Page 1

Page 2

HEWLETT

PACKARD

CERTIFICATION

Hewlett-Packard Company certifies that this product met its published specifications at the time of shipment

from the factory. Hewlett-Packard further certifies that its calibration measurements are traceable to the United

States National Bureau of Standards, to the extent allowed by the Bureau's calibration facility, and to the calibration facilities of other International Standards Organization members.

WARRANTY

This Hewlett-Packard product is warranted against defects in material and workmanship for a period of one

year from date of shipment. During the warranty period, Hewlett-Packard Company will, at its option, either

repair or replace products which prove to be defective.

For warranty service or repair, this product must be returned to a service facility designated by

shall prepay shipping charges to -hp- and -hp- shall pay shipping charges to return the product to Buyer. However,

Buyer shall pay all shipping charges, duties, and taxes for products returned to

HP software and firmware products which are designated by HP for use with a hardware product, when properly

installed on that hardware product, are warranted not to fail to execute their programming instructions due

to defects in materials and workmanship. If HP receives notice of such defects during their warranty period,

HP shall repair or replace software media and firmware which do not execute their programming instructions

due to such defects. HP does not warrant that the operation of the software, firmware or hardware shall be

uninterrupted or error free.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from improper or inadequate maintenance by

Buyer, Buyer-supplied software or interfacing, unauthorized modification or misuse, operation outside of the

environmental specifications for the product, or improper site preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. HEWLETT-PACKARD SPECIFICALLY DISCLAIMS THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE BUYER'S SOLE AND EXCLUSIVE REMEDIES. HEWLETT-PACKARD

SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER

-hp- from another country.

LEGAL THEORY.

-hp-. Buyer

ASSISTANCE

Product maintenance agreements and other customer assistance agreements are available for Hewlett-Packard

products.

For any assistance, contact your nearest Hewlett-Packard Sales and Service Office. Addresses are provided at

the back of this manual.

Page 3

Reproduced With Permission Courtesy Agilent Technologies, Inc.

Page 4

HEWLETT

PACKARD

SAFETY SUMMARY

The following general safety precautions must be observed during all phases of operation, service, and repair

of this instrument. Failure to comply with these precautions or with specific warnings elsewhere in this manual

violates safety standards of design, manufacture, and intended use of the instrument. Hewlett-Packard Company assumes no liability for the customer's failure to comply with these requirements. This is a Safety Class

1

instrument.

GROUND THE INSTRUMENT

To minimize shock hazard, the instrument chassis and cabinet must be connected to an electrical ground.

The instrument is equipped with a three conductor ac power cable. The power cable must either be plugged

into an approved three-contact electrical outlet or used with a three-contact to two-contact adapter with the

grounding wire (green) firmly connected to an electrical ground (safety ground) at the power outlet. The power

(lEC)

jack and mating plug of the power cable meet International Electrotechnical Commission

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable gases or fumes. Operation of any electrical instru-

ment in such an environment constitutes a definite safetv hazard.

safety standards.

KEEP AWAY FROM LIVE CIRCUITS

Operating personnel must not remove instrument covers. Component replacement and internal adjustments

must be made by qualified maintenance personnel. Do not replace components with power cable connected.

Under certain conditions, dangerous voltages may exist even with the power cable removed. To avoid injuries,

always disconnect power and discharge circuits before touching them.

DO NOT SERVICE OR ADJUST ALONE

Do not attempt internal service or adjustment unless another person, capable of rendering first aid and resus-

citation, is present.

DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT

Because of the danger of introducing additional hazards, do not install substitute parts or perform any unautho-

rized modification to the instrument. Return the instrument to a Hewlett-Packard Sales and Service Office

for service and repair to ensure that safety features are maintained.

DANGEROUS PROCEDURE WARNINGS

Warnings, such as the example below, precede potentially dangerous procedures throughout this manual. Instruc-

tions contained in the warnings must be followed.

Dangerous voltages, capable of causing death, are present in this instrument. Use

extreme caution when handling, testing, and adjusting.

Page 5

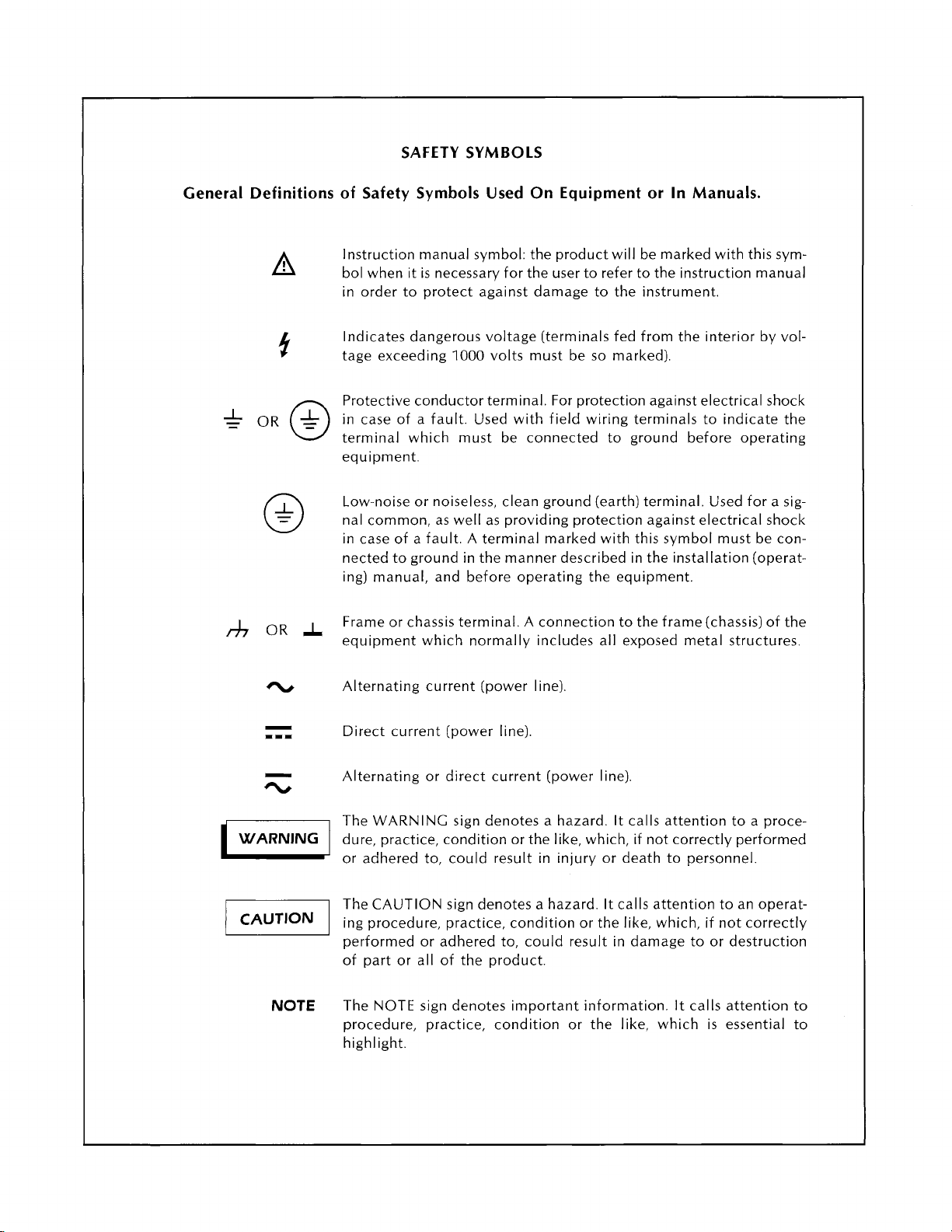

SAFETY SYMBOLS

General Definitions of Safety Symbols Used On Equipment or In Manuals.

Instruction manual symbol: the product will be marked with this symbol when it is necessary for the user to refer to the instruction manual

in order to protect against damage to the instrument.

Indicates dangerous voltage (terminals fed from the interior by vol-

1000

tage exceeding

Protective conductor terminal. For protection against electrical shock

in case of a fault. Used with field wiring terminals to indicate the

terminal which must be connected to ground before operating

equipment.

Low-noise or noiseless, clean ground (earth) terminal. Used for a signal common, as well as providing protection against electrical shock

in case of a fault. A terminal marked with this symbol must be connected to ground in the manner described in the installation (operat-

ing) manual, and before operating the equipment.

volts must be so marked).

WARNING

a

NOTE

Frame or chassis terminal. A connection to the frame (chassis) of the

equipment which normally includes all exposed metal structures.

Alternating current (power line).

Direct current (power line).

Alternating or direct current (power line)

The WARNING sign denotes a hazard. It calls attention to a procedure, practice, condition or the like, which, if not correctly performed

or adhered to, could result in injury or death to personnel.

The CAUTION sign denotes a hazard. It calls attention to an operat-

ing procedure, practice, condition or the like, which, if not correctly

performed or adhered to, could result in damage to or destruction

of part or all of the product.

The NOTE sign denotes important information. It calls attention to

procedure, practice, condition or the like, which is essential to

highlight.

Page 6

Page 7

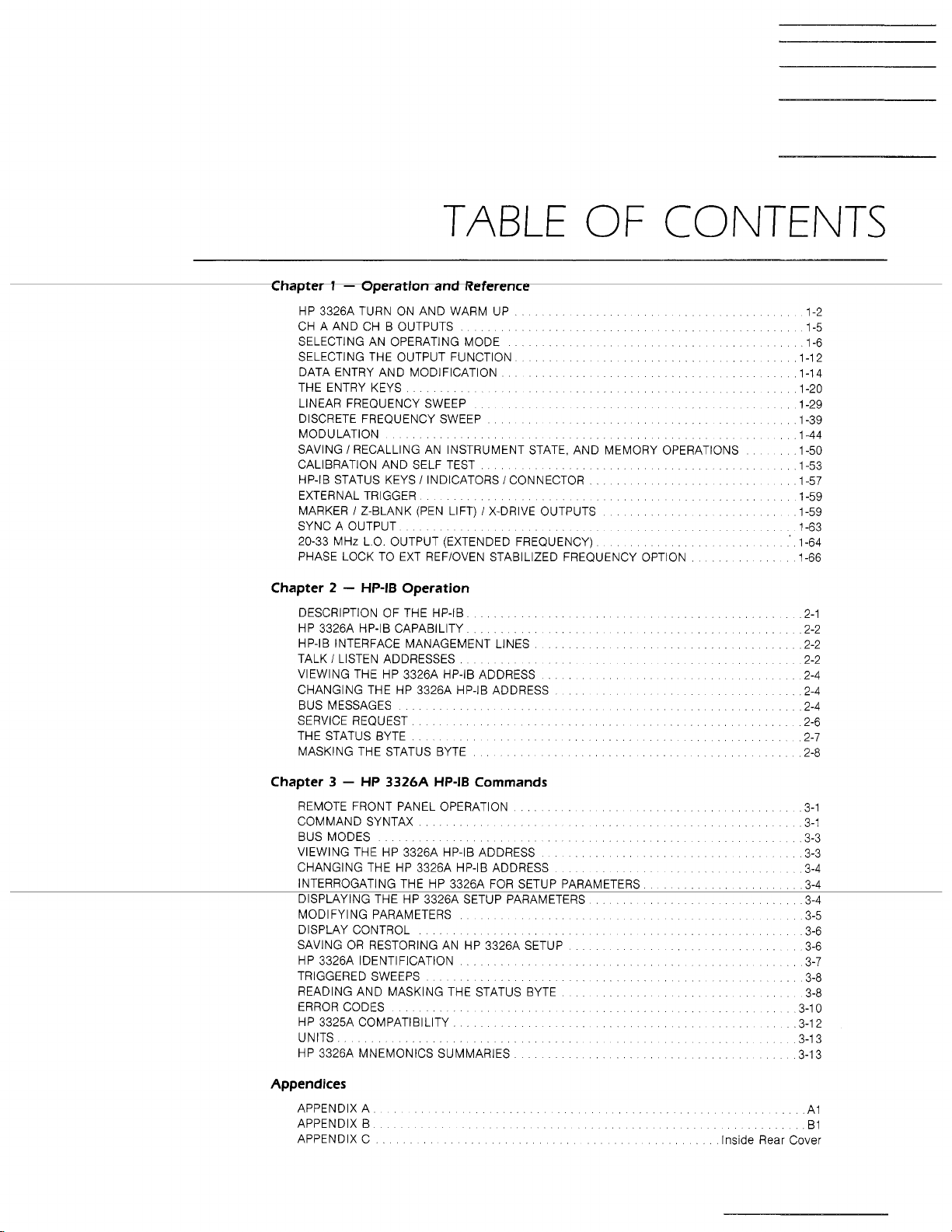

TABLE

OF CONTENTS

.

HP 3326A TURN ON AND WARM UP

CH A AND CH B OUTPUTS

SELECTING AN OPERATING MODE

SELECTING THE OUTPUT FUNCTION

DATA ENTRY AND MODIFICATION

THE ENTRY KEYS

LINEAR FREQUENCY SWEEP

DISCRETE FREQUENCY SWEEP

MODULATION

SAVING

CALIBRATION AND SELF TEST

HP-IB STATUS KEYS

EXTERNAL TRIGGER

MARKER

SYNC A OUTPUT

20-33 MHz L.O. OUTPUT (EXTENDED FREQUENCY)

PHASE LOCK TO EXT REFIOVEN STABILIZED FREQUENCY OPTION

Chapter

DESCRIPTION OF THE HP-IB

HP 3326A HP-IB CAPABILITY

HP-IB INTERFACE MANAGEMENT LINES

TALK

VIEWING THE HP 3326A HP-IB ADDRESS

CHANGING THE HP 3326A HP-IB ADDRESS

BUS MESSAGES

SERVICE REQUEST

THE STATUS BYTE

MASKING THE STATUS BYTE

I

RECALLING AN INSTRUMENT STATE. AND MEMORY OPERATIONS 1-50

1

Z-BLANK (PEN LIFT) 1 X-DRIVE OUTPUTS

2

.

HP-IB

I

LISTEN ADDRESSES

........ ......

I

INDICATORS / CONNECTOR

Operation

.... .... ....

, , ,

.... .......

...... ......

.......

. . . . .

. . ........ . .

...

. . . . ... ...

... . . ...

... ... . . . . .....

........ ... ....

. . .......

. . .......

. .

.... .........

........ .....

....... . .

. .

.....

. . ....

. . ....

...

.......

. . .

1-2

1-5

1-6

1-12

1-14

1-20

1-29

1-39

1-44

1-53

1-57

1-59

1-59

1-63

1-64

1-66

2-1

2-2

2-2

2-2

2-4

2-4

2-4

2-6

2-7

2-8

Chapter

3

.

HP

3326A

REMOTE FRONT PANEL OPERATION

COMMAND SYNTAX

BUS MODES

VIEWING THE HP 3326A HP-IB ADDRESS

CHANGING THE HP 3326A HP-IB ADDRESS

INTERROGATING THE HP 3326A FOR SETUP PARAMETERS

DISPLAYING THE HP 3326A SETUP PARAMETERS

MODIFYING PARAMETERS

DISPLAY CONTROL

SAVING OR RESTORING AN HP 3326A SETUP

HP 3326A IDENTIFICATION

TRIGGERED SWEEPS

READING AND MASKING THE STATUS BYTE

ERROR CODES

HP 3325A COMPATIBILITY

UNITS

HP 3326A MNEMONICS SUMMARIES

HP-IB

Commands

.... . . ...

............ ...

...... ........

..... ...... . .

. . ...

..................

....

. . ....

........

.....

........ . .

.... . . . .

. . . . .....

...........

....

......

. . ....

....

...

Appendices

APPENDIX A A 1

APPENDIX

APPENDIX C lns~de Rear Cover

B

3-1

3-1

3-3

3-3

3-4

3-4

....

3-4

3-5

3-6

3-6

3-7

3-10

3-1 2

3-13

3-13

3-8

3-8

B1

Page 8

Page 9

CHAPTER

I

OPERATION AND REFERENCE

Page 10

Chapter

1

.

Table of Contents

HP 3326A TURN ON AND WARM UP

CH A AND CH B OUTPUTS

AN

SELECTING

OPERATING MODE

...................................

