Page 1

Service Manual

HP OmniBook 300, 425, 430, 530

Page 2

Notice

In a continuing effort to improve the quality of our products,

technical and environmental information in this document is

subject to change without notice.

Hewlett-Packard makes no warranty of any kind with regard to

this material, including, but not limited to, the implied warranties

of merchantability and fitness for a particular purpose. HewlettPackard shall not be liable for errors contained herein or for

incidental or consequential damages in connection with the

furnishing, performance, or use of this material.

Hewlett-Packard assumes no responsibility for the use or

reliability of its software on equipment that is not furnished by

Hewlett-Packard.

As an ENERGY STAR partner, HP has determined that these

products meet the ENERGY STAR guidelines for energy

efficiency.

All Certifications may not be completed at product introduction.

Please check with your HP reseller for certification status.

This equipment is subject to FCC rules. It will comply with the

appropriate FCC rules before final delivery to the buyer.

ENERGY STAR is a service mark of the U.S. Environmental

Protection Agency. IBM and OS/2 are registered trademarks of

International Business Machines Corporation. Pentium and the

Intel Inside logo are registered trademarks of Intel Corporation.

LapLink Remote Access is a trademark of Traveling Software,

Inc. Microsoft, MS-DOS, and Windows are registered

trademarks, and the Genuine Microsoft Products logo is a

trademark of Microsoft Corporation in the United States of

America and in other countries.

Hewlett-Packard Company 1996.

All Rights Reserved. Reproduction, adaptation, or translation

without prior written permission is prohibited except as allowed

under copyright laws.

Printed in U.S.A.

5965-0244

Page 3

Table of Contents

Table of Figures......................................................................................................................... iv

Introduction .................................................................................................................................v

Product Overview........................................................................................................................ 1

Product Features ..................................................................................................................... 2

OmniBook 300, 425, and 430...............................................................................................2

OmniBook 530 .....................................................................................................................3

Product Comparisons...............................................................................................................4

Product at a Glance.................................................................................................................6

Troubleshooting...........................................................................................................................9

OmniBook Self-Test...............................................................................................................10

Loop Back Connectors........................................................................................................10

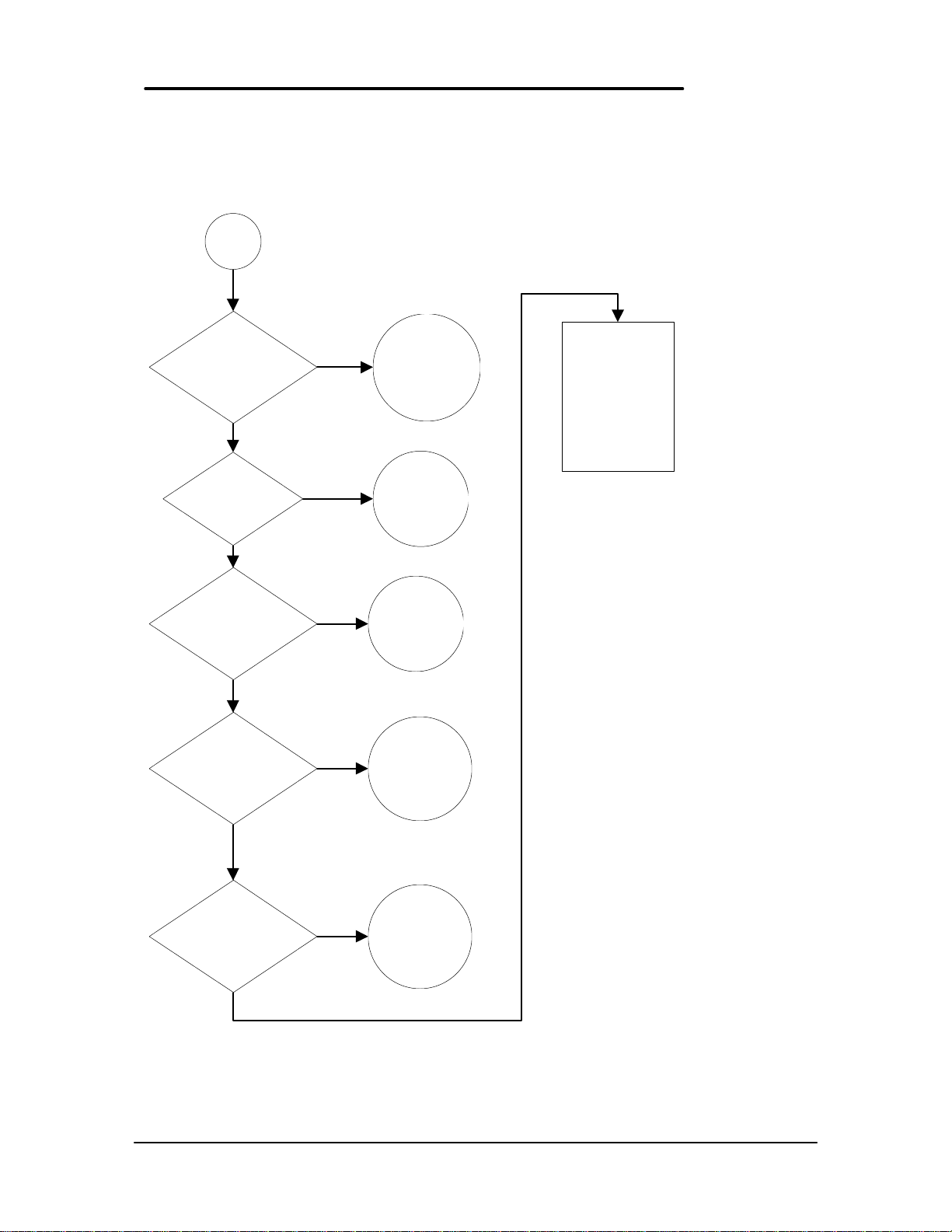

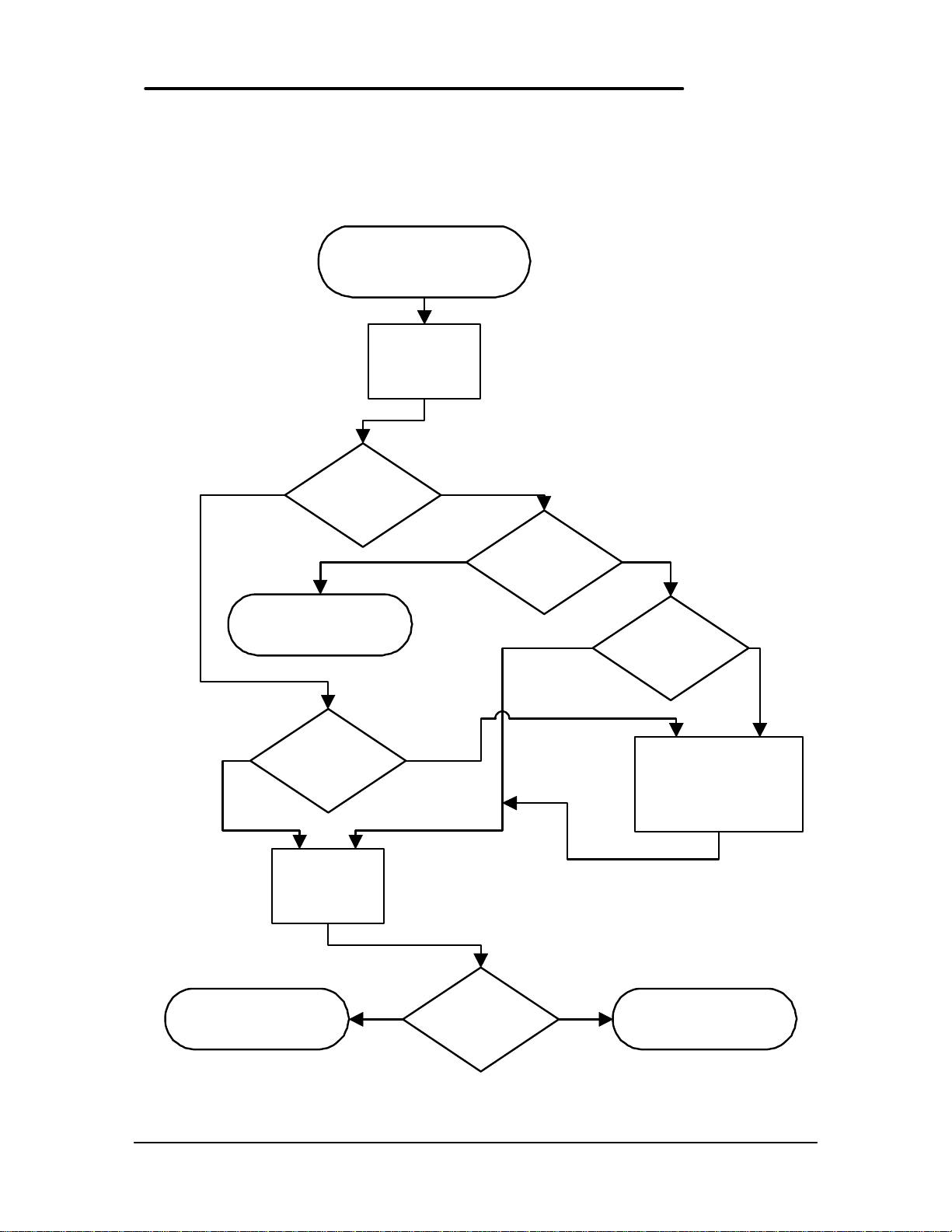

Troubleshooting Flowchart.....................................................................................................12

Main Troubleshooting Flowchart.........................................................................................13

Power Source Problems.....................................................................................................15

Boot-Up Problems..............................................................................................................18

Display Problems ...............................................................................................................19

Hard Disk Problems............................................................................................................ 20

Memory Problems..............................................................................................................23

Power Management Problems ............................................................................................25

Pop-Out Mouse Problems...................................................................................................28

Floppy Drive Problems.......................................................................................................32

Parallel Port Problems........................................................................................................35

Serial Port Problems ..........................................................................................................37

PCMCIA Problems ............................................................................................................. 39

IR Port Problems................................................................................................................43

Hardware Repair .......................................................................................................................45

Battery (End User Replaceable).............................................................................................46

Memory (End User Replaceable) ........................................................................................... 48

Hard Disk Drive/Flash Card and System ROM (End User Replaceable) .................................50

Mouse (End User Replaceable).............................................................................................. 52

Small Parts (End User Replaceable)......................................................................................53

Battery Door.......................................................................................................................53

Battery Door Latch..............................................................................................................53

Blank Modem Door.............................................................................................................53

Memory Door .....................................................................................................................53

I/O Door .............................................................................................................................53

Rubber Feet ....................................................................................................................... 53

PCMCIA Card Tray.............................................................................................................53

Display (HP Authorized Service Providers Only)....................................................................54

Keyboard (HP Authorized Service Providers Only) ................................................................62

Logic PCA Board (HP Authorized Service Providers Only).....................................................63

Paw Carrier (Paw Active) (HP Authorized Service Providers Only)........................................65

Other Components (HP Authorized Service Providers Only)..................................................66

Appendix A - Technical and Resource Specifications ................................................................ 67

Mass Storage Specifications..................................................................................................67

Card Services and Socket Services Version Matrix................................................................67

Memory Map.......................................................................................................................... 68

Upper Memory Block Space...................................................................................................68

DOS Conventional Memory ................................................................................................... 68

Appendix B - Power On Self Test Codes...................................................................................69

Beep Codes...........................................................................................................................69

Display Codes........................................................................................................................70

Appendix C - Password Policy...................................................................................................75

ii

Page 4

Appendix D - Part Numbers .......................................................................................................77

iii

Page 5

Table of Figures

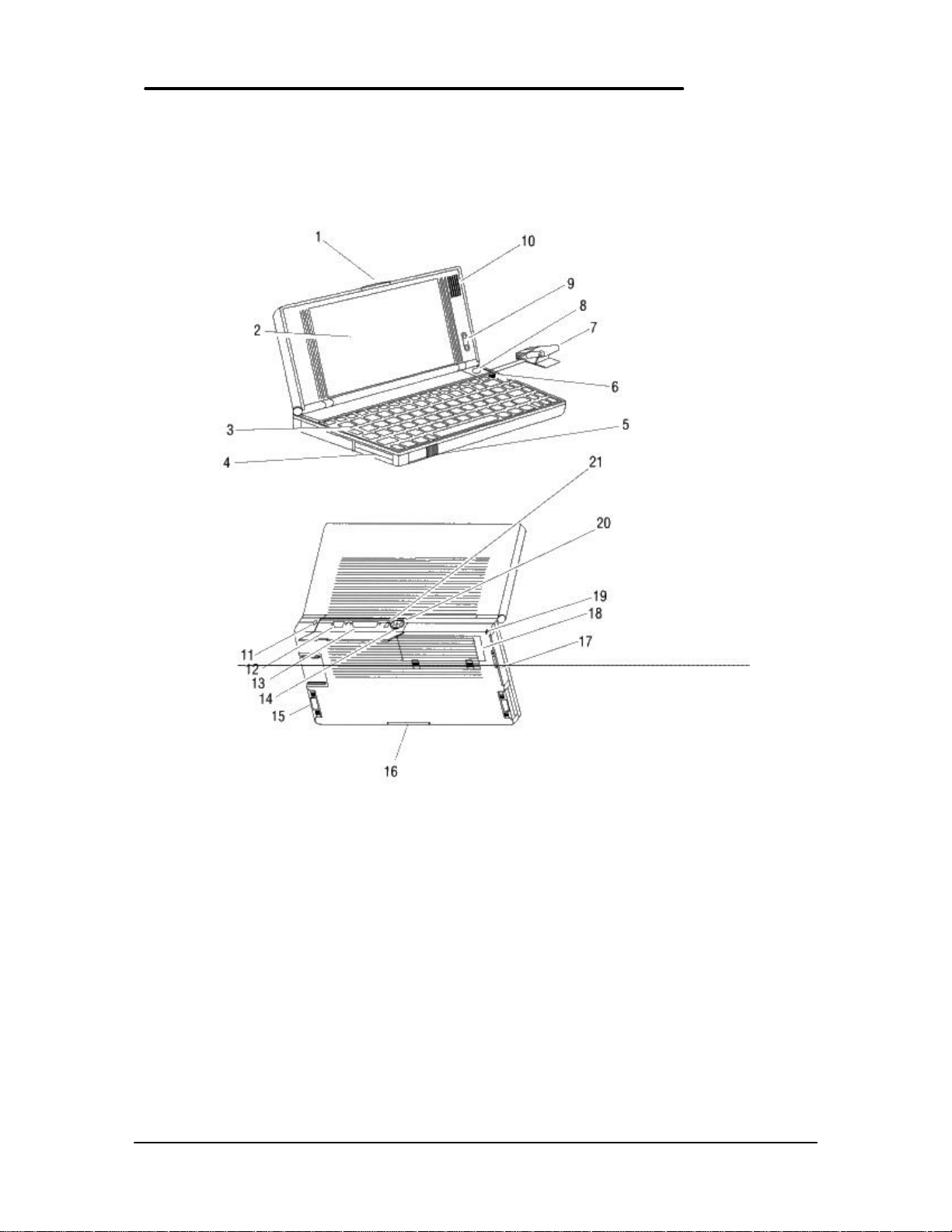

Figure 1 - OmniBook 300, 425, and 430 Features .......................................................................2

Figure 2 - OmniBook 530 Features.............................................................................................. 3

Figure 3 - Serial Loop Back Connector......................................................................................11

Figure 4 - Parallel Loop Back Connector ...................................................................................11

Figure 5 - OmniBook Memory Modules .....................................................................................48

Figure 6 - Removing the Memory Module..................................................................................49

Figure 7 - Removing Card Slot Tray..........................................................................................51

Figure 8 - Removing the Mouse ................................................................................................52

Figure 9 - Outer Bottom Case Components...............................................................................54

Figure 10 - Backplane Standoffs................................................................................................55

Figure 11 - Bottom Case Tabs ...................................................................................................55

Figure 12 - Bottom Case Prying Locations.................................................................................56

Figure 13 - I/O Port Prying Location ..........................................................................................56

Figure 14 - Disconnecting Display Cable ................................................................................... 57

Figure 15 - Keyboard Flex Cables ............................................................................................. 58

Figure 16 - Display Grounding Eyelets.......................................................................................58

Figure 17 - Display Cable Probe Position ..................................................................................60

Figure 18 - Reconnecting Display Cable....................................................................................60

Figure 19 - I/O Port Eyelets (all present).................................................................................... 61

Figure 20 - I/O Port Eyelets (two matched sets).........................................................................61

Figure 21 - I/O Port Eyelets (only one matched set)...................................................................61

Figure 22 - I/O Port Eyelets (no eyelet in position one)..............................................................61

Figure 23 - Logic Board PCA Removal......................................................................................63

Figure 24 - Paw Carrier Removal .............................................................................................. 65

iv

Page 6

Introduction

This document provides reference information for the HP OmniBook 300, HP OmniBook 425,

HP OmniBook 430, and HP OmniBook 530. It is intended to be used by HP-qualified service

personnel to help with the installation, servicing, and repair of these HP OmniBook PCs.

