Page 1

M274

M277

M252n M252dw

ColorLaserJet Pro M252

ColorLaserJet Pro MFP M274

ColorLaserJet Pro MFP M277

Troubleshooting manual

www.hp.com/support/colorljM252

www.hp.com/support/colorljM274MFP

www.hp.com/support/colorljMFPM277

For printer part removal and part number

information, see the Repair Manual

Page 2

Page 3

HP Color LaserJet Pro M252, HP Color

LaserJet Pro MFP M274 and M277

Troubleshooting Manual

Page 4

Copyright and License

© Copyright 2015 HP Development Company,

L.P.

Reproduction, adaptation, or translation

without prior written permission is prohibited,

except as allowed under the copyright laws.

The information contained herein is subject to

change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products and

services. Nothing herein should be construed

as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or

omissions contained herein.

Edition 2, 10/2015

Page 5

Conventions used in this guide

TIP: Helpful hints or shortcuts.

Reinstallation tip: Reinstallation helpful hints, shortcuts, or considerations.

NOTE: Information that explains a concept or how to complete a task.

IMPORTANT: Information that help the user to avoid potential printer error conditions.

CAUTION: Procedures that the user must follow to avoid losing data or damaging the printer.

WARNING! Procedures that the user must follow to avoid personal injury, catastrophic loss of data, or

extensive damage to the printer.

ENWW iii

Page 6

iv Conventions used in this guide ENWW

Page 7

For additional service and support information

HP service personnel, go to the Service Access Work Bench (SAW) at http://h41302.www4.hp.com/km/saw/

home.do.

Channel partners, go to HP Channel Services Network (CNS) at https://h30125.www3.hp.com/hpcsn.

●

To access HP PartSurfer information from any mobile device, go to http://partsurfermobile.hp.com/ or

scan the Quick Response (QR) code below.

●

Install and congure

●

Printer specications

●

Up-to-date control panel message (CPMD) troubleshooting

●

Solutions for printer issues and emerging issues

●

Remove and replace part instructions and videos

●

Service advisories

●

Warranty and regulatory information

ENWW v

Page 8

vi For additional service and support information ENWW

Page 9

Table of contents

1 Theory of operation ....................................................................................................................................... 1

Related documentation and software ................................................................................................................... 2

Basic operation ...................................................................................................................................................... 3

Sequence of operation ........................................................................................................................ 4

Formatter-control system ..................................................................................................................................... 5

Sleep delay .......................................................................................................................................... 5

Printer job language (PJL) ................................................................................................................... 5

Printer management language (PML) ................................................................................................. 6

Control panel ....................................................................................................................................... 6

Walk-up USB (touchscreen models only) ............................................................................................ 6

Wireless (wireless models only) .......................................................................................................... 6

Low end data model (LEDM) ................................................................................................................ 6

Advanced control language (ACL) overview ........................................................................................ 6

Near eld communication (NFC) (wireless models only) .................................................................... 7

CPU ....................................................................................................................................................... 7

Input/output ........................................................................................................................................ 7

USB .................................................................................................................................... 7

USB hosts .......................................................................................................................... 7

10/100 networking ........................................................................................................... 7

Fax (M277 models only) .................................................................................................... 7

Memory ................................................................................................................................................ 7

Firmware ........................................................................................................................... 7

Nonvolatile random access memory (NVRAM) ................................................................. 7

Flash memory ................................................................................................................... 7

Random access memory (RAM) ........................................................................................ 8

HP Memory enhancement technology (MEt) .................................................................... 8

Engine-control system .......................................................................................................................................... 9

Engine control unit (ECU) .................................................................................................................. 10

DC controller ................................................................................................................... 10

High-voltage power supply ............................................................................................ 11

Motors ............................................................................................................................. 11

Fans ................................................................................................................................. 12

ENWW vii

Page 10

Solenoids ......................................................................................................................... 12

Switches .......................................................................................................................... 13

Sensors ........................................................................................................................... 14

Low-voltage power supply ................................................................................................................ 15

Overcurrent/overvoltage protection .............................................................................. 15

Low-voltage power supply unit failure detection .......................................................... 15

Engine laser scanner system ............................................................................................................................... 16

Laser failure detection ...................................................................................................................... 16

Image formation system ..................................................................................................................................... 17

Image formation process .................................................................................................................. 17

Step 1: Primary charging ................................................................................................ 17

Step 2: Laser-beam exposure ......................................................................................... 19

Step 3: Development ...................................................................................................... 19

Step 4: Primary transfer ................................................................................................. 20

Step 5: Secondary transfer ............................................................................................. 20

Step 6: Separation ........................................................................................................... 21

Step 7: Fusing .................................................................................................................. 21

Step 8: Drum cleaning ..................................................................................................... 21

Toner cartridges ................................................................................................................................ 23

Design ............................................................................................................................. 23

Memory chip .................................................................................................................... 24

HP Cartridges with JetIntelligence ................................................................................. 24

HP Cartridge Policy ....................................................................................... 24

Anti-theft or cartridge protection ................................................................ 24

Intermediate transfer belt (ITB) assembly ........................................................................................ 24

Engine pickup, feed, and delivery system ........................................................................................................... 26

Priority input slot pickup ................................................................................................................... 29

Cassette pickup ................................................................................................................................. 30

Duplexing unit ................................................................................................................................... 30

Duplex reverse and duplex feed control ........................................................................ 31

Duplex pickup operation ................................................................................................. 31

Jam detection .................................................................................................................................... 32

Scanning and image capture system .................................................................................................................. 33

Automatic document feeder (ADF) system ......................................................................................................... 34

ADF simplex operation ...................................................................................................................... 34

Fax functions and operation (fax models only) .................................................................................................. 35

Computer and network security features ......................................................................................... 35

PSTN operation .................................................................................................................................. 35

Receive faxes when you hear fax tones ............................................................................................ 35

Distinctive ring function .................................................................................................................... 36

Set up the distinctive ring function ................................................................................ 36

viii ENWW

Page 11

Fax by using voice over IP (VOIP) services ........................................................................................ 36

The fax subsystem ............................................................................................................................ 37

Fax card in the fax subsystem ........................................................................................................... 37

Safety isolation ............................................................................................................... 37

Safety-protection circuitry ............................................................................................. 37

Data path ......................................................................................................................... 37

Hook state ....................................................................................................................... 38

Downstream device detection ........................................................................................ 38

Hook switch control ........................................................................................................ 38

Ring detect ...................................................................................................................... 38

Line current control ......................................................................................................... 38

Billing or metering tone lters ....................................................................................... 39

Fax page storage in ash memory .................................................................................................... 39

Stored fax pages ............................................................................................................. 39

