Page 1

SERVICE MANUAL

HP M1403A

DIGITAL UHF TELEMETRY SYSTEM

SERIAL NUMBERS

This manual applies to units with the following serial number prefixes.

For serial numbers prefixed higher or lower than the number indicated,

refer to Section 1. Antenna system components are not serialized.

HP M1400A Transmitter Serial Prefix: 3032A

HP M1400B Transmitter Serial Prefix: XXXXX

HP M1401A Receiver Mainframe Serial Prefix:

HP M1402A Receiver Module Serial Prefix:

3148A

3148A

HP Part No. M1403-90030

Printed in U.S.A.

Second Edition

III I III1111 Ill1 II Ill1 RA

June 1997

Page 2

@ Copyright Hewlett-Packard Company 1997. This document contains or refers to proprietary

information which is protected by copyright. All rights are reserved. Copying or other

reproduction of this document is prohibited without the prior written permission of

Hewlett-Packard Company.

Page 3

Printing History

First Edition ..,,...................................,,......,......................~J~uary 1997

Warning

FCC WARNING:

This equipment generates, uses, and can radiate radio-frequency energy,

and if not installed and used in accordance with this manual, may cause

interference to radio communications.

Operation of this equipment in a residential area may cause interference,

in which case the users, at their own expense, must take whatever

measures may be required to correct the interference.

iii

Page 4

Page 5

Contents

1.

General

1.1 Description

1.1.1 Instrument Identification

1.1.2 Manual

1.1.3 Inquiries

1.1.4 Unpacking and Inspection

1.1.5

Claims

1.1.6

Functional Description

1.1.7 Ordering

1.1.8 Accessories.

1.1.9 Controls and Indicators

1.1.10 System INOPs and Alarms

1.1.11

1.2 Specifications

1.2.1 Specifications

1.2.2 Site Requirements

1.3 System Configurations and

1.3.1 Serial Distribution Network (SDN) Connections

1.3.2 Analog Output Option Wiring Configurations

1.3.3 Non-SCC Configurations

1.3.4 Pistol-grip Termination Tool

1.4 Configuration Parameters

1.4.1 ECG Parameters

1.4.2 ST Segment Analysis/Two-Channel Delayed Recording (Option C01)

1.4.3 Alarms.

1.4.4 Transmitter Button

1.4.5 Languages

1.4.6 Self-Tests

1.4.7 Serial Distribution Network

1.5 Instrument Installation

1.5.1 Wall Mount Installation

1.5.2 Receiver Module Installation

1.5.3 Antenna System Installation

Use with Other HP Products

1.2.2.1 Antenna System Site Information

1.3.3.1 Direct Connection to an HP Central Monitor

1.3.3.2 Direct Connection to an HP 78508A PIC

Parameters

1.5.1.1 Wall Mount Installation, HP M1403A Option #R86

1.5.1.1.1 Location of Mount

1.5.1.1.2 Installing Mount Base or Shelf

1.5.1.1.3 Installing Surface Wall Mount Base or Shelf on Solid Concrete or

1.5.1.1.4 Installing Surface Wall Mount Base or Shelf on Drywall

1.5.1.1.5 Installing HP M1401A Receiver Mainframe

1.5.1.2 WallMount Installation, HP M1403A Option #R90

...............................

.......................

Changes

...............................

and

Repackaging

Information

and Site Requirements

...............................

...............................

Solid Block Walls

(Plasterboard) Construction

...........................

.......................

.......................

........................

.........................

.............................

........................

......................

............................

..........................

Cabling

........................

......................

.........................

...........................

..........................

..............................

..............................

......................

..........................

........................

......................

..........................

.....................

...................

.................

....................

.................

.....................

.....................

.....................

.............

..............

............

..............

..........

...........

..........

1-1

1-1

1-2

1-2

1-3

1-3

1-3

1-5

1-27

1-27

1-28

1-30

1-31

1-31

1-39

1-39

1-40

1-40

1-48

1-48

1-48

1-48

1-57

1-59

1-59

1-62

1-62

1-63

1-63

1-63

1-64

1-67

1-67

1-67

1-69

1-71

1-73

1-74

1-77

1-77

1-79

1-79

Contents-1

Page 6

1.5.4 Analog Output Option (J01) Installation

................

1.5.5 ST Segment Analysis and Two-Channel Delayed Recording Option (C01)

Installation

1.5.6 Electrical Installation

1.5.6.1 Rear Panel Settings and Connections

1.5.6.1.1 Instrument Grounding and Power Cord

1.5.6.1.2 Instrument Power Fuses

1.5.6.2 Signal Connections

1.5.7 Transmitter Installation

...............................

.........................

................

.............

....................

........................

........................

1.5.7.1 Learning the Transmitter Code at a Patient Information Center

1.5.7.2 Learning the Transmitter Code at a Central Monitor

Part 1 - To enter the Discharge Task Window

Part 2 - To Learn the Transmitter Code

2. Theory of Operation

2.1 Introduction

...............................

2.1.1 General Information

2.1.2 Overall Functional Description

2.1.3 ECG Monitoring Capabilities

2.1.3.1 Fallback Mode

2.1.3.2 Extended Monitoring

2.2 Detailed Functional Description

2.2.1 HP M1400A and HP M1400B Transmitter

2.2.1.1 Electrode Lead Set

2.2.1.2 RF Module

............................

2.2.1.3 Transmitter Motherboard Assembly

2.2.1.3.1 ECG Hybrid PCB

2.2.1.3.2 Digital Hybrid PCB

2.2.1.3.3 Power Supply Hybrid PCB

2.2.1.4 Transmitter Signal

2.3 HP M1402A Receiver Module

2.3.1 RF Section

..............................

2.3.2 Digital Baseband Section

2.3.2.1 Detector

.............................

2.3.2.2 Microcontroller

2.3.2.3 Peripheral Devices

2.4 HP M1401A Receiver Mainframe

2.4.1 Power Supply

............................

2.4.2 Antenna Distribution Assembly

2.4.3 Receiver Backplane

2.4.4 Digital Backplane

2.4.5 Rack Interface

2.4.6 Utility CPU

2.4.7 SDN Interface

...........................

............................

.............................

............................

2.4.8 Turbo Processor Card and EPROM Board

...............

..................

.........................

....................

......................

..........................

.......................

......................

...............

........................

................

.......................

......................

...................

........................

.......................

.......................

..........................

........................

.....................

....................

..........................

................

........

2.4.9 Configurable Processor Card (Option CO3 or upgraded mainframe only)

Data Processing

Memory Array

2.4.10 Analog Output

2.5 Dynamic UHF Antenna System

2.5.1 HP M1408A Active Antenna/Combiner

2.5.2 HP M1406A Line Amplifier

.............................

..............................

...........................

......................

.................

......................

2.5.3 HP 78103A Two-Way and HP 78104A Four-Way Splitters and Combiners .

2.5.4 DC Power System

..........................

...

1-79

1-79

1-79

1-79

1-80

1-82

1-82

1-82

1-82

1-84

1-84

1-84

2-1

2-1

2-1

2-3

2-3

2-3

2-4

2-4

2-5

2-6

2-6

2-6

2-7

2-8

2-8

2-9

2-9

2-9

2-9

2-10

2-10

2-12

2-14

2-14

2-14

2-15

2-15

2-15

2-15

2-16

2-16

.

2-18

2-18

2-18

2-21

2-21

2-21

2-23

2-23

Contents-Z

Page 7

3. Maintenance

3.1 Performance Assurance Checks

3.1.1 System Performance Check

......................

......................

3.1.2 Receiver Mainframe and SDN System Connections Diagnostic Check

3.1.3 Radio Frequency Link and Receiver Module Diagnostic Check

3.1.4 Antenna System Check

3.1.5 Cooling Fan and Filter Maintenance

3.2 Calibration

................................

3.3 Specification Checks

3.3.1 Carrier Frequency Stability Check

3.3.1.1 Frequency Drift

3.3.1.2 Frequency Mismatch

3.3.2 Transmitter Battery Current Check

3.3.3 Receiver Mainframe Supply Voltage Checks

3.3.4 Antenna System Supply Voltage Check

3.4 Patient Safety Checks (U.S.A.)

3.4.1 Test Equipment Required

3.4.1.1 Checks Using Dempsey Safety Analyzer

3.4.1.2 Checks Using Conventional Test Equipment

3.4.2 Isolation from System Cabling

3.4.3 Isolation from Wall and Ceiling Mounts

3.4.4 Chassis to Ground Resistance Check

3.4.5 Chassis Leakage Current Test

3.5 Cleaning, Disinfection, and Sterilization

3.5.1 Cleaning

3.5.2 Disinfection

3.5.3 Sterilization

...............................

.............................

.............................

........................

..................

...........................

...................

.........................

.......................

..................

..............

.................

......................

.......................

..............

............

.....................

.................

..................

.....................

..................

......

...

3-1

3-1

3-2

3-5

3-6

3-7

3-9

3-9

3-9

3-9

3-9

3-10

3-11

3-12

3-13

3-13

3-13

3-14

3-14

3-14

3-14

3-16

3-18

3-18

3-18

3-19

4. Troubleshooting

4.1 Introduction

4.1.1 Bootstrap Sequence

4.1.2 Troubleshooting Matrix

...............................

.........................

........................

4.1.3 Abnormal Bootstrap Sequence (for M1401A Receiver Mainframes without

Option C03 or mainframes with the Turbo Processor Card)

........

4.1.4 Abnormal Bootstrap Sequence (for M1401A Receiver Mainframes with

Option C03 or mainframes with the 40 MHz CPC card installed )

4.2 Antenna System Troubleshooting

4.3 Radio Frequency (RF) Troubleshooting (Option C03 only)

4.3.1 RF History Strip Recording

To Print an RF History Strip Recording

4.3.1.1 Received Signal Strength and Invalid Data

4.3.1.2 Aligned Notation

.........................

4.3.2 RF Measurement INOP

RF Performance INOPs

..........................

4.4 Telemetry Service Screens

4.4.1 Telemetry Service Screen Access

.....................

..........

......................

..................

.............

........................

........................

...................

4.4.1.1 Accessing the Telemetry Service Screens with an HP 78560 or a CCM

lower than Release C.

........................

4.4.1.2 Accessing the Telemetry Service Screens with a CCM Release C or

Higher ................................

4.4.2 Telemetry Service I Screen

4.4.3 Status Log Screen

4.4.3.1 Log Entries

..........................

............................

4.4.4 Erase Verification Screen

4.4.5 Cancel Print Verification Screen

......................

.......................

....................

......

4-1

4-2

4-4

4-11

4-12

4-13

4-14

4-14

4-15

4-15

4-16

4-17

4-17

4-18

4-18

4-18

4-20

4-20

4-22

4-22

4-24

4-24

Contents-3

Page 8

4.4.6 Demonstration Verification Screen

4.4.7 INOP Log Control Screen

4.4.8 INOP Sort Bed Screen

4.4.8.1 Log Entries

............................

4.4.9 INOP Sort Time Screen

4.4.9.1 Log Entries

4.4.10

Examine Revisions Screen

4.4.10.1

Examine Revisions Information

............................

4.4.11 Examine Configuration Screen

4.5 Error Codes

4.5.1 Error Code

4.6

Fault Isolation

4.6.1 Turbo Processor

4.6.2

Utility CPU Errors

4.6.3 Rack

4.6.4 SDN

...............................

Fields

...........................

..............................

or 40 MHz CPC Card Errors

..........................

Interface Errors

Errors

.............................

4.6.5 Software/Configuration

5.

Service

5.1 Preventive Maintenance

5.1.1 Cleaning

...............................

5.1.2 Mechanical Inspection

5.1.3 Electrical Inspection

5.1.4 Cooling Fan and Air Filter Check

.......................

........................

........................

......................

.........................

Errors

.........................

........................

.........................

...................

..................

....................

..............

.....................

...................

5.1.5 Upgrading the Receiver Mainframe Software and EEPROM

To Connect the CPC Programming Tool

5.2 Removal and Replacement Procedures

5.2.1 Preparation and Precautions

5.2.1.1 Anti-Static Mats and Straps

5.2.1.2 Disconnection Procedure

5.3 HP M1400A/HP M1400B Transmitter

5.3.1 Disassembly and Assembly Procedures

5.3.1.1 Transmitter Bottom Cover Assembly

Transmitter Top Cover Assembly

5.3.1.2 Battery Contacts

.........................

......................

5.3.1.3 Transmitter VCXO Module

5.3.1.5 Transmitter Motherboard Assembly

5.3.1.6 Transmitter Case Assembly

5.4 HP M1401A Receiver Mainframe

5.4.1 Removal Flow Diagram

5.4.2 Procedures

5.4.2.1 Dress Cover

5.4.2.2 Top Cover

5.4.2.3 Receiver Module

5.4.2.4 Power Fuses

..............................

...........................

............................

.........................

...........................

.....................

........................

5.4.2.5 Antenna Distribution Board

5.4.2.6 Receiver Backplane

5.4.2.7 Fan

5.4.2.8 Air Filter

...............................

.............................

5.4.2.9 Power Supply

........................

..........................

5.4.2.10 On-board Transformer Fuses

5.4.2.11 Rack Interface Board

......................

5.4.2.12 Blank Function Card Cover

5.4.2.13 Function Cards

5.4.2.14 EPROM Board

.........................

..........................

..................

...................

.....................

....................

.....................

...................

.................

................

.....................

................

....................

....................

...................

...................

.......

4-24

4-24

4-29

4-30

4-32

4-32

4-34

4-34

4-36

4-37

4-37

4-71

4-71

4-71

4-71

4-72

4-72

5-1

5-1

5-2

5-2

5-2

5-2

5-2

5-4

5-4

5-5

5-5

5-6

5-8

5-8

5-9

5-11

5-11

5-11

5-11

5-12

5-12

5-17

5-17

5-17

5-17

5-18

5-18

5-19

5-19

5-20

5-20

5-22

5-22

5-22

5-22

5-23

Contents-4

Page 9

5.4.2.15 EEPROM Chip

5.4.2.16 Analog Link Cable

5.4.2.17 Power Rod

5.4.2.18 Digital Backplane

5.4.2.19 Antenna Cable (Rear panel to antenna distribution board)

5.4.2.20 Function Card Guide

5.4.2.21 Foot

..............................

5.5 HP M1402A Receiver Module

5.5.1 Removal Flow Diagram

5.5.2 Procedures

..............................

5.5.2.1 Receiver Shield

5.5.2.2 Short Receiver Gasket

5.5.2.3 Loop Receiver Gasket

5.5.2.4 Receiver VCXO Module

5.5.2.5 Receiver Microcontroller

5.5.2.6 RF Cable

.............................

5.5.2.7 Receiver Board Assembly

6. Replaceable Parts

6.1 Introduction

...............................

6.1.1 Ordering New Parts.

6.1.2 Unlisted Parts

............................

6.1.3 Exchange Program

6.1.4 Analog Output Option Replaceable Parts ................

6.1.5 ST Segment Analysis and Two-Channel Delayed Recording Option

Replaceable Parts

............................

6.1.6 40 MHz CPC Card Option C03 Replaceable Parts

6.1.7 Receiver Backplane Assembly M1401-60300 Pinouts

6.1.8 Digital Backplane Assembly M1401-60400, Connector Pinouts ......

..........................

........................

...........................

........................

.......................

.......................

........................

..........................

......................

.......................

......................

.....................

.....................

.........................

..........................

............

..........

.....

