Page 1

TM 11-6625-1576-15

DEPARTMENT OF THE ARMY TECHNICAL MANUAL

ORGANIZATIONAL, DS, GS, AND DEPOT

MAINTENANCE MANUAL

DISTORTION ANALYZER

HEWLETT-PACKARD MODELS

333A AND 334A

HEADQUARTERS, DEPARTMENT OF THE ARMY

MAY 1967

Page 2

TM 11-6625-1576-15

Be careful when working on the power supply and

on the 115-volt ac line connections.

WARNING

DANGEROUS VOLTAGES

EXIST IN THIS EQUIPMENT

DO NOT TAKE CHANCES

!

Page 3

This manual contains copyrighted material originally

prcpared by the Hewlett-Packard Co.

TM11-6625-1576-15

TECHNICAL MANUAL

NO. 11-6625-1576-5 )

Organizational, DS, GS, and Depot Maintenance

DISTORTION ANALYZER, HEWLETT-PACKARD MODELS 333A AND 334A

Section

I GENERAL INFORMATION . . . . . . . . . 1-2.1

1-A.1 Scope . . . . . . . . . . . . . . . . .1-2.1

Index of Publications. . .

l-A.2

Forms and Records . . . . . . . . . . .

l-A.3

l-1. Description . . . . . . . .1-3

1-6. Accessory Features . . . . . . . .1-3

1-8. Options Available . . . . . . . . .1-3

1-11. Modifications

Section

INSTALLATION . . . . . . . . . . . . . .2-1

II

2-1. Introduction . . . . . . . . . . . . . .2-1

2-3. Inspection . . . . . . . . . . . . . . 2-1

2-5. Power Requirements . . . . . . . . . . 2-1

2-7. Three-Conductor Power Cable . . . 2-1

2-10. Installation . . . . . . . . . . . . . . 2-1

2-12. Bench Installation . . . . . . . . . 2-1

2-14. Rack Installation . . . . . . . . . . 2-1

2-16. Repackaging for Shipment . . . . . . 2-1

Section

OPERATING INSTRUCTIONS . . . . . . . 3-1

III

3-1. Introduction . . . . . . . . . . . . . 3-1

3-4. Controls and Indicators . . . . . . . 3-1

3-6. Adjustment of Mechanical Zero . . . 3-1

3-8. General Operating Information . . . 3-1

Input Connections . . . . . . . . . 3-1

3-9.

3-11. Voltmeter Characteristics . . . . . 3-1

3-14. Use of Output Terminals . . . . . . 3-1

3-16. Operating Procedures . . . . . . . . 3-2

3-18. Distortion Measurement . . . . . . 3-2

Section

IV

THEORY OF OPERATION . . . . . . . . . . 4-1

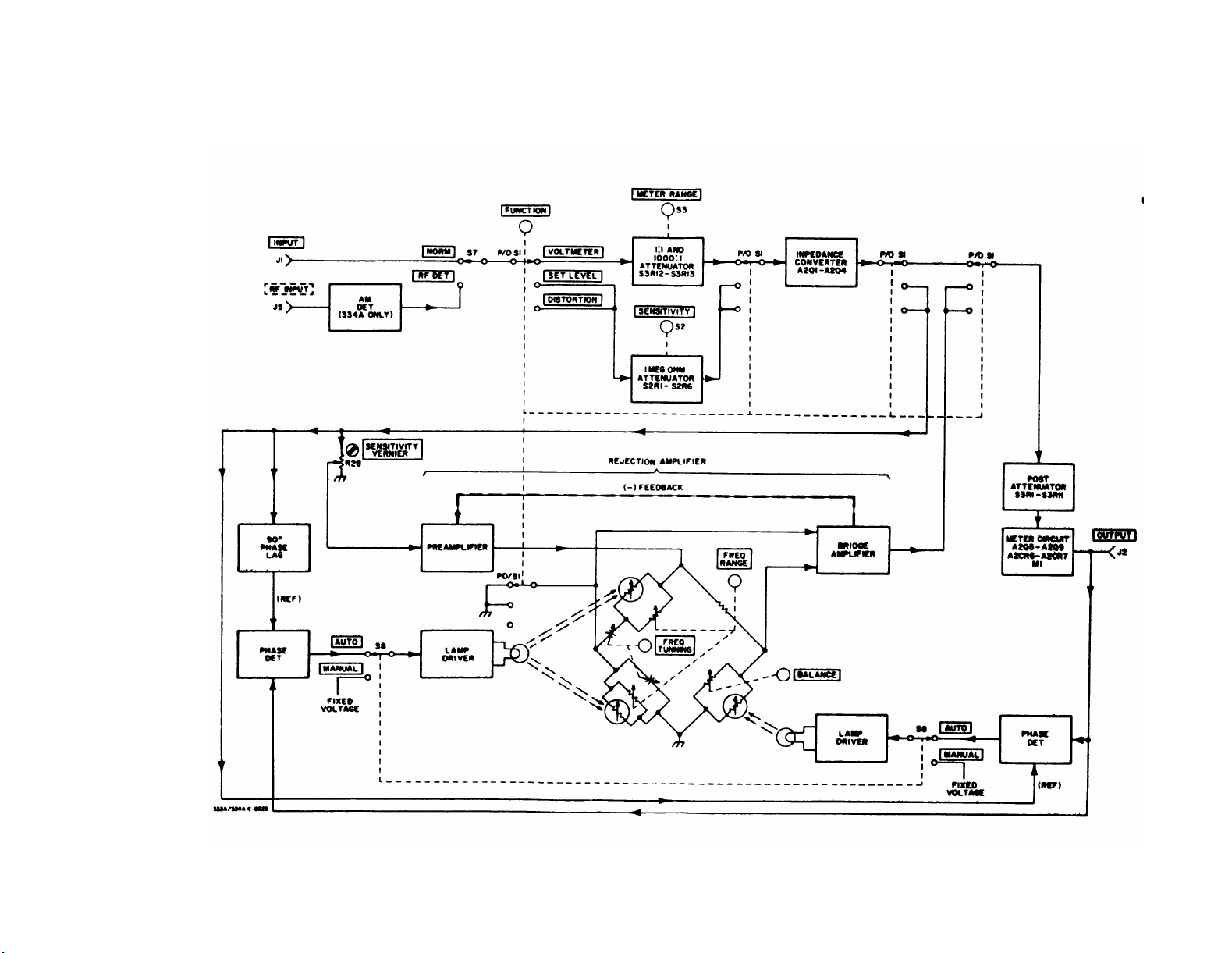

4-1. Overall Description . . . . . . . . 4-1

4-3. Block Diagram Description . . . . . 4-1

4-4. Distortion Measuring Operation . . 4-1

4-6. Distortion Measurement in AM

.

4-8. Voltmeter Operation . . . . . . . . 4-1

4-10. Schematic Theory . . . . . . . . . . 4-1

4-11. Impedance Converter Circuit . . . 4-1

4-14. Rejection Amplifier Circuit . . . . 4-2

4-36. High Pass Filter . . . . . . . . . . . 4-5

4-38. Meter Circuit . . . . . . . . . . . . 4-5

4-46. Power Supply Circuit . . . . . . . . . . 4-7

4-51. RF Detector Circuit (334A only) . l 4-7

Carriers . . . . . . . . . . . . . 4-1

. . . . . . . . . . . . . . . . . . . . . . . . 1-3

)

)

Page

1-2.1

1-2.1

Page

Page

Page

HEADQUARTERS

DEPARTMENT OF THE ARMY

Washington, D.C., 19

Section V (Cont ‘d)

5-9. Fundamental Rejection Check . .

5-10. Second Harmonic Accuracy Check

5-11. Distortion Introduced by Instru-

5-12. Frequency Calibration Accuracy

5-13. Input Resistance Check . . . . . .

5-14. Input Shunt Capacitance Check . .

5-15. Minimum Input Level Check . . .

5-16. DC Isolation Check . . . . . . . .

5-17. Voltmeter Accuracy Check . . . .

5-18. High Pass Filter Check . . . . . .

5-19. Voltmeter Frequency Response

5-20. Residual Noise Check . . . . . . .

5-21. AM Detector Check (Model 334A

5-22. Adjustment and Calibration

5-25. Meter Mechanical Zero Set . . . .

5-27. Power Supply and Bias

5-28. A3R16 and A3R30 Distortion

5-29. Bridge Balance Adjustment (C3) .

5-30. Voltmeter Gain Adjustments . . .

5-31. Voltmeter Frequency Response

5-32. Sensitivity Switch Calibration . . .

5-33. Troubleshooting Procedures . . . .

5-39. Bottom Shield Removal . . . . . .

5-41. Servicing Etched Circuit Boards .

5-44.

Section

VI

SCHEMATIC DIAGRAMS

6-1. Schematic Diagrams

ment Check and Automatic

Control Loop Operation . . . .

Check . . . . . . . . . . . .

Check . . . . . . . . . . . . . . . .

only) . . . . . . . . . . . . . . .

Procedure. . . . . . . . . . . . . . .

Adjustments. . . . . . . . . . .

Adjust. . . . . . . . . . . . . .

Adjustment . . . . . . . . . . .

Servicing Rotary Switches . . . .

