Page 1

HP OmniBER 718/719

HP 37718A

HP 37719A

Installation and

Verification

Manual

Page 2

Copyright HewlettPackard Ltd.1999

All rights reserved.

Reproduction, adaption, or

translation without prior

written permission is

prohibited, except as

allowed under the

copyright laws.

HP Part No. 37718-90069

First Edition, May 99

Printed in U.K.

Documentation

Warranty

The information contained

in this document is subject

to change without notice.

Hewlett-Packardmakesno

warranty of any kind with

regard to this material,

including, but not limited

to, the implied warranties

or merchantability and

fitness for a particular

purpose.

Hewlett-Packard shall not

be liable for errors

contained herein or for

incidental orconsequential

damages in connection

with the furnishing,

performance, or use of this

material.

WARNING

For details of safety, see

Safety information in this

manual.

Hewlett-Packard Limited

Telecommunications Networks Test Division

South Queensferry

West Lothian, Scotland EH30 9TG

Page 3

Installation and Verification Manual

HP Part Number 37718-90069

Printed in U.K. May 1999

HP OmniBER 718/719

Page 4

2

Page 5

Contents

1 General Information

Warranty 1-1

Responsibilities of the Customer 1-2

Certification 1-3

Assistance 1-3

Notice 1-3

Restricted Rights Legend 1-3

Instruments Covered By Manual 1-4

Storage and Shipment 1-4

Repackaging for Shipment 1-4

Weight and Dimensions 1-5

Safety Precautions for the Operator 1-6

Lifting/Carrying the HP 37718A/19A 1-6

Safety Symbols 1-7

Operators Maintenance 1-8

Cleaning 1-8

Power Supply Fuse Replacement 1-9

Statement of Compliance 1-10

Australian EMC Regulations 1-10

Noise Declaration (German) 1-10

Electromagnetic Compatibility 1-11

Electrostatic Discharge 1-11

2 Installation

Initial Inspection 2-1

Operating Environment 2-2

Preparation for Use 2-3

Power Requirements 2-3

Fuses 2-3

Fuse Replacement 2-3

iii

Page 6

Contents

Connecting to the Power Supply 2-4

Connecting to the Network 2-6

All Connectors 2-6

Electrical Interface Connectors 2-6

Optical Interface Connectors 2-9

Connecting Accessories 2-11

10 Base-T Lan Connection Radiated Emissions 2-11

Hewlett-Packard Interface Bus 2-12

Additional Precautions for Service Engineers 2-14

Safety Precautions 2-14

ESD Precautions 2-14

Front Panel Soft Recovery (Cold Start) 2-16

3 Performance Tests

Introduction 3-1

Equipment Required 3-1

Performance Test Record 3-1

Calibration Cycle 3-1

Option Configuration 3-1

Recall Default Settings 3-4

Self Test 3-5

PDH/DSn Internal Transmitter Clock Accuracy & Offset 3-10

Specifications 3-10

Equipment Required 3-10

E1 (2.048Mb/s) Frequency Accuracy 3-11

E2 (8.448Mb/s) Frequency Accuracy 3-12

E3 (34.368Mb/s) Frequency Accuracy 3-12

E4 (139.264Mb/s) Frequency Accuracy 3-13

DS1 (1.544Mb/s) Frequency Accuracy 3-13

DS3 (44.736Mb/s) Frequency Accuracy 3-14

PDH/DSn Transmitter Output 3-15

iv

Page 7

Contents

Specification 3-15

Equipment Required 3-16

Procedure - 34.368 Mb/s 3-19

Procedure - 8.448 Mb/s 3-21

Procedure - 2.048 Mb/s 3-23

Procedure - DSX-3 3-26

Procedure - DSX-1 3-28

PDH/DSn Receiver Equalization 3-32

Specifications 3-32

Description 3-32

Equipment Required 3-32

Procedure 3-33

PDH/DSn Receiver Monitor Levels 3-39

Specifications 3-39

Description 3-39

Equipment Required 3-39

External Mux/Demux 3-44

Specifications 3-44

Description 3-44

Equipment Required 3-44

PDH/DSn Frequency Measurement and Looped Clock 3-54

Specifications 3-54

Equipment Required 3-54

SDH/SONET Transmitter Clock Accuracy 3-58

Specification 3-58

Description 3-58

Equipment Required 3-58

Procedure 3-58

External Clock/Data Reference Inputs & Clock Reference Output 359

Specifications 3-59

SDH/SONET Frequency Offsets 3-64

Specifications 3-64

v

Page 8

Contents

Description 3-64

Equipment Required 3-64

Procedure 3-64

STM-0/STS-1 Transmitter Output Waveshape 3-66

Specifications 3-66

Description 3-66

Equipment Required 3-66

Procedure 3-66

STM-1/STS-3 Transmitter Output Waveshape 3-70

Specifications 3-70

Description 3-70

Equipment Required 3-70

Procedure 3-70

SDH/SONET Receiver Equalization 3-75

Specifications 3-75

Equipment Required 3-75

Procedure 3-77

SDH/SONET Receiver Monitor Levels 3-78

Specifications 3-78

Description 3-78

Equipment Required 3-78

Procedure 3-78

Multirate Optical Interfaces 3-82

Specification (1310 nm Transmitter) 3-82

Specification (1550 nm Transmitter) 3-82

Specification (Receiver) 3-82

Description 3-83

Equipment Required 3-83

PDH Transmit/Receive Jitter Amplitude Accuracy 89

Specifications 89

Description 89

Equipment Required 89

Procedure 90

vi

Page 9

Contents

TX/RX Jitter Accuracy Test Setup, Ranges (1/1.6 UIp-p) 93

External Jitter Generation and Demod Output 98

SDH Transmit/Receive Jitter Amplitude Accuracy 101

Specifications 101

Description 101

Equipment Required 102

Procedure 103

External Jitter Generation and Demod Output 117

Performance Test Record 121

Jitter Performance Test Record (options 204, 205 & 206) 131

4 Terms

ETSI/ANSI Conversion and Equivalent Terms 4-1

5 Self Test Overview

Self Tests 5-1

OVERALL FUNCTION SELF TESTS 5-1

All Tests (test time - up to 1 Hour depending on options) 5-2

SPECIFIC MEASUREMENT HARDWARE/FUNCTION TESTS 5-2

PDH Test (test time- approximately 20 minutes) 5-3

BER Test (test time- approximately 20 minutes) 5-4

JITTER Test (test time- approximately 20 minutes) 5-6

6 Option Structure/Module Configuration

Option Structure/Module Configuration 6-1

vii

Page 10

Contents

viii

Page 11

General Information

Warranty

1 General Information

Warranty

HP PRODUCT DURATION OF WARRANTY

HP 37718A/19A 3 years

1 HPwarrantsHP hardware,accessoriesandsuppliesagainstdefectsin

materials and workmanship for the period specified above. If HP

receives notice of such defects during the warranty period, HP will, at

itsoption,eitherrepairorreplaceproductswhichprovetobedefective.

Replacement products may be either new or like-new.

2 HPwarrants that HP software will not fail to execute itsprogramming

instructions, for the period specified above, due to defects in material

and workmanship when properly installed and used. If HP receives

notice of such defects during the warranty period, HP will replace

software media which does not execute its programming instructions

due to such defects.

3 HP does not warrant that the operation of HP products will be

uninterrupted or error free. If HP is unable, within a reasonable time,

to repair or replace any product to a condition as warranted, customer

will be entitled to a refund of the purchase price upon prompt return

of the product.

4 HP products may contain remanufactured parts equivalent to new in

performance or may have been subject to incidental use.

5 The warranty period begins on the date of delivery or on the date of

installation if installed by HP. If customer schedules or delays HP

installation more than 30 days after delivery, warranty begins on the

31st day from delivery.

6 Warranty does not apply to defects resulting from (a) improper or

inadequatemaintenanceorcalibration,(b)software,interfacing,parts

or supplies not supplied by HP, (c) unauthorized modification or

misuse, (d) operation outside of the published environmental

specifications for the product, or (e) improper site preparation or

maintenance.

1-1

Page 12

General Information

Warranty

7 TO THE EXTENT ALLOWED BY LOCAL LAW, THE ABOVE

WARRANTIESAREEXCLUSIVEANDNOOTHERWARRANTYOR

CONDITION,WHETHERWRITTEN OR ORAL, IS EXPRESSED OR

IMPLIED AND HP SPECIFICALLY DISCLAIMS ANY IMPLIED

WARRANTIES OR CONDITIONS OF MERCHANTABILITY,

SATISFACTORY QUALITY, AND FITNESS FOR A PARTICULAR

PURPOSE.

8 HPwillbeliablefordamage to tangible property per incident up to the

greater of $300,000 or the actual amount paid for the product that is

the subject of the claim, and for damages for bodily injury or death, to

the extent that all such damages are determined by a court of

competent jurisdiction to have been directly caused by a defective HP

product.

9 TOTHE EXTENT ALLOWED BY LOCAL LAW, THE REMEDIES IN

THIS WARRANTY STATEMENT ARE CUSTOMER'S SOLE AND

EXCLUSIVE REMEDIES. EXCEPT AS INDICATED ABOVE, IN NO

EVENT WILL HP OR ITS SUPPLIERS BE LIABLE FOR LOSS OF

DATA OR FOR DIRECT, SPECIAL, INCIDENTAL,

CONSEQUENTIAL (INCLUDING LOST PROFIT OR DATA), OR

OTHER DAMAGE, WHETHER BASED IN CONTRACT, TORT, OR

OTHERWISE.

FOR CONSUMER TRANSACTIONS IN AUSTRALIA AND NEW

ZEALAND: THE WARRANTY TERMS CONTAINED IN THIS

STATEMENT, EXCEPT TO THE EXTENT LAWFULLY PERMITTED,

DO NOT EXCLUDE, RESTRICT OR MODIFY AND ARE IN ADDITION

TO THE MANDATORY STATUTORY RIGHTS APPLICABLE TO THE

SALE OF THIS PRODUCT TO YOU.

