Page 1

XLS80e

Panel Configuration

Manual

March 2007, Issue 9

Page 2

i

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

Quick Contents Reference by

Section

XLS80e

0 1

2 3

4 5

6 7

8 9

User Menu:

3:Log/display/print menu

4:Set Clock

5:View Alarm Count

6:

Service Mon 01-May-2000 11:20:07

Configuration

User Menu:

1:

2:Disable/enable

3:Log/display/print menu

4:Set Clock

Service Mon 01-May-2000 11:20:07

Test

DISPLAY:

SUMMARY - SEE SECTION

DETAILED DESCRIPTION OF MENUS, SEE SECTION:

4

CONFIGURATION MENU:

OVERVIEW - SEE SECTION

DETAILED DESCRIPTIONS, SEE SECTION:

3

12

12

10

ALSO:

TIME-OF-DAY - SEE SECTION

SENSITIVITY & DELAYS RECOMMENDATIONS - SEE SECTION

UPGRADING THE SOFTWARE - SEE APPENDIX

AVAILABLE LOOP DEVICES - SEE APPENDIX

XLSNET - SEE APPENDIX

9

13

1

2

3

POWER ON SEE SECTION 2

CONFIGURATION:

1:

2:Zone Text Editor

3:Panel Text Editor

4:Control Matrix Configuration

Service Mon 01-May-2000 11:20:07

Loop Device Configuration

5

6

7

CONFIGURATION:

4:Control Matrix Configuration

5:Network Configuration

6:Panel Settings

7:

