HP Indigo press 3050, Indigo press 3500, Indigo press 5500, Indigo press 5000 Troubleshooting Manual

Page 1

HP Indigo press series 5000 and HP Indigo press series 3000

Banding

Troubleshooting Guide

Page 2

Page 3

HP Indigo Sheet-fed Presses

HP Indigo press 3050, HP Indigo press 3500,

HP Indigo press 5000 and HP Indigo press 5500

Troubleshooting Guide for

Customer Engineers

Banding

Page 4

Copyright

© 2008 Copyright Hewlett-Packard

Development Company, L.P.

Reproduction, adaptation, or translation

without prior written permission is prohibited,

except as allowed under the copyright laws.

The information contained herein is subject

to change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products and

services. Nothing herein should be construed

as constituting an additional warranty. HP

shall not be liable for technical or editorial

errors or omissions contained herein.

HP, HP Indigo Press, HP Indigo Press RIP,

and HP ElectroInk are trademarks or

registered trademarks of HP.

All other products or name brands are

trademarks of their respective holders.

The HP Indigo press is a Class 1 Laser

Product containing high voltage power

supplies and laser light sources.

There is no danger to persons or equipment

when the system is operated in accordance

with the directions provided by HP in this and

other publications. All high voltage power

supplies and laser sources are located

behind protective covers. Warning labels are

attached to each protective cover. Do not

remove covers.

Confidentiality notice

This troubleshooting guide and any

information contained herein is confidential

and should not be disclosed to any third

party outside of HP Indigo. Do not copy

and/or disseminate any information

contained in this guide. This guide should

be maintained in a manner which shall

ensure compliance with the confidentiality

requirements set forth herein.

This document contains valuable trade

secrets and confidential information of

Hewlett-Packard Company. Nothing herein

may be copied, reproduced or distributed in

any form or medium, or disclosed to any

third party in any manner, without prior

written authorization of Hewlett-Packard

Company. The copyright notice, which

appears in this document, is purely

precautionary and shall not be deemed to

constitute publication or intent to publish, in

whole or in part.

Part Number:

CA293-04200

First Edition:

July 2008

Page 5

Contents

Preface ...................................................................................................................................4

General safety instructions.................................................................................................................. 4

About this troubleshooting guide......................................................................................................... 4

Documentation conventions used in this guide .................................................................................. 4

Introduction.............................................................................................................................5

What is banding .................................................................................................................................. 5

Troubleshooting Methodology............................................................................................................. 6

The banding troubleshooting overview ............................................................................................... 6

Banding troubleshooting road map ..................................................................................................... 7

Banding troubleshooting.........................................................................................................8

Pre-troubleshooting checklist.............................................................................................................. 8

Identifying the banding type ................................................................................................................ 9

Troubleshooting by banding type...................................................................................................... 10

Causes of Banding ...............................................................................................................12

(C) Consumables banding ................................................................................................................ 12

(E) Electrical banding........................................................................................................................ 12

(WH) Writing head banding............................................................................................................... 13

(LUT) Screening and machine LUT artifact banding ........................................................................ 13

(M) Mechanical interferences............................................................................................................ 14

Appendix 1 Banding Types - Samples................................................................................. 15

Constant - Single banding................................................................................................................. 15

Constant - Group banding................................................................................................................. 16

Random banding............................................................................................................................... 16

Periodic banding ............................................................................................................................... 17

Appendix 2 Gear Transmission Schemas ...........................................................................18

Appendix 3 Periodic banding table – caused by gears and rotating parts...........................19

Appendix 4 Constant banding table.....................................................................................21

Appendix 5 Troubleshooting constant banding caused by gear teeth ................................. 22

Locating a defective or dirty tooth on the ITM drum gear or impression drum gear......................... 22

Locate the defective or dirty tooth on the PIP drum gear ................................................................. 22

Appendix 6 Second transfer banding - troubleshooting procedure...................................... 24

Appendix 7 Optional alternative mechanical banding diagnostic method............................ 25

EN Contents 3

Page 6

Preface

Welcome to the HP Indigo Sheet-fed Presses banding troubleshooting guide for customer engineers. The

purpose of this guide is to assist customer engineers in:

• Understanding the causes of banding phenomena,

• Diagnosing banding issues, and

• Systematically applying recommended solutions.

This guide was initiated by members of the manufacturing print quality forum. Recommended solutions have

been collected from manufacturing and R&D engineers. Procedures applicable to the HP Indigo press 3050

are noted.

As this is the first edition of the guide, these recommended solutions may not be exhaustive and we look

forward to more input from the field. Please address feedback and comments to gennady.meltser@hp.com.

General safety instructions

• HP Indigo presses must be operated and maintained only by properly trained personnel.

• All operating safety procedures listed in the online help and in the User Guide should be read and

understood.

• Customer engineers should not perform any actions on the press other than the procedures for which

they have been trained.

About this troubleshooting guide

• Troubleshooting diagnostic jobs must always be deleted from the client press before leaving the client

site.

• Follow the steps described for each possible solution. Some procedures are described in full, others

make reference to appendices at the end of the guide and some refer to other reference manuals.

• The guide assumes that the customer engineer has at least 6 months of experience on the HP Indigo

presses.

Documentation conventions used in this guide

• Keyboard keys to press appear in all capital letters, for example: Press the SHIFT key.

• Menu options are indicated in bold type, for example: On the File menu, click New.

• Menu path notation example: Perform the Adjustments > Suction Cup Margin Adjustment wizard.

• Window names appear in italics, for example: After selecting the options in the Print window, click

OK.

• References to other sections in the guide appear in quotes and bold, for example: See “Appendix 1

Banding Types - Samples” on page 15.

