Page 1

Honeywell

THE Y343B IGNITION PACKAGE PROVIDES

DIRECT SPARK IGNITION (DSI) FOR GAS

HEATING SYSTEMS. THE PACKAGE IN

CLUDES THE S87D ELECTRONIC MODULE,

Q354A FLAME SENSOR, Q347A SPARK IG

NITER-SENSOR AND 392286-1 IGNITION

CABLE.

DEPENDABLE BURNER IGNITION

□ Spark generated by electronic module and

internal step-up transformer.

SOLID STATE DESIGN

□ Compact, solid state components provide

accurate, long-lasting performance.

□ No mechanical friction or wear.

MAXIMUM OPERATING SAFETY

□ Proves presence of flame on burner igni

tion, then protects against burner flame-out

and interruption of electric power or gas sup

ply during run cycle.

□ Open or short circuit in any electronic com

ponent results in safety shutdown.

USES FLAME RECTIFICIATION PRINCIPLE

□ Any false flame signal, including electrical

short or ground, results in safety shutdown.

□ Ignition is started, main burner is ignitied,

burner flame is proved and continuously

monitored during main burner-on period. Ig

nition spark is discontinued when flame is

proved.

CONVENIENT REMOTE

RESTART PROCEDURE

□ After safety shutdown, equipment must be

manually reset from remote thermostat or

temperature controller.

□ System automatically locks out after

trial-for-ignition. If malfunction exists, correc

tion must be made before system is manually

reset.

LOW VOLTAGE CONTROL CIRCUIT

□ Permits use of 24 V thermostat for op

timum temperature control.

□ Reduced wiring costs — both on appliance

and on job.

GAS VALVE CONTROL

□ S87D internal relay switches the gas valve

on and off.

□ System can be used with a 2-stage gas

valve, if desired.

ALARM CONTROL

□ Optional alarm circuit provides 24 Vac for

an automatic visual or audible signal if any

part of system malfunctions and causes a

lockout.

L.H.

1-83»

Form Number 68-0014

©Honeywell Inc. 1983

Y343B1002

Page 2

The Y343B1002 Direct Spark Gas Burner Ignition

Package includes the S87D Electronic Module, Q347A

Spark Igniter-Sensor, Q354A Flame Sensor and

392286-1 Ignition Cable Assembly.

Other controls needed to complete the heating sys

tem include a 24 V, DSI gas valve; 24 V thermostat:

24 V transformer and high temperature limit

controller.

S87D CONTROL MODULE

The S87D contains the electronic components of

the system and also serves as a central v\/iring panel

for the external controls. Powered by a 24 V trans

former and controlled by a thermostat, it performs the

following functions.

1. Checks for a false flame condition (short to

ground). Module will lock out if false flame condition

is present.

2. Generates a potential of 15,000 V (open circuit)

at the spark-igniter stud for direct ignition of the main

burner.

3. Operates gas valve (internal relay controls inde

pendent gas valve circuit).

4. Senses the presence of main burner flame and

discontinues ignition spark. If the burner fails to ignite

within the trial-for-ignition period, safety lockout oc

curs.

5. If there is a loss of power, the system will shut

down safely. Start-up is initiated when power is

restored.

6. If there is a loss of main burner flame, the timed

trial-for-ignition is repeated. Safety shutdown occurs

if flame is not reestablished within the trial-for-ignition

period.

7. Normally closed contacts in internal relay may

be used for an alarm circuit to signal safety shutdown

of system.

ELECTRICAL RATINGS:

Voltage and Frequency—24 Vac, 60 Hz.

Current Rating—0.2 A plus gas valve current draw.

SAFETY LOCKOUT TIMING: 11 seconds.

FLAME FAILURE REIGNITION TIME: 0.8 seconds

maximum.

FLAME CURRENT SIGNAL REQUIRED: 1.5 pA dc

minimum.

SPARK GENERATOR VOLTAGE: 15,000 V open

circuit.

MOUNTING: Mounts in any position. See Fig. 1.

DIMENSIONS: See Fig. 1.