5-23

5-23

5-24

5-24

5-24

5-25

5-25

5-26

5-26

5-28

5-28

5-28

5-28

5-29

5-29

5-29

5-29

6-1

6-1

6-1

6-3

6-10

6-11

6-11

6-11

6-13

A. HP M1403J DIGITAL UHF TELEMETRY SYSTEM

General..

Differences Between Models

Specifications

Ordering Information

Frequency Options

Theory of Operation

Overall Functional Description

ECG Monitoring Capabilities

HP M1400J Transmitter

Electrode Lead Set

RF Module

Transmitter Motherboard Assembly

ECG Hybrid PCB.

Digital Hybrid PCB

Test/ID PCB

Power Supply Hybrid PCB

Transmitter Signal

HP M1402J Receiver Module

HP M1401A Receiver Mainframe

Dynamic UHF Antenna System

Maintenance and Troubleshooting

Replaceable Parts

.................................

........................

...............................

...........................

.............................

.............................

.......................

........................

..........................

............................

...............................

....................

...........................

...........................

..............................

.......................

...........................

........................

......................

.......................

......................

..............................

A-1

A-1

A-1

A-4

A-5

A-8

A-8

A-9

A-9

A-9

A-9

A-10

A-10

A-10

A-10

A-10

A-10

A-11

A-11

A-11

A-11

A-11

Contents-5

Page 10

B. HP Viridia Digital Transmitter Detailed Functional Description

Objectives

Concepts

Digital Transmitter

Electrode Lead Set

Three-Electrode Leadset

Five-Electrode Leadset

Case Assembly

Nurse Call Button

Leads Off LEDs

Main PCB

ECG Analog Section

Transmitter Digital Section

ECG Front End Interface

Lead Sense Circuit

Nurse Call Button

Leads Off LEDs

Serial Infrared Port

Power Supply Control

Memory Section

Power Supply

..................................

..................................

..............................

..............................

..........................

...........................

................................

.............................

..............................

................................

.............................

..........................

..........................

.............................

.............................

............

............

...........................

..............................

...............................

RF Section ................................

SpO2 Module ................................

Detailed SpO2 Circuit Description

ASIC

...................................

Digital Signal Processor (DSP)

Main Processing CPU

LED Driver

................................

Self-Test Circuit

............................

..............................

RCode Measurement Circuit

Disassembling the Transmitter

To Remove the Battery

To Replace the Battery

...........................

...........................

To Remove the Battery Door (M2601-40013)

To Replace the Battery Door

To Remove the Battery Contact Assembly (M2601-60008)

To Replace the Battery Contact Assembly

To Remove the Transmitter Case Assembly (M2601-60400)

To Replace the Transmitter Case Assembly

To Remove the Main Cage Brace

To Replace the Main Cage Brace

To Remove the SpO2 Board Assembly

To Replace the SpO2 Assembly

To Remove the Transmitter Main Board

To Replace the Transmitter Main Board

Ordering Parts for the HP Viridia Digital Transmitter

A Note on Ordering Parts for the Transmitter

......................

........................

........................

........................

.................

........................

........... B-12

..................

.......... B-13

.................

......................

......................

....................

.......................

...................

...................

..............

................

B-1

B-1

B-1

B-2

B-3

B-3

B-3

B-3

B-4

B-4

B-4

B-5

B-5

B-5

B-6

B-6

B-6

B-6

B-6

B-6

B-7

B-7

B-7

B-8

B-8

B-9

B-9

B-9

B-9

B-10

B-10

B-10

B-11

B-11

B-12

B-14

B-15

B-15

B-16

B-16

B-17

B-18

B-19

B-19

Index

Contents-6

Page 11

Figures

1-1. HP Digital UHF Telemetry System ......................

1-2. SDN Communication Diagram .......................

1-3. HP M1401A Receiver Mainframe Connections to SDN System .........

1-4. LDC Connections from Receiver Mainframe to Wall Box

1-5. Combinations without an SCC

1-6. CCM Combinations without an SCC . . . . . . .

1-7. Direct Connection to an HP Central Monitor

1-8. Analog Output Wiring Configurations

1-9. Direct Connection to HP 78508A Patient Information System .........

1-10. HP 78511B Equipment Cabinet Cable Installation ..............

1-11. Termination Procedures at PIC .......................

1-12. MTA Pistol Grip Tool (8710-1303) ......................

1-13. MTA Pistol Grip Tool Termination Procedure and Contact Inspection .....

1-14. Locating the Wall Mount ..........................

1-15. Installation on Hollow Block Wall ......................

1-16. Installation on Drywall Construction ....................

1-17. Anchorage Method for Drywall Construction ................

1-18. Installation of HP M1403A Option 78599AI #R90 Rack Mount into EIA Cabinet

1-19. Receiver Module Installation ........................

1-20. Voltage Selector and Fuse Panel ......................

1-21. HP 78508A PIC Learn Code Screen

1-22. HP 78560A Central Monitor Learn Code Screen

2-1. Block Diagram of HP M1403A Digital UHF Telemetry System

2-2. Block Diagram of HP M1400A/HP M1400B Transmitter ............

2-3. Block Diagram of HP M1402A Receiver Module ...............

2-4. Block Diagram of HP M1402A Receiver Module RF Section

2-5. Block Diagram of HP M1401A Receiver Mainframe ..............

2-6. Block Diagram of HP M1401A Receiver Mainframe (option C03) with 40 MHz

CPC Card ...............................

2-7. Block Diagram of Analog Output System ..................

2-8. Block Diagram of Typical Antenna Subsystem ................

2-9. Block Diagram of the Active Antenna/Combiner ...............

3-1. Demonstration Mode Screen ........................

3-2. Receiver Module LED Indicators ......................

3-3. HP M1408A Active Antenna/Combiner Power-on LED ............

3-4. Cooling Fan and Filter Locations ......................

3-5. Transmitter Battery Current Check .....................

3-6. Receiver Mainframe Supply Voltage Test Points ...............

3-7. Dempsey Safety Analyzer, Model 431F-1D ..................

3-8. Chassis to Ground Resistance Test Setup ...................

3-9. Chassis Leakage Current Test Setup .....................

4-1. Example of an RF History Strip Recording ..................

4-2. Password Screen (Normal Access) ......................

4-3. Telemetry Service I Screen .........................

4-4. Status Log Screen .............................

4-5. Erase Verification Screen ..........................

....................

.....................

..............

..............

.................

...............

...........

.........

..........

1-2

1-41

1-42

1-43

1-45

1-46

1-47

1-50

1-51

1-53

1-54

1-55

1-56

1-70

1-72

1-75

1-76

1-78

1-80

1-81

1-83

1-85

2-2

2-4

2-10

2-11

2-13

2-17

2-20

2-22

2-24

3-4

3-5

3-6

3-8

3-10

3-11

3-13

3-15

3-17

4-14

4-19

4-21

4-23

4-25

Contents-7

Page 12

4-6. Cancel Print Verification Screen

4-7. Demo Verification Screen

4-8. INOP Log Control Screen

4-9. INOP Sort Bed Screen (INOPs Totaled)

4-10. INOP Sort Time Screen

4-11. Examine Revisions Screen

4-12. Examine Configuration Screen

5-1. HP M1400A/HP M1400B Transmitter, Exploded View

5-2. HP M1401A Receiver Mainframe, Service Map

5-3. (Part 1 of 2) HP M1401A Receiver Mainframe, Exploded View

5-3. (Part 2 of 2) HP M1059-68501 Utility CPU Board

5-4. Removal Flow Diagram-HP M1401A Receiver Mainframe

5-5. Power Supply Removal

5-6. HP M1402A Receiver Module, Exploded View

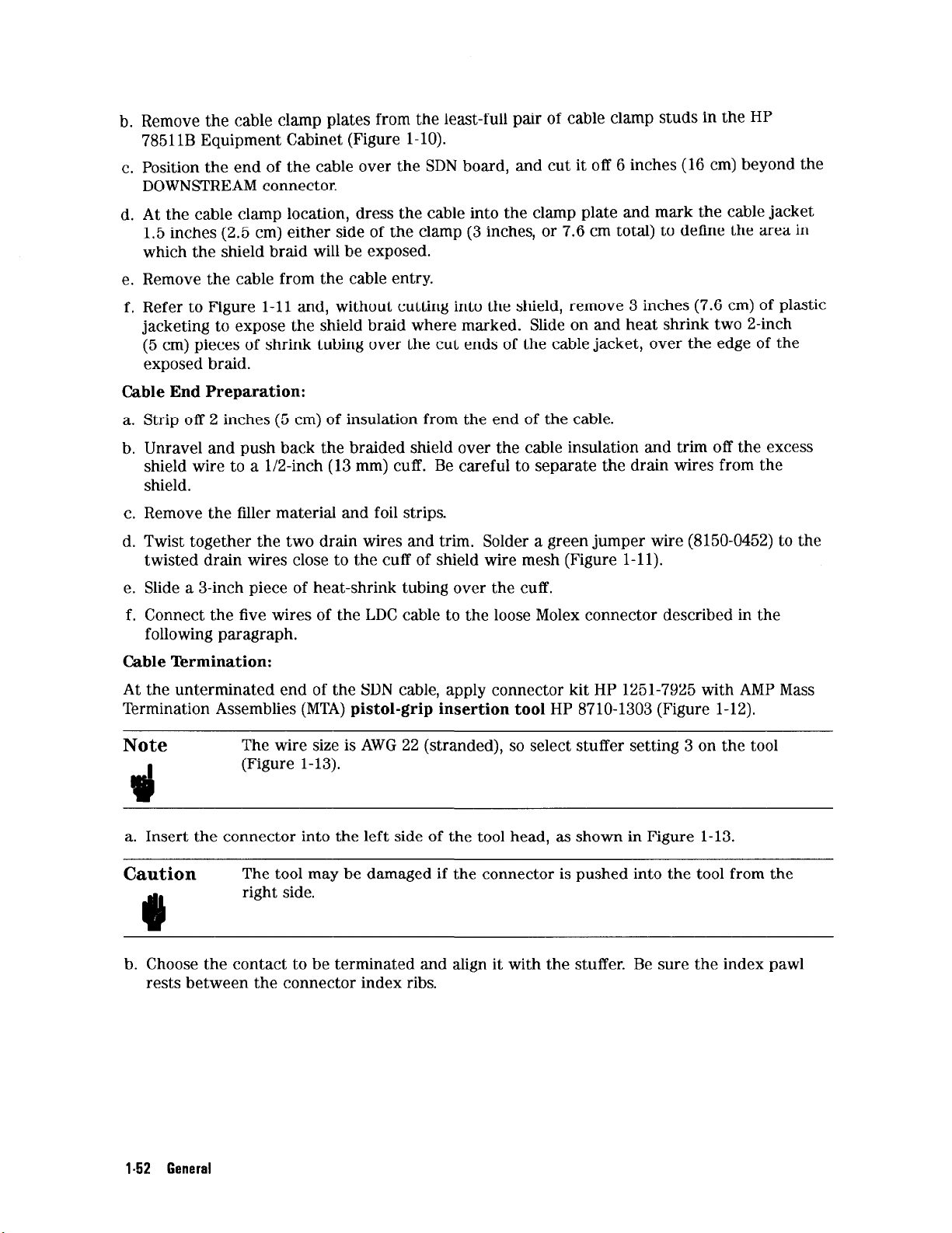

5-7. Removal Flow Diagram-HP M1402A Receiver Module

6-1. PC Board Identification and Cabling

6-2. Receiver Backplane Assembly M1401-60300, Replaceable Parts and Pinouts . .

6-3. Digital Backplane Assembly M1401-60400, Connector Pinouts

A-1. Block Diagram of HP M1400J Transmitter

B-1. Block Diagram of HP Viridia Digital Transmitter

B-2. SpO2 Board Block Diagram

B-3. Digital Transmitter Exploded View

..........................

..........................

...........................

...........................

......................

....................

.........................

.......................

.............

................

........

...............

..........

................

............

.....................

........

..................

...............

.........................

.....................