It is a self-paced guide designed to train you to install, configure, and repair the OmniBook

Notebook PC. You can follow it without having any equipment available.

The following table lists additional sources where supplementary information can be obtained:

Resource Number/Address Comments

HP External Web http://hpcc998.external.hp.com/mcd/ No usage restriction

HP-MCD Internal Web http://webmcd.cv.hp.com Restricted to HP internet

access only

HP MCD Service

Engineer

svc-eng_mcd@om.cv.hp.com Email address for service

related questions and

issues

v

Page 7

Part 1

Product Overview

• Product Features

• Product Comparisons

• Product at a Glance

Page 8

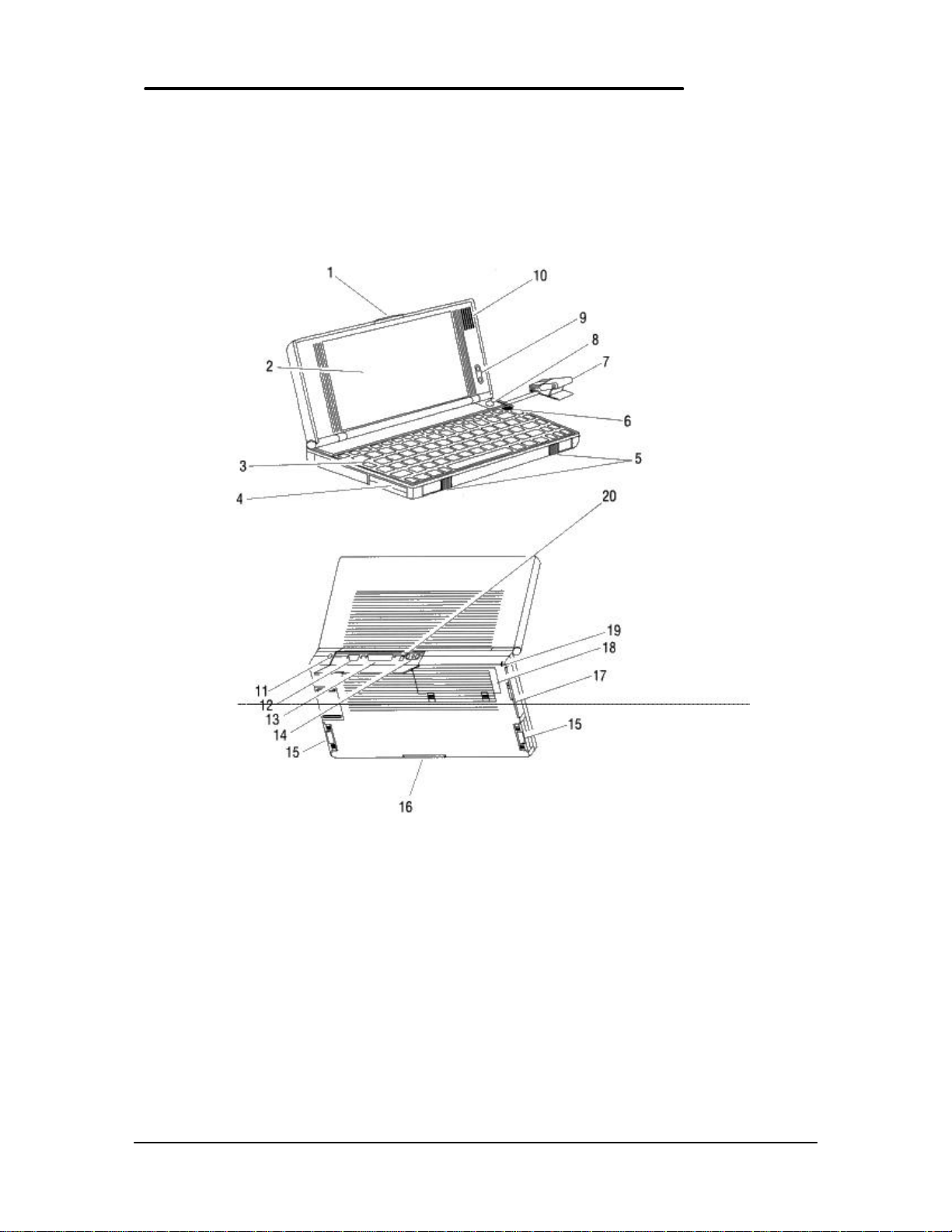

Product Features

OmniBook 300, 425, and 430

Figure 1 - OmniBook 300, 425, and 430 Features

1. Latch 11. AC adapter socket

2. Display 12. Serial port connector

3. Keyboard 13. Parallel port connector

4. Card slot A 14. Infrared port

5. Card-eject levers 15. System slots (C and D)

6. On/Off key 16. Memory-expansion slot

7. Mouse 17. Modem port

8. Mouse-eject button 18. Battery compartment

9. Display contrast buttons 19. Security ring

10. Speaker 20. Reset button

2

Page 9

OmniBook 530

Figure 2 - OmniBook 530 Features

1. Latch 12. Serial port connector

2. Display 13. Parallel port connector

3. Keyboard 14. VGA output connector

4. Card slots 15. System slots

5. Card-eject levers 16. Memory-expansion slot

6. On/Off key 17. Modem port

7. Mouse 18. Battery compartment

8. Mouse-eject button 19. Security ring

9. Display contrast buttons 20. Infrared port

10. Speaker 21. Reset button

11. AC adapter socket

3

Page 10

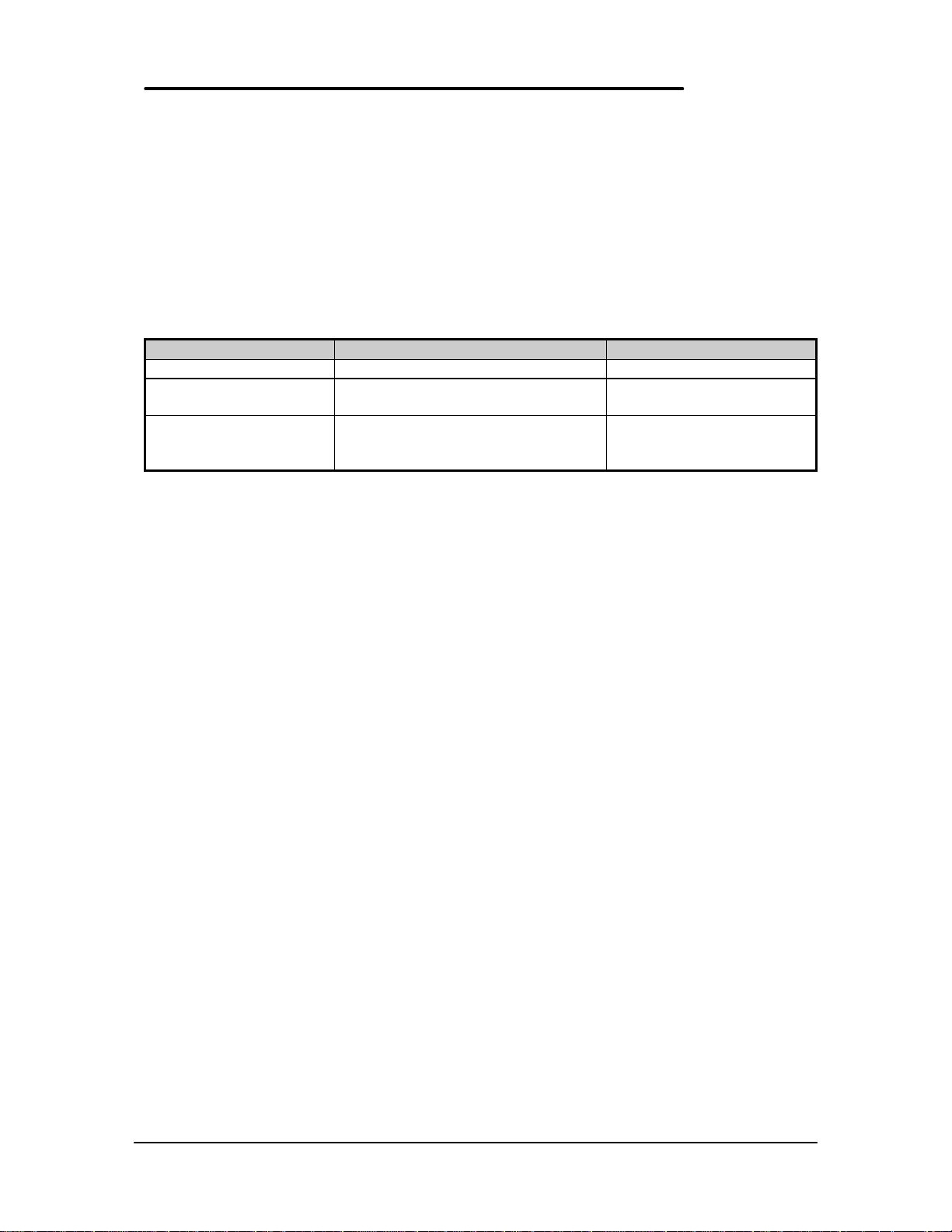

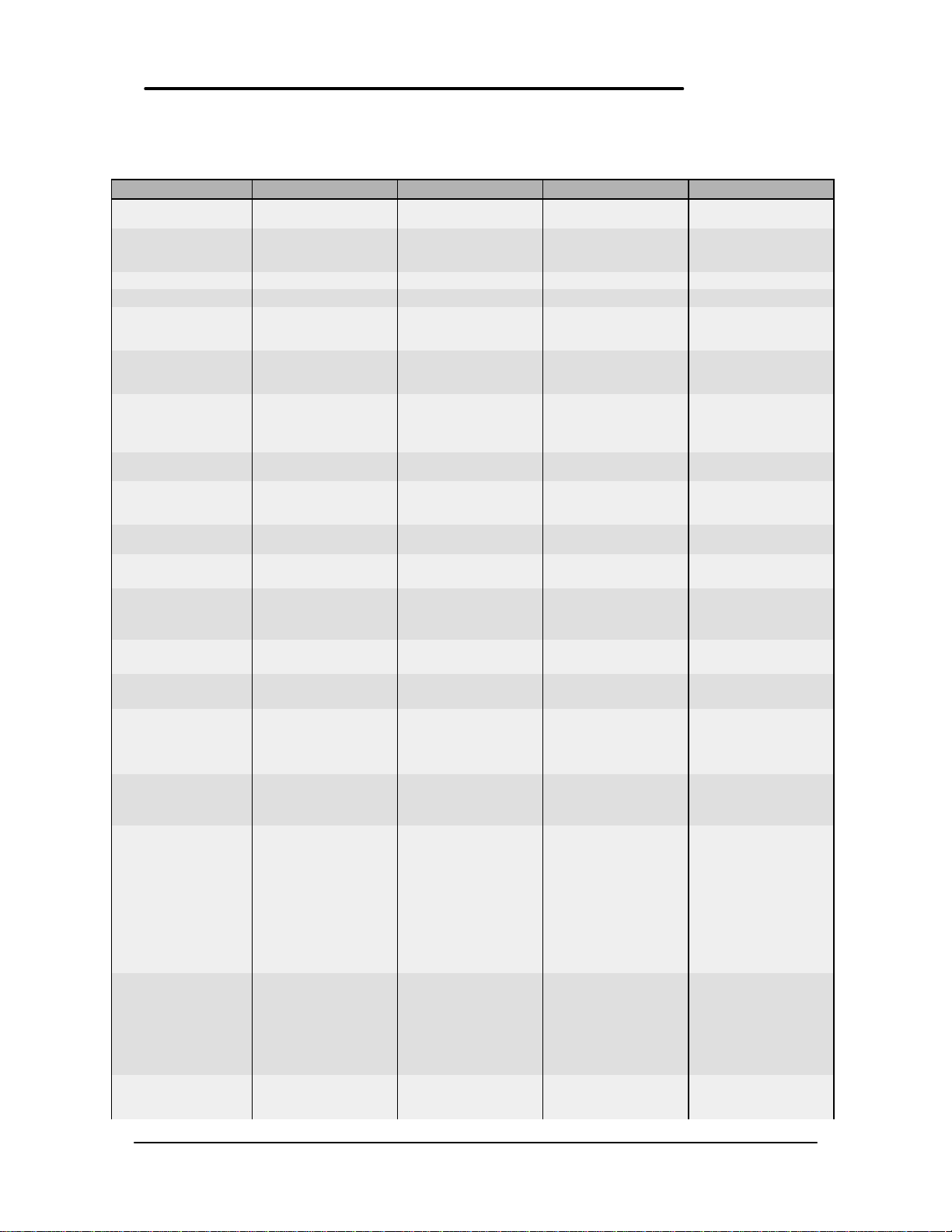

Product Comparisons

OmniBook 300 OmniBook 425 OmniBook 430 OmniBook 530

Size Closed

Weight

Processor

Clock Speed

Display

VGA-out Support

Battery

Battery Life

AC Adapter

Recharge Time

Operating

Temperature

Storage

Temperature (with

data retention)

