Page 1

Errata

4342A Q-meter Operating and

Service Manual

04342-90006

March 1983

Thanks to John Day who provided this scanned copy

Title & Document Type:

Manual Part Number:

Revision Date:

HP References in this Manual

This manual may contain references to HP or Hewlett-Packard. Please note that HewlettPackard's former test and measurement, semiconductor products and chemical analysis

businesses are now part of Agilent Technologies. We have made no changes to this

manual copy. The HP XXXX referred to in this document is now the Agilent XXXX.

For example, model number HP8648A is now model number Agilent 8648A.

About this Manual

We’ve added this manual to the Agilent website in an effort to help you support your

product. This manual provides the best information we could find. It may be incomplete

or contain dated information, and the scan quality may not be idea l. If we find a better

copy in the future, we will add it to the Agilent website.

Support for Your Product

Agilent no longer sells or supports this product. You will find any other available

product information on the Agilent Test & Measurement website:

www.tm.agilent.com

Search for the model number of this product, and the resulting product page will guide

you to any available information. Our service centers may be able to perform calibration

if no repair parts are needed, but no other support from Agilent is available.

Page 2

MET6LoGY

JAN 21 1986

thERATING

i

.

AND

SERVICE MANUAL

434.2A.

HEWLETT

I?!!

PACKARD

Page 3

COPYRIGHT AND DISCLAIMER NOTICE

Copyright - Agilent Technologies, Inc. Reproduced with the permission of Agilent

Technologies Inc. Agilent Technologies, Inc. makes no warranty of any kind with regard

to this material including, but not limited to, the implied warranties of merchantability

and fitness for a particular purpose. Agilent Technologies, Inc. is not liable for errors

contained herein or for incidental or consequential damages in connection with the

furnishing, performance, or use of this material or data.

Page 4

CERTI FI CATI 0 N,

The Hewlett-Packard Company certifies that this instrument was

thoroughly tested and inspected and found to meet its published

specifications when it was shipped

Packard -Company further

ments are traceable to the U.S. National Bureau

the extent allowed by the Bureau’s calibration facility.

certifies

from

the factory. The Hewlett-

that its calibration meusure-

of

Standards to

WARRANTY AND ASSISTANCE

All Hewlett-Packard products are warranted against defects in

materials and workmanship. This warranty applies for one year

from the date of delivery, or, in the case of certain major compo-

nents listed in the operating manual, for the specified period. We

will repair or replace products which prove to be defective during

the warranty period provided they are returned to Hewlett-

Packard. No other warranty is expressed or implied. We are not

liable for consequential damages.

Service contracts or customer assistance agreements are available

for Hewlett-Packard products that require maintenance and re-

pair on-site.

For any assistance, contact your nearest Hewlett-Packard Sales and

Service Office. Addresses are provided at the back of this manual.

Page 5

OPERATING AND SERVICE

MODEL 4342A

Q METER

SERIAL NUMBERES COVERED

This manual applies directly to Model 43428 Q Meter

with serial prefixed 12125. Backdating changes in

SectionVII cover instruments with serials 12125-00590

and below. Instruments with higher serial prefix will

be covered in an Updating Manual Supplement at the

first of the manual.

MANUAL

This manual cover-es Option 001 instruments as well

as the standard instrument.

aCOPYRIGHT: YOKOGAWA-HEWLETT-PACKARD, LTD., 1970

9-1, TAKAKURA-CHO, HACHIOJI-SHI, TOKYO, JAPAN

Manual Part No. 04342-90009

Microfiche Part No. 04342-90059

OPTIONS COVERED

Printed: MAR. 1983

HEWLETT

PACKARD

Page 6

Table

of Contents

Model 4342A

TABLE OF CONTENTS

Section

GENERAL INFORMATION

I

Title Page

...................................

l-l. Introduction.. .......................................

1-3.

How the 4342A Measures

l-8. Instruments Covered by Manual

1-13.

Specifications .......................................

1-15. Accessories Supplied

1-17. Accessories Available

l-19. Options..

II INSTALLATION

2-l. Introduction

2-3. Initial Inspection

...........................................

...........................................

.........................................

.....................................

2-4. Mechanical Check

2-6.

Performance Check

2-8. Damage Claim

2-11. Storage and Shipment

.............................

.......................

................................

............................... I-3

..............................

............................. 2-I

.................................

.................................

2-12. Packaging .....................................

2-13. Environment

2-14.

2-15.

2-16.

III OPERATION

3-l.

3-3.

Power Connection

Line Voltage

Power Cable

........................................................................................

Introduction

Panel Controls, Connectors and Indicators

3-5. Q Measurement General

...................................

....................................

...................................

...................................

.............................. 3-l

3-8. Go/No-Go Function ..................................

3-10. Measurement Terminals

3-12. How to Connect Unknown

..............................

..............................

3-14. Measurement Parameters and Connection Methods

3-16.

3-18.

3-20.

3-22.

3-24.

Direct Method Limitations

Expansion of Measurement Ranges

Capacitance Measurement

Resistance Measurement

High Q Measurement

....................... 3-5

....................... 3-6

........................

........................... 3-7

3-26. Supplemental Equipment Used in Parallel

......................... 3-7

.........................

3-30.

3-31.

and Series Methods

Basic Q Meter Measurements

Quality Factor and Inductance

Measurements (Direct Connection)

3-33. Q Measurement

3-35.

dQ Measurement

3-37. Inductance Measurement

3-39.

3-41.

3-42.

3-45.

Inductance Measurement (at a desired frequency).

Measurement Requiring Corrections

Effects of Distributed Capacitance

Measuring Distributed Capacitance

(Preferred Method)

3-47.

Measuring Distributed Capacitance

(Approximate Method, Cd IlOpF)

3-49. Correction for Q

3-55.

Parallel and Series Connection Measurement Methods

................................

...............................

........................

................... 3-13

.........................

...............................

3-56. General .......................................

3-60.

3-64.

Parallel Measurements

Additional Error Discussion

...............................

3-65. High Inductance Measurement

3-67.

3-69.

3-71.

Low CapacitanceMeasurement (~45OpF) ..........

High Resistance Measurement

Dielectric Measurement

...................

....................

................... 3-20

........................

.............

...............

........... 3-11

................

............

1-I

l-l

l-2

l-2

l-3

1-3

l-3

2-l

2-i

2-l

2-I

i::

2-l

2-I

i-t

-

2-1

;-;

-

3-l

3-l

3-5

3-5

...... 3-5

3-6

3-6

3-11

3-11

3-12

3-12

.. 3-13

3-13

3-14

3-15

3-16

... 3-1’7

3-17

3-17

3-18

3-18

3-19

3-21

Page 7

Model 43426 Table of Contents

Section Title Page

3-73. Series Measurements ................................

3-23

3-74. Low Inductance Measurement .................... 3-23

3-76. High Capacitance Measurement (>450pF) .........

3-24

3-78. Self-resonant Frequency Measurement

of High Capacitors .......................... 3-24

3-80. Low Resistance Measurement

....................

3-26

IV THEORY OF OPERATION ................................... 4-l

4-l.

4-3.

Introduction.. ....................................... 4-1

Q Determination and Measurement ..................... 4-l

4-6. Simplified Block Diagram ............................. 4-l

4-8. Block Diagram Description ...........................

4-l

4-10. Oscillator and Impedance Converter (AlAl) ....... 4-l

4-12.

4-14. ALC Amplifier (P/O A8)

4-16. Q/AQ Range Attenuator (A3) .....................

RF Power Amplifier (AlA2) ..................... 4-l

........................

4-2

4-2

4-18. Tuning Capacitor and Injection Transformer (A2). .. 4-2

4-21.

4-24. DC Amplifier (A6)

4-26.

4-28. Circuit Details

4-29. LC Oscillator (P/O AlAl) .......................

RF Amplifier and Detector (A5) .................. 4-2

Q Limit Selector (A7) ...........................

..............................

......................................

4-2

4-2

4-2

4-2

4-31. Impedance Converter (P/O AlAl) and RF

Power Amplifier (AlA2) .... 4-3

4-33.

4-35. Q Range Attenuator (A3)

4-37.

ACL Amplifier (P/O A8) ........................ 4-3

........................

4-3

Impedance Converter, RF Amplifier

and Detector (A5)

...... 4-3

4-39. DC Amplifier (A6) .............................. 4-3

4-41. Q Limit Selector (A7)

4-43. Power Supply (P/O ~8)

........................... 4-3

.........................

4-3

V MAINTENANCE

5-l.

Introduction ......................................... 5-l

............................................

5-3. Test Equipment Required ............................. 5-l

5-5.

Q Accuracy Considerations ........................... 5-l

5-7. Option .............................................. 5-l

5-9. Performance Checks

5-11. Frequency Accuracy Check..

5-12.

5-13.

QRange Check.. ............................... 5-3

AQ Range Check ............................... 5-4

5-14. Capacitance Accuracy Check

5-15. Q Limit Operation Check

.................................

....................

....................

........................ 5-5

5-16. Adjustment and Calibration Procedures ................

5-18.