Service Mon 05-DEC-2005 11:20:07

Virtual Point Configuration

14

8, 11

15

Page 3

ii

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

Contents

1 Introduction 1

1.1 Associated Documents 1

1.2 System Design and Planning 1

1.3 Glossary of Icons 2

1.4 Software Version Number 4

1.5 EN54 Functions 4

1.6 Ancillary Functions 5

2 Power On/Start Up 7

3 Panel Configuration Overview 9

3.1 Where to Access the Configuration Actions 9

3.2 Configuration Actions 10

3.3 Using the Panel Controls and Indicators 11

3.3.1 Pushbuttons 11

3.3.2 Liquid Crystal Display 12

3.4 Using the Off-line Support Tool 13

3.5 Passcodes 13

3.6 Learn Devices on Loops 14

3.7 Configure Group of Devices 15

3.8 Configure Individual Device 15

3.9 Text Editing 16

3.10 Control Matrix 16

3.11 Time-of-Day 17

3.12 Setting the Clock 17

3.13 Panel Settings 17

3.14 System Networking 18

3.15 Delays 19

3.16 Virtual Point Configuration 19

4 The Display - Tabs, Events and

Menus 20

4.1 Introduction 20

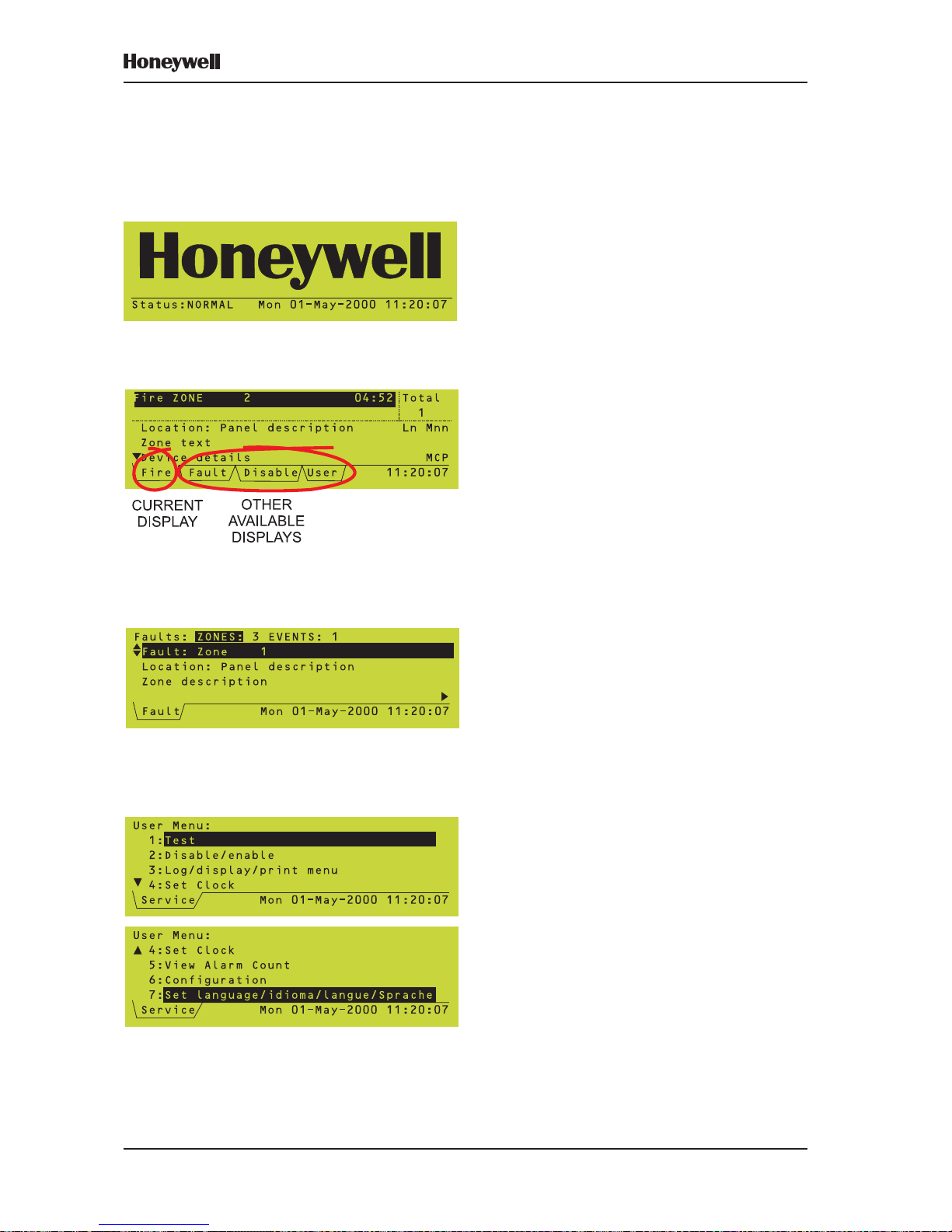

4.1.1 Status: NORMAL 20

4.1.2 Tabs 20

4.1.3 Events 20

4.1.4 Menus 20

4.2 Tabs 21

4.3 Event Displays 22

Page 4

iii

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

4.4 Menu Displays 25

4.4.1 To Display the User Menu 25

4.4.2 To Navigate Through the Menus 26

4.4.3 Menu Structure 27

5 Loop Device Configuration 29

5.1 Configure Individual Device 29

5.1.1 Select a Device 29

5.1.2 Change Device Configuration

- Sensors 31

5.1.3 MULTI, MCS & GAS Sensitivities 37

5.1.4 Change Device Configuration

- Modules 39

5.2 Configure Group of Devices 43

5.3 Learn Devices on Loops 45

5.3.1 Starting the Procedure 45

5.3.2 Run in Auto-Learn Mode 47

5.3.3 Run in Manual Learn Mode 49

5.3.4 Error Messages 49

5.3.5 End of Learn Process 50

5.4 Change Zone Number 50

6 T ext Editing 51

6.1 Text Editing Pushbuttons 51

6.2 The Character Set 52

6.3 Zone Text Editing 52

6.4 Panel Text Editing 53

7 Control Matrix 54

7.1 Introduction 54

7.1.1 EN54 Requirements 55

7.2 Input Categories 56

7.3 Output Categories 58

7.4 Output Modes 59

7.5 Review/Edit Control Matrix 61

7.5.1 Review Entries 61

7.5.2 Edit Entries 62

7.6 Defining a Control Matrix Entry 63

7.6.1 Input Definitions 63

7.6.2 Output Definitions 69

7.6.3 Completion of New Entry 75

7.7 Disablement/Enablement Function 76

Page 5

iv

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

7.8 Extinguishing System Function 77

7.8.1 T ypes of Control Matrix Entry 77

7.8.2 Minimum Configuration 77

7.8.3 Device Selection 78

7.8.4 HOLD Options 78

7.9 Logic Operation with Transfer Flags 79

7.9.1 Example Logic Operations 79

7.10 Print Control Matrix 81

8 Change Passcode 82

8.1 Introduction 82

8.2 How to Change a Passcode 83

9 Time-of-day Programming 85

9.1 Time-of-day Program Editing 85

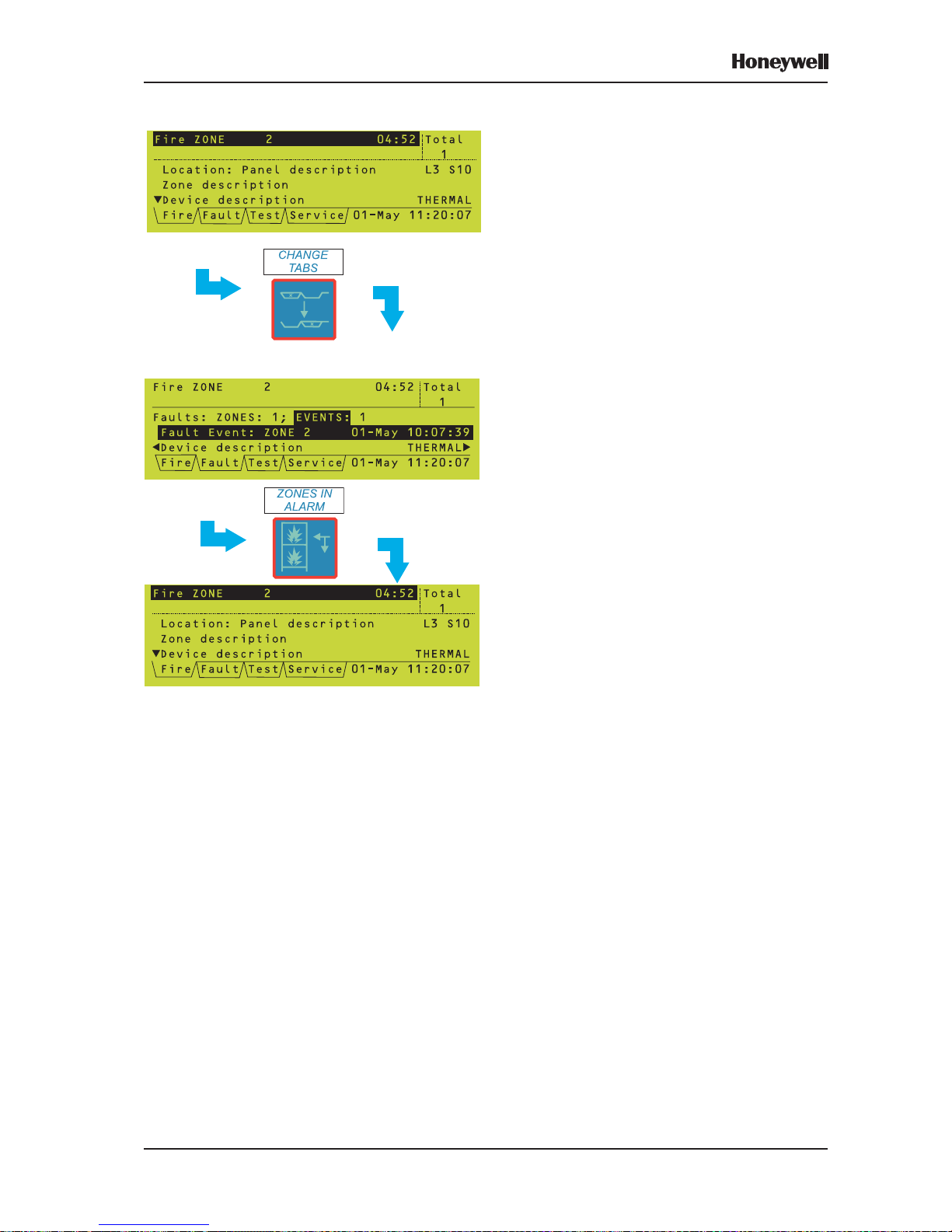

9.2 Manual Override 87

9.3 DISABLEMENT and

ENABLEMENT Override 88

9.4 MULTI Thermal-Only Mode 89

9.5 Link to Day/Night Switch 89

10 Setting the Clock 90

11 Panel Settings 91

11.1 Internal Buzzer Options 91

11.2 LED ‘Blinking’ Mode 92

11.3 Number of LOOPS on Panel 93

11.4 Pulsing Sounder Modes 94

11.5 Walk Test Options (MCP/Sounder) 94

11.6 Automatic Test Options 95

11.7 Disablement Options 95

11.8 Loop Options 97

11.9 Panel Functions 97

11.10 Access Level for MUTE BUZZER etc. 98

11.11 Unlatched Non-alarm Input Logging 98

11.12 Relay Circuits SILENCE Option 99

11.13 Mains/PSU Fault Delays 99

11.14 LCD Backlight ‘On’ Duration 100

11.15 Blank Lines Between Printed Events 100

11.16 Isolated RS232 Port Set-up 101

11.17 Diagnostic RS232 Port Set-up 102

11.18 Remote Fire Output Options 103

Page 6

v

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

11.19 Day/Night Modes Configuration 104

11.20 Extinguishing System 105

11.21 Alarm Coincidence 106

11.22 Network Settings 107

11.23 Thermal Alarm Verification Time 107

12 User Menu at Level 3 Access 108

12.1 Control Output Tests 108

12.1.1 CMX Modules 109

12.1.2 Local Sounder Circuits 1 10

12.1.3 Relay Circuits 110

12.1.4 Virtual Output Points 111

12.1.5 Loop Sounders and Boosters 111

12.2 Bad Poll Log 112

12.3 Display Active Control Matrix Rules 112

12.4 Unconfigured Devices Scan Menu 112

12.4 Commissioning Mode for MCS Sensors 113

13 Sensitivity and Alarm Delay

Recommendations 114

13.1 Analogue Sensors Sensitivity 114

13.2 Analogue Device Verification 114

13.3 Module Delays 115

14 Master/Slave Network 116

14.1 Introduction 116

14.1.1 Number of Stations on Network 1 1 6

14.1.2 Number of Zones on Network 1 1 7

14.1.3 Information Distribution via Network 1 18

14.2 Network Configuration Procedures 119

14.2.1 Station Type 120

14.2.2 THIS Panel 121

14.2.3 Associate Repeaters with Panel 122

14.2.4 Completion of Network Configuration 122

14.3 Print Network Configuration 122

15 Virtual Point Configuration 123

15.1 Virtual Output Points 123

15.2 Virtual Input Points 124

15.3 Virtual Output Backup Sounder 124

Page 7

vi

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

Appendix 1

Upgrading the Panel Software A1-1

Appendix 2

Available Loop Device Types A2-1

Appendix 3

XLSNET Network Configuration A3-1

Page 8

1 Honeywell, Issue 9

March 2007

XLS80e Fire Alarm Control Panels

1 Introduction

This manual provides recommended procedures

for the successful configuration of a complete

Honeywell XLS80e Series integrated Fire Control

System (including repeater panels). The

procedures also apply for XLS80e Series

stand-alone Fire Control units.

The XLS80e Series intelligent fire alarm

controllers are designed for use with

Honeywell’s range of addressable analogue

sensors, control and monitoring modules and

addressable call points. A unique signalling

protocol is used, with digital address and

control signals and analogue pulse width

monitoring for the reply data from devices.

The serial communications interface operates

under RS485 protocol. It enables the

connection between control panels and

repeaters.

1.1 Associated Documents

This manual should be read in conjunction with

the following documents:

a. XLS80e Series Installation &

Commissioning Manual

b. XLS80e Series Operating Manual

(ref. 997-474-000-x).

1.2 System Design and Planning

It is assumed that the system, of which the

XLS80e Series fire control equipment is a part,

has been designed by a competent fire alarm

system designer in accordance with the

requirements of EN54 Part 14, BS 5839 Part 1:

1988 and any other local codes of practice that

are applicable.

Be aware that....

This manual is not intended to be a fire

detection system design guide and should only

be used by (or under the supervision of) a

qualified system design engineer.

Some features of the XLS80e Series control

panel may , if used inappropriately , contravene

the requirements of EN54. Where there is a

possibility of such an occurrence, a suitable

warning is given with brief details of the EN54

requirement. A typical EN54 non-compliance

warning is illustrated at left.

EN54-2: 13.7

Maximum of 512

Sensors and/or MCPs

per panel unless

ELIBs are used

Page 9

2Honeywell, Issue 9

March 2007

XLS80e Fire Alarm Control Panels

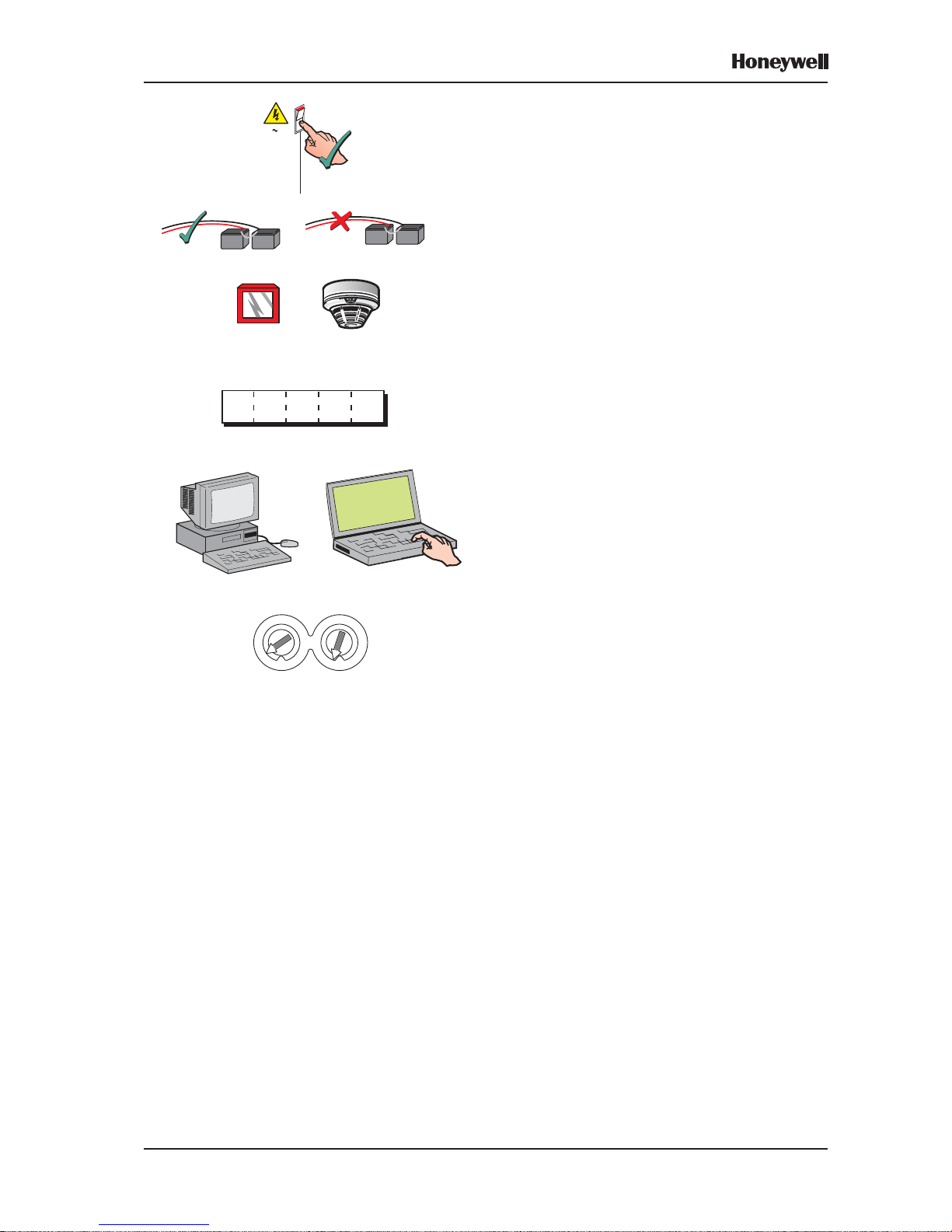

1.3 Glossary of Icons

Throughout this manual, and the other related

XLS80e Series manuals, a number of icons

are used in the illustrations to help clarify, or

simplify, p articular configuration procedures.

