Page 1

User Service Guide

HP Integrity rx4640 Server

Manufacturing Part Number: A6961-96013

First Edition

August 2006

© Copyright 2006 Hewlett-Packard Development Company, L.P.

Page 2

Legal Notices

Copyright Notices. © Copyright 2006 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice.

The only warranties for HP products and services are set forth in the express warranty statements

accompanying such products and services. Nothing herein should be construed as constituting an additional

warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

Printed in U.S.A.

Intel, Intel Inside, Itanium, and the Intel Inside logo are trademarks or registered trademarks of Intel

Corporation or its subsidiaries in the United States and other countries.

Linux is a U.S. registered trademark of Linus Torvalds.

Microsoft and Windows are U.S. registered trademarks of Microsoft Corporation.

2

Page 3

About This Document

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

New and Changed Information in This Edition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Publishing History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Document Organization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Typographic Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

HP-UX Release Name and Release Identifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

HP Encourages Your Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1. Introduction

Server Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Server Dimensions and Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Server Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Processors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

PCI Riser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Internal Core I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

External Core I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Power Supply Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Motherboard Manageability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Enhanced Server Manageability Using Management Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Hard Disk Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Supported Operating Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Contents

2. Controls, Ports, and LEDs

Front Panel Controls, Ports, and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Hard Disk Drive LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

DVD/DVD-R/DVD-RW Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Rear Panel Controls, Ports, and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Power Supply Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Management Processor LAN LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Locator LED and Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Gigabit Ethernet Card LAN Ports (Core I/O) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Internal Controls, Ports, and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

QuickFind Diagnostic Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

I/O Baseboard LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3. Powering Off and Powering On the Server

Power States. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Powering Off the Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Powering Off the Server Using the iLO MP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Powering Off the Server Manually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Powering On the Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Powering On the Server Using the iLO MP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Powering On the Server Manually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3

Page 4

Contents

4. Removing and Replacing Components

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Service Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Accessing a Rack Mounted Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Extending the Server from the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Inserting the Server into the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Accessing a Pedestal Mounted Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Removing and Replacing the Front Bezel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Removing the Front Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Replacing the Front Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Removing and Replacing the Front and Top Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Removing the Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Replacing the Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Removing the Top Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Replacing the Top Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Removing and Replacing the Memory Extender Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Removing the Memory Extender Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Replacing the Memory Extender Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Removing and Replacing Server Memory DIMMs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Removing Server Memory DIMMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Installing Memory DIMMs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

16 DIMM Memory Extender Board Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

32 DIMM Memory Extender Board Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Removing and Replacing the Processor Extender Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Removing the Processor Extender Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Replacing the Processor Extender Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Removing and Replacing a Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Processor Load Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Removing a Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Replacing a Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Removing and Replacing Hot-Swap Chassis Fans. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Removing a Hot-Swap Chassis Fan Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Replacing a Hot-Swap Chassis Fan Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Removing and Replacing the I/O Baseboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Removing the I/O Baseboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Replacing the I/O Baseboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Removing and Replacing Hot-Plug PCI-X Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

PCI-X Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Operating System Support for Hot-Plug PCI-X Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

PCI-X Hardware and Software Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

PCI-X Slot Locations and Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Hot-Plug Operation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Removing and Replacing OLX Dividers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Removing an OLX Divider . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Replacing an OLX Divider . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Removing and Replacing Core I/O Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

4

Page 5

Contents

PCI Slot Locations and Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Removing and Replacing the SCSI Core I/O Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Removing and Replacing the LAN Core I/O Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Removing and Replacing the Server Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Removing and Replacing Hard Disk Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Removing a Hard Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Replacing a Hard Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Removing and Replacing the SCSI Backplane Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Removing the SCSI Backplane Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Replacing the SCSI Backplane Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Removing and Replacing the Midplane Riser Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Removing the Midplane Riser Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Replacing the Midplane Riser Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Removing and Replacing the Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Power Supply Load Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Removing a Hot-Swap Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Replacing a Hot-Swap Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Removing and Replacing the Power Distribution Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Removing the Power Distribution Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Replacing the Power Distribution Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Removing and Replacing the DVD Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Removing the DVD Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Replacing the DVD Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Removing and Replacing the DVD I/O Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Removing the DVD I/O Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Replacing the DVD I/O Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Removing and Replacing the Display Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Removing the Display Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Replacing the Display Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Removing and Replacing the QuickFind Diagnostic Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Removing the QuickFind Diagnostic Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Replacing the QuickFind Diagnostic Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

5. Troubleshooting

Troubleshooting Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Troubleshooting Methodology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Possible Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

The Server Does Not Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

The Server Does Not Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

The Server Has Intermittent Failures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

The Server LED or Diagnostic LEDs Are Not On and No Error Messages Appear . . . . . . . . . . . . . 115

Power Shuts Off and Does Not Come Back On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Troubleshooting Using LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Front Control Panel LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Hard Disk Drive LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

DVD/DVD-R/DVD-RW Drive LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

5

Page 6

Contents

QuickFind Diagnostic Panel LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

I/O Baseboard LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Power Supply Status LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

iLO MP LAN LED Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Locator LED and Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

PCI-X LEDs and Hardware Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Online Diagnostics/Exercisers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Offline Support Tool Availability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Offline Support Tools List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

General Diagnostic Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Fault Management Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

HP-UX Fault Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Recommended Cleaning Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Where to Get Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Information to Collect Before you Contact Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Online Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Phone Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

A. Parts Information

Field Replaceable Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

B. Booting the Operating System

Operating Systems Supported on HP Integrity Servers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Configuring System Boot Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Booting and Shutting Down HP-UX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Adding HP-UX to the Boot Options List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Standard HP-UX Booting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Single-User Mode HP-UX Booting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

LVM Maintenance Mode HP-UX Booting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Shutting Down HP-UX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Booting and Shutting Down HP OpenVMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Adding HP OpenVMS to the Boot Options List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Booting HP OpenVMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Shutting Down HP OpenVMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Booting and Shutting Down Microsoft Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Adding Microsoft Windows to the Boot Options List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Booting the Microsoft Windows Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Shutting Down Microsoft Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Booting and Shutting Down Linux . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Adding Linux to the Boot Options List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Booting the Red Hat Enterprise Linux Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Booting the SuSE Linux Enterprise Server Operating System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Shutting Down Linux . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

C. Utilities

6

Page 7

Contents

Extensible Firmware Interface Boot Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

EFI Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

EFI/POSSE Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

baud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

boottest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

cpuconfig . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

ioconfig. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

default . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

errdump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

lanaddress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

monarch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

pdt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

sysmode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Specifying SCSI Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Using the SCSI Setup Utility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Using the Boot Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Boot From File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Add Boot Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Edit Boot Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Remove Boot Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

BootNext Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

AutoBoot Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Driver Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Driver Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Console Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

System Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Using the System Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Using the Security Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

7

Page 8

Contents

8

Page 9

Tables

Table 1. Publishing History Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 2. HP-UX 11i Releases. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 1-1. Server Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 3-1. Power States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 4-1. Quads on the 16 DIMM Memory Extender Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 4-2. DIMM Filler Requirements for 16 DIMM Extender Board . . . . . . . . . . . . . . . . . . . . . . . 50

Table 4-3. Quads on the Optional 32 DIMM Memory Extender Board. . . . . . . . . . . . . . . . . . . . . . . 51

Table 4-4. DIMM Filler Requirements for 32 DIMM Extender Board . . . . . . . . . . . . . . . . . . . . . . . 51

Table 4-5. Processor Load Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 4-6. Hot-Plug Operation and OS Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Table 4-7. Hot-Plug Hardware and Software Interfaces and OS Availability . . . . . . . . . . . . . . . . . 73

Table 4-8. PCI-X Card vs. Slot Frequency/Bus Mode Compatibility for Shared Slots . . . . . . . . . . . 75

Table 5-1. Front Control Panel LED Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Table 5-2. Hot-Swap Disk Drive LED Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Table 5-3. DVD Drive LED Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Table 5-4. QuickFind Diagnostic Panel LED Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Table 5-5. I/O Baseboard LEDs, Buttons and Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Table 5-6. Power Supply Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Table 5-7. iLO MP LED Status Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Table 5-8. PCI-X LED Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Table 5-9. Online Support Tools List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Table 5-10. Offline Support Tools List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Table 5-11. General Diagnostic Tools List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Table 5-12. Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Table A-1. Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Table C-1. EFI Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Table C-2. Communications Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Table C-3. Console Output Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Table C-4. Console Output Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Table C-5. Console Output Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Table C-6. Console Output Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

