HP Integrity rx2800 i2, AH395-9013J User's & Service Manual

HPE Integrity rx2800 i2 Server User Service Guide

Abstract

This document contains specific information that is intended for users of this Hewlett Packard

Enterprise product.

Part Number: AH395-9013J

Published: September 2017

Edition: 13

Contents

Overview................................................................................................ 11

Site preparation.....................................................................................20

Server subsystems......................................................................................................................12

Internal components.........................................................................................................13

I/O subsystem.................................................................................................................. 15

RAID support....................................................................................................................15

Controls and ports.......................................................................................................................16

Front panel controls and ports......................................................................................... 17

Storage and media devices...................................................................................17

Rear panel controls and ports.......................................................................................... 18

Server dimensions and weight....................................................................................................20

Grounding................................................................................................................................... 20

Server electrical specifications....................................................................................................20

System power specifications............................................................................................20

Power consumption and cooling...................................................................................... 21

Server physical and environmental specifications...................................................................... 22

Unpacking and inspecting the server............................................................................... 23

Verifying site preparation.......................................................................................23

Inspecting the shipping containers for damage.....................................................23

Unpacking the server.............................................................................................23

Verifying the inventory...........................................................................................23

Returning damaged equipment............................................................................. 24

Unloading the server with a lifter........................................................................... 24

Installing the server.............................................................................. 25

Safety information....................................................................................................................... 25

Preventing electrostatic discharge.............................................................................................. 25

Installation sequence and checklist............................................................................................ 26

Installing the server into a rack or pedestal................................................................................ 26

Rack installation............................................................................................................... 26

Hewlett Packard Enterprise rack........................................................................... 26

Non-Hewlett Packard Enterprise rack................................................................... 26

Pedestal kit installation.....................................................................................................27

Remove the rails from the server.......................................................................... 27

Attaching the pedestal kit top and bottom............................................................. 27

Attaching the bezel cover...................................................................................... 30

Attaching the pedestal kit side pieces................................................................... 30

Attaching the pedestal feet....................................................................................32

Connecting server cables........................................................................................................... 33

AC input power.................................................................................................................33

Power states..........................................................................................................33

Applying standby power to the server................................................................... 34

Connecting to the LAN..................................................................................................... 34

Setting up the system................................................................................................................. 35

Setup checklist................................................................................................................. 35

Accessing UEFI or the OS from iLO MP.....................................................................................35

UEFI Front Page.............................................................................................................. 37

2 Contents

Saving UEFI configuration settings....................................................................... 39

Booting and installing the operating system.....................................................................39

Operating system is loaded onto the server.....................................................................39

Operating system is not loaded onto the server...............................................................39

OS login prompt............................................................................................................... 40

Powering on and powering off the server....................................................................................40

Power states.....................................................................................................................40

Powering on the server.................................................................................................... 40

Powering on the server using the iLO 3 MP..........................................................40

Powering on the server manually.......................................................................... 41

Powering off the server.................................................................................................... 41

Powering off the server using the iLO 3 MP..........................................................41

Powering off the server manually.......................................................................... 41

Installing the latest firmware using Smart Update Manager....................................................... 42

Troubleshooting installation issues............................................................................................. 42

Operating system procedures............................................................. 43

Operating systems supported on the server............................................................................... 43

Installing the operating system onto the server.......................................................................... 43

Installing the operating system from the DVD drive or tape drive.................................... 43

Installing the operating system using HP Ignite-UX......................................................... 45

Installing HPE OpenVMS with Infoserver Utility...............................................................45

Installing the operating system with Virtual Media........................................................... 45

Configuring system boot options.................................................................................................45

Booting and shutting down HP-UX............................................................................................. 46

Adding HP-UX to the boot options list..............................................................................46

HP-UX standard boot....................................................................................................... 47

Booting HP-UX from the UEFI Boot Manager....................................................... 48

Booting HP-UX from the UEFI Shell......................................................................48

Booting HP-UX in single-user mode................................................................................ 49

Booting HP-UX in LVM-maintenance mode..................................................................... 49

Shutting down HP-UX...................................................................................................... 49

Booting and shutting down OpenVMS........................................................................................ 49

Adding OpenVMS to the Boot Options list....................................................................... 50

Booting OpenVMS........................................................................................................... 51

Booting OpenVMS from the UEFI Boot Manager..................................................51

Booting OpenVMS from the UEFI Shell................................................................ 51

Shutting down OpenVMS.................................................................................................52

Booting and shutting down Microsoft Windows operating systems............................................ 52

Adding Microsoft Windows operating systems to the boot options list.............................53

Booting the Microsoft Windows operating system........................................................... 54

Shutting down Microsoft Windows................................................................................... 55

Shutting down Windows operating systems from the command line.................... 56

Optional components........................................................................... 57

Installing a hot-pluggable SAS hard drive...................................................................................57

Installing a hot-swappable power supply.................................................................................... 58

Removing the access panel........................................................................................................60

Removing the PCI riser cage...................................................................................................... 60

Removing expansion slot covers................................................................................................ 61

Installing expansion boards........................................................................................................ 62

Installing a half-length expansion board...........................................................................63

Installing a full-length expansion board............................................................................63

Installing DIMMs..........................................................................................................................64

Contents 3

Memory configurations.....................................................................................................64

Supported DIMM sizes.......................................................................................... 64

Memory expansion board locations and slot IDs...................................................65

Memory loading rules and guidelines....................................................................66

Installing DIMMs...............................................................................................................67

Installing a processor.................................................................................................................. 68

Processor load order........................................................................................................69

Installing a processor and heat sink module.................................................................... 69

HPE Trusted Platform Module (TPM)......................................................................................... 75

Installing a Trusted Platform Module (TPM) and TPM security rivet................................76

Verifying installed components in the server...............................................................................79

Completing installation................................................................................................................81

Troubleshooting.................................................................................... 82

How to contact Hewlett Packard Enterprise................................................................................82

Methodology............................................................................................................................... 82

General troubleshooting methodology............................................................................. 82

Recommended troubleshooting methodology .................................................................83

Basic and advanced troubleshooting tables.....................................................................84

Troubleshooting tools..................................................................................................................91

LEDs ................................................................................................................................91

Front panel LEDs...................................................................................................92

Rear panel LEDs................................................................................................. 100

Diagnostics.....................................................................................................................101

Online diagnostics and exercisers................................................................................. 102

Online support tool availability.............................................................................102

Online support tools list....................................................................................... 102

Offline support tools list..................................................................................................103

Fault management overview.......................................................................................... 104

HP-UX fault management.............................................................................................. 104

WBEM indication providers................................................................................. 105

OpenVMS fault management and monitoring................................................................ 105

Errors and reading error logs.................................................................................................... 105

Event log definitions....................................................................................................... 105

Using event logs.............................................................................................................106

iLO 3 MP event logs.......................................................................................................106

System event log review................................................................................................ 107

Supported configurations.......................................................................................................... 107

Server block diagram..................................................................................................... 108

System build-up troubleshooting procedure...................................................................108

Installation troubleshooting........................................................................................................110

Installation troubleshooting methodology....................................................................... 110

Installation troubleshooting using the server power button.............................................111

Server does not power on...............................................................................................111

UEFI menu is not available.............................................................................................112

Operating system does not boot.....................................................................................112

Operating system boots with issues...............................................................................112

Intermittent server issues............................................................................................... 112

SATA DVD+RW drive issues..........................................................................................113

SAS disk drive issues.....................................................................................................113

Console issues............................................................................................................... 113

Troubleshooting the processor and memory.............................................................................114

Troubleshooting the server processor............................................................................114

Processor load order........................................................................................... 114

Processor module behaviors............................................................................... 114

4 Contents

Customer messaging policy.................................................................................114

Troubleshooting the server memory...............................................................................117

Memory DIMM load order.................................................................................... 117

Memory subsystem behaviors............................................................................. 117

Customer messaging policy.................................................................................118

Troubleshooting the power subsystem......................................................................................118

Power subsystem behavior............................................................................................ 119

Power LED button.......................................................................................................... 119

Troubleshooting the cooling subsystem....................................................................................120

Cooling subsystem behavior.......................................................................................... 120

Troubleshooting the I/O.............................................................................................................121

I/O subsystem behaviors................................................................................................121

Customer messaging policy........................................................................................... 121