Advantages of ash memory storage ............................................................................ 39

2 Solve problems ............................................................................................................................................ 41

Troubleshooting process ..................................................................................................................................... 42

Solve problems checklist ................................................................................................................... 42

Print the menu map ........................................................................................................ 43

Print a conguration page .............................................................................................. 43

Print the service page (includes the event log) .............................................................. 44

Determine the problem source ......................................................................................................... 44

Troubleshooting owchart ............................................................................................. 44

Power subsystem .............................................................................................................................. 45

Power-on checks ............................................................................................................. 45

Power-on troubleshooting overview ........................................................... 45

Control panel checks ......................................................................................................................... 49

Tools for troubleshooting .................................................................................................................................... 50

Individual component diagnostics .................................................................................................... 50

Tools for troubleshooting: LED diagnostics ................................................................... 50

Network port LEDs ....................................................................................... 50

Two-line control panel LEDs ........................................................................ 51

Tools for troubleshooting: Engine diagnostics .............................................................. 51

Engine test .................................................................................................... 51

Diagrams ........................................................................................................................................... 52

Diagrams: Block diagrams .............................................................................................. 52

Sensors and switches ................................................................................... 52

Diagrams: Printed circuit assembly (PCA) connector locations ..................................... 53

Diagrams: Formatter connections ............................................................... 53

Diagrams: DC controller connections ........................................................... 55

ENWW ix

Page 12

Diagrams: External plug and port locations ................................................................... 56

Diagrams: Locations of major components ................................................................... 57

Major components (printer base) ................................................................. 57

Motors and fan .............................................................................................. 58

Rollers (printer base) .................................................................................... 59

PCAs (printer base) ....................................................................................... 60

Diagrams: Timing chart .................................................................................................. 61

Diagrams: Circuit diagrams ............................................................................................. 62

Advanced conguration with HP Embedded Web Server (EWS) and HP Device Toolbox

(Windows) .......................................................................................................................................... 63

Print quality troubleshooting tools .................................................................................................. 66

Repetitive defects ruler .................................................................................................. 66

Use a ruler to measure between repetitive defects ..................................... 66

Calibrate the printer to align the colors ......................................................................... 70

Control panel menus ......................................................................................................................... 71

2-line control-panel view (M252n model) ...................................................................... 71

Touchscreen control-panel view (M252dw model) ........................................................ 72

Home screen layout ...................................................................................... 73

Touchscreen control-panel view (M274 and M277 models) .......................................... 74

Home screen layout ...................................................................................... 75

Setup menu ..................................................................................................................... 76

HP Web Services menu ................................................................................. 76

Reports menu ............................................................................................... 77

Self Diagnostics menu .................................................................................. 79

Fax Setup menu ............................................................................................ 79

System Setup menu ..................................................................................... 82

Service menu ................................................................................................ 86

Network Setup menu .................................................................................... 88

Quick Forms menu ........................................................................................ 89

Function specic menus ................................................................................................. 90

USB menu ..................................................................................................... 90

Fax Menu (M277 models only) ..................................................................... 90

Copy menu (M274 and M277 models only) .................................................. 92

Scan menu (M274 and M277 models only) .................................................. 94

Apps .............................................................................................................. 94

Control panel message document (CPMD) ........................................................................................ 95

Control-panel message types ......................................................................................... 95

Control-panel messages and event log entries ............................................................. 95

Alpha Error Messages ................................................................................... 95

49.XX.YY Error Messages ............................................................................ 105

50.XX fuser errors ...................................................................................... 106

x ENWW

Page 13

51.XX and 52 Laser/Scanner Errors ........................................................... 107

54.XX Error Messages ................................................................................ 108

55.XXXX Error Messages ............................................................................ 108

57.XX Error Messages ................................................................................ 109

58.XX Error Messages ................................................................................ 109

59.XX Error Messages ................................................................................ 110

79 Errors ..................................................................................................... 111

Tools for troubleshooting: Event log messages ............................................................................. 112

Print an event log .......................................................................................................... 112

View the event log ........................................................................................................ 112

Event-log messages ..................................................................................................... 113

Solve image quality problems ........................................................................................................................... 119

Improve print quality ...................................................................................................................... 119

Repetitive defects ruler ................................................................................................ 119

Print from a dierent software program ..................................................................... 120

Check the paper-type setting for the print job ............................................................ 120

Check the paper type setting (Windows) ................................................... 120

Check the paper type setting (Mac OS X) ................................................... 120

Check toner-cartridge status ....................................................................................... 121

Print and interpret the print quality page .................................................................... 121

Clean the printer ........................................................................................................... 122

Print a cleaning page .................................................................................. 122

Clean the scanner glass strip and platen ................................................... 123

Visually inspect the toner cartridge ............................................................................. 123

Check paper and the printing environment .................................................................. 124

Step one: Use paper that meets HP specications .................................... 124

Step two: Check the environment .............................................................. 124

Calibrate the printer to align the colors ....................................................................... 124

Check other print job settings ...................................................................................... 125

Check the EconoMode settings .................................................................. 125

Adjust color settings (Windows) ................................................................ 126

Try a dierent print driver ............................................................................................ 127

Clean the printer ................................................................................................................................................ 129

Print a cleaning page ....................................................................................................................... 129

Clean the scanner glass strip and platen ........................................................................................ 129

Clean the pickup and separation rollers ......................................................................................... 130

Clean the pickup rollers and separation pad in the document feeder ........................................... 131

Clean the touchscreen ..................................................................................................................... 131

Solve paper-handling problems ........................................................................................................................ 132

Printer feeds incorrect page size .................................................................................................... 132

Printer pulls from incorrect tray ..................................................................................................... 132

ENWW xi

Page 14

Printer will not duplex or duplexes incorrectly ............................................................................... 132

Paper does not feed from Tray 2 .................................................................................................... 133

Output is curled or wrinkled ............................................................................................................ 133

Printer does not pick up paper or misfeeds .................................................................................... 134

The printer does not pick up paper .............................................................................. 134

The printer picks up multiple sheets of paper ............................................................. 134

The document feeder jams, skews, or picks up multiple sheets of paper (M274

and M277 models) ........................................................................................................ 135

Paper does not feed automatically .............................................................................. 135

Prevent paper jams ............................................................................................................................................ 136

Clear paper jams ................................................................................................................................................ 137

Introduction ..................................................................................................................................... 137

Experiencing frequent or recurring paper jams? ............................................................................ 137

Paper jam locations ......................................................................................................................... 138

Clear paper jams in the document feeder (M274 and M277 models only) .................................... 140

Clear paper jams in the single-sheet slot (Tray 1) .......................................................................... 142

