HP HPWT-DL00, HPWT-MH00, HPWT-ML00, HPWA-DH00, HPWA-DL00 Datasheet

...

Super Flux LEDs

Technical Data

H

SunPower Series

HPWA-MH00

HPWA-DH00

HPWA-ML00

HPWA-DL00

HPWR-M300

HPWT-MH00

HPWT-DH00

HPWT-ML00

HPWT-DL00

Benefits

• Fewer LEDs Required

• Lowers Total System Cost

Features

• High Flux Output

• Designed for High Current

Operation

• Low Thermal Resistance

• Low Profile

• Meets SAE/ECE/JIS

Automotive Color

Requirements

• Packaged in Tubes for Use

with Automatic Pick and

Place Equipment

Applications

• Automotive Exterior

Lighting

• Moving Message Panels

• Small and Large Area

Displays

• Backlighting

Description

This revolutionary package design

allows the lighting designer to

reduce the number of LEDs

required and provide a more

uniform and unique illuminated

appearance than with existing

LED solutions. This is possible

through the package’s efficient

optical design and high-current

capabilities. The low profile

package can be easily coupled to

reflectors or lenses to efficiently

distribute light and provide the

desired illuminated appearance.

This product family employs red,

red-orange, and amber LED

materials, which allow designers

to match the color of popular

lighting applications, such as

automotive tail, stop, and turn

signal lamps, and area displays.

Included in this family is the

world’s brightest amber LED

material, which is ideal for area

displays and general backlighting

applications.

Device Selection Guide

Total Flux Viewing Angle

Part Number LED Color φv (mlm) @ 70 mA

HPWR-M300 TS AlGaAs Red 800 90

HPWA-MH00 AS AlInGaP Red-Orange 1250 90

HPWA-DH00 60

HPWA-ML00 AS AlInGaP Amber 1250 90

HPWA-DL00 60

HPWT-MH00 TS AlInGaP Red-Orange 2500 70

HPWT-DH00 40

HPWT-ML00 TS AlInGaP Amber 2500 70

HPWT-DL00 40

Notes:

1. φV is the total luminous flux output as measured with an integrating sphere.

2. θ1/2 is the off axis angle from optical centerline where the luminous intensity is 1/2 the on-axis value.

5964-2064E

[1]

Typ. 2θ1/2 (Degrees) Typ.