The following icons are used to advise or

indicate:

a. DO follow the recommended procedure or

method.

b. DO NOT use this procedure or method.

c. Inspection of an item or sub-assembly is

required at this point.

d. Following a defined process meets the

required approval/inspection criteria or

standards.

e. Following a defined process does not meet

the required approval/inspection criteria or

standards.

f. Additional items to be considered.

g. This icon placed next to a pushbutton

requires you to press it while configuring

the panel. Where two or more icons are

used, a number may be placed on or near

each hand to indicate the order of selection:

1 coming before 2.

h. Activity process step - flow arrow for single

action or iterative actions.

i. Leader arrow - used with activity processes.

j. Sounder operating/Sounder not operating

or silenced.

k. Internal buzzer operating/not-operating or

silenced.

l. Digital clock timer - press and hold the

applicable pushbutton for the time indicated.

00:00:03

Page 10

3 Honeywell, Issue 9

March 2007

XLS80e Fire Alarm Control Panels

m. Mains power connected and switched ON.

n. Panel batteries power connected/

disconnected.

o. Manual Call Point (MCP)/Sensor.

p. Access 3A passcode entry requested to

continue with selected panel configuration

action (access 2 & 3 shown with three

asterisks).

q. IBM-compatible Personal Computer (PC)/

laptop.

r. Loop device address switch.

1

22

33

4455

66

77

81 8

0

09

9

230 V AC

50/60 Hz

Access 3A

*****

Page 11

4Honeywell, Issue 9

March 2007

XLS80e Fire Alarm Control Panels

1.4 Software Version Number

The XLS80e Series control panel software

version can be viewed by performing a lamp

test function.

Software version numbers are displayed for

the following:

a. The panel.

b. The Loop Interface PCB.

c. The Enhanced Loop Interface PCB.

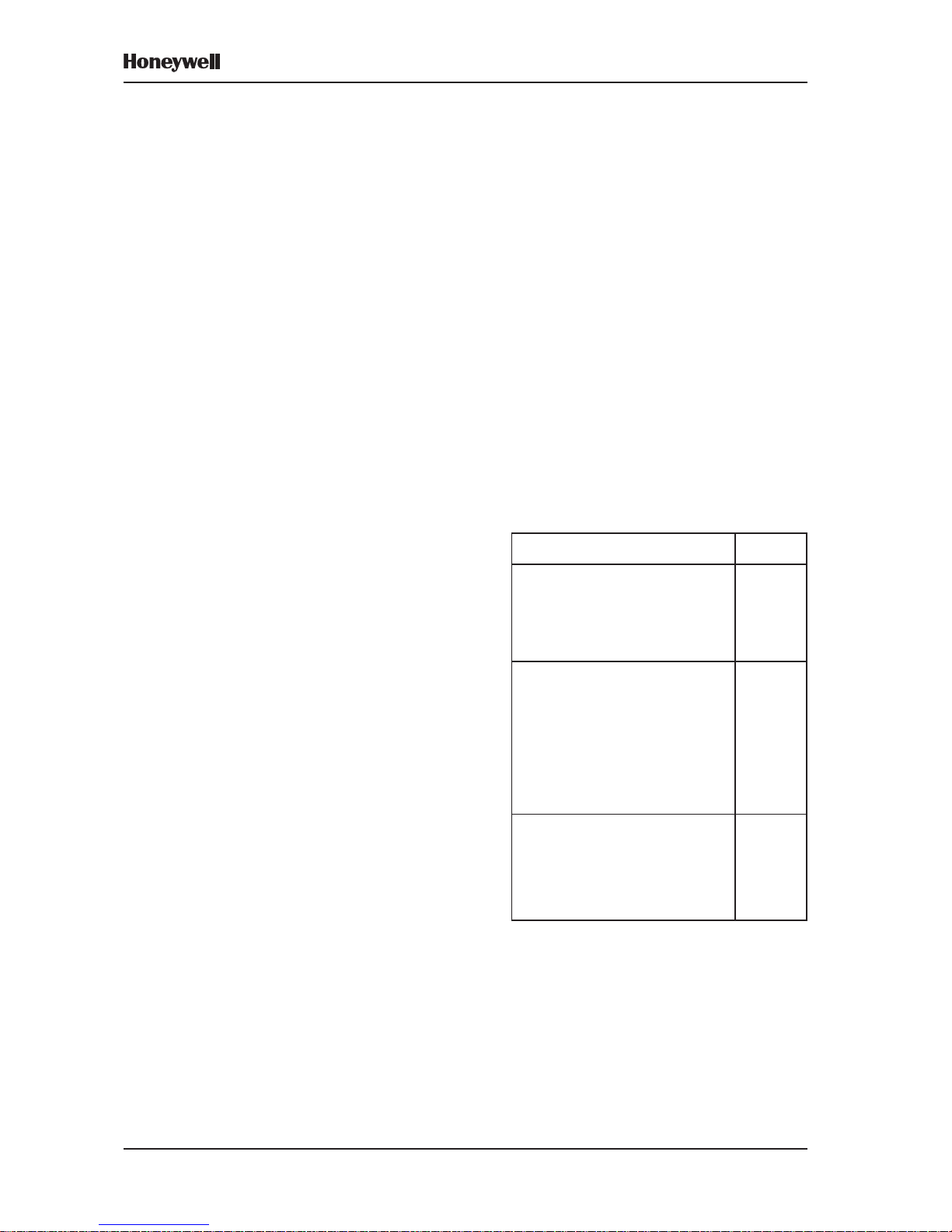

1.5 EN54 Functions

This fire control panel complies with the

requirements of EN54-2/4:1997. In addition to

the basic requirements of EN54-2, the panel

may be configured to conform with the

following optional functions - the applicable

clauses of EN54-2 are referenced as follows.

Options Clause

Indications:

Fault signals from points 8.3

Recording of the numbers of

entries into fire alarm condition 7.13

Controls:

Coincidence detection 7.12

Delay of the actioning of outputs 7.11

Disablement of each address

point 9.5

Test condition 10

Outputs:

Fire alarm devices 7.8

Fire alarm routing equipment 7.9

Fault warning routing equipment 8.9

Page 12

5 Honeywell, Issue 9

March 2007

XLS80e Fire Alarm Control Panels

The following features are provided by the

Power Supply Unit (PSU) of the XLS80e Series

Fire Control Panel Range to comply with

EN 54-4:

Feature of the XLS80e PSU EN 54-4

Clause

Derive power from the mains

supply 5.1

Derive power from a standby

battery source 5.2

Charge and monitor the standby

battery / batteries 5.3

Detect and signal various PSU

faults 5.4

1.6 Ancillary Functions

The following is a list of ancillary functions that

are provided by the XLS80e Series Fire Control

Panel Range in addition to those required by

EN54-2/4. These functions are described in

the section of this manual as referenced

(except the Sounder volt-free contact option,

which is described in the Installation and

Commissioning Manual):

Ancillary Function Manual

Section Refs.

Change sensitivity 5.1.2.7, 13

Control Matrix:

Output modes 7.4

Input type filtering 7.6.1.1

Output type filtering 7.6.2.2

Time-of-day filtering 7.6.2.2

Auto disable/enablement 7.7

Networking 14

Time-of-day functions -

disablements/configuration 3.11

Self-learn configuration 5.3.2

Module supervision options 5.1.1.4

Module silence options 5.1.4.7

Text editing 6

Sensor LED blinking mode 1 1 .1

Sounder pulsing periods 1 1. 4

Signal degraded monitoring

period 11.8

(continued)

Page 13

6Honeywell, Issue 9

March 2007

XLS80e Fire Alarm Control Panels

Ancillary Function Manual

Section Refs.

Loop start-up boost 1 1. 8

Calendar-based automatic

test selection 11.6

Automatic cancellation of

disablements 11.7

Mains Fail Fault

additional delay 1 1.13

RS232 Printer Output &

PC Interface 11.1

T emporary Configurations 1 1.1, 11.2

Volt-free cont act

output option 7.7

1

Extinguishing system 7.6.1.6

features 7.6.2.5

7.8, 1 1.20

1

Installation and Commissioning Manual

CAUTION:

This product is not compliant

with EN 12094-1.

EN

12094-1

!

EN

12094-1

!

Fire extinguishing installations in

Europe are required to be certified as

compliant to this standard.

