Page 1

HP Integrity rx2800 i4 Server

nl

User Service Guide

Abstract

This document contains specific information that is intended for users of this HP product.

This document provides system information, server specifications, and installation procedures for the HP Integrity rx2800 i4

Server. It also provides information on parts, troubleshooting, diagnosing server issues, and how to remove and replace server

components.

HP Part Number: AT101-9014A

Published: November 2012

Edition: 1

HP Confidential

Page 2

© Copyright 2012 Hewlett-Packard Development Company, L. P.

Legal notices

The information contained herein is subject to change without notice.

The only warranties for HP products and services are set forth in the express warranty statements accompanying such products and services. Nothing

herein should be construed as constituting an additional warranty. HP shall not be liable for technical or editorial errors or omissions contained

herein.

Acknowledgements

Intel® Itanium® is a trademark of Intel Corporation in the U.S. and other countries.

Windows® is a U.S. registered trademark of Microsoft Corporation.

Revision history

The publishing history table identifies the publication dates of this manual. Updates are made to this publication on an unscheduled, as needed,

basis. The updates will consist of a complete replacement manual and pertinent online or CD documentation.

The document printing date and part number indicate the current edition. The printing date changes when a new edition is printed. Minor changes

might be made at reprint without changing the printing date. The document part number changes when extensive changes are made. The latest

version of this document can be found online at:

http://www.hp.com/go/Integrity_Servers-docs

Table 1 Publishing history details

Document manufacturing

part number

AT101-9014A

Operating systems

supported

• HP-UX

Publication dateEdition numberSupported product

versions

November 2012Firstrx2800 i4

Page 3

Contents

1 Overview..................................................................................................8

Server subsystems.....................................................................................................................9

Internal components.............................................................................................................9

I/O subsystem...................................................................................................................11

RAID support.....................................................................................................................11

Controls and ports..................................................................................................................12

Front panel controls and ports.............................................................................................12

Storage and media devices............................................................................................12

Rear panel controls and ports..............................................................................................13

2 Site preparation.......................................................................................14

Server dimensions and weight..................................................................................................14

Grounding.............................................................................................................................14

Server electrical specifications..................................................................................................14

System power specifications................................................................................................14

Power consumption and cooling..........................................................................................15

Server physical and environmental specifications........................................................................16

Unpacking and inspecting the server....................................................................................16

Verifying site preparation...............................................................................................16

Inspecting the shipping containers for damage.................................................................17

Unpacking the server.....................................................................................................17

Verifying the inventory...................................................................................................17

Returning damaged equipment.......................................................................................17

Unloading the server with a lifter.....................................................................................17

3 Installing the server...................................................................................18

Safety information..................................................................................................................18

Preventing electrostatic discharge..............................................................................................18

Installation sequence and checklist............................................................................................19

Installing the server into a rack or pedestal.................................................................................19

Rack installation.................................................................................................................19

HP rack.......................................................................................................................19

Non-HP rack.................................................................................................................19

Pedestal kit installation........................................................................................................19

Remove the rails from the server......................................................................................19

Attaching the pedestal kit top and bottom........................................................................20

Attaching the bezel cover...............................................................................................22

Attaching the pedestal kit side pieces..............................................................................23

Attaching the pedestal feet.............................................................................................25

Connecting server cables.........................................................................................................25

AC input power.................................................................................................................25

Power states.................................................................................................................26

Applying standby power to the server..............................................................................26

Connecting to the LAN.......................................................................................................26

Setting up the system...............................................................................................................26

Setup checklist...................................................................................................................27

Accessing UEFI or the OS from iLO MP......................................................................................27

UEFI Front Page.................................................................................................................28

Saving UEFI configuration settings...................................................................................30

Booting and installing the operating system...........................................................................30

Operating system is loaded onto the server...........................................................................31

Operating system is not loaded onto the server......................................................................31

HP Confidential Contents 3

Page 4

OS login prompt................................................................................................................31

Powering on and powering off the server...................................................................................31

Power states......................................................................................................................31

Powering on the server.......................................................................................................31

Powering on the server using the iLO 3 MP.......................................................................31

Powering on the server manually.....................................................................................32

Powering off the server.......................................................................................................32

Powering off the server using the iLO 3 MP.......................................................................32

Powering off the server manually.....................................................................................33

Installing the latest firmware using HP Smart Update Manager (HPSUM)........................................33

Troubleshooting installation issues.............................................................................................33

4 Operating system procedures.....................................................................34

Operating system supported on the server..................................................................................34

Installing the operating system onto the server............................................................................34

Installing the operating system from the DVD drive or tape drive...............................................34

Installing the operating system using HP Ignite-UX..................................................................35

Installing the operating system with Virtual Media.......................................................................35

Configuring system boot options...............................................................................................36

Booting and shutting down HP-UX.............................................................................................36

Adding HP-UX to the boot options list...................................................................................37

HP-UX standard boot..........................................................................................................37

Booting HP-UX from the UEFI Boot Manager.....................................................................38

Booting HP-UX from the UEFI Shell...................................................................................38

Booting HP-UX in single-user mode.......................................................................................38

Booting HP-UX in LVM-maintenance mode.............................................................................39

Shutting down HP-UX..........................................................................................................39

5 Optional components................................................................................40

Installing a hot-pluggable SAS hard drive..................................................................................40

Installing a hot-swappable power supply....................................................................................41

Removing the access panel......................................................................................................42

Removing the PCI riser cage.....................................................................................................43

Removing expansion slot covers................................................................................................44

Installing expansion boards.....................................................................................................45

Installing a half-length expansion board................................................................................45

Installing a full-length expansion board.................................................................................45

Installing DIMMs....................................................................................................................46

Memory configurations.......................................................................................................46

Memory riser locations and slot IDs.................................................................................46

Supported DIMM sizes...................................................................................................47

Memory loading rules and guidelines..............................................................................48

Installing DIMMs................................................................................................................48

Installing a processor..............................................................................................................50

Processor load order..........................................................................................................50

Installing a processor and heat sink module..........................................................................51

HP Trusted Platform Module (TPM).............................................................................................56

Verifying installed components in the server...............................................................................57

Completing installation............................................................................................................58

6 Troubleshooting........................................................................................59

How to contact HP..................................................................................................................59

Methodology.........................................................................................................................59

General troubleshooting methodology..................................................................................59

Recommended troubleshooting methodology ........................................................................60

Basic and advanced troubleshooting tables...........................................................................61

HP Confidential4 Contents

Page 5

Troubleshooting tools..............................................................................................................64

LEDs ................................................................................................................................65

Front panel LEDs...........................................................................................................65

System health LED.....................................................................................................66

Locator Switch/LED (UID)...........................................................................................66

SID LEDs.................................................................................................................66

FRU and CRU health LEDs.........................................................................................68

System Event Log LED................................................................................................68

Hard drive LEDs.......................................................................................................68

Optical drive...........................................................................................................70

Rear panel LEDs............................................................................................................70

Power supply...........................................................................................................71

Diagnostics.......................................................................................................................71

Online diagnostics and exercisers........................................................................................71

Online support tool availability.......................................................................................72

Online support tools list.................................................................................................72

Offline support tools list......................................................................................................73

Fault management overview................................................................................................73

HP-UX fault management.....................................................................................................73

WBEM indication providers............................................................................................73

Errors and reading error logs...................................................................................................73

Event log definitions...........................................................................................................73

Using event logs................................................................................................................74

iLO 3 MP event logs...........................................................................................................74

System event log review......................................................................................................75

Supported configurations.........................................................................................................75

System build-up troubleshooting procedure............................................................................75

Installation troubleshooting.......................................................................................................77

Installation troubleshooting methodology...............................................................................77

Installation troubleshooting using the server power button........................................................77

Server does not power on...................................................................................................77

UEFI menu is not available..................................................................................................78

Operating system does not boot..........................................................................................78

Operating system boots with issues......................................................................................78

Intermittent server issues......................................................................................................78

SATA DVD+RW drive issues................................................................................................78

SAS disk drive issues..........................................................................................................79

Console issues...................................................................................................................79

Troubleshooting the processor and memory................................................................................79

Troubleshooting the server processor....................................................................................79

Processor load order......................................................................................................79

Processor module behaviors............................................................................................79

Customer messaging policy............................................................................................80

Troubleshooting the server memory.......................................................................................82

Memory DIMM load order.............................................................................................82

Memory subsystem behaviors..........................................................................................82

Customer messaging policy............................................................................................82

Troubleshooting the power subsystem .......................................................................................83

Power subsystem behavior...................................................................................................83

Power LED button...............................................................................................................83

Troubleshooting the cooling subsystem.......................................................................................84

Cooling subsystem behavior................................................................................................84

Troubleshooting the iLO 3 MP subsystem....................................................................................85

iLO 3 MP LAN LED on the rear panel...................................................................................85

Troubleshooting the I/O subsystem ...........................................................................................85

HP Confidential Contents 5

Page 6

I/O subsystem behaviors....................................................................................................85

Customer messaging policy.................................................................................................86

Verifying SAS hard drive operation.......................................................................................87

System LAN LEDs...............................................................................................................88

Troubleshooting the boot process..............................................................................................88

Troubleshooting the firmware....................................................................................................89

Identifying and troubleshooting firmware issues......................................................................89

Updating firmware.............................................................................................................90

Troubleshooting the system console...........................................................................................90

Troubleshooting the server environment .....................................................................................91

7 Removal and replacement procedures.........................................................92

Server components list.............................................................................................................92

Required tools........................................................................................................................94

Safety considerations..............................................................................................................94

Server warnings and cautions..............................................................................................94

Preparation procedures...........................................................................................................94

Extending the server from the rack........................................................................................95

Accessing internal components for a pedestal-mounted server..................................................96

Powering off the server.......................................................................................................99

Removing the server from the rack........................................................................................99

Removing the server from the pedestal kit............................................................................100

Required tools.............................................................................................................100

Power off the server and remove cables..........................................................................100

Removing the pedestal kit..................................................................................................100

Accessing the product rear panel.......................................................................................103

Cable management arm with left-hand swing..................................................................103

Cable management arm with right-hand swing................................................................103

Removing and replacing a SAS hard drive blank......................................................................104

Removing and replacing a hot-plug SAS hard drive...................................................................104

Removing and replacing a power supply blank.........................................................................105

Removing and replacing a hot-swap power supply....................................................................105

Removing and replacing the access panel................................................................................106

Removing and replacing the optical drive filler..........................................................................107

Removing and replacing the optical drive................................................................................107

Removing and replacing a hot-swap fan..................................................................................108

Removing and replacing the power supply backplane...............................................................109

Removing and replacing the hard drive backplane....................................................................110

Removing and replacing the PCI riser cage..............................................................................111

Removing and replacing expansion slot covers.........................................................................111

Removing and replacing expansion boards..............................................................................111

Removing and replacing a half-length expansion board........................................................112

Removing and replacing a full-length expansion board.........................................................113

Removing and replacing the cache module..............................................................................114

Removing and replacing the super capacitor pack....................................................................115

Removing and replacing the processor baffle...........................................................................116

Removing and replacing a processor and heat sink module.......................................................117

Removing and replacing DIMMs.............................................................................................120

Removing and replacing the PDH battery (system battery)..........................................................122

Removing and replacing the SID.............................................................................................122

Removing and replacing the intrusion switch cable....................................................................125

Removing and replacing the system board...............................................................................126

8 Support and other resources....................................................................132

Contacting HP......................................................................................................................132

Information to collect before you contact HP........................................................................132

HP Confidential6 Contents

Page 7

HP contact information.....................................................................................................133

Online support...........................................................................................................133

Phone support............................................................................................................133

Subscription service..........................................................................................................133

HP Insight Remote Support Software........................................................................................133

Related information...............................................................................................................134

Documentation feedback..................................................................................................134

Typographic conventions...................................................................................................134

Related documents...........................................................................................................135

Customer self repair..............................................................................................................135

Standard terms, abbreviations and acronyms................................................136

A Utilities.................................................................................................137

SAS disk setup.....................................................................................................................137

Using the saupdate command...........................................................................................137

Get mode..................................................................................................................137

Set mode...................................................................................................................137

Updating the firmware using saupdate................................................................................138

Determining the Driver ID and CTRL ID................................................................................139

Using the ORCA menu-driven interface...............................................................................139

Creating a logical drive...............................................................................................140

Deleting a logical drive................................................................................................140

Adding a RAID Advanced Pack license key....................................................................140

Viewing RAID advanced pack license keys.....................................................................141

UEFI...................................................................................................................................141

UEFI shell and HP POSSE commands..................................................................................142

Drive paths in UEFI...............................................................................................................144

Using the boot maintenance manager.....................................................................................145

Boot options....................................................................................................................146

Add boot option.........................................................................................................146

Delete boot option......................................................................................................147

Change boot order.....................................................................................................147

Driver options..................................................................................................................148

Add driver option........................................................................................................148

Delete driver option.....................................................................................................149

Change driver order....................................................................................................149

Console options...............................................................................................................150

Boot from file...................................................................................................................150

Set boot next value..........................................................................................................150

Set time out value............................................................................................................151

Reset system....................................................................................................................151

iLO MP................................................................................................................................151

Index.......................................................................................................153