4-26

4-27

4-28

4-31

4-33

4-35

4-36

5-7

5-13

5-14

5-15

5-16

5-21

5-26

5-27

6-2

6-12

6-13

A-9

B-2

B-8

B-21

Contents-8

Page 13

Tables

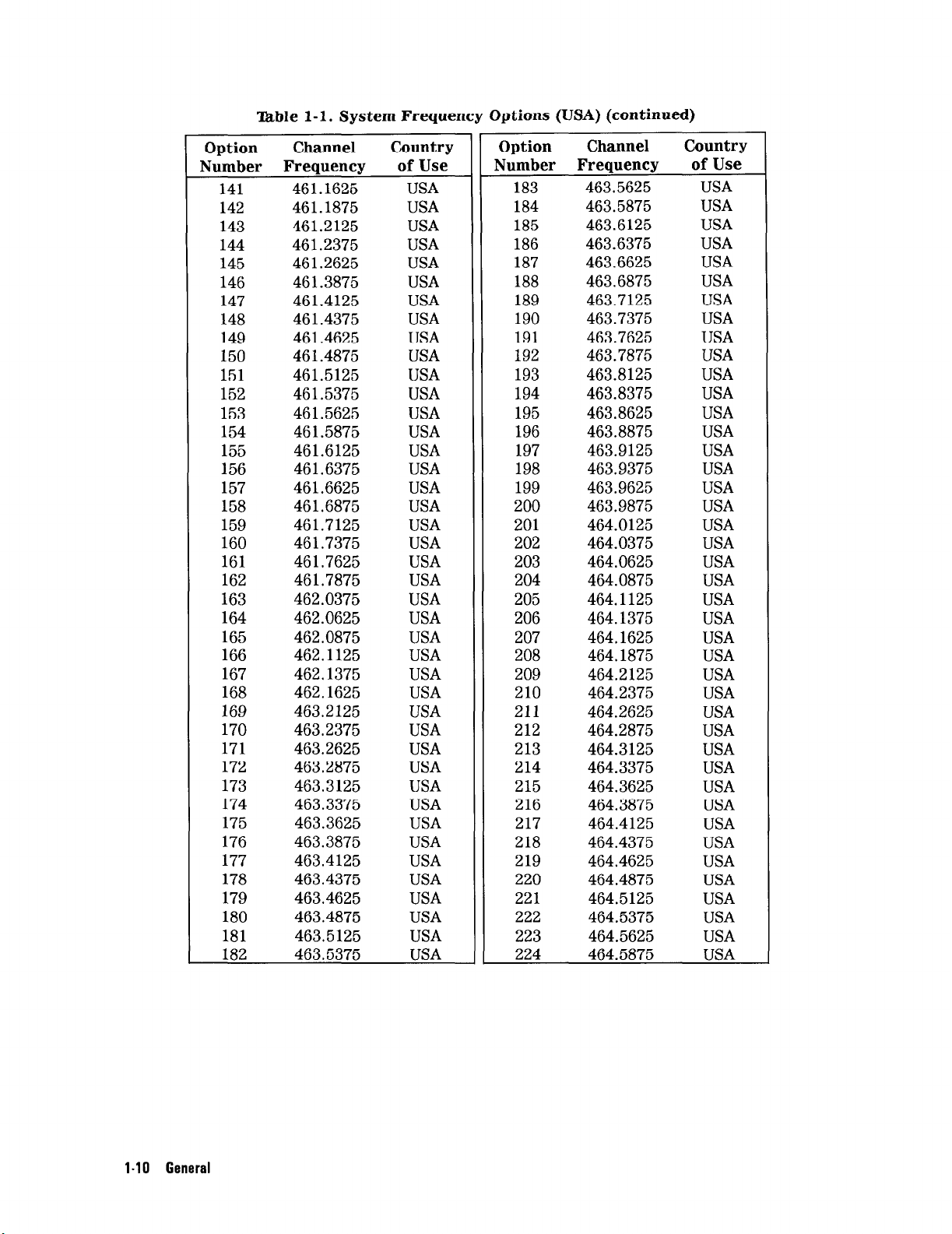

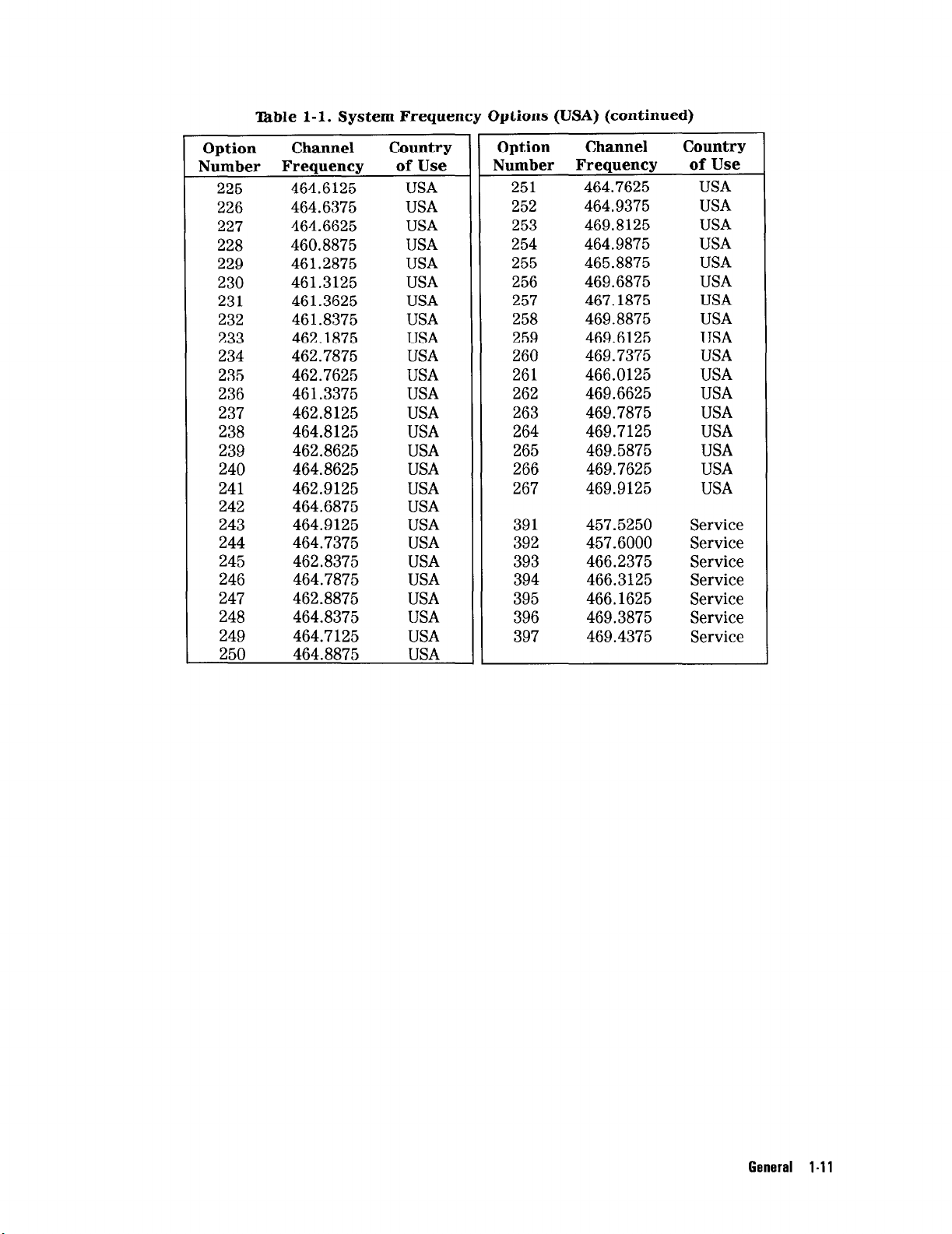

1-1. System Frequency Options (USA) ......................