Troubleshooting the iLO 3 MP subsystem................................................................................ 123

iLO 3 MP LAN LED on the rear panel............................................................................ 123

Troubleshooting the I/O subsystem ......................................................................................... 124

Verifying SAS hard drive operation................................................................................ 124

System LAN LEDs..........................................................................................................124

Troubleshooting the boot process.............................................................................................125

Troubleshooting the firmware....................................................................................................126

Identifying and troubleshooting firmware issues............................................................ 126

Updating firmware.......................................................................................................... 127

Troubleshooting the system console.........................................................................................127

Troubleshooting the server environment ..................................................................................128

Removal and replacement procedures............................................. 129

Server components list............................................................................................................. 129

Required tools...........................................................................................................................132

Safety considerations................................................................................................................132

Server warnings and cautions........................................................................................132

Preparation procedures............................................................................................................ 133

Extending the server from the rack................................................................................ 134

Accessing internal components for a pedestal-mounted server.................................... 135

Powering off the server.................................................................................................. 138

Removing the server from the rack................................................................................ 139

Removing the server from the pedestal kit.....................................................................139

Required tools..................................................................................................... 139

Power off the server and remove cables.............................................................139

Removing the pedestal kit..............................................................................................139

Access the product rear panel....................................................................................... 143

Cable management arm with left-hand swing..................................................... 143

Cable management arm with right-hand swing................................................... 144

Removing and replacing a power supply blank........................................................................ 144

Removing and replacing a hot-plug SAS hard drive................................................................. 145

Removing and replacing a power supply blank........................................................................ 146

Removing and replacing a hot-swap power supply.................................................................. 146

Removing and replacing the access panel............................................................................... 148

Removing and replacing the optical drive filler......................................................................... 148

Removing and replacing the optical drive................................................................................. 148

Removing and replacing a hot-swap fan...................................................................................150

Removing and replacing the power supply backplane..............................................................151

Removing and replacing the hard drive backplane...................................................................152

Removing and replacing the PCI riser cage............................................................................. 153

Removing and replacing expansion slot covers........................................................................153

Removing and replacing expansion boards..............................................................................153

Contents 5

Removing and replacing a half-length expansion board................................................ 154

Removing and replacing a full-length expansion board................................................. 155

Removing and replacing the cache module..............................................................................156

Removing and replacing the super capacitor pack................................................................... 157

Removing and replacing the processor baffle...........................................................................159

Removing and replacing a processor and heat sink module.................................................... 160

Removing and replacing DIMMs...............................................................................................164

Removing and replacing the PDH battery (system battery)......................................................166

Removing and replacing the SID.............................................................................................. 167

Removing and replacing the intrusion switch cable.................................................................. 170

Removing and replacing the system board...............................................................................171

Support and other resources.............................................................177

Accessing Hewlett Packard Enterprise Support....................................................................... 177

Accessing updates....................................................................................................................177

Websites................................................................................................................................... 178

Customer self repair..................................................................................................................178

Documentation feedback.......................................................................................................... 178

Standard terms, abbreviations and acronyms................................. 179

Utilities................................................................................................. 181

SAS disk setup..........................................................................................................................181

Using the saupdate command .................................................................................... 181

Get mode.............................................................................................................181

Set mode............................................................................................................. 182

Updating the firmware using saupdate ....................................................................... 183

Determining the Driver ID and CTRL ID.........................................................................184

Using the ORCA menu-driven interface.........................................................................184

Creating a logical drive........................................................................................185

Deleting a logical drive........................................................................................ 185

Adding a RAID Advanced Pack license key........................................................185

Viewing RAID advanced pack license keys.........................................................187

UEFI..........................................................................................................................................187

UEFI shell and HPE POSSE commands....................................................................... 188

Drive paths in UEFI...................................................................................................................191

Using the boot maintenance manager...................................................................................... 192

Boot options................................................................................................................... 193

Add boot option................................................................................................... 194

Delete boot option............................................................................................... 195

Change boot order.............................................................................................. 196

Driver options................................................................................................................. 197

Add driver option................................................................................................. 198

Delete driver option............................................................................................. 199

Change driver order............................................................................................ 199

Console options............................................................................................................. 200

Boot from file.................................................................................................................. 200

Set boot next value........................................................................................................ 200

Set time out value.......................................................................................................... 201

Reset system..................................................................................................................201

iLO MP...................................................................................................................................... 202

6 Contents

Warranty and regulatory information................................................203

Warranty information.................................................................................................................203

Regulatory information..............................................................................................................203

Belarus Kazakhstan Russia marking............................................................................. 203

Turkey RoHS material content declaration.....................................................................204

Ukraine RoHS material content declaration................................................................... 204

Contents 7

Notices

The information contained herein is subject to change without notice. The only warranties for Hewlett

Packard Enterprise products and services are set forth in the express warranty statements accompanying

such products and services. Nothing herein should be construed as constituting an additional warranty.

Hewlett Packard Enterprise shall not be liable for technical or editorial errors or omissions contained

herein.

Confidential computer software. Valid license from Hewlett Packard Enterprise required for possession,

use, or copying. Consistent with FAR 12.211 and 12.212, Commercial Computer Software, Computer

Software Documentation, and Technical Data for Commercial Items are licensed to the U.S. Government

under vendor's standard commercial license.

Links to third-party websites take you outside the Hewlett Packard Enterprise website. Hewlett Packard

Enterprise has no control over and is not responsible for information outside the Hewlett Packard

Enterprise website.

Acknowledgments

Intel® and Itanium® are trademarks of Intel Corporation in the United States and other countries.

Microsoft®, Windows®, and Windows Server® are trademarks of the Microsoft group of companies.

Revision history

The publishing history table identifies the publication dates of this manual. Updates are made to this

publication on an unscheduled, as needed, basis. The updates will consist of a complete replacement

manual and pertinent online or CD documentation.

The document printing date and part number indicate the current edition. The printing date changes when

a new edition is printed. Minor changes might be made at reprint without changing the printing date. The

document part number changes when extensive changes are made. The latest version of this document

can be found online at:

http://www.hpe.com/info/Integrity Servers-docs

Document

manufacturing

Operating systems

supported

Supported product

versions

Edition number Publication date

part number

AH395-9004A

AH395-9013A

• HP-UX

• Microsoft

Windows

• HP-UX

®

®

rx2800 i2 First November 2010

rx2800 i2 Second February 2011

• OpenVMS

• Microsoft

Windows

Table Continued

Document

manufacturing

part number

Operating systems

supported

Supported product

versions

Edition number Publication date

AH395-9013A_

ed3

AH395-9013B

AH395-9013C

AH395-9013D

• HP-UX

• OpenVMS

• Microsoft

Windows

• HP-UX

• OpenVMS

• Microsoft

Windows

• HP-UX

• OpenVMS

• Microsoft

Windows

• HP-UX

rx2800 i2 Third March 2011

rx2800 i2 Fourth May 2011

rx2800 i2 Fifth August 2011

rx2800 i2 Sixth November 2011

AH395-9013E

AH395-9013F

• OpenVMS

• Microsoft

Windows

• HP-UX

• OpenVMS

• Microsoft

Windows

• HP-UX

• OpenVMS

• Microsoft

Windows

rx2800 i2 Seventh February 2012

rx2800 i2 Eighth August 2012

Table Continued

Document

manufacturing

part number

Operating systems

supported

Supported product

versions

Edition number Publication date

AH395-9013G

AH395-9013J

• HP-UX

• OpenVMS

• Microsoft

Windows

• HP-UX

• OpenVMS

• Microsoft

Windows

rx2800 i2 Ninth February 2013

rx2800 i2 Tenth September 2017

Overview

Table 1: Hardware specifications for the server

Component Server

Processors One or two Itanium dual-core or quad-core processors:

Memory Supports up to twenty-four Double Data Rate 3 (DDR3) DIMMs mounted on

• 1.6-GHz Dual-core Processor 10-MB cache

• 1.46-GHz Quad-core Processor 16-MB cache

• 1.73-GHz Quad-core Processor 20-MB cache

expansion boards that attach to the system board.

Supported DIMM sizes are as follows:

• 2 GB

• 4 GB

• 8 GB

• 16 GB

Minimum memory configuration is 4 GB (2 x 2-GB DIMMs).