9

Page 10

Tables

10

Page 11

Figures

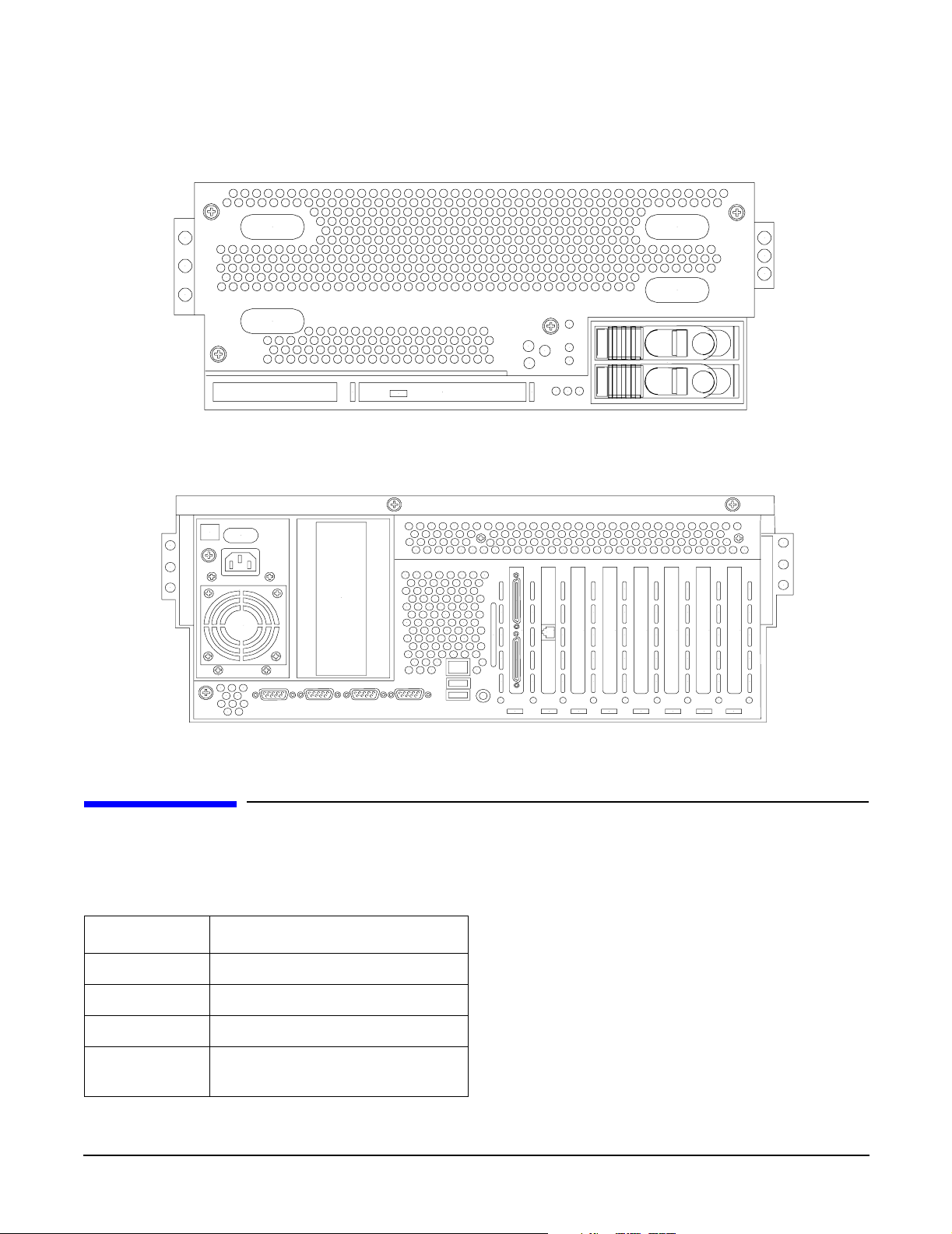

Figure 1-1. HP Integrity rx4640 Server with Front Bezel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 1-2. HP Integrity rx4640 Server (front view with bezel removed) . . . . . . . . . . . . . . . . . . . . 21

Figure 1-3. HP Integrity rx4640 Server (rear view). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 2-1. Front View with Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 2-2. Accessing the Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 2-3. Control Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 2-4. Hard Disk Drive LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 2-5. DVD–ROM Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 2-6. Rack Mount and Pedestal Rear View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 2-7. Power Supply Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 2-8. MP LAN LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 2-9. Core I/O LAN Port LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 2-10. QuickFind Diagnostic Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 2-11. I/O Baseboard LEDs, Buttons, and Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 4-1. Accessing 25MM Torx Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 4-2. Pedestal Mounted HP Integrity rx4640 Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 4-3. Removing and Replacing the Front Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 4-4. Removing and Replacing the Front Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 4-5. Removing and Replacing the Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 4-6. Opening the Memory Extender Board Latches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 4-7. Removing and Replacing the Memory Extender Board. . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 4-8. Inserting DIMM into Extender Board Slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 4-9. 16 DIMM Extender Board Slot IDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 4-10. 32 DIMM Extender Board Slot IDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 4-11. Opening the Processor Extender Board Latches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 4-12. Removing and Replacing the Processor Extender Board. . . . . . . . . . . . . . . . . . . . . . . 53

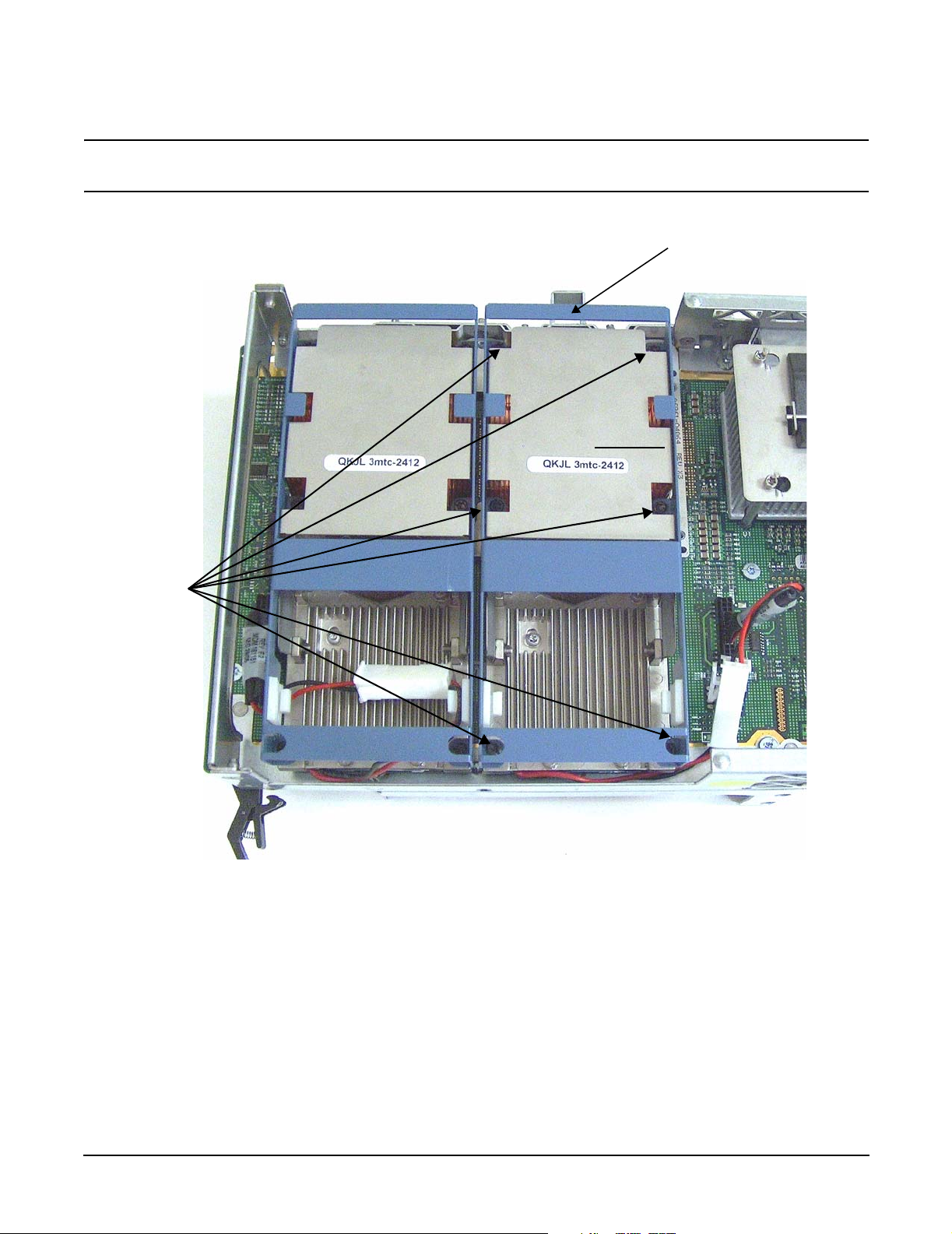

Figure 4-13. Processor Slot Locations on the Processor Extender Board . . . . . . . . . . . . . . . . . . . . . 56

