HP ProLiant DL320 Generation 3 Server

Maintenance and Service Guide

March 2005 (Second Edition)

Part Number 373044-002

© Copyright 2005 Hewlett-Packard Development Company, L.P.

Microsoft and Windows NT are U.S. registered trademarks of Microsoft Corporation.

Intel, Celeron, and Pentium® are U.S. registered trademarks of Intel Corporation or its subsidiaries in the United

States and other countries.

Linux is a U.S. registered trademark of Linus Torvalds.

The information contained herein is subject to change without notice. The only warranties for HP products and

services are set forth in the express warranty statements accompanying such products and services. Nothing herein

should be construed as constituting an additional warranty. HP shall not be liable for technical or editorial errors

or omissions contained herein.

March 2005 (Second Edition)

Part Number 373044-002

Contents

About This Guide

Audience Assumptions............................................................................................................................... vii

Technician Notes........................................................................................................................................ vii

Where to Go for Additional Help.............................................................................................................. viii

Integrated Management Log ............................................................................................................... viii

Telephone Numbers............................................................................................................................ viii

Chapter 1

Illustrated Parts Catalog

Customer Self Repair ................................................................................................................................ 1-1

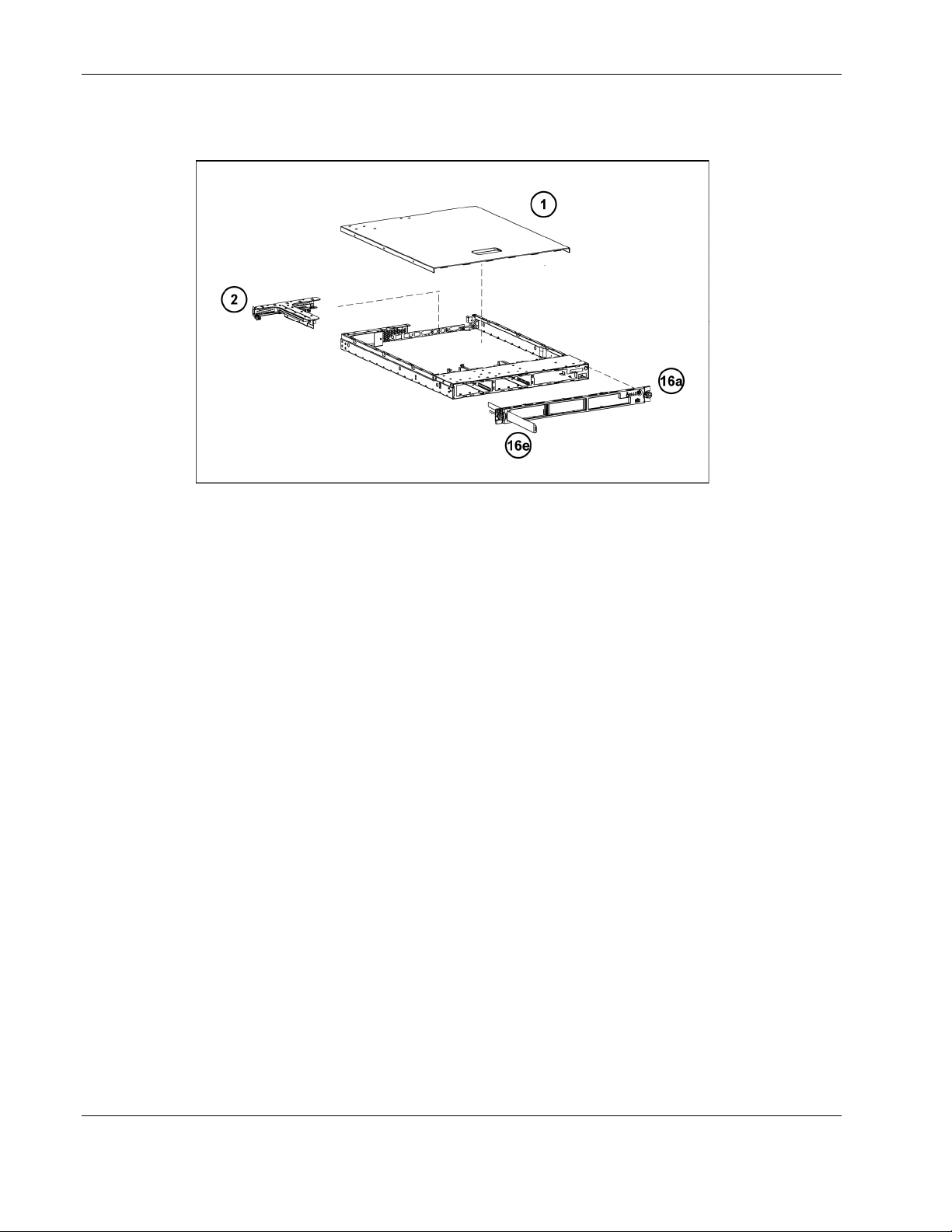

Mechanical Parts Exploded View ............................................................................................................. 1-2

System Components Exploded View ........................................................................................................ 1-3

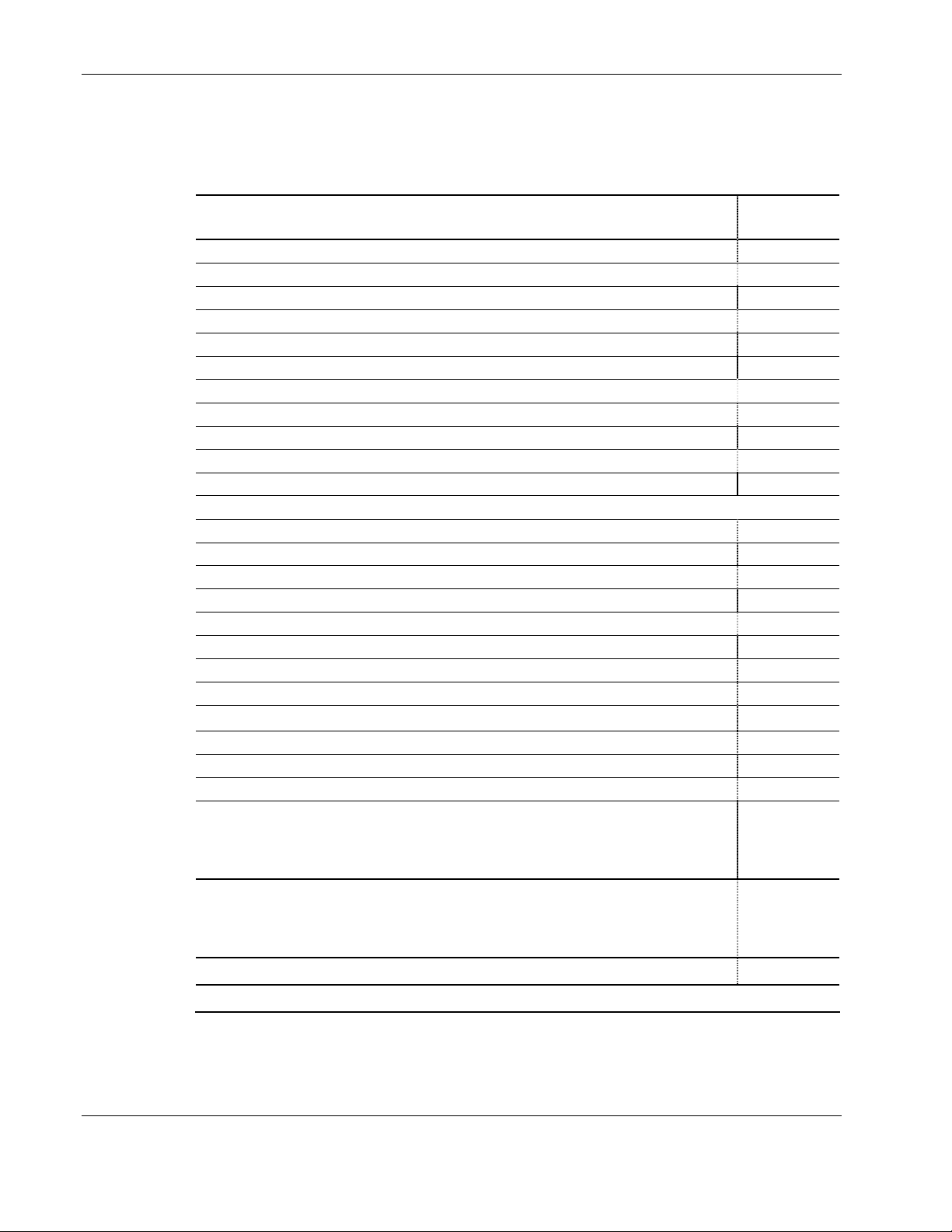

Mechanical Parts and System Components Spares List............................................................................ 1-4

Chapter 2

Removal and Replacement Procedures

Required Tools and Software .................................................................................................................... 2-1

Safety Considerations................................................................................................................................ 2-1

Electrostatic Discharge Information.......................................................................................................... 2-1

Symbols on Equipment ............................................................................................................................. 2-2

Rack Warnings .......................................................................................................................................... 2-2

Server Warnings and Precautions.............................................................................................................. 2-3

Removal and Replacement Procedures ..................................................................................................... 2-3

Powering Down the Server........................................................................................................................ 2-4

Access Panel.............................................................................................................................................. 2-5

Drive Assembly......................................................................................................................................... 2-7

LED/PWR Switch Board .................................................................................................................... 2-7

Diskette Drive ..................................................................................................................................... 2-8

Optical Drive....................................................................................................................................... 2-9

Hard Drive Overview .............................................................................................................................. 2-11