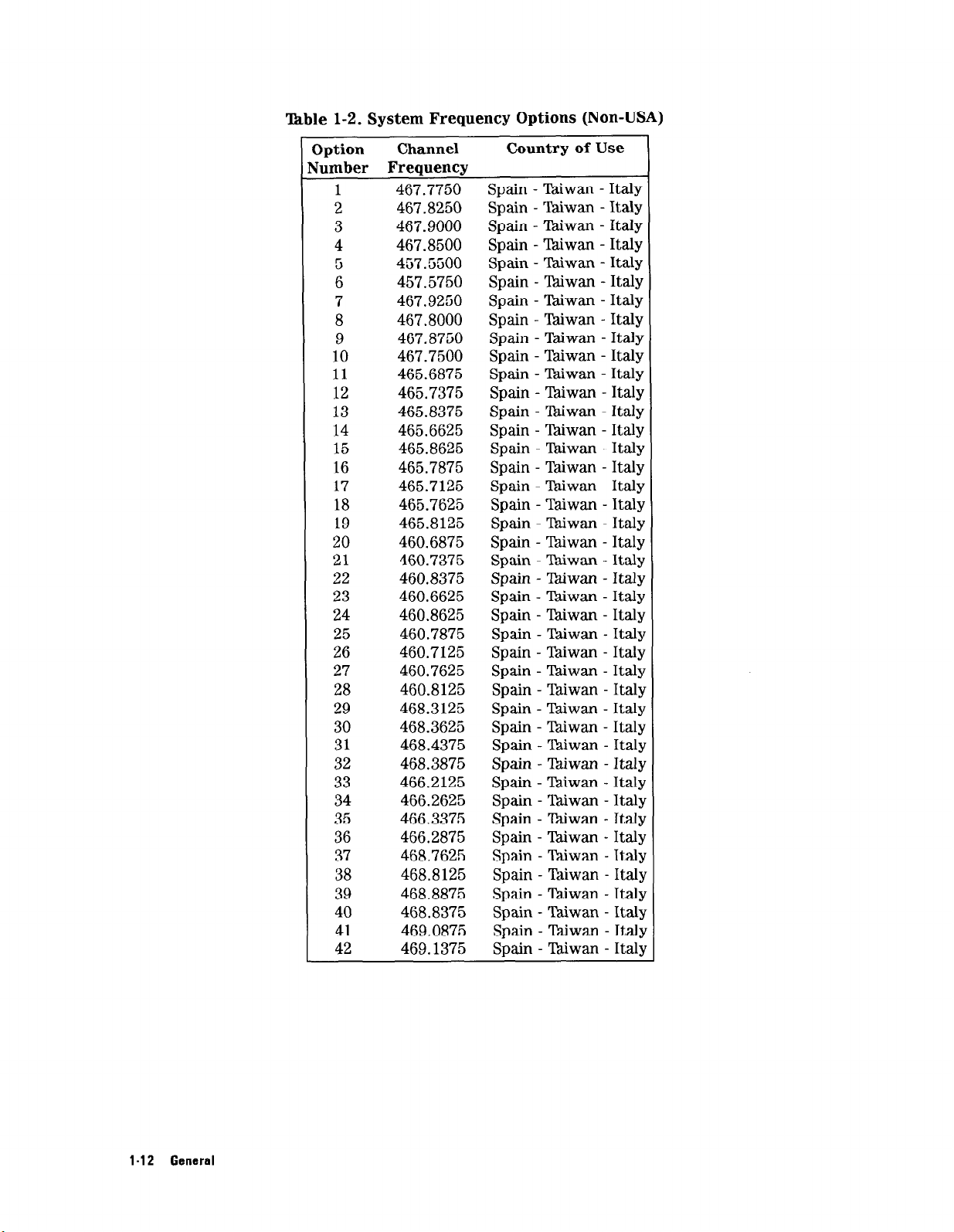

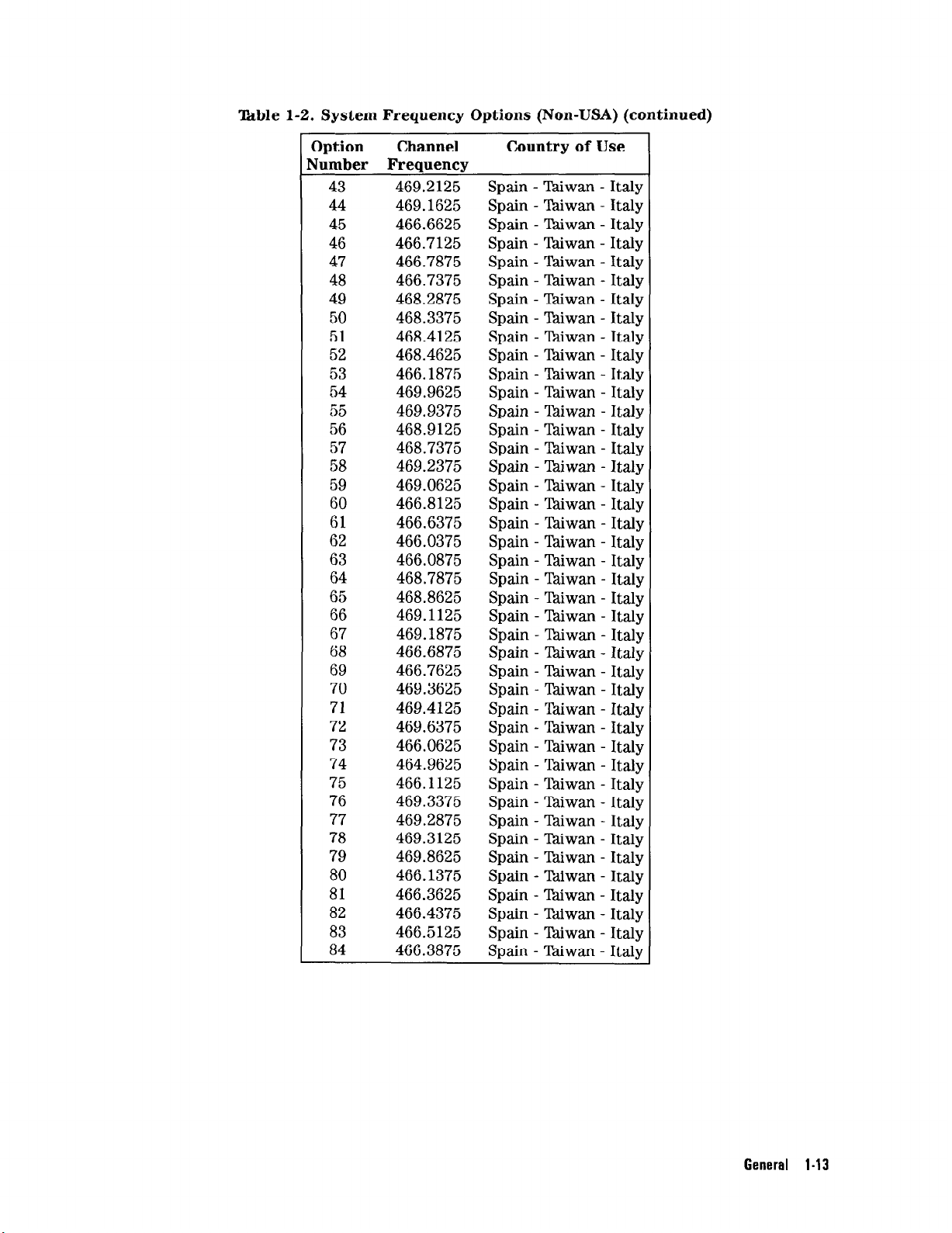

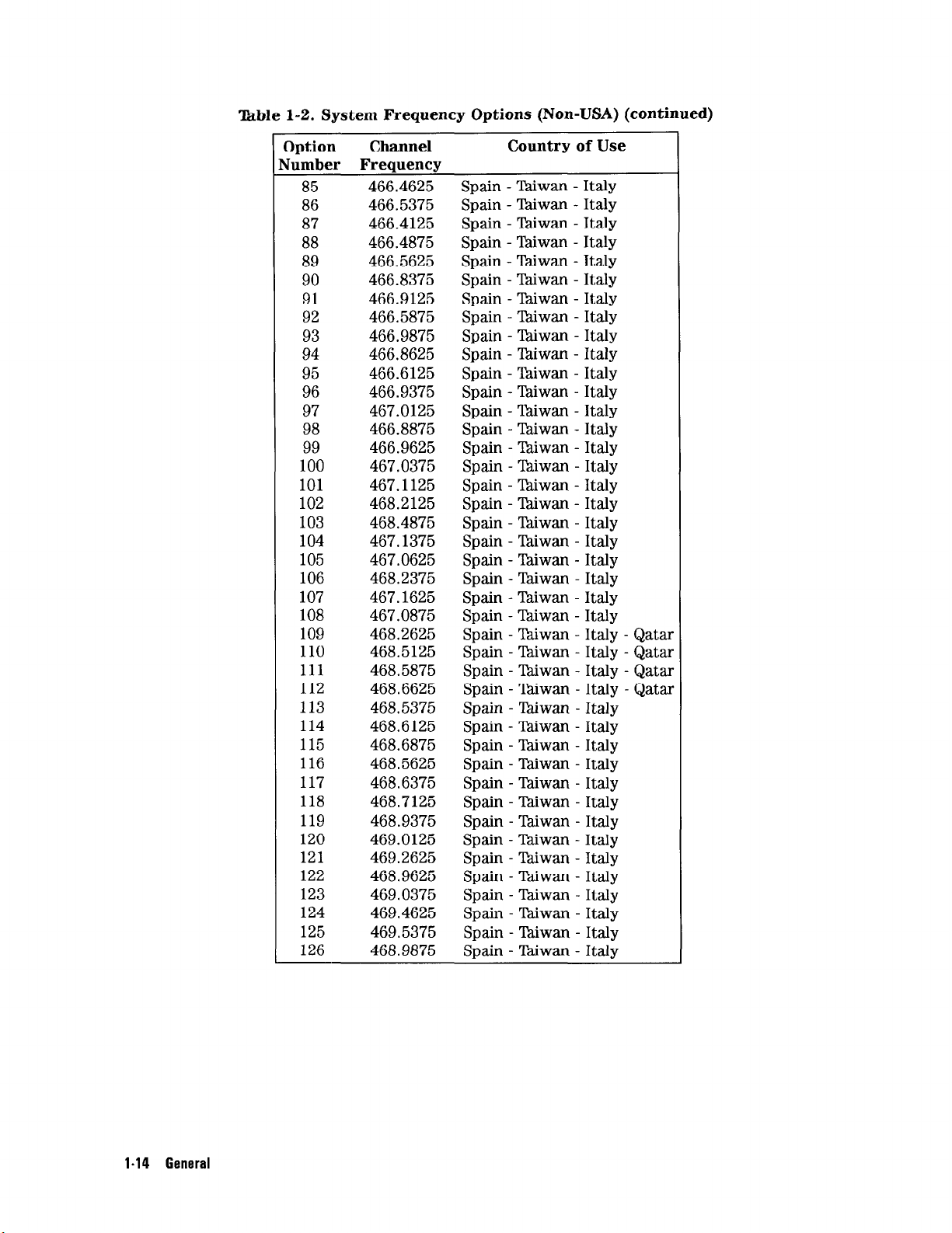

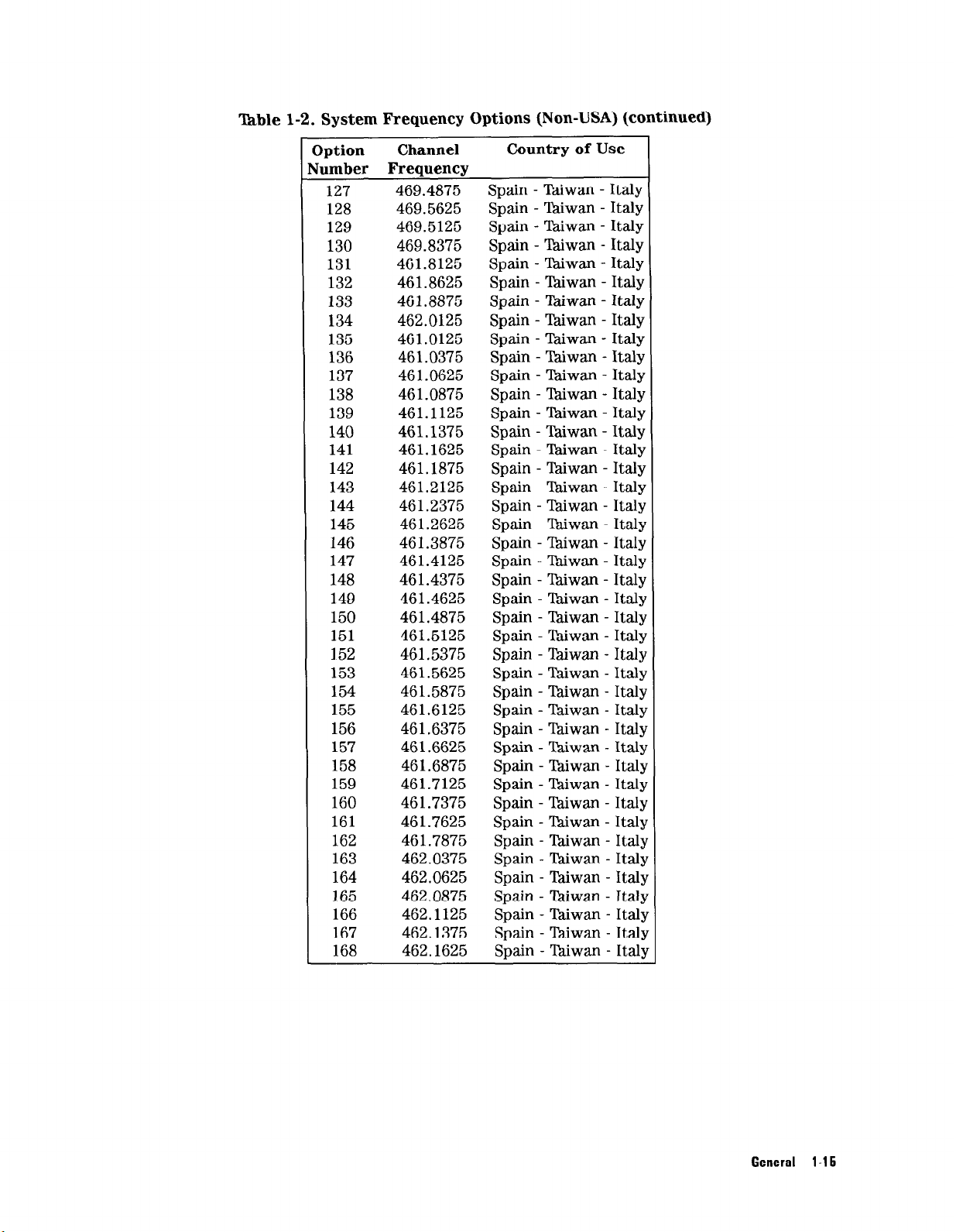

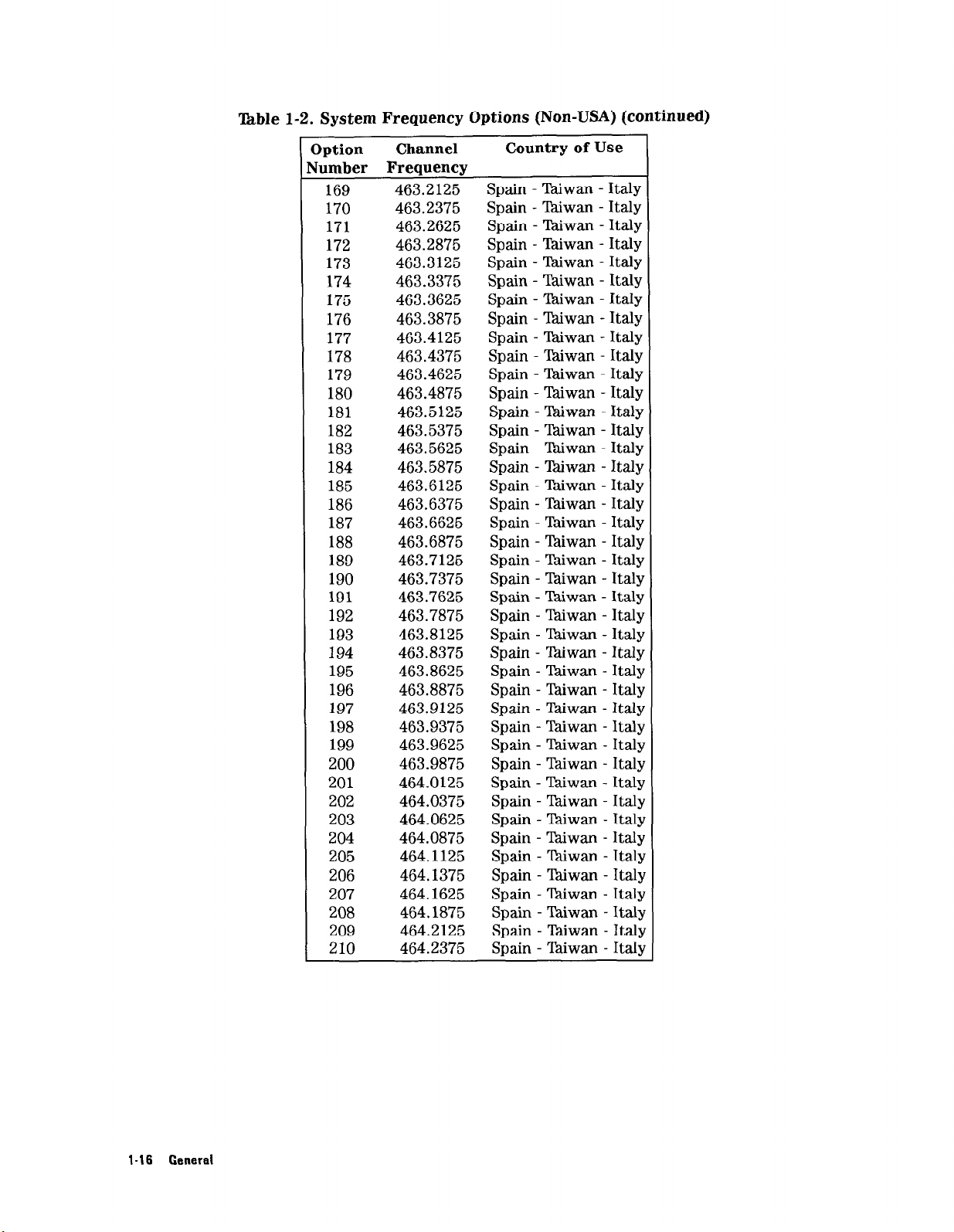

1-2. System Frequency Options (Non-USA) ....................

1-3. Specifications ...............................

1-4. HP M1403A Configuration Checklist .....................

3-1. Approved Cleaning Solutions and Disinfectants ...............

4-1. System Troubleshooting ..........................

4-2. Operating System (16400) Fatal Error Codes

4-3. Operating System (16400) Non-Fatal Error Codes

4-4. Global Information Handler (16500) Fatal Error Codes

4-5. Recorder Manager (17004) Module Error Codes

4-6. ECG (25000) Module Error Codes

4-7. Heart Module (25001) Fatal Error Codes ...................

4-8. Heart Module (25001) Non-Fatal Error Codes ................

4-9. Rack Manager (25010) Fatal Error Codes ..................

4-10. Alarm Manager (25011) Fatal Error Codes ..................

4-11. Alarm Manager (25011) Non-Fatal Error Codes ................

4-12. SDN (25020) Fatal Error Codes .......................

4-13. SDN (25020) Non-Fatal Error Codes .....................

4-14. INOP Module (25100) Error Codes ......................

4-15. Service Module (25101) Fatal Error Codes ..................

4-16. User Interface (25102) Error Codes .....................

4-17. Three-Channel ST (32734) Module Error Codes ................

6-1. Products

6-2. Receiver Module Exchange Assemblies (M1402A) . . . . . . . . . . . . . . .

6-3. Receiver Mainframe Exchange Assemblies (M1401A) .............

6-4. Receiver Module Replaceable Parts (M1402A) ................

6-5. Transmitter Replaceable Parts (HP M1400A/HP M1400B) ...........

6-6. Receiver Mainframe Replaceable Parts (M1401A) ...............

6-7. Active Antenna/Combiner Replaceable Parts .................

6-8. Line Amplifier Replaceable Parts (M1406A) .................

6-9. Multiple Unit Power Supply Replaceable Parts (M1407A) ...........

6-10. Wall and Rack Mount Replaceable Parts ...................

6-11. Miscellaneous Antenna System Replaceable Parts ..............

6-12. Analog Output Option Replaceable Parts ..................

6-13. ST Segment Analysis and Two-Channel Delayed Recording Option Replaceable

Parts .................................

6-14. 40 MHz CPC Card Option C03 Replaceable Parts ...............

A-1. Specifications ...............................

A-2. System Frequency Options (JAPAN) .....................

A-3. Products

A-4. Receiver Module Replaceable Parts (M1402J) . . . . . . . . . . . . . . . . .

A-5. Transmitter Replaceable Parts (HP M1400J) .................

B-1. Digital Transmitter Exchange and New Assemblies ..............

......................

.................

...............

............

...............

