Page 1

HP Indigo Division Service Instructions

filename: CA294-00570.doc page 1 of 18

2 Million Imp - Preventive Maintenance Guide

Purpose

Routine press maintenance

Service instruction details

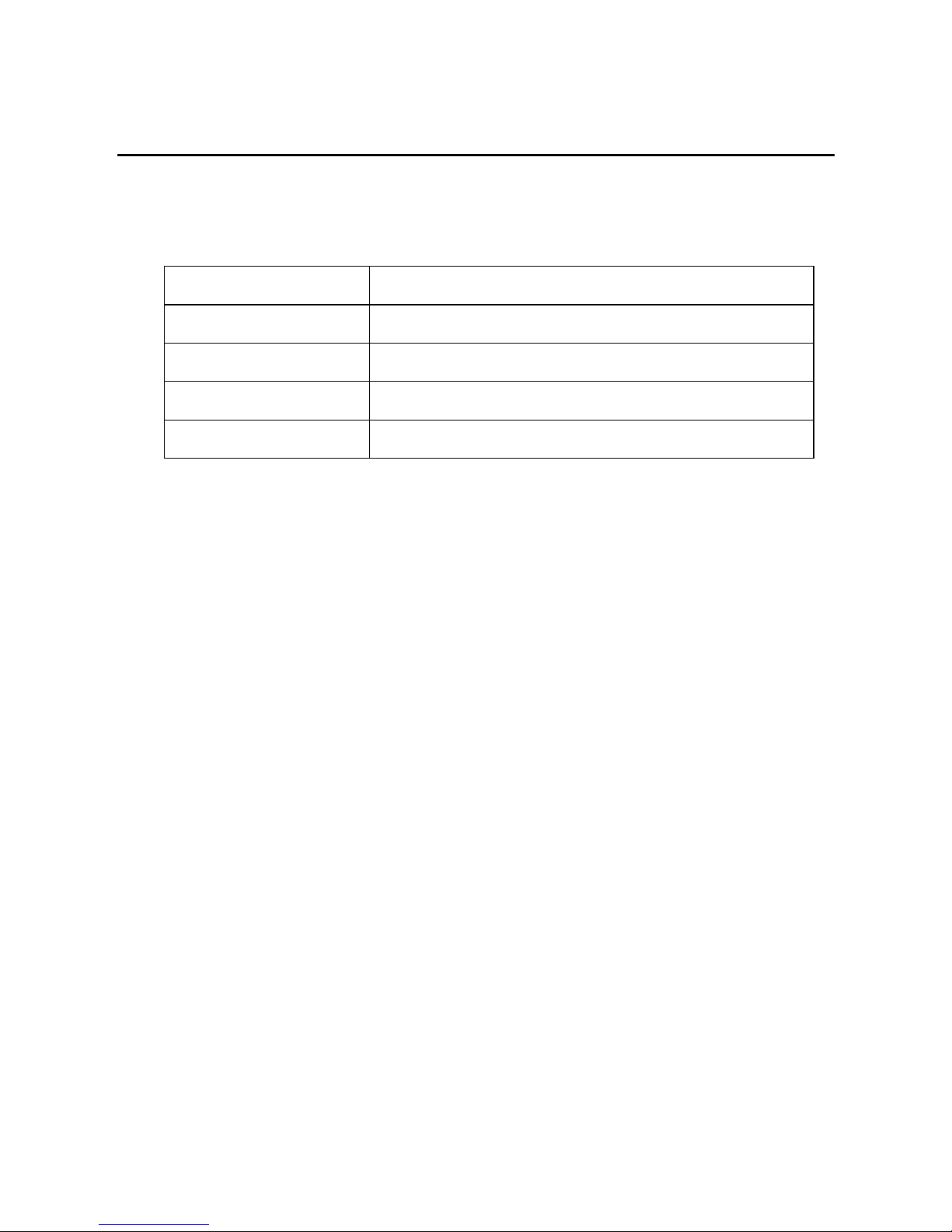

Item Details

Scope HP Indigo press 5000, all serial numbers

Document Number CA294-00570

Date 13-Mar-06

Security level HP confidential

Contents

Service instruction details.........................................................................................................................1

Overview...................................................................................................................................................2

Monthly maintenance procedure.........................................................................................................2

2 million impressions maintenance procedure....................................................................................2

Monthly maintenance...............................................................................................................................3