Guidelines for Installing SATA Hard Drives ................................................................................... 2-11

Guidelines for Installing SCSI Hard Drives ..................................................................................... 2-11

Hard Drive Identification Numbers .................................................................................................. 2-11

SATA Hard Drives.................................................................................................................................. 2-12

SCSI Hard Drives.................................................................................................................................... 2-13

PCI Riser Board Assembly...................................................................................................................... 2-15

Expansion Board............................................................................................................................... 2-16

Single Channel Wide Ultra320 SCSI Adapter.................................................................................. 2-17

Integrated SATA RAID Controller Module ..................................................................................... 2-17

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide iii

Contents

Fan Assembly...........................................................................................................................................2-17

Fans..........................................................................................................................................................2-19

Cables.......................................................................................................................................................2-21

SATA Drive Cables...........................................................................................................................2-21

Power Supply...........................................................................................................................................2-23

Battery...................................................................................................................................................... 2-24

Memory Modules.....................................................................................................................................2-26

Processor.................................................................................................................................................. 2-29

System Board........................................................................................................................................... 2-31

Chapter 3

Diagnostic Tools

SmartStart Software ................................................................................................................................... 3-1

SmartStart Scripting Toolkit ...................................................................................................................... 3-1

HP Instant Support Enterprise Edition....................................................................................................... 3-2

ROM-Based Setup Utility..........................................................................................................................3-2

ROMPaq Utility ......................................................................................................................................... 3-3

System Online ROM Flash Component Utility .........................................................................................3-3

Integrated Management Log ...................................................................................................................... 3-3

Integrated Lights-Out Technology............................................................................................................. 3-4

Automatic Server Recovery.......................................................................................................................3-4

HP Systems Insight Manager.....................................................................................................................3-4

HP Insight Diagnostics ..............................................................................................................................3-5

USB Support .............................................................................................................................................. 3-5

Internal USB Functionality ........................................................................................................................ 3-5

Chapter 4

Component Identifications

Rear Panel Components.............................................................................................................................4-2

Expansion Slot Component ................................................................................................................. 4-3

System Board Components .................................................................................................................4-4

System Switches ........................................................................................................................................4-5

System Maintenance Switch (SW1)....................................................................................................4-5

Non-Maskable Interrupt Switch (NMI button/SW3)...........................................................................4-6

Front Panel Buttons and LEDs ..................................................................................................................4-6

Rear Panel LEDs........................................................................................................................................4-7

System Board LEDs................................................................................................................................... 4-8

Chapter 5

Specifications

System Unit................................................................................................................................................5-2

Power Supply.............................................................................................................................................5-2

Memory...................................................................................................................................................... 5-3

Optical CD-ROM Drive............................................................................................................................. 5-4

Integrated Intel ICH6A SATA Controller .................................................................................................5-5

Optional Hard Drives.................................................................................................................................5-5

SATA Hard Drives..............................................................................................................................5-5

Integrated Broadcom 10/100/1000 Gigabit Server Auto-Switching Network Interface Controller (NIC) 5-6

iv HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide

Contents

Index

List of Figures

1-1 Mechanical parts exploded view......................................................................................................... 1-2

1-2 System components exploded view .................................................................................................... 1-3

2-1 Removing the access panel ................................................................................................................. 2-6

2-2 Loosen the thumbscrew and slide the assembly toward the back of the server .................................. 2-7

2-3 Removing the LED/PWR switch board.............................................................................................. 2-8

2-4 Remove the diskette drive................................................................................................................... 2-9

2-5 Remove the Optical drive ................................................................................................................. 2-10

2-6 SATA device numbers...................................................................................................................... 2-12

2-7 Removing the SATA hard drive tray from the chassis ..................................................................... 2-12

2-8 Removing the SATA hard drive from a hard drive tray ................................................................... 2-13

2-9 Removing the SCSI hard drive tray from the chassis ....................................................................... 2-14

2-10 Removing the SCSI hard drive from a hard drive tray ..................................................................... 2-14

2-11 Removing the PCI riser board........................................................................................................... 2-15

2-12 Removing an expansion board from the PCI riser board assembly .................................................. 2-16

2-13 Disconnecting the fan assembly power cables (processor heatsink removed for clarity)................. 2-18

2-14 Lifting the fan assembly out of the chassis ....................................................................................... 2-18

2-15 Locating the system fans................................................................................................................... 2-19

2-16 Removing one fan from the fan assembly ........................................................................................ 2-20

2-17 Disconnecting the SATA cables ....................................................................................................... 2-21

2-18 Disconnecting the drive assembly cables.......................................................................................... 2-22

2-19 Removing the power supply ............................................................................................................. 2-23

2-20 Locating and removing the system battery ....................................................................................... 2-25

2-21 Identifying DIMM sockets on the system board............................................................................... 2-26

2-22 Removing a DIMM from a DIMM socket........................................................................................ 2-27

2-23 Installing a DIMM in a DIMM socket.............................................................................................. 2-28

2-24 Locating the processor on the system board ..................................................................................... 2-29

2-25 Loosening screws on the heatsink and removing the heatsink ......................................................... 2-30

2-26 Removing the processor from the system board............................................................................... 2-31

2-27 Removing the system board.............................................................................................................. 2-32

4-1 Rear panel components ....................................................................................................................... 4-2

4-2 Expansion slot component .................................................................................................................. 4-3

4-3 System board components .................................................................................................................. 4-4

4-4 System switches.................................................................................................................................. 4-5

4-5 Front panel LEDs................................................................................................................................ 4-7

4-6 Rear panel LEDs................................................................................................................................. 4-8

4-7 System board status LEDs .................................................................................................................. 4-9

List of Tables

1-1 Mechanical and System Spare Parts List ............................................................................................ 1-4

2-1 System Fans ...................................................................................................................................... 2-19

2-2 DIMM Socket Identification............................................................................................................. 2-26

4-1 Rear Panel Components...................................................................................................................... 4-2

4-2 Expansion Slot Component................................................................................................................. 4-3

4-3 System Board Components................................................................................................................. 4-4

4-4 System Switches ................................................................................................................................. 4-5

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide v

Contents

4-5 System Maintenance Switch (SW1) Settings ......................................................................................4-6

4-6 Front Panel LEDs ................................................................................................................................4-7

4-7 Rear Panel LEDs .................................................................................................................................4-8

4-8 System board status LEDs................................................................................................................... 4-9

5-1 System Unit Specifications..................................................................................................................5-2

5-2 Power Supply Specifications...............................................................................................................5-2

5-3 Power Supply Specifications

continued ..................................................................................................5-3

5-4 SDRAM DIMM Specifications...........................................................................................................5-3

5-5 Optical CD-ROM Drive Specifications...............................................................................................5-4

5-6 Intel ICH6A SATA Controller Specifications.....................................................................................5-5

5-7 SATA Hard Drive Specifications........................................................................................................5-5

5-8 Integrated NC7782 10/100/1000 Gigabit Server Auto-Switching NIC Specifications (WOL and PXE

capable) ...............................................................................................................................................5-6

vi HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide

This maintenance and service guide can be used for reference when servicing an HP ProLiant

DL320 Generation 3 server.

WARNING: To reduce the risk of personal injury from electric shock and hazardous

energy levels, only authorized service technicians should attempt to repair this

equipment. Improper repairs can create conditions that are hazardous.

Audience Assumptions

This guide is for service technicians. HP assumes you are qualified in the servicing of

computer equipment and trained in recognizing hazard in products with hazardous energy

levels and are familiar with weight and stability precautions for rack installations.

Technician Notes

WARNING: Only authorized technicians trained by HP should attempt to repair this

equipment. All troubleshooting and repair procedures are detailed to allow only

subassembly/module-level repair. Because of the complexity of the individual boards

and subassemblies, no one should attempt to make repairs at the component level or

to make modifications to any printed wiring board. Improper repairs can create a safety

hazard.

WARNING: To reduce the risk of personal injury from electric shock and hazardous

energy levels, do not exceed the level of repairs specified in these procedures.

Because of the complexity of the individual boards and subassemblies, do not attempt

to make repairs at the component level or to make modifications to any printed wiring

board. Improper repairs can create conditions that are hazardous.

WARNING: To reduce the risk of electric shock or damage to the equipment:

• Disconnect power from the system by unplugging all power cords from the power

supplies.

• Do not disable the power cord grounding plug. The grounding plug is an important

safety feature.

About This Guide

• Plug the power cord into a grounded (earthed) electrical outlet that is easily

accessible at all times.

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide vii

About This Guide

CAUTION: To properly ventilate the system, you must provide at least 7.6 cm (3.0 in) of

clearance at the front and back of the server.

CAUTION: The computer is designed to be electrically grounded (earthed). To ensure proper

operation, plug the AC power cord into a properly grounded AC outlet only.

NOTE: Any indications of component replacement or printed wiring board modifications may void any

warranty.

Where to Go for Additional Help

In addition to this guide, the following information sources are available:

• HP ProLiant DL320 Generation 3 Server User Guide

• Server Quick Reference Guide

• Server training guides

• Server advisories and bulletins

• QuickFind information services

• HP Systems Insight Manager software (HP SIM)

• HP ProLiant Servers Troubleshooting Guide

• HP ROM-Based Setup and Utility User Guide

• HP Integrated Lights-Out User Guide

• QuickSpecs

Integrated Management Log

The server includes an integrated, nonvolatile management log that contains fault and

management information. The contents of the Integrated Management Log (IML) can be

viewed with HP SIM.

Telephone Numbers

For the name of the nearest HP authorized reseller:

• In the United States, call 1-800-345-1518.

• In Canada, call 1-800-263-5868.

• In other locations, refer to the HP website.