Maximum memory configuration is 384 GB (24 x 16 GB DIMMs).

NOTE:

For additional restrictions on memory configuration, see Installing DIMMS

Installing DIMMs on page 67.

Disk drives One to eight hot-plug SAS hard drives

PCI slots I/O riser options:

• One full height full length PCIe x8 and two low profile PCIe x4 slots

• One full height full length PCIe x8 and one low profile PCIe x8 slots

SAS controller Eight port SAS controller or eight port SAS controller with internal RAID

LAN ports Four GigE LAN ports

Table Continued

Overview 11

Component Server

Management ports One serial port, four USB 2.0 ports, one 1G/100/10 LAN port, and two VGA ports

NOTE:

The serial port is intended primarily for use as a serial console port. It can be

configured through iLO 3 for use with other serial devices (subject to OS and

device limitations and dependencies). The serial port reverts to console

mode settings if the server is disconnected from AC power or if the iLO is

reset by the iLO Physical Presence button.

Optical drive

Power supply One (AH395A) or two power supplies (AH396A) are standard. Supplies are dual

One SATA DVD+RW drive

range input: 100-120VAC & 200-240VAC capable. 1+1 redundancy is possible with

the second supply.

Server subsystems

IMPORTANT:

100-120 VAC input limits configuration and redundancy options. For details,

see Removing and replacing a hot-swap power supply on page 146.