5-19. Oscillator Level Adjustment

Power Supply Adjustment

........................

.....................

5-20. Oscillator Frequency Adjustment ................. 5-8

5-21.

5-22.

5-23. Frequency Response Adjustment

5-24. Q Limit Selector Adjustment

5-25. Option 001 Maintenance Instructions

Q Voltmeter Adjustment ........................ 5-9

Q Analog Output Adjustment .....................

.................

.....................

...................

5-27. Option 001 Performance Checks ..................

5-29. Option 001 Calibration and Adjustment Procedures . 5-13

5-31.

Dial Re-stringing Instructions .........................

5-34. Frequency Dial ................................. 5-14

5-35.

L/C Dial

......................................

5-36. AC Dial .......................................

5-37. Troubleshooting Guides ...............................

5-39. High Frequency Line Noise

5-40.

Operating in a Strong Electromagnetic Field .......

......................

5-41. Operating in High Humidity Environment .......... 5-18

5-l

5-3

5-3

5-4

5-8

5-8

5-8

5-10

5-11

5-11

5-12

5-12

5-14

5-14

5-14

5-18

5-18

5-18

. .

111

Page 8

Table of Contents

List of Tables

Model 4342A

Section

5-42.

5-43.

5-44.

5-45.

5-46.

Elementary Troubleshooting Guide

Meter Zeroing Troubles ........................

Incorrect Q Meter Indication

Low Q Indication in High Frequency

Faulty Q Limit Operation

VI REPLACEABLE PARTS

6-l.

Introduction.. ....................................... 6-l

Title

.................................... 6-l

6-6. Ordering Information .................................

VII MANUAL CHANGES AND OPTIONS

7-1.

7-3.

7-5.

Options

Special Instruments .................................

Manual Changes .....................................

............................................. 7-l

7-7. Later Instruments

7-8.

7-9.

VIII CIRCUIT DIAGRAMS

Earlier Instruments ............................

Option 001 Instruments .........................

.......................................

..........................

..............................

8-l. Introduction .........................................

8-4.

APPENDIX OPTION 001

I

II Manual Changes

III

GeneralNotes

.......................................

........................................ A-l

Replaceable Parts

Circuit Diagrams

................................... A-l

.....................................

....................................

Page

.....................

5-18

5-18

..................... 5-18

Measurements

.......... 5-19

....................... 5-19

A-l

A-2

6-l

7-l

7-l

7-l

7-l

7-l

7-l

8-l

8-l

8-l

Number

l-l.

l-2.

2-l.

3-l.

3-2.

3-3.

3-4.

5-l.

5-2.

5-3.

5-4.

5-5.

5-6.

5-7.

5-8.

5-9.

6-l.

6-2.

7-l.

LIST OF TABLES

Title

Specifications

Accessories - Typical Values

.......................................

.........................

AC Line Fuse .......................................

Methods of Connecting Unknown .......................

16451A (4342A-KOl) Typical Characteristics

............ 3-21

Formulas for Calculating Q and Impedance Parameters

from Parallel and Series Measurements

Formulas Relating Series and Parallel Components

.......... 3-27

...... 3-27

Recommended Test Equipment ........................

Q Correlation Factors

Frequency Accuracy Check

............................... 5-l

........................... 5-2

QRange Check ......................................

Capacitance Accuracy Check

Adjustable Components

Frequency Adjustment.

Frequency Accuracy Check (Option 001)

Frequency Adjustment (Option 001).

List of Reference Designators and Abbreviations

.......................... 5-5

............................... 5-7

............................... 5-8

................

.................... 5-13

........ 6-l

Reference Designation Index ..........................

Backdating Changes

..................................

Page

1-2

l-3

2-l

3-10

5-o

5-3

5-12

6-3

7-l

iv

A-l.

A-2.

Reference Designation Index for Option 001 (Al Al Ass’y). .

Reference Designation Index for Option 001 (A5

Ass’y)

....

A-3

A-5

Page 9

Model 4342A List of Illustrations

LIST OF ILLUSTRATIONS

Number Title

l-l.

3-l.

3-2.

3-3.

3-4.

3-5.

3-6.

3-7.

3-8.

3-9.

Model 4342A Q Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Controls

................................

Rear Panel Controls and Connectors

Measurement Terminal Circuit

Inductance Measurement Ranges vs. Frequency

Ranges of Measurable Resistance

Zeroing Procedure

...................................

Distributed Capacitance in Direct Connection ........... 3-11

Distributed Capacitance Circuit Model

Typical Variation of Effective Q and

Inductance with Frequency ....... 3-14

3-10.

3-11.

4-l. Series Resonant Circuit

4-2.

4-3.

5-l.

5-2.

5-3.

5-4.

5-5.

5-6.

5-7.

5-8.

5-9.

5-10.

5-11.

5-12.

5-13.

Correction Chart for Distributed Capacitance ........... 3-14

Residual Parameters .................................

..............................

Model 43426 Simplified Block Diagram

Constant Voltage Injection System

Q Range Check

AQ

Range Check

......................................

.....................................

Capacitance Accuracy Check

Model 4342A Adjustment Locations

Model 4342A Assembly Locations

Voltmeter Adjustment

................................ 5-10

Frequency Response Adjustment

Frequency Dial Restringing

Main C Dial Restringing

AC Dial Restringing

.............................. 5-16

..................................

Tuning Capacitor Disassembly (top view) ............... 5-19

Troubleshooting, Oscillator Section

Troubleshooting, Voltmeter Section

Page

l-l

3-2

...................

.......................

(direct method)

......................

.........

3-4

3-5

3-6

3-7

3-8

................. 3-13

3-17

4-o

.................

.....................

..........................

....................

...................... 5-6

......................

........................... 5-15

4-O

4-2

5-2

5-3

5-4

5-6

5-11

5-17

................... 5-21

...................

5-19

6-l.

6-2.

6-3.

6-4.

Exploded View of Oscillator Ass’y

.....................

Exploded View of Tuning Capacitor Ass’y

Exploded View of Q Range Attenuator Ass'y

Exploded View of Frequency Multiplier, Over Limit

Indicator, and Frequency Scale Indicator

6-5.

6-6.

6-7.

6-8.

7-1. A7 04342-7707 .......................................

7-2. All 04342-7711

7-3.

8-1.

8-2.

8-3.

Exploded View of Main and Vernier Capacitor

Exploded View of Oscillator Lever Ass’y

Exploded View of Rear Panel

Exploded View of Handle Section

Partial Schematic of Power Supply

...................................... 7-2

Schematic Diagram Notes . .

Function Overall Block Diagram

Oscillator

Ass'y Al,

Q Range Attenuator

..........................

......................

.................... 7-5

. . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

. . . . . . . . . . . . . . . . . . . . . . 8-3

Power Supply & ACL Amplifier Ass’y A8,

Frequency Multiplier & Over Limit Indicator

.............. 6-24

.............

..........

Dial Ass’y

...... 6-28

...............

Ass'y A3,

Ass'y

AlO.. 8-5

6-22

6-26

6-27

6-29

6-30

6-32

7-2

Page 10

List of Illustrations

Model 4342A

Number Title Page

8-4. Tuning Capacitor Ass’y A2, QRange Attenuator Ass’y A3,

8-5.

8-6. Q Limit Selector Ass’y A7

8-7.

A-l

A-2.

Impedance Converter Ass’y A4,

Meter Scale Indicator Ass’y All . . . . . . . . . . . . . . . . . . . . . . . 8-7

Q Range Attenuator Ass’y A3, Impedance Converter, RF

Amplifier &Detector Ass’y A5, DC Amplifier Ass’y A6,

Meter Scale Indicator Ass’y All . . . . . . . . . . . . . . . . . . . . . . 8-9

Frequency Multiplier & Over Limit Indicator Ass’y A 10 . . 8-11

Power Supply & ALC Amplifier Ass’y A8

Oscillator Ass’y Al (Option 001) . . . . . . . . . . . . . . . . . . . . . .

Impedance Converter, RF Amplifier & Detector

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

Ass’y A5 (Option 001) . . . . . A-9

8-13

A-7

Page 11

Model 4342A

Section I

Paragraphs l-1 and 1-2

SECTION I

GENERAL INFORMATION

l-l. INTRODUCTION.

1-2.

The HP Model 4342A Q Meter is designed

to meet the requirements for making easy and

accurate quality factor measurements in the

laboratory, on the production line, or in QA

incoming inspection areas. The direct read-

ing,expanded scale of the 4342.4 permits measurement of Q from 5 to 1000 and the reading

of very small changes in Q resulting from

variation in test parameters. The long frequency dial scale and the pushbutton range

selector continuously cover the frequency

range of 22kHz to 7OPlHz (in seven - l/3 de-

cade steps) and permit setting the frequency

to an accuracy of 1.5% with 1% resolution.

The calibrated long-scale capacitance dials

permit reading the capacitance of the

tuning capacitor at an accuracy of 1% and

provides the capability for varying the

capacitance with O.lpF resolution on the

vernier scale. Inductance of sample can be

read directly from the inductance scale ad-

jacent to the capacitance scale at seven

specific frequencies by setting the frequency

dial to the "L" point on each frequency range.

