Hotpoint Ariston AW129 Instruction Manual

User guide

WASHING MACHINE

NA

NA

English,1

AW 129

SP

Español, #

F

Français, 49

Contents

NA

Description, 2

Important Safety Instructions, 3-4

Your safety and that of your family

Warnings about installation

Technical details

Unpacking, Installation, 5-6-7-8-9

Unpacking and levelling

Remove the shipping bolts

Water and Electric connections

Final Installation Checklist

Washing Machine Description

and Option Modifiers, 10-11

Control panel

Washing Options

Variable spin

Variable temperature

Programs, 12

Program table

Detergent Dispenser and Tips, 13

Detergent dispenser

Before washing

Starting a Wash Program

and Washcare Tips, 14-15-16-17-18

Laundry preparation

Typical wash loads and laundry preparation

Washcare tips and understanding fabric care labels (symbols)

Operating the washing machine

Stain removal chart

Care and Maintenance, 19

Switching off the water or electricity supply

Cleaning the machine

Cleaning the door bowl

Checking the water inlet hose

Drum maintenance

Cleaning the detergent dispenser drawer

Troubleshooting, 20-21

Service, 22

Before calling for Assistance

Warranties, 23

Ariston Statement of Warranties

1

NA

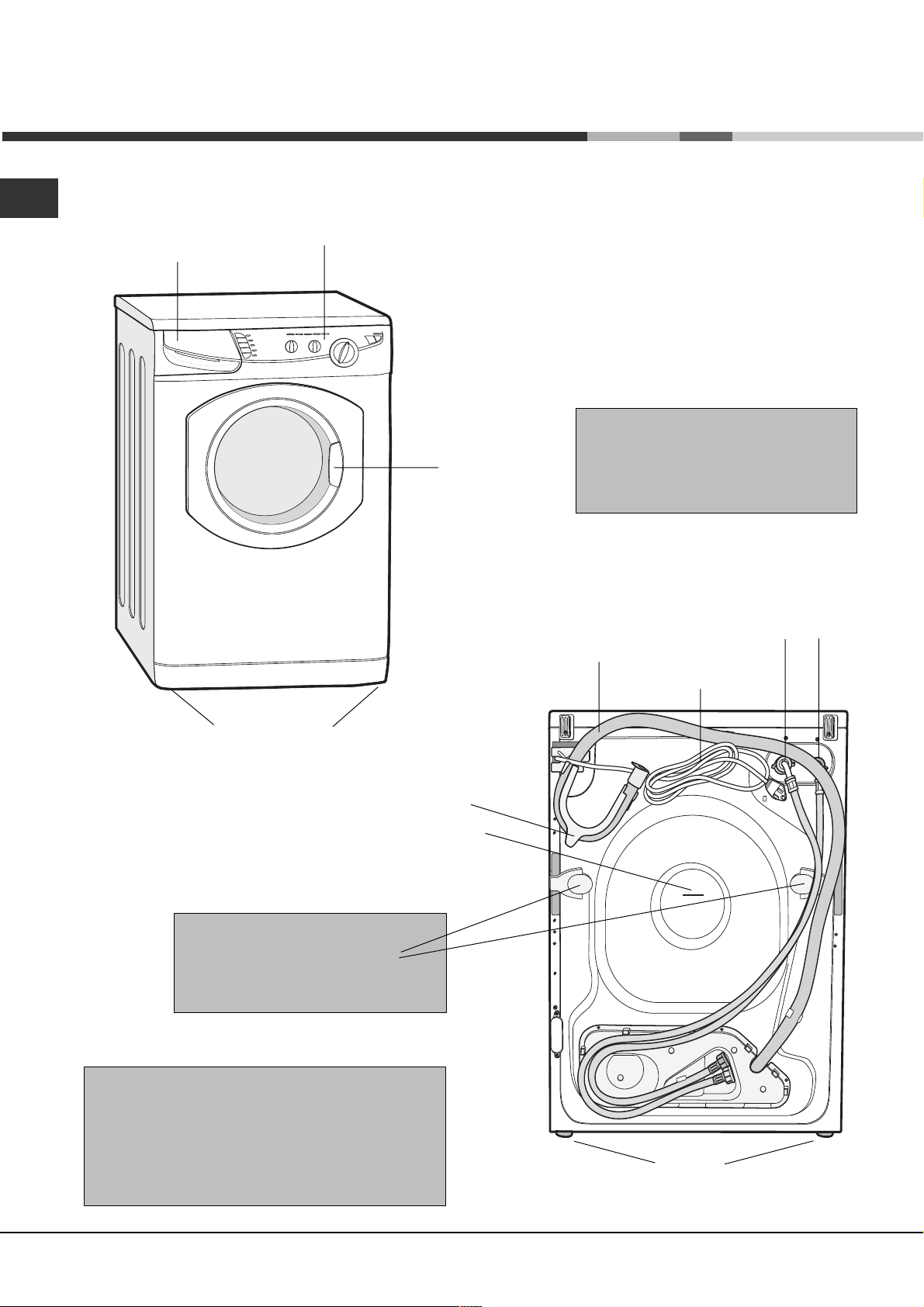

Description

Control panel

( Varies by Model)

Dispenser drawer

Interlocking door

and release lever

Please record the Model number

and Serial number of your machine

located behind the door for future

reference.

Front adjustable feet

Hooked end support

Plumbing indicator line

Two shipping bolts under

the plastic covers !

BOTH must be removed BEFORE

you use your machine (see page 6)

Hot and Cold water

inlet points

Drainage hose

Power cord

! The machine was designed and built in

compliance with the appliance international

safety regulations.

The following information is provided for your

safety and should consequently be read

carefully.

2

Back feet

Important Safety Instructions

INTRODUCTION

Congratulations on your new Ariston washing machine. This is a highly sophisticated engineered product that

will give you many years of satisfaction. Please spend a few moments reading the Owner Manual. This will

show you ways to best utilize your valuable purchase

Save these instructions

Your washing machine has been built in compliance with the strictest international

safety regulations, to protect you and all your family

WARNING

To reduce the risk of fire, electrical shock, or injury to persons when using

your appliance, follow basic precautions, including the following:

NA

1. Read all instructions before using the appliance.

2. Install and level the clothes washer on a floor that