12 Server subsystems

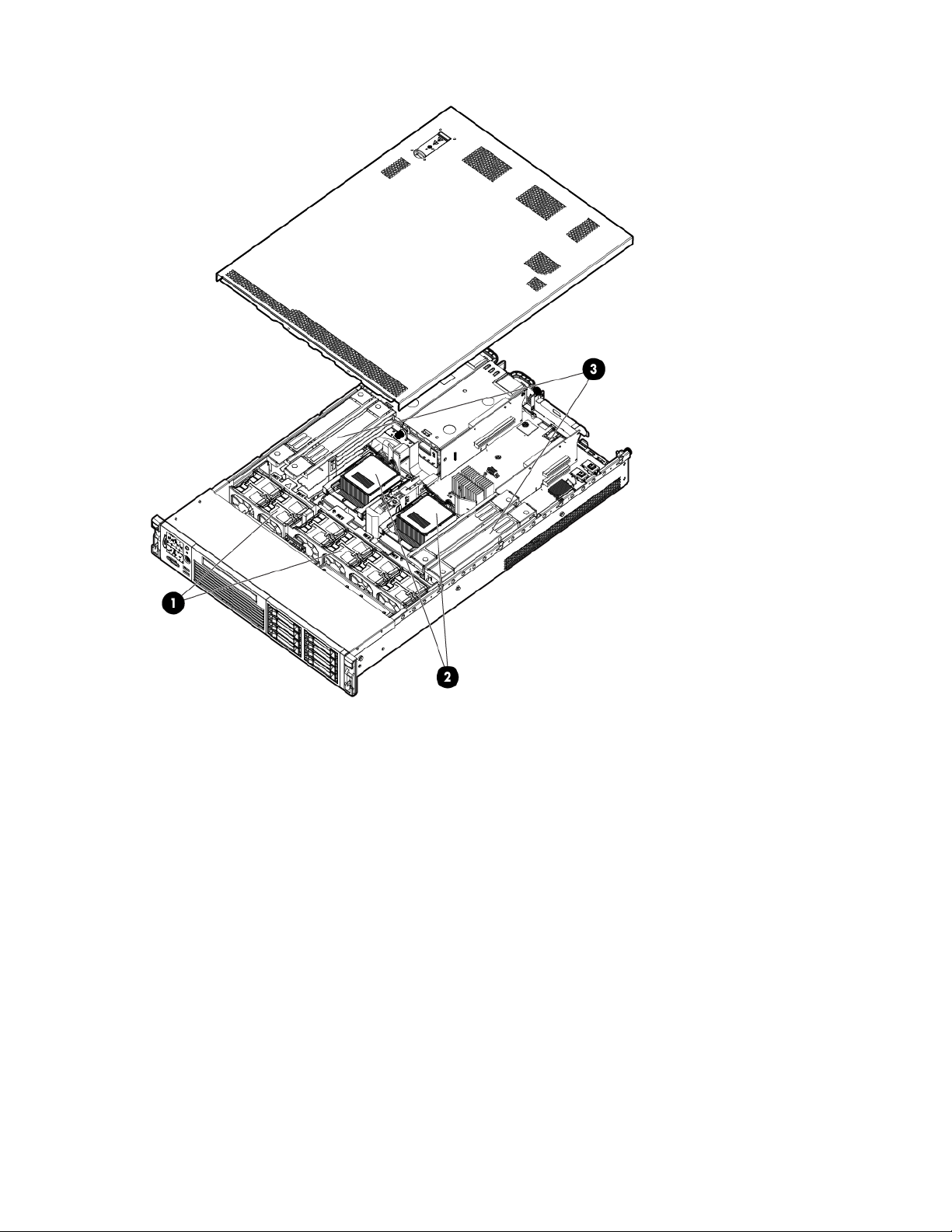

Internal components

Figure 1: Internal components

• Fans

• Processors

• DIMM expansion boards

Internal components 13

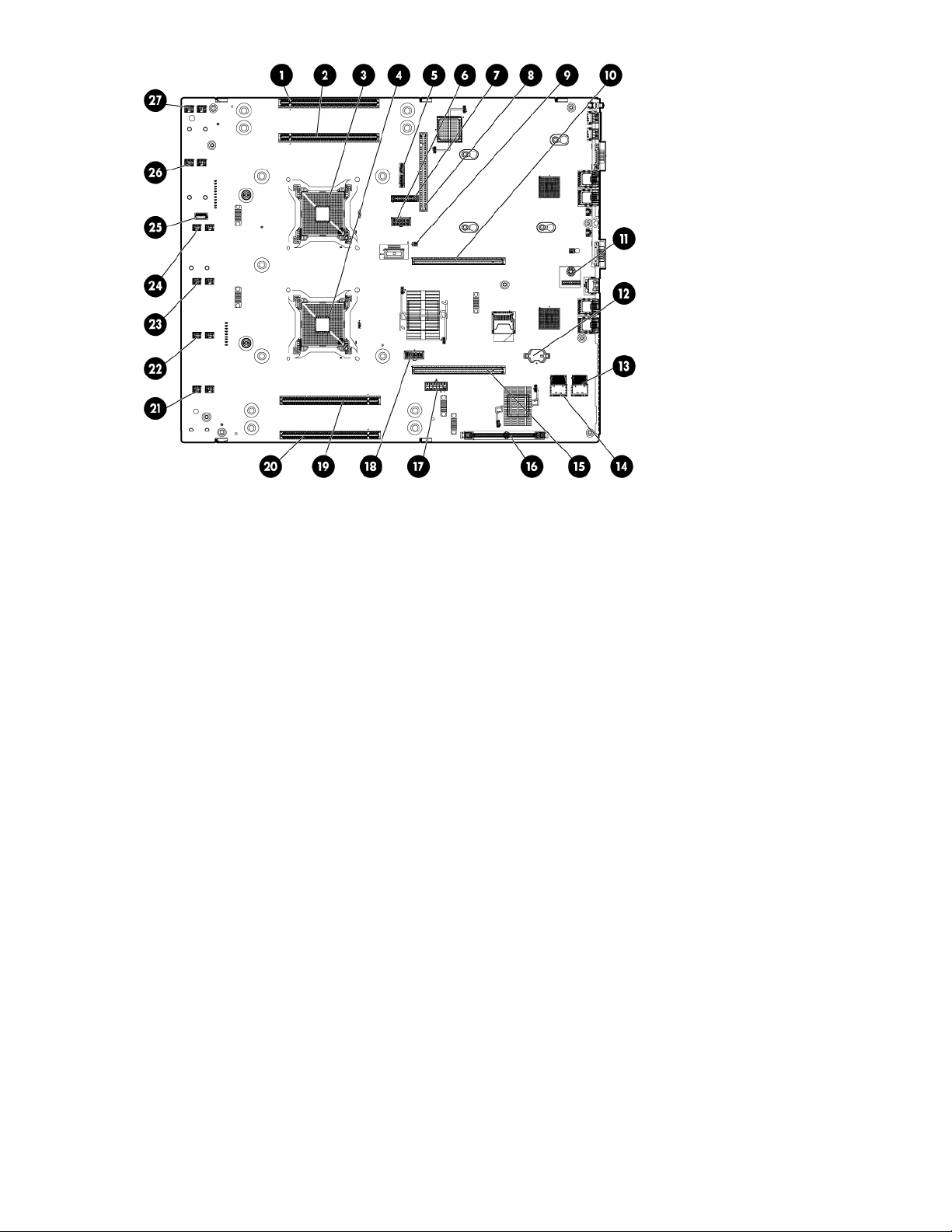

Figure 2: System board components

• Memory expansion board connector 1

• Memory expansion board connector 2

• Processor socket 0

• Processor socket 1

• SATA optical drive connector

• CPU 0 power connector

• Front I/O connector

• Power supply backplane connector

• Intrusion switch connector

• Primary riser connector

• TPM connector

• System battery

• SAS B connector

• SAS A connector

• Secondary riser connector

• SAS cache module connector

• SAS power connector

• CPU 1 power connector

• Memory expansion board connector 3

14 Overview

• Memory expansion board connector 4

• Fan 6 connector

• Fan 5 connector

• Fan 4 connector

• Fan 3 connector

• Internal USB connector

• Fan 2 connector

• Fan 1 connector

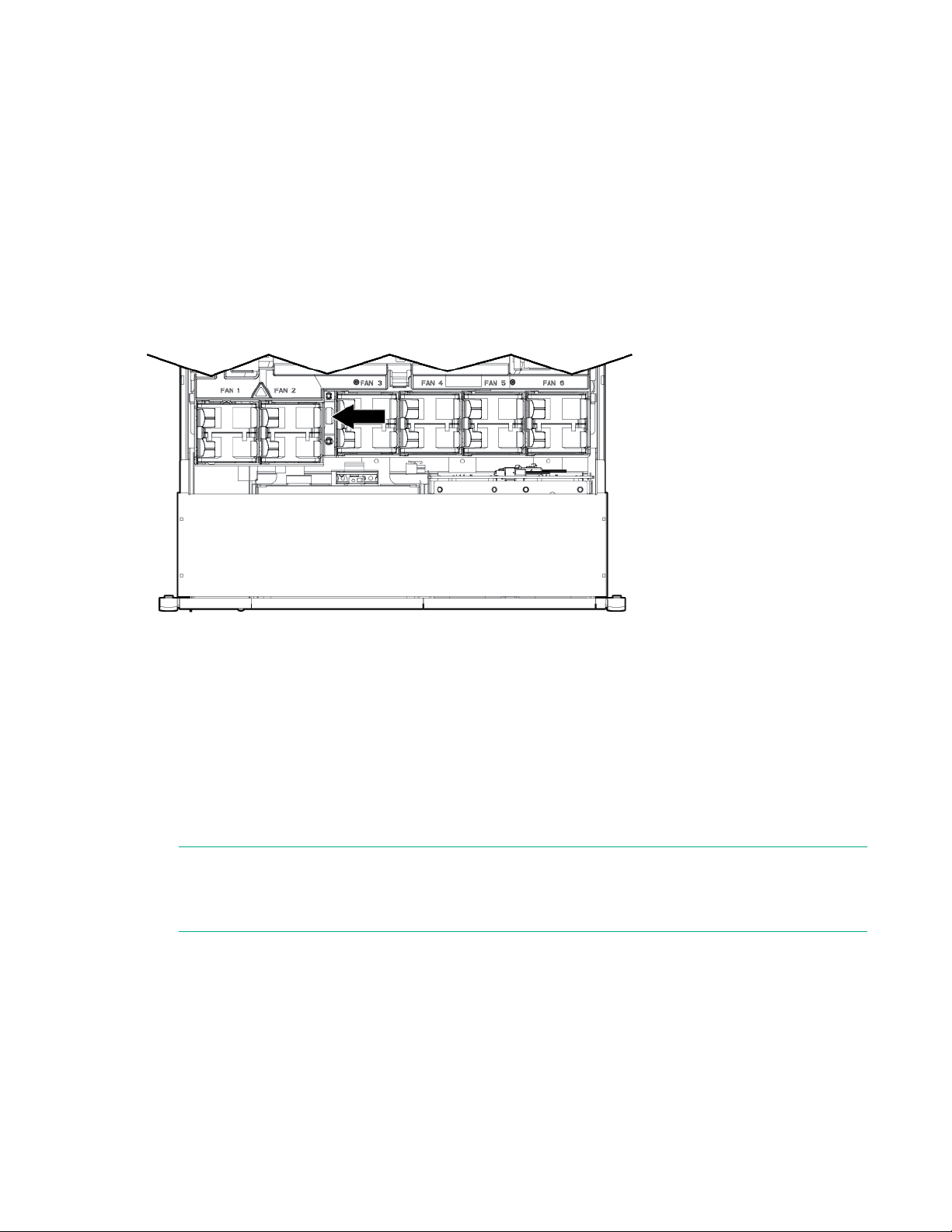

Figure 3: Internal USB location

I/O subsystem

The I/O subsystem consists of the core I/O and two optional I/O riser boards. Wake-on-LAN is not

enabled on any PCIe Public slots. The server does not support PCI Hot Plug (PHP).

The standard I/O Riser supports one full-height, full-length PCIe x8 and two full-height, half-length PCIe

x4 add-in cards. The second riser option supports one full-height, full-length PCIe x8, and one full-height,

half-length PCIe x8 add-in cards.

NOTE:

All PCIe x8 slots are electrically connected as x8 slots but are physically loaded with x16

connectors.

The secondary I/O riser position can either be a riser that supports one full-height, full-length PCIe x8 and

two low-profile PCIe x4 add-in cards or a riser that supports one full-height, full-length PCIe x8 and one

low profile PCIe x8.

RAID support

The following levels of RAID support are offered:

• Zero memory

I/O subsystem 15

◦ RAID 0, 1, 10

◦ Maximum 8 drives, 2 logical volumes

◦ No cache or super capacitor needed. Performance improved with cache.

NOTE:

To use all 8 disks with the zero memory option, the following RAID configurations are

supported:

– RAID 0: 1 or 2 LUNs striped with up to 8 disks

– RAID 10: 1 or 2 LUNs striped and mirrored with even number of up to 8 disks

– RAID 1: 1 LUN using 2 mirrored disks, and one additional LUN in RAID 0 or 10

Example configurations of eight disks with zero memory

– LUN 1: RAID 1 bays 1 and 2

– LUN 2: RAID 0 bays 3, 4, 5, 6, and 7

– Hot Spare: bay 8

– LUN 1: RAID 10 bays 1, 2, 3, and 4

– LUN 2: RAID 10 bays 5, 6, 7, and 8

– LUN 1: RAID 0 bays 1, 2, and 3

– LUN 2: RAID 10 bays 5, 6, 7, and 8

– Hot Spare: bay 4

• Full feature

◦ RAID 0, 10, 5

◦ Cache needed and installing it automatically enables the full feature firmware stack. Super

capacitor is optional.

• Advanced pack

◦ RAID 6, 50, 60

◦ Cache needed. Advanced Pack license must be entered to enable. Super capacitor is required.

To enable Advanced Pack licensing, see Adding a RAID Advanced Pack license key on page 185.

