Page 1

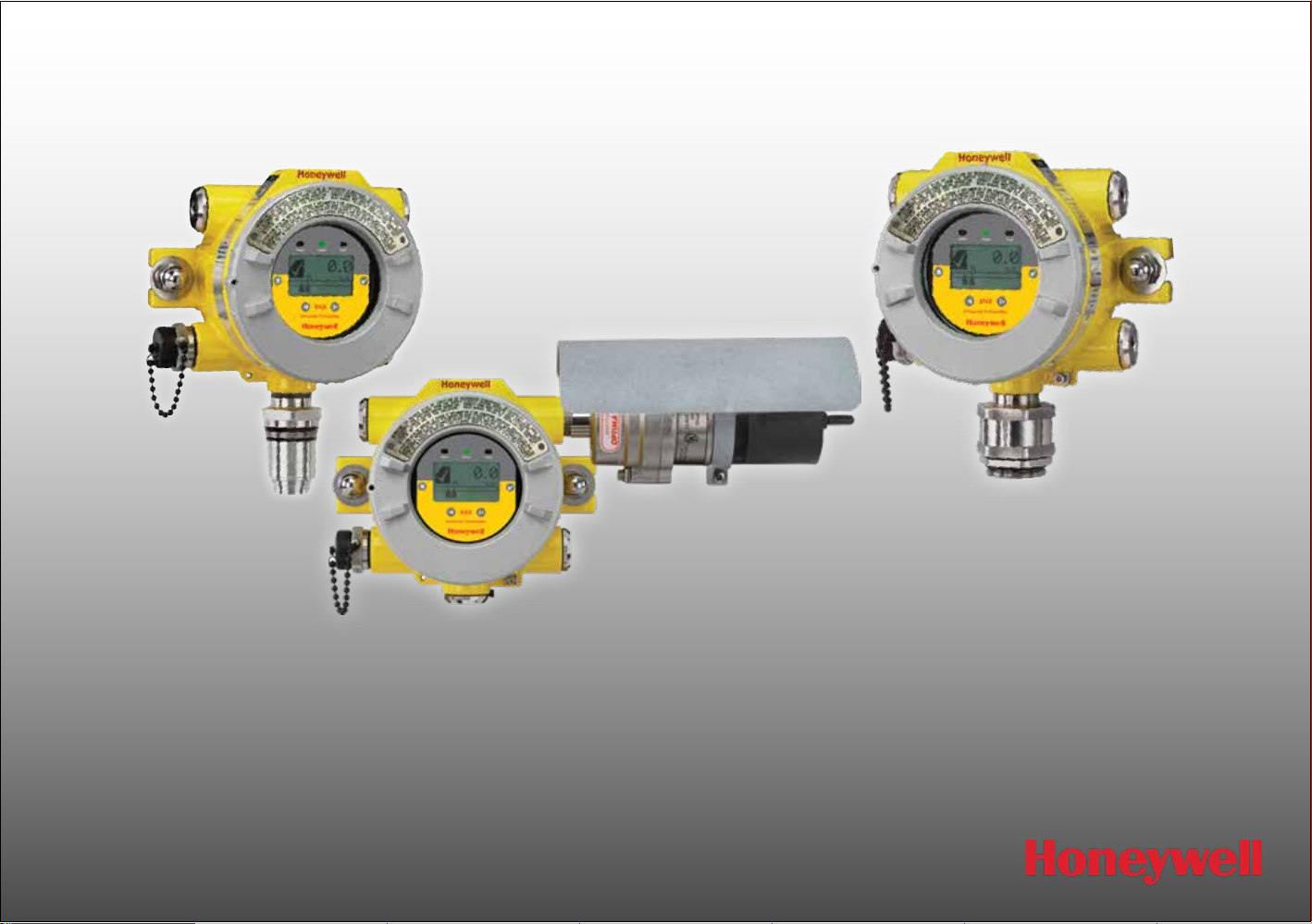

XNX

● Table of Contents

● Safety and Information

● Introduction

● Specications

● Control Drawings

● HART

Protocol

Technical

Manual

● Installation and Operation

● Calibration

● Maintenance

● Warnings/Faults

● Modbus Protocol

● Warranty

● Index

Page 2

This page is intentionally left blank

Page 3

XNX Universal Transmitter

TOC

Table of Contents

Safety and Information ���������������������������������������������������������������������5

Warnings�������������������������������������������������������������������������������������6

Hazardous Location Installation Requirements �������������������������8

Special Conditions for Safe Use �������������������������������������������������8

Cautions �������������������������������������������������������������������������������������8

Notes ������������������������������������������������������������������������������������������8

Information ����������������������������������������������������������������������������������9

Contacting Honeywell Analytics ��������������������������������������������������9

Revision History ��������������������������������������������������������������������������9

Introduction �������������������������������������������������������������������������������������10

Product Description �����������������������������������������������������������������11

The Transmitter �������������������������������������������������������������������11

20 mA/HART Output �����������������������������������������������������������12

Communications �����������������������������������������������������������������12

Certifications �����������������������������������������������������������������������12

Patents ��������������������������������������������������������������������������������13

Glossary �����������������������������������������������������������������������������13

Product Overview ���������������������������������������������������������������������14

Enclosure ����������������������������������������������������������������������������14

Cover ����������������������������������������������������������������������������������15

POD �����������������������������������������������������������������������������������15

Options �������������������������������������������������������������������������������������16

Local HART �����������������������������������������������������������������������16

Relays ���������������������������������������������������������������������������������16

Modbus ������������������������������������������������������������������������������17

FOUNDATION Fieldbus ������������������������������������������������������17

Accessories ������������������������������������������������������������������������17

The Front Panel ������������������������������������������������������������������������20

Controls and Navigation �����������������������������������������������������21

The General Status Screen ������������������������������������������������21

Entering the Menu ��������������������������������������������������������������22

Displaying Transmitter Information ��������������������������������������23

Main Menu ��������������������������������������������������������������������������������24

Menu Navigation �����������������������������������������������������������������������25

Installation and Operation ���������������������������������������������������������������29

Sensor Mounting and Location �������������������������������������������������30

Mounting the T ransmitter ����������������������������������������������������30

Wiring the Transmitter ���������������������������������������������������������32

General Wiring Considerations �������������������������������������������33

Loading �������������������������������������������������������������������������������33

Isolation ������������������������������������������������������������������������������33

Circuit Protection ����������������������������������������������������������������33

Distance Considerations for Installation������������������������������33

Single Transmitter ���������������������������������������������������������������34

Multiple Transmitters Connected to a Single Power Source 34

Multiple Transmitters Connected in a “Daisy-Chain”

Configuration ����������������������������������������������������������������������34

Power Source Selection ������������������������������������������������������35

Wire Selection ���������������������������������������������������������������������35

Single Transmitter Distances ����������������������������������������������36

Daisy-Chained Transmitter Distances ���������������������������������36

POD Connections ���������������������������������������������������������������38

4-20mA Output, Common Connections, and Power ����������39

Settings ������������������������������������������������������������������������������39

FOUNDATION Fieldbus Wiring �������������������������������������������41

Terminal Block Connections �����������������������������������������������41

Table of Contents

1

Page 4

XNX Universal Transmitter

✓

X

?

?

?

Table of Contents

EC Personality Wiring ���������������������������������������������������������42

Electrochemical Sensor Installation ������������������������������������43

EC Sensor Remote Mounting Kit ����������������������������������������44

mV Personality Wiring ���������������������������������������������������������46

mV Remote Sensor Mounting ���������������������������������������������47

IR Personality Wiring ����������������������������������������������������������49

Searchpoint Optima Plus/Searchline Excel Connections ���50

Connecting Generic mA Devices ����������������������������������������50

Attaching the Searchpoint Optima Plus to the Transmitter �53

Searchline Excel/Searchpoint Optima Plus Remote

Installation ���������������������������������������������������������������������������53

Searchpoint Optima Plus/Searchline Excel Wiring �������������54

Options �������������������������������������������������������������������������������������56

Local HART Interface ����������������������������������������������������������56

Point-to-Point Mode ������������������������������������������������������������56

Multidrop Mode �������������������������������������������������������������������57

Cable Length ����������������������������������������������������������������������58

Relays ���������������������������������������������������������������������������������58

Modbus ������������������������������������������������������������������������������59

FOUNDATION Fieldbus ������������������������������������������������������60

Powering the Transmitter the First Time ������������������������������61

IR Units Configured for Searchline Excel ���������������������������62

Remote Calibration of MPD Sensors ����������������������������������63

Configuring the Transmitter �������������������������������������������������������63

Configure Menu ��������������������������������������������������������������64

Select Language �������������������������������������������������������������64

Set Date and Time ���������������������������������������������������������65

Set mV Sensor Type �������������������������������������������������������66

Set mA Sensor Type �������������������������������������������������������67

Gas Selection �������������������������������������������������������������������67

Changing the Gas or Units Name ���������������������������������������69

Gas Selections and Alarm Limits Based on mV Sensor Type

��������������������������������������������������������������������������������������������69

Range and Alarms ����������������������������������������������������������74

Latching/Non-Latching Alarms ���������������������������������������77

Set Units ��������������������������������������������������������������������������78

mA Levels �����������������������������������������������������������������������79

Calibration Interval ����������������������������������������������������������79

Accept New Sensor Type ������������������������������������������������80

Beam Block Options �����������������������������������������������������81

Path Length ��������������������������������������������������������������������82

Unit ID �����������������������������������������������������������������������������83

Relay Options �����������������������������������������������������������������84

Fieldbus Options �����������������������������������������������������������85

Configure Security �����������������������������������������������������������86

Verifying the Configuration��������������������������������������������������������87

Test Menu ������������������������������������������������������������������������87

Inhibit ������������������������������������������������������������������������������87

Force Relays ������������������������������������������������������������������89

Alarm/Fault Simulation ���������������������������������������������������89

Information Menu ������������������������������������������������������������91

Alarm/Fault Status ����������������������������������������������������������91

Transmitter Data �������������������������������������������������������������91

Transmitter Status ����������������������������������������������������������92

Sensor Data ��������������������������������������������������������������������92

Sensor Status �����������������������������������������������������������������93

Table of Contents

2

Page 5

XNX Universal Transmitter

?

Table of Contents

Gas Data ��������������������������������������������������������������������������93

Range/Alarm Settings�����������������������������������������������������94

mA Level Settings �����������������������������������������������������������94

Fieldbus Settings �����������������������������������������������������������95

Relay Data ����������������������������������������������������������������������95

Event History ����������������������������������������������������������������97

Calibration ������������������������������������������������������������������������������������100

Gas Calibration Menu���������������������������������������������������101

Zero and Span Calibration for EC/mV Sensors and

Searchpoint Optima ����������������������������������������������������������102

Using the Calibration Cup �������������������������������������������������105

Zero and Span Calibration of EC Sensors ������������������������105

Zero and Span Calibration for MPD Sensors ��������������������110

EC Sensor Operational Life ����������������������������������������������113

Functional Gas T esting (Bump T esting) ����������������������������113

Calibrate mA Output ���������������������������������������������������114

Align Excel (Searchline Excel) �������������������������������������115

Soft Reset ��������������������������������������������������������������������115

Maintenance ���������������������������������������������������������������������������������116

MPD Sensor Cartridge Replacement �������������������������������117

EC Sensor Cartridge and Cell Replacement ��������������������118

Warnings and Faults ���������������������������������������������������������������������120

Warning Messages �����������������������������������������������������������121

Notes ��������������������������������������������������������������������������������125

Fault Messages �����������������������������������������������������������������126

Notes ��������������������������������������������������������������������������������133

Informational Messages ����������������������������������������������������135

Specifications �������������������������������������������������������������������������������137

Product Specifications ������������������������������������������������������������138

SENSOR DATA �����������������������������������������������������������������140

Operating and Storage Conditions for Performance Tested

EC Cartridges �������������������������������������������������������������������140

Detectable Gases and Performance ���������������������������������������141

EC Sensor Performance Data, Factory Mutual Verified ����������142

EC Sensor Performance Data, DEKRA EXAM Verified ����������143

Other EC Sensors ������������������������������������������������������������������144

Footnotes (see table on previous page): ��������������������������145

Notes (see table on previous page): ���������������������������������145

EC Sensor Cross-sensitivity ���������������������������������������������������146

Notes ��������������������������������������������������������������������������������153

MPD Sensor Performance Data ���������������������������������������������154

Notes �������������������154

EN60079-29-1 Performance Approved Gases for mV Sensor

Types ��������������������������������������������������������������������������������������155

Notes �������������������155

Other Sensor Performance Data ��������������������������������������������155

Certifications by Part Number Series �������������������������������������156

Notes �������������������157

Certification Labels ����������������������������������������������������161

Product Identification �������������������������������������������������������������163

EC Replacement Sensors ������������������������������������������������������164

EC Replacement Cells �����������������������������������������������������������165

MPD (Multi Purpose Detector) ������������������������������������������������166

Accessories/Spares ����������������������������������������������������������������167

EC Declaration of Conformity �������������������������������������������������171

�����������������������������������������������������������������������������������������������171

Table of Contents

3

Page 6

XNX Universal Transmitter

Table of Contents

Control Drawings ��������������������������������������������������������������������������172

XNX UL/CSA/FM/ATEX/IECEx/INMETRO/RUSSIA ���������������173

Remote Sensor Mount ������������������������������������������������������������177

HART Protocol ������������������������������������������������������������������������������178

HART Interface �����������������������������������������������������������������������179

HART Sink, Source, and Isolated Wiring ��������������������������������182

DevComm PC-based HART Interface ������������������������������������185

Functions ��������������������������������������������������������������������������������186

Configuration Summary ����������������������������������������������������186

Information Screens ����������������������������������������������������������187

Event History ��������������������������������������������������������������������187

Test �����������������������������������������������������������������������������������187

Calibration �������������������������������������������������������������������������188

Configuration ��������������������������������������������������������������������188

Handheld Online Menus ���������������������������������������������������������189

Modbus Protocol ���������������������������������������������������������������������������191

Modbus and the XNX transmitter ��������������������������������������������192

Modbus Registers �������������������������������������������������������������������194

Warranty ���������������������������������������������������������������������������������������198

Warranty Statement ����������������������������������������������������������������199

Warranty Conditions ���������������������������������������������������������199

Consumer Claims �������������������������������������������������������������199

Index ���������������������������������������������������������������������������������������������200

Table of Contents

4

Page 7

XNX Universal Transmitter

Safety and Information

Safety and Information

5

Page 8

XNX Universal Transmitter

WARNING

!

Read and understand this manual before installing, operating, or

maintaining the transmitter. Pay particular attention to these warnings and

cautions. All of the warnings and cautions shown here are repeated in the

appropriate sections of the manual.

• Warnings identify hazardous or unsafe practices which could result in severe injury

or death.

Warnings

• Installation must be in accordance with the recognized standards of the

appropriate authority in the country concerned.

• Any work on the interior of the detector must be conducted only by Honeywelltrained personnel

• Before carrying out any work, ensure that local regulations and site procedures

are followed. Appropriate standards must be followed to maintain the overall

certification of the sensor.

• To reduce the risk of ignition in hazardous atmospheres, disconnect the equipment

from the supply circuit before opening the sensor enclosure. Keep the assembly

tightly closed during operation. Conduit runs must have a seal fitting connected

within 18 inches (45 cm) of the enclosure.

• Never open the XNX enclosure under power unless the area is known to be nonhazardous.

• Do not use the XNX Universal Transmitter in oxygen-enriched atmospheres. In

oxygen-enriched atmospheres, the electrical safety is not guaranteed.