4 Preface EN

Page 7

Introduction

What is banding

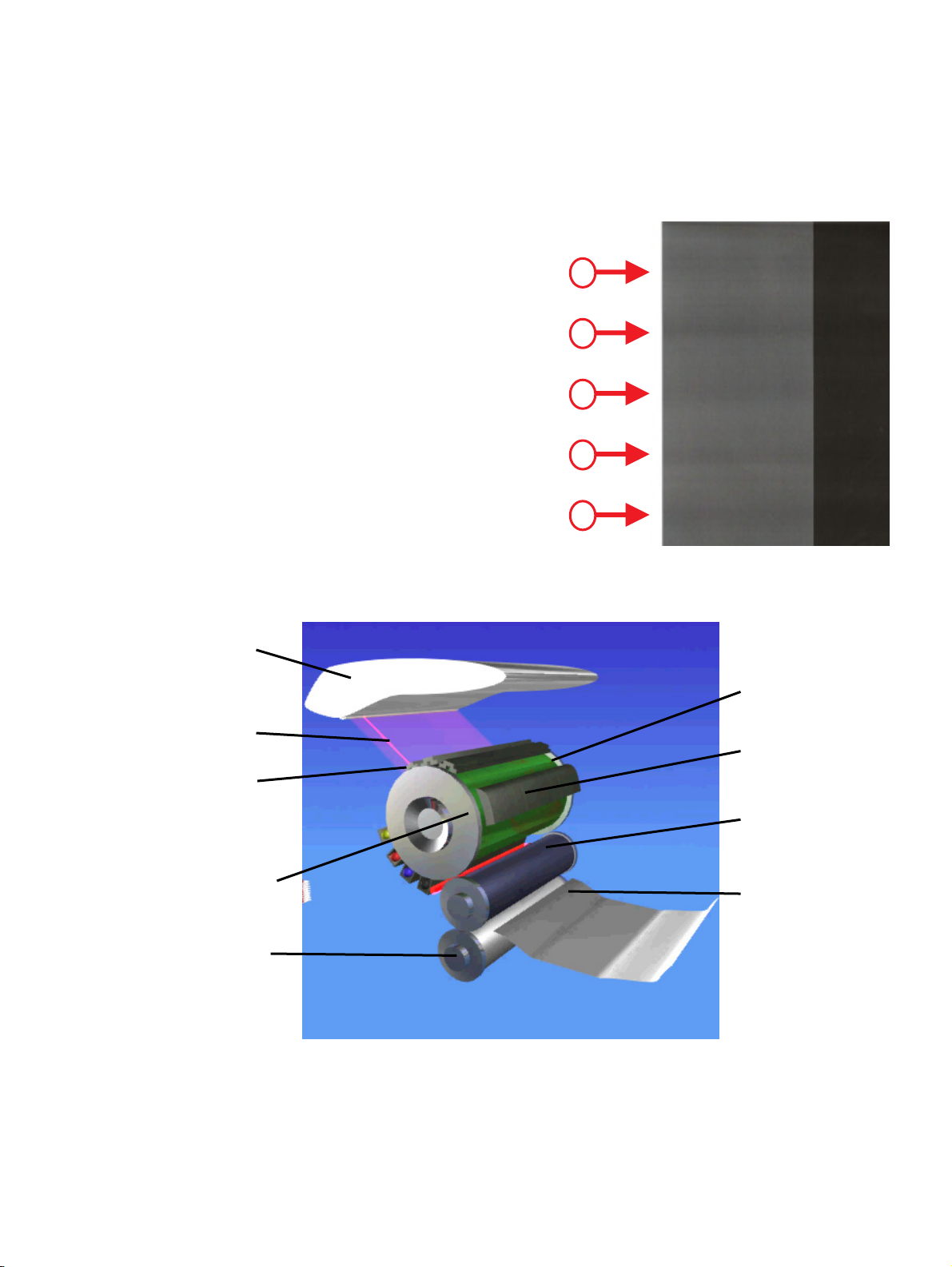

• Banding appears as sets of lines across the width of

the page.

• Banding results from interference in the image

production process at sensitive stages:

• Image writing

• Image generation

• First transfer

• Second transfer

• Interference has two effects:

• Changes the rotation speed of the drums. This

interferes with the vertical placement of rows of

dots. When the drums:

• Slow down - several rows of dots are printed

closer together - dark banding.

• Speed up - several rows of dots are printed

further apart - lighter banding.

• Changes in pressure interferes with dot size:

• Too much pressure - dot smearing - dark banding.

• Too little pressure - dot shrinking - lighter banding.

Writing head

Leading edge

5 visible bands

1

2

3

4

5

Figure 1 Banding across page width

Laser beams

Left scorotron

PIP drum sholder

Impression drum

PIP drum gear teeth

Cleaning station

ITM drum

Paper entering the

paper path

Figure 2 Image processing system

EN Introduction 5

Page 8

Troubleshooting Methodology

Perform the following steps:

1. Perform all the steps in the “Pre-troubleshooting checklist” on page 8.

2. “Identifying the banding type” see page 9.

3. Perform all the steps in the relevant troubleshooting topic - “Troubleshooting by banding type” on

page 10.