Flat oscillator output, automatically levelcontrolled over the entire frequency ranges,

is a feature of the 4342A.

This advantage

obviates the necessity for frequent oscil-

lator level adjustments to maintain the out-

put level constant or the use of a

specially

matched fragile thermocouple level meter.

The high reliability of the instrument and

ease of operation are the direct results of

these measurement advancements in the 4342A.

For determing the resistance, reactance, or

quality factor of capacitance and inductance

samples in the high frequency region, the

4342A is a most versatile measuring instru-

ment. The 4342,1 can measure the dissipation

factor and dielectric constant of insulating

materials, coefficient of coupling, mutual

inductance, and the frequency characteristics

of transformers. Accessories which extend

the measurement capabilities, designed for

Figure l-l. Model 4342A Q Meter.

Page 12

Section I

Paragraphs 1-3 to l-12

Model 4342A

user convenience, have broad applications

in testing components and electronic materials, in physical and chemical research, and

in related scientific fields.

Pushbutton operation of frequency range and

Q/AQ range selection provides for straight-

forward measurement.

meter scales,

multipliers are used,

and reading speed.

l-3. How The 4342A Measures.

l-4. The Q Meter is basically composed of a

stable, variable oscillator, a tuning circuit

for taking resonance with an unknown sample,

and a high input impedance RF voltmeter connected across the variable capacitor which is

a section of the tuning circuit.

To measure the quality factor of a sample, a

stable oscillator signal is injected into the

series tuning circuit composed of the vari-

able capacitor and the unknown (inductor).

At the tuned frequency, the RF voltmeter

(called Q voltmeter) indicates a peak value

in the signal level increase (resonance) and

is proportional to the quality factor of the

sample measured.

signal with a low output impedance and by

measuring the signal level of the series re-

sonant circuit with a high impedance volt-

meter, the quality factor of the unknown

samnle can be accurately determined at the

resonant frequency.

parameters of the sample can be measured

(directly and indirectly) as factors of the

resonant frequency and the tuning capacity

which can be read from their respective dial

scales.

l-5. For accurate measurements, the 4342A

employs a unique constant voltage injection

system and a low output impedance injection

transformer. The oscillator signal is automatically leveled by an ALC loop to provide

the constant injection voltage required by

the Q range in use.

of an oscillator level control or the fragile

thermocouple level meter (as used in tradi-

tional Q Meters).

transformer along with the high quality low

loss tuning capacitor contribute minimal additional loss to the measurement circuit (resonant circuit) and greatly improve the Q ac-

curacy in high Q measurements.

l-6. High stability of the Q voltmeter virtually eliminates the need for Q-zero adjustments in routine measurements. Troublesome

zero settings prior to each adjustment are

thus eliminated, ensuring simple and rapid operation. Accurate determination of Q changes

l-2

frequency dials, and frequency

Automatic indication of

adding to the simplicity

By injecting an oscillator

Additionally, various

This obviates the need

The unique injection

in delta-Q measurements can be obtained in all

Q ranges by using the expanded resolution

(X10) capability.

l-7. The unique Q Limit selector is especially useful in Go/No-Go checking on the

production line. The high response speed of

the Go/No-Go indicator (compared to using a

meter pointer deflection method) permits

faster Go/No-Go testing. For even easier

testing, external indicating devices may be

remotely controlled by the Go/No-Go output

signal (on the rear panel).

1-8. INSTRUMENTS COVERED BY MANUAL.

l-9. Hewlett-Packard uses a two-section

nine character serial number which is marked

on the serial number plate (Figure 1-2) attached to the instrument rear panel.

first four digits and the letter are the serial prefix and the last five digits are the

suffix. The letter placed between the two

sections identifies country where instrument

was manufactured.

all identical instruments; it changes only

when a change is made to the instrument.

suffix, however,

and is different for each instrument.

contents of this manual apply to instruments

with the serial number prefix(es) listed

under SERIAL NUMBERS on the title page.

l-10. An instrument manufactured after the

printing of this manual may have a serial

number prefix that is not listed on the title

page.

dicates that the instrument is different from

those described in this manual. The manual

for this new instrument may be accompanied by

a yellow Manual Changes supplement or have a

different manual part number. This supplement contains

plains how to adapt the manual to the newer

instrument.

l-11. In addition to change information, the

supplement may contain information for correcting errors (called Errata) in the manual.

To keep this manual as current and accurate

as possible, Hewlett-Packard recommends that

you periodically request the latest Manual

Changes supplement. The supplement for this

manual is identified with this manual's title

page.

are available from ltewlett-Packard. If the

serial prefix or number of an instrument is

lower than that on title page of this manual,

see Section VII Manual Changes.

1-12.

number prefix that is not listed on the title

page or in the Manual Changes supplement,

contact your nearest Hewlett-Packard office.

This unlisted serial number prefix in-

Complimentary copies of the supplement

For information concerning a serial

The prefix is the same for

is assigned sequentially

"change information" that ex-

The

The

The

Page 13

Model 4342A

Paragraphs l-13 to l-22

Section I

1-13. SPECIFICATIONS.

1-14. Complete specifications of the Model

4342A Q Meter are given in Table l-1. These

specifications are the performance standards

or limits against which the instrument is

tested. The test procedures for testing the

instrument to determine if it meets its specifications are covered in Section V Mainte-

nance Paragraph 5-9 Performance Checks.

When the 4342A Q Meter is shipped from the

factory, it meets the specifications listed

in Table l-l.

l-15. ACCESSORIES SUPPLIED.

1-16. Fuses (HP Part No. 2110-0339 and 2110-

0044), the Operating and Service Manual, and

a power cord are furnished with the 4342A.

One of four types of power cords (HP Part No.

8120-1703, -0696, -1692 or -1521) is fur-

nished depending on the instrument destin-

ation. All accessories supplied are packed

in the instrument carton.

l-17. ACCESSORIES AVAIALABLE.

l-18.

devices which extend or enhance the measure-

ment capabilities of the 4342A.

ing accessories are available for use with

the 4342A Q Meter:

Accessories are specially designed

The follow-

16014A Series Loss Test Adapter:

The 16014A Series Loss Test Adapter is

a special terminal adapter designed

for measuring low impedance components,

low-value inductors and resistors, and

also high value capacitors.

adapter adds convenience in connecting

components in series with the test

circuit of the 4342A Q Meter.

sists of a teflon printed-circuit

base on which are mounted binding

posts to accept the supplemental inductors,

series terminals for the unknown.

16451A Dielectric Test Adapter (4342A-KOl):

The 16451A Dielectric Test Adapter is

a test fixture for measuring the dielectric constant or dielectric loss

angle (tan 6) of insulating materials.

The 16451A has a pair of precision

variable electrodes (one side is fixed)

which hold the sample and which op-

erate similar to a micrometer to per-

mit direct reading of electrode spac-

ing. This test adapter is directly

attached to 4342A measurement

terminals.

Typical performance, characteristics, and additional information regarding these accessories are given in Table l-2.

and a pair of low-inductance

The

It con-

16470 Series Supplemental Inductors:

A range of 20 inductors (model num-

bers 16471A to 1649OA), which can be

supplied separately or as a set, are

available for use with the 4342A Q

Meter.

reference devices when measuring the

RF characteristics of capacitors, re-

sistors, or insulating materials.

4342A option 001 instruments, the

Model 16465A Inductor is additionally

available.

terminals including a guard terminal

for stabilization of measurements.

16462A Auxiliary Capacitor:

The 16462A Auxiliary Capacitor is de-

signed to extend the Q and L measurement capabilities of the 4342A. It is

especially useful when measuring small

inductors at low frequencies.

These inductors are useful as

These inductors have three

For

1-19. OPTIONS.

l-20. An option is a standard modification

performed in the instrument to meet a special

requirement desired by a user.

strument model is ordered with an option number, the corresponding optional parts are

installed in/or packaged with instrument at

the factory.

lower measurement frequency range is avail-

able for installation in the 4342A.

l-21.

l-22.

frequency range, 1OkHz to 32MHz, instead of

the standard frequency range of 20kHz to

70MHz. All specifications that apply to Option 001 instruments are given in Table 1-1.

Option 001.

The 4342A Option 001 covers a lower

An Option for obtaining a

When an in-

1-3

Page 14

Section I

Table l-l

Model 4342A

Table l-1. Specifications (Sheet 1 of 2).

FREQUENCY CHARACTERISTICS

Measurement Frequency Range:

22kHz to 70MHz in 7 bands (22 to

70kHz, 70 to 220kHz,

700 to 2200kHz, 2.2 to 7MHz, 7 to

22MHz, and 22 to 70MHz).

Frequency Dial Accuracy:

21.5% at 22kHz to 22MHz,

22%

at 22MHz to 70MHz,

-cl%

at "L" point on frequency dial.

Frequency Dial Resolution:

Approximately 21%.

Q MEASUREMENT CHARACTERISTICS

Q Range:

5 to 1000 in

to 100, 50 to 300, and 200 to 1000).