Figure 4-14. Removing the Processor Sequencer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 4-15. Unlocking the Processor from the Processor Extender Board. . . . . . . . . . . . . . . . . . . 58

Figure 4-16. CPU 1 Socket Unlocked . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 4-17. Processor Cable Routed Correctly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 4-18. Locking the Processor to the Processor Extender Board . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 4-19. Installing Sequencer on Extender Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 4-20. Removing and Replacing the Chassis Fans 0 and 1. . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 4-21. Removing and Replacing the Chassis Fan 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 4-22. I/O Baseboard Locking Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 4-23. Removing the I/O Baseboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 4-24. I/O Baseboard Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Figure 4-25. Slot ID Numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Figure 4-26. PCI-X OLX Divider Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Figure 4-27. Inserting PCI-X Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Figure 4-28. Opening and Closing the OLX Divider Latch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Figure 4-29. Removing and Replacing the OLX Divider. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

11

Page 12

Figures

Figure 4-30. Slot ID Numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Figure 4-31. SCSI I/O Card Latch Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Figure 4-32. Inserting SCSI I/O Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Figure 4-33. LAN I/O Card Latch Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Figure 4-34. Battery Location on the I/O Baseboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Figure 4-35. Hard Disk Drive and Slot Locations on the Front of the Server . . . . . . . . . . . . . . . . . 91

Figure 4-36. Removing and Replacing a Hard Disk Drive in Slot 2 . . . . . . . . . . . . . . . . . . . . . . . . . 91

Figure 4-37. Installing a Volume Filler in Slot 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Figure 4-38. Removing and Replacing the SCSI Backplane Board . . . . . . . . . . . . . . . . . . . . . . . . . 94

Figure 4-39. Removing and Replacing the Midplane Riser Board . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Figure 4-40. Removing and Replacing the Hot-Swap Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . 99

Figure 4-41. Removing and Replacing the Power Distribution Board . . . . . . . . . . . . . . . . . . . . . . 101

Figure 4-42. Removing and Replacing the DVD Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Figure 4-43. Removing and Replacing the DVD I/O Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Figure 4-44. Removing and Replacing the Display Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Figure 4-45. Removing and Replacing the QuickFind Diagnostic Board. . . . . . . . . . . . . . . . . . . . 110

Figure 5-1. Front Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Figure 5-2. Hot-Swap Disk Drive LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Figure 5-3. DVD–ROM Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Figure 5-4. QuickFind Diagnostic Label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Figure 5-5. I/O Baseboard LEDs, Buttons and Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Figure 5-6. Power Supply Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Figure 5-7. iLO MP LAN LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Figure C-1. EFI Boot Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

12

Page 13

Figures

13

Page 14

Figures

14

Page 15

About This Document

This document provides information and instructions on servicing and troubleshooting the HP Integrity

rx4640 server.

The document printing date and part number indicate the document’s current edition. The printing date

changes when a new edition is printed. Minor changes may be made at reprint without changing the printing

date. The document part number changes when extensive changes are made.

Document updates may be issued between editions to correct errors or document product changes. To ensure

that you receive the updated or new editions, you should subscribe to the appropriate product support service.

See your HP sales representative for details.

The latest version of this document can be found on line at http://www.docs.hp.com.

Intended Audience

This document is intended to provide technical product and support information for authorized service

providers, system administrators, and HP support personnel.

This document is not a tutorial.

New and Changed Information in This Edition

This guide has been updated with:

• This document is being updated as part of the continuous product improvement (CPE) initiative to

enhance the current HP Integrity BL60p server blade documentation.

Publishing History

The publishing history below identifies the edition dates of this manual. Updates are made to this publication

on an unscheduled, as needed, basis. The updates will consist of a complete replacement manual and

pertinent on-line or CD documentation.

Table 1 Publishing History Details

Document

Manufacturing

Part Number

A6961-96013 HP-UX, Windows®,

Operating Systems

Supported

Linux®, OpenVMS®

Supported Product Versions

rx4640 August 2006

Publication

Date

15

Page 16

Document Organization

This guide is divided into the following chapters.

Chapter 1 Introduction Use this chapter to learn about the features and specifications of the HP

Integrity rx4640 server.

Chapter 2 Controls, Ports, and LEDs Use this chapter to learn about the locations of the external

controls, ports, and LEDs on the server.

Chapter 3 Powering Off and Powering On the Server Use this chapter to learn about powering

the server off and on.

Chapter 4 Removing and Replacing Components Use this chapter to learn how to remove and

replace the field replaceable components (FRUs) on the server.

Chapter 5 Troubleshooting Use this chapter to learn about troubleshooting problems you may

encounter with the server.

Appendix A Parts Information Use this appendix to learn the location and part numbers of the server

components.

Appendix B Operating System Boot and Shutdown Use this appendix to learn about booting and

shutting down the operating system on the server.

Appendix C Utilities Use this appendix for information regarding the utilities available for the server.

Appendix D Console Setup and Connection Use this appendix to learn about the process for setting

up a console session and connecting to the server.

Typographic Conventions

This document uses the following conventions.

WAR NING A warning lists requirements that you must meet to avoid personal injury.

CAUTION A caution provides information required to avoid losing data or avoid losing system

functionality.

NOTE A note highlights useful information such as restrictions, recommendations, or important

details about HP product features.

Book Title The title of a book. On the Web and on the Instant Information CD, it may be a hot link to

the book itself.

KeyCap The name of a keyboard key or graphical interface item (such as buttons, tabs, and menu

items). Note that

Emphasis Text that is emphasized.

Bold Text that is strongly emphasized.

Bold The defined use of an important word or phrase.

Return and Enter both refer to the same key.

ComputerOut Text displayed by the computer.

UserInput Commands and other text that you type.

16

Page 17

Command A command name or qualified command phrase.

Option An available option.

Screen Output Example of computer screen output.

[] The contents are optional in formats and command descriptions. If the contents are a list

separated by |, you must select one of the items.

{} The contents are required in formats and command descriptions. If the contents are a list

separated by |, you must select one of the items.

... The preceding element may be repeated an arbitrary number of times.

| Separates items in a list of choices.

HP-UX Release Name and Release Identifier

Each HP-UX 11i release has an associated release name and release identifier. The uname (1) command with

the -r option returns the release identifier. This table shows the releases available for HP-UX 11i.

Table 2 HP-U X 1 1i Rel ea se s

Release Identifier Release Name Supported Processor Architecture

B.11.11 HP-UX 11i v1 PA-RISC

B.11.20 HP-UX 11i v1.5 Intel® Itanium®

B.11.22 HP-UX 11i v1.6 Intel Itanium

B.11.23 HP-UX 11i v2.0 Intel Itanium

Related Documents

You can find other information on HP server hardware management, Microsoft® Windows®, and diagnostic

support tools in the following publications.

Web Site for HP Technical Documentation:

http://docs.hp.com

Server Hardware Information:

http://docs.hp.com/hpux/hw/

Windows Operating System Information

You can find information about administration of the Microsoft Windows operating system at the following

Web sites, among others:

• http://docs.hp.com/windows_nt/

• http://www.microsoft.com/technet/

Diagnostics and Event Monitoring: Hardware Support Tools

Complete information about HP’s hardware support tools, including online and offline diagnostics and event

monitoring tools, is at the http://docs.hp.com/hpux/diag/ Web site. This site has manuals, tutorials,

FAQs, and other reference material.

17

Page 18

Web Site for HP Technical Support:

http://us-support2.external.hp.com/

Books about HP-UX Published by Prentice Hall

The http://www.hp.com/hpbooks/ Web site lists the HP books that Prentice Hall currently publishes, such

as HP-UX books including:

• HP-UX 11i System Administration Handbook

http://www.hp.com/hpbooks/prentice/ptr_0130600814.html

• HP-UX Virtual Partitions

http://www.hp.com/hpbooks/prentice/ptr_0130352128.html

HP Books are available worldwide through bookstores, online booksellers, and office and computer stores.

HP Encourages Your Comments

HP encourages your comments concerning this document. We are truly committed to providing

documentation that meets your needs.

Please send comments to: netinfo_feedback@cup.hp.com.

Please include title, manufacturing part number, and any comment, error found, or suggestion for

improvement you have concerning this document. Also, please include what we did right so we can

incorporate it into other documents.

18

Page 19

1 Introduction

The HP Integrity rx4640 server is a 4-processor/8-core IPF rack-mount server based on the Itanium2

processor family architecture. The supported operating systems include HP-UX, Windows, Linux, and

OpenVMS. The server accommodates up to 32 DIMMs and internal peripherals; including two hard disk

drives, and a DVD. Its high availability features include hot-swap fans and 200-240 VAC power supplies,

hot-plug disk drives, and hot-plug PCI-X cards.