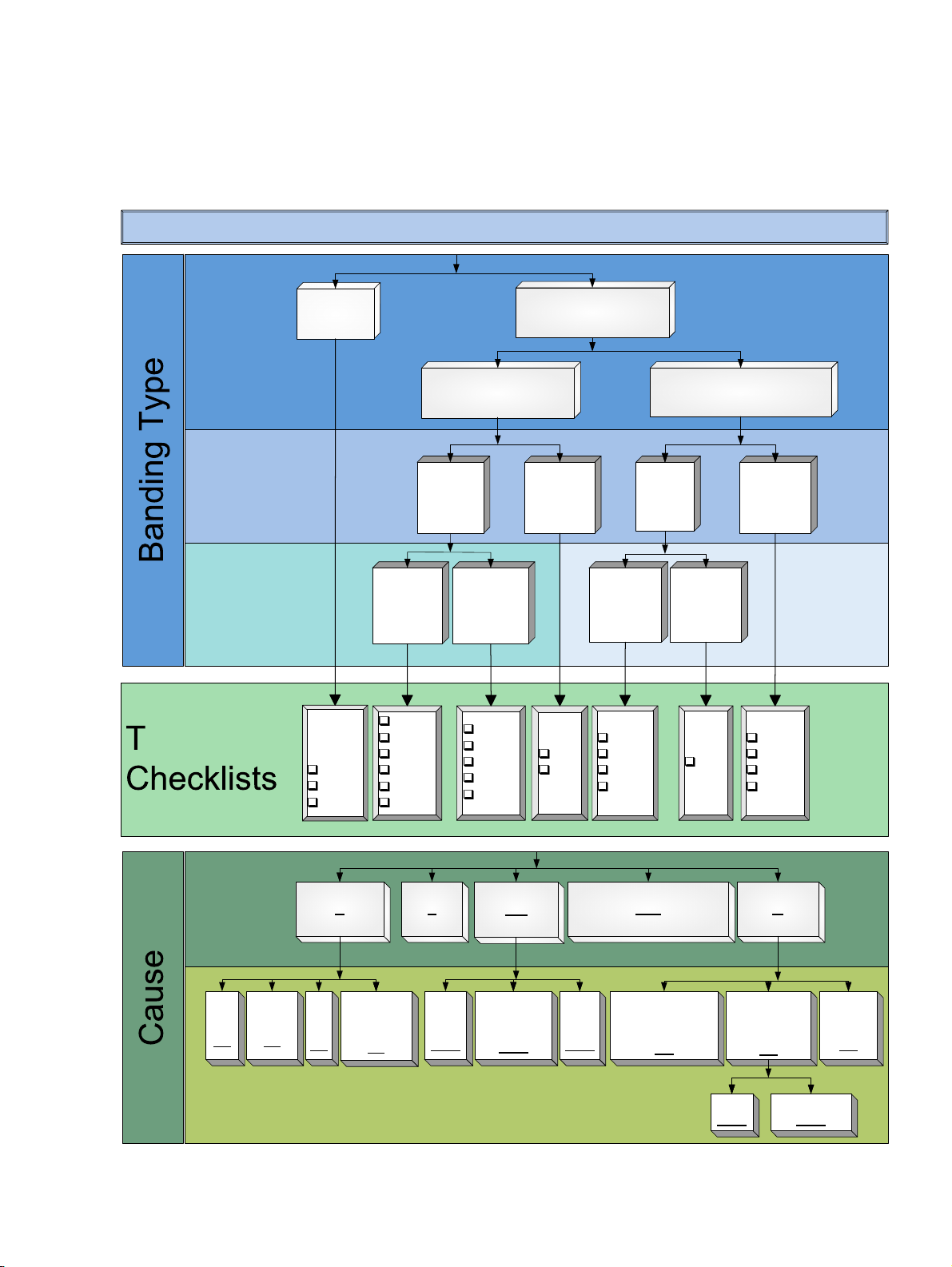

The banding troubleshooting overview

This is the summary of most of the banding diagnosis steps in this document. There are 3 sections:

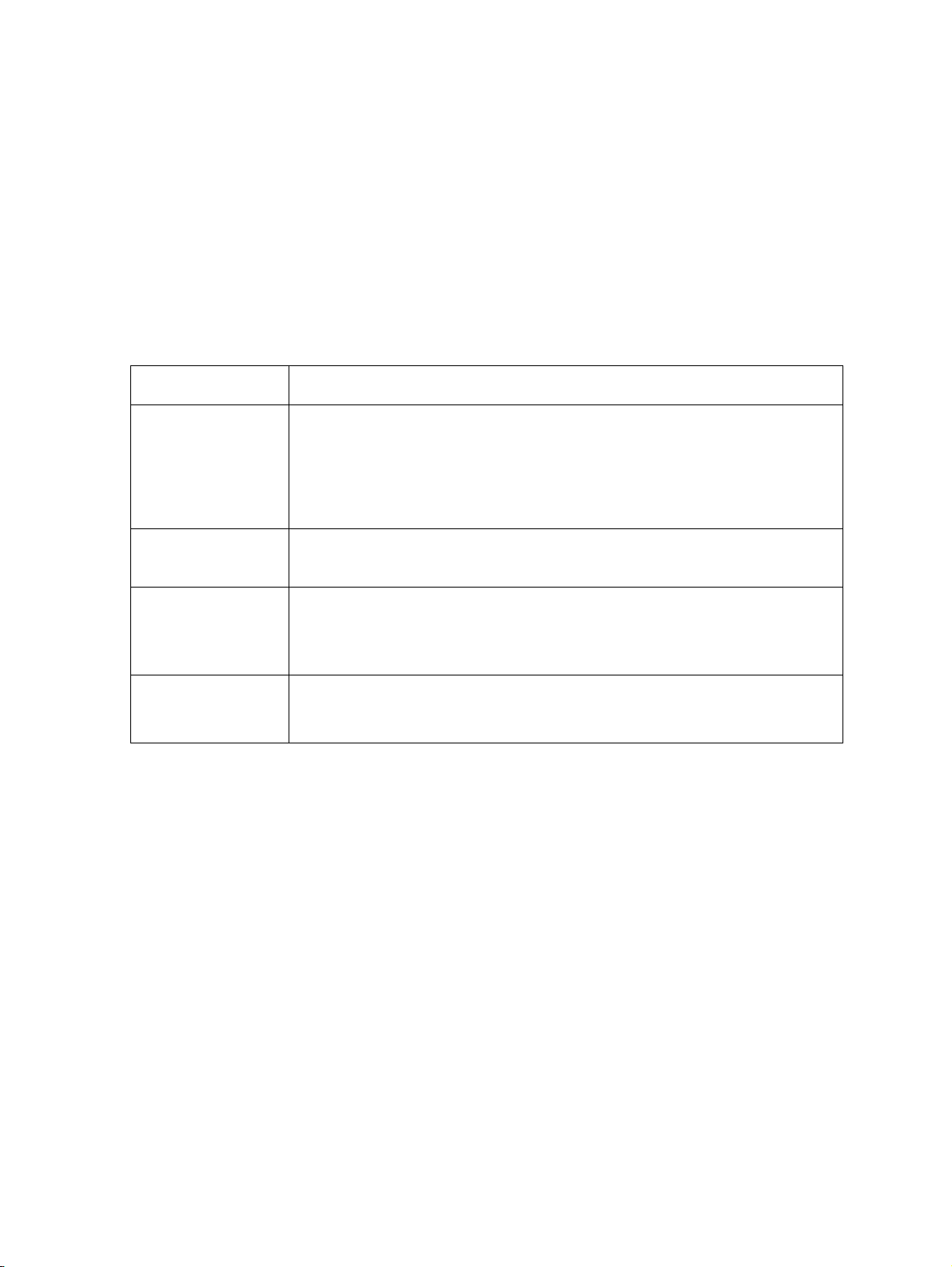

Banding Type

Defines banding by its appearance on the print sample job. There are four major types:

Banding type Possible causes

Random banding

Constant banding

Periodic banding

Vibration banding

Electronic, Electrical failures:

• Short circuits

• Faulty or unstable bias contacts

• Static charge breakthrough

• Faulty grounding, etc…

• Local loads

• Faulty consumables

Gear transmission:

• Gear or pully

Most often:

• Constant group banding

• Dynamic mirror / prism

malfunction

• Encoder malfunction

• Main drive / controller

malfunction

• Drum teeth issues

Rotating parts:

• BID unit

• Cleaning station

• Writing head polygon etc.

Can also be:

• Periodic group

• Random group

Troubleshooting Checklists

• These are checklists suspected causes and possible solutions, based on banding type, and are

listed from the most likely to less common.