Page 14

7

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

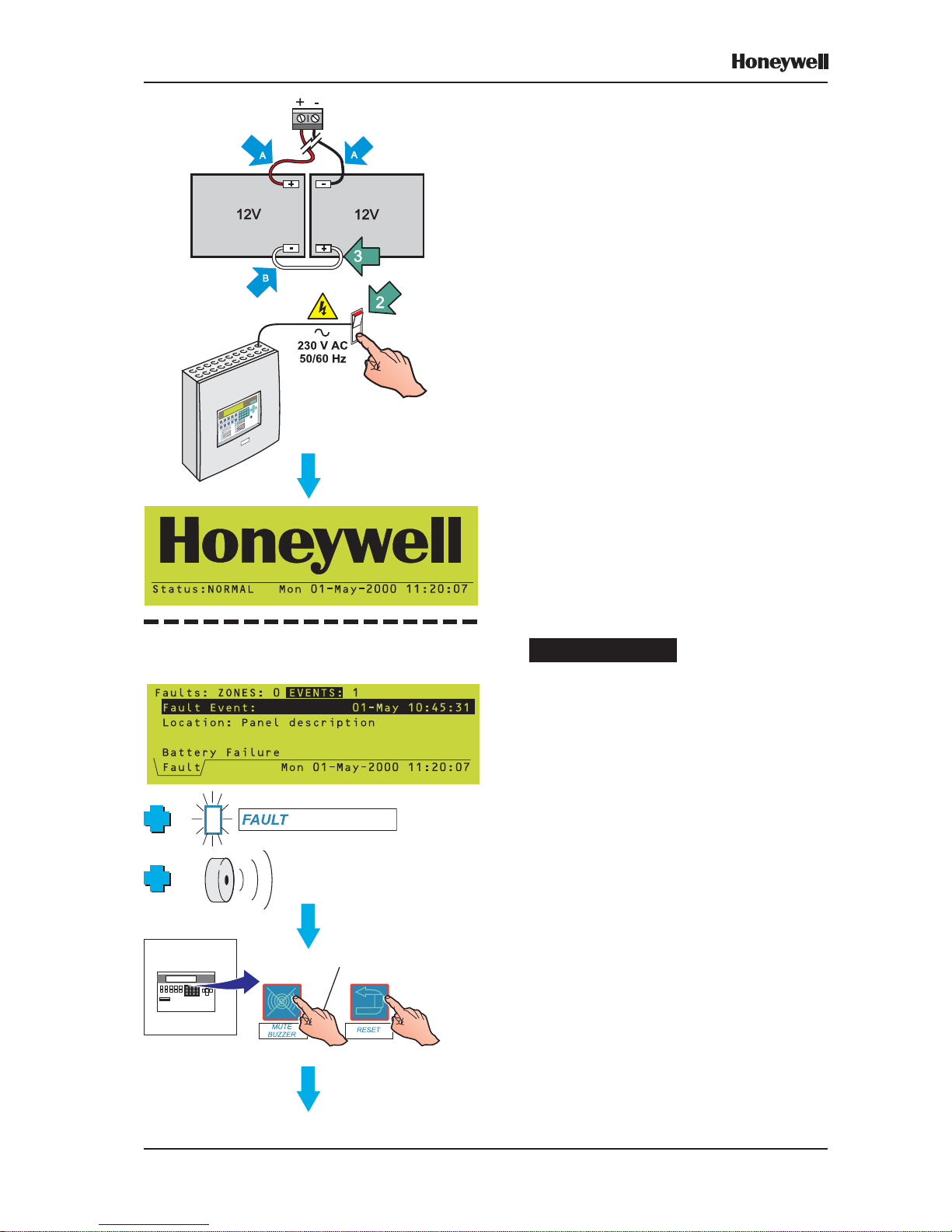

2 Power On/Start Up

To power up the system from a completely

powered-down condition:

1 Connect the two leads (A) from within the

panel to the two 12 V sealed lead-acid

batteries and then fit one end only of the

supplied interlink (B).

2 Connect and switch on the mains supply.

3 Connect the interlink to the remaining

terminal - but see item a. below.

After a few seconds the Status: NORMAL

display appears, indicating that the panel is

now ready to accept panel configuration

instructions. If the display is too dark to read,

adjust the contrast (see Section 3.3.2.1).

Be advised that....

a. If the battery connections are not completed

within 60 seconds of the mains supply

being switched on, the panel will indicate a

charger/battery fault. If this occurs:

1 Press the MUTE BUZZER pushbutton to

silence the buzzer (access level 1 or 2,

depending upon panel configuration).

2 After all necessary connections are

completed, press the RESET pushbutton

to clear the fault condition (access level 2).

IF BATTERIES ARE NOT CONNECTED WITHIN

60 SECONDS OF POWER-ON:

ALL FAULT INDICATIONS ARE CANCELLED

Page 15

8

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

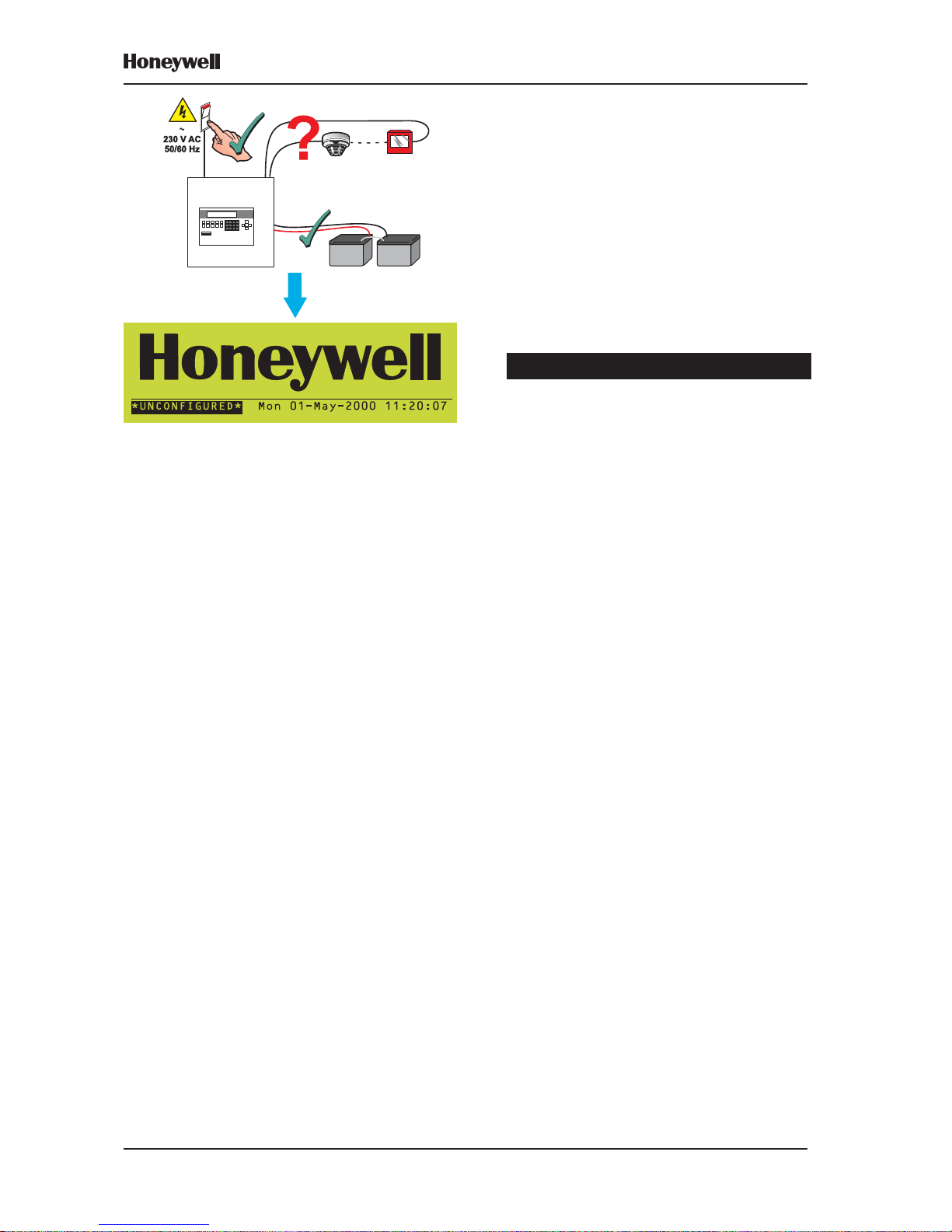

b. If the panel has not been configured with

any sensor or module data, i.e. the normal

system status at initial power up, the panel

displays ‘*UNCONFIGURED*’ unless it is

part of a network, in which case it displays

‘NORMAL’.

Powering up a network - special considerations

Master/Slave network

The following is recommended:

i When configuring a panel (either directly

or using the Offline Support Tool), first

disconnect the panel from the network.

When the COMMS FAIL message is

displayed (may take up to 2 minutes for a

Slave), press MUTE BUZZER to stop the

buzzer.

ii When all panels have been configured,

remove power from all of them. Connect

the Master panel to the network - set the

termination link on its RS485 PCB to the

‘ON’ (lower) position if it is not already so

configured (see Section 6 of the XLS80e

Series Installation and Commissioning

Manual).

iii Power-on just the Master panel. Wait until it

reports COMMS FAIL. Use MUTE BUZZER

to mute the buzzer. W ait one minute.

iv Connect and power-on each Slave panel

and Repeater in turn. There is no time

restriction on doing this. When all the

panels have been powered-on, wait one

minute, then press the RESET pushbutton

at the Master panel. The network should

stabilise (i.e. no error messages or buzzers).

v If the site arrangement does not require that

a termination link be set at the Master (see

Section 6 of the XLS80e Series Installation

and Commissioning Manual), fit the

termination links at the correct panels and

then set the link at the Master panel to the

‘OFF’ (upper) position. This can be done

with the system powered-on.

XLSNET peer-to-peer network

When all panels have been powered-up, allow

time for the network to settle. When no new fault

messages are being generated, press RESET .

Page 16

9

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

3 Panel Configuration Overview

This section gives a brief guide to the methods

for configuring the XLS80e Series panels.

3.1 Where to Access the Configuration

Actions

The panel can be configured at one of the

following:

a. The panel, using its controls and indicators.

This is the slowest method, so the

manufacturer recommends that you only

use this method to perform small-scale

operational amendments after the panel is

fully commissioned. Refer to Section 3.3.

b. Off-line, using a Personal Computer (PC,

e.g. a laptop) running the Off-line Support

Tool. The updated configuration is

subsequently uploaded to the panel via its

internal RS232 port. Refer to Section 3.4.

At the start

The Access 3 passcode is required to configure

the panel. Refer to Section 3.5.