May 1967

Page

5-1

5-2

5-2

5-3

5-4

5-4

5-4

5-4

5-5

5-5

5-6

5-6

5-6

5-7

5-7

5-7

5-9

5-9

5-10

5-10

5-10

5-11

5-11

5-11

5-13

Page

6-1

6-1

Section Page

V MAINTENANCE. . . . . . . . . . . . . 5-1

5-l. Introduction. . . . . . . . . . . 5-1

5-2. Test Equipment Required . . . . . 5-1

5-5. Performance Checks. . . . . . . . . 5-1

iii

Page 4

Page 5

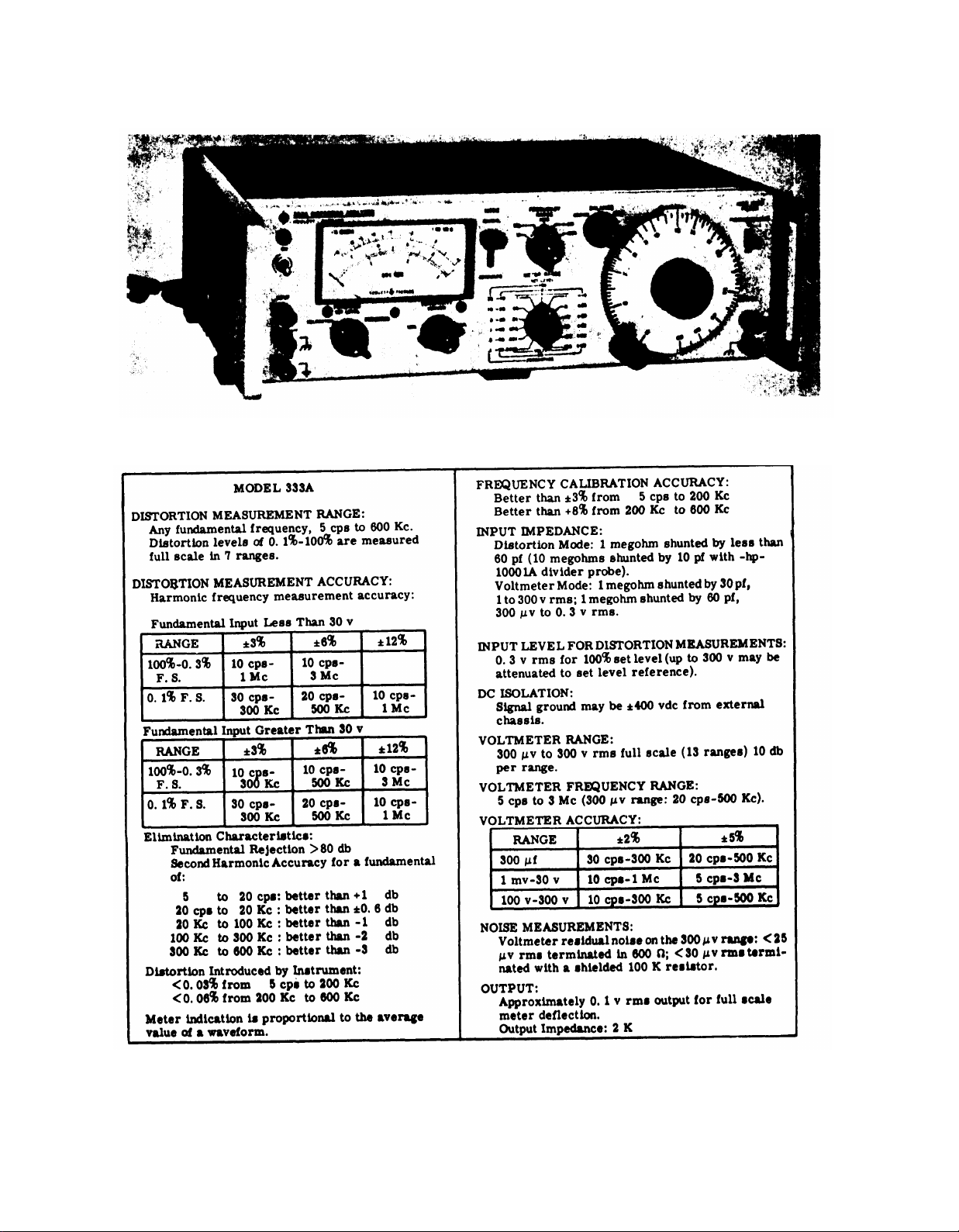

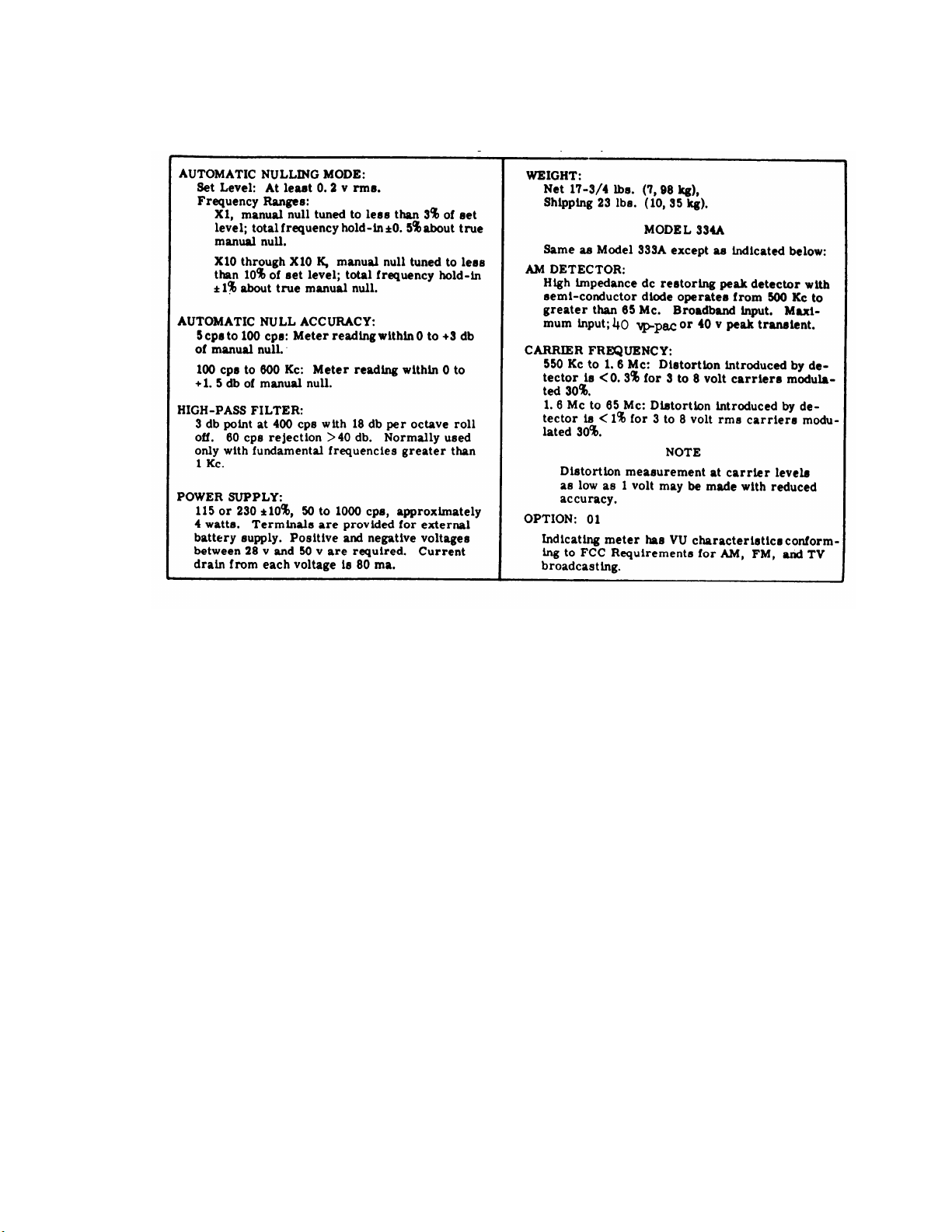

Model 333A/334A

TM 11-6625-1576-15

Section 1

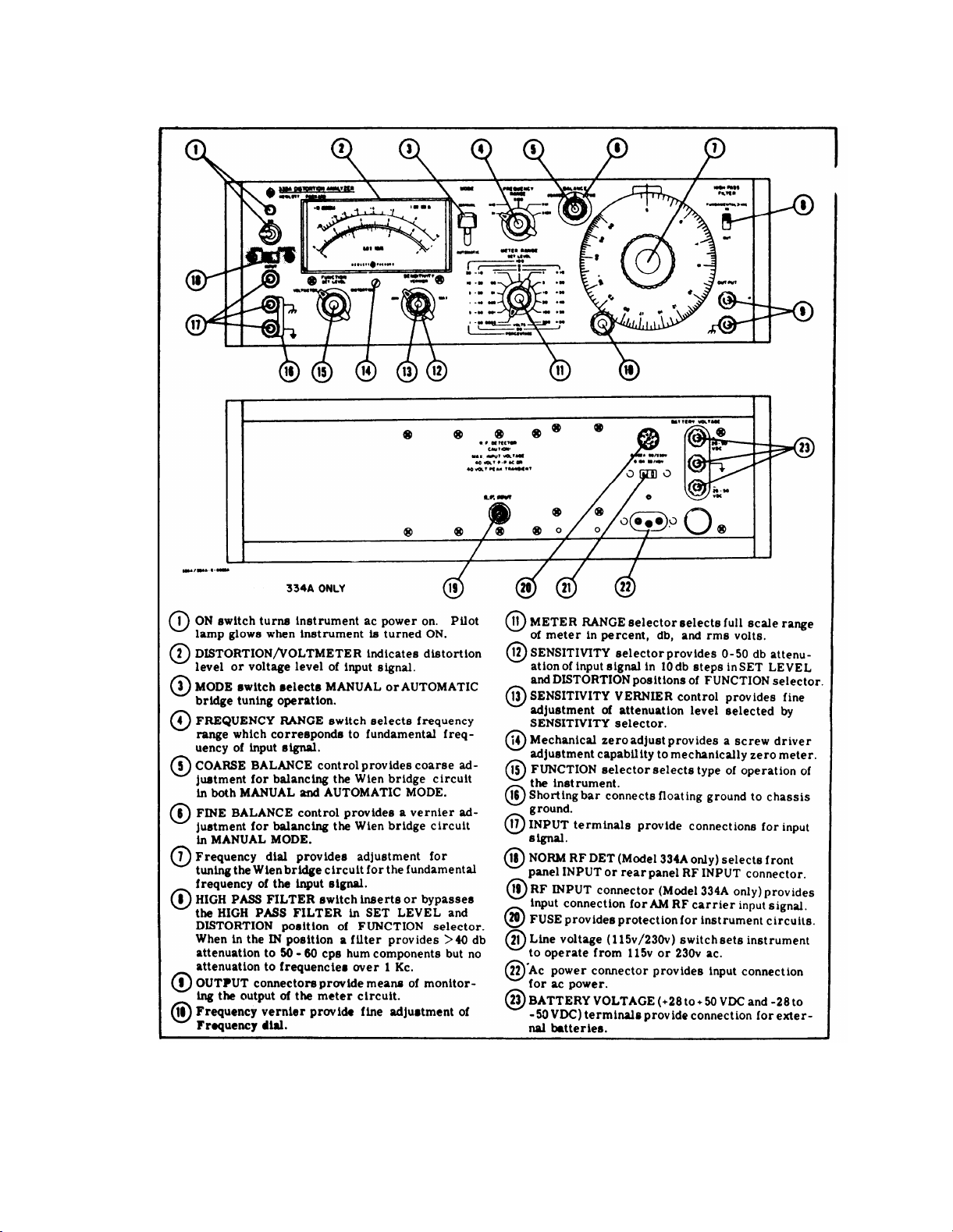

Figure 1-1 and Table 1-1

Figure 1-1. Model 333A Distortion Analyzer

Table 1-1. Specifications

1-1

Page 6

TM 11-6625-1576-15

Section I

Table 1-1

Model 333A/334A

Table 1-1. Specifications (Cont ‘d)

1-2

Page 7

TM 11-6625-1576-15

SECTION I

GENERAL INFORMATION

1-A.1 Scope

This manual includes installation and operation instructions and

covers operator’s, organizational, direct support (DS), general support

(GS), and depot maintenance. It describes Hewlett-Packard (Federal support

Code 80537) Distortion Analyzer Models 333A and 334A (fig. l-l). A

basic issue items list for this equipmnent is not included as part of

this manual.

1-A.2 Index of Publications

Refer to the latest issue of DA Pam 310-4 to determine whether there

are new editions, changes, or additional publications pertaining to the

equipment. DA Pam 310-4 is an index of current technical manuals,

technical bulletins, supply manuals (types 7, 8, and 9), supply bulletins,

lubrication orders, and modification work orders that are available through

publications supply channels. The index lists the individual parts (-10,

-20, - 35P, etc) and the latest changes to and revisions of each equipment

publication.

l-A.3 Forms and Records

a. Reports of Maintenance and Unsatisfactory

ment forms and records in accordance with instructions in TM 38-750.

b. Report of Damaged or Improper Shipment. Fill out and forward

DD Form 6 (Report of Damaged or Improper Shipment) as prescribed in

AR 700-58 (Army), NAVSANDA Publication 378 (Navy), and AFR ‘71-4

air Force).

c. Reporting of Equipment Manual Improvements. Report of errors,

omissions, and recommendations for improving this manual by the

individual user is encouraged.

2028 (Recommended Changes to DA Publications) and forwarded direct

to Commanding General, U. S. Army Electronics Command,

ATTN: AMSEL-MR-NMP-AD, Fort Monmouth, New Jersey 07703.