Monthly maintenance (continued)............................................................................................................4

Monthly maintenance (continued)............................................................................................................5

2 million imp. maintenance.......................................................................................................................6

2 million imp. maintenance (continued)....................................................................................................7

Quick check maintenance table ...............................................................................................................8

Special tools and jigs..............................................................................................................................12

Monthly routine parts..............................................................................................................................12

Upon reaching 1 million impressions ................................................................................................12

2 million imp. routine parts .....................................................................................................................12

Mandatory replacement.....................................................................................................................12

Conditional replacement ...................................................................................................................12

Appendix A - Imaging oil pump maintenance.........................................................................................13

Appendix B - Vacuum pump maintenance.............................................................................................14

Appendix C - Grease and oil types.........................................................................................................17

Revision history......................................................................................................................................18

Confidentiality Notice..............................................................................................................................18

Page 2

2 Million Imp - Preventive Maintenance Guide - HP Indigo press 5000

CA294-00570 rev 01 page 2 of 18

Overview

The preventive maintenance schedule is based on monthly visits, which include performing

procedures based on the press impression counter according to the following schedule:

Monthly maintenance procedure

To be performed monthly, without regard to the impression counter. The following parts will be

replaced only if 1 million impressions were made since the last replacement:

• Carbon filters

• Cleaning station sponge roller

• Suction cups

2 million impressions maintenance procedure

To be performed when the press has printed 2 million or more impressions since the last 2 million

impression procedure was performed. The 2 million impression procedure is performed in addition to

the monthly impression procedure.

These maintenance routines are complementary to the operator routines, and do not replace them.

The operator will continue the press maintenance on a daily and weekly basis. Check that the press is

properly maintained by the operator. If there are signs of negligence, report back to your regional

manager.

The following 2 million impression kit is available: CA290-00960.

Before every visit, verify that you have all the necessary parts. For your convenience, a short list is

provided on page 12.

Note that some of the parts are included as ‘conditional’ - subject to replacement, if needed, following

inspection. Order and replace if needed.

Page 3

2 Million Imp - Preventive Maintenance Guide - HP Indigo press 5000

CA294-00570 rev 01 page 3 of 18

Monthly maintenance

Date: Time spent:

HP Indigo press 5000 S/N: Service person:

Customer name: Country/State:

Required parts

Complete CE kit. See page 12.

General inspection

Check for external dirt, leakage and signs of improper

maintenance. Initiate a service call if there is a

leakage problem.

Verify that daily and weekly operator routines have

been performed correctly. See the latest User Guide.

Verify that all lubrication points have been oiled and

greased properly. See the latest User Guide.

Inform your regional manager if the press is not

properly maintained.

Config save

Perform Config save to update the customer diskette.

Ink unit

Calibrate the density sensors.

Calibrate the ink conductivity sensors.

Calibrate the ink flow rate.

ITM Drum

Clean ITM slip ring (the bias contacts path) using IPA.

Clean the ITM thermostat slip ring.

Verify the temperature sensor reading, and calibrate,

if required.

Make sure that the surface facing the IR sensor is

clean.

Inspect and thoroughly clean the ITM hood wire mesh

filter on the rear wall using IPA soaked cloth.

Caution: Shut down the press before removing the

mesh.

Page 4

2 Million Imp - Preventive Maintenance Guide - HP Indigo press 5000

CA294-00570 rev 01 page 4 of 18

Monthly maintenance (continued)

IMP drum

Inspect grippers area, and pay special attention to

cleanliness.

Check the stop stations for freedom of movement.

Make sure that the gripper cam followers are secured

to the drum.

Make sure that the dummy cam followers move

freely, and inspect the springs.

Oil the dummy cam follower arms and gripper arms.

Perfector

If 1 million impressions have been reached, replace

the suction cups.

Scorotrons

Perform a general inspection.

Inspect the inside housing sides for the formation of

insulating layer. Clean with IPA soaked cloth. Use an

abrasive cleaning pad, if required.

Inspect each corona unit for loose or broken grid rails.

Glue or replace, if necessary.

If 1 million impressions have been reached, replace

the four carbon filters.

PTE – air knife

Perform a general inspection, and check for paper

chips.

Clean the PTE shield.

Clean and check the LED operation.

Cleaning station

If 1 million impressions have been reached, clean the

wetting roller.

If 1 million impressions have been reached, replace

the sponge roller.

Check the imaging oil flow rate.