Responsibilities of the Customer

The customer shall provide:

1 Access to the products during the specified periods of coverage to

perform maintenance.

2 Adequateworkingspace around the products for servicing by Hewlett-

Packard personnel.

3 Access to and use of all information and facilities determined

necessary by Hewlett-Packard to service and/or maintain the

products.(Insofar as these items may contain proprietary or classified

information, the customer shall assume full responsibility for

1-2

Page 13

General Information

Warranty

safeguarding and protection from wrongful use.)

4 Routine operator maintenance and cleaning as specified in the

Hewlett-Packard Operating and Service Manuals.

5 Consumablessuchaspaper,disks,magnetictapes,ribbons,inks,pens,

gases, solvents, columns, syringes, lamps, septa, needles, filters, frits,

fuses, seals, detector flow cell windows, etc.

Certification

Hewlett-Packard Company certifies that this product met its published

specifications at the time of shipment from the factory. Hewlett-Packard

further certifies that its calibration measurements are traceable to the

United States National Bureau of Standards, to the extent allowed by

the Bureau's calibration facility and to the calibration facilities of other

International Standards Organization members!

Assistance

Product maintenance agreements and other customer assistance

agreements are available for Hewlett-Packard products.

Notice

The information contained in this document is subject to change without

notice.

Hewlett-Packard shall not be liable for errors contained herein or for

incidental or consequential damages in connection with the furnishing,

performance or use of this material.

This document contains proprietary information which is protected by

copyright. All rights are reserved. No part of this document may be

photocopied or reproduced without the prior written consent of the

manufacturer, Hewlett-Packard Ltd.

Restricted Rights Legend

Use, duplication, or disclosure by the government is subject to

restrictions as set forth in subdivision (b)(3)(ii) of the Rights in Technical

Data and Computer Software clause at 52.227-7013. Hewlett-Packard

Company; 3000 Hanover Street; Palo Alto, California 94304.

1-3

Page 14

General Information

Instruments Covered By Manual

Instruments Covered By Manual

Attached to the rear panel of the instrument is a serial number plate.

The serial number plate has a two letter reference denoting country of

origin (GB = Great Britain) and an eight digit serial number. The serial

number is unique to each instrument and should be quoted in all

correspondence with Hewlett-Packard, especially when ordering

replacement parts. Refer to Chapter 6 for instrument options covered.

Serial Number Plate

Storage and Shipment

The instrument may be stored or shipped in environments within the

following limits:

Temperature -20o C to +70o C

-15o C to +50o C with lid printer

Altitude Up to 15,200 meters (50,000 feet)

The instrument should also be protected from temperature extremes

which could cause condensation within the instrument.

Repackaging for Shipment

Tagging for Service. If the instrument is being returned to Hewlett-

Packard for service, please complete a repair tag and attach it to the

instrument.

1-4

Page 15

General Information

Weight and Dimensions

Original Packaging. Containers and materials identical to those used

in factory packaging are available from Hewlett-Packard offices. If the

instrument is being returned to Hewlett-Packard for servicing, attach a

tag indicating the type of service required, return address, model

number, and full serial number. Mark the container FRAGILE to ensure

careful handling. In any correspondence, refer to the instrument by

model number and full serial number.

Other Packaging. The following general instructions should be

followed when repackaging with commercially available materials:

• Wrap instrument in heavy paper or plastic. If the instrument is being

shippedto Hewlett-Packard,attacha tag indicating thetype of service

required, return address, model number and full serial number.

• Use a strong shipping container. A double wall carton made of 350

pound test material is adequate.

• Use a layer of shock absorbing material 70 to 100 mm (3 to 4 inch)

thick, around all sides of the instrument to provide firm cushioning

and prevent movement inside the container. Protect the Front Panel

controls and Rear Panel connectors with cardboard.

• Seal shipping container securely.

• Mark shipping container FRAGILE to ensure careful handling.

• In any correspondence, refer to instrument by model number and full

serial number.

Weight and Dimensions

Weight: 18 kg (40 lb) fully loaded

Dimensions: 190mm (7.5in) high, 340mm (14in) wide, 420mm (17in)

deep (including cover).

1-5

Page 16

General Information

Safety Precautions for the Operator

Safety Precautions for the Operator

The following general safety precautions must be observed during all

phases of operation, service, and repair of this instrument. Failure to

comply with these precautions or with specific warnings elsewhere in

this manual violates safety standards of design, manufacture, and

intended use of the instrument. Hewlett-Packard Company assumes no

liability for the customer’s failure to comply with these requirements.

In particular, the operator should note the following safety information:

• “Safety Symbols” on page 1-7

• “Connecting to the Power Supply” on page 2-4

• “Operating Environment” on page 2-2

• “Fuse Replacement” on page 2-3

• “Operators Maintenance” on page 1-8

• “Lifting/Carrying the HP 37718A/19A” on page 1-6

DO NOT operate damaged equipment: Whenever it is possible that the

safety protection features built into this product have been impaired,

either through physical damage, excessive moisture, or any other reason,

REMOVE POWER and do not use the product until safe operation can be

verified by service-trained personnel. If necessary, return the product to

a Hewlett-Packard Sales and Service Office for service and repair to

ensure the safety features are maintained.

Lifting/Carrying the HP 37718A/19A

Before attempting to lift or carry the instrument consider the following basic lifting

techniques to help avoid personal injury.

Using both arms to lift instrument.

• Reach for the instrument - bend your knees and waist, and keep your back

straight.

• GRASP the instrument firmly.

• LIFT with your legs.

• KEEP your shoulders level.

1-6

Page 17

General Information

Safety Precautions for the Operator

Safety Symbols

The following symbols on the instrument and in the manual indicate precautions

which must be taken to maintain safe operation of the instrument

The Instruction Documentation Symbol. The product is

marked with this symbol when it is necessary for the user to

refer to the instructions in the supplied documentation.

Indicates the field wiring terminal that must be connected to

earth ground before operating the equipment - protects

against electrical shock in case of fault.

Frame or chassis ground terminal - typically connects to the

equipment's metal frame.

Alternating current (AC)

Direct current (DC)

WARNING

CAUTION

Indicates hazardous voltages

Warning denotes a hazard. It calls attention to a procedure,

which if not correctly performed or adhered to could result

in injury or loss of life. Do not proceed beyond a warning

note until the indicated conditions are fully understood and

met.

Caution denotes a hazard. It calls attention to a procedure,

which if not correctly performed or adhered to could result

in damage to or destruction of the instrument. Do not proceed beyond a warning note until the indicated conditions

are fully understood and met.

Indicates that a laser is fitted. The user must refer to the

manual for specific Warning or Caution information to

avoid personal injury or damage to the product.

1-7

Page 18

General Information

Operators Maintenance

Operators Maintenance

WARNING NO OPERATOR SERVICEABLE PARTS INSIDE. REFER

SERVICING TO QUALIFIED PERSONNEL. TO PREVENT

ELECTRICAL SHOCK DO NOT REMOVE COVERS.

Maintenance appropriate for the operator is:

• Cabinet cleaning

• Optical Connector Cleaning

• Power supply fuse replacement

• Ensure ventilating fan cover is clean.

Cleaning

Cabinet Cleaning

Clean the cabinet using a dry cloth only.

Optical Connector Cleaning

It is recommended that the optical connectors be cleaned at regular

intervals using the following materials:

Description HP PartNumber

Blow Brush 9300-1131

Isopropyl Alcohol 8500-5344

Lens Cleaning Paper 9300-0761

Adhesive Tape Kit 15475-68701

CAUTION Do not insert any tool or object into the IN or OUT ports of the instrument

as damage to or contamination of the optical fibre may result.

1 Recall Default settings (STORED SETTINGS 0) and remove the

1-8

Page 19

General Information

Operators Maintenance

power from the HP 37718A/19A.

2 Remove the adapters from the IN and OUT ports.

3 Usingtheblowbrushwiththebrushremovedblow through the ferrule

of the standard flexible connector and the adapter.

CAUTION If the optical fibre of the fixed connector requires further cleaning this

entails disassembly of the module which should only be carried out by

suitably trained service personnel.

4 Applysome isopropyl alcohol to a piece of the cleaning paper and clean

the barrel of the adapter. Using a new piece of cleaning paper, clean

the face of the adapter. Repeat this operation, using a new piece of

cleaning paper each time.

5 Lightly press the adhesive side of the tape provided against the front

of the adapter,then remove it quickly - repeat twice.This removes any

particles of cleaning paper which may be present.

6 Replace the adapters on the flexible connector.

Power Supply Fuse Replacement

See “Fuse Replacement” on page 2-3

1-9

Page 20

General Information

Statement of Compliance

Statement of Compliance

This instrument has been designed and tested in accordance with IEC

Publication 1010-1 + A1:1992 Safety requirements for Electrical

Equipment for Measurement, Control and Laboratory Use, and has been

supplied in a safe condition. The instruction documentation contains

information and warnings which must be followed by the user to ensure

safe operation and to maintain the instrument in a safe condition.

The CE mark shows that the product complies with all

relevant European legal Directives.

This is a symbol of an Industrial Scientific and Medical

ISM 1-A

Group 1 Class A product.

The CSA mark is a registered trademark of the Canadian Standards Association.

Australian EMC Regulations

The C-Tick mark is a registered trademark of the

Spectrum Management Agency of Australia. This

signifies compliance with the Australian EMC

Framework Regulations under the terms of the

Radiocommunications Act of 1992.

Noise Declaration (German)

LpA<70dB

am Arbeitsplatz (operator position)

normaler Betrieb (normal position)

nach DIN 45635 pt.19 (per ISO 7779)

1-10

Page 21

General Information

Electromagnetic Compatibility

Electromagnetic Compatibility

This product has been designed to meet the protection requirements of

the European Communities Electromagnetic Compatibility (EMC)

directives:

EN55011:1991 (Group 1, Class A)

EN50082-1:1992

- IEC 1000-4-2 (1995) ESD

- IEC 1000-4-3 (1995) Radiated Susceptibility

- IEC 1000-4-4 (1995) EFT

In order to preserve the EMC performance of the product, any cable

which becomes worn or damaged must be replaced with the same type

and specification.