• The sensor must be earthed/grounded for intrinsic safety, electrical safety and to

limit the effects of radio frequency interference. Earth/ground points are provided

inside and outside the unit. EMI note for applications using shielded cable: Cable

shield must provide 90% coverage of the wiring. Cable shield terminations must

be made at the cable glands with suitable EMI type glands. Avoid terminating

cable shields at the Earth ground lug inside the XNX enclosure. In cases where

wiring is in pipe, a shielded cable is not required. The external terminal is only a

supplemental bonding connection where local authorities permit or require such a

connection.

• Take care when handling EC sensor cells as they may contain corrosive solutions.

Do not tamper or in any way disassemble the sensor cells. Do not expose to

temperatures outside the recommended range. Do not expose the sensor to

organic solvents or flammable liquids.

• At the end of their working lives, sensors must be disposed of in an

environmentally safe manner, in accordance with local waste management

requirements and environmental legislation. Alternatively, sensors may be securely

packaged, clearly marked for environmental disposal, and returned to Honeywell

Analytics. Do NOT incinerate sensors as they may emit toxic fumes.

• High off-scale readings may indicate an explosive concentration of gas.

• Verify all outputs, including display, after installation, after service events, and

periodically to ensure the safety and integrity of the system.

• Do not use the transmitter in oxygen-enriched atmospheres. Concentrations

displayed will be adversely affected by oxygen depletion.

• After changing parameters with a handheld device, verify that the parameter

settings are correct at the transmitter.

• The factory-set passcodes must be reset to prevent unauthorized access to the

transmitter’s menus.

• When the transmitter is equipped with the optional Remote Mount Kit, the remote

sensor must be securely mounted in a fixed position. The Remote Sensor kit is not

intended to be used as a handheld sensor.

Safety and Information

6

Page 9

XNX Universal Transmitter

• Enclosures of remotely mounted sensors contain aluminum. When installed in

Zone 1 locations, be careful to avoid ignition hazards due to impact or friction.

• Install the junction box according to local codes and manufacturer’s requirements.

• The enclosures of remotely mounted 705HT sensors contain aluminum. When

installed in Zone 1 locations, be careful to avoid ignition hazards due to impact or

friction.

• Power off the transmitter before changing S3 or S4. Failure to do this will

permanently damage the transmitter. Both switches must be set in either Source

or Sink prior to applying power.

• Do not set the minimum or maximum controller alarm levels at less than 10% or

greater than 90% of the full scale range of the sensor. CSA and FM agency limits

are 60% LEL or 0.6mg/m3.

• When configuring or communicating with the transmitter using the front panel

displays, resume monitoring by exiting all menus and returning to the General

Status menu manually. No time outs are invoked.

• When selecting a new target gas for units with a Searchpoint Optima Plus, the

sensor must be recalibrated.

• XNX Universal Transmitters carrying UL/CSA/FM approvals that are configured for

devices measuring %LEL will not allow adjustments to the full scale value. The

range is fixed at 100%.

• There is a potential loss of sensitivity during exposure to high concentrations

of H2S. Under these conditions, set the control unit to latch at overrange. In

standalone configuration, set alarms to latching. When resetting the overrange or

alarm, verify correct operation of the transmitter.

• Keep the passwords in a secure area to prevent unauthorized access to the

transmitter. If the passwords are lost, resetting the transmitter will require a

service technician.

• When the transmitter is placed in Inhibit Mode, alarms are silenced. This will

prevent an actual gas event from being reported. Inhibit Mode must be limited

to testing and maintenance only. Exit Inhibit Mode after testing or maintenance

activities.

• Honeywell recommends periodic bump tests (every 30 days or in accordance

with customer site procedures) to the sensor to insure proper operation and

compliance with the functional safety rating of the installation.

• Honeywell Analytics recommends bump testing of ClO2, Cl2, HF, and HCl sensors

frequently and in accordance with customer site procedures to ensure proper

operation and compliance with the functional safety rating of the installation.

• As some test gases are hazardous, exhaust the flow housing outlet to a safe area.

• Exposure to desensitizing or contaminating substances or concentrations causing

operation of any alarm may affect sensor sensitivity. Following such events, verify

sensor performance by performing a functional gas test (bump test).

• When servicing or replacing sensors, reduce the risk of ignition in hazardous

atmospheres by declassifying the area or disconnecting the equipment from the

supply circuit before opening the sensor enclosure. Keep the assembly tightly

closed during operation.

• Take appropriate precautions when using toxic, flammable, or pressurized

cylinders.

• XNX transmitter is SIL2 approved and please refer to XNX transmitter safety

manual (1998-0808) for the detail of SIL certificate.

ELECTROSTATIC DISCHARGE

To minimize the risk of electrostatic discharge:

• Ground the transmitter adequately

• Install the transmitter in a manner that will prevent accidental electrostatic

discharges, e.g. ensure that objects do not rub against the housing etc.

• Clean the enclosure with a damp cloth when necessary

Safety and Information

7

Page 10

XNX Universal Transmitter

CAUTION

!

NOTE

Hazardous Location Installation Requirements

• Read and understand this manual prior to installation and use.

• Use only certified cable glands for installation.

• Shielded armored cable is required for CE compliance.

• To reduce the risk of ignition in hazardous atmospheres, conduit runs must have a

pour gland installed within 18 inches (45 cm) of the enclosure.

• All ¾ inch NPT conduit, stopping plugs, and adapters must be installed with 5¼

threads (minimum) engaged to maintain the explosion-proof rating.

• The XNX cover assembly must be fully seated to the enclosure (7 threads

minimum) to maintain the explosion-proof rating.

• Use only the supplied stopping plugs (Honeywell part number 1226-0258) with the

XNX Universal Transmitter.

• For units fitted with the optional relay module: relay contact ratings are 250 VAC

5A, 24 VDC 5A resistive loads only.

• Use copper conductors only. Tighten terminal block screws to 4.5 lb/in (max).

• For XNX-UT**-***** transmitters, refer to XNX control drawing 1226E0402.

Special Conditions for Safe Use

• The following applies to the HART Barrier intrinsically safe circuits: For installations

in which both the Ci and Li of the intrinsically safe apparatus exceed 1% of the Co

and Lo parameters of the associated apparatus (excluding the cable), then 50% of

Co and Lo parameters are applicable and shall not be exceeded, i.e., the Ci of the

device plus the C of the cable must be less than or equal to 50% of the Co of the

associated apparatus, and the Li of the device plus the L of the cable must be less

than or equal to 50% of the Lo of the associated apparatus.

• For circuits connected to the EC barrier in which the capacitance and inductance

exceed 1% of the permitted values, the maximum permitted capacitance is limited

to 600 nF for group IIC and 1uF for group IIIC.

• The connection to the HART circuit shall be rated a minimum of IP 6X.

• Delays resulting from transmission errors between sensor and transmitter extend

response times T90 by more than one-third. The period until fault indication is 10

seconds.

• The HART interface is subject of this EC-type examination certificate only for the

purpose of configuration and maintenance. The options “Modbus interface” and

“FOUNDATION Fieldbus interface” are not subject of this EC-type examination

certificate.

• Long-term exposure (>20 minutes) to concentrations exceeding the full-scale

range of the H

value may then decrease even though high levels of toxic gas are still present. If

such conditions can occur, set the control unit to latch at overrange. In standalone

operation, set alarms to latching. When resetting the overrange or alarm, verify the

correct operation of the transmitter. Before re-calibrating the transmitter, verify the

absence of gas.

• The flameproof joints are not intended to be repaired.

S sensor Type 2 can cause it to lose sensitivity. The measured

2

Cautions

Caution messages address situaltions that could result in damage to the

transmitter or sensors.

Notes

!

Notes relate helpful information.

Waste Electrical and Electronic Equipment (WEEE) Directive

This symbol indicates that the product must NOT be disposed of as general

industrial or domestic waste. This product should be disposed of through

suitable WEEE disposal facilities. For more information about disposal of this

product, contact your local authority, distributor or the manufacturer.

Safety and Information

8

Page 11

XNX Universal Transmitter

Information

Honeywell Analytics assumes no responsibility for equipment that is not

installed and used following the procedures in the Technical Manual.

Ensure that the appropriate equipment has been installed. If in doubt,

contact Honeywell Analytics.

Honeywell Analytics assumes no responsibility for errors or omissions in

this document or the consequences of those errors or omissions. Contact

Honeywell Analytics with corrections. Honeywell Analytics reserves the

right to revise this document without notice. Contact the local distributor or

Honeywell Analytics if additional information is needed.

XNX® is a registered trademark of Honeywell International.

TM

Reex

is a trademark of Honeywell International.

HART® is a registered trademark of the HART Communication

Foundation.

Modbus® is a registered trademark of Schneider Automation Inc.

FOUNDATIONTM is a trademark of Fieldbus Foundation.

Unistrut® is a registered trademark of Unistrut Corporation.

Windows® is a registered trademark of Microsoft Corporation.

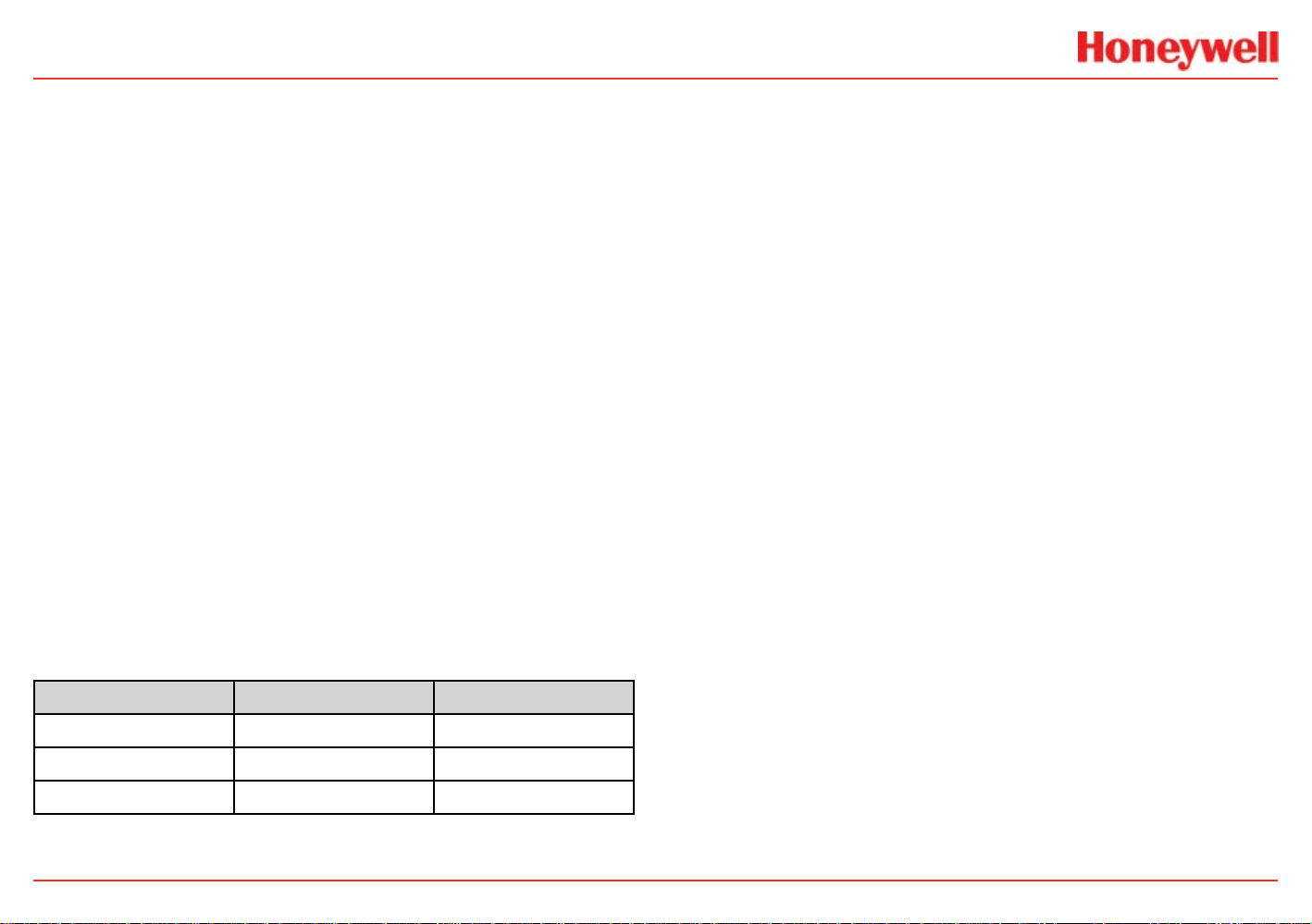

Revision History

Revision Comment Date

Rev 13 ECO 9425 Oct 2018

Rev 14 ECO 9443 Jan 2019

Rev 15 ECO 2019-4777 Sep 2019

Contacting Honeywell Analytics

www.honeywellanalytics.com

Europe, Middle East, Africa, India

Life Safety Distribution GmbH

Javastrasse 2

8604 Hegnau

Switzerland

Tel: +41 (0)44 943 4300

Fax: +41 (0)44 943 4398

India Tel: +91 124 4752700

gasdetection@honeywell.com

Americas

Honeywell Analytics Inc.