Utility cabinet

Perform general inspection.

Externally clean the heat exchanger, if necessary.

Drain water separator - open service valve for 30

seconds.

Page 5

2 Million Imp - Preventive Maintenance Guide - HP Indigo press 5000

CA294-00570 rev 01 page 5 of 18

Monthly maintenance (continued)

Lubrication

Make sure that all lubrication points have been oiled

and greased properly. See "Appendix C - Grease and

oil types" on page 17.

BID engage

Verify that the BID fans are working properly.

Ventilation system

Make sure that all the Amateks are working

properly:

Scorotron (suction and blower).

ITM input fan.

Air knife (suction and blower).

Bottom cooling.

Print quality

Perform the following:

Print Fine_Tune job, adjust if necessary.

Print a gray_20 job, and verify the quality of the print.

Check writing head deskew, and adjust, if necessary.

Use the gray_20 job to observe banding of ~3.5 mm

along the format that appears due to an incorrect

deskew adjustment.

Print the CATP job. Check the press performance

according to the table of specifications attached to the

job.

Send 2 copies of each job marked with the press

serial number and the date to your service center.

Page 6

2 Million Imp - Preventive Maintenance Guide - HP Indigo press 5000

CA294-00570 rev 01 page 6 of 18

2 million imp. maintenance

NOTE: To be performed together with the monthly routines.

Date: Time spent:

HP Indigo press 5000 S/N: Service person:

Customer name: Country/State:

Required parts

Complete CE kit. See page 12.

ITM drum

Check the bias carbon brush on the rear wall, and

replace, if required.

Check the ITM overheat thermal fuse carbon brushes

on the front wall, and replace, if required.

Make sure that the housing did not come loose from

the press wall.

Note: See "Conditional replacement" on page 12.

PIP drum

Check the grounding brush, and replace, if required.

Check the condition of the SofSub (PIP underlayer).

IMP drum

Replace the gripper clamps.

Check the grippers magnet gap, and adjust as

required.

Cleaning station

Replace the sponge roller.

Check the drive belt tension.

Paper transport

Clean all rollers and sensors.

Clean paper path.

Clean Feeder elastic bridge conveyor belts with IPA.

Clean Feeder drawer tray.

Clean paper transport sensors.

Replace exit roller and springs.

Page 7

2 Million Imp - Preventive Maintenance Guide - HP Indigo press 5000

CA294-00570 rev 01 page 7 of 18

2 million imp. maintenance (continued)

Clean the lower feed roller and pinch rollers (IFR) with

IPA.

Check the duplex conveyor-impression drum gap, and

adjust, if necessary.

Replace perfector suction cups.

Clean Stacker paper path with IPA.

Check Stacker flipping wheels.

Check that the paper buckle is correct. Adjust if

necessary.

Perform the suction cup margin adjustment wizard.

Perform the full placement adjustment wizard.

Utility cabinet

Check oil level in solid air compressor.

Clean vacuum pump filters. See "Appendix B Vacuum pump maintenance" on page 14.

Drain water separator - open service valve for 30

seconds.

Chiller unit

Check water level.

Clean the water filter, and replace, if needed. See the

chiller manual.

Inline densitometer

Print a new reference densitometer full calibration

strip if one is not available, and perform the validation

procedure. See the HP Indigo service instruction for

the Inline Densitometer.

Instruct the operator to store the strip in a dark, clean

place.

Lubrication

Make sure that all lubrication points have been oiled

and greased properly, including the exit elevator

gears and chains. See "Appendix C - Grease and oil

types" on page 17. For a complete list, check the

User Guide, or view the press On-line documentation

videos (OPD).