can support the weight.

3. This appliance must be properly grounded. Never

plug the appliance cord into a receptable which is not

grounded adequately and in accordance with local and

national codes. See installation instructions for grounding

this appliance.

4. To avoid the possibility of fire or explosion:

- Do not wash articles that have been previously cleaned

in, washed in, soaked in, or spotted with gasoline, dry

cleaning solvents, other flammable, or exlosive

substances as they give off vapors that could ignite or

explode.

- Do not add gasoline, dry cleaning solvents, or other

flammable or explosive substances to the wash water.

These substances give off vapors that could ignite or

explode.

- Under certain conditions hydrogen gas may be

produced in a hot water system that has not been used

for 2 weeks or more. HYDROGEN GAS IS EXPLOSIVE.

If the hot water system has not been used for such a

period, before using a washing machine, turn on all hot

water faucets and let the water flow from each for

several minutes. This will release any accumulated

hydrogen gas. As the gas is flammable do not smoke

or use an open flame during this time.

- To reduce the risk of fire, clothes, cleaning rags, mop

heads and the like which have traces of any flammable

substances, such as vegetable oil, petroleum based

oils or distillates, waxes, fats, etc. must not be placed in

the washing machine. These items may contain some

flammable substances after laundering, which may

smoke or catch fire by itself.

5. Always be sure to unplug the washing machine

from the electrical supply before attempting any service.

6. Do not insert/pull out the mains plug with wet hands.

7. Do not pull out the mains plug by tugging the cable.

To reduce the risk of fire or electrical shock, DO NOT use

an extension cord or an adapter to connect the washing

machine to the electrical power supply.

8. Caution when draining hot water.

9. The washing machine must only be used for its intended

purpose.

10. Make sure that all water connections to the washing

machine have shut-off valve(s) and that they are readily

accessible. Close the washing machine shut-off valve(s) at

the end of each wash day.

Check the fill hose connections on a regular basis to assure

that they are tight and not leaking.

11. Do not allow children to play on or in the appliance.

Close supervision of children is necessary when the

appliance is used near children.

12. Before the appliance is removed from service or

discarded, remove the door.

13. Do not reach into the appliance if the tub or drum is

moving.

14. Do not install or store this appliance where it will be

exposed to the weather.