HP Confidential Contents 7

Page 8

1 Overview

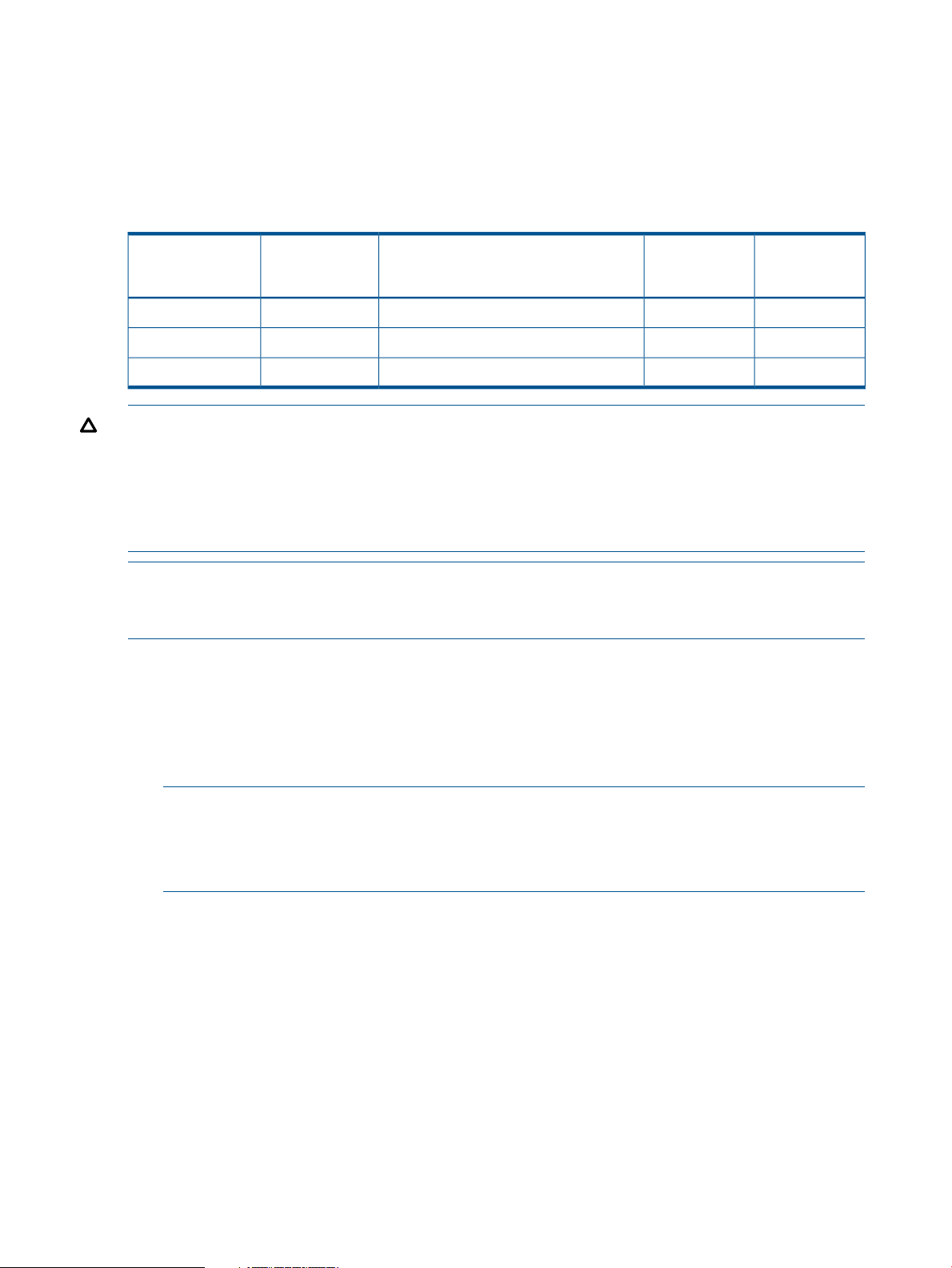

Table 2 Hardware specifications for the server

ServerComponent

One or two Itanium quad-core or eight-core processors:Processors

• 2.53 / 2.67 GHz eight-core 32-MB cache (170W)

• 2.13 / 2.40 GHz eight-core 24-MB cache (170W)

• 2.40 / 2.67 GHz quad-core 32-MB cache (170W)

• 1.73 / 2.40 GHz quad-core 20-MB cache (130W)

Memory

Management I/O

Supports up to 24 Double Data Rate 3 (DDR3) DIMMs mounted on memory risers that attach

to the system board.

IMPORTANT: DIMMs must be rated for 1.35 volts.

Supported DIMM sizes are as follows:

• 4 GB

• 8 GB

• 16 GB

Minimum memory configuration is 8 GB (2 x 4 GB DIMMs) with a single CPU.

Maximum memory configuration 384 GB (24 x 16 GB DIMMs).

One to eight hot-plug SAS hard drivesDisk drives

I/O riser options:PCI slots

• One full height full length PCIe x8 and two low profile PCIe x4 slots

• One full height full length PCIe x8 and one low profile PCIe x8 slots

Eight port SAS core I/O card or eight port SAS core I/O card with internal RAIDSAS I/O

Four GigE LAN portsLAN I/O

One serial port, four USB 2.0 ports, one 1G/100/10 LAN port, and two VGA ports

NOTE: The serial port is intended primarily for use as a serial console port. It can be

configured through iLO 3 for use with other serial devices (subject to OS and device limitations

and dependencies).

Power supply

One SATA DVD+RW driveOptical drive

One power supply which supports dual range operation (Low-line 100-120 & High-line

200-240). At low-line only 800 watts are available.

IMPORTANT: The 800 W redundancy does not apply to all configurations.