Page 8

2 Million Imp - Preventive Maintenance Guide - HP Indigo press 5000

CA294-00570 rev 01 page 8 of 18

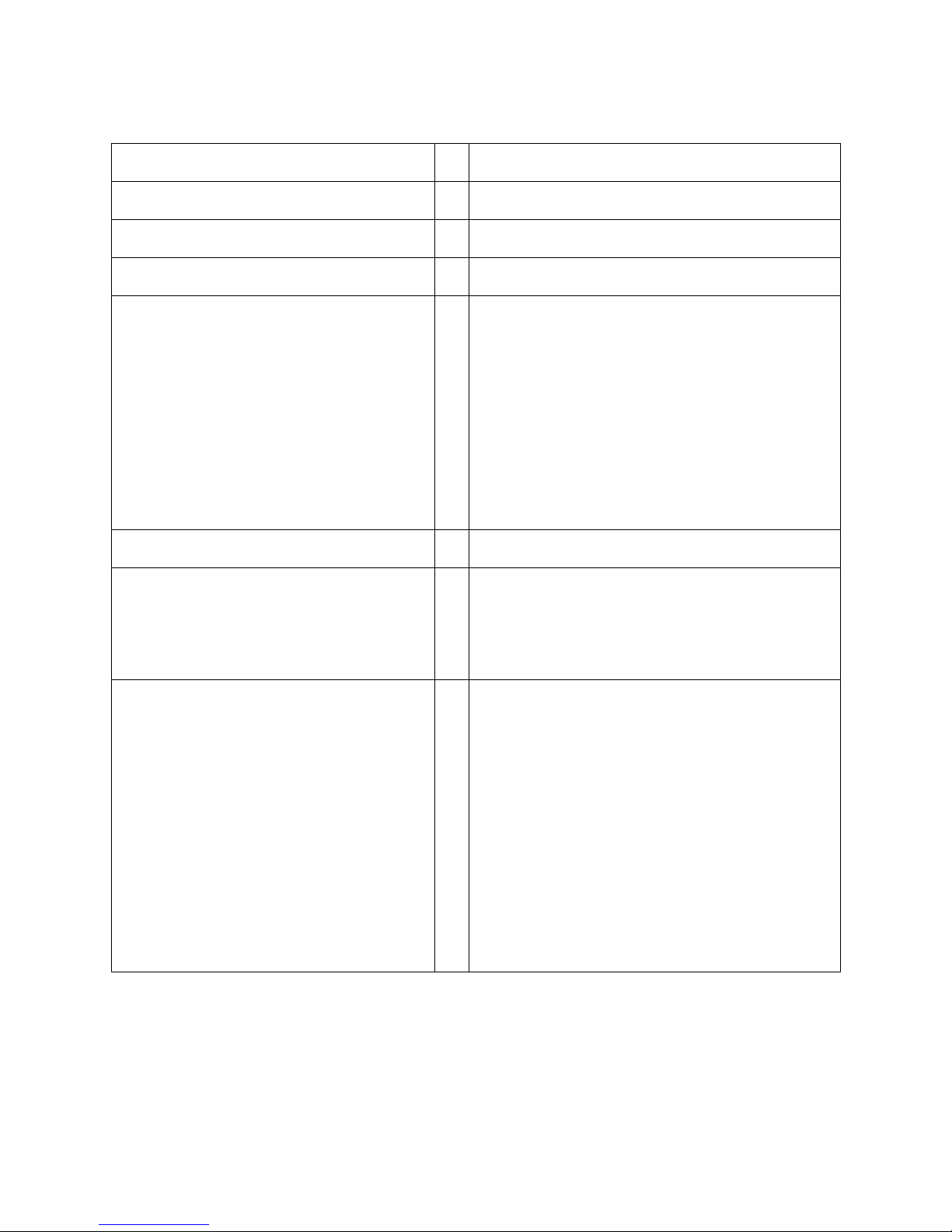

Quick check maintenance table

Component Mo 2M X Procedure

General inspection

9

9

9

9

Check for external dirt, leakage and signs of improper

maintenance. Initiate a service call if there is a leakage problem.

Verify that daily and weekly operator routines have been

performed correctly. See the latest User Guide.

Verify that all lubrication points have been oiled and greased

properly. See the latest User Guide.

Inform your regional manager if the press is not properly

maintained.

Config save

9

Perform Config save to update the customer diskette.

Ink unit

9

9

9

Calibrate the density sensors.

Calibrate the ink conductivity sensors.

Calibrate the ink flow rate.

ITM drum

9

9

9

9

9

9

9

9

Clean ITM slip ring (the bias contacts path) using IPA.

Clean the ITM thermostat slip ring.

Verify the temperature sensor reading, and calibrate, if required.

Make sure that the surface facing the IR sensor is clean.

Inspect and thoroughly clean the ITM hood wire mesh filter on

the rear wall using IPA soaked cloth. Caution: Shut down the

press before removing the mesh.

Check the bias carbon brush on the rear wall, and replace, if

required.

Check the ITM overheat thermal fuse carbon brushes on the

front wall, and replace, if required.