Controls and ports

16 Controls and ports

Front panel controls and ports

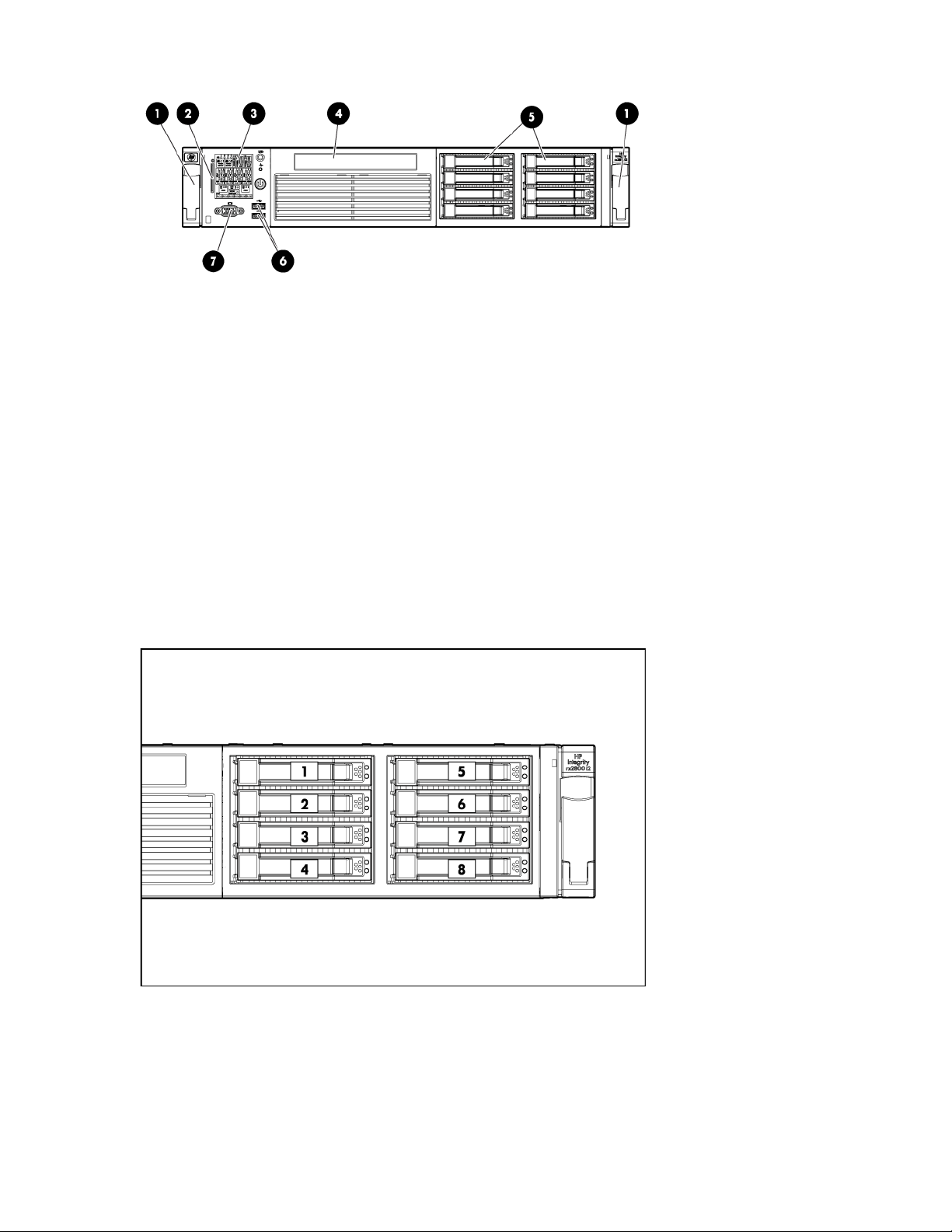

Figure 4: Front panel components

1. Quick release levers

2. iLO 3 information pull tab

3. SID

4. Optical drive bay

5. Hard drive bays

6. USB connectors

7. Video connector

Storage and media devices

The server supports up to eight hot-plug SAS HDDs, and one optical (SATA DVD+RW) drive, with LEDs

that indicate activity and device statuses.

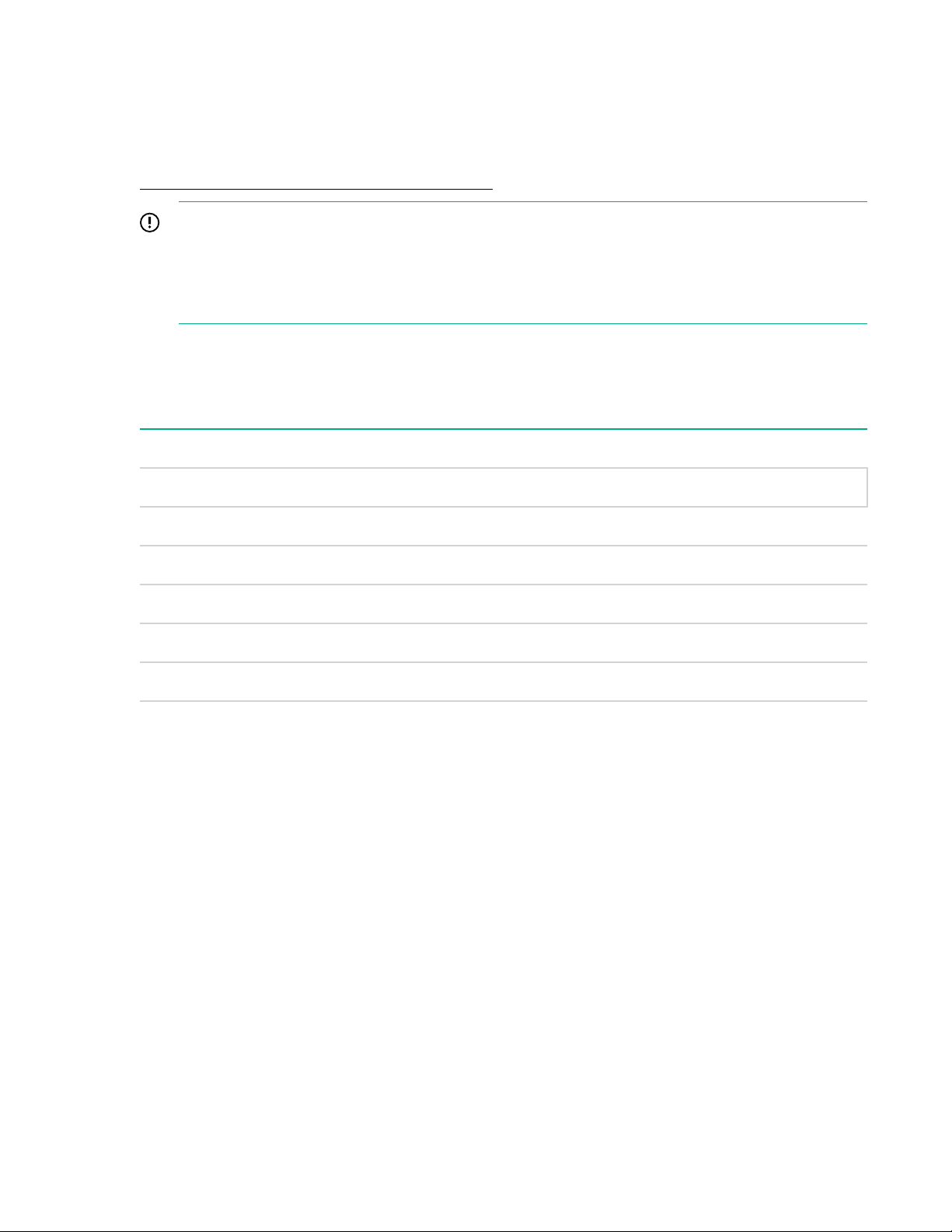

Figure 5: SAS device numbers

Front panel controls and ports 17

Rear panel controls and ports

The server rear panel includes communication ports, I/O ports, USB ports, AC power connectors, and the

locator LED and button. LEDs located on the rear panel of the server signal the operational status of the

rear panel components.

Figure 6: Rear panel components

1. PCI 5

2. PCI 6

3. PCI 4

4. PCI 2

5. PCI 3

6. PCI 1

7. Power supply 2

8. Power supply 2 LED

9. Power supply 2 power connector

10. Power supply 1

11. Power supply 1 LED

12. Power supply 1 power connector

13. UID LED button

14. USB connectors (2)

15. Video connector

16. NIC 1 connector

17. NIC 2 connector

18. iLO 3 physical presence pinhole button

19. Serial connector

20. iLO 3 connector

18 Rear panel controls and ports

21. NIC 3 connector

22. NIC 4 connector

23. NIC link LED

24. NIC activity LED

Overview 19

Site preparation

For information on general computer room site preparation, see the HPE Generalized Site Preparation

Guide on the Hewlett Packard Enterprise website:

http://www.hpe.com/info/Integrity_Servers-docs

IMPORTANT:

To avoid hardware damage, allow the thermal mass of the product to equalize to the temperature

and humidity of the installation facility after removing the shipping materials. A minimum of one hour

per 10° C (50° F) of temperature difference between the shipping facility and installation facility is

required.