Q Tolerance:

quency 22kHz - 30MHz 30MHz - 70MHz

:

5 - 300

300 - 600

600 - 1000

Q Resolution:

Upper scale: 1 from 20 to

Lower scale: 0.5 from 5 to

AQ Range:

0 to 100 in 4 ranges, 0 to 3, 0 to

10, 0 to 30, 0 to 100.

4 ranges (5 to 30, 20

% of indicated value

(at 25'C)

27% 210%

210% 215%

215% ?20%

220 to 700kHz,

100,

30.

AQ Tolerance:

210% of full scale.

AQ Resolution:

Upper scale:

Lower scale:

I

NDUCTANCE MEASUREMENT CHARACTERISTICS

L Range:

0.09nH to 1.2H, direct reading for

seven specific frequencies as marked

at the frequency dial "L" scale point

and selected by the frequency range

switches.

L Accuracy:

?3%

after compensation for residual

inductance (approx. 1OnH).

TUNING CAPACITOR CHARACTERISTICS

Capacitance Range:

Main dial capacitor: 25 to 470pF

Vernier dial capacitor:

Capacitance Dial Accuracy:

Main dial: *l% or 1pF whichever is

Vernier dial: +O.lpF.

Capacitance Resolution:

Main dial: 1pF from 25 to 30pF,

Vernier d ial: O.lpF.

0.1 from 0 to 10,

0.05 from 0 to 3.

-5 to +5pF

greater.

2pF from 30 to 200pF,

5pF from 200 to 470pF.

1

l-4

Page 15

Model 4342A Section I

Table l-1

Table 1-l.

REAR PANEL OUTPUTS

Frequency Monitor:

17OmVrms min. into SOR.

Q Analog Output:

1V +-50mV dc at full scale, proportional to meter deflection, output

impedance approx. 1kR.

Over Limit Signal Output:

Single pole relay contact output,

one side grounded, relay contact

capacity 0.5.4/15VA.

Over Limit Display Time:

Switch-selectable, lsec. or

continuous.

GENERAL

Operating Temperature Range:

o"c to 50°C.

Warm-up Time: 30 minutes.

Power: 115 or 230V +lO%,

approx. 25VA.

Weight: Approx. 31 lbs (

Specifications (Sheet 2 of 2).

48 - 440Hz,

4kd.

OPTION 001:

This option covers a frequency range

of 10kHz to 32MHz. Specifications

are identical with those of the

standard model except as noted below.

Oscillator Frequency Range:

1OkHz to 32MHz in 7 bands (10 to

32kHz, 32 to lOOkf-Iz, 100 to 320kHz,

320 to lOOOkHz, 1 to 3.2MHz, 3.2 to

IOMHz, and 10 to 32MHz).

Frequency Accuracy:

i-1.5%

at 1OkHz to 1OMllz.

+_2% at 1OMllz to 32MHz.

21% at "L" point on frequency dial.

Q Tolerance: % of indicated value

(at 25'C)

1 5 - 300 1 300 - 600 1 600 - 1000 1

I 27% I ?lO% I

?15%

DIMENSIONS:

NOTE :

DLL(ENSIW IN INCHES AND OALLIYETERSI.

I

:& (41

Accessories Furnished:

Power Cord

Accessories Available:

16471A through 16490A,

and 16465A

Supplemental

16462A Auxiliary Capacitor.

16014A Series Loss Test Adapter.

16451A Dielectric Test Adapter.

Extender Board 15pin

(Part No. 5060-4940).

Extender Board 6pin

(Part

No.

5060-0651).

Inductors.

l-5

Page 16

Section I Model 43426

Table l-2

Table l-2. Accessories - Typical Values.

16471A - 1649OA, 164656 Supplemental Inductors

Approx. resonant frequency

Model Inductance

16471A 130

mH

for tuning capacitance of

400pF

lOOpF 50pF

22 40 62 kHz below 300( 30 kHz)*

16472A 52 mH 35 70

Q Limit

100 kHz below 300( 50 kHz)* 8

Capaci-

tance

(PF)

16473A 25 mH 50 100 140 kHz below 300( 70 kHz)*

16474A 10 mH 80 160 220 kHz below 300(100 kHz)* 8

l6475A 5.2mH 110 220 300 kHz below 300(150 kHz)*

16476A 2.8mH 150 300 420 kHz below 300(200 kHz)* 8

16477A 1 mH 250 500 700 kHz below 300(300 kHz)*

l6478A 520 /JH 350 700 1000 kHz below 300(500 kHz)* 8

16479A 250 PH 500 1000

1400 kHz below 300( lMHz)* 7

16480A 100 IJ.H 800 1600 2200 kHz below 300( lMHz)* 7

16481A 56 PH ** 1 2.2 3.lMHz below 300( lMHz)* 7

16482A 28

FH

1.5 3 4.2MHz below 3OO(l. SMHz)*

16483A 10 /JH 2.5 5 7 MHz below 300(2. SMHz)* 6

16484A 5.21~.H 3.5 7 10 MHz below 300( lOMHz)*

16485A 2.51~.H 5 10 14 MHz below 300( lSMHz)*

l6486A 1 PH 8 16

22 MHz below 300( 20MHz)* 6

8

8

8

8

7

6

6

lOOpF 35pF

16487A 0.52pH 22MHz 35MHz below 300( 35MHz)* 6

16488A 0.28~~ 30MHz 5OMHz below 300( SOMHz)*

16489A

0.1 IJ.H 5OMHz 70MHz below 300( 7OMHz)*

16490A 0.07pH 6OMHz 1 OOMHz below 300( 70MHz)*

400pF

lOOpF 50pF

**16465A 630 mH 10 20 28 kHz below 300( 12 kHz)*

* The frequency in parentheses indicates frequency at which maximum Q factor is obtained

(for the respective inductor).

** Approx. resonant frequency for tuning capacitance of 450pF.

*** For 43426 Option 001 only. use

16462A

16014A Series Loss Test Adapter

Auxilialy

Capacitance Range: 300pF to 2700pF in steps

of 300pF. 10 ranges including OFF position.

Capacitance Accuracy: +l% on all ranges.

5000 at 20kHz on all ranges.

Q:

Residual inductance: approx. O.luH.

Residual capacitahce at OFF position:

approx. 23pF.

Useable Frequency Range: 1OkHz to 10MHz.

Capacitor

Measurable Capacitance Range: 450pF to 0.225uF

Measurable Resistance Range: 1Om.Q to 80R at

lOMHz, 4R to 8kR

Stray Capacitance Between Unknown Terminals:

approx. 3pF.

Insulation Resistance between Unknown Terminals

approx. 1OMR at 1MHz.

Residual Inductance: approx. 30nH

16451A Dierectric Test Adapter

(refer to Page 3-21 Table 3-2).

at

1OkHz.

4

3

2

9

l-6

Page 17

Model 4342A

Section II

Paragraphs 2-l to 2-16

SECTION II

INSTALLATION

2-l. INTRODUCTION

2-2. This sectioncontains informationfor unpacking,

inspection, repacking, storage, and installation of the

Model 4342A.

2-3. INITIAL INSPECTION

2-4. MECHANICAL CHECK

2~5. If damage to the shipping carton is evident, ask

that the carrier’s agent be present when the instrument

is unpacked. Inspect the instrument for mechanical

damage. Also check the cushioning material for signs

of severe stress.

2-6. PERFORMANCE CHECKS

2-7. The electrical performance of the Model4342A

should be verified upon receipt. Performance checks

suitable for incoming inspectionare given in Section

V, Maintenance.

2-8. DAMAGE CLAIMS

2-9. If the instrument is mechanically damaged in

transit, notify the carrier and the nearest Hewlett-

Packard field office immediately. A list of field offices

is on the backof this manual. Retain the shipping carton andpadding material for the carrier’s inspection.

The fieldoffice will arrange for replacement or repair

of your instrument without waiting for claim settle-

ments against the carrier.

2-10. Before shipment this instrument was inspected

and found free of mechanical and electrical defects.

If there is any deficiency, or if electrical performance

is not within specifications, notify your nearest

Hewlett-Packard Sales and Service Office.

sq in. bursting test) with a layer of excelsior

about 6 inches thick packed firmly against all

surfaces of the instrument.

2-13. ENVIRONMENT. Conditions during storage

and shipment should normally be limited as follows:

a. Maximum altitude, 20,000 feet

b. Minimum temperature, -40” F (-40” C)

C.

Maximum temperature, 167” F (75°C)

2-14.

2-15.

from

and Line frequency from 50 to 400Hz. A slide

switch on the rear panel permits quick conversion for

operating from either voltage. Insert a narrow- blade

screwdriver in the switch slot and slide the switch

the right for 115-volt operation (“115” marking exposed) or to the left for 230-voltoperation (“230” marking exposed). The Model 4342A is supplied with 115volt fuse; for 230-volt operation, be sure to replace

this fuse with that listed in Table 2-I.