15. Do not tamper with controls.

16. Do not repair or replace any part of the appliance or

attempt any servicing unless specifically recommended in

the user-maintenance instructions or in published user-repair

instructions that you understand and have the skills to carry

out.

17. Do not use fabric softeners or products to reduce static

unless recommended by the manufacturers of the fabric

softener product.

18. Do not machine wash fiberglass materials. Small

particles can stick to fabrics washed in following loads and

cause skin irritation.

19. Inlet hoses are subject to damage and deterioraton

over time. Check the hoses periodically for bulges, kinks,

cuts, wear or leaks and replace them every five years.

3

NA

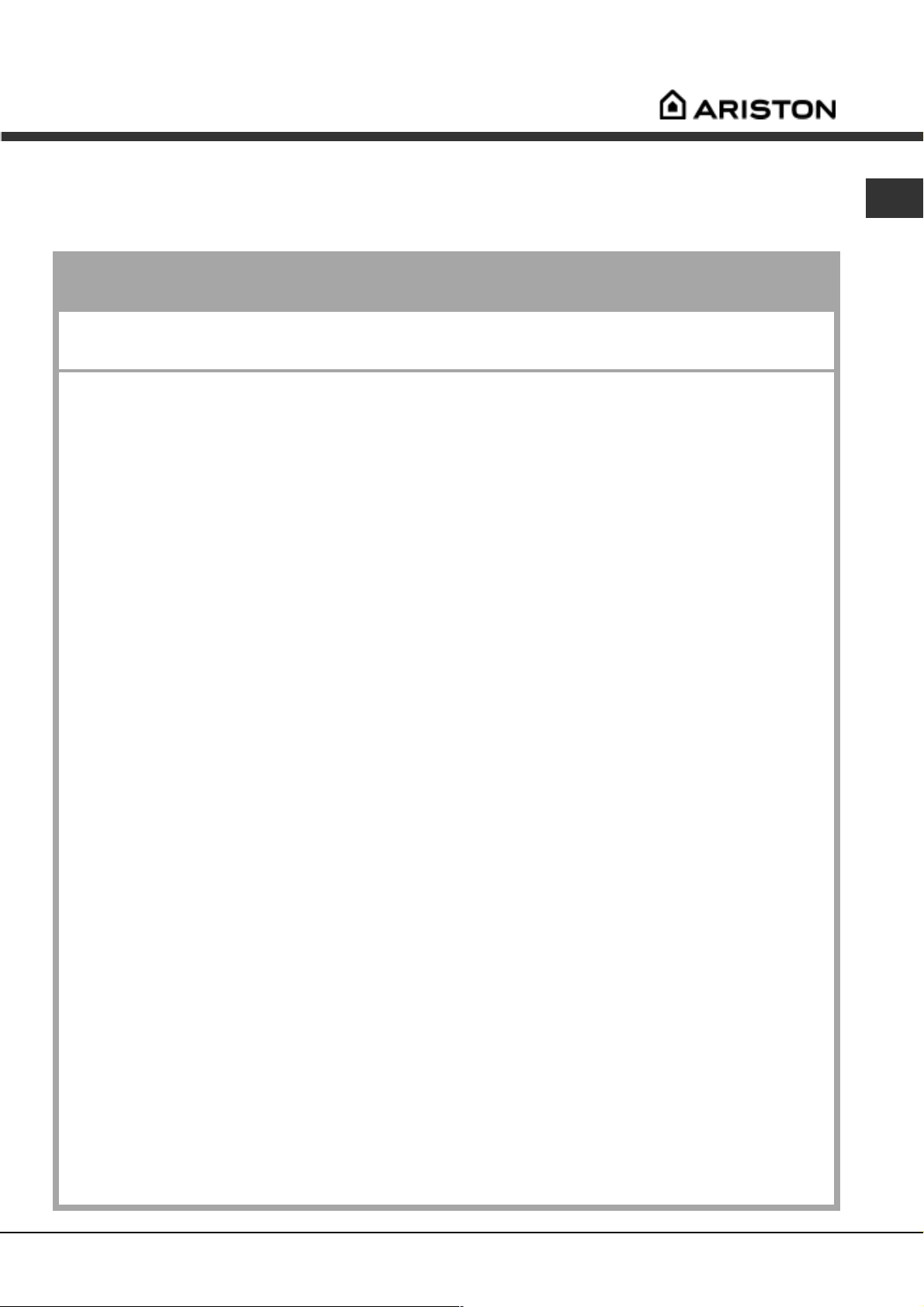

Technical details

Model AW 129

Dimensions

Capacity

Electric

connections

Water

connections

Spin speed

U

®

L

C

US LISTED

23.4" (59.5 cm) wide

33.4" (85 cm ) high

23.6" (60 cm ) deep

from 2 to 15 L bs (7 kg)