Server dimensions and weight

Table 2: Rack or pedestal-mounted server dimensions

Dimensions and weight Value

Data center server dimensions

Depth 69.2 cm (27.25 in)

Width 48.3 cm (19 in)

Height 8.9 cm (3.5 in)

Weight Maximum configuration – 30 kg (66 lb)

Rack unit 2U

Grounding

The site building must provide a safety ground/protective earth for each AC service entrance to all

cabinets.

Install a PE conductor that is identical in size, insulation material, and thickness to the branch-circuit

supply conductors. The PE conductor must be green with yellow stripes. The earthing conductor is to be

connected from the unit to the building installation earth or, if supplied by a separately derived system, at

the supply transformer or motor-generator set grounding point.

Server electrical specifications

System power specifications

Available power (output) is the maximum DC power that the power supply can supply to the system.

Maximum input power is what the power supply requires from the AC line to deliver that maximum DC

output (given worst case efficiency and maximum loading).

Maximum input current is the worst case/highest current given the lowest input voltage and the maximum

input power.

20 Site preparation

Table 3: System power specifications

Parameter

Input voltage 100 V AC 110 - 120 V AC 200 - 240 V AC

Input current (maximum) 9.3 A 9.5 A 6.6 A

Input frequency 47 to 63 Hz 47 to 53 Hz 57 to 63 Hz

Power supply maximum output power 800 W (MAX)

If an overload triggers the power supply overload protection, the system is immediately powered off. To

reset the power supply unit:

Procedure

1. Disconnect the power cord.

2. Determine what caused the overload by contacting a Hewlett Packard Enterprise support

3. Reconnect the power cord.

4. Reboot the system.

When you use the front panel power button to turn off the server, power consumption falls below the low

power consumption, but does not reach zero. To reach zero power consumption in "off" mode, either

unplug the server or use a power block with a switch.

+12V /66.7A MAX

+12VSB /2.5A

MAX

representative.

NOTE:

If an overload occurs twice, an undetected short circuit exists.

900 W (MAX)

+12V /75A MAX

+12VSB /2.5A

MAX

1200 W (MAX)

+12V /100A MAX

+12VSB /2.5A

MAX

Power consumption and cooling

The power consumptions listed in Standard configuration power consumption are valid for a standard

configuration as shipped.

All information in this section is based on primary power consumptions with one power supply installed.

Table 4: Standard configuration power consumption

Standard configuration Power consumption

One 1.46 GHz quad-core processor, 4 GB

memory, one 1200 W power supply, and one SAS

disk drive

360 W (maximum) 1228 Btu/h (maximum)

Power consumption and cooling 21

Table 5: Additional component power consumption

Additional component Power consumption

Processor 130 W 443.6 Btu/h

SAS disk drive (with I/O access) 23 W 78.4 Btu/h

SAS disk (idle) 16 W 54.5 Btu/h

PCIe card 10 to 25 W 34.12 Btu/h to 85.30 Btu/h

Server physical and environmental specifications

Operating temperature and humidity ranges might vary, depending on the installed mass storage devices.

High humidity levels can cause improper disk operation. Low humidity levels can aggravate static

electricity issues and cause excessive wear of the disk surface.

NOTE:

De-rate maximum dry bulb temperature 1°/300 m (1000 ft) above 900 m (3000 ft).

Table 6: Environmental specifications (system processing unit with hard disk)

Parameter Value

Data Center Server Office Friendly Server

Operating temperature (up to 1524 m/5000 ft) +5° C to +35° C (+41° F to +95° F)

Non-operating temperature - 40° C to +70° C (40° F to 158° F)

Over-temperature shutdown +38° C (+100° F)

Operating humidity 15% to 80% RH noncondensing

Non-operating humidity 8% to 90% RH at 65° C noncondensing

Acoustic Noise Emission (ISO 9296)

Sound Power

Level

Sound Pressure Level LpAm = 52.7 dB LpAm = 42.4 dB

Altitude

Operating altitude 0 to 3000 m (10,000 ft) maximum

Maximum configuration (disk

active)

LwAd = 7.0 B LwAd = 6.0 B

Non-operating altitude 0 to 4,600 m (15,000 ft) maximum

22 Server physical and environmental specifications

Unpacking and inspecting the server

This section describes pre installation procedures. Ensure that you have adequately prepared your

environment for installing the new server, received the components that you ordered, and verified that the

server and the containers are in good condition after shipment.

Verifying site preparation

• Gather LAN information. The MAC addresses for the iLO 3 MP LAN and the system LAN are located

on the iLO Network Information Tag.

• Establish a method to connect to the server console.

• Verify electrical requirements. Ensure that grounding specifications and power requirements are met.

• Validate server physical space requirements.

• Confirm environmental requirements.

For server-specific information on electrical, physical space, and environmental requirements, see the site

prep guide. For general site preparation information, see the HPE Generalized Site Preparation Guide

on the Hewlett Packard Enterprise website.

Inspecting the shipping containers for damage

Under normal shipping conditions, Hewlett Packard Enterprise shipping containers protect the contents.

After the equipment arrives, carefully inspect each carton for signs of shipping damage. Shipping damage

constitutes moderate to severe damage, such as punctures in the corrugated carton, crushed boxes, or

large dents. Normal wear or slight damage to the carton is not considered shipping damage. If you find

shipping damage to the carton, immediately contact your Hewlett Packard Enterprise customer service

representative.

Unpacking the server

Procedure

1. Follow the instructions printed on the outside top flap of the carton to remove the banding and the

outer carton from the server pallet.

2. Remove all inner accessory cartons and the top foam cushions, leaving only the server.

IMPORTANT:

Inspect each carton for shipping damage as you unpack the server.

Verifying the inventory

The sales order packing slip lists all the equipment shipped from Hewlett Packard Enterprise. Use this

packing slip to verify that all equipment has arrived.

NOTE:

To identify each item by part number, see the sales order packing slip.

Unpacking and inspecting the server 23

Returning damaged equipment

If the equipment is damaged, immediately contact your Hewlett Packard Enterprise customer service

representative. The service representative initiates appropriate action through the transport carrier or the

factory and assists you in returning the equipment.

Unloading the server with a lifter

WARNING:

Use caution when using a lifter. Because of the weight of the server, to avoid injury, you must center

the server on the lifter forks before lifting it off the pallet.

NOTE:

Hewlett Packard Enterprise recommends that you follow your local guidelines when lifting

equipment.

Procedure

1. Unpack the server.

2. Unroll the bottom corrugated tray corresponding to the side on which the lifter is to be placed, and then

slide the server as close to that edge of the pallet as possible.

3. Break off any foam packaging that can prevent the lifter from being fully inserted under the server. Do

not remove the foam packaging from the corners of the server. This foam is required to elevate the

server and to enable the forks of the lifter to be placed under the server.

4. Insert the lifter forks under the server.

5. Carefully roll the lifter forward until it is fully positioned against the side of the server.

6. Slowly raise the server off the pallet until it clears the pallet cushions.

7. Carefully roll the lifter and server away from the pallet. Do not raise the server any higher than

necessary when moving it over to the rack.

24 Returning damaged equipment

Installing the server

Safety information

Follow the instructions carefully to prevent injury and equipment damage when performing removal and

replacement procedures. Voltage might be present within the server. Many assemblies are sensitive to

damage by ESD.

Follow the safety considerations listed to ensure safe handling of components, to prevent injury, and to

prevent damage to the server:

• If installing a hot-swappable or hot-pluggable component when power is applied (fans are running),

reinstall the server cover immediately to prevent overheating.

If installing a hot-pluggable component, complete the required software intervention prior to removing

the component.

• If installing an assembly that is neither hot-swappable nor hot-pluggable, disconnect the power cable

from the external server power receptacle before starting the installation.

WARNING:

Ensure that the system is powered off and all power sources are disconnected from the server

before removing or installing server hardware (unless you are removing or installing a hotswappable or hot-pluggable component). Voltage is present at various locations within the server

whenever an AC power source is connected. This voltage is present even when the main power

switch is off. Failure to observe this warning might result in personal injury or equipment

damage.

• Do not wear loose clothing that might snag or catch on the server or on other components.

• Do not wear clothing subject to static charge buildup, such as wool or synthetic materials

• If installing an internal assembly, wear an antistatic wrist strap and use a grounding mat, such as those

included in the Electrically Conductive Field Service Grounding Kit.