At the finish

A ‘Confirm Changes’ prompt is displayed. The

changes you have made are not permanently

stored in the panel’s memory unless you press

to select ‘confirm’. If you press to select

‘cancel’, the changes are lost.

OR

Access 3

***

Page 17

10

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

3.2 Configuration Actions

The following configuration actions can be

performed:

a. An unconfigured panel can scan the loops

and learn what devices are installed, either

automatically or with manual user

intervention. Refer to Section 3.6.

b. Groups of devices on a configured panel can

be selected for deletion or change to a

different logical type. Refer to Section 3.7.

c. Individual devices can be added, removed

or changed manually. Refer to Section 3.8 .

d. The panel zone and device text descriptions

can be edited. Refer to Section 3.9.

e. The relationship between input devices (e.g.

sensors, manual call points) and output

devices (e.g. sounders) can be configured.

This is done in the Control Matrix, which is

a table of inputs, outputs and relationships.

Refer to Section 3.10.

g. The status of devices (e.g. the sensitivity)

can be set to vary depending upon the time

of day. Refer to Section 3.11.

h. The panel clock can be adjusted. Refer to

Section 3.12.

i. Various temporary and permanent

configuration options can be set. Refer to

Section 3.13.

j. The panel can be configured to be part of a

network. Refer to Section 3.14.

k. Sounders or remote fire outputs can be

delayed. Refer to Section 3.15.

l. Virtual input and output points can be

configured. Refer to Section 3.16.

LOOP DEVICE CONFIGURA TION - Sections 3.6-3.8

TEXT EDITING - Section 3.9

CONTROL MA TRIX - Section 3.10

TIME-OF-DA Y - Section 3.11

CLOCK SETTINGS - Section 3.12

P ANEL SETTINGS - Section 3.13

NETWORKING - Section 3.14

Z X C V B N M

Q W E R T Y U I O P

A S D F G H J K L

?

?

DELAYS - Section 3.15

Certain options on non-configuration menus

also require the access level 3 or 3A passcodes.

These options are described in Section 12.

VIRTUAL POINT CONFIGURA TION - Section 3.16

Page 18

11

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

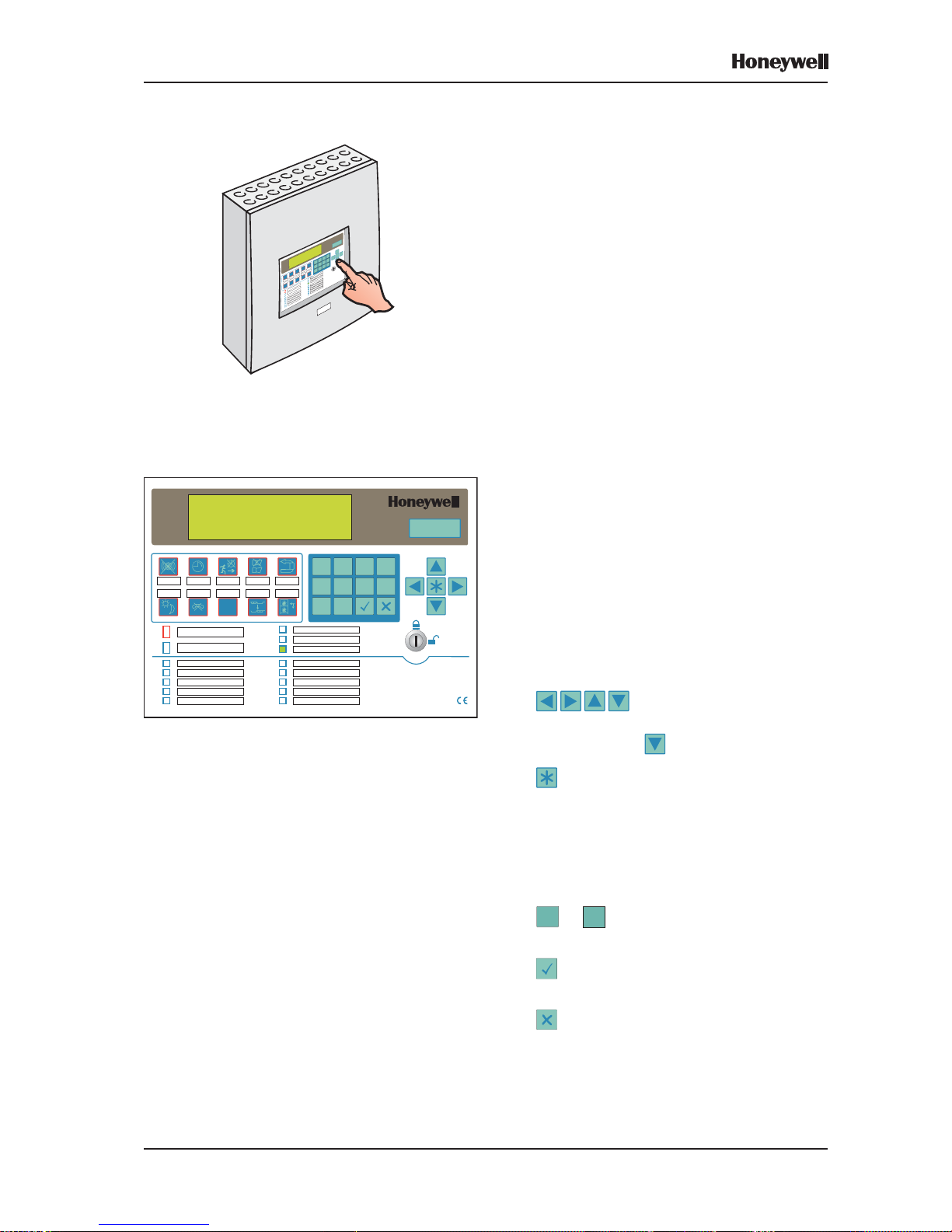

3.3 Using the Panel Controls and

Indicators

All of the configuration operations described in

this manual can be done using the panel

pushbuttons and Liquid Crystal Display (LCD),

with no external equipment required.

The panel remains ‘on watch’ during the

configuration sequence, and will therefore

respond appropriately to any fire or fault

conditions that arise.

The manufacturer recommends that you keep

a secure copy of the system configuration on a

PC as a backup, in case of difficulties in the

configuration sequence.

3.3.1 Pushbuttons

OPERA TING PUSHBUTTONS

CHANGE TABS - Scrolls through the tabbed

displays. Refer to Section 4.2 for further

information.

RESET - Restores normal operating status

when all alarm conditions have been removed.

Note: The other operating pushbuttons are not

used during configuration. Their

operation is described in the XLS80e

Series Operating Manual (997-474).

CURSOR AND NUMERIC PUSHBUTTONS

- Used to move around the LCD

menus. When the panel status is normal and if

the printer is fitted, advances the printer paper.

Used to: select menu options, select quick

methods of dis/enablement and walk test

cancellation, control the event log display , select

loop device parameters for edit, display existing

time-of-day programs, create a new Control

Matrix entry and select characters during text

editing.

0

to 9 - Used to select items and enter

data on the LCD.

- Used to accept an item or state on the

LCD.

- Used to cancel an item or state on the

LCD.

KEYSWITCH - Setting the keyswitch to the

right has the same effect as entering an

access 2 passcode. Set it to the centre to

deselect access 2.

XLS80e

0 1

2 3

4 5

6 7

8 9

ENDDELAY /

EVACUATE

MUTE

BUZZER

EXTEND

DELAY

SILENCE/

RESOUND

RESET

DAY

MODE

FIREO/P

DISABLE

CHANGE

TABS

ZONESIN

ALARM

PRE-ALARM

FIRE

FAULT

SYSTEM FAULT

SOUNDER FAULT/ DISABLED

FIRE O/PFAULT / DISABLED

FIRE O/PACTIVE

DAYMODE

DELAYSACTIVE

TECHNICALALARM

DISABLEMENT

TEST

POWER

EN54-2/41997

Page 19

12

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

3.3.2 Liquid Crystal Display

The 6-line x 40 character display (using 240 x

64 pixels) provides a menu structure for the

operation and configuration of the panel. Most

of the operations described in this manual are

accessed from the Configuration Menu.

Further information about the display is given

in Section 4.

3.3.2.1 LCD Contrast Adjustment

This adjustment procedure as shown at left is

only available within the first two minutes after

power is applied to the panel.

To adjust the LCD contrast at other times,

select LAMP TEST (refer to the XLS80e Series

Operating Manual 997-474, Section 6.4 Lamp

Test) while at access level 3. Hold while

the test progresses. The contrast then cycles

and the remainder of the procedure is as shown

at left.

HOLD

THE DISPLA Y CYCLES BETWEEN MAXIMUM AND

MINIMUM CONTRAST :

MOMENT ARILY

WHEN THE REQUIRED CONTRAST IS PRESENT

ON THE DISPLAY, RELEASE .

TO FINE-ADJUST , USE:

WHEN COMPLETED, PRESS:

TO INVOKE THE SELECTED CONTRAST VALUE.

AND

AND PRESS

Page 20

13

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

3.4 Using the Off-line Support T ool

This is a means of preparing the configuration

data, using an optionally-supplied software tool

which you can use without any connection to

the panel:

i. Save the prepared data to your PC hard disk.

ii. When the panel is ready to accept the

configuration data, simply connect it to your

PC, for the final data transfer to be made.

The XLS80e Off-line Support T ool is a complete

package for off-line configuration preparation. It

is supplied with all necessary panel configuration

instructions, consequently no further details are

given here.

This software package is available from

HONEYWELL or your supplier (Part Number:

020-558-100).

3.5 Passcodes

A passcode is required for all configuration

functions. You will be asked for the passcode

at the appropriate time (Sections 4.4.1 and 12.1

give examples). There are three access

passcodes:

Access 2 - Permits operation of the panel

pushbutton controls and provides access to

all menus except the Configuration menu.

It can be overridden by the panel keyswitch.

Note: Some menus have options which can

only be accessed using an Access 3 or

Access 3A passcode; these options are

described in Section 12.

Access 3 - Provides access to the

Configuration menu. Most operations

described in this manual require this

passcode.

