Page 1

HPE Integrity rx2800 i6 & rx2900 i6

Installation Guide

Abstract

This document provides installation procedures for the HPE Integrity rx2800 i6 and rx2900 i6

Servers.

Part Number: 881360-001a

Published: August 2017

Edition: 2

Page 2

©

Copyright 2017 Hewlett Packard Enterprise Development LP

Notices

The information contained herein is subject to change without notice. The only warranties for Hewlett

Packard Enterprise products and services are set forth in the express warranty statements accompanying

such products and services. Nothing herein should be construed as constituting an additional warranty.

Hewlett Packard Enterprise shall not be liable for technical or editorial errors or omissions contained

herein.

Confidential computer software. Valid license from Hewlett Packard Enterprise required for possession,

use, or copying. Consistent with FAR 12.211 and 12.212, Commercial Computer Software, Computer

Software Documentation, and Technical Data for Commercial Items are licensed to the U.S. Government

under vendor's standard commercial license.

Links to third-party websites take you outside the Hewlett Packard Enterprise website. Hewlett Packard

Enterprise has no control over and is not responsible for information outside the Hewlett Packard

Enterprise website.

Acknowledgements

Intel®, Itanium®, Pentium®, Intel Inside®, and the Intel Inside logo are trademarks of Intel Corporation in

the United States and other countries.

Microsoft® and Windows® are either registered trademarks or trademarks of Microsoft Corporation in the

United States and/or other countries.

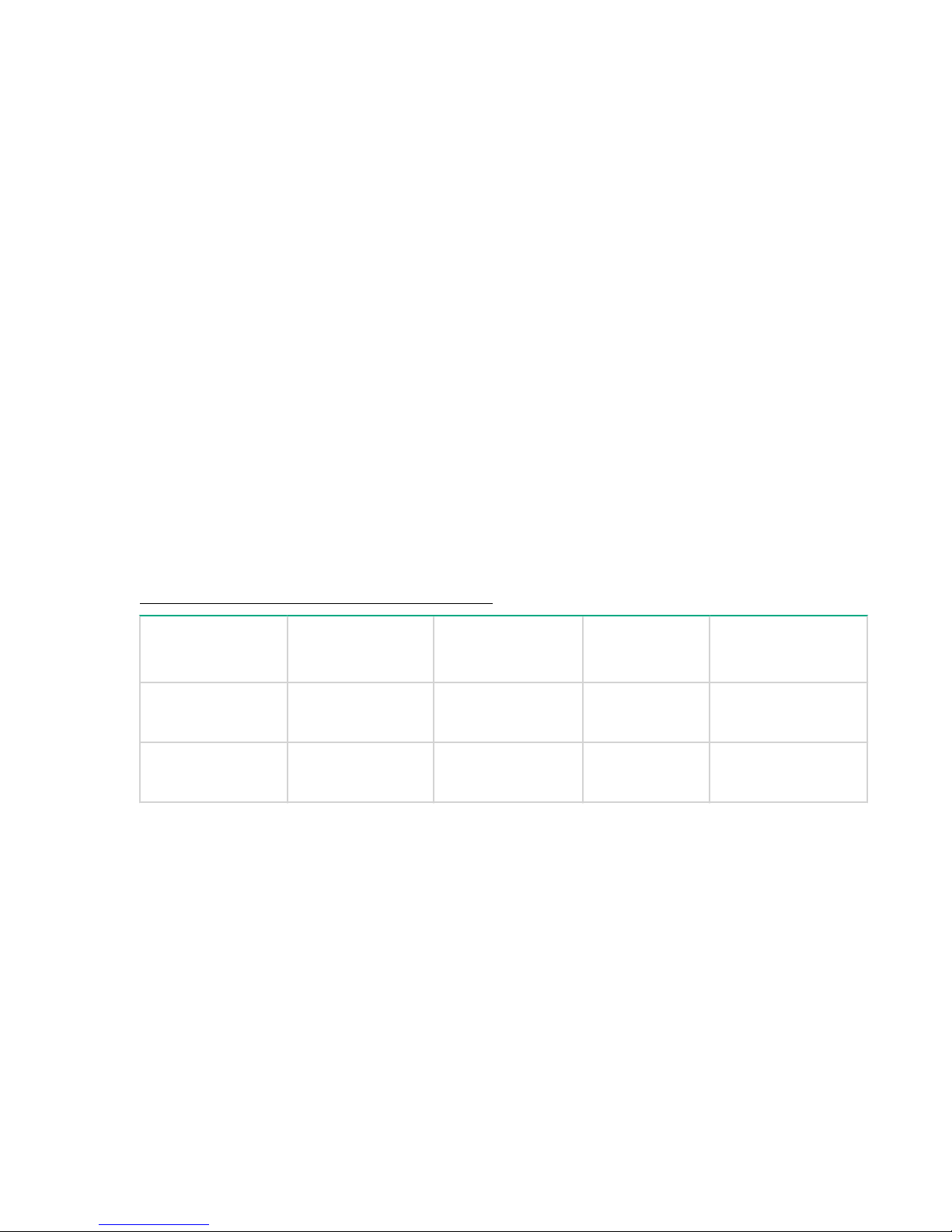

Revision history

The latest version of this document can be found online at:

http://www.hpe.com/info/Integrity_Servers-docs

Document

manufacturing

part number

881360-001 • HP-UX 11iv3 • rx2800 i6

881360-001a • HP-UX 11iv3 • rx2800 i6

Operating

systems

supported

Supported

product versions

• rx2900 i6

• rx2900 i6

Edition number Publication date

First June 2017

Second August 2017

Page 3

Contents

Installing the server................................................................................ 4

Safety information......................................................................................................................... 4

Preventing electrostatic discharge................................................................................................ 4

Installation sequence and checklist.............................................................................................. 5

Installing the server into a rack or pedestal.................................................................................. 5

Rack installation................................................................................................................. 5

Pedestal kit installation.......................................................................................................5

Connecting server cables........................................................................................................... 12

AC input power.................................................................................................................12

Connecting to the LAN..................................................................................................... 13

Setting up the system................................................................................................................. 13

Setup checklist................................................................................................................. 13