Operating and

Storage Humidity

Mass Storage

Available

Memory

Memory

Expansion

Available

Input/Output

Keyboard and

Mouse

Expandability

16.3 x 28.2 x 3.6 cm

(6.4 x 11.1 x 1.4 in)

1.31 kg (2.888 lb)

w/flash

1.36 kg (2.998) w/hdd

386SXLV 486SLC/e 486SLC/e Intel© 486SX

20 MHz 25 MHz 25 MHz 33 MHz

640 x 480 VGA

9-inch diagonal LCD

16 shades of gray

none none none 640 x 480, 16 or 256

4.8 Vdc nickel-metalhydride rechargeable

1.5 V alkaline AA (flash

version only)

5 hours w/hdd

9 hours w/flash

100 to 240 Vac (50 to

60 Hz) input

12 Vdc output

less than 1.5 hours

w/ac adapter

0 to 40 C (32 to 104 F) 0 to 40 C (32 to 104 F) 0 to 40 C (32 to 104 F) 0 to 40 C (32 to 104 F)

0 to 55 C (32 to 131 F) 0 to 55 C (32 to 131 F) 0 to 55 C (32 to 131 F) 0 to 55 C (32 to 131 F)

90% relative humidity at

40 C (104 F) maximum

40-MB hard disk

10-MB flash disk

2 MB RAM 2 MB RAM 2 MB RAM on 40-

2-MB, 4-MB 2-MB, 4-MB 2-MB, 4-MB 4-MB, 8-MB

9-pin, 115K baud,

RS-232 port

25-pin parallel port

115K baud,

bidirectional infrared

port

Communication port

for optional

fax/modem

85 keys

Industry-standard, fullsized key spacing

Embedded numeric

keypad

9 Fn keys

Built-in pop-up mouse

PCMCIA, Type II,

Version 2.0 card slots

Two slots available with

16.3 x 28.2 x 3.6 cm

(6.4 x 11.1 x 1.4 in)

1.31 kg (2.888 lb)

w/flash

1.36 kg (2.998) w/hdd

640 x 480 VGA

9-inch diagonal LCD

16 shades of gray

4.8 Vdc nickel-metalhydride rechargeable

1.5 V alkaline AA (flash

version only)

4.5 hours w/hdd

8 hours w/flash

100 to 240 Vac (50 to

60 Hz) input

12 Vdc output

less than 1.5 hours

w/ac adapter

90% relative humidity at

40 C (104 F) maximum

40-MB hard disk

10-MB flash disk

9-pin, 115K baud,

RS-232 port

25-pin parallel port

115K baud,

bidirectional infrared

port

Communication port

for optional

fax/modem

85 keys

Industry-standard, fullsized key spacing

Embedded numeric

keypad

12 Fn keys

Built-in pop-up mouse

PCMCIA, Type II,

Version 2.0 card slots

Two slots available with

16.3 x 28.2 x 3.6 cm

(6.4 x 11.1 x 1.4 in)

1.36 kg (2.998 lb) 1.36 kg (2.998 lb)

640 x 480 VGA

9-inch diagonal LCD

4.8 Vdc nickel-metalhydride rechargeable

1.5 V lithium AA

4.5 hours 4 hours

100 to 240 Vac (50 to

60 Hz) input

12 Vdc output

less than 1.5 hours

w/ac adapter

90% relative humidity at

40 C (104 F) maximum

105-MB hard disk

16.3 x 28.2 x 3.6 cm

(6.4 x 11.1 x 1.4 in)

640 x 480 VGA

9-inch diagonal LCD

colors

800 x 600, 16 colors

4.8 Vdc nickel-metalhydride rechargeable

100 to 240 Vac (50 to

60 Hz) input

12 Vdc output

less than 1.5 hours

w/ac adapter

90% relative humidity at

40 C (104 F) maximum

130-MB hard disk

40-MB hard disk

4 MB RAM

MB version

4 MB RAM on 105MB version

9-pin, 115K baud,

RS-232 port

25-pin parallel port

115K baud,

bidirectional infrared

port

Communication port

for optional

fax/modem

85 keys

Industry-standard, fullsized key spacing

Embedded numeric

keypad

12 Fn keys

Built-in pop-up mouse

PCMCIA, Type II,

Version 2.0 card slots

One slot available with

9-pin, 115K baud,

RS-232 port

25-pin parallel port

115K baud,

bidirectional infrared

port

Communication port

for optional

fax/modem

85 keys

Industry-standard, full-

sized key spacing

Embedded numeric

keypad

12 Fn keys

Built-in pop-up mouse

Two PCMCIA Type II

slots (one Type III slot)

Optional floppy disk

4

Page 11

OmniBook 300 OmniBook 425 OmniBook 430 OmniBook 530

the flash disk version

One slot available with

the hard disk version

Pre-installed

Software

MS© Windows 3.1*

MS DOS© 5.0*

MS Word 2.0*

MS Excel 4.0*

LapLink Remote

™

Access

Phone Book

Appointment Book

HP Financial Calculator

*(Note: All components not included can be installed from a retail copy. License for full Microsoft Word, Microsoft Excel, MSDOS, and Microsoft Windows is included with purchase.)

the flash disk version

One slot available with

the hard disk version

MS© Windows 3.1*

MS DOS© 5.0*

MS Word 2.0*

MS Excel 4.0*

LapLink Remote

™

Access

Phone Book

Appointment Book

HP Financial Calculator

the hard disk version drive

MS© Windows 3.1

MS DOS© 6.2

LapLink Remote

™

Access

Phone Book

Appointment Book

HP Financial Calculator

MS© Windows 3.11

MS DOS© 6.2

LapLink Remote

Access

Phone Book

Appointment Book

HP Financial Calculator

™

5

Page 12

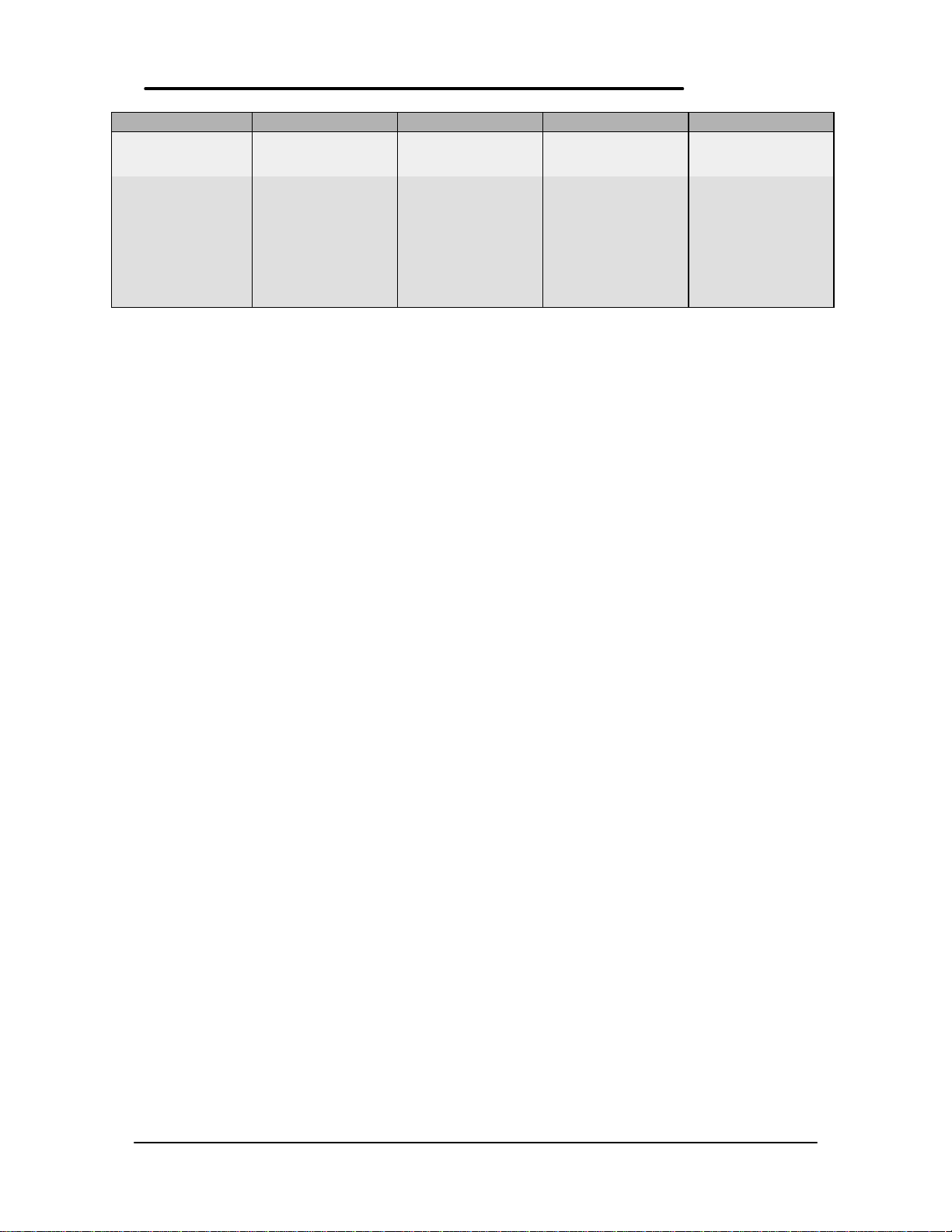

Product at a Glance

29

35

33

10

6

2

2

18

2

2

14

28

14

27

17

32

11

5

13

2

2

2

13

16

16

1

1

9

1

1

13

15

7

24

12

30

20

21

22

2

2

2

6

19

8

25

5

13

10

2

2

26

23

4

31

34

3

6

Page 13

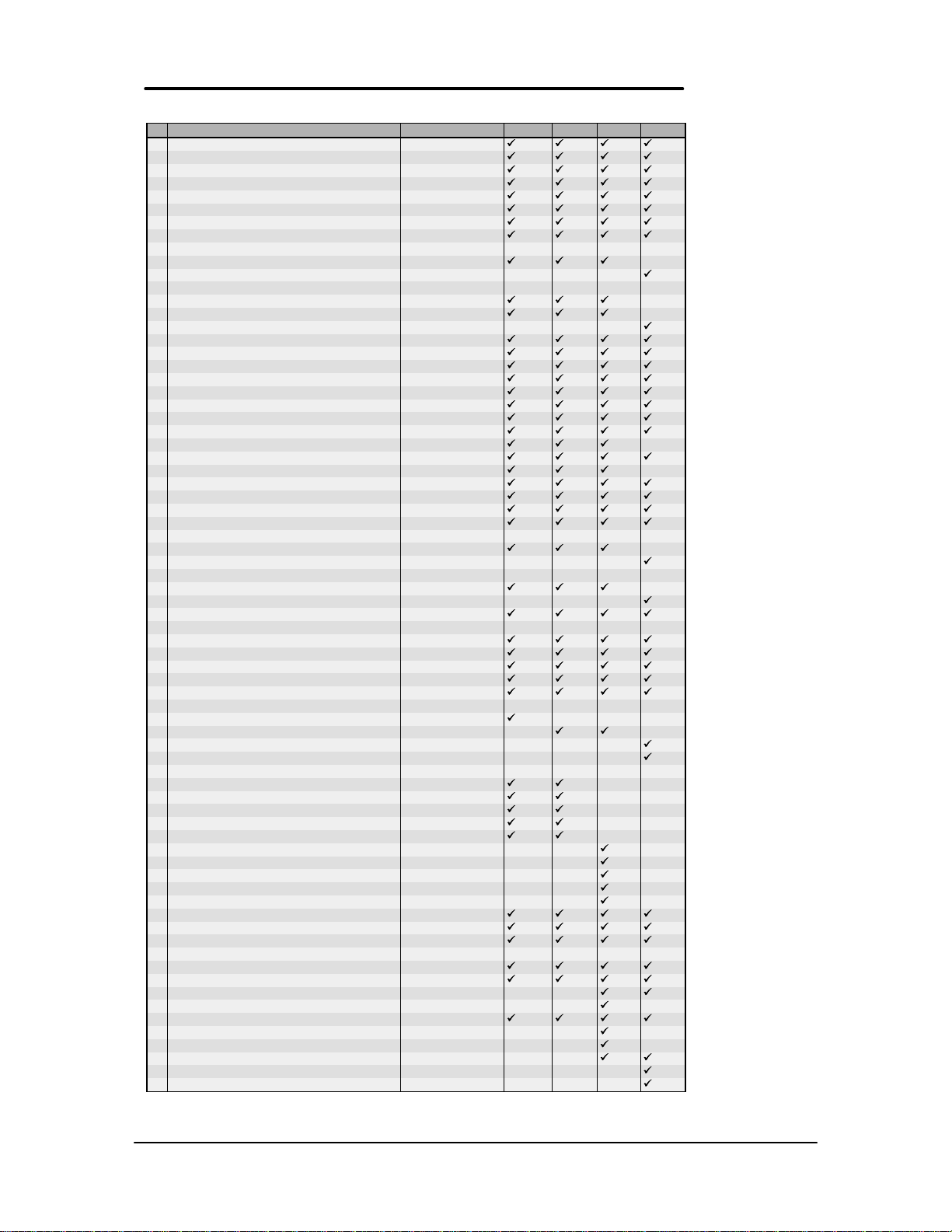

Description Part Number OB300 OB425 OB430 OB530

1 Standoff 0380-4060

2 Screw M2x4.6mm (T6) 0515-2396

3 Mouse 5061-4390

4 Arm Eject Mouse Spring F1030-00016

5 Pivot Door Spring F1030-00026

6 Spring Card Eject F1030-00029

7 Mouse Latch Spring F1030-00030

8 Mylar Mouse Shield F1030-20001

9 Door Battery

Door Battery (10 pack) F1030-60912

Door Battery (silver) F1052-40012

10 Pivot Door

Pivot Door (PCMCIA) A F1030-40013

Pivot Door (PCMCIA) B F1030-40014

Pivot Door (PCMCIA) Left F1052-40007

11 Door Modem Blank F1030-40016

12 Door RAM F1030-40017

13 Rubber Foot F1030-40018

14 Hinge Cap F1030-40019

15 Mouse Button Latch F1030-40021

16 Battery Door Latch F1030-40025

17 Security Latch F1030-40033

18 Eject Button A F1030-40044

19 Eject Button B F1030-40045

20 Eject Arm Left F1030-40046

21 Eject Arm Right F1030-40047

22 Paw Carrier Srvc Assy F1030-60901

23 Arm Eject Mouse F1030-40050

24 Door I/O F1030-60908

25 Pivot Bracket F1030-60909

26 Bottom Case

Bottom Case F1030-60910

Bottom Case (silver) F1052-60908

27 Top Case

Top Case F1030-60911

Top Case (silver) F1052-60907

28 LCD Display Assy (new) F1030-60904

29 Keyboard

Keyboard USA F1030-80013

Keyboard German F1030-80031

Keyboard Spanish F1030-80032

Keyboard French F1030-80033

Keyboard International English F1030-80057

30 Logic PCA

Logic PCA (new) F1030-60907

Logic PCA (new) F1033-60907

Logic PCA (new) F1052-60906

Logic PCA (exchange) F1052-69008

31 System ROM

System ROM (ABA) - US English F1033-60908

System ROM (ABB) Int. English F1033-60909

System ROM (ABD) German F1033-60910

System ROM (ABF) French F1033-60911

System ROM (ABE Spanish) F1033-60912

System ROM (ABA) US English F1037-60903

System ROM (ABB) Int. English F1037-60904

System ROM (ABD) German F1037-60905

System ROM (ABE) Spanish F1037-60906

System ROM (ABF) French F1037-60907

32 Battery Pack F1045-60901

33 Hard Drive Tray F1065-60029

34 Flash Tray F1030-60923

35 Mass Storage

5 MB Flash Disk Card F1012-60902

10 MB Flash Disk Card F1013-60901

20 MB Flash Disk Card F1014-60901

40 MB Hard Drive (DOS/Win/PIM) F1035-60901

40 MB Hard Drive (unprogrammed) F1050-60901

105 MB Hard Drive (DOS/Win/PIM) F1037-60908

105 MB Hard Drive (Word/Excel) F1037-60909

105 MB Hard Drive (unprogrammed) F1039-60901

130 MB Hard Drive (unprogrammed) F1057-60901

130 MB Hard Drive (programmed) F1052-60909

Note, this is a partial parts list. For a complete parts list, please refer to Appendix D or the current Product

Support Plan.