Clear paper jams in Tray 2 ............................................................................................................... 144

Clear paper jams in the rear door and the fuser area (simplex models) ........................................ 147

Clear paper jams in the output bin .................................................................................................. 149

Clear paper jams in the duplexer (duplex models) ......................................................................... 150

Solve performance problems ............................................................................................................................ 152

Solve connectivity problems ............................................................................................................................. 153

Solve USB connection problems ..................................................................................................... 153

Solve wired network problems ....................................................................................................... 153

Introduction .................................................................................................................. 153

Poor physical connection .............................................................................................. 153

The computer is using the incorrect IP address for the printer ................................... 153

The computer is unable to communicate with the printer ........................................... 154

The printer is using incorrect link and duplex settings for the network ..................... 154

New software programs might be causing compatibility problems ........................... 154

The computer or workstation might be set up incorrectly .......................................... 154

The printer is disabled, or other network settings are incorrect ................................. 154

Solve wireless network problems ................................................................................................... 154

Introduction .................................................................................................................. 154

Wireless connectivity checklist ..................................................................................... 155

The printer does not print after the wireless conguration completes ...................... 155

The printer does not print, and the computer has a third-party rewall installed ..... 156

The wireless connection does not work after moving the wireless router or printer . 156

Cannot connect more computers to the wireless printer ............................................ 156

The wireless printer loses communication when connected to a VPN ........................ 156

The network does not appear in the wireless networks list ........................................ 156

xii ENWW

Page 15

The wireless network is not functioning ...................................................................... 156

Perform a wireless network diagnostic test ................................................................ 157

Reduce interference on a wireless network ................................................................. 157

Service mode functions ..................................................................................................................................... 158

Service menu ................................................................................................................................... 158

Secondary service menu ................................................................................................................. 159

Printer resets ................................................................................................................................... 160

Restore the factory-set defaults .................................................................................. 160

NVRAM initialization ..................................................................................................... 161

Super NVRAM initialization ........................................................................................... 161

Solve fax problems (fax models only) ............................................................................................................... 163

Checklist for solving fax problems .................................................................................................. 163

Perform a fax diagnostic test ......................................................................................................... 164

Solve general fax problems ............................................................................................................ 164

Faxes are sending slowly .............................................................................................. 164

Print quality of a photo is poor or prints as a gray box. ............................................... 165

Fax quality is poor ......................................................................................................... 165

You touched the Cancel button to cancel a fax, but the fax was still sent ............. 166

No fax address book button displays ........................................................................... 166

Not able to locate the fax settings in HP Web Jetadmin .............................................. 166

The header is appended to the top of the page when the overlay option is enabled . 166

A mix of names and numbers is in the recipients box .................................................. 166

A one-page fax prints as two pages ............................................................................. 167

A document stops in the document feeder in the middle of faxing ............................ 167

The volume for sounds coming from the fax accessory is too high or too low ........... 167

Use fax over VoIP networks .......................................................................................... 167

Solve problems receiving faxes ...................................................................................................... 167

Solve problems sending faxes ........................................................................................................ 172

Fax error messages on the control panel ....................................................................................... 173

The No Fax Detected message displays ....................................................................... 173

The Communication error message appears ............................................................... 173

No Dial Tone .................................................................................................................. 174

The Fax is busy message appears ................................................................................ 175

The No fax answer message appears ........................................................................... 175

Document feeder paper jam ......................................................................................... 176

The Fax storage is full message appears ..................................................................... 176

Scanner error ................................................................................................................ 176

The control panel displays a Ready message with no attempt to send the fax .......... 176

The control panel displays the message "Storing page 1" and does not progress

beyond that message ................................................................................................... 177

Faxes can be received, but not sent ............................................................................. 177

ENWW xiii

Page 16

Printer is password protected ...................................................................................... 177

Unable to use fax functions from the control panel .................................................... 178

Unable to use speed dials ............................................................................................. 178

Unable to use group dials ............................................................................................. 178

Receive a recorded error message from the phone company when trying to send

a fax ............................................................................................................................... 178

Unable to send a fax when a phone is connected to the printer .................................. 179

Troubleshoot fax codes and trace reports ...................................................................................... 179

View and interpret fax error codes ............................................................................... 179

Fax trace report ............................................................................................................ 180

Fax logs and reports ........................................................................................................................ 180

Print all fax reports ....................................................................................................... 180

Print individual fax reports ........................................................................................... 181

Set the fax error report ................................................................................................. 181

Set the fax-error-correction mode ................................................................................................. 181

Change the fax speed ...................................................................................................................... 182

Use fax on a DSL, PBX, or ISDN system ........................................................................................... 182

DSL ................................................................................................................................ 182

PBX ................................................................................................................................ 182

ISDN ............................................................................................................................... 183

Solve email problems ........................................................................................................................................ 184

Cannot connect to the email server ................................................................................................ 184

Validate the SMTP gateway (Windows) .......................................................................................... 184

Validate the LDAP gateway (Windows) ........................................................................................... 184

Update the rmware ......................................................................................................................................... 185

Method one: Update the rmware using the control panel ........................................................... 185

Method two: Update the rmware using the Firmware Update Utility .......................................... 186

Appendix A Certicates of volatility ............................................................................................................... 187

Certicate of volatility ....................................................................................................................................... 188

Index ........................................................................................................................................................... 195

xiv ENWW

Page 17

List of tables

Table 1-1 Sequence of operation .......................................................................................................................................... 4

Table 1-2 Printer motors1 ................................................................................................................................................... 11

Table 1-3 Printer fan ........................................................................................................................................................... 12

Table 1-4 Solenoids ............................................................................................................................................................ 12

Table 1-5 Switches .............................................................................................................................................................. 13

Table 1-6 Sensors ............................................................................................................................................................... 14

Table 1-7 Image formation process ................................................................................................................................... 17

Table 1-8 Switches and sensors for the pickup, feed, and delivery system ...................................................................... 27

Table 1-9 Motors and solenoids for the pickup, feed, and delivery system ...................................................................... 28

Table 2-1 Troubleshooting owchart ................................................................................................................................. 44

Table 2-2 Formatter connections—M252 models ............................................................................................................. 53

Table 2-3 Formatter connections—M277 models ............................................................................................................. 54

Table 2-4 DC controller connectors .................................................................................................................................... 55

Table 2-5 Major components (printer base) ....................................................................................................................... 57

Table 2-6 Rollers (printer base) .......................................................................................................................................... 59

Table 2-7 Main PCAs (printer base) ..................................................................................................................................... 60

Table 2-8 Repetitive image defects .................................................................................................................................... 66

Table 2-9 HP Web Services menu ....................................................................................................................................... 76