SELECTING THE OUTPUT FUNCTION

DATA ENTRY AND MODIFICATION

THE ENTRY KEYS 1-20

LINEAR FREQUENCY SWEEP

..........................................

................................

DISCRETE FREQUENCY SWEEP 1-39

MODULATION

SAVING

I

AND

MEMORY OPERATIONS

CALIBRATION AND SELF TEST

HP-IB STATUS KEYS

EXTERNAL TRIGGER

MARKER

SYNC A OUTPUT 1.63

20-33

MHz

.............................................

RECALLING AN INSTRUMENT STATE,

................................

I

INDICATORS I CONNECTOR

........................................

I

Z-BLANK (PEN LIFT) I X-DRIVE OUTPUTS

..........................................

L.O.

OUTPUT (EXTENDED FREQUENCY)

........................

1.2

1-5

..........................

..........................

..........................

1-6

1-12

1-14

1-29

..............................

1-44

...............................

1.50

1.53

...............

1.57

1.59

.............

............

1-59

1-64

PHASE LOCK TO EXT REFIOVEN STABILIZED

FREQUENCY OPTION 1-66

......................................

Page 11

Qservice ----- This Document is a complete scan from the Original HP - Agilent Manual ----- Qservice

Page 12

Turn

on and Warm

up

HP 3326A TURN

ON

Turn On and Power

Connect the HP 3326A to a suitable power source and depress the POWER switch to

POWER

apply power to the entire HP 3326A. When power is applied, the HP 3326A initially displays "HP 3326A" followed by a list of the options installed. The HP 3326A then initiates a series of self tests and calibrates internal circuits. During a self test, all indicators (except the EXT REF indicator) and display segments are illuminated then

extinguished, and a series of internal tests are initiated. After each internal test, PASS

FAIL followed by a test number is displayed to indicate the test results. During a

or

self test, the outputs are disabled.

AND WARM UP

Up

Self

Tests

When power is removed from the HP 3326A with the POWER key, the

frequency reference circuits (Option 001) to maintain frequency accuracy.

Turn On State

The initial state of the HP 3326A at power up is dependent upon the setting of internal

the setup state selected prior to removing power can be selected as the turn on state.

Warm

Up

An HP 3326A without the high stability frequency reference (Option 001) requires 30

HP

3326A is

in a standby condition. In the standby condition, power is applied to the high stability

switches. The normal turn on state is the preset state described in "The Preset State

and the INSTR PRESET Key". However, through the use of the internal SAVE switch,

Setting of internal switches must be done by qualified service personnel. The location

and settings of the SAVE switch are described in the HP

minutes of operation to meet all specifications. An HP 3326A with Option 001 requires

15

minutes of operation to meet frequency specifications if power is disconnected for

less than 24 hours. If power is disconnected from the HP 3326A with Option 001 for

3326A Service Manual.

Page 13

Turn

on

and Warm up

more than 24 hours, up to 72 hours of operation may be required to meet frequency

001

specifications. The HP 3326A with Option

requires 30 minutes of operation to meet

other specifications.

NOTE

When power is removed from the HP

the POWER key, the

dition. In the standby condition, power is applied

to the high stability frequency reference circuits

00

(Option

1)

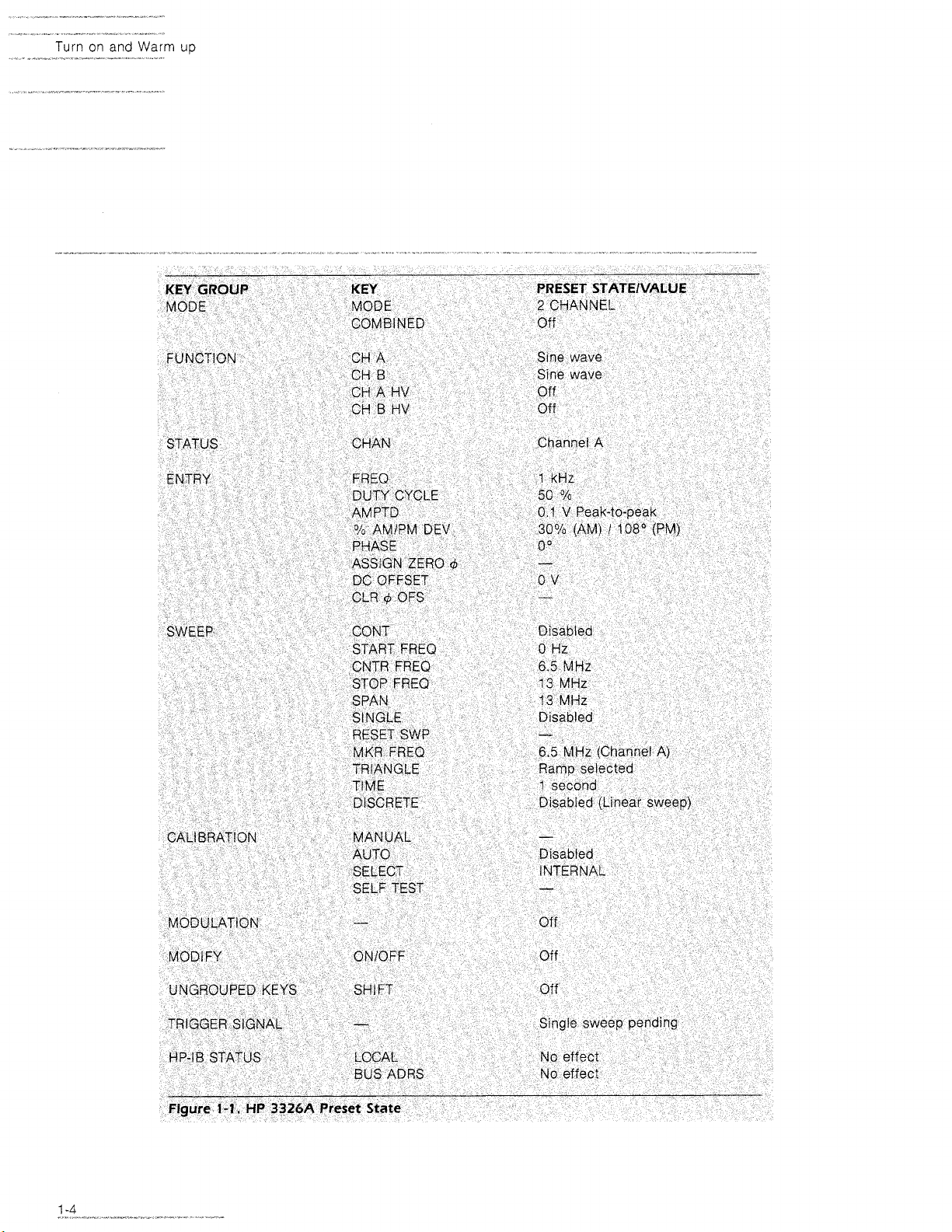

The Preset State and the lnstr Preset Key

INSTR

PRESET

The preset state of the HP 3326A is listed in Figure

the preset state by pressing the green INSTR PRESET (INSTRument PRESET) key. INSTR

PRESET provides a convenient starting state for establishing an instrument setup. INSTR

PRESET does not destroy instrument states or discrete frequency sweep elements stored

in the internal nonvolatile memory.

3326A

HP

3326A

to maintain frequency accuracy.

is in a standby con-

1-1.

The HP 3326A is restored to

with

HP-IB

Example:

"RST"

Page 14

Turn on and Warm

up

Page 15

CH A and

CH

B Outputs

CH A AND

CH

B

OUTPUTS

CH A and CH B Output Connectors

The CH A (channel

on the front panel. Option 003, Rear Panel Main Signal Outputs, replaces the front panel

A

channel

The channel

tive output for combined and internal modulation operation. For combined and internal

modulation operation, the channel B output is is used internally and is unavailable at

the CH B connector.

and B outputs with rear panel outputs.

A

A)

and CH B (channel B) output connectors are normally located

connector, in addition to being the output for channel

A,

is also the ac-

Q

The output impedance is 50

20 dB over the range of 100 kHz to 13 MHz. The output impedance with the high voltage option enabled is less than 2

of 50 kHz to 1 MHz. Both outputs share the same ground and may be floated up to

+

42 volts peak.

The maximum peak voltage lac + dc) that can be

safely applied between chassis and the outer conductor of the

tors is

from 0 to 100 kHz, with a return loss of greater than

Q

from 0 to 50 kHz, and less than 10 D over the range

HP

+

42

3326A

volts peak.

input and output connec-

Page 16

Setup For Viewing Output

Figure 1-2 illustrates a simple setup to view the HP 3326A outputs and observe the

effects of changing the HP 3326A settings. For example purposes, the selection of an

oscilloscope

displaying both channels simultaneously.

Waveforms

is

not critical although a dual channel oscilloscope has the advantage of

SELECTING AN OPERATING MODE

The

Mode

Key

The MODE key selects the operating mode of the HP 332614. Each time the MODE key

2

is pressed, the operating mode sequences through the

and PULSE operating modes, The mode selected is indicated by the illuminated indicator. COMBINED operation is enabled by pressing the blue SHIFT key prior to the MODE

key. The operating modes affect operating limits, operating characteristics, and selec-

B

tion of the CH A and CH

limits are included in the applicable sections for the characteristics and limits. When

the 2 PHASE or PULSE mode is selected, the HP 3326A performs an internal phase

calibration. During a mode change, the channel

outputs. The effects on the operating characteristics and

CHANNEL, 2 PHASE, 2 TONE,

A

and B outputs are disabled.

Page 17

Z

Channel

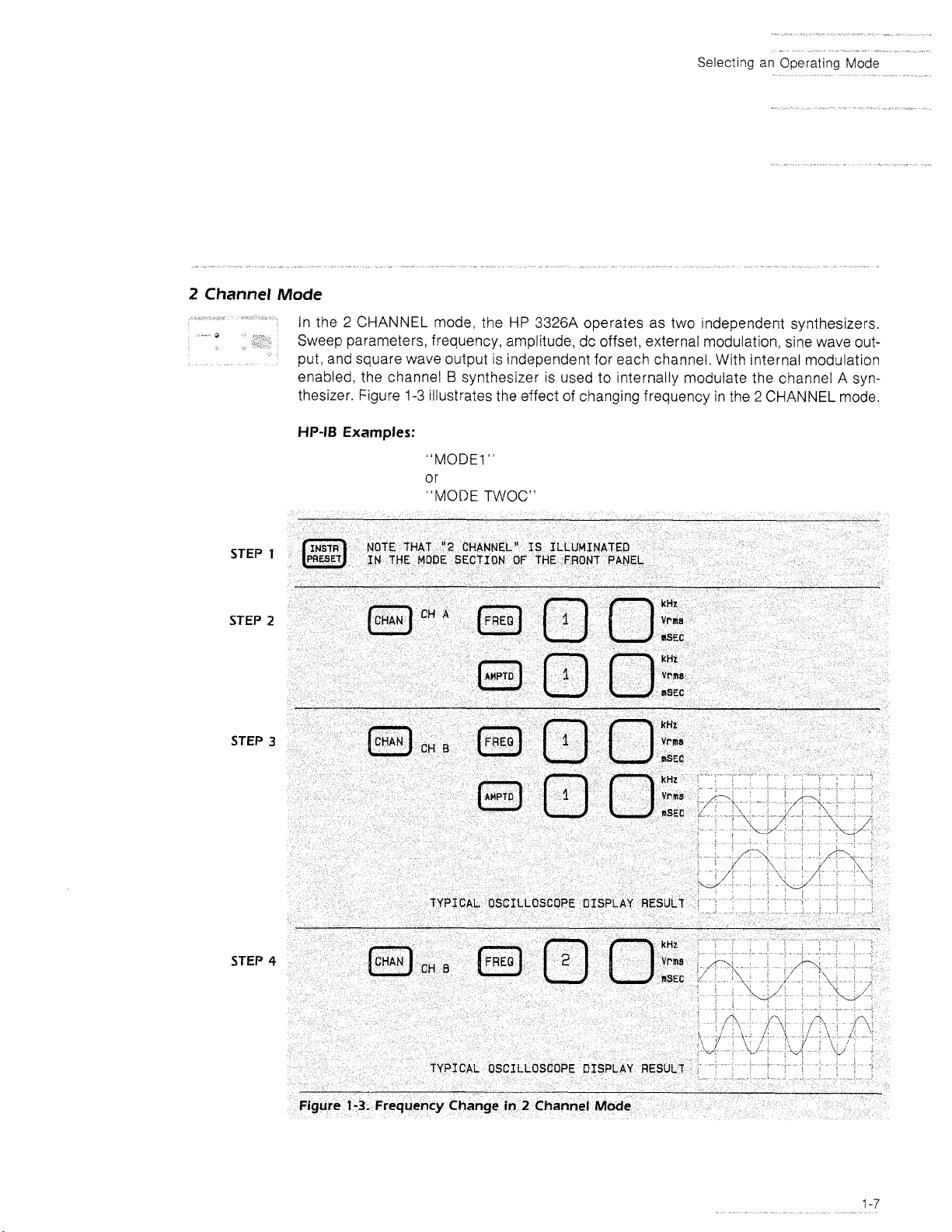

Mode

STEP

STEP

STEP

In the 2 CHANNEL

mode, the

HP

3326A

operates as two independent synthesizers.

Sweep parameters, frequency, amplitude, dc offset, external modulation, sine wave output, and square wave output is independent for each channel. With internal modulation

B

enabled, the channel

thesizer. Figure

HP-18

Examples:

1-3

synthesizer is used to internally modulate the channel A syn-

illustrates the effect of changing frequency in the 2 CHANNEL

"MODE1"

or

"MODE TWOC"

1

2

3

mode.

STEP

4

Page 18

-*

Selectmg

7-

2

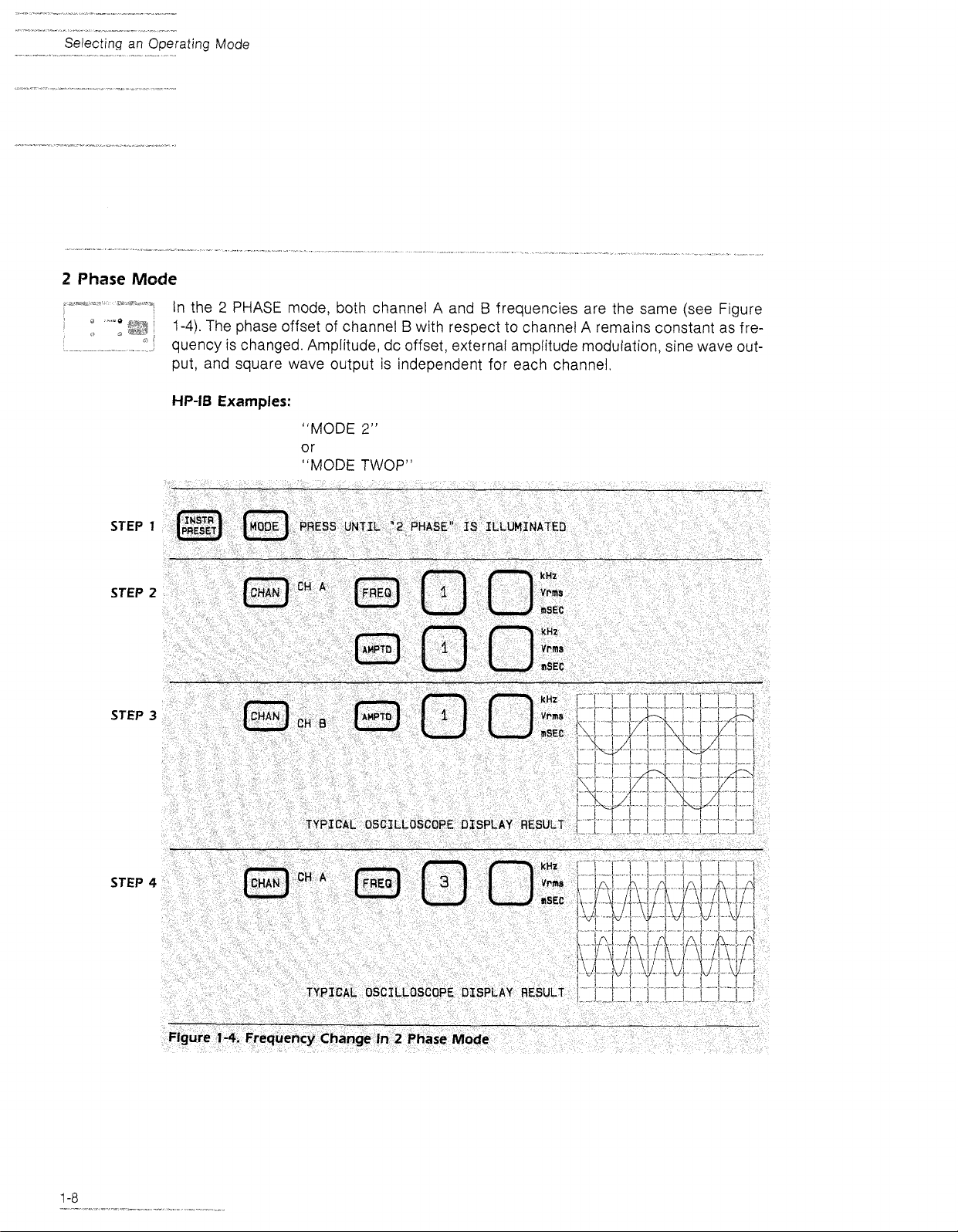

Phase

-

an

Operating

-"

Mode

Mode

STEP

STEP

STEP

In the 2 PHASE

1-4).