Accessing UEFI or the OS from iLO MP.....................................................................................14

UEFI Front Page.............................................................................................................. 15

Booting and installing the operating system.....................................................................18

Operating system is loaded onto the server.....................................................................18

Operating system is not loaded onto the server...............................................................18

OS login prompt............................................................................................................... 19

Powering on and powering off the server....................................................................................19

Power states.....................................................................................................................19

Powering on the server.................................................................................................... 19

Powering off the server.................................................................................................... 20

Installing the latest firmware using Smart Update Manager (SUM)............................................ 21

Support and other resources...............................................................22

Accessing Hewlett Packard Enterprise Support......................................................................... 22

Accessing updates......................................................................................................................22

Customer self repair....................................................................................................................23

Remote support.......................................................................................................................... 23

Warranty information...................................................................................................................23

Regulatory information................................................................................................................24

Documentation feedback............................................................................................................ 24

Contents 3

Page 4

Installing the server

Safety information

Follow the instructions carefully to prevent injury and equipment damage when performing removal and

replacement procedures. Voltage might be present within the server. Many assemblies are sensitive to

damage by ESD.

Follow the safety considerations listed to ensure safe handling of components, to prevent injury, and to

prevent damage to the server:

• If installing a hot-swappable or hot-pluggable component when power is applied (fans are running),

reinstall the server cover immediately to prevent overheating.

If installing a hot-pluggable component, complete the required software intervention prior to removing

the component.

• If installing an assembly that is neither hot-swappable nor hot-pluggable, disconnect the power cable

from the external server power receptacle before starting the installation.

WARNING:

Ensure that the system is powered off and all power sources are disconnected from the server

before removing or installing server hardware (unless you are removing or installing a hotswappable or hot-pluggable component). Voltage is present at various locations within the server

whenever an AC power source is connected. This voltage is present even when the main power

switch is off. Failure to observe this warning might result in personal injury or equipment

damage.

• Do not wear loose clothing that might snag or catch on the server or on other components.

• Do not wear clothing subject to static charge buildup, such as wool or synthetic materials

• If installing an internal assembly, wear an antistatic wrist strap and use a grounding mat, such as those

included in the Electrically Conductive Field Service Grounding Kit.

• Handle accessory boards and components by the edges only. Do not touch any metal edge

connectors or any electrical components on accessory boards.

Preventing electrostatic discharge

To prevent damaging the system, be aware of the precautions you need to follow when setting up the

system or handling parts. A discharge of static electricity from a finger or other conductor might damage

system boards or other static-sensitive devices. This type of damage might reduce the life expectancy of

the device.

To prevent electrostatic damage:

• Avoid hand contact by transporting and storing products in static-safe containers.

• Keep electrostatic-sensitive parts in their containers until they arrive at static-free workstations.

• Place parts on a grounded surface before removing them from their containers.

• Avoid touching pins, leads, or circuitry.

• Always be properly grounded when touching a static-sensitive component or assembly.

4 Installing the server

Page 5

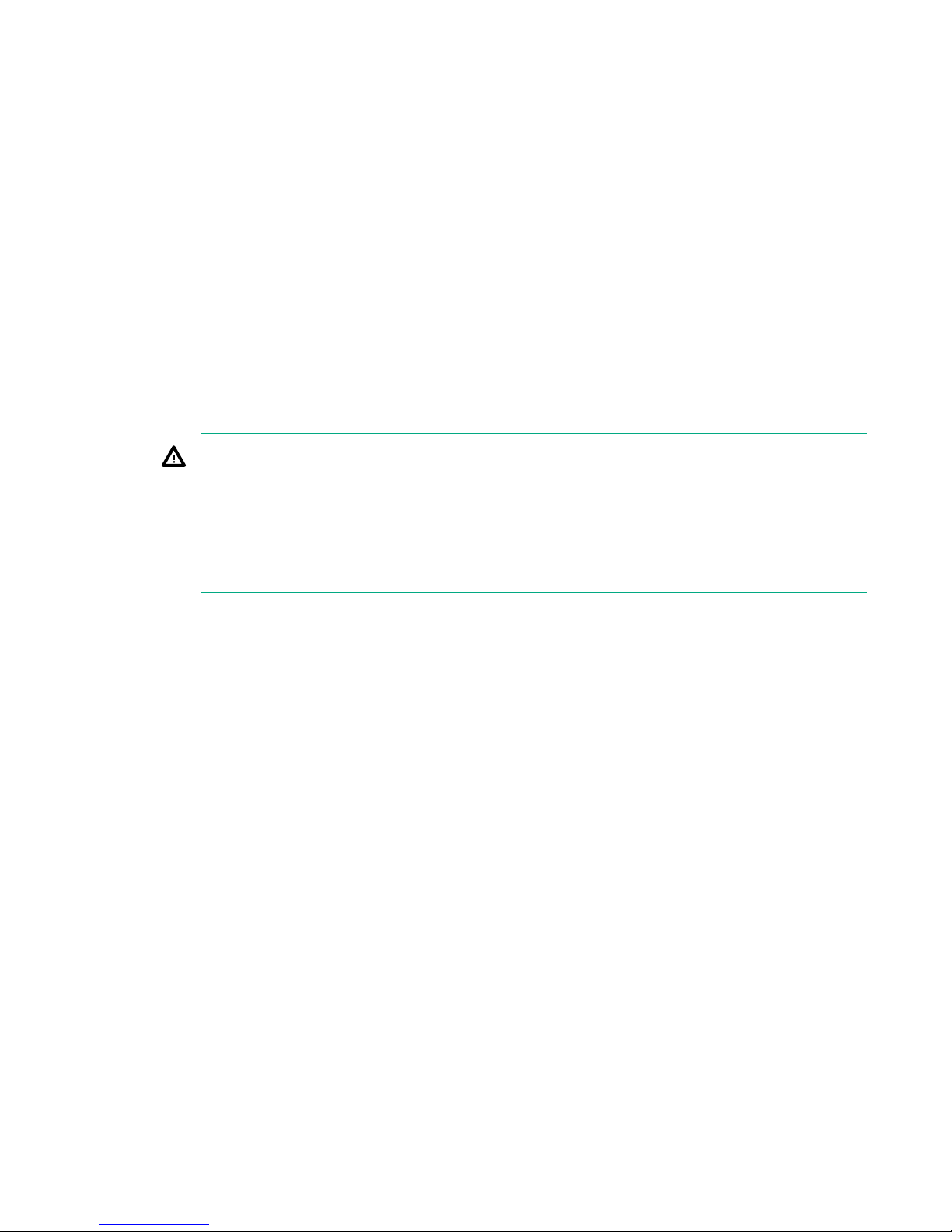

Installation sequence and checklist

Step Description Completed

1 Perform site preparation.

2 Install the server into a rack or pedestal.

3 Connect cables to the server.

a. Connect the AC input power cable.

b. Connect LAN core I/O cable.

c. Connect the iLO 3 MP LAN cable.