HP Confidential8 Overview

Page 9

Server subsystems

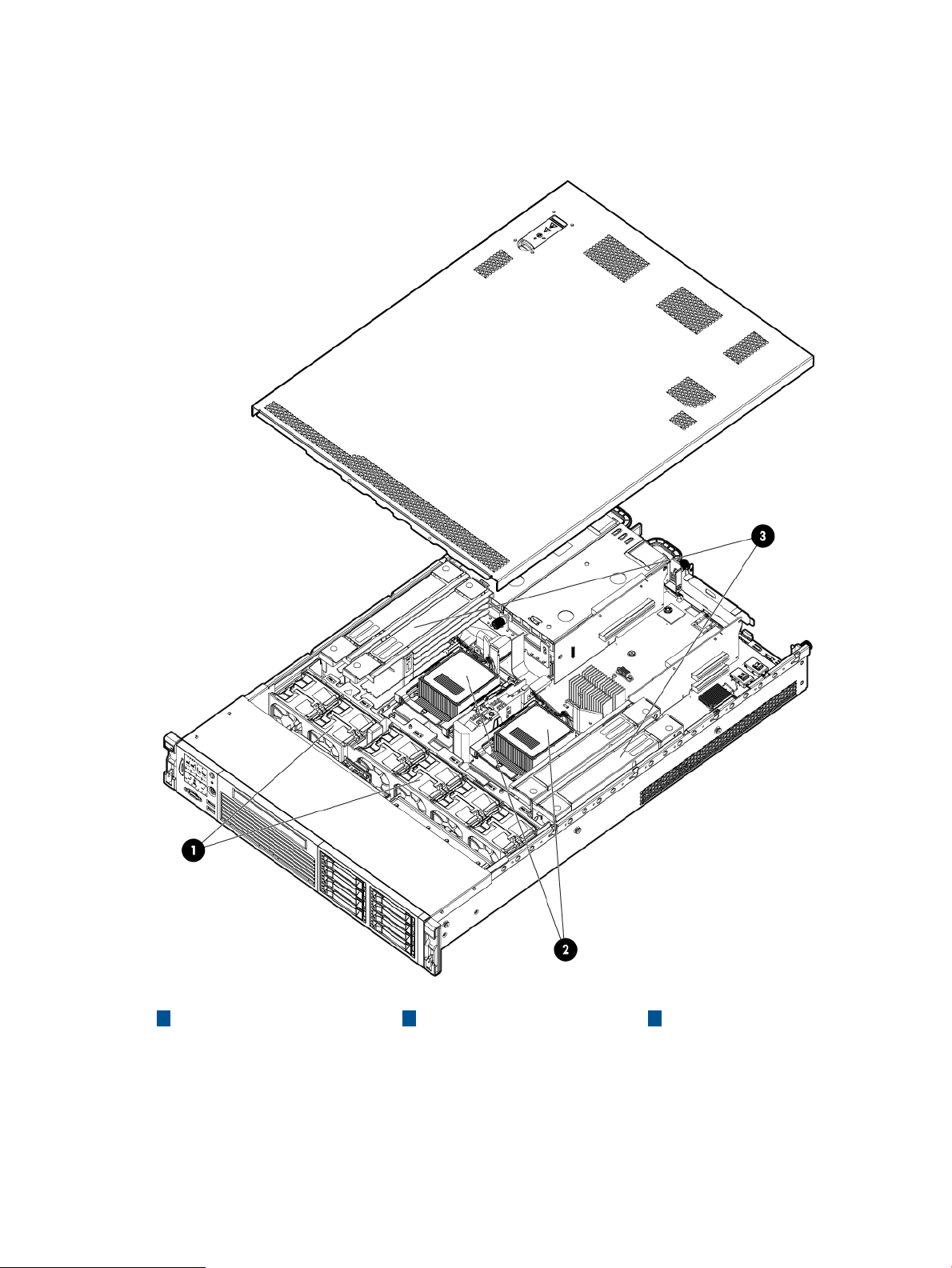

Internal components

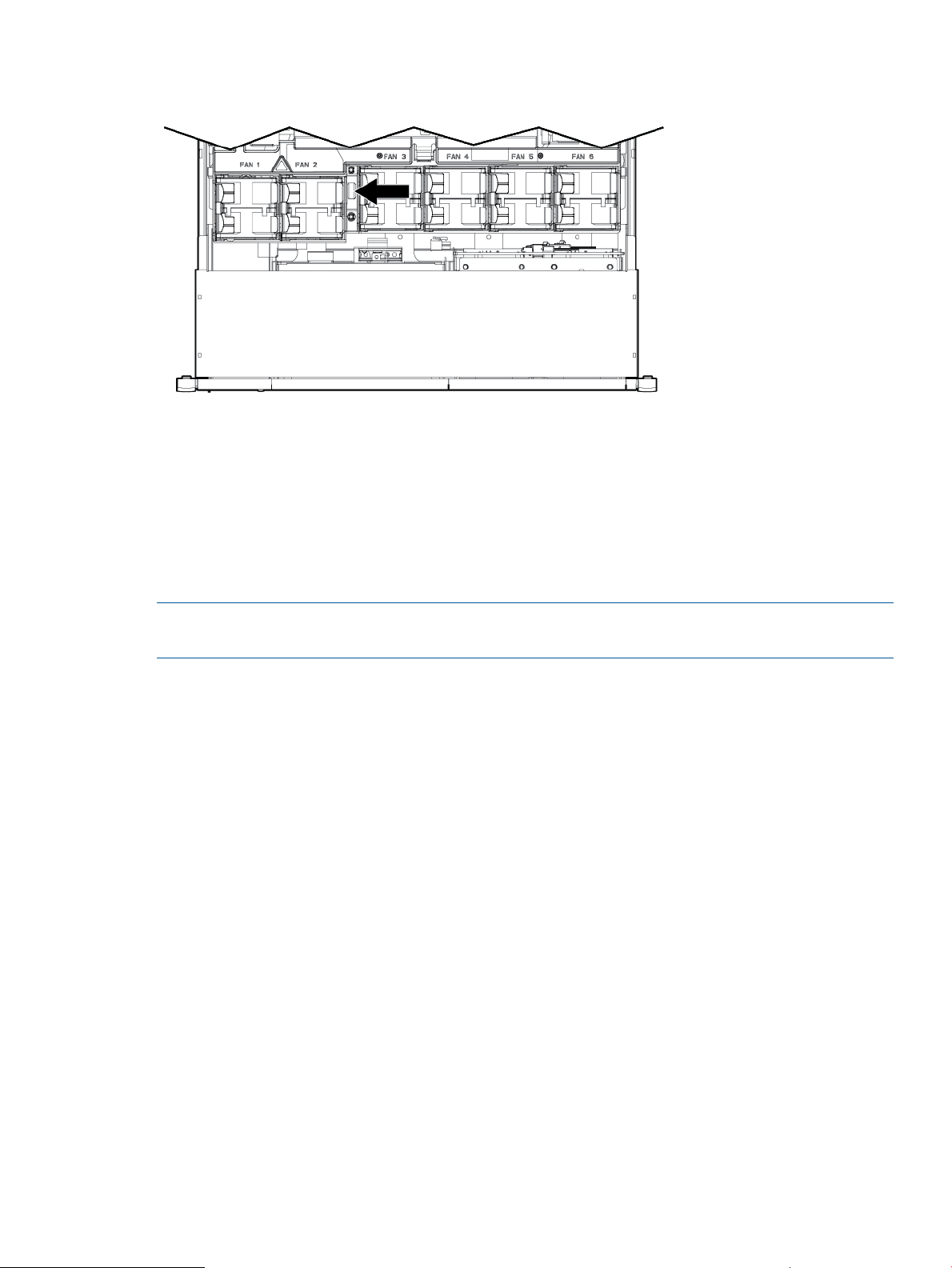

Figure 1 Internal components

321

DIMM risersProcessorsFans

HP Confidential Server subsystems 9

Page 10

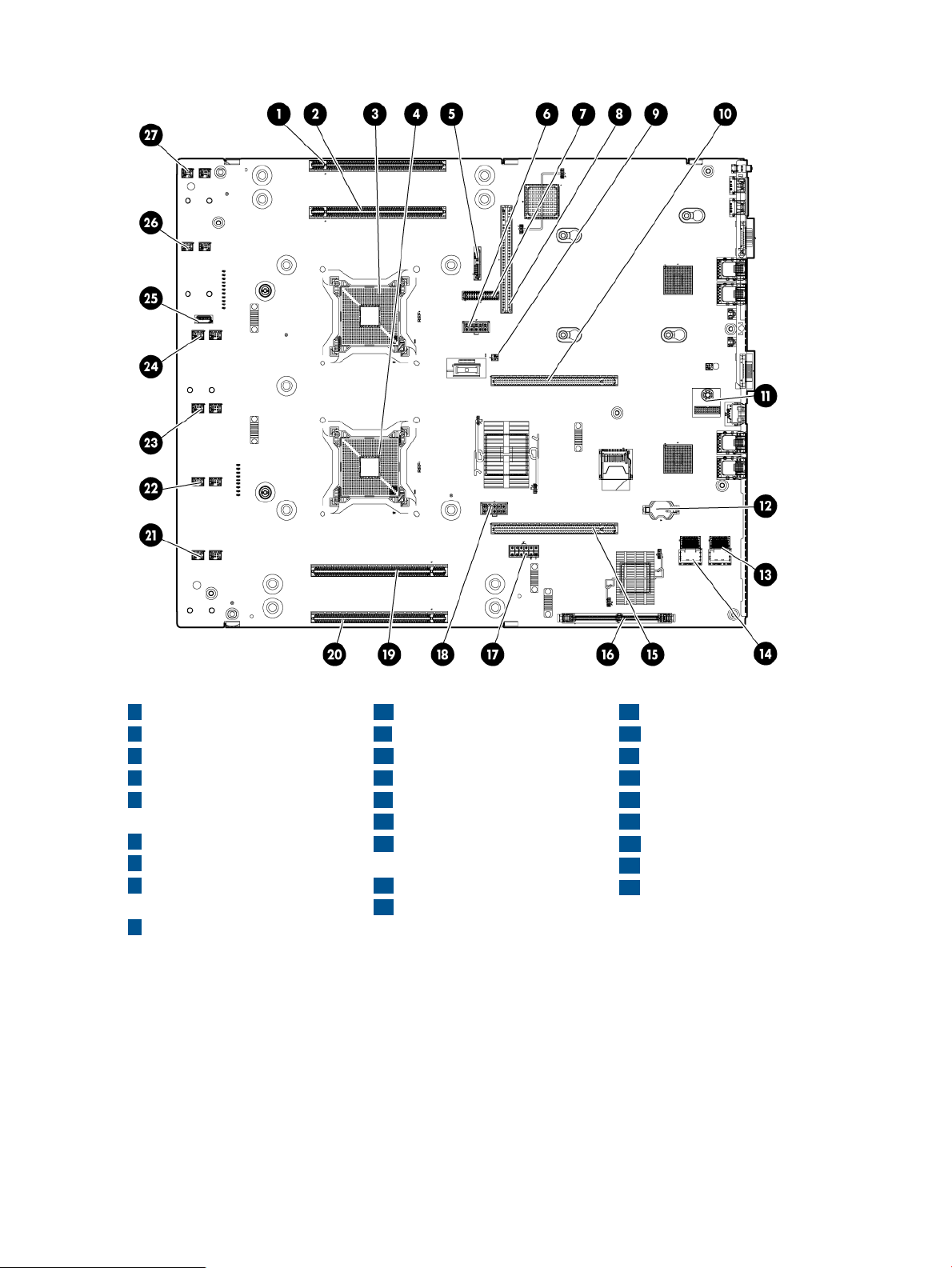

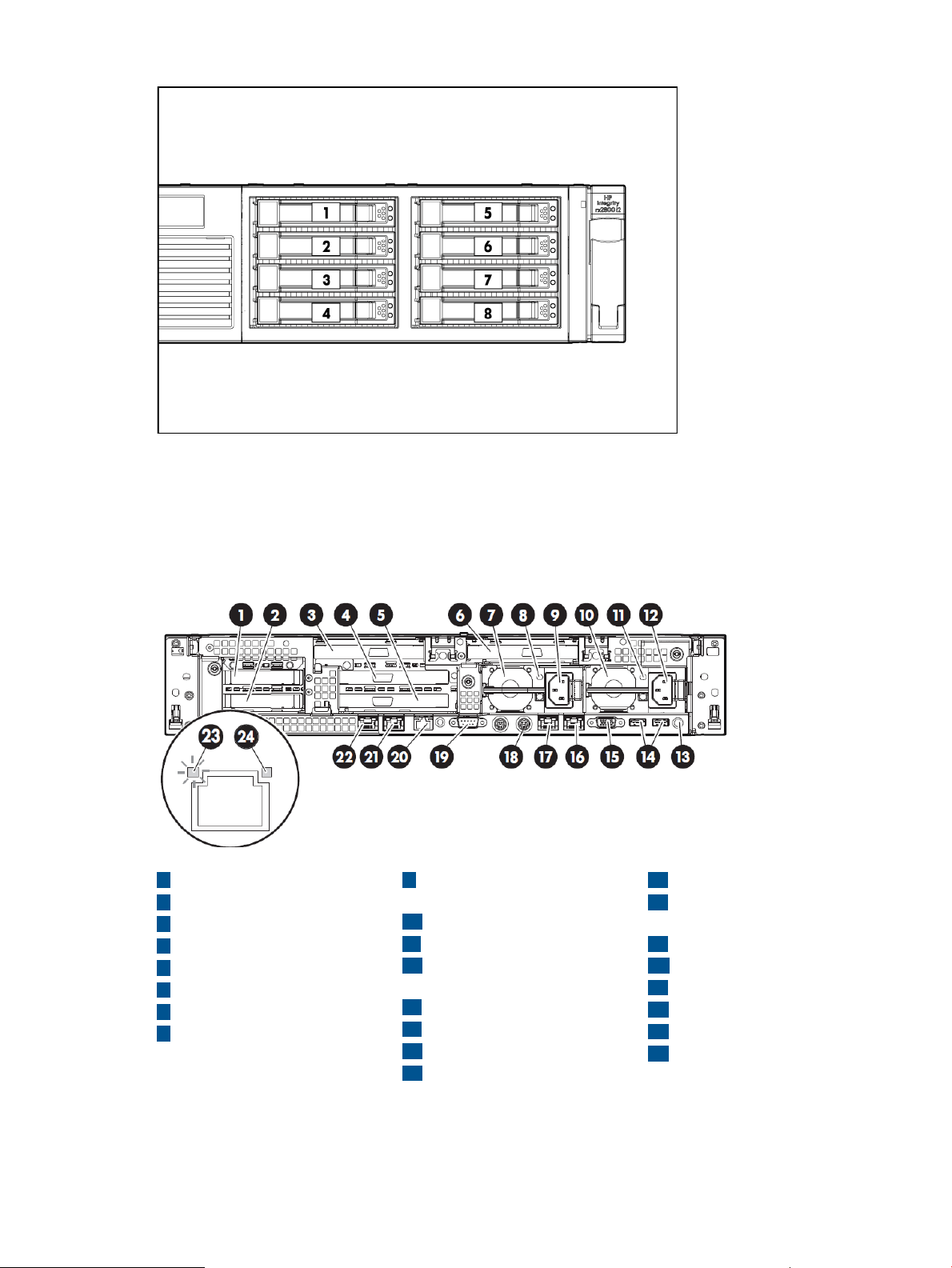

Figure 2 System board components

1

Memory riser connector 1

2

Memory riser connector 2

3

Processor socket 0

4

Processor socket 1

5

SATA optical drive

connector

6

CPU 0 power connector

7

Front I/O connector

8

Power supply backplane

connector

9

Intrusion switch connector

10

Primary riser connector

11

TPM connector

12

System battery

13

SAS B connector

14

SAS A connector

15 24

Secondary riser connector Fan 3 connector

connector

17

SAS power connector

18

CPU 1 power connector

19

Memory riser connector 3

20

Memory riser connector 4

21

Fan 6 connector

22

Fan 5 connector

23

Fan 4 connector

2516

Internal USB connectorSAS cache module

26

Fan 2 connector

27

Fan 1 connector

HP Confidential10 Overview

Page 11

Figure 3 Internal USB location

I/O subsystem

The I/O subsystem consists of the core I/O and two optional I/O riser boards. Wake-on-LAN is

not enabled on any PCIe Public slots. The server does not support PCI Hot Plug (PHP).

The standard I/O Riser supports one full-height, full-length PCIe x8 and two full-height, half-length

PCIe x4 add-in cards. The second riser option supports one full-height, full-length PCIe x8, and one

full-height, half-length PCIe x8 add-in cards.

NOTE: All PCIe x8 slots are electrically connected as x8 slots but are physically loaded with x16

connectors.

The secondary I/O riser position can either be a riser that supports one full-height, full-length PCIe

x8 and two low-profile PCIe x4 add-in cards or a riser that supports one full-height, full-length PCIe

x8 and one low profile PCIe x8.

RAID support

The following levels of RAID support are offered:

• Zero memory

◦ Maximum 8 drives, 2 logical volumes

◦ No cache or super capacitor needed. Performance improved with cache.

• Full feature

◦ Cache needed and installing it automatically enables the full feature firmware stack.

• Advanced pack

RAID 0, 1, 10◦

RAID 0, 10, 5◦

Super capacitor is optional.

RAID 6, 50, 60◦

◦ Cache needed. Advanced Pack license must be entered to enable. Super capacitor is

required.

HP Confidential Server subsystems 11

Page 12

To enable Advanced Pack licensing, see “Adding a RAID Advanced Pack license key” (page 140).

NOTE: To utilize all 8 disks with the zero memory option, the following RAID configurations are

possible:

• RAID 0: 1 or 2 LUNs striped with up to 8 disks

• RAID 10: 1 or 2 LUNs striped & mirrored with even number of up to 8 disks

• RAID 1: 1 LUN using 2 mirrored disks, and one additional LUN in RAID 0 or 10

Example Configurations 8 Disks with Zero Memory

• LUN 1: RAID 1 bays 1 & 2

• LUN 2: RAID 0 bays 3, 4, 5, 6, & 7

• Hot Spare: bay 8

• LUN 1: RAID 10 bays 1, 2, 3, & 4

• LUN 2: RAID 10 bays 5, 6, 7, & 8

• LUN 1: RAID 0 bays 1, 2, & 3

• LUN 2: RAID 10 bays 5, 6, 7, & 8

• Hot Spare: bay 4

Controls and ports

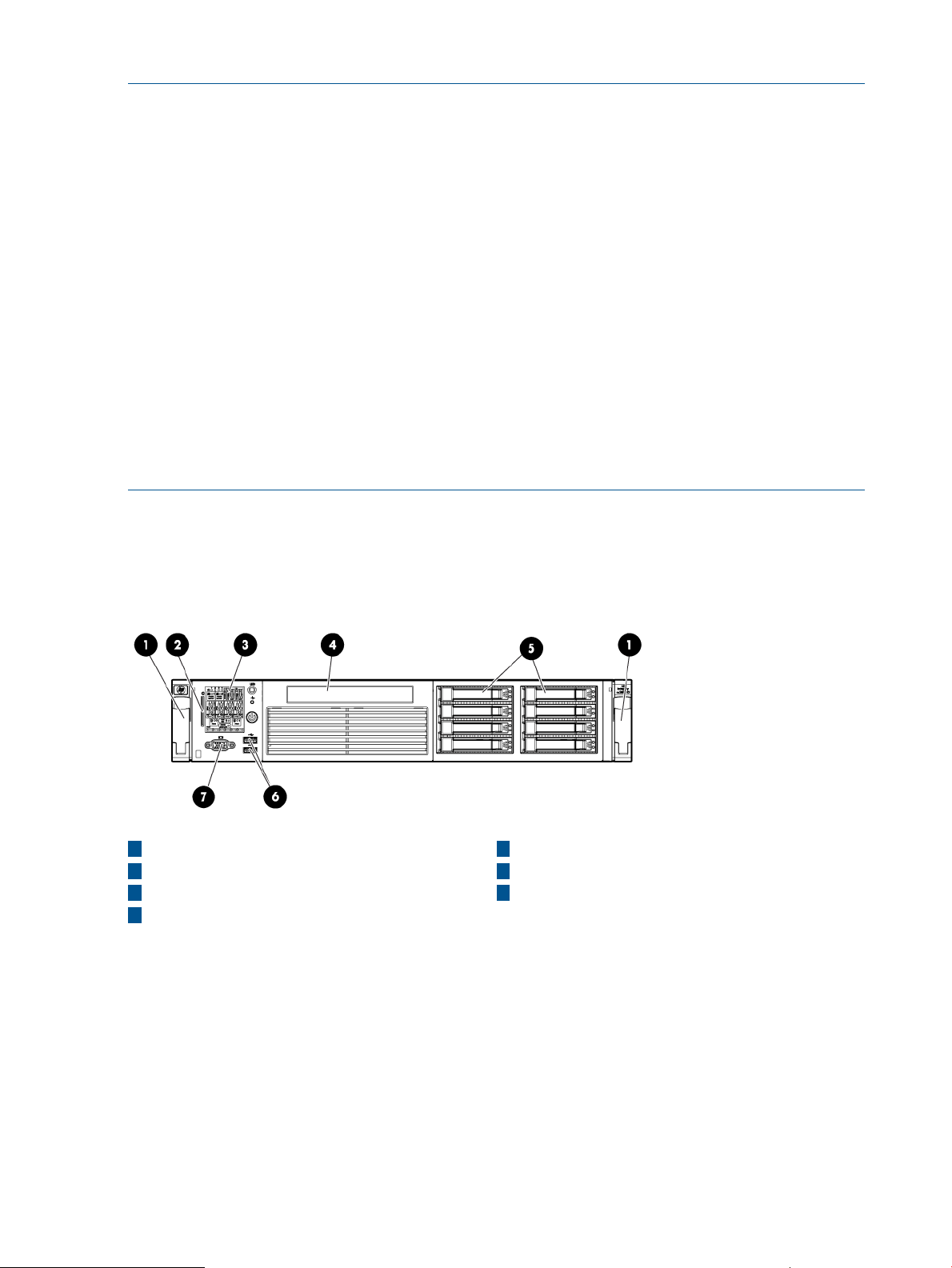

Front panel controls and ports

Figure 4 Front panel components

1

Quick release levers

2

iLO 3 information pull tab

SID Video connector

4

Optical drive bay

Storage and media devices

The server supports up to eight hot-plug SAS HDDs, and one optical (SATA DVD+RW) drive, with

LEDs that indicate activity and device statuses.