voltage 120 Volts 60 Hz

maximum pressure 100 psi (689.6 kPa)

minimu m pres sure 20 psi (137.9 kPa)

drum capacity 54 litres

up to 1200 rpm

Th is app liance w as tested by UL

and conform s with bo th Canadian

and U.S. UL s afety requ iremen ts

and displays their Mark

Indesit Com pany offer their

cus tomers products w ith the

ENER GY STAR Label

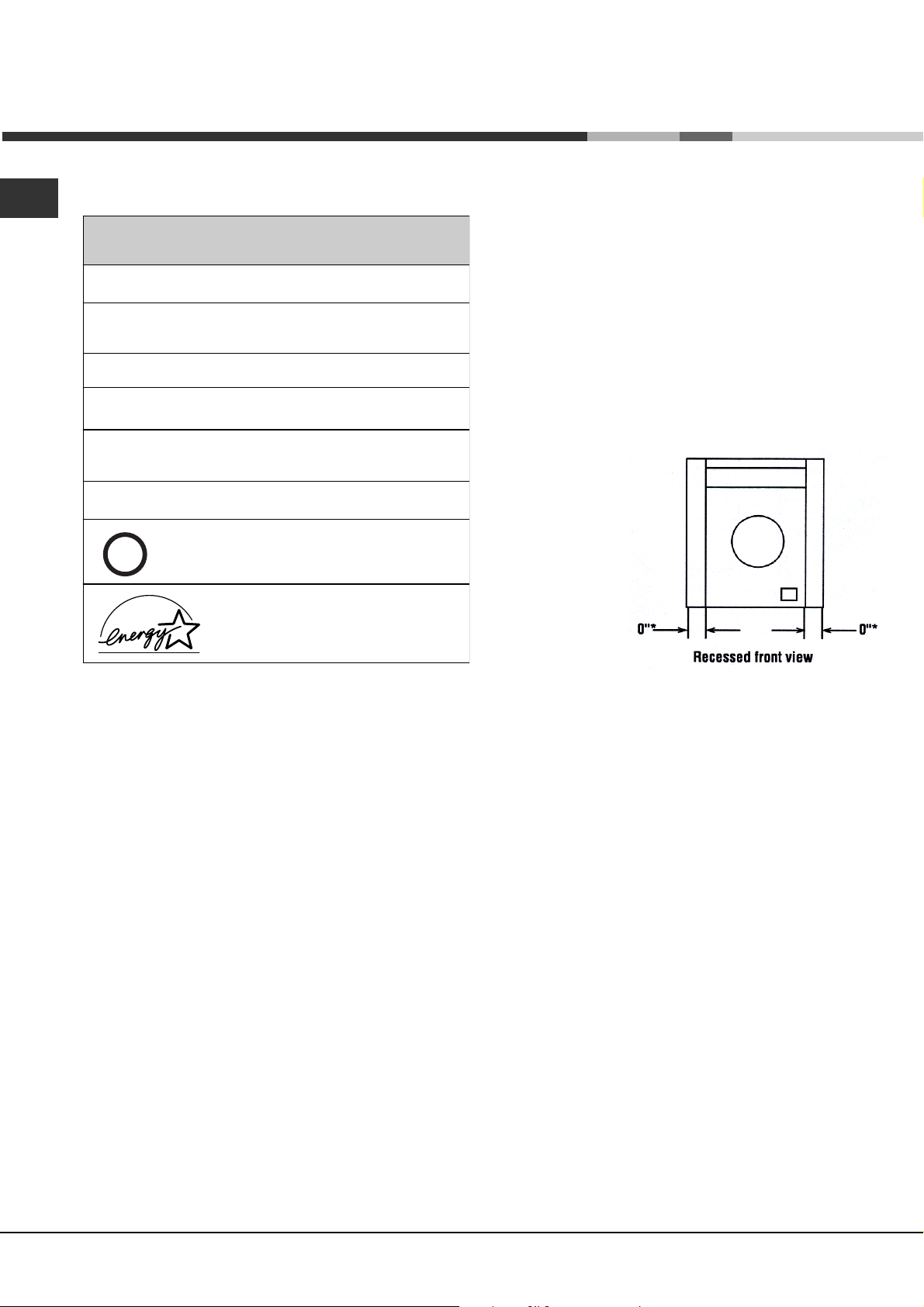

RECESSED, CLOSET AND ALCOVE

INSTALLATION (Instructions)