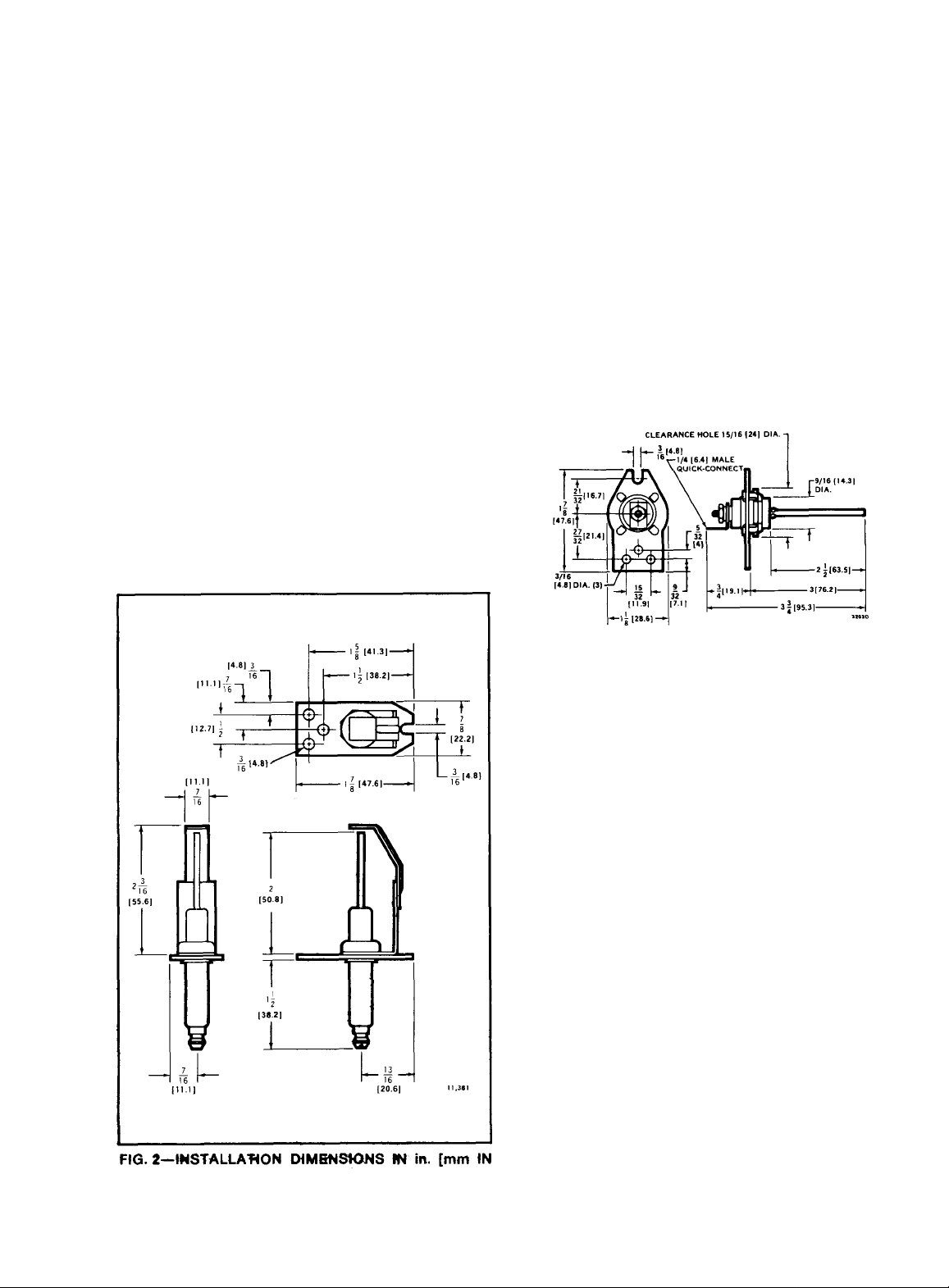

FIG. 1—DIMENSIONS FOR S87 IN in. [mm IN

BRACKETS].

(continued on page 3)

ORDERING INFORMATION

WHEN PURCHASING REPLACEMENT AND MODERNIZATION PRODUCTS FROM YOUR TRADELINE

WHOLESALER OR YOUR DISTRIBUTOR, REFER TO THE TRADELINE CATALOG OR PRICE SHEETS FOR

COMPLETE ORDERING NUMBER, OR SPECIFY—

Combination gas control (for DSI

1. Order number Y343B1002.

2. Safety lockout timing (11 seconds).

3. DSI system controls, as required.

a. 24 V, 60 Hz transformer.

b. Low voitage thermostat or temperature controller.

IF YOU HAVE ADDITIONAL QUESTIONS, NEED FURTHER INFORMATION, OR WOULD LIKE TO COMMENT ON OUR

PRODUCTS OR SERVICES, PLEASE WRITE OR PHONE:

1. YOUR LOCAL HONEYWELL RESIDENTIAL SALES OFFICE (CHECK WHITE PAGES OF YOUR PHONE

DIRECTORY).

2. RESIDENTIAL DIVISION CUSTOMER SERVICE

HONEYWELL INC., 1885 DOUGLAS DRIVE NORTH

MINNEAPOLIS, MINNESOTA 55422 (612)542-7500

(IN CANADA—HONEYWELL LIMITED/HONEYWELL LIMITEE, 740 ELLESMERE ROAD, SCARBOROUGH,

ONTARIO M1P 2V9). INTERNATIONAL SALES AND SERVICE OFFICES IN ALL PRINCIPAL CITIES OF THE

WORLD.

c.

application).