5

Hard drive bays

6

USB connectors

73

HP Confidential12 Overview

Page 13

Figure 5 SAS device numbers

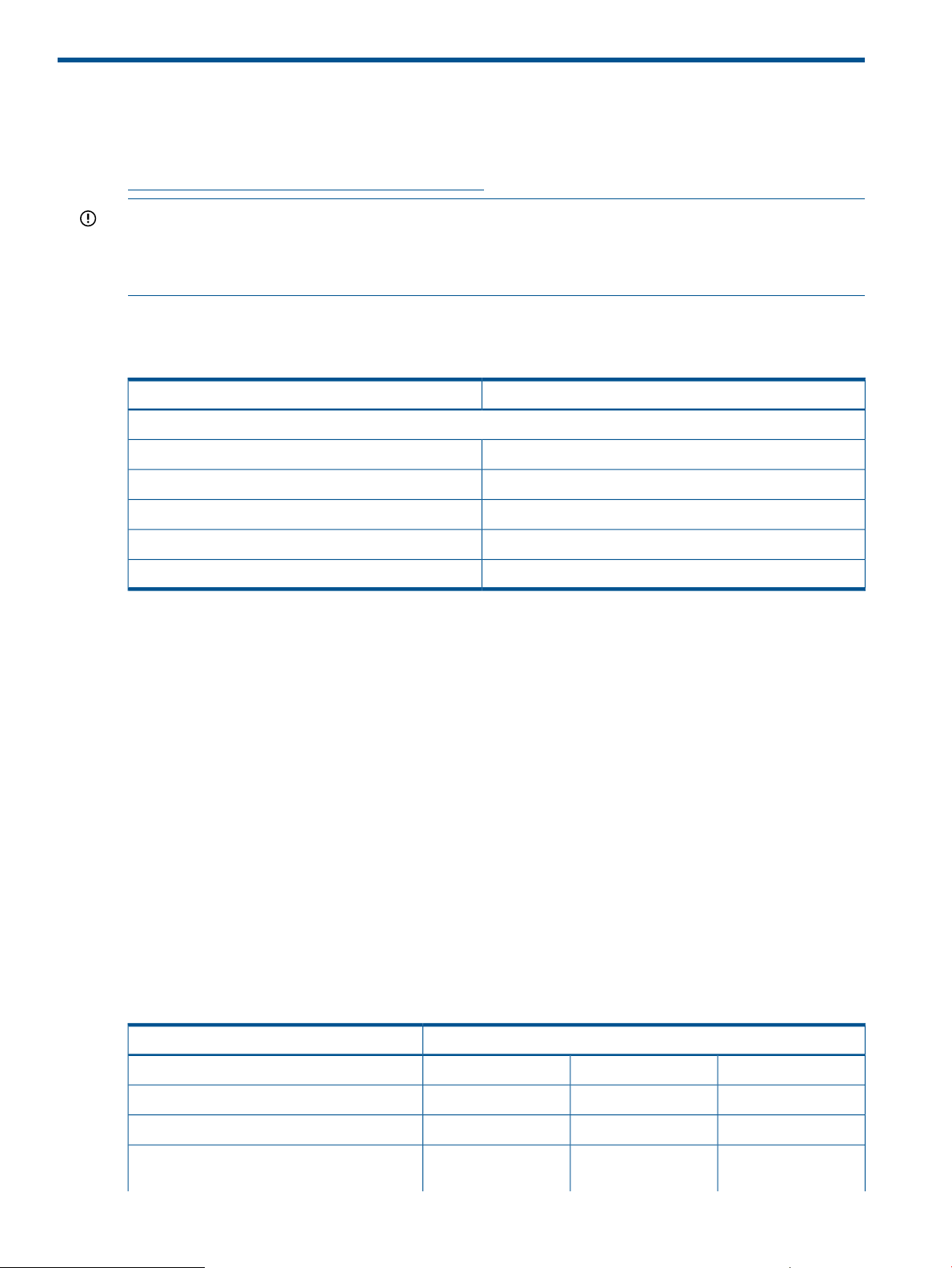

Rear panel controls and ports

The server rear panel includes communication ports, I/O ports, USB ports, AC power connectors,

and the locator LED and button. LEDs located on the rear panel of the server signal the operational

status of the rear panel components.

Figure 6 Rear panel components

1

PCI 5

2 18

PCI 6 iLO 3 physical presence

3

PCI 4

4

PCI 2

5

PCI 3

6

PCI 1

7

Power supply 2

8

Power supply 2 LED

9

Power supply 2 power

connector

10

Power supply 1

11

Power supply 1 LED

connector

13

UID LED button

14

USB connectors (2)

15

Video connector

16

NIC 1 connector

17

NIC 2 connector

pinhole button

19

Serial connector

2012

iLO 3 connectorPower supply 1 power

21

NIC 3 connector

22

NIC 4 connector

23

NIC link LED

24

NIC activity LED

HP Confidential Controls and ports 13

Page 14

2 Site preparation

For information on general computer room site preparation, see the HP Generalized Site Preparation

Guide on the HP website:

http://www.hp.com/go/Integrity_Servers-docs

IMPORTANT: To avoid hardware damage, allow the thermal mass of the product to equalize to

the temperature and humidity of the installation facility after removing the shipping materials. A

minimum of one hour per 10° C (50° F) of temperature difference between the shipping facility

and installation facility is required.

Server dimensions and weight

Table 3 Rack or pedestal-mounted server dimensions

Data center server dimensions

ValueDimensions and weight

69.2 cm (27.25 in)Depth

48.3 cm (19 in)Width

8.9 cm (3.5 in)Height

Maximum configuration – 30 kg (66 lb)Weight

Grounding

The site building must provide a safety ground/protective earth for each AC service entrance to

all cabinets.

Install a PE conductor that is identical in size, insulation material, and thickness to the branch-circuit

supply conductors. The PE conductor must be green with yellow stripes. The earthing conductor is

to be connected from the unit to the building installation earth or, if supplied by a separately

derived system, at the supply transformer or motor-generator set grounding point.

Server electrical specifications

System power specifications

Available power (output) is the maximum DC power that the power supply can supply to the system.

Maximum input power is what the power supply requires from the AC line to deliver that maximum

DC output (given worst case efficiency and maximum loading).

Maximum input current is the worst case/highest current given the lowest input voltage and the

maximum input power.

Table 4 System power specifications

2URack unit

Parameter

Power supply maximum output power

800 W (MAX)

+12V /66.7A MAX

900 W (MAX)

+12V /75A MAX

200 - 240 V AC110 - 120 V AC100 V ACInput voltage

6.6 A9.5 A9.3 AInput current (maximum)

57 to 63 Hz47 to 53 Hz47 to 63 HzInput frequency

1200 W (MAX)

+12V /100A MAX

HP Confidential14 Site preparation

Page 15

Table 4 System power specifications (continued)

Parameter

If an overload triggers the power supply overload protection, the system is immediately powered

off. To reset the power supply unit:

1. Disconnect the power cord.

2. Determine what caused the overload by contacting an HP support representative.

3. Reconnect the power cord.

4. Reboot the system.

NOTE: If an overload occurs twice, an undetected short circuit exists.

When you use the front panel power button to turn off the server, power consumption falls below

the low power consumption, but does not reach zero. To reach zero power consumption in "off"

mode, disconnect all power supplies from their power sources.

Power consumption and cooling

The power consumptions listed in Table 5 (page 15) are valid for the configuration shown. Please

use the HP Power Advisor tool to obtain power information for other configurations or utilization

factors.

+12VSB /2.5A MAX+12VSB /2.5A MAX+12VSB /2.5A MAX

Table 5 Standard configuration power consumption

one 1200 W power supply, and one SAS disk drive

Power consumptionStandard configuration

1228 Btu/h (maximum)360 W (maximum)One 1.46 GHz quad-core processor, 4 GB memory,

HP Confidential Server electrical specifications 15

Page 16

Server physical and environmental specifications

NOTE: De-rate maximum allowable dry-bulb temperature 1 °C/175 m above 900 m.

Table 6 Environmental specifications (system processing unit with hard disk)

Parameter

Maximum Airflow

(CFM)

1

Acoustic Noise Emission (ISO 9296)

Sound Power Level

Altitude

1

Maximum operating temperature range up to 3050 m (10000 ft). For higher altitudes, de-rate the maximum temperature

by 1° C/175 m (574 ft) above 900 m (3000 ft)

2

Two eight-core processor modules•

+5° C to +40° C (+41° F to +104° F)Operating temperature (up to 3050 m / 10000 ft)

- 40° C to +80° C (–40° F to 176° F)Non-operating temperature

+51° C (+124° F)Over-temperature shutdown

-12 ˚C DP and 8% RH to 85% RHOperating humidity

8% to 90% RH non-condensingNon-operating humidity

2

0 to 3000 m (10,000 ft) maximumOperating altitude

0 to 4,600 m (15,000 ft) maximumNon-operating altitude

Value

Office Friendly ServerData Center Server

213 CFM193 cubic feet/minute

LwAd = 6.0 BLwAd = 7.0 BMaximum configuration (disk active)

LpAm = 42.4 dBLpAm = 52.7 dBSound Pressure Level

• Twenty-four DIMMs on four memory risers

• Eight hard disk drive

• Six cards on two risers

• Two power supplies

Unpacking and inspecting the server

This section describes pre installation procedures. Ensure that you have adequately prepared your

environment for installing the new server, received the components that you ordered, and verified

that the server and the containers are in good condition after shipment.

Verifying site preparation

• Gather LAN information. The MAC addresses for the iLO 3 MP LAN and the system LAN are

located on the iLO Network Information Tag.

• Establish a method to connect to the server console.

• Verify electrical requirements. Ensure that grounding specifications and power requirements

are met.

• Validate server physical space requirements.

• Confirm environmental requirements.

For server-specific information on electrical, physical space, and environmental requirements, see

the site prep guide. For general site preparation information, see the HP Generalized Site

Preparation Guide on the HP website at http://www.hp.com/go/Integrity_Servers-docs.

HP Confidential16 Site preparation

Page 17

Inspecting the shipping containers for damage

Under normal shipping conditions, HP shipping containers protect the contents. After the equipment

arrives, carefully inspect each carton for signs of shipping damage. Shipping damage constitutes

moderate to severe damage, such as punctures in the corrugated carton, crushed boxes, or large

dents. Normal wear or slight damage to the carton is not considered shipping damage. If you find

shipping damage to the carton, immediately contact your HP customer service representative.

Unpacking the server

1. Follow the instructions printed on the outside top flap of the carton to remove the banding and

the outer carton from the server pallet.

2. Remove all inner accessory cartons and the top foam cushions, leaving only the server.

IMPORTANT: Inspect each carton for shipping damage as you unpack the server.

Verifying the inventory

The sales order packing slip lists all the equipment shipped from HP. Use this packing slip to verify

that all equipment has arrived.

NOTE: To identify each item by part number, see the sales order packing slip.

Returning damaged equipment

If the equipment is damaged, immediately contact your HP customer service representative. The

service representative initiates appropriate action through the transport carrier or the factory and

assists you in returning the equipment.

Unloading the server with a lifter

WARNING!

Use caution when using a lifter. Because of the weight of the server, to avoid injury, you must

center the server on the lifter forks before lifting it off the pallet.

NOTE: HP recommends that you follow your local guidelines when lifting equipment.

1. Unpack the server.

2. Unroll the bottom corrugated tray corresponding to the side on which the lifter is to be placed,

and then slide the server as close to that edge of the pallet as possible.

3. Break off any foam packaging that can prevent the lifter from being fully inserted under the

server. Do not remove the foam packaging from the corners of the server. This foam is required

to elevate the server and to enable the forks of the lifter to be placed under the server.

4. Insert the lifter forks under the server.

5. Carefully roll the lifter forward until it is fully positioned against the side of the server.

6. Slowly raise the server off the pallet until it clears the pallet cushions.

7. Carefully roll the lifter and server away from the pallet. Do not raise the server any higher

than necessary when moving it over to the rack.

HP Confidential Server physical and environmental specifications 17

Page 18

3 Installing the server

Safety information

Follow the instructions carefully to prevent injury and equipment damage when performing removal

and replacement procedures. Voltage might be present within the server. Many assemblies are

sensitive to damage by ESD.

Follow the safety considerations listed to ensure safe handling of components, to prevent injury,

and to prevent damage to the server:

• If installing a hot-swappable or hot-pluggable component when power is applied (fans are

running), reinstall the server cover immediately to prevent overheating.

• If installing a hot-pluggable component, complete the required software intervention prior to

removing the component.

• If installing an assembly that is neither hot-swappable nor hot-pluggable, disconnect the power

cable from the external server power receptacle before starting the installation.

WARNING! Ensure that the system is powered off and all power sources are disconnected

from the server before removing or installing server hardware (unless you are removing or

installing a hot-swappable or hot-pluggable component). Voltage is present at various locations

within the server whenever an AC power source is connected. This voltage is present even

when the main power switch is off. Failure to observe this warning might result in personal

injury or equipment damage.

• Do not wear loose clothing that might snag or catch on the server or on other components.

• Do not wear clothing subject to static charge buildup, such as wool or synthetic materials.

• If installing an internal assembly, wear an antistatic wrist strap and use a grounding mat, such

as those included in the Electrically Conductive Field Service Grounding Kit.