For HP technical support:

viii HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide

About This Guide

• In North America:

− Call 1-800-HP-INVENT (1-800-474-6836). This service is available 24 hours a day,

7 days a week. For continuous quality improvement, calls may be recorded or

monitored.

− If you have purchased a Care Pack (service upgrade), call 1-800-633-3600. For more

information about Care Packs, refer to the HP website.

y Outside North America, call the nearest HP Technical Support Phone Center. For

telephone numbers for worldwide Technical Support Centers, refer to the HP website

www.hp.com

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide ix

This chapter provides the illustrated parts breakdown and spare parts list for the

HP ProLiant DL320 Generation 3 Server. Table 1-1 in this chapter provides names and

ordering numbers for all referenced spare parts.

Customer Self Repair

HP's customer self-repair program offers you the fastest service under either warranty or

contract. It enables HP to ship replacement parts directly to you so that you can replace them.

Using this program, you can replace parts at your own convenience.

A convenient, easy-to-use program:

z An HP support specialist will diagnose and assess whether a replacement part is required

to address a system problem. The specialist will also determine whether you can replace

the part.

1

Illustrated Parts Catalog

z Replacement parts are express-shipped. Most in-stock parts are shipped the very same

day you contact HP. You may be required to send the defective part back to HP, unless

otherwise instructed.

z Available for most HP products currently under warranty or contract. For information on

the warranty service, refer to the HP website

(http://h18004.www1.hp.com/products/servers/platforms/warranty/index.html

For more information about HP's customer self-repair program, contact your local service

provider. For the North American program, refer to the HP website

(http://www.hp.com/go/selfrepair

Customer replaceable parts are identified in the following tables.

).

).

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide 1-1

Illustrated Parts Catalog

Mechanical Parts Exploded View

Figure 1-1: Mechanical parts exploded view

1-2 HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide

System Components Exploded View

Figure 1-2: System components exploded view

Illustrated Parts Catalog

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide 1-3

Illustrated Parts Catalog

Mechanical Parts and System Components Spares List

Table 1-1: Mechanical and System Spare Parts List

Item Description Spare Part Number Customer

Mechanical Components

1 Access panel 378631-001 Yes

2 PCI-X riser board assembly 361387-001 Yes

3 Fan assembly 378701-001 Yes

Power

4 500-Watt power supply 378630-001 Yes

Boards

5 LED/PWR switch board 378627-001 Yes

6 PCI Express board* 378626-001 Yes

7 System board 378623-001 Yes

8 SATA Backplane 378625-001 Yes

Processor

9 a) 2.93-GHz Intel® Celeron® processor 378619-001 Yes

b) 3.4-GHz Intel Pentium® 4 processor 1MB* 378620-001 Yes

c) 3.4-GHz Intel Pentium 4 processor 2 MB * 384787-001 Yes

d) 3.6-GHz Intel Pentium 4 processor 1 MB* 378621-001 Yes

10 Heatsink 378622-001 Yes

Memory

11 a) PC3200 DDR ECC Registered DIMM 512 MB 351657-001 Yes

b) PC3200 DDR ECC Registered DIMM 1 GB* 351658-001 Yes

Mass Storage Devices

12 Optical devices/diskette assembly

a) CD-ROM 390629-001 Yes

b) DVD-ROM * 383981-001 Yes

c) SCSI hard drive

1. SCSI 18-GB U320 HD

2. SCSI 36-GB U320 HD

3. SCSI 72-GB U320 HD

d) SATA hard drive

1. SATA 80-GB HD

2. SATA 160-GB HD

3. SATA 250-GB HD

e) Diskette drive assembly* 390530-001 Yes

1. 289240-001

2. 289241-001

3. 289243-001

1. 353042-001

2. 353043-001

3. 353044-001

Self Repair

Yes

Yes

Yes

Yes

Yes

Yes

* Not shown

continued

1-4 HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide

Illustrated Parts Catalog

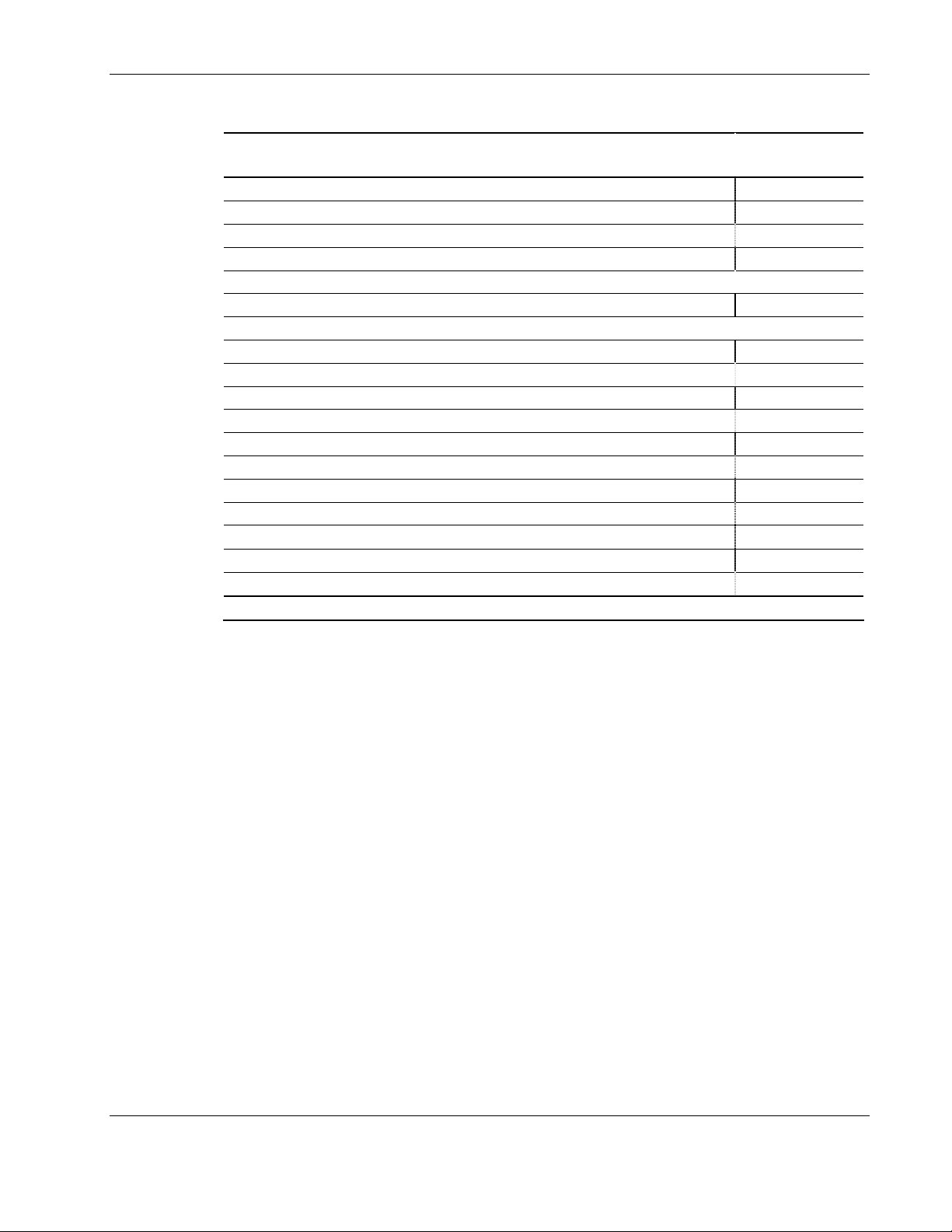

Table 1-1: Mechanical and System Spare Parts List continued

Item Description Spare Part

Number

Miscellaneous

13 Replacement battery, 3-V lithium* 234556-001 Yes

14 SATA cable kit* 378629-001 Yes

15 Cable kit* 378628-001 Yes

a) hard drive cable* Yes

b) Optical device/diskette assembly drive cable* Yes

c) USB* Yes

16 Miscellaneous plastics kit 378632-001 Yes

a) Bezel Yes

b) PCI card guide Yes

c) Bezel screws* Yes

d) Air baffle Yes

e) Pull tab Yes

17 Return kit* 378633-001 Yes

18 Country kit* 378675-001 Yes

Option Kit Spares

19 Rack mounting hardware kit* 360104-001 Yes

20

* Not shown

Cable management arm Kit*

360105-001 Yes

Customer Self

Repair

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide 1-5

Removal and Replacement Procedures

This chapter provides subassembly and module-level removal and replacement procedures

for HP ProLiant DL320 Generation 3 Servers. After completing all necessary removal and

replacement procedures, run the diagnostics program to verify that all components operate

properly.

Required Tools and Software

You may need the following items for some procedures:

z Phillips screwdriver

z T-15/T-10 Torx screwdriver

z SmartStart CD

- ROM-Based Setup Utility (RBSU)

- Array Diagnostics Utility (ADU)

2

- Diagnostics software

z Wrist strap

Safety Considerations

z Before performing any service procedure, review all safety information.

Electrostatic Discharge Information

An electrostatic discharge (ESD) can damage static-sensitive devices or microcircuitry.

Proper packaging and grounding techniques are required to prevent damage. To prevent

damage due to ESD, observe the following precautions:

z Transport products in static-safe containers such as conductive tubes, bags, or boxes.

z Keep electrostatic-sensitive parts in their containers until they arrive at static-free

stations.

z Cover workstations with approved static-dissipating material. Use a wrist strap

connected to the work surface as well as properly grounded tools and equipment.

z Keep the work area free of nonconductive materials such as ordinary plastic assembly

aids and foam packing.