4 Connect and set up the console for access.

5 Power on the server.

6 From iLO MP, access UEFI.

7 Boot the operating system.

8 Using Smart Update Manager (HPSUM), download the latest firmware.

Installing the server into a rack or pedestal

Rack installation

HPE rack

HPE servers that are installed into racks are shipped with equipment-mounting slides. The HPE 2U Quick

Deploy Rail System Installation Instructions for HPE Products ships with each set of slides. Follow the

steps in this installation guide to determine where and how to install the server into the rack.

For more information on rack deployment, stabilization and transportation, see the 10000 Series G2

Rack Best Practices Guide.

Non-HPE rack

For information on installing a rx2800 i6 server in a third party rack, see the QuickSpecs located on the

HPE Integrity rx2800 i6 Server product page at

http://h41370.www4.hpe.com/quickspecs/overview.html

To view the QuickSpecs, click the HTML or PDF link under Quick Specs.

Pedestal kit installation

If you order the rackless configuration option, the server ships with a pedestal mount. The pedestal mount

is packaged in a separate carton that is attached to the server carton.

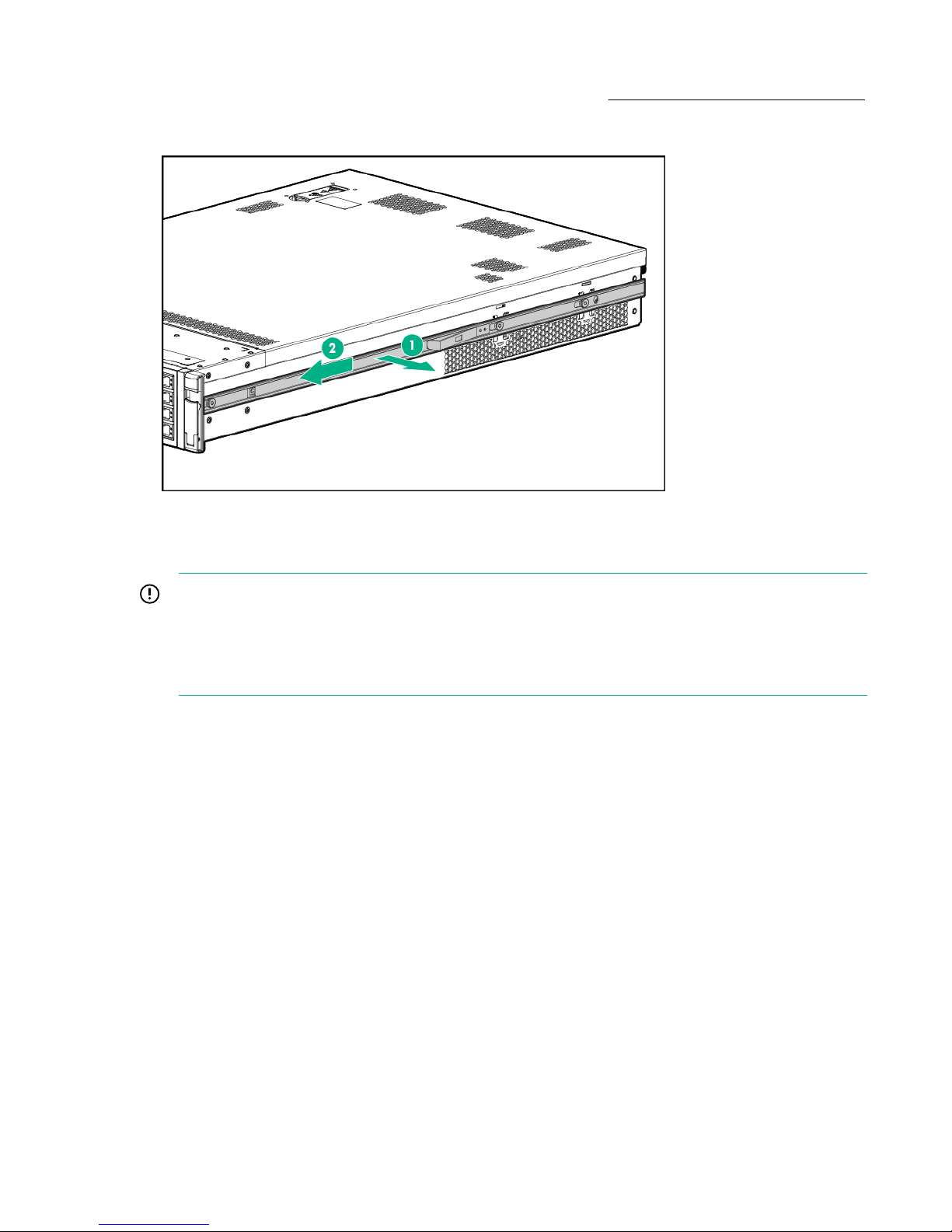

Remove the rails from the server

I If your server has rails when you receive it, you need to remove the rails before mounting it in the

pedestal kit. To remove the component:

Installation sequence and checklist 5

Page 6

Procedure

1. Slightly pull the rail lock away from the rail to unlock the rail. See Removing the rails from the server

2. Slide the rail toward the front of the server to disengage the rail from the posts on the server.

3. Repeat these steps for the rail on the other side of the server.

Figure 1: Removing the rails from the server

Attaching the pedestal kit top and bottom

IMPORTANT:

In this document the server top, bottom, right and left refer to the server as faced from the front with

the server in a horizontal orientation. The pedestal kit components are referred to by the final

position with the server in a vertical orientation. For example, the pedestal kit bottom attaches to the

server right side

6 Attaching the pedestal kit top and bottom

Page 7

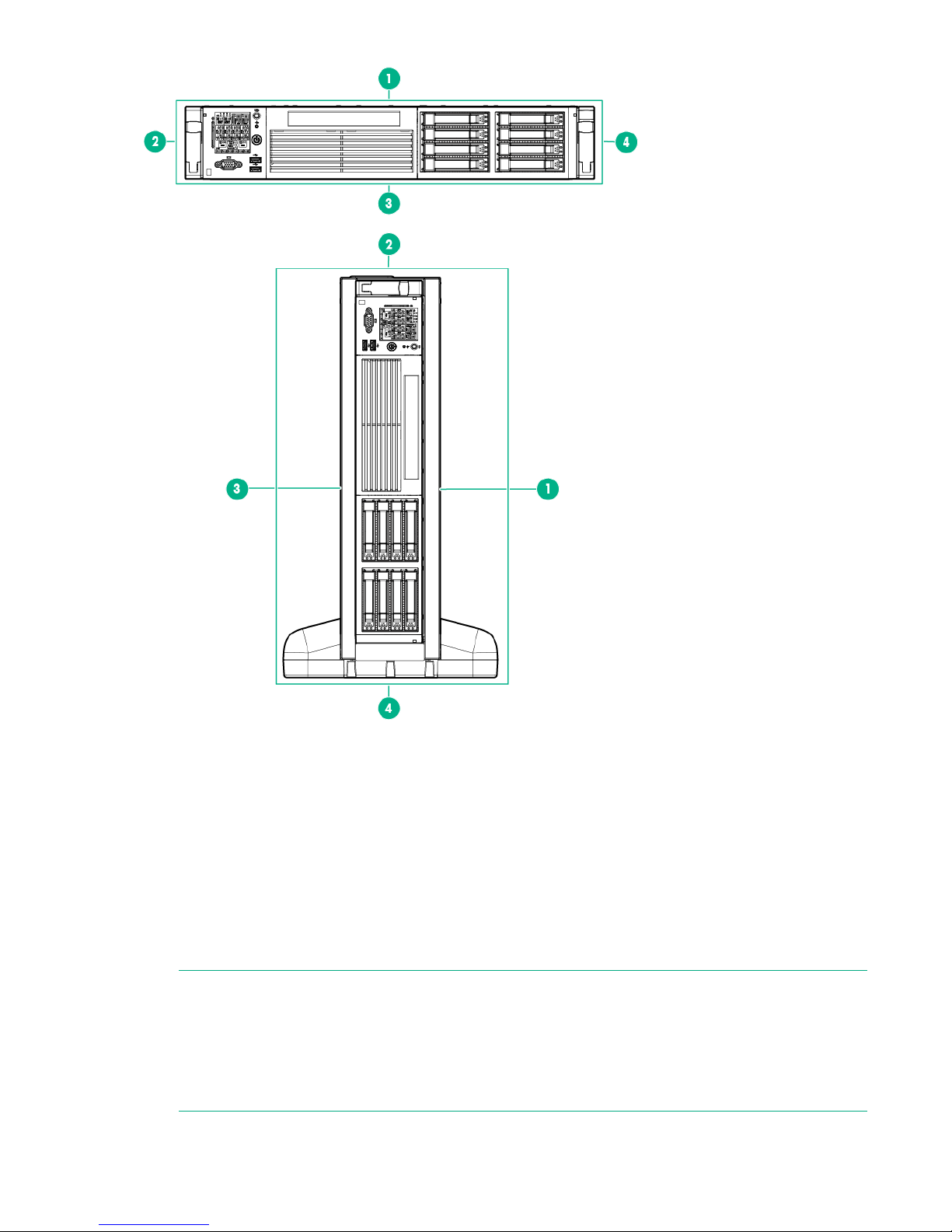

Figure 2: Front of server

1. Server top/pedestal right

2. Server left/pedestal top

3. Server bottom/pedestal left

4. Server right/pedestal bottom

The pedestal kit bottom attaches to the right side of the server when the server is in the horizontal

position. The pedestal kit top attaches to the left side of the server when in the server is in the horizontal

position. The pedestal bottom can be distinguished from the pedestal top by the pedestal feet slots.

Procedure

NOTE:

The bottom piece of the pedestal is taller than the server, so try to position the server so the right

side (in the horizontal position) of the server hangs off the edge of the work surface by a few inches

to allow the bottom piece to be attached to the server chassis. If that is not possible, then raise up

the server approximately three inches from the work surface to enable the pedestal kit bottom piece

to be attached to the server right side.