Reports should be submitted on DA Form

Equipment. Use equip-

1-2.1

Page 8

Page 9

TM 11-6625-1576-15

Model 333A/334A

1-1. DESCRIPTION.

1-2. The Hewlett-Packard Models

Distortion Analyzers are solid state

measuring distortion and ac voltages.

333A and 334A include two control loops that automatically tune both legs of a bridge circuit which re -

jects the fundamental when the rejection circuit is

initially set within the range of the loops. A high im pedance detector which operates from 500 Kc to greater

than 65 Mc provides the capability” of monitoring the

distortion of the amplitude modulation on an rf carrier.

1-3. Distortion levels of O. 1% to 1OO% full scale are

measured in seven ranges for any fundamental fre quency of 5 cps to 600 Kc.

to 3Mc. The high sensitivity of these instruments requires only O. 3 v rms for the 100% set level reference.

The distortion characteristics can be monitored at the

OUTPUT connectors with an oscilloscope, a true rms

voltmeter, or a wave analyzer. The instruments are

capable of an isolation voltage of 400 volts above chassis

ground.

1-4. The voltmeter can be used separately for general

purpose voltage and gain measurements. It has a fre quency range of 5 cps to 3 Mc (20 cps to 500 Kc for 300

pv range) and a voltage range of 300 pv to 300 v rms

full scale.

1-5. The AM detector included in the Model 334A is

a broadband dc restoring peak detector consisting of a

semiconductor diode and filter circuit. AM distortion

levels as low as O. 3% can be measured on a 3 v to 8 v

rms carrier modulated 30% in the standard broadcast

Harmonics are indicated up

333A and 334A

instruments for

The Models

Paragraphs l-l to l-13

Section I

band, and lower than 1% distortion can be measured

at the same level of the carrier up to 65 Mc.

1-6. ACCESSORY FEATURES.

1-7. The accessory available with the 333A and 334A

Distortion Analyzers is a voltage divider probe, -hpModel No. 1000lA. The features of the probe are:

a. 10 megohms shunted by 10 pf, giving 10:1

attenuation.

b. DC to 30 Mc bandwidth.

c. 2% division accuracy.

d. 600 v peak input.

e. 5 ns rise-time.

1-8. OPTION.

1-9. Option 0l is a standard -hp- Model 333A or 334A

with a special meter and meter amplifier, compen-

sated to permit response to VU (volume units)

characteristics.

1-11. Modifications

1-12, Specification C10-334A is a standard

334A Distortion Analyzer modified by placing

the INPUT and OUTPUT terminals on the rear

panel of the instrument. The rear terminals

are binding post connectors and are in

parallel with the front panel terminals.

Due to the rear terminal leads, the shunt

capacitance of the instrument is increased

by 20pF .

1-3

Page 10

Page 11

TM 11-6625-1576-15

Model333A/334A

Paragraphs 2-1 to 2-19

SECTION II

INSTALLATION

Section II

2-1. INTRODUCTION.

2-2. This section contains information and instructions necessary for the installation and shipping of the

Models 333A/334A Distortion Analyzers. Included

are initial inspection procedures, power and grounding

requirements,installation information, and instruc tions for repackaging for shipment.

2-3. INSPECTION.

2-4. This instrument was carefully inspected both

mechanically and electrically before shipment. It

should be physically free of mars or scratches and in

perfect electrical order upon receipt. To confirm

this, the instrument should be inspected for physical

damage in transit. Also check for supplied accessories,

and test the electrical performance of the instrument

using the procedure outlined in Paragraph 5-5.

2-5. POWER REQUIREMENTS.

2-6. The Model 333A/334A can be operated from any

ac source of 115 or 230 volts (+10%), at 50- 1000 cps.

With the instrument disconnected from the ac power

source, move the slide (located on the rear panel) un-

til the desired line voltage appears. The instrument

can be battery operated by connecting two 28-50 V

batteries (rated 80 milliamperes) to the battery ter-

minal on the rear panel. Power dissipation is 10 watts

maximum.

2-7. THREE-CONDUCTOR POWER CABLE.

2-8. To protect operating personnel, the National

Electrical Manufacturers’ Association (NEMA) recom-

mends that the instrument panel and cabinet be grounded.

All Hewlett-Packard instruments are equipped with a

three -conductor power cable, which when plugged into an appropriate receptacle, grounds the instrument

The offset pin on the power cable three-prong connec-

tor is the ground wire.

2-9. To preserve the protection feature when operat-

ing the instrument from a two-contact outlet, use a

three-prong to two-prong adapter and connect the

green pigtail on the adapter to ground.

2-10. INSTALLATION.

2-11 The Model 333A/334A is fully transistorized;

therefore, no special cooling is required. However,

the instrument should not be operated where the ambient temperature exceeds 55 C (191 F).

2-12. BENCH INSTALLATION.

2-1% The Model 333A/34A is shipped with plastic

feet and tilt stand in place, ready for use as a bench

instrument.

2-14. RACK INSTALLATION.

2-15. The Model 333A/334A may be rack mounted by

using the 5“ RackMount Kit (-hp- Part No. 5060-0775).

Instructions for the conversion are included with the

The rack mount for the Model 333A/334A is an

kit.

ELA standard width of 19 inches. when mounted in a

rack using the rack mount kit, additional support at

the rear of the instrument should be provided if vibra

tion or similar stress is likely.

2-16. REPACKAGING FOR SHIPMENT.

2-17. The following paragraphs contain a general guide

for repackaging of the instrument for shipment. Refer

to Paragraph 2-18 if the original container is to be

used; 2-19 if it is not.

2-18. If original container is to be used, proceed as

follows:

a. Place instrument in original container if avail-

able.

b. Ensure that container is well sealed with strong

tape or metal bands.

2-19. If original container is not to be used, proceed

as follows:

a. Wrap instrument in heavy paper or plastic be-

fore placing in an inner container.

b. Place packing material around all sides of in-

strument and protect panel face with cardboard strips.

c. Place instrument and inner container in a heavy

carton or wooden box and seal with strong tape or

metal bands.

d. Mark shipping container with “DELICATE

INSTRUMENT," "“RAGILE,” etc.

2-1

Page 12

TM 11-6625-1576-15

Section III

Figure 3-1

Model 333A/334A

3-0

Figure 3-1. Front and Rear Panel Description

Page 13

TM 11-6625-1576-15

Model 333A/334A

Paragraphs-3-l to 3-15

Section III

SECTION III

OPERATING INSTRUCTIONS

3-1. INTRODUCTION.

3-2. The Models 333A and 334A Distortion Analyzers

measure total harmonic distortion from 5 cps to 600

Kc. Harmonics up to 3 Mc are included. The sharp

elimination characteristics, >80 db, the low level of

instrument induced distortion, and the meter accuracy

of the 333A and the 334A result in accurate measurement of low level harmonic content in the input signal.

3-3. An RMS voltmeter is inherent in the 333A and

334A, The voltmeter provides a full scale sensitivity

of 300 u volts rms (residual noise <25 u volts). The

voltmeter frequency range is from 5 cps to 3 Mc except on the 0. 0003 volt range, which is from 20 cps to

500 Kc.

3-4. CONTROLS AND INDICATORS.

3-5. Figure 3-1 illustrates and describes the function

of all front and rear panel controls, connectors, and

indlcators.

keyed to a drawing included within the figure.

3-6. ADJUSTMENTS OF MECHANICAL ZERO.

3-7. The procedure for adjustment of mechanical

zero is given in Section V, Paragraph 5-25.

3-8. GENERAL OPERATING INFORMATION.

3-9. INPUT CONNECTIONS.

3-10. Signal source can be connected to the 333A and

334A through twisted pair leads or a shielded cable

with banana plug connectors. Keep all test leads as

short as possible to avoid extraneous pickup from

stray ac fields,

battery operation is recommended to avoid ground

loops.

by connecting only one instrument in a test setup

directly to power line ground through a NEMA (threeprong) connector,

the power source through a three-prong to two-prong

adapter and leave the pigtail disconnected. Both the

333A and 334A have a dc isolation of ±400 vdc from

the external chassis with the shorting bar, (item 16 ,

Figure 3-1), disconnected.

3-11. VOLTMETER CHARACTERISTICS.

9-12. The RMS VOLTS markings on the meter face are

based on the ratio between the average and effective

(rms) values of a pure sine wave. The ratio of aver-

age to effective values in a true sine wave is approxi-

mately O. 9 to 1.When the meter is used to measure

complex waves,

rms value of the signal applied. This deviation of

meter indication exists because the ratios of average

to effective values are usually not the same in a com plexwave as in a sine wave. The amount of deviation

depends on magnitude and phase relation between

harmonics and fundamental frequency of the signal

The description of each component is

When measuring low-level signals,

Another method for avoiding ground loops is

Connect all other instruments to

the voltage indicated may not be the

applied. Table 3-1 shows the deviation of the meter

indication of a sine wave partly distorted by harmonic..

As indicated in the table, harmonic content of less

than approximately 10% results in very small errors.