Table 2-10 Reports menu ................................................................................................................................................... 77

Table 2-11 Self Diagnostics menu ...................................................................................................................................... 79

Table 2-12 Fax Setup menu ................................................................................................................................................ 79

Table 2-13 System Setup menu ......................................................................................................................................... 82

Table 2-14 Service menu .................................................................................................................................................... 86

Table 2-15 Network Setup menu ........................................................................................................................................ 88

Table 2-16 Quick Forms menu ............................................................................................................................................ 89

Table 2-17 USB menu ......................................................................................................................................................... 90

Table 2-18 Fax Menu ........................................................................................................................................................... 90

Table 2-19 Copy menu ........................................................................................................................................................ 92

Table 2-20 Scan menu ........................................................................................................................................................ 94

Table 2-21 Event-log messages (X=0: black cartridge, X=1: cyan cartridge, X=2: magenta cartridge, X=3: yellow

cartridge) .............................................................................................................................................................................. 113

Table 2-22 Fax event log codes ........................................................................................................................................ 118

ENWW xv

Page 18

Table 2-23 Repetitive image defects ............................................................................................................................... 119

Table 2-24 Solve performance problems ......................................................................................................................... 152

Table 2-25 Service menu .................................................................................................................................................. 158

Table 2-26 Secondary service menu ................................................................................................................................ 159

Table 2-27 Solve problems receiving faxes ..................................................................................................................... 167

Table 2-28 Solve problems sending faxes ....................................................................................................................... 172

xvi ENWW

Page 19

List of gures

Figure 1-1 Basic operation .................................................................................................................................................... 3

Figure 1-2 Engine-control system ........................................................................................................................................ 9

Figure 1-3 Engine control unit ............................................................................................................................................ 10

Figure 1-4 High-voltage power supply ............................................................................................................................... 11

Figure 1-5 Low-voltage power supply ............................................................................................................................... 15

Figure 1-6 Laser scanner system ....................................................................................................................................... 16

Figure 1-7 Image-formation process ................................................................................................................................. 17

Figure 1-8 Primary charging ............................................................................................................................................... 18

Figure 1-9 Laser-beam exposure ....................................................................................................................................... 19

Figure 1-10 Development ................................................................................................................................................... 19

Figure 1-11 Primary transfer .............................................................................................................................................. 20

Figure 1-12 Secondary transfer ......................................................................................................................................... 20

Figure 1-13 Separation ....................................................................................................................................................... 21

Figure 1-14 Fusing .............................................................................................................................................................. 21

Figure 1-15 Drum cleaning ................................................................................................................................................. 22

Figure 1-16 Toner cartridge system ................................................................................................................................... 23

Figure 1-17 ITB assembly ................................................................................................................................................... 25

Figure 1-18 Paper path ....................................................................................................................................................... 26

Figure 1-19 Switches and sensors for the pickup, feed, and delivery system .................................................................. 27

Figure 1-20 Motors and solenoids for the pickup, feed, and delivery system .................................................................. 28

Figure 1-21 Duplexing unit controls ................................................................................................................................... 30

Figure 2-1 Engine test page ................................................................................................................................................ 46

Figure 2-2 Engine test page ................................................................................................................................................ 47

Figure 2-3 Engine test page ................................................................................................................................................ 48

Figure 2-4 Engine test page ................................................................................................................................................ 51

Figure 2-5 Sensors and switches ........................................................................................................................................ 52

Figure 2-6 Formatter connections—M252 models ........................................................................................................... 53

Figure 2-7 Formatter connections—M274 and M277 models .......................................................................................... 54

Figure 2-8 DC controller PCA connectors ........................................................................................................................... 55

Figure 2-9 Major components (printer base) ..................................................................................................................... 57

Figure 2-10 Motors and fan ................................................................................................................................................ 58

Figure 2-11 Rollers (printer base) ...................................................................................................................................... 59

ENWW xvii

Page 20

Figure 2-12 Main PCAs (printer base) ................................................................................................................................. 60

Figure 2-13 General timing chart ....................................................................................................................................... 61

Figure 2-14 General circuit diagram (printer base) ............................................................................................................ 62

Figure 2-15 Examples of repetitive defects ....................................................................................................................... 67

Figure 2-16 Place the ruler on the page ............................................................................................................................. 68

Figure 2-17 Locate the next repetitive defect ................................................................................................................... 68

Figure 2-18 Determine the defective assembly ................................................................................................................. 69

Figure 2-19 Print quality page ......................................................................................................................................... 122

Figure A-1 Certicate of volatility M252 (1 of 2) .............................................................................................................. 188

Figure A-2 Certicate of volatility M252 (2 of 2) .............................................................................................................. 189

Figure A-3 Certicate of volatility M274 (1 of 2) .............................................................................................................. 190

Figure A-4 Certicate of volatility M274 (2 of 2) .............................................................................................................. 191

Figure A-5 Certicate of volatility M277 (1 of 2) .............................................................................................................. 192

Figure A-6 Certicate of volatility M277 (2 of 2) .............................................................................................................. 193

xviii ENWW

Page 21

1 Theory of operation

●

Related documentation and software

●

Basic operation

●

Formatter-control system

●

Engine-control system

●

Engine laser scanner system

●

Image formation system

●

Engine pickup, feed, and delivery system

●

Scanning and image capture system

●

Automatic document feeder (ADF) system

●

Fax functions and operation (fax models only)

ENWW 1

Page 22

Related documentation and software

HP service personnel, go to the Service Access Work Bench (SAW) at http://h41302.www4.hp.com/km/saw/

home.do.

Channel partners, go to HP Channel Services Network (CSN) at https://h30125.www3.hp.com/hpcsn.