• Work through the recommended solutions sequentially until the issue is resolved.

• If the issue remains unresolved escalate it to your technical specialist.

Banding Cause (Causes of interference)

Causes are graded from most common to least common.

• Consumables ware and tare.

• Electrical issues.

• Writing head installation and adjustments.

• Screening and LUT calibration artifacts.

• Mechanical pressure, velocity and local loads.

6 EN

Page 9

Banding troubleshooting road map

High-level usage summary:

• Define the banding type and work through the relevant troubleshooting checklist to resolve the issue.

• For details on how to use this table see the “Troubleshooting Methodology” on page 6.

For sample pictures see figures in “Appendix 1 Banding Types - Samples“ on page 15.

ButtonBanding Troubleshooting

Banding

Consistency

Band

grouping

Separations

roubleshooting

Random

banding

E.g. Figure 12

Any

cause

Often:

E

M3

WH2

Constant

In each

Separation

E.g. Figure 9

E

C2

C4

LUT

M1

M2.1

Constant banding

(same position on page)

Constant

Single

Separations

.

E.g. Figure 10

In some

E

C1

LUT

M1

M2.1

Group

E.g. Figure 11

Repeatable

banding

Not shifted

between

Pages

E.g. Figure 13

M1

M3

Periodic banding

(specific frequency on page)

Periodic

Single

Shifted

between

Pages

E.g. Figure 14

LUT

M2.1

M2.2

WH1

C3

Periodic

Group

E.g. Figure 15

Band shifting

between pages

WH2

WH3

M2

M3

Banding

cause

PIP

Blanket

foil

C1

C2

Cause detail

Consumables

C

See page 12

Impression

BID

C3

paper

C4

Electrical

E

See page 12

Focus

WH1

Writing head

WH

See page 13

Dynamic

Mirror/Prism

WH2

Screening / Machine LUT

LUT

See page 13

Other

WH3

Local loads /

Pressure changes

See Appx. 4

M1

Mechanical

See page 14

Gear

Transmission

See Appx. 2 & 3

M2

Teeth

M2.1

M

Vibration

M3

Gear run-out

M2.2

EN 7

Page 10

Banding troubleshooting

Pre-troubleshooting checklist

Before troubleshooting a banding problem, it is imperative that the press is printing properly with all settings

at their nominal or default positions. Banding symptoms will be misleading, amplified or exaggerated if the

press is not set up in this way, not clean or not adjusted properly.

1. Load the banding troubleshooting diagnostic jobs onto the press computer:

• TS_1on_3off horizontal lines.jlt • TS_1on_3off vertical lines.jlt

• TS_Registration 4 pix.jlt • TS_Grey20.jlt

• TS_Banding2_Rev03.jlt

These jobs can be copied from CD or downloaded from the HP Indigo documentation portal:

http://h21021.www2.hp.com/C5/Test%20Jobs/default.aspx

2. Load the recommended paper: 100 - 150 gsm glossy paper, (minimum) size: 320 x 460 long grain.

3. Print a "base point" reference set of prints: TS_Banding2, TS_Gray20, TS_Registration 4 pix.

4. Adjust first transfer.

5. Check that the substrate thickness is defined correctly.

6. Check that the PIP foil age is below 35K impressions and installed correctly.

7. Check that the blanket age is below 25K impressions and installed correctly.

8. Perform a Machine LUT calibration.

9. Check that the impression paper is clean and installed correctly.

10. Check that the PIP break is functioning correctly.

11. Clean all BID units.

12. Check that all press gears are clear of paper, dry ink and other obstructions.

13. Check that all press gears are greased, and oiling points are oiled - daily and monthly routine.

8 Banding troubleshooting EN

Page 11

Identifying the banding type

1. Print 5 copies of the following banding diagnostic jobs:

Print job Diagnostic purpose

TS_Gray20 Defining Banding Consistency

TS_Banding2 Identifying which Separations banding occurs

TS_Registration 4 pix Identify misregistration - banding is accompanied by waves – vertical misregistration

2. Throw away the 1st copy of each job.

3. Inspect copies from 2

1. Arrange the 4 copies of each job side by side on a large surface.

2. Mark major banding on each print sample.

nd

to 5

th

as follows:

Figure 3 TS_Gray20 job Figure 4 TS_Banding2 job

4. If the Banding consistency appears to be Random banding, the cause is probably not mechanical.

Troubleshooting:

Work through the “Random banding - troubleshooting checklist” in the “Banding troubleshooting road

map” on page 7.

5. If the Banding consistency appears to be Repeatable banding (repeated on each page or separation):

Determine if the cause of the banding is mechanical or not:

1. Print 3 copies of the TS_1on_3off horizontal lines job, and the TS_1on_3off vertical lines job.

2. Note: The TS_1on_3off horizontal lines job is extremely sensitive to banding. Ignore any new

bands that may appear. At this stage ONLY focus on the specific banding identified on the

TS_Banding2 job, TS_Gray20 job and customer jobs.

3. Compare the two jobs:

Job comparison Action

Same banding appears at the

same places on both jobs

Horizontal lines job:

•

Has specific banding,

but the vertical lines job:

•

None or much less

Inconclusive

Perform “Troubleshooting Repeatable banding with Nonmechanical causes” on page 10.

•

Perform “Troubleshooting Constant banding with

Mechanical causes” on page 10.

•

Perform “Troubleshooting Periodic banding” on page 11.

Perform “Appendix 7 Optional alternative mechanical banding

diagnostic method” on page 25.

EN Banding troubleshooting 9

Page 12

Troubleshooting by banding type

Troubleshooting Repeatable banding with Non-mechanical causes

• The banding cause is probably not mechanical:

• This is because the TS_1on_3off vertical lines job is not sensitive to mechanical banding.

• But sometimes the cause could still be mechanical, caused by pressure variations. For example

BID pressure, 1

• The same banding appears at the same places on both jobs:

st

or 2nd pressure.

Figure 5 TS_1on_3off horizontal lines Figure 6 TS_1on_3off vertical lines

Troubleshooting:

Work through the “Troubleshooting checklists” in the “Banding troubleshooting road map”

on page 7, for the following banding causes: Electrical, Consumables or LUT.

Troubleshooting Constant banding with Mechanical causes

• The TS_1on_3off horizontal lines job has your specific banding, but the TS_1on_3off vertical

lines job does not at all or has much less:

Figure 7 TS_1on_3off horizontal lines Figure 8 TS_1on_3off vertical lines

(has banding) (has no banding)

The banding cause is probably mechanical

(due to velocity changes or image writing placement problem or image transfer).