Installing the server 7

Page 8

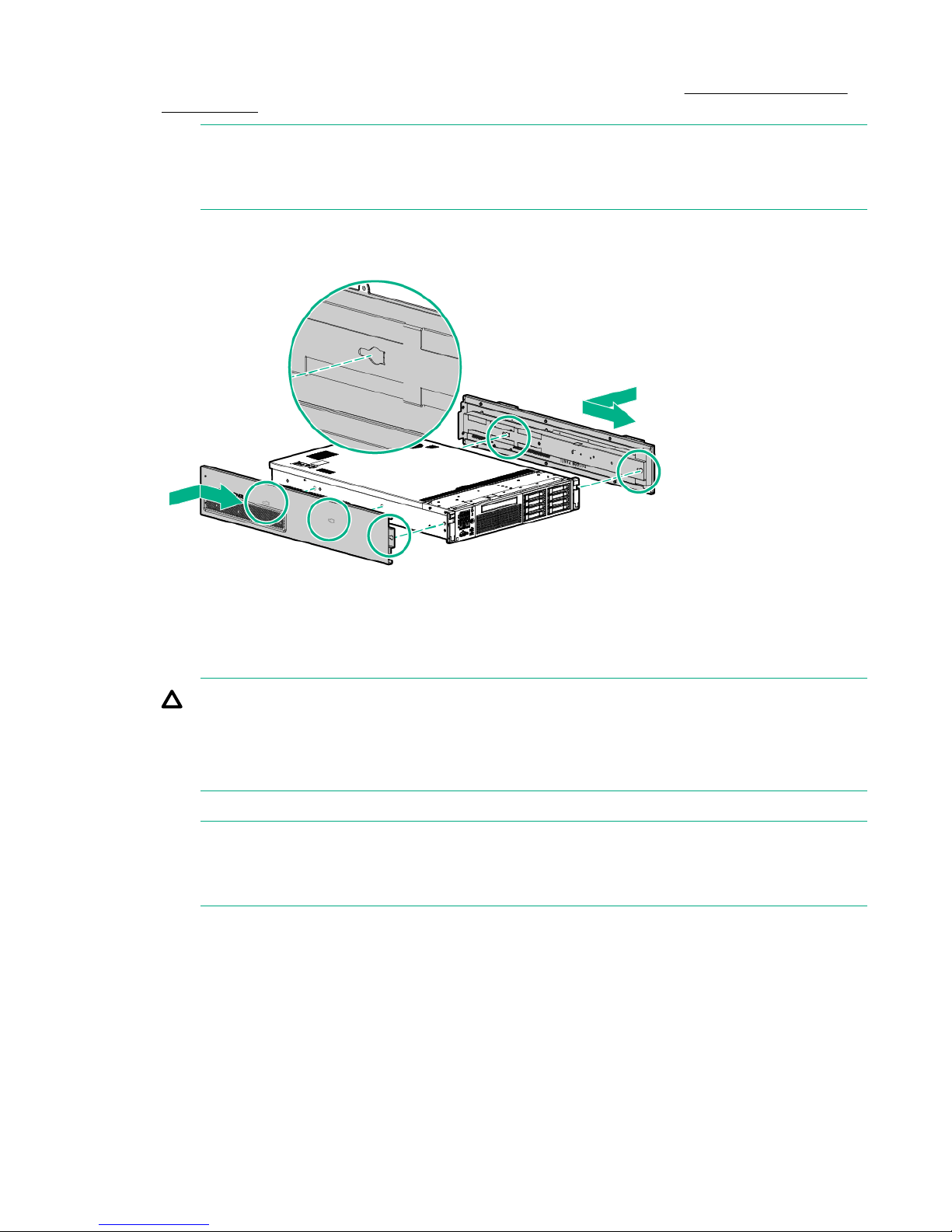

To attach the components.

1. Align the holes in the pedestal component with the posts on the server. See Installing the pedestal

bottom piece.

NOTE:

One of the holes in the pedestal component contains the locking mechanism. This makes the

hole appear partially blocked.

2. Hold the pedestal component flush against the server.

3. Slide the pedestal component forward until it locks into place.

Figure 3: Installing the pedestal bottom piece

4. Stand the server up on the bottom piece of the pedestal kit that was just installed so the server is in

the vertical position.

CAUTION:

The server is heavy. Be careful when lifting it to the vertical position.

Without the feet installed, the server might tip over easily. Be careful when working near the

server to avoid tipping it over.

5. Align the holes in the pedestal top piece with the posts on the server

NOTE:

One of the holes in the pedestal component contains the locking mechanism. This makes the

hole appear partially blocked.

6. Hold the pedestal top piece flush against the server.

7. Slide the pedestal top piece forward until it locks into place.

8. The top and bottom pedestal kit pieces are now in place.

Attaching the bezel cover

To attach the bezel cover:

8 Attaching the bezel cover

Page 9

Procedure

1. Apply the rx2800 i6 product label provided in the pedestal kit to the bottom front of the bezel cover

2. Attach the bezel cover to the front of the server starting from the bottom of the pedestal kit.

3. Push the bezel cover into place against the pedestal kit top piece until the tabs on the bezel cover

(label can be seen in the figure below.)

snap into place.

Figure 4: Attaching the bezel cover

Attaching the pedestal kit side pieces

The pedestal kit right side piece attaches to the top of the server. The top cover of the server might have

ventilation holes in it to enable proper air flow and cooling. The right side piece of the pedestal kit also

has ventilation holes in it to enable the proper cooling and air flow. Follow these steps to attach the

pedestal kit right side piece.

CAUTION:

The ventilation holes in the pedestal kit right side piece must be matched up with the ventilation

holes on the top cover of the Integrity rx2800 i6 Server to enable proper cooling and air flow. Failure

to heed this warning causes the server to shut down with an overtemp condition.

To attach the component:

Procedure

1. Align the posts on the pedestal kit right side piece with the slots in the pedestal kit top and bottom.

2. Hold the pedestal side flush against the server and slide it toward the front of the server.

Attaching the pedestal kit side pieces 9

Page 10

Figure 5: Attaching the pedestal kit side piece

3. Secure the pedestal side by hand tightening the captive thumb screws on the rear of the server.

10 Installing the server

Page 11

Figure 6: Thumb screw locations

Repeat these steps to install the left side piece.

Attaching the pedestal feet

The pedestal feet slide into the slots on the pedestal bottom, two on each side. The feet are all the same

and can be mounted in any slot on the bottom piece of the pedestal kit.

Attaching the pedestal feet 11

Page 12

Figure 7: Attaching the feet

Connecting server cables

AC input power

The server can receive AC input from two different AC power sources. The power receptacles are located

at the rear of the server.

A maximum of two power supplies can be installed in the server. Installing two power supplies in the

server provides 1+1 redundancy, meaning that if one power supply fails, there is still enough power

supplied to the server to operate. You must promptly replace the failed power supply to restore 1+1

functionality.

All high-line (220 V) configurations are capable of 1+1 redundancy. Low-line (110 V) configurations can

maintain 1+1 redundancy as long as the total power consumed does not exceed 800 W.

A minimum of one power supply is required to power the server. If only one power supply is installed in

the server, there is no 1+1 capability.

Power states

The server has the following power states:

• Standby power

• Full power

• Off

12 Connecting server cables

Page 13

Table 1: Power states

Power states Power cable

plugged into

receptacle?

Standby power Yes No Yes No

Full power Yes Yes Yes Yes

Off No No No No

NOTE:

If the power restore feature is set to Always On through the iLO 3 MP PR command, the server

automatically powers on to the full power state when the power cord is plugged in to the server.