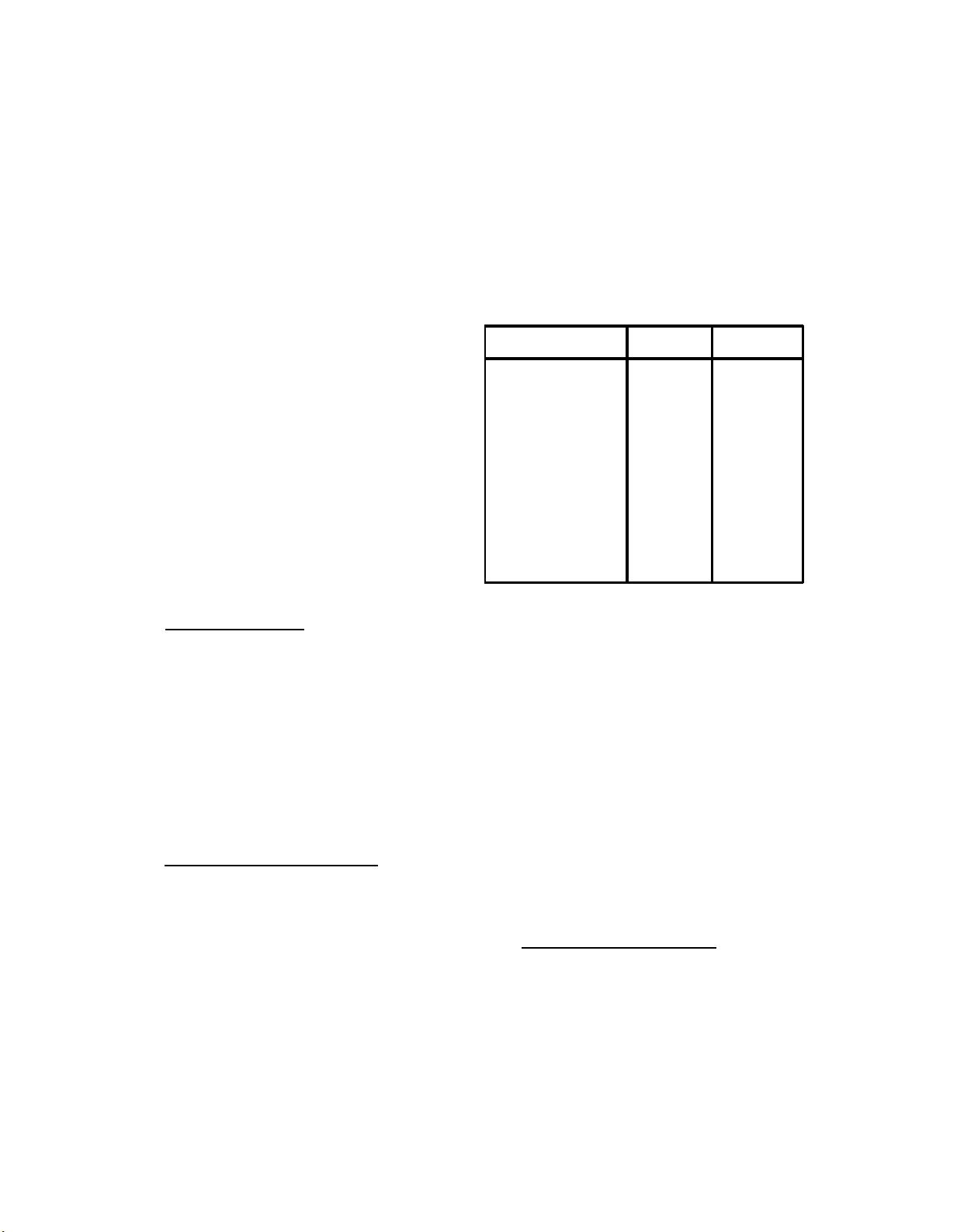

Table 3-1

Effect of Harmonics on Voltage Measurements

Input Voltage True

Characteristic

Fundamental = 100

Fundamental +10% 100. s

2nd harmonic

Fundamental +20%

2nd harmonic

Fundamental +50%

2nd harmonic

Fundamental +10%

3rd harmonic

Fundamental +20%

3rd harmonic

Fundamental +50%

3rd harmonic

This chart is universal in application

since time errors are inherent in

all average-responding type voltagemeasuring instruments.

3-13. In distortion measurements where the fundamental frequency is suppressed and the remainder of the

signal is measured, the reading obtained on an average-

responding meter may deviate from the true total rms

value. When residual wave contains many inharmonically related sinusoids, the maximum error in the distortion reading is about 11% low for distorilon levels

below 10%.

Measured Maximum Error Total

Distortion In Meter Indication Distortion

2. 5%

This example represents the maximum possible error,

and in most cases the error is less. In distortion

measurements, the reading of an average-responding

meter is sufficiently close to the rms value to be

satisfactory under most measurement conditions.

3-14. USE OF OUTPUT TERMINALS.

3-15. The OUTPUT terminals provide a O. 1 v rms

output for full scale meter deflection

minals can be used to monitor the output signal with

an oscilloscope,

analyzer. The combination of the distortion meter

and oscilloscope provides more significant information

+0. 11 X O. 025 =

0.00027

RMS Value

100 100

102

112

100.5

102

112

NOTE

a true rms voltmeter, or a wave

Meter

Indication

100

100-102

100-110

96-104

94-108

90-116

0.025 +0. 0027 =

0.0277 or 2.8%

These ter-

3-l

Page 14

TM 11-6625-1576-15

Section III

Paragraphs 3-16 to 3-22

about the device under test than the expression of dis-

tortion magnitude alone.

Information obtained from

the oscilloscope pattern is specific and reveals the

nature of the distortion that sometimes occurs at such

low levels that it is difficult to detect in the presence

of hum and noise.

The impedance at the OUTPUT

terminals is 2000 ohms, therefore, capacitive loads

greater than 50 pf should ‘be avoided to maintain the

accuracy of meter readings.

3-16. OPERATING PROCEDURES.

3-17. The 333A and 334A Distortion Analyzers can be

operated from an ac power source ( 115/230 volt) or a

dc power source (+28 to +50 and -28 to -50 volt source).

If a dc source is used, check the -25 v output. If

necessary, adjust the power supply according to the

procedures in Paragraph 5-27.

3-18. DISTORTION MEASUREMENT.

3- 19. DISTORTION MEASUREMENT IN PERCENT,

AUTOMATIC MODE.

a. Position FUNCTION selector to SET LEVEL.

b. Position MODE switch to MANUAL.

c. If fundamental frequency is 1 Kc or greater,

position HIGH PASS FILTER SWITCH to IN.

d. Rotate SENSITIVITY selector to MIN position.

NOTE

The bandwith of the SENSITIVITY se-

lector is reduced in the two extreme

CCW positions (positions used with an

input signal greater than 30 v).

e. Position METER RANGE selector to SET LEVEL

100%).

f. Connect test leads from device under test to

INPUT terminals.

REMOVE SHORTING STRAP BETWEEN

FLOATING GROUND ~ AND CHASSIS

GROUND (+) TERMINALS ON FRONT

PANEL INPUT TERMINALS WHEN

MEASURING DISTORTION BETWEEN

TWO POINTS WHICH ARE BOTH ABOVE

GROUND POTENTIAL.

g. With SENSITIVITY VERNIER control max. CCW,

position SENSITIVITY selector for meter indication

greater than 1/3 full scale.

NOTE

If unable to adjust for full scale deflection which indicates input signal is be-

low O. 3 volts, use manual mode and

position METER RANGE selector down-

scale. Use this new position as the 100%

SET LEVEL position, thus making the

next range 30%, etc.

h. Adjust SENSITIVITY VENIER control for full

scale deflection.

j. Position FRIQUENCY RANGE selector and

frequency dial to fundamental frequency of input signal.

3-2

Model 333A/334A

k. Position FUNCTION selector to DISTORTION,

m. Adjust METER RANGE selector and frequency

dial vernier control for minimum meter indication.

n. Adjust COARSE and FINE BALANCE controls

for further reduction of meter indication. Meter indication must be less than 10%of SET LEVEL indication.

p. Position MODE switch to AUTOMATIC.

r. Observe percentage of distortion indicated on

meter. Meter indication is in conjunction with METER

RANGE selector. For example, if meter indicates

.4 and METER RANGE selector is on 1% position,

distortion measured is 0.4%.

NOTE

RMS voltage of input signal being analyzed for distortion can be measured

by positioning FUNCTION selector to

VOLTMETER position.

DISTORTION MEASUREMENT IN PERCENT,

3-20.

MANUAL MODE.

NOTE

In MANUAL mode the accuracy of dis tortion measurements is affected by

frequency stability of the input signal.

An inaccuracy in distortion indications

occure when the frequency drift of the input signal exceeds the bandwidth of the

rejection curve.

Perform steps a through n in Paragraph 3-19.

a.

Repeat steps m and n until no further reduction

b.

in meter

-

indication can be obtained.

c. Observe percentage of distortion indicated on

meter.

3-21. DISTORTION MEASUREMENT IN DB,

AUTOMATIC MODE .

a. Perform steps a through g of Paragraph 3-19.

b. Adjust SENSITIVITY VERNIER control for 0 db

meter indication.

c. Perform steps j through 3-19.

d. Observe meter indication for distortion in db.

NOTE

Distortion in db is obtained by algebraically adding meter indication to

db indicated by METER RANGE se-

lector: for example, If meter indicates -2 and METER RANGE selector is on -20 db position, distortion

measured is -22 db.

3-22. DISTORTION MEASUREMENT IN DB, MANUAL

MODE .

NOTE

Notes in Paragraphs 3-20 and 3-21

apply.

a. Perform steps a through g of Paragraph 3-19.

b. Adjust SENSITIVITY VERNIER control for O db

meter indication.

Page 15

Model 333A/334A

c. Perform steps j through n of Paragraph 3-19.

d. Repeat steps m and n until no further reduction

n meter indication can be obtained.

e. Observe meter indication for distortion in db.

3-23. DISTORTION MEASUREMENT OF AM RF

CARRIERS. (334A Only)

a. Set NORM - RF SET selector to RF SET.

OBSERVE MAXIMUM INPUT VOLTAGES

AS INDICATED ON REAR PANEL.

b. Connect Input to RF INPUT on rear panel.

c. Adjust SENSITIVITY VERNIER control for O db

meter indication.

d. Perform steps j through n of Paragraph 3-19.

e. Refer to Paragraph 3-20 for manual measure-

ment in percent.

TM 11-6625-1576-15

Paragraphs 3-23 to 3-27

3-25. The 333A and 334A perform as general purpose

AC Voltmeters when the FUNCTION selector is set

to VOLTMETER position.

NOTE

With the FUNCTION selector in VOLT-

METER position, the SENSITIVITY selector is disabled.

a, Position METER RANGE selector to a range

exceeding the value of the signal to be measured.

b. Connect signal to INPUT terminals.

c. Select a METER RANGE to give a reading as

close to full scale as possible and observe meter

indication.

3-26. OUTPUT TERMINALS.

3-27. In VOLTMETER or SET LEVEL position of

FUNCTION selector, the 333A/334A can be used as a

low distortion, high gain, wideband preamplifier. A

portion of the meter input (O. 1 v RMS output for full

scale meter deflection) is provided at the OUTPUT

terminal J2. In the DISTORTION position, the distor-

tion is provided for monitoring purposes.

Section III

the

f. Refer to Paragraph 3-21 and 3-22 for automatic

and manual measurement in db.

-24. VOLTMETER MODE.

NOTE

If DBM measurements are to be made,

the DB markings on the METER RANGE

switch must each be lowered by 10.

That is, the DB marking for the O. 3 v

range becomes-10 DBM, 1 v range becomes O DBM, 3 v range becomes +10

DBM etc. If the other DB markings are

used, the DBM readings will be 10 DBM

high.

DO NOT EXCEED THE VOLTAGES

LISTED BELOW TO PREVENT BLOWING

FUSE F2:

VOLTMETER.= -1 V RANGE

AND BELOW, AND DISTORTION

ANALYZER, MODE-MAXIMUM

SENSITIVITY.

1. 300 V ABOVE 100 CPS

2. 50 V ABOVE 1 KC

IF LOW FREQUENCIES ARE NOT TO

BE MEASURED, Cl MAY BE REPLACED

WITH A SMALLER CAPACITOR, AND

THE VOLTAGE LIMITS OF F2 MAY BE

RAISED ACCORDINGLY.

3-3

Page 16

TM11-6625-1576-15

Section IV

Figure 4-1

Model 333A/334A

Figure 4-1. Block Diagram

Page 17

TM 11-6625-1576-15

Model 333A/334A

paragraphs 4-1 to 4-12

Section IV

SECTION IV

THEORY OF

4-1. OVERALL DESCRIPTION.

4-2. Models 333A and 334A Distortion Analyzers include an impedance converter, a rejection amplifier,

a metering circuit, and a power supply, The Model

334A also contains an

of the instruments is shown in Figure 4-1. The im pedance converter provides a low noise input circuit

with a high input impedance independent of source

impedance placed at the INPUT terminals. The re-

jection amplifier rejects the fundamental frequency of

an input signal and passes the remaining frequency

components on to the metering circuit for measuring

distortion.

indications of distortion and voltage levels on the front

panel meter, M 1. The AM detector (Model 334A only)

detects the modulating signal from the RF carrier and

filters any RF components from the modulating signal

before it is applied to the impedance converter circuit.

4-3. BLOCK DIAGRAM DESCRIPTION.

4-4. DISTORTION MEASURING OPERATION.