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide 2-1

Removal and Replacement Procedures

z Ensure proper grounding before touching a static-sensitive component or assembly.

z Avoid touching pins, leads, or circuitry.

z Always place drives with the Printed Circuit Board (PCB) assembly-side down.

z Use conductive field service tools.

Symbols on Equipment

Any surface or area of the equipment marked with these symbols indicates the

presence of a hot surface or hot component.

WARNING: To reduce the risk of injury from a hot component, allow the surface to cool

before touching it.

To reduce the risk of injury from electric shock hazards, do not open this enclosure.

WARNING: Any surface or area of the equipment marked with these symbols indicates

the presence of electric shock hazards. The enclosed area contains no

operator-serviceable parts.

This symbol indicates the presence of electric shock hazards. The enclosed area

contains no user or field-serviceable parts. Do not open for any reason.

WARNING: To reduce the risk of injury from electric shock hazards, do not open this

enclosure.

Any RJ-45 receptacle marked with these symbols indicates a network interface

connection.

WARNING: To reduce the risk of electric shock, fire, or damage to the equipment, do

not plug telephone or telecommunications connectors into this receptacle.

This label or equivalent is located on the surface of the CD-ROM or DVD-ROM

drive. This label indicates that the product is classified as a Class 1 Laser Product.

Rack Warnings

WARNING: To reduce the risk of personal injury or damage to equipment, always be

sure that the rack is adequately stabilized before extending a component from the rack.

A rack may become unstable if more than one component is extended for any reason.

Extend only one component at a time.

WARNING: To reduce the risk of personal injury or damage to the equipment, be sure

that:

z The leveling jacks are extended to the floor.

z The full weight of the rack rests on the leveling jacks.

z The stabilizers are attached to the rack, if it is a single rack installation.

z The racks are coupled together in multiple rack installations.

2-2 HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide

WARNING: When installing the server in a telco rack, make certain that the rack frame

is adequately secured to the building structure at the top and bottom.

WARNING: To reduce the risk of personal injury or damage to the equipment, at least

two people are needed to safely unload the rack from the pallet. An empty 42U rack

weighs 115 kg (253 lb), is over 2.1 m (7 ft) tall, and may become unstable when being

moved on its casters. Do not stand in front of the rack as it rolls down the ramp from

the pallet. Handle the rack from both sides.

Server Warnings and Precautions

WARNING: To reduce the risk of personal injury from hot surfaces, allow the hot-plug

drives and the internal system components to cool before touching them.

WARNING: To reduce the risk of electric shock or damage to the equipment:

Do not disable the power cord grounding plug. The grounding plug is an important

safety feature.

Plug the power cord into a grounded (earthed) electrical outlet that is easily accessible

at all times.

Unplug the power cord from the power supply to disconnect power to the equipment.

CAUTION: Protect the server from power fluctuations and temporary interruptions with a

regulating uninterruptible power supply (UPS). This device protects the hardware from

damage caused by power surges and voltage spikes and keeps the system in operation

during a power failure.

CAUTION: The server

cooling is not achieved if the system access panel is removed.

must always be operated with the system access panel closed. Proper

Removal and Replacement Procedures

Removal and Replacement Procedures

Use the procedures in this section to perform service events on the ProLiant DL320 G3

Server.

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide 2-3

Removal and Replacement Procedures

Powering Down the Server

The server does not completely power down when the front panel power button is pressed.

The button toggles server power between On and Standby. In Standby, the server removes

power from most electronics and drives, portions of the power supply and some internal

circuitry remain active. To completely remove all power from the system, disconnect the

power cord from the server.

WARNING: To reduce the risk of injury from electric shock, remove the power cord to

completely disconnect power from the system.

WARNING: To reduce the risk of personal injury or damage to the equipment, be sure

that only one component is extended at a time. A rack may become unstable if more

than one component is extended at the same time.

WARNING: Because the rack allows you to stack computer components in a vertical

rather than a horizontal plane, you must take precautions to provide for rack stability

and safety to protect both personnel and property. Heed all cautions and warnings

throughout the installation instructions that come with the server.

WARNING: To reduce the risk of personal injury or damage to the equipment, place the

server on a sturdy table or workbench whenever it is removed from the rack for device

accessibility. Refer to the HP ProLiant DL320 Generation 3 Server User Guide for

further information on working with racks.

CAUTION: Moving the Power On/Off switch to the Off position does not completely remove

system power. Some portions of the power supply and some internal circuitry remain active.

Disconnect all power cords from the server to remove all power from the system.

CAUTION: ESD can damage electronic components. Be sure you are properly grounded

before beginning any installation procedure. For more information, see “Electrostatic

Discharge Information” in this chapter.

NOTE: Microsoft® Windows NT® users may use the Power Down Manager to power down the server.

For information on this system utility, refer to the NTREADME.HLP file on the NT Software Support

Diskettes.

2-4 HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide

To power down the server:

1. Press the power button to toggle the server to standby. The power LED on the power

button changes from green to amber.

2. Listen for the fan noise to stop to indicate that the server is powered down.

3. Disconnect the power cord first from the AC outlet and then from the server. The power

LEDs turn off.

4. Disconnect all remaining cables on the server rear panel, including cables extending from

external connectors on expansion boards.

5. Remove the server from the rack and position it securely on a workbench or other solid

surface for stability and safety.

Access Panel

To access the system board, processor, memory modules, expansion slot, and other internal

components, remove the access panel. Observe the following warnings and cautions.

Removal and Replacement Procedures

WARNING: The front panel Power On/Off switch does not completely shut off all

system power. Portions of the power supply and some internal circuitry remain active

until AC power is removed.

WARNING: To reduce the risk of personal injury from hot surfaces, allow the internal

system components to cool before touching them.

CAUTION: Do not operate the server without the access panel installed. The access panel is

required for proper airflow. Operating the server without the access panel prevents proper

airflow and results in improper cooling and possible thermal damage.

CAUTION: Before removing the server access panel, be sure that the server is powered

down and that the power cord is disconnected from the server and the electrical outlet.

CAUTION: To avoid the risk of damage to the system or expansion boards, remove all power

cords before installing or removing expansion boards. When the Power On/Off switch is in the

Off position, auxiliary power is still connected to the PCI expansion slot and may damage the

card.

CAUTION: ESD can damage electronic components. Ensure proper grounding before

beginning any installation procedure.

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide 2-5

Removal and Replacement Procedures

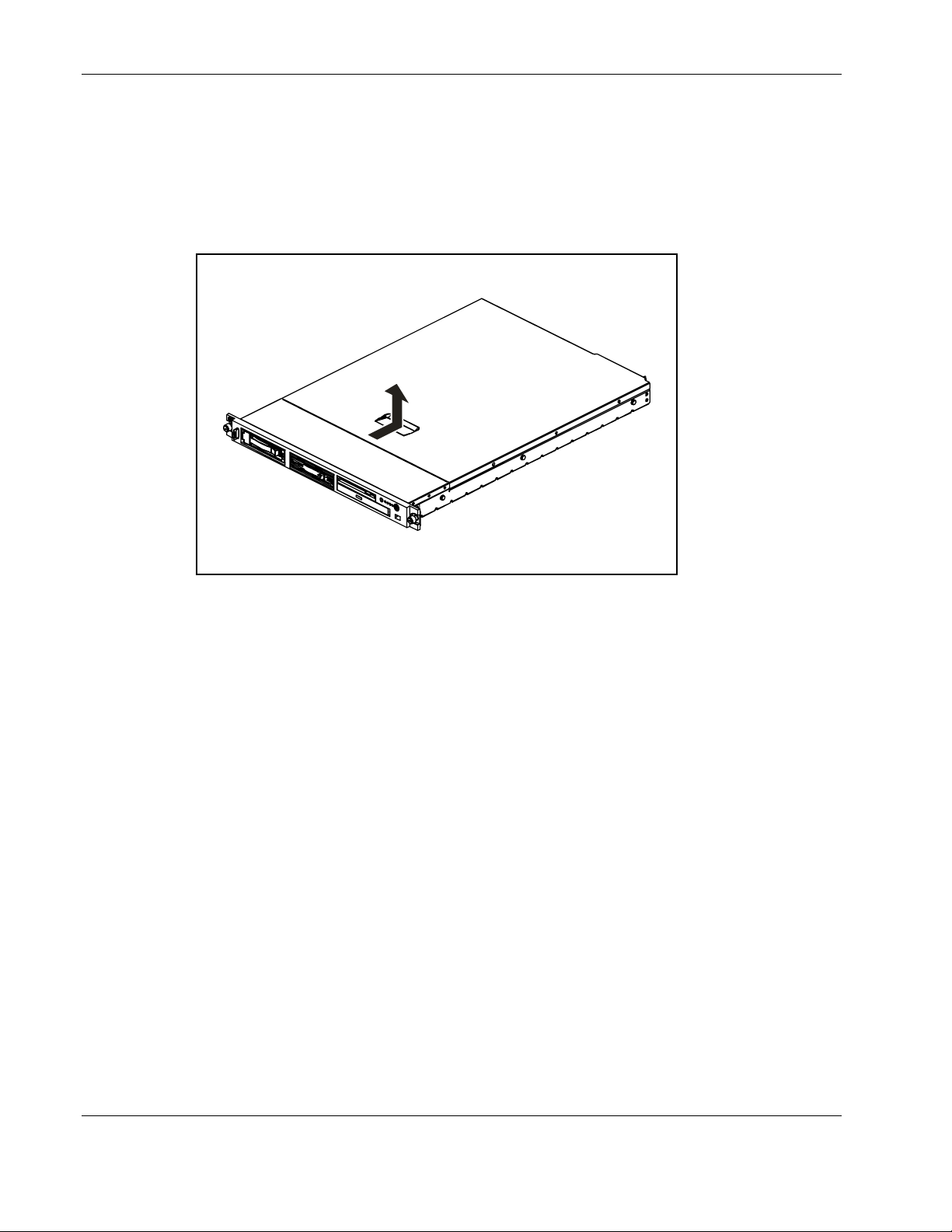

To remove the access panel:

1. Power down the server. See “Powering Down the Server” in this chapter.

2. Loosen rear thumbscrew by using the T-15/T-10 Torx screwdriver or the flat screwdriver.

3. Slide the access panel approximately 1.25 cm (0.5 in) toward the rear of the unit and lift

the panel to remove it.