• Handle accessory boards and components by the edges only. Do not touch any metal edge

connectors or any electrical components on accessory boards.

Preventing electrostatic discharge

To prevent damaging the system, be aware of the precautions you need to follow when setting up

the system or handling parts. A discharge of static electricity from a finger or other conductor might

damage system boards or other static-sensitive devices. This type of damage might reduce the life

expectancy of the device.

To prevent electrostatic damage:

• Avoid hand contact by transporting and storing products in static-safe containers.

• Keep electrostatic-sensitive parts in their containers until they arrive at static-free workstations.

• Place parts on a grounded surface before removing them from their containers.

• Avoid touching pins, leads, or circuitry.

• Always be properly grounded when touching a static-sensitive component or assembly.

HP Confidential18 Installing the server

Page 19

Installation sequence and checklist

Perform site preparation (see The HP Integrity rx2800 i4 Server User Service Guide).1

Install the server into a rack or pedestal.2

Connect cables to the server.3

a. Connect the AC input power cable.

b. Connect LAN core I/O cable.

c. Connect the iLO 3 MP LAN cable.

Connect and set up the console for access.4

Power on the server.5

From iLO MP, access UEFI.6

Boot the operating system.7

Using HP Smart Update Manager (HPSUM), download the latest firmware.8

Installing the server into a rack or pedestal

CompletedDescriptionStep

Rack installation

HP rack

HP servers that are installed into racks are shipped with equipment-mounting slides. The HP 2U

Quick Deploy Rail System Installation Instructions for HP Products ships with each set of slides.

Follow the steps in this installation guide to determine where and how to install the server into the

rack.

For more information on rack deployment, stabilization and transportation, see the 10000 Series

G2 Rack Best Practices Guide.

http://www.hp.com/go/rackandpower

Non-HP rack

For information on installing a rx2800 i4 server in a third party rack, see the QuickSpecs located

on the HP Integrity rx2800 i4 Server product page at

http://h18000.www1.hp.com/products/quickspecs/14464_div/14464_div.HTML

To view the QuickSpecs, click the HTML or PDF link under Quick Specs.

Pedestal kit installation

If you order the rackless configuration option, the server ships with a pedestal mount. The pedestal

mount is packaged in a separate carton that is attached to the server carton.

Remove the rails from the server

If your server has rails when you receive it, you need to remove the rails before mounting it in the

pedestal kit. To remove the component:

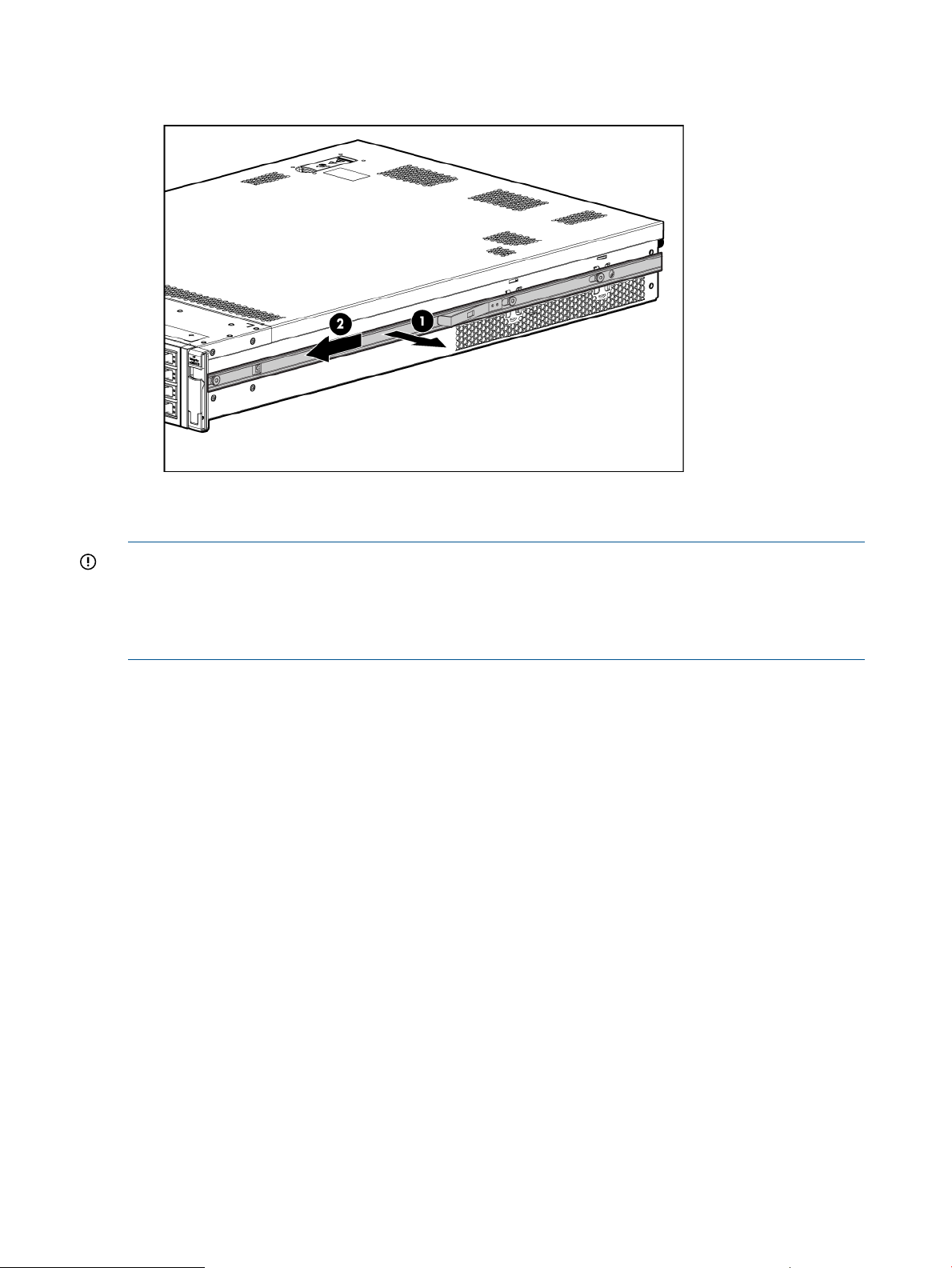

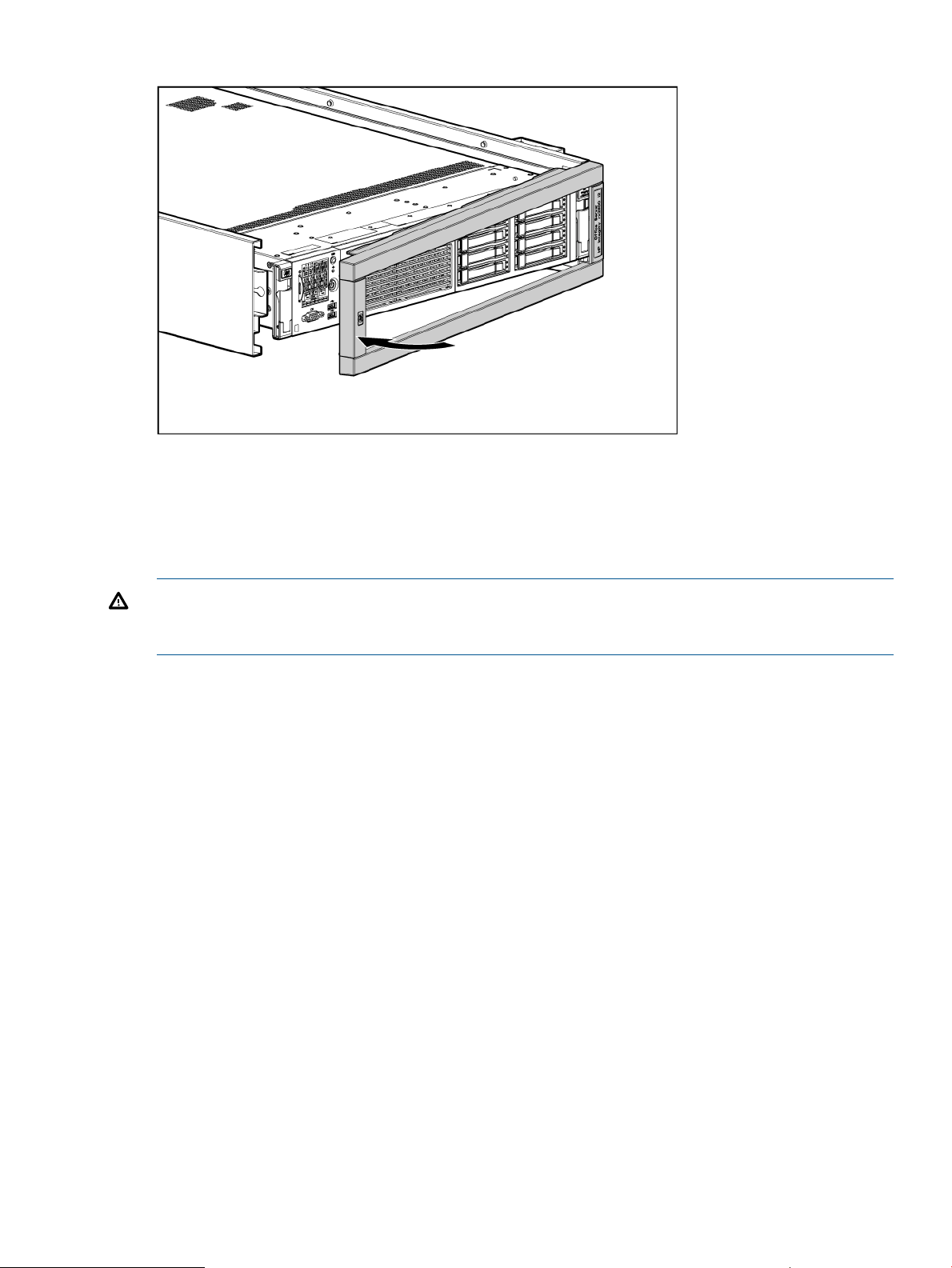

1. Slightly pull the rail lock away from the rail to unlock the rail. See Figure 7 (page 20).

2. Slide the rail toward the front of the server to disengage the rail from the posts on the server.

HP Confidential Installation sequence and checklist 19

Page 20

3. Repeat these steps for the rail on the other side of the server.

Figure 7 Removing the rails from the server

Attaching the pedestal kit top and bottom

IMPORTANT:

In this document the server top, bottom, right and left refer to the server as faced from the front

with the server in a horizontal orientation. The pedestal kit components are referred to by the final

position with the server in a vertical orientation. For example, the pedestal kit bottom attaches to

the server right side.