This chapter addresses the following topics:

• “Server Overview” on page 20.

• “Server Dimensions and Weight” on page 21.

• “Server Components” on page 22.

• “Supported Operating Systems” on page 24.

Chapter 1

19

Page 20

Introduction

Server Overview

Server Overview

The HP Integrity rx4640 server is a 4U high Electronics Industry Association (EIA) enclosure, which mounts

in any standard 19” EIA rack. All external cabling enters and exits from the rear of the enclosure. With the

server installed in the rack, service access is enhanced by the use of chassis slides. It has bays to

accommodate 1 + 1 redundant, hot-swappable power supplies, accessible from the rear of the enclosure. There

are two low-profile hot swappable hard disk drives accessible from the front, as well as a slim-line optical

drive for a CD-R, CD-RW, DVD-R or DVD+RW. There are N + 1 redundant, hot-swappable server fans, all

clearly identified and easily accessible. Server status indication, a power switch, server locator switch and

LED are located in the front within the control panel access door on the bezel. There is also a server locator

switch and LED located on the front and back of the server for easy identification in the rack. Refer to the HP

Integrity rx4640 Site Preparation Guide for more detailed server specifications and requirements. Figure 1-1,

Figure 1-2, and Figure 1-3 show the top, front, and rear views of the server.

Figure 1-1 HP Integrity rx4640 Server with Front Bezel

20

Chapter 1

Page 21

Server Dimensions and Weight

Figure 1-2 HP Integrity rx4640 Server (front view with bezel removed)

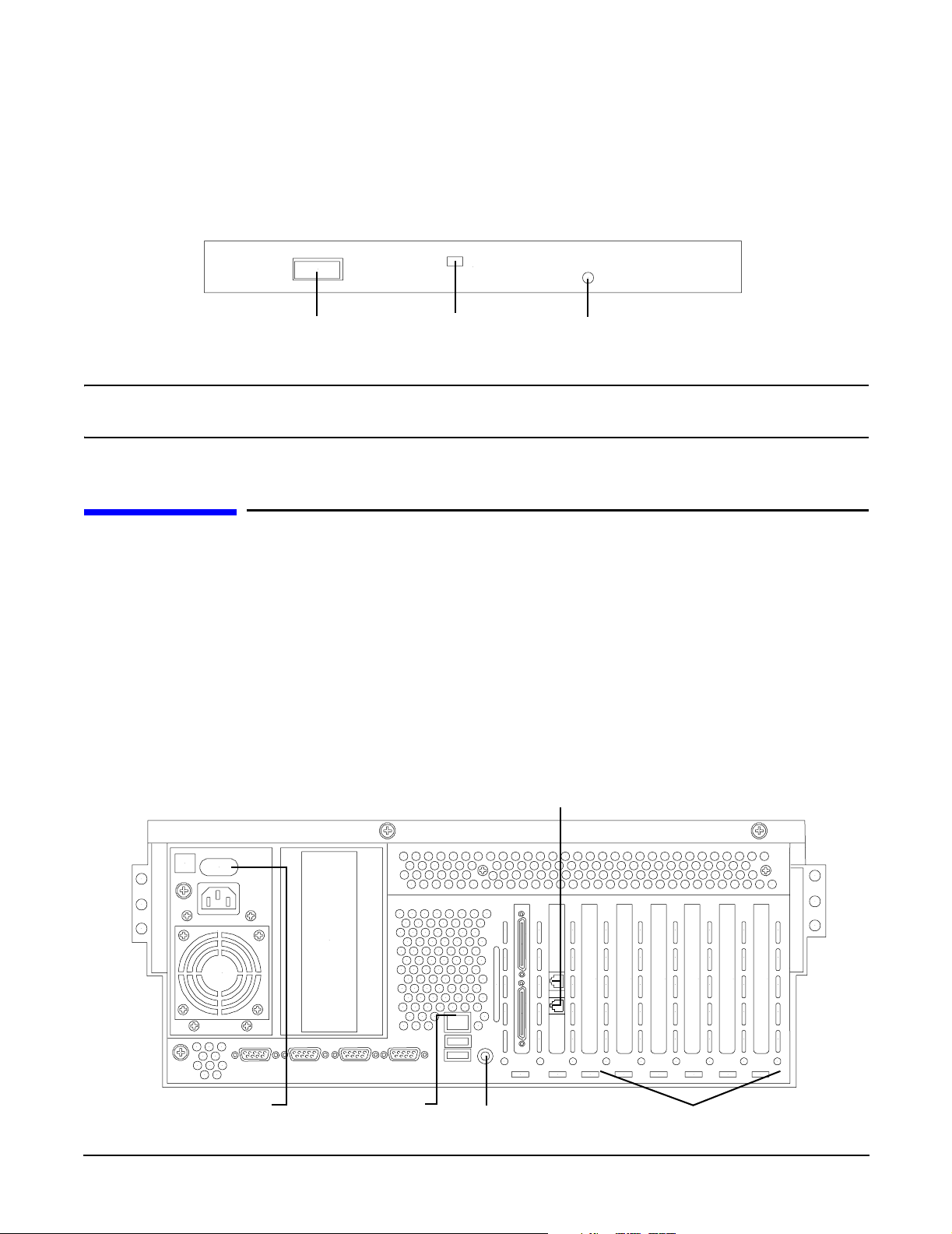

Figure 1-3 HP Integrity rx4640 Server (rear view)

Introduction

Server Dimensions and Weight

Table 1-1 shows the dimensions and weight of the HP Integrity rx4640 server.

Table 1-1 Serv e r Dime ns ions

Dimensions Value

Height 17.46 cm (6.87 in.)

Width 44 cm (17.32 in.)

Depth (63.8 cm (25.1 in.)

Weight Unloaded - 40 kg (95 lb)

Fully loaded - 100 kg (220 lb)

Chapter 1

21

Page 22

Introduction

Server Components

Server Components

The following components comprise the HP Integrity rx4640 server.

Processors

The following processors are available for the rx4640 server:

• 1.6 GHz / 18 MB cache

• 1.6 GHz / 24 MB cache

These processors are dual core processors. The processor configuration options are 1-processor/2-core (1p/2c),

2p/4c, 3p/6c, or 4p/8c.

Memory

• 16 DIMM slots on standard memory extender board

• 32 DIMM slots on optional memory extender board

• Minimum memory size of 1 GB (four 256 MB DIMMs in

• Maximum memory size of 128 GB (4 GB DIMMs on 32-slot memory extender board)

• 256 MB, 512 MB, 1 GB, 2 GB, and 4 GB standard 184 pins 2.5V DDR 200, CL2, registered, ECC

• 200 MHz memory bus frequency, 400 MTransfers/s data, 12.8 GB/s peak data bandwidth

• DIMMs loaded by quads enable interleaved mode and chip spare

PCI Riser

• Two dedicated PCI slots (LAN and SCSI)

• Four hot-plug PCI-X 66 MHz, 64-bit, 3.3V, 25W slots with shared busses and I/O. Slots 3 and 4 share a

PCI-X bus and slots 5 and 6 share a PCI-X bus

• Two hot-plug PCI-X 133 MHz 64-bit 3.3V 25W slots

Internal Core I/O

• Dual channel SCSI U320 interface, two internal 68-pin connectors, two 68-pin external connectors

• The SCSI backplane is configured as either one or two channels

• One internal IDE connector for a slim-line optical device (CD and DVD)

• No floppy connector

External Core I/O

• Three external DB-9 ports (MP local, auxiliary, remote)

• Two external USB 2.0 ports

• Two SCSI Ultra320 68-pin connectors

22

Chapter 1

Page 23

• Two 10/100/1000Base-T ethernet LAN port

• One 10/100 integrated Lights Out Management Processor (iLO MP) LAN port

• One VGA port

Power Supply Unit

• 1200 W output power

• Redundant and hot-swap power supplies

Motherboard Manageability

• Baseboard Management Controller (BMC)

• Temperature monitoring and fans regulation by BMC

• Includes diagnostic panel LED display that shows server health

• Hardware diagnostics by BMC displayed by diagnostic panel LED

• IPMI protocol for communication between BMC/server/MP card

Introduction

Server Components

• Locator front/rear LEDs

• Field replacement units monitoring by BMC

Enhanced Server Manageability Using Management Processor

• LAN, telnet, and SSH console

•Web GUI

• Serial port for local console

• Serial port for modem console

• Duplication of console screen content across all consoles

Hard Disk Drives

• Two low-profile, hot-pluggable Ultra320 SCSI disk bays

• Disk options:

— 36 GB 15K RPM SCSI disk

— 73 GB 15K RPM SCSI disk

— 146 GB, 10K RPM SCSI disk

— 300 GB, 10K RPM SCSI disk

• Minimum server configuration includes one hard disk drive

Chapter 1

23

Page 24

Introduction

Supported Operating Systems

Supported Operating Systems

The following operating systems are supported on the entry-class HP Integrity servers:

• HP-UX 11i Version 2 (B.11.23)

• HP OpenVMS I64

• Microsoft® Windows® Server 2003

• Red Hat Enterprise Linux 4

• SuSE Linux Enterprise Server 10

For more operating system information, see Appendix B, “Booting the Operating System,” on page 139.