Make sure that the housing did not come loose from the press

wall.

Note: See Conditional replacement on page 12.

PIP drum

9 9

Check the grounding brush, and replace, if required.

Check the condition of the SofSub (PIP underlayer).

Page 9

2 Million Imp - Preventive Maintenance Guide - HP Indigo press 5000

CA294-00570 rev 01 page 9 of 18

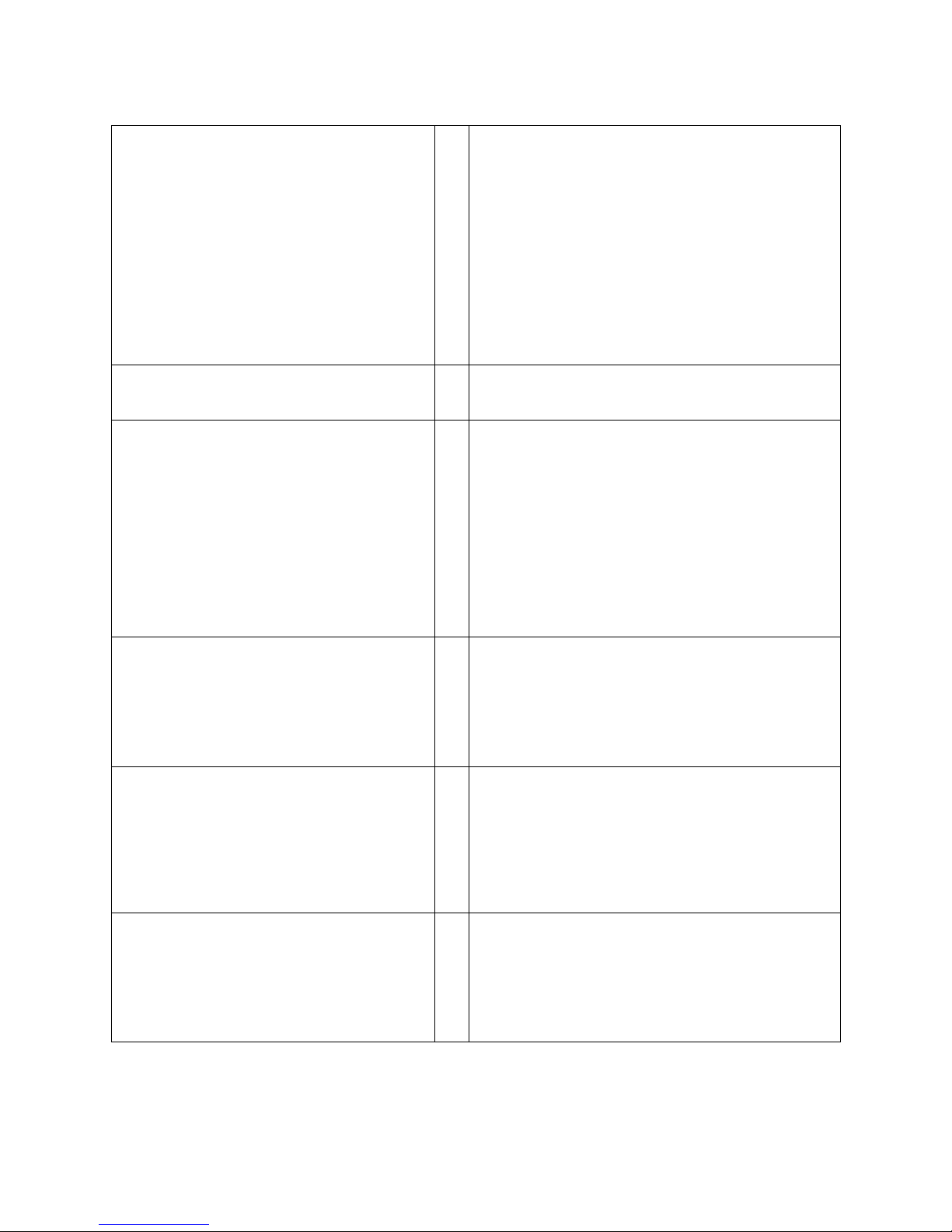

IMP drum

9

9

9

9

9

9

9

Inspect grippers area, and pay special attention to cleanliness.

Check the stop stations for freedom of movement.

Make sure that the gripper cam followers are secured to the

drum.

Make sure that the dummy cam followers move freely, and

inspect the springs.