High iimit temperature controiler and

d.

auxiiiary safety controis.

Aiarm signai (if required).

e.

Page 3

AMBIENT TEMPERATURE RATING: Minus 40 F to

plus 175 F [minus 40 C to plus 79 C].

WIRING CONNECTIONS: 1/4 in. [6.4 mm] male

quick-connect terminals, for all except ALARM ter

minal. ALARM terminal, 1/4 in. [6.4 mm] female

quick-connect. 1/4 in. [6.4 mm] diameter stud

base for ignition cable.

REPLACEMENT PARTS: 3 A fuse.

Q347A SPARK IGNITER-SENSOR

The Q347A, powered by the S87D Electronic Mod

ule, produces a spark for direct ignition of the main

burner. The Q347A consists of an inner electrode

(insulated rod) and an outer electrode (rigid, formed

strap bent at end to extend over tip of inner rod). Tip of

electrodes extend into path of main burner gas; arcing

across spark gap ignites gas.

SPARK GAP: 5/32 in. [4 mm].

LENGTH OF ELECTRODE ASSEMBLY (mounting sur

face to tip): 2-3/8 in. [60.3 mm].

ELECTRODE MATERIAL: Kanthal.

MAXIMUM TEMPERATURE RATINGS: 1800 F [982 C]

at tip of electrode assembly, 1250 F [677 C] at

ceramic insulator.

WIRING CONNECTION: 1/4 in. [6.4 mm] diameter base

stud for ignition cable.

MOUNTING: Bracket, see Fig. 2.

DIMENSIONS: See Fig. 2.

Q354A FLAME SENSOR

The Q354A consists of a flame rod supported in a

ceramic insulator with mounting bracket. Positioned so

that the end of the flame rod is immersed in the main

burner flame, and with the burner head serving as the

ground area, it operates on the flame rectification

principle. In the presence of main burner flame, a direct

current is established to prove burner ignition and to

continuously monitor the flame during the burner-on

period.

MAXIMUM TEMPERATURE RATING: 2200 F [1204 C]

at tip of rod, 1250 F [677 C] at ceramic insulator.

WIRING CONNECTION: 1/4 in. [6.4 mm] male

quick-connect terminal.

FLAME ROD MATERIAL: Kanthal.

MOUNTING: Bracket, see Fig. 3.

DIMENSIONS: See Fig.3.

BRACKETS] OF Q347A.

FIG. 3—DIMENSIONS IN in. [mm IN BRACKETS] OF

Q354A.

392286-1 IGNITION CABLE

This cable is used to connect the Q347A Spark

Igniter-Sensor to the S87 Electronic Module.

CABLE: No. 16 gauge high tension, 485 F [251 C]

heated, oil resistant.

LENGTH: 30 in. [762 mm].

CONNECTORS (2): 1/4 in. [6.4 mm] diameter spring

clip type with insulating boot. Two straight boots.

GAS CONTROLS

Combination gas controls are directly controlled by

the internal relay in the S87D. Maximum electrical

rating for DSI gas valve control is 2.0 A. See individual

publication for complete specifications and installation

instructions on the following recommended

gas controls.