405 Barclay Blvd.

Lincolnshire, IL 60069

USA

Tel: +1 847 955 8200

Toll free: +1 800 538 0363

Fax: +1 847 955 8210

detectgas@honeywell.com

Asia Pacific

Honeywell Analytics Asia Pacific

7F SangAm IT Tower, 434 Worldcup Buk-ro,

Mapo-gu, Seoul 03922

Korea

Tel: +82-2-69090300

Fax: +82-2-69090328

analytics.ap@honeywell.com

Technical Services

EMEA: HAexpert@honeywell.com

US: HA.us.service@honeywell.com

Safety and Information

9

Page 12

XNX Universal Transmitter

Introduction

XNX Universal Transmitter Technical Manual

10

Page 13

XNX Universal Transmitter

e

r

ype

y

ppo

o

s

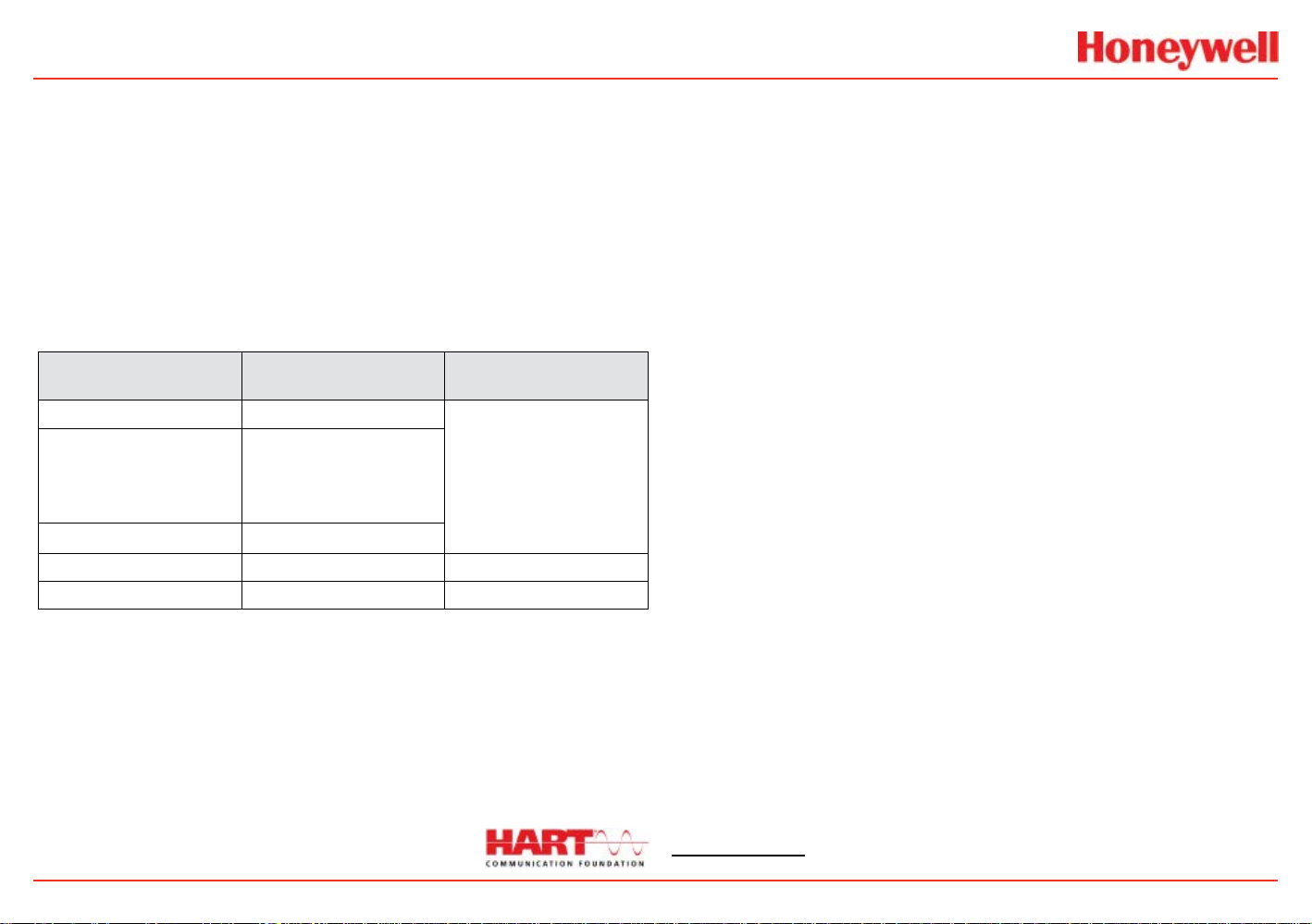

Product Description

The Transmitter

The transmitter is a comprehensive gas detection system

designed to operate in hazardous locations

sensor technologies –catalytic bead, electrochemical (EC),

or infrared (IR)– to detect toxic gases, ammable gases, and

oxygen depletion gas hazards. Each technology has a dedicated

personality board.

Catalytic bead technology is used with the mV personality

board. Catalytic bead sensors respond to a wide variety of

combustibles so are typically used for ammable gas detection.

Electrochemical technology is used with the electrochemical

board. EC sensors measure toxic gases in low concentrations.

The EC sensors employ the patented Reex™ cell fault

diagnosis routine. Reex checks for cell presence, cell dry-out,

and cell open or short circuit. Reex is automatically initiated

by the transmitter at eight-hour intervals. It is also initiated on

power up or sensor exchange. In the event of a cell failing this

test, a sensor fault code is displayed. Reex diagnostics occur in

the rst minutes of the power up sequence.

Infrared technology is used with the IR board. IR sensors

optically absorb gases that fall into the infrared spectrum.

For additional information about any of these sensor types, refer

to the applicable data sheet for the supported sensor in Figure 1.

The transmitter also allows for an optional communication

board. There are three types of boards: relay, Modbus

1

There are three main types of gas hazards: ammable, toxic, and asphyxiant. A am-

mable gas hazard is one in which there is a risk of re and/or explosion (e.g., a situation

in which a gas such as methane, butane, or propane is present). A toxic gas hazard is

one in which there is a risk of poisoning (e.g., a gas such as carbon monoxide, hydrogen

sulde, or chlorine is present). An asphyxiant hazard would include a risk of suffocation

through oxygen deciency. (Oxygen can be consumed or displaced by another gas.)

Introduction

1

and utilize multiple

®

, or

FOUNDATIONTM Fieldbus. See the Communications section for

additional information.

XNX Universal Transmitter

Searchline Excel

Searchpoint Optima Plus

705

705HT

CI

H

2

CIO

CO

F

2

Personality Sensor Type Supported Sensors

rsonality Senso

NH

2

NO

H2S

2

NO

HF

EtO

HCN

HCI

O

3

2

PH

3

SO

2

2

O

3

Su

Sensepoint

Sensepoint HT

ted Sens

Multi-Purpose

Detector (MPD)

Catalytic Bead

Infrared Flammable

Infrared Methane/CO

IR Point and Open-Path Infrared Searchpoint Optima Plus, Searchline Excel

mV Flammable and Toxic

XNX EC Toxic and O

Sensing

2

705, 705HT, Sensepoint, Sensepoint HT, MPD

(Catalytic Bead Flammable, IR Flammable and IR CO

Electrochemical sensors, with Hot Swap, pre-calibrated

through Intrinsically Safe (IS) barrier

.

Figure 1. XNX Universal Transmitter and supported sensing technologies

The transmitter relies on 4-20mA output, refreshed at least every

two seconds (once per second is typical), in which the output is

proportional to the gas concentration.

11

2

)

2

Page 14

XNX Universal Transmitter

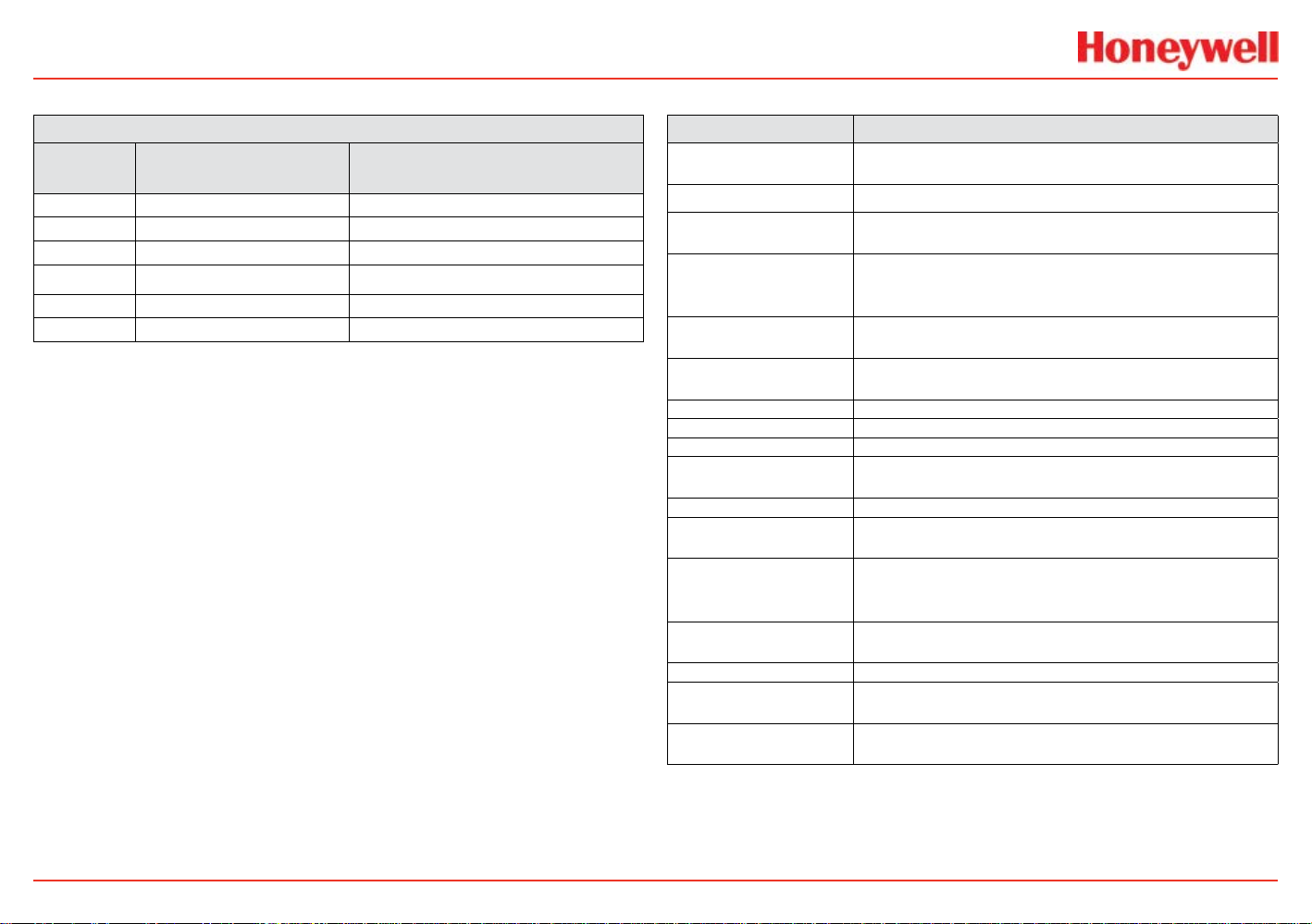

20 mA/HART Output

All XNX Transmitters provide a 20mA Current Loop with HART

Communication which can be user congured for Sink, Source

(3-Wire) or Isolated (4-Wire) electrical interface based on

installation requirements.

The 20mA current loop output provides an analog indication of

special states, a proportional output to gas concentration and

overrange indication as shown in the table below. In the event of

a simultaneous alarm and fault, an alarm condition will always

override fault or warning state.

Output Description* Notes

1.0 mA Fault

Warm-up

2.0 mA

3.0 mA Warning

4-20 mA Gas Concentration

21 mA Overrange

*Alarm conditions always take priority over faults and warnings.

Inhibit

Bump Test

Calibration

Special

State

Indication

HART Protocol provides communications with the transmitter

from a remote control system for Conguration, Status, and

Diagnostics. (See the HART Protocol section for additional

information)

Communications

The XNX® Universal Transmitter is registered with the HART®

Communication Foundation. The transmitter

features HART over 4-20mA as standard.

Introduction

Additional optional communication interfaces are available:

relay communication, Modbus, or FOUNDATION Fieldbus.

Each communication option has a dedicated option board. For

additional information, refer to the Options section.

Certifications

XNX-UT**-****** Versions are UL and CSA listed for installation in

Class I, Division 1, Groups A, B, C and D Hazardous Locations.

FM Approvals evaluation includes Class I, Zone 1, Group IIC,

as well as performance tests for specic sensor/transmitter

combinations. The CSA or FM certication does not cover daisychained XNX combustible gas transmitters, the use of HART,

Modbus, or FOUNDATION Fieldbus protocols for combustible

gas performance. HART, Modbus, or FOUNDATION Fieldbus

protocols can be used only for data collection or record keeping

with regards to combustible gas. The EC cartridge

remote mount kit are UL classied to Canandian and US

standards.

XNX-AM **-***** versions are certied to comply with the

European Community ATEX Directive and the prescribed

protection methods for installation in potentially explosive

atmospheres.

XNX-BT**-***** versions are UL listed and INMETRO approved for

compliance with both U.S. and Brazilian standards.

See the Sensor Data section for additional information on

applicable approvals by part number and the Operating and

Storage Conditions for Performance Tested EC Sensors section

for marking.

2

“Cartridge” and “sensor” are used interchangeably in this document.

12

2

and EC

Page 15

XNX Universal Transmitter

Patents

Patents Applicable to the XNX Universal Transmitter

Patent

Number

6,123,818 Reflex patent Implemented in XNX

6,251,232 Reflex patent Implemented in XNX

6,351,982 Flammable sensor housing XNX accepts this sensor

6,395,230 Pellistor Sensor used in XNX

7,225,661 Gas calibration adapter Applicable to XNX

7,716,962 Method of gas calibration Used to calibrate XNX ECC cartridges

Description Application

Glossary

Term Description

bump test

ferrite bead a device that suppresses noise in a circuit

FOUNDATION Fieldbus

HART Protocol

intrinsic safety

IP rating

latching alarm an alarm that, once activated, must be manually reset

magnetic wand a small device used to change the transmitter’s settings

Modbus a digital communications protocol based on RS-485 topology

non-latching alarm

pellistor/bead an electronic device used to detect combustible gases

personality board

POD

span calibration

sticky gases gases that tend to coat the surfaces they contact

toxic gases

zero calibration

a brief exposure to a gas to verify that a detector is working;

also known as a functional test

an open architecture, digital, serial communication system

administered by the Fieldbus Foundation

Highway Addressable Remote Transducer Protocol; a bidirectional analog communication system developed by the

HART Communication Foundation

design parameters for the safe operation of electrical equipment in hazardous environments; commonly abbreviated IS

Ingress Protection; a system for describing a device’s protection against dry materials and liquids (e.g., IP66/67)

an alarm that automatically resets when the cause of the

alarm is removed

a component of the transmitter that allows its operation to

focus on different sensing technologies

Personality, Options, and Display; the group of components

including an XNX transmitter’s personality board, display, communication board, etc.

adjustment of a detector so that its scale corresponds to a gas

concentration range from 0% to 100%

gases that are poisonous to humans (refer to the gas’s Safety

Data Sheet for details)

adjustment of a detector so that its zero reading corresponds

to a test gas concentration of 0%

Introduction

13

Page 16

XNX Universal Transmitter

CAUTION

!