1-8

1-12

1-31

1-65

3-19

4-4

4-38

4-48

4-49

4-50

4-51

4-52

4-53

4-54

4-57

4-59

4-60

4-61

4-61

4-63

4-65

4-70

6-3

6-4

6-4

6-5

6-6

6-7

6-8

6-8

6-8

6-8

6-9

6-10

6-11

6-11

A-2

A-5

A-11

A-12

A-12

B-20

Contents-9

Page 14

Page 15

General

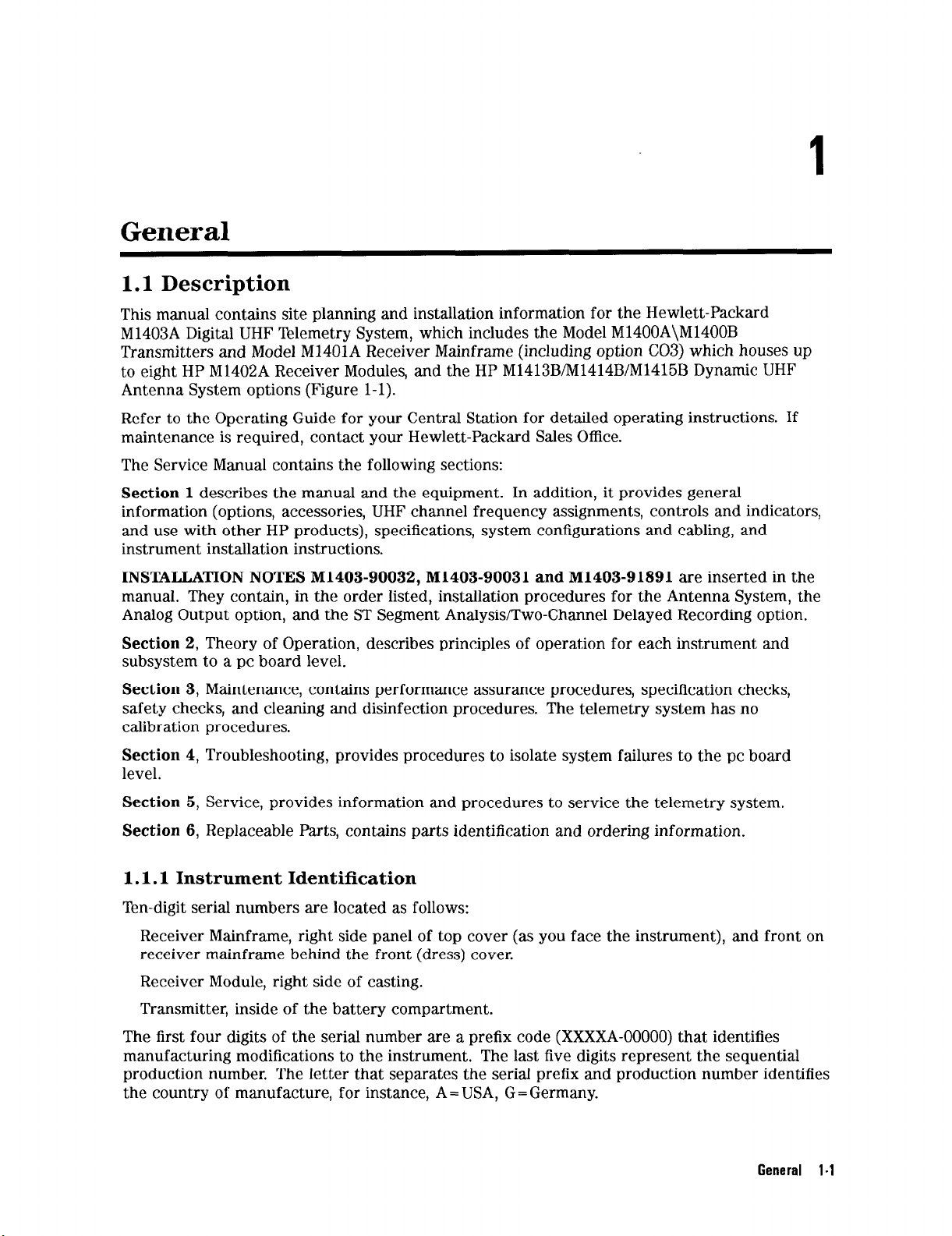

1.1 Description

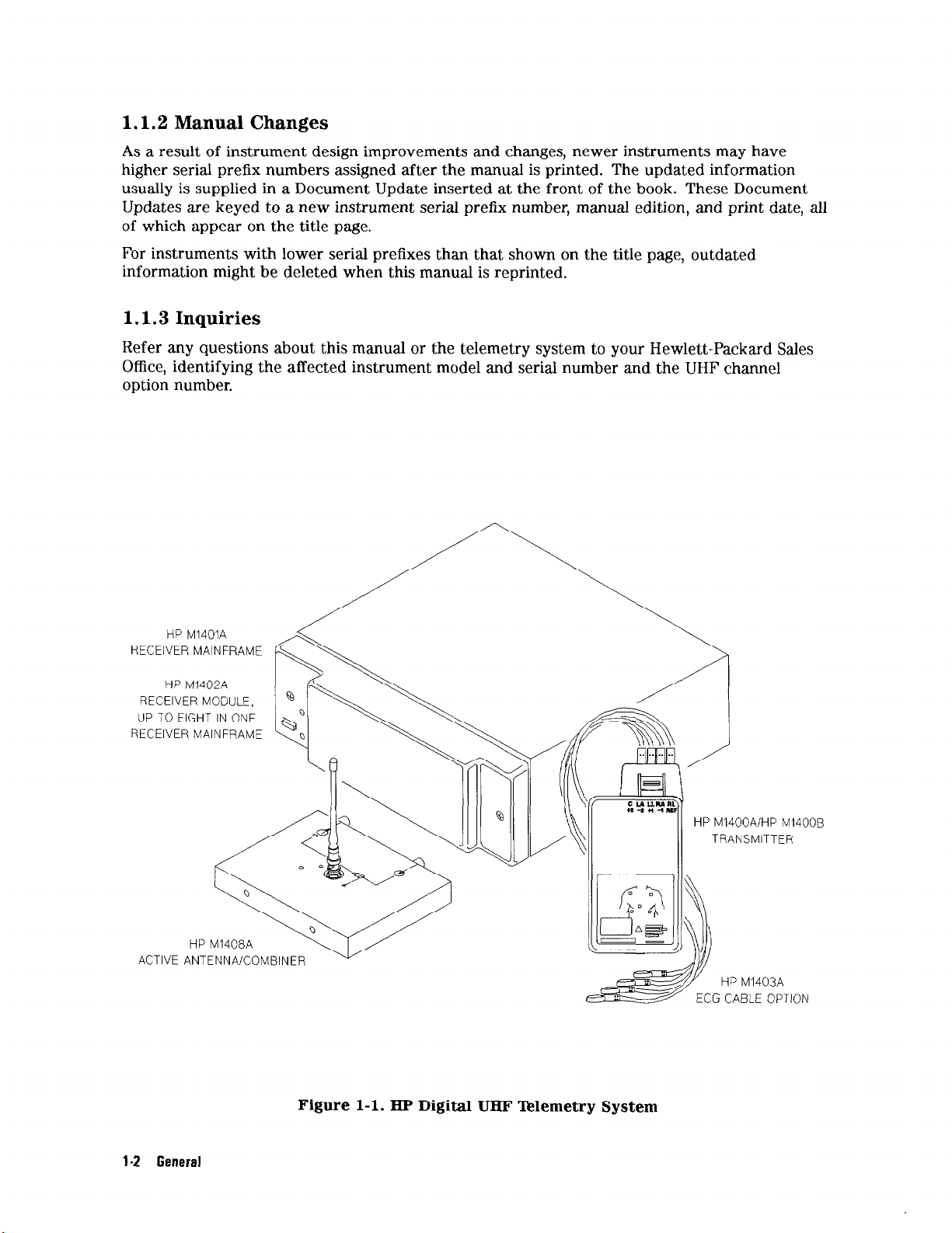

This manual contains site planning and installation information for the Hewlett-Packard

M1403A Digital UHF Telemetry System, which includes the Model M1400A\M1400B

Transmitters and Model M1401A Receiver Mainframe (including option C03) which houses up

to eight HP M1402A Receiver Modules, and the HP M1413BN1414BIM1415B Dynamic UHF

Antenna System options (Figure l-l).

Refer to the Operating Guide for your Central Station for detailed operating instructions. If

maintenance is required, contact your Hewlett-Packard Sales Office.

The Service Manual contains the following sections:

1

Section 1

information (options, accessories, UHF channel frequency assignments, controls and indicators,

and use with other HP products), specifications, system configurations and cabling, and

instrument installation instructions.

INSTALLATION NOTES M1403-90032, M1403-90031 and M1403-91891

manual. They contain, in the order listed, installation procedures for the Antenna System, the

Analog Output option, and the ST Segment Analysis/Two-Channel Delayed Recording option.

Section 2,

subsystem to a pc board level.

Section

safety checks, and cleaning and disinfection procedures. The telemetry system has no

calibration procedures.

Section

level.

Section

Section

1.1.1 Instrument Identification

Ten-digit serial numbers are located as follows:

Receiver Mainframe, right side panel of top cover (as you face the instrument), and front on

receiver mainframe behind the front (dress) cover.

describes the manual and the equipment. In addition, it provides general

are inserted in the

Theory of Operation, describes principles of operation for each instrument and

3, Maintenance, contains performance assurance procedures, specification checks,

4, Troubleshooting, provides procedures to isolate system failures to the pc board

5, Service, provides information and procedures to service the telemetry system.

6, Replaceable Parts, contains parts identification and ordering information.

Receiver Module, right side of casting.

Transmitter, inside of the battery compartment.

The first four digits of the serial number are a prefix code (XXXXA-00000) that identifies

manufacturing modifications to the instrument. The last five digits represent the sequential

production number. The letter that separates the serial prefix and production number identifies

the country of manufacture, for instance, A=USA, G=Germany.

General 1-l

Page 16

1.1.2 Manual Changes

As a result of instrument design improvements and changes, newer instruments may have

higher serial prefix numbers assigned after the manual is printed. The updated information

usually is supplied in a Document Update inserted at the front of the book. These Document

Updates are keyed to a new instrument serial prefix number, manual edition, and print date, all

of which appear on the title page.

For instruments with lower serial prefixes than that shown on the title page, outdated

information might be deleted when this manual is reprinted.

1.1.3 Inquiries

Refer any questions about this manual or the telemetry system to your Hewlett-Packard Sales

Office, identifying the affected instrument model and serial number and the UHF channel

option number.

HP M1401A

RECEIVER MAINFRAME

HP M1402A

RECEIVER MODULE,

UP TO EIGHT IN ONE

RECEIVER MAINFRAME

HP M1408A

ACTIVE ANTENNA/COMBINER

l-2 General

Figure l-l. HP Digital UHF Telemetry System

Page 17

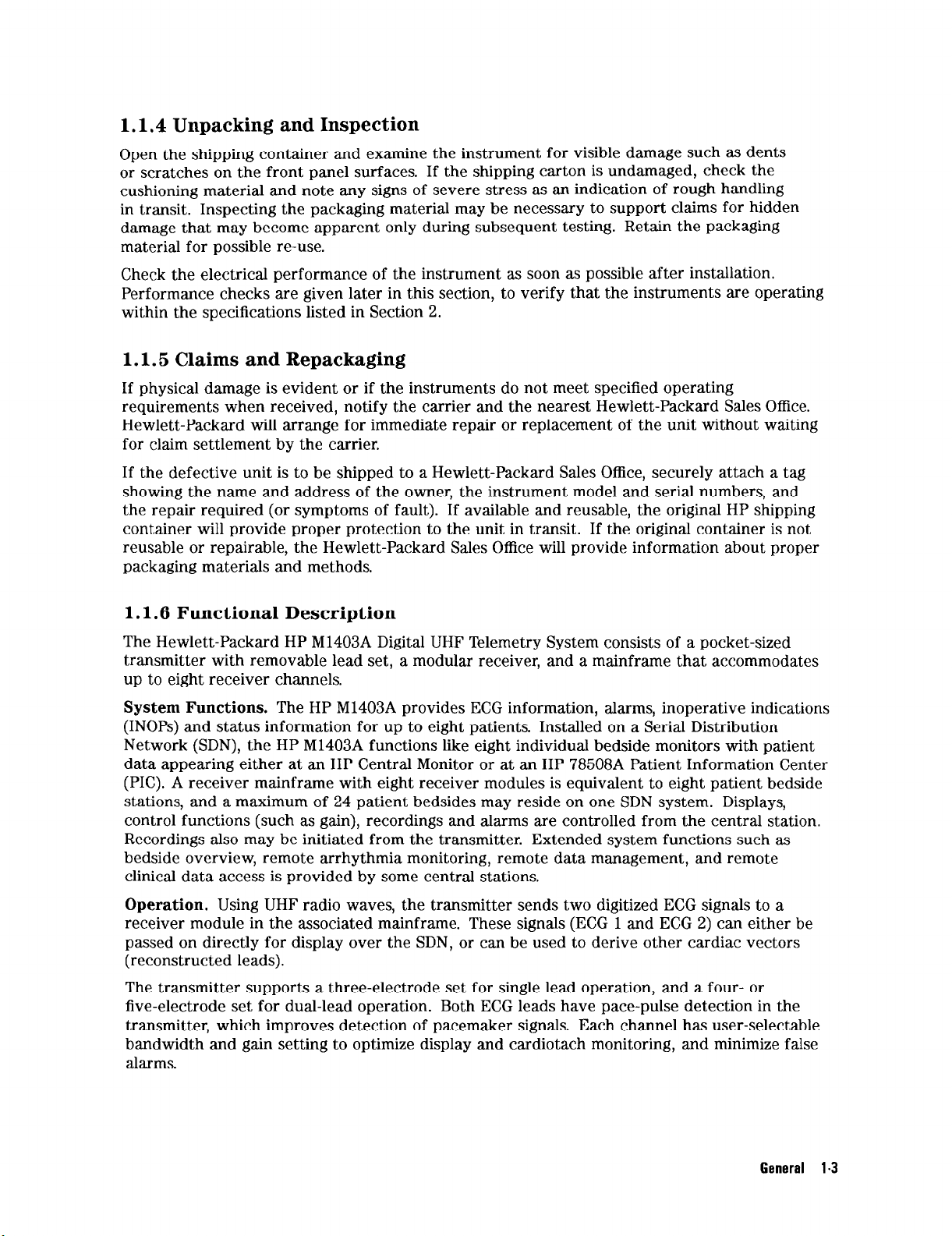

1.1.4 Unpacking and Inspection Open the shipping container and examine the instrument for visible damage such as dents

or scratches on the front panel surfaces. If the shipping carton is undamaged, check the

cushioning material and

note

any signs of severe stress as

an

indication of rough handling

in transit. Inspecting the packaging material may be necessary to support claims for hidden

damage that may become apparent only during subsequent testing. Retain the packaging

material for possible re-use.

Check

Performance checks are given later in this section, to verify

the

electrical performance of the instrument as soon as possible after installation.

that

the instruments are operating

within the specifications listed in Section 2.

1.1.5 Claims and Repackaging

If physical damage is evident or if the instruments do not meet specified operating

requirements when received, notify the carrier and the nearest Hewlett-Packard Sales Office.

Hewlett-Packard will arrange for immediate repair or replacement of the unit without waiting

for claim settlement by the carrier.

If the defective unit is to be shipped to a Hewlett-Packard Sales Office, securely attach a tag

showing the name and address of the owner, the instrument model and serial numbers, and

the repair required (or symptoms of fault). If available and reusable, the original HP shipping

container

will

provide proper protection to

the

unit in transit. If the original container is not

reusable or repairable, the Hewlett-Packard Sales Office will provide information about proper

packaging materials and methods.

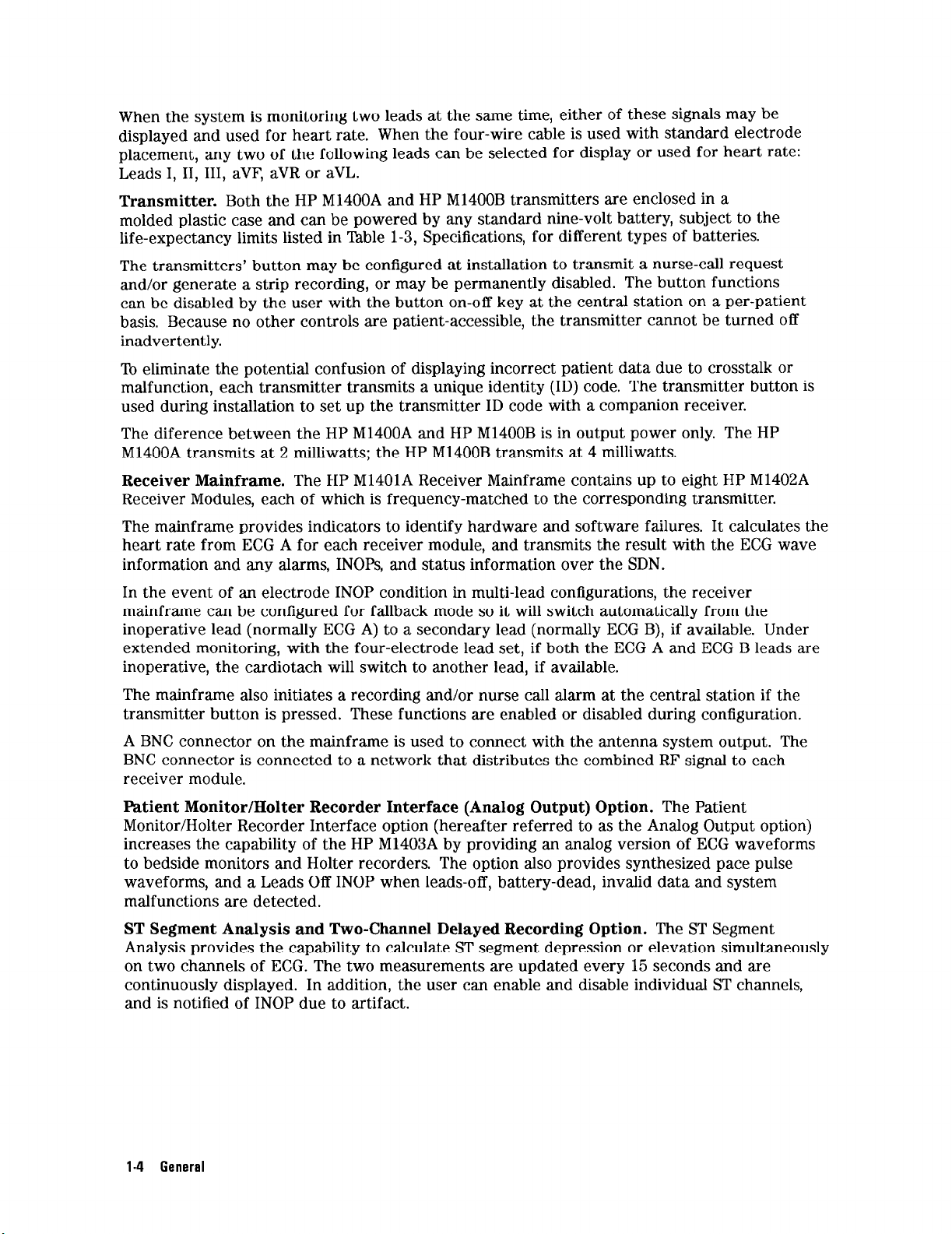

1.1.6 Functional Description

The Hewlett-Packard HP M1403A Digital UHF Telemetry System consists of a pocket-sized

transmitter with removable lead set, a modular receiver, and a mainframe that accommodates

up to eight receiver channels.

System Functions.

The HP M1403A provides ECG information, alarms, inoperative indications

(INOPs) and status information for up to eight patients. Installed on a Serial Distribution

Network (SDN), the HP M1403A functions like eight individual bedside monitors with patient

data appearing either at an HP Central Monitor or at

an

HP 78508A Patient Information Center

(PIC). A receiver mainframe with eight receiver modules is equivalent to eight patient bedside

stations, and a maximum of 24 patient bedsides may reside on one SDN system. Displays,

control functions (such as gain), recordings and alarms are controlled from the central station.

Recordings also may be initiated from

the

transmitter. Extended system functions such as

bedside overview, remote arrhythmia monitoring, remote data management, and remote

clinical data access is provided by some central stations.

Operation.

Using UHF radio waves, the transmitter sends two digitized ECG signals to a

receiver module in the associated mainframe. These signals (ECG 1 and ECG 2) can either be

passed on directly for display over the SDN, or can be used to derive other cardiac vectors

(reconstructed leads).

The transmitter supports a three-electrode set for single lead operation, and a four- or

five-electrode set for dual-lead operation. Both ECG leads have pace-pulse detection in the

transmitter, which improves detection of pacemaker signals. Each channel

has

user-selectable

bandwidth and gain setting to optimize display and Cardiotach monitoring, and minimize false

alarms.