4-5. For distortion measurement, the input signal is

applied to the impedance converter, Assembly A2,

through the FUNCTION selector, S1, and the one megohm attenuator, The one megohm attenuator, a voltage

divider network provides 50 db attenuation in 10 db

steps. The desired level of attenuation is selected by

the SENSITIVITY selector, S2. The impedance converter provides an impedance conversion and unity

gain between the instrument INPUT terminals and the

input of the rejection amplifier. The rejection amplifier consists of a preamplifier, a Wien bridge, and a

bridge amplifier. The SENSITIVITY VERNIER control,

at the input of the preamplifier, provides a set level

signal to obtain a full scale reading on the meter for

any voltage level at the input of the instrument. With

the FUNCTION selector in the SET LEVEL position, a

ground is applied in the Wien bridge circuit to allow

a signal reference level to be set up on the meter.

With the FUNCTION selector in the DISTORTION position, the Wien bridge is used as an interstate coupling

network between the preamplifier and bridge amplifier.

The Wien bridge is tuned and balanced to reject the

fundamental frequency of the applied input signal. Two

automatic control loops consisting of two phase detec tors, lamp drivers, lamps, and photocells provide fine

tuning and balance in the AUTOMATIC MODE. The

remaining frequency components are applied to the

bridge amplifier and are measured as distortion by

the metering circuit.

bridge amplifier to the preamplifier narrows the re-

jection response of the Wien bridge. The output of

the rejection amplifier is applied to the metering cir -

cuit through the post-attenuator. The post-attenuator

is used to limit the input signal level applied to the

metering circuit to 1 mv for full scale deflectlon.

The metering circuit sensitivity is increased to 300

u

V for full scale deflection on the 300 pv range. The

metering circuit provides a visual indication of the

The metering circuit provides visual

AM detector. A block diagram

Negative feedback from the

OPERATION

distortion level of the input signal. In addition to the

visual indication provided by the meter, the OUTPUT

terminals provide a means of monitoring the distortion

components.

4-6. DISTORTION MEASUREMENT IN AM

CARRIERS.

4-7. The Model 334A Distortion Analyzer contains an

AM detector circuit for measuring envelope distortion

in AM carriers.The input signal is applied to the input of the AM detector circuit where the modulating

signal is recovered from the RF carrier. The signal

is then applied to the impedance converter circuit

through the one megohm attenuator and then through

the same circuits previously described in the distortion measuring mode operation.

4-8. VOLTMETER OPERATION.

4-9. In the voltmeter mode of operation, the input

signal is applied to the impedance converter circuit

through the 1:1 and 1000:1 attenuator. The 1:1 atten-

uation ratio is used in the .0003 to .3 VOLTS position

of the METER RANGE selector S3, and the 1000:1

attenuation ratio is used in the 1 to 300 VOLTS posit ions.

METER position, the output of the impedance converter

bypasses the rejection amplifier and is applied to the

metering circuit through the post-attenuator (METER

RANGE selector).Metering circuit sensitivity is in-

creased from 1 mv for full scale deflection to 300 uv

on the 300

suring operation.The function of the post-attenuator

and metering circuit is the same for voltmeter opera-

tion as for the distortion measuring operation.

4-11. IMPEDANCE CONVERTER CIRCUIT.

4-12. The input signal to the distortion analyzer is

applied to the impedance converter circuit (refer to

Figure 6-2) through the 1:1 and 1000:1 attenuator

S3R12 in the voltmeter mode of operation and through

the one megohm attenuator S2R1 through S2R6 in the

distortion mode of operation. Capacitive dividers

S2C10 through S2C 10 in the attenuator keep the frequency

response flat.

distortion, high input impedance amplifier circuit

wit h gain independent of the source impedance placed

at the INPUT terminals. Instrument induced distortion of the signal being measured is minimized by

keeping the input impedance and the gain of the impedance converter linear. The input impedance is kept

linear by use of local positive feedback from the source

of A2Ql to the gate of A2Q1 and to the protective diodes

A2CR2 and A2CR3. Thus signals with large source

impedance can be measured accurately. Overall induced distortion is further minimized by a high open

loop gain and 100% negative feedback. The high open

loop gain is achieved by local positive feedback from

With the FUNCTION selector in the VOLT-

uv range, as it was in the distortion mea-

4-10. SCHEMATIC THEORY.

The impedance converter is a low

4-1

Page 18

TM11-6625-1576-15

Section IV

Paragraphs 4-13 to 4-25 and Figure 4-2

the emitter of A2Q3 to the collector of A2Q2. Overall

negative feedback from the emitter circuit of A2Q4 to

the source of A2Q1 results in unity gain from the impedance converter.

4-13. The bias points of the transistors in the impedance converter are selected to minimize instrument

induced distortion. A2Q 1, an extremely low noise,

high impedance field effect transistor, is the major

component that makes linearity of the Impedance converter independent of the signal source impedance.

4-14. REJECTION AMPLIFIER CIRCUIT.

4-15. The rejection amplifier circuit (see Figures 6-3

and 6-6) consists of the preamplifier (A3Q1) thru A3Q3),

the Wien bridge resistive leg and auto control loop

(A5Q1 thru A5Q9 with associated lamp and photocell),

the reactive leg and auto control loop (A5Q10 thru

A5Q 18 with associated lamp and photocell), and the

bridge amplifier (A3Q4 thru A3Q6).

4-16. PREAMPLIFIER CIRCUIT.

4-17. The signal from the impedance converter is ap-

plied to the preamplifier, which is used during SET

LEVEL and DISTORTION measuring operations. Negative feedback from the junction of A3R1O and A3R11 is

applied to the junction of A3R2 and A3C2 to establish

the operating point for A3Q1. Negative feedback from

the emitter of A3Q3 is applied to the emitter of A3Q1

to stabilize the preamplifier. The preamplifier, like

the impedance converter, is designed for high open

loop gain and low closed loop gain to minimize instru-

ment induced distortion.

4-18. WIEN BRIDGE CIRCUIT.

4-19. In the distortion measuring operation the Wien

bridge circuit is used as a rejection filter for the

fundamental frequency of the input signal. With the

FUNCTION selector, S1, in the DISTORTION position,

the Wien bridge is connected as an interstage coupling

network between the preamplifier circuit and the bridge

amplifier circuit. The bridge is tuned to the fundamen-

tal frequency of the input signal by setting the FREQUENCY RANGE selector, S4, for the applicable frequency range, and tuning the capacitors C4A through

C4D. The bridge circuit is balanced by adjusting the

COARSE balance control, R4, and the FINE balance

control, R5.

In the AUTOMATIC MODE fine tuning

and balancing are accomplished by photoelectric cells

which are in the resistive and reactive legs of the

Wien bridge. The error signals for driving the photo-

cells are derived by detecting the bridge output using

the input signal as a reference.

4-20. When the Wien bridge is not tuned exactly to the

frequency to be nulled, a portion of the fundamental

frequency will appear at the bridge output. The phase

of this signal depends on which leg of the bridge is not

tuned, or on the relative errors in tuning if neither is

set correctly. The magnitude of the signal is proportional to the magnitude of the tuning error of either or

both legs of the bridge.

4-2

Model 333A/334A

Figure 4-2. Bridge Waveforms

4-21. Figure 4-2a is a sinusoid input to the Wien bridge.

If the resistive leg of the bridge i

S slightly unbalanced,

the output of the bridge is very small, but has the

waveform shown in Figure 4-2b and is in phase with

the input.

approaches zero

larger, but 180° out of phase, if the null position is

passed.

As the resistive leg is tuned, the signal

amplitude at null and then becomes

When the resistive leg is correctly tuned

and the reactive leg is tuned through null, a similar

waveform is produced, Figure 4-2c. The only difference is that the reactive signal is 90° out of phase with

the resistive signal.

4-22. When the bridge output is detected using the

input signal as the reference, the error signals in

phase or 180° out of phase with the reference develop

a voltage which is used to vary the resistance in the

resistive leg of the bridge, to tune it to the correct

null position, Signals of the form in Figure 4-2c do

not develop any voltage as the resistive detector is

insensitive to input differing from the reference by 90° .

4-23. In an independent, but similar control loop, the

bridge input signal is shifted 90° and used as the

reference signal for the detector. This detector

develops control voltages to null the reactive leg of

the bridge, but is insensitive to signals of the form

in Figure 4-2b which are caused by small tuning

errors of the resistive branch.

4-24. The result is that the two control loops derive

information from a common source and develop two

independent control signals for nulling the two legs

of the bridge. These control voltages are used to

vary the brilliance of lamps, which in turn causes

resistance changes in photocells which form part of

the Wien bridge.

4-25. Refer to Figure 4-3 for the phase relationship

of the bridge error signal and reference voltage at the

base of A5Q4. The shaded portions of the error signals (b and c) indicate that part of the error signal

which contributes to the dc lamp control voltage. As

indicated in d, any error signal that is 90° out of

phase with the reference does not affect the dc lamp

control voltage.

Page 19

Model 333A/334A

4-26. The operation of the reactive branch control loop

is similar to that of the resistive branch. The phase

delay circuit (Figure 6-6), A5Q15, A5Q16, S4AF and

S4C1 through S4C5, shifts the reference voltage 90º,

as shown in Figure 4-3f.

A5Q12 sensitive to components of the bridge error

signal that are 90° out of phase (g and h). The output

of the lamp driver, Q14, controls the brilliance of

A6DS2, which varies the resistance of A6V2 through

A6V5 to tune the branches of the reactive leg. Deck

AR of the FREQUENCY RANGE switch, S4, switches

A5R56 in parallel with A5R55 on the top three frequency

ranges.

A6DS2 will become brighter, and lower the

This makes the detector

TM 11-6625-1576-15

Section IV

Paragraphs 4-26 to 4-27 and Figure 4-3

resistance of A6V2 through A6V5, making variation

in resistance less than on the two lower ranges.

However, less variation in resistance is needed to

tune the leg, because the impedance in the reactive leg

becomes progressively less as the higher frequency

ranges are selected.

4-27. Any error signal that is not an integral multiple

of 90 is the result of the reactive leg of the bridge

being detuned, and the resistive leg being unbalanced.

For example, an error signal that is 45º out of phase

(Figure 4-3e and j) will result in outputs from both

detectors to tune the bridge and reject the fundamental.

.

Figure 4-3. Reference and Error Phase Relationship

4-3

Page 20

TM 11-6625-1576-15

Section IV

Paragraphs 4-28 to 4-35 and Figures 4-4 to 4-5

Figure 4-4. Wien Bridge Circuit and Rejection Characteristics

4-28. When the bridge circuit is tuned and balanced,

the voltage and phase of the fundamental, which appears

at junction of the series reactive leg (S4R1, 3, 5, 7,

or 9 and C4A/B) and the shunt reactive leg (S4R11,

13, 15, 17, or 19, and C4C/D), is the same as at the

midpoint of the resistive leg (A3R12 and A3R14). When

these two voltages are equal and in phase, the funda-

mental frequency will not appear at the drain of the

field effect transistor A3Q4. For frequencies other

than the fundamental,the reactive leg of the Wien

bridge offers various degrees of attenuation and phase

shift which cause a voltage at the output points of the

bridge. This difference voltage between the reactive

leg and resistive leg is amplified by A3Q4, A3Q5, and

A3Q6.

circuit and the rejection characteristics for it.

Figure 4-4 illustrates a typical Wien bridge

positive half of the signal will be passed, and if it is

out of phase, the negative half will be passed.

4-32. The normal working voltage at TP3 is between

0 and -1 volt. The dc output of the filter network

causes the voltage at TP3 to go in a positive direction

(toward zero) for in phase error signals, and in a

negative direction (toward

signals. The change in base voltage is then amplified

by A5Q5 and lamp driver A5Q6. This will change the

brilliance of lamp A6DS1, which will vary the resistance of A6V1 in the direction necessary to balance

the resistive leg of the bridge.