7

Page 14

Page 15

Part 2

Troubleshooting

• OmniBook Self Test

• Troubleshooting Flowchart

Page 16

OmniBook Self-Test

The OmniBook Self-Test provides on-board hardware and firmware diagnostics. To operate the

self-test, perform the following steps:

1. Save all files and close all applications: The OmniBook is reset at the end of the self-test.

2. Turn the OmniBook OFF.

3. Press and hold the [Esc] key and press [ON]. You will hear a short three-tone beep.

4. Self Test will initialize and start.

5. To run a test:

Highlight the test name and press [ENTER].

Highlight the test name and press [Ctrl][ENTER] to run a longer

and more extensive version of a test--not available for all tests.

The test runs and its results are reported.

6. To run several tests in a continuous loop:

Highlight one or more using [ space bar ] and press [ENTER].

Each test runs and its results are reported.

Press [Backspace] to stop the loop.

7. To exit the self-test, press [Esc].

Interpretation of test results

A result of “OK” on any test indicates that the test did not find problems while the unit was

operating in its current state. A “BAD” result indicates that the test found a problem while the

unit was operating in its current state. A “BAD” result should always be confirmed by running the

test in a loop for several iterations or running the long version of the test. Further inspection of

the unit to rule out configuration or installation conflicts is necessary prior to diagnosing the unit

as needing repair.

Any test that is halted by [Backspace] is shown as “aborted” and no results are displayed.

The OmniBook will not enter sleep mode while the self-test is executing.

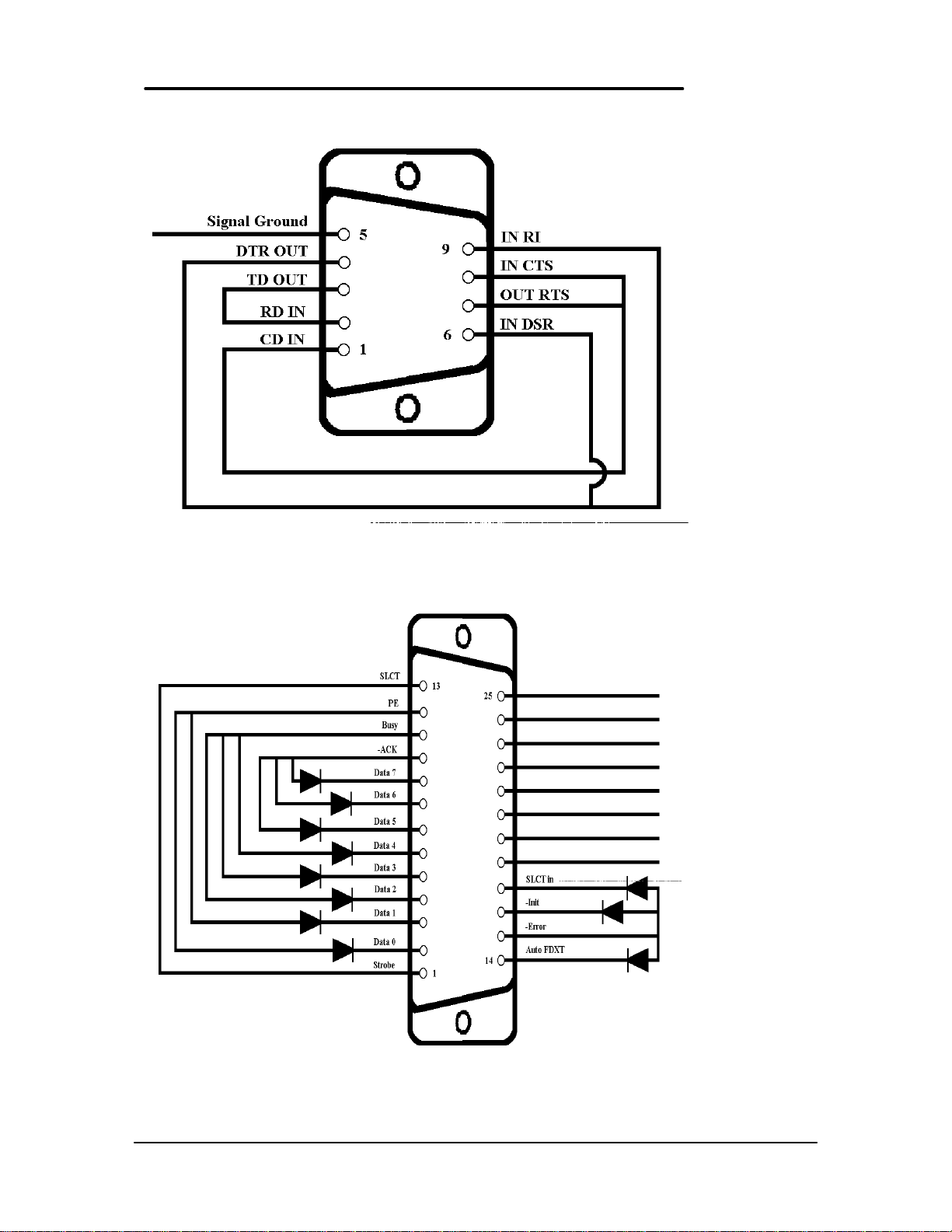

Loop Back Connectors

In order to run the RS232 serial port or parallel port self-test, a loop back connector is needed.

The loop back may be placed on either the OmniBook port or at the end of the corresponding

cable. This feature is also helpful in diagnosing a defective serial or parallel cable.

Loop back connectors may be purchased or can easily be constructed. The following illustrations

identify the correct pin-out configurations for the serial and parallel loop back connectors.

10

Page 17

Figure 3 - Serial Loop Back Connector

Figure 4 - Parallel Loop Back Connector

11

Page 18

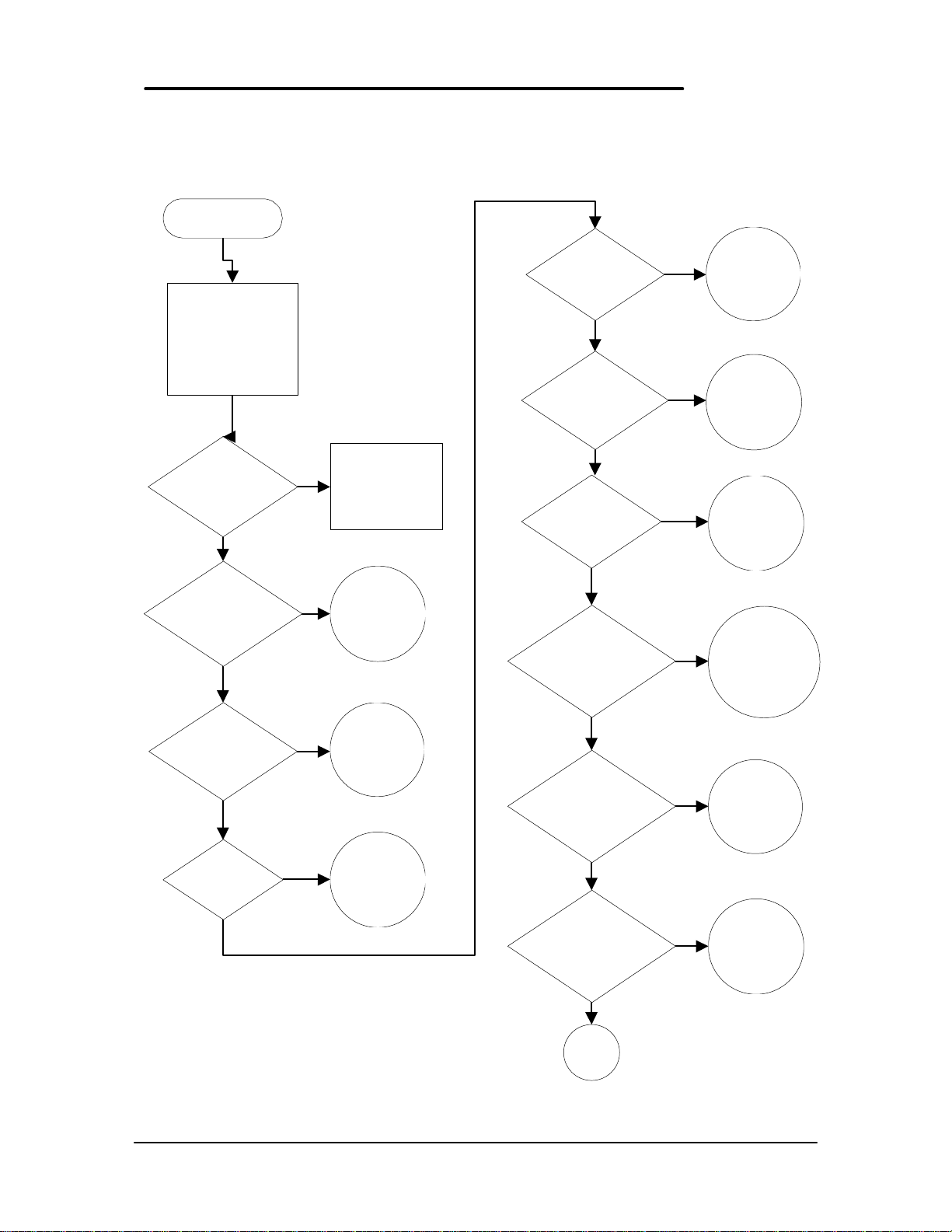

Troubleshooting Flowchart

The following series of flowcharts is intended as a guide for troubleshooting the OmniBook 300,

425, 430, and 530. Each technician should still rely on personal experience and supplemental

knowledge when diagnosing a problem.

These tips should be kept in mind when referencing the troubleshooting flowcharts:

• Use the Main Troubleshooting Flowchart to isolate the problem to a particular area.

• Use the additional individual troubleshooting flowcharts to narrow down the problem to a

specific component or item.

• Always use supplemental information resources, including the Product Support Plan, Service

Notes, and the World Wide Web, to aid in diagnosing problem areas.

12

Page 19

Main Troubleshooting Flowchart

START

Get user

information:

Name

Telephone number

Unit serial number

Repair history

Yes

Eliminate all

obvious physical

problems?

Yes

OB unit's power

light comes on?

Yes

No

Isolate damage.

No

Refer to repair

process

See Power

Source

flowchart

See DOS or

Windows?

Yes

Memory OK? (No

memory errors)

Yes

Hard disk

operates OK?

Yes

Unit has at least 1-

1/2 hours battery

life?

No

No

No

No

See Hard

Disk

flowchart

See

Memory

flowchart

See Hard

Disk

flowchart

See Power

Management

flowchart

Single beep

during boot-up?

Yes

See

something in

display?

No

No

See Boot-

up

flowchart

See Display

flowchart

Yes

Pop-out mouse

works correctly?

Yes

External floppy

drive operates

correctly?

Yes

A

No

No

See Mouse

flowchart

See Floppy

Drive

flowchart

13

Page 20

Main Troubleshooting Flowchart (continued)

A

Parallel port

operates correctly?

Yes

Serial port

operates

correctly?

Yes

External VGA

operates correctly?

Yes

PCMCIA cards

operate correctly?

No

No

No

No

See Parallel

Port flowchart

See Serial

Port

flowchart

See Serial

Port

flowchart

See PCMCIA

flowchart

If you still have

a problem, it's

in software or in

a part of the

unit not covered

by these

flowcharts.

Infrared port

operates correctly?

14

No

See IR

flowchart

Yes

Page 21

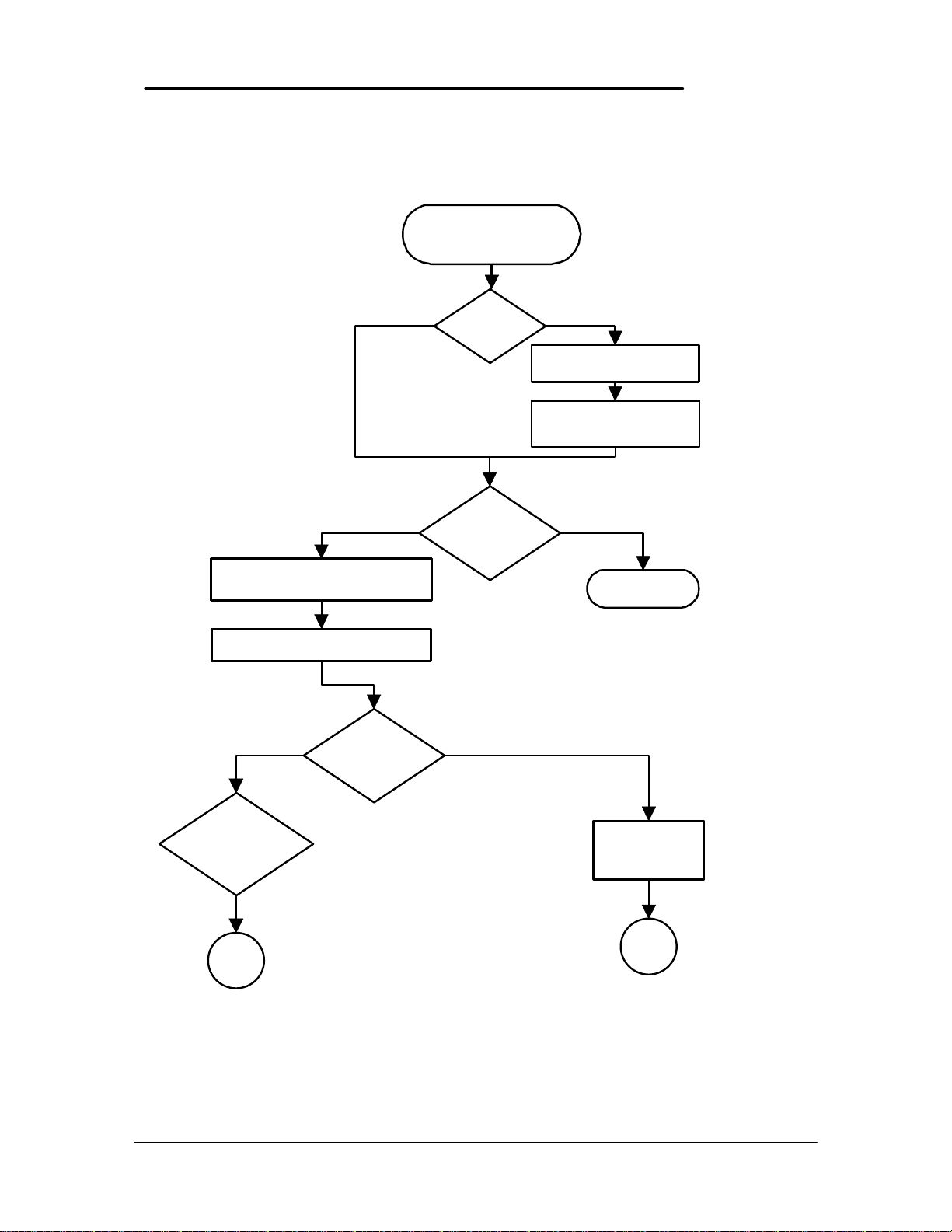

Power Source Problems

continuously (not

No power

Start:

lamp, or low battery

life

Yes

Connect OB to ac adapter, plug

adapter into wall socket

Turn on Omnibook

Yes

See power

light?