General l-3

Page 18

When the system is monitoring two leads at the same time, either of these signals may be

displayed and used for heart rate. When the four-wire cable is used with standard electrode

placement, any two of the following leads can be selected for display or used for heart rate:

Leads I, II, III, aVF, aVR or aVL.

Transmitter.

molded plastic case and

Both the HP M1400A and HP M1400B transmitters are enclosed in a

can

be powered by any standard nine-volt battery, subject to the

life-expectancy limits listed in ‘Pdble l-3, Specifications, for different types of batteries.

The transmitters’ button may be configured at installation to transmit a nurse-call request

and/or generate a strip recording, or may be permanently disabled. The button functions

can be disabled by the user with the button on-off key at the central station on a per-patient

basis. Because no other controls are patient-accessible, the transmitter cannot be turned off

inadvertently.

To eliminate the potential confusion of displaying incorrect patient data due to crosstalk or

malfunction, each transmitter transmits a unique identity (ID) code. The transmitter button is

used during installation to set up the transmitter ID code with a companion receiver.

The diference between the HP M1400A and HP M1400B is in output power only. The HP

M1400A transmits at 2 milliwatts; the HP M1400B transmits at 4 milliwatts.

Receiver Mainframe.

The HP M1401A Receiver Mainframe contains up to eight HP M1402A

Receiver Modules, each of which is frequency-matched to the corresponding transmitter.

The mainframe provides indicators to identify hardware and software failures. It calculates the

heart rate from ECG A for each receiver module, and transmits the result with the ECG wave

information and any alarms, INOPs, and status information over the SDN.

In the event of an electrode INOP condition in multi-lead configurations, the receiver

mainframe can be configured for fallback mode so it will switch automatically from the

inoperative lead (normally ECG A) to a secondary lead (normally ECG B), if available. Under

extended monitoring, with the four-electrode lead set, if both the ECG A and ECG B leads are

inoperative, the Cardiotach will switch to another lead, if available.

The mainframe also initiates a recording and/or nurse call alarm at the central station if the

transmitter button is pressed. These functions are enabled or disabled during configuration.

A BNC connector on the mainframe is used to connect with the antenna system output. The

BNC connector is connected to a network that distributes the combined RF signal to each

receiver module.

Patient Monitor/Halter Recorder Interface (Analog Output) Option.

The Patient

Monitor/Halter Recorder Interface option (hereafter referred to as the Analog Output option)

increases the capability of the HP M1403A by providing

an

analog version of ECG waveforms

to bedside monitors and Holter recorders. The option also provides synthesized pace pulse

waveforms, and a Leads Off INOP when leads-off, battery-dead, invalid data and system

malfunctions are detected.

ST Segment Analysis and Two-Channel Delayed Recording Option.

The ST Segment

Analysis provides the capability to calculate ST segment depression or elevation simultaneously

on two channels of ECG. The two measurements are updated every 15 seconds and are

continuously displayed. In addition, the user can enable and disable individual ST channels,

and is notified of INOP due to artifact.

l-4 General

Page 19

With the Two-Channel Delayed Recording option, the user can initiate two-channel manual

or automatic delayed recordings through a PIC-manually by pressing the nurse call button,

or automatically by patient alarm. The recorder strip contains data beginning 10 seconds

prior to the initiation and ending 5 seconds after the initiation, for a total run time of 15

seconds. Delayed recordings may be preempted by recordings of a higher priority and saved as

superseded data. Delayed recordings can be cancelled entirely by pressing the STOP button on

the

recorder faceplate.

Antenna System.

The Dynamic UHF Antenna System minimizes signal-to-noise degradation by

using high-performance, active antenna/combiners with integrated amplifiers to ensure uniform

performance throughout the covered area.

1.1.7 Ordering Information

HP M1403A System Options

Note:

HP M1403A frequency options are listed in Tables l-l and l-2.

The standard system is specified by HP M1403A and one option between A01 and A08. Each

system consists of one or more transmitters with matched receiver modules and one mainframe

with SDN system output. Order ECG cables separately.

Channel System, includes 1 transmitter, 1 receiver module, and 1

A01

A02

A03

A04

A05

A06

A07

A08

Separate Instrument Options

1

Channel

2

Channel System, includes 3 transmitters, 3 receiver modules, and

3

Channel System, includes 4 transmitters, 4 receiver modules, and

4

Channel System, includes 5 transmitters, 5 receiver modules, and

5

Channel System, includes 6 transmitters, 6 receiver modules, and

6

Channel System, includes 7 transmitters, 7 receiver modules, and

7

Channel System, includes 8 transmitters, 8 receiver modules, and

8

System,

includes 2 transmitters, 2 receiver modules, and

mainframe.

1 mainframe.

1 mainframe.

1 mainframe.

1 mainframe.

1 mainframe.

1 mainframe.

1 mainframe.

A10 Replacement transmitter

All

Al2

Al3

Additional transmitter with receiver module, matched pair

Additional receiver module

Additional mainframe only, standard SDN output

co3 Receiver Mainframe with 40 Mhz CPC card

Output Options

co1 ST Segment Analysis/Two-Channel Delayed Recording

JO1 Patient Monitor/Halter Recorder Interface

ECG Cable Options

KOl

K20

K21

K22

K23

K24

K25

K30

K31

K32

K33

K34

K35

Disposable pouch accessory kit

3-lead patient cable with snap connector (USA)

3-lead patient cable with grabber connector (USA)

4-lead patient cable with snap connector (USA)

4-lead patient cable with grabber connector (USA)

5-lead patient cable with snap connector (USA)

5-lead patient cable with grabber connector (USA)

3-lead patient cable with snap connector (IEC)

3-lead patient cable

with

grabber connector (IEC)

4-lead patient cable with snap connector (IEC)

4-lead patient cable with grabber connector (IEC)

5-lead patient cable with snap connector (IEC)

5-lead patient cable with grabber connector (IEC)

General l-5

Page 20

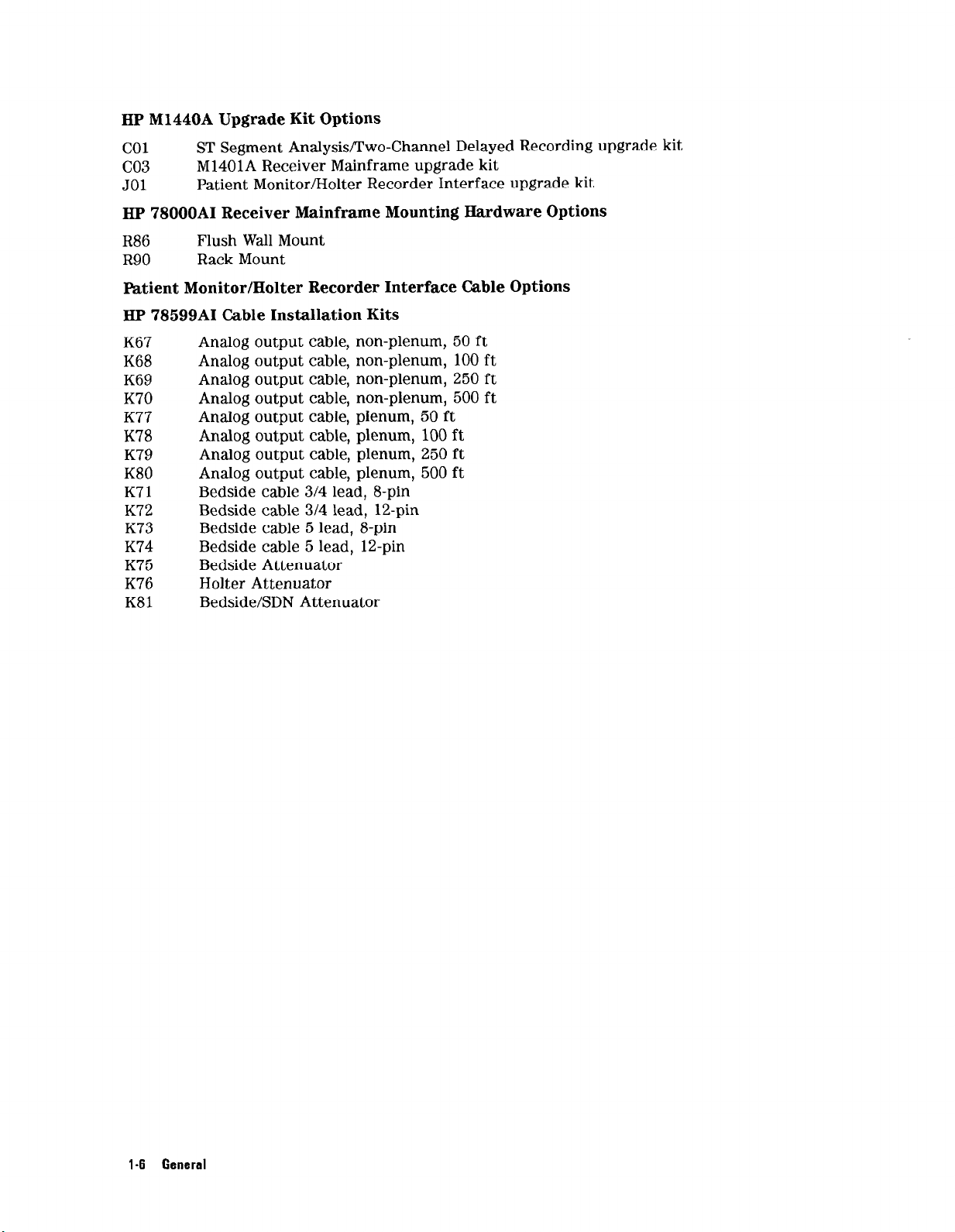

HP M1440A Upgrade Kit Options

co1

co3

JO1

HP 78000AI Receiver Mainframe Mounting Hardware Options

R86

R90

Fdtient Monitor/Halter Recorder Interface Cable Options

HP 78599AI Cable Installation Kits

K67

K68

K69

K70

K77

K78

K79

K80

K71

K72

K73

K74

K75

K76

K81

ST Segment Analysis/Two-Channel Delayed Recording upgrade kit

M1401A Receiver Mainframe upgrade kit

Patient Monitor/Halter Recorder Interface upgrade kit

Flush Wall Mount

Rack Mount

Analog output cable, non-plenum, 50 ft

Analog output cable, non-plenum, 100 ft

Analog output cable, non-plenum, 250 ft

Analog output cable, non-plenum, 500 ft

Analog output cable, plenum, 50 ft

Analog output cable, plenum, 100 ft

Analog output cable, plenum, 250 ft

Analog output cable, plenum, 500 ft

Bedside cable 314 lead, 8-pin

Bedside cable 314 lead, 12-pin

Bedside cable 5 lead, 8-pin

Bedside cable 5 lead, 12-pin

Bedside Attenuator

Holter Attenuator

Bedside/SDN Attenuator

l-6 General

Page 21

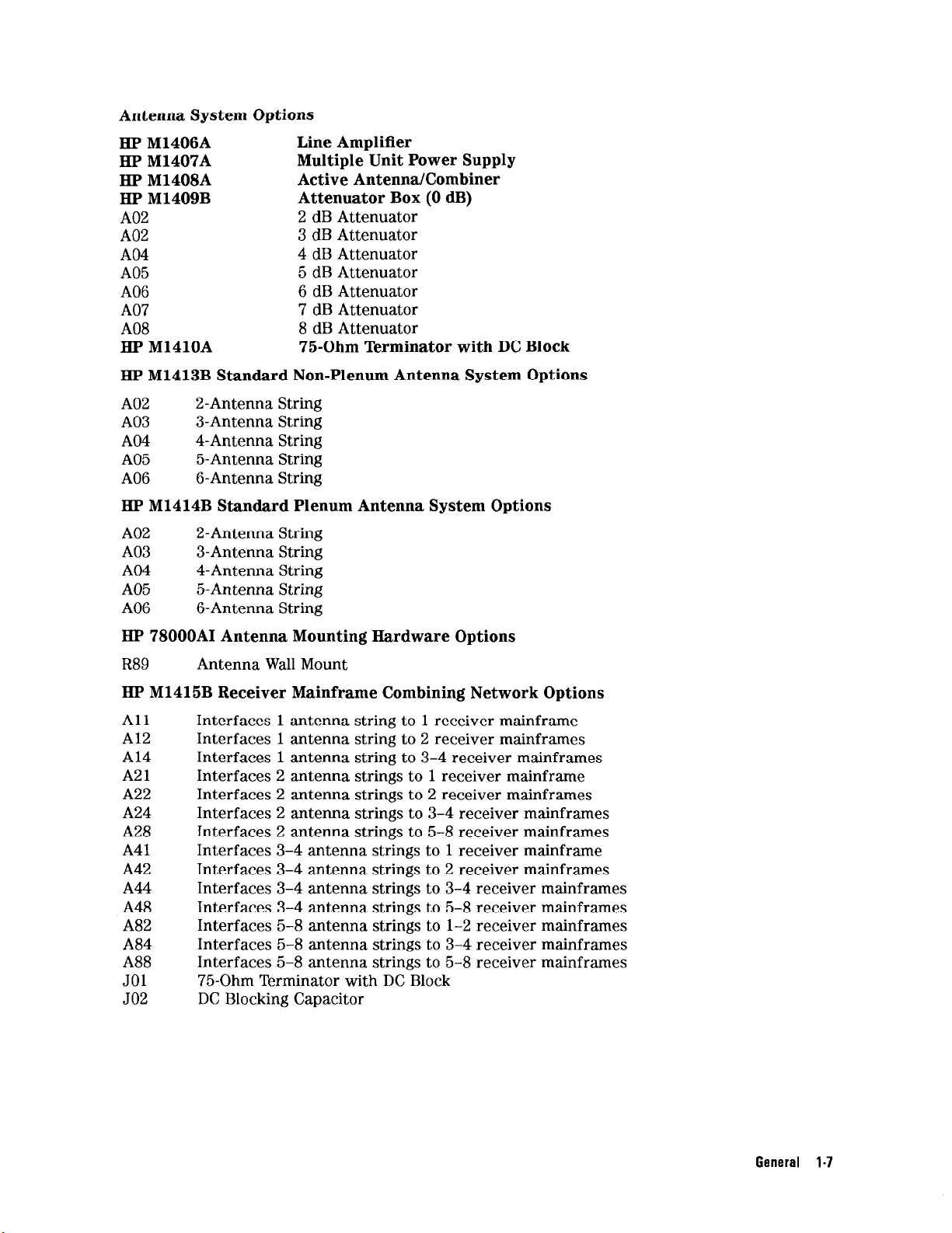

Antenna System Options

HP M1406A

HP M1407A

HP M1408A

HP M1409B

A02

A02

A04

A05

A06

A07

A08

HP M1410A

HP M1413B Standard Non-Plenum Antenna System Options

A02

A03

A04

A05

A06

HP M1414B Standard Plenum Antenna System Options

A02

2-Antenna String

3-Antenna String

4-Antenna String

5-Antenna String

6-Antenna String

2-Antenna String

Line Amplifier

Multiple Unit Power Supply

Active Antenna/Combiner

Attenuator Box (0 dB)