The phase offset of channel B with respect to channel A remains constant as fre-

mode, both channel A and B frequencies are the same (see Figure

quency is changed. Amplitude, dc offset, external amplitude modulation, sine wave output, and square wave output is independent for each channel,

HP-18

Examples:

"MODE

2"

or

"MODE

1

2

3

TWOP"

STEP

4

Page 19

Selectmg an Operating

Mode

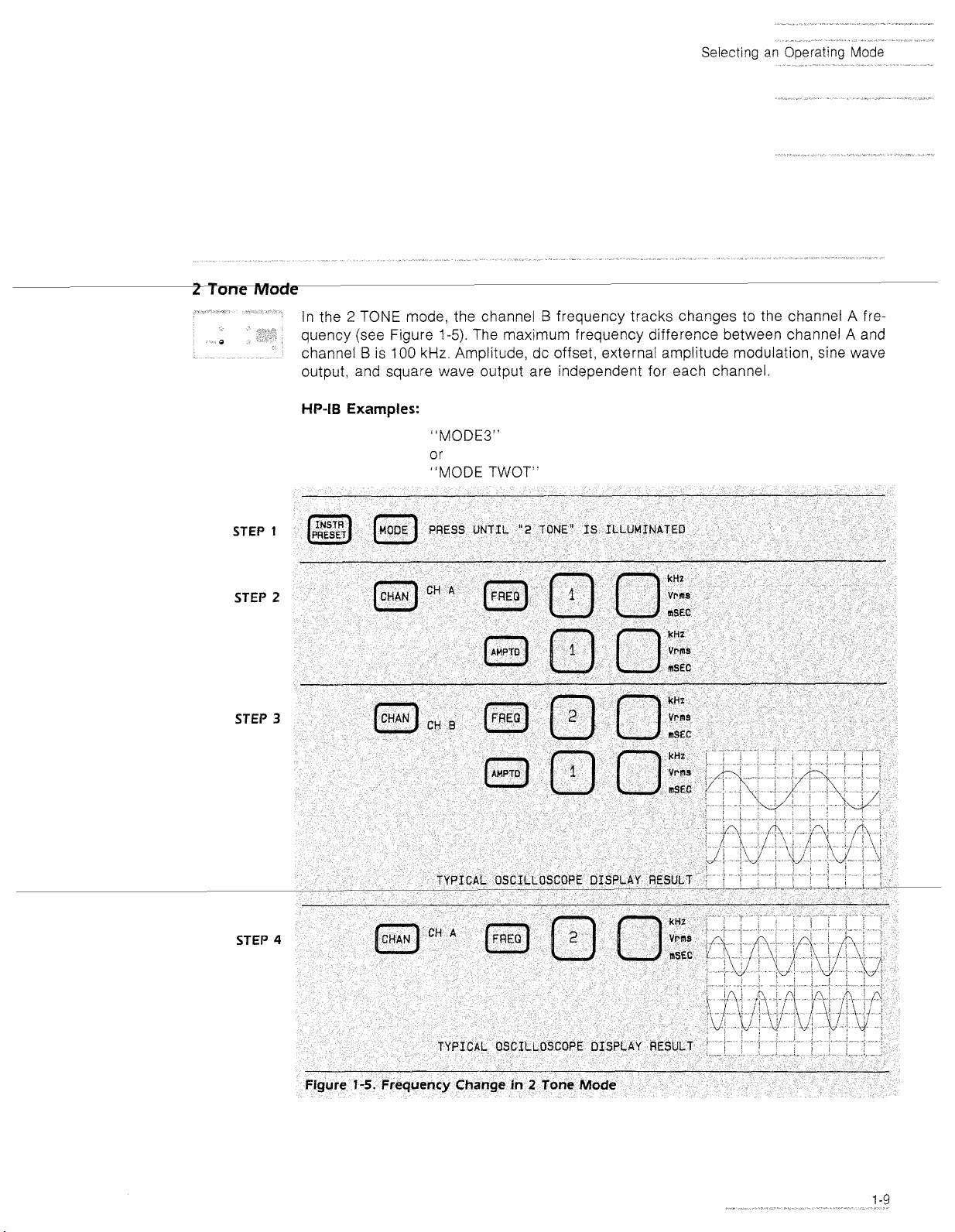

In the 2 TONE mode, the channel B frequency tracks changes to the channel A fre-

1-5).

quency (see Figure

B

channel

is 100 kHz. Amplitude, dc offset, external amplitude modulation, sine wave

The maximum frequency difference between channel A and

output, and square wave output are independent for each channel.

HP-IB

Examples:

"MODE3"

or

"MODE TWOT"

STEP

STEP

STEP

STEP

1

2

3

4

Page 20

ating

Mode

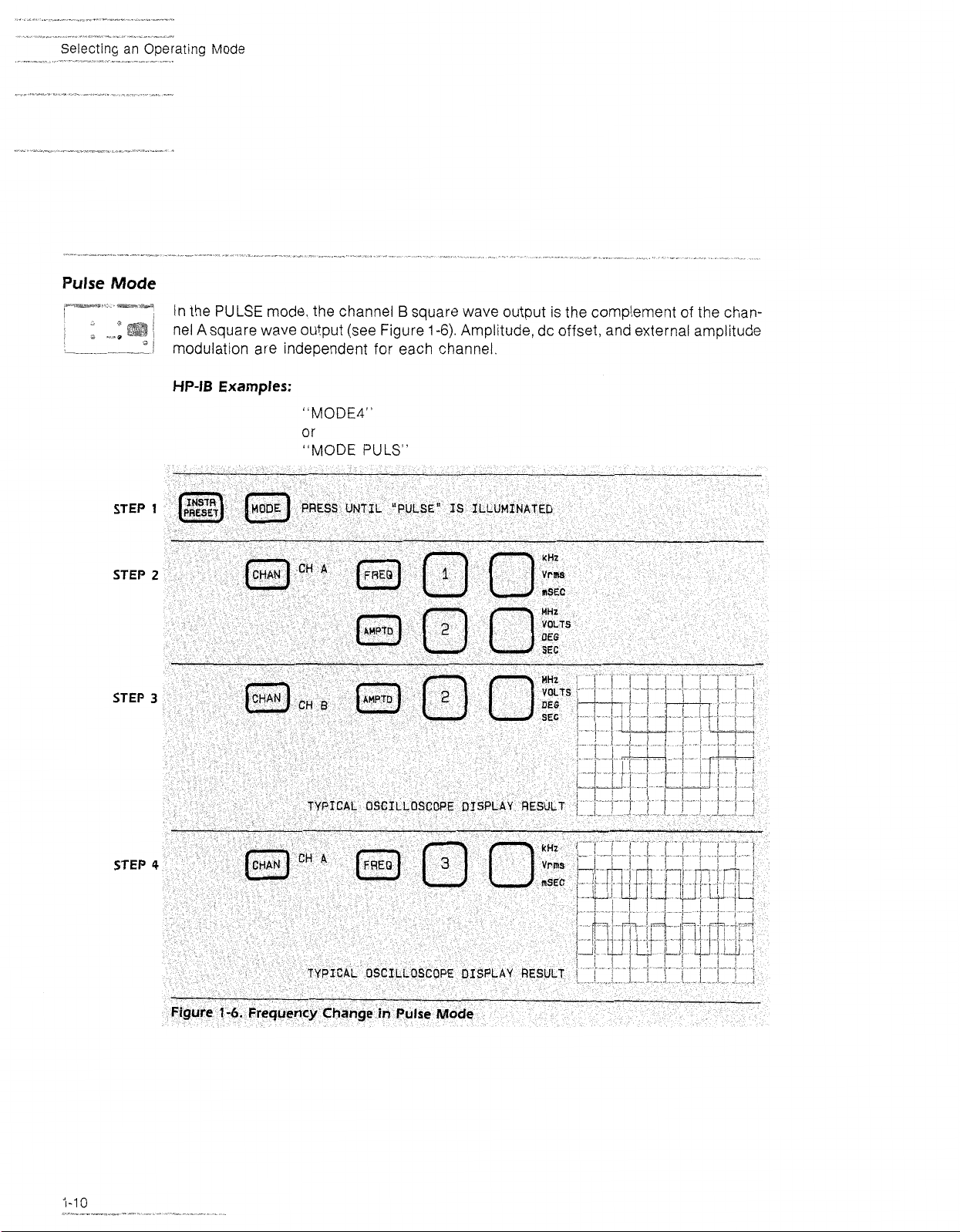

Pulse

,-*-m,s

Mode

---,*

S

STEP

STEP

STEP

In the

PULSE

nel A square wave output (see Figure

,

mode, the channel B square wave output

1-6).

modulat~on are independent for each channel

HP-IB

Examples:

"MODE$"

or

"MODE

1

2

3

PULS"

IS

the complement of the chan-

Amplitude, dc offset, and external amplitude

STEP

4

Page 21

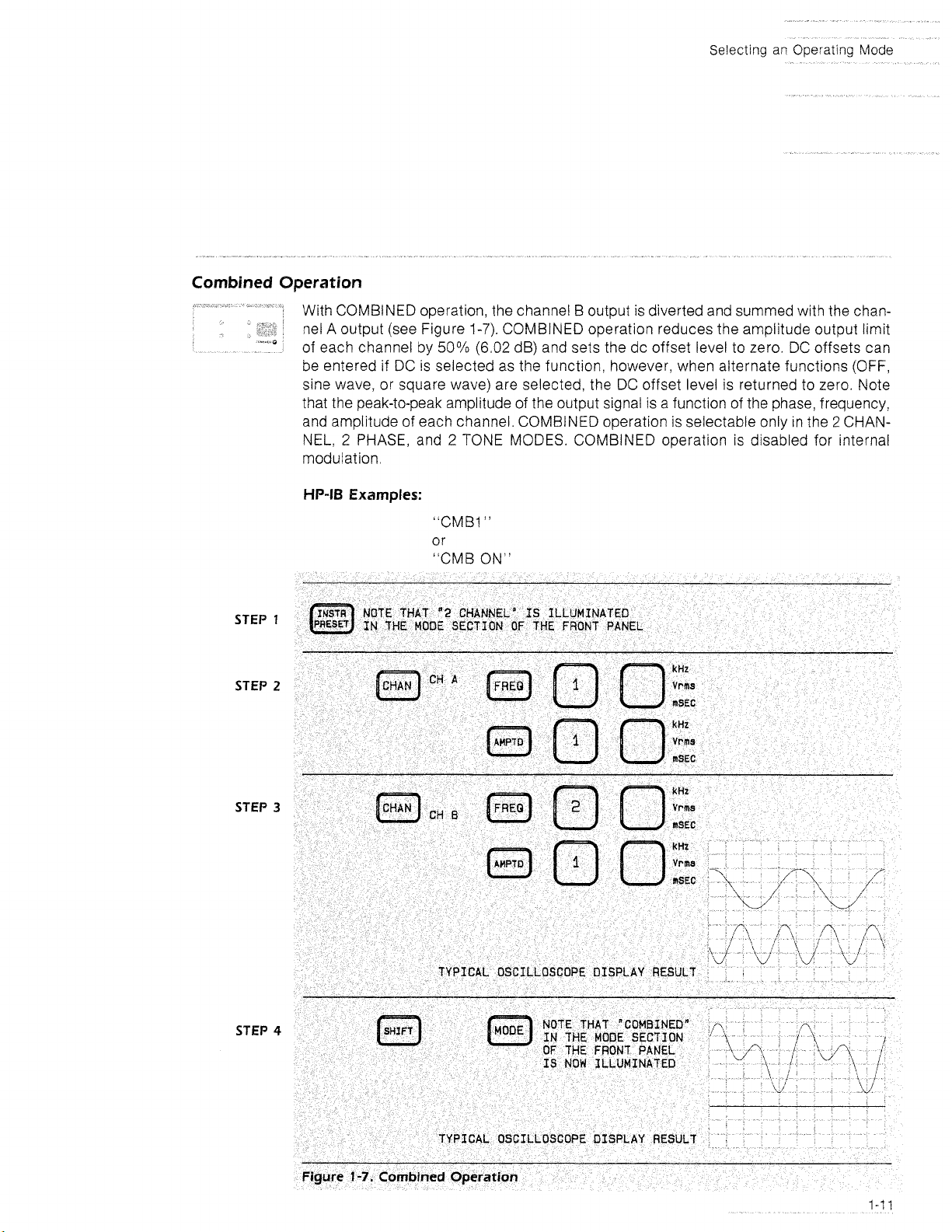

Combined Operation

With COMBINED operation, the channel B output is diverted and summed with the channel A output (see Figure

of each channel by

be entered if DC is selected as the function, however, when alternate functions (OFF,

sine wave, or square wave) are selected, the DC offset level is returned to zero. Note

that the peak-to-peak amplitude of the output signal is a function of the phase, frequency!

and amplitude of each channel. COMBINED operation is selectable only in the

NEL,

2

modulation.

HP-IS

Examples:

1-7).

