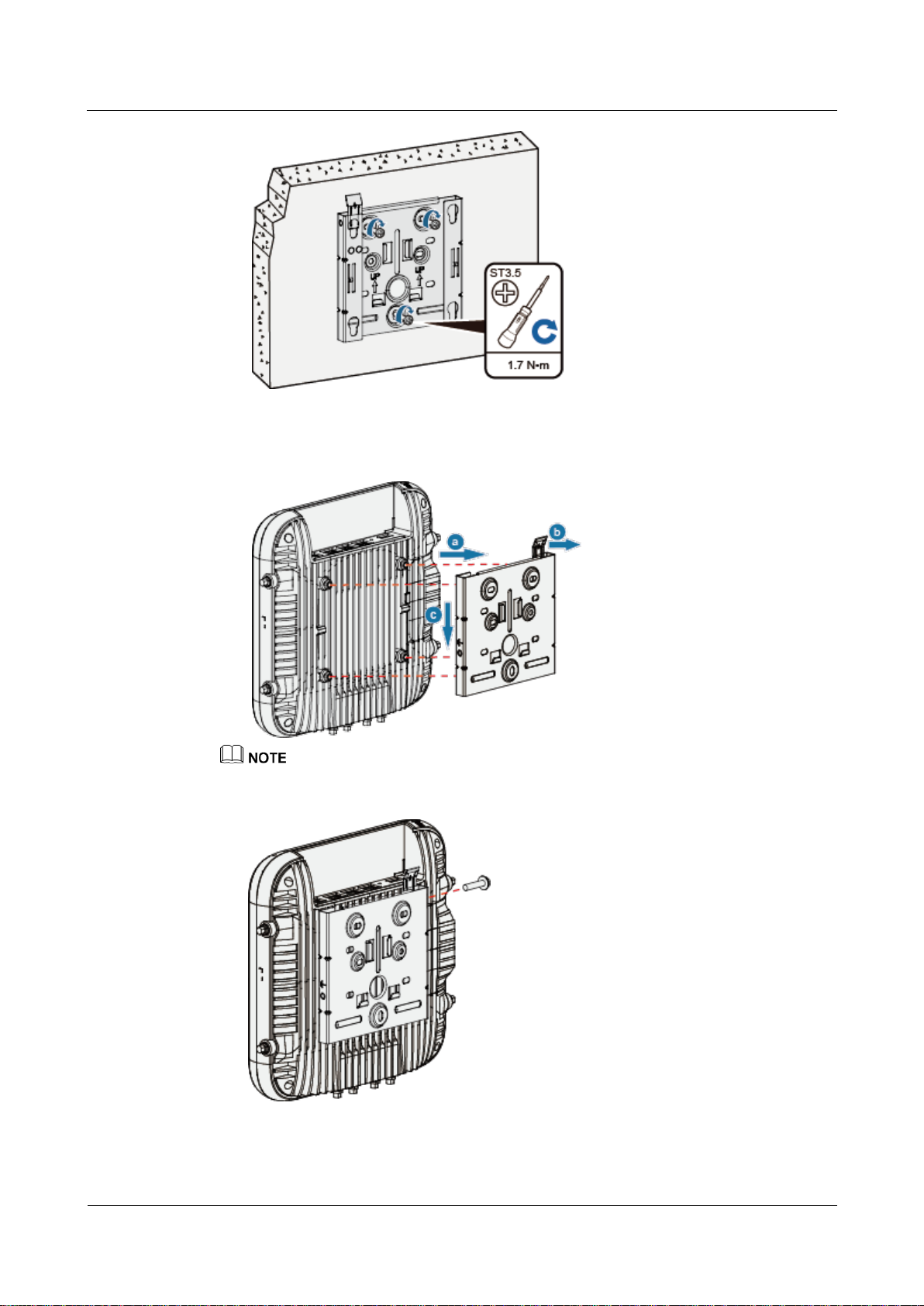

Mounting kits and expansion bolts are required to install the AP on a wall. The procedures are

as follows:

When fixing the sheet metal mounting bracket, ensure that the arrows point upwards on the

label.

1. Fix a mounting bracket to the wall against the wall and mark the drilling positions

through holes of the bracket.

2. Use a 6 mm drill bit to drill 25 mm to 30 mm deep holes in the drilling positions.

Hammer the expansion tubes into the holes until the expansion tubes are completely

embedded into the wall.

3. Fix the mounting bracket to the wall and use the Phillips screwdriver to fasten three

expansion screws into the expansion tubes.

Page 20

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

2 AP Installation

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

13

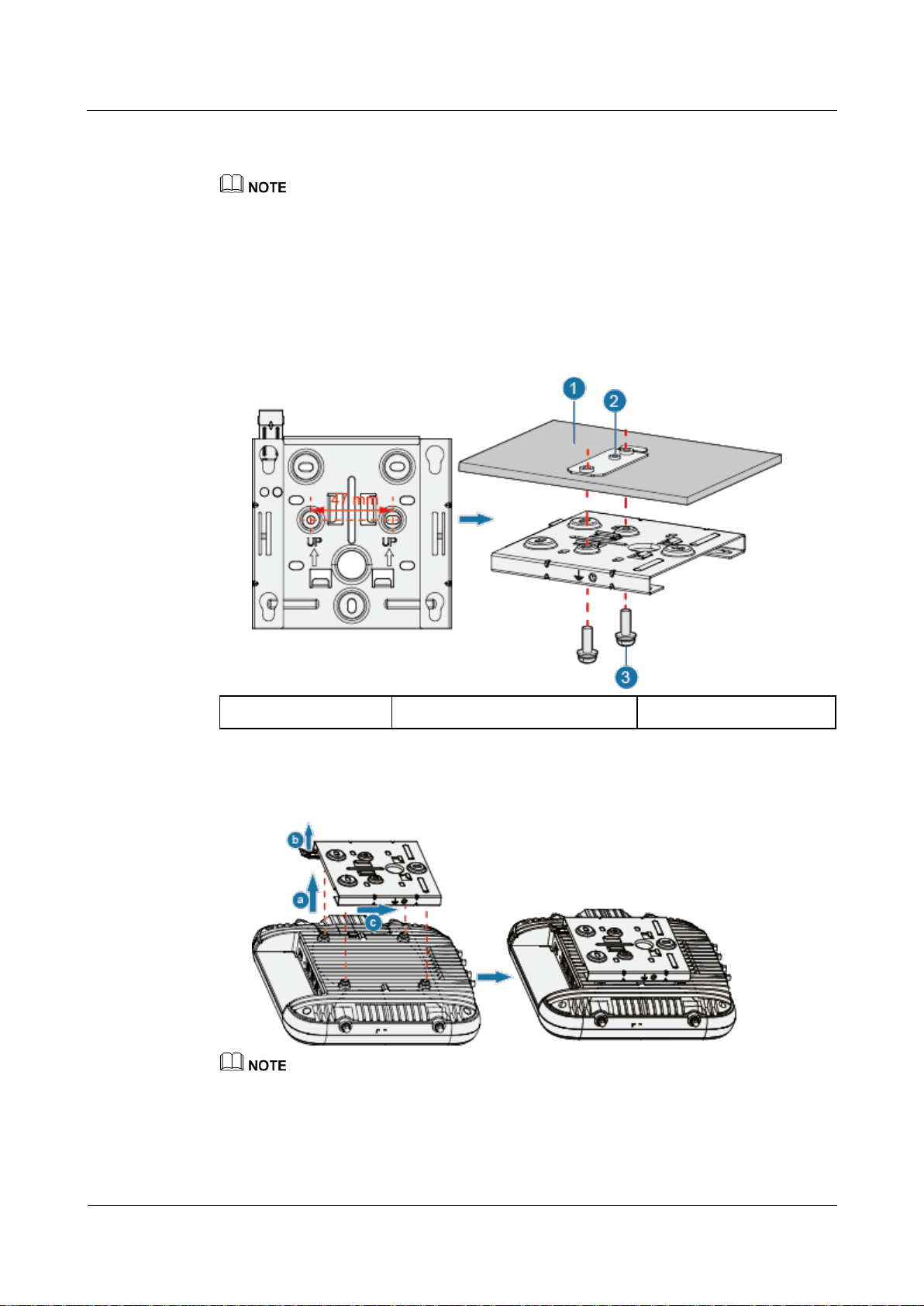

4. Connect the cables. For details, see 2.7 Cable Connection.

5. Align the rubber feet of the device over the mounting slots on the mounting bracket and

vertically push the AP to secure it. When the spring clip is popped up, push the AP

downward until it snaps into place (you can hear a click).