HP Confidential20 Installing the server

Page 21

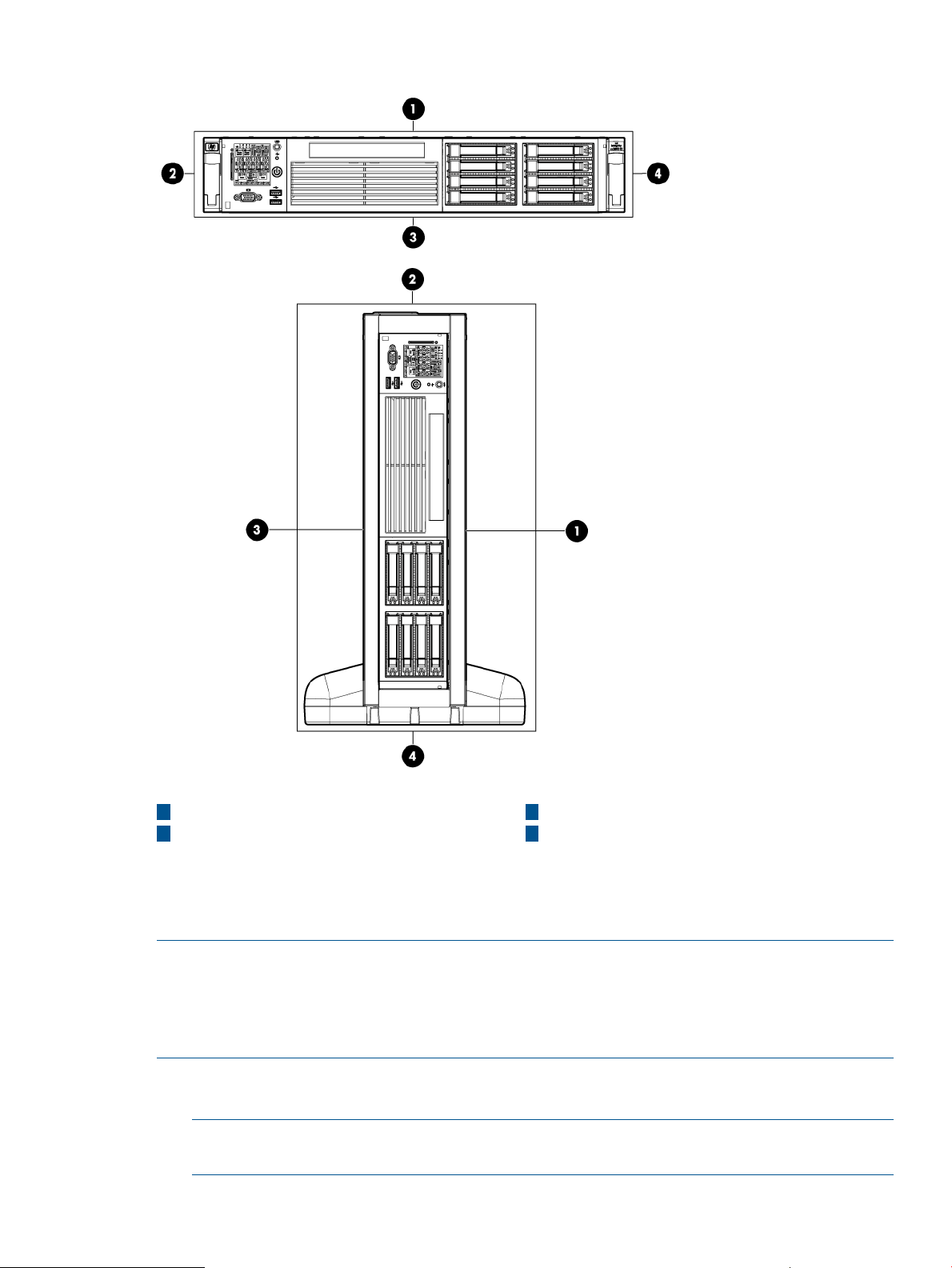

Figure 8 Front of server

1

Server top/pedestal right

2 4

Server left/pedestal top Server right/pedestal bottom

3

Server bottom/pedestal left

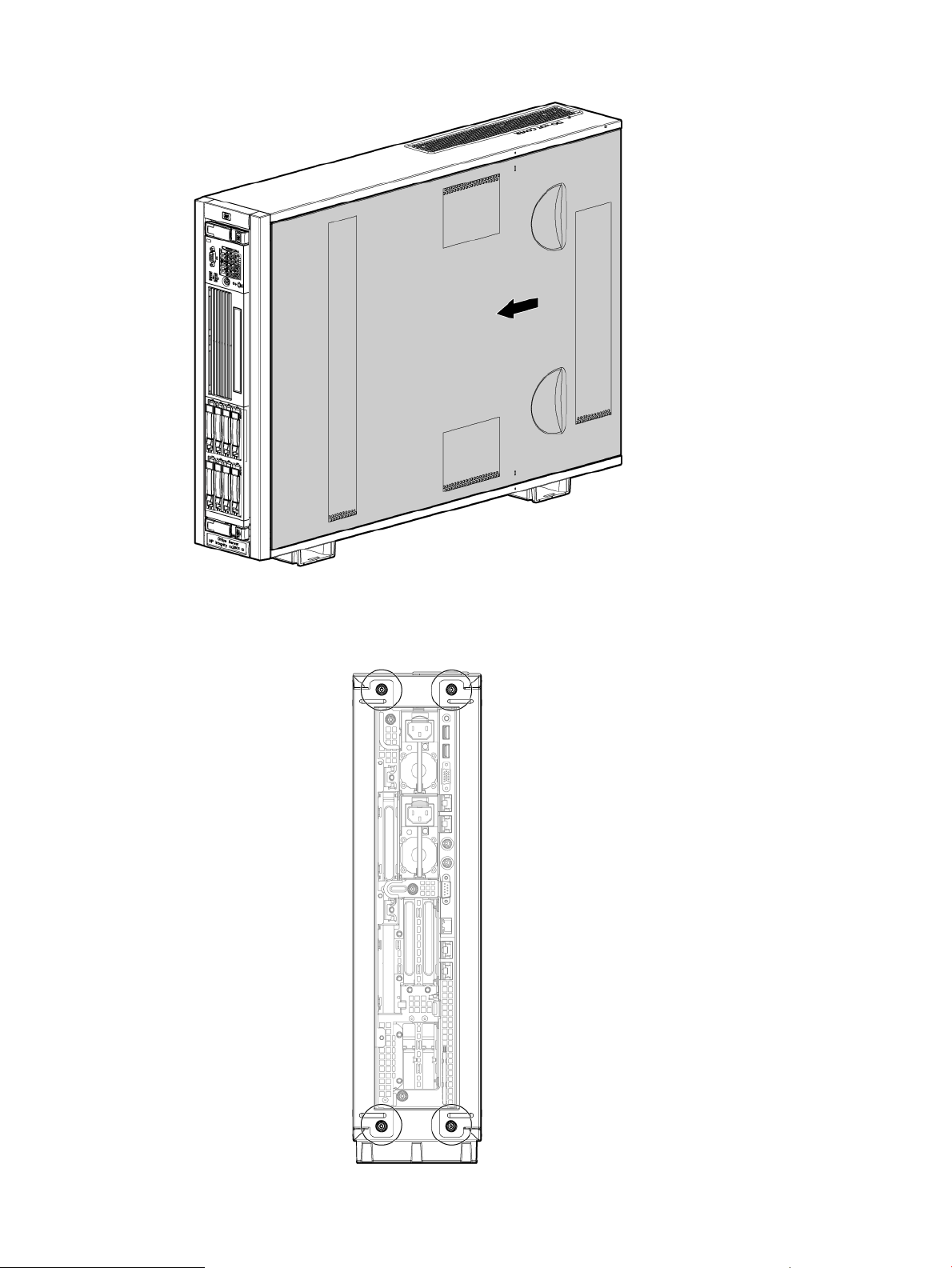

The pedestal kit bottom attaches to the right side of the server when the server is in the horizontal

position. The pedestal kit top attaches to the left side of the server when in the server is in the

horizontal position. The pedestal bottom can be distinguished from the pedestal top by the pedestal

feet slots.

NOTE: The bottom piece of the pedestal is taller than the server, so try to position the server so

the right side (in the horizontal position) of the server hangs off the edge of the work surface by a

few inches to allow the bottom piece to be attached to the server chassis. If that is not possible,

then raise up the server approximately three inches from the work surface to enable the pedestal

kit bottom piece to be attached to the server right side.

To attach the components.

1. Align the holes in the pedestal component with the posts on the server. See Figure 9 (page 22).

NOTE: One of the holes in the pedestal component contains the locking mechanism. This

makes the hole appear partially blocked.

HP Confidential Installing the server into a rack or pedestal 21

Page 22

2. Hold the pedestal component flush against the server.

3. Slide the pedestal component forward until it locks into place.

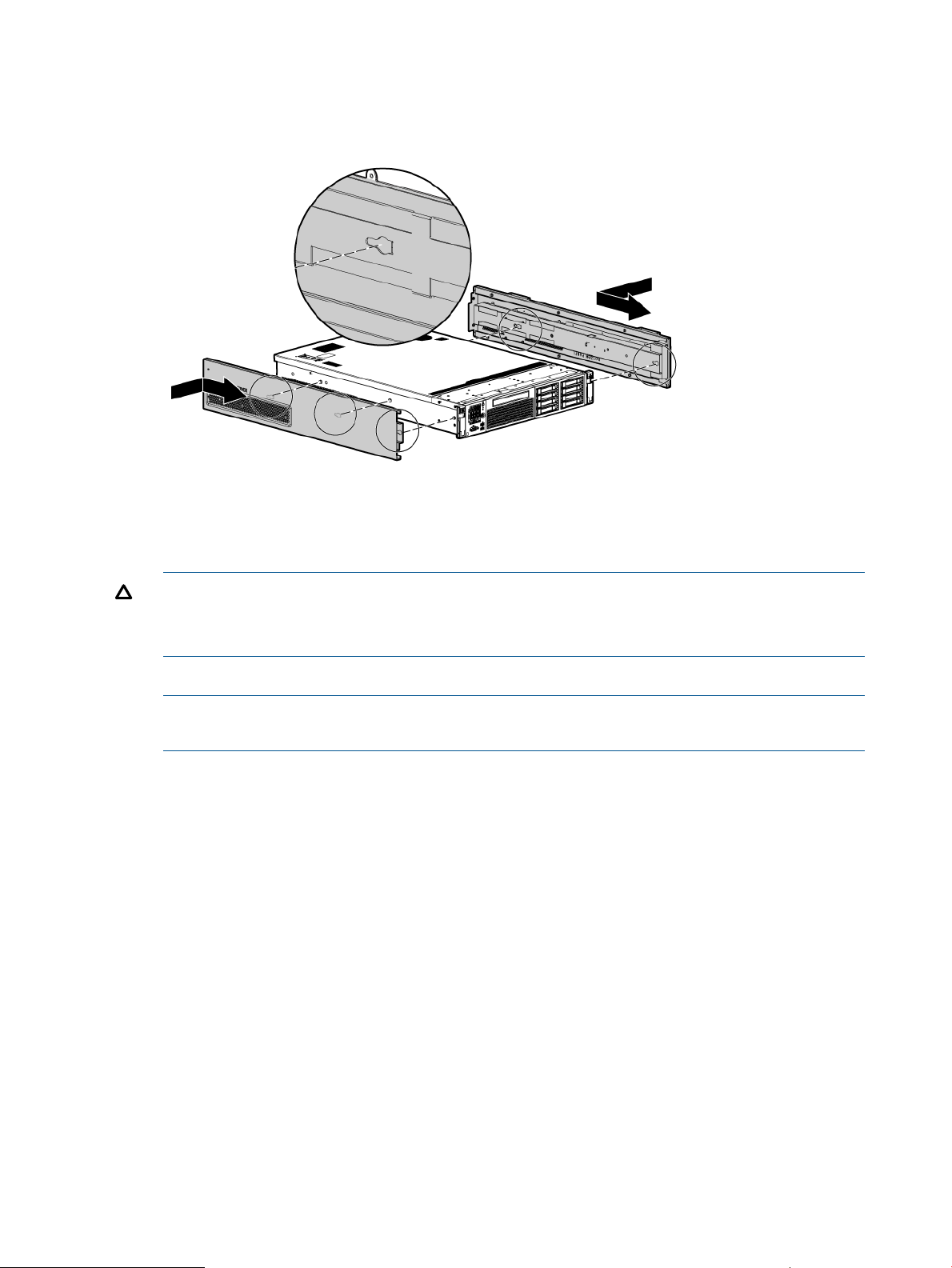

Figure 9 Installing the pedestal bottom piece

4. Stand the server up on the bottom piece of the pedestal kit that was just installed so the server

is in the vertical position.

CAUTION: The server is heavy. Be careful when lifting it to the vertical position.

Without the feet installed, the server might tip over easily. Be careful when working near the

server to avoid tipping it over.

5. Align the holes in the pedestal top piece with the posts on the server.

NOTE: One of the holes in the pedestal component contains the locking mechanism. This

makes the hole appear partially blocked.

6. Hold the pedestal top piece flush against the server.

7. Slide the pedestal top piece forward until it locks into place.

8. The top and bottom pedestal kit pieces are now in place.

Attaching the bezel cover

To attach the bezel cover:

1. Apply the rx2800 i4 product label provided in the pedestal kit to the bottom front of the bezel

cover (label can be seen in the figure below.)

2. Attach the bezel cover to the front of the server starting from the bottom of the pedestal kit.

3. Push the bezel cover into place against the pedestal kit top piece until the tabs on the bezel

cover snap into place.

HP Confidential22 Installing the server

Page 23

Figure 10 Attaching the bezel cover

Attaching the pedestal kit side pieces

The pedestal kit right side piece attaches to the top of the server. The top cover of the server might

have ventilation holes in it to enable proper air flow and cooling. The right side piece of the

pedestal kit also has ventilation holes in it to enable the proper cooling and air flow. Follow these

steps to attach the pedestal kit right side piece.

WARNING! The ventilation holes in the pedestal kit right side piece must be matched up with

the ventilation holes on the top cover of the HP Integrity rx2800 i4 Server to enable proper cooling

and air flow. Failure to heed this warning causes the server to shut down with an overtemp condition.

To attach the component:

1. Align the posts on the pedestal kit right side piece with the slots in the pedestal kit top and

bottom.

2. Hold the pedestal side flush against the server and slide it toward the front of the server.

HP Confidential Installing the server into a rack or pedestal 23

Page 24

Figure 11 Attaching the pedestal kit side piece

3. Secure the pedestal side by hand tightening the captive thumb screws on the rear of the server.

Figure 12 Thumb screw locations

HP Confidential24 Installing the server

Page 25

Repeat these steps to install the left side piece.

Attaching the pedestal feet

The pedestal feet slide into the slots on the pedestal bottom, two on each side. The feet are all the

same and can be mounted in any slot on the bottom piece of the pedestal kit.

Figure 13 Attaching the feet

Connecting server cables

AC input power

The server can receive AC input from two different AC power sources. The power receptacles are

located at the rear of the server.

A maximum of two power supplies can be installed in the server. Installing two power supplies in

the server provides 1+1 redundancy, meaning that if one power supply fails, there is still enough

power supplied to the server to operate. You must promptly replace the failed power supply to

restore 1+1 functionality.

All high-line (220 V) configurations are capable of 1+1 redundancy. Low-line (110 V) configurations

can maintain 1+1 redundancy as long as the total power consumed does not exceed 800 W.

A minimum of one power supply is required to power the server. If only one power supply is

installed in the server, there is no 1+1 capability.

HP Confidential Connecting server cables 25

Page 26

Power states

The server has the following power states:

• Standby power

• Full power

• Off

Table 7 Power states

Power states

Power cable

plugged into

receptacle?

Power activated through the iLO 3 PC

command; or front panel power button

activated?

Standby DC

voltage applied?

DC voltage

applied?

NoYesNoYesStandby power

YesYesYesYesFull power

NoNoNoNoOff

CAUTION: If the server is expected to remain in standby mode for more than 30 minutes, AC

power should be completely removed from the server. You can do this by switching off the circuit

breakers that are part of the building installation, disconnecting or switching off a power distribution

unit, or by physically removing the power cords from the server.

Be aware that removing AC power from the server for an extended period can drain the system

battery.

NOTE: If the power restore feature is set to Always On through the iLO 3 MP PR command, the

server automatically powers on to the full power state when the power cord is plugged in to the

server.

The HP Integrity rx2800 i4 Server User Service Guide shows the ports and power supplies located

on the rear panel of the server.

Applying standby power to the server

1. Plug the power cord into the receptacle in power supply.

2. Plug the other end of the power cord into an AC outlet.

NOTE: The LED on the power supply does not illuminate in the standby power state. The

LED is green when the server is powered on to full power.