Figure 2-1: Removing the access panel

To replace the access panel, reverse steps 1 through 3.

2-6 HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide

Drive Assembly

The server contains a removable media drive assembly including one LED/PWR switch

board, one optical drive, and one diskette drive.

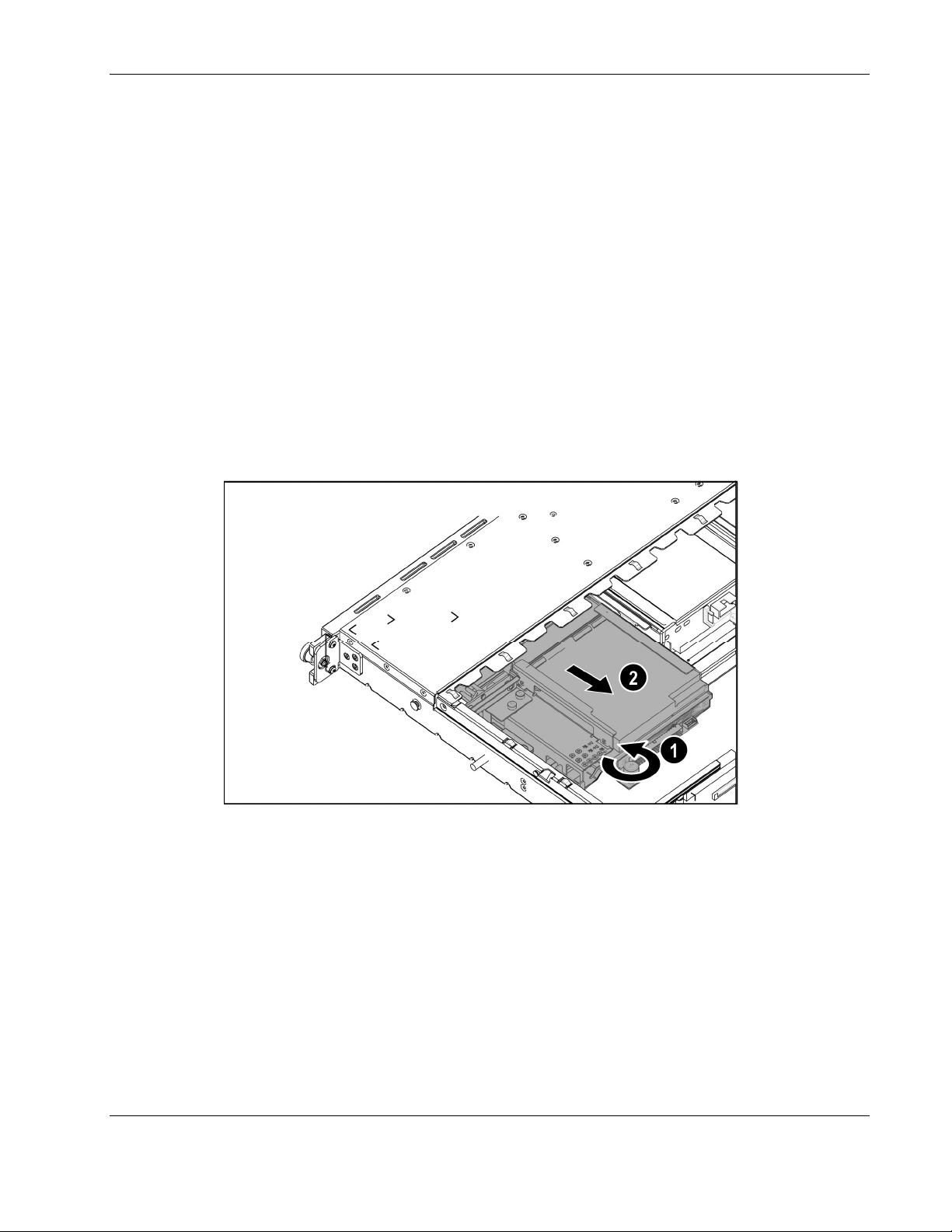

To remove the drive assembly:

1. Power down the server. See “Powering Down the Server” in this chapter.

2. Remove the access panel. See “Access Panel” in this chapter.

3. Disconnect the LED/PWR switch board cable from the system board.

4. Disconnect the diskette drive cable from the diskette drive.

5. Disconnect the two optical drive cables from the optical drive.

6. Remove the fan module.

7. Loosen the one thumbscrew of the drive assembly (1).

8. Slide the drive assembly gently toward the back of the server (2).

Removal and Replacement Procedures

Figure 2-2: Loosen the thumbscrew and slide the assembly toward

the back of the server

IMPORTANT : Carefully remove the LED/PWR switch board to avoid damaging the LEDs.

Reverse steps 1 through 8 to replace the drive assembly.

LED/PWR Switch Board

To remove the LED/PWR switch board:

1. Power down the server. See “Powering Down the Server” in this chapter.

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide 2-7

Removal and Replacement Procedures

2. Remove the access panel. See “Access Panel” in this chapter.

3. Disconnect the drive assembly cables. See “Drive Assembly” in this chapter.

4. Unscrew both LED/PWR switch board screws from the drive assembly (1) and remove

the LED/PWR switch board (2).

Figure 2-3: Removing the LED/PWR switch board

IMPORTANT: Carefully remove the LED/PWR switch board to avoid damaging the LEDs.

Reverse steps 1 through 4 to replace the LED/PWR switch board.

Diskette Drive

To remove the diskette drive:

1. Power down the server. See “Powering Down the Server” in this chapter.

2. Remove the access panel. See “Access Panel” in this chapter.

3. Disconnect the drive assembly cables. See “Drive Assembly” in this chapter.

4. Remove the LED/PWR switch board. See “LED/PWR Switch Board” in this chapter.

5. Remove the 4 screws holding diskette drive (1) and slide the drive out of the assembly

(2).

2-8 HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide

Removal and Replacement Procedures

Figure 2-4: Remove the diskette drive

To replace the diskette drive, reverse steps 1 through 5.

NOTE: See the HP ProLiant DL320 Generation 3 Server User Guide for instructions on installing the

diskette drive.

NOTE: If the diskette drive must be replaced due to failure, the diskette drive cable must be removed

from the failed drive and installed on the replacement. See Chapter 1, “Illustrated Parts Catalog,” for

illustrations.

Optical Drive

To remove the optical drive:

1. Power down the server. See “Powering Down the Server” in this chapter.

2. Remove the access panel. See “Access Panel” in this chapter

3. Disconnect the drive assembly cables. See “Drive Assembly” in this chapter.

4. Remove 4 screws holding optical drive (1) and slide the drive out of the assembly (2).

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide 2-9

Removal and Replacement Procedures

Figure 2-5: Remove the Optical drive

To replace the optical drive, reverse steps 1 through 4.

NOTE: See the HP ProLiant DL320 Generation 3 Server User Guide for instructions on installing the

optical drive.

NOTE: If the drive must be replaced due to failure, the optical drive backplane must be removed from

the failed drive and installed on the replacement. See Chapter 1, “Illustrated Parts Catalog,” for

illustrations.

2-10 HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide

Hard Drive Overview

The server contains two drive bays for SATA hard drives or non-hot pluggable SCSI hard

drives. Two individual SATA channels exist, one for each of the hard drives. The server ships

standard with two 1-inch drive trays for use with two 1-inch pluggable SATA hard drives.

The following sections provide general guidelines and installation procedures for installing or

upgrading hard drives.

Guidelines for Installing SATA Hard Drives

When installing SATA hard drives in the server, observe the following general guidelines:

z Populate hard drive bays starting with the lowest SATA device number. Device 0 serves

as the primary boot drive.

z Set the jumpers on both SATA drives to Cable-Select mode.

z Do not add more than two SATA drives in the DL320 G3 server.

IMPORTANT: SATA hard drives must be configured to the Cable-Select mode.

NOTE: SATA drives are set to Cable-Select mode by default.

NOTE: Refer to the documentation shipped with the hard drive to determine how to set the jumpers on

the SATA hard drives to Cable-Select mode, if they are not already set in Cable-Select mode.

Removal and Replacement Procedures

Guidelines for Installing SCSI Hard Drives

Each SCSI hard drive installed in the server must be configured with a unique SCSI ID

number. Unique identification allows the system to search for the lowest numbered drive to

use as a bootable partition. By default, the jumpers on SCSI hard drives are set to ID 0 and

may need to be reset when the drive is installed as an optional or replacement drive in the

server.

CAUTION: Before removing the server access panel, be sure that the server is powered

down and that the power cord is disconnected from the server and the electrical outlet.

NOTE: SCSI drives are set to Cable-Select mode by default.

Hard Drive Identification Numbers

The servers include two 1-inch hard drive trays. Hard drives installed in the server are labeled

as Device 1 and Device 2 in Figure 2-6 for clarification.

IMPORTANT: Always populate hard drive bays starting with the lowest hard drive number.