2 dB Attenuator

3 dB Attenuator

4 dB Attenuator

5 dB Attenuator

6 dB Attenuator

7 dB Attenuator

8 dB Attenuator

75-Ohm Terminator with DC Block

A03 3-Antenna String

A04 4-Antenna String

A05

A06

5-Antenna String

6-Antenna String

HP 78000AI Antenna Mounting Hardware Options

R89

HP M1415B Receiver Mainframe Combining Network Options

All

Al2

Al4

A21

A22

A24

A28

A41

A42

A44

A48

A82

A84

A88

JO1

JO2

Antenna Wall Mount

Interfaces 1 antenna string to 1 receiver mainframe

Interfaces 1 antenna string to 2 receiver mainframes

Interfaces 1 antenna string to 3-4 receiver mainframes

Interfaces 2 antenna strings to 1 receiver mainframe

Interfaces 2 antenna strings to 2 receiver mainframes

Interfaces 2 antenna strings to 3-4 receiver mainframes

Interfaces 2 antenna strings to 5-8 receiver mainframes

Interfaces 3-4 antenna strings to 1 receiver mainframe

Interfaces 3-4 antenna strings to 2 receiver mainframes

Interfaces 3-4 antenna strings to 3-4 receiver mainframes

Interfaces 3-4 antenna strings to 5-8 receiver mainframes

Interfaces 5-8 antenna strings to l-2 receiver mainframes

Interfaces 5-8 antenna strings to 3-4 receiver mainframes

Interfaces 5-8 antenna strings to 5-8 receiver mainframes

75-Ohm Terminator with DC Block

DC Blocking Capacitor

General l-7

Page 22

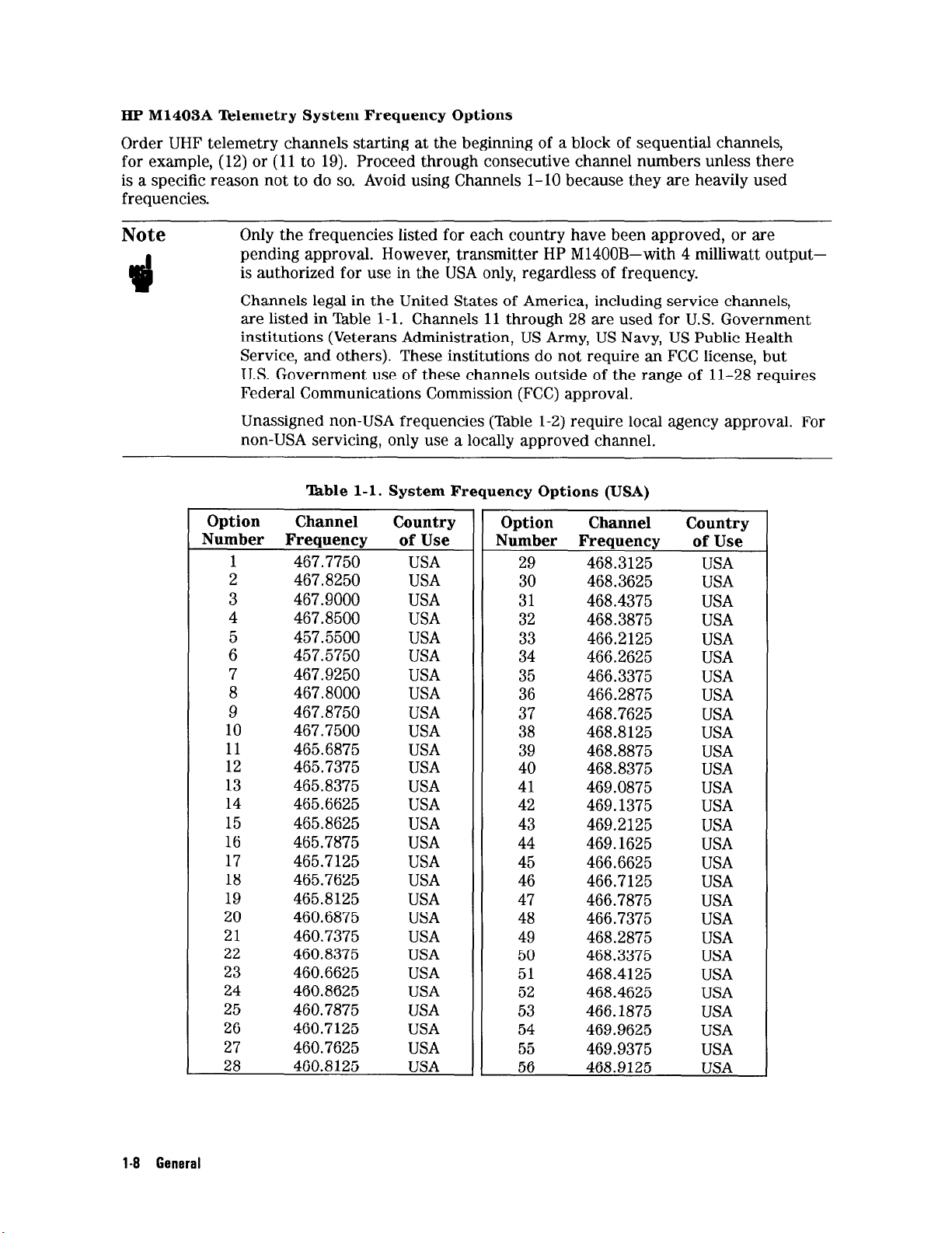

HP M1403A Telemetry System Frequency Options

Order UHF telemetry channels starting at the beginning of a block of sequential channels,

for example, (12) or (11 to 19). Proceed through consecutive channel numbers unless there

is a specific reason not to do so. Avoid using Channels l-10 because they are heavily used

frequencies.

Only

the

Note

frequencies listed for each country have been approved, or are

pending approval. However, transmitter HP M1400B-with 4 milliwatt outputis authorized for use in the USA only, regardless of frequency.

Channels legal in the United States of America, including service channels,

are listed in ‘Ihble l-l. Channels 11 through 28 are used for U.S. Government

institutions (Veterans Administration, US Army, US Navy, US Public Health

Service, and others). These institutions do not require an FCC license, but

U.S. Government use of these channels outside of the range of 11-28 requires

Federal Communications Commission (FCC) approval.

Unassigned non-USA frequencies (Table l-2) require local agency approval. For

non-USA servicing, only use a locally approved channel.

‘kble l-l. System Frequency Options (USA)

Option Channel

Number Freauencv of Use

1

2

467.7750 USA

467.8250

3 467.9000

4

5

6

7

8

467.8500

457.5500 USA

457.5750

467.9250

467.8000

9 467.8750

10

11

12

467.7500

465.6875

465.7375

13 465.8375

14

15

16

17

465.6625

465.8625 USA

465.7875

465.7125

18 465.7625

19 465.8125

20 460.6875

21

22

23

24

25

460.7375

460.8375 USA

460.6625

460.8625 USA

460.7875

26 460.7125

27

460.7625 USA

28 460.8125

Country Option

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

Channel

Number Frequency

29

30

468.3125 USA

468.3625

Country

31 468.4375

32 468.3875 USA

33

466.2125

34 466.2625 USA

35

466.3375

36 466.2875

37

38

468.7625

468.8125

39 468.8875 USA

40 468.8375

41

42

43

469.0875

469.1375 USA

469.2125

44 469.1625

45

466.6625

46 466.7125

47 466.7875 USA

48 466.7375 USA

49 468.2875 USA

50

51

52

53

468.3375

468.4125

468.4625

466.1875

54 469.9625

55 469.9375

56

468.9125

of Use

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

1-8 General

Page 23

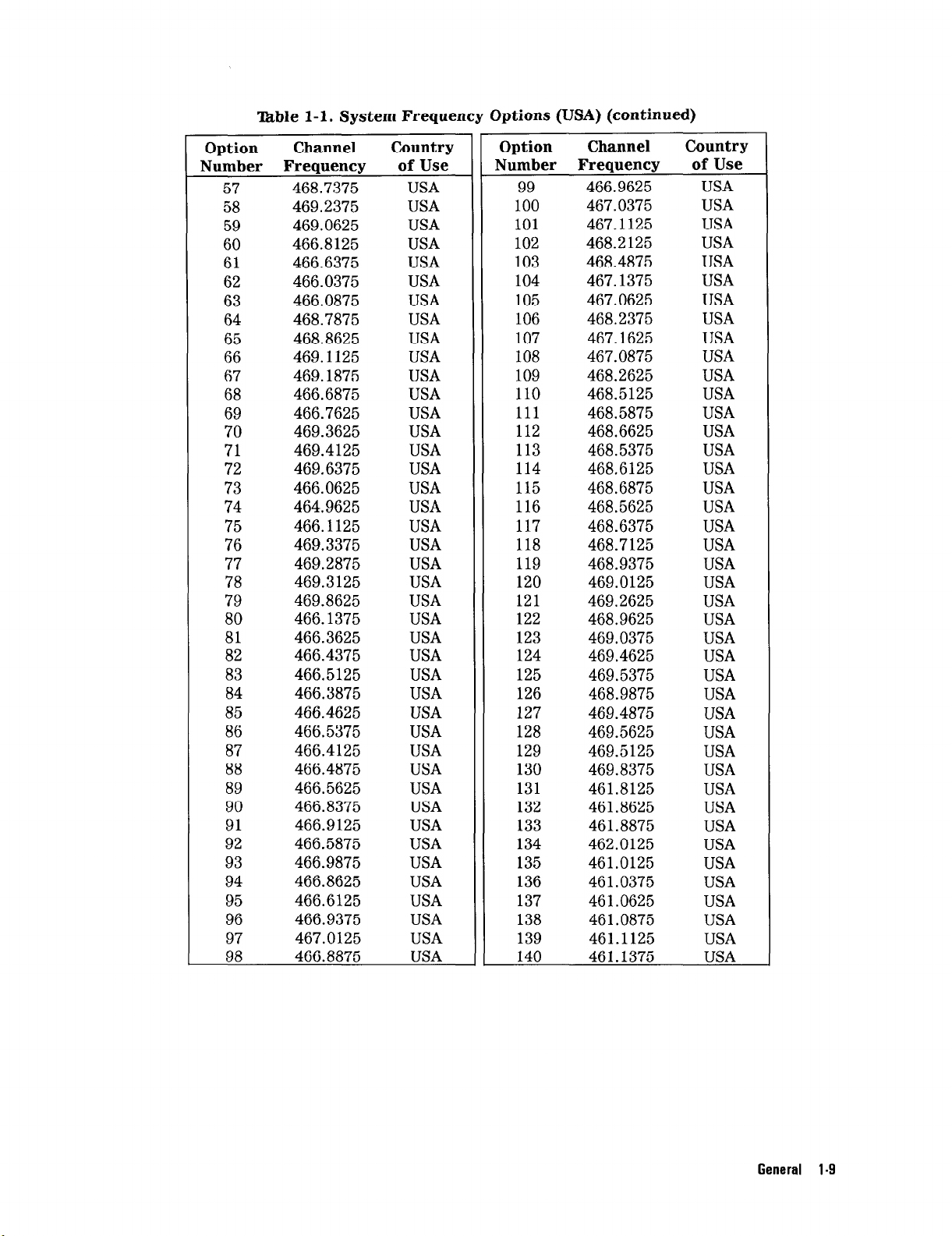

‘Ihble l-l. System Frequency Options (USA) (continued)

Option

Number Frequency

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

Channel

468.7375 USA

469.2375

469.0625 USA

466.8125 USA

466.6375

466.0375

466.0875 USA

468.7875 USA

468.8625 USA

469.1125 USA

469.1875 USA

466.6875 USA

466.7625

469.3625 USA

469.4125 USA

469.6375

466.0625 USA

464.9625 USA

466.1125

469.3375

77 469.2875 USA

78

79

469.3125

469.8625

80 466.1375 USA

81 466.3625 USA

82

466.4375

83 466.5125

84 466.3875

85

466.4625

86 466.5375

87 466.4125

88 466.4875

89

90

91

466.5625

466.8375

466.9125

92 466.5875

93 466.9875 USA

94 466.8625 USA

95 466.6125 USA

96 466.9375

97 467.0125 USA

98

466.8875 USA

Country

of Use

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

Option

Number Freauencs

99

Channel Country

466.9625

100 467.0375

101

102

103

104

105

106

107

108

467.1125 USA

468.2125 USA

468.4875 USA

467.1375 USA

467.0625 USA

468.2375 USA

467.1625 USA

467.0875 USA

109 468.2625 USA

110 468.5125 USA

111

112

113

114

468.5875 USA

468.6625 USA

468.5375

468.6125 USA

115 468.6875 USA

116 468.5625 USA

117

468.6375 USA

118 468.7125

119 468.9375

120 469.0125

121

122

123

124

125

126

127

128

129

130

131

132

469.2625

468.9625 USA

469.0375

469.4625

469.5375 USA

468.9875 USA

469.4875

469.5625

469.5125 USA

469.8375

461.8125

461.8625

133 461.8875

134 462.0125

135 461.0125

136

137

461.0375

461.0625 USA

138 461.0875

139 461.1125

140 461.1375 USA

of Use

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

General l-9

Page 24

able l-l. System Frequency Options (USA) (continued)

Option

Number Frequency of Use

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164 462.0625

165 462.0875

166

167 462.1375

168

169

170 463.2375

171

172

173 463.3125

174 463.3375

175 463.3625

176 463.3875

177

178 463.4375

179 463.4625

180

181 463.5125

182 463.5375

Channel Country

461.1625

461.1875

461.2125

461.2375

461.2625

461.3875

461.4125

461.4375

461.4625

461.4875

461.5125

461.5375

461.5625

461.5875

461.6125

46 1.6375

461.6625

461.6875

461.7125

461.7375

461.7625

461.7875

462.0375

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

462.1125

USA

USA

462.1625

463.2125

USA

USA

USA

463.2625

463.2875

USA

USA

USA

USA

USA

USA

463.4125

USA

USA

USA

463.4875

USA

USA

USA

Option

Number Frequency

183

184

185

186

187

188

189

190

Channel Country

of Use

463.5625

463.5875

463.6125 USA

463.6375 USA

463.6625 USA

463.6875 USA

463.7125 USA

463.7375 USA

191 463.7625 USA

192 463.7875 USA

193

194

195

463.8125 USA

463.8375 USA

463.8625 USA

196 463.8875 USA

197 463.9125 USA

198 463.9375 USA

199 463.9625 USA

200 463.9875 USA

201 464.0125

202 464.0375 USA

203 464.0625 USA

204 464.0875

205

206

464.1125

464.1375

207 464.1625 USA

208 464.1875 USA

209 464.2125

210

211

212

213

214

464.2375

464.2625

464.2875

464.3125

464.3375

215 464.3625

216

464.3875

217 464.4125

218 464.4375

219

464.4625 USA

220 464.4875

221

222

464.5125

464.5375

223 464.5625 USA

224

464.5875

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

l-10 General

Page 25

‘lhble l-l. System Frequency Options (USA) (continued)

Option

Number Frequency

Channel Country

225 464.6125

226 464.6375

227 464.6625

228 460.8875

229 461.2875

230 461.3125

231 461.3625

232 461.8375

233 462.1875

234 462.7875

235 462.7625

236 461.3375

237 462.8125

238 464.8125

239 462.8625

240 464.8625

241 462.9125

242 464.6875

243 464.9125

244 464.7375

245 462.8375

246 464.7875

247 462.8875

248 464.8375

249 464.7125

250 464.8875

of Use

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

Option

Number Frequency

Channel

Country

of Use

251 464.7625 USA

252 464.9375 USA

253 469.8125 USA

254 464.9875 USA

255 465.8875 USA

256 469.6875 USA

257 467.1875 USA

258 469.8875 USA

259 469.6125 USA

260 469.7375 USA

261 466.0125 USA

262 469.6625 USA

263 469.7875 USA

264 469.7125 USA

265 469.5875 USA

266 469.7625 USA

267 469.9125 USA

391 457.5250 Service

392 457.6000 Service

393 466.2375 Service

394 466.3125 Service

395 466.1625 Service

396 469.3875 Service

397 469.4375 Service

General l-11

Page 26

T&ble l-2. System Frequency Options (Non-USA)