Troubleshooting:

1. Measure the distance from the leading edge of the sheet to the banding.

2. Check if the banding is in the “Appendix 4 Constant banding table” on page 21:

• If the banding is in the table, perform the relevant “Diagnostic tips” on page 21.

• If not, the cause is probably defective or dirty gear teeth – see “Appendix 5

Troubleshooting constant banding caused by gear teeth” on page 22.

10 Banding troubleshooting EN

Page 13

N

Troubleshooting Periodic banding

Troubleshooting:

1. Classify the Band grouping: (Single or Group).

2. Mark as many continuous bands as you can on the print sample.

3. Measure banding periods in millimeters (mm).

4. Calculate the banding frequency (in mm or Hz) - see calculation below.

5. Determine if the cause of the banding is mechanical or not:

• Print 3 copies of the TS_1on_3off horizontal lines job, and the TS_1on_3off vertical lines job.

• Note: The TS_1on_3off horizontal lines job is extremely sensitive to banding. Ignore any new

bands that may appear. At this stage ONLY focus on the specific banding identified on the

TS_Banding2 job, TS_Gray20 job and customer jobs.

• Compare the two jobs:

Job comparison Action

Same banding appears at

the same frequency on both

jobs

Horizontal lines job:

•

Has specific banding,

but the vertical lines job:

•

None or much less

Inconclusive

Periodic banding frequency calculation

Notes:

• Marking the bands:

• In general, mark the bottom edge of bands (or group of bands).

• Sometimes there is no clear edge. Mark the center of the bands (or group of bands).

• Measuring the distance between bands (or group of bands).

• Keep consistent - bottom edge to bottom edge, or center to center.

Steps:

1. Measure the distance between 1

2. Count the number of bands (or group of bands)

on the page.

3. Apply the formulas as follows:

Where:

F (mm) = Frequency in mm

F (Hz) = Frequency in Hertz

X = Distance between 1

N = Number of bands (or groups) marked

mmF

)(

HzF =

and measured on the page

=

X

1218

mmF

Determine the cause of the banding as follows:

Locate the banding frequency (that you calculated above) in

“Appendix 3 Periodic banding table – caused by gears and

rotating parts” on page 19.

•

If table shows that the cause is a gear then:

Identify the gear using the “Appendix 2 Gear Transmission

Schemas” on page 18.

•

If the table shows that the cause is not a gear then:

Investigate the relevant component for possible defect or

malfunction.

Perform “Appendix 7 Optional alternative mechanical banding

diagnostic method” on page 25.

st

and last band.

1)(−

)(

st

and last band

X

EN Banding troubleshooting 11

Page 14

Causes of Banding

(C) Consumables banding

There are four major causes:

Press component Possible Causes Appearance / Banding type

Burns, stains, short circuits,

(C1) PIP foil

(C2) Blanket

(C3) BID unit

(C4) Impression paper

mechanical damage and poor

installation.

Mechanical damage after

PSTB jams, stains, electrical /

bias contact issues and poor

installation.

Developer roller stains, voltage

instability.

Impression paper folded. May appear like a single constant banding.

Usually appears like constant banding in some

alternate separations (1

Usually appears like constant banding in each

separation.

Usually appears like periodic banding shifted

between pages.

st

& 3rd or 2nd & 4th).

General solutions for Consumables banding

1. Clean the BID unit.

2. Check that the PIP foil, blanket and impression paper are correctly installed.

3. Replace consumables if necessary.

(E) Electrical banding

Press

component

ITM bias

Scorotrons

BID

ITM bias instability during 1st transfer or short circuits on the PIP foil.

Interferes with the density of dots and / or solid areas.

Low charge creates random background areas around dots.

BID unit voltage instability.

Possible Causes

General solutions for electrical banding

1. Look for faulty bias contacts.

2. Check that the PIP drum is grounded correctly.

3. Check for a faulty BID unit or BID power supply board.

4. Look for short circuits e.g. Blanket on ITM drum has raised areas that touch the anti-dripping tray.

12 Causes of Banding EN

Appearance / Banding

type

Dark and / or light lines

that repeat down the

sheet. Usually appears as

random banding with

sharp edges.

Page 15

(WH) Writing head banding

Press component Possible Causes Appearance / Banding type

(WH1)

Focus adjustment

(WH3)

(WH2)

Dynamic mirror

(WH3) Writing head

press interfaces

Faulty focus adjustment

•

Focus adjustment.

•

Image scaling adjustment.

•

De-skew calibration.

Dynamic mirror malfunction (or

dynamic prism in the HP Indigo

press 3050).

Faulty Writing head installation

on press interfaces.

General solutions for banding caused by the writing head

1. Adjust the writing head focus and leveling.

2. Verify that the writing head parameter files correspond to the writing head serial number.

Reinstall the writing head parameters.

3. Physically unlock the dynamic mirror according to the instruction sticker on the writing head.

4. Adjust image scaling.

5. Check the de-skew calibration.

6. Check the writing head mechanical installation.

7. Check the press installation - press wheels should not touch the floor.

Usually produces 2.25 mm period banding.

0.375 mm period banding.

This can cause any type of banding.

Usually accompanied by random misregistration

issues.

Usually vibration banding 0.7—2.5 mm - constant

groups or periodic groups. (Especially on the HP

Indigo press 3050.)

(LUT) Screening and machine LUT artifact banding

• Screening banding is caused by intrinsic screening artifacts, for example:

• 3.8 mm period banding on Sequin screening.

• Machine LUT banding is caused by faulty machine LUT generation.

Images most affected are screen tints that change from say 5% to 100% in a gradual way:

• Vignettes are light to dark or dark to light areas of a single color.

• Blends are composed of process colors (C, M, Y, and K) that change from one specific color to

another.

• Vignettes and blends may also exhibit some banding if they contain too many steps or if the

machine LUT is not correct.

• For example if the machine LUT was set to the following numbers:

• Step 20 is 20, step 30 is 32, step 40 is 38 and step 50 is 50. (Note that these numbers

are within normal tolerance.)

• If a vignette falls within this range, a band will be created between 30% and 40%.

• The LUT in this example, actually compresses the vignette and generates banding.