In a scenario with heavy vibrations, tighten the AP to the mounting bracket using M4x30 screws with a

torque of 1.4N•m. This prevents the AP falling off from due to vibrations. In normal scenarios, you do

not need to install these screws.

Page 21

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

2 AP Installation

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

14

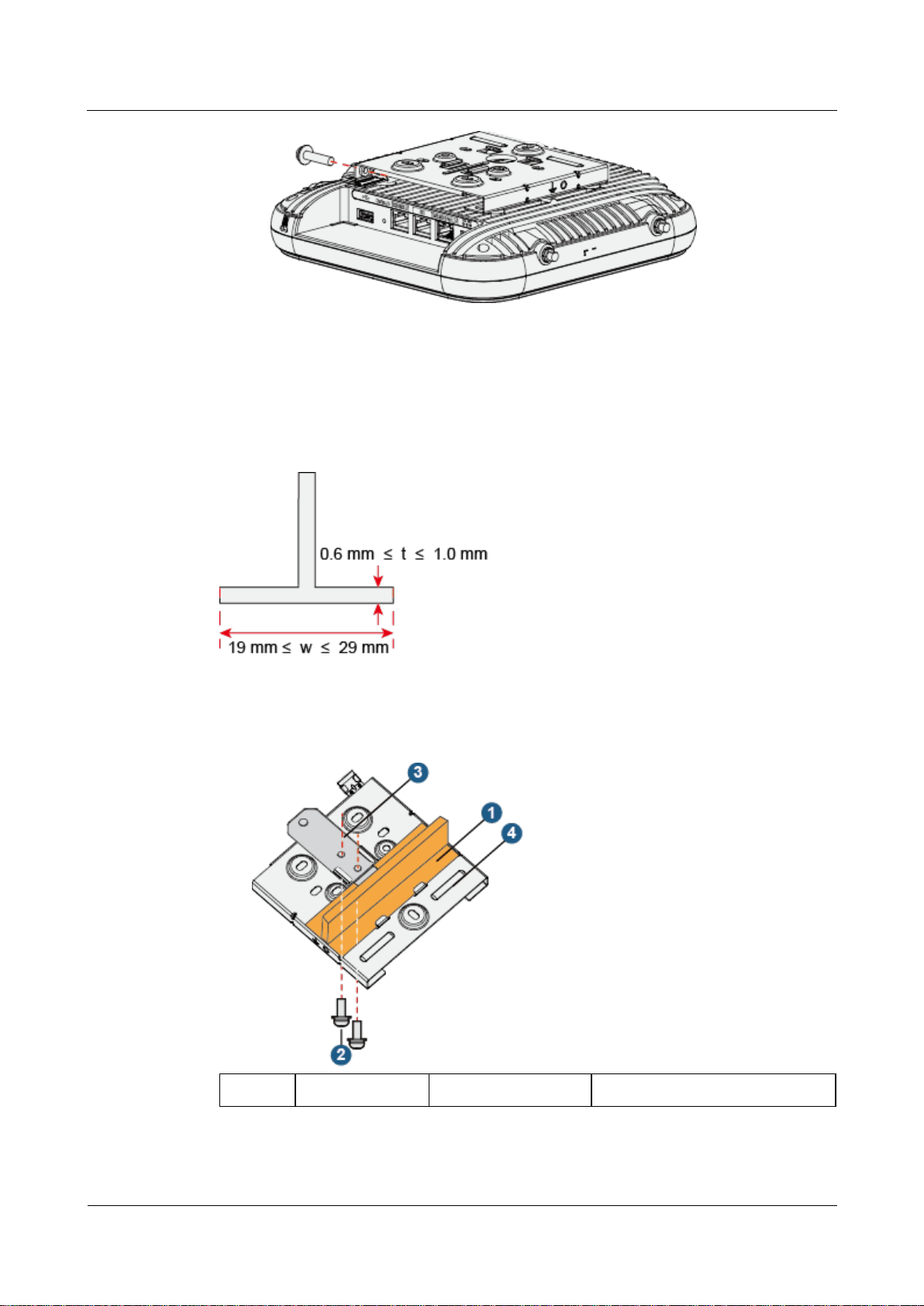

2.6.2 Installing the Device on a Ceiling

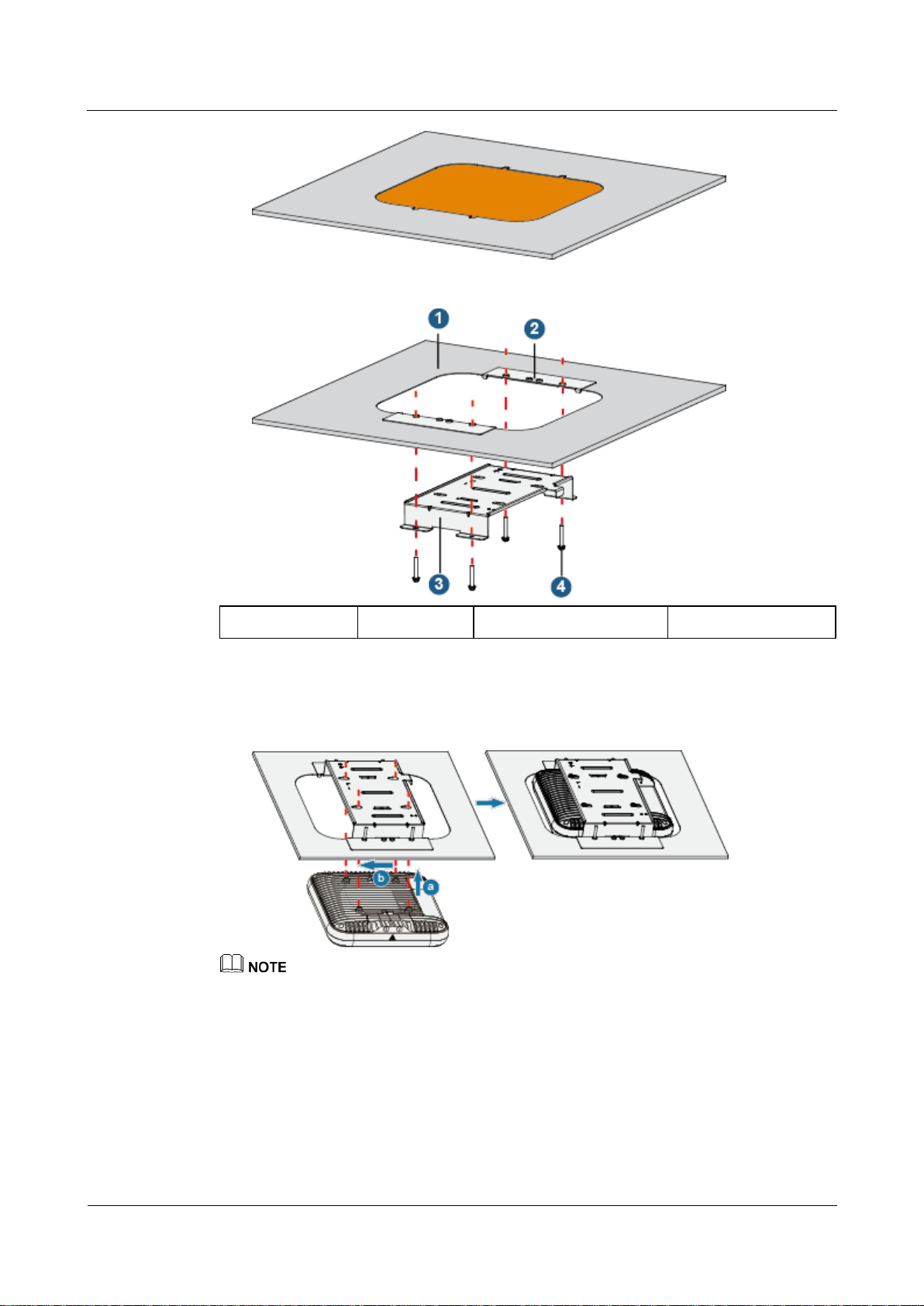

1. Ceiling tile

2. Adjustable buckle

3. M4x30 screw

A ceiling needs to bear the weight of four times the total weight of the device and mounting bracket

without damage.

1. Remove a ceiling tile, determine locations of mounting holes based on the distance

between two installation holes on the mounting bracket, use a hammer drill to drill holes

on the ceiling tile, and fix the mounting bracket to the ceiling tile(with a tightening

torque of 1.4 N•m).

The screws provided for ceiling-mounting of APs are 30 mm long and can be used to fix

an AP on a ceiling no thicker than 15 mm. To install APs on thicker ceilings, you need to

purchase longer screws.

2. Connect the cables. For details, see 2.7 Cable Connection.

3. Align the rubber feet of the device over the mounting slots on the mounting bracket and

vertically push the AP to secure it. When the spring clip is popped up, push the AP

horizontally until it snaps into place (you can hear a click).

Ensure that the AP is correctly installed on the mounting bracket and there is 200 mm space above

and around the AP for maintenance.