The machine may be installed in a recessed area,

closet or alcove.

The installation spacing is in inches and is the minimum

acceptable.

Additional spacing should be considered for easy

installation, servicing and in compliance with local codes

or ordinances.

Other installation must use the minimum dimensions

indicated .

Minimum

installation

spacing

* Additional clearances

for wall, door and floor

moldings maybe required.

As a result of technological progress, the manufacturer reserves the right to make any improvements to its

appliances without giving prior notice to its clientele.

4

Unpacking

! Keep this instruction book on hand in order to refer to it when necessary. Take it you when you move, and

should you sell this appliance or pass it on to an other party, make sure that this booklet is supplied along with

the appliance so that the new owner may be informed about warnings and suggestions on how the works.

Unpacking

NA

1. Using scissors, cut

carefully along one

corner post to remove

the film.

2. Open the door, check

inside the drum and

remove the

accessories bags.

! Retain all packaging

material until

installation is

complete.

5. Remove the polystyrene

base.

6. ! IMPORTANT

check when

unpacking your

machine:

! This is the part of the

polystyrene base and should

have stayed intact when

you removed the base.

If it has broken off and is still

in the machine

it while the machine is still

laying on its side on the top

cap.

remove

3. Lift of the polystyrene

top cap and remove the

four corner posts.

4. Carefully lay the left side

of the machine down

onto the top cap.

! We reccomend that

a second person help

to raise and lower

the machine.

7. Stand the machine

upright.

Protect the environment

Please dispose of the

packaging material carefully

and considerately.

! Continue to read the rest

of these instructions

carefully; the following

pages contain important

information on installation

and troubleshooting.

5

NA

Remove the Shipping Bolts

IMPORTANT: Read these instructions to remove the 2

shipping bolts (see Description

for location). Situated on one

either side of the rear panel,

BOTH shipping bolts MUST be

removed before use.

! Failure to do so may cause

damage to your machine.

It is important the transit bolt and

spacer (see pic) come out intact.

1. Use a crosshead screwdriver

to remove the yellow plastic

covers.

Location

Where you install your machine will affect its performance:

! For your safety and to comply with electrical

regulations, seek professional advice if you want to install

your machine in a bath or shower room.

Make sure that the electrical socket and water taps are

easily accessible. You should switch off the machine's

electrical and water supplies when you are not using

it for extended periods.

Make sure that you allow enough space for the

machine. Select a space at least 23.6 (60 cm) wide,

23.6 (60 cm) deep and 33.4 (85 cm) high. Also

leave enough space to open the door fully, so that you

can load and unload it easily.

Where possible, the machine should be positioned on

a solid floor to minimise vibration.

Take care when you move the machine not to rip any

floor coverings. The weight of the machine may cause

indentations in some floor coverings.

2. Unscrew the bolt using a 13

mm wrench.

3.

STOP when 3 threads can be

seen.

4. Hold, slide sideways and pull to

remove.

5. For safety, replace both yellow plastic covers over the

holes left by removing the two bolts.

Did you know?

Levelling

Your machine will be noisy if the two front feet are not

adjusted so that the machine stands firm and level.

! The machine should be levelled from side to side and

from front to back.

1. Move your machine into its final location.

- Take care not to trap or kink the hoses.

2. Turn one or both front feet counter-clockwise by hand

until the feet cannot be turned any more.

When adjusting the feet, use a spirit level to check the

machine stands level, from side to side and from front to

back.

The spring on each foot will stop

them coming loose.

! If it is placed on a fitted or loose

carpet, adjust the feet in such a

way as to allow enough room for

ventilation beneath the machine.

! Packaging materials are

not children's toys.

the shipping bolts are fitted to ensure that your machine is undamaged during delivery.