Battery in

Omnibook?

HP ac adapter

and cable?

No

NoYes

Turn Omnibook off

Remove and reinsert

battery

No

Done

Light on

intermittent)?

A

Try different

power socket

B

15

Page 22

Power Source Problems (continued)

continuously (not

Recheck cables,

ac adapter, cable, or

temperature within

A B

Yes

Yes

specification?

Go to Power

Management

Problems

flowchart

Light on

intermittent)?

Ambient

Bring

Done:

temperature within

specifications

No

No

Yes

connections:

ac adapter to

Light still

intermittent?

Suspect bad

Done:

connector

No

Done

Yes

Try different

power socket

See power

light?

Power

Done:

source problem

Ensure power

coming from

wall socket

Ensure battery

installed

correctly

No

C

16

Page 23

Power Source Problems (continued)

substitute known

C

Yes

Done: Original ac

adapter or cable

See steady

power light?

bad

Yes

Yes

Can you

substitute known

good ac adapter?

No

See steady

power light?

Yes

No

No

Can you

good OB?

Yes

No

Ac adapter

warm?

No

Done: Suspect

original OB base

unit bad

Done: Suspect bad

ac adapter or cable

17

Page 24

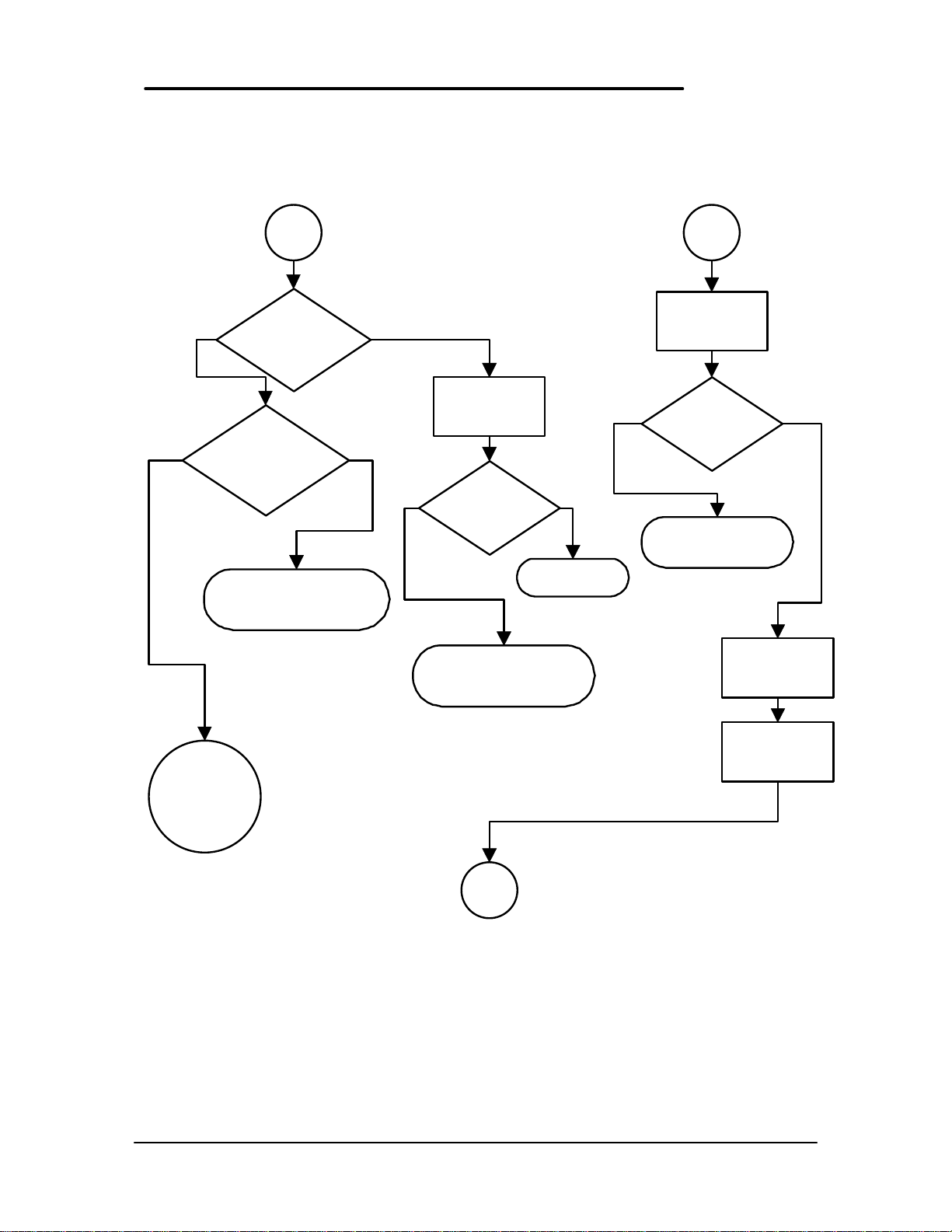

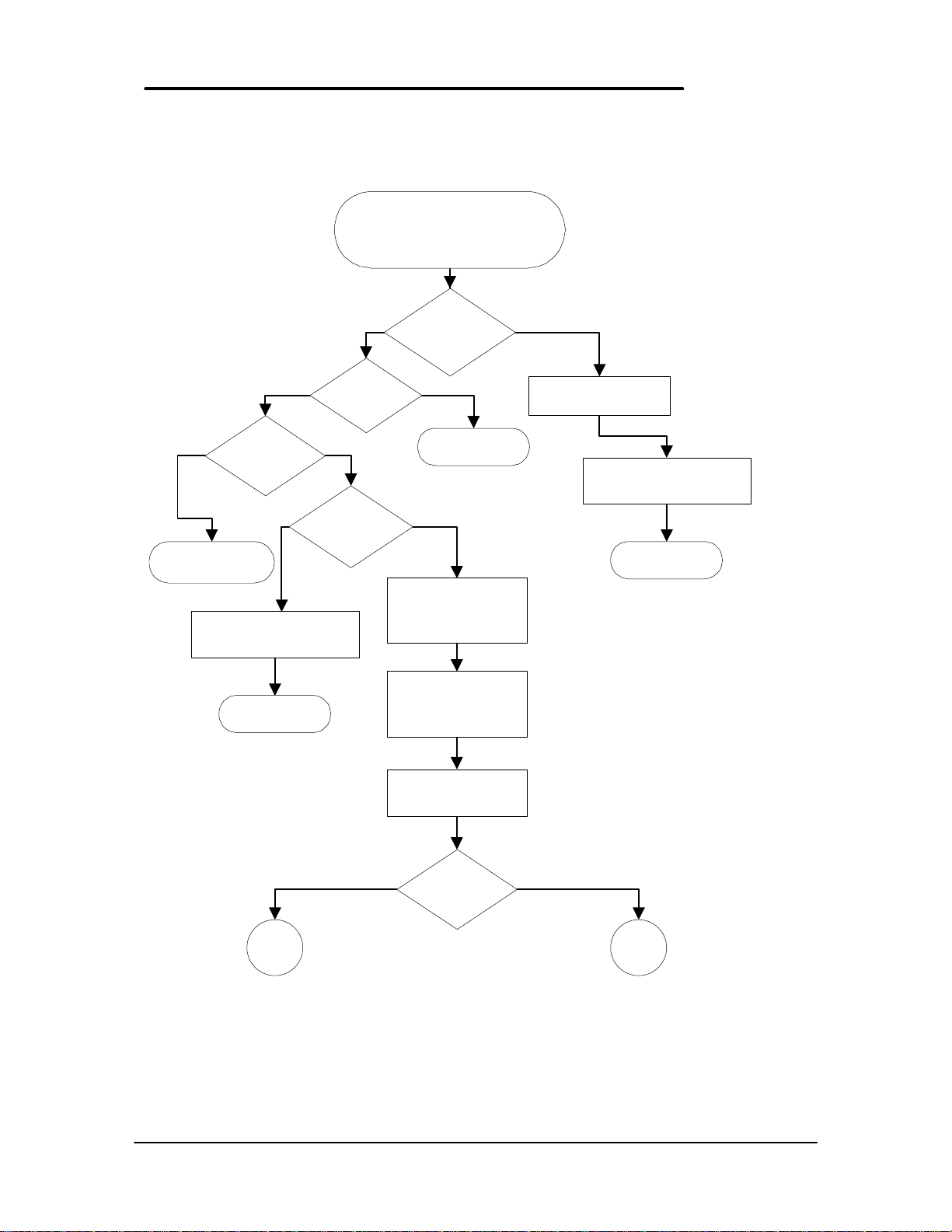

Boot-Up Problems

Windows or DOS

Multiple beeps Single beeps

: Problems during

Start

bootup

Press Ctrl Alt

Del to get a

clean boot

Hear

single or multiple

beeps during

boot?

Yes No

See

prompt in

display?

Yes

Done

Done

OB

support utility

disk available?

Insert OB

support utility

disk and reboot

Yes

No

See prompt to

enter time and

date?

No

Yes

OB

support utility

disk available?

Suspect software

problem: locate OB

support utility disk and

call back

Suspect bad

Done:

Omnibook base unit

No

18

Page 25

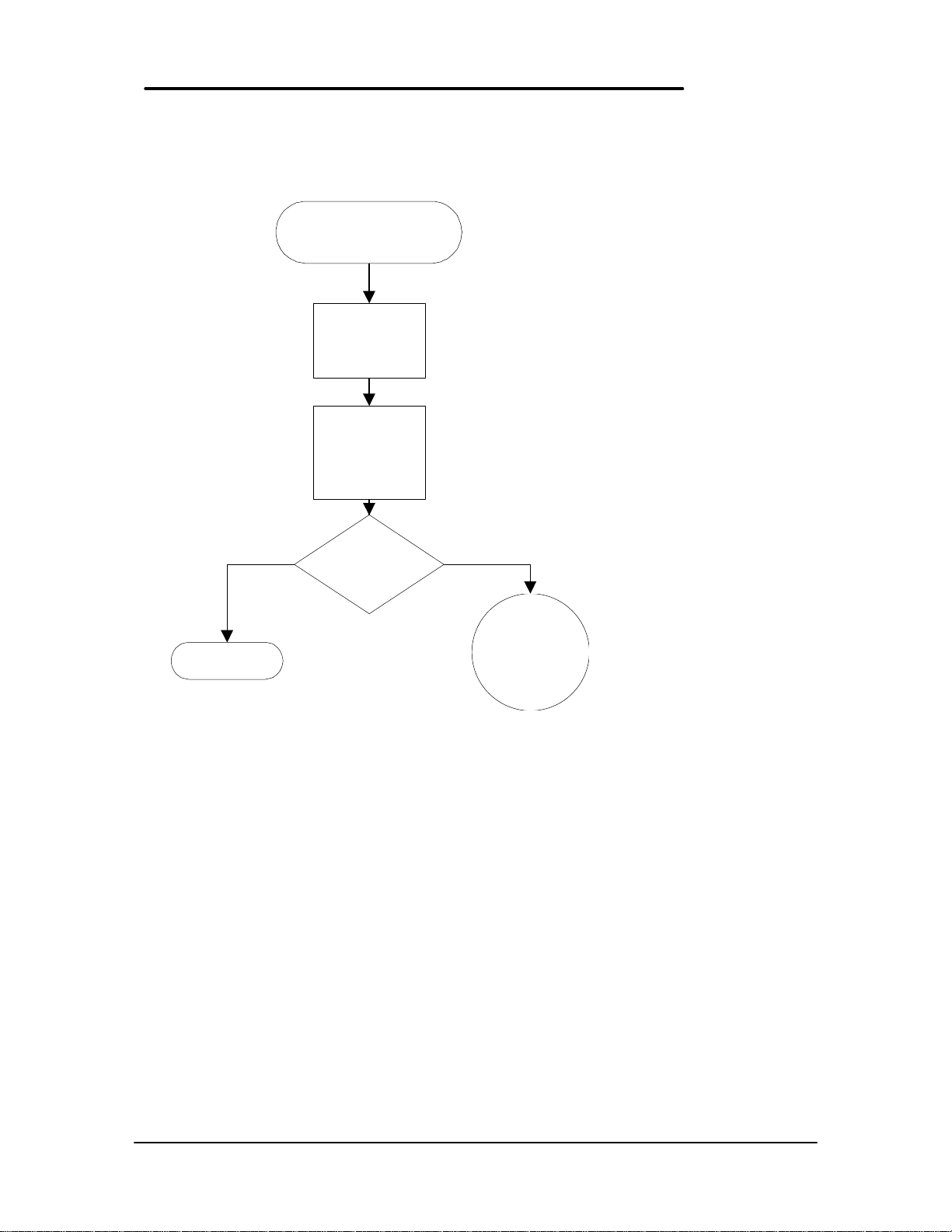

Display Problems

Start:

Power light on, but no

display

Physical

inspection of

display

Adjust brightness

and contrast

controls

Done

Yes No

See anything in

display?

Go to Boot-Up

Problems

flowchart

19

Page 26

Hard Disk Problems

Start: Hard disk fails to boot

up to DOS or Windows; or

other hard disk problems

Yes

Yes

Done: Hard

disk bad

Insert hard disk containing

Noisy?

Yes

system disk"?

system files

Done

Yes

HP hard

disk?

No

See "Non-

See

anything in

drive C:?

No

Done

No

Suspect corrupt files

on hard disk

Boot from OB

companion disk in

drive A:

No

Insert hard disk in C:

Speech: Need hard disk to

boot correctly

Done

20

Do

SCANDISK C:

Yes

A B

Soft checking

OK?