In a scenario with heavy vibrations, tighten the AP to the mounting bracket using M4x30 screws

with a torque of 1.4N•m. This prevents the AP falling off from due to vibrations. In normal scenarios,

you do not need to install these screws.

Page 22

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

2 AP Installation

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

15

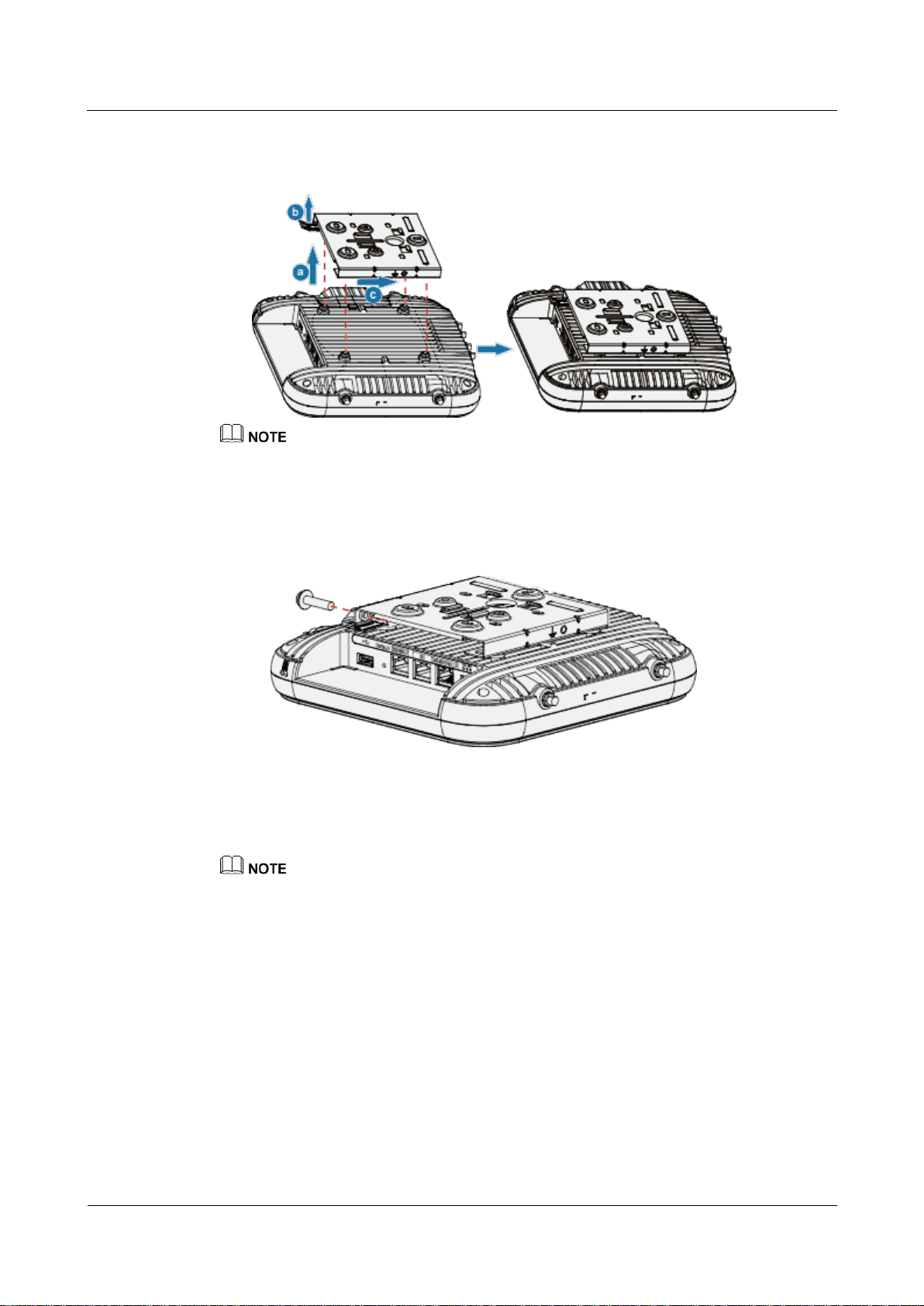

2.6.3 Installing the Device on a T-rail

1. T-rail

2. M4x30 Screw

3. Adjustable buckle

4. Sheet metal mounting bracket

A T-rail needs to bear the weight of four times the total weight of the device and mounting

bracket without damage. Figure 2-3 shows the T-rail dimensions requirements (t: thickness; w:

width).

Figure 2-3 Section of a T-rail

1. Remove two ceiling tiles around the T-rail, use screws to fix the adjustable buckle to the

mounting bracket, hook the adjustable buckle to the T-rail, and secure the screw on the

adjustable buckle to fasten the mounting bracket and T-rail.

2. Connect the cables. For details, see 2.7 Cable Connection.

Page 23

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

2 AP Installation

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

16

3. Align the rubber feet of the device over the mounting slots on the mounting bracket and

vertically push the AP to secure it. When the spring clip is popped up, push the AP

horizontally until it snaps into place (you can hear a click).

Before fixing the adjustable buckle with a screw, adjust the buckle to a proper position based on the

T-rail width.