Oil the dummy cam follower arms and gripper arms.

Replace the gripper clamps.

Check the grippers magnet gap, and adjust as required.

Perfector

9

Replace suction cups (x8).

Scorotrons

9

9

9

9

Perform a general inspection.

Inspect the inside housing sides for the formation of insulating

layer. Clean with IPA soaked cloth. Use an abrasive cleaning

pad, if required.

Inspect each corona unit for loose or broken grid rails. Glue or

replace, if necessary.

If 1 million impressions have been reached, replace the four

carbon filters.

PTE - air knife

9

9

9

Perform a general inspection, and check for paper chips.

Clean the PTE shield.

Clean and check the LED operation.

Cleaning station

9

9

9

9

9

If 1 million impressions have been reached, clean the wetting

roller.

If 1 million impressions have been reached, replace the sponge

roller.

Check the imaging oil flow rate; run imaging oil for 1 minute

before calibration.

Replace the sponge roller.

Check the drive belt tension.

Page 10

2 Million Imp - Preventive Maintenance Guide - HP Indigo press 5000

CA294-00570 rev 01 page 10 of 18

Paper transport

9

9

9

9

9

9

9

9

9

9

9

9

9

9

Clean all rollers and sensors.

Clean paper path.

Clean Feeder elastic bridge conveyor belts with IPA.

Clean Feeder drawer tray.

Clean paper transport sensors.

Replace exit roller and springs.

Clean the lower feed roller and pinch rollers with IPA.

Check the duplex conveyor-impression drum gap, and adjust, if

necessary.

Replace perfector suction cups.

Clean Stacker paper path with IPA.

Check Stacker flipping wheels.

Check that the paper buckle is correct. Adjust if necessary.

Perform the suction cup margin adjustment wizard.

Perform the full placement adjustment wizard.

Utility cabinet

9

9

9

9

9

9

Perform general inspection.

Externally clean the heat exchanger, if necessary.

Drain water separator - open service valve for 30 seconds.

Check oil level in solid air compressor.

Clean vacuum pump filters. See "Appendix B - Vacuum pump

maintenance" on page 14.

Drain water separator - open service valve for 30 seconds.

Chiller unit

9 9

Check water level.

Clean the water filter, and replace, if needed. See chiller manual.