No

Page 27

Hard Disk Problems (continued)

A B

Do hard checking.

Save logs.

Let SCANDISK repair errors.

Yes

Space available on

hard disk within

spec?

Boot from drive C:

Yes

Boots without

errors?

No

No

Done: Hard

disk bad

Do hard checking.

Save logs.

Let SCANDISK repair errors.

Boot from OB companion

disk in drive A:

Do SCANDISK C:

Do CHKDSK C:

Yes

Number of bad

sectors out of

spec?

No

Suspect software problem

Done

Go to Boot-Up

Problems

flowchart

Done: Hard

disk bad

Boot from OB companion

disk in drive A:

Do

SCANDISK C: /AUTOFIX

C

21

Page 28

Hard Disk Problems (continued)

C

Remove disk from

drive A:

Boot from drive C:

Done

Yes

DOS and Windows

boot OK?

Boot from drive A:

Back up hard disk to A:

Reformat hard disk

Reload image

No

Give customer general data

recovery hints

Yes No

Is

customer willing

to reformat hard

disk?

Done: Customer must

purchase another

hard disk

22

Done

Page 29

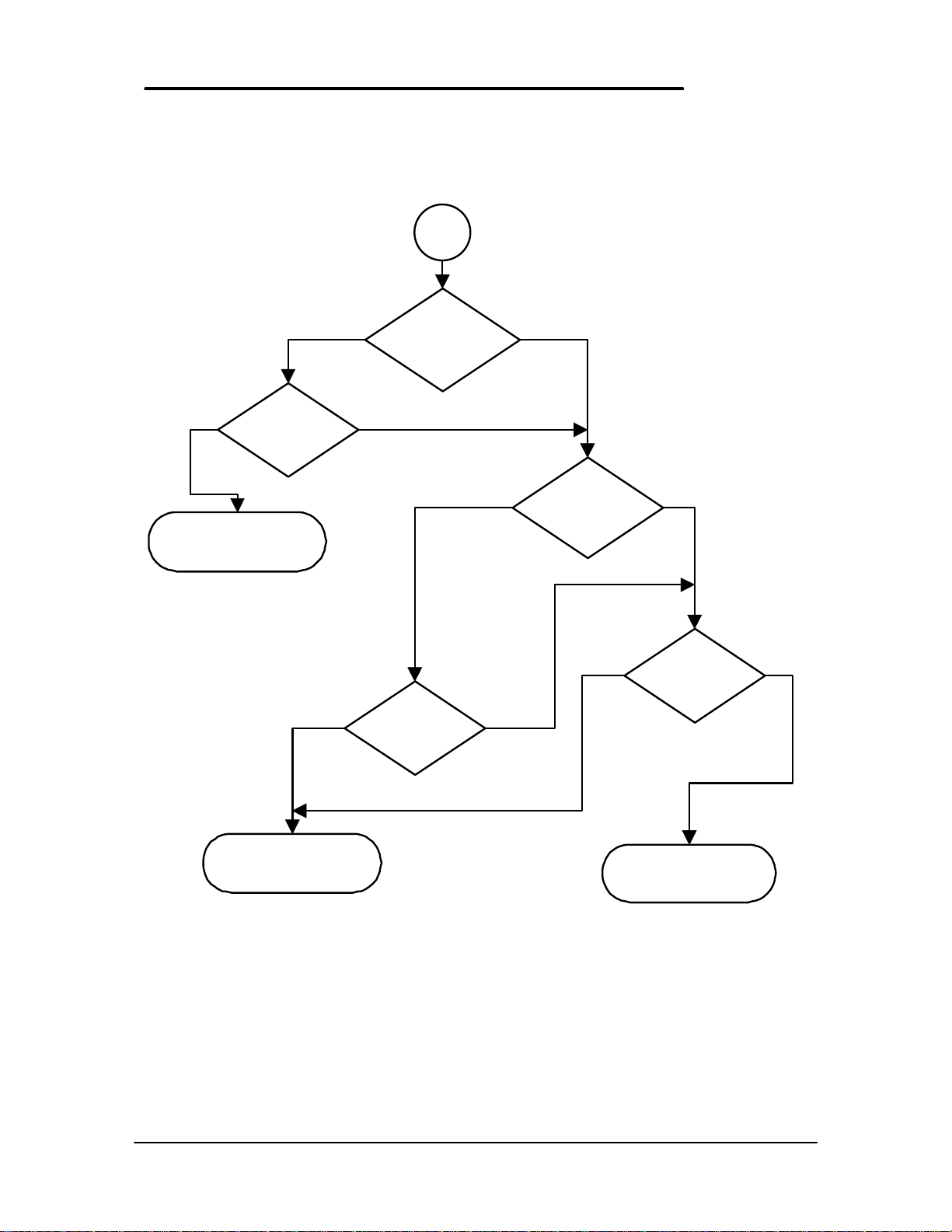

Memory Problems

software

Start: Problem with

plug-in memory

Run long OB

memory self-test

Yes

Run different

software to

eliminate

potential

Memory

Yes

self-test

Yes

Run short OB

memory self-test

Memory

self-test OK?

No

Done: Suspect bad

memory module

Intermittent

problem?

No

No

Yes

End current

session.

Exit software

and turn off OB

Remove OB

battery,

disconnect ac

adapter

Remove and

examine

memory module

Module

appropriate and

compatible?

No

Yes

Done: Suspect

memory module

problem

Memory

appears OK

now?

No

Done

With memory

module

removed,

replace battery,

attach ac

adapter

A

Done: Memory

inappropriate for

this model OB

23

Page 30

Memory Problems (continued)

(memory module

memory self-test

(without memory

memory self-test

(without memory

Done: Suspect OB

Power up OB

removed)

A

Done: Suspect bad

memory module

Yes

Memory

problem

disappears?

Yes

No

Yes

Run long OB

module)

Memory

self-test OK?

Run short OB

module)

Memory

self-test OK?

No

No

24

Done: Suspect

memory module bad

base unit bad

Page 31

Power Management Problems

Start: Low

battery life

Yes

Yes

HP battery?

Contacts dirty?

Physically OK?

Ac adapter

attached to OB

sufficiently?

Yes

Physical

inspection:

and wall?

Has unit

recharged

Power on

during

recharge?

No

Attach ac adapter

No

Recharge sufficiently

No

Ensure power on

Yes

Yes

Yes

Yes

See OB

power icon?

Is

Windows

running?

Power icon in

Control Panel?

1-1/2

hours per

charge?

Done

OB

Yes

No

Done: Suspect

software problem

No

Start Windows

No

Power Mgmnt

icon in OB Tools?

No

Speech:

Standard or Off

means

processor

always on; uses

more power

No

Yes

DOS

or Windows

running?

No

Start DOS or

Windows

Enable OB

power

management

A

Done

25

Page 32

Power Management Problems (continued)

A

Yes

temperature in

Yes

Ensure ac

adapter plugged

into OB and wall

Clean boot:

Ctrl Alt Del, press

F4 during boot

Yes

Ambient

spec?

"Bad/no

battery"

message?

"Bad/no

battery"

message?

No

No

Yes

PCMCIA cards

No

installed?

Speech: PCMCIA

power even when

Remove PCMCIA

cards, recharge

Yes

Bring ambient

temperature

within

specification,

recharge battery

No

cards can use

not on

battery

Does

battery indicator

reach full charge?

Yes

3rd-party

software

installed?

Speech: DOS

games, TSR's,

other software

can reduce

battery life

No

Charging circuitry

may be defective

No

26

Done: Replace

battery or use OB on

ac power only

Yes

Done

Get

1-1/2 hours

battery life?

Disable 3rd-party

software and

recharge battery

No

B

Page 33

Power Management Problems (continued)

running

Get 1-1/2 hours

Get 1-1/2 hours

Done: Suspect bad

B

Done

Yes

battery life?

Done

Yes

No

Use MSD to

determine what

TSR's are

Disable TSR's

No

battery life?

or old battery

27

Page 34

Pop-Out Mouse Problems

obvious physical

Start: OB popout

mouse problem

Eliminate

problems

Yes

Yes

Yes

See

Windows?

Is

mouse OB

popout mouse?

See mouse

pointer?

No

Start

Windows

running

No

Disable other

mouse

Enable OB

popout mouse

No

Yes

A B

Does mouse

pointer move?

28

Done: Suspect

software problem

(Windows problem)

Page 35

Pop-Out Mouse Problems (continued)

A

Yes

Is mouse jittery,

intermittent?

Yes

No

Reaches all 4

corners of

screen?

Yes

Done: Mouse

should be OK

Suspect bad

mouse

C

No

Can you

calibrate

mouse?

No

29

Page 36

Pop-Out Mouse Problems (continued)

B

Look at mouse in

Windows Control

Yes

See OB punch

Panel

button?

Suspect software

configuration

correct OB

mouse driver

Yes

Mouse driver

No

Set Control Panel

for OB punch

button mouse

problem

Check for

No

OK?

Done: Replace with known

good version of correct

OB mouse driver

Yes

Setup shows

correct mouse

driver?

Configure Setup

for correct OB

mouse driver

Yes

moves?

Done: Mouse

OK

Mouse

Suspect bad

mouse

No

No

30

Done

Yes

OB mouse

works OK?

Exit Windows,

run Setup from

DOS command

line

No

C

Page 37

Pop-Out Mouse Problems (continued)

reinsert

unit

solved.

Done: Suspect bad

C

Boot normally to

Windows

Yes

Clean boot:

Ctrl Alt Del,

press F5 when

starting

Run OB

diagnostic

program

Does mouse

pass all tests?

Remove mouse

from OB base

unit, examine

mouse, and

No

Yes

Yes

Put known good

OB mouse in

suspect base

Yes

Known good

mouse works?

Can you put

suspect mouse in

known good OB?

Suspect mouse

works in known

good OB?

No

No

No

Yes

OB mouse

operates

correctly?

Done

No

Done: Suspect

software problem

Yes

Run OB

diagnostic

program

Does mouse

pass all tests?

No

OB base unit

Suspect bad

mouse.

Replace mouse.

Have customer

call back if

problem not

Done

31

Page 38

Floppy Drive Problems

obvious physical

Cable connected

Start: External

floppy disk drive

problem

Yes

Cable is

correct one?

Eliminate

problems:

Cable OK?

Pins not bent?

and solidly in

connectors?

Yes

Yes

known good disk

External

FDD is HP

device?

No

Inserts, ejects

cleanly?

No

No

Done

Yes

Done

Locate and

attach correct

cable

Drive works

OK?

No

Yes

A B

Has drive ever

worked?

32

No

Done: Suspect bad

or damaged drive

Page 39

Floppy Drive Problems (continued)

A

Clean boot:

Ctrl Alt Del, press

F5 during boot

Done

Yes

With original OB

turned on,

connect good

drive and cable

With known good

OB turned on,

connect original

drive and cable

Yes

you swap with known

good drive and

Yes

Drive works

OK?

Can

cable?

Good drive

works OK?

No

No

Suspect software

problem (proceed

to B)

No

Run short self-

test twice

Yes

With known good

OB turned on,

connect original

drive and cable

Drive passes

self-test OK?

No

Done: Suspect

bad drive

Yes

Suspect software

problem

Original drive

works OK?

No

Original drive or

cable bad

Yes

Original OB base

unit bad

Original drive

works OK?

No

Suspect software

problem

33

Page 40

Floppy Drive Problems (continued)

boot

Disk self-test

Change diskette,

with known good

self-test

Clean boot:

Ctrl Alt Del,

press F5 during

B

Run OB disk

self-test:

Put empty,

known good

disk, formatted

for DOS, in

drive. Press

Enter.

Repeat disk

self-test

formatted floppy

long-term disk

Yes

Yes

Insert blank,

disk, do

Long-term

self-test OK?

Boot from drive

A: with OB

companion disk

Boots OK?

No

Yes

No

Yes

Suspect bad

floppy diskette;

replace floppy

one

OK?

run self-test

again

Self-test

OK?

No

No

34

Done: If long-term self-test

works but floppy drive still has

problem, suspect runtime

environment software problem

Done: Suspect

bad floppy drive

Page 41

Parallel Port Problems

boot

Other printer

Run OB self-test

Start: Problem with

parallel port

Use PRN

command to

print a file

Yes

Troubleshoot

Laplink Remote

Problem with

Laplink Remote?

Physical

inspection:

Cable

connected?

Cable pins OK?

Clean boot:

Ctrl Alt Del,

press F5 during

No

Yes

Done: Parallel

port OK

Attach OB and

use PRN

command to

print file on

different printer

Yes

Prints file

OK?

available?

Prints file

OK?

No

NoYes

No

Exit to DOS

Yes

See

Windows?

No

Done: Suspect bad

printer or cable

diagnostics:

CDIAG or

OBTEST,

depending on

unit

A

35

Page 42

Parallel Port Problems (continued)

On line?

DOS on desktop

A

Printer plugged

Attach printer to

Clean boot to

press F5 during

Yes

Reconfirm:

in?

On?

desktop PC

PC:

Ctrl Alt Del,

boot

PRN prints

file OK?

Yes

No

Self-test

OK?

No

Done: Bad OB

base unit

36

Done: Suspect

original OB bad

Done: Suspect bad

printer or cable

Page 43

Serial Port Problems

Run OB self-test

Start: Problem with

serial port

Install loopback

connector

procedure

Yes No

Self-test

OK?

Yes

Troubleshoot

Laplink Remote

Problem with

Laplink Remote?

Physical

inspection:

Cable

connected?

Bent pins?

Cable appears

OK?

Connected to

what?

Modem?

Printer?

Other?

No

Done: Serial port

OK

Done: Suspect bad

serial port in OB

base unit

Yes No

Loopback

connector

available?

A

37

Page 44

Serial Port Problems (continued)

potential software

device and cable

Ensure proper

default serial

port

configuration

A

Done

Yes No

Serial port

works OK?

Yes

Yes

Done

Can you

eliminate all

conflicts?

Serial port

works OK?

No

Eliminate

software

conflicts

No

Plug another

into serial ports

38

Yes

Done: Suspect

original device or

cable bad

Serial port

works OK?

No

Done: Suspect bad

OB base unit serial

port

Page 45

PCMCIA Problems

Start: PCMCIA card

problem

Determine type of

card

Yes

Seek additional

information on

card

Known issue

with this card?

No

Yes

Yes

Has any software been

loaded or modified

since card worked?

Suspect software

configuration

problem

Has card ever

worked?

No

Yes

No

Remove card

(with power on or

off)

Visually inspect

card:

Connectors bent?

Damaged?

Wet?

Inspection

reveals

problems?

No

Done: Suspect bad

PCMCIA card

A

Reinsert card

B

39

Page 46

PCMCIA Problems (continued)

A

Clean boot:

Ctrl Alt Del, press

F5 during boot

Run OB self-test

Yes

Done: Software

configuration or setup

Self-test

OK?

problem

No

Suspect bad card

Exit to DOS

prompt

Press Ctrl Alt Del

Yes

See Windows

Yes

display?