3ption

Jumber Frequency

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

Channel

467.7750

467.8250

467.9000

467.8500

457.5500

457.5750

467.9250

467.8000

467.8750

467.7500

465.6875

465.7375

465.8375

465.6625

465.8625

465.7875

465.7125 Spain - Diwan - Italy

465.7625

465.8125 Spain - lkiwan - Italy

460.6875

460.7375

460.8375

460.6625

460.8625

460.7875

460.7125 Spain - Taiwan - Italy

460.7625

460.8125 Spain - Taiwan - Italy

468.3125 Spain - Thiwan - Italy

468.3625

468.4375

468.3875 Spain - Thiwan - Italj

466.2125

466.2625 Spain - Ylkiwan - Itall

466.3375 Spain - Biwan - Italy

466.2875

468.7625

468.8125

468.8875

468.8375

469.0875 Spain - lkiwan - Ital

469.1375

Country of Use

Spain - Taiwan - Italy

Sbain - Tmiwan - Italy

Spain - Taiwan - Italy

Spain - Tkiwan - Italy

Spain - Taiwan - Italy

Spain - Thiwan - Italy

Spain - Taiwan - Italy

Spain - Wwan - Italy

Spain - Taiwan - Italy

Spain - Thiwan - Italy

Spain - Biwan - Italy

Spain - lhiwan - Italy

Spain - Biwan - Italy

Spain - Taiwan - Italy

Spain - Wwan - Italy

Spain - YIhiwan - Italy

Spain - Taiwan - Italy

Spain - Taiwan - Italy

Spain - lkiwan - Italy

Spain - Lhiwan - Italy

Spain - Taiwan - Italy

Spain - Taiwan - Italy

Spain - Tdiwan - Italy

Spain - Taiwan - Italy

Spain - Ykiwan - Italy

Spain - Thiwan - Italy

Spain - TIMwan - Italy

Spain - Tkiwan - ItaIq

Spain - Taiwan - Italy

Spain - Taiwan - Ital

Spain - Taiwan - Itall

Spain - Taiwan - Italy

Spain - Tdiwan - Ital

1-12 General

Page 27

‘kble 1-2. System Frequency Options (Non-USA) (continued)

Option

Jumber Frequency

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

Channel

469.2125

469.1625

466.6625

466.7125

466.7875

466.7375

468.2875

468.3375

468.4125

468.4625

466.1875

469.9625

469.9375

468.9125

468.7375

469.2375

469.0625

466.8125

466.6375

466.0375

466.0875

468.7875

468.8625

469.1125

469.1875

466.6875

466.7625

469.3625

469.4125

469.6375

466.0625

464.9625

466.1125

469.3375

469.2875

469.3125

469.8625

466.1375

466.3625

466.4375

466.5125

466.3875

Country of Use

Spain - lkiwan

Spain - lhiwan

Spain - lhiwan

Spain - Taiwan

Spain - lhiwan

Spain - Taiwan

Spain - Ykiwan

Spain - Yhiwan

Spain - l%iwan

Spain - T%iwan

Spain - Taiwan

Spain - Taiwan

Spain - Taiwan

Spain - lhiwan

Spain - X&wan

Spain - Tdiwan

Spain - lkiwan

Spain - l%iwan

Spain - lhiwan

Spain - Taiwan

Spain - lhiwan

Spain - Tkiwan

Spain - ‘Pdiwan

Spain - 7Mwan

Spain - Tkiwan

Spain - Thiwan

Spain - lhiwan

Spain - Taiwan

Spain - Tkiwan

Spain - Wwan

Spain - lhiwan

Spain - Taiwan

Spain - lhiwan

Spain - Taiwan

Spain - Tkiwan

Spain - Wwan

Spain - lhiwan

Spain - lkiwan

Spain - Biwan

Spain - Tbiwan

Spain - lhiwan

Spain - Biwan

- Italy

- Italy

- Italy

- Italy

- Italy

- Italy

- Italy

- Italy

- Italy

- Italy

- Italy

- Italy

- Italy

- Italy

- Italy

- Italy

- Italy

- Italy

- Italy

- Italy

- Italy

- Italy

- Italy

- Italy

- Italy

- Italy

- Italy

- ItalJm

- Italy

- Italy

- Italy

- Italy

- Italj

- Ital)

- Italy

- Italy

- Italy

- Ttalq

- Italy

- Italy

- Italy

- Italy

General I-13

Page 28

Ikble 1-2. System Frequency Options (Non-USA) (continued)

Option

dumber Frequency

Channel

85 466.4625

86 466.5375

87 466.4125

88 466.4875

89 466.5625

90 466.8375

91 466.9125

92 466.5875

93 466.9875

94 466.8625

95 466.6125

96 466.9375

97 467.0125

98 466.8875

99 466.9625

100 467.0375

101 467.1125

102 468.2125

103 468.4875

104 467.1375

105 467.0625

106 468.2375

107 467.1625

108 467.0875

109 468.2625

110 468.5125

111 468.5875

112 468.6625

113 468.5375

114 468.6125

115 468.6875

116 468.5625

117 468.6375

118 468.7125

119 468.9375

120 469.0125

121 469.2625

122 468.9625

123 469.0375

124 469.4625

125 469.5375

126 468.9875

Country of Use

Spain - Tkiwan -

Spain - lhiwan Spain - Taiwan Spain - Taiwan Spain - Taiwan Spain - Yt%iwan Spain - Tdiwan Spain - l%.iwan Spain - Ciiwan Spain - Thiwan Spain - %iwan Spain - lhiwan Spain - Taiwan Spain - lkiwan -

Spain - Tdiwan Spain - lkiwan Spain - l%.iwan Spain - lkiwan Spain - Taiwan Spain - Wwan Spain - lhiwan Spain - Taiwan Spain - Taiwan Spain - Ythiwan Spain - ‘Jkiwan Spain - Wwan Spain - ‘hiwan Spain - ‘hiwan Spain - Taiwan Spain - Taiwan Spain - Thiwan Spain - Taiwan Spain - Taiwan Spain - ‘Pdiwan Spain - lkiwan Spain - lhiwan Spain - ‘Pdiwan Spain - Taiwan Spain - Taiwan Spain - Tkiwan -

Spain - Thiwan -

Spain - lkiwan -

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy - Qatar

Italy - Qatar

Italy - Qatar

Italy - Qatar

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy

Italy

I-14 General

Page 29

l’hble 1-2. System Frequency Options (Non-USA) (continued)

3ption

lumber Frequency

Channel

Country of Use

127 469.4875 Spain - Taiwan - Italy

128 469.5625 Spain - Zwan - Italy

129 469.5125 Spain - Thiwan - Italy

130 469.8375 Spain - lhiwan - Italy

131 461.8125 Spain - Thiwan - Italy

132 461.8625 Spain - Taiwan - Italy

133 461.8875 Spain - lhiwan - Italy

134 462.0125 Spain - ‘Pdiwan - Italy

135 461.0125 Spain - T&wan - Italy

136 461.0375 Spain - Taiwan - Italy

137 46 1.0625 Spain - Tbiwan - Italy

138 461.0875 Spain - lhiwan - Italy

139 461.1125 Spain - Thiwan - Italy

140 461.1375 Spain - Taiwan - Italy

141 461.1625 Spain - l&wan - Italy

142 461.1875 Spain - Taiwan - Italy

143 461.2125 Spain - lhiwan - Italy

144 461.2375 Spain - lhiwan - Italy

145 461.2625 Spain - ‘Pdiwan - Italy

146 461.3875 Spain - lhiwan - Italy

147 461.4125 Spain - Thiwan - Italy

148 461.4375 Spain - tiwan - Italy

149 461.4625 Spain - Tkiwan - Italy

150 461.4875 Spain - Taiwan - Italy

151 461.5125 Spain - Taiwan - Italy

152 461.5375 Spain - lztiwan - Italy

153 461.5625 Spain - Taiwan - Italy

154 461.5875 Spain - Taiwan - Italy

155 461.6125 Spain - T&wan - Italy

156 461.6375 Spain - Thiwan - Italy

157 461.6625 Spain - Taiwan - Italy

158 461.6875 Spain - Tkiwan - Italy

159 461.7125 Spain - Tkiwan - Italq

160 461.7375 Spain - Taiwan - Italq

161 461.7625 Spain - tiwan - Italy

162 461.7875 Spain - tiwan - Ital)

163 462.0375 Spain - Taiwan - Italy

164 462.0625 Spain - Taiwan - Italj

165 462.0875 Spain - Taiwan - Ital

166 462.1125 Spain - lhiwan - Italy

167 462.1375 Spain - lhiwan - Italy

168 462.1625 Spain - lkiwan - Italy

General l-15

Page 30

‘kble 1-2. System Frequency Options (Non-USA) (continued)

Iption

lumber Frequency

Channel

Country of Use

169 463.2125 Spain - lhiwan - Italy

170 463.2375 Spain - lhiwan - Italy

171 463.2625 Spain - lhiwan - Italy

172 463.2875 Spain - %iwan - Italy

173 463.3125 Spain - Taiwan - Italy

174 463.3375 Spain - Thiwan - Italy

175 463.3625 Spain - lhiwan - Italy

176 463.3875 Spain - Thiwan - Italy

177 463.4125 Spain - Taiwan - Italy

178 463.4375 Spain - Taiwan - Italy

179 463.4625 Spain - Taiwan - Italy

180 463.4875 Spain - T&wan - Italy

181 463.5125 Spain - Taiwan - Italy

182 463.5375 Spain - Tdiwan - Italy

183 463.5625 Spain - TGwan - Italy

184 463.5875 Spain - l&wan - Italy

185 463.6125 Spain - l%iwan - Italy

186 463.6375 Spain - TPdiwan - Italy

187 463.6625 Spain - lhiwan - Italy

188 463.6875 Spain - Taiwan - Italy

189 463.7125 Spain - lkiwan - Italy

190 463.7375 Spain - Taiwan - Italy

191 463.7625 Spain - Taiwan - Italy

192 463.7875 Spain - Yhiwan - Italy

193 463.8125 Spain - lhiwan - Italy

194 463.8375 Spain - Taiwan - Italy

195 463.8625 Spain - %.iwan - Italy

196 463.8875 Spain - Taiwan - Italy

197 463.9125 Spain - l%iwan - Italy

198 463.9375 Spain - Taiwan - Italy

199 463.9625 Spain - Taiwan - Italy

200 463.9875 Spain - Y&wan - Italy

201 464.0125 Spain - Taiwan - Italy

202 464.0375 Spain - lhiwan - Italy

203 464.0625 Spain - l%iwan - Italy

204 464.0875 Spain - Tdiwan - Italy

205 464.1125 Spain - Thiwan - Italy

206 464.1375 Spain - Biwan - Italy

207 464.1625 Spain - Taiwan - Italy

208 464.1875 Spain - Taiwan - Italy

209 464.2125 Spain - LMwan - Italy

210 464.2375 Spain - Thiwan - Italy

I-16 General

Page 31

‘kble l-2. System Frequency Options (Non-USA) (continued)

Iption

umber Frequency

211

212

213

214

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239

240

241

242

243

244

245

246

247

248

249

250

251

252

Channel

464.2625

464.2875

464.3125

464.3375

464.3625

464.3875

464.4125

464.4375

464.4625

464.4875

464.5125

464.5375

464.5625

464.5875

464.6125

464.6375

464.6625

460.8875

461.2875

461.3125

461.3625

461.8375

462.1875

462.7875

462.7625

461.3375

462.8125

464.8125

462.8625

464.8625

462.9125

464.6875

464.9125

464.7375

462.8375

464.7875

462.8875

464.8375

464.7125

464.8875

464.7625

464.9375

Country of Use

Spain - Taiwan - Italy

Spain - %iwan - Italy

Spain - Thiwan - Italy

Spain - Tbiwan - Italy

Spain - lkiwan - Italy

Spain - lhiwan - Italy

Spain - lkiwan - Italy

Spain - lhiwan - Italy

Spain - Taiwan - Italy

Spain - lhiwan - Italy

Spain - Taiwan - Italy

Spain - lhiwan - Italy

Spain - Thiwan - Italy

Spain - Taiwan - Italy

Spain - Yhiwan - Italy

Spain - lhiwan - Italy

Spain - Taiwan - Italy

Spain - %iwan - Italy

Spain - lhiwan - Italy

Spain - Thiwan - Italy

Spain - lhiwan - Ita

Spain - lhiwan - Italy

Spain - lhiwan - Italy

Spain - tiwan - Ital

Spain - Tkiwan - ItaIJ

Spain - Taiwan - Ital)

Spain - Taiwan - Italy

Spain - Taiwan - Ital

Spain - Thiwan - Itall

Spain - Taiwan - Italy

Spain - Taiwan - Ital

Spain - Taiwan - Itall

Spain - ‘Pdiwan - Italy

Spain - T&wan - Italy

Spain - Xwan - Ital!

Spain - !4kiwan - Ital!

Spain - Taiwan - Ital!

Spain - Tkiwan - Ital!

Spain - E&wan - Ital!

Spain - Taiwan - Ital!

Spain - Taiwan - Ital:

Spain - Thiwan - Italy

General 1-17

Page 32

‘Ihble 1-2. System Frequency Options (Non-USA) (continued)

Iption

lumber Frequency

Channel

Country of Use

253 469.8125 Spain - Wwan - Italy

254 464.9875 Spain - Taiwan - Italy

255 465.8875 Spain - lhiwan - Italy

256 469.6875 Spain - Taiwan - Italy

257 467.1875 Spain - Taiwan - Italy

258 469.8875 Spain - Tdiwan - Italy

259 469.6125 Spain - lkiwan - Italy

260 469.7375 Spain - lkiwan - Italy

261 466.0125 Spain - Taiwan - Italy

262 469.6625 Spain - Taiwan - Italy

263 469.7875 Spain - lkiwan - Italy

264 469.7125 Spain - lkiwan - Italy

265 469.5875 Spain - lkiwan - Italy

266 469.7625 Spain - Taiwan - Italy

267 469.9125 Spain - Thiwan - Italy

501 412.6250 Australia - Spain

502 412.6750 Australia - Spain

503 412.7250 Australia - Spain

504 412.7750 Australia - Spain

505 412.8250 Australia - Spain

506 412.7000 Australia - Spain

507 412.6500 Australia - Spain

508 412.7500 Australia - Spain

509 412.8000 Australia - Spain

510 469.5000 Australia - Italy - Spair

511 469.5250 Australia - Italy - Spair

512 469.5500 Australia - Italy - Spair

513 469.5750 Australia - Italy - Spair

514 469.6000 Australia - Italy - Spair

515 469.6250 Australia - Italy - Spair

516 469.6500 Australia - Italy - Spair

517 469.6750 Australia - Italy - Spair

518 469.7000 Australia - Italy - Spail

519 469.7250 Australia - Italy - Spair

520 412.6000 Australia - Spain

521 412.4750 Australia - Spain

522 412.5000 Australia - Spain

523 412.5250 Australia - Spain

524 412.5500 Australia - Spain

525 412.5750 Australia - Spain

526 412.8500 Australia - Spain

527 412.8750 Australia - Spain

1-l 8 General

Page 33

‘lhble 1-2. System Frequency Options (Non-USA) (continued)

3ption

lumber Frequency

528

529

530

531

532

533

534

535

536

537

538

539

540

541

542

543

544

545

Channel

412.9000

412.9250

412.9500

456.2100

456.2500