Ensure that the AP is correctly installed on the mounting bracket and there is 200 mm space above

and around the AP for maintenance.

In a scenario with heavy vibrations, tighten the AP to the mounting bracket using M4x30 screws

with a torque of 1.4N•m. This prevents the AP falling off from due to vibrations. In normal scenarios,

you do not need to install these screws.

2.6.4 Installing an AP into a Ceiling

An AP can be installed in a removable or irremovable ceiling. For details, see Installing an AP

in a Removable Ceiling and Installing an AP in an Irremovable Ceiling.

This mode is not applicable to the AP with external antennas (including IoT card antennas and AP

antennas).

You need to purchase a plastic enclosure, mounting bracket, and other accessories separately. The

part number is 21242880.

A ceiling needs to bear the weight of four times the total weight of the device and mounting bracket

without damage.

The screws provided for ceiling-mounting of APs are 30 mm long and can be used to fix an AP on a

ceiling no thicker than 15 mm. To install APs on thicker ceilings, you need to purchase longer

screws.

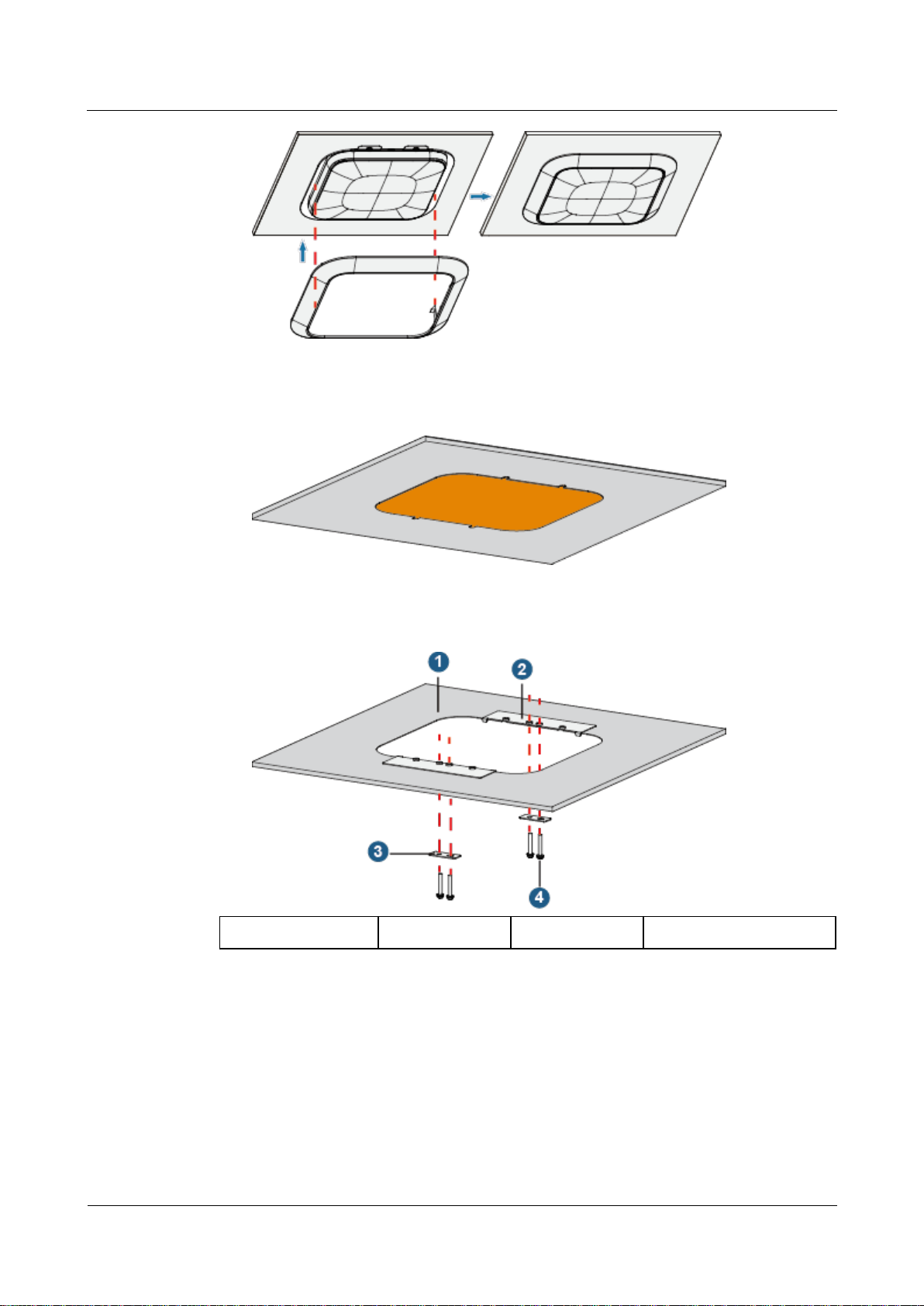

Installing an AP in a Removable Ceiling

1. Remove a ceiling tile, draw the AP mounting position on the ceiling tile using an

opening mold, and cut an opening.

Page 24

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

2 AP Installation

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

17

1. Ceiling tile

2. Clamp 1

3. Mounting bracket

4. M4x30 screws

2. Use M4x30 screws to tighten the mounting bracket, ceiling tile, and clamp 1 to the

ceiling tile (with a tightening torque of 1.2 Nm).

3. Install the ceiling tile. For details, see Connect the cables. For details, see 2.7 Cable

Connection.

4. Align the rubber feet of the device over the mounting slots on the mounting bracket and

vertically push the AP to secure it. When the spring clip is popped up, push the AP

horizontally until it snaps into place (you can hear a click).

Ensure that the AP's network interfaces point to the same direction as the spring clip of the mounting

bracket. Otherwise, installation cannot continue.

5. Install the plastic enclosure. Ensure that the clamping hook of the enclosure points to the

same direction as the AP's network interfaces. Push the enclosure vertically until the

enclosure surface is aligned with that of the AP (you can hear a click).

Page 25

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

2 AP Installation

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

18

Installing an AP in an Irremovable Ceiling

1. Ceiling tile

2. Clamp 1

3. Clamp 2

4. M4x30 screws

1. Draw the AP mounting position on the ceiling tile using an opening mold and cut an

opening.

2. Use clamp 1 to align with the dent of the opening on the ceiling tile and mark the two

holes in the middle of clamp 1. Drill two holes with a diameter of 5 mm on both sides of

the opening on the ceiling tile. Use four M4x30 screws to tighten clamps 1 and 2 to the

ceiling tile (with a tightening torque of 1.2 Nm).

3. Install the mounting bracket, cables, AP, and enclosure. For details, see steps 2, 3, 4, and

5 in Installing an AP in a Removable Ceiling.

2.6.5 Removing an AP

Flip the spring clip on the mounting bracket and slip the AP towards the spring clip. Release

the spring clip until the rubber feet of the AP enter the mounting keyholes. Remove the AP

from the mounting bracket.

Page 26

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

2 AP Installation

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

19

Figure 2-4 Removing an AP

Model

Appearance

AP7052

DN

If a captive screw is installed, remove the screw and then follow the preceding steps to uninstall the

AP.

An AP is secured to the mounting bracket using a self-locking mechanism. Therefore, before

installing an enclosure for an AP, remove all screws. Remove the AP and mounting bracket together

from the ceiling, and then remove the AP from the mounting bracket.

2.7 Cable Connection

Table 2-4 describes the cable connections.

Table 2-3 Appearance of the AP

Page 27

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

2 AP Installation

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

20

Table 2-4 Cable connections

No.