...both of the shipping bolts must be removed before using the machine, not doing so will lead to

excessive vibration, movement of the machine and could eventually lead to internal damage.

...the majority of problems with noisy machines are due to the shipping bolts not being removed,

closely followed by the feet not being adjusted correctly to level the machine.

...you will be charged for a service engineers visit if a problem with your machine is caused by

incorrect installation or misuse.

6

Installation

Water Connection

Caution

1. The washing machine must only be operated

with cold and hot (max. 140°F//60°C) tap water.

Do not connect the appliance to the mixer tap of an

unpressured hot-water boiler.

2. To prevent water damage, the hot and cold water

valves should be accessible when the washer is in

place and should always be turned off when the

washer is not in use.

! Remember: please use the new hoses supplied,

fitted to the machine. Old hoses may cause leaks due

to worn out washers or may be split due to water

pressure.

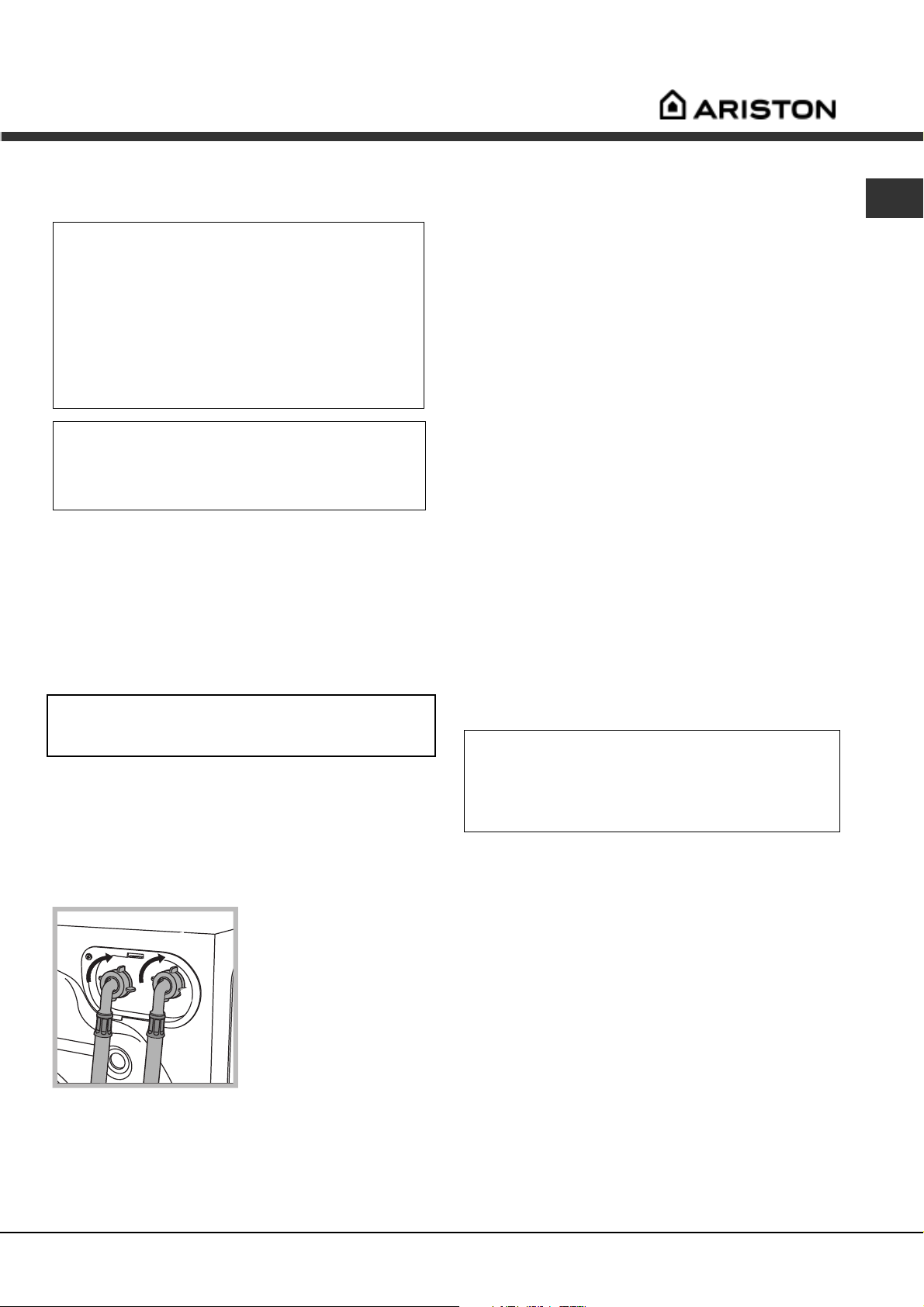

Connecting the water inlet hoses

Included in the accessories supplied with the machine

are 2 inlet hoses. The straight end of these hoses should

be connected to the supply.