Ports and power supplies are located on the rear panel of the server.

Power activated through the iLO 3

PC

command; or front panel power

button activated?

Applying standby power to the server

Procedure

1. Plug the power cord into the receptacle in power supply.

2. Plug the other end of the power cord into an AC outlet.

Standby DC

voltage

applied?

DC voltage

applied?

NOTE:

The LED on the power supply does not illuminate in the standby power state. The LED is green

when the server is powered on to full power.

If the power restore feature is set to Always On through the iLO 3 MP PR command, the server

automatically powers on to the full power state when the power cord is plugged into the server.

3. If the server has two power supplies, plug the second power cord into the power supply.

4. Plug the other end of the power cord into an AC outlet.

Connecting to the LAN

The server has four LAN ports that provide network connectivity. The HPE Integrity rx2800 i6 Server User

Service Guide shows the available LAN ports for the server.

Procedure

1. Obtain valid IP addresses for each LAN port you plan to activate.

2. Connect the LAN cable from an available LAN port into a live connection on the network.

Setting up the system

For more information on using the iLO 3 MP, see the HPE Integrity iLO 3 Operations Guide.

Setup checklist

Use the checklist in Setup checklist while setting up the Integrity iLO 3.

Applying standby power to the server 13

Page 14

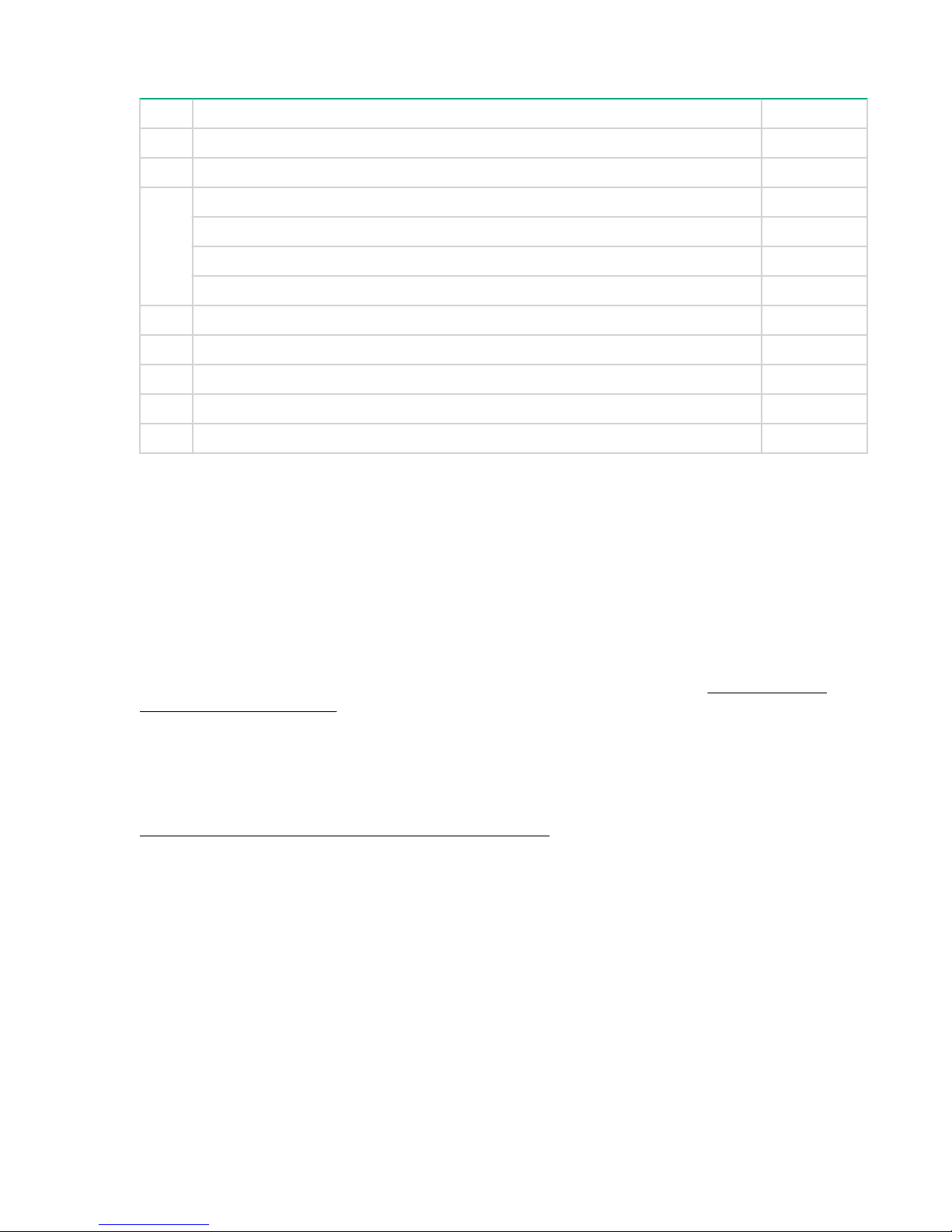

Table 2: Setup checklist

Step Action Procedure Status

Standard setup

1 Preparation

2 Configure the iLO 3 MP

LAN

3 Log on to the iLO 3 MP

4 Change default user

name and password

5 Set up user accounts

6 Set up security access

1. Determine an access method to select and connect

the cables.

2. Determine a LAN configuration method and assign

an IP address if necessary.

Select one of the three methods to configure the LAN

for iLO 3 MP access:

• DHCP with DNS

• RS-232 serial port

• Static IP address

Log on to the iLO 3 MP from a supported web browser

or command line using the default user name and

password.

Change the default user name and password on the

administrator account to your predefined selections.

Set up the user accounts if you are using the local

accounts feature.

Set up the security access settings.

Accessing UEFI or the OS from iLO MP

The Unified Extensible Firmware Interface is an architecture that provides an interface between the

server OS and the server firmware. UEFI provides a standard environment for booting an OS and running

preboot applications.

Use this procedure to access UEFI or the OS from the iLO MP. Your security parameters were set

regarding remote access.