2 Chapter 1 Theory of operation ENWW

Page 23

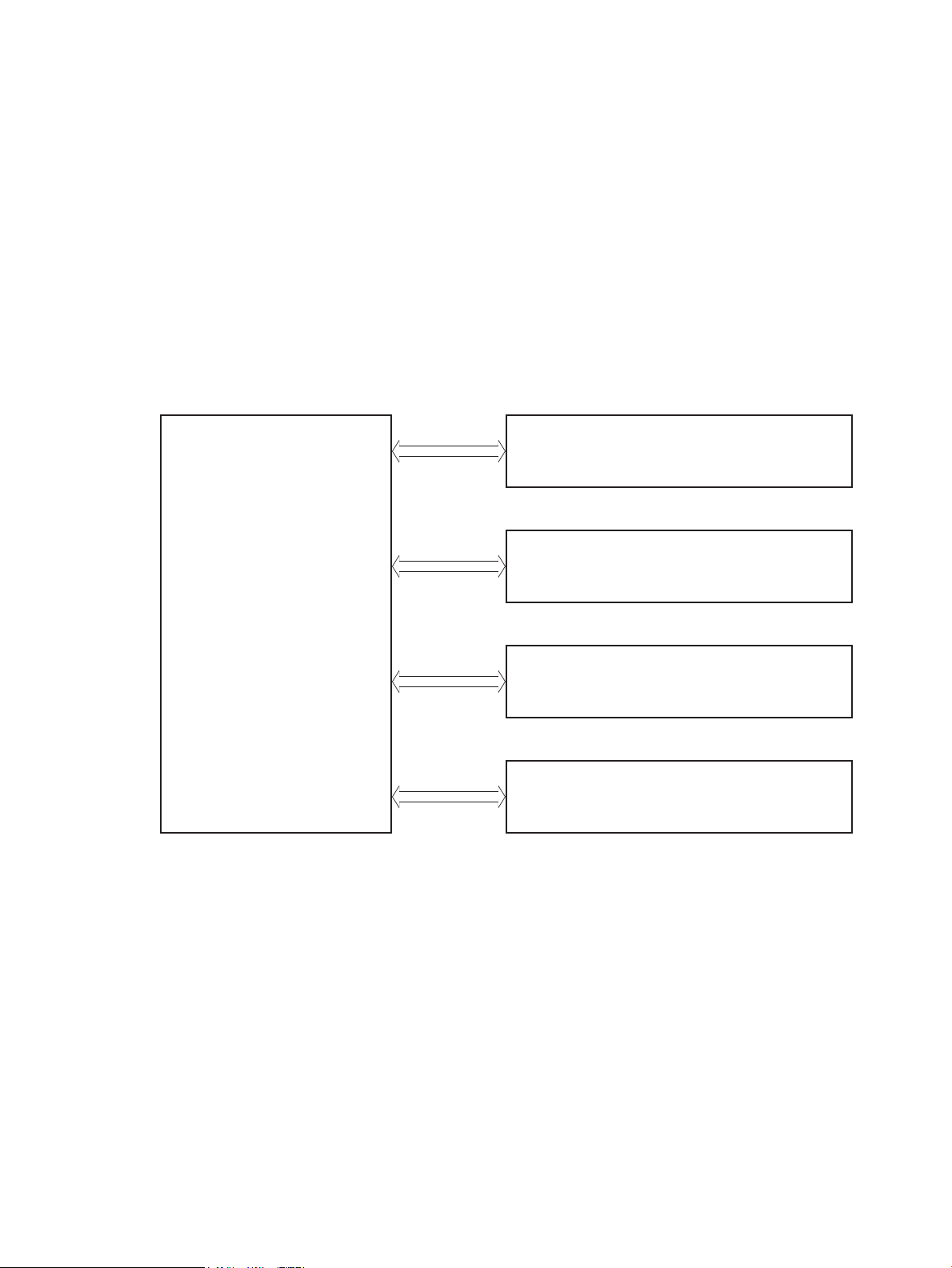

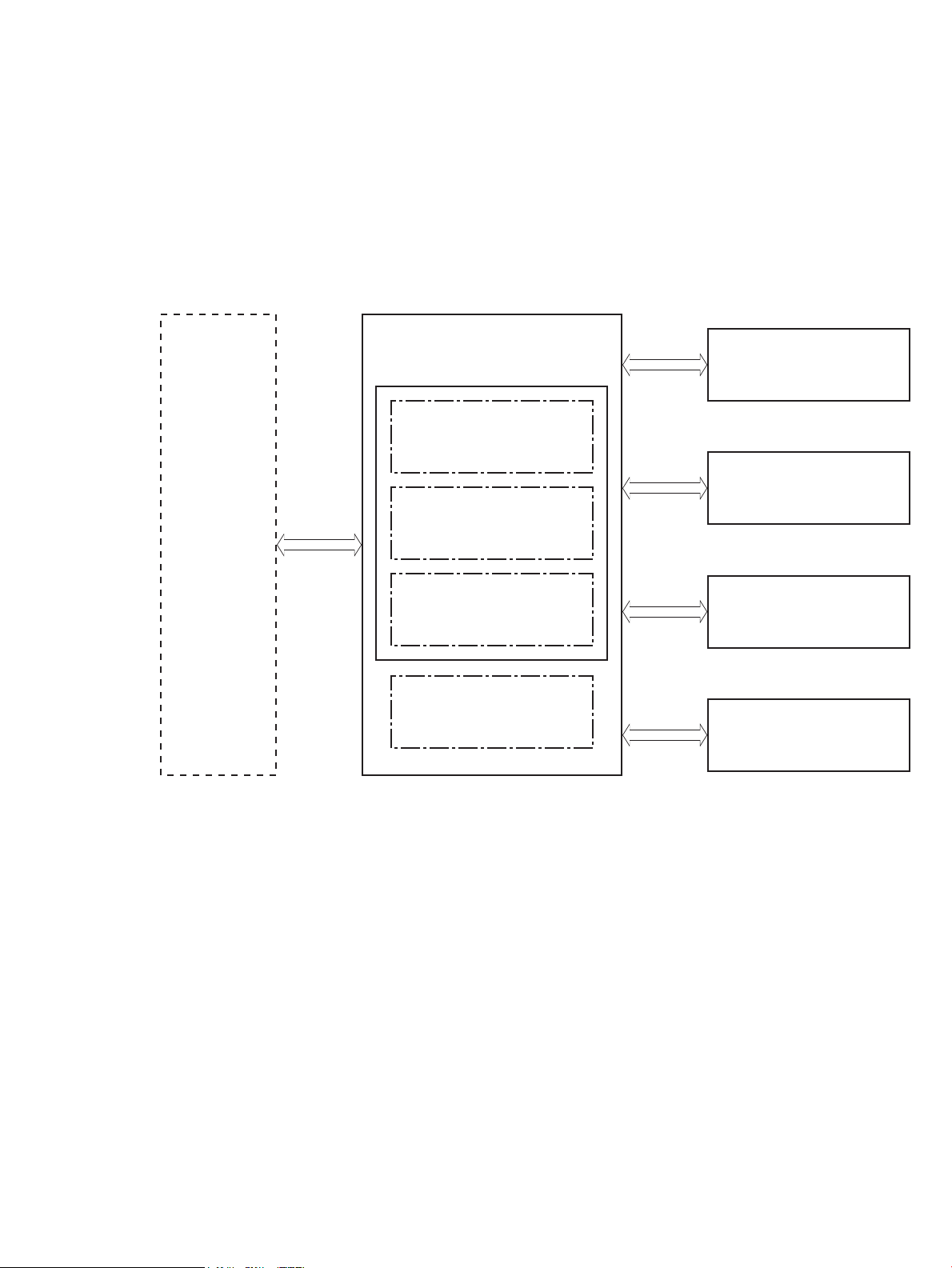

Basic operation

Engine-control system

Laser scanner system

Image-formation system

Pickup, feed and delivery system

Scanner system (M274 and M277 models only)

The printer routes all high-level processes through the formatter, which stores font information, processes

the print image, and communicates with the host computer.