24

Chapter 1

Page 25

2 Controls, Ports, and LEDs

This chapter describes the controls, ports, and indicators found on the front panel, rear panel, and internal

locations of the HP Integrity rx4640 server.

This chapter addresses the following topics:

• “Front Panel Controls, Ports, and LEDs” on page 26.

• “Rear Panel Controls, Ports, and LEDs” on page 28.

• “Internal Controls, Ports, and LEDs” on page 31.

Chapter 2

25

Page 26

Controls, Ports, and LEDs

Front Panel Controls, Ports, and LEDs

Front Panel Controls, Ports, and LEDs

The front panel of the HP Integrity rx4640 server provides the controls and indicators commonly used for

operation. Figure 2-1, Figure 2-2, and Figure 2-3 show the controls, ports, and LEDs on the front panel and

control panel.

Figure 2-1 Front View with Bezel

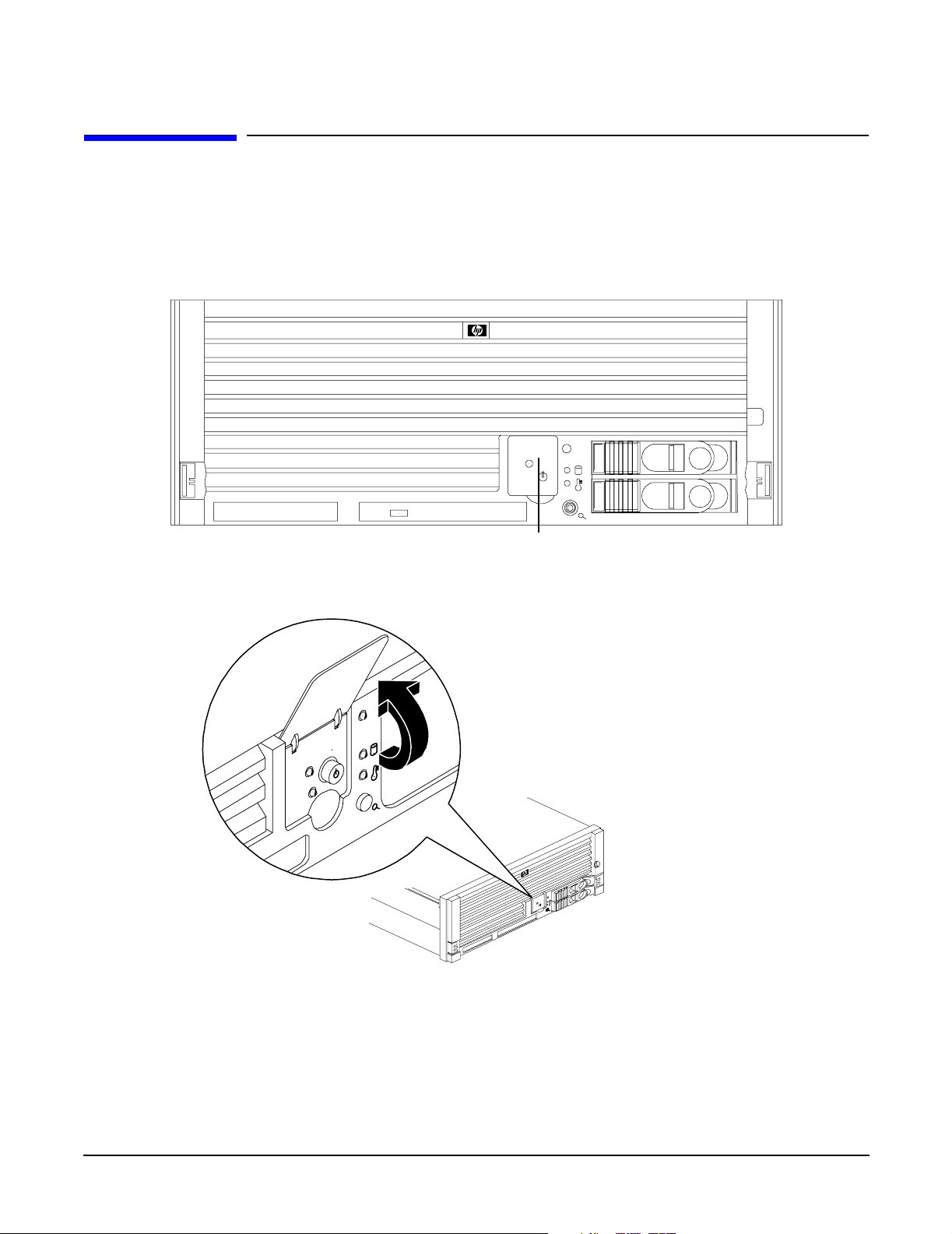

Figure 2-2 Accessing the Control Panel

Control Panel

26

Chapter 2

Page 27

Controls, Ports, and LEDs

Front Panel Controls, Ports, and LEDs

Figure 2-3 Control Panel LEDs

Server LED

Power LED

Power button

ToC/NMI button

NOTE For troubleshooting information regarding control panel LEDs, see “Front Control Panel LED

Indicators” on page 117.

Disk LED

Thermal LED

Locator

button/LED

Hard Disk Drive LED Indicators

The hot-swap disk drives have two LEDs per drive, as described below. Figure 2-4 shows the hard disk drive

LEDs.

• Status LED - The drive status LED displays green when disk power is on, and is off when disk power is

off.

• Activity LED - The drive activity LED is green and indicates disk drive activity. This LED is controlled by

the disk drive directly and turns on when a drive is accessed.

Figure 2-4 Hard Disk Drive LED Indicators

Status LED

Activity LED

NOTE For troubleshooting information regarding the hard disk drive LEDs, see “Hard Disk Drive

LED Indicators” on page 118.