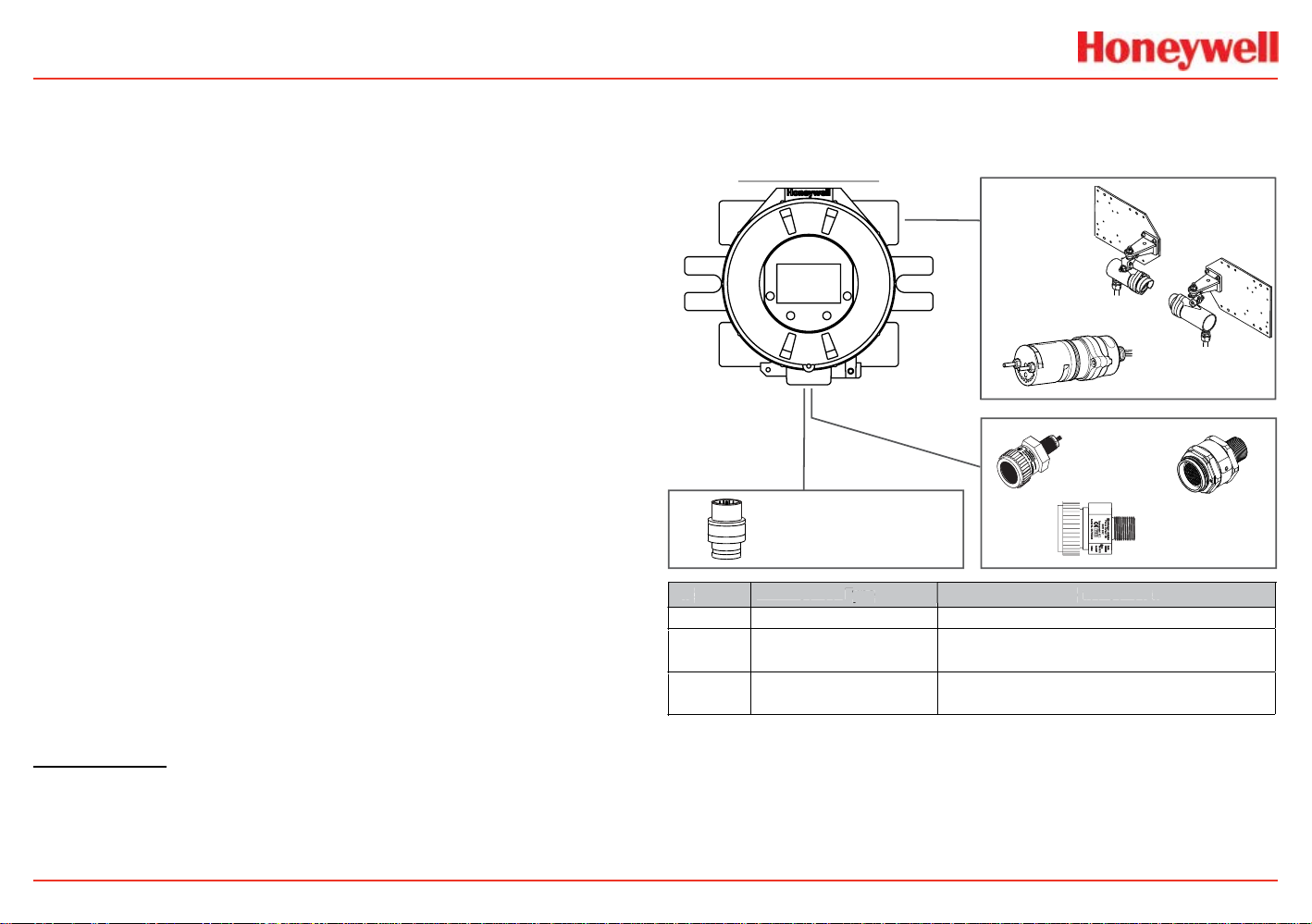

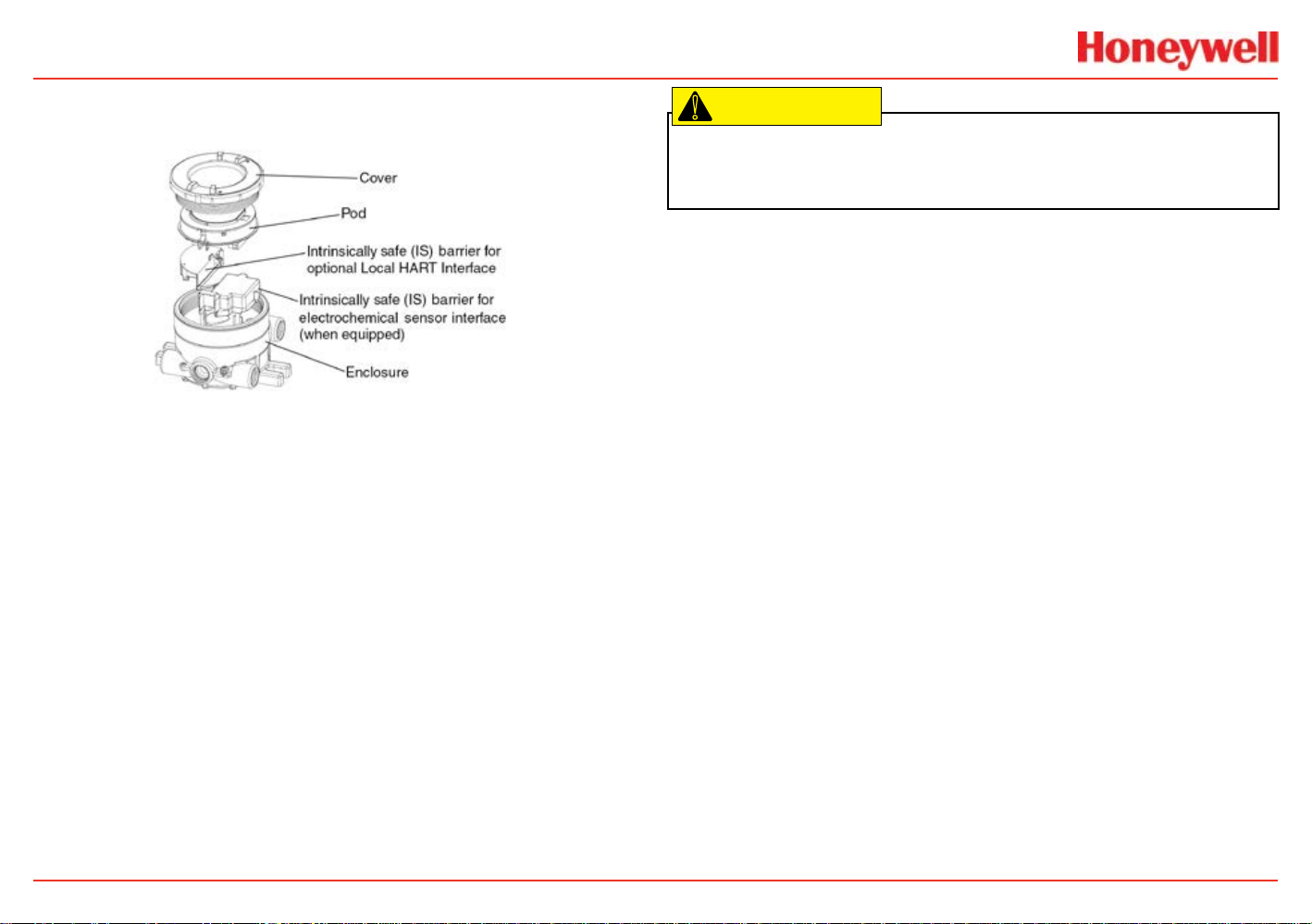

Product Overview

The transmitter is comprised of these main parts:

Figure 2. XNX exploded view

Enclosure

Available in either Stainless Steel or Aluminum, with 3/4” NPT

(UL/CSA or UL/ INMETRO) or M25 (ATEX/IECEx only) threaded

cable/conduit ports, the transmitter enclosure is explosionproof and suitable for use in -40°F to +149°F (-40°C to +65°C)

operating conditions. A 5-coat marine nishing process provides

the highest degree of corrosion protection. For more information

on performance specications, see the Specications section.

The enclosure is equipped with up to ve threaded cable/conduit

ports providing functional and exible congurations based on

sensor and option choices. See Cable/conduit port assingments

for port assignments and restrictions.

Stopping plugs (PN# 1226-0257 or 1226-0258) have been

provided to seal unused cable/conduit ports and have been

Agency evaluated/approved for use with the XNX enclosure only.

The number of stopping plugs varies among available

congurations.

Caution: The stopping plugs are for use only with the XNX transmitter. Do not use them

with any other device.

Mounting lugs integral to the enclosure allow easy installation

on a at surface or 2”-6” (50-150 mm) diameter pipe with the

optional Pipe Mount Kit or to ceilings with the Ceiling Mount

Bracket Kit.

Introduction

14

Page 17

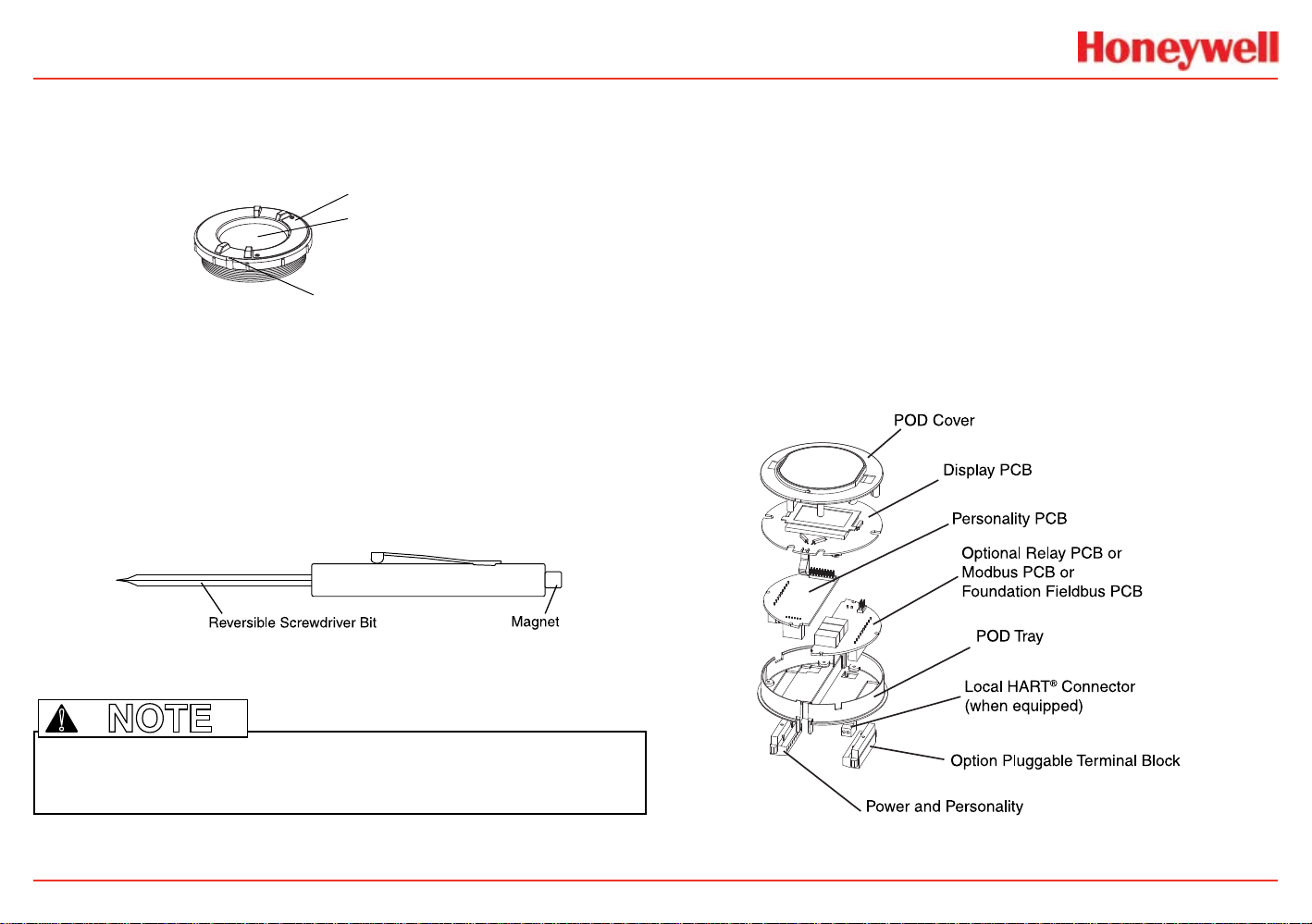

XNX Universal Transmitter

Cover Lock Screw, requires a

2mm hex key (included)

Tempered Glass Window

Cover

NOTE

Cover

The transmitter cover is supplied in the identical material

specied for the enclosure.

Figure 3. XNX cover components

A tempered glass window requires the use of the supplied magnetic

wand/screwdriver to activate the four user interface switches

located on the front of the display module. This allows for non-

intrusive setup and operation.

A locking screw integrated into the cover provides positive

locking that can be loosened by using the supplied 2mm hex

key.

Figure 4. Magnetic wand/screwdriver

POD

The POD (Personality, Options, and Display) includes circuit

boards for the personality module, optional interfaces, and

display.

The personality module, or circuit board, determines the

transmitter behavior based on the sensor type attached to

the transmitter (electrochemical cell, catalytic bead sensor, or

infrared) and provides the necessary interface. Connection to the

attached sensor is made through the sensor connector.

The optional communication boards vary depending on the

option selected when ordered. Only one of the three available

interface options (relays, Modbus, or FOUNDATION Fieldbus)

can be attached to the transmitter.

!

Note: When attaching the cover or stopping plugs, coat the threads with a suitable antiseize compound to prevent corrosion.

Introduction

Figure 5. POD, exploded view

15

Page 18

XNX Universal Transmitter

NOTE

Options

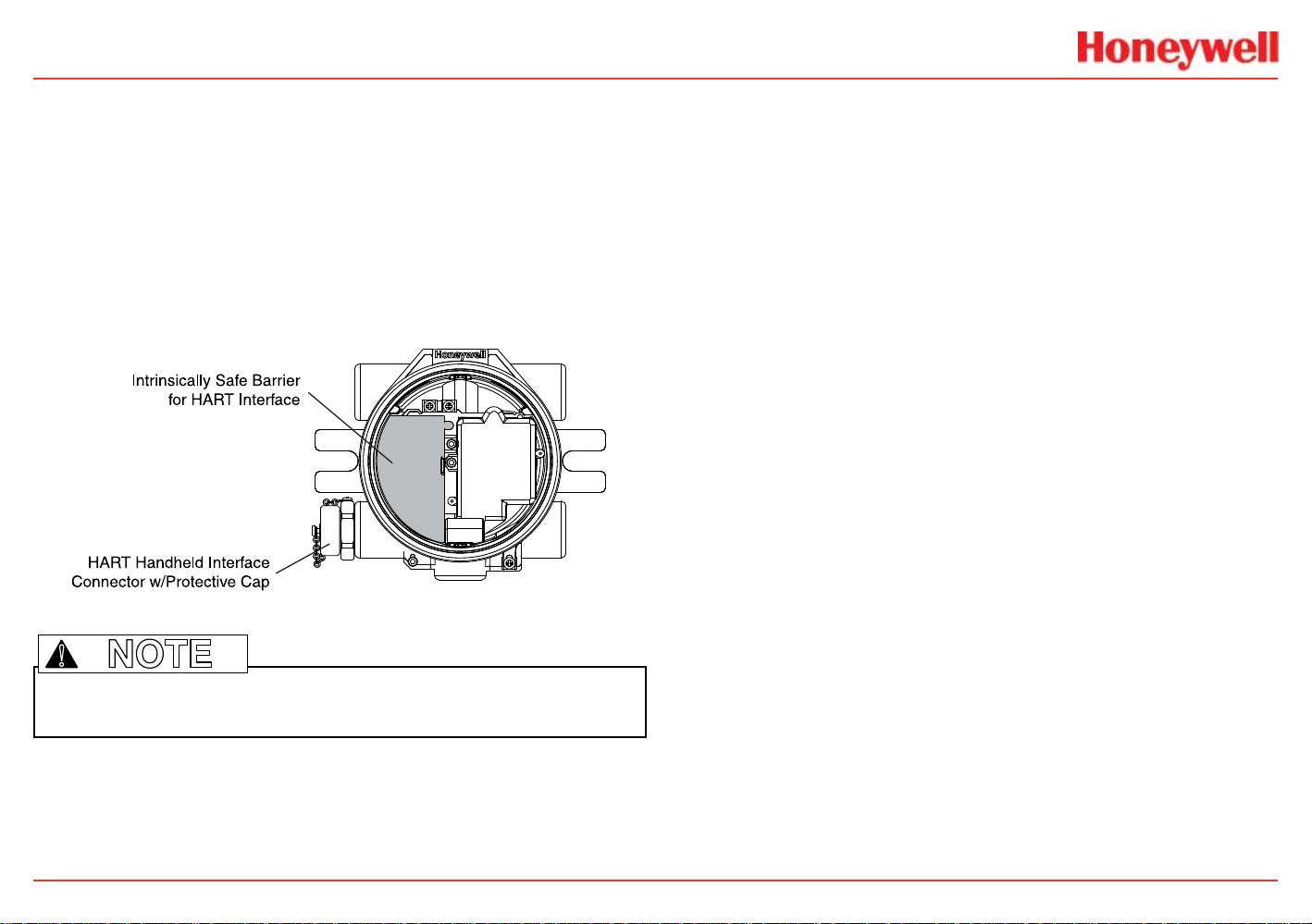

Local HART

Available with any sensor technology or personality, an external

access to the HART interface in the transmitter is provided.