68-0014

Page 4

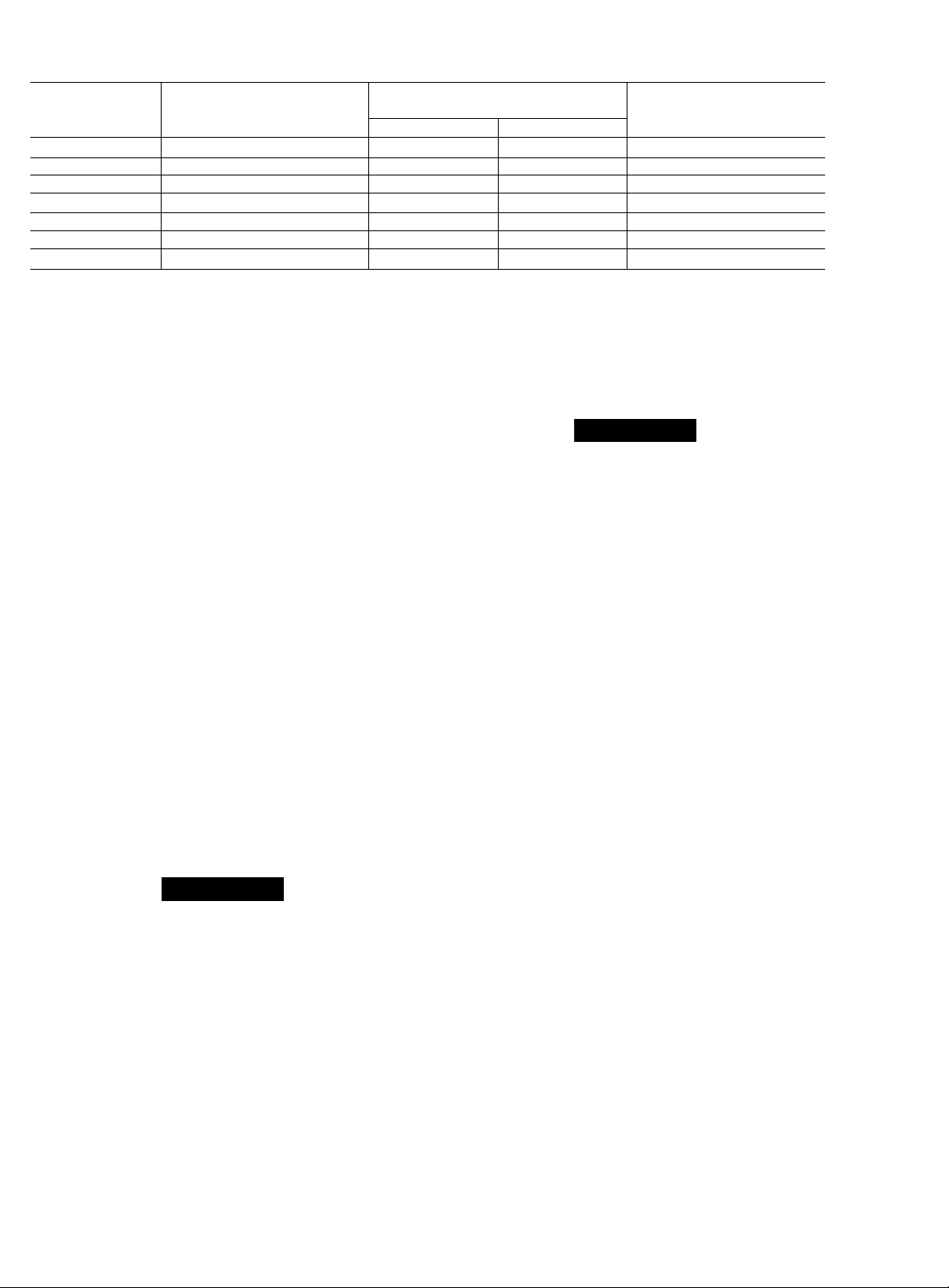

TABLE 1—GAS CONTROLS.

CAPACITY RANGE OF

TYPE OF PRESSURE

MODEL NO.

V845A

VR8450A

V845C Step-open

VR8450C Step-open noto 290 3.1 to 7.8

VR8540A

VR8590A

VR8600A

REGULATOR

Standard noto 335 3.1 to 9.5 60-2315

Standard noto 290 3.1 to 7.8 68-0016

Two-stage noto 290 3.1 to 7.8 68-0021

Negative

Negative 37 to 400 I.Oto 11.3 68-0017

STANDARD MODEL

cfh mVhr

noto 335 3.1 to 9.5 60-2315

37 to 400

I.Oto 11.3

PUBLICATION FORM

NUMBER

68-0016

68-0017

AUXILIARY CONTROLS

REQUIRED FOR BASIC DSI SYSTEM

1. TRANSFORMER. Select transformer with ade

quate VA. S87D requires a 24 Vac transformer. For

common system transformers, capacity must be ade

quate for S87D, temperature controller, gas control and

any other device powered by the transformer (see

Table 2).

2. LOW VOLTAGE TEMPERATURE CONTROLLER.

Select a 24 Vac thermostat for single-stage or

two-stage burner control (depending on heating sys

tem).

DETERMINED BY PARTICULAR APPLICATION

Refer to separate publications for information on the

controls utilized by the appiiance manufacturer. These

INSTALLATION

WHEN INSTALLING THIS IGNITION PACKAGE. ..

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on

the product to make sure it is suitable for your

application.

3. The installer must be a trained, experienced

service technician.

4. After installation is complete, check out system

operation.

controis are:

1. High iimit temperature controlier and other safety

controis as required.

2. Gas vaive. Refer to Tabie 1 above.

3. Alarm signal as desired for the circuit under

control of the S87D.

CAUTION

1. When using a common transformer to power

both S87D and gas control circuit, use a good

quality transformer of adequate VA. If trans

former VA is inadequate, the S87D internal

relay may chatter.

2. When two or more transformers are used, they

must be properly phased and grounded.

S87D CONTROL MODULE

Select a location within 30 in. [762 mm] maximum of

the burner that will permit a direct cable route to the

Q347A spark igniter. Ready access to the terminals is

necessary for wiring and servicing. Do not exceed the

ambient temperature rating given in the SPECIF

ICATION section.

The S87 may be mounted in any position. See Fig. 1

for mounting dimensions. Use No. 6-32 machine screws

or No. 8 sheetmetal screws 1 in. long for fastening.