POWER CONNECTION

LINE VOLTAGE. The Model 4342Aoperates

either 115 or 230 volt (*lo%) ac line voltage

Table 2-l. AC Line Fuse

Conversion 115-volt

Slide Switch Right

(“115’)

AC Line Fuse 0.6 amperes

Slow-Blow

2110-0339

230-volt

Left

(“230”)

0.3 amperes

Slow-Blow

21 lo-0044

to

2-11. STORAGE AND SHIPMENT

2-12. PACKAGING. To protect valuable electronic

equipment during storage or shipment always use the

best packaging methods available,

Packard field office can provide packing material such

as that used,for original factory packaging. Contract

packaging companies in many cities can provide dependable custom packaging on short notice. Here are

a few recommended packaging methods :

a. RUBBERIZED HAIR.

of instrument with protective wrapping paper.

Pack instrument securely in strong corrugated

container (350 lb/sq in. bursting test) with 2inch rubberized hair pads placed along all surfaces of the instrument. Insert fillers between

pads and container to ensure a snug fit.

b. EXCELSIOR. Cover painted surfaces of instru-

ment with protective wrapping paper. Pack in-

strument in strong corrugated container (350 lb/

Cover painted surfaces

Your Hewlett-

CAUTION

To avoiddamage to theinstrument, before

connecting the power cable, set the 115/

230-volt switch for the line voltage to be

used.

2-16. POWER CABLE, To protect operating personnel, the National Electrical Manufacturers Association (NEMA) recommends that instrument panels and

cabinets be grounded. Accordingly, the Model 4342A

is equipped with a detachable three.-conductor power

cable which, when plugged into an appropriate recepta-

cle, grounds panel and cabinet. The offset pin of the

three-prong connector is the ground pin. Proceed as

follows for power cable installation.

a. Connect flatplug (3-terminal connector) to LINE

jack at rear of instrument.

b. Connect plug (a-blade with round grounding pin)

to J-wire (grounded) power outlet. Exposed

2-l

Page 18

Section II

portions of instrument are grounded through the

round pin on the plug for safety; when only 2blade outlet is available, use connector adapter

(HP Part No. 1251-0048). Then connect short

wire from slide of adapter to groundto preserve

the protection feature.

Model 4342A

2-2

Page 19

Model 4342A

Section III

Paragraphs 3-1 to 3-9

SECTION III

OPERATION

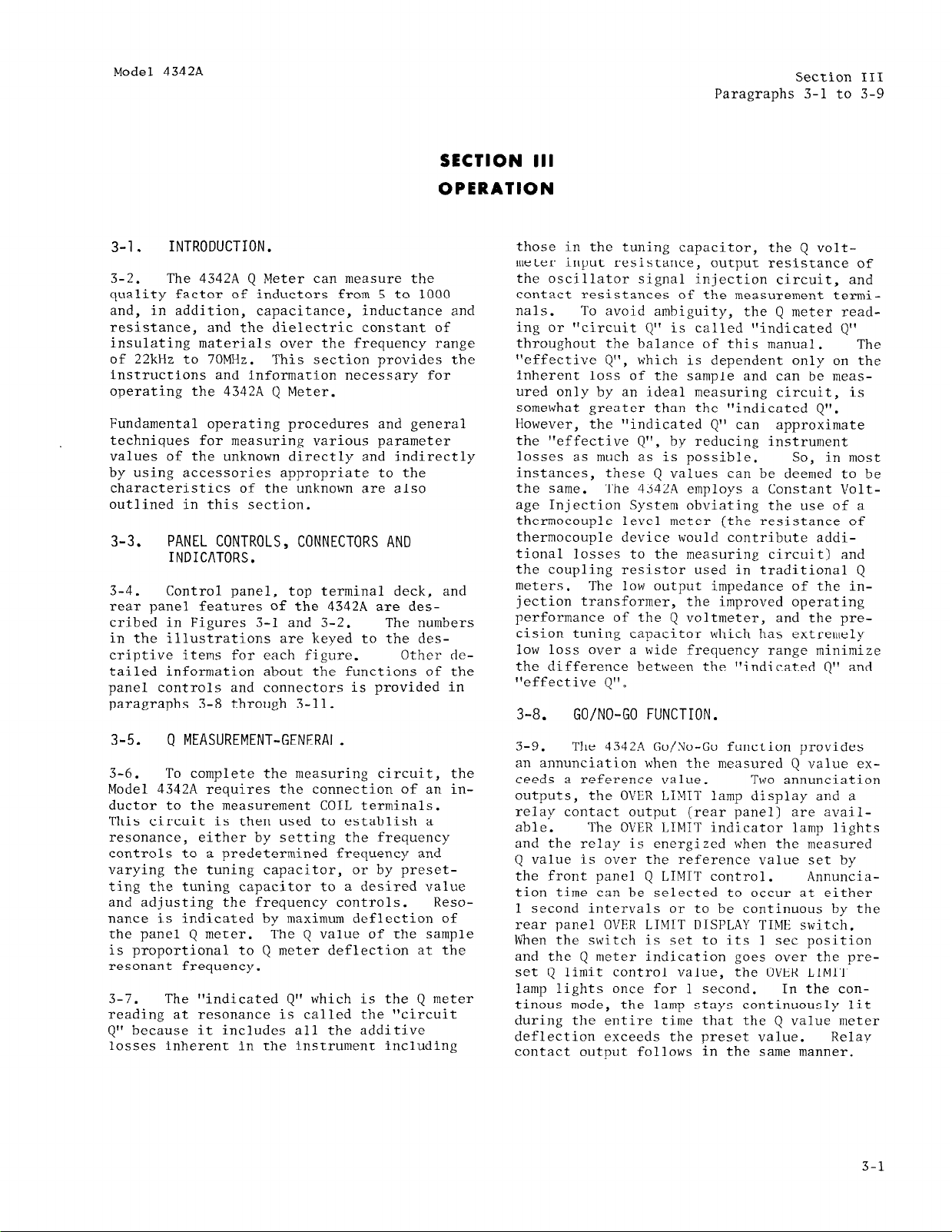

3-1. INTRODUCTION.

3-2.

quality factor of inductors from 5 to 1000

and,

resistance, and the dielectric constant of

insulating materials over the frequency range

of 22kHz to 70MHz.

instructions and information necessary for

operating the 4342A Q Meter.

Fundamental operating procedures and general

techniques for measuring various parameter

values of the unknown directly and indirectly

by using accessories appropriate to the

characteristics of the unknown are also

outlined in this section.

3-3. PANEL CONTROLS, CONNECTORS AND

3-4. Control panel, top terminal deck, and

rear panel features of the 4342A are described in Figures 3-1 and 3-2. The numbers

in the illustrations are keyed to the descriptive items for each figure. Other detailed information about the functions of the

panel controls and connectors is provided in

paragraphs 3-8 through 3-11.

3-5. Q MEASUREMENT-GENERAL.

3-6. To complete the measuring circuit, the

Model 4342A requires the connection of an inductor to the measurement COIL terminals.

This circuit is then used to establish a

resonance, either by setting the frequency

controls to a predetermined frequency and

varying the tuning capacitor, or by presetting the tuning capacitor to a desired value

and adjusting the frequency controls. Reso-

nance is indicated by maximum deflection of

the panel Q meter. The Q value of the sample

is proportional to Q meter deflection at the

resonant frequency.

3-7. The "indicated Q" which is the Q meter

reading at resonance is called the "circuit

Q" because it includes all the additive

losses inherent in the instrument including

The 4342A Q Meter can measure the

in addition, capacitance, inductance and

This section provides the

INDICATORS.

those in the tuning capacitor, the Q volt-

meter input resistance, output resistance of

the oscillator signal injection circuit, and

contact resistances of the measurement termi-

nals.

ing or "circuit Q" is called "indicated Q"

throughout the balance of this manual. The

"effective Q", which is dependent only on the

inherent loss of the sample and can be meas-

ured only by an ideal measuring circuit, is

somewhat greater than the "indicated Q".

However, the "indicated Q" can

the "effective Q", by reducing instrument

losses as much as is possible. So, in most

instances, these Q values can be deemed to be

the same. The 4342A employs a Constant Voltage Injection System obviating the use of a

thermocouple level meter (the resistance of

thermocouple device would contribute additional losses to the measuring circuit) and

the coupling resistor used in traditional Q

meters.

jection transformer, the improved operating

performance of the Q voltmeter, and the pre-

cision tuning capacitor which has extremely

low loss over a wide frequency range minimize

the difference between the "indicated Q" and

"effective Q".

3-8. GO/NO-GO FUNCTION.

3-9. The 4342.4 Go/No-Go function provides

an annunciation when the measured Q value exceeds a reference value.

outputs, the OVER LIVIT lamp display and a

relay contact output (rear panel) are available. The OVER LIMIT indicator lamp lights

and the relay is energized when the measured

Q value is over the reference value set by

the front panel Q LIMIT control. Annunciation time can be selected to occur at either

1 second intervals or to be continuous by the

rear panel OVER LIMIT DISPLAY TIME switch,

When the switch is set to its 1 set position

and the Q meter indication goes over the pre-

set Q limit control value, the OVER LIMIT

lamp lights once for 1 second. In the con-

tinous mode,

during the entire time that the Q value meter

deflection exceeds the preset value. Relay

contact output follows in the same manner.