General solutions for screening and machine LUT artifact banding

1. Run the Machine LUT generation wizard.

2. Try to print with a different job screen definition for a diagnostic.

3. Replace - blanket. (Run the Machine LUT generation wizard, print again).

4. Replace - PIP (Run the Machine LUT generation wizard, print again).

5. Check the Ink density and conductivity calibration.

Run the Machine LUT generation wizard again.

EN Causes of Banding 13

Page 16

(M) Mechanical interferences

There are two major mechanical interferences: local loads and gear transmission issues:

(M1) Local load

Local loads in the press reduce the velocity of, or cause pressure changes in, the set of image

processing drums, for a moment. This interferes with dot placement at sensitive stages of image

production and transfer:

• Image writing phase - Writing head to PIP drum.

• Image transfer phase - 1

- 2

Local loads occur at:

• Each separation - Example - at the start of 2

• Some separations - Example - during paper input or output.

General solutions for banding caused by local loads – check for:

1. Correct press adjustments - For example 2nd pressure, gripper shaft magnets.

2. Damaged or loose parts in paper path - Gripper shaft assembly, stop station assembly.

3. ITM drum radial freedom - This may produce banding under 2

such cases local loads affect both pressure between drums and drum rotation speed.

4. Parts that vibrate under specific loads that may interfere with the writing head.

- For example on the HP Indigo press 3050 - stop finger noise during paper feed.

(M2) Gear transmission issues interfering with dot placement

Gear transmission issues in the drums and gears, during image writing and transfer, interferes with

dot placement. Banding patterns are created in relation to gear diameter and distance between teeth.

Gear transmission issues are cause by:

Gear transmission issue Possible symptom Possible cause

Periodic banding down

Gear meshing

(M2.1) Defective gear teeth

(M2.2) Gear run out (gear not

centered on its shaft)

the page with tooth to

tooth at a constant

frequency.

Periodic single banding

Periodic groups of

banding

Solutions for gear transmission issues:

1. Clean gears.

2. Grease gears.

3. For Direct Drive presses (HP Indigo press 3500, HP Indigo press 5000, HP Indigo press 5500):

3.1. For banding frequencies: 101.5 mm (12Hz), 50.8 mm (24Hz) and 25.4 mm (48Hz) - This

is related to the main motor, small drive gear (gear 14) and the flywheel - Run the

Harmonic and Torque compensation wizard.

3.2. If the wizard did not correct the issues then - Replace defective gears, main motor or

flywheel where necessary.

4. For non-Direct Drive press (HP Indigo press 3050) -

4.1. Replace defective gears, shafts and bearings where necessary.

There are two other mechanical interferences: pressure and vibration issues:

Pressure issues interfering with dot size

Pressure variations may interfere with dot size and also causes dot smearing.

(M3) Vibration of certain parts

Vibration of certain parts interferes with dot placement or causes dot smearing.

• E.g. 1 - BID unit vibration, 1 separation job can produce groups of 6.8 - 7.0 mm periodic banding.

• E.g. 2 - Writing head vibration usually caused by press operation or local loads. 0.7 - 2.5 mm

frequency range - constant groups or periodic groups - especially for HP Indigo press 3050.

st

transfer - PIP drum to ITM drum.

nd

transfer - ITM drum to impression drum.

nd

transfer pressure.

nd

transfer start or end loads. In

•

Incorrect gear / drum assembly

•

Defective gear (factory error - out of spec)

•

New gear not meshing smoothly with worn gear

•

Defective tooth

•

Incorrect gear assembly

•

Defective bearing (that supports the gear shaft)

14 Causes of Banding EN

Page 17

Appendix 1 Banding Types - Samples

Constant - Single banding

Figure 9 Each separation

Figure 10 Some separations

EN Appendix 1 Banding Types - Samples 15

Page 18

Constant - Group banding

Random banding

Figure 11 Constant group

Figure 12 Random banding

16 Appendix 1 Banding Types - Samples EN

Page 19

Periodic banding

Periodic - Single banding

Figure 13 Not shifted between pages Figure 14 Shifted between pages

Periodic - Group banding

Figure 15 Periodic - Group banding Figure 16 Periodic banding

EN Appendix 1 Banding Types - Samples 17

Page 20

Appendix 2 Gear Transmission Schemas

These schemas are used to locate a gear, when you know the number of teeth in the gear.

How to use these schemas:

1. Identity the gear using the “Appendix 3 Periodic banding table – caused by gears and rotating

parts” on page 19, and get the number of teeth.

2. Locate the gear on the relevant Gear Transmission Schema for your press (see below).

18 Appendix 2 Gear Transmission Schemas EN

Page 21

Appendix 3 Periodic banding table – caused

by gears and rotating parts

This table is used to identity a gear or pulley / other component, when you know the frequency of the banding

or misregistration. How to use this table:

1. Measure the frequency of the banding or misregistration using the “Periodic banding frequency

calculation” on page 11.

2. Identity the gear or pulley / other component in the table below.

• If table shows that the cause is a gear or pulley then:

Identify the gear using the “Appendix 2 Gear Transmission Schemas” on page 18.

• If the table shows that the cause is another component (shown in grey) then:

Investigate the relevant component for possible defect or malfunction.

Vmachine (process) = 1218 [mm/sec]

Gear/Pulley

Banding

Frequency

[mm]

1624.0 0.75 Rotor B pulley 48 Paper feed 3050

Gear/Pulley

Banding

Frequency

[Hz]

Gear or Pulley /

Other component

No. of

teeth

Gear type /

Sub-assembly

Press type

1107.3 1.1 Gear PIP 148 Drive 5000/3050

1072.2 1.136 Rotor A pulley 32 Paper feed 3050

1072.2 1.136 Rotor A pulley 114 Paper feed 3050

529.6 2.3 Helical Gear ITM 74 Drive 5000/3050

529.6 2.3 Gear Impression 114 Drive 5000/3050

529.6 2.3 ITM Spur Gear 114 Drive 5000/3050

133.5 9.07 Developer pulley 34 BID 3050/5000

131 9.3 Developer roller 60 BID 3050/5000

112.8 11 Impression brake gear 24 Paper feed 5000

103.6 11.8 Hand wheel gear 22 Drive 3050/5000

101.5 12 Gear Plastic "frog" 108 Drive 3050

101.5 12 Small drive Gear 14 Drive 3050/5000

99.8 12.2 Timing pulley 24 Cleaning 3050/5000

93.1 13 Impression brake gear 19 Paper feed 5000

89.6 13.6 Gear Imp/Paper feed 19 Paper feed 3050

75.2 16.2 BID motor pulley 19 BID 3050/5000

67.3 18.1 Sponge pulley 17 BID 3050/5000

66.6 18.3 Timing pulley 16 Cleaning 3050/5000

56.4 21.6 Flywheel pulley 44 Drive 3050

56.4 21.6 Flywheel gear 60 Drive 3050

52.4 23.3 Squeegee roller 24 BID 3050/5000

EN Appendix 3 Periodic banding table – caused by gears and rotating parts 19

Page 22

Gear/Pulley

Banding

Frequency

[mm]