Fasten securely.

CAUTION

1. Disconnect power supply before wiring to pre

vent electrical shock or equipment damage.

2. If a new gas control is to be installed, turn off

gas supply before starting installation. Be sure

to conduct a Gas Leak Test after the gas

control is installed (follow manufacturer’s

instructions).

IMPORTANT-

If this is a replacement application, follow the

appliance manufacturer’s instructions. The manu

facturer usually provides wiring diagrams,

start-up and checkout instructions and service

procedures for their system. If manufacturer’s

instructions are not available, the information

below may be used as a general guide.

Q347A SPARK IGNITER-SENSOR

The Q347A should be rigidly mounted in an ac

cessible location. It must remain in a fixed position

relative to the main burner. The Q347 may be mounted

on a separate bracket or on the same bracket with the

Q354A Flame Sensor. On multiple burners, the 0347

may be mounted at one end of the row and the 0354 at

the other end to delay spark cutoff until all burners are

ignited.

IMPORTANT-

The ignition cable limits the distance between the

0347 and S87 to 30 in. [762 mm] or less. This may

affect the location selected for the 0347 and/or

S87. Ignition cable must not touch grounded

object or current-carrying wires.

Page 5

Position the Q347 so that only the tips of the elec

trodes are immersed in the burner flame. The burner

must ignite smoothly — usually this will be ac

complished with tip of electrodes (spark gap) spaced

approximately 1/4 in. [6.4 mm] from the surface of the

burner. Gas must flow into one of the three open sides

of the spark gap (where outer electrode does not block

gas). The center electrode must not be near any

ground.

The spark gap is factory-adjusted to 5/32 in. [4 mm].

If this setting is disturbed in shipment or installation,

readjust by carefully bending the bent tip of the ground

(outer) electrode only.

Q354A FLAME SENSOR

The Q354 should be rigidly mounted in an accessible

location. It must remain in a fixed position relative to the

main burner. Mount the Q354 on a separate bracket or

on the same bracket with the Q347 Spark Igniter.

Tip of rod must be immersed in main burner flame.

Depth of immersion (usually about 1 In. [25.4 mm]) and

distance from rod to burner surface (usually 1/4 in. [6.4

mm]) depends on type of burner and flame configura

tion. Position selected must produce sensor current of

1.5 microamperes (minimum). See Fig. 9, Page 10, to

measure current.

The main burner serves as the grounding area for

the flame signal. Install ground wire from the main

burner to the ground terminal of the S87D.

WIRING

■GENERAL PRECAUTIONS-

1. Check the wiring diagram furnished by the

appliance manufacturer, if available, for

circuits differing from the ones shown in this

publication. Carefully follow all instructions af

fecting the general procedures outlined below.

2. All wiring must comply with applicable elec

trical codes and ordinances.

3. Disconnect the power supply before wiring to

prevent electrical shock and equipment

damage.

4. The flame sensor leadwire should be kept as

short as possible and should not be allowed to

rest against grounded metal surfaces.

5. A common ground is required for the S87D

Electroic Module, Q347A Spark Ig

niter-Sensor, Q354A Flame Sensor and main

burner. The S87 ground (GND) terminal in

ternally grounds one side of the transformer.

Any auxiliary controls or limits used must not

be in the grounded leg.

6. Ignition cable should not touch any metal sur

face or current-carrying wires. It must not be

more than 30 in. [762 mm] long.

7. Do not short valve terminals as this may burn

out the temperature controller or the

transformer.

AUXILIARY CONTROLS

CAUTION

1. If a common transformer is used to power both

the S87D and the burner valve circuit, its

capacity (VA) must be adequate for all of the

system components (see Table 2).

2. Turn off gas supply before beginning installa

tion. After Installing gas control, be sure to

conduct Gas Leak Test, page 8.

Install the auxiliary controls required in the complete

control system, following the instructions of the ap

pliance or control manufacturer.

TABLE 2—TRANSFORMER RATINGS FOR

S87D AND DUAL VALVE COMBINATION

MINIMUM

VA

RATING CURRENT

(24 V transformer)

20

30

40 1.1 to 1.4

55 1.5 to 2.0

GAS CONTROL.

TOTAL

VALVE S87D

(in amperes)

Up to 0.6 0.2

0.7 to 1.0

CURRENT

(in amperes)

0.2

0.2

0.2

S87D CONTROL MODULE

1. Connect the system components to the S87D

quick-connect terminals as shown in the wiring dia

grams. Refer to the appliance manufacturer's instruc

tions for wiring any other auxiliary controls.

2. Adjust thermostat heat anticipator to match

system current draw. The current draw equals the total

current required for the S87D (0.2 A) plus the gas valve.

Gas valve must be designed for DSI application.