COMBINED operation reduces the amplitude output limit

50%

(6.02 dB) and sets the dc offset level to zero. DC offsets can

2

CHAN-

PHASE, and 2 TONE MODES. COMBINED operation is disabled for internal

STEP

STEP

STEP

"CMBI

"

or

"CMB ON"

1

2

3

STEP

4

Page 22

Selecting the Output Function

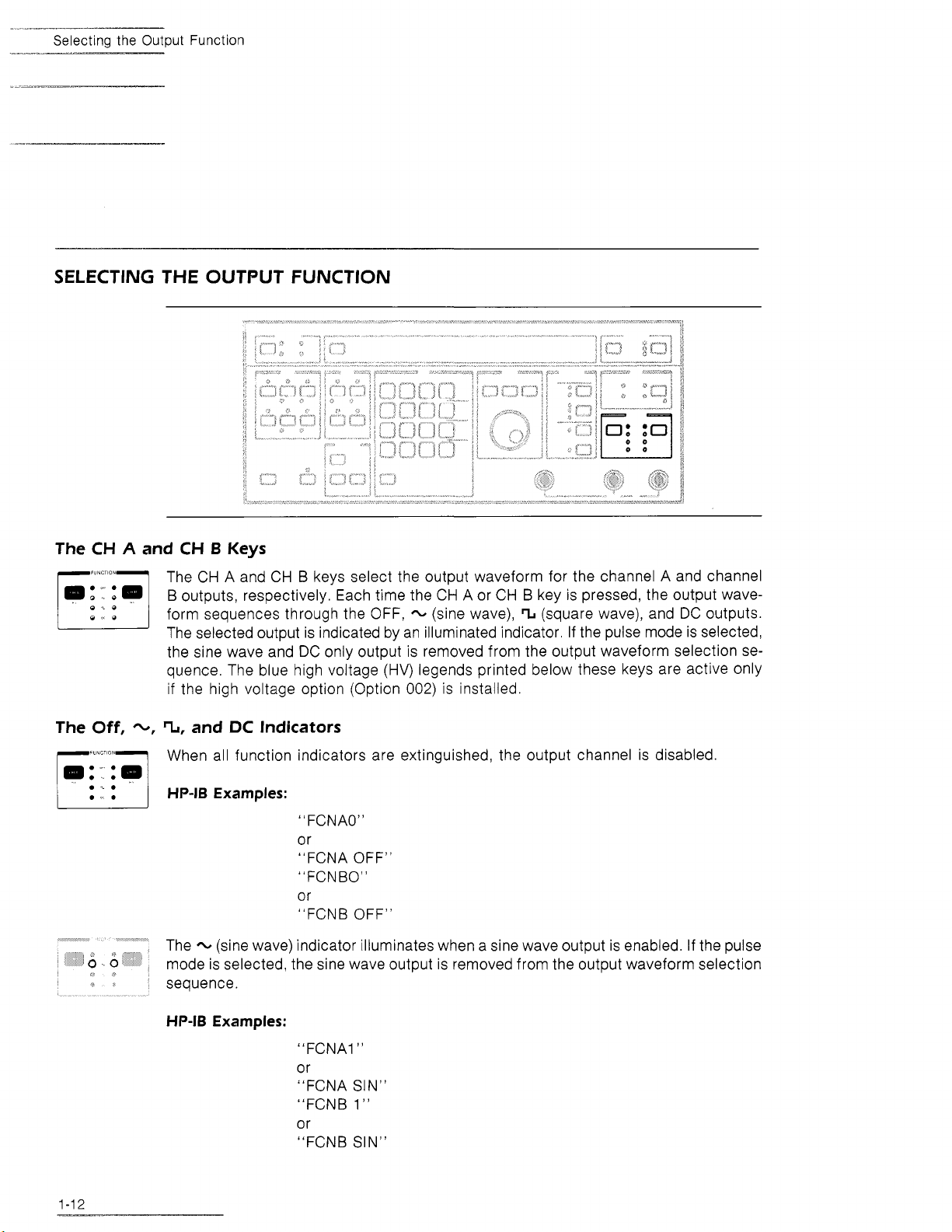

SELECTING THE OUTPUT FUNCTION

The

The

CH

Off,

A

and

CH

B

Keys

The CH A and CH B keys select the output waveform for the channel A and channel

B

outputs, respectively. Each time the CH A or CH B key is pressed, the output waveform sequences through the OFF,

The selected output is indicated by an illuminated indicator. If the pulse mode is selected,

the sine wave and DC only output is removed from the output waveform selection sequence. The blue high voltage (HV) legends printed below these keys are active only

if the high voltage option (Option

-,

TI,

and

DC

Indicators

When all function indicators are extinguished, the output channel is disabled.

HP-16 Examples:

"

FCNAO"

or

"FCNA OFF"

"FCNBO"

or

"FCNB OFF"

-

The

mode is selected, the sine wave output is removed from the output waveform selection

sequence.

(sine wave) indicator illuminates when a sine wave output is enabled. If the pulse

-

(sine wave), % (square wave), and DC outputs.

002)

is installed.

HP-I6 Examples:

"FCNA1"

or

"FCNA SIN"

"FCNB

or

"FCNB SIN"

1"

Page 23

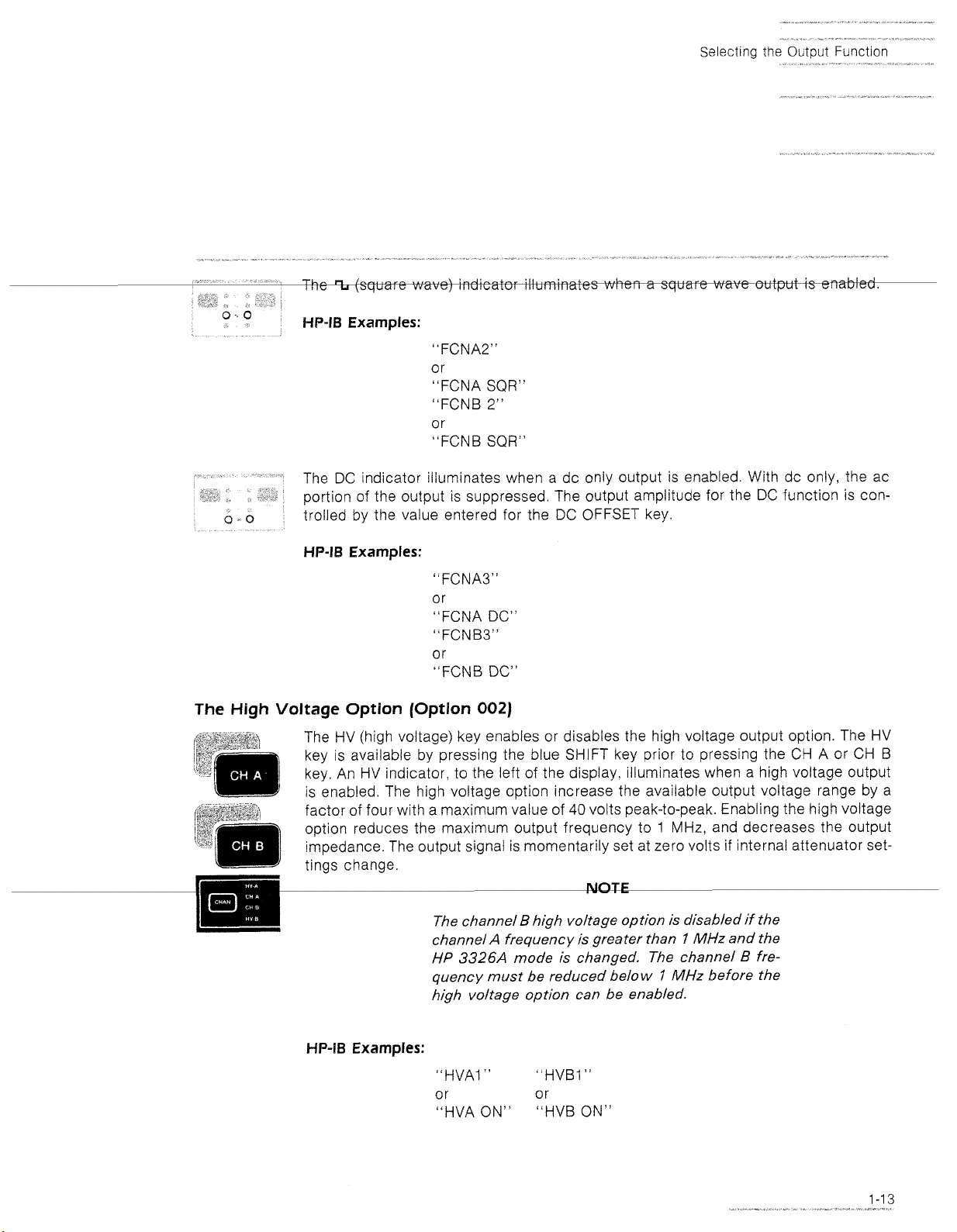

HP-18

Examples:

"

FCNA2"

Selectmg the

Output

Function

or

"FCNA SQR"

"FCNB

2"

or

"FCNB

SQR"

The DC indicator illuminates when a dc only output is enabled. With dc only, the ac

portion of the output is suppressed. The output amplitude for the DC function is controlled by the value entered for the DC OFFSET key.

The

HP-18

Examples:

High

Voltage Option (Option

The HV (high voltage) key enables or disables the high voltage output option. The HV

key is available by pressing the blue

key.

An

HV indicator, to the left of the display, illuminates when a high voltage output

is enabled. The high voltage option increase the available output voltage range by a

factor of four with a maximum value of

option reduces the maximum output frequency to

impedance. The output signal is momentarily set at zero volts if internal attenuator set-

tings change.

"FCNAS"

or

"FCNA DC"

"FCNBS"

or

"FCNB

DC"

002)

SHIFT

40

The channel B high voltage option is disabled if the

channel

HP

quency must be reduced below

high voltage option can be enabled.

A

frequency is greater than

3326A

mode is changed. The channel B fre-

key prior to pressing the CH A or CH

volts peak-to-peak. Enabling the high voltage

1

MHz, and decreases the output

WTE

I

MHz

and the

i'

MHz

before the

B

HP-IB

Examples:

"HVAI

"

"HVBI

"

or or

"HVA ON" "HVB ON"

Page 24

Data Entry and Modification

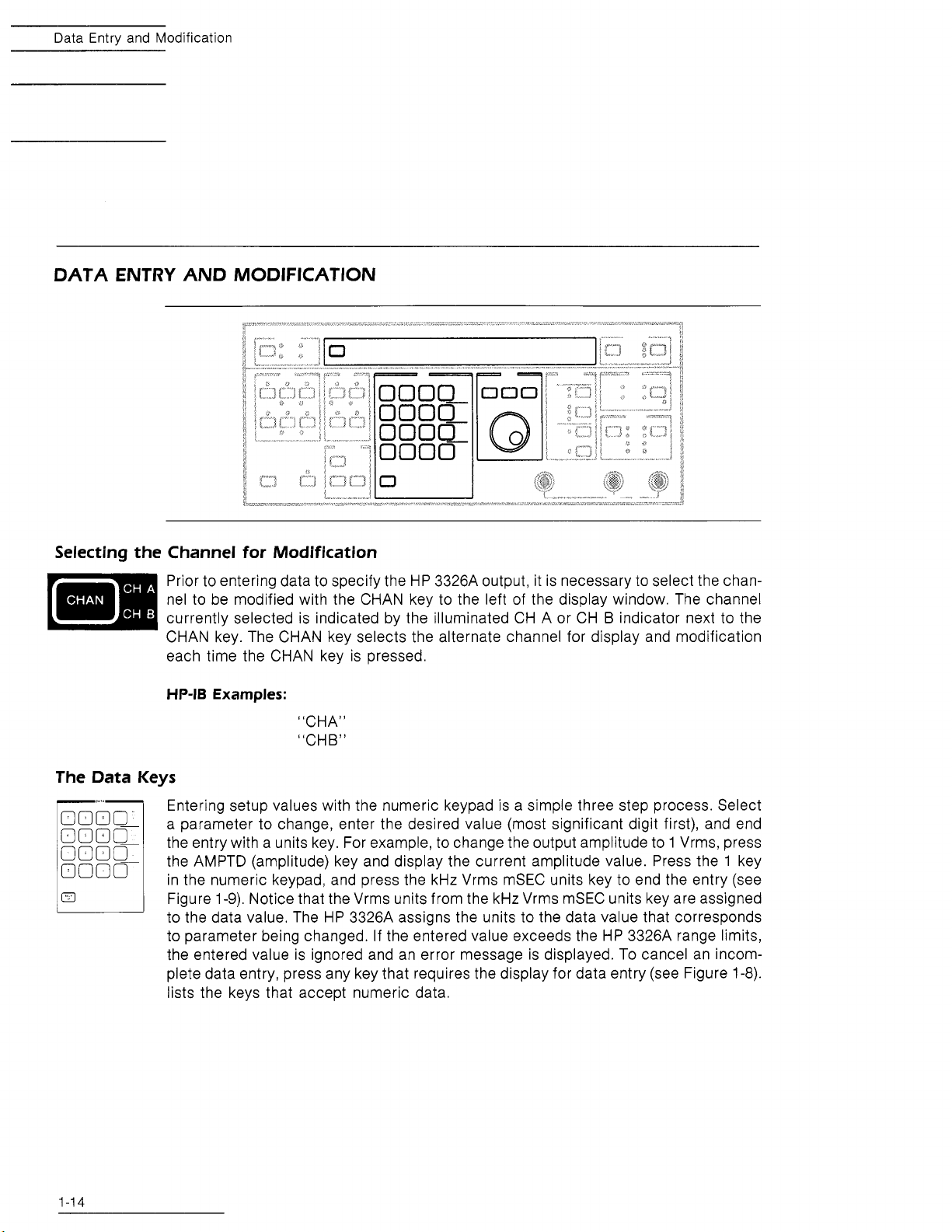

DATA ENTRY AND MODIFICATION

Selecting the Channel for Modification

Prior to entering data to specify the HP 3326A output, it is necessary to select the chan-

nel to be modified with the CHAN key to the left of the display window. The channel

currently selected is indicated by the illuminated CH A or CH

CHAN key. The CHAN key selects the alternate channel for display and modification

each time the CHAN key is pressed.

HP-IB

Examples:

"CHA"

"CHB"

The Data Keys

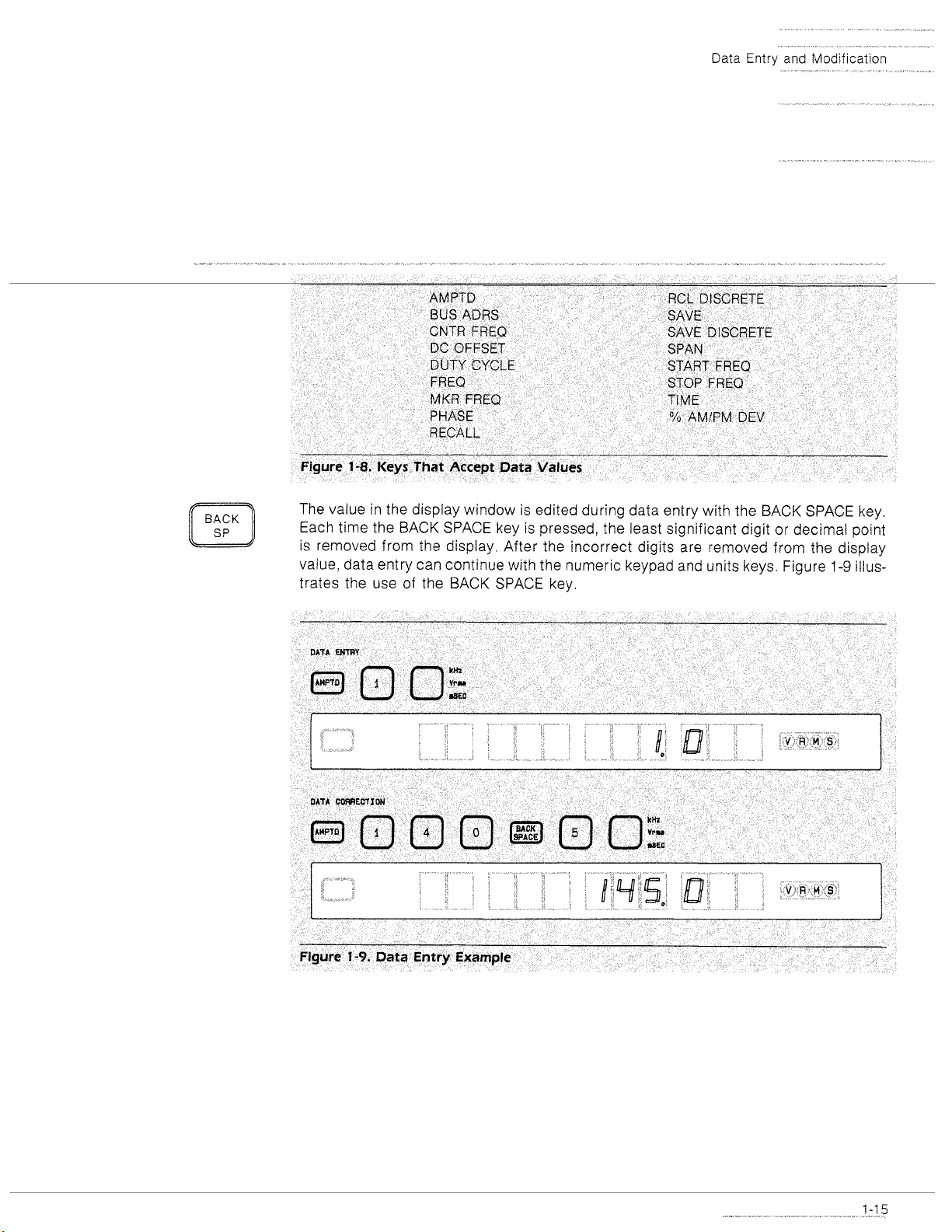

Entering setup values with the numeric keypad is a simple three step process. Select

a parameter to change, enter the desired value (most significant digit first), and end

the entry with a units key. For example, to change the output amplitude to 1 Vrms, press

the AMPTD (amplitude) key and display the current amplitude value. Press the 1 key

in the numeric keypad, and press the kHz Vrms mSEC units key to end the entry (see

Figure 1-9). Notice that the Vrms units from the kHz Vrms

to the data value. The HP 3326A assigns the units to the data value that corresponds

to parameter being changed. If the entered value exceeds the HP 3326A range limits,

the entered value is ignored and an error message is displayed. To cancel an incom-

plete data entry, press any key that requires the display for data entry (see Figure

lists the keys that accept numeric data.