To avoid ambiguity, the Q meter read-

approximate

The low output impedance of the in-

Two annunciation

the lamp stays continuously lit

3-l

Page 20

Section III

Figure 3-l

Model 4342A

3-2

LINE PUSH ON/OFF Switch:

1.

power on/off switch.

FREQUENCY RANGE Selector: These push- The frequency is read from FREQHENCY

2.

buttons select the desired measurement scale @and the multiplier indicator

frequency range from among the seven

ranges covering 22kHz to 7OMllz (10kHz

to 32MHz for Option 001). The inductance range which may be measured

directly at the "L" scale frequency

point on the selected frequency range

is labeled on the panel adjacent to

the pushbuttons.

Figure 3-l.

Instrument

Front Panel Controls (Sheet 1 of 2).

3. FREQUENCY Dial Control: This dial

wheel varies the measurement frequency

as well as the FREQUENCY dial scale@.

0

Q LIMIT Control:

4.

sets the low limit of the Q value for

Go/No-Go checks. The Q LIMIT setting

dial scale numbers are related to

meter deflection (% of full scale).

This dial control

Page 21

Model

4342A

Section III

Figure 3-l

Frequency Multiplier Indicator: The

5.

Frequency multiplier indicators, ad-

jacent to the frequency dial scale,

light and correspond with the settings

of the frequency range selector @

pushbuttons.

6.

FREQUENCY Scale:

The Frequency scale

comprises two scales with ranges of

2.2 to 7.0 and 7 to 22 (1.0 to 3.2 and

3.2 to 10 for Option 001). One or the

other of the scales is automatically

illuminated depending on the FREQUENCY

RANGE selector @ setting.

OVER LIMIT Display: The letters "OVER

7.

LIMIT" are displayed when the measured

Q value exceeds the limit value set by

the Q LIMIT control 0.

Measurement Terminals: These binding

8.

post terminals facilitate connection

of the unknown and the various measurement aid accessories. A simplified

terminal circuit schematic is provided

by the top panel label.

9.

Q Meter:

At

maximum meter pointer de-

flection, this meter indicates the Q

value of the sample or of the measuring circuit as well as the optimum

tuning point. The outer two scales (0

to 100 and 0 to 30) are the Q readings.

The inner two reverse scales (10 to 0

and 3 to 0) provide hQ readings when

making AQ measurements. Meter scale

indicators at the left end of scale

automatically light to indicate the

appropriate scale (to read) on the se-

lected

Meter Pointer Adjustment Screw:

10.

Q/hQ

range.

adjustment screw zero-sets the meter

pointer so it is exactly over the zero

calibration mark when the instrument

is off.

AQ ZERO Controls:

11.

These coarse and

fine controls adjust the meter indication for zero (reference) scale in AQ

measurements.

This function applies

only to AQ measurements.

This

L Scale: This dial scale allows di-

12.

rect reading of inductance sample

values at the "L" frequency. An "L"

scale frequency point, common to and

useable on all frequency ranges, is

labeled with a blue letter on the FRE-

QUENCY scale 0.

The L scale indi-

cates the inductance value of the un-

known when resonated with the tuning

capacitance at the "L" frequency.

13. AC Scale: This dial scale permits the

reading of the capacitance of a

vernier tuning capacitor from -5pF to

+5pF in O.lpF steps. The actual tuning capacitance is sum of the C Scale

@ and the AC Scale readings. A small

change in the tuning capacitance ad-

justment point resulting from a

variation in test parameters can be

accurately read from the spread AC

scale.

14. C Scale:

This dial scale is for reading the capacitance of the main tuning

capacitor which may be varied from

25pF to 470pF.

A

C scale reading is

exact (calibrated) when the AC scale@

is set to OpF.

15.

AC Dial Control: This dial wheel

varies the vernier tuning capacitor

and moves the AC Scale 0. The control employs a string drive mechanism

which facilitates easy adjustment of

vernier capacitor.

L/C Dial Control: This dial wheel

16.

varies the main tuning capacitor as

well as moving the C scale @ and L

scale 0.

Q/ AQ RANGE Selector: These push-

17.

buttons select the desired Q range

(either 30, 100, 300 or 1000 full

scale).

AQ button enables AQ measure-

ment and expands Q resolution by ten

times (3, 10, 30 or 100 full scale).

Figure 3-l. Front Panel Controls (Sheet 2 of 2).

3-3

Page 22

Section III

Figure 3-2

Model 4342A

1

METER ZERO AD<J: This trimmer adjust-

1.

ment electrically zero-sets the meter

pointer so that it is exactly over the

zero calibration mark when the instru-

ment is on.

FUSE: Instrument power fuse is in-

2.

stalled in this fuse holder. Appropriate current rating for the fuse required is labeled on the rear panel.

VOLTAGE SELECTOR: This slide switch

3.

selects the appropriate ac operating

power voltage (115V or 230V +lO%).

Selection of the ac voltage must be

made before the instrument is connected to power line.

LINE Receptacle: Male ac power line

4.

receptacle with center ground pin for

powering the instrument from a 115V or

23OV, 48 - 440Hz line. Before con-

necting power cord (furnished), VOLTAGE SELECTOR @ should be properly set.

OVER LIMIT DISPLAY TIME Switch: This

5.

slide switch sets "OVER LIMIT" annunciation time for Go/No-Go checks to

either 1 second (1 set) or to contin-

ous (00).

OVER LIMIT SIC. OUTPUT Connector:

6.

Relay contact output for Go/No-Go

checks. Center and outer conductors

of this BNC connector are internally

short-circuited when measured Q value

exceeds the limit value set by the Q

LIMIT control.

7.

Q .4NALOG OUTPUT Connector: 0 to 1v

analog output proportional to meter

deflection.

Output impedance is ap-

proximately 1kR.

FREQUENCY MONITOR Connector:

8.

connector provides a portion of inter-

nal oscillator output for monitoring

oscillator frequency with external e-

quipment (such as a frequency counter).

Output level is 17OmVrms min. and

output impedance is 50R.

9.

Measurement Terminals: These six

binding post terminals, including the

two shield terminals, provide the con-

nection capabilities for attaching the

unknown sample as well as supplemental

inductors, auxiliary capacitors, and

other devices and accessories used in

making measurements.

This BNC

3-4

Figure 3-2. Rear Panel Controls and Connectors.

Page 23

Model 4342A

Section III

Paragraphs 3-10 to 3-17

3-10. MEASUREMENT TERMINALS.

3-11. Six binding post terminals, including

two shield terminals, mounted on the instrument top deck, facilitate connection of unknown samples and accessories to the measuring circuit. Figure 3-3 illustrates the

measurement terminals circuit configuration.

Shield terminals 3 and 6, and binding post 4

are directly connected to instrument chassis

(grounded). Binding posts 1 and 2 are the LO

and HI COIL terminals, respectively, to which

an inductor is connected to compose the circuit to be resonated. Inductors can be meas-

ured by connecting them to the COIL terminals

(1 and 2) and by taking resonance with the

tuning capacitor.

injected into the measuring circuit between

LO COIL terminal 1 and GND terminal 4. Bind-

ing posts 4 and 5 are CAPACITOR terminals

which are used for doing parallel connection

measurements (outlined in paragraph 3-19).

Shield terminals 3 and 6 are used for connec-

tion to the shield terminal of an inductor or

to the guard terminal of the device connected

between HI COIL terminal 5 and GND terminal 4.

3-12. HOW TO CONNECT UNKNOWN.

3-13. There are three basic methods of connecting unknown sample to the measuring cir-

cuit of the Q Meter. The characteristics of

the unknown, the parameter value to be measured, and the measurement frequency are the

factors which guide the selection of an appropriate connection method. The fundamental

operating procedures for each individual connection method are outlined in Table 3-l.

The oscillator signal is

3-14. MEASUREMENT PARAMETERS AND CONNECTION

METHODS.

3-15. The connection to the measuring circuit of the 4342A, when measuring quality

factor, inductance, capacitance, resistance

or dielectric constant, may be either a di-

rect, parallel, or a series connection and

depends upon the sample. As the sample

values and measurement parameters are the

guidelines for selecting an appropriate connection method, a discussion of the measurement capabilities unique to each connection

method will help you to make straight-forward

measurements. The measurement range limits

of the individual connection methods and

associated reasoning are outlined in the

paragraphs which follow.

3-16.

3-17.

method in taking Q meter measurement parameters, only the quality' factor, inductance,

equivalent series resistance, and distributed

capacitance of the inductor can be read from

Q meter indications. In addition, the quality factor and the inductance measurement

ranges covered by the direct connection

method are dependent on sample inductance and

measurement frequency. This is because the

sample value and measuring frequency must

satisfy the following mathematical relationship so as to resonate with the measuring

circuit:

Direct Method Limitations.