-1 v) for out of phase error

4-29. The Wien bridge circuit is designed to cover a

continuous frequency range of over a decade for each

position of the FREQUENCY RANGE selector, S4. S4

provides course tuning of the reactive leg by changing

the bridge circuit constants in five steps at 1 decade

per step. For the automatic control loop, the reference

voltage is taken from R6 at the input to the rejection

amplifier and applied to the buffer amplifier A5Q7.

The reference voltage is amplified and clipped by A5Q8

and A5Q9 and coupled to the detector A5Q4. The output

of the metering circuit, which contains the fundamental

frequency if either leg of the bridge is untuned, is ap-

plied to the buffer amplifier A5Q1. It is amplified by

A5Q2 and A5Q3 and coupled to the detector A5Q4.

4-30. Refer to Figure 4-5 simplified partial schematic

for detector operation.

to both resistive and reactive detector circuits.

4-31. The signals from the error amplifier, (A5Q2

and A5Q3) will be equal and of opposite phase, and will

cancel out each other when the detector, A5Q4 is off.

However,

square wave gates A5Q4 on, the signal from the col-

lector of A5Q3 will be shorted to ground. Thus the

signal from the collector of A5Q2 will be coupled

through the filter network to the base of AQ5. If the

signal from A5Q2 is in phase with the reference, the

when the positive half of the reference

The discussion is applicable

4-4

Figure 4-5. Auto Control Loop Detector

4-33. When the FUNCTION selector is set to the VOLT-

METER or SET LEVEL position, the junction of the

series and shunt reactive branches of the Wien bridge

is connected to circuit ground through R19 by S1BF

which disables the frequency rejection characteristic

of the bridge circuit. With the bridge circuit disabled,

the rejection amplifier circuit provides one db of gain

for the fundamental frequency and the harmonics. In

the SET LEVEL operation, this signal is used to establish the SET LEVEL reference.

4-34. BRIDGE AMPLIFIER CIRCUIT.

4-35. The bridge amplifier circuit consists of three

stages of amplification, A3Q4 through A3Q6. The

Page 21

TM 11-6625-1576-15

Figure 4-6. Rejection Amplifier Block Diagram and Typical Frequency Rejection Characteristic

first stage of amplification, A3Q4, is a field effect

transistor which amplifies the difference signal between

the gate and the source.

The field effect transistor

is selected for maximum noise performance with the

high impedances of the Wien bridge circuit. The signal

from the drain is applied to the two stage feedback amplifier A3Q5 and A3Q6. The output of A3Q6 is coupled

to the meter circuit by the post attenuator S3R1 through

S3R11. Negative feedback from the output of the bridge

amplifier is applied to the preamplifier circuit to narrow the frequency rejection characteristic. It can be

noted from the rejection characteristic (refer to Figure

4-4) for the bridge that the rejection of harmonic voltages is not constant.

Typically the second harmonic

is attenuated several db more than the third harmonic

and the third more than the fourth. The result of the

negative feedback is illustrated by the rejection charac-

teristic shown in dashed lines on the attenuation and

phase characteristic of Figure 4-4. Figure 4-6 shows

a simplified block diagram of the rejection amplifier

with the typical frequency-rejection characteristic.

Refer to Figure 4-7, Bandwidth Versus Null Depth for

further detail on the rejection characteristic.

4-36. HIGH PASS FILTER.

4-37. The HIGH PASS FILTER (see Figure 6-3) is

normally used when the fundamental of the input signal

is greater than 1 Kc.

In the voltmeter mode of operation, the filter is not used. In the SET LEVEL and

DISTORTION position of the FUNCTION switch the

filter presents >50 db attenuation to 50 or 60 cycle

hum components, but offers no attenuation to frequencies over 1 Kc.

The filter assembly, A7, consists of

A7C1, A7C2, and A7L1. The filter can be inserted

or bypassed by the HIGH PASS FILTER switch, S9.

4-38. METER CIRCUIT.

4-39. The meter circuit (refer to Figure 6-4) consists

of the post attenuator,

the meter amplifier circuit,

and the meter rectifier circuit.

4-40. POST ATTENUATOR.

4-41. The post attenuator, S3R1 through S3R11, is a

series of resistive networks which attenuate the input

signal in 10 db steps.

The attenuator is used in con-

junction with either the input sensitivity attenuator or

the 1000:1 attenuator to limit the signal level to the

meter amplifier to 1 mv for full scale deflection on

all ranges from 1 mv to 300 v full scale. The meter

circuit sensitivity is increased to 300 uv for full scale

deflection on the 300

V range by switching resistors

u

A2R29 and A2R30 into the calibration network. Resistor A2R41 and capacitor A2C29 are also switched into

Paragraphs 4-36 to 4-45 and Figure 4-6

Section IV

the calibration network on the 300

Pv range to extend

the passband of the amplifier.

4-42. METER AMPLIFIER CIRCUIT.

4-43. The meter amplifier circuit consists of a five

stage amplifier circuit,

A2Q5 through A2Q9, which

develops the current for full scale meter deflection.

Negative dc feedback from the emitter circuit of

A2Q8 is applied to the base of A2Q5 to stabilize the

dc operating point of the meter amplifier circuit and

to minimize the tendency for dc drift due to ambient

temperature changes.

A2R51 and A3CR8 are electric-

ally in the circuit only when the meter circuit is over-

loaded. When the voltage on the emitter of A2Q9 becomes abnormally large during an overload, A2CR8

breaks down and provides a lower resistance charging

path for A2C15 which reduces the transient recovery

time of the meter circuit.

Negative ac feedback is

applied from the collector circuit of A2Q9 to the emitter circuit of A2Q5. This feedback is used to ensure

flat frequency response, to improve linearity, and to

reduce the effect of variation of transistor parameters

with environmental changes.

In this manner, the

calibration of the instrument is made dependent on

high quality passive components.

4-44, METER RECTIFIER CIRCUIT.

4-45. The meter rectifier is connected in a bridge type

of configuration with a diode in each upper branch and

a dc milliammeter connected across the midpoints of

the bridge.

strated in Figure 4-8.

The simplified meter rectifier is illu-

The generator represented by

A2Q5 through A2Q9 with the internal impedance R

provides the meter,

M1, with current for full scale

deflection and develops a voltage across the calibration

network which closes the ac feedback loop. Capacitors

A2C27 and A2C28 are used as coupling capacitors for

the ac feedback loop, output signal to the OUTPUT

connector, and the bridge error signal to the input of

the automatic fine tuning loops. The mechanical inertia

of the meter and A2C26 prevents the meter from re-

sponding to individual current pulses.

Therefore,

the meter indication corresponds to the average value

of the current pulses rather than the peak value. The

meter is calibrated to indicate the rms value of a sine

wave. Resistor A2R45 impresses a fixed bias across

diodes A2CR6 and A2CR7 (biasing them close to the

barrier voltage) to make the meter circuit response

linear to large variations in signal amplitude. The

linearity of this type of circuit is also increased by

including the meter circuit in the overall feedback

loop.

4-5

O

Page 22

TM 11-6625-1576-15

Section IV

Figure 4-7

Model 333A/334A

4-6

Figure 4-7. Bandwidth Versus Null Depth

Page 23

TM 11-6625-1576-15

model

333A/334A

Paragraphs 4-46 to 4-52 and Figure 4-8

Section IV

Figure 4-8. Simplified Metering Circuit

4-46. POWER SUPPLY CIRCUIT.

4-47. The power supply circuit (refer to Figure 6-5)

consists of a +25 voIt series regulated supply and a

-25 volt series regulated supply which is the reference

supply for the +25 volt supply.

4-48. The -25 volt regulated supply is of the conventional series regulator type. The amplifier A1Q5 is

used to increase the loop gain of the circuit, thus improving voltage regulation. The positive feedback ap-

plied to the junction of A1R1l and A1R12 is used to

further improve the line frequency suppression of the

circuit.

4-49. The +25 volt regulated supply is of the conventional series regulator type and operates the same as

the -25 volt regulated supply.

4-50. Diodes A1CR5 and A1CR6 are coupling and pro-

tection diodes for external battery supplies. The diodes

protect the series regulator circuits from application

of incorrect polarity at the battery input terminals.

The diodes also protect external batteries from being

charged when the ac power is being used with batteries

connected to the battery terminals.

4-51. RF

4-52. The RF detector circuit consists of a rectifier

A4CR1 and filter circuit shown on the schematic diagram of Figure 6-2. The RF signal is applied to the

circuit through the RF INPUT connector on the rear

panel. The rectifier diode A4CR1 recovers the modulating signal from the RF carrier and the filter circuit

removes any RF components before the signal is ap pIied to the impedance converter circuit through the

NORM -RF DET switch, S7.

DETECTOR CIRCUIT. (334A only)

4-7

Page 24

TM 11-6625-1576-15

Section V

Table 5-1

Model 333A/334A

Table 5-1. Test Equipment Required

5-0

Page 25

Model 333A/334A

SECTION V

MAINTENANCE

TM 11-6625-1576-15

Paragraphs 5-l to 5-9 and Figure 5-1

Section V

5-1. INTRODUCTION.

5-2. This section contains maintenance and service

information for the 333A and 334A Distortion Analyz -

Included are Performance Checks, Adjustment

ers.

and Calibration Procedures, and Troubleshooting

Techniques.

5-3. TEST EQUIPMENT REQUIRED.

5-4. Test equipment used in the calibration of the 333A

and 334A is given in Table 5-1, Test Equipment Re-

quired.

used,

commercially available test equipment.

5-5. PERFORMANCE CHECKS.

5-6. The Performance Checks are in-cabinet procedures that can be used to verify instrument performance,

maintenance, to check specifications after a repair,

or for incoming quality control inspection.

5-7. Performance Checks for both the 333A and 334A

are provided. The performance checks are applicable

to both instruments except where noted in paragraph

heading.

5-8. The Performance Checks are performed with the

ac power cord connected to nominal line voltage (115

v/230 V) 50 to 1000 cps, MODE SWITCH to MANUAL,

HIGH PASS FILTER to OUT, and NORM RF DET switch

to NORM, unless otherwise specified. Selector positions for the SENSITIVITY Selector will be referred

to as follows: MIN=Position 1, next step-Position 2,

etc, to Max= Position 6.

5-9.

Set

This table lists the type of equipment to be

required characteristics, and recommended

These procedures can be used for periodic

FUNDAMENTAL REJECTION CHECK

a.

Connect 33lA/332A as shown in Figure 5-1.

b.

Set Distortion Analyzer controls as follows:

FUNCTION Selector . . . . . . VOLTMETER

METER RANGE Selector . . . . . . . 1 VOLT

FREQUENCY RANGE Selector . . . . . . X1OO

Frequency Dial . . . . . . . . . . . . . . . 50

filter (White Instr Lab Model

2640)

. . . . . . . . . . . . . . . . .. . . . . . . .5Kc

to 5 K

on Distortion Analyzer meter.

LEVEL. Switch METER RANGE to O. 3 VOLTS. Adjust

SENSITIVITY controls for full scale meter indication.

as follows:

for maximum meter reading (approximately 1 Kc).

meter indication.

TORTION. Adjust BALANCE controls and FREQUENCY dial for null indication on Distortion Analyzer

meter. Reduce Distortion Analyzer METER RANGE

selector setting as necessary to maintain deflection

on meter scale.