Electrostatic Discharge

When an air discharge is applied to the HP 37718A/19A in accordance

with IEC 801-2 (1991), degradation in performance may be observed in

the form of occasional bit errors being counted.

See also “10 Base-T Lan Connection Radiated Emissions” on page 2-11

1-11

Page 22

General Information

Electromagnetic Compatibility

Declaration of Conformity

according to ISO/IEC Guide 22 and EN45014

Manufacturer’s Name: Hewlett Packard Ltd.

Manufacturer's Address:

Declares that the product

Product Name:

Model Numbers:

Product Options:

Conforms with the protection requirements of European Council Directive 89/336/EEC on the approximation

of the laws of the member states relating to electromagnetic compatibility.

Against EMC test specifications EN 55011:1991 (Group 1, Class A) and EN 50082-1:1992

As Detailed in:

Assessed by:

Technical Report Number:6893/2200/CBR, dated 21 August 1997

Supplementary Information:

The product conforms to the following safety standards:

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC, and carries the

CE-marking accordingly.

Telecomms Networks Test Division

South Queensferry

West Lothian, EH30 9TG

Scotland, United Kingdom

Communications performance Analyzer

HP 37718A

This declaration covers all options of the above products as

detailed in TCF A-5951-9852-01

Electromagnetic Compatibility (EMC)

Technical Construction File (TCF)No. A-5951-9852-01

Dti Appointed Competent Body

EMC Test Centre,

GEC-Marconi Avionics Ltd.,

Maxwell Building,

Donibristle Industrial Park,

KY11 5LB

Scotland, United Kingdom

IEC 61010-1:1992

EN 61010-1:1993

CSA-C22.2 No. 1010 Series M-93

EN 60825-1(1994) / IEC 825-1 (1993)

South Queensferry, Scotland

Location Date W.R. Pearson / Quality Manager

1-12

9 September

1998

Page 23

General Information

Electromagnetic Compatibility

Declaration of Conformity

according to ISO/IEC Guide 22 and EN45014

Manufacturer’s Name: Hewlett Packard Ltd.

Manufacturer's Address:

Declares that the product

Product Name:

Model Numbers:

Product Options:

Conforms with the protection requirements of European Council Directive 89/336/EEC on the approximation

of the laws of the member states relating to electromagnetic compatibility.

Against EMC test specifications EN 55011:1991 (Group 1, Class A) and EN 50082-1:1992

As Detailed in:

Assessed by:

Technical Report Number:6893/2200/CBR, dated 21 August 1997

Supplementary Information:

The product conforms to the following safety standards:

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC, and carries the

CE-marking accordingly.

Telecomms Networks Test Division

South Queensferry

West Lothian, EH30 9TG

Scotland, United Kingdom

Communications Performance Analyzer

HP 37719A

This declaration covers all options of the above products as

detailed in TCF A-5951-9852-01

Electromagnetic Compatibility (EMC)

Technical Construction File (TCF)No. A-5951-9852-01

Dti Appointed Competent Body

EMC Test Centre,

GEC-Marconi Avionics Ltd.,

Maxwell Building,

Donibristle Industrial Park,

KY11 5LB

Scotland, United Kingdom

IEC 61010-1:1992

EN 61010-1:1993

CSA-C22.2 No. 1010 Series M-93

EN 60825-1(1994) / IEC 825-1 (1993)

South Queensferry, Scotland

Location Date W.R. Pearson / Quality Manager

9 September

1998

1-13

Page 24

General Information

Electromagnetic Compatibility

1-14

Page 25

Installation

Initial Inspection

2 Installation

Initial Inspection

WARNING TO AVOID HAZARDOUS ELECTRICAL SHOCK, DO NOT

PERFORM ELECTRICAL TESTS WHEN THERE ARE SIGNS OF

SHIPPING DAMAGE TO ANY PORTION OF THE OUTER

ENCLOSURE (COVERS, PANELS, METERS).

Inspect the shipping container for damage. If the shipping container or

cushioning material is damaged, it should be kept until the contents of

the shipment have been checked for completeness and the instrument

has been checked both mechanically and electrically. Procedures for

checking electrical operation are given in Chapter 3. If the contents of

the shipment are incomplete, if there is mechanical damage or defect,

notify the nearest Hewlett-Packard Office. If the instrument does not

pass the electrical performance tests given in Chapter 3, notify the

nearest Hewlett-Packard office. If the shipping container is also

damaged, or the cushioning material shows signs of stress, notify the

carrier as well as the nearest Hewlett-Packard office. Keep the shipping

materials for the carrier’s inspection. The Hewlett-Packard office will

arrange for repair or replacement without waiting for claim settlement.

2-1

Page 26

Installation

Operating Environment

Operating Environment

This instrument is designed for Indoor use only.

DO NOT operate the product in an explosive atmosphere or in the

presence of flammable gasses or fumes.

This instrument may be operated in environments within the following

limits:

Temperature: 0o C to +45o C

+5oC to +40oC for Jitter operation.

+5o C to +35o C with lid printer

Altitude up to 3050m (10,000ft)

Humidity up to 95% relative humidity to 40o C, but it should be

protected from temperature extremes which may cause

condensation.

To ensure adequate cooling do not obstruct air vents in the instrument

cabinet. Do not for example operate the instrument if it is standing on its

rear feet, as air vents may be obstructed by floor covering.

CAUTION This instrument is designed for use in Installation Category II and

Pollution Degree 2 per IEC 1010 and 644 respectively.

CAUTION VENTILATION REQUIREMENTS: When installing the instrument in a

cabinet, the convection into and out of the instrument must not be

restricted. If the total power dissipated in the cabinet is greater than 800

watts, then forced convection must be used.

2-2

Page 27

Installation

Preparation for Use

Preparation for Use

WARNING FOR CONTINUED PROTECTION AGAINST FIRE HAZARD

REPLACE FUSE ONLY WITH SAME TYPE AND RATINGS (see

“Fuses” on page 2-3).

WARNING If this instrument is not used as specified, the protection

provided by the equipment could be impaired. This instrument

must be used in a normal condition only (in which all means for

protection are intact).

Power Requirements

The HP 37718A/19A Communications Performance Analyzer requires a

power source of 90 V to 132 V ac or 198 V to 264 V ac at a frequency

between 47 Hz and 63 Hz (nominal).

Total power consumption is 450 VA (maximum).

The fuse rating for the power source is given in the following Table.

Fuses

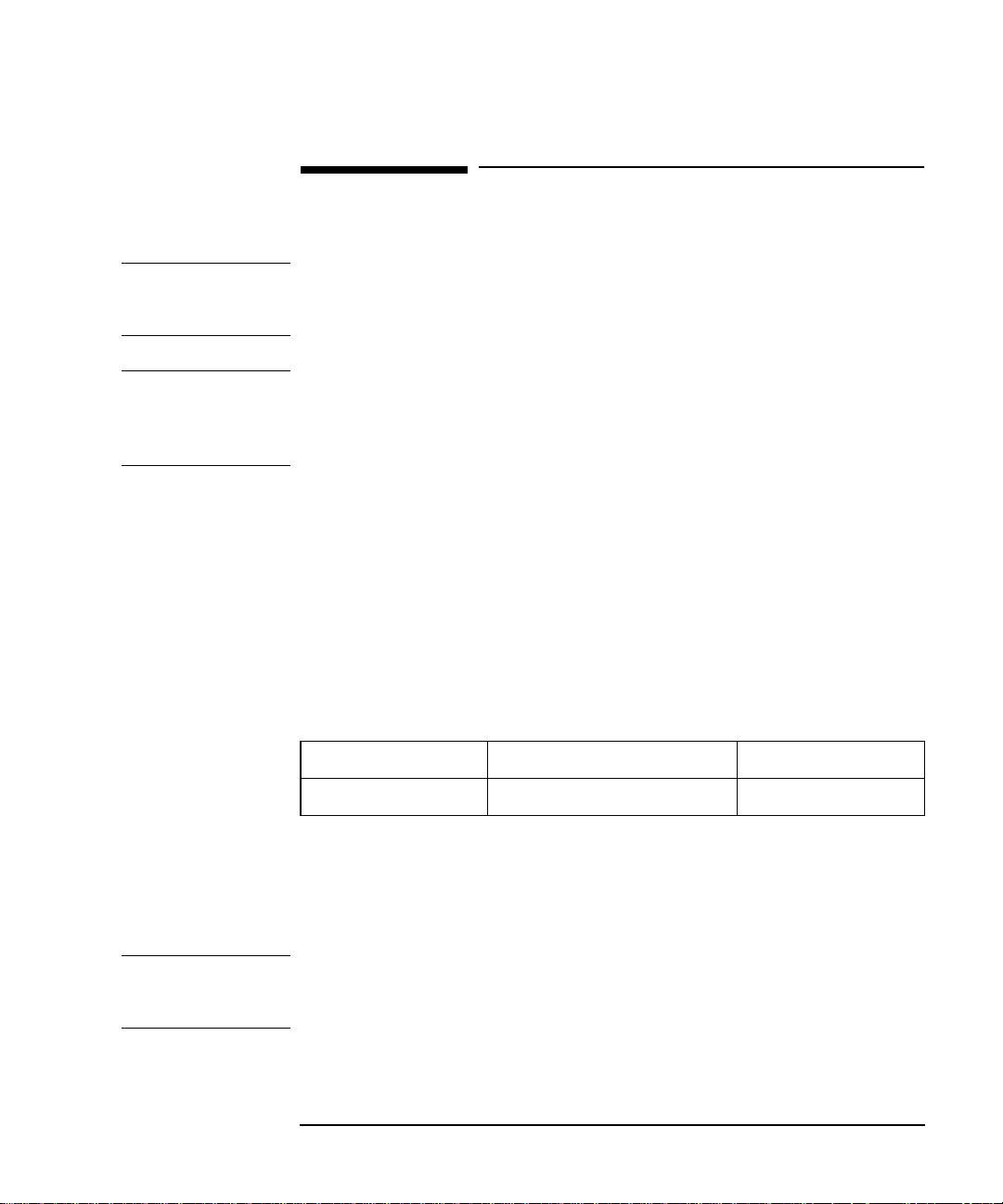

Line Voltage Fuse Rating HP Part Number

90V to 264V 5A Timed, 250V 2110-1120

Fuse Replacement

Only the ac line fuse located at the rear of the instrument may be

replaced by the operator.