If the power restore feature is set to Always On through the iLO 3 MP PR command, the server

automatically powers on to the full power state when the power cord is plugged into the server.

3. If the server has two power supplies, plug the second power cord into the power supply.

4. Plug the other end of the power cord into an AC outlet.

Connecting to the LAN

The server has four LAN ports that provide network connectivity. The HP Integrity rx2800 i4 Server

User Service Guide shows the available LAN ports for the server.

1. Obtain valid IP addresses for each LAN port you plan to activate.

2. Connect the LAN cable from an available LAN port into a live connection on the network.

Setting up the system

For more information on using the iLO 3 MP, see the HP Integrity iLO 3 Operations Guide.

HP Confidential26 Installing the server

Page 27

Setup checklist

Use the checklist in Table 8 while setting up the Integrity iLO 3.

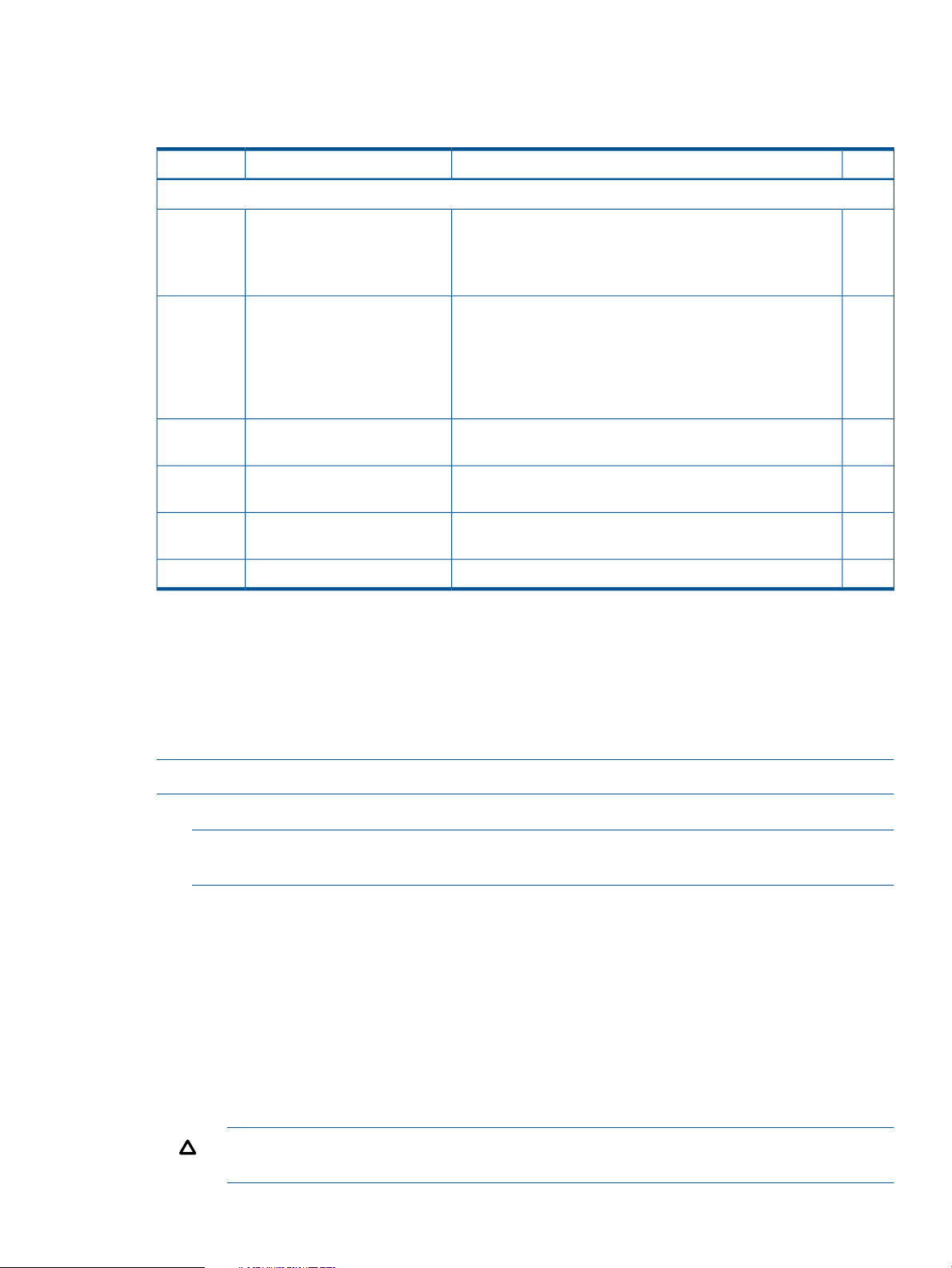

Table 8 Setup checklist

Standard setup

StatusProcedureActionStep

Preparation1 1. Determine an access method to select and connect the

cables.

2. Determine a LAN configuration method and assign an IP

address if necessary.

Configure the iLO 3 MP LAN2

Log on to the iLO 3 MP3

4

Change default user name and

password

Set up user accounts5

Select one of the three methods to configure the LAN for iLO

3 MP access:

• DHCP with DNS

• RS-232 serial port

• Static IP address

Log on to the iLO 3 MP from a supported web browser or

command line using the default user name and password.

Change the default user name and password on the

administrator account to your predefined selections.

Set up the user accounts if you are using the local accounts

feature.

Set up the security access settings.Set up security access6

Accessing UEFI or the OS from iLO MP

The Unified Extensible Firmware Interface is an architecture that provides an interface between the

server OS and the server firmware. UEFI provides a standard environment for booting an OS and

running preboot applications.

Use this procedure to access UEFI or the OS from the iLO MP. Your security parameters were set

regarding remote access.

NOTE: Commands are case-insensitive.

1. From the MP Main Menu, enter the commandco to access the Console.

NOTE: Terminal windows must be set to a window size of 80 columns x 25 rows for optimal

viewing of the console at UEFI.

2. After memory test and CPU late self test the following message appears:

Press Ctrl-C now to bypass loading option ROM UEFI drivers.

The prompt times out if Ctrl-C is not pressed within a few seconds. If Ctrl-C is pressed, you are

presented with two options:

• Bypass loading from I/O slots.

• Bypass loading from I/O slots and core I/O.

The Bypass loading from I/O slots and core I/O option may be useful if a bad core I/O

UEFI driver is preventing system boot. USB drives can still be used at the UEFI shell to

update core I/O drivers.

CAUTION: Pressing Ctrl-C before the prompt does not work and might disable this

feature. Therefore, be sure to wait for the prompt before pressing Ctrl-C.

HP Confidential Accessing UEFI or the OS from iLO MP 27

Page 28

After selecting an option, the boot proceeds.

NOTE: If no option is selected, the boot proceeds after a few seconds.

3. Depending on how the server was configured from the factory and if the OS is installed at

the time of purchase, you are taken to:

• UEFI shell prompt

• OS login prompt

If the server has a factory-installed OS, you can interrupt the boot process to configure your

specific UEFI parameters.

If you are at the UEFI shell prompt, go to “UEFI Front Page” (page 28).

If you are at the OS login prompt, go to “OS login prompt” (page 31).

UEFI Front Page

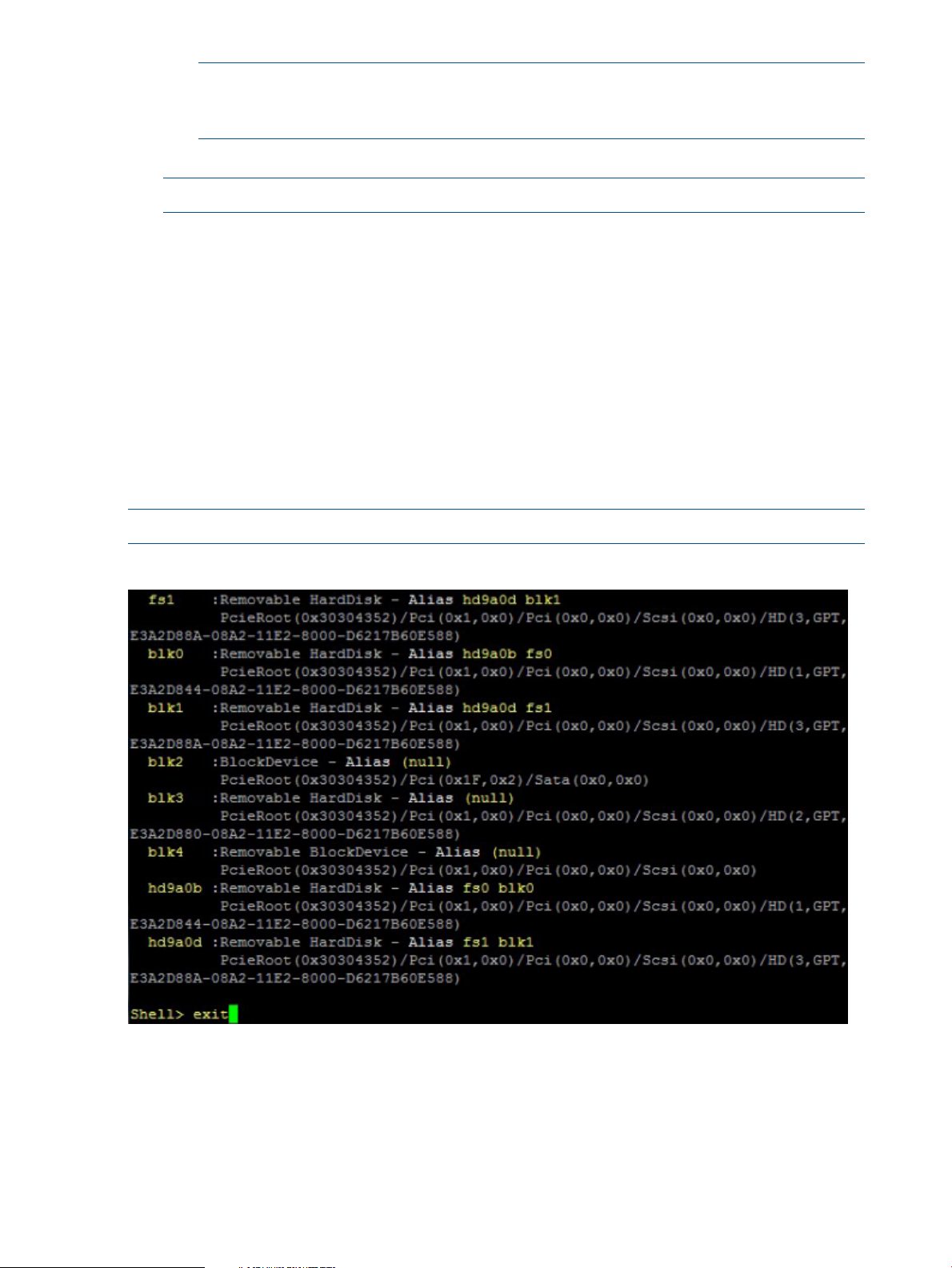

If you are at the UEFI shell prompt, enter the command exit to navigate to the UEFI Front Page.

NOTE: The (0x30304352) means this is in Bay 2.

NOTE: The prompt might take several minutes to appear, and the period that you can

press Ctrl-C is very short. For typical boots, HP recommends that you let the prompt time

out.

Figure 14 Shell map page

HP Confidential28 Installing the server

Page 29

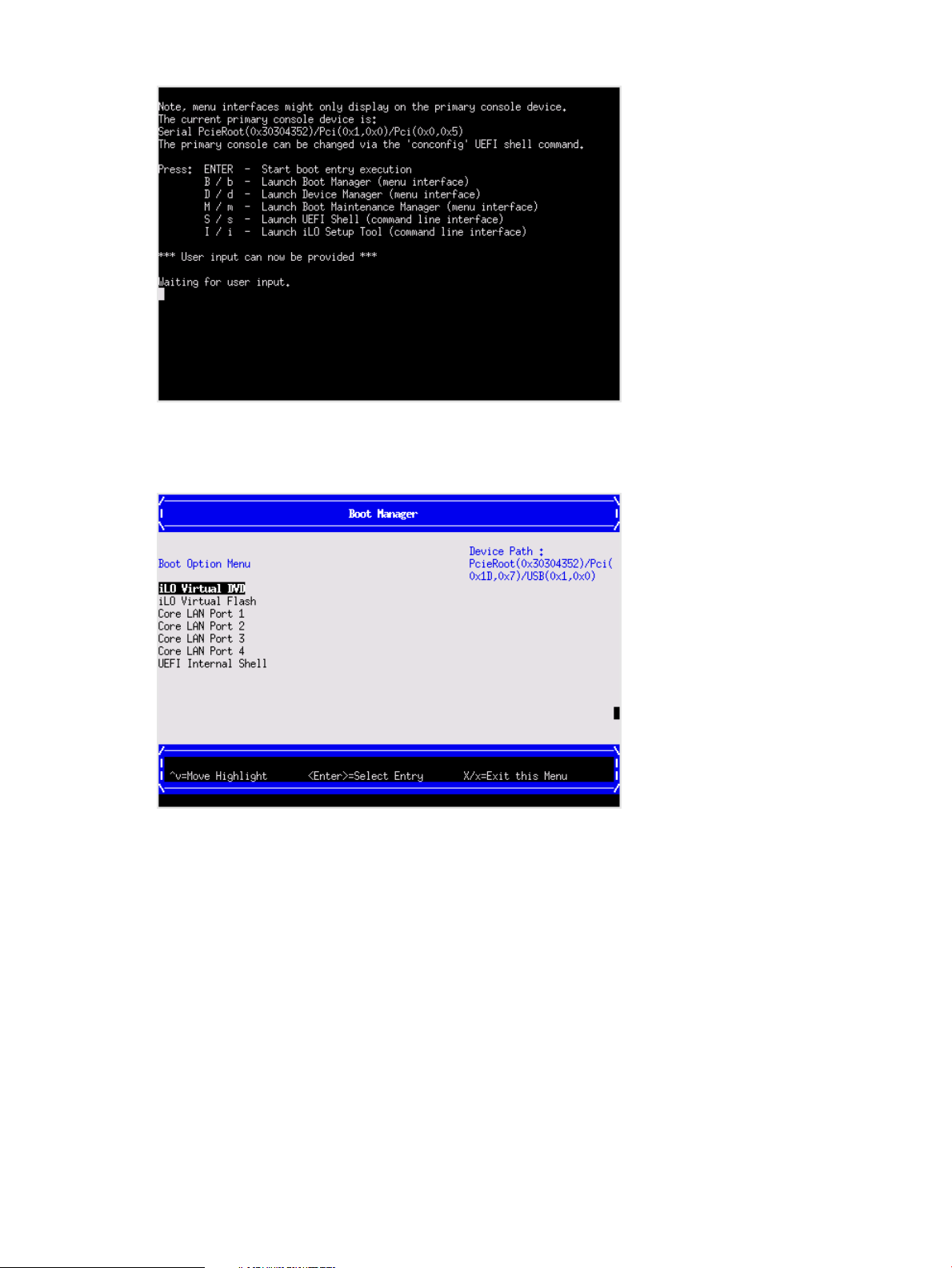

Figure 15 UEFI front page

To view boot options, or launch a specific boot option, press B to launch the Boot Manager.