Chapter 2

27

Page 28

Controls, Ports, and LEDs

Rear Panel Controls, Ports, and LEDs

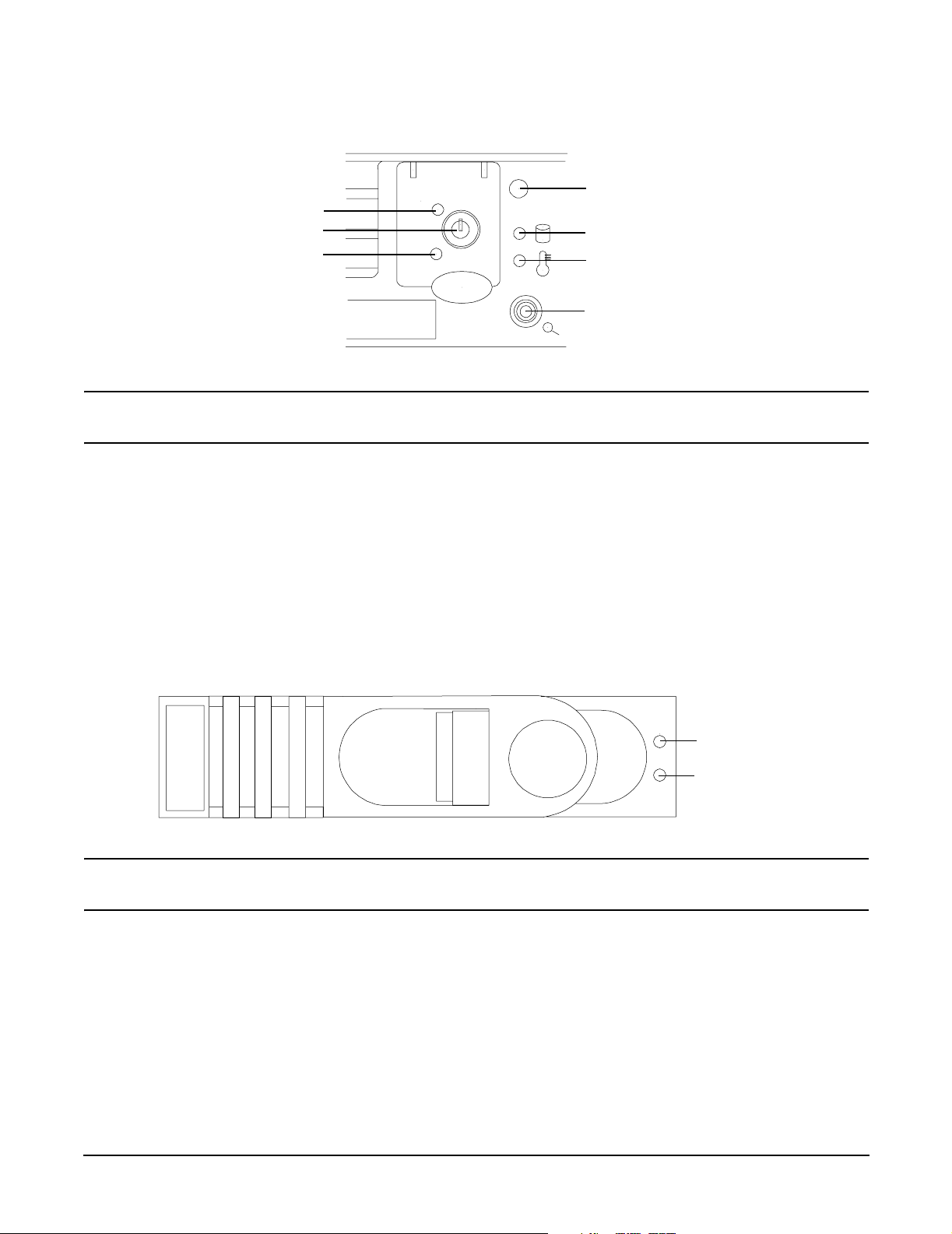

DVD/DVD-R/DVD-RW Drives

The HP server is delivered with one DVD drive (DVD-R and DVD-RW optional). Each of these devices has one

activity LED. Figure 2-5 shows the location of the DVD LEDs.

Figure 2-5 DVD–ROM Drive

Eject Button Activity LED Emergency Eject

NOTE For troubleshooting information regarding the DVD LEDs, see “DVD/DVD-R/DVD-RW Drive

LED Indicators” on page 118.

Rear Panel Controls, Ports, and LEDs

The HP server rear panel includes communication ports, I/O ports, AC power connectors, two power supply

bays, attention LED indicators for the hot-plug PCI boards, and the locator LED/button. Figure 2-6 shows the

LEDs located on the rear panel of the HP server. They include the:

• Power supplies

• Management Processor LAN

• 2 port Gigabit ethernet card LAN

• PCI slots 3-8

Figure 2-6 Rack Mount and Pedestal Rear View

Gigabit Ethernet LAN ports

Power supply LEDs

28

MP LAN LEDs

Locator button/LED

6 PCI attention LEDs

Chapter 2

Page 29

Controls, Ports, and LEDs

Rear Panel Controls, Ports, and LEDs

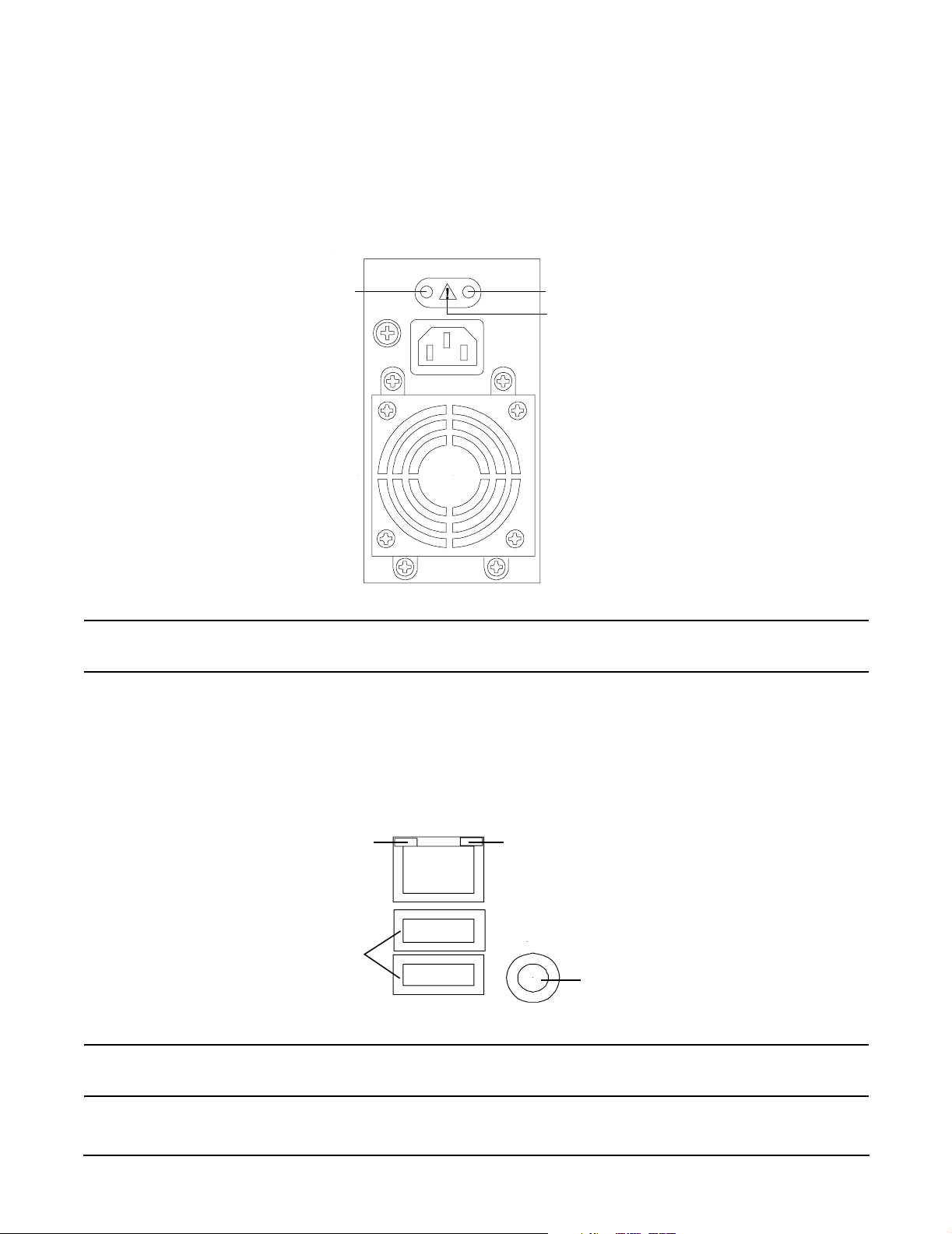

Power Supply Status LEDs

Each 200-240 VAC power supply unit has three status LEDs located on the power supply accessible from the

rear panel. Consolidated status of all power supplies is reported by the front control panel by the power status

LED. Figure 2-7 shows the location of the power supply status LEDs on the rear of the enclosure.

Figure 2-7 Power Supply Status LEDs

Predict fail

LED-amber

NOTE For troubleshooting information regarding the power supply status LEDs, see “Power Supply

Status LED Indicators” on page 123.

Power LED-green

Fail LED-amber

Management Processor LAN LEDs

The internal Management Processor (MP) LAN uses an RJ-45 type connector. This connector has two LEDs

(LAN link and LAN activity) that signal status and activity. Figure 2-8 shows the MP LAN LEDs and USB

ports on the rear panel of the server.

Figure 2-8 MP LAN LEDs

10M Link/Activity, Amber LED

USB Ports

NOTE For troubleshooting information regarding the iLO MP LAN LEDs, see “iLO MP LAN LED

Indicators” on page 124.

Chapter 2

100M Link/Activity, Green LED

Locator Button and LED

29

Page 30

Controls, Ports, and LEDs

Rear Panel Controls, Ports, and LEDs

Locator LED and Button

An LED and button is provided on the rear panel of the server. Another single blue LED and button is on the

front control panel that enables/disables the locator function. See Figure 2-8 for the location of the locator

button.

Gigabit Ethernet Card LAN Ports (Core I/O)

The 2-Port core I/O Gigabit ethernet card uses two RJ-45 LAN connectors. These connectors have no LEDs.

Figure 2-9 shows the two core I/O LAN ports.

Figure 2-9 Core I/O LAN Port LEDs

RJ-45 Connectors

30

Chapter 2

Page 31

Controls, Ports, and LEDs

Internal Controls, Ports, and LEDs

Internal Controls, Ports, and LEDs

The HP Integrity rx4640 server contains internal controls, switches, and LEDs inside the server. This

includes a diagnostic LED panel located under the top panel; and reset buttons, switches, and LEDs located

on the I/O baseboard.