See DOS

prompt?

B

No

No

Exit to DOS

prompt

40

Yes

Done: Return card

to HP

HP card?

No

Done: Contact card

vendor

Remove card and

run CARDINFO

Interpret

CARDINFO

results

C

Page 47

PCMCIA Problems (continued)

C

Yes

Suspect bad card

Done: Suspect bad

OB base unit

Hardware

problem in both

slots?

Yes

No

Hardware

problem?

Check CONFIG.SYS

and AUTOEXEC.BAT

Done

Yes

No

Software

problem?

No

Insert card in top

slot

Run CARDINFO

Insert same card

in bottom slot

Run CARDINFO

Yes

Done: Replace

Card is HP

card

device?

No

Done: Contact

card vendor

Interpret results

D

41

Page 48

PCMCIA Problems (continued)

D

Done: Suspect bad

OB base unit

Seek further

information -

consult with

Yes

Technical

Support

Hardware

problem in one

slot only?

Yes

No

Software

problem in both

slots?

Yes No

Done: Suspect software

configuration problem

No

Software

problem in one

slot only?

Done

42

Page 49

IR Port Problems

environment OK:

Done: Suspect bad

Start: Problem with

Yes

Troubleshoot

Laplink Remote

infrared (IR) port

Problem with

Laplink Remote?

No

Clean boot:

Ctrl Alt Del,

press F5 during

boot

Run OB self-test

Physical

inspection:

IR port not

covered?

Painted over?

Obscured?

Ensure

operating

distance within

specification (1

meter or less)

Ensure

operating

Not next to

bright or

oscillating light?

Done: Suspect

software problem

Done: Suspect no

problem or software

problem

Yes

Run IR self-test

Yes

IR self-test

in proper

environment

IR self-test

OK?

OK?

No

Move OB to

different desk,

room

Run IR self-test

in proper

environment

No

OB base unit

43

Page 50

Page 51

Part 3

Hardware Repair

• Battery

• Memory

• Hard Disk Drive/Flash Card and

System ROM

• Mouse

• Small Parts

• Display

• Keyboard

• Logic PCA Board

• Paw Carrier

• Other Components

CAUTION: Always provide proper grounding when performing any of the

following repairs. An electrostatic discharge may cause irreparable

damage to the OmniBook and its components

Page 52

Battery

(End User Replaceable)

All of the monochrome OmniBook models use the same HP Nickel-Metal-Hydride (NiMH)

Battery Pack, part number F1045A (service replacement part number F1045-60901). However,

for some models, 1.5 V AA batteries can be used in place of the NiMH battery pack. The

following table lists all of the monochrome OmniBooks and the batteries that can be used safely

in each model.

OmniBook 300 OmniBook 425 OmniBook 430 OmniBook 530

Flash Disk

Version

Hard Disk

Version

• NiMH Battery

Pack

• AA Alkaline

• AA Lithium

• NiMH Battery

Pack

• AA Lithium

• NiMH Battery

Pack

• AA Alkaline

• AA Lithium

• NiMH Battery

Pack

• AA Lithium

not applicable not applicable

• NiMH Battery

Pack

• AA Lithium

• NiMH Battery

Pack

WARNING:

Required Equipment

• none

Removal Procedure

1. Release the two latches on the battery cover on the bottom case, then remove the cover.

Refer to the below illustration.

2. Do one of the following to remove the battery:

• If an OmniBook battery pack is installed, lift it out by its tab.

• If AA batteries are installed in place of the OmniBook battery pack, lift each out

Do not mutilate, puncture, or dispose of batteries in fire. The batteries can

burst or explode, releasing hazardous chemicals.

A nickel-metal-hydride rechargeable battery pack must be recycled or

disposed of properly. Recycle or discard used size-AA batteries according

to the manufacturer’s instructions.

individually.

46

Page 53

Replacement Procedure

1. To replace the battery, do one of the following:

• To replace the OmniBook battery pack, insert the rounded side of the pack into the

compartment first. It is not possible to fully insert the battery pack incorrectly.

• To replace AA batteries, orient them as shown by the symbols in the battery

compartment.

2. Replace and latch the battery cover.

47

Page 54

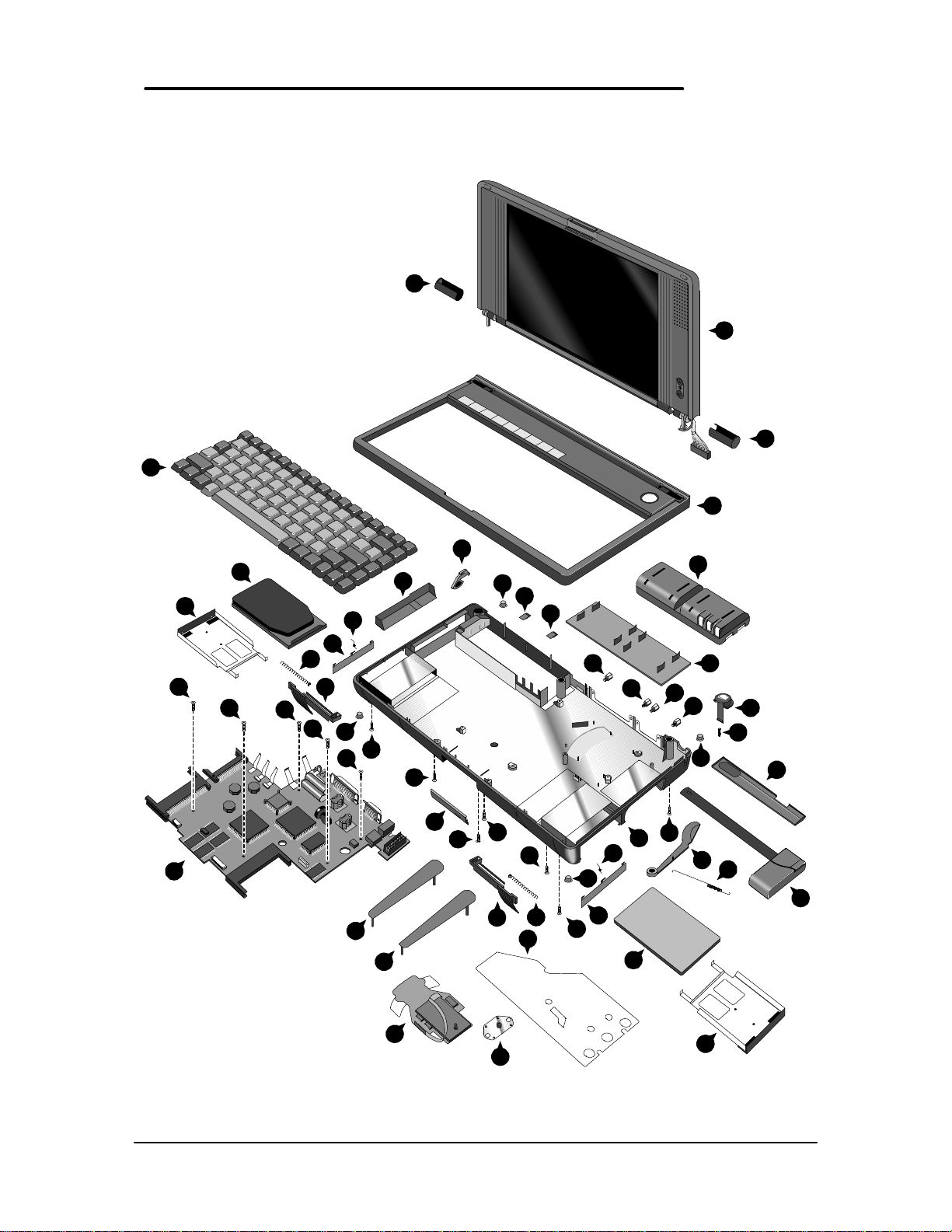

Memory

(End User Replaceable)

The OmniBook 530 uses a unique memory module that is not compatible with the OmniBook

300, 425, or 430. The table below summarizes the compatibility of the memory modules for

each OmniBook model.

Memory

Module

2-MB F1041A F1041-60901

4-MB F1042A F1038-60901

4-MB F1054A F1054-60901

8-MB F1055B F1055-60002

The following illustration provides a visual representation of the physical differences between the

memory module for the OmniBook 300, 425, and 430 and the memory module for the OmniBook

530.

Accessory

Number

Service Replacement OB 300 OB 425 OB 430 OB 530

OmniBook 300, 425, and 430 OmniBook 530

Figure 5 - OmniBook Memory Modules

48

Page 55

Required Equipment

• Probe (or similar device) for the OmniBook 300, 425, and 430 only

CAUTION:

Removal Procedure

1. Remove the battery and ac adapter from the OmniBook.

2. Slide the memory door off (see below illustration).

Figure 6 - Removing the Memory Module

3. Perform the appropriate action for the corresponding OmniBook:

• OmniBook 300, 425, or 430 -- Use a probe or similar device to pull on the small post

• OmniBook 530 -- Flip out the plastic tab on the memory module and pull the module

To avoid damage due to electrostatic discharge, handle the memory module

by the edges only.

located on the front edge of the memory module.

out.

Replacement Procedure

1. Insert the memory module into the slot. (It is not possible to completely insert the memory if

it is upside down.)

• OmniBook 300, 425, 430 -- the small post on the board faces the bottom surface of the

OmniBook.

• OmniBook 530 – the plastic tab on the board faces the bottom surface of the

OmniBook.

2. Press in the module until it seats fully.

3. Replace the slot cover.

4. Replace the battery and press reset.

49

Page 56

Hard Disk Drive/Flash Card and System ROM

(End User Replaceable)

The Hard Disk Drives for the OmniBook 300, 425, 430, and 530 can be reimaged if necessary.

If the software is corrupted, or otherwise damaged, on the hard drive, it can be reformatted and

the software reloaded. Also, if the hard drive fails and must be replaced, a blank hard drive can

be ordered and the appropriate software loaded. The below procedures indicate the proper

actions necessary for reloading software on each OmniBook model.

For the OmniBook 300 and 425:

1. Place the hard drive into the OmniBook.

2. Reformat the hard drive.

3. Run OBSETUP /F from the System ROM to reload the software onto the hard drive.

For the OmniBook 430:

1. Place the hard drive into the OmniBook.

2. Reboot and press Alt then D to boot from the System ROM.

3. Reformat the hard drive.

4. Reload the software image from a set of OmniBook 430 Recovery Disks. The Recovery

Disks are available on the HP Internal WW Web at

http://webmcd.cv.hp.com/prodsupp/archive/.

For the OmniBook 530:

1. Place the hard drive into the OmniBook.

2. Boot from the Companion Disk or other bootable floppy disk.

3. Reformat the hard drive.

4. Reload the software image from a set of OmniBook 530 Recovery Disks. The Recovery

Disks are available on the HP Internal WW Web at

http://webmcd.cv.hp.com/prodsupp/archive/.

50

Page 57

Required Equipment

• none

Removal Procedure

1. Exit all applications, including Windows.

2. Turn the OmniBook off and remove the battery and ac adapter.

3. Turn the OmniBook over, release the two latches on the bottom of the tray, and pull out the

tray. See below illustration.

Figure 7 - Removing Card Slot Tray

4. Lift the Hard Disk, Flash Card, or System ROM out of the tray.

Replacement Procedure

1. Reverse the above steps to replace the Hard Disk, Flash Card, or System ROM.

2. Replace the battery and ac adapter.

3. Press reset.

51

Page 58

Mouse

(End User Replaceable)

Required Equipment

• none

Removal Procedure

1. Press the mouse-eject button to eject the mouse.

2. Pull the mouse firmly away from the OmniBook (see below illustration). The entire mouse

assembly will pull free.

Figure 8 - Removing the Mouse

Replacement Procedure

1. Place the end of the mouse “stick” into the mouse housing.

2. Slide the mouse into the slot and firmly push the mouse until it is completely flush with the

side of the OmniBook.

52

Page 59

Small Parts

(End User Replaceable)

The following small parts are all end user replaceable.

Battery Door

Push the two battery door latches away from the battery door. Remove the battery door by lifting

up at the notch in the bottom case. Place the battery door, tab side first, over the battery

compartment. Slide the two battery latches in place to secure the door.

Battery Door Latch

Once the battery door is removed (see above), the battery door latches will slide out of the

bottom case. To replace, align the sides of the latches with the groves in the slots. Press firmly

into place.

Blank Modem Door

Use a flat-blade screwdriver or similar device to press the small latch on the bottom of the blank

modem door. Pull the door free of the bottom case. To replace, simply reinsert the door into the

modem slot and press firmly.

Memory Door

Use a flat-blade screwdriver or similar device to pry the memory door from the bottom case.

Replace by aligning the edges of the door with the slots on the bottom case. Press firmly into

place.

I/O Door

To remove the I/O door, open it fully. Flex the middle of the door until the side pins clear the

holes in the back case. Reverse to replace.

Rubber Feet

Place a probe or similar device between the rubber foot and the plastic of the bottom case. Pry

upward to pop the foot out. To replace, firmly press the foot into the hole.

PCMCIA Card Tray

Slide the two tray latches toward each other. Pull the tray out of the card slot. If present,

remove the PCMCIA card from the tray. To replace the tray, insert into the appropriate card slot.

Slide the two latches away from each other to secure the tray.

53

Page 60

Display

(HP Authorized Service Providers Only)

Required Equipment

• Appropriate ESD station

• Torx #6 screwdriver

• 5mm Hexdriver

• Two small flat tip screwdrivers (or similar prying devices)

• Probe

Removal Procedure

1. Remove the battery, ac adapter, mass storage, system card (if applicable), memory module

(if installed), modem (if installed), mouse, and any installed PCMCIA accessory cards.

2. Remove the four Rubber Feet and seven Screws from the bottom case (see below

illustration).

Door - Battery

Screw

M2x4.6mm(T6)

(Qty 6)

Battery

Figure 9 - Outer Bottom Case Components

Rubber Foot

(Qty 4)

54

Page 61

3. Remove the I/O Door and the four standoffs located on the I/O backplane (see figure below).

Figure 10 - Backplane Standoffs

4. Two flat tip screwdrivers, or similar prying devices, are needed to remove the Top Case and

Display Assemblies. Four plastic tabs hold the Top Case and Bottom Case together. Two

tabs are located in each PCMCIA slot (see below illustration). Note, the screws seen in the

PCMCIA slot do not need to be removed.

Figure 11 - Bottom Case Tabs

55

Page 62

Place a prying device at a tab location between the metal and plastic of the Bottom Case

(see figure below, left). Place another prying device in the PCMCIA eject button (see figure

below, right). To release the tab, simultaneously twist prying device A while lifting on prying

device B. Use caution with this maneuver, as the plastic tabs can break off the Bottom

Case. If this occurs, the Bottom Case must be replaced.

Prying device “A”

Prying device “B”

Figure 12 - Bottom Case Prying Locations

5. Perform step four for each of the four tabs.

6. Once the Bottom Case tabs are released, the Bottom Case and Top Case are being held

together only by the display cable and the two keyboard cables. Do not allow the Top

Case and Bottom Case to separate at this point. The display cable and keyboard

cables will be damaged if they are not properly disconnected.