• Handle accessory boards and components by the edges only. Do not touch any metal edge

connectors or any electrical components on accessory boards.

Preventing electrostatic discharge

To prevent damaging the system, be aware of the precautions you need to follow when setting up the

system or handling parts. A discharge of static electricity from a finger or other conductor might damage

system boards or other static-sensitive devices. This type of damage might reduce the life expectancy of

the device.

To prevent electrostatic damage:

• Avoid hand contact by transporting and storing products in static-safe containers.

• Keep electrostatic-sensitive parts in their containers until they arrive at static-free workstations.

• Place parts on a grounded surface before removing them from their containers.

Installing the server 25

• Avoid touching pins, leads, or circuitry.

• Always be properly grounded when touching a static-sensitive component or assembly.

Installation sequence and checklist

Step Description Completed

1 Perform site preparation (see Site preparation on page 20).

2 Install the server into a rack or pedestal.

3 Connect cables to the server.

a. Connect the AC input power cable.

b. Connect LAN core I/O cable.

c. Connect the iLO 3 MP LAN cable.

4 Connect and set up the console for access.

5 Power on the server.

6 From iLO MP, access UEFI.

7 Boot the operating system.

8 Using Smart Update Manager, download the latest firmware.

Installing the server into a rack or pedestal

Rack installation

Hewlett Packard Enterprise rack

Hewlett Packard Enterprise servers that are installed into racks are shipped with equipment-mounting

slides. The HPE 2U Quick Deploy Rail System Installation Instructions for HPE Products ships with each

set of slides. Follow the steps in this installation guide to determine where and how to install the server

into the rack.

For more information on rack deployment, stabilization and transportation, see the 10000 Series G2 Rack

Best Practices Guide.

http://www.hpe.com/info/rackandpower

Non-Hewlett Packard Enterprise rack

For information on installing a HPE Integrity rx2800 i2 server in a third party rack, see the QuickSpecs

located on the rx2800 i2 server product page.

http://www.hpe.com

26 Installation sequence and checklist

Search for "Integrity rx2800 i2 server" and click the product link for more information and

QuickSpecs.

Pedestal kit installation

If you order the rackless configuration option, the server ships with a pedestal mount. The pedestal mount

is packaged in a separate carton that is attached to the server carton.