1-25

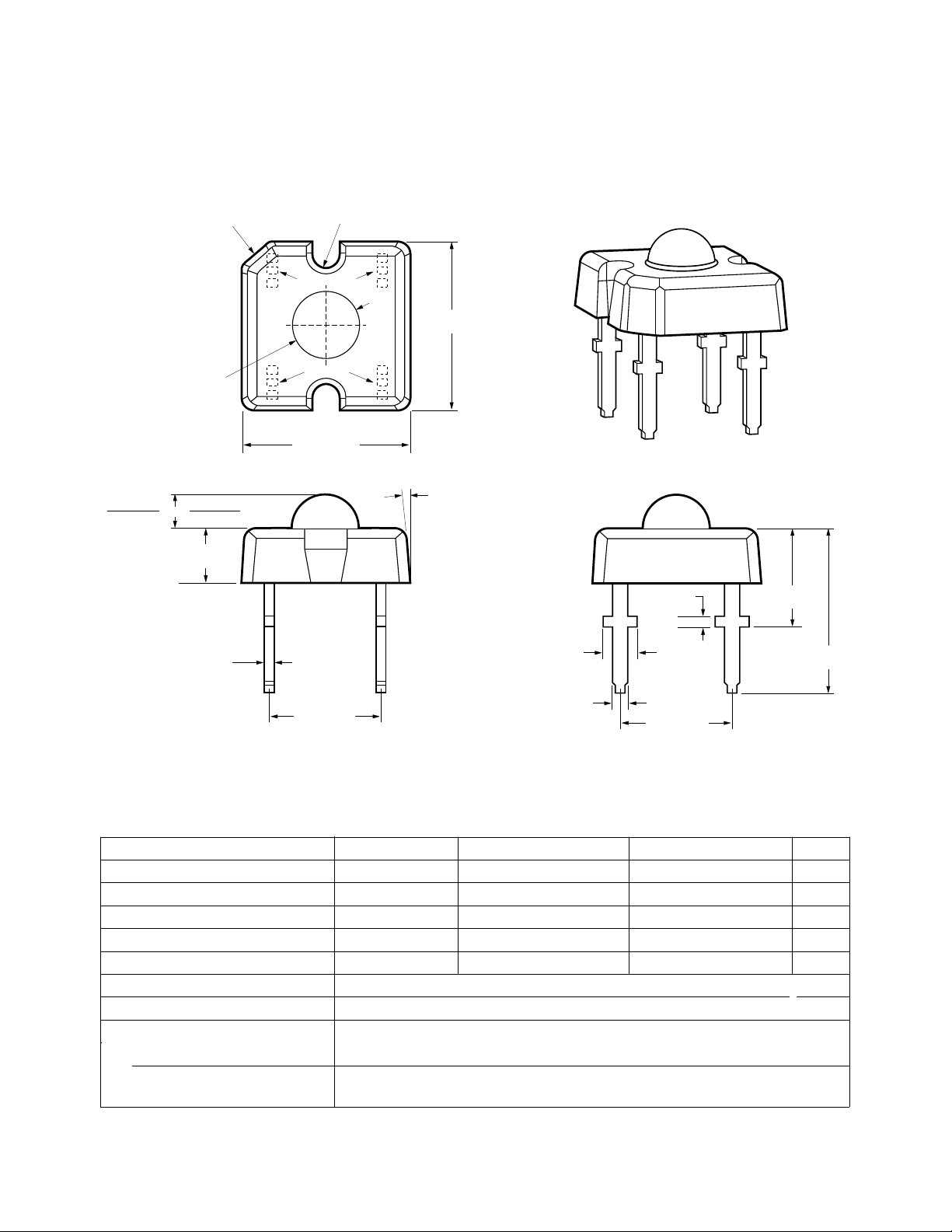

Outline Drawing

CHAMFER 1.25 x 1.25

(0.049 x 0.049)

2 x R

(0.027 ± 0.008)

C C

CATHODE

0.69 ± 0.20

7.62 ± 0.50

(0.300 ± 0.020)

MX00

1.50 (0.059)

(0.016 ± 0.008)

3.00 ± 0.20

φ

(0.118 ± 0.008)

OR

1.90 (0.075)

2.50 ± 0.50

(0.098 ± 0.020)

0.40 ± 0.20

ANODE

A A

7.62 ± 0.50

(0.300 ± 0.020)

DX00

TYP.

5.08 ± 0.30

NOTES:

1. DIMENSIONS ARE IN MILLIMETERS (INCHES).

2. DIMENSIONS WITHOUT TOLERANCES ARE NOMINAL.

3. CATHODE LEADS ARE INDICATED WITH A "C" AND

ANODE LEADS ARE INDICATED WITH AN "A".

(0.200 ± 0.012)

5.0° TYP.

1.55 ± 0.20

(0.061 ± 0.008)

0.76 ± 0.10

(0.030 ± 0.004)

TYP.

TYP.

0.50 (0.020)

TYP.

5.08 ± 0.20

(0.200 ± 0.008)

4.40 ± 0.20

(0.173 ± 0.008)

7.50 ± 0.20

(0.295 ± 0.008)

Absolute Maximum Ratings at T

= 25°C

A

Parameter HPWR-M300 HPWA-MX00/DX00 HPWT-MX00/DX00 Units

DC Forward Current

[1]

70 70

[2,3]

70

[2,3]

Power Dissipation 161 147 193 mW

Reverse Voltage (IR = 100 µA) 10 10 10 V

Operating Temperature Range -40 to +100 -40 to +100 -40 to +100 °C

Storage Temperature -55 to +100 -55 to +100 -55 to +100 °C

High Temperature Chamber 125°C, 2 hrs. max.

LED Junction Temperature 125°C

Solder Conditions

Preheat Temperature 100° C

Solder Temperature 260°C for 5 seconds

[1.5 mm (0.06 in.) below seating plane]

Notes:

1. Derate linearly as shown in Figure 4a and 4b.

2. Drive Currents between 10 mA and 30 mA are recommended for best long term performance.

3. Operation at currents below 10 mA is not recommended, please contact your Hewlett-Packard sales representative.

1-26

mA

Loading...

Loading...