NOTE:

Commands are case-insensitive.

Procedure

1. From the MP Main Menu, enter the commandco to access the Console.

NOTE:

Terminal windows must be set to a window size of 80 columns x 25 rows for optimal viewing of

the console at UEFI

2. After memory test and CPU late self test the following message appears:

Press Ctrl-C now to bypass loading option ROM UEFI drivers.

14 Accessing UEFI or the OS from iLO MP

Page 15

• Bypass loading from I/O slots.

• Bypass loading from I/O slots and core I/O.

The Bypass loading from I/O slots and core I/O option may be useful if a bad core I/O UEFI driver

is preventing system boot. USB drives can still be used at the UEFI shell to update core I/O drivers.

CAUTION:

Pressing Ctrl-C before the prompt does not work and might disable this feature. Therefore, be

sure to wait for the prompt before pressing Ctrl-C.

NOTE:

The prompt might take several minutes to appear, and the period that you can press Ctrl-C is

very short. For typical boots, Hewlett Packard Enterprise recommends that you let the prompt

time out.

After selecting an option, the boot proceeds.

NOTE:

If no option is selected, the boot proceeds after a few seconds.

3. Depending on how the server was configured from the factory and if the OS is installed at the time of

purchase, you are taken to:

a. UEFI shell prompt

b. OS login prompt

If the server has a factory-installed OS, you can interrupt the boot process to configure your specific

UEFI parameters.

If you are at the UEFI shell prompt, go to "UEFI Front Page"

If you are at the OS login prompt, go to "OS login prompt"

UEFI Front Page

If you are at the UEFI shell prompt, enter the command exit to navigate to the UEFI Front Page

UEFI Front Page 15

Page 16

Figure 8: Shell map page

Figure 9: UEFI front page

To view boot options, or launch a specific boot option, press B to launch the Boot Manager.

16 Installing the server

Page 17

Figure 10: Boot Manager screen

To configure specific devices, press D to launch the Device Manager. This is an advanced feature and

must only be performed when directed.

Figure 11: Device Manager screen

To perform maintenance on the system such as adding, deleting, or reordering boot options, press M to

launch the Boot Maintenance Manager.

Installing the server 17

Page 18

Figure 12: Boot Maintenance Manager screen

To perform more advanced operations, press S to launch the UEFI Shell.

To view the iLO LAN configuration, press I to launch the iLO Setup Tool.

Saving UEFI configuration settings

You can configure other UEFI settings at this time. For more UEFI configuration options, see the HPE

Integrity rx2800 i6 Server User Service Guide.

Booting and installing the operating system

From the UEFI Front Page prompt, you can boot and install in either of two manners:

• If your OS is loaded onto your server, see Operating System Is loaded onto the server.

.

• If the OS is not installed onto your server, see Operating system is not loaded onto the server

.

Operating system is loaded onto the server

If the OS is loaded on your server, normally UEFI automatically boots to the OS. If the UEFI Front Page is

loaded, press ENTER t to start auto boot, or B to select a specific boot option for your OS.

• Use your standard OS login procedures, or see your OS documentation to log in to your OS.

Operating system is not loaded onto the server

If the OS is not already on the server, the three installation options are: using Ignite UX or vMedia, or

loading from a DVD.

18 Saving UEFI configuration settings

Page 19

OS login prompt

If your server is at the OS login prompt after you establish a connection to the server, use your standard

OS log in procedures, or see your OS documentation for the next steps.

Powering on and powering off the server

Power states

The server has the following power states:

• Standby power

• Full power

• Off

Table 3: Power states

Power states Power cable

plugged into

receptacle?

Standby power Yes No Yes No

Full power Yes Yes Yes Yes

Off No No No No

NOTE:

If the power restore feature is set to Always On through the iLO 3 MP PR command, the server

automatically powers on to the full power state when the power cord is plugged in to the server.

Ports and power supplies are located on the rear panel of the server.

Powering on the server

Power on the server to full power using the following methods if the server is in the standby power state:

• iLO 3 MP PC command

• Power button

Power activated through the iLO 3

PC

command; or front panel power

button activated?

Standby DC

voltage

applied?

DC voltage

applied?

Powering on the server using the iLO 3 MP

NOTE:

If the power restore feature is set to Always On through the iLO 3 MP PR command, the server

automatically powers on to the full power state when the power cord is plugged in to the server.

Procedure

1. Plug all power cables into the receptacles on the rear panel of the server.

2. Initiate a console session, and access the MP Main Menu.

3. Enter the commandCM to enable command mode.

OS login prompt 19

Page 20

4. Enter the commandPC to use the remote power control command. A command output similar to the

one shown below will appear:

NOTE:

Your display may not match the display shown.

Figure 13: Power Control Menu screen

5. Enter the command ON to power on the server, and enter YES when prompted to confirm the action.

6. Boot the operating system.

For more information, see the operating system documentation.

Powering on the server manually

NOTE: If the power restore feature is set to Always On through the iLO 3 MP PR command, the

server automatically powers on to the full power state when the power cord is plugged in to the

server.

Procedure

1. Plug all power cables into the receptacles on the rear panel of the server.

2. Press the power button to start the server.

3. Start the operating system. For more information, see the operating system documentation.

Powering off the server

If the server is in the standby or full power state, power off the server by using either of the following

methods:

• iLO 3 MP PC command

• Power button

Powering off the server using the iLO 3 MP

Procedure

1. Gracefully shut down the operating system. See the operating system documentation for more

information.

2. Initiate a console session, and access the MP Main Menu.

20 Powering on the server manually

Page 21

3. Enter CM to enable command mode.

4. Enter PC to use the remote power control command.

5. Enter OFF to power off the server, and enter YES when prompted to confirm the action.

CAUTION:

The main DC voltage is now removed from the system However, AC voltage for standby power

is still present in the server.

6. Unplug all power cables from the receptacles on the rear panel of the server.

Powering off the server manually

Procedure

1. Gracefully shut down the operating system. For more information, see the operating system

documentation.

2. To power off the server, press the power button.

CAUTION:

The main DC voltage is now removed from the system. However, AC voltage for standby power

is still present in the server.