Figure 16 Boot Manager screen

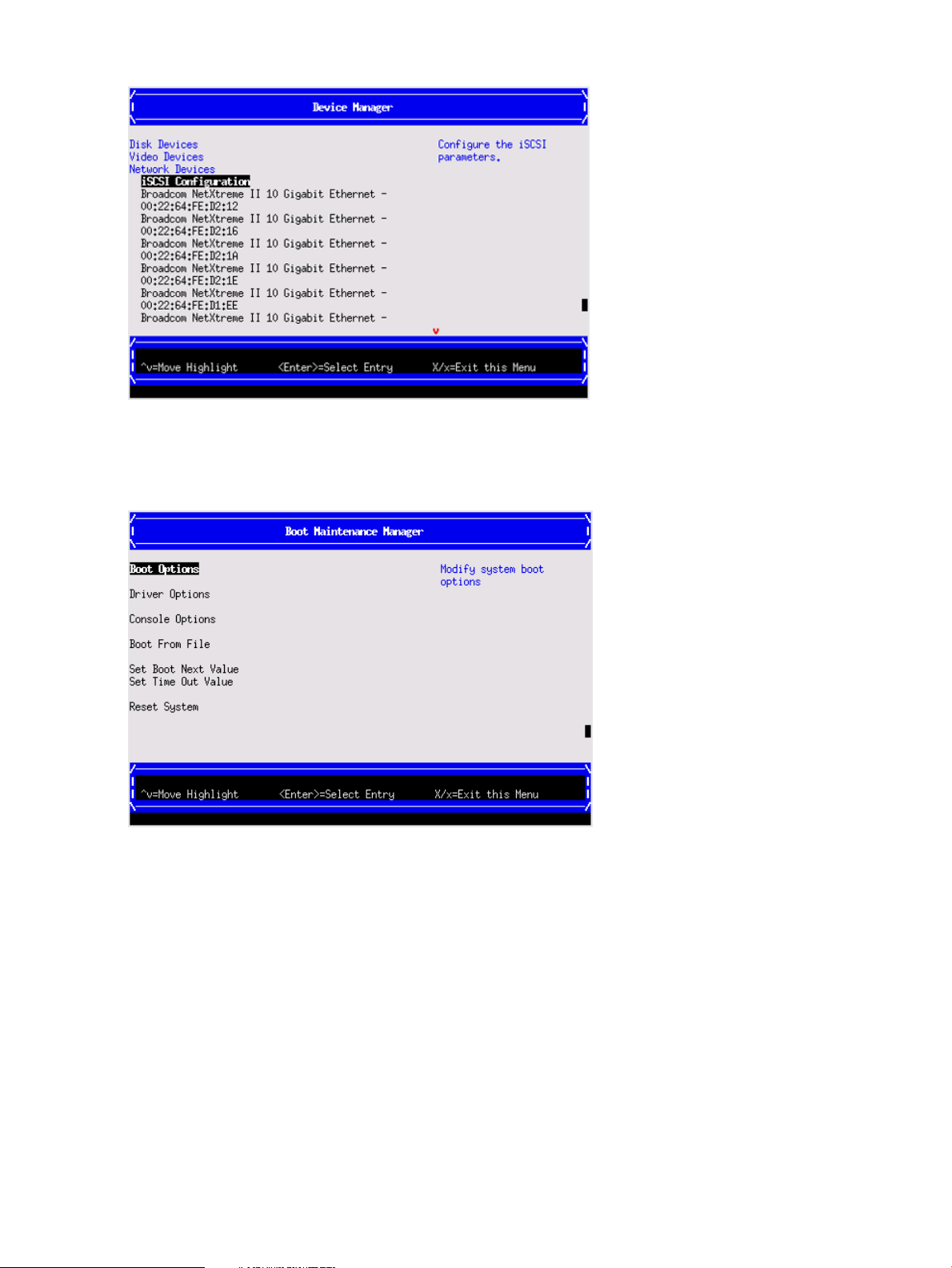

To configure specific devices, press D to launch the Device Manager. This is an advanced feature

and must only be performed when directed.

HP Confidential Accessing UEFI or the OS from iLO MP 29

Page 30

Figure 17 Device Manager screen

To perform maintenance on the system such as adding, deleting, or reordering boot options, press

M to launch the Boot Maintenance Manager.

Figure 18 Boot Maintenance Manager screen

To perform more advanced operations, press S to launch the UEFI Shell.

To view the iLO LAN configuration, press I to launch the iLO Setup Tool.

Saving UEFI configuration settings

You can configure other UEFI settings at this time. For more UEFI configuration options, see the HP

Integrity rx2800 i4 Server User Service Guide.

Booting and installing the operating system

From the UEFI Front Page prompt, you can boot and install in either of two manners:

• If your OS is loaded onto your server, see “Operating system is loaded onto the server”

(page 31).

• If the OS is not installed onto your server, see “Operating system is not loaded onto the server”

(page 31).

HP Confidential30 Installing the server

Page 31

Operating system is loaded onto the server

If the OS is loaded on your server, normally UEFI automatically boots to the OS. If the UEFI Front

Page is loaded, press ENTER to start auto boot, or B to select a specific boot option for your OS.

• Use your standard OS login procedures, or see your OS documentation to log in to your OS.

Operating system is not loaded onto the server

If the OS is not already on the server, the three options are: using Ignite-UX or vMedia, or loading

from a DVD. For details on all of these options, see the HP Integrity rx2800 i4 Server User Service

Guide.

OS login prompt

If your server is at the OS login prompt after you establish a connection to the server, use your

standard OS log in procedures, or see your OS documentation for the next steps.

Powering on and powering off the server

Power states

The server has the following power states:

• Standby power

• Full power

• Off

For details about server power states, see Table 7 (page 26).

NOTE: If the power restore feature is set to Always On through the iLO 3 MP PR command, the

server automatically powers on to the full power state when the power cord is plugged in to the

server.

Powering on the server

Power on the server to full power using the following methods if the server is in the standby power

state:

• iLO 3 MP PC command

• Power button

Powering on the server using the iLO 3 MP

NOTE: If the power restore feature is set to Always On through the iLO 3 MP PR command, the

server automatically powers on to the full power state when the power cord is plugged in to the

server.

1. Plug all power cables into the receptacles on the rear panel of the server.

2. Initiate a console session, and access the MP Main Menu.

3. Enter the commandCM to enable command mode.

4. Enter the commandPC to use the remote power control command. A command output similar

to the one shown below will appear:

NOTE: Your display may not match the display shown.

HP Confidential Powering on and powering off the server 31

Page 32

Figure 19 Power Control Menu screen

5. Enter the command ON to power on the server, and enter YES when prompted to confirm the

action.

6. Boot the operating system.

For more information, see the operating system documentation.

Powering on the server manually

NOTE: If the power restore feature is set to Always On through the iLO 3 MP PR command, the

server automatically powers on to the full power state when the power cord is plugged in to the

server.

1. Plug all power cables into the receptacles on the rear panel of the server.

2. Press the power button to start the server.

3. Start the operating system. For more information, see the operating system documentation.

Powering off the server

If the server is in the standby or full power state, power off the server by using either of the following

methods:

• iLO 3 MP PC command

• Power button

Powering off the server using the iLO 3 MP

1. Gracefully shut down the operating system. See the operating system documentation for more

information.

2. Initiate a console session, and access the MP Main Menu.

3. Enter CM to enable command mode.

4. Enter PC to use the remote power control command.

5. Enter OFF to power off the server, and enter YES when prompted to confirm the action.

CAUTION: The main DC voltage is now removed from the system However, AC voltage for

standby power is still present in the server.

6. Unplug all power cables from the receptacles on the rear panel of the server.

HP Confidential32 Installing the server

Page 33

Powering off the server manually

1. Gracefully shut down the operating system. For more information, see the operating system

documentation.

2. To power off the server, press the power button.

CAUTION: The main DC voltage is now removed from the system. However, AC voltage

for standby power is still present in the server.

3. Unplug all power cables from the receptacles on the rear panel of the server.

Installing the latest firmware using HP Smart Update Manager (HPSUM)

The HP Smart Update Manager utility enables you to deploy firmware components from either an

easy-to-use interface or a command line. It has an integrated hardware discovery engine that

discovers the installed hardware and the current versions of firmware in use on target servers. This

prevents extraneous network traffic by only sending the required components to the target. HPSUM

also has logic to install updates in the correct order and ensure all dependencies are met before

deployment of a firmware update. It also contains logic to prevent version-based dependencies

from preventing a successful installation and ensures updates are handled in a manner that reduces

any downtime required for the update process. HP Smart Update Manager does not require an

agent for remote installations. After the installation is complete, HP Smart Update Manager also

removes all remote files associated with the installation.

Key features of HP Smart Update Manager are:

• GUI and CLI

• Dependency checking, which ensures appropriate installation order and dependency checking

between components

• Intelligent deployment of only required updates

• Improved deployment performance

• Remote command-line deployment

At this time, firmware updates on Integrity systems through HPSUM are done remotely. For example,

HPSUM runs on an x86 Linux or Windows management system and updates targeted Integrity

systems through the network. HPSUM supports firmware updates on rx2800 i4 servers. Firmware

bundles for these servers are available and can be downloaded from the HP website at http://

www.hp.com.

For more information about HPSUM, see the HP Smart Update Manager User Guide (http://

www.hp.com/go/hpsum/documentation).

Troubleshooting installation issues

To troubleshoot issues that might occur during server installation, see the HP Integrity rx2800 i4

Server User Service Guide.

HP Confidential Installing the latest firmware using HP Smart Update Manager (HPSUM) 33

Page 34

4 Operating system procedures

Operating system supported on the server

• HP-UX 11i v3 HWE 1209 or later

NOTE: Wake-On-LAN (WOL) is supported with Integrity rx2800 i4 Servers running HP-UX 11i

v3.

Installing the operating system onto the server

The following procedures describe generalized operating system installation. For more details, see

the operating system documentation.

Installing the operating system from the DVD drive or tape drive

NOTE: Commands are not case-sensitive.

NOTE: Tapeboot requires an add-on AM311A Integrity Smart Array P411/256 HBA running

5.06 firmware or later.

1. Insert the OS Media into the DVD (internal to system) or tape drive (external to system).

2. Power on the server and boot to UEFI. If the server is already powered on, then using the

reset command at the UEFI prompt, reboot to UEFI.

3. From the UEFI Front Page, press S to launch the UEFI Shell.

NOTE: If the device is already selected or you already know the device name, skip the

following step.

If you are using a tape device: When the UEFI shell comes up you should see a message

similar to the following on the console:

HP Smart Array P411 Controller (version 5.06)

Tape Drive(s) Detected:

Port: 2E, box:0, bay: 5 (SAS)

If you do not see a line starting with Port and ending with (SAS), the tape is NOT connected

correctly, or it is not responding.

HP Confidential34 Operating system procedures

Page 35

4. Locate the device you want to boot from.

a. For DVD, locate the device:

fs2:\> map

Device mapping table

fs6: Removable CDRom - Alias cd66d0a blk6

PcieRoot(0x30304352)/Pci(0x1D,0x7)/USB(0x3,0x0)/CDROM(0x0)

i. To list all the device names from the UEFI Shell prompt, use the map command.

ii. From the list generated by the map command, locate the device name (in this example,

fs6).

NOTE: Your DVD drive might not be named fs6. Make sure you verify the ID

appropriate to your DVD device.

Tape will autoboot without the need to select a boot image.

iii. At the UEFI Shell prompt, specify the device name for the DVD-ROM.

iv. Enter the appropriate UEFI install command, as in the following example:

HP-UX

Shell> fs6:

fs6:\> install

b. For tape, locate the device:

• To boot from tape once you are at the UEFI shell:

Shell> tapeboot select

01

PcieRoot(0x30304352)/Pci(0x8,0x0)/Pci(0x0,0x0)/SAS(0x50060B00007F6FFC,0x0,0x1,NoTopology,0,0,0,0x0)

Select Desired Tape: 01 <<input 01

◦ If the correct media is installed, it will boot from tape when you enter the index

number.

◦ If there is no media in the SAS tape drive and you select 1, you will see the

following message:

tapeboot: Could not load tapeboot image