B

indicator next to the

mSEC units key are assigned

1-8).

Page 25

Data

Entry

and Modif~cation

The value in the display window is edited during data entry with the BACK SPACE key.

Each time the BACK SPACE key is pressed, the least significant digit or decimal point

is removed from the display. After the incorrect digits are removed from the display

1-9

value, data entry can continue with the numeric keypad and units keys. Figure

illus-

trates the use of the BACK SPACE key.

L

Figure

1-9.

Data

Entry

Example

I

Page 26

Data Entry and Modification

Error

Messages

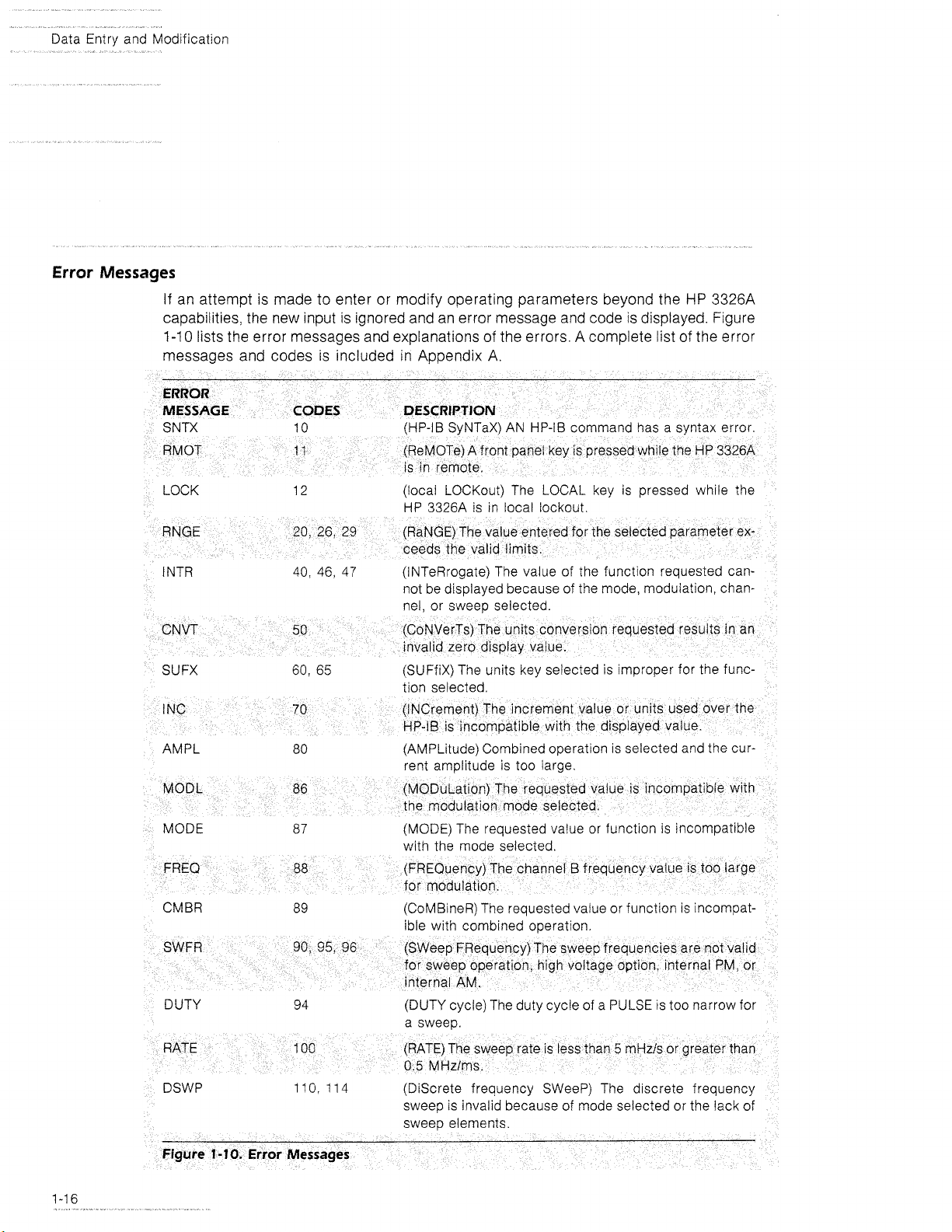

If an attempt is made to enter or modify operating parameters beyond the

capabilities, the new input is ignored and an error message and code is displayed. Figure

1-1

messages and codes is included

LOCK 12 (local LOCKout) The LOCAL key is pressed while the

1

NTR 40, 46, 47

SUFX 60, 65

HP

3326A

0

lists the error messages and explanations of the errors. A complete list of the error

in

Appendix A.

IS

rn

HP 3326A

(INTeRrogate) The value of the functron requested cannot be displayed because of the mode, modulation, channel, or sweep selected.

(SUFfiX) The units key selected is improper for the function selected

local lockout

AMPL 80 (AMPLltude) Combined operation is selected and the cur-

rept amolitude is too larae

MODE 87 (MODE) The requested value or function is incompatible

with the mode selected.

CMBR 89 (CoMBineR) The requested value or function is incompat-

ible with combined operation.

DUTY

DSWP

94

110,

114

(DUTY cycle) The duty cycle of a PULSE

a sweeo.

(Discrete frequency SWeeP) The d~screte frequency

sweep

is

invalid because of mode selected or the lack of

sweeD elements.

IS

too narrow

for

Page 27

Data Entry and Modification

--

-*

-

DSHV

DSML

DSMD 117 (Discrete Sweep

P

OF

115

116

123

130, 136,

CRPT

160

(Discrete Sweep High Voltage) The high voltage option is

enabled and a discrete frequency element frequency ex-

1

ceeds

(Discrete Sweep ModuLation) Tee chanqel B frequency

exceeds ihe

kHz internal AV lrmit dcirir,g a discrete frequency sweep.

ments in memory are incom~atible with the mode selected.

(Phase OFfset) Cannot cfear phase offset of channel A.

138 (High Voltage) The high voltage (HV) option cannot be ena-

bled because the output frequency 1s qreater than

(CoRruPT) An error is detected in an instrument state

recalled from memory. The instrument state is replaced

(B

impedance for the channel

MHz.

5

OverLoad) The channel B output

kHz rnternal Pm limit or exceeds tne 100

MoDe) The discrete frequency sweep ele-

1

MHz,

IS

overloaded The load

B

output is too low or a volt-

AVCO 173 (channel A Voltage Controlled Oscillator) The channel A

voltaqe controlled oscrllator is unlocked

sensed, but the HP

MCAL

PCAL 191 (Phase CALibration) A phase calibration is unsuccessful

L

ACA

OCAL

PASS

L

FA1

192

192

193-1 94

-

(Mod~lation CAL~Dration) An internal AM or

is ~nsuccessful.

(Amplitude CALibration) An amplitude call~ration is

successfu!.

(Offset CALibration)

A self test is successfvl.

A self test is unsuccessful.

3326A cannot lock to it

A

dc offset calibration

PM

calibration

is

unsuccessful

un-

Page 28

Data Entry and Mod~f~cation

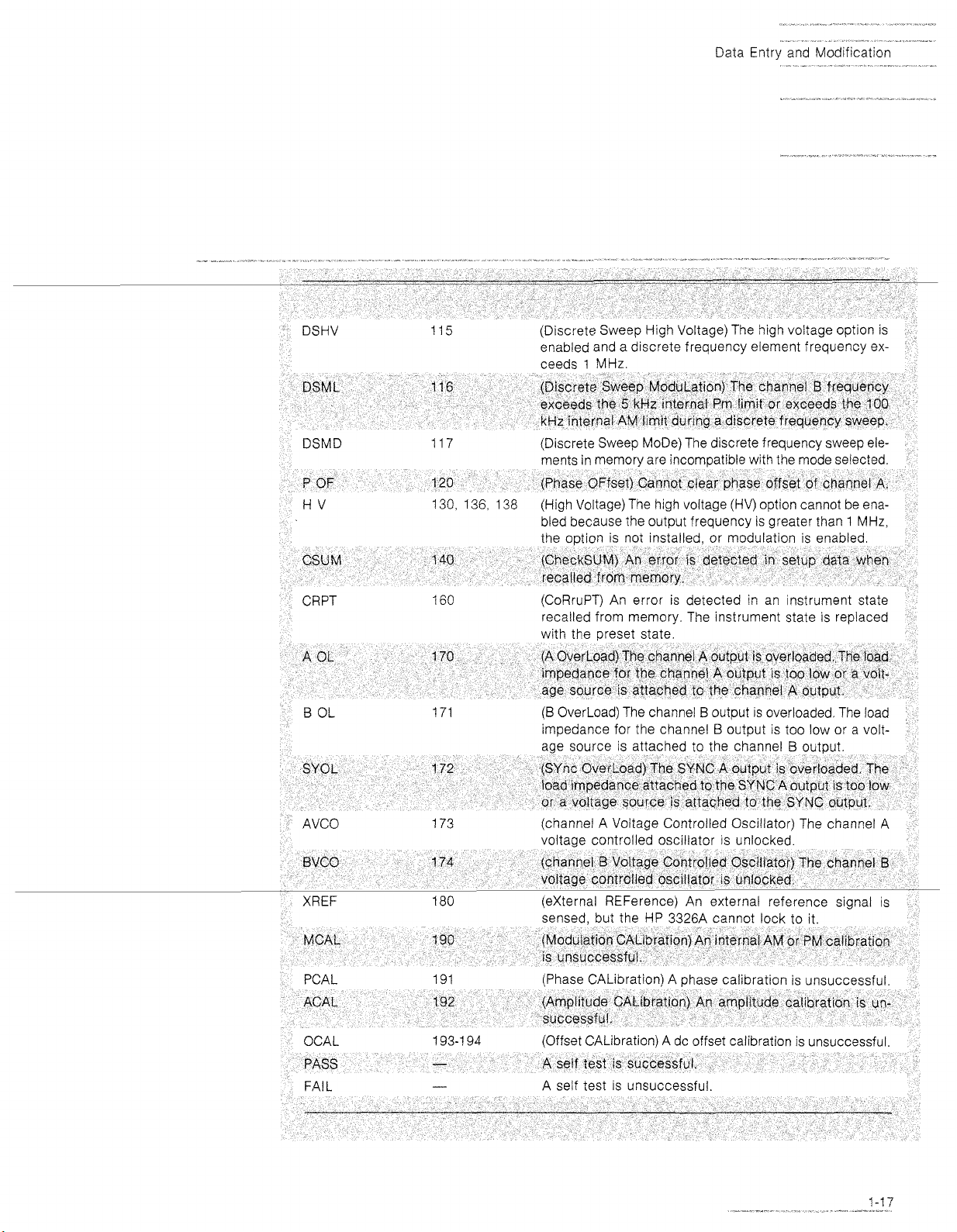

Viewing Setup Parameters

The current value of a setup parameter is displayed when a front panel key that accepts entries from the keypad (such as the FREQ or AMPTD key) is pressed. Figure

1-8

lists the front panel keys that accept entries from the keypad. Selecting one of these

keys does not alter the current setup values. An error message is displayed if the key

pressed is inactive for the mode selected. Pressing the CHAN key alternates the display between the channel A and B values for the parameter selected.

Units Conversion

The units keys, in addition to ending data entry, can perform units conversion on dis-

played values. Pressing a units key converts the value to the equivalent value for the

units key pressed. For example, if the display value is in

units key converts the display value to dBV. Converting units does not alter the current

setup. The message "Error

results in a zero display value that is inconsistent with the current value. For example,

converting 0.000001

units conversion.

Hz

to

dBm, pressing the dBV

50

CNVT" (CoNVerT) is displayed if the conversion would

MHz

would erroneously display 0

MHz,

Figure 1-1 1 illustrates

O/O

Figure

1-1

1.

Units Conversion

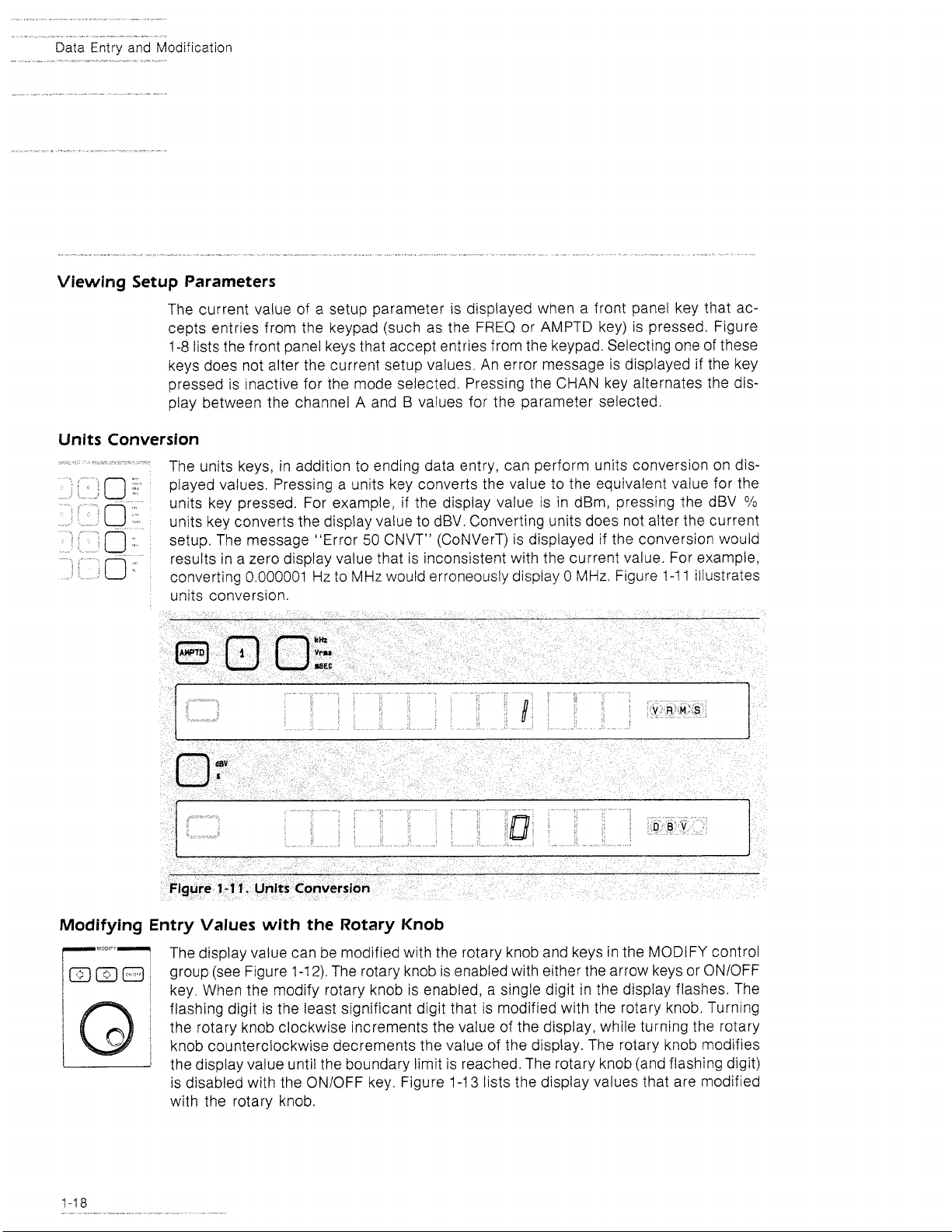

Modifying Entry Values with the Rotary Knob

The display value can be modified with the rotary knob and keys in the MODIFY control

group (see Figure

key. When the modify rotary knob is enabled,

flashing digit is the least significant digit that is modified with the rotary knob. Turning

the rotary knob clockwise increments the value of the display, while turning the rotary

l

knob counterclockwise decrements the value of the display. The rotary knob modifies

the display value until the boundary limit is reached. The rotary knob (and flashing digit)

is disabled with the

with the rotary knob.

1-1

2).