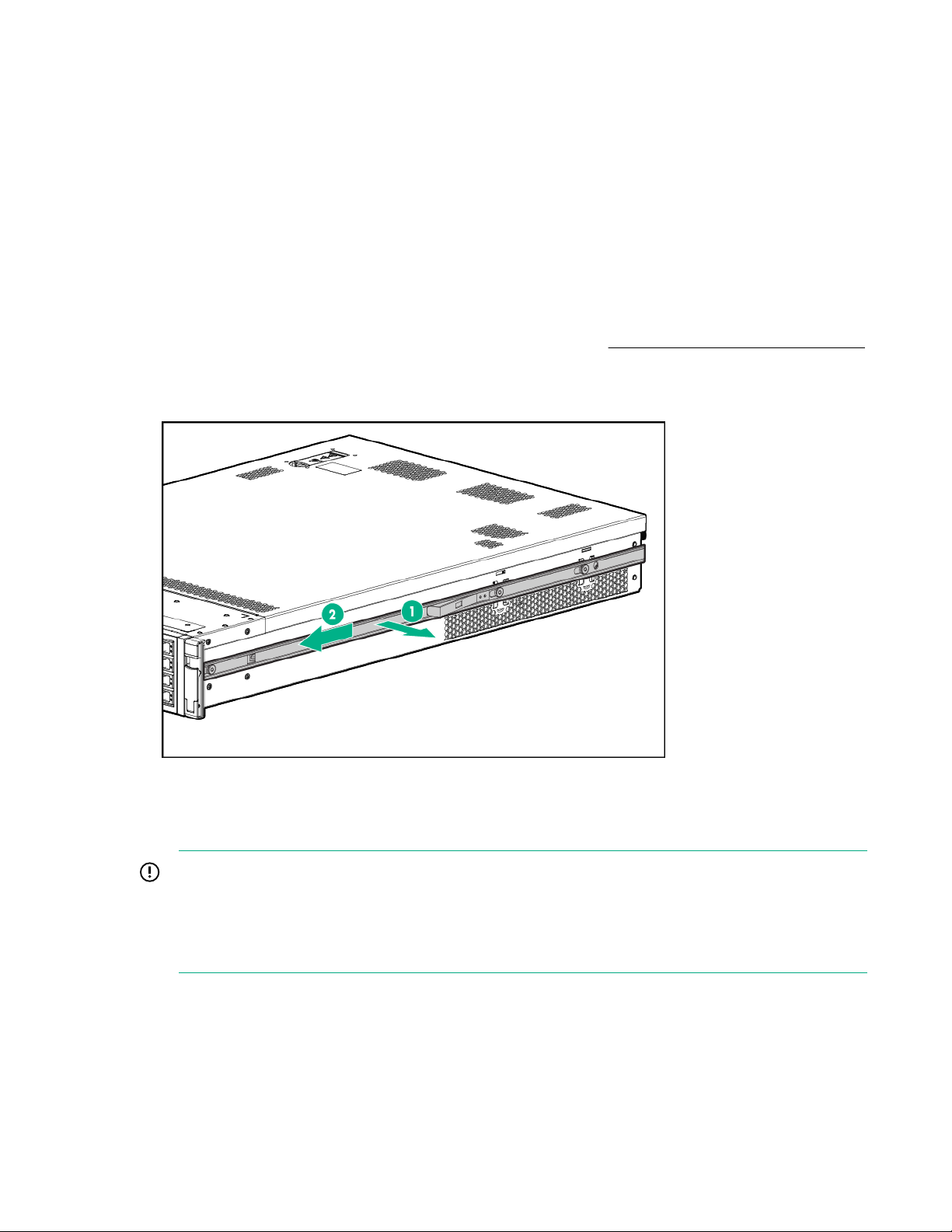

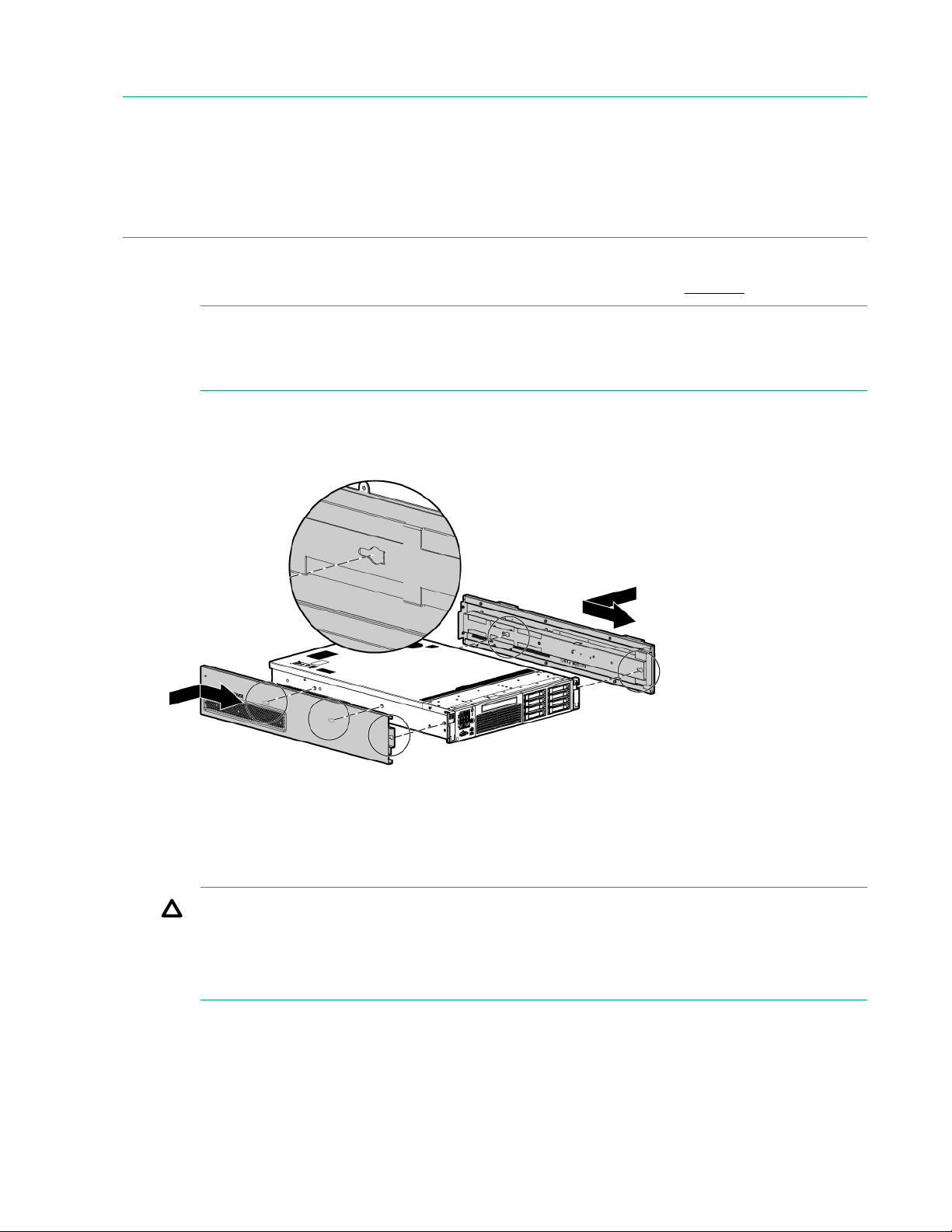

Remove the rails from the server

I If your server has rails when you receive it, you need to remove the rails before mounting it in the

pedestal kit. To remove the component:

Procedure

1. Slightly pull the rail lock away from the rail to unlock the rail. See Removing the rails from the server

2. Slide the rail toward the front of the server to disengage the rail from the posts on the server.

3. Repeat these steps for the rail on the other side of the server.

Figure 7: Removing the rails from the server

Attaching the pedestal kit top and bottom

IMPORTANT:

In this document the server top, bottom, right and left refer to the server as faced from the front with

the server in a horizontal orientation. The pedestal kit components are referred to by the final

position with the server in a vertical orientation. For example, the pedestal kit bottom attaches to the

server right side

Pedestal kit installation 27

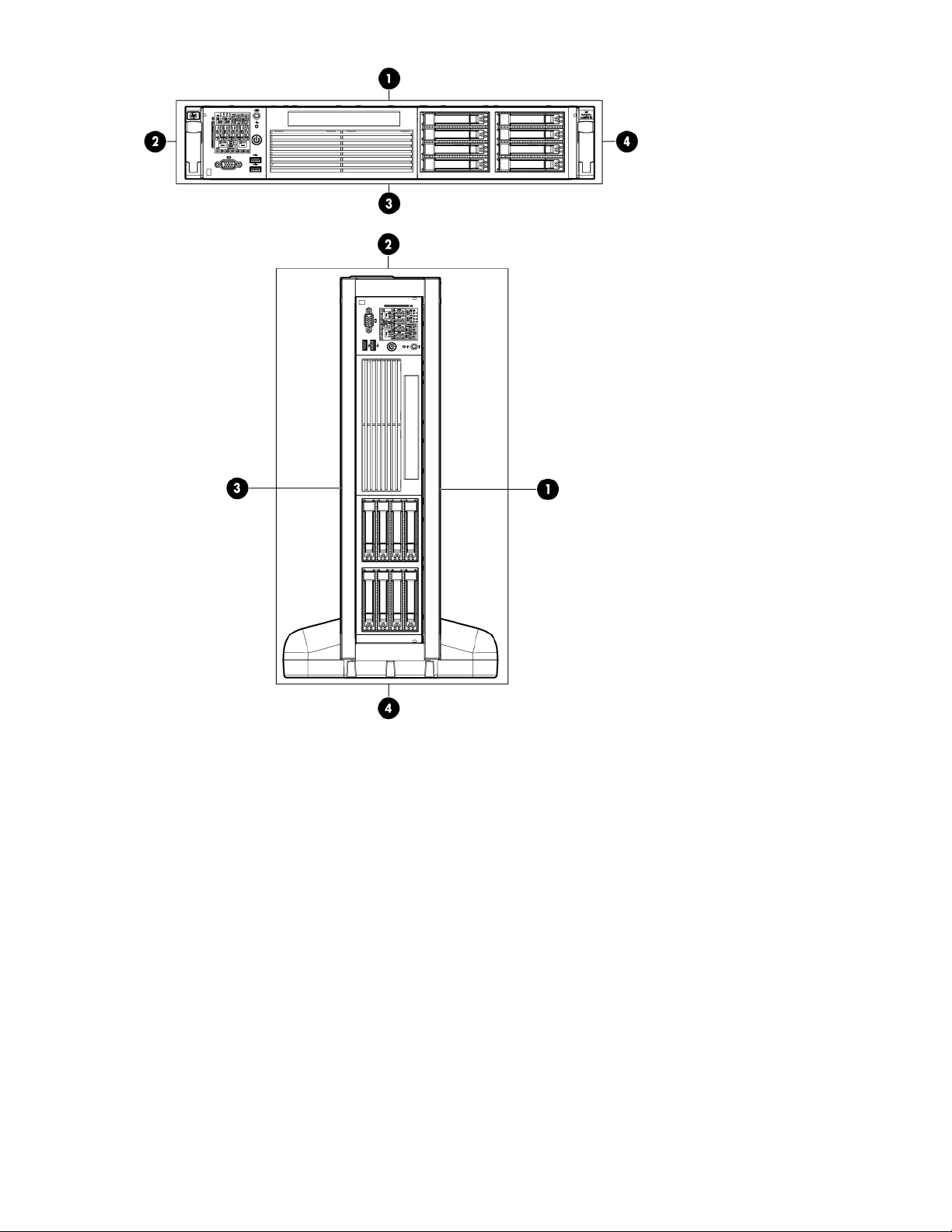

Figure 8: Front of server

1. Server top/pedestal right

2. Server left/pedestal top

3. Server bottom/pedestal left

4. Server right/pedestal bottom

The pedestal kit bottom attaches to the right side of the server when the server is in the horizontal

position. The pedestal kit top attaches to the left side of the server when in the server is in the horizontal

position. The pedestal bottom can be distinguished from the pedestal top by the pedestal feet slots.

28 Installing the server

Procedure

NOTE:

The bottom piece of the pedestal is taller than the server, so try to position the server so the right side (in the

horizontal position) of the server hangs off the edge of the work surface by a few inches to allow the bottom

piece to be attached to the server chassis. If that is not possible, then raise up the server approximately

three inches from the work surface to enable the pedestal kit bottom piece to be attached to the server right

side.

To attach the components.

1. Align the holes in the pedestal component with the posts on the server. See Figure 9.

NOTE:

One of the holes in the pedestal component contains the locking mechanism. This makes the

hole appear partially blocked.

2. Hold the pedestal component flush against the server.

3. Slide the pedestal component forward until it locks into place.

Figure 9: Installing the pedestal bottom piece

4. Stand the server up on the bottom piece of the pedestal kit that was just installed so the server is in

the vertical position.

CAUTION:

The server is heavy. Be careful when lifting it to the vertical position.

Without the feet installed, the server might tip over easily. Be careful when working near the

server to avoid tipping it over.

5. Align the holes in the pedestal top piece with the posts on the server

Installing the server 29

NOTE:

One of the holes in the pedestal component contains the locking mechanism. This makes the

hole appear partially blocked.

6. Hold the pedestal top piece flush against the server.

7. Slide the pedestal top piece forward until it locks into place.

8. The top and bottom pedestal kit pieces are now in place.

Attaching the bezel cover

To attach the bezel cover:

Procedure

1. Attach the bezel cover to the front of the server starting from the bottom of the pedestal kit.

2. Push the bezel cover into place against the pedestal kit top piece until the tabs on the bezel cover

snap into place.

Figure 10: Attaching the bezel Cover

Attaching the pedestal kit side pieces

The pedestal kit right side piece attaches to the top of the server. The top cover of the server might have

ventilation holes in it to enable proper air flow and cooling. The right side piece of the pedestal kit also

has ventilation holes in it to enable the proper cooling and air flow. Follow these steps to attach the

pedestal kit right side piece.

30 Attaching the bezel cover

Loading...

Loading...