Gear/Pulley

Banding

Frequency

[Hz]

Gear or Pulley /

Other component

No. of

teeth

Gear type /

Sub-assembly

Press type

50.8 24 Main motor 14 Drive 5000

34 36 Main motor + controller 14 Drive 5000

33.5 36.4 Rotor A pulley 32 Paper feed 3050

32.7 37.2 Cleaner roller 15 BID 3050/5000

31.5 38.5 Helical Gear ITM 74 Drive 5000

25.4 48 Main motor + controller 14 Drive 5000

9.4 130 Paper feed pulley 31 Paper feed 3050

9.4 130 Rotor A pulley 114 Paper feed 3050

7.3 167.8 Small drive Gear 14 Drive 3050/5000

7.3 167.8 Helical ITM Gear 74 Drive 3050/5000

7.3 167.8 PIP Gear 148 Drive 3050/5000

6.8 179.4 BID unit vibration - BID 3050/5000

4.7 260 Impression Gear 114 Drive 3050/5000

4.7 260 Gear Imp/Paper feed 19 Paper feed 3050

4.7 260 Gear Imp/Paper feed 24 Paper feed 3050

4.7 260 Gear Imp/Paper feed 62 Paper feed 3050

4.7 260 Impression brake gear 24 Paper feed 5000

4.7 260 Impression brake gear 19 Paper feed 5000

4.2 292 Timing pulley 24 Cleaning 3050/5000

4.2 292 Timing pulley 16 Cleaning 3050/5000

3.8 325 De-skew (in Sequin) - S/W screening 3050/5000

3.4 358 Black screen artifact (in HDI-180 lpi) - S/W screening 5000

2.25 542 Polygon - W. Head 3050/5000

2.2 544.2 Developer Gear 40 BID 3050/5000

2.18 558.3 Rear gear mesh - BID 3050/5000

1.8 to 2.5 487-676 General Resonance - W. Head 3050/5000

1.3 949.3 Main Motor Pulley 20 Drive 3050

1.3 949.3 Flywheel pulley 44 Drive 3050

1.15 1,094 Polygon - W. Head 3050/5000

1.0 1,220 Dynamic Prism - W. Head 3050

0.9 1,294.50 Flywheel gear 60 Drive 3050

0.9 1,294.50 Gear Plastic "frog" 108 Drive 3050

0.8 1,627 Polygon - W. Head 3050/5000

0.375 3,253 Scan frequency - W. Head 3050/5000

20 Appendix 3 Periodic banding table – caused by gears and rotating parts EN

Page 23

Appendix 4 Constant banding table

Diagnostic table for constant banding caused by local loads and other causes.

Distance from LE Local loads

mm deg

31-39 65-70

46 75

71-106 95-110

143-155 140-148

173-180 160-165

262 & 350

Couple

220 & 278

Couple

300 245

350 278

350±5 278±5

Gripper

shaft

action

Press

action

Opening Sheet exit 1

st

1

transfer

start

Opening Sheet exit 2

Opening Simplex 1

Opening Simplex 2

nd

2

transfer

start, end

Closing Simplex 1

nd

2

transfer

start

nd

2

transfer

start

Sepr.

num

st

1st transfer

Each

nd

st

1st transfer

nd

Each 1

st

Each 1

Each 1

Occurs Diagnostic tips

Image

writing

Image

writing

Image

writing

st

transfer

st

1

transfer

st

transfer

st

transfer

Print a single proof for diagnostic.

Related to stop stations, gripper shaft,

and magnets adjustment. (SS2 on).

Related to 1st pressure incorrect

adjustment. (too high)

Print a single proof for diagnostic.

Related to stop stations, gripper shaft,

and magnets adjustment. (SS2 on).

Related to stop stations, gripper shaft,

and magnets adjustment. (SS1 on).

Related to stop stations, gripper shaft,

and magnets adjustment. (SS1 on).

Sometimes accompanied by bad

transfer between the banding.

Related to:

st

pressure incorrect adjustment (too

-1

low):

- ITM bearings

- ITM radial freedom

Related to stop stations, gripper shaft,

and magnets adjustment. (SS1 on).

Related to substrate definition and 2

nd

pressure adjustment. Use “Appendix

6 Second transfer banding troubleshooting procedure” on page

24 for troubleshooting.

Electrical banding,

Gripper clamp touches the blanket.

Related to banded gripper clamps,

incorrect gripper shaft adjustments,

and bubbles on blanket.

350-455

Group

355 282

397 310

278-350

Group

Exit roller

"jumps"

Closing Simplex 2

nd

2

transfer

start

Each

nd

Each

Image

writing

Image

writing

Image

writing

Print with no exit roller for diagnostic.

Replace springs.

Related to stop stations, gripper shaft,

and magnets adjustment. (SS1 on).

Related to substrate definition and 2

pressure adjustment. Use “Appendix

6 Second transfer banding troubleshooting procedure” on page

24 for troubleshooting.

EN Appendix 4 Constant banding table 21

nd

Page 24

Appendix 5 Troubleshooting constant

banding caused by gear teeth

• A defective or dirty tooth on one of main gears causes constant banding.

• You will probably not find them it in the Constant banding table.

• Constant banding - Some separations

A defective tooth on the PIP gear usually causes banding on the some separations. This is because

alternate separations are produced on the same side of the PIP drum (MK on one side of the PIP and YC

on the other side).

• Constant banding - Each separation

A defective tooth on the ITM gears or impression drum usually causes banding that appears on each

separation.

Locating a defective or dirty tooth on the ITM drum gear or

impression drum gear

Banding due to a defective or dirty tooth on ITM drum appears on each separation.

1. Mark the banding on your print sample.

2. Press the Inching button and insert the printed page into the grippers.

3. Using the hand wheel, manually rotate the press, and keep your eye on your band.

4. Stop rotating one or two centimeters before your band reaches the ITM drum.

5. Mark the gear tooth (e.g. with a small sticker or with tip-ex) in line with your band. See Figure 17.

6. The defective or dirty tooth will be in a range of 3 to 5 teeth on either side of your mark.

7. Clean and inspect this area.

The banding

Location of problematic tooth

Figure 17 Marking the defective or dirty tooth on the ITM drum

Locate the defective or dirty tooth on the PIP drum gear

Banding appears on some separations: alternate separations (1st & 3rd or 2nd & 4th).