An intrinsically safe (IS) barrier inside the transmitter gives

the user full control using a handheld eld communicator

for programming and conguration. The external interface is

installed in the lower left cable/conduit port of the transmitter

and is intrinsically safe. For more information, see the HART

Protocol section.

Figure 6. XNX Universal Transmitter with HART interface IS barrier

!

Note: POD options are either relay, Modbus, or FOUNDATION Fieldbus.

Relays

The relay option (XNX-Relay) provides 3 form “C” (SPDT)

normally open/normally closed (NO/NC) contacts for alarm and

fault indication. A remote reset input (TB4) is provided to silence

alarms. Momentarily closing the the circuit between the pins of

TB4 performs the same function as the Reset Alarms & Faults

command.

The remote reset switch (designated TB-4 and labeled “Remote

Reset SW”) is located on the relay option board. It provides

a remote hardware-based reset of faults and alarms to the

transmitter. In the event that direct access to the local and

®

HART

transmitter may be reset remotely using a momentary switch.

This will momentarily close the circuit between the two pins of

TB4, providing the same functionality as a Reset Alarms & Faults

command performed from the main screen of thelocal user or the

HART interfaces.

Relays are not available when the Modbus

Fieldbus options are installed.

The transmitter has three relays: relay 1 is for alarm level 1, relay 2

is for alarm level 2, and relay 3 is for faults and special states. Two

alarm levels can be set, allowing, for example, a level 1 alarm for

the immediate area when a certain gas concentration is detected

and a plant-wide level 2 alarm when a greater gas concentration is

detected.

The maximum refresh rate of the relays is 2 seconds. See the Set

Alarm Values section for more information.

interfaces is not possible, alarms and faults from an XNX

®

or FOUNDATION

Introduction

16

Page 19

XNX Universal Transmitter

NOTE

Modbus

The optional Modbus interface allows the transmitter to connect

to a bus of devices and transmit data to PLCs or controllers.

(For more information, see the Modbus

Connections to the transmitter are made through a pluggable

terminal block on the Modbus interface circuit board. Modbus

RTU protocol uses ASCII/Hex protocols for communication.

Protocol Manual).

FOUNDATION Fieldbus

FOUNDATION eldbus is a digital communication system which

supports several types of messages. Unlike many traditional

systems which require a set of wires for each device, multiple

FOUNDATION eldbus devices can be connected with a

single set of wires. FOUNDATION eldbus overcomes some

of the disadvantages of proprietary networks by providing a

standardized network for connecting systems and devices.

!

Note: FOUNDATION Fieldbus XNX transmitters require a separate power source and

cannot be powered via the bus.

Accessories

Refer to the Accessories/Spares section for part numbers.

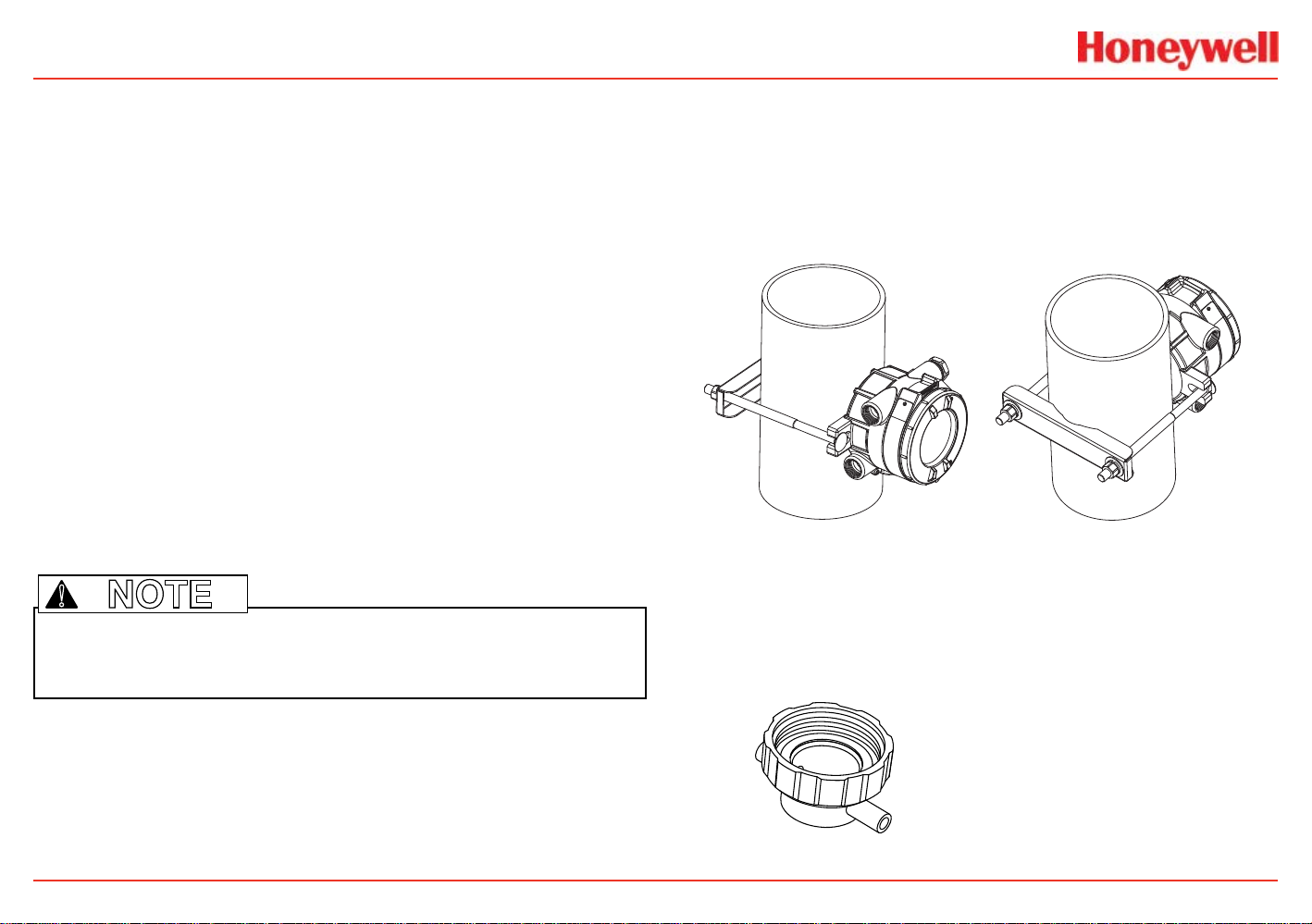

Pipe Mount Kit

The pipe mount kit allows the transmitter to be mounted to pipe

from 2”-6” (50-150 mm) in diameter. The kit includes the pipe

mount bracket, two carriage bolts, nuts, and lock washers.

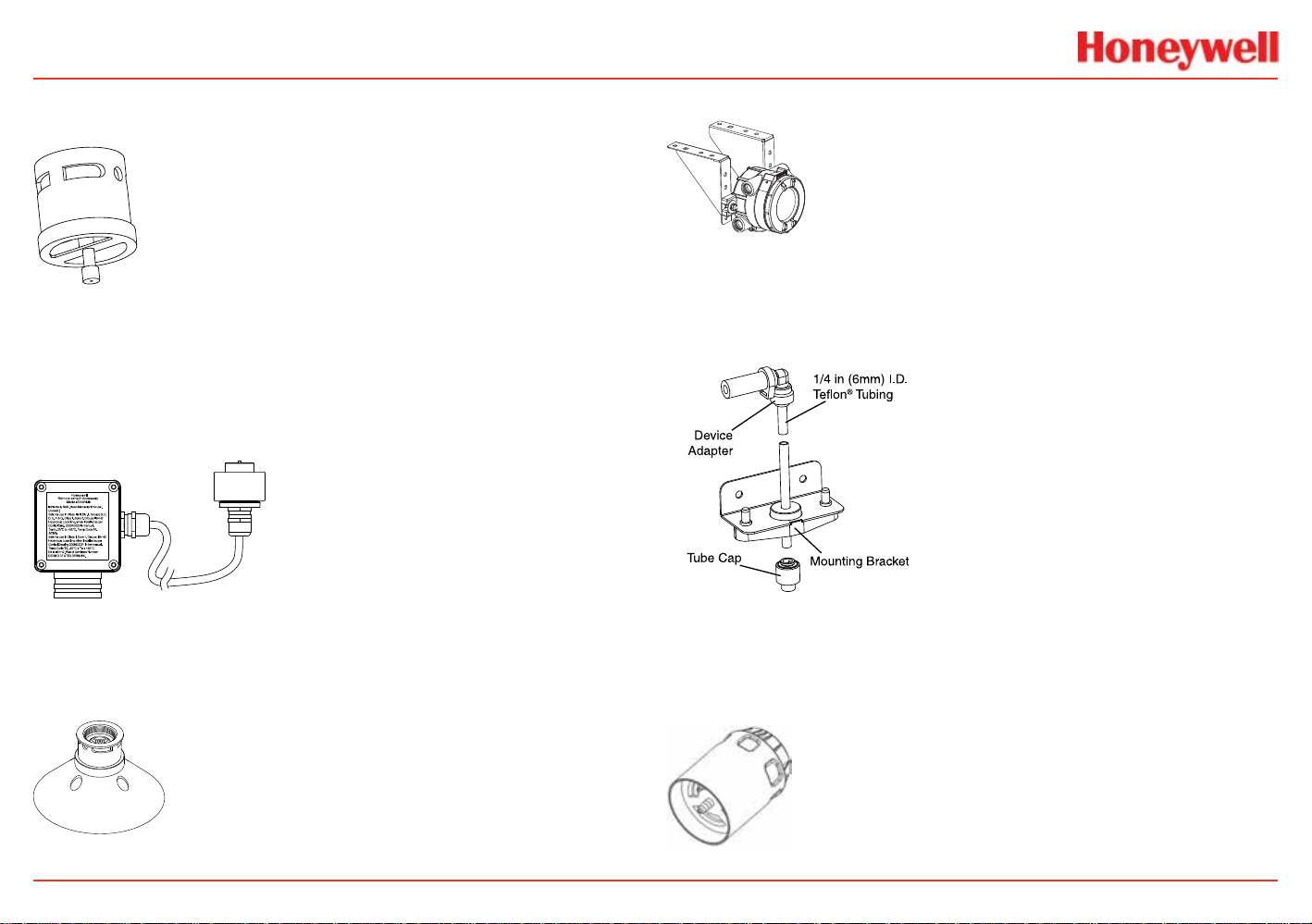

Calibration Gas Flow Adaptor

The calibration gas ow adaptor is used to apply calibration test

gas to the sensor. It attaches to the bottom of the sensor and

can be tted without removing the standard weatherproof cover.

See the Calibration section for details on gas calibration.

Introduction

17

Page 20

XNX Universal Transmitter

Weatherproof Cover

The weatherproof cap protects sensors from harsh weather.

Remote Sensor Mounting Kit for EC Sensors

The remote sensor mounting kit allows EC sensors to be

remotely mounted via an IS cable kit, available in various

lengths. The kit includes shielded cable, cable glands, and

remote terminal box. The cable can be cut to the required length

then terminated at the remote terminal box.

Ceiling Mount Bracket Kit

The optional ceiling mount bracket kit includes

two stainless steel ceiling mount brackets, bolts,

and nuts.

Remote Gassing Kit

The remote gassing kit enables gas

to be applied remotely for

performing functional response

checks (bump tests). The kit

Includes: 50’ Teon® tubing, a

mounting bracket, a tube cap, and

device adapters in 1/4” and 1/8”

(6.3 mm and 3.2 mm) ID to attach to

bump test ports on the

weatherproof cap of the device.

Collecting Cone

The collecting cone improves detection of lighter-than-air gases

such as hydrogen and methane.

Introduction

Extreme Weather Protector

The extreme weather protector protects the sensor from

environmental conditions in outdoor exposure applications.

18

Page 21

XNX Universal Transmitter

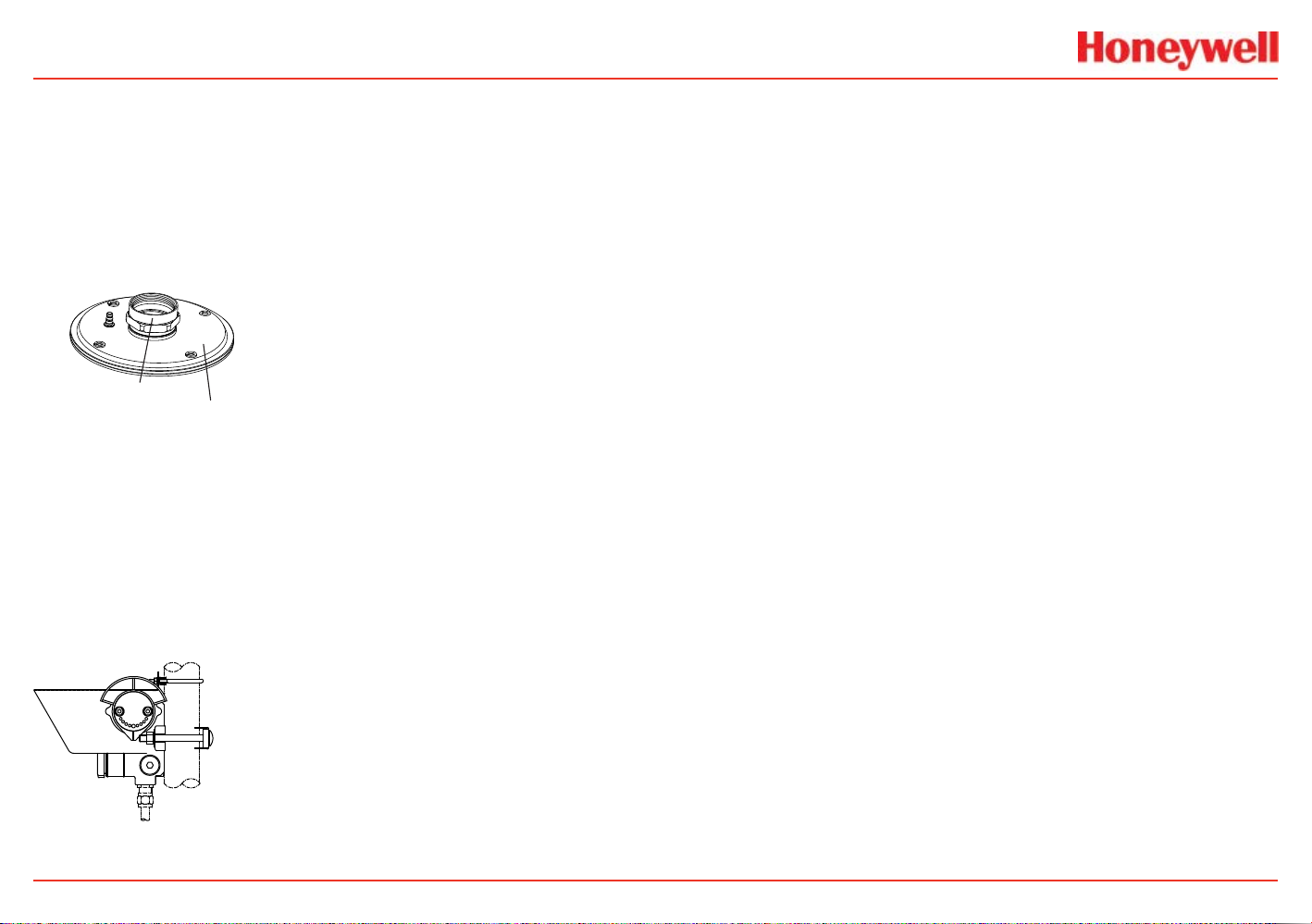

Duct Mount Kit

The duct mount kit can be used with the EC sensor to detect O

CO, H

, and H2S gases in ducts. When combined with the MPD

2

Interface Adapter (available separately), the duct mount kit can

accommodate the MPD to detect ammable gases in ducts.