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide 2-11

Removal and Replacement Procedures

Figure 2-6: SATA device numbers

SATA Hard Drives

To remove a hard drive from the hard drive bay:

1. Power down the server. See “Powering Down the Server” in this chapter.

2. Flip open the tray lever to release the hard drive tray (1), and then slide the tray out of the

chassis (2).

Figure 2-7: Removing the SATA hard drive tray from the chassis

2-12 HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide

Removal and Replacement Procedures

3. Remove the four screws that secure the hard drive to the hard drive tray (1).

4. Remove the hard drive from the hard drive tray (2).

Figure 2-8: Removing the SATA hard drive from a hard drive tray

To replace the SATA hard drive, reverse steps 1 through 4.

IMPORTANT: While replacing the drive, make sure that the LED light pipes of the tray are seated

properly in their slots.

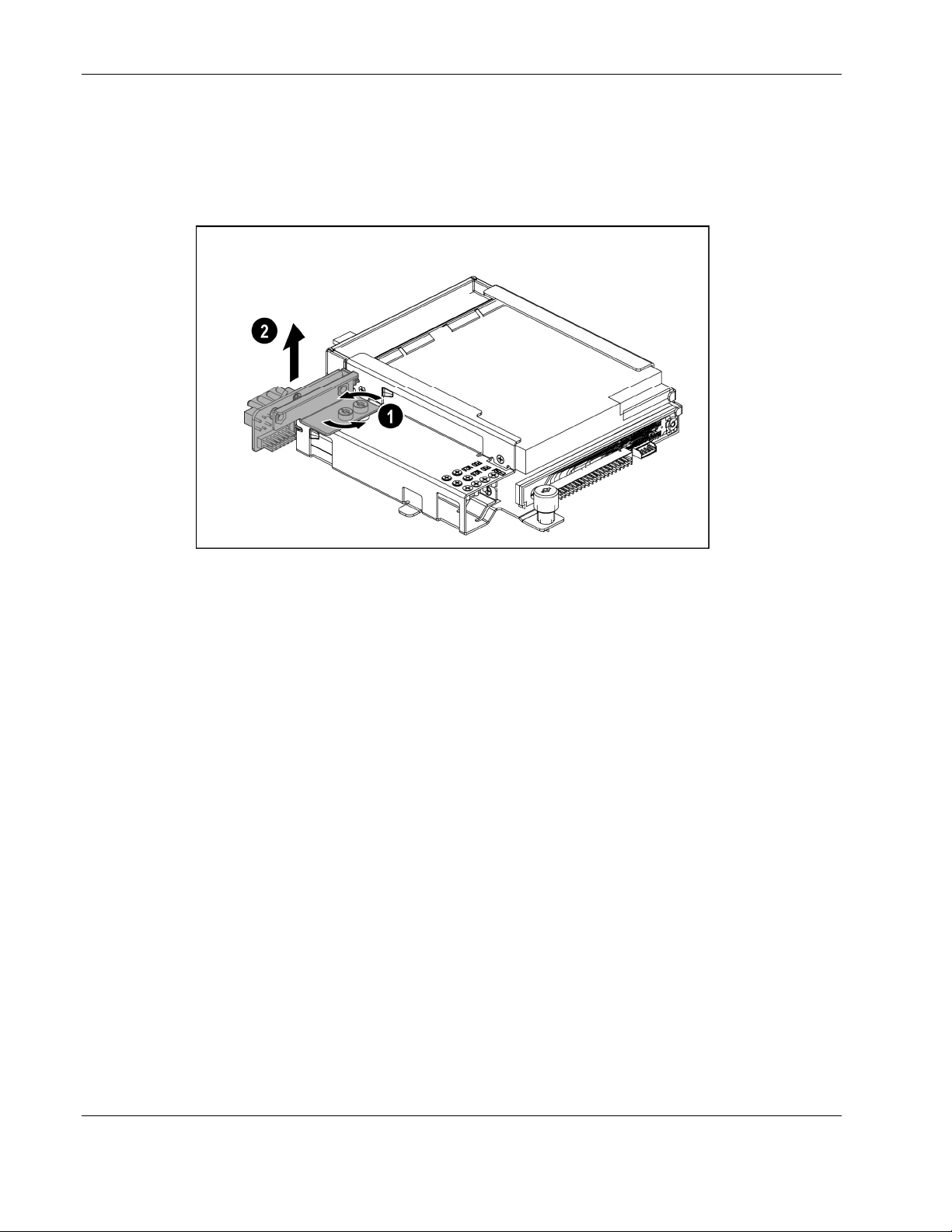

SCSI Hard Drives

To remove a hard drive from the hard drive bay:

1. Power down the server. See “Powering Down the Server” in this chapter.

2. Remove the access panel. See “Access Panel” in this chapter.

3. Disconnect the SCSI cables from the hard drives.

4. Disconnect the power cables from the hard drives.

5. Loosen the thumbscrew that secures the hard drive tray to the chassis (1).

6. Slide the tray toward the front of the server and lift the tray out of the chassis (2).

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide 2-13

Removal and Replacement Procedures

Figure 2-9: Removing the SCSI hard drive tray from the chassis

7. Remove the four screws at the bottom side that secure the hard drive to the hard drive

tray (1).

8. Remove the hard drive from the hard drive tray (2).

Figure 2-10: Removing the SCSI hard drive from a hard drive tray

CAUTION: Review “Guidelines for SCSI Hard Drives” in this chapter to ensure proper jumper

settings and hard drive configuration.

CAUTION: When connecting the power cable to the hard drives, ensure that the connectors

are installed so that the red wire faces right when viewed from the front of the server.

2-14 HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide

IMPORTANT: Ensure that the hard drives are installed with the data and power connectors along the

bottom of the tray, facing away from the front vent holes..

To replace the SCSI hard drive, reverse steps 1 through 8.

PCI Riser Board Assembly

To remove the PCI riser board assembly:

1. Power down the server. See “Powering Down the Server” in this chapter.

2. Remove the access panel. See “Access Panel” in this chapter.

3. Disconnect any cables connecting an existing expansion board to the system board.

4. Unscrew the 2 thumbscrews on rear of chassis (1).

5. Lift and remove the PCI riser board from the server chassis (2).

Removal and Replacement Procedures

Figure 2-11: Removing the PCI riser board

CAUTION: When removing the PCI riser board assembly, be careful to avoid damaging to

the system cables.

CAUTION: Be careful to remove the large PCI expansion board, if it is present in the

assembly, since it is guided and supported with a bracket at its end.

When replacing an expansion board, refer to “Expansion Board” following this procedure.

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide 2-15

Removal and Replacement Procedures

IMPORTANT: Do not replace the PCI riser board assembly in the chassis unless all installation and

cabling procedures are complete.

Reverse steps 1 through 5 to replace the PCI riser board assembly, ensuring that the assembly

seats properly in the retainers on the rear of the chassis and the guide located on the system

board.

Expansion Board

To remove an expansion board:

CAUTION: To avoid the risk of damage to the system or expansion boards, remove all power

cords before installing or removing an expansion board. When the front panel power switch is

off, auxiliary power is still connected to the PCI expansion slot and may damage the card.

1. Power down the server. See “Powering Down the Server” in this chapter.

2. Remove the access panel. See “Access Panel” in this chapter.

3. Disconnect all cables from the expansion board.

4. Remove the PCI riser board assembly. See “PCI Riser Board Assembly” in this chapter.

5. Apply even pressure to pull the expansion board out of its socket in the PCI riser board

assembly.

Figure 2-12: Removing an expansion board from the PCI riser

board assembly

Reverse steps 1 through 5 to replace an expansion board. Use the PCI card guide on the

assembly to position the board in the socket.

IMPORTANT: Be sure that the expansion board is seated securely in the expansion slot before

replacing the PCI riser board assembly and access panel.

2-16 HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide

Single Channel Wide Ultra320 SCSI Adapter

To remove a single channel wide ultra320 SCSI adapter:

1. Locate the PCI-X slot 1 riser connector. See Figure 4-2 in the Chapter 4 Connectors,

Switches, and LED Indicators.

2. Remove the PCI riser board assembly. See “PCI riser board assembly” in this chapter.

3. Remove a single channel-wide ultra320 SCSI adapter. See “Expansion Board” in this

chapter.

Reverse steps 2 through 3 to replace a single channel-wide ultra320 SCSI adapter. Use the

PCI card guide on the assembly to position the adapter in the socket.

Integrated SATA RAID Controller Module

To remove an integrated SATA RAID controller module:

1. Locate the PCI-X slot 1 riser connector. See Figure 4-2 in the Chapter 4 Connectors,

Switches, and LED Indicators.

Removal and Replacement Procedures

2. Remove the PCI riser board assembly. See “PCI riser board assembly” in this chapter.

3. Remove an integrated SATA RAID controller module. See “Expansion Board” in this

chapter.

Reverse steps 2 through 3 to replace an integrated SATA RAID controller module. Use the

PCI card guide on the assembly to position the module in the socket.

Fan Assembly

To remove the fan assembly:

1. Power down the server. See “Powering Down the Server” in this chapter.

2. Remove the access panel. See “Access Panel” in this chapter.

3. Lift the air baffle from the server chassis.

4. Disconnect the fan assembly power cables (1 to 4) from the fan connectors on the system

board.

WARNING: To reduce the risk of personal injury from hot surfaces, allow the internal system

components to cool before touching them.

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide 2-17

Removal and Replacement Procedures

Figure 2-13: Disconnecting the fan assembly power cables

(processor heatsink removed for clarity)

5. Push in and hold the fan assembly tab to unlock the fan assembly from the chassis (1)

6. Lift the fan assembly out of the chassis (2)

Figure 2-14: Lifting the fan assembly out of the chassis

Reverse steps 1 through 6 to replace the fan assembly.