Page 11

2 Million Imp - Preventive Maintenance Guide - HP Indigo press 5000

CA294-00570 rev 01 page 11 of 18

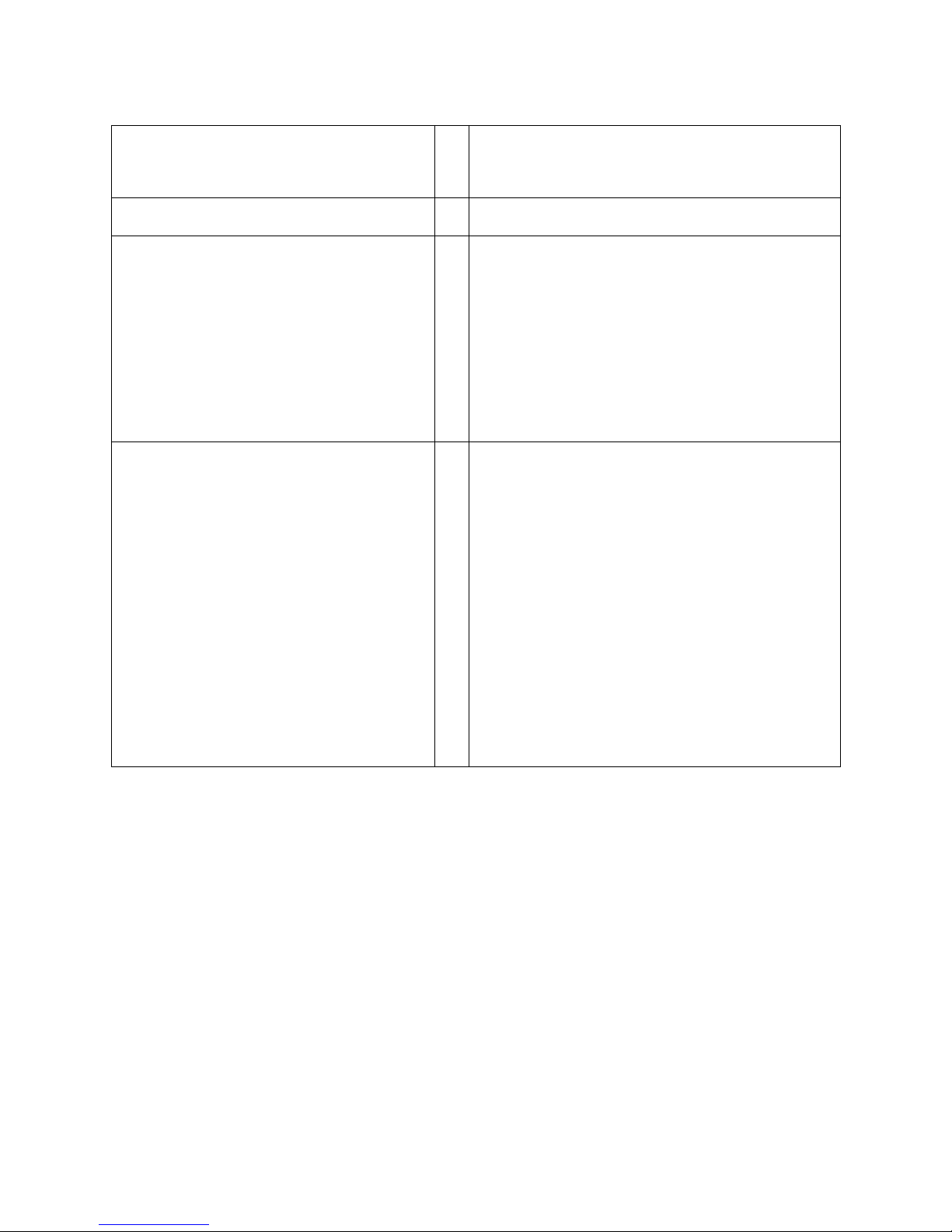

Inline densitometer

9

9

Print a new reference densitometer full calibration strip, if one is

not available, and perform the validation procedure. See the HP

Indigo service instruction for the Inline Densitometer.

Instruct the operator to store the strip in a dark, clean place.

Lubrication

9

9

Make sure that all lubrication points have been oiled and greased

properly. See "Appendix C - Grease and oil types" on page 17.

Make sure that all lubrication points have been oiled and greased

properly, including the exit elevator gears and chains. See

"Appendix C - Grease and oil types" on page 17. For a complete

list, check the User Guide, or view the press On-line

documentation videos (OPD).

BID engage

9

Verify that the BID fans are working properly.

Ventilation system

9

9

9

9

Make sure that all the Amateks are working properly:

Scorotron (suction and blower).

ITM input fan.

Air knife (suction and blower).

Bottom cooling.

Print quality

9

9

9

9

9

Perform the following:

Print Fine_Tune job, adjust if necessary.

Print a gray_20 job, and verify the quality of the print.

Check writing head deskew, and adjust, if necessary. Use the

gray_20 job to observe banding of ~3.5 mm along the format that

appears due to an incorrect deskew adjustment.

Print the CATP job. Check the press performance according to

the table of specifications attached to the job.

Send 2 copies of each job, marked with the press serial number

and the date, to your service center.

Page 12

2 Million Imp - Preventive Maintenance Guide - HP Indigo press 5000

CA294-00570 rev 01 page 12 of 18

Special tools and jigs

Density sensor cleaning paper MJX-0221-51

Monthly routine parts

Checklist/BOM (CA290-00960)

Upon reaching 1 million impressions

Part number Description Quantity

MFL-0013-01 Carbon filter 4

MPT-1078-51 Gray sponge roller 1

MKT-1060-01 Suction cups kit 1

2 million imp. routine parts

Mandatory replacement

Part number Description Quantity

MFL-0013-01 Carbon filter 4

CA244-11150 Gripper clamp 6

MPT-1078-51 Gray sponge roller 1

CA245-04160 Exit roller 1

MPT-4737-01 Exit roller springs 2

Conditional replacement

Part number Description Quantity

EZO-2111-02

EZO-2113-01

CA244-09380

Carbon brush (rear ITM & PIP)

Thermal carbon brush (front ITM)

Carbon brush (new type for ITM)