The rotary knob is enabled with either the arrow keys or ONIOFF

ONIOFF key. Figure

a

single digit in the display flashes. The

1-1

3

lists the display values that are modified

I

Page 29

Data

Entry

and Mod~fication

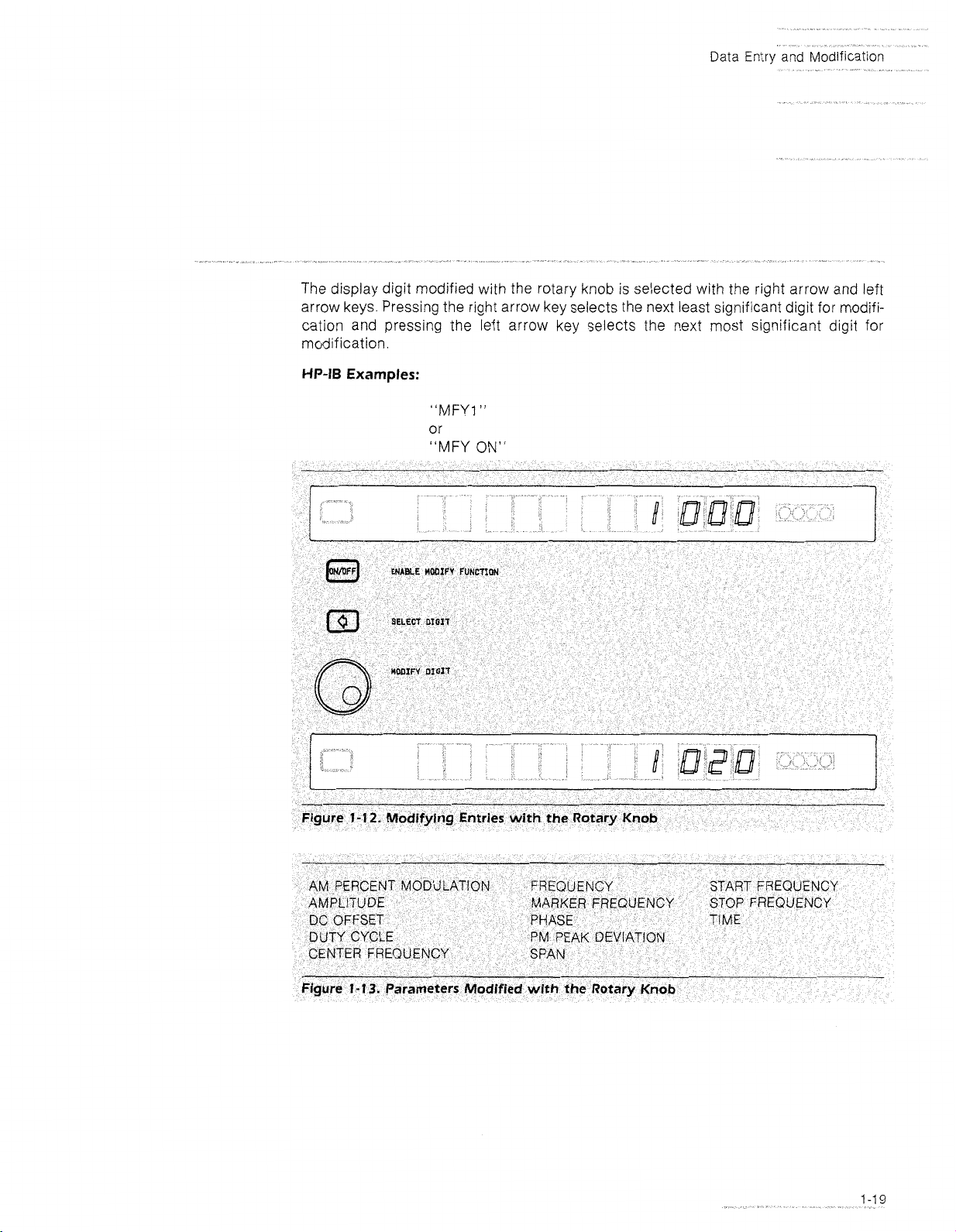

The display digit modified with the rotary knob

is

selected with the right arrow and left

arrow keys. Pressing the right arrow key selects the next least significant digit for modification and pressing the left arrow key selects the next most significant digit for

modification.

HP-IB

Examples:

"MFY1

"

or

"MFY

ON"

Figure

1-12.

Modifying Entries with the Rotary

Knob

Page 30

---

The

Entry

Keys

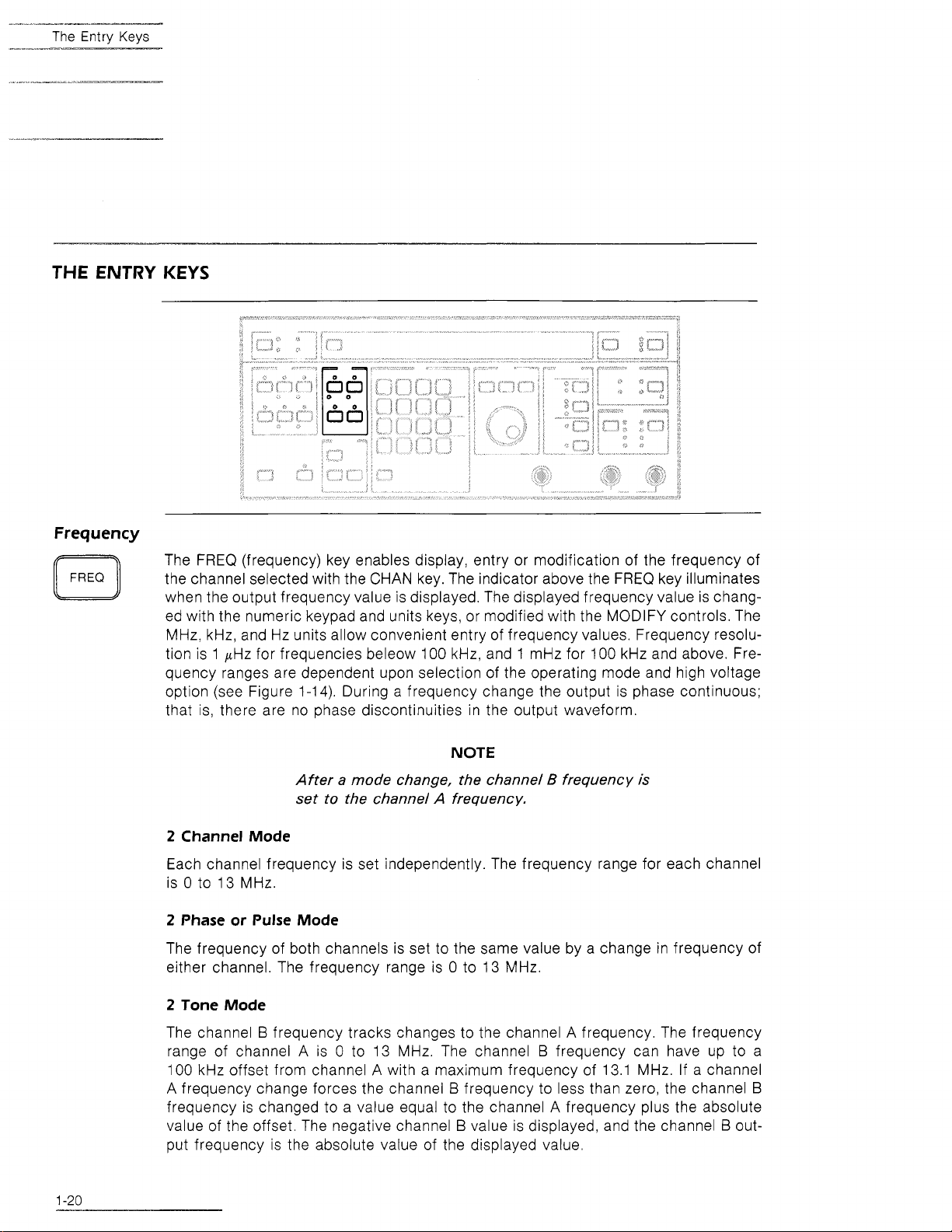

THE ENTRY KEYS

Frequency

The FREQ (frequency) key enables display, entry or modification of the frequency of

the channel selected with the CHAN key. The indicator above the FREQ key illuminates

when the output frequency value is displayed. The displayed frequency value is chang-

ed with the numeric keypad and units keys, or modified with the MODIFY controls. The

MHz, kHz, and Hz units allow convenient entry of frequency values. Frequency resolution is 1

pHz for frequencies beleow 100 kHz, and 1 mHz for 100 kHz and above. Frequency ranges are dependent upon selection of the operating mode and high voltage

option (see Figure 1-14). During a frequency change the output is phase continuous;

that is, there are no phase discontinuities in the output waveform.

NOTE

After a mode change, the channel B frequency

set to the channel A frequency.

2 Channel Mode

is

Each channel frequency is set independently. The frequency range for each channel

0

to 13 MHz.

is

2 Phase or Pulse Mode

The frequency of both channels is set to the same value by a change in frequency of

0

either channel. The frequency range is

to 13 MHz.

2 Tone Mode

The channel B frequency tracks changes to the channel A frequency. The frequency

0

range of channel A is

100 kHz offset from channel

A frequency change forces the channel

to 13 MHz. The channel B frequency can have up to a

A

with a maximum frequency of 13.1 MHz. If a channel

B

frequency to less than zero, the channel

B

frequency is changed to a value equal to the channel A frequency plus the absolute

B

value of the offset. The negative channel

value is displayed, and the channel B out-

put frequency is the absolute value of the displayed value.

Page 31

The

Entry

Keys

The frequency range of channel A is 0 to

is 0 to

Internal Amplitude Modulation

The frequency range of channel

is

HV Option

0

to

5

kHz.

I00 kHz.

A is

0

to

13

13

MHz.

The frequency range of channel

MHz.

The frequency range of channel

With the high voltage option enabled, the frequency output is 0 to

2

TONE

mode, the maximum channel B frequency is

HP-I6 Example:

NOTE

After a mode change, the channel B frequency is

set to the channel

quency is set to greater than

B

high voltage option is disabled, To enable the high

voltage option, reduce the channel B frequency to

I

below

MHz.

A

frequency. If the channel 5 fre-

I

MHz,

1

.I

MHz.

the channel

"FR7.500003MHZ"

1

MHz.

B

B

In the

Page 32

The Entry Keys

Amplitude

The AMPTD (amplitude) key enables display, entry, or modification of the amplitude

of the channel selected with the CHAN key. The indicator above the AMPTD key illuminates when an amplitude value is displayed. The displayed amplitude value is

changed with the numeric keypad and units keys, or modified with the MODIFY controls. The VOLTS, Vrms,

The amplitude range without dc offset is from

(4

mV peak-to-peak to 40 V peak-to-peak with high voltage enabled). The amplitude range

dBm, and dBV units allow convenient entry of amplitude values.

1

mV peak-to-peak to

10

V peak-to-peak

is dependent upon selection of COMBINED operation, internal modulation, dc offset,

and high voltage option (see Figure

1-1

5).

The output signal is momentarily set at zero

volts if internal attenuator settings change.

Internal Modulation

With internal modulation, the channel B amplitude is controlled by the % AMlPM DEV

key. Internal modulation uses the channel B output internally and a signal is unavailable at the CH B connector.

High

Voltage Option

With the high voltage option, the upper amplitude limit is increased to 40 volts peak-to-

4

peak and the lower amplitude limit is increased to

output needs to be enabled prior to entering voltage values greater than

Combined

mV peak-to-peak. The high voltage

10

volts.

For COMBINED operation, the output of channel B is diverted and summed with the

(6.02

channel A output. The amplitude limit of each channel is reduced by 50%

The upper amplitude limit for COMBINED operation is

rt

5

volts

(2

20 volts with the

dB).

high voltage option enabled). Note that the output amplitude level is dependent upon

phase, frequency, and amplitude values.

Page 33

DC

The Entry Keys

Offset

The limit for an ac output with a dc offset is

1-1

6

high voltage option enabled). Figure

HP-IB

Example

"AM1

.125VOH

illustrates dc offset versus amplitude.

t

5

volts peak

(k

20

volts peak with the

Page 34

*

The

DC

OFFSET

c3

-"

Entry

Keys

Offset

The DC OFFSET key enables display, entry, or modification of the dc offset of the channel

1-17).

selected with the CHAN key (see Figure

key illuminates when a dc offset value is displayed. The displayed dc offset value is

changed with the numeric keypad and VOLTS units key, or modified with the MODIFY

controls. The maximum dc offset range is

option enabled). The dc offset range is dependent upon amplitude, and selection of combined operation, internal modulation, and high voltage option. Figure

HP

imum output of the

nal attenuator settings change.

3326A.

The output signal is momentarily set at zero volts if inter-

The indicator above the DC OFFSET

+

5

volts

(-+

20

volts with the high voltage

1-1

5

lists the max-

STEP

STEP

1

2

Page 35

The Entry Keys

AC

with

DC

Offset

The maximum dc offset is a function of the selected ac amplitude. The maximum am-

+

5

plitude for ac plus dc is

versus amplitude (with combined operation, internal modulation, and high voltage option disabled) is illustrated in Figure 1-16. The maximum ac and dc outputs and maxi-

mum dc offsets for the

volts peak

HP

3326A are:

(+

20 with the high voltage option). DC offset

AC AMPLITUDE

1.0 to 10 Vpp

0.1

to 1.0 Vpp

10 to 100 mVpp

1 to 10 mvpp 55 mV t4.5 mV

DC

Only

With the output FUNCTION set to DC, the output level is controlled by DC OFFSET entries. The maximum dc output is

Cornblned

For COMBINED operation with a sine wave, square wave, or OFF output FUNCTION

selected, the dc offset is set to zero.

High Voltage Option

With the high voltage option enabled, the dc offset range is + 20 volts (ac + dc peak

value or dc only). DC offset with the high voltage option is independent of the ac amplitude except that the combination of ac plus dc cannot exceed

Internal Modulation

With internal modulation, the channel B dc offset is disabled.

HP-IB Example

MAXIMUM AC

+

5.0 V k4.5 V

+

0.5 V

+

50 mV

+

5

volts peak

+

DC MAXIMUM DC OFFSET

t

0.45 V

5

45 mV

(+

20 with the high voltage option).

+

20 volts.

"OF3VO"

Page 36

Phase

STEP

STEP

STEP

The PHASE key enables display, entry, or modification of the phase of the channel

selected with the CHAN key. The indicator above the PHASE key illuminates when a

phase value is displayed. The displayed phase value is changed with the numeric keypad and DEG

display range is

degrees entered through the keypad are accepted and the value is displayed modulo

720. The effect of the phase offset is dependent upon selection of the operating mode.

Figure

1

2

3

(DEGrees) units key, or modified with the MODIFY controls. The phase

a

720 degrees with a resolution of 0.01 degrees. Phase values of

1-18

illustrates the effect of changing phase.

i:

1440

2

Channel

Changing phase in the 2 CHANNEL mode changes the phase of a channel with respect

to the initial waveform. The phase of channel A and

2

Phase Mode

Without an external phase reference, a change in the phase of channel A is made with

respect to the initial channel

in the phase of channel A is made with respect to the external reference. Channel

uses channel A as the phase reference, and a change to the channel B phase is made

with respect to the current channel A waveform.

Mode

B

are independent.

A

waveform. With an external phase reference, a change

B

Page 37

The

Entry

Keys

2

Tone Mode

Changing phase in the 2 TONE mode changes the phase of a channel with respect to

B

the initial waveform. The phase of channel A and

are independent.

Pulse Mode

A change in the phase of channel A is made with respect to the initial channel A wave-

B

form. The channel

to display the channel

output is the complement of the channel A output. An attempt

B

phase results in the display of the "Error

47

INTR" (INTeR-

rogate) message.