Access 3A - Certain operations (changing

passcodes, and panel settings) require this

passcode.

Default passcodes are supplied with the panel.

These can be changed and the manufacturer

strongly recommends that you do so once

commissioning has been completed (see

Section 8 for default passcodes and the means

of changing the passcodes from these defaults).

Passcodes are not required for off-line

configuration using a PC, but they are required

when uploading or downloading configuration

data using this method.

Access 2

Access 3A

**

*****

*

Access 3

**

*

Page 21

14

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

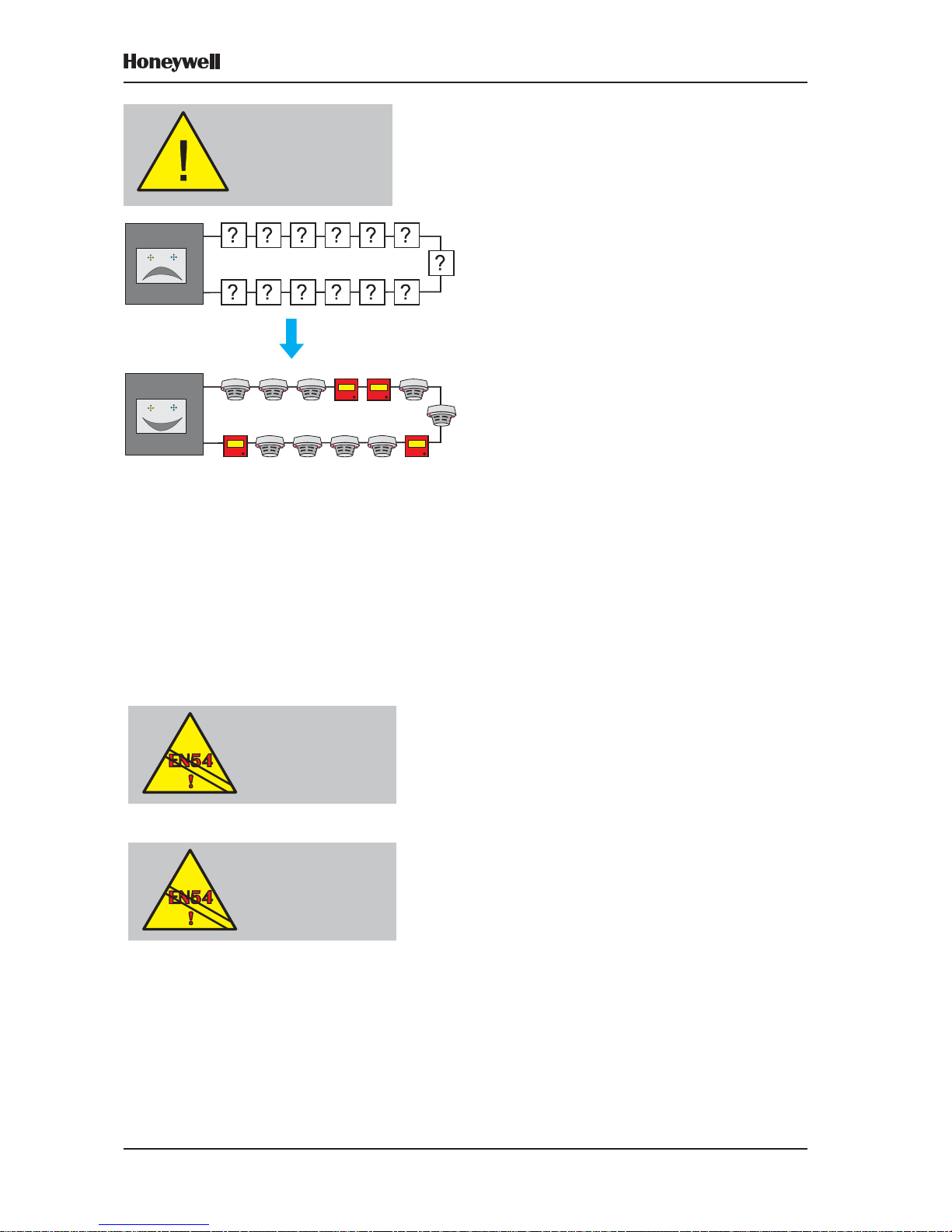

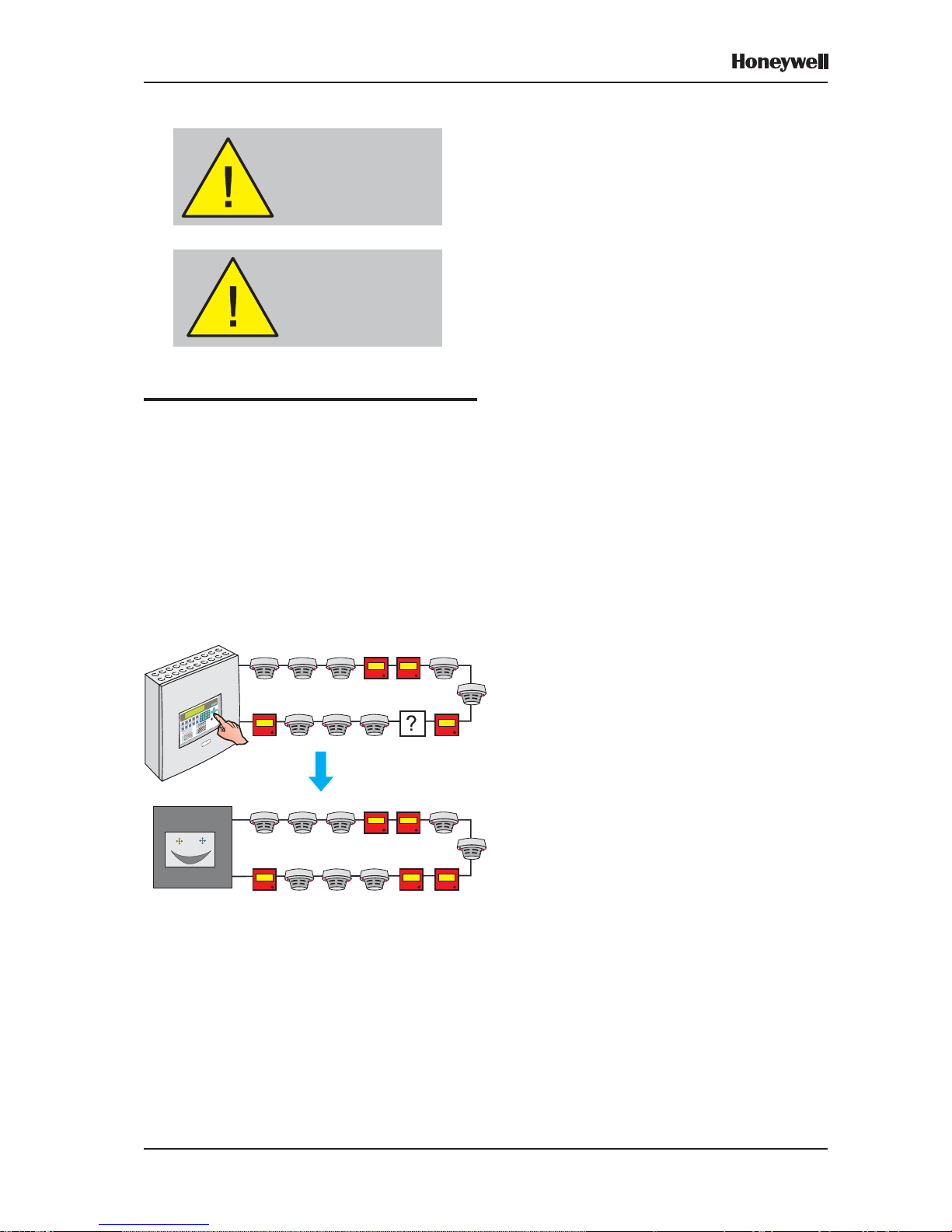

3.6 Learn Devices on Loops

The panel scans the loops and detects what

devices are fitted. This can be done on an

unconfigured panel. Section 5.3 describes how

to start, run and end a configuration learn.

There are two learn methods:

a. Auto-Learn. Loop device decisions are made

without the need for user intervention. Refer

to Section 5.3.2.

b. Manual Learn. Prompts the user each time

a new or changed device is detected. Refer

to Section 5.3.3.

Limitations on the Number of Devices

The XLS80e Series Control Panel design allows

for the connection of up to 198 loop devices per

analogue loop; i.e. up to 99 sensors and 99

modules. The maximum number of devices per

panel is:

a. 1584, if the Enhanced Loop Interface Board

(ELIB) is used for loops 3 to 8.

b. 512, if the Loop Interface Board (LIB) is used

for loops 3 to 8.

T o comply with EN54-2 in the event of a system

fault, a maximum of 512 sensors and/or MCPs

should be connected to the control panel across

those analogue loops that are not connected

to an ELIB. This number includes all

conventional zone detectors and/or MCPs

connected.

If the number of sensors and/or MCPs connected

to a loop exceeds 32, then isolators MUST be

used to segregate parts of the loop. This will

ensure that a short or open circuit will not cause

the loss of more than 32 sensors or MCPs. For

the XLS80e Series, do not place more than 25

loop devices between isolators (20 if FET

isolators are used).

There may be a further restriction, depending

on the types of sensor used, because of drive

limitations of the isolators. HONEYWELL

provide a PC-based tool to simplify loop loading

calculations. Contact the Te chnical Support

Department or your supplier for further

information.

EN54-2: 12.5.2

Maximum of 32 Sensors

and/or MCPs between

isolators

Before configuring

your panel, ensure all

loop devices are

installed

and each loop is

connected

EN54-2: 13.7

Maximum of 512

Sensors and/or

MCPs per panel unless

ELIBs are used

Page 22

15

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

Limitations of the Auto-learn Method

If the auto-learn method is used on an

incomplete system it will give the false

impression that the system is fully operational.