Cable or Device

Description

1

USB flash drive

or USB cable

Connects to a USB flash drive or other storage devices to

extend the storage space of the AP. The USB2.0 standard

is supported.

2

Network cable

The service network cable and PoE input cable cannot

be connected to the console port. Otherwise, the AP

may be damaged when using PoE power supply.

If the AP needs to connect to the Ethernet, ensure that

the Ethernet cable is working properly. If the Ethernet

cable is not working properly, for example, RJ45

connectors are short-circuited, the AP may fail to be

powered on or fail to work. Before connecting an

Ethernet cable to the AP, use the cable test tool to

check whether the cable is qualified. If the cable is

unqualified, replace it.

For the supported network cable types and length

requirements, see Connecting Network Cables.

3

DC power adapter

When the AP uses the DC power supply, use a power

adapter for power supply; otherwise, the AP may be

damaged.

4

RF cable

Connects an antenna to an IoT card through a radio cable.

5

Antenna

Connects a 2.4 GHz or 5 GHz antenna to the AP to send

and receive wireless signals.The port type is N-type

female.The port is applicable only to an AP that supports

external antennas.

6

Antenna

Connects a 5 GHz antenna to the AP to send and receive

wireless signals.The port type is N-type female.The port

is applicable only to an AP that supports external

antennas.

No priorities are distinguished for DC and PoE power supply modes, DC and GE/PoE_IN support

HSB.

Two PoE channels have no priority and can serve as HSB for each other when they have the same

input power type.

When installing a cable, you must make a drip loop to prevent water from flowing into

devices along the cable. For the method of making the drip loop, see 5.8 Guide to Making

Drip Loops.

Pay attention to the following points when bundling the cables:

Different types of cables must be separately routed with the minimum spacing of 30 mm

and cannot be entangled or crossed. Cables should be parallel or separated using

dedicated separators.

Bundled cables are closely arranged, straight, tidy, and undamaged.

Page 28

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

2 AP Installation

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

21

Interface Rate

Network Cable Type

Maximum Transmission

Distance

GE

CAT5e or higher

100 m

2.5GE

CAT5e or higher unshielded

twisted pair (UTP)

100 m

CAT5e or higher shielded

twisted pair (STP)

200 m

When the transmission

distance is greater than 100

m, this network cable can

only be used to connect the

following switches:

S6720-52X-PWH-SI-AC

F

S6720-52X-PWH-SI

S6720-56C-PWH-SI-AC

S6720-56C-PWH-SI

S6320-32C-PWH-SI

S6720-32C-SI-AC

S6720-32C-SI-DC

S6720-32C-PWH-SI-AC

S6720-32C-PWH-SI

5GE

CAT5e UTP

100 m (Only the first 30

m of cables is bundled in

6-a-1 mode.)

55 m (All cables are

bundled.)

100 m (Each cable is

bundled separately.)

CAT5e STP

100 m

CAT6 or higher

100 m

Cable ties are bound neatly facing the same direction, and those at the same horizontal

line must be in a straight line. Cable tie tails should be cut smoothly and evenly.

Labels or nameplates must be attached to the cables after they are installed.

Connecting Network Cables

Table 2-5 Network cable types supported by Ethernet interfaces and maximum transmission

distances

6-a-1 stands for the six-around-one cable bundle mode, with one cable in the center and six cables

bundled evenly around it.

Page 29

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

2 AP Installation

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

22

Connecting UTP network cables to 5GE interfaces poses high risks and is not recommended. The

causes are as follows:

802.3bz requires that the ALSNR value for alien crosstalk between network cables be greater than 0,

but the standards for Cat5e and Cat6 unshielded twisted pairs do not specify the required ALSNR

value. Therefore, such cables may not meet the crosstalk requirement in 802.3bz, causing severe

problems such as continuous packet loss.

According the cabling specification TIA TSB-5021, using Cat5e and Cat6 cables for 5G poses high

risks.

Currently, no clear onsite testing or evaluation method is available for checking whether ALSNR of

cables conforms to 802.3bz.

If Cat5e and Cat6 unshielded twisted pairs do not meet the 5G requirement, you are advised to

replace them with shielded twisted pairs or reduce the rate of interfaces to 2.5G.

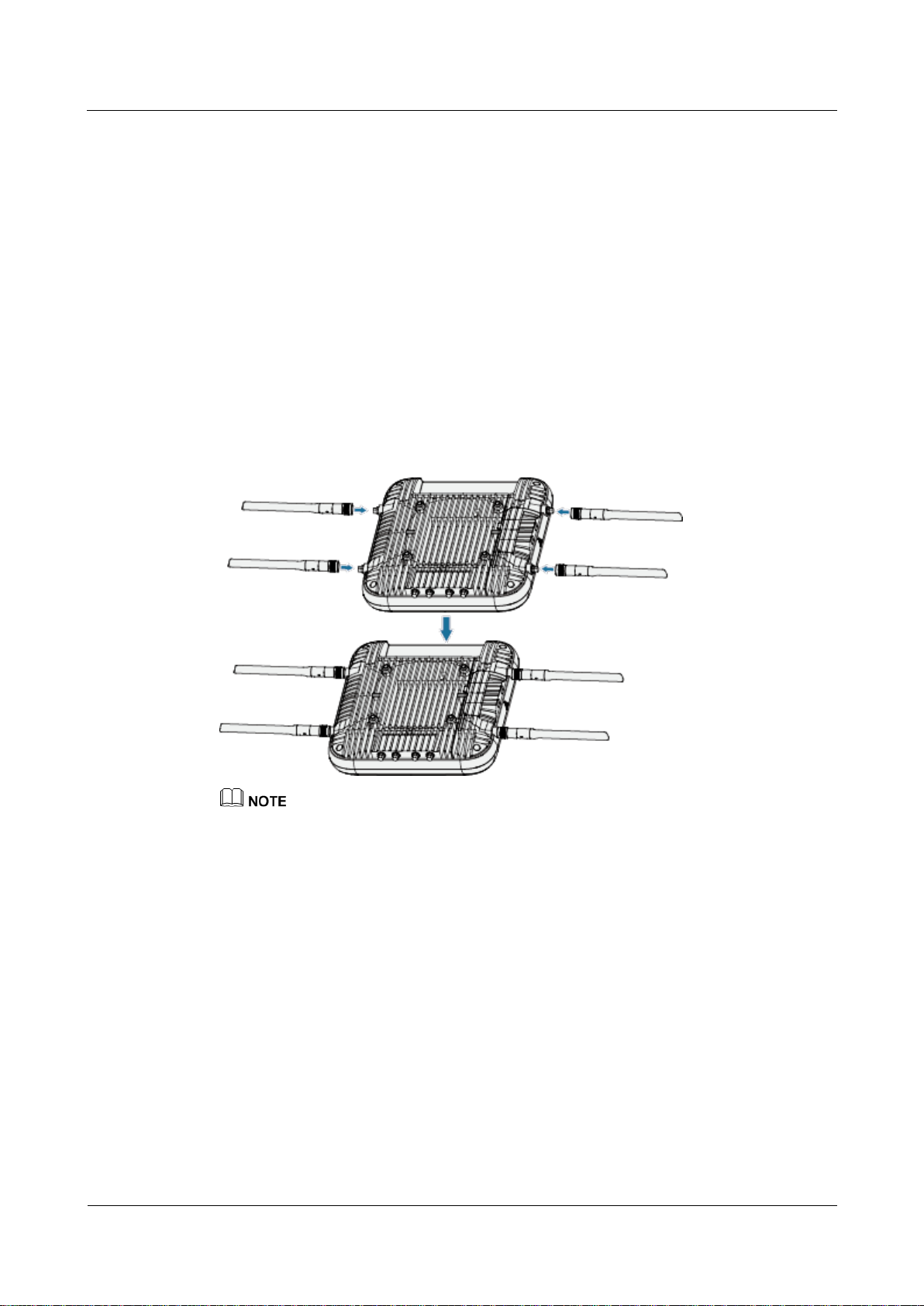

Connecting Antennas

Connect the antennas delivered in the installation accessory package of the AP to the 2.4G/5G

RF ports on the AP, tighten the nuts (with a torque of 0.8 N•m), and adjust antenna angles as

required.