When using the direct connection

(2Trf)2LC = 1 . . . . . . . . . . . . . . . . . (eq. 3-l)

Where, f: Measurement frequency

L: Inductance of sample

Tuning capacitance (read from

c:

C dial scale; 25pF to 470pF)

SHIELD

0

0

3

Figure 3-3.

SHIELD

0

0

6

Measurement Terminal Circuit.

For example, if the measurement frequency is

lMHz, the inductance range of a sample which

can be measured directly by the 4342A is approximately 54uH to 1.2mH. And, for a given

inductance, the measurement frequency range

is indicated. For example, a 1OuH inductor

can be measured over a frequency range of ap-

proximately 2.3MHz to 11MHz. Additionally,

the quality factor of sample must be below

1000 (upper range limit). Figure 3-4 sh/ows

the relationships between the measurement fre-

quency and the inductance limits measurable

with the 4342A alone (without using any supplemental equipment). In Figure 3-4, the

shaded area denotes the applicable induct-

ances and useable frequencies. The seven

bold lines in the shaded area indicate the "L"

frequencies and the ranges of inductance

which can be read from the L/C dial L scale

3-5

Page 24

Section III

Paragraphs 3-18 to 3-23

Model 4342A

at these particular L frequencies. The induc-

tance at a measurement frequency other than

the "L" frequency can be determined by substi-

tuting frequency and L/C dial (C scale) read-

ings in equation 3-l.

3-18. Expansion of measurement ranges.

3-19.

For higher or lower value inductances

(above or below the shaded area in Figure

3-4), a parallel or series connection of the

unknown to the measuring circuit enables the

measurement to be made. To obtain the value

of the desired parameter, these methods em-

ploy a comparison of the Q meter indications.

The Q meter measuring circuit is first resonated with a reference inductor.

Then the

sample is connected in parallel or in series

with the measuring circuit and the circuit

again resonated.

The sample value is calcu-

lated from the difference in Q meter indica-

tion measurements made before and after connecting the sample. In the equation from

which the sample values are obtained, the

values inherent in the reference inductor are

subtracted from the measurement quantities.

Consequently, the characteristics of the reference inductor do not (theoretically) affect

measurement results.

In addition to their expanded measurement

ranges,

the parallel and series methods have

some measurement capability advantages which

do not appear when using direct methods.

A detailed description of these advantages is

given in the discussion in paragraph 3-58.

3-20. Capacitance Measurement.

3-21. For capacitor samples, either a paral-

lel or series connection method may be used

when measuring either the capacitance or the

Q value. The criteria for selecting the ap-

propriate connection method concerns only the

sample value and is irrespective of the measurement frequency. Capacitances higher than

approximately 450pF (up to approximately

0.2uF) are normally measured by the series

method and lower capacitances are easily

measured by the parallel method. Generally,

capacitors can be measured at the desired

frequency by using an appropriate inductor as

a measurement aid.

3-22. Resistance Measurement.

3-23. Resistance values are fundamentally

calculated from measured Q values. Thus, the

connection method selected depends upon the

sample value and the measurement frequency.

Figure 3-5 shows approximate limits for both

parallel and series measurements.

The upper

shaded area indicates the combinations of frequency and measurable resistance values for

parallel measurements. Similarly, the lower

shaded area indicates the values for series

measurements. For sample values between the

upper and lower shaded areas, it is difficult

3-6

I I I III I I III I I III I I III

IOK lOOK

Figure 3-4.

FREQUENCY (Hz)

Inductance Measurement Ranges

IM IOM l3OM

vs. Frequency (direct method).

Page 25

Model 4342A

Section III

Paragraphs 3-24 to 3-29

to measure with either connection method.

These limits are based on the use of a reference inductor having a Q value of 280.

Parallel measurement low limits can be ex-

tended by using an external capacitor connected to the measurement CAPACITOR (HI and

GND)

terminals.

3-24. High Q Measurement.

3-25. Measurement of high quality factors up

to 10000 can also be made by the parallel or

series connection methods. These methods

enable the measurement of low loss samples

and are especially useful in the measurement

of high Q capacitors.

As

inherent losses in

the instrument will cause larger incremental

measurement errors in higher Q measurements,

these residual loss factors should be taken

into consideration in the accuracies of measured values. In high Q measurements, the

measured Q should be deemed to be only a

rough approximation of the sample Q value.

A

detailed discussion on parallel and series

connection measurement errors is provided in

paragraph 3-60 and those which follow.

3-26.

Supplemental Equipment Used in

Parallel and Series Methods.

3-27. For use with the 4342A as reference

inductors, the Model 16470A series supple-

mental inductors are available. The

16470A

series inductors have various inductances

(from 0.07pH to 630mH) and totally cover the

frequency range of 1OkHz to 70MHz when used

with the 4342A as measurement aids. The reference inductor must be resonated alone

(before connecting unknown) at the desired

measurement frequency to take its inherent

values for reference. And, of course, the

useable frequency range of each individual

supplemental inductor depends upon the inductance of the individual coil. This frequency range is indicated on a label attached

to the case of each inductor. Detailed data

and information on the supplemental inductors

is tabulated in Table 1-2.

3-28. Inductor samples whose inductance is

somewhat lower than the low limits of the

measurement range of the 4342A may be meas-

ured by using an external high Q capacitor to

extend the available tuning capacitance range.

The external capacitor is connected between

HI and GND measurement terminals; its capacitance, thereby, adds to the tuning capacitance. For this special purpose, the HP

16462A Auxiliary Capacitor is available.

This capacitor module combines nine capacitors from 300pF to 2700pF (in 300pF steps) and,

when used with the 4342A, allows measurement

of low inductances to approximately l/6.7 of

the measurement

low limit

of the instrument.

IOK 22K IOOK IM IOM 70M

Figure 3-5.

MEASURING FREQUENCY IN Hz

Ranges of Measurable Resistance.

3-29.

Dielectric constant of an insulating

material is calculated from the capacitance

value of the sample held between a pair of

electrodes whose dimensions are accurately

known. Model 16451A Dielectric Test Adapter

is the test fixture which is specially designed for measuring dielectric constant

(E)

and dielectric loss angle (tan 6) and is directly attached to the 4342A measurement

terminals. The 16451A has a pair of variable

precision electrodes which can hold materials

measuring up to a maximum of 1Omm in thick-

ness. The electrodes operate similar to a

micrometer permitting direct reading of elec-

trode spacing (0 to 1Omm) with 0.02mm resolution.

The diameter of the electrodes has

been designed so as to simplify the associat-

ed calculations. Measurement time is thus

greatly shortened.

3-7

Page 26

Section III

Figure 3-6

Model 4342A

3-8

I I

1

Figure 3-6.

1

Zeroing Procedure (sheet 1 of 2).

J’

Page 27

Model 4342A

Mechanical zero adiustment

The meter is properly zero-set when the pointer sets exactly over

the zero calibration scale mark and the instrument is in its normal

operating environment.

To check the meter mechanical zero, turn the

instrument off and allow 30 seconds to completely deenergizethe z

strument.

the meter is not over zero,

Rotate meter pointer adjustment screw @ clockwise until meter

a.

To obtain maximum accuracy and mechanical stability, if

zero-set the meter as follows:

is moving toward zero in an upscale direction.

b. Continue rotating screw clockwise and stop when pointer is

exactly at zero. If the pointer overshoots, continue rotating

the adjustment screw clockwise to do steps a and b once again.

C.

When the pointer is exactly over zero, rotate adjustment screw

slightly counterclockwise to relieve tension on pointer suspension. If pointer moves off zero, repeat steps a, b and c, but

rotate less counterclockwise.

Section

Figure 3-6

TTT

Electrical zero adiustment

The meter pointer should set exactly over the zero scale mark when instrument is

turned on and nothing is connected to measurement terminals.

Turn the instru-

ment on and allow at least 15 minuts warm-up time to let the instrument reach a

stable operating condition. If meter pointer is not over zero, zero-set the

meter as follows:

Set FREQUENCY RANGE selector @to 22k - 70k (10k - 32k for Option

a.

001) and Q RANGE@ to 1000.

Adjust rear panel METER ZERO ADJ control@ so that the meter

b.

pointer is exactly over zero.

Figure 3-6. Zeroing Procedure (sheet 2 of 2).

3-9

Page 28

Section III

Table 3-l

Model 4342A

Table 3-1.

Direct Connection.

HI HI

osc frequency.

Parallel Connection.

LO

osc -

(Bl

I

E

HI

-

v-

UNKNOWN

b

ON0

Methods of Connecting Unknown.