IMPORTANT: See the server hood label or “System Board Connector,” in Chapter 4, “Connectors,

Switches, and LED Indicators,” for correct fan cable connections.

2-18 HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide

Fans

Removal and Replacement Procedures

The server contains four system fans. The fans are located on the fan assembly. Use Figure 215 and Table 2-1 to locate the system fans.

Figure 2-15: Locating the system fans

NOTE: Fans are spared and replaced individually. Each fan listed in Table 2-1 is a separate spare.

Table 2-1: System Fans

Item Component

1 Fan 1

2 Fan 2

3 Fan 3

4 Fan 4

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide 2-19

Removal and Replacement Procedures

To remove one fan from the fan assembly:

1. Loosen the screws (1)

2. Slide the fan out of the assembly (2).

Figure 2-16: Removing one fan from the fan assembly

Reverse steps 1 and 2 to replace the fan.

2-20 HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide

Cables

This section contains removal and replacement procedures for SATA drive cables that ship

with the server.

SATA Drive Cables

To remove the SATA drive cables:

1. Power down the server. See “Powering Down the Server” in this chapter.

2. Remove the access panel. See “Access Panel” in this chapter.

3. Remove the fan assembly. See “Fan Assembly” in this chapter.

4. Disconnect the following cables:

a. The system board (1) (4)

b. The hard drive(s) (2) from the backplane

c. The power cables (3) (7)

d. The diskette drive (5)

Removal and Replacement Procedures

e. The optical drive (6)

Figure 2-17: Disconnecting the SATA cables

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide 2-21

Removal and Replacement Procedures

Figure 2-18: Disconnecting the drive assembly cables

Reverse steps 1 through 6 to replace the cables.

2-22 HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide

Power Supply

To remove the power supply:

1. Power down the server. See “Powering Down the Server” in this chapter.

2. Remove the access panel. See “Access Panel” in this chapter.

3. Disconnect the removable media and hard drive power cables (1)

4. Disconnect the auxiliary power supply cable (2) and the main power supply cable (3)

from the power supply connector on the system board by pressing each locking tab on

the side of the connector and pulling upwards.

5. Remove the four screws that secure the power supply unit to the chassis (4).

6. Lift the power supply from the server (5).

Removal and Replacement Procedures

Figure 2-19: Removing the power supply

Reverse steps 1 through 6 to replace the power supply.

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide 2-23

Removal and Replacement Procedures

Battery

If the server no longer automatically displays the correct date and time, check the battery that

provides power to the real-time clock. If necessary, replace a used battery with a CR2032

lithium battery. Under normal use, battery life is at least 5 years.

WARNING: This server contains either an internal lithium manganese dioxide, or a

vanadium pent oxide battery. A risk of fire and burns exist if the battery pack is not

handled properly. To reduce the risk of personal injury:

z Do not attempt to recharge.

z Do not expose to temperatures higher than 60°C (140°F).

z Do not disassemble, crush, puncture, short external contacts, or dispose of in fire

or water.

z Replace only with the spare designated for this product.

CAUTION: Loss of BIOS settings occurs when the battery is removed. BIOS settings must be

reconfigured whenever the battery is replaced.

CAUTION: Batteries, battery packs, and accumulators should not be disposed of together

with general household waste. Use the public collection system or return used batteries to the

authorized partners or their agents for proper recycling and disposal.

To remove the battery:

1. Power down the server. See “Powering Down the Server” in this chapter.

2. Remove the access panel. See “Access Panel” in this chapter.

3. Locate the battery on the system board.

4. If necessary, remove the PCI riser board assembly to access the battery location. See

“PCI Riser Board Assembly” in this chapter.

5. Press the battery release lever away from the battery (2).

6. Lift the battery on the lever side and pull it out of the holder (3).

2-24 HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide

Removal and Replacement Procedures

Figure 2-20: Locating and removing the system battery

IMPORTANT: Do not bend the retaining clip during battery replacement. For proper operation, the clip

must maintain a position of contact with the battery.

Reverse steps 1 through 6 to replace the battery, ensuring that the new battery is installed

with the positive side up.

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide 2-25

Removal and Replacement Procedures

Memory Modules

The server supports up to four PC3200 DDR ECC unbuffered SDRAM DIMMs installed in

four sockets on the system board.

Figure 2-21: Identifying DIMM sockets on the system board

Table 2-2: DIMM Socket Identification

Item Description

1 DIMM socket 1A

2 DIMM socket 2A

3 DIMM socket 3B

4 DIMM socket 4B

Observe the following guidelines when installing additional memory:

z DIMMs must be industry-standard, 512-MB or 1-GB,

3-cm (1.2-in), 184-pin PC3200, 400-MHz DDR ECC memory unbuffered DIMMs. The

DDR memory DIMMs must support CAS Latency 2, where CL=2 or greater. They must

also contain the mandatory Joint Electronic Device Engineering Council (JEDEC)

Serial Presence Detect (SPD) information.

z DIMMs installed in the server must be unbuffered DDR1/400, 2.5 volts and 64-bits

wide.

z Do not mix ECC and non-ECC DIMMs or DIMMs of different speeds. If different types

of DIMMs are mixed, the system will not function properly.

2-26 HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide

Removal and Replacement Procedures

z If only one DIMM is installed, HP recommends installing it in slot 1A.

z All DIMMs installed must be of the same speed (DDR PC3200).

z For best performance the amount of memory in bank A should equal to the amount in

bank B.

IMPORTANT: A DIMM can be installed only one way. Be sure to match the key slots on the module

with the tabs on the memory slot. Push the module down into the slot until it is fully inserted and

properly seated. The system will not recognize improperly aligned or seated DIMMs.

To remove a DIMM from the system board:

1. Power down the server. See “Powering Down the Server” in this chapter.

CAUTION: ESD can damage electronic components. Ensure that you are properly grounded

before beginning any installation procedure. Refer to “Electrostatic Discharge Information” in

this chapter.

2. Remove the access panel. See “Access Panel” in this chapter.

3. Press both DIMM socket latches outward (1). This action releases the DIMM and

partially lifts it out of the socket.

4. Lift out the DIMM (2).

5. Align the key slot in the bottom edge of the DIMM with the tab in the expansion socket.

Figure 2-22: Removing a DIMM from a DIMM socket

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide 2-27

Removal and Replacement Procedures

To install a DIMM:

1. Gently push the DIMM into the socket on the system board (1). When the DIMM is

properly seated, the latches close (2).

Figure 2-23: Installing a DIMM in a DIMM socket

CAUTION: Use only HP supplied DIMMs. DIMMs from other sources can adversely affect

data integrity.

2. Press down firmly on the DIMM while pushing the latches inward until the latches snap

into place.

2-28 HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide

Processor

To remove the processor:

1. Power down the server. See “Powering Down the Server” in this chapter.

2. Remove the access panel. See “Access Panel” in this chapter.

3. Locate the processor on the system board.

4. Remove the air baffle.

Removal and Replacement Procedures

CAUTION: Always use a new heatsink when replacing processors. Failure to use new

components can cause damage to the processor.

Figure 2-24: Locating the processor on the system board

WARNING: To reduce the risk of personal injury from hot surfaces, allow the internal

system components to cool before touching them.

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide 2-29

Removal and Replacement Procedures

5. Loosen the four screws securing the heatsink:

a. Loosen each screw three or four turns in the order shown in the illustration.

b. Fully loosen the screws to free the heatsink, being careful not to remove the screw

assemblies from the heat sink.

CAUTION: Heatsink retaining screws should be tightened or loosened in diagonally opposite

pairs (in an "X" pattern). Do not over tighten the screws as this may damage the board,

connectors, or screws. Using the wrench supplied with the system will reduce the possibility of

over tightening the screws.

Figure 2-25: Loosening screws on the heatsink and removing the

heatsink

6. Remove the heatsink from the top of the processor.

7. Lift the processor locking lever (1) and the cover (2)

8. Lift the processor from the socket (3).

2-30 HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide

Removal and Replacement Procedures

Figure 2-26: Removing the processor from the system board

Reverse steps 1 through 8 to reinstall the processor and heatsink. Care should be taken to

install the processor in its right orientation.

CAUTION: Heatsink retaining screws should be tightened or loosened in diagonally opposite

pairs (in an "X" pattern). Do not over tighten the screws as this may damage the board,

connectors, or screws. Using the wrench supplied with the system will reduce the possibility of

over tightening the screws.

CAUTION: Always use a new heatsink when replacing processors. Failure to use new

components may result in damage to the processor.

System Board

To remove the system board:

1. Power down the server. See “Powering Down the Server” in this chapter.

2. Remove the access panel. See “Access Panel” in this chapter.

3. Remove the PCI riser board assembly. See “PCI Riser Board Assembly” in this chapter.

4. Remove any DIMMs. See “Memory Modules” in this chapter.

5. Disconnect the fan cables. See “Fans” in this chapter.

6. Remove the fan assembly. See “Fan Assembly” in this chapter.

7. Disconnect power supply cables from the system board, the hard drive backplane, and

the optical drive backplane. See “Power Supply” in this chapter.

8. Disconnect the SATA drive cables. See “Cables” in this chapter.

9. Disconnect the diskette drive cable. See “Cables” in this chapter.

10. Disconnect the optical drive cable. See “Cables” in this chapter.

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide 2-31

Removal and Replacement Procedures

11. Disconnect the LED/PWR switch board cable. See “Cables” in this chapter.

12. Remove the processor. See “Processor” in this chapter.

CAUTION: Always use a new heatsink when replacing processors on the system. Failure to

use new components may result in damage to the processor. See “Processor” in this chapter.