Q347A SPARK IGNITER AND IGNITION CABLE

1. Connect the GND burner, quick-connect terminal

on the S87D to one of the mounting screws on the

Q347A as shown in Fig. 4. The S87 and 0347 must have

a common ground. Use thermoplastic insulated wire

with a minimum rating of 105 C [221 F] for the ground

wire; asbestos insulation is not acceptable. If neces

sary, use a shield to protect the wire from radiant heat

generated by the burner.

2. Connect one end of the ignition cable (supplied

with the Y343B package) to the ignition terminal on the

S87 and the other end to the Q347.

NOTE: Ignition cable must not run in contact with a

metal surface or current-carrying wires. Use ceramic

or plastic standoff insulators to protect voltage to

spark electrode from being reduced. If cable passes

through a metal panel, use an insulated bushing in

the panel to prevent voltage reduction to spark

electrode.

68-0014

Page 6

Q354A FLAME SENSOR

1. Mate quick-connect terminals (1/4 in. [6.4 mm})'

are provided on both the Q354 and S87D. Connect the

SENSOR terminal on the S87 to the terminal on the

Q354 as shown in Fig. 4. Use thermopiastic insulated

wire with a minimum rating of 105 C [221 F] for the

fiame sensor ieadwire; asbestos insulation is not

acceptabie.

The auxiliary controls (transformer, thermostat,

limit) must be connected to the 24 V terminal,

gas valve must be connected to the VALVE

terminals and the alarm control to the ALARM

terminal on the S87D. Only one side of the

transformer secondary can be connected to the

24 V (GND) terminal. A short to ground could

cause the system to malfunction.

Connect the system transformer, thermostat, high

temperature iimit controller, combination gas valve and

alarm (if used) as shown in Fig. 4.

FIG. 4—WIRING HOOKUP FOR Y343B PACKAGE IN A

TYPICAL DSI HEATING SYSTEM.

FIG. 5—WIRING HOOKUP FOR Y343B PACKAGE IN A TYPICAL HEATING- COOLING SYSTEM.

Page 7

FIG. 6—WIRING HOOKUP FOR Y343B PACKAGE IN A TYPICAL TWO-STAGE DSI HEATING SYSTEM.

A \ POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

/ 2\ ALTERNATE LIMIT CONTROLLER LOCATION.

A 3 A REPLACEABLE FUSE.

FIG. 7—S87D SIMPLIFIED SCHEMATIC DIAGRAM.

- INTERNAL WIRING

-EXTERNAL WIRING

ANY DUAL VALVE

• - O AS COWTROL—-

68-0014

Page 8

The following start-up and checkout procedures are

basic to the S87. If possible, refer to the specific

instructions provided by the appliance manufacturer

since the appiication and controls used may differ.

NOTE: If one of the system components fails, the S87

will either not operate or it will go into safety iockout

(depending on the type of failure). If the system does

not perform as outlined in START SYSTEM and

CHECK SAFETY LOCKOUT steps below, refer to the

SERVICE section to determine the cause.

START SYSTEM

1. Turn on power and gas suppiy.

2. Perform the following Test for Gas Leaks.

VZ;m777777777777777777777777777r7777rT7^

CHECK SAFETY LOCKOUT

1. With the system power off and the temperature

controller set to call for heat, manually shut off the gas

supply.

2. Turn power on to energize the S87 and begin

spark ignition. Immediately start timing.

3. Determine the number of seconds to safety

lockout (spark cutoff). It should not exceed the time

shown in Table 3.

TABLE 3—S87 LOCKOUT TIMES.

SPECIFIED S87 LOCKOUT

TIME (stamped on

S87 Control Module)

11.0 sec.

SAFETY LOCKOUT TIME

SHOULD NOT EXCEED—

15.0 sec.

W/W////////////////////////////////A

DO NOT OMIT THIS TEST.

With main burner in operation, paint pipe joints,

gas tubing connections, and valve gasket lines

with rich soap and water solution. Bubbles in

dicate gas leaks. To stop leak, tighten joints

and/or screws, or replace gasket. Never use a

flame to check for gas leaks.

3. Set temperature controller to call for heat and

watch for spark at the igniter. Time the length of the

spark operation; it must be within the lockout timing

period (see Table 3).

4. Check that the system starts as follows: Spark

turns on, gas valve opens at once, and burner ignites

after gas reaches the main burner. Once burner flame

is established, spark igniter shuts off.

NOTE: If the gas control has been replaced or serviced,

lightoff may not be satisfactory until air has been

purged from the gas line or the gas input and

combustion air have been adjusted (see manufac

turer’s instructions).

OPERATION

4. After spark cutoff, manually reopen gas supply

cock. No gas should flow to the main burner.

5. Reset system as described below.

RESET S87 AFTER SAFETY LOCKOUT

If the control goes into safety lockout, it will remain

locked out until the system is reset.