Asgn

Clr

C$

Zero

C$

Offset

The ASGN ZERO 4 (ASSIGN ZERO phase) key asslgns zero to the phase offset between

channel A and

ing the phase of the output waveforms The ASGN ZERO

the blue SHIFT key prior to the PHASE key

phase value

summed modulo

assignments

The stored phase offset value

offset) indicator illuminates when a phase offset value

B

(or between channel A and an external phase reference) wlthout chang-

4

key

IS

selected by pressmg

If

channel A

IS

changed to zero If channel B is selected, the phase offset value

720

and stored in an internal phase offset regrster

of zero phase sums the

displayed

IS

recalled with the

phase value into the phase offset register

CLR

IS

selected, the channel A

Subsequent

OFS key The OFS (phase

IS

stored

IS

HP-IS Example

"ZPH"

The CLR p OFS (CLeaR phase OFfSet) key restores the channel B phase offset value

to the display without chang~ng the phase of the output waveforms. If the current channel

B

phase value is nonzero, the phase offset is summed to the phase value modulo

720

The CLR 4 OFS key is selected by pressing the blue SHIFT key prior to the

DC

OFFSET key The CLR 4 OFS key extinguishes the 4 OFS indicator Pressing the CLR

4

OFS key with channel A selected displays the message "Error 120 P OF" (Phase

OFfset).

HP-IB Example

"COF"

Page 38

The

Duty

Entrv

Cycle

iL:

(~~

,~

Keys

(Pulse

Width)

The DUTY CYCLE key enables display, entry, or modification of the duty cycle of the

A

pulse mode channel

waveform. The DUTY CYCLE key is selected by pressing the

blue SHIFT key prior to the FREQ key. The DUTY CYCLE indicator illuminates when

the duty cycle value is displayed. After selection of the DUTY CYCLE key, the duty cycle

value is changed with the numeric keypad and

controls. The duty cycle range is from 1

width of 20 nanoseconds. The resolution of the duty cycle is 0.01

O/O

units key, or modified with the MODIFY

O/O

to 99% of the period with a minimum pulse

O/O.

The duty cycle

remains constant for changes in frequency provided the pulse width is greater than

20 nanoseconds. Figure 1-19 illustrates the effect on changes in duty cycle.

HP-IS

Example

STEP

STEP

STEP

1

2

3

Page 39

Linear Frequency Sweep

LINEAR FREQUENCY

Linear sweeps are phase continuous over the full frequency range; that is, there are

no phase discontinuities in the swept output waveform. Single or continuous (see Figure

-20),

and ramp or triangle (see Figure 1-21) linear sweeps are selectable. Linear sweep

1

parameters are entered with the START FREQ (START FREQuency), STOP FREQ (STOP

FREQuency), CNTR FREQ (CeNTeR FREQuency), SPAN, TIME, AND MKR-CF keys.

The MKR FREQ (MarKeR FREQuency) key allows the rear panel TTL level MARKER

OUT (MARKER OUTput) signal to be specified.

SWEEP

Page 40

Single Sweep

Sweep

The SINGLE key initiates a single linear sweep. The indicator above the SINGLE key

illuminates when a single sweep is in progress. With a ramp sweep selected (i.e. TRIANGLE indicator extinguished), the SINGLE key initiates a sweep from the start frequency to the stop frequency over the specified sweep time. Upon reaching the stop

frequency, the frequency is quickly changed to the start frequency. With a TRIANGLE

sweep selected, the SINGLE key initiates a sweep from the start frequency to the stop

frequency over the specified sweep time. The stop frequency is maintained until the

SINGLE key is pressed. Pressing the SINGLE key initiates another sweep from the stop

frequency to the start frequency.

HP-IB Example:

Continuous Sweep

The CONT (CONTinuous) key initiates a continuous linear sweep. The indicator above

the CONT key illuminates when a continuous sweep is in progress. With a ramp sweep

selected (i.e. TRIANGLE indicator extinguished), the CONT key initiates

sweep from the start frequency to the stop frequency over the specified sweep time.

Upon reaching the stop frequency, the frequency is quickly changed to the start fre-

quency in preparation for the next sweep. With a TRIANGLE sweep selected, the CONT

key initiates a repetitive sweep from the start frequency to the stop frequency and back

to the start frequency. Each sweep (from either the start frequency to stop frequency,

or from stop frequency to start frequency) is over the specified sweep time.

HP-16 Example:

"SS"

"SC"

a.

repetitive

Page 41

Page 42

Linear Frequency Sweep

Start Frequency

START

The START FREQ (START FREQuency) key enables display, entry, or modification of

the linear sweep start frequency of the channel selected with the CHAN key. The indicator above the START FREQ key illuminates when a start frequency value is displayed.

The displayed frequency value is changed with the numeric keypad and units keys, or

modified with the MODIFY controls. The MHz, kHz, and Hz units allow convenient entry

of frequency values. Frequency resolution is

1

pHz for frequencies below 100 kHz and

1 mHz for frequencies above 100 kHz. Start frequency values may be greater than the

stop frequency values for a sweep from a high frequency to a low frequency.

2

Channel Mode

Each channel start frequency is set independently. The frequency range of each chan-

nel is 0 to 13 MHz.

2

Phase or Pulse Mode

The start frequency of both channels is set to the same value by a change in start fre-

quency of either channel. The frequency range is 0 to 13 MHz.

2

Tone Mode

The channel B start frequency tracks changes to the channel A start frequency. The

A

channel

have up to a 100 kHz offset from channel

If

a channel A frequency change forces the channel B frequency to less than zero, the

channel

start frequency range is 0 to 13 MHz. The channel B start frequency can

A

with a maximum frequency of 13.1 MHz.

B

frequency is displayed as a negative value while the channel B output fre-

quency is the absolute value of the displayed value.

Internal Phase Modulation

The start frequency range of channel A is 0 to 13 MHz. The start frequency range of

channel

Internal Amplitude Modulation

B

is 0 to 5 kHz.

The start frequency range of channel A is 0 to 13 MHz. The start frequency range of

channel

HV Option

B

is 0 to 100 kHz.

With the high voltage option enabled, the start frequency range is 0 to 1 MHz. In the

2 TONE mode, the maximum channel

HP-16 Example:

B

start frequency is 1.1 MHz.

"ST1.512525KHZ"

Page 43

Linear Frequency

Sweep

The STOP FREQ (STOP FREQuency) key enables display, entry, or modification of the

linear sweep stop frequency of the channel selected with the CHAN key. The indicator

above the STOP FREQ key illuminates when

a

stop frequency value is displayed. The

displayed frequency value is changed with the numeric keypad and units keys, or modified with the MODIFY controls. The MHz, kHz, and Hz units allow convenient entry of

frequency values. Frequency resolution is 1 pHz for frequencies below 100 kHz and

1 mHz for frequencies above 100 kHz.

2

Channel Mode

Each channel stop frequency is set independently. The frequency range of each channel is 0 to 13 MHz.

2

Phase or Pulse Mode

The stop frequency of both channels is set to the same value by a change in stop fre-

quency of either channel. The frequency range is 0 to 13 MHz.

2

Tone Mode

The channel B stop frequency tracks changes to the channel A stop frequency. The

stop frequency range of channel A is 0 to 13 MHz. The channel

B

stop frequency can

have up to a 100 kHz offset from channel A, wit'h a maximum frequency of 13.1 MHz.

B

If a channel A frequency change forces the channel

B

channel

frequency is changed to a value equal to the channel A frequency plus the

frequency to less than zero, the

absolute value of the offset.

Internal Phase Modulation

The stop frequency range of channel A is 0 to 13 MHz. The stop frequency range of

channel

Internal Amplitude Modulation

B

is 0 to 5 kHz.

The stop frequency range of channel A is 0 to 13 MHz. The stop frequency range of

channel

HV

B

Option

is 0 to 100 kHz.

With the high voltage option enabled, the stop frequency range is 0 to 1 MHz. In the

2

TONE mode, the maximum channel B frequency is 1.1 MHz.

HP-16 Example:

"SP7.512525KHZ"

Page 44

Linear

Time

Frequency

Sweep

The TlME key enables display, entry, or modification of the linear sweep time for both

channels. The indicator above the TIME key illuminates when a time value is displayed.

The displayed time value is changed with the numeric keypad and units keys, or modi-

fied with the MODIFY controls. The SEC and mSEC units keys end entry of numeric

1000

values. The time range is 5 milliseconds to

seconds, with a resolution of 1 mil-

lisecond.

HP-IB Example:

"ST1 M25MS"

Marker Frequency

The MKR FREQ (MarKeR FREQuency) key enables display, entry, or modification of

the marker frequency of the channel selected with the CHAN key. The indicator above

the MKR FREQ key illuminates when the marker frequency value is displayed. The dis-

played frequency value is changed with the numeric keypad and units keys, or modified with the MODIFY controls. The MHz, kHz, and Hz units allow convenient entry of

frequency values. Frequency resolution is

1 mHz for frequencies above 100 kHz. Only one marker is available.

For a marker signal to be generated, the MKR FREQ must be within 3 milliseconds of

the start or stop frequency. The following equation may be used to determine the approximate marker offset from the start or stop frequency:

I

pHz for frequencies below 100 kHz and

NOTE

When different start or stop frequencies are entered

for each channel, selecting alternate channels can

have the apparent effect of changing the marker

frequency, Although the marker occurs at the same

time, each channel may have a unique frequency

at that time.

x

MARKER OFFSET

1

0.003

SPAN

SWEEP TlME

The marker value is accepted and the message "Error 24 RNGE" is displayed if the

marker value is outside the sweep frequency span. The Z-BLANK output is coincident

with the start and stop frequencies and may be used for the marker of these frequencies.

HP-1B Example:

Page 45

Triangle

Linear Frequency Sweep

The TRIANGLE key selects either a triangle or ramp sweep. The TRIANGLE key is

selected by pressing the blue SHIFT key prior to the MKR FREQ key. The TRIANGLE

indicator is illuminated when a triangle sweep is selected, and extinguished when a

ramp sweep is selected.

HP-If3

Examples:

"SMI

"

"SM2"

or or

"SM RAMP" "SM TRGL"

STEP

STEP

STEP

1

Z

3

STEP

4

Page 46

L~near

Frequency

Sweep

Reset

Span

Sweep

.

,

B

,,

The RESET SWP (RESET SWeeP) key resets the sweep circuits to the start of the sweep.

During reset, the HP 3326A also checks the sweep limits.

HP-I6 Example:

"SRE"

The SPAN key enables display, entry, or modification of the total linear sweep frequency

span of the channel selected with the CHAN key. The SPAN key is available by pressing the blue SHIFT key prior to pressing the STOP FREQ (STOP FREQuency) key. The

SPAN key, with the CNTR FREQ (CeNTeR FREQuency) key, provides an alternate entry

for the frequency sweep start and stop values. The SPAN indicator illuminates when

SPAN is selected and the SPAN value is displayed. The displayed frequency span value

is changed with the numeric keypad and units keys, or modified with the MODIFY controls. The MHz, kHz, and Hz units allow convenient entry of frequency values. Frequency

resolution is 1

pHz for frequencies below 100 kHz and 1 mHz for frequencies above

100 kHz.

NOTE

Frequency spans must be consistent with the operating limits and the value entered for the center frequenc y. Excessive frequency spans are s ymmetrica//y reduced around the current center frequency

to bring the start or stop frequencies within limits.

2

Channel Mode

The frequency span of each channel is set independently. The frequency range of each

channel is 0 to 13 MHz,

2

Phase

or

Pulse Mode

The frequency span of both channels is set to the same value by a change in the fre-

0

quency span of either channel. The frequency range is

2

Tone Mode

to 13 MHz.

The frequency span range for channel A is 0 to 13 MHz. Changing the channel A frequency span also changes the channel

current start and stop frequency offsets. The channel

B

center frequency and span to maintain the

B

frequency span may be set

so that the start and stop frequencies are within 100 kHz of the channel A start and

B

stop frequencies. If a channel A frequency change forces the channel

less than zero, the channel

B

channel

frequency.

B

output frequency is changed to the absolute value of the

frequency to

Page 47

HV Option

Linear Frequency

NOTE

The difference (offset) between the channelA and

B

frequencies will normally change during a sweep

to maintain the offsets entered for the sweep start

and stop frequencies. If a constant offset is desired,

there must be a constant offset between the start

and stop frequency values for channel

A

and

5.

Sweep

With the high voltage option enabled, the maximum frequency span is 1 MHz. In the

2

TONE

mode, the maximum channel B frequency span is 1.1 MHz.

HP-IB Example:

Center Frequency

The CNTR FREQ (CeNTeR FREQuency) key enables display, entry, or modification of

the linear sweep center frequency of the channel selected with the CHAN key. The

CNTR FREQ key is available by pressing the blue SHIFT key prior to the START FREQ

key. The CNTR FREQ key, along with the SPAN key, provides an alternate entry of the

frequency sweep start and stop values.

The displayed frequency value is changed with the numeric keypad and units keys, or

modified with the MODIFY controls. The MHz, kHz, and Hz units allow convenient entry

of frequency values. The frequency resolution is 1

and 1 mHz for frequencies above 100 kHz. If the center frequency causes the sweep

start or stop frequency to exceed the HP

Z

Channel Mode

The center frequency of each channel is set independently. The frequency range of

each channel is 0 to 13 MHz.

2

Phase or Pulse

The center frequency of both channels is set to the same value by a change in center

frequency of either channel. The frequency range is 0 to 13 MHz.

pHz for frequencies below 100 kHz

3326A limits, the frequency span is reduced,

Mo

2

Tone Mode

The channel A center frequency has the range of 0 to 13 MHz. The start and stop frequencies of channel

maintain the current offset. The channel

offset from channel

100 kHz of the channel

HP-IS Example:

B

tracks changes to the channel A start and stop frequencies to

B

center frequency can have up to a 100 kHz

A

providing the channel B start and stop frequencies are within

A

start and stop frequencies.

"CF5.512525KHZ"

Page 48

L~near Frequency Sweep

Marker to Center Frequency

The MKR

quency set for the marker, The MKR

key prior to the

quency limits, the frequency band is reduced.

2

Channel Mode

The center frequency of each channel is set independently. The frequency range of

each channel is

2

Phase or Pulse Mode

The center frequency of both channels is set to the same value by a change in the

center frequency of either channel. The frequency range is 0 to 13 MHz.

2

Tone Mode

The channel A center frequency has the range of 0 to 13 MHz. The start and stop frequencies of channel

maintain the current offset. The channel

offset from channel

100 kHz of the channel

HP-IB

--

CF (MarKeR to Center Frequency) key centers the sweep band on the fre-

-

CF key is selected by pressing the blue SHIFT

CONT

Example:

key. If either the sweep start or stop frequency exceeds the fre-

0

to 13 MHz.

B

tracks changes to the channel A start and stop frequencies to

B

center frequency can have up to a 100 kHz

A

providing the channel B start and stop frequencies are within

A

start and stop frequencies.

"CFM"

Page 49

DISCRETE FREQUENCY SWEEP

D~screte Frequency Swee~

Discrete

Recall

Discrete

During a discrete frequency sweep, the HP 3326A sequences through the discrete frequency sweep elements (channel

volatile memory with the SAVE DISCRETE key (see Figure 1-22). Discrete frequency

sweep element frequencies are entered with the FREQ

times are entered with the TlME key. The HP 3326A always sequences through the

discrete frequency sweep elements from element

SINGLE sweep selected, the HP 3326A sequences through the elements each time

the SINGLE key is pressed. With CONT sweep selected, the HP

through the elements continuously. The message "Error 11

SWeeP) is displayed if no discrete frequency sweep elements are stored in memory.

Selecting TRIANGLE for a discrete frequency sweep cancels the discrete frequency

sweep and selects a linear sweep.

The DISCRETE key enables and disables discrete frequency sweeps. The DISCRETE

key is available by pressing the blue SHIFT key prior

DISCRETE indicator illuminates when discrete frequency sweeps are enabled.

HP-IB

Examples:

"SM3"

0

r

"SM DSCR"

A

and B frequencies, and dwell time) stored in non-

(FREQuency) key, and dwell

00

to the last element entered. With

3326A sequences

0

DSWP" (Discrete frequency

to

pressing the TlME key. The

-

The RCL DISCRETE (ReCaLI DISCRETE) key followed by a discrete element number

A

replaces the channel

for a d~screte frequency sweep element The RCL DISCRETE key 1s avadable by pressing the blue SHIFT key prlor to pressing the RECALL key. Val~d discrete elements numbers range from

d~splays the message "Error

HP-IB

Example:

and B frequency values and time values with the values stored

00

to 62. Recalling a null discrete frequency sweep element number

20

RNGE

"

Page 50

Discrete Frequency

Save

Discrete

The SAVE DISCRETE key followed by a dlscrete frequency sweep element number stores

the current channel A and

memory The SAVE DISCRETE key is available by pressing the blue SHIFT key prlor

to pressing the SAVE key Vahd discrete frequency sweep element numbers range from

00

bers must start with

be recalled, ed~ted, and replaced in any order Stormg a discrete frequency sweep ele-

ment wlth a

sage "Error 23 RNGE" (RaNGE) The message "Error

SWeeP) is displayed ~f a d~screte frequency element

changed.