The basic printer operation comprises the following systems:

●

Engine control system

●

Laser scanner system

●

Image-formation system

●

Pickup, feed, and delivery system

●

Integrated scanner system (M274 and M277 models only)

Figure 1-1 Basic operation

ENWW Basic operation 3

Page 24

Sequence of operation

The DC controller PCA controls the operating sequence, as described in the following table.

Table 1-1 Sequence of operation

Period Duration Description

Waiting From the time the power is turned on,

the door is closed, or when the printer

exits sleep mode until the printer is

ready for printing

Standby From the end of the waiting sequence,

the last rotation until the formatter

receives a print command, or until the

printer is turned o

Initial rotation From the time the formatter receives

a print command until the paper

enters the paper path

●

Heats the fuser lm in the fuser

●

Pressurizes the fuser pressure roller

●

Detects the toner cartridges

●

Separates all of the developer rollers from the photosensitive

drums

●

Rotates and stops each motor

●

Rotates and stops the main fan

●

Cleans the intermediate transfer belt (ITB) and secondary

transfer roller

●

Detects cable breakage on the thermistor

●

Detects any residual paper in the engine

●

The printer is in the Ready state

●

The printer enters sleep mode if the sleep command is received

from the formatter

●

The printer calibrates if it is time for an automatic calibration

●

Rotates each motor and the main fan

●

Activates the high-voltage power supply

Printing From the time the rst sheet of paper

enters the paper path until the last

sheet has passed through the fuser

Last rotation From the time the last sheet of paper

exits the fuser until the motors stop

rotating

●

Prepares the laser scanner unit

●

Warms the fuser to the correct temperature

●

Forms the image on the photosensitive drums

●

Transfers the toner to the paper

●

Fuses the toner image onto the paper

●

Moves the last printed sheet into the output bin

●

Stops each motor and the main fan

●

Stops the high-voltage power supply

●

Stops the laser scanner unit

●

Stops the fuser

●

Cleans the ITB and secondary transfer roller

●

If the DC controller receives another print command, the printer

enters the initial rotation period when the last rotation is

complete.

4 Chapter 1 Theory of operation ENWW

Page 25

Formatter-control system

The formatter is involved in the following procedures:

●

Controlling the sleep delay function

●

Receiving and processing print data from the various printer inputs

●

Monitoring control-panel functions and relaying printer status information (through the control panel

and the bidirectional input/output)

●

Developing and coordinating data placement and timing with the DC controller PCA

●

Storing font information

●

Communicating with the host computer through the bidirectional interface

The formatter receives a print job from the bidirectional interface and separates it into image information and

instructions that control the printing process. The DC controller PCA synchronizes the image-formation

system with the paper input and output systems, and then signals the formatter to send the print-image

data.

Sleep delay

When the printer is in sleep delay mode, the control-panel backlight is turned o, but the printer retains all

printer settings, downloaded fonts, and macros. The default setting is a 15-minute idle time. The setting can

be changed or turned o from the control panel menus.

The printer exits sleep delay mode and enters the warm-up cycle when any of the following occurs:

●

A print job, valid data, or a PML or PJL command is received at the serial port.

●

The control panel is touched.

●

A document is loaded in the document feeder or the scanner lid is opened.

●

A tray is opened.

TIP: Error messages override the sleep delay message. The printer enters sleep mode at the appropriate

time, but the error message continues to display.

Printer job language (PJL)

Printer job language (PJL) is an integral part of conguration, in addition to the standard printer command

language (PCL). With standard cabling, use PJL to perform a variety of functions.

●

Dynamic I/O switching. The printer can be congured with a host on each I/O by using dynamic I/O

switching. Even when the printer is oine, it can receive data from more than one I/O simultaneously,

until the I/O buer is full.

●

Context-sensitive switching. The printer can automatically recognize the personality (PS or PCL) of each

job and congure itself in that personality.

●

Isolation of print environment settings from one print job to the next. For example, if a print job is sent

to the printer in landscape mode, the subsequent print jobs are printed in landscape mode only if they

are formatted for it.

ENWW Formatter-control system 5

Page 26

Printer management language (PML)

The printer management language (PML) allows remote conguration and status monitoring through the I/O

ports.

Control panel

The formatter sends and receives printer status and command data to and from the control panel.

Walk-up USB (touchscreen models only)

This printer features printing from a USB ash drive. This printer supports printing the following types of les

from the USB ash drive:

●

.pdf

●

.jpg

●

.prn and .PRN

●

.cht and .CHT

●

.pxl

●

.pcl and .PCL

●

.ps and .PS

●

.doc and .docx

●

.ppt and .pptx

When a USB ash drive is inserted into the front of the printer, the control panel displays the USB Flash Drive

menu. The les present on the USB ash drive can be accessed from the control panel. Any les in a

supported format on the USB ash drive can be printed directly from the printer control panel. Pages also can

be scanned and saved to the USB ash drive from the control panel.

Wireless (wireless models only)

Wireless models contain a wireless card to enable 802.11b/g/n wireless communication.

Low end data model (LEDM)

The low-end data model (LEDM) provides one consistent data representation method and denes the

dynamic and capabilities tickets shared between clients and devices, as well as the access protocol, event,

security, and discovery methods.

Advanced control language (ACL) overview

The advanced control language (ACL) is a language that supports printer control and rmware downloads in

printers that support both PJL/PCL and host-based printing. Each sequence of ACL commands must be

preceded by a unied exit command (UEL) and an @PJL ENTER LANGUAGE=ACL command. The ACL sequence

is always followed by a UEL. Any number of commands can be placed between the UELs. The only exception to

these rules is the download command. If a rmware download is completed, the download command must be

the last command in the sequence. It will not be followed by a UEL.

6 Chapter 1 Theory of operation ENWW

Page 27

The rmware searches for the UEL sequence when parsing commands. However, while downloading binary

data such as host-based code or NVRAM data the rmware suspends UEL parsing. To handle hosts that

“disappear” during binary sequences, the rmware times out all ACL command sessions. If a timeout occurs

during a non-download command sequence, it is treated as the receipt of a UEL. If a timeout occurs during

rmware download, the printer resets.