To reset the system, adjust the thermostat setting

below room temperature, wait 30 seconds, and move

the thermostat setting up to call for heat. Normal

ignition should occur as described in START SYSTEM,

above.

CHECKOUT

Start system and observe operation through at least

one complete cycle to make certain all controls are

operating safely.

OPERATION

The S87D is powered by a 24 Vac transformer and

activated when the temperature controller calls for

heat. Operation is as follows (refer to Fig. 8).

When the S87 is activated, an internal transformer

provides power to the electronic generator circuit for

spark ignition and the safety lockout timing begins. At

the same time, the S87 opens the gas control’s main

valves which allows gas to flow to the main burner.

Power is supplied to the generator until:

• the main burner lights and flame sensor current

reaches 1.5 uA, or...

• the safety lockout timing period ends.

If the main burner lights, a circuit is completed

through the flame to the burner head to ground. This

current flow returns the safety lockout timer to the reset

(normal) condition and interrupts the spark ignition

circuit. Should the current flow be interrupted; i.e.,

flame-out condition, the trial-for-ignition begins again.

The S87 will keep the gas control main valve open as

long as there is a call for heat and current through the

flame sensing circuit. If, however, the safety lockout

timing period ends before the main burner lights or the

flame sensor establishes enough current, the system

will go into safety lockout.

When the system goes into safety lockout, power to

the generator is interrupted, the gas control circuit is

interrupted and the alarm relay circuit is completed.

The system will stay locked out until it is reset by

moving the thermostat set point below room tem

perature, no call for heat, for 30 seconds.Then,

re-energize the system by moving the thermostat set

point 5 F [2.8 C] above room temperature.

Page 9

1J TEMPERATURE CONTROLLER

CALLS FOR HEAT

POWER INTERRUPTION >

-1

SVSTLM SHUTS OFF, RESTARTS WHEN

i

/ SVS'

POw

POWER IS RESTORED.

SPARK GENERATOR POWERED

0”

MAIN VALVE OPERATORS OPEN

I IF FLAME CURRENT SENSED

MAIN BURNER OPERATION

TEMPERATURE CONTROLLER

SATISFIED

FIG. 8—NORMAL SYSTEM SEQUENCE OF OPERATION.

• IMPORTANT -

1. Only persons trained and experienced in DSI

systems should service this equipment.

2. If a condition exists that causes the S87D

electronic module to go into safety lockout,

meter readings must be taken quickly after

restart — within trial-for-ignition period.

3. Always de-energize the system for at least 30

seconds before recycling for further tests.

4. The S87D electronic module cannot be re

paired. If the troubleshooting procedure in

dicates a malfunction in the S87, it must be

replaced.

5. The following service procedures are for the

S87 and basic DSI systems. On all installa

tions, refer to the appliance manufacturer’s

service instructions.

PRELIMINARY CHECK

The following checks should be made before trou

bleshooting the system.

1. Check for power to the heating appliance and the

S87D.

2. Check fuse on S87D electronic module and re

place if blown.

3. Make certain that the manual shutoff gas cock in

the supply line and on the combination gas control

valve are open.

4. Make certain that all wiring connections are clean

and tight.

5. Make certain the S87 is not in safety lockout.

De-energize the system by moving the thermostat set

point below room temperature. Wait at least 30 seconds

and re-energize the system by moving the thermostat

set point 5 F [2.8 C] above room temperature.

6. Check ceramic insulator on flame sensor and

spark igniter. A cracked insulator will allow current to

leak to ground. Replace device If insulator is cracked.

7. Check the flame sensor and its mounting bracket.

Correct the position if bent out of shape.

8. Review the S87 normal sequence of operation.

See START SYSTEM section.

IF NO SPARK. S87 GOES

INTO LOCKOUT AFTER \

TIMING PERIOD. SVSTEM I

MUST BE RESET 7

IF FLAME CURRENT NOT SENSED

K

S87D COMPONENT CHECKS

SPARK IGNITION CIRCUIT

The step-up transformer in the S87 provides spark

ignition at 15,000 volts (open circuit). To check the

spark ignition circuit, proceed as follows:

1. Shut off gas supply to the gas control.

2. Disconnect the ignition cable at the S87 stud

terminal to isolate the circuit from the spark-igniter.

Prepare a short jumper wire, using heavily insulated

wire such as ignition cable.

CAUTION

Do not allow fingers to touch either the stripped

end of the jumper or the stud terminal. This is a

very high voltage circuit and electricai shock

can result.

3. Perform this test immediately upon energizing

the system — before the S87D goes into safety lockout

and interrupts the spark circuit. Touch one end of the

jumper firmly to the S87 GND terminal. (DO NOT

remove the existing ground lead.) Slowly move the

other end of the jumper wire toward the stud terminal

on the S87 to establish a spark. Pull the wire away from

the stud and note the length of gap at which spark

discontinues.