Inductors can usually be measured by connecting

them directly to the COIL terminals as shown in

Figure A. The measuring circuit is resonated by

adjusting either the L/C dial or the FREQUENCY

dial controls. The quality factor (indicated Q) of

0

the sample is read at maximum deflection of the Q

Meter. Setting the FREQUENCY dial to the "L"

scale point and taking resonance with the L/C dial

control permits reading the inductance of the

sample directly from the inductance scale (adjacent

to the tuning capacitor scale). Otherwise the

0

GND

inductance can be calculated from the frequency and

capacitance dial readings at the desired resonant

The parallel connection is suitable for high imped-

ance measurements. High inductances, high resist-

ances, and small capacitances can be measured by

connecting the samples to the CAPACITOR terminals

as shown in Figure B. Before connecting a sample,

the measuring circuit is resonated with a stable

inductor (such as a 16470 series supplemental

inductor) connected to the HI and LO COIL terminals

to obtain a reference Q reading and a capacitance

dial reading. The measuring circuit is again re-

sonated with the sample connected to the CAPACITOR

terminals by re-adjusting the L/C dial for maximum

Q meter deflection.

sample are derived from the Q meter readings and

the L/C dial readings obtained before and after

connecting the unknown sample. The derivation of

parameter values related to the unknown are detailed in paragraphs 3-64 through 3-72.

The parameter values of the

Series Connection.

3-10

HI

h

osc

(Cl

HI

0

GND

The Series connection is suitable for low impedance

measurements. Low inductances, low resistances and

high capacitances can be measured by connecting the

sample in series with a stable inductor as shown in

Figure C.

The 16014A Test Adapter is useful for

making the series connection to the unknown sample.

First,

a shorting strap is attached to the unknown

connection terminals in parallel with the sample

and the measuring circuit resonated with the L/C

control. For reference, the Q meter and capacitance dial readings are noted. The shorting strap

is then disconnected (or removed) and resonance of

the measuring cicuit is again taken by adjusting

the L/C dial.

The parameter values of the unknown

can be derived from the Q meter and capacitance

dial readings obtained before and after disconnecting the shorting strap. The derivation of the

parameter values related to the unknown are described in paragraphs 3-73 through 3-81.

Page 29

Model 4342A

Section III

Paragraphs 3-30 to 3-34

Direct Connection Measurements

3-30. BASIC Q METER MEASUREMENTS.

3-31. QUALITY FACTOR AND INDUCTANCE

MEASLREMENT~ (DIRECT C~NNK-U~N).

3-32. This paragraph and those which follow

describe the fundamental operating procedures

for quality factor and inductance measurements which are typical applications of the

Q Meter. An inductor usually has some

distributed capacitance (Cd).

resonant frequency (fo) of the inductor is

determined by its self-inductance and the Cd.

The 4342A measuring circuit consideration of

distributed capacitance is shown in Figure

3-7. If the Q meter indication is Qt when Cd

is zero, then the presence of Cd will influence the voltage across the resonating induc-

tor such that the Q meter will actually indicate a Q value lower than Qt. The indicated

Q value (Qi) and the Qt can be correlated by

a correction factor (which is a function of

Cd and the tuning capacitance) each with the

other. A similar correction factor also

applies to difference of inductance readings

resulting from the presence of Cd.

tailed discussion of correction factors is

given in paragraph 3-50. When the Cd is less

than l/20 of the tuning capacitance, the

difference between Qi and Qt (Li and Lt are

similar in meaning) is within 5%.

The self-

A de-

Adjust L/C dial control for maximum

C.

panel Q meter deflection on the

instrument.

Note

Alternatively, the resonance may be

taken by setting the L/C dial to a

desired position and adjusting the

FREQUENCY dial for maximum Q meter

deflection.

Depress Q RANGE button as appropriate

d.

for obtaining a Q meter deflection

more than one-third of full scale and

less than full scale.

Re-adjust L/C dial (or FREQUENCY dial)

e.

control for maximum deflection. If

panel meter deflection exceeds full

scale,

up-range the Q RANGE and continue the adjustment. For easily obtaining a precise resonance, use the

AC dial control.

Note

The AC dial control facilitates

accurate adjustment for establishing resonance especially in high Q

measurements.

rI

I

Cd +

I

I

L,

GND

Figure 3-7.

Distributed Capacitance in

Direct Connection.

3-33. Q Measurement.

3-34.

To read the quality factor of an in-

ductance sample directly from the Q meter

indication, proceed as follows:

a. Connect unknown to measurement COIL

(HI and LO) terminals.

Depress an appropriate FREQUENCY RANGE

b.

button and set FREQUENCY dial control

to the desired frequency.

0

Read panel Q meter indication on the

f.

meter scale designated by the appro-

priate scale lamp indicator lit.

Note

The measured Q value corresponds to

the "indicated Q" of the sample.

To derive series equivalent resistance

g*

of the sample, substitute the Q meter

FREQUENCY, C dial, AC dial, and Q

readings in the following equation:

Rs = l/wCQWO.l59/fCQ . . . . . (eq. 3-2)

Where, Rs: equivalent series resist-

ance in ohms.

f: frequency dial reading in

hertz.

0: 2~r times the frequncy

(2wf).

c: sum of C and AC dial read-

ings in farads.

panel Q meter reading.

Q:

3-11

Page 30

Section III

Paragraphs 3-35 to 3-38

Direct Connection Measurements

AQ

3-35.

3-36.

cal,

accurately on the normal Q scale.

Measurement.

When two Q values are nearly identi-

the difference is difficult to read

The AQ

feature of the 4342A provides accurate read-

ings for changes in Q on all Q ranges by providing ten times resolution, namely: 0 to 3,

0 to 10, 0 to 30, and 0 to 100.

To make a AQ

measurement, proceed as follows:

Connect the sample inductor to the

a.

measurement COIL (HI and LO) terminals

Resonate the inductor using the

b,

same

procedure as described in Q Measurement (para. 3-34) steps b, c, d and e.

c. Note panel Q meter reading.

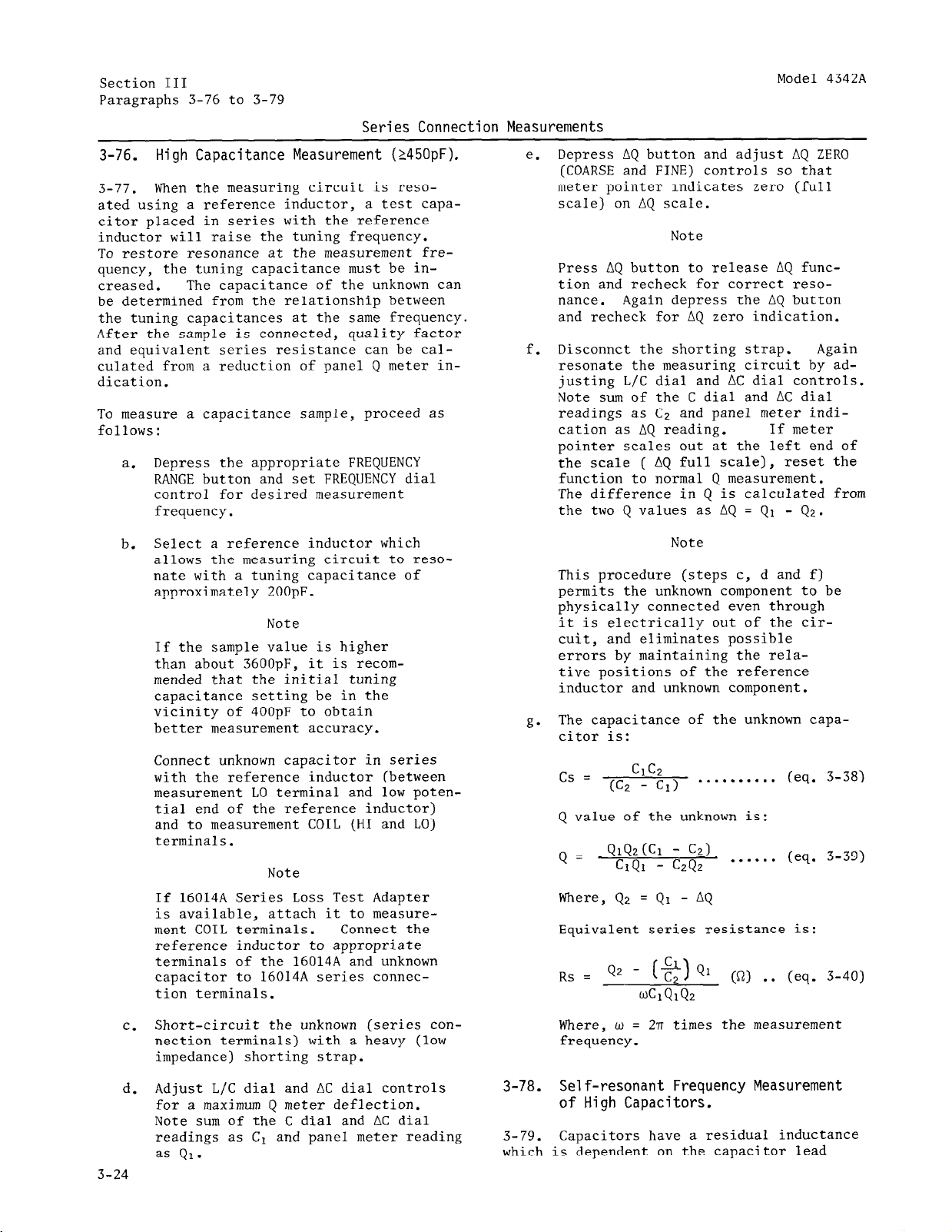

Depress AQ button and set AQ COARSE