The 90° angled end of these hoses should be connected

to the inlet valves on the back of the machine to make a

water tight seal on each connection (see below figure).

The couplings should be tightened by hand, a tool should

only be used if a leak occurs. Do not use excessive

force.

Repair or replacement of a part should be made only by

a qualified service technician to prevent personal injury or

damage to the machine. Inlet valves are color coded:

Red = Hot / White = Cold

Drainage Connection

Standpipe Diameter/Capacity. Needs a 1 1/4 minimum

diameter standpipe with a minimum carry-away capacity of

7 gallons per minute.

Top of Standpipe. Must be between 25 - 34 inches (6286 cm) high measured from the bottom of the machine.

Outlet End of Drain Hose (provided with the unit).

Must be at least 20 above the bottom of the washer. An

air break must be available at the standpipe to avoid

siphoning. No more than 6 of the drain hose should be

inserted into the drain pipe to prevent siphoning.

! Although you may need to move the hooked end support

along the grey drainage hose,, DO NOT remove it.

! Whichever draining method you use, make sure that the

hooked end support is fixed level to, or above the

Plumbing Indicator Line.

You should carefully position the drain hose to avoid

kinks and ensure proper drainage of the water.

The outlet end of the drain hose must be at least 25 (62

cm) above the base machine. At this point it s possible

for the water to be discharged into a sink or drain pipe, but

an air break must be available at this 24 height to prevent

the machine from syphoning (see figures page 8).

No more than 6 of the drain hose should be inserted

in the drain pipe.

Important.

Make sure that the drain hose is not kinked and the

water flow has not been restricted.

The machine must rest solid on a sturdy floor for

optimum performance and minimum vibration.

NA

Connection.

1. Screw the cold water

H

C

onto the hot water supply until tight.

4. Turn on the hot water supply and check for leaks,

tighten if necessary.

fill hose (C blue connector)

onto the cold water supply

until tight.

2. Turn on the cold water

supply and check for

leaks, tighten if necessary.

3. Screw the hot water fill

hose (H red connector)

Hints and tips

! Make sure there are no kinks or bends in the

hose.

! The water pressure at the supply tap must be

within the values indicated in the Technical

details table (see table on page 4).

Always use a new inlet hose.

Check the water inlet hose at least once a year,

replace if cracked as worn hoses could split under

water pressure.

Do not overtighten. The couplings should be

tightened by hand; a tool should only be used if a

leak occurs. Do not use excessive force.