Near eld communication (NFC) (wireless models only)

This printer supports near eld communication (NFC) capabilities. NFC enables an easy one-to-one HP

wireless direct print connection using a simple device-to-device touch. Mobile device users can quickly

connect to the printer and print documents and images from a mobile device, such as a smartphone or tablet,

by touching the device to the NFC icon on the printer.

CPU

The formatter incorporates an 800 MHz processor.

Input/output

The following sections discuss the input and output features of the printer.

USB

The printer includes a universal serial bus (USB) 2.0 connection.

USB hosts

The printer includes USB hosts for USB ash drive and wireless communication control.

10/100 networking

The printer includes a 10/100 network (ethernet) connection.

Fax (M277 models only)

The M277 models include a fax phone line connection.

Memory

If the printer encounters a problem when managing available memory, a clearable warning message displays

on the control panel.

Firmware

Memory on the formatter stores the rmware. A remote rmware upgrade process is used to overwrite and

upgrade the rmware.

Nonvolatile random access memory (NVRAM)

The printer uses nonvolatile memory (NVRAM) to store I/O and information about the print environment

conguration. The contents of NVRAM are retained when the printer is turned o or disconnected.

Flash memory

NOR: Stores microprocessor control programs and internal character sets (fonts).

ENWW Formatter-control system 7

Page 28

NAND: Stores fax memory (M277 models only) and driver installation software.

Random access memory (RAM)

The M252n model comes with 128 MB of memory installed. All other models come with 256 MB of memory

installed. The formatter has 256 MB NAND Flash.

HP Memory enhancement technology (MEt)

The HP Memory Enhancement technology (MEt) eectively doubles the standard memory through a variety of

font- and data-compression methods.

NOTE: The MEt is available only in PCL mode; it is not functional when printing in PS mode.

8 Chapter 1 Theory of operation ENWW

Page 29

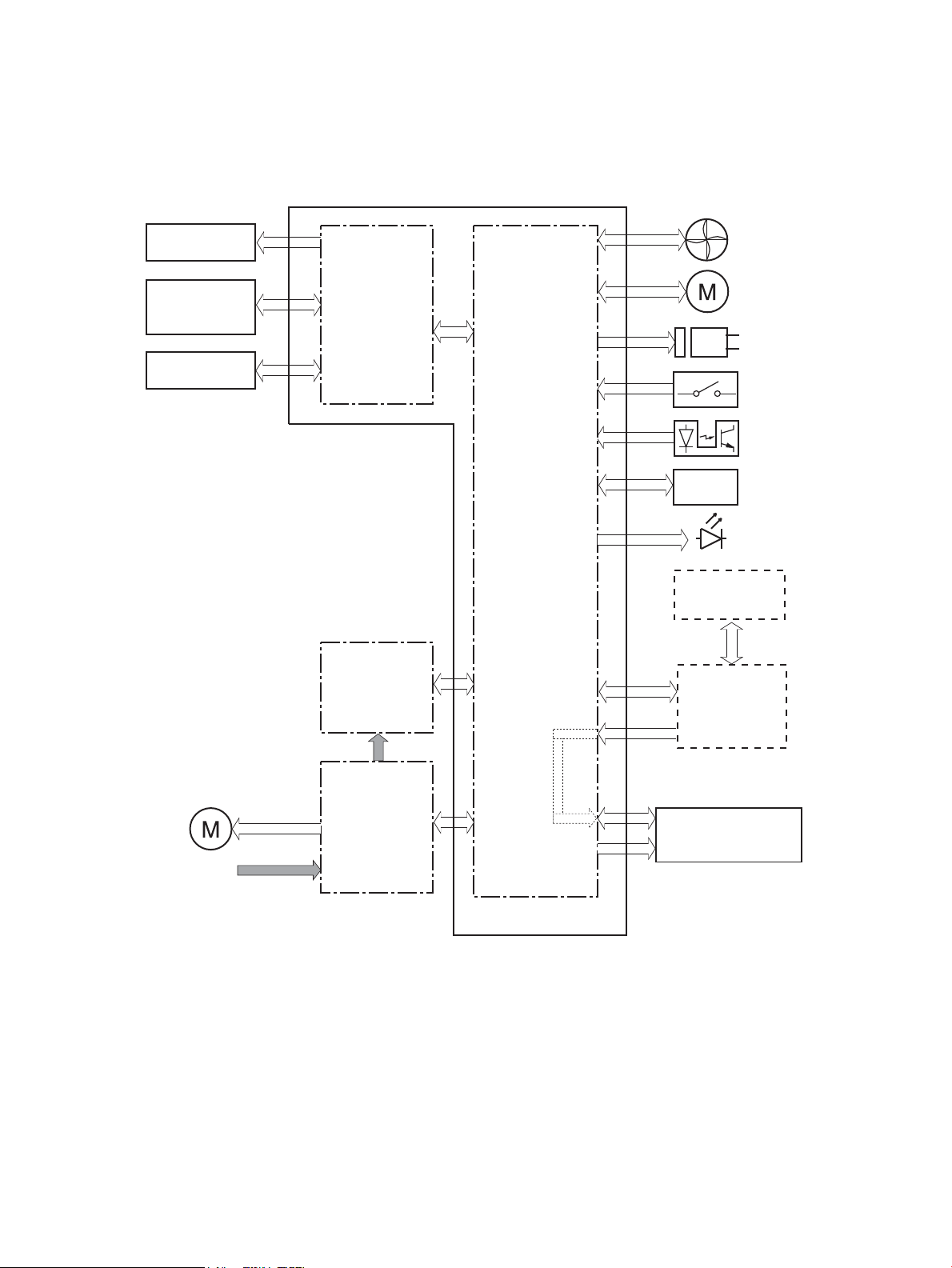

Engine-control system

Formatter

DC controller

Low-voltage power supply

Laser scanner system

Image-formation system

Pickup, feed and delivery

system

High-voltage power supply

Fuser control

Engine controller

Formatter-control system

Scanner system

(M274, M277 models only)

The engine-control system receives commands from the formatter and coordinates all the other systems.

The engine-control system contains the following components:

●

Engine control unit: DC controller and high-voltage power supply

●

Low-voltage power supply

●

Fuser control

Figure 1-2 Engine-control system

The formatter receives a print job from the bidirectional interface and separates it into image information and

instructions that control the printing process. The DC controller PCA synchronizes the image-formation

system with the paper input and output systems, and then signals the formatter to send the print-image

data.

ENWW Engine-control system 9

Page 30

Engine control unit (ECU)

ITB assembly

Secondary

transfer roller

Cartridge

(Y/M/C/K)

High-voltage

power supply

LED

Fan

Motor

Solenoid

Switch

Photointerrupter

Sensor

Formatter

Control panel

Laser scanner

assembly

AC input

Low-voltage

power supply

Fuser

Motor

DC controller

Engine control unit

The engine control unit includes the DC controller and the high-voltage power supply.