The duct mount kit includes the adapter, gasket, and required

fasteners. For MPD applications, order both the Duct Mount Kit

and the MPD Interface Adapter.

1226A0382 MPD Adapter Ring

S3KDMK EC/MPD Duct Adapter Kit

Sunshade

The sunshade is used in environments with high heat and/

or direct sunlight. It protects the sensor from environmental

conditions in outdoor applications, helping to keep the internal

components within the specied temperature ranges. The

sunshade can be mounted to 2-inch pipe or to a wall with

suitable 6mm fasteners.

,

2

Introduction

19

Page 22

XNX Universal Transmitter

Move Right/Increase Value Mov e Left/Decrease Value

Fault LED (yellow)

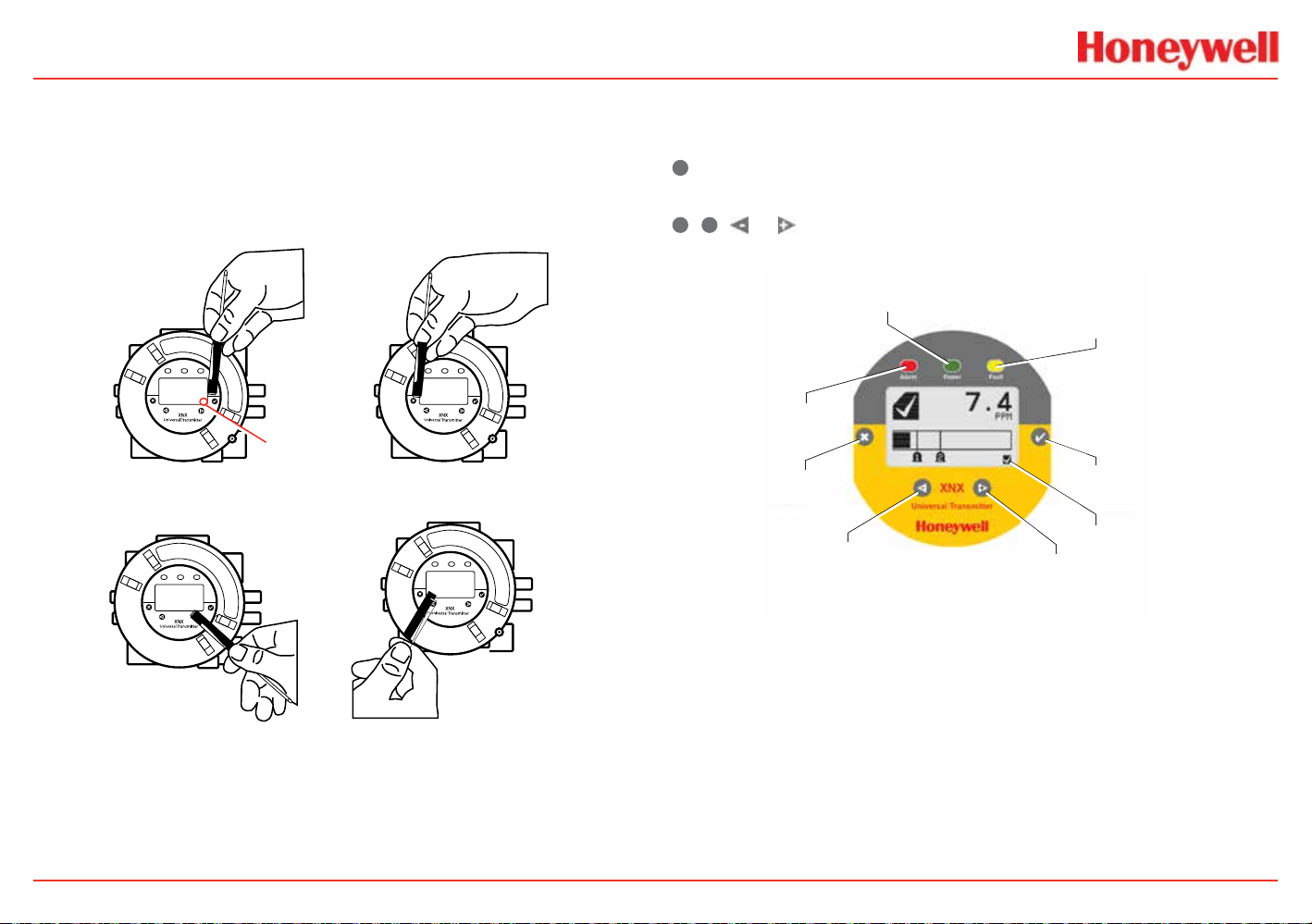

The Front Panel

The transmitter uses magnetic switches to enable non-intrusive

operation. To activate a magnetic switch, hold the magnetic end

of the screwdriver up to the glass window and slowly swipe the

magnet directly over the switch area. For best results, hold the

screwdriver as illustrated in Figure 7.

Switch Actuation

Enter/Accept

Visual Indicator

Escape/Back

In some menus where displayed values can be changed, the

magnet must be swiped over the switch to cause the numeral

on the display to advance through the available values. Use the

✖

switch to return to a previous menu or eld.

For the purposes of this manual, the instruction to use

✓, ✖

, or , means to activate the relevant magnetic switch as

described above.

Power LED (green)

Alarm LED (red)

Escape

Move Left

Decement Value

Figure 8. Front panel display of the transmitter

Enter/Accept

Switch Actuation

Visual Indicator

Move Right

Increment Value

Figure 7. Using the magnetic wand

A visual indication of the switch actuation will appear in

the lower right corner of the display each time the switch is

activated.

Introduction

20

Page 23

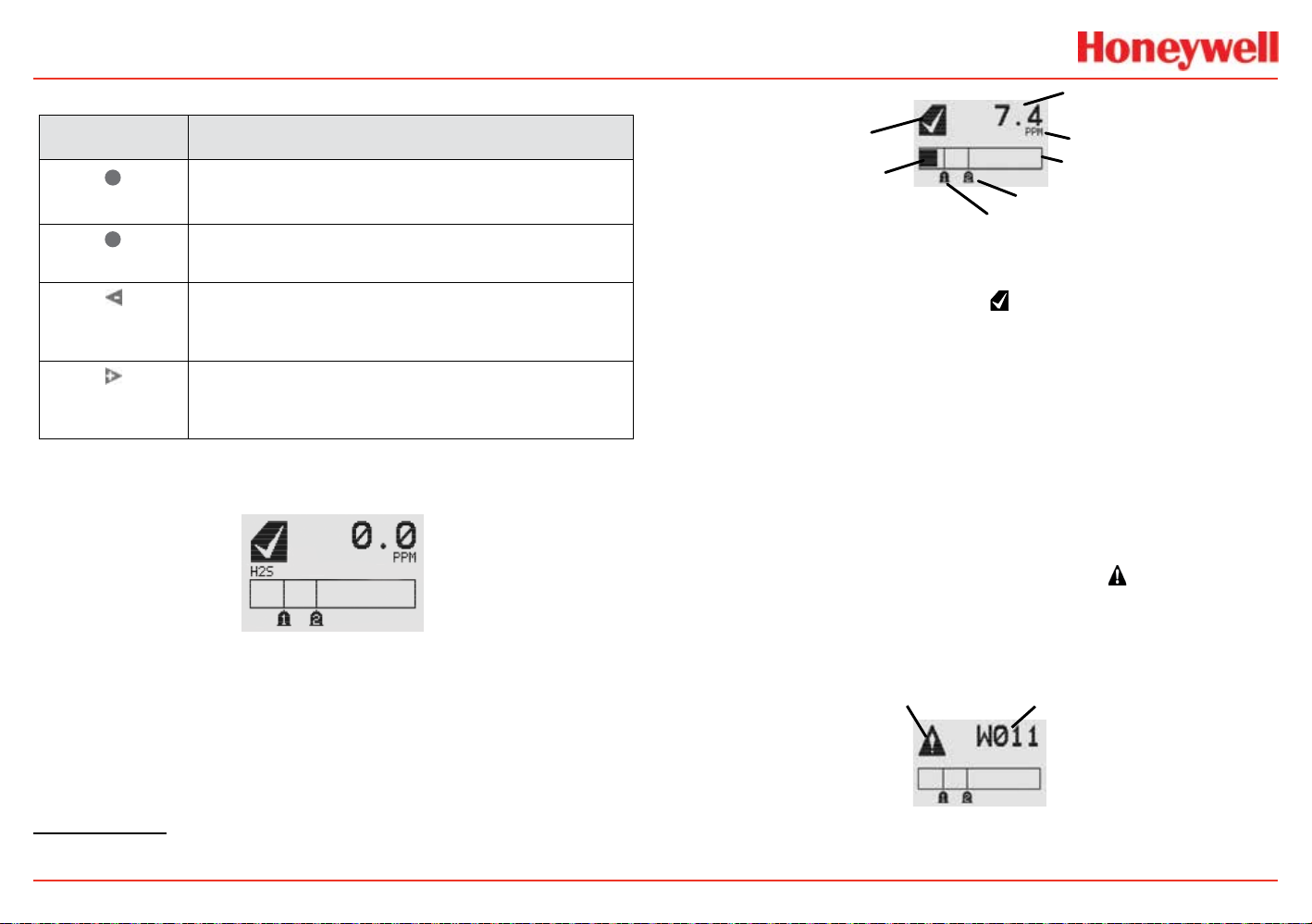

XNX Universal Transmitter

Current Concentration Level

Alarm 1 Set Point

Current Concentration Le

Warning Code

Warning Icon

Controls and Navigation

Command Description

✓

Enter/Accept

✖

Escape/Back

Move Left/

Decrease Value

Move Right/

Increase Value

The Enter/Accept switch is used to access menus,

accept changes and to answer “yes” to system

prompts.

The Escape/Back switch is used to return to previous

menus or to answer “no” to system prompts.

The Left/Decrement arrow is used to move through

menu options or decrease values when entering text or

numbers.

The Right/Increment arrow is used to move through

menu options or increase values when entering text or

numbers.

The General Status Screen

\

Figure 9. General Status screen

The General Status screen shows the status of the transmitter.

Warnings, faults, alarm levels, and current concentration levels

are displayed continuously.

3

(Numeric)

Status Indicator

vel

(Bar Graph)

Figure 10. General Status screen, normal operating mode

Concentration Units

Full Scale

Alarm 2 Set Point

The Normal Operating Mode icon indicates proper operation.

The display also shows the concentration level of the target gas

in two ways. In the rst, a numeric value is shown in the upper

right corner of the display in the units selected (ppm, %LEL,

%VOL). The second concentration display is shown in the form

of a bar graph representing the current concentration against

full scale and in relation to the dened alarm levels. For more

information on setting range and alarm levels, see the Range/

Alarm Settings section. See the EC Sensor Performance Data,

Factory Mutual Veried, EC Performance Data, DEKRA EXAM

Veried and the Other EC Sensors sections for negative drift and

zero deviation values.

When a warning is triggered, the warning icon

appears and

information is displayed on the General Status Screen. The

information displayed alternates between screens displaying the

gas concentration and the warning code. See the Warnings and

Faults section for more warning code information.

3

The LCD screen’s refresh rates are 500 milliseconds when the LCD heater is off and 1 second

with the heater on.

Introduction

Figure 11. General Status Warning detail

21

Page 24

XNX Universal Transmitter

Concentration

Alar

Alarm Level Triggered

Alarm Level Triggered

m Setpoints Flash

NOTE

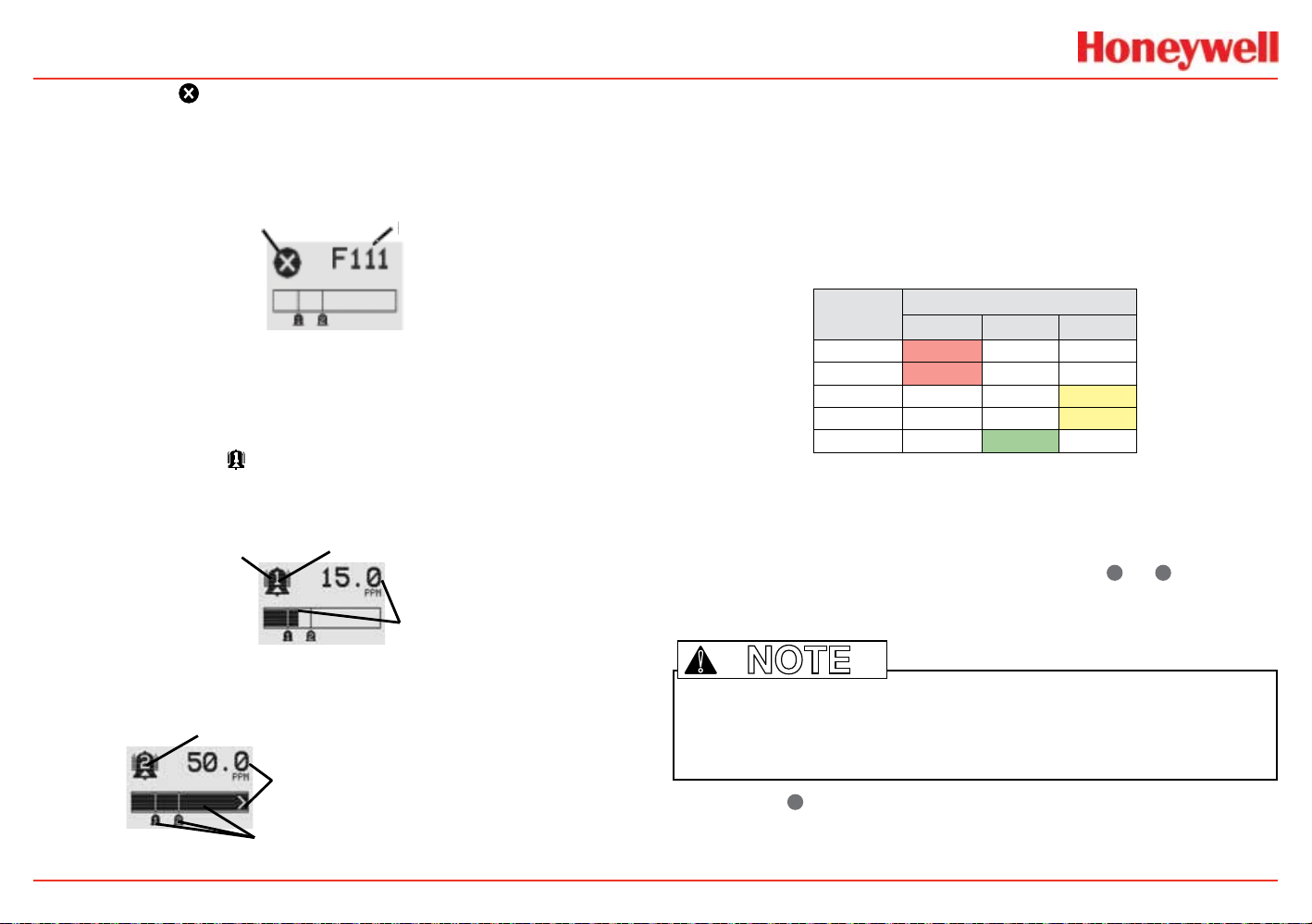

If the fault icon is displayed, a fault condition has been

triggered and the display will alternate between the target gas

concentration and the fault code. See the Warnings and Faults

section for more fault code information.