7

Installation

NA

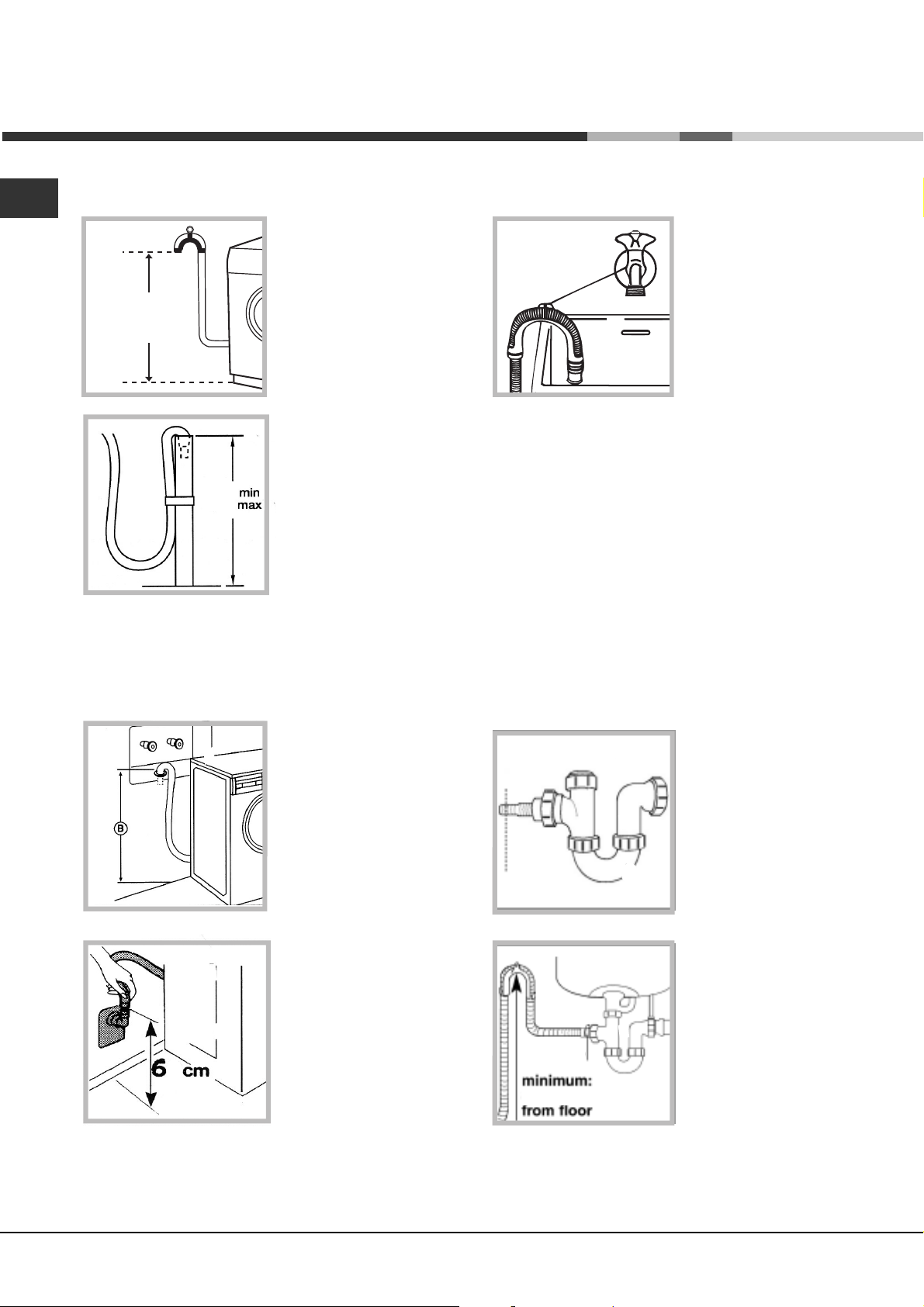

Floor Standpipe Drain

(A)

25"-34"

62 - 86

inches

cm

25”

34”

Top of standpipe must

be at least 25 inches (62

cm) high and no higher

than 34 inches (86 cm)

from the bottom of the

washer (A).

Sink Drainpipe Method

Entry into the sink drain

system must be above the

trap (see fig. aside ).

When routing the drain

hose through cabinets or

walls use aprotective

material such as

electrical duct tape to

cover sharp edges that

could damage the drain

hose. Use a suitable

clamp to secure the drain

hose to the Y branch or

the disposer. With a sink drainpipe system (see figures

aside and below), you may connect directly:

1) to a disposer by following the manufacturers

attachement method.

2) directly to a Y branch tail piece (Available at

most hardware stores).

3) through the floor to a separate trap. The trap

must be vented to prevent siphoning. To provide

proper venting , install an Air Gap Kit (available at

most hardware stores).

4) To the faucet using a Faucet Adapter Kit (available

separately). It will supply water from your faucet and

discharge water directly into your sink drain.

Wall Standpipe Drain

#^

Top of standpipe must

be at least 25 inches

(62 cm) min.; 34 inches

(86 cm) max from end of

drain hose to bottom of

washer (B) (See figures

aside and below).

Under Sink Method

Hose

clamp

620 mm

1. Cut the blocked end of

the under sink drainage

unit.

2. Fix the hooked end

supporta minimum of

620 mm from the floor.

3. Use a hose clip clamp

to securely attach the

grey drainage hose

end to the under sink

drainage unit using a

hose. clamp

8

Loading...

Loading...