In such cases, the auto-learnt data MUST be

checked carefully against the system

specification.

During the auto-learn procedure, input

module logical types are set to defaults.

Modules not conforming to the defaults must

be re-configured using the Manual Learn or

Configure Individual Device procedures.

3.7 Configure Group of Devices

On a configured panel, this configuration

method allows a group of devices at consecutive

addresses to be deleted or all set to the same

type.

Refer to Section 5.2.

3.8 Configure Individual Device

This configuration method requires the user to

select each loop device and set all parameters

and conditions, e.g. sensitivity, time-of-day,

device text, etc. appropriate to it.

It can also be used to add further details to the

configuration resulting from the auto-learn

method.

Refer to Section 5.1.

Note: Sensitivity and alarm verification delay

recommendations are given in

Section 13.

Caution - a false indication

of a fully-functional system

is given if the Auto-learn

procedure is used on an

incomplete system.

Input module types are

set to defaults during the

Auto-learn procedure

and may require manual

re-configuration.

Page 23

16

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

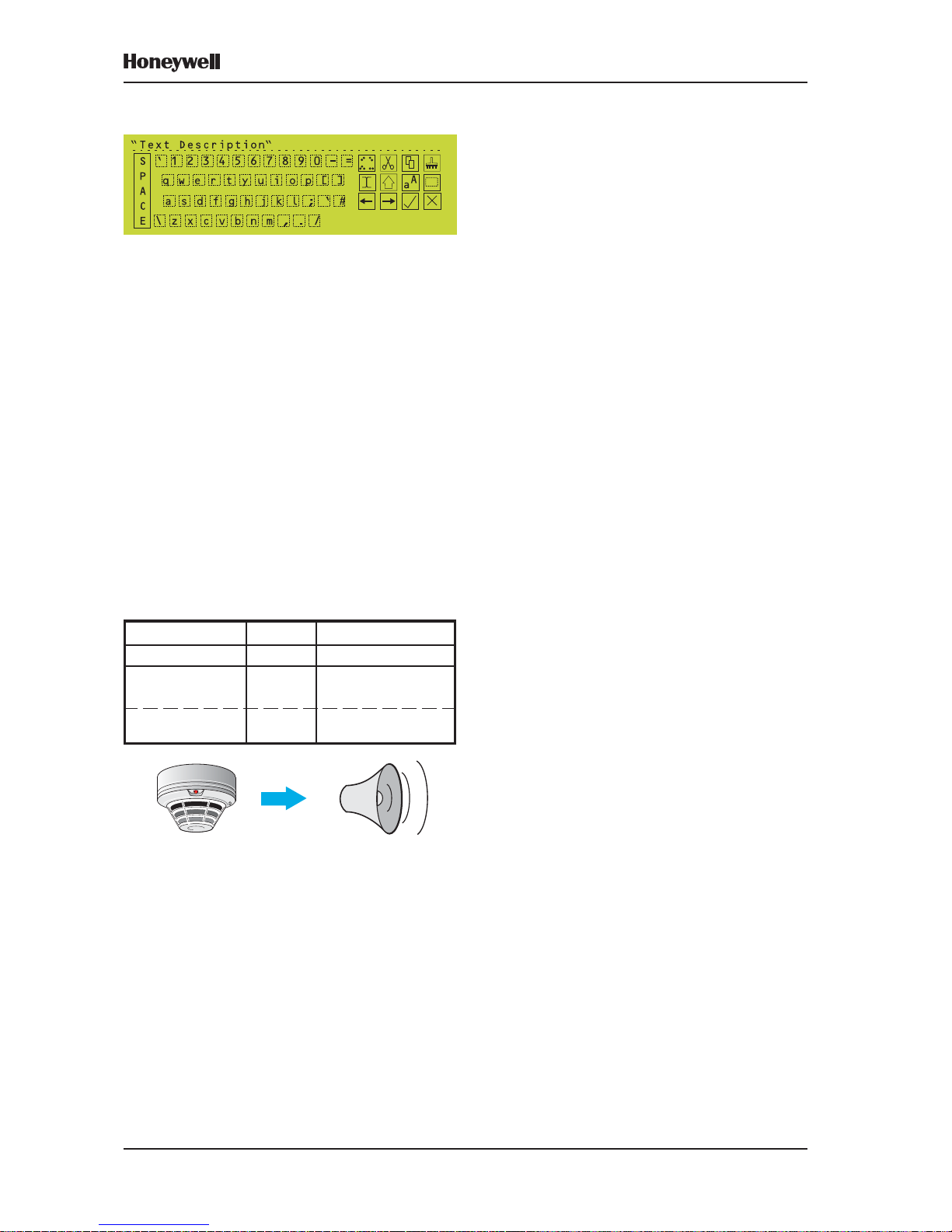

3.9 T ext Editing

There are three types of text that can be entered

and edited:

a. The panel or site name.

b. The zone description.

c. The device location text, which is shown on

the display when the system status is not

normal (i.e. alarm, test etc.). The device

description is also used at the printer, if

fitted.

The text is entered and edited from a text editor

which uses the LCD and the panel pushbuttons.

Refer to Section 6.

For panel and zone descriptions, the text editor

is invoked from dedicated menu options

(Sections 6.4 and 6.3 respectively). For device

location text it is invoked during the Configure

Devices on Loops procedure (Sections 5.1.2.3

and 5.1.4.3) or Virtual Point Configuration

procedure (Section 15).

3.10 Control Matrix

This very versatile system allows you to define

exactly which outputs (bells, etc.) are to be

activated depending upon which inputs

(sensors, etc.) have given a fire indication.

The capacity of the system is 512 matrix

entries.

Certain auxiliary functions may be specified

using the Control Matrix.

Refer to Section 7.

<Entry 1 input> activates: <Entry 1 output>

<Entry 2 input> activates: <Entry 2 output>

<Entry 3 input> activates: <Entry 3 output>

⇓ ⇓ ⇓ ⇓ ⇓ ⇓ ⇓ ⇓ ⇓ ⇓ ⇓ ⇓ ⇓ ⇓ ⇓ ⇓ ⇓ ⇓

<Entry 512 input> activates: <Entry 512 output>

CONTROL MA TRIX:

E.G.

Page 24

17

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

3.11 Time-of-Day

This facility allows panel functions to be

modified depending upon the time of day . There

are three major applications:

a. Altering the sensitivity of sensors at certain

times of day - see Section 5.1.2.7.

b. Making some actions in the Control Matrix

(e.g. a delay) apply only at certain times of

day - see Section 7.6.2.2.

c. Cancelling all disablements on the panel at

certain times of day (not EN54-2 compliant)

- see Section 11.7.

Note: A Control Matrix entry can be used to

control disablement and enablement

functions, independent of the CANCEL

DISABLE function (see Section 7.7).

A typical Time-of-day program consists of one

or two daily periods specified by start and end

times, with an optional alternative for weekends.

Up to seven such programs can be in operation

in any one panel.

These programs run completely independently

of each other. Any particular sensor sensitivity ,

or Control Matrix entry , may be modified only

according to one of the programs.

Full details on Time-of-day program editing are

given in Section 9.

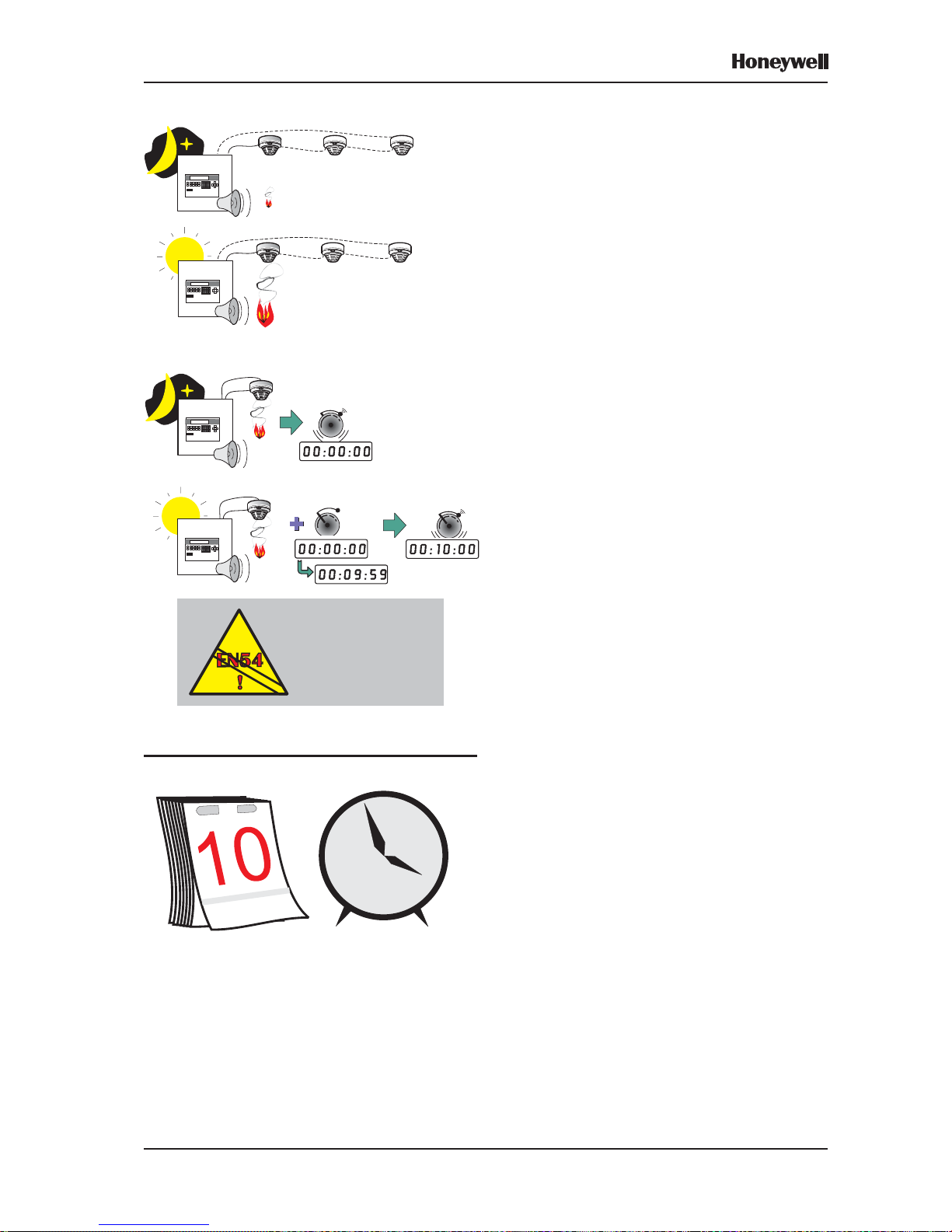

3.12 Setting the Clock

This facility allows:

a. The date and time to be adjusted.

b. The clock running speed to be adjusted.

c. The start and end dates of Summer Time to

be selected.