13. Remove all screws that secure the system board to the chassis (1).

14. Lift the system board up and away from the standoffs (2).

Figure 2-27: Removing the system board

Reverse steps 1 through 14 to replace the system board.

2-32 HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide

This chapter provides an overview of the software and firmware diagnostic tools available for

HP ProLiant DL320 Generation 3 Servers.

SmartStart Software

SmartStart is a collection of software that optimizes single-server setup, providing a simple

and consistent way to deploy server configuration. SmartStart has been tested on many

ProLiant server products, resulting in proven, reliable configurations.

SmartStart assists the deployment process by performing a wide range of configuration

activities, including:

z Configuring hardware using embedded configuration utilities, such as RBSU and ORCA.

z Preparing the system for installing "off-the-shelf" versions of leading operating system

software

3

Diagnostic Tools

z Installing optimized server drivers, management agents and utilities automatically with

every assisted installation

z Testing server hardware using the Insight Diagnostics Utility.

z Installing software drivers directly from the CD. With systems that have internet

connection, the SmartStart Autorun Menu provides access to a complete list of ProLiant

system software.

z Enabling access to the Array Configuration Utility, Array Diagnostics Utility, and Erase

Utility

SmartStart is included in the HP ProLiant Essentials Foundation Pack. For more information

about SmartStart software, refer to the HP ProLiant Essentials Foundation Pack or the HP

website (http://www.hp.com/servers/smartstart

SmartStart Scripting Toolkit

The SmartStart Scripting Toolkit is a server deployment product that delivers an unattended

automated installation for high-volume server deployments. The SmartStart Scripting Toolkit

is designed to support ProLiant BL, ML, and DL servers. The toolkit includes a modular set

of utilities and important documentation that describes how to apply these new tools to build

an automated server deployment process.

).

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide 3-1

Diagnostic Tools

Using SmartStart technology, the Scripting Toolkit provides a flexible way to create standard

server configuration scripts. These scripts are used to automate many of the manual steps in

the server configuration process. This automated server configuration process cuts time from

each server deployed, making it possible to scale server deployments to high volumes in rapid

fashion.

For more information, and to download the SmartStart Scripting Toolkit, refer to the HP

website (http://www.hp.com/servers/sstoolkit

).

HP Instant Support Enterprise Edition

ISEE is a proactive remote monitoring and diagnostic tool to help manage your systems and

devices, a feature of HP support. ISEE provides continuous hardware event monitoring and

automated notification to identify and prevent potential critical problems. Through remote

diagnostic scripts and vital system configuration information collected about your systems,

ISEE enables fast restoration of your systems. Install ISEE on your systems to help mitigate

risk and prevent potential critical problems.

For more information on ISEE, refer to the HP website

(http://www.hp.com/servers/smartstart

).

To download HP ISEE, visit the HP website (http://www.hp.com/servers/smartstart

For installation information, refer to the HP ISEE Client Installation and Upgrade Guide.

ROM-Based Setup Utility

RBSU, an embedded configuration utility, performs a wide range of configuration activities

that may include:

z Configuring system devices and installed options

z Displaying system information

z Selecting the operating system

z Selecting the primary boot controller

z Configuring memory options

z Language selection

For more information on RBSU, refer to the HP ROM-Based Setup Utility User Guide on the

Documentation CD or the HP website (http://www.hp.com/servers/smartstart

NOTE: Enable the SATA SW RAID option under the Advanced Options menu to enable RAID

capability for the server.

).

).

3-2 HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide

ROMPaq Utility

Flash ROM enables you to upgrade the firmware (BIOS) with system or option ROMPaq

utilities. To upgrade the BIOS, insert a ROMPaq diskette into the diskette drive and boot the

system.

The ROMPaq utility checks the system and provides a choice (if more than one exists) of

available ROM revisions. This procedure is the same for both system and option ROMPaq

utilities.

For more information about the ROMPaq utility, refer to the HP website

(http://www.hp.com/servers/manage

).

System Online ROM Flash Component Utility

The Online ROM Flash Component Utility enables system administrators to efficiently

upgrade system or controller ROM images across a wide range of servers and array

controllers. This tool has the following features:

z Works offline and online

Diagnostic Tools

z Supports Microsoft® Windows NT®, Windows® 2000, Windows Server 2003, Novell

Netware, and Linux operating systems

IMPORTANT: This utility supports operating systems that may not be supported by the server. For

operating systems supported by the server, refer to the HP website

(http://www.hp.com/go/supportos

z Integrates with other software maintenance, deployment, and operating system tools

z Automatically checks for hardware, firmware, and operating system dependencies, and

installs only the correct ROM upgrades required by each target server

To download the tool and for more information, refer to the HP website

(http://h18000.www1.hp.com/support/files/index.html).

Integrated Management Log

The IML records hundreds of events and stores them in an easy-to-view form. The IML

timestamps each event with 1-minute granularity.

You can view recorded events in the IML in several ways, including the following:

z From within HP SIM

z From within Survey Utility

).

z From within operating system-specific IML viewers

{ For NetWare: IML Viewer

{ For Windows: IML Viewer

{ For Linux: IML Viewer Application

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide 3-3

Diagnostic Tools

z From within HP Insight Diagnostics

For more information, refer to the Management CD in the HP ProLiant Essentials Foundation

Pack.

Integrated Lights-Out Technology

The iLO subsystem is a standard component of selected ProLiant servers that provides server

health and remote server manageability. The iLO subsystem includes an intelligent

microprocessor, secure memory, and a dedicated network interface. This design makes iLO

independent of the host server and its operating system. The iLO subsystem provides remote

access to any authorized network client, sends alerts, and provides other server management

functions.

Using iLO, you can:

z Remotely power up, power down, or reboot the host server.

z Send alerts from iLO regardless of the state of the host server.

z Access advanced troubleshooting features through the iLO interface.

z Diagnose iLO using HP SIM through a web browser and SNMP alerting.

For more information about iLO features, refer to the HP Integrated Lights-Out User Guide

on the Documentation CD or on the HP website (http://www.hp.com/servers/lights-out

Automatic Server Recovery

ASR is a feature that causes the system to restart when a catastrophic operating system error

occurs, such as a blue screen, ABEND, or panic. A system fail-safe timer, the ASR timer,

starts when the System Management driver, also known as the Health Driver, is loaded.

When the operating system is functioning properly, the system periodically resets the timer.

However, when the operating system fails, the timer expires and restarts the server.

ASR increases server availability by restarting the server within a specified time after a

system hang or shutdown. At the same time, the HP SIM console notifies you by sending a

message to a designated pager number that ASR has restarted the system. You can disable

ASR from the HP SIM console or through RBSU.

HP Systems Insight Manager

HP SIM is a web-based application that allows system administrators to accomplish normal

administrative tasks from any remote location, using a web browser. HP SIM provides device

management capabilities that consolidate and integrate management data from HP and thirdparty devices.

IMPORTANT: You must install and use HP SIM to benefit from the Pre-Failure Warranty for

processors, hard drives, and memory modules

).

3-4 HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide

For additional information, refer to the Management CD in the HP ProLiant Essentials

Foundation Pack.

HP Insight Diagnostics

The HP Insight Diagnostics utility displays information about the server hardware and tests

the system to be sure it is operating properly. The utility has online help and can be accessed

using the SmartStart CD. Online Diagnostics for Microsoft Windows is available for

download from the HP website (http://www.hp.com/support

USB Support

HP provides both standard USB support and legacy USB support. Standard support is

provided by the operating system through the appropriate USB device drivers. HP provides

support for USB devices before the operating system is loaded through legacy USB support,

which is enabled by default in the system ROM. HP hardware supports USB version 1.1 or

2.0, depending on the version of the hardware.

Legacy USB support provides USB functionality in environments where USB support is

normally not available. Specifically, HP provides legacy USB functionality for:

Diagnostic Tools

).

z POST

z RBSU

z Diagnostics

z DOS

z Operating environments which do not provide native USB support

For more information on ProLiant USB support, refer to the HP website

(http://h18004.www1.hp.com/products/servers/platforms/usb-support.html).

Internal USB Functionality

An internal USB connector is available for use with USB devices. The internal connector is

on a dedicated bus and is separate from the front USB port. This solution provides for use of

a permanent boot drive from a USB drive key installed in the front internal connector,

avoiding issues of clearance on the front of the rack and physical access to secure data.

For additional security, you can disable the internal, front or rear USB connectors through

RBSU.

An internal USB connector is available for use with USB drive keys only. The internal

connector shares the same bus with the front external USB connector, and connecting a

device to both the front internal and front external USB connectors is not supported. This

solution provides for use of a permanent boot drive from a USB drive key installed in the

front internal connector, avoiding issues of clearance on the front of the rack and physical

access to secure data.

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide 3-5

Diagnostic Tools

For additional security, you can individually disable the front, rear, and internal USB

connectors through RBSU. Disabling the rear USB connectors in RBSU disables both rear

USB ports.

3-6 HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide

Component Identifications

This chapter contains illustrations and tables identifying and describing components,

connectors, switches, and LED indicator locations on the front panel, rear panel, system

board, and hard drives for the HP ProLiant DL320 Generation 3 server.

4

HP ProLiant DL320 Generation 3 Server Maintenance and Service Guide 4-1

Component Identifications

Rear Panel Components

Figure 4-1 and Table 4-1 show the components and connectors on the rear panel of the server.

Figure 4-1: Rear panel components

Table 4-1: Rear Panel Components

Item Description

1 Rear USB connectors 1 & 2

2 Video connector

3 Mouse connector