Figure 1-3 Engine control unit

DC controller

The DC controller PCA controls the operation of the printer and its components. The DC controller PCA starts

printer operation when the power is turned on and the power supply sends DC voltage to the DC controller

PCA. After the printer enters the standby sequence, the DC controller PCA sends out various signals to operate

motors, solenoids, and other electrical components based on the print command and image data that the

host computer sends.

10 Chapter 1 Theory of operation ENWW

Page 31

High-voltage power supply

Y

M

C

K

ITB

High-voltage power supply

Static charge

eliminator

T1 bias and

developing bias

circuit (YMC)

T2 bias circuit

ITB cleaning brush

bias circuit

T2 roller

Cartridge

DC controller

ITB cleaning brush

Engine controller

T1 bias and

developing bias

circuit (Bk)

Static charge

eliminator bias

circuit

The DC controller controls the high-voltage power supply to generate high-voltage biases. The high-voltage

power supply generates the high-voltage biases that are applied to the following components:

●

Primary charging roller (in the toner cartridges)

●

Developer roller (in the toner cartridges)

●

Primary transfer roller

●

Secondary transfer roller

●

ITB cleaning brush

●

Static charge eliminator

Figure 1-4 High-voltage power supply

Motors

The printer includes four motors that aect the paper-feed and image-formation processes.

Table 1-2 Printer motors

Component name Abbreviation Components driven

Main motor M701

ENWW Engine-control system 11

1

●

Photosensitive drum

●

Developer

●

Intermediate transfer belt (ITB)

Page 32

Table 1-2 Printer motors1 (continued)

Component name Abbreviation Components driven

Fuser motor M702

Pickup motor M703

Scanner motor M704

1

Because the integrated scanner assembly on the M274 and M277 models is a whole unit replacement, those motors are not included

on this list.

●

Pressure roller

●

Pressure/release of the pressure roller

●

Output roller

●

Duplex feed roller (duplex models only)

●

Pickup roller

●

Feed roller

●

Feed roller Registration roller

●

Duplex re-pickup roller (duplex models only)

●

Scanner mirror

The DC controller determines the following motor failures:

●

ITB motor start-up failure

●

ITB motor rotation failure

●

Developer alienation failure

Fans

Solenoids

The printer has one fan for preventing the printer from overheating and for cooling the delivered media.

Table

1-3 Printer fan

Component name Abbreviation Cooling area Type Speed

Main fan FM1

●

Toner cartridges

●

Low-voltage power supply area

Intake Full/Half

The DC controller determines the fan motor1 failure.

The printer has four solenoids. Solenoids are used for printer operation control.

1-4 Solenoids

Table

Component abbreviation Component name

SL711 Developer alienation solenoid

SL712 Pickup solenoid

SL713 Duplex re-pickup solenoid (duplex models only)

SL714 Duplex switchback solenoid (duplex models only)

12 Chapter 1 Theory of operation ENWW

Page 33

Switches

The printer has seven switches. Switches are used for printer operation control.

Table 1-5 Switches

Component abbreviation Component name

SW1 Developer home position detection switch

SW2 Fuser pressure release detection switch

SW3 Rear door switch, left

SW4 Front door switch

SW5 Priority slot media presence detection switch

SW6 Rear door switch, right (simplex models only)

SW601 Power switch

ENWW Engine-control system 13

Page 34

Sensors

The printer has 10 sensors. Sensors are used for remote detection of various functions during printer

operation.

Table 1-6 Sensors

Component abbreviation Component name

SR601 Media width sensor, right

SR602 Media width sensor, left

SR603 Priority slot top sensor

SR604 Registration sensor

SR606 Loop sensor (simplex models only)

SR607 Fuser delivery sensor

SR608 Output sensor (M252dw, M274 and M277 models only)

SR616 Loop sensor (duplex models only)

(NA) Registration density sensor

(NA) Environment sensor (measures temperature and humidity)

14 Chapter 1 Theory of operation ENWW

Page 35

Low-voltage power supply

Power switch

SW601

Low-voltage

power supply

AC input

DC controller

Fuse

FU101

Rectifying

circuit

+24V

generation

circuit

+3.3V

generation

circuit

Protection

circuit

+3.3VA

+24VA

PWSV

+3.3V

control circuit

Formatter, Contol panel

+3.3VC

+24V

control circuit

+3.3VB

+3.3VD

Front door switch

SW4

+3.3VA

+3.3VC

+24VB (Nebula only)

+24VB

REM24V

+24VB1

The low-voltage power supply converts AC power from the power receptacle into DC power to cover the DC

loads.

Figure 1-5 Low-voltage power supply

Overcurrent/overvoltage protection

The low-voltage power supply has a protective function against overcurrent and overvoltage conditions to

prevent failures in the power supply circuit. If an overcurrent or overvoltage event occurs, the system

automatically cuts o the output voltage.

Low-voltage power supply unit failure detection

If the DC power is not being supplied from the low-voltage power supply, the protective function might have

activated. In this case, turn o the power switch, and then disconnect the power cord. Do not connect the

power cord or turn the power switch on again until the root cause is found.

The DC controller determines a low-voltage power supply failure, stops 24V output and noties the formatter

when it detects that the 24V output is higher than the specied voltage.

ENWW Engine-control system 15

Page 36

Engine laser scanner system

Beam detect

sensor

Laser assembly

Scanner mirror

Scanner motor assembly

Photosensitive drum (K)

Photosensitive drum (C)

Photosensitive drum (M)

Photosensitive drum (Y)

DC controller

The formatter sends video signals to the DC controller, which controls the laser scanner. When the laser

scanner system receives those signals, it converts them to latent images on the photosensitive drum.

Figure 1-6 Laser scanner system

Laser failure detection

The optical unit failure detection sensor manages the laser scanner unit failure-detection functions. The DC

controller identies the laser scanner unit failure and noties the formatter if the laser scanner unit

encounters the following conditions:

●

Scanner motor start-up failure

●

Scanner motor rotational failure

16 Chapter 1 Theory of operation ENWW

Page 37

Image formation system

Latent image formation

Developing

Transfer

Fusing

Drum cleaning

Pickup

Registration

6. Separation

7. Fusing

Delivery

4. Primary transfer

2. Laser-beam exposure

3. Developing

8. Drum cleaning

1. Priminary charging

: Paper path

: Direction of drum rotation

: Functional block

: Step

5. Secondary transfer

YM C K

Image formation process

The image-formation system consists of 10 steps divided into six functional blocks.

Figure 1-7 Image-formation process