4. A spark length of 1/8 in. [3.2 mm] or more

indicates satisfactory voltage output. If no arc can be

established or the maximum spark is less than 1/8 in.

[3.2 mm], and power to the S87 input terminals was

proved, replace the S87.

IGNITION CABLE

Check the electrical continuity of the ignition cable

and make certain the cable is not in contact with metal

surfaces. The total cable length should not exceed 3 ft

[0.9 m]. A loose connection to the spark igniter-sensor

may not conduct a signal even though spark ignition is

satisfactory. Check connections to the stud terminal on

the S87D and the boot connection to the spark ig

niter-sensor and make certain they are clean and tight.

68-0014

Page 10

GROUNDING CONNECTIONS

A common ground is required for the burner, spark

igniter-sensor mounting bracket and the GND terminal

of the S87. If ground is poor or erratic, safety shutdown

may occur occasionally even though operation is normai at time of checkout. Therefore, if nuisance shut

downs have been reported, be sure to check ground

connections.

Electrical ground connections at the spark ig

niter-sensor and the S87D must be clean and tight. If

leadwire is damaged or deteriorated, use only No. 14 or

No. 18 gauge, moisture-resistant, thermoplastic in

sulated wire with 105 C [221 F] minimum rating as

replacement.

FLAME SENSOR CIRCUIT

The S87D provides ac power to the flame sensor

which the burner flame rectifies to direct current. If the

flame signal back to the S87 is not at least 1.5 pA dc, the

system will lock out.

The output of the flame sensing circuit can be

checked directly on the S87D. Check the flame sensing

circuit as follows.

1. Connect a meter (dc microammeter scale) in

series with the sensor wire as shown in Fig. 9. Use the

Honeywell W136A Test Meter or equivalent. Disconnect

the sensor wire at the S87D. Connect the red (positive)

lead of the meter to the free end of the sensor wire.

Connect the black (negative) meter lead to the sensor

terminal on the S87.

2. Restart the system and read the meter. The flame

sensor current must be at least 1.5pA and steady. If the

reading is less than 1.5 pA or unsteady, see LOW OR

UNSTEADY FLAME CURRENT section, below.

Burner Flame

The flame sensor must be constantly immersed in

flame. Check burner flame conditions as shown in

Fig. 10. If necessary, improve the flame condition or

relocate the flame sensor to a place on the main burner

where flame conditions are better.

Flame Sensor

The flame signal is best when about 1 in. [25.4 mm]

of flame rod is immersed in the burner flame. A bent

flame rod or mounting bracket can affect flame signal.

Bend flame rod bracket to correct position if necessary.

Excess temperature at the ceramic flame rod insulator

may cause leakage to ground, decreasing the flame

signal. Replace the flame sensor if the ceramic insulator

is cracked, and relocate the sensor to an area of lower

ambient temperature if necesary.

Electrical Connections and Shorts

Connections at the flame sensor must be clean and

tight. If wiring needs replacement, use moistureresistant No. 18 wire rated for continuous duty up to 105

C [221 Fj.

FLAME SENSOR CURRENT CHECK—USE iiA SCALE

FIG. 9—S87 FLAME CURRENT MEASUREMENT.

LOW OR UNSTEADY FLAME CURRENT

If the current to the S87D flame circuit is less than 1.5

uA or is unsteady, check the burner flame and flame

sensor location and electrical connections as follows.

CHECKOUT AFTER SERVICE

Perform the following steps before leaving the job

(described in CHECKOUT section)—

• START SYSTEM

• SAFETY LOCKOUT CHECK

• SAFETY LOCKOUT RESET

Also perform any other checks recommended by the

heating appiiance manufacturer if system components

other the the Y343B were serviced.

10

Page 11

start the system by setting the thermostat (tem

perature controller) to call tor heat. Observe the system

response and establish the type of malfunction or

deviation from normal operation by using Table 4.

Use Table 4 by following the instructions in the

boxes. If the condition is true or okay (answer is yes), go

TABLE 4—S87 DIRECT SPARK IGNITION SYSTEM TROUBLESHOOTING

DIRECT SPARK IGNITION SYSTEM TROUBLESHOOTING TABLE

down to the next box. If the condition is not true or not

okay (answer is no), go to the box at right. Continue

checking and answering conditions in each box until a

problem and/or repair is explained. After any main

tenance or repair, the troubleshooting sequence should

be repeated until normal system operation is obtained.

HONEYWELL MINNEAPOLIS, MN 55408 INTERNATIONAL Sales Offices in all principal cities of the world. Manufacturing in

Australia, Canada, Finland, France, Germany, Japan,.Mexico, Spain, Taiwan, United Kingdom, U.S.A.

PRINTED IN U.S.A

Loading...

Loading...