WARNING ALL OTHER FUSE REPLACEMENT SHOULD ONLY BE

CARRIED OUT BY SUITABLY TRAINED SERVICE PERSONNEL

AWARE OF THE HAZARDS INVOLVED.

2-3

Page 28

Installation

Preparation for Use

WARNING BEFORE REMOVING THE FUSE, THE AC LINE POWER CORD

SHOULD BE DISCONNECTED FROM THE POWER SOURCE

AND THE OTHER END DISCONNECTED FROM THE

INSTRUMENT.

WARNING ONLY USE A FUSE OF THE CORRECT RATING AS LISTED IN

“Fuses” on page 2-3. DO NOT use repaired fuses or short-circuited

fuseholders: For continued protection against fire, replace the line fuse(s)

only with fuse(s) of the same voltage and current rating and type.

The fuse is removed by inserting a suitable flat bladed tool into the slot

in the fuse cap and turning counter-clockwise. The cap and the fuse can

then be removed and the fuse changed for another of the correct rating.

The fuse rating and HP part number are listed in “Fuses” on page 2-3.

Connecting to the Power Supply

WARNING This is a Safety Class I instrument (providedwith a protective earthing ground,

incorporated in the powercord). The mains plug shall only be inserted in a

socket outlet provided with a protective earth contact. Any interruption of the

protective conductor inside or outside of the instrument is likely to make the

instrument dangerous. Intentional interruption is prohibited.

CAUTION Before switching on this instrument, make sure that the line supply voltage is in the

specified ranges. Range selection is automatic.

2-4

Page 29

Installation

Preparation for Use

Power Cord

WARNING TO AVOID THE POSSIBILITY OF INJURY OR DEATH, THE

FOLLOWING PRECAUTIONS MUST BE FOLLOWED BEFORE

THE INSTRUMENT IS SWITCHED ON:-

WARNING (a) Note that the protection provided by grounding the

instrument cabinet may be lost if any power cable other than the

three-pronged type is used to couple the ac line voltage to the

instrument.

WARNING (b) If this instrument is to be energized via an auto-transformer

to reduce or increase the line voltage, make sure that the common

terminal is connected to the neutral pole of the power source.

WARNING (c) The power cable plug shall only be inserted into a socket

outlet provided with a protective ground contact. The protective

action must not be negated by the use of an extension cord

without a protective conductor (grounding).

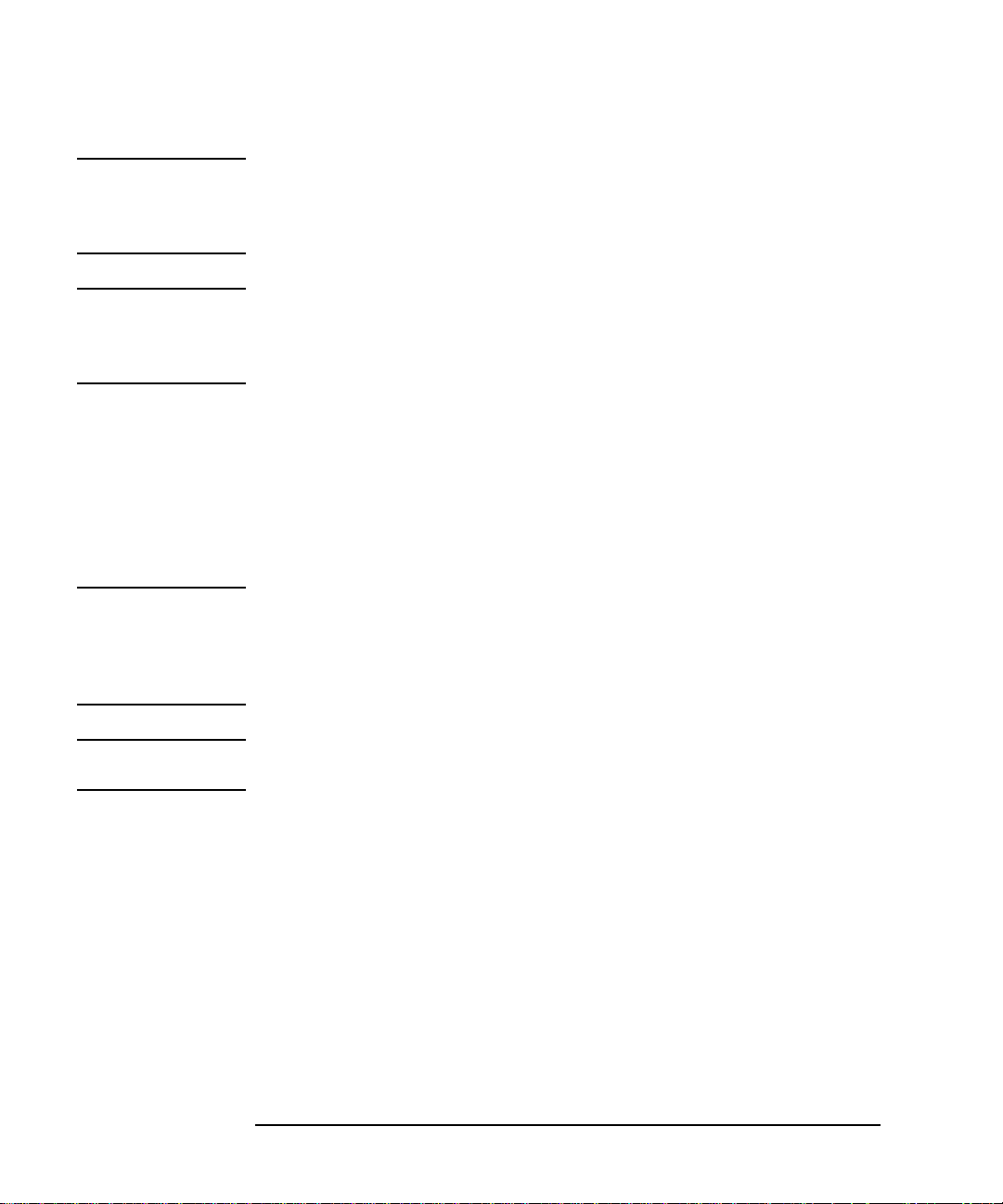

The power cord supplied with each instrument varies with the country of

destination. The following figure illustrates the standard power plug and

cord configurations that are commonly used. The part number shown

beneath each plug is the part number of the appropriate power cord and

plug. If the appropriate power cord is not included with the instrument

notify the nearest Hewlett-Packard office and a replacement will be

provided.

Power Cord Configurations and Part Numbers

2-5

Page 30

Installation

Connecting to the Network

Connecting to the Network

The network connectors are located on the modules at the side of the

instrument. The connections available depend on the options fitted to

your instrument.

Before Connecting, note the Warning and Caution information given.

All Connectors

CAUTION When connecting or disconnecting, ensure that you are grounded or,

make contact with the metal surface of the Mainframe with your free hand to bring

you, the module, and the mainframe to the same static potential.

Modules remain susceptible to ESD damage while the module is installed in the

Mainframe

Additional ESD information is required when servicing see “AdditionalPrecautions

for Service Engineers” on page 2-14

RECEIVER

2,8,34,140 IN

TRANSMIT

2,8,34,140 OUT

DS3, 2Mb/s,

34Mb/s 75Ω IN

DS3, 2Mb/s,

34Mb/s 75ΩOUT

Electrical Interface Connectors

PDH receiver input interface. Allows the connection of 75 Ω unbalanced

data signals (all rates) and 120 Ω balanced data signals at 2 Mb/s.

PDH transmitter output interface. Provides 75 Ω unbalanced data

output (all rates) and 120 Ω balanced data output at 2 Mb/s

PDH/DSn receiver input interface. Allows the connection of 75Ω

unbalanced DS3, 2 Mb/s and 34.368 Mb/s data signals.

PDH / DSn transmitter output interface. Provides 75 Ω unbalanced DS3,

2 MB/s and 34 Mb/s data output. A “keep alive” signal is output when the

transmit signal is SDH/SONET.

2-6

Page 31

Installation

Connecting to the Network

DS1 100

2Mb/s 120Ω IN

DS1 100

2Mb/s 120Ω OUT

52/155 Mb/s

DATA IN

52/155 Mb/s

DATA OUT

64k REF IN

1.5M REF IN

2M REF IN

REF OUT

MUX

Ω,

Ω,

PDH / DS1 receiver input interface. Allows the connection of 100 Ω

balanced DS1 and 120 Ω balanced 2 Mb/s data signals.

PDH / DS1 transmitter output interface. Provides 100 Ω balanced DS1

and 120 Ω balanced 2 Mb/s data signals. A “keep alive” signal is output

when the transmit signal is SDH/SONET.

SDH/SONET receiver input interface. Allows the connection of 75 Ω

unbalanced STM 0/1, STS 1/3 electrical signals.

SDH/SONET transmitter output interface. Provides a 75 Ω unbalanced

STM 0/1, STS 1/3 electrical output.

These ports allow connection of timing reference signals.

Provides a 2 MHz reference Clock Output.

Allows the insertion of an external 2 Mb/s tributary into the transmitted

payload.

MUX DS1 100

MUX 2 Mb/s 75

DEMUX DS1

100

Ω

DEMUX

2 Mb/s 75

Ω

Ω Allows an externally supplied DS1 signal to be inserted in any or all

timeslot(s) of a DS3 signal. In conjunction with the SDH/SONET module

a DS1 signal can be inserted into a VT1.5 or TU-11.