7. Use a prying device to increase the separation of the Top Case and Bottom Case (see figure

below). Do not separate the Top Case and Bottom Case more than 1 cm. A separation

greater than 1 cm will damage the keyboard flex cables by pulling them out of the

zero-force insertion connectors. The intent is to be able to view the display cable, located

to the left of the ac adapter socket.

Display Cable

56

Figure 13 - I/O Port Prying Location

Page 63

8. With the separation increased slightly, the display cable can be disconnected using a probe.

Use caution to keep the OmniBook on a level surface. With the Top Case partially

separated, small internal parts may dislodge when the OmniBook is tilted at a sharp

angle. Place the probe at the base of the display cable connector between the two rows of

pins. Use a rocking motion to lift the cable from the connector. See the below illustration for

proper placement of the probe.

Figure 14 - Disconnecting Display

Cable

9. With the display cable removed, the Top Case and Bottom Case can be opened partially to

gain access to the keyboard flex cables (see below illustration). Do not open the unit

completely as this will damage the keyboard flex cables by pulling them out of the

zero-force insertion connectors. Open the zero-force insertion connectors and remove

the keyboard flex cables. The Top Case can now be removed completely from the Bottom

Case.

57

Page 64

Figure 15 - Keyboard Flex Cables

10. To separate the Keyboard from the Display, five grounding eyelets must be removed from

the display posts (see below illustration). Use caution when removing the grounding

eyelets, as they can be broken off easily. If this happens, the assembly must be

replaced. To prevent the eyelets from breaking, bend the grounding eyelet tabs at the

farthest point from the eyelet.

Figure 16 - Display Grounding Eyelets

58

Proper Tab Bend

Page 65

11. To remove the Display from the Top Case, the display cable and two grounding cables must

be guided through the holes in the Top Case.

Replacement Procedure

1. Guide the display posts, display cable and two grounding cables on the Display through the

holes in the Top Case.

2. Replace the grounding eyelets over the display posts (see Figure 16). Use caution when

replacing the grounding eyelets, as they can be broken off easily. If this happens, the

assembly must be replaced.

3. Press the Display and Top Case firmly at each display post to snap the assembly in place.

4. Position the Top Case and Display Assembly over the Bottom Case and insert the two

keyboard flex cables into the zero-force insertion connectors. Ensure the connectors are

fully closed. Once the keyboard flex cables are secured in the connectors, do not

allow them to be pulled out. This will damage the cables.

59

Page 66

5. To reconnect the display cable, position a probe in the cable as shown in the below

illustration.

Figure 17 - Display Cable Probe Position

6. Use the probe to connect the display cable into the connector as shown below. Use caution

to keep the OmniBook on a level surface. With the Top Case partially separated,

small internal parts may dislodge when the OmniBook is tilted at a sharp angle.

Figure 18 - Reconnecting Display Cable

7. With the display cable reconnected, the I/O grounding eyelets must be slid into place. Use

caution when positioning the I/O grounding eyelets as they can be broken off easily.

It is acceptable to reassemble the OmniBook with certain I/O grounding eyelets broken if

there is at least one eyelet in each of the four positions AND at least two matched sets

remaining. See Figure 19, Figure 20, Figure 21, and Figure 22 for examples.

60

Page 67

Figure 19 - I/O Port Eyelets (all present)

Figure 20 - I/O Port Eyelets (two matched sets)

Figure 21 - I/O Port Eyelets (only one matched set)

Acceptable to reassemble

All eyelets are present.

Acceptable to reassemble

There are two matched sets

and at least one eyelet in

each position.

Not acceptable to

reassemble

Not acceptable to

reassemble

There are two matched set, but

Figure 22 - I/O Port Eyelets (no eyelet in position one)

8. Open the display and firmly press the Top Case and Bottom Case together around the entire

parameter of the OmniBook. This will lock the tabs of the two cases.

9. Replace the seven screws and four standoffs and the remainder of the components.

61

Page 68

Keyboard

(HP Authorized Service Providers Only)

Required Equipment

• Appropriate ESD station

• Torx #6 screwdriver

• Two small flat tip screwdrivers (or similar prying devices)

• Probe

Removal Procedure

1. Follow the Display Removal Procedure to separate the Display and Top Case from the

Bottom Case.

2. Once the Display is removed, the Keyboard must now be separated from the Top Case.

Hold the Top Case and Keyboard Assembly exactly as shown in the below illustration.

Top Case and

Keyboard

Assembly

(upside down)

Keyboard

(upside down)

Backside of the

Top Case icon

panel.

Figure - Keyboard Removal Hand Placement

3. Apply even upward pressure with the fingers of the left hand. At the same time use the tip of

the thumb of the right hand to twist the backside of the Top Case icon panel inward and

toward the keyboard. There will be a slight bending in the plastic of the Top Case. This is

normal and will not damage the assembly.

Replacement Procedure

1. To replace the Keyboard, snap it into the Top Case. Ensure the entire perimeter of the

Keyboard is securely snapped into place.

2. Follow the Display Replacement Procedure to replace the Display and remaining

components.

62

Page 69

Logic PCA Board

Spring

Spring

(HP Authorized Service Providers Only)

Required Equipment

• Appropriate ESD station

• Torx #6 screwdriver

• Two small flat tip screwdrivers (or similar prying devices)

• Probe

Removal Procedure

1. Follow the Display Removal Procedure to separate the Display and Top Case Assembly from

the Bottom Case.

2. Remove the Eject Arms (both right and left) and Mouse Button Latch and Spring (see below

illustration). Note, the Mouse Latch Spring is very small and can be misplaced easily.

Screw

M2x4.6mm(T6)

(Qty 5)

Eject Arm Left

Logic PCA

Eject Arm

Mouse

Button

Latch

Mouse

Latch

Spring

Eject Arm

Eject Button A

Paw Carrier

Flex Cable Slot

Eject Button B

Eject Arm

Figure 23 - Logic Board PCA Removal

63

Page 70

3. The Eject Buttons and Springs do not need to be removed to gain access to the Logic Board.

However, because they can be dislodged easily, setting them aside is recommended.

4. Remove the Paw Carrier Flex Cable from the zero-force insertion slot.

5. Remove the five (5) screws from the Logic Board (see previous illustration).

6. The Logic Board can now be lifted from the Bottom Case.

Replacement Procedure

1. To replace the Logic Board, reverse the steps in the Removal Procedure. Ensure the Paw

Carrier flex cable is positioned properly – the end of the cable should be folded along the

holes in the cable. This folded portion then needs to be placed between the posts and

guided on the bottom case.

2. Follow the Display Replacement Procedure to replace the Display and remaining

components.

64

Page 71

Paw Carrier (Paw Active)

Tabs (Qty 2)

(HP Authorized Service Providers Only)

Required Equipment

• Appropriate ESD station

• Torx #6 screwdriver

• Two small flat tip screwdrivers (or similar prying devices)

• Probe

Removal Procedure

1. Follow the Logic Board PCA Removal Procedure.

2. Remove the Mylar Mouse Shield. Refer to the below illustration for location of components.

3. The Mouse Eject Arm and Eject Arm Spring may be removed at this point for convenience.

4. Gently bend the Pivot Bracket Tabs upward. Take caution not to break these tabs. If this

occurs the Bottom Case must be replaced.

5. Remove the Pivot Bracket.

6. Lift the Paw Carrier from the plastic posts holding it in place.

Mylar Mouse

Shield

Pivot Bracket

Paw Carrier

Pivot Bracket

Mouse Eject

Arm

Eject Arm

Bottom Case

Figure 24 - Paw Carrier Removal

Replacement Procedure

1. To replace the Paw Carrier, reverse the steps in the Removal Procedure.

2. Follow the Logic Board PCA Replacement Procedure to replace the Logic Board and

remaining components.

Spring

65

Page 72

Other Components

(HP Authorized Service Providers Only)

The below table list additional replaceable components and the disassembly procedure(s)

necessary to gain access to each.

Component Disassembly

Procedure(s)

Top Case Display

Keyboard

Bottom Case Display

Logic PCA Board

Paw Carrier

Mouse Button Latch

Mouse Latch Spring

Mylar Mouse Shield

Pivot Bracket

Eject Buttons (A&B)

Eject Arms (L&R)

Eject Arm Spring

Pivot Doors (A&B)

Pivot Door Spring

Hinge Cap Display Torx #6 screwdriver

Security Latch Display Torx #6 screwdriver

Display Torx #6 screwdriver

Display

Logic PCA Board

Display Torx #6 screwdriver

Display Torx #6 screwdriver

Equipment Special Notes

Torx #6 screwdriver

5mm hexdriver

Two flat tip screwdrivers

Probe

Torx #6 screwdriver

5mm hexdriver

Two flat tip screwdrivers

Probe

5mm hexdriver

Two flat tip screwdrivers

Probe

Torx #6 screwdriver

5mm hexdriver

Two flat tip screwdrivers

Probe

5mm hexdriver

Two flat tip screwdrivers

Probe

5mm hexdriver

Two flat tip screwdrivers

Probe

5mm hexdriver

Two flat tip screwdrivers

Probe

5mm hexdriver

Two flat tip screwdrivers

Probe

The Hinge Caps

simply slide off of the

ends of the Display.

Use a probe to

remove the Security

Latch from the

Bottom Case.

66

Page 73

Appendix A - Technical and Resource

Specifications

Mass Storage Specifications

40MB 105MB 131MB Flash Disk

Cards (Typical)

Average seek < 19 ms 19 ms 19ms 2-3 ms

Track to Track

seek

Average Latency 6.67 ms 6.72 ms 6.72 ms NA

Rotational speed 4503 rev/m 4464 rev/m 4464 rev/m NA

Data transfer

rate

Buffer to disc

Buffer to host

Buffer size 32 Kbytes static

Spindle start

time

5 ms 6 ms 6 ms NA

13-21 Mbits /sec

4.5 Mbytes /sec

RAM

1 sec typical

3 sec maximum

11.4 - 19.2 Mbits/sec

4 Mbytes /sec

31 Kbytes 31 Kbytes NA

<2 sec maximum <2 sec maximum NA

11.4 - 19.2 Mbits/sec

4 Mbytes/sec

2.5 MBytes/sec

6.0 MBytes/sec

Card Services and Socket Services Version Matrix

OB300 OB425 OB430 OB530

Card Services

Socket Services

Card BIOS 1.0 Card BIOS 1.0 Card BIOS 1.0 2.1

1.01a 1.08 1.14 2.1

67

Page 74

Memory Map

300/425 430 430

SYSTEM BIOS

F

VGA BIOS

SYSTEM BIOS

ROM

E

DOS

D

PCMCIA

C

UMB SPACE

B

A

VGA RAM

VGA RAM

VGA BIOS

UMB SPACE

PCMCIA

UMB

SPACE

Upper Memory Block Space

OB300/425 OB430 OB530

UMB Space Available

DOS Conventional Memory

Windows DOS Box

(with LapLink Remote)

Exit Windows (with out

LapLink Remote)

68

64k 64k + 32k 112k contiguous

OB300 OB425 OB430 OB530

315 KB 315 505 404

435 KB 435 533 437

Page 75

Appendix B - Power On Self Test Codes

Beep Codes

Beep Codes are used to identify a Power On Self Test (POST) error that

occurs when the screen is not available. Once the screen is operational,

diagnostic messages are reported to the screen. There are beep codes for

both fatal and nonfatal system board errors.

The codes are shown as x-y-z where 2-2-1 represents 2 beeps - pause - 2

beeps - pause - 1 beep.

Fatal Errors

1-1-1 CPU failure

1-1-3 CMOS failure

1-1-4 BIOS Checksum failure

1-2-1 8253 timer failure

1-2-2 DMA setup failure

1-2-3 DMA page register failure

1-3-1 RAM refresh not verified

1-3-2 SMI RAM bad

1-3-3 Low 64K RAM failure

1-3-4 Low 64K RAM even/odd failure

1-4-1 Low 64K RAM address line failure

1-4-2 Low 64K RAM parity error

2-1-1 Low 64K RAM bit 0 error

2-1-2 Low 64K RAM bit 1 error

2-1-3 Low 64K RAM bit 2 error

2-1-4 Low 64K RAM bit 3 error

2-2-1 Low 64K RAM bit 4 error

2-2-2 Low 64K RAM bit 5 error

2-2-3 Low 64K RAM bit 6 error

2-2-4 Low 64K RAM bit 7 error

2-3-1 Low 64K RAM bit 8 error

2-3-2 Low 64K RAM bit 9 error

2-3-3 Low 64K RAM bit 10 error

2-3-4 Low 64K RAM bit 11 error

2-4-1 Low 64K RAM bit 12 error

2-4-2 Low 64K RAM bit 13 error

2-4-3 Low 64K RAM bit 14 error

2-4-4 Low 64K RAM bit 15 error

3-1-1 DMA #2 register error

3-1-2 DMA #1 register error

3-1-3 8259 #1 error

3-1-4 8259 #2 error

3-2-4 8042 KB controller error

3-3-4 Video initialization error

3-4-1 Video retrace failure

3-4-2 Video ROM-scan in progress

3-4-3 Video ROM-scan error

Non-Fatal Errors

4-2-1 8253 timer tick test

4-2-2 Shutdown/Restart sequence

4-2-3 Gate A20 failure

4-2-4 Unexpected virtual mode interrupt

4-3-1 RAM test in progress

4-3-3 8253 timer channel 2 test

4-3-4 Time of day clock test

4-4-1 Serial port test

4-4-2 Parallel port test

4-4-3 Math coprocessor test

69

Page 76

Display Codes

There are a number of Power On Self Test (POST) tests that are performed after the Beep Code

tests. Failure of one or more of these tests will result in a displayed failure code (such as 0240).

It is extremely important not to interpret a failure code immediately as a hardware failure. The

failure should be confirmed with a clean boot. A clean boot is defined as pressing the reset

button after removing all accessories (including memory cards, external floppy drive, modems,

PCMCIA cards, and printers) and providing a reliable power source.

The following list explains a number of POST Display Codes. Note, not all codes are available

on all models of the OmniBook.

No Error; Self-Test

Routine Passed

80x86 Microprocessor

Error

BIOS ROM Checksum

Errors

Real Time Clock Errors

CMOS Errors

8041 Errors

0000h test passed

000fh MPU failed self test

0010h errors relating to the BIOS rom

checksums

0011h

0110h 011X where X = bad register

0120h RTC clock tick error

0240h CMOS power bad

0241h CMOS checksum bad

0280h HP checksum bad

0282h EISA checksum bad

error code 0281 was previously used

0301h did not read 0AAH command

0302h did not respond to 0AAH command

0303h bad Response to 0AAH command

0305h did not respond when setting keyclick

volume

0306h did not read 0C0H command

0307h did not respond to 0C0H command

0308h keyboard fuse is open

0311h did not read 060H command

0312h did not read data for 060H command

0341h did not read kbd interface test cmd

0342h did not respond to kbd intrf test

0342h add 1-4 to this to get

00343h kbd clock line stuck low