Sweep

B

frequency values and dwell t~me value In nonvolatile

to 62. When initially entering discrete frequency sweep elements, the element num-

00

and be sequential Exlst~ng discrete frequency elements may

nonsequential

number, or using a number greater than 62 displays the mes-

11

7

DSWP" (Discrete frequency

IS

entered after the mode

IS

Discrete frequency sweep element storage uses the same nonvolatile memory as the

SAVE key stores. Discrete sweep frequency storage memory is assigned by the

3326A. Discrete frequency sweep elements are stored in the following memory

HP

registers:

DISCRETE

FREQUENCY

ELEMENT

NUMBER

00 - 06

-

13

07

-

20

14

21

-

27

28

-

34

-

41

35

42

-

48

49

-

55

56 - 62

MEMORY

REGISTER

9

8

7

6

5

4

3

2

1

Saving an operating state in a memory register that interrupts the contiguous memory

used to save discrete frequency sweep elements displays the "Error 23 RNGE" (RaNGE)

message. Saving an operating state in the lowest memory register occupied by dis-

crete frequency sweep elements reclaims that memory register for operating state

storage.

HP-IS

Example:

Page 51

Single Sweep

The SINGLE key initiates a single discrete frequency sweep. The indicator above the

SINGLE key illuminates when a single sweep is in progress. The SINGLE key initiates

a sweep from the discrete frequency sweep element 00 to the last entered element.

During a sweep, the SINGLE key causes the HP

crete frequency sweep element to the next discrete frequency sweep element.

HP-IB Example:

Continuous Sweep

"SS"

Discrete Frequency

3326A to step from the current dis-

Sweep

Clear Discrete

Time

The CONT (continuous) key initiates a continuous discrete frequency sweep. The indi-

a

cator above the CONT key illuminates when

HP-IB Example:

"SC"

The CLR DISCRETE (CLeaR DISCRETE) key replaces the discrete frequency sweep

elements stored in nonvolatile memory with the preset operating state. The CLR

DISCRETE key is available by pressing the blue

PRESET key,

HP-IB Example:

"DRST"

The TIME key enables display, entry, or modification of the discrete frequency sweep

element dwell time for both channels. After selection of the TIME key, the time value

is changed with the numeric keypad and units

trols. The SEC and

from

5

milliseconds to 1000 seconds with a resolution of 1 millisecond.

HP-IB Example:

mSEC units keys end entry of numeric values. The time range is

continuous sweep is in progress.

SHIFT key prior to the green INSTR

keys! or modified with the MODIFY con-

Reset Sweep

"STIM25MS"

The RESET SWP (reset sweep) key resets the sweep circuits to the start of the sweep.

For triggered operation, manually resetting the sweep circuits before the trigger

minimizes the delay between the trigger and start of sweep.

HP-IB Example:

"SRE"

Page 52

Discrete Frequency Sweep

STEP

1

STEP

2

STEP

STEP

3

4

Flgure

1-22.

Discrete Frequency

Sweep

>

Page 53

Page 54

-=

"

Modulation

The keys in the MODULATION key block enable and disable modulation. Each time a

modulation key is pressed, the modulation indicators sequence through the available

selections. Available modulation selections are dependent on the mode. Figure

1-24

lists the types of modulation available for the operating modes. If a modulation type

B

is unavailable, check the mode of operation, channel

frequency, and COMBINED operation. Modulation is disabled by pressing each of the MODULATION selection keys and

extinguishing all of the MODULATION indicators, by changing the mode, or by presetting the HP

3326A. Figure 1-23 illustrates modulation definition. Figures 1-25 and 1-26

illustrates the effect of internal AM and PM modulation.

Page 55

Modulation

lnternal

AM1 %AM

Internal amplitude modulation is enabled in the 2 CHANNEL mode when the channel

A INT AM (INternal Amplitude Modulation) indicator is illuminated. lnternal amplitude

B

modulation uses the channel

synthesizer as the modulation source for channel A,

thus only the channel A output is active. For internal amplitude modulation, 100 kHz

is the maximum channel

B

frequency, lnternal amplitude modulation limits the values

entered for the channel A amplitude to 50% (6.02 dB) of the normal range.

When internal modulation is selected, the channel

B

high voltage option is disabled.

If internal modulation cannot be selected (i.e. the INT AM indicator does not illuminate),

check that the

2

CHANNEL mode is selected, COMBINED operation is disabled, and

the channel B frequency is below 100 kHz.

HP-1%

Example:

"AIAl

"

or

"AIA ON"

Percent

AM

The %AMIPM DEV (percent Amplitude ModulationlPhase Modulation DEViation) key

enables display, entry, or modification of the modulation percentage. The %AMIPM

DEV key is selected by pressing the blue SHIFT key prior to the AMPTD key. The

%AMIPM DEV indicator illuminates when the modulation value is displayed. After selec-

tion of the %AM/PM DEV key, the modulation value is entered or modified with the

O/O

numeric keypad and

tion value ranges from 0 to 100% with 0.1

units key, or modified with the MODIFY controls. The modula-

O/O

resolution. With 0% amplitude modulation, the channel A output level is equal to the amplitude entered for the AMPTD key.

The modulation value is used for both AM and PM. If the displayed modulation value

%

is in degrees, pressing the

if

larly:

the displayed value is in degrees, pressing the DEG units key converts the dis-

units key converts the displayed value to percent. Simi-

played value to degrees.

HP-1%

Example:

Page 56

Modulation

STEP

1

STEP

internal

''uo

a

2

PMlPM

DEV

Internal phase modulation is enabled in the 2 CHANNEL mode when the channel A INT

PM (internal Phase Modulation) indicator is illuminated (see Figure 1-26). Internal phase

modulation uses the channel B synthesizer as the modulation source for channel A.

A

Thus, only the channel

maximum channel B frequency.

When internal modulation is selected, the channel

If

internal modulation cannot be selected (i.e. the INT

2

check that the

the channel B frequency is below

HP-IS

Example:

CHANNEL mode is selected, COMBINED operation is disabled, and

"AIPI

or

"AIP ON"

output is active. For internal phase modulation, 5 kHz is the

B

high voltage option is disabled.

PM

indicator does not illuminate),

5

kHz.

"

Page 57

0

ZGrnv;;

,.

STEP

1

The %AMIPM DEV (percent Amplitude ModulationIPhase Modulation DEViation) key

enables display, entry, or modification of the phase modulation deviation. The %AM/PM

DEV key is selected by pressing the blue SHIFT key prior to the AMPTD key. The

%AM/PM DEV indicator illuminates when the phase modulation deviation value is dis-

played. After selection of the O/oAM/PM DEV key, the phase modulation deviation is en-

tered or modified with the numeric keypad and DEG units key, or modified with the

MODIFY controls. The phase modulation deviation ranges from

0

to

360"

with

0.01"

resolution. The modulation value is used for both AM and PM. If the displayed modula-

O/O

tion value is in degrees, pressing the

cent. Similarly, if the displayed value is

units key converts the displayed value to per-

in

degrees, pressing the DEG units key con-

verts the displayed value to degrees.

HP-IS

Example:

STEP

STEP

2

3

Page 58

Modulation

External AM

Either channel is amplitude modulated by an external source through the rear panel

A-AMPTD MOD IN (channel AAMPliTuDe MODulation INput) or B-AMPTD MOD IN (chan-

nel B AMPliTuDe MODulation INput) connector when the respective channel EXT AM

(EXTernal Amplitude Modulation) indicator is illuminated. The voltage range for the

+

A-AMPTD MOD IN or B-AMPTD MOD IN connector is

input results in 100% modulation. A 0 volt input results in an output equal to the ampli-

tude entered for the AMPTD key. For channel A, a

+

level. For channel B, a

tude modulation frequency into the HP 3326A is 100 kHz. Amplitude modulation limits

the values entered for the channel A amplitude to 50% (6.02 dB) of the normal range.

1 volt input results in a minimum level. The maximum ampli-

1.0 volt. A 2 volt peak-to-peak

-

1 volt input results in a minimum

HP-16 Example:

External PM and Sync PM

External phase modulation is enabled when the EXT PM (EXTernal Phase Modulation)

or (AB) SYNC PM (channel

nated. Channel A is phase modulated by an external source through the rear panel

A-PHASE MOD INlSYNC PM IN (channel A PHASE MODulation INput/SYNChronous

Phase Modulation INput) connector when the channel A EXT PM or (AB) SYNC PM indi-

cator is illuminated. For synchronous phase modulation, channel B phase is held constant relative to the channel A phase. Channel B is phase modulated by an external source

through the rear panel B-PHASE MOD IN (channel B PHASE MODulation INput) con-

nector when the channel B EXT PM indicator is illuminated. The voltage range for the

A-PHASE MOD INISYNC PM IN or B-PHASE MOD IN connector is

responds to

lation. The maximum frequency into the HP 3326A for phase modulation is

modulation selection is dependent on the mode selected (see Figure 1-23).

2

Channel Mode

+

'AEAI

or

"AEA ON"

"BEAI

0

"BEA ON"

360" phase modulation. A 0 volt input results in an output with 0' modu-

"

"

r

A

and B SYNChronous Phase Modulation) indicator is illumi-

+

1

.O

volt which cor-

5

kHz. Phase

Channel A is phase modulated by an external source through the rear panel A-PHASE

MOD INISYNC PM IN connector when the channel A EXT PM indicator is illuminated.

Channel B is phase modulated by an external source through the rear panel B-PHASE

MOD IN connector when the channel B EXT PM indicator is illuminated.

Page 59

Modulation

2

Phase, 2 Tone, or Pulse Mode

Both channels are synchronously phase modulated by an external source through the

rear panel A-PHASE MOD INISYNC PM IN connector when the (AB) SYNC PM indicator is illuminated. Channel

the rear panel B-PHASE MOD IN connector when the channel

B

is also phase modulated by an external source through

B

EXT

PM indicator is

illuminated.

HP-IB Example:

"AEPI

"

or

"AEP ON"

"

"BEPI

or

"BEP ON"

"

"SPEI

or

"SPE ON"

Disabling Modulation

Modulation is disabled by pressing the MODULATION selection keys corresponding to

an illuminated indicator until all the indicators are extinguished. Modulation is also disabled by changing the mode with the MODE key or presetting the HP

HP-IB Example:

3326A.

"NOM"

Page 60

SavingIRecalling an Instrument

State

SAVINGIRECALLING AN INSTRUMENT STATE, AND MEMORY OPERATIONS

Save

Recall

The SAVE key, followed by a digit from 0 to

9,

saves the current operating state in nonvolatile memory. The digit following the SAVE key specifies the memory register for

storing the operating state. If two operating states are saved in the same memory

0

register, the operating state saved first is erased. Although

is a valid entry for a memory

register, the contents of this memory register are replaced with the current operating

state when power is removed from the

HP

3326A.

Saving an operating state in a memory register that interrupts contiguous memory used

by discrete frequency sweep elements displays the "Error 23 RNGE" (RaNGE) message. Saving an operating state in the lowest memory register occupied by discrete

frequency sweep elements reclaims that memory register for operating state storage.

HP-16 Example:

The RECALL key, followed by a digit from 0 to

0

nonvolatile memory. The digits

to 9 select the memory register for the recall opera-

9,

recalls an operating state saved in

tion. Recalling a memory register with discrete frequency sweep elements generates

20

the "Error

HP-I6 Example:

RNGE" (RaNGE) error message.

"RCL3"

Page 61

Memory register 0 contains the last operating state prior to removing power. The last

operating state established prior to removing power is restored by pressing the RECALL

key followed by the digit

Through the use of the internal SAVE switch, the setup state stored in register 0 can

be selected as the turn on state. Setting of internal switches must be done by qualified

service personnel. The location and settings of the SAVE switch are described in the

Memory Clear

Recall Discrete

The RCL DISCRETE (ReCaLI DISCRETE) key followed by a discrete frequency sweep

element number replaces the channel A and

the values stored for the discrete frequency sweep element. The RCL DISCRETE key

discrete frequency sweep elements numbers range from

crete frequency sweep element displays the message "Error 20 RNGE" (RaNGE).

0.

HP

3326A Service Manual.

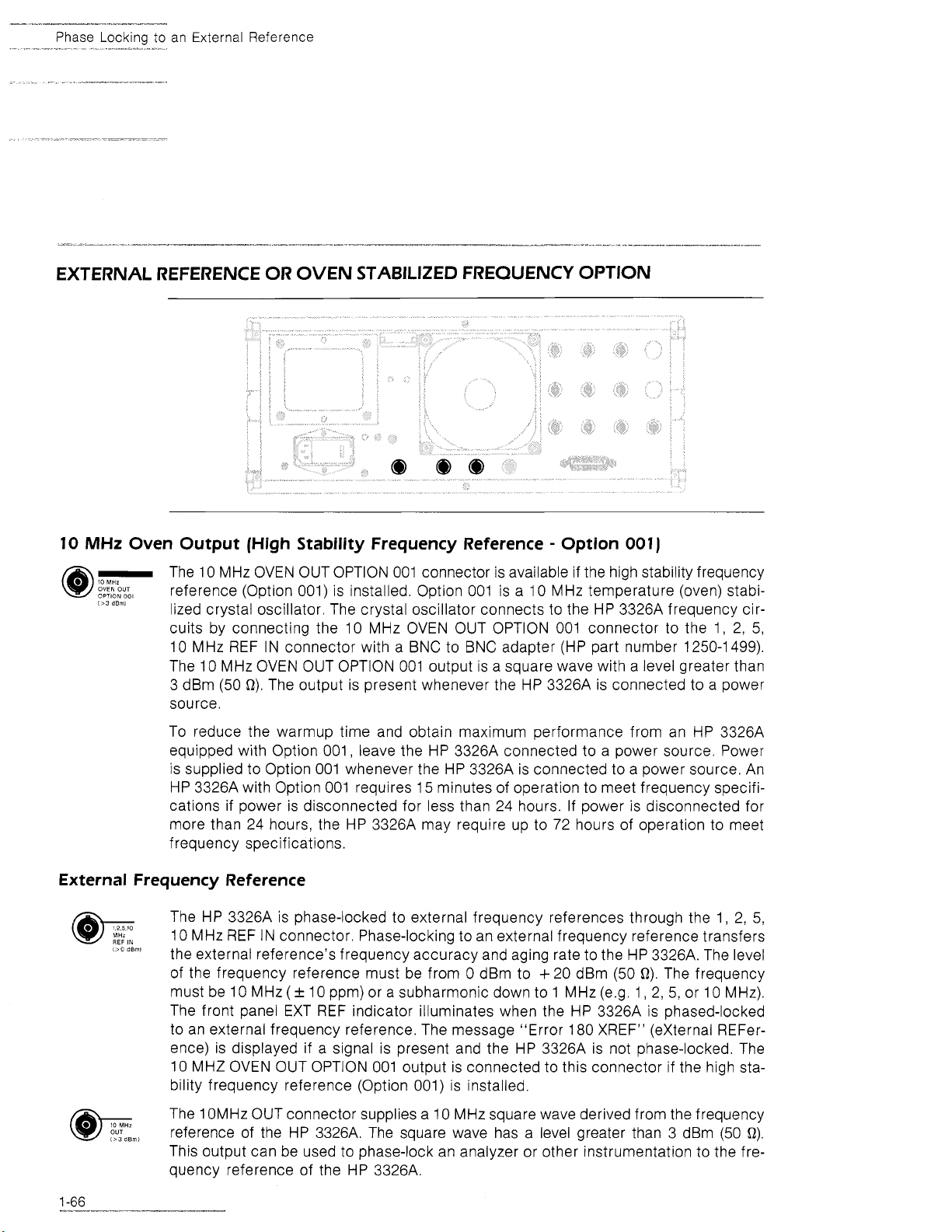

Applying power to the HP 3326A with the blue SHIFT key pressed replaces the contents of all nonvolatile memory registers with the INSTR PRESET state. All saved oper-