3. Unplug all power cables from the receptacles on the rear panel of the server.

Installing the latest firmware using Smart Update Manager

(SUM)

The Smart Update Manager utility enables you to deploy firmware components from either an easy-to-use

interface or a command line. It has an integrated hardware discovery engine that discovers the installed

hardware and the current versions of firmware in use on target servers. This prevents extraneous network

traffic by only sending the required components to the target. SUM also has logic to install updates in the

correct order and ensure all dependencies are met before deployment of a firmware update. It also

contains logic to prevent version-based dependencies from preventing a successful installation and

ensures updates are handled in a manner that reduces any downtime required for the update process.

Smart Update Manager does not require an agent for remote installations. After the installation is

complete, Smart Update Manager also removes all remote files associated with the installation.

Key features of Smart Update Manager are:

• GUI and CLI

• Dependency checking, which ensures appropriate installation order and dependency checking

between components

• Intelligent deployment of only required updates

• Improved deployment performance

• Remote command-line deployment

At this time, firmware updates on Integrity systems through SUM are done remotely. For example, SUM

runs on an x86 Linux or Windows management system and updates targeted Integrity systems through

the network. SUM supports firmware updates on rx2800 i6 servers. Firmware bundles for these servers

are available and can be downloaded from the Hewlett Packard Enterprise website at http://

www.hpe.com.

For more information about SUM, see the Smart Update Manager User Guide (http://www.hpe.com/

info/hpsum/documentation).

Powering off the server manually 21

Page 22

Support and other resources

Accessing Hewlett Packard Enterprise Support

• For live assistance, go to the Contact Hewlett Packard Enterprise Worldwide website:

http://www.hpe.com/assistance

• To access documentation and support services, go to the Hewlett Packard Enterprise Support Center

website:

http://www.hpe.com/support/hpesc

Information to collect

• Technical support registration number (if applicable)

• Product name, model or version, and serial number

• Operating system name and version

• Firmware version

• Error messages

• Product-specific reports and logs

• Add-on products or components

• Third-party products or components

Accessing updates

• Some software products provide a mechanism for accessing software updates through the product

interface. Review your product documentation to identify the recommended software update method.

• To download product updates:

Hewlett Packard Enterprise Support Center

www.hpe.com/support/hpesc

Hewlett Packard Enterprise Support Center: Software downloads

www.hpe.com/support/downloads

Software Depot

www.hpe.com/support/softwaredepot

• To subscribe to eNewsletters and alerts:

www.hpe.com/support/e-updates

• To view and update your entitlements, and to link your contracts and warranties with your profile, go to

the Hewlett Packard Enterprise Support Center More Information on Access to Support Materials

page:

www.hpe.com/support/AccessToSupportMaterials

IMPORTANT:

Access to some updates might require product entitlement when accessed through the Hewlett

Packard Enterprise Support Center. You must have an HPE Passport set up with relevant

entitlements.

22 Support and other resources

Page 23

Customer self repair

Hewlett Packard Enterprise customer self repair (CSR) programs allow you to repair your product. If a

CSR part needs to be replaced, it will be shipped directly to you so that you can install it at your

convenience. Some parts do not qualify for CSR. Your Hewlett Packard Enterprise authorized service

provider will determine whether a repair can be accomplished by CSR.

For more information about CSR, contact your local service provider or go to the CSR website:

http://www.hpe.com/support/selfrepair

Remote support

Remote support is available with supported devices as part of your warranty or contractual support

agreement. It provides intelligent event diagnosis, and automatic, secure submission of hardware event

notifications to Hewlett Packard Enterprise, which will initiate a fast and accurate resolution based on your

product's service level. Hewlett Packard Enterprise strongly recommends that you register your device for

remote support.

If your product includes additional remote support details, use search to locate that information.

Remote support and Proactive Care information

HPE Get Connected

www.hpe.com/services/getconnected

HPE Proactive Care services

www.hpe.com/services/proactivecare

HPE Proactive Care service: Supported products list

www.hpe.com/services/proactivecaresupportedproducts

HPE Proactive Care advanced service: Supported products list

www.hpe.com/services/proactivecareadvancedsupportedproducts

Proactive Care customer information

Proactive Care central

www.hpe.com/services/proactivecarecentral

Proactive Care service activation

www.hpe.com/services/proactivecarecentralgetstarted

Warranty information

To view the warranty for your product or to view the Safety and Compliance Information for Server,

Storage, Power, Networking, and Rack Products reference document, go to the Enterprise Safety and

Compliance website:

www.hpe.com/support/Safety-Compliance-EnterpriseProducts

Additional warranty information

HPE ProLiant and x86 Servers and Options

www.hpe.com/support/ProLiantServers-Warranties

HPE Enterprise Servers

www.hpe.com/support/EnterpriseServers-Warranties

HPE Storage Products

www.hpe.com/support/Storage-Warranties

Customer self repair 23

Page 24

HPE Networking Products

www.hpe.com/support/Networking-Warranties

Regulatory information

To view the regulatory information for your product, view the Safety and Compliance Information for

Server, Storage, Power, Networking, and Rack Products, available at the Hewlett Packard Enterprise

Support Center:

www.hpe.com/support/Safety-Compliance-EnterpriseProducts

Additional regulatory information

Hewlett Packard Enterprise is committed to providing our customers with information about the chemical

substances in our products as needed to comply with legal requirements such as REACH (Regulation EC

No 1907/2006 of the European Parliament and the Council). A chemical information report for this product

can be found at:

www.hpe.com/info/reach

For Hewlett Packard Enterprise product environmental and safety information and compliance data,

including RoHS and REACH, see:

www.hpe.com/info/ecodata

For Hewlett Packard Enterprise environmental information, including company programs, product

recycling, and energy efficiency, see:

www.hpe.com/info/environment

Documentation feedback

Hewlett Packard Enterprise is committed to providing documentation that meets your needs. To help us

improve the documentation, send any errors, suggestions, or comments to Documentation Feedback

(docsfeedback@hpe.com). When submitting your feedback, include the document title, part number,

edition, and publication date located on the front cover of the document. For online help content, include

the product name, product version, help edition, and publication date located on the legal notices page.

24 Regulatory information

Loading...

Loading...