Ω Allows an externally supplied 2.048 Mb/s signal to be inserted in any or

all timeslot(s) of a 34 Mb/s signal. In conjunction with the SDH module a

2.048 Mb/s signal can be inserted into a TU-12.

Allows a DS1 signal to be dropped from any timeslot of a DS3 signal. In

conjunction with the SDH/SONET module this port allows the

demultiplexing of a DS1 signal carried in a VT1.5

Allows a 2.048 Mb/s signal to be dropped from any timeslot of an 8.448

Mb/s, 34.368 Mb/s or 139.264 Mb/s signal.

2-7

Page 32

Installation

Connecting to the Network

CLOCK TRIGGER

DCC

Reference SDH/SONET clock trigger output 51 MHz; nominal +/- 400

mV into 50 ohms.

Allows the Drop and Insert of Regenerator Section (192 kb/s) and

Multiplexer Section (576 kb/s) Data Communication Channels (DCC).

The following connections are available:

Table 1 DCC Connector Pin-out

Pin Number Connection

1 Shield Ground

2 Data input for Tx(-)

3 Tx Clock

4 Data Output from Rx(-)

5NC

6 Rx Clock(-)

7NC

8 Signal Ground

9 Data Input for Tx(+)

PROTECTED

MONITOR POINT

INPUT

10 Tx Clock(+)

11 Data output from Rx(+)

12 NC

13 Rx Clock(+)

14 NC

15 NC

52/155/622 Mb/s (NRZ); Line Code NRZ; Level nominal 1 V p-p into 50 ohms;

SMA connector.

2-8

Page 33

Installation

Connecting to the Network

Optical Interface Connectors

For your protection, review all laser information given in this manual

before installing or using the instrument.

WARNING To prevent personal injury, avoid use that may be hazardous to

others, and maintain the module in a safe condition Ensure the

information given below is reviewed before operating the

module.

Laser Product Classification

All optical modules are classified as Class I (non-hazardous) laser

product in the USA which complies with the United States Food and

Drug Administration (FDA) Standard 21 CFR Ch.1 1040.10, and are

classified as Class 1 (non-hazardous) laser products in Europe which

complies with EN 60825-1 (1994).

To avoid hazardous exposure to laser radiation, it is recommended that

the following practices are observed during system operation:

• ALWAYS DEACTIVATE THE LASER BEFORE CONNECTING

OR DISCONNECTING OPTICAL CABLES.

• When connecting or disconnecting optical cables between the module

and device-under-test, observe the connection sequences given below.

Connecting: Connect the optical cable to the input of the device-

under-test before connecting to the module’s Optical

Out connector.

Disconnecting: Disconnect the optical cable from the module’s Optical

Out connector before disconnecting from the device-

under-test. Always fit the fibre optic connector dust

caps over the laser aperture.

• NEVER examine or stareinto the open end of a broken, severed, ordisconnected optical cable when it is connected to the module’s Optical

Out connector.

• Arrange for service-trained personnel, who are aware of the hazards

involved, to repair optical cables.

2-9

Page 34

Installation

Connecting to the Network

CAUTION 1. Use of controls or adjustments or performance of procedures other than

those specified herein may result in hazardous radiation exposure.

2. Always fit the fibre optic connector dust caps on each connector when

not in use. Before connection is made, always clean the connector ferrule

tip with acetone or alcohol and a cotton swab. Dry the connector with

compressed air. Failure to maintain cleanliness of connectors is liable to

cause excessive insertion loss.

Laser Warning Symbols

The front panel of the optical module has the following label:

CLASS 1 LASER PRODUCT

NOTE CLASS 1 LASER PRODUCT translates as follows:

Finnish - LUOKAN 1 LASERLAITE

Finnish/Swedish - KLASS 1 LASER APPARAT

OPTICAL IN

OPTICAL OUT

This label indicates that the radiant energy present in this instrument is

non-hazardous.

Allows connection of an optical signal, wavelength 1200 to 1600 nm, at a

maximum power level of -8 dBm. NEVER EXCEED +3 dBm.

Accepts STM-0, STM-1, STM-4 and STM-16. Also accepts SONET

signals, STS-1, STS-3, STS-12, STS-48, OC-1, OC-3, OC-12 and OC-48.

Provides an STM-0, STM-1, STM-4 or STM-16 optical signal (OC-1, OC3, OC-12 or OC-48 SONET signals) at wavelength1280 to 1330nm, and/

or 1550 to 1565 nm, at a nominal power level of +1 dBm.

Cleaning Optical Connectors

See “Optical Connector Cleaning” on page 1-8

2-10

Page 35

Installation

Connecting Accessories

Connecting Accessories

LID

VGA

HANDSET

Printer

HP-IB, RS232,

PARALLEL ONLY

Remote Control

HP-IB, RS232,

10 BASE -T

Provides the output for the option 602 printer which is fitted in the cover

(LID) of the instrument.

Provides the output for a display monitor.

Allows connection of a telephone handset for communication across the

network.

External printer connection details are given in the Users Guide.

The port selected for external printer use is not available for remote

control.

Remote control connection is given in the Remote Control Manual.

The port selected for remote control use is not available for an external

printer.

10 Base-T Lan Connection Radiated Emissions

To ensure compliance with EN 55011 (1991) a category 5, FTP patch

lead, RJ45 cable should be used to connect the LAN port on the processor

module marked

"10 Base-T".

2-11

Page 36

Installation

Connecting Accessories

Hewlett-Packard Interface Bus

The HP 37718A/19A Communications Performance Analyzer (Option 601) is

connected to the HP-IB by means of an appropriate HP-IB cable.The HP-IB

interconnecting cables available are listed in the following table.

HP-IB Interconnecting Cables

Length Accessory Number

1 meter HP 10833A

2 meters HP 10833B

4 meters HP 10833C

0.5 meter HP 10833D

To achieve interface design performance standards, restrictions are placed on the

HP-IB system cable lengths. These restrictions allow the bus interface electronics to

maintain correct line voltage levels and timing relationships.

When connecting an HP-IB system the following rules should be observed:

The total HP-IB cable length used must be less than or equal to 20 meters (65.6

feet).

The total HP-IB cable length used must be less than or equal to 2 meters (6 feet)

× the total number of devices connected to the bus.

A standard HP-IB connector is provided on the instrument. The connections are

shown in the following figure. The mating connector part number is HP 1251-0293

or Amphenol 57-30240.

2-12

Page 37

Installation

Connecting Accessories

HP-IB Connections

HP-IB Address Selection

The HP 37718A/19A (Option 601) HP-IB address is accessed on the OTHER

display under the REMOTE CONTROL function.

The address can be set to any value between 0 and 30 inclusive.

2-13

Page 38

Installation

Additional Precautions for Service Engineers

Additional Precautions for Service Engineers

Safety Precautions

DO NOTsubstitute parts or modify equipment: Because of the danger of

introducing additional hazards, do not install substitute parts or perform

any unauthorized modification to the product. Return the product to a

Hewlett-Packard Sales and Service Office for service and repair to

ensure the safety features are maintained.

DO NOT service or adjust alone: Under certain conditions, dangerous

voltages may exist even with the equipment switched off. To avoid

dangerous electrical shock, service personnel must not attempt internal

service or adjustment unless another person, capable of rendering first

aid and resuscitation, is present.

Review “Safety Precautions for the Operator” on page 1-6

ESD Precautions

CAUTION When making connections to the modules, review “Connecting to the Network” on

page 2-6

The module contains components sensitive to electrostatic discharge.

To prevent component damage, carefully follow the handling precautions presented

below.

The smallest static voltage most people can feel is about 3500 volts. It

takes less than one tenth of that (about 300 volts) to destroy or severely

damage static sensitive circuits. Often, static damage does not

immediately cause a malfunction but significantly reduces the

component’s life. Adhering to the following precautions will reduce the

risk of static discharge damage.

• Keep the module in its conductive storage box when not installed in

the Mainframe. Save the box for future storage of the module.

• Before handling the module, select a work area where potential static

sources are minimized. Avoid working in carpeted areas and non-conductive chairs. Keep body movement to a minimum. Hewlett-Packard

2-14

Page 39

Installation

Additional Precautions for Service Engineers

recommends that you use a controlled static workstation.

• Handle the module by its front-panel. Avoid touching any components

or edge connectors. When you install the module, keep one hand in

contact with the protective bag as you pick up the module with your

other hand. Then, before installing the module, ensure that you are

grounded or make contact with the metal surface of the Mainframe

with your free hand to bring you, the module, and the mainframe to

the same static potential. This also applies whenever you con-

nect/disconnect cables on the front-panel.

2-15

Page 40

Installation

Additional Precautions for Service Engineers

Front Panel Soft Recovery (Cold Start)

Use the following procedure if you need to perform a front panel soft

recovery (i.e. cold start) of the instrument.

Soft Recovery Procedure

1 Switch off the instrument.

2 On the instrument front panel - press and hold softkeys 0 and 4

simultaneously (the softkeys immediately below the display; key 0 is

on the extreme left).

3 Power up the HP 37718A or HP 37719A while holding the softkeys

pressed.

4 Whenthe LOS LED has flashed OFF and then ON again, the keys can

be released.

5 The LOS LED will flash OFF/ON again several times (7), followed by

an audible ‘beep’ and the display indicating ‘Initializing Instrument’.

6 Once the initiations is complete the display will indicate:

‘Firmware Revision Update’

‘Default settings assumed’

Hit any key to attempt restart’

7 Hit any key, then wait approximately 10 seconds. The instrument

should return to its default settings and normal operation.

2-16

Page 41

Performance Tests

3 Performance Tests

Introduction

The procedures given in this Section, test the HP 37718A/19A

performance using the Specifications provided, as performance

standards. Tests are intended to be performed in the recommended order

for a full instrument calibration check. Tests can be run individually,

however it will be assumed that any preceding test would meet

specifications.

Equipment Required

Equipment required for the Performance Tests is given in this Chapter.

Any equipment which meets or exceeds the critical specification of the

equipment listed, may be substituted. Recommended models are those

typically used in HP Service Centers. Alternative models are also listed.