Fault Icon

Figure 12. General Status Fault detail

Fault Code

In the event of multiple warnings or faults, the user can view all

messages with the transmitter’s Event History function.

When an Alarm icon

is displayed, the target gas

concentration exceeds one or both preset alarm levels. The

General Status Screen displays the gas concentration and the

alarm level exceeded.

m Icon

Target Gas

Figure 14. General Status Overrange detail

Negative values are not displayed and do not appear on the

4-20 mA output, but they are indicated by faults or warnings

when preset thresholds are exceeded. (See zero deviation in the

Specications section)

In addition to the graphic alarm, fault, and warning indicators,

the LEDs on the front panel ash in these patterns based on the

condition:

Condition

Alarm 1 Solid

Alarm 2 Flashing

Warning Solid

Fault Flashing

Health Flashing

1

The refresh rate of the LEDs is 0.5 second.

2

Special states (Warmup, Inhibit) are not indicated by the Fault LED.

Red Green Yellow

LED1

2

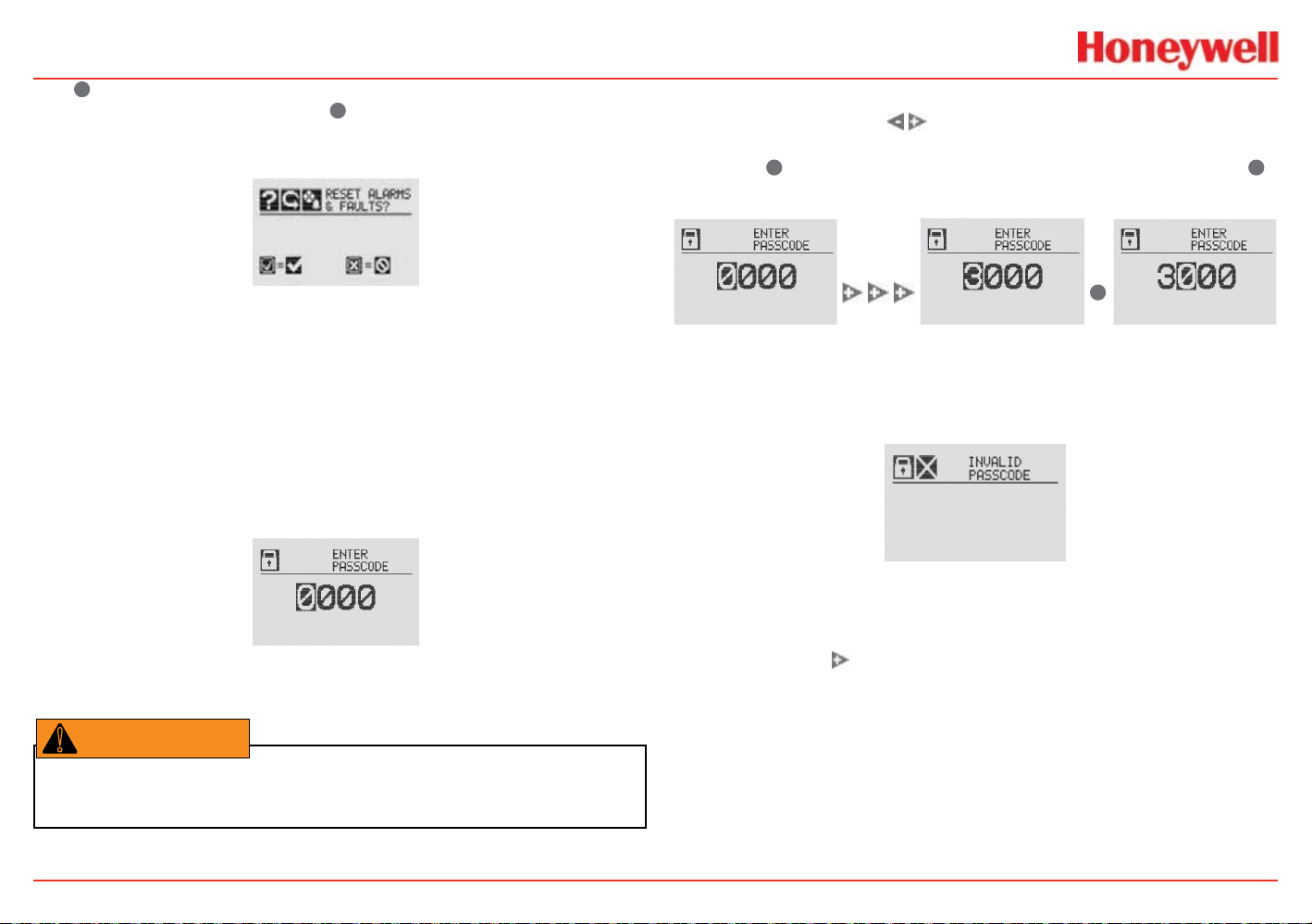

Entering the Menu

Swiping the magnet over the magnetic switch ✓ or ✖ allows the

user to reset faults or alarms, display current settings, or make

adjustments to the device.

Figure 13. General Status Alarm detail

In an overrange condition, the alarm icon will display and the target

gas concentration bar graph and alarm setpoints will ash.

Full Scale

Concentration

Concentration Bar, Alar

Introduction

!

Note: If the Easy Reset option is set to Lock, alarms and faults cannot be reset

without logging in or entering a passcode. For more information, see the Configure

Security section.

Swiping the ✖ or “escape” magnetic switch activates the Alarm

Reset screen and allows alarms to be silenced and faults to be

reset.

22

Page 25

XNX Universal Transmitter

WARNING

!

The ✓ switch resets all alarms and faults and returns to the

General Status screen. Use the

Status screen without resetting the alarms and faults.

Figure 15. Alarm Reset screen

Two authorization levels control access based upon the security

level of the user: Level 1 (routine maintenance) and Level 2

(technician and password administrator). The default passcodes

for both levels are “0000” and must be changed after installation

to control access (see the Configure Security section). In

general, access to neither security level restricts the user to

viewing the transmitter’s display. If desired, the Easy Reset from

Main Status option

access to either security level.

allows alarm and fault resets without requiring

Figure 16. Passcode screen

✖

switch to return to the General

When the Passcode screen is displayed, the rst passcode digit

is highlighted. Use the

through the values. Once the correct value is displayed for the

rst digit,

moves to the previous digit of the passcode.

Repeat for each of the remaining digits in the passcode. If the

passcode is entered incorrectly, the Invalid Passcode screen is

displayed and the user is returned to the General Status screen.

✓

accepts the value and moves to the next digit or ✖

✓

switches to increase or decrease

Figure 17. Entering the passcode

Figure 18. Invalid Passcode screen

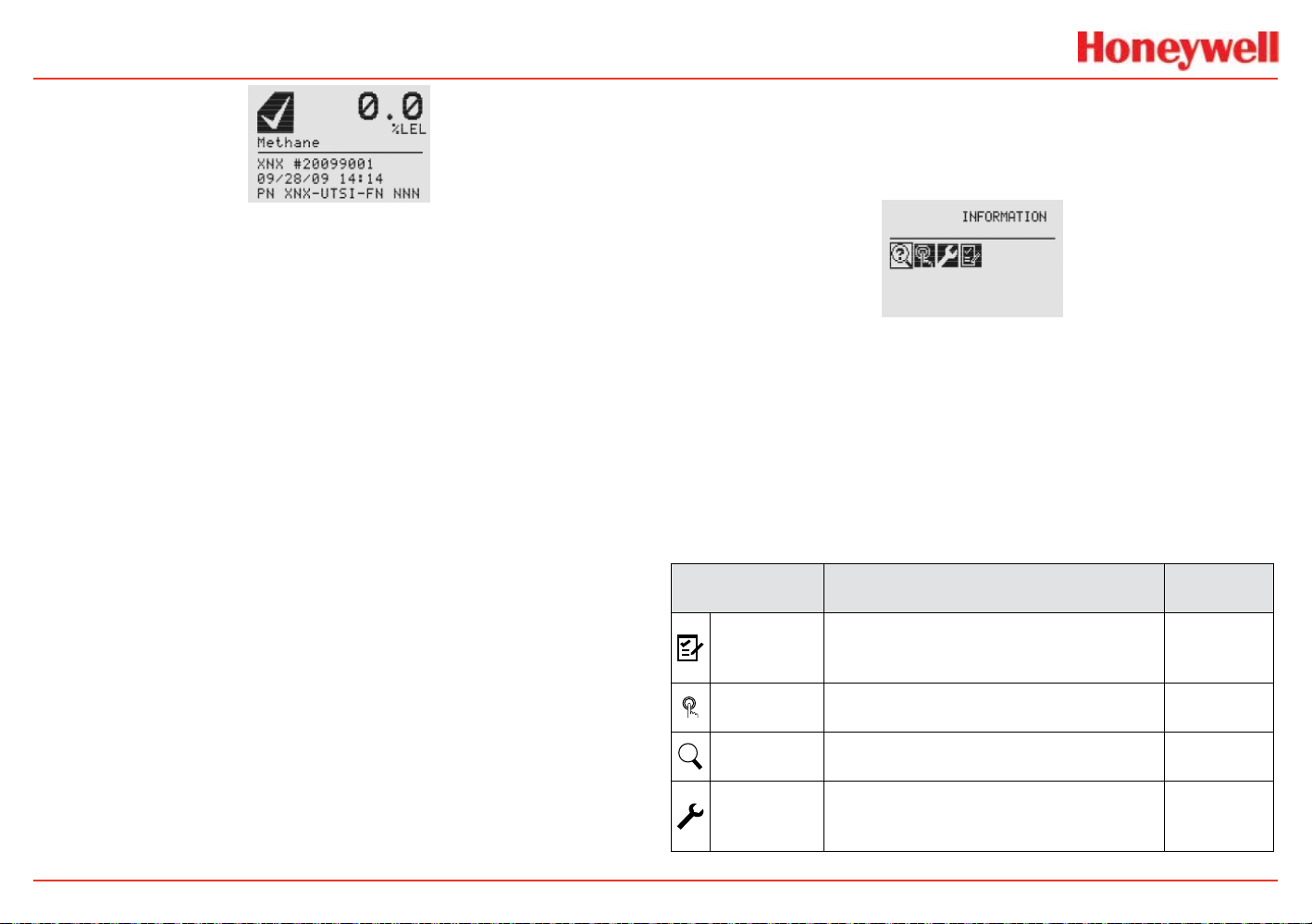

Displaying Transmitter Information

While in the General Status display, swipe the magnet over the

magnetic switch

The General Status display will replace the bar graph in the

lower portion of the screen with the unit’s serial number, the

date and time, and the unit’s part number.

to display information about the transmitter.

Warning: The factory-set passcodes must be reset to prevent unauthorized access to

the transmitter’s menus.

Introduction

23

Page 26

XNX Universal Transmitter

?

Figure 19. General Status Screen with unit information

Main Menu

Once the proper passcode has been entered, the transmitter

displays the Main Menu.

Figure 20. The Main Menu

From the Main Menu, a Level 1 user can:

• display the current settings/conguration

• test the transmitter

• calibrate and bump test the transmitter

• congure the unit for language, date and time

The Main Menu consists of these options:

Introduction

24

Menu Description

Configure

Test

Information

Gas

Calibration

Provides access to settings to configure the

transmitter and connected devices

Provides access to tools and settings to allow

simulation of gas events to test the system

Displays current settings for the transmitter

including optional relays and Modbus

Displays the interface to calibrate sensors

attached directly to the transmitter

See

Section...

Configuring

the

Transmitter

Tes t Menu

Information

Menu

Gas

Calibration

Menu

Page 27

XNX Universal Transmitter

Menu Navigation

Introduction

25

Page 28

XNX Universal Transmitter

Information Mode

Alarm/Fault Status

Alarm/Fault

Conrm Alarm/Fault Reset

Reset Alarm/Fault

Date & Time

Transmitter ID, Serial #, Revision

Transmitter Data

Transmitter Status

Transmitter Status

Sensor Type, Serial #, Revision

Sensor Data

Sensor Status

Sensor Status

Gas Name, ID, Range

Gas Data

Range Settings, Alarm Settings

Range/Alarm Settings

mA Level Settings

mA Level Settings

Relay Settings

4

Relay Settings

Fieldbus Settings

5

Fieldbus Settings

Event History

Increment Next/Previous Event

Increment Next/Previous Hour

Increment Next/Previous Day

Increment Next/Previous Alarm

Increment Next Previous Fault

4 Optional relay only

Introduction

5 Optional FOUNDATION Fieldbus and Modbus only

26

Page 29

XNX Universal Transmitter

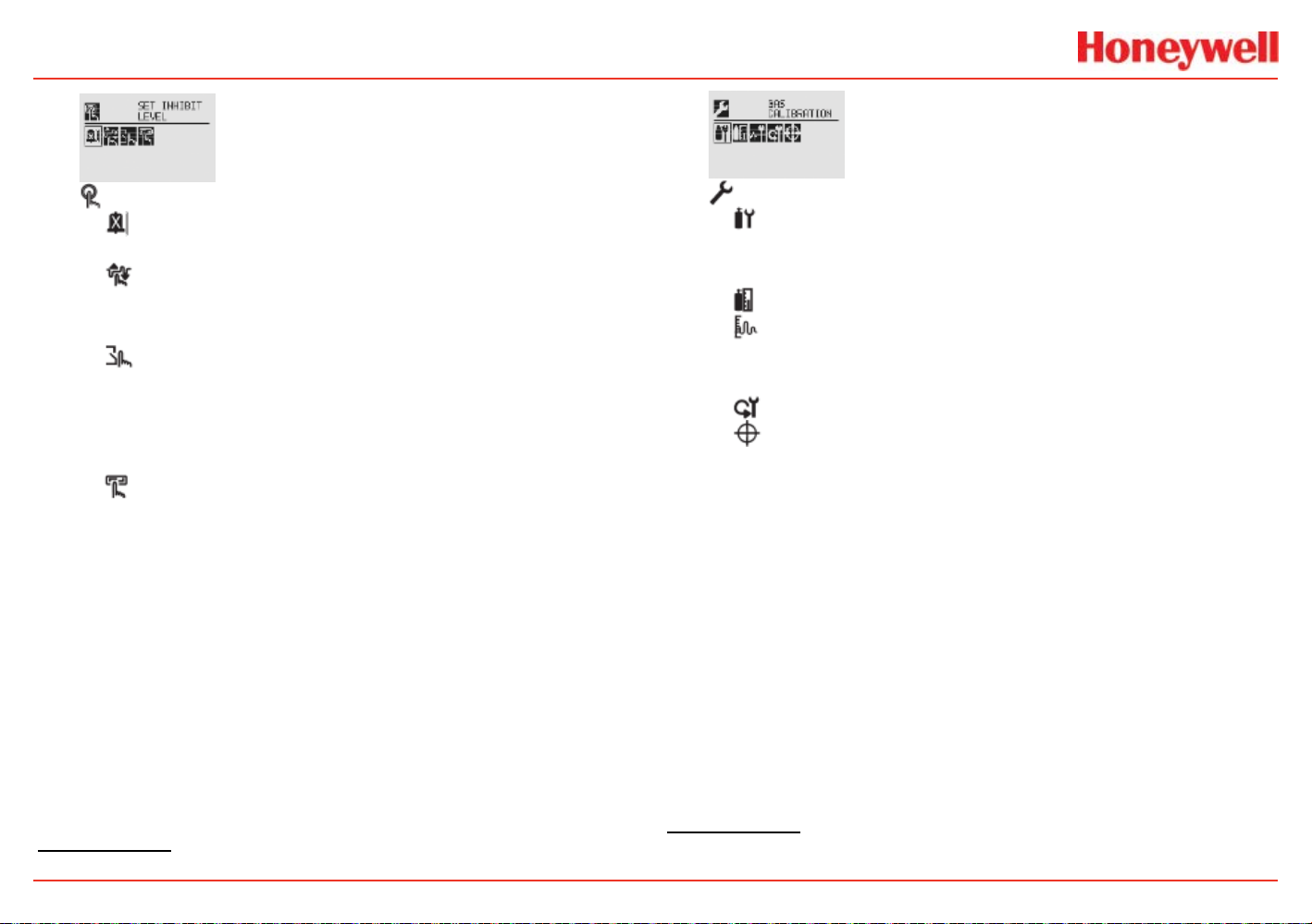

Test Mode

Inhibit

Enable/Disable Inhibit

Force mA Output

Select Current: 0 to 22 mA

Accept

Force Relay

6

Select Relay 1

Select Relay 2

Select Relay 3

Accept

Alarm/Fault Simulation

Alarm 1 Simulation

Alarm 2 Simulation

Warning Simulation

Fault Simulation

Calibration Mode

Gas Calibration

Enter Span Gas Concentration (Oxygen)