Do not connect the antennas delivered in the installation accessory package of the AP to 5G antenna

interfaces. Otherwise, the AP and antennas may be damaged. The 5G antenna interfaces can be

connected only to remote antennas through feeder cables.

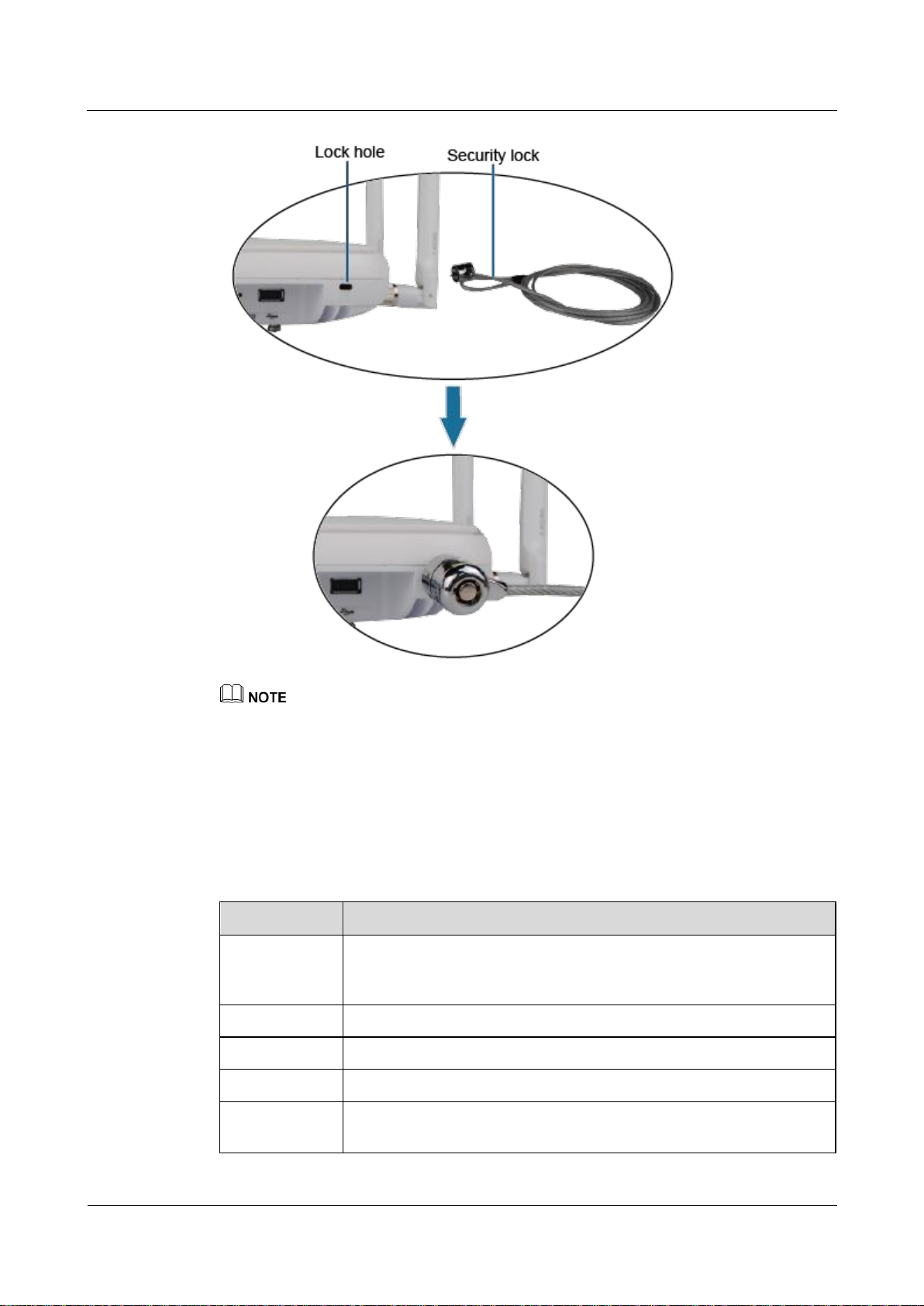

2.8 Connecting the Security Lock

There is a security slot on the device. You can lock the device to an immovable object to

prevent theft. The detailed procedures are as follows:

1. Fasten the cable of the security lock to an immovable object around.

2. Insert the security lock into the security slot and lock it.

Page 30

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

2 AP Installation

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

23

No.

Check Item

1

The device is installed by strictly following the design draft. The

installation position meets space requirements, with maintenance space

reserved.

2

The device is securely installed.

3

The power cables are intact and not spliced.

4

Terminals of the power cables are welded or cramped firmly.

5

All power cables are not short-circuited or reversely connected and must

be intact with no damage.

You need to purchase the security lock separately.

2.9 Checking the Device After Installation

Table 2-6 shows the items to be checked after installation is complete. For more details, see

Installation Checklist in the appendix.

Table 2-6 Installation checklist

Page 31

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

2 AP Installation

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

24

No.

Check Item

6

The power cables and ground cables are separated from other cables and

bundled separately.

7

Connectors of signal cables are complete, intact, and tightly connected.

The signal cables are not damaged or broken.

8

Labels on cables are clear and correct.

2.10 Powering on the AP

After the AP is powered on, observe the indicator on the AP to check the system running

status. For details, see 1.2 Indicator Description.

Do not frequently power on and off the device.

Page 32

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

3 Logging In to the Device

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

25

About This Chapter

Parameter

Default Setting

User name

admin

Password

admin@huawei.com

3.1 Logging In to the Device Using STelnet/Telnet

3.2 Logging In to the Device Through the Web System

3.3 Logging In to the Device Through the Console Port

3 Logging In to the Device

3.1 Logging In to the Device Using STelnet/Telnet

You can log in to the device using STelnet V2 or Telnet to configure, manage, and maintain

the device in the CLI.

By default, only the STelnet V2 service is enabled on the device.

Telnet has security vulnerabilities. You are not advised to enable the Telnet service.

Device connections are classified into wired and wireless connections.

In versions earlier than V200R007C20, APs support wired connections.

In V200R007C20 and later, Fat APs support both wired and wireless connections, and

Fit APs and cloud APs support wired connections.

Before logging in to the device, complete the following tasks:

Power on the device.

Prepare network cables used to connect device interfaces for wired connections. No

network cable is required for wireless connections.

The following table lists the default configuration of the device. You are advised to change the

default user name and password on your first login.

Table 3-1 Default configuration of the device

Page 33

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

3 Logging In to the Device

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

26

Parameter

Default Setting

IP address

Wired connection: 169.254.1.1

Wireless connection: 192.168.1.1

Subnet mask

Wired connection: 255.255.0.0

Wireless connection: 255.255.255.0

SSID

HUAWEI-XXXX, applicable to wireless

connections of Fat APs (XXXX specifies the

last four bits of the AP's MAC address.)