QuickFind Diagnostic Panel

The QuickFind diagnostic panel has 58 single color LEDs and one multi-color LED for temperature. The

LEDs are normally off. The appropriate LED is turned on when an error is detected or a replacement part is

required. You can access the QuickFind diagnostic panel by removing the top cover. See “Removing the Top

Cover” on page 43. Figure 2-10 shows the QickFind diagnostic panel LEDs.

Figure 2-10 QuickFind Diagnostic Panel

NOTE For a complete description of QuickFind diagnostic LED states, see “QuickFind Diagnostic

Panel LED Indicators” on page 119.

Chapter 2

31

Page 32

Controls, Ports, and LEDs

Internal Controls, Ports, and LEDs

I/O Baseboard LED Indicators

There are various LEDs, sensors, reset, and attention buttons located on the HP Integrity rx4640 server I/O

baseboard. They are shown in Figure 2-11.

Figure 2-11 I/O Baseboard LEDs, Buttons, and Sensors

Battery

3.3VSB

power

LED

BMC

reset

button

5V VRM

LED

MP soft

reset

button

MP self-test

LED

MP heartbeat LED

BMC heartbeat LED

3.3V VRM LED

locator button/LED

12V VRM LED

PCI attention

LED

6X

PCI attention

button (doorbell)

6X

PCI power LED

6X

PCI attention LED

6X

NOTE For a complete description of the baseboard LEDs, see “I/O Baseboard LED Indicators” on

page 121.

32

Chapter 2

Page 33

3 Powering Off and Powering On the Server

This chapter provides information and procedures for powering off and powering on the server.

This chapter addresses the following topics:

• “Power States” on page 34.

• “Powering Off the Server” on page 34.

• “Powering On the Server” on page 35.

Chapter 3

33

Page 34

Powering Off and Powering On the Server

Power States

Power States

The server has three power states:

• Standby power

• Full power

•Off

Plug the power cord into the appropriate receptacle on the rear of the chassis to achieve the standby power

state; the front panel power button is not turned on. Full power occurs when the power cord is plugged into

the appropriate receptacle, and either the power is activated through the iLO MP PC command, or the power

button is activated. In the off state, the power cords are not plugged in. Table 3-1 lists the server power states.

Table 3-1 Powe r Stat e s

Power Cable

Power S tates

Standby power Yes No Yes No

Fu l l po wer Ye s Yes Yes Yes

Off No No No No

NOTE If the power restore feature is set to Always On through the iLO MP PR command, the server

automatically powers on to the full power state.

Plugged Into

Receptacle?

Power Activated through the

iLO MP PC Command; or

Front Panel Power Button

Activated?

AC Voltage

Applied

DC Voltage

Applied

Powering Off the Server

Power off the server using the following methods if the server is in either the standby or full power state:

•iLO MP PC command

• Power button

Powering Off the Server Using the iLO MP

To power off the server through the iLO MP, follow these steps:

Step 1. Gracefully shut down the operating system. See Appendix B, “Booting the Operating System,” on

page 139, or your operating system documentation for more information.

Step 2. Initiate a console session, and access the

Step 3. Enter CM to access the

34

Command Menu.

iLO MP Main Menu.

Chapter 3

Page 35

Powering Off and Powering On the Server

Powering On the Server

Step 4. Enter PC to use the remote power control command.

Step 5. Enter OFF to power off the server, and enter YES when prompted to confirm the action.

IMPORTANT The main DC voltage is now removed from the server; however, AC voltage for

standby power is still present in the server.

Step 6. Unplug all power cables from the receptacles on the rear panel of the server.

Powering Off the Server Manually

Manually power off the server through the power button by following these steps:

Step 1. Gracefully shut down the operating system. See Appendix B, “Booting the Operating System,” on

page 139, or your operating system documentation for more information.

Step 2. Press the power button to power off the server.

IMPORTANT The main DC voltage is now removed from the server; however, AC voltage for

standby power is still present in the server.

Step 3. Unplug all power cables from the receptacles on the rear panel of the server.

Powering On the Server

Power on the server to full power using the following methods if the server is in the standby power state:

•iLO MP PC command

• Power button

Powering On the Server Using the iLO MP

NOTE If the power restore feature is set to Always On through the iLO MP PR command, the server

may automatically power on to the full power state.

To power on the server through the iLO MP, follow these steps:

Step 1. Plug all power cables into the receptacles on the rear panel of the server.

Step 2. Initiate a console session, and access the iLO MP Main Menu.

Step 3. Enter CM. to enable command mode.

Step 4. Enter PC to use the remote power control command.

Step 5. Enter ON to power on the server, and enter YES when prompted to confirm the action.

Chapter 3

35

Page 36

Powering Off and Powering On the Server

Powering On the Server

Step 6. Start the operating system. See Appendix B, “Booting the Operating System,” on page 139, or your

operating system documentation for more information.

Powering On the Server Manually

NOTE If the power restore feature is set to Always On through the iLO MP PR command, the server

may automatically power on to the full power state.

To manually power on the server, follow these steps:

Step 1. Plug all power cables into the receptacles on the rear panel of the server.

Step 2. Press the power button to start the server.

Step 3. Start the operating system. See Appendix B, “Booting the Operating System,” on page 139, or your

operating system documentation for more information.

36

Chapter 3

Page 37

4 Removing and Replacing Components

This chapter describes the procedure for removing and replacing the different components in the HP Integrity

rx4640 server.

This chapter addresses the following topics:

• “Safety Information” on page 38

• “Service Tools Required” on page 38

• “Accessing a Rack Mounted Server” on page 38

• “Accessing a Pedestal Mounted Server” on page 40

• “Removing and Replacing the Front Bezel” on page 41

• “Removing and Replacing the Front and Top Covers” on page 42

• “Removing and Replacing the Memory Extender Board” on page 44

• “Removing and Replacing Server Memory DIMMs” on page 46

• “Removing and Replacing the Processor Extender Board” on page 52

• “Removing and Replacing a Processor” on page 55

• “Removing and Replacing Hot-Swap Chassis Fans” on page 63

• “Removing and Replacing the I/O Baseboard” on page 66

• “Removing and Replacing Hot-Plug PCI-X Cards” on page 71

• “Removing and Replacing OLX Dividers” on page 81

• “Removing and Replacing Core I/O Cards” on page 85

• “Removing and Replacing the Server Battery” on page 89

• “Removing and Replacing Hard Disk Drives” on page 90

• “Removing and Replacing the SCSI Backplane Board” on page 93

• “Removing and Replacing the Midplane Riser Board” on page 95

• “Removing and Replacing the Power Supplies” on page 98

• “Removing and Replacing the Power Distribution Board” on page 100

• “Removing and Replacing the DVD Drive” on page 102

• “Removing and Replacing the DVD I/O Board” on page 104

• “Removing and Replacing the Display Board” on page 107

• “Removing and Replacing the QuickFind Diagnostic Board” on page 109

Chapter 4

37

Page 38

Removing and Replacing Components

Safety Information

Safety Information

Follow the procedures listed below to ensure safe handling of components and to prevent harm to both you

and the HP server:

• Use an antistatic wrist strap and a grounding mat, such as those included in the Electrically Conductive

Field Service Grounding Kit (HP 9300-1155).

• Handle accessory boards and components by the edges only. Do not touch any metal-edge connectors or

any electrical components on accessory boards.

• Do not wear clothing subject to static charge build-up, such as wool or synthetic materials.

WAR NING Hazardous voltages are present inside the HP server. Always remove AC power

from the server and associated assemblies while working inside the unit. Serious

injury may result if this warning is not observed.

Service Tools Required

Service of this product may require one or more of the following tools:

• Electrically conductive field service kit (P/N 9300-1155)

• 1/4 inch flat blade screwdriver

• ACX-15 torx screwdriver

• ACX-25 torx screwdriver

Accessing a Rack Mounted Server

The HP Integrity rx4640 server is designed to be rack mounted. The following procedure explains how to gain

access to your HP Integrity rx4640 server that is mounted in an approved rack. For rack installation

instructions, review the document titled Installation Guide, Mid-Weight Slide Kit, 5065-7291. This document

can be accessed at: http://www.hp.com/racksolutions.

WAR NING Ensure that all anti-tip features (front and rear anti-tip feet installed; adequate

ballast properly placed; and so on) are employed prior to extending the server.

38

Chapter 4

Page 39

Removing and Replacing Components

Accessing a Rack Mounted Server

Extending the Server from the Rack

NOTE Ensure that there is enough area (Approximately 1.5 meters [4.5 ft.]) to fully extend the server

out the front and work on it.