Enter Span Gas Concentration (Not Oxygen)

Bump Test

mA Output Calibration

Adjust 4 mA Output

Adjust 20 mA Output

Soft Reset

Align Excel

7

8

6 Optional relay only

Introduction

7 Searchpoint Optima and Searchline Excel only

8 Searchline Excel only

27

Page 30

XNX Universal Transmitter

Conguration Mode

Select Language

Set Date & Time

Set Date Format

Set Year, Month, Day

Set Hours, Minutes, Seconds

Sensor Type Selection

Set mV Sensor Type

Set mA Sensor Type

Gas Selection

Changing the Gas or Units Name

Gas Selections and Alarm Limits Based on mV

Sensor Type

Range & Alarms

Set Range

Alarm 1 Type

Alarm 1 Setpoint

Alarm 1 Latching or Non-latching

Alarm 2 Type

Alarm 2 Setpoint

Alarm 2 Latching or Non-latching

Selecting the Numeric Format

Latching/Non-latching

Change Meas. Units

mA Output Levels

Change mA for Inhibit

9 Catalytic bead sensor only

10 Searchpoint Optima and Searchline Excel only

11 ECC and mV only

Introduction

9

10

11

Change mA for Warning

Change mA for Overrange

Change mA for Low Signal

Change mA for Blocked Beam

Set Calibration Interval

Accept New Sensor Type

Information screen identifying previous sensor and

new sensor

Screen displays new type and old type

Set Beam Block

13

Select Beam Block Threshold

Select Time to Beam Block

Select Time to Fault

Set Path Length

14

Set New Path Length

Congure Unit ID

Edit ID

Clear ID

Default ID

Relay Options

15

Select A1

Select A2

Fieldbus Options

16

Change Fieldbus Address

Change Fieldbus Speed

Security

Reset and LVL1

LVL1 Code

LVL2 Code

12 Electrochemical and catalytic bead sensors only

13 Searchline Excel only

14 Searchline Excel only

15 Optional relay only

16 Optional FOUNDATION Fieldbus and Modbus only

28

12

Page 31

XNX Universal Transmitter

Installation and Operation

XNX Universal Transmitter Technical Manual

29

Page 32

XNX Universal Transmitter

WARNING

!

CAUTION

!

Sensor Mounting and Location

Warning: Installation must be in accordance with the recognized standards of the

appropriate authority in the country concerned.

Warning: Before carrying out any work, ensure that local regulations and site procedures

are followed. Appropriate standards must be followed to maintain the overall certification

of the sensor.

Caution: Locate transmitters and sensors in accordance with relevant local and national

legislation, standards, and codes of practice.

Caution: Do not locate the transmitter where it will be exposed to direct sunlight.

Caution: Replace a detector only with another of the same type.

Caution: Mount detectors where the gas is most likely to be present.

When determining the placement of sensors, follow the advice of

safety and engineering personnel and experts having specialist

knowledge of gas dispersion, the process plant system, and

the equipment involved. Record the agreement reached on the

location of sensors. Consider these factors when locating gas

sensors:

• possible damage caused by natural events such as rain or

ooding

• ease of access for functional testing and servicing

• how escaping gas may behave due to natural or forced air

currents.

Mounting the Transmitter

The transmitter can be mounted in a number of ways using

the integral mounting tabs. The transmitter can be attached

to at wall surfaces or to Unistrut®. With the optional pipe

mount kit, the unit can be mounted to pipe of diameter 2” to

6” (50 to 150mm). A ceiling mount bracket kit is also available.

7.75"

196.85 mm

6.00"

15.4 mm

5.6"

124.24 mm

0.55"

14.35 mm

1.67"

42.41 mm

Figure 22. XNX Universal Transmitter mounting dimensions and clearances

113.8 mm

1.2"

31.75mm

4.48"

2.054"

52.18mm

0.625"

15.88mm

1.768"

44.90 mm

1.768"

44.90 mm

0.945"

24mm

3.176"

80.67 mm

6.138"

158.75mm

Installation and Operation

30

Page 33

XNX Universal Transmitter

WARNING

!

NOTE

Warning: Any work on the interior of the detector must be conducted only by Honeywelltrained personnel

Warning: To reduce the risk of ignition in hazardous atmospheres, disconnect the

equipment from the supply circuit before opening the sensor enclosure. Keep the

assembly tightly closed during operation. Conduit runs must have a seal fitting connected

within 18 inches (45 cm) of the enclosure.

Warning: Never open the XNX enclosure under power unless the area is known to be

non-hazardous.

Warning: When the transmitter is equipped with the optional Remote Mount Kit, the

remote sensor must be securely mounted in a fixed position. The Remote Sensor kit is not

intended to be used as a handheld sensor.

!

Note: Agency certifications require that EC and mV sensors face down. Optima

sensors must be mounted horizontally.

The transmitter is congured with ve cable/conduit ports built

into the housing for wiring and mounting sensors. Figure 23

provides the guidelines to proper installation of the transmitter.

While relay wiring can use any

available cable/conduit port in

the enclosure, to avoid electrical

noise do not use the same

cable/conduit port for both relay

reset and relay signal lines.

Option Position

Local HART® Option B

XNX Electrochemical Sensor - Local/Remote C

MPD, 705 Series, Sensepoint Series C

Searchpoint Optima Plus A or E

Searchline Excel Typically C

Remote Sensor Connection (except EC) Any remaining

Searchpoint Optima Plus - Remote Any remaining

Modbus Any remaining

Relays Any remaining

Foundation Fieldbus Any remaining

Power Any remaining

Figure 23. Cable/conduit port assignments

Installation and Operation

31

Page 34

XNX Universal Transmitter

Integral Mounting Lugs

Figure 24. XNX Universal Transmitter mounting lugs

Wiring the Transmitter

The transmitter is available in sensor technologies, or personality

options, which support a variety of sensors and applications.

Each of the personalities use a dedicated interface board.

Pluggable terminal blocks are used for easy connection and

service. The personality boards and optional communication

interfaces are enclosed in plastic housings comprising the

electronics POD (Personality, Options, and Display). The

Personality circuit board determines the transmitter’s behavior

based on the type of sensor attached to the interface. See

Specications for drift and zero deviation values.

This table illustrates the three transmitter congurations and the

sensors supported by each.

XNX IR Personality XNX EC Personality

Searchline Excel

Generic mA Sensors XNX EC Sensor Remote Mount Kit

Searchpoint Optima Plus Local/

Remote

XNX EC Sensor

Figure 25. Optional pipe and ceiling mounts

Installation and Operation

XNX mV Personality

705 Local / Remote MPD Local (cat bead and IR) Sensepoint Local / Remote

705HT Local / Remote MPD Remote Sensepoint PPM Local/Remote

Sensepoint HT Remote

Figure 26. XNX Transmitter personalities

32

Page 35

XNX Universal Transmitter

CAUTION

!

WARNING

!

Caution: Before wiring the transmitter, confirm that the correct personality and

communication boards are installed.

performance of the transmitter. For best reliability use resistive

loads only.

Isolation

Isolate the power and signal-carrying conductors.

General Wiring Considerations

For proper operation of the transmitter and sensor technologies,

consideration of wiring-induced voltage drops, transient

electrical noise, and dissimilar earth ground potentials is

imperative in the design and installation of the system.

Warning: The sensor must be earthed/grounded for intrinsic safety, electrical safety

and to limit the effects of radio frequency interference. Earth/ground points are provided

inside and outside the unit. EMI note for applications using shielded cable: Cable shield

must provide 90% coverage of the wiring. Cable shield terminations must be made at the

cable glands with suitable EMI type glands. Avoid terminating cable shields at the Earth

ground lug inside the XNX enclosure. In cases where wiring is in pipe, a shielded cable is

not required. The external terminal is only a supplemental bonding connection where local

authorities permit or require such a connection.

Loading

When wiring for DC power, 4-20mA signal, remote wiring to

sensors must be sized sufciently to provide adequate voltages

for the line length and the loads that will be used.

Circuit Protection

Supply circuits must provide over-current protection. Consider

inrush current in specifying any DC supply. Power supply range

is 16 to 32 VDC for EC and mV versions, 18 to 32 VDC for

Searchpoint Optima Plus and Searchline Excel, and 16 to 32

VDC depending on the limitations of the device for the generic

4-20mA input.

Distance Considerations for Installation

Adequately powering the transmitter is the factor that

determines an installation’s maximum distance. The 4-20 mA

output signal will easily handle the distance back to the control

equipment.

The primary factors determining distance are the minimum oper-

ating voltage of the transmitter and/or sensor; the maximum

current draw of the transmitter/sensor, the resistance of the

wire used, the power supply voltage, and the current capacity

of power supply. An additional consideration is the type of

installation; specically, how many transmitters/sensors are

drawing power from the same power supply and whether these

transmitters are using the same pair of wires (“daisy-chained”) or

have their own connections.

The use of high inrush or inductive loads may affect the

Installation and Operation

33

Page 36

XNX Universal Transmitter

Power Supply Power Supply Power Supply

Power Supply

Types of Installations

There are three basic types of installation: a single transmitter;

multiple transmitters connected to a single power source; and

multiple transmitters connected in a “daisy-chain” conguration.

Single Transmitter

This is the simplest type of installation. It consists of a single

XNX transmitter installation per power source.

Figure 27. Single transmitter installation

Advantages:

Advantages:

• Maximum distance between power source and transmitters

• Fewer power sources.

Disadvantages:

• Larger power source will be needed

• If a power source fails, several monitoring points fail.

Multiple Transmitters Connected in a “Daisy-Chain”

Configuration

This conguration consists of two or more transmitters installed

in a line. The power connections are installed as an extension of

the previous transmitter, with the rst transmitter being the only

one actually wired to the power source.

• Maximum distance between power source and transmitter

• Smaller power source

• If a power source fails, only one monitoring point fails.

Disadvantage:

• Multiple transmitters require multiple power sources.

Multiple Transmitters Connected to a Single Power Source

This is two or more transmitters sharing a single power source

with each transmitter having its own dedicated wiring to the

power source.

Figure 28. Multiple transmitters powered by a single power supply

Installation and Operation

Power Supply

Figure 29. Daisy-chained transmitters from one power supply

Advantages:

• Less wire needed for installation

• Fewer power sources.

Disadvantages:

• Requires a larger power source

• Shorter distance between power source and transmitters.

• If a power source fails, several monitoring points fail.

34

Page 37

XNX Universal Transmitter

NOTE

!

Note: CSA/FM certification does not cover daisy-chained XNX combustible gas transmitters.

Power Source Selection

For each type of installation, selection of power supply is

important. Power supplies are rated by voltage and power. The

nominal voltage for all XNX transmitters is 24V with the power

required depending on the number of points using the same

power supply.

As a general guideline, the power supply should be capable

of providing more power than is required by the installation. A

10 watt power supply is ne for a single XNX mV with catalytic

sensor (6.5 watts required, see the following table) but is

inadequate for a single XNX IR with Searchpoint Optima Plus (10

watts required).

XNX Universal Transmitter Maximum Power Consumption

-40°C to +65°C -10°C to +65°C

HART over 4-20mA

with Relay, Mod-

bus, or Foundation

Fieldbus

(watts)

Configuration

transmitter with toxic

sensors

transmitter with

catalytic sensors

transmitter with

infrared cartridge

HART

over

4-20mA

(watts)

HART over 4-20mA

with Relay, Modbus

FoundationTM Fieldbus

(watts)

®

, or

HART

over

4-20mA

(watts)

5.1 6.2 3.4 4.5

5.4 6.5 3.7 4.8

5.4 6.5 3.7 4.8

XNX Universal Transmitter Maximum Power Consumption

-40°C to +65°C -10°C to +65°C

HART over 4-20mA

with Relay, Mod-

bus, or Foundation

Fieldbus

(watts)

Configuration

transmitter with

Searchpoint Optima

Plus

transmitter with

Searchline Excel

HART

over

4-20mA

(watts)

HART over 4-20mA

with Relay, Modbus

FoundationTM Fieldbus

(watts)

®

, or

HART

over

4-20mA

(watts)

8.6 9.7 6.9 8.0

12.1 13.2 10.4 11.5

To determine the wattage required, add the maximum power

requirements of all the points that will share the power supply.

For example, consider a system with two XNX mV transmitters

with catalytic sensors (6.5 watts each) and one XNX IR with

Searchpoint Optima Plus (10 watts). A 25 watt power supply

would probably handle this installation, but a 30 watt power

supply would be a better choice.

Wire Selection

The type of wire used for connections has an effect on the

distance of the installation. This is because some of the voltage

is dropped across the cable between the power supply and the

transmitter.

Thinner wire (i.e., 18 AWG) will lose more voltage than thicker

wire (i.e., 12 AWG). The amount of voltage lost depends on how

much current is being drawn through the wire; more current

means more loss. If too much voltage is ropped across in the

wiring, there may not be enough at the distant point to allow the

transmitter to operate.

Installation and Operation

35

Page 38

XNX Universal Transmitter

Single Transmitter Distances

For installations that have dedicated wiring between the

transmitter and the power supply, use the following chart. These

distances assume stranded wire is used. If multiple transmitters

are using the same power supply, make sure the power

supply wattage rating is high enough to power all transmitters

simultaneously.

OR

Power Supply

Configuration

transmitter mV or EC

with sensor

transmitter IR with

Searchpoint Optima Plus

transmitter IR with

Searchline Excel

Figure 30. Single transmitter distances

Single Transmitter Distances

18 AWG

[1.0 mm2]

1140 feet

[347 meters]

[551 meters]

660 feet

[201 meters]

[323 meters]

550 feet

[168 meters]

[270 meters]

Power Supply

16 AWG

[1.5 mm2]

1810 feet

1060 feet

890 feet

14 AWG

[2.0 mm2]

2890 feet

[880 meters]

1690 feet

[515 meters]

1410 feet

[430 meters]

12 AWG

[3.5 mm2]

4620 feet

[1408

meters]

2690 feet

[820 meters]

2260 feet

[690 meters]

Daisy-Chained Transmitter Distances