Wireless password

None, applicable to wireless connections of

Fat APs

For a Fit AP and cloud AP, you can perform the following operations:

If the Fit AP is already online on the AC, you can remotely log in to the AC on a local terminal and

run the display ap all command to check the IP address of the device.

If the Fit AP in any version is offline or the Fit AP in V200R007C10 or later does not go online, you

can access the device through the offline management VAP for operations. By default, the SSID of

the offline management VAP is hw_manage_xxxx (xxxx specifies the last four bits of the AP's MAC

address) and the password is hw_manage. After the IP address of the PC is set to 169.254.2.x/24

(169.254.2.1 excluded and 169.254.2.100 recommended), the connection is set up, you can log in to

the AP using STelnet for operations.

If the cloud AP is offline or does not go online, you can access the device through the offline

management VAP for operations. By default, the SSID of the offline management VAP is

hw_manage_xxxx (xxxx specifies the last four bits of the AP's MAC address) and the password is

hw_manage. After the PC dynamically obtains an IP address and connects to the AP, you can log in

to the AP using STelnet for operations.

The following example uses the default parameters and is used for reference only.

Wired Connection Mode

Step 1 Use a network cable to connect a PC to any network port of the AP or that of the switch on

the same network segment as the AP.

Step 2 Assign the PC with an IP address on the same network segment as the default IP address of

the device so that the PC and device are reachable to each other.

If the device uses the default settings, the IP address of the PC must be in the network

segment 169.254.0.0/16 but cannot be 169.254.1.1. 169.254.1.100 is recommended.

Step 3 Start the CLI on the PC and access the IP address 169.254.1.1 of the device using STelnet V2.

Step 4 Enter the user name and password as prompted to log in to the user interface.

----End

Wireless Connection Mode

Step 1 By default, STAs search for the WLAN HUAWEI-XXXX within the wireless signal coverage

of a Fat AP. STAs can access the WLAN without entering the password. If the SSID and

Page 34

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

3 Logging In to the Device

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

27

password have been configured, use the specified SSID and password to set up a wireless

connection.

Step 2 Start the CLI on the STA and access the IP address 192.168.1.1 of the device using STelnet

V2.

Step 3 Enter the user name and password as prompted to log in to the user interface.

----End

Method of Obtaining Upgrade and Configuration Documentation

To perform subsequent upgrades and configurations after login to the device, visit Huawei

enterprise technical support website http://support.huawei.com/enterprise and search for

product documentation by keyword. The search method is described as follows:

Fit AP:

− Upgrade: Search for Fit AP upgrade guide, and refer to the upgrade guide in the

documentation of the correct version.

− Configuration: Search for AC6605 product documentation, and refer to the

configuration guide in the documentation of the correct version.

Fat AP:

− Upgrade: Search for Fat AP upgrade guide, and refer to the upgrade guide in the

documentation of the correct version.

− Configuration: Search for Fat AP product documentation, and refer to the

configuration guide in the documentation of the correct version.

cloud AP:

− Upgrade: Search for cloud AP upgrade guide, and refer to the upgrade guide in the

documentation of the correct version.

− Online configuration: Search for cloud AP product documentation, and refer to

the configuration guide in the documentation of the correct version.

− Service configuration after APs go online: Search for CloudCampus solution

product documentation, and refer to the deployment guide in the documentation

of the correct version.

3.2 Logging In to the Device Through the Web System

The built-in web system allows you to use a browser to log in to the device. You can

configure, manage, and maintain a Fat AP and cloud AP on the GUI. On the web page, you

are prompted to configure and manage a Fit AP on the AC.

Device connections are classified into wired and wireless connections.

In versions earlier than V200R007C20, APs support wired connections.

In V200R007C20 and later, Fat APs support both wired and wireless connections, and

Fit APs and cloud APs support wired connections.

Before logging in to the device, complete the following tasks:

Power on the device.

Prepare network cables used to connect device interfaces for wired connections. No

network cable is required for wireless connections.

Page 35

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

3 Logging In to the Device

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

28

The following table lists the default configuration of the device. You are advised to change the

Parameter

Default Setting

User name

admin

Password

admin@huawei.com

IP address

Wired connection: 169.254.1.1

Wireless connection: 192.168.1.1

Subnet mask

Wired connection: 255.255.0.0

Wireless connection: 255.255.255.0

SSID

HUAWEI-XXXX, applicable to wireless

connections of Fat APs (XXXX specifies the

last four bits of the AP's MAC address.)

Wireless password

None, applicable to wireless connections of

Fat APs

default user name and password on your first login.

Table 3-2 Default configuration of the device

For a Fit AP and cloud AP, you can perform the following operations:

If the Fit AP in any version is offline or the Fit AP in V200R007C10 or later does not go online, you

can access the device through the offline management VAP for operations. By default, the SSID of

the offline management VAP is hw_manage_xxxx (xxxx specifies the last four bits of the AP's MAC

address) and the password is hw_manage. After the IP address of the PC is set to 169.254.2.x/24

(169.254.2.1 excluded and 169.254.2.100 recommended), the connection is set up, , and you can log

in to the AP using web system for operations.

If the cloud AP is offline or does not go online, you can access the device through the offline

management VAP for operations. By default, the SSID of the offline management VAP is

hw_manage_xxxx (xxxx specifies the last four bits of the AP's MAC address) and the password is

hw_manage. After the PC dynamically obtains an IP address and connects to the AP, you can log in

to the AP using web system for operations.

The following example uses the default parameters and is used for reference only.

Wired Connection Mode

Step 1 Use a network cable to connect a PC to any network port of the AP or that of the switch on

the same network segment as the AP.

Step 2 Assign the PC with an IP address on the same network segment as the default IP address of

the device so that the PC and device are reachable to each other.

If the device uses the default settings, the IP address of the PC must be in the network

segment 169.254.0.0/16 but cannot be 169.254.1.1. 169.254.1.100 is recommended.

Step 3 Open the browser on the PC, enter http://IP address in the address box, and press Enter to

log in. Select a language for the web system, enter the default user name and password, and

click Login to enter the web system home page.

----End

Page 36

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

3 Logging In to the Device

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

29

Wireless Connection Mode

Step 1 By default, STAs search for the WLAN HUAWEI-XXXX within the wireless signal coverage

of a Fat AP. STAs can access the WLAN without entering the password. If the SSID and

password have been configured, use the specified SSID and password to set up a wireless

connection.

Step 2 Open the browser on the STA, enter http://IP address in the address box, and press Enter to

log in. Select a language for the web system, enter the default user name and password, and

click Login. The web system home page is displayed.

----End

Method of Obtaining Upgrade and Configuration Documentation

To perform subsequent upgrades and configurations after login to the device, visit Huawei

enterprise technical support website http://support.huawei.com/enterprise and search for

product documentation by keyword. The search method is described as follows:

Fit AP:

− Upgrade: Search for Fit AP upgrade guide, and refer to the upgrade guide in the

documentation of the correct version.

− Configuration: Search for AC6605 product documentation, and refer to the

configuration guide in the documentation of the correct version.

Fat AP:

− Upgrade: Search for Fat AP upgrade guide, and refer to the upgrade guide in the

documentation of the correct version.

− Configuration: Search for Fat AP product documentation, and refer to the

configuration guide in the documentation of the correct version.

cloud AP:

− Upgrade: Search for cloud AP upgrade guide, and refer to the upgrade guide in the

documentation of the correct version.

− Online configuration: Search for cloud AP product documentation, and refer to

the configuration guide in the documentation of the correct version.