To extend the server from the rack, perform the following steps:

Step 1. Remove the T-25 screws that fasten the server to the rack. See Figure 4-1, “Accessing 25MM Torx

Screws.”

Step 2. Flip out the two pull handles at either end of the front bezel and slowly pull the unit forward by the

handles. The server is fully extended when the rail clips are locked in place. When fully extended,

the front and top covers are fully accessible.

Figure 4-1 Accessing 25MM Torx Screws

25MM Torx

screw 2X

Inserting the Server into the Rack

To insert the server into the rack, perform the following steps:

Step 1. Press the rail clips on either side of the server inward and push the server into the rack until it

stops.

Step 2. Replace the T-25 screws that fasten the server to the rack.

Chapter 4

39

Page 40

Removing and Replacing Components

Accessing a Pedestal Mounted Server

Accessing a Pedestal Mounted Server

The HP Integrity rx4640 server is also designed to be pedestal mounted. You do not need to remove the

pedestal from the HP server to gain access to internal components. The front bezel, front cover, and top cover

may be removed with the pedestal attached to the HP server.

WAR NING Ensure that the HP server is properly grounded when performing

remove-and-replace procedures. Use an antistatic wrist strap and grounding mat

similar to those found in the HP Electrically Conductive Field Service Kit.

Figure 4-2 Pedestal Mounted HP Integrity rx4640 Server

40

Chapter 4

Page 41

Removing and Replacing Components

Removing and Replacing the Front Bezel

Removing and Replacing the Front Bezel

The server does not have to be turned off to remove the front bezel. Figure 4-3 shows how to remove the front

bezel.

Figure 4-3 Removing and Replacing the Front Bezel

Removing the Front Bezel

To remove the front bezel, perform the following step:

Step 1. Grasp the front bezel at the outer edges and pull straight out.

Replacing the Front Bezel

To replace the front bezel, perform the following step:

Step 1. Push the front bezel straight into the chassis until it snaps into place.

Chapter 4

41

Page 42

Removing and Replacing Components

Removing and Replacing the Front and Top Covers

Removing and Replacing the Front and Top Covers

The following procedures detail how to remove and replace the front and top covers of the HP Integrity

rx4640 server. Figure 4-4 shows how to remove the front cover.

NOTE When the front or top cover is removed the chassis fan units increase to high speed to assist

cooling. When the top cover is replaced at the end of the operation, the chassis fans return to

normal speed.

Figure 4-4 Removing and Replacing the Front Cover

Slots

Slots

Thumbscrews

Removing the Front Cover

To remove the front cover, perform the following steps:

Step 1. If rack mounted, slide the HP server out from the rack until it stops. See “Extending the Server

from the Rack” on page 39.

Step 2. Remove the front bezel. See “Removing the Front Bezel” on page 41.

Step 3. Using a torx T15 driver, loosen the four captive thumbscrews that hold the front cover in place.

Step 4. Raise the cover slightly, and pull the cover toward the front of the server to free the tabs from the

slots in the chassis.

42

Chapter 4

Page 43

Removing and Replacing Components

Removing and Replacing the Front and Top Covers

Replacing the Front Cover

To replace the front cover, perform the following steps:

Step 1. Align the tabs at the rear of the front cover with the corresponding slots in the chassis and fully

seat the tabs into the slots. Figure 4-4 shows how to install the front cover.

Step 2. Tighten the four thumbscrews securely.

Step 3. Replace the front bezel. See “Replacing the Front Bezel” on page 41.

Step 4. If rack mounted, slide the HP server into the rack until it stops. See “Inserting the Server into the

Rack” on page 39.

Removing the Top Cover

To remove the top cover, perform the following steps:

Step 1. If rack mounted, slide the HP server out from the rack until it stops. See “Extending the Server

from the Rack” on page 39.

Figure 4-5 Removing and Replacing the Top Cover

Thumbscrews

Step 2. Loosen the two captive thumbscrews that hold the top cover in place.

Step 3. Pull the cover toward the rear of the server to free the tabs from the slots in the chassis and lift it

straight up.

Chapter 4

43

Page 44

Removing and Replacing Components

Removing and Replacing the Memory Extender Board

Replacing the Top Cover

To replace the top cover, perform the following steps:

Step 1. Align the tabs at the rear of the top cover with the corresponding slots in the chassis, fully seat the

tabs into the slots, and push forward until it seats.

Step 2. Using a torx T15 driver, tighten the two thumbscrews securely.

Step 3. If rack mounted, slide the HP server into the rack until it stops. See “Inserting the Server into the

Rack” on page 39.

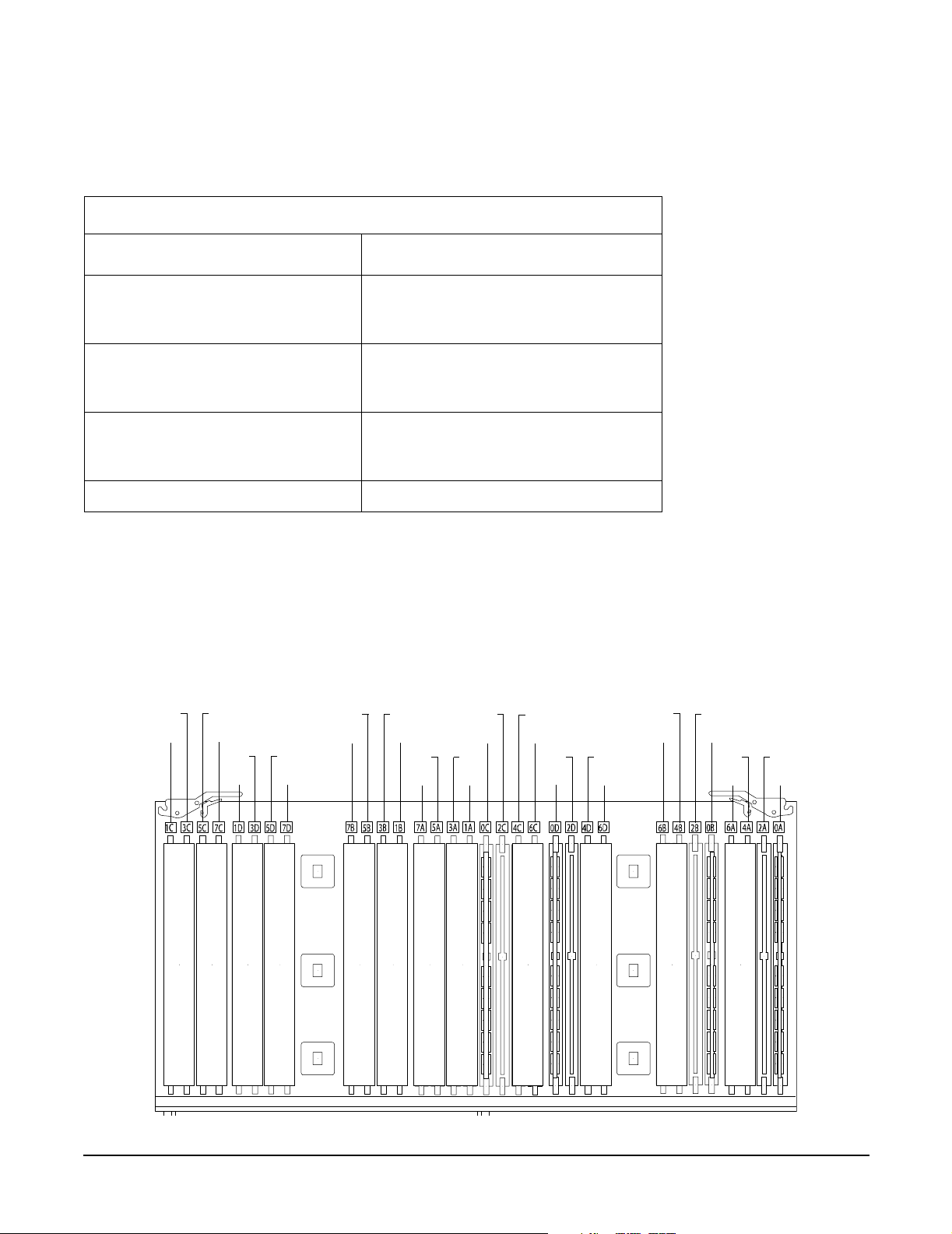

Removing and Replacing the Memory Extender Board

The memory extender board is located directly under the front cover of the chassis. The standard memory

extender board can hold up to 16 DIMMs. The high capacity memory extender board can hold up to 32