Performance Test Record

The results of the Performance Tests may be recorded on the Test

Records at the end of this Chapter.The Performance Test Record lists all

the tested specifications and the acceptable limits. The results recorded

at incoming inspection may be used for comparison during periodic

maintenance, troubleshooting or after repair or adjustment.

Calibration Cycle

This instrument requires periodic verification of performance.

Depending on use and environmental conditions, the instrument should

be checked approximately once every 2 years, using these Performance

Tests.

Option Configuration

Please refer to Chapter 6 and the instrument Specifications for

information on option configuration.

3-1

Page 42

Performance Tests

Table 3-1 Recommended Test Equipment

Instrument Critical Specification Recommended

Model

Oscilloscope 400 MHz Bandwidth, 1 MΩ Input Termination

Telecom mask measurement capability.

Frequency Synthesizer 75Ω Output, Sinewave to 80 MHz,

Amplitude to 3 V pk-pk at 10 kHz, 1 Hz resolution

Signal Generator Sinewave 700 kHz to 170 MHz, Amplitude 500 mV HP 8657A

Frequency Counter Range 0 to 200 MHz, 2 channels with accuracy

<0.1ppm. (Ratio Mode)

Spectrum Analyzer** Frequency >2.5 Gb/s. Resolution bandwidth 10 Hz. HP 8560E

Optical Coupler** 1310 and 1510 nm. 10/90% output. HP 15477C

Optical Power Meter

and Sensor Module

Lightwave Converter Wavelength 1300 to 1560 nm, Conversion Gain >300

Optical Attenuator Wavelength 1200 - 1600 nm, Range 0 - 30 dB HP 8157A or

FC/PC Optical

Interface Connector

Optical Cables Unique HP 11871A (Qty 2)

PDH Structured Test

Set

Range -8 dBm to -15 dBm, Wavelength1270-1560 nm HP 8153A and HP

volts/watt, Frequency Response < 3 dB down at 1 GHz.

Unique HP 81000FI (Qty 4)

Unique HP37718A/37719Aor

HP 54520A opt 001

or HP 54810A opt 001

HP 3335A opt 001 or

HP 3325B & HP

8657A with 50/75Ω

matching pad

HP 5325A opt 010

or HP 53181A opt 001

81536A

HP 11982A opt 012

HP 8156A opt 100

HP 37717C opt UKJ

64 kb/s Clock

Generator

75Ω Attenuator Kit 0 to 200 MHz 3, 6, 10, 20 dB fixed attenuator pads HP 86213A

Cable Simulator #E1 75Ω coaxial cable 6dB loss at 1 MHz 8120-0049 (120 m)*

Cable Simulator #E2

Cable Simulator #E3 75Ω coaxial cable 12dB loss at 17 MHz 8120-0049 (120 m)*

Cable Simulator #E4 75Ω coaxial cable 12dB loss at 70 MHz 8120-0049 (80 m)*

64 kb/s ternary clock. HP 37732A

75Ω coaxial cable 6dB loss at 4 MHz

8120-0049 (80 m)*

3-2

Page 43

Performance Tests

Table 3-1 Recommended Test Equipment, continued

Instrument Critical Specification Recommended

Model

Cable Simulator #E1-M 75Ω coaxial cable 3dB loss at 1 MHz 8120-0049 (60 m)*

Cable Simulator #E2-M

Cable Simulator #E3-M 75Ω coaxial cable 6dB loss at 17 MHz 8120-0049 (60 m)*

Cable Simulator #E4-M 75Ω coaxial cable 6dB loss at 70 MHz 8120-0049 (40 m)*

Cable Simulator #DS1 75Ω coaxial cable. Equivalent to 655 feet ABAM cable. 8120-0049 (80m)*

Cable Simulator #DS3 75Ω coaxial cable. Equivalent to 450 feet of 728A cable 8120-0049 (55m)*

Cable Simulator STM-0/

STS-1

Cable Simulator STM-1/

STS-3

75

Ω

Termination 0 to 200 MHz HP 15522-80010

T Connector BNC to Dual BNC HP 1250-0781

Adaptor SMA to BNC 1250-1787 (Qty 2)

Adaptor Type N to BNC HP 1250-1534 (Qty 2)

Adaptor Type N to N HP 1250-1528 (Qty 2)

Balanced/Unbalanced

Converter

Blocking Capacitor 0.18uF 200V HP 10240B

75Ω coaxial cable 3dB loss at 4 MHz

Ω

coaxial cable 6dB loss at 26 MHz 8120-0049 (50 m)*

75

75

Ω

coaxial cable 12dB loss at 78 MHz 8120-0049 (75 m)*

Ω

balanced: 75Ω Unbalanced (nominal) HP 15508B (Qty 2)

110

8120-0049 (40 m)*

* Note: Cable lengths quoted are typical for the half bit rate loss. Ideally, cables should be

trimmed to correct length/loss by measuring with a Network Analyzer.

** Note: Spectrum Analyzer/Optical Coupler are only required for 37718A Jitter options.

Self Test Loopback Cables and Accessories

HP E4545A 3m fibre optic cable FC/CP connectors. (supplied accessory)

HP E4546A FC/CP 15 dB attenuator. (supplied accessory)

HP 15525A 75 ohm BNC, 3 off.

HP 15512A Siemens 3 pin (Option 010 units)

HP 15670A Bantam 110 ohm (Option 011 units), 2 off.

DCC 15 pin loopback plug - see figure in DCC Test.

Formatted floppy disk.

3-3

Page 44

Performance Tests

Recall Default Settings

The Performance Tests require the HP 37718A/19A to be set to a predefined (default) state at the beginning of each test.

1 Using , display softkeys, and set up the

OTHER

OTHER

STORED

SETTINGS

display as shown opposite

.

2 Press to recall the instrument default settings.The

RECALL

instrument display will blank for a few seconds while the settings are

recalled and the status display will indicate stored settings number 0

recalled.

3-4

Page 45

Performance Tests

Self Test

Self Test

Description

Before carrying out the performance tests run Self Test to ascertain the

integrity of the HP 37718A/19A. These tests take at least 1 hour to

complete depending on the options fitted. Alternatively you can run

Confidence Tests which only takes 2 to 3 minutes to complete. This is not

a full verification but performs BER measurements with internal and

external loopbacks fitted.

Run Confidence TESTS

1 Choose TEST TYPE on the

display.

CAUTION Safety precaution, care and connection cleanliness are essential to avoid

optical signal degradation or damage. see Operators Maintenance in

chapter 1 and see Optical Interface Connectors in chapter 2 if in doubt.

The use of air-gap attenuators is not recommended.

Failure to attenuate the optical signal could result in damage to the

optical receiver.

CONF. TESTS

OTHER

SELF TEST

3-5

Page 46

Performance Tests

Self Test

NOTE If the Optical Interface is a Dual WavelengthOption the 1550 nm IN and

OUT ports are not connected at this stage and can be tested later.

If any or all of these connections are not made the HP 37718A/19A will

FAIL Self Test.

2 Make the loopback connections listed below:

Connect the 15 dB optical attenuator provided at the Optical OUT and

then connect the attenuator output to Optical IN using the optical

cable supplied with your instrument.

Connect Multirate Analyser IN to OUT

Connect Transmit module 75Ω OUT to Receive module 75Ω IN

Connect Transmit module 100/120Ω OUT to Receive module 100/

120Ω IN

3 Press to activate the Self Test.TESTSTATUS RUNNING

RUN/STOP

will be displayed.

The information pertaining to TEST TYPE, TEST NUMBER and

SUBTEST NUMBER will change as the Self Test progresses.

If the HP 37718A/19A is functioning correctly, after a time of 2 to 3

minutes, TEST STATUS PASSED is displayed.

If TEST STATUS [FAIL nnn] is displayed, check the displayed error

information and check loopback connections are correct. Repeat the

test and if the problem persists contact your local HP representative.

See Chapter 5 for information.

NOTE Each individual self test requires unique loopback connections. To obtain

a list of the connections required move the highlighted cursor to

CABLING INFO and press . The Loopbacks list will appear on the

SET

display. Also refer to Chapter 5 for Self Test connection information.

3-6

Page 47

Performance Tests

Self Test

Run ALL TESTS

1 Choose TEST TYPE on the display.

ALL TESTS

OTHER

SELF TEST

2 Insert a formatted disk into the instrument disk drive.

3 Make the loopback connections listed below:

Connect the 15 dB optical attenuator provided to Optical OUT and

connect the attenuator output to Optical IN.

Connect Multirate Analyser IN to OUT

Connect Transmit module 75Ω OUT to Receive module 75Ω IN

Connect Transmit module 100/120Ω OUT to Receive module 100/

120Ω IN

Connect Transmit module 75Ω MUX to Receive module 75Ω DEMUX

Connect Transmit module 100/120Ω MUX to Receive module 100/

120Ω DEMUX

4 Press to activate the Self Test.TESTSTATUS RUNNING

RUN/STOP

will be displayed.

The information pertaining to TEST TYPE, TEST NUMBER and

SUBTEST NUMBER will change as the Self Test progresses.

If the HP 37718A/19A is functioning correctly, after a time of at least

1 hour, TEST STATUS PASSED is displayed.

If TEST STATUS [FAIL nnn] is displayed, check the displayed error

information and check loopback connections are correct. Repeat the

test and if the problem persists contact your local HP representative.

See Chapter 5 for information.

3-7

Page 48

Performance Tests

Self Test

1550 nm Dual Wavelength Tests:

If a Dual Wavelength Optical Interface is fitted, repeat the

CONFIDENCE test with 1550 nm selected.

1 Select 1550 nm OPTICS wavelength

2 Connect1550 nm OUT to IN via 15dB Optical Attenuator.Ensure the

attenuator is inserted in the OUT port.

3 Run the test.

3-8

Page 49

Performance Tests

Self Test

DCC Port Tests:

1 Select BER TESTS

2 Make the following connections at the Multirate Analyzer DCC port.

3 Run the BER TESTS.

3-9

Page 50

Performance Tests

PDH/DSn Internal Transmitter Clock Accuracy & Offset

PDH/DSnInternalTransmitterClock Accuracy & Offset

Specifications

Rate Frequency

E4

E3

E2

E1

DS1

DS3

NOTE The Rates available are dependent on the HP 37718A/19A option.