2

2

1

MPT-8383-51 Wetting roller assembly 1

Page 13

2 Million Imp - Preventive Maintenance Guide - HP Indigo press 5000

CA294-00570 rev 01 page 13 of 18

Appendix A - Imaging oil pump maintenance

Figure 1 Imaging oil system

Printing engine

frame

Ink cabinet

Imaging oil refill

funnel assembly

Heat exchanger

Imaging agent refill

funnel assembly

C

leaning station

Imaging oil

filter assembly

Imaging oil

tank

Imaging oil

tank gauge

Tank level tube

Imaging oil pump

Figure 2 Oiling points for the imaging oil pump

Oiling points

Page 14

2 Million Imp - Preventive Maintenance Guide - HP Indigo press 5000

CA294-00570 rev 01 page 14 of 18

Appendix B - Vacuum pump maintenance

To perform vacuum pump maintenance, do the following:

1. Remove the water and process oily waste bottles from their positions behind the lower service

door at the press rear. See Figure 3.

Figure 3 Press rear

1

2

3

1

2

3

1 - Waste bottles 2 - Vacuum pump 3 - Removable door

2. Lift up the lower door and remove it. See Figure 3.

3. Disconnect the fast-on tube. See Figure 4.

Figure 4 Vacuum pump location

1

3

2

1

3

2

1 - Fast-on tube 2 - Vacuum pump filters 3 - Muffler filter

4. Remove the vacuum pump filters. See Figure 4.

Page 15

2 Million Imp - Preventive Maintenance Guide - HP Indigo press 5000

CA294-00570 rev 01 page 15 of 18

Figure 5 Vacuum pump assembly

(8-10) - Vacuum pump filters 6 - Muffler box 11 - Muffler filter

2 - Vane 4 - End plate 5 - Gasket

7 - Vacuum pump filter O-ring

5. Remove the muffler box with its five retaining screws. See Figure 5.

For 2 million preventive maintenance

1. Clean the vacuum pump filters using pressurized air. See Figure 5.

2. Clean the muffler box with a clean, dry cloth. See Figure 5.

3. Clean the muffler filter. See Figure 5.

For 8 million preventive maintenance

1. Remove the end plate with its five retaining screws. See Figure 5.

2. Remove the four old vanes. See Figure 5 and Figure 6.

Page 16

2 Million Imp - Preventive Maintenance Guide - HP Indigo press 5000

CA294-00570 rev 01 page 16 of 18

Figure 6 Vacuum pump vanes

11

3. Clean the inside of the pump. See Figure 6.

4. Install new vanes. See Figure 6.

5. Reinstall the end plate and its five retaining screws with a new gasket from the maintenance

kit.

6. Install new O-rings and clean filters. See Figure 5.

7. Reinstall muffler box.

8. Reconnect the fast-on tube.

Page 17

2 Million Imp - Preventive Maintenance Guide - HP Indigo press 5000

CA294-00570 rev 01 page 17 of 18

Appendix C - Grease and oil types

Item Type Supplier

Grease, mechanic:

General greasing points

NLGI #1

Shell Alvania 1 EP or R1

Mobilux EP1

Or equivalent

Purchase locally

Gear oil sep 32:

General oiling points

ISO VG100

Sell GC SE100

Mobil DTE Heavy

Esso Spartan EP-100

Or equivalent

Purchase locally

Grease BG-87 Molykote:

For main drum (PIP, ITM,

and impression) gear

lubrication only.

Molykote BG-87

Or equivalent

Purchase locally

Oil, compressor:

ISO VG32 or VG46

Shell Tellus 32 or 46

Mobil DTE 24 or 46

Or equivalent

Purchase locally

Note:

For further information, contact your local Customer Center.

Page 18

2 Million Imp - Preventive Maintenance Guide - HP Indigo press 5000

CA294-00570 rev 01 page 18 of 18

Revision history

Revision Description

00 Initial document

01 Updated part numbers

Responsible engineer Michael Selinger

Group manager Neev Elbaz

R&D engineer Michal Lavi

Engineering Ami Kellner

Documentation manager Ronit Shugal

Written by John Burket/William Easley/Isaac Diwan

Confidentiality Notice

This document contains valuable trade secrets and confidential information of Hewlett-Packard Company. Nothing herein may

be copied, reproduced or distributed in any form or medium, or disclosed to any third party in any manner, without prior written

authorization of Hewlett-Packard Company. The copyright notice, which appears in this document, is purely precautionary and

shall not be deemed to constitute publication or intent to publish, in whole or in part.

©Copyright Hewlett-Packard Company, 2005. All rights reserved.

Loading...

Loading...