The defective or dirty tooth may be on either half of the PIP drum. Null cycles can occur at any point in

between separations. This makes it difficult to determine which PIP half has the defective tooth. Therefore

we will troubleshoot both halves of the PIP drum at the same time.

22 Appendix 5 Troubleshooting constant banding caused by gear teeth EN

Page 25

Steps

1. Use one of the banding diagnostic jobs. Mark the banding on your print sample.

2. Read the position of the banding on the printed scale from the leading edge of page, in degrees.

3. For example: you have banding at 240 deg.

4. Manually set the machine angle position to: Encoder Half “0”, Current Position “240” see Figure 18:

Figure 18 Troubleshooting both halves of the PIP drum

Shaft with leveling

ring (this is

approximately in

line with the laser

beams).

Mark a point

on the PIP

drum shoulder

Empty location

of the left

scorotron

PIP drum

shoulder

Figure 19 Marking the location on the gear tooth on the PIP drum shoulder

5. Take out the left scorotron unit.

6. Mark the PIP drum shoulder with a sticker or marker directly below the shaft with the leveling ring.

See Figure 19.

7. Manually set the machine angle position to: Encoder Half “1” and the same Current Position “240”.

See Figure 18.

8. Mark the drum shoulder for the other drum half using the same process.

9. These marks are on the front side of the PIP drum. The dirty or damaged tooth is in line with one of

these points.

10. Manually rotate the press until one of the marks is visible from the paper input side.

11. Mark the tooth that is in line with the mark on the PIP shoulder.

12. Manually rotate the press until the second mark is visible from the paper input side.

13. Mark the tooth that is in line with the mark on the PIP shoulder.

14. The defective or dirty tooth will be in a range of 3 to 5 teeth on either side of your mark.

15. Clean and inspect these areas on both halves of the PIP drum.

EN Appendix 5 Troubleshooting constant banding caused by gear teeth 23

Page 26

Appendix 6 Second transfer banding troubleshooting procedure

2nd transfer banding is visible at 278 degrees and 310 degrees. 278 degree banding is a technology issue and

exists on ALL normally calibrated presses. The procedure below reduces this banding to an acceptable level.

Note: Reprint the banding diagnostic job (TS_Banding2 job or TS_Gray20 job) and reevaluate

the banding level for each cycle of troubleshooting in the following procedure.

• After each troubleshooting cycle, keep print samples for your reference.

• Follow the defined troubleshooting step order.

• Contact your technical specialist to make a decision about part replacement.

• Remember, after each part replacement, reprint and reconsider banding levels from the beginning.

Steps

• Prior to troubleshooting, clean, oil and grease the press.

• Perform the procedure described in the “Pre-troubleshooting checklist” on page 8.

1. Check:

1.1. Substrate thickness and glossiness definition.

1.2. Impression paper thickness definition and correct installation.

1.3. Blanket correct installation - especially not overlapping the ITM drum shoulder.

1.4. Reset 2

2. Perform:

2.1. First transfer calibration.

2.2. Machine LUT generation or at least color adjustment.

3. Replace:

3.1. Blanket. (Note: A new blanket will have a high level of 2nd transfer banding. Before printing

the banding diagnostic, print 200-500 impressions to get realistic banding level.)

3.2. PIP foil.

3.3. Impression paper.

4. Check:

4.1. PIP brake correct operation.

4.2. Impression drum brake correct operation.

4.3. All press fans are working correctly.

4.4. All ventilation hoses are firmly connected to the correct places - especially the ITM feed fan.

4.5. Print with no exit roller for diagnostic.

4.6. Run at least 3000 impressions to stabilize IR sensor body temperature.

4.7. Run the ITM IR sensor adjustment wizard.

4.8. Run the Impression drum IR sensor calibration wizard.

Note:

• Temperature changes of more than 5 deg Celsius required 2

• Make sure that your external thermometer is perfectly calibrated.

5. Adjust:

5.1. Run the Impression engage calibration wizard.

5.2. 2

5.2.1. On the Substrate screen, when adjusting the gap, set the Current Position between 310 –

315 deg. (This is the position at which the 2

5.3. Adjust the 2

5.3.1. Run the press. Perform fine tuning according to the Balancing the second transfer pressure

with SPV document (CA293-04790).

Note: For HP Indigo press 5000 with HP Indigo press software version 7.4.3 and higher - The

SPV software tool can be used for adjusting 2

nd

pressure correction in the Blanket MMI screen, or in the Paper Definition.

nd

transfer gap (5000, 3000).

nd

transfer pressure. Run the wizard (5500).

nd

transfer gap readjustment.

nd

transfer begins.)

nd

transfer pressure tuning.

24 Appendix 6 Second transfer banding - troubleshooting procedure EN

Page 27

Appendix 7 Optional alternative mechanical

banding diagnostic method

If a "TS_1on_3off vertical line transparent diagnostic foil" is available, you can check if banding is

mechanical by doing the following:

Note:

You can create this foil for yourself by running the TS_1on_3off vertical line transparent diagnostic

foil job on transparent substrate. You can download the job from the HP Indigo documentation

portal: http://h21021.www2.hp.com/C5/Test%20Jobs/default.aspx

1. Print a TS_1on_3off horizontal lines job.

2. Put the transparency on the TS_1on_3off horizontal lines job. See Figure 20.

3. Rotate the transparency and look for a “wave" appearance at the location of the banding.

4. If there is a “wave”/s appearance, define its period and position – this is a mechanical issue or a

writing head writing issue.

5. If no “wave”/s appear, look for an Electrical, Consumables, Pressure variation or software cause

of the problem.

Extreme interruption

of smooth "Moire

waves” indicates

mechanical cause of

the banding. See the

“Banding

troubleshooting

road map” on page

7 for troubleshooting.

Figure 20 Detecting interruptions in the "Moire waves”

EN Appendix 7 Optional alternative mechanical banding diagnostic method 25

Page 28

Notes

Page

number

Remarks

26 Notes EN

Page 29

Page 30

Copyright © 2008 Hewlett-Packard Company

This is an HP Indigo digital print. Printed in Israel.

www.hp.com/go/indigo

reorder: P/N CA293-04200

Loading...

Loading...