139.264 MHz ± 4.5 ppm

34.368 MHz ± 4.5 ppm

8.448 MHz ±4.5 ppm

2.048 MHz ±4.5 ppm

1.544 MHz ±4.5 ppm

44.736 MHz ±4.5 ppm

Description

This test verifies that the PDH transmit data rates are within limits.

These limits assume the instrument is within the calibration cycle. The

Frequency Offset capability (deviation from Standard Bit Rate) is also

checked.

ForE1 to E4 a Frequency Counter connected to the PDH/DSn Signal Out

port measures the data rate on an "all ones" pattern. This gives an

indirect measure of the internal transmitter clock frequency as the data

is clocked by the internal clock oscillator. Because the Frequency

Counter triggers from the positive pulses only, the frequency count will,

for Ternary signals E1, E2 & E3, be half the selected data rate.

For DS-1 and DS-3 the Frequency Counter is connected to the CLOCK

OUT port.

Equipment Required

Frequency Counter : HP 5335A Option 010

75Ω Termination : HP 15522-80010

T Connector : HP 1250-0781

3-10

Page 51

Performance Tests

PDH/DSn Internal Transmitter Clock Accuracy & Offset

Procedure

1 Recallthe HP 37718A/19A DEFAULT SETTINGS as shown on Page3-

4.

2 Connect the 75Ω OUT port of the PDH/DSn module to the Frequency

Counter. Terminate the Frequency Counter input in 75Ω (use the T

connector).

3 Set the display as shown opposite

NOTE When changing the PDH Rate or Offset value the VCXO takes time to

settle. As a consequence the frequency counter reading will not stabilize

until "VCXO OUTPUT BIT RATE SETTLING" clears from the STATUS

line of the display.

TRANSMIT

E1 (2.048Mb/s) Frequency Accuracy

4 Adjust the Frequency Counter ATTEN and Trigger Level to obtain a

stable reading and ensure that the frequency counter reading is

between 1023995Hz and 1024005Hz.

5 Select FREQUENCY OFFSET [+50PPM].

6 Adjust the Frequency Counter ATTEN and Trigger Level to obtain a

stable reading and ensure that the frequency counter reading is

between 1024046.5Hz and 1024055.5Hz.

3-11

Page 52

Performance Tests

PDH/DSn Internal Transmitter Clock Accuracy & Offset

7 Select FREQUENCY OFFSET [-50PPM].

8 Adjust the Frequency Counter ATTEN and Trigger Level to obtain a

stable reading and ensure that the frequency counter reading is

between 1023944Hz and 1023953Hz.

E2 (8.448Mb/s) Frequency Accuracy

9 Select SIGNAL [8Mb/s]; PATTERN [ALL 1’s] on the

display.

10 Adjust the Frequency Counter ATTEN and Trigger Level to obtain a

stable reading and ensure that the frequency counter reading is

between 4223981Hz and 4224019Hz.

11 Select FREQUENCY OFFSET [+30PPM].

12 Adjust the Frequency Counter ATTEN and Trigger Level to obtain a

stable reading and ensure that the frequency counter reading is

between 4224107.5Hz and 4224145.7 Hz.

13 Select FREQUENCY OFFSET [-30PPM].

14 Adjust the Frequency Counter ATTEN and Trigger Level to obtain a

stable reading and ensure that the frequency counter reading is

between 4223854Hz and 4223892Hz.

TRANSMIT

E3 (34.368Mb/s) Frequency Accuracy

15 Select SIGNAL [34Mb/s] PATTERN [ALL 1’s] on the

display.

16 Adjust the Frequency Counter ATTEN and Trigger Level to obtain a

stable reading and ensure that the frequency counter reading is

between 17183922.7Hz and 17184077.4Hz.

TRANSMIT

17 Select FREQUENCY OFFSET [+20PPM]

18 Adjust the Frequency Counter ATTEN and Trigger Level to obtain a

stable reading and ensure that the frequency counter reading is

between 17184266 and 17184421Hz.

19 Select FREQUENCY OFFSET [-20PPM]

20 Adjust the Frequency Counter ATTEN and Trigger Level to obtain a

stable reading and ensure that the frequency counter reading is

between 17183579Hz and 17183734Hz.

3-12

Page 53

Performance Tests

PDH/DSn Internal Transmitter Clock Accuracy & Offset

21 Select FREQUENCY OFFSET [USER OFFSET] [+100PPM]

22 Adjust the Frequency Counter ATTEN and Trigger Level to obtain a

stable reading and ensure that the frequency counter reading is

between 17185641Hz and 17185796Hz.

23 Select FREQUENCY OFFSET [USER OFFSET] [-100PPM]

24 Adjust the Frequency Counter ATTEN and Trigger Level to obtain a

stable reading and ensure that the frequency counter reading is

between 17182205Hz and 17182359Hz.

E4 (139.264Mb/s) Frequency Accuracy

25 Select SIGNAL [140Mb/s] PATTERN [ALL 1’s] on the

display.

26 Adjust the Frequency Counter ATTEN and Trigger Level to obtain a

stable reading and ensure that the frequency counter reading is

between 69631686.5Hz and 69632318.5Hz.

27 Select FREQUENCY OFFSET [+15PPM].

28 Adjust the Frequency Counter ATTEN and Trigger Level to obtain a

stable reading and ensure that the frequency counter reading is

between 69632731Hz and 69633358Hz.

29 Select FREQUENCY OFFSET [-15PPM].

30 Adjust the Frequency Counter ATTEN and Trigger Level to obtain a

stable reading and ensure that the frequency counter reading is

between 69630642Hz and 69631269Hz.

TRANSMIT

DS1 (1.544Mb/s) Frequency Accuracy

31 Connect the CLOCK OUT port of the PDH/DSn module to the

Frequency Counter.

32 Select SIGNAL [DS1 1.5Mb/s] on the display.

33 Adjust the Frequency Counter ATTEN and Trigger Level to obtain a

stable reading and ensure that the frequency counter reading is

between 1543993Hz and 1544007Hz.

TRANSMIT

34 Select FREQUENCY OFFSET [+32PPM]

35 Adjust the Frequency Counter ATTEN and Trigger Level to obtain a

stable reading and ensure that the frequency counter reading is

3-13

Page 54

Performance Tests

PDH/DSn Internal Transmitter Clock Accuracy & Offset

between 1544042Hz and 1544056Hz.

36 Select FREQUENCY OFFSET [-32PPM]

37 Adjust the Frequency Counter ATTEN and Trigger Level to obtain a

stable reading and ensure that the frequency counter reading is

between 1543944Hz and 1543958Hz.

DS3 (44.736Mb/s) Frequency Accuracy

38 Connect the CLOCK OUT port of the PDH/DSn module to the

Frequency Counter.

39 Select SIGNAL [DS3] on the display.

40 Adjust the Frequency Counter ATTEN and Trigger Level to obtain a

stable reading and ensure that the frequency counter reading is

between 44735799Hz and 44736201Hz

41 Select FREQUENCY OFFSET [+20PPM]

42 Adjust the Frequency Counter ATTEN and Trigger Level to obtain a

stable reading and ensure that the frequency counter reading is

between 44736693Hz and 44737096Hz.

43 Select FREQUENCY OFFSET [-20PPM]

44 Adjust the Frequency Counter ATTEN and Trigger Level to obtain a

stable reading and ensure that the frequency counter reading is

between 44734904Hz and 44735307Hz.

45 Disconnect all the test equipment.

TRANSMIT

3-14

Page 55

Performance Tests

PDH/DSn Transmitter Output

PDH/DSn Transmitter Output

Specification

Rate Level Waveshape

DSX-1

DS1-LO As DSX-1 with 655' ABAM

DS3-HI 0.9V pk (nominal)

DSX-3 560mV pk (nominal) Fits mask T1.102-1993

DS3-900 330mV pk (nominal)

E1 Balanced

E1 Unbalanced

E2 Unbalanced

E3 Unbalanced

E4 Unbalanced

NOTE The Rates available are dependent on the HP 37718A/19A option

Description

This test ensures the transmitter output level and pulse shape meet the

required specifications at all PDH/DSn rates. The Transmitter output is

connected to an Oscilloscope and the waveshape compared with the

predefined masks stored in the Oscilloscope memory. The signal levels

are also measured using the Oscilloscope.

3.0V 20%

Cable

3.00V 10%

2.37V 10%

2.37V 10%

1.0V 10%

0.5V 10%

Fits mask T1.102-1993

As per ITU rec G703

As per ITU rec G703

As per ITU rec G703

As per ITU rec G703

As per ITU rec G703

3-15

Page 56

Performance Tests

PDH/DSn Transmitter Output

Equipment Required

Oscilloscope : HP 54520A Option 001

110Ω/75Ω Balanced to

Unbalanced Converter

75Ω Termination

Procedure

NOTE This performance test is written using the HP 54520A Oscilloscope with

Option 001 - TelecomMasks Application. If any other Oscilloscope is used

the keystrokes given in this procedure will not apply.

The Positive pulse masks are contained in the ROOT directory of the

TelecomMask Application Disk and the Negative pulse masks are in the

INV_MASK directory.

Installing the Telecom Masks Option

1 Insert the Disk containing the Telecom Mask into the Oscilloscope

Disk Drive.

2 Press SHIFT (Blue Key) DISK

3 Press softkey then softkey

139.264 Mb/s - All 1’s Pulse

1 Recall the HP 37718A Default Settings as shown on page 3-4.

DIRECTORY ROOT DIRECTORY

: HP 15508B

: HP 15522-80010

2 Set the display as shown below.

3-16

TRANSMIT

Page 57

Performance Tests

PDH/DSn Transmitter Output

3 Connect the PDH/DSn 75Ω OUT port to the Oscilloscope CHAN 1,

terminate in 75Ω.

4 Select CHAN 1 on the Oscilloscope and set to 1MΩ input impedance.

Load the Telecom Mask

5 Onthe Oscilloscope, use the following key sequence to select and load

the required Telecom Mask:

a/ SHIFT (Blue Key) APPLICATION.

b/ softkey.