− Service configuration after APs go online: Search for CloudCampus solution

product documentation, and refer to the deployment guide in the documentation

of the correct version.

3.3 Logging In to the Device Through the Console Port

Before logging in to the device, complete the following tasks:

Power on the device.

Prepare a console cable.

Prepare terminal simulation software.

If your PC's operating system provides terminal simulation software (like HyperTerminal in Windows

2000/XP), you do not need to install additional terminal simulation software. If the PC runs on an

operating system without terminal simulation software (like Windows 7), install third-party terminal

simulation software on the PC by referring to the user manual or online help.

Page 37

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

3 Logging In to the Device

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

30

Step 1 Use a console cable to connect the PC to the console port of the device.

Step 2 Start terminal emulation software on the PC, create a connection, and set communication

parameters as follows:

Baud rate (B): 9600

Data bits (D): 8

Parity (P): None

Stop bits (S): 1

Flow control (F): None

Step 3 Press Enter and enter the authentication information as prompted to log in to the user view.

(The following information is only for reference.)

For a Fit AP, enter the default user name admin and password admin@huawei.com.

You are advised to change the default user name and password on your first login.

Login authentication

Username: admin

Password:

Info: You are advised to change the password to ensure security.

For a Fat AP and Cloud AP, set a passowrd of console, and use the password to log in.

Please configure the login password:

Info: A plain text password is a string of 8 to 16 case-sensitive characters and must

be a combination of at least two of the follow

ing: uppercase letters A to Z, lowercase letters a to z, digits, and special characters.

A cipher text password contains 56 or 68 ch

aracters.

Enter password:

Confirm password:

----End

Method of Obtaining Upgrade and Configuration Documentation

To perform subsequent upgrades and configurations after login to the device, visit Huawei

enterprise technical support website http://support.huawei.com/enterprise and search for

product documentation by keyword. The search method is described as follows:

Fit AP:

− Upgrade: Search for Fit AP upgrade guide, and refer to the upgrade guide in the

documentation of the correct version.

− Configuration: Search for AC6605 product documentation, and refer to the

configuration guide in the documentation of the correct version.

Fat AP:

− Upgrade: Search for Fat AP upgrade guide, and refer to the upgrade guide in the

documentation of the correct version.

− Configuration: Search for Fat AP product documentation, and refer to the

configuration guide in the documentation of the correct version.

cloud AP:

Page 38

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

3 Logging In to the Device

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

31

− Upgrade: Search for cloud AP upgrade guide, and refer to the upgrade guide in the

documentation of the correct version.

− Online configuration: Search for cloud AP product documentation, and refer to

the configuration guide in the documentation of the correct version.

− Service configuration after APs go online: Search for CloudCampus solution

product documentation, and refer to the deployment guide in the documentation

of the correct version.

Page 39

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

4 Hardware Failures

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

32

About This Chapter

Power Supply Mode

Possible Cause

Power supply using a power module

The device is powered off.

The power cable is not securely

connected to the device.

The power supply unit has failed.

− If the device connects to an external

power source, its power adapter may

fail.

− If the device has a built-in power

supply, the device itself may be

faulty.

PoE power supply

The power sourcing equipment does not

support the PoE function or is faulty.

The power sourcing equipment does not

support the required power supply mode.

The power sourcing equipment does not

provide sufficient power.

The power sourcing equipment is

incorrectly configured (the PoE function

This section describes common methods for troubleshooting typical hardware faults.

4.1 A Device Fails to Be Powered On

4 Hardware Failures

4.1 A Device Fails to Be Powered On

Fault Description

The indicator of a device is off.

Possible Causes

Page 40

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

4 Hardware Failures

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

33

Power Supply Mode

Possible Cause

is disabled or the power-off time range is

improperly set).

The line is faulty (the network cable or

distribution frame is damaged).

The device is faulty.

Power Supply Mode

Troubleshooting Procedure

Power supply using a power module

1. Check whether the device is powered

off.

2. Check that the power cable is securely

connected to the device.

3. Check whether the power supply is

normal.

Replace the power adapter with a normal

one. If the device is powered on, the

original power adapter is faulty. Contact

technical support personnel or Huawei

agent and ask them to replace the power

adapter.

4. If the device still cannot be powered on,

the device itself is faulty. Contact

technical support personnel or Huawei

agent and ask them to replace the device.

PoE power supply

1. Check whether the power sourcing

equipment supports PoE or is faulty.

2. Check whether the power output mode

of the power sourcing equipment is

supported by the powered device.

3. Check whether the power sourcing

equipment can support the maximum

power consumption of the device.

4. Check whether the configuration on the

power sourcing equipment causes PoE

power supply errors, such as the PoE

function is disabled or the power-off

time range is incorrectly set.

5. Check whether the network cable or

distribution frame is faulty.

6. If the device still cannot be powered on,

the device itself is faulty. Contact

technical support personnel or Huawei

agent and ask them to replace the device.

Troubleshooting Procedure

Page 41

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

4 Hardware Failures

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

34

The output power of an 802.3af PSE port is 15.4 W, that of an 802.3at PSE port is 30 W, and that of an

802.3bt PSE port is 60 W.

Page 42

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

5 Appendix

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

35

About This Chapter

5.1 On-site Cable Assembly and Installation

5.2 Environmental Requirements for Device Operation

5.3 Equipment Grounding Specifications

5 Appendix

5.4 Engineering Labels for Cables

5.5 Guide to Using Optical Modules

5.6 Fault Tag

5.7 Installation Checklist

5.8 Guide to Making Drip Loops

5.9 Power Adaptation Solution

5.1 On-site Cable Assembly and Installation

5.1.1 Cable Assembly Precautions

Checking the Appearance of Cables

If the cable jacket or insulation is visibly dirty, clean it before assembly.

If the jacket or insulation of a cable has visible damage, irreparable scuffing, or other

defects, do not use the cable.

If the shield layer of a cable is damaged, do not use the cable.

If the cable jacket or insulation cracks after the cable is bent or twisted, discard this cable

and check whether other cables have the same problem. If other cables have the same

problem, replace these cables.

Checking the Appearance of Connectors

Do not use connectors with visible defects, damage, rust or scuffing.

Page 43

AP7052DN&AP7152DN

Hardware Installation and Maintenance Guide

5 Appendix

Issue 01 (2017-12-29)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

36

Do not use connectors if their shells or pins have exposed part or uneven plating, or their

pins are lost, broken, or bent.

Do not use connectors that have dirt on their pins or in their jacks or if there are

conductors between pins or between pins and the shell.

Precautions for Assembly

Use dedicated tools or tools delivered by Huawei and follow the methods given here

during assembly.

Hold terminals of cables instead of pulling the cables themselves when installing or

removing cable components.

Take the following precautions when cutting or stripping cables:

− Make cables slightly longer than necessary.

− Coil cables longer than 2 m (6.56 ft) after cutting. Bind and fasten the coils using

bundling ropes. The inner diameters of the coils should be larger than 20 times the

outer diameters of the cables.

− When stripping the jackets of cables, avoid damaging the shield layers (braid or

aluminum foil), insulation, core conductors, and other jackets that do not need to be

stripped.

− After assembling cables, cut all visible cross sections of jackets to ensure that the

cross sections are arranged neatly.

− Do not touch the core conductors of cables with your hands. Terminate exposed

conductors in a timely way after stripping off insulation so that the surface of the

conductors does not become oxidized.

Take the following precautions when crimping and connecting cables or connectors:

− The terminals and conductors should be connected tightly after they are crimped.

They should not be moved or turned.

− Cut all the exposed copper wires.

− Try to avoid a second crimping of sleeves.