Analyzer meter,

continue to adjust for a null indication. Reduce Wave

Analyzer RANGE setting as necessary to maintain

deflection on meter scale.

c. Set Test Oscillator (-hp - Model 651A) frequencv

C and adjust amplitude for indication of 1.0 volt

d. Switch Distortion Analyzer FUNCTION to SET

e. Set Wave Analyzer controls (-hp - Model 302A)

SCALE VALUE . . . . . . . . . . RELATIVE

MAX INPUT VOLTAGE . . . . . . . . ...1

RANGE . . . . . . . . . . . . . . 0 DECIBELS

MODE SELECTOR . . . . . . . . . .NORMAL

f. Adjust Wave Analyzer FREQUENCY controls

g. Adjust Wave Analyzer REF ADJUST for O db

NOTE

If the range of the REF ADJUST control

is insufficient to set meter to O db reference,adjust the Distortion Analyzer

SENSITIVITY VERNIER control slightly

to set reference.

Switch Distortion Analyzer FUNCTION to DIS-

h.

j. After achieving null indication on Distortion

The Distortion Analyzer OUTPUT is a O

to O. 1 volt signal representing a percent-

age of full scale,

observe Wave Analyzer mete r and

NOTE

regardless of RANGE

Figure 5-1. Test Setup for Fundamental Rejection Check

5-1

Page 26

TM 11-6625-1576-15

Section V

Paragraphs 5-10 to 5-11, Figure 5-2 and Table 5-2

setting.

switch represents 10 db fundamental rejection. Therefore, the total fundamental

rejection is the sum of the Wave Analyzer

reading and the 333A/334A indication.

k. The Distortion Analyzer METER RANGE setting

plus the Wave Analyzer RANGE setting plus the two

meter indications shall total more than -80 db.

5-10. SECOND HARMONIC ACCURACY CHECK.

a. Connect Test Oscillator (-hp-Model 651A) 600Ω

output to Distortion Analyzer *

b. Set Distortion Analyzer controls as follows:

FUNCTION Selector . . . . . . . SET LEVEL

FREQUENCY RANGE . . . . . . . . . . . X1

Frequency Dial . . . . . . . . . . . . . . .20

METER RANGE Selector . . . . . . . . . 0 DB

c. Set Test Oscillator controls (-hp- Model 651A)

as follows:

FREQUENCY RANGE . . . . . . . . . . . X10

FREQUENCY Dial. . . . . . . . . . . . . 2

OUTPUT ATTENUATOR . . . . . 1.0 VOLTS

AMPLITUDE . . . . . . . . . . . . . . l Volt

d. Adjust Distortion Analyzer SENSITIVITY controls for a meter reading of O db.

e. Switch Distortion Analyzer FUNCTION selector

to DISTORTION. Adjust Frequency dial and BALANCE

controls for a null indication on meter.

f. Switch Distortion Analyzer FUNCTION selector

to SET LEVEL.

g. Adjust Test Oscillator frequency to 40 cps. Adjust AMPLITUDE control for a O db indication on the

Distortion Analyzer meter.

h. Switch Distortion Analyzer FUNCTION selector

to DISTORTION. The meter reading shall not change

more than ±0. 6 db.

Each decrease of the RANGE

Model 333A/334A

j. Repeat steps a through h at the frequency settings

indicated in Table 5-2.

change within the limits specified.

Table 5-2. Second Harmonic Accuracy Check

5-11.

DISTORTION INTRODUCED BY INSTRUMENT

CHECK AND AUTOMATIC CONTROL LOOP

OPERATION.

Connect 333A/334A as shown in Figure 5-2.

a.

Set Distortion Analyzer controls as follows:

b.

FUNCTION Selector . . . . . . . SET LEVEL

SENSITIVITY Selector

SENSITIVITY VERNIER Control . . full CCW

METER RANGE Selector . . . . . . . . . . 0 db

FREQUENCY RANGE Selector . . . . . . . Xl

Frequency Dial . . . . . . . . . . . . . . .5

Set oscillator for approximately 1 volt output at

c.

5 cycles.

d. Set filter box for 5 cycles.

e. Adjust oscillator amplitude for an indication of

+2 db on the Distortion Analyzer meter.

f. Switch Distortion Analyzer FUNCTION selector

to DISTORTION. Adjust frequency dial and BALANCE

controls for a null meter indication.

lower 1/3 of meter scale, decrease METER RANGE

selector setting. )

g. The meter indication at “null” shall be at least

-8 db on the -60 db METER RANGE which is equiva-

lent to -70 db. Note reading.

The meter readings shall

. Position 1 step CCW

from Full CW position

(If reading is in

5-2

Figure 5-2. Instrument Induced Distorition and Automatic Control Loop Test Setup

Page 27

Model 333A/334A

TM 11-6625-1576-15

Section V

Paragraph 5-12, Table 5-3, and Figure 5-3

h. Set METER RANGE to O. 01 volt RANGE and off-

set frequency dial to a lower reading so that meter

cads full scale.

id note distortion level. Distortion level should be

within +3 -O db of manually nulled reading.

j. Set MODE switch to MANUAL (and meter range

to o. 01).

dial reading so that meter reads full scale. Return

MODE switch to automatic. Distortion reading should

be within +3 -O db of manually nulled reading obtained

in step g of this paragraph.

k. Set MODE switch to MANUAL and adjust fre quency dial for null.

trol CW with METER RANGE set at 0. 01 so that meter

reads full scale. Return MODE Switch to AUTOMATIC.

Distortion reading should be within +3 -0 db of manually

nulled reading obtained in step g of this paragraph.

m. Set MODE switch to MANUAL and METER

RANGE to O. 01.

CCW so that meter reads +2 db. Set Mode switch to

Automatic. Distortion reading should be within +3 -O

of manually nulled reading obtained in step g of

this paragraph.

n. Repeat steps b through m with controls set as

indicated in Table 5-3. Except in steps j thru m use

METER RANGE setting of O. 03 to obtain +2 db reading

when detuning Frequency Dial and COARSE BALANCE

Control to verify automatic control loop operation.

Table 5-3. Distortion Introduced By Instrument Check

5-12. FREQUENCY CALIBRATION ACCURACY

a. Connect 333A/334A as shown in Figure 5-3.

Offset frequency dial past null to a higher

CHECK.

Set MODE switch to AUTOMATIC

Adjust COURSE BALANCE Con-

Adjust COARSE BALANCE Control

NOTE

From 5 cps to 10 cps the FREQUENCY

dial may be as much as 3% low. In this

test the dial is held constant, and the input frequency is varied and monitored.

If the dial is low, the input frequency at

null will be high.

put frequency is measured, it will be low

when the dial is low.

Kc the dial may be as much as 8% high,

Consequently, a low frequency reading at

null would indicate that the dial is reading

high.

b.

Set Distortion Analyzer controls as follows:

FUNCTION Selector . . . . . . . SET LEVEL

METER RANGE Selector . . . . . . . . 0 DB

SENSITIVITY Selector . . . . . . . . . . MIN.

FREQUENCY RANGE Selector . . . . . .Xl

Frequency Dial . . . . . . . . . . . . . . . .5

Set Test Oscillator controls (-hp- Model 203A)

c.

as follows:

FREQUENCY RANGE . . . . . . . . . . . X1

FREQUENCY DIAL . . . . . . . . . . . . . . 5

OUTPUT ATTENUATOR . . . . . . 1.0 VOLT

d. Set Electronic Counter controls (-hp - Model

5532A) as follows:

SENSITIVITY . . . . . . . . . . 3 VOLTS RMS

Function Switch. . . . .

DISPLAY . . . . . . . . . . . . . . Fu1l CCW

e. Adjust Test Oscillator AMPLITUDE control for

a full scale indication on the Distortion Analyzer meter.

f. Switch Distortion Analyzer FUNCTION selector

to DISTORTION.

g. Adjust Test Oscillator FREQUENCY DIAL for

a null indication on the Distortion Analyzer meter.

(If reading is in lower 1/3 of meter scale, decrease

METER RANGE selector setting, )

h. Adjust Distortion Analyzer BALANCE controls

for a null indication on the meter. Repeat steps g and

h until a null is reached.

If the period of the in-

From 200 Kc to 600

1 PERIOD AVERAGED

Figure 5.-3. Test Setup for Frequency Calibration Accuracy Check

5-3

Page 28

TM11-6625-1576-15

Section v

Paragraphs 5-13 to 5-16 and Table 5-4

j. The Electronic Counter shall indicate the period

of 5 cps -3%, i. e. 194 to 200 msec.

k. Repeat steps b through h with controls set as

indicated in Table 5-4. The Electronic Counter shall

indicate the Test Oscillator output frequencies within

the limits indicated.

5-13. INPUT RESISTANCE CHECK

a. Connect Test Oscillator (-hp- Model 651A) 600

Ω output to Distortion Analyzer INPUT terminals.

b. Set Distortion Analyzer controls as follows:

FUNCTION Selector . . . . . . VOLTMETER

SENSITIVITY Selector . . . . . . . . . MAX.

SENSITIVITY VERNIER Control . . . . . MIN.

METER RANGE Selector. . . . . . . 1 VOLT

c. Set Test Oscillator controls as follows:

FREQUENCY RANGE . . . . . . . . . . X10

FREQUENCY Dial . . . . . . . . . . . . . 10

OUTPUT ATTENUATOR . . . . . . 1.0 VOLT

d. Adjust Test Oscillator AMPLITUDE control for

an indication of 1.0 volt (E

Analyzer meter.

e. Connect a 100 K

carbon film resistor in series with the Distortion

) rms on the Distortion

in

Ω (R

) ±1. 0%, 1/2 watt, fixed

a

Analyzer INPUT. Note the Distortion Analyzer meter

reading (E

).

o

f. Calculate the Distortion Analyzer input resistance using the following formula:

Model 333A/334A

e. Set Distortion Analyzer controls as follows:

.

FUNCTION Selector . . . . . .DISTORTION

SENSITIVITY Selector . . . . . . . . . . MIN.

METER RANGE Selector . . . . . . . VOLTS

f. Measure Capacitance at each SENSITIVITY

selector setting of the Distortion Analyzer. The L - C

meter shall indicate less than 60 pf on each of these

settings.

5-15. MINIMUM INPUT LEVEL CHECK.

a. Connect Test Oscillator (-hp- Model 651A) 600

Ω output to Distortion Analyzer INPUT terminals l

Terminate test oscillator with

Ω ±1% 1/2 w resistor.

600

Set Distortion Analyzer controls as follows:

b.

FUNCTION Selector . . . . . . . VOLTMETER

METER RANGE Selector . . . . . . .3 VOLT

SENSITIVITY Selector . . . . . . . . . MIN.

SENSITIVITY VERNIER . . . . . . . . , CCW

Set Test Oscillator for 20 cps.

c.

d.

Adjust Test Oscillator amplitude for a Distortion

-

Analyzer

meter indication O. 3 volts.

e. Switch Distortion Analyzer FUNCTION selector

to SET LEVEL.

f. Switch SENSITIVITY selector to MAX and

VERNIER to full CW. The SENSITIVITY controls shall

have sufficient range to give a full scale meter reading.

g. The input resistance shall be 1 M

Ω ±5%.

h. Switch FUNCTION selector to Distortion and

calculate the input resistance in this position. It shall

be 1 M

Ω ±5%.

INPUT SHUNT CAPACITANCE CHECK.

5-14.

Set Distortion Analyzer controls as follows:

a.

FUNCTION Selector . . . . . . . VOLTMETER

METER RANGE Selector . . . . . . . 1 VOLT

Connect an L - C meter to the 333A/334A and

b.

measure the input capacitance.

c. The L - C meter shall indicate less than 30 pf.

d. Switch the Distortion Analyzer on the 0. 3 range

and measure capacitance. Meter shall indicate less

than 60 pf.