TELECOM MASK/MASK

c/ Use ENTRY/MEASURE control to select 139BIN1 in the

highlighted MSK FILES window.

d/ softkey.

LOAD SETUP 8 M1M2

Compare Pulse with Mask

6 On the Oscilloscope, use the following key sequence to compare the

pulse with the mask:

a/ RECALL 8

b/ DEFINE MEAS

c/ softkey

COMPARE

d/ softkey

TEST ON

e/ softkey

M1M2

f/ softkey

AFTER FAIL CONTINUE

g/ RUN

7 The Oscilloscope will automatically display and compare an isolated

positivepulsewith the mask limits.A PASSmessage should appear on

the Oscilloscope.

NOTE It may be necessary to visibly fit the waveform to the mask by adjusting

the Oscilloscope vertical position and horizontal delay to obtain a PASS

on the Mask.

8 Measure the peak pulse amplitude at the mid pulse-width using the

Oscilloscope and verify that this is between 450 mV and 550 mV. (i.e.

900 mV-1.1V Pk-Pk)

All 0’s Pulse

9 Select PATTERN [ALL 0’s] on the display.

TRANSMIT

3-17

Page 58

Performance Tests

PDH/DSn Transmitter Output

Load the Telecom Mask

10 On the Oscilloscope, use the following key sequence to select and load

the required Telecom Mask:

a/ SHIFT (Blue Key) APPLICATION.

b/ softkey.

TELECOM MASK/MASK

c/ Use ENTRY/MEASURE control to select 139BIN0 in the

highlighted MSK FILES window.

d/ softkey.

LOAD SETUP 8 M1M2

Compare Pulse with Mask

11 On the Oscilloscope, use the following key sequence to compare the

pulse with the mask:

a/ RECALL 8

b/ DEFINE MEAS

c/ softkey

COMPARE

d/ softkey

TEST ON

e/ softkey

M1M2

f/ softkey

AFTER FAIL CONTINUE

g/ RUN

12 The Oscilloscope will automatically display and compare an isolated

positivepulsewith the mask limits.A PASSmessage should appear on

the Oscilloscope.

NOTE It may be necessary to visibly fit the waveform to the mask by adjusting

the Oscilloscope vertical position and horizontal delay to obtain a PASS

on the Mask.

13 Measure the peak pulse amplitude at the mid pulse-width using the

Oscilloscope and verify that this is between 450 mV and 550 mV. (i.e.

900 mV-1.1V Pk-Pk)

14 Select PATTERN to [ALL 0’s] on the display.

TRANSMIT

15 On the Oscilloscope, use the following key sequence to access the

inverted mask.

a/ SHIFT (Blue Key) DISK

b/ softkey

DIRECTORY

c/ Use ENTRY/MEASURE control to highlight INV_MASK

d/ softkey

CHANGE DIRECTORY

16 Repeat steps 5 to 13 to check pulses against Inverted masks.

3-18

Page 59

Performance Tests

PDH/DSn Transmitter Output

Procedure - 34.368 Mb/s

Positive Pulse

1 Recall the HP 37718A/19A Default Settings as shown on page 3-4.

2 Set the display as shown opposite.

TRANSMIT

3 Connect the PDH/DSn 75Ω OUT port to the Oscilloscope CHAN 1,

terminate in 75Ω.

4 Select CHAN 1 on the Oscilloscope and set to 1MΩ input impedance.

Load the Telecom Mask

5 Onthe Oscilloscope, use the following key sequence to select and load

the required Telecom Mask:

a/ SHIFT (Blue Key) APPLICATION.

b/ softkey.

TELECOM MASK/MASK

c/ Use ENTRY/MEASURE control to select 34MG703 in the

highlighted MSK FILES window.

d/ softkey.

LOAD SETUP 8 M1M2

Compare Pulse with Mask

6 On the Oscilloscope, use the following key sequence to compare the

pulse with the mask:

a/ RECALL 8

3-19

Page 60

Performance Tests

PDH/DSn Transmitter Output

b/ DEFINE MEAS

c/ softkey

COMPARE

d/ softkey

TEST ON

e/ softkey

M1M2

f/ softkey

AFTER FAIL CONTINUE

g/ RUN

7 The Oscilloscope will automatically display and compare an isolated

positivepulsewith the mask limits.A PASSmessage should appear on

the Oscilloscope.

NOTE It may be necessary to visibly fit the waveform to the mask by adjusting

the Oscilloscope vertical position and horizontal delay to obtain a PASS

on the Mask.

8 Measure the peak pulse amplitude at the mid pulse-width using the

Oscilloscope and verify that this is between 900 mV and 1.100 Volts.

Negative Pulse

9 On the Oscilloscope, use the following key sequence to access the

inverted mask.

a/ SHIFT (Blue Key) DISK

b/ softkey

DIRECTORY

c/ Use ENTRY/MEASURE control to highlight INV_MASK

d/ softkey

CHANGE DIRECTORY

Load the Telecom Mask

10 On the Oscilloscope, use the following key sequence to select and load

the required Telecom Mask:

a/ SHIFT (Blue Key) APPLICATION.

b/ softkey.

TELECOM MASK/MASK

c/ Use ENTRY/MEASURE control to select 34MG703 in the

highlighted MSK FILES window.

d/ softkey.

LOAD SETUP 8 M1M2

Compare Pulse with Mask

11 On the Oscilloscope, use the following key sequence to compare the

pulse with the mask:

a/ RECALL 8

b/ DEFINE MEAS

c/ softkey

COMPARE

3-20

Page 61

Performance Tests

PDH/DSn Transmitter Output

d/ softkey

TEST ON

e/ softkey

M1M2

f/ softkey

AFTER FAIL CONTINUE

g/ RUN

12 The Oscilloscope will automatically display and compare an isolated

positivepulsewith the mask limits.A PASSmessage should appear on

the Oscilloscope

NOTE It may be necessary to visibly fit the waveform to the mask by adjusting

the Oscilloscope vertical position and horizontal delay to obtain a PASS

on the Mask.

13 Measure the peak pulse amplitude at the mid pulse-width using the

Oscilloscope and verify that this is between 900 mV and 1.100 Volts.

Procedure - 8.448 Mb/s

Positive Pulse

1 Recall the HP 37718A/19A Default Settings as shown on page 3-4.

2 Set the display as shown opposite.

TRANSMIT

3 Connect the PDH/DSn 75Ω OUT port to the Oscilloscope CHAN 1,

terminate in 75Ω.

4 Select CHAN 1 on the Oscilloscope and set to 1MΩ input impedance.

3-21

Page 62

Performance Tests

PDH/DSn Transmitter Output

Load the Telecom Mask

5 Onthe Oscilloscope, use the following key sequence to select and load

the required Telecom Mask:

a/ SHIFT (Blue Key) APPLICATION.

b/ softkey.

TELECOM MASK/MASK

c/UseENTRY/MEASURE control to select 8MG703 in thehighlighted

MSK FILES window.

d/ softkey.

LOAD SETUP 8 M1M2

Compare Pulse with Mask

6 On the Oscilloscope, use the following key sequence to compare the

pulse with the mask:

a/ RECALL 8

b/ DEFINE MEAS

c/ softkey

COMPARE

d/ softkey

TEST ON

e/ softkey

M1M2

f/ softkey

AFTER FAIL CONTINUE

g/ RUN

7 The Oscilloscope will automatically display and compare an isolated

positivepulsewith the mask limits.A PASSmessage should appear on

the Oscilloscope.

NOTE It may be necessary to visibly fit the waveform to the mask by adjusting

the Oscilloscope vertical position and horizontal delay to obtain a PASS

on the Mask.

8 Measure the peak pulse amplitude at the mid pulse-width using the

Oscilloscope and verify that this is between 2.133V and 2.607 Volts.

Negative Pulse

9 On the Oscilloscope, use the following key sequence to access the

inverted mask.

a/ SHIFT (Blue Key) DISK

b/ softkey

DIRECTORY

c/ Use ENTRY/MEASURE control to highlight INV_MASK

d/ softkey

CHANGE DIRECTORY

3-22

Page 63

Performance Tests

PDH/DSn Transmitter Output

Load the Telecom Mask

10 On the Oscilloscope, use the following key sequence to select and load

the required Telecom Mask:

a/ SHIFT (Blue Key) APPLICATION.

b/ softkey.

TELECOM MASK/MASK

c/UseENTRY/MEASURE control to select 8MG703 in thehighlighted

MSK FILES window.

d/ softkey.

LOAD SETUP 8 M1M2

Compare Pulse with Mask

11 On the Oscilloscope, use the following key sequence to compare the

pulse with the mask:

a/ RECALL 8

b/ DEFINE MEAS

c/ softkey

COMPARE

d/ softkey

TEST ON

e/ softkey

M1M2

f/ softkey

AFTER FAIL CONTINUE

g/ RUN

12 The Oscilloscope will automatically display and compare an isolated

positivepulsewith the mask limits.A PASSmessage should appear on

the Oscilloscope

NOTE It may be necessary to visibly fit the waveform to the mask by adjusting

the Oscilloscope vertical position and horizontal delay to obtain a PASS

on the Mask.

13 Measure the peak pulse amplitude at the mid pulse-width using the

Oscilloscope and verify that this is between 2.133V and 2.607 Volts.

Procedure - 2.048 Mb/s

Positive Pulse

1 Recall the HP 37718A/19A Default Settings as shown on page 3-4.

3-23

Page 64

Performance Tests

PDH/DSn Transmitter Output

2 Set the display as shown below.

TRANSMIT

3 Connect the PDH/DSn 75Ω OUT port to the Oscilloscope CHAN 1,

terminate in 75Ω.

4 Select CHAN 1 on the Oscilloscope and set to 1MΩ input impedance.

Load the Telecom Mask

5 Onthe Oscilloscope, use the following key sequence to select and load

the required Telecom Mask:

a/ SHIFT (Blue Key) APPLICATION.

b/ softkey.