5-4

DC ISOLATION CHECK.

5-16.

Connect 333A/334A as shown in Figure 5-4.

a.

REMOVE SHORTING BARS BETWEEN

POWER LINE GROUND TERMINALS ON

DISTORTION ANALYZER INPUT TERMINALS AND FUNCTION GENERATOR OUTPUT TERMINALS.

b.

Set Distortion Analyzer controls as follows:

FUNCTION Selector . . . . . .VOLTMETER

METER RANGE Selector . . . . . . . 1 VOLT

c. Apply ac power to dc power supply and set for

400 v. Set Power SuppIy controls but do not apply dc

to the Distortion Analyzer.

d. Set Function Generator for 1 Kc and adjust the

amplitude control for an indication of 0. 9 on the Distortion Analyzer meter.

Page 29

TM 11-6625-1576-15

Model 333A/334A

Figure 5-4. DC Isolation Check Test Setup

e. Apply the 400 v dc to the Distortion Analyzer.

There shall be no change in the indication on the Dis tortion Analyzer meter, or any indication on the ammeter of the power supply.

5-17. VOLTMETER ACCURACY CHECK

a. Connect Voltmeter Calibrator (-hp- Model 738B)

and Variable Line Transformer (Superior Type UC1M)

to Distortion Analyzer as shown in Figure 5-5. Re-

move shorting bar between power line ground and circuit ground terminals.

b, Set Variable Line Transformer for 115 v output.

c. Set Distortion Analyzer FUNCTION Selector to

VOLTMETER.

d. Set voltmeter calibrator for 400 cps output.

e. Check the Distortion Analyzer voltmeter full

scale readings on all ranges against the appropriate

rms input voltages from the voltmeter calibrator. The

voltmeter accuracy shall be within ±2%,

f. Set the Distortion Analyzer METER RANGE

selector to 1 VOLT range.

Paragraphs 5-17 to 5-18 and Figures 5-4 to 5-5

g. Check the Distortion Analyzer voltmeter tracking at 0. 1 volt increments from 0. 1 volt to 1 volt. The

voltmeter tracking accuracy shall be within ± 1%.

h. Repeat steps d through g with the variable Line

Transformer set to 105 v & 125 v.

5-18. HIGH PASS FILTER CHECK

Connect the 333A/334A as shown in Figure 5-6.

a.

b.

Set Distortion Analyzer controls as follows:

FUNCTION Selector. . . . . . . SET LEVEL

METER RANGE Selector . . . . SET LEVEL

HIGH PASS FILTER switch . . . . . . . In

SENSITIVITY Selector . . . . . . . . Position 5

SENSITIVITY VERNIER . . . . . . . CCW

c. Adjust frequency response test set to 5Kc and

set output amplitude to obtain a zero db indication on

Distortion Analyzer.

d. Adjust frequency response test set meter to set

level reference.

e. Set frequency response test set to 1 Kc and adjust

output amplitude so that test set meter reads set leveI.

Section V

Figure 5-5. Voltmeter Accuracy check Test Setup

5-5

Page 30

TM 11-6625-1576-15

Section V

Paragraphs 5-19 to 5-21, Figure 5-6 and Table 5-5

f. Reading on Distortion Analyzer shall be within

O. 5 db of zero db setting.

g. Set frequency response test set to 60 cps and

adjust the output amplitude so that test set meter reads

set level.

h. Switch Distortion Analyzer Meter Range to 0. 003

volt range,

j. Reading should be > -40 db.

Model 333A/334A

n. Repeat steps b through k with the Variable Line

Transformer set to 105 v and 125 v.

Table 5-5. Voltmeter Frequency Response Check

5-19, VOLTMETER FREQUENCY RESPONSE CHECK.

a. Connect Distortion Analyzer to test equipment

as shown in Figure 5-6.

b. Set Distortion Analyzer controls as follows:

FUNCTION Selector . . . . . . . .VOLTMETER

METER RANGE Selector. . . . . .0.01 VOLTS

c. Set the Variable Line Transformer output to 115 v.

d. Adjust the Oscillator for an indication of O. 9 at

400 cps on the Distortion Analyzer meter.

e. Adjust the Frequency Response Test Set METER

SET control to SET LEVEL indication on the meter.

f. Switch the Oscillator RANGE switch to X 1 and

set the Frequency Dial to 5.

g. Readjust the Oscillator AMPLITUDE control

until the Frequency Response Test Set meter indicates

SET LEVEL.

h. The Distortion Analyzer meter shall indicate

between 0.855 and 0.945 (±5%).

j. Set the Oscillator to the frequencies listed in

Table 5-5. Repeat step g after each setting. The Dis tortion Analyzer meter shall indicate 0.9 ± the tolerances indicated.

k. Switch the Frequency Response Test Set RANGE

SELECTOR to the 1-3 Mc position. Set the FREQ.

TUNING dial to the frequencies listed in Table 5-5.

Adjust the Frequency Response Test Set AMPLITUDE

control until the meter indicates SET LEVEL after

each frequency setting. The Distortlon Analyzer meter

shall indicate 0.9 ± the tolerances indicated.

5-6

5-20. RESIDUAL NOISE CHECK

a. Connect a shielded 600 Ω resistor across the

Distortion Analyzer INPUT terminals. (See Figure

5-7 for details on constructing shielded load. ) Secure

the shorting bar between the power line ground and circuit ground terminals.

b. Set Distortion controls

FUNCTION Selector . . . . . . . VOLTMETER

METER RANGE Selector . . . . 0.0003 VOLTS

c. The meter shall indicate less than 25 µ volts.

d. Remove the 600

100 K ohm resistor across the INPUT terminals. (See

Figure 5-7 for details on constructing shielded load. )

e. The meter shall indicate less than 30 µ volts.

5-21. AM DETECTOR CHECK (Model 334A only).

a. Connect Signal Generator (hp- Model 606A) 50

RF OUTPUT to Distortion Analyzer RF INPUT.

b. Set Distortion Analyzer controls as follows:

FUNCTION Selector . . . . . . . SET LEVEL

NORM-RF DET Switch . . . . . . . RF DET

METER RANGE Selector . . . . . . . . . 0 DB

FREQUENCY RANGE Selector . . . . . X100

FREQUENCY Dial . . . . . . . . . . . . . 10

χοντρολσ as follows:

Ω resistor. Connect a shielded

Page 31

TM 11-6625-1576-15

Model 333A/334A

#

c. Set Signal Generator controls as follows:

FREQUENCY. . . . . . . . . . . . . . . l Mc

MODULATION SELECTOR . . . . . . . EXT

ATTENUATOR/VERNIER . . . . . 3.O VOLTS

Modulate Signal Generator output 30% with a 1000

cps signal using a 203A Function Generator or

comparable oscillator.

d. Adjust Distortion Analyzer SENSITIVITY Select-

or and VERNIER control for 0 DB reference.

e. Switch FUNCTION selector to DISTORTION. Ad-

just BALANCE controls and Frequency Dial for null

indication.

f. Distortion shall be more than -40 db down.

5-22. ADJUSTMENT AND CALIBRATION

PROCEDURE.

5-23. The following is a complete adjustment and calibration procedure for the 333A and 334A. Before

proceeding with these adjustments, the Performance

Checks should be performed to determine whether

adjustments are necessary, If your instrument does

not meet the test limits specified in the following

steps, refer to Troubleshooting Procedure, Paragraph

5-33. Adjustment locations are shown in Figure 5-8.

5-24. The Adjustment and Calibration Procedure is

performed with the ac power cord connected to nominal line voltage ( 115 v/230 v) 50 to 1000 cps, MODE

Figure 5-7. Shielded Load Assembly

Table 5-6. Power Supply Adjustments

Paragraphs 5-23 to 5-27, Figure 5-7 and Table 5-6

No.

Connector, male

1

Connector, male w/insulator

2

Lug, terminal 90°

3

4

Resistor, 100 K

metal film

4

Resistor, 600 K

5

Washer, int. lock

6

Spacer, 6-32 threaded

Shield

7

8

Screw, bind. head, 6-32 x 1/4 in

switch to MANUAL, HIGH PASS FILTER to OUT, and

NORM RF DET switch to NORM, unless otherwise

specified.

5-25. METER MECHANICAL ZERO SET.

5-26. The meter is properly zero-set when the pointer

rests over the zero calibration mark on the meter

scale and the meter is in its normal operating environment and turned off, Adjust the zero-set, if necessary,

as follows:

wise until meter pointer is to the left of zero and mov-

ing upscale toward zero.

stop when pointer is exactly at zero. If the pointer

overshoots zero, repeat step a.

ment screw approximately 2 degrees counterclockwise.

This is enough to free the zero adjustment screw from

the meter suspension.

step, repeat steps a through c.

5-27. POWER SUPPLY AND BIAS ADJUSTMENTS

measurement points, adjustments, voltage limits and

line regulation specifications.

Description

Ω, 1/2 W, 5%

Ω, 1/4 w, O. 5%

metal film

a. Rotate mechancial zero-adjustment screw clock-

b. Continue to rotate adjustment screw clockwise;

c. When pointer is exactly on zero, rotate adjust-

If pointer moves during this

a. Refer to Table 5-6 for the power supply and bias

-hp- Part No.

1251-0174

1251-0175

0360-0042

0758-0053

0757-1037

2190-0007

0380-0058

1251-1073

2470-0001

Section V

* Referenced to -25 volt supply;

* * This voltage has been adjusted for optimum distortion performance. Do not readjust unless A2Q1 is changed.

‡ This voltage has been adjusted for optimum distortion performance,

-25 volt supply must be adjusted first.

Do not readjust unless A3Q4 is changed.

5-7

Page 32

TM11-6625-1576-15

Section

V

Figure 5-8

Model 333A/334A

.

5-8

Figure 5-8 Component and Adjustment Location

Page 33

TM 11-6625-1576-15

Model 333A/334A

b. Remove top and bottom covers.

c. Secure the shorting bar between the power line

ground and circuit ground INPUT terminals.

d. Connect common lead of VTVM (-hp- Model

412A) to either INPUT ground terminals.

e. Perform the measurements and adjustments

listed in Table 5-6.

DO NOT ALLOW PROBE TO SHORT TP1

TO GROUND. IF THIS HAPPENS, A2Q4

MAY BE DESTROYED.

5-28. A3R16 AND A3R30 DISTORTION ADJUST.

a. Connect test equipment to the 333A/334A as

shown in Figure 5-9.

b. Set Distortion Analyzer controls as follows:

A3R16 ADJ

FUNCTION Selector . .

METER RANGE Switch . SET LEVEL SET LEVEL

FREQUENCY RANGE . . . . . . X1K . . . . X100

Selector

FREQUENCY Dial. . . . . . . . . . 5 . . . . . . 50

SENSITIVITY Selector . . . Position 5 . . Position 5

SENSITIVITY VERNIER . . . . CCW . . . . CCW

c. Adjust Filter Set to 5 Kc.

d. Set Function Generator for 5 Kc and adjust the

output amplitude for +2 db reading on the Distortion

Analyzer.

e. Switch Distortion Analyzer to DISTORTION and

obtain best null (minimum of 40 db down from +2 db

reference).

necessary.

f. Set MODE switch to Automatic and METER

RANGE switch to 0.0003 range and adjust A3R16 for

minimum distortion reading (minimum of 70 db down