Refer to Section 10.

3.13 Panel Settings

For a number of panel functions, various options

are available e.g. Pulsing Sounder Modes,

Access Level for MUTE BUZZER etc, Relay

Circuits SILENCE Option. Some options are

temporary , most are permanent.

Refer to Section 11.

EN54-2: 9.1.2

Disablement and

re-enablement MUST be

a manual operation.

NIGHT - SET TO HIGH SENSITIVITY

DAY - SET T O LOW SENSITIVITY

NIGHT - CONTROL MA TRIX

HAS NO DELAY SET

DAY - CONTROL MA TRIX

HAS DELAY SET

Page 25

18

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

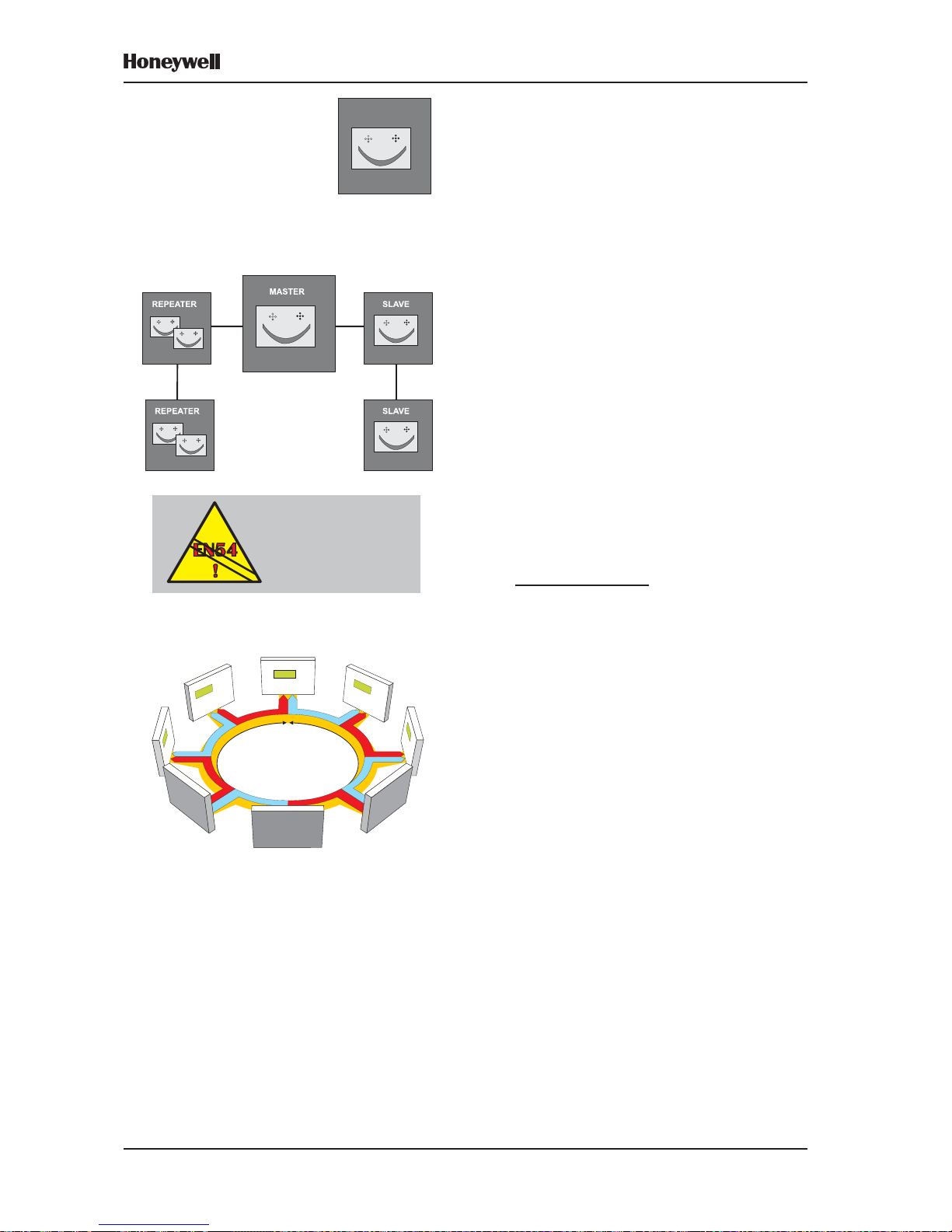

3.14 System Networking

The XLS80e Fire Control system is designed

so that control panels can work either as standalone units or networked with other panels.

When networked, each panel supervises its

own detection system of up to eight loops of

sensors and modules and functions

independently of all other panels.

A communication system enables events at

any panel to be relayed to other panels. This

causes appropriate annunciations and actions

at those panels.

Network Programming

The XLS80e Series panel can be used with one

of two networks:

a. Master/Slave network. Refer to Section 14

for further information.

b. XLSNET peer-to-peer fault-tolerant network.

Refer to Appendix 3 for further information.

Local Codes of Practice

Master/Slave network: The existence of network

communications is not, normally, intended to

replace the essential functions of the individual

panels (considered as isolated systems) but

to supplement and extend the facilities offered.

This means that each panel must be configured,

independently of the others, to comply with the

appropriate Code of Practice in force in the area

of the installation (i.e. in respect of the activation

of alarm devices in response to an Alarm of

Fire). This compliance must be maintained at

all times, even when communication with other

panels is suspended.

The Master/Slave

network does not

provide the transmission

path integrity required

by EN54-2: 12.5.3

OR

XLSNET PEER-TO-PEER NETWORK

XLS80e:

ST AND-ALONE

OR

MASTER/SLAVE NETWORK

RS485

Page 26

19

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

3.15 Delays

Either the sounders or the fire alarm routing

equipment (remote fire outputs) which is used

to summon the fire brigade can be delayed:

a. To activate sounders immediately but delay

the remote fire outputs, use the Day/Night

Modes Configuration Option

(Section 11.19). The delay may be

extended to allow investigation. MCPs are

normally configured to override any delay.

b. T o delay sounders but activate the remote

fire outputs immediately, use the Control

Matrix to put an output delay on modules of

type BELL (Section 7.6.2.2). The delay

must then be enabled by the Operator (see

997-474, Operating Manual Section 7.5).

MCPs are normally configured to override

any delay .

3.16 Virtual Point Configuration

Up to 64 Virtual Input Points and up to 512

Virtual Output Points can be configured. They

are used with external systems (e.g. a Voice

Alarm panel) with which they communicate via

an RS232 port. They must be placed in a zone;

they then become possible inputs to or outputs

from the Control Matrix. Further information is

given in Section 15.

Page 27

20Honeywell, Issue 9

March 2007

XLS80e Fire Alarm Control Panels

4 The Display - Tabs, Events

and Menus

4.1 Introduction

4.1.1 Status: NORMAL

The Status: NORMAL display appears when:

a. No alarm or test conditions exist, and

b. No menus are being accessed.

4.1.2 Tabs

When conditions other than Status: NORMAL

exist, the LCD displays event data. More than

one type of data may be available for display

at any one time (eg, Fire Alarms, Fault s, Menus

etc.). When this occurs, the types of data

available are identified by tabs at the bottom

of the display .

4.1.3 Events

Fire Alarms, Pre-alarms, Faults, Disablement s,

Tests, Evacuate mode and Auxiliary input

activations are shown on Event displays. A

Fault event display is shown.

4.1.4 Menus

Menus displays are arranged in a heirarchy,

the top of which is a User Menu from which

other menus are accessed.

Page 28

21 Honeywell, Issue 9

March 2007

XLS80e Fire Alarm Control Panels

4.2 Tabs

When tabs are displayed, use the CHANGE

TABS key to scroll through the tabs and thus

display the corresponding data.

The tabs are (in descending order of priority):

EXTINGUISHING (if about to release;

otherwise priority is below FIRE)

FIRE

TECH. ALARM

PRE-ALARM

FAULT

DISABLE

TEST

EVACUATE

AUX

MAINT (access level 3 only unless Maintenance

Urgent)

USER (at access level 2) or

SERVICE (at access level 3)

The tabs are displayed in this order from left

to right. All the tabs display events except for

the USER and SERVICE tabs, which display

menus. The current tab is that without a line

above it.

Note: If there is insufficient room to display all

the tabs, the ones at the right (those with

the lowest priority) are omitted.

Use ZONES IN ALARM to go directly to the

FIRE tab without scrolling through the other

tabs. If there is more than one zone in alarm,

subsequent operations of the ZONES IN

ALARM pushbutton scroll through these

zones.

Note: If the FIRE tab is present but not

selected, and for 20 seconds none of

the panel pushbuttons are pressed, the

FIRE tab is then selected automatically .

Note: If the SERVICE or USER tab is selected,

and for 2 minutes none of the panel

pushbuttons are pressed, the tab is

deselected automatically and all

passcodes are cancelled (except the

access level 2 passcode when the

keyswitch is set to the horizontal

position).

Page 29

22Honeywell, Issue 9

March 2007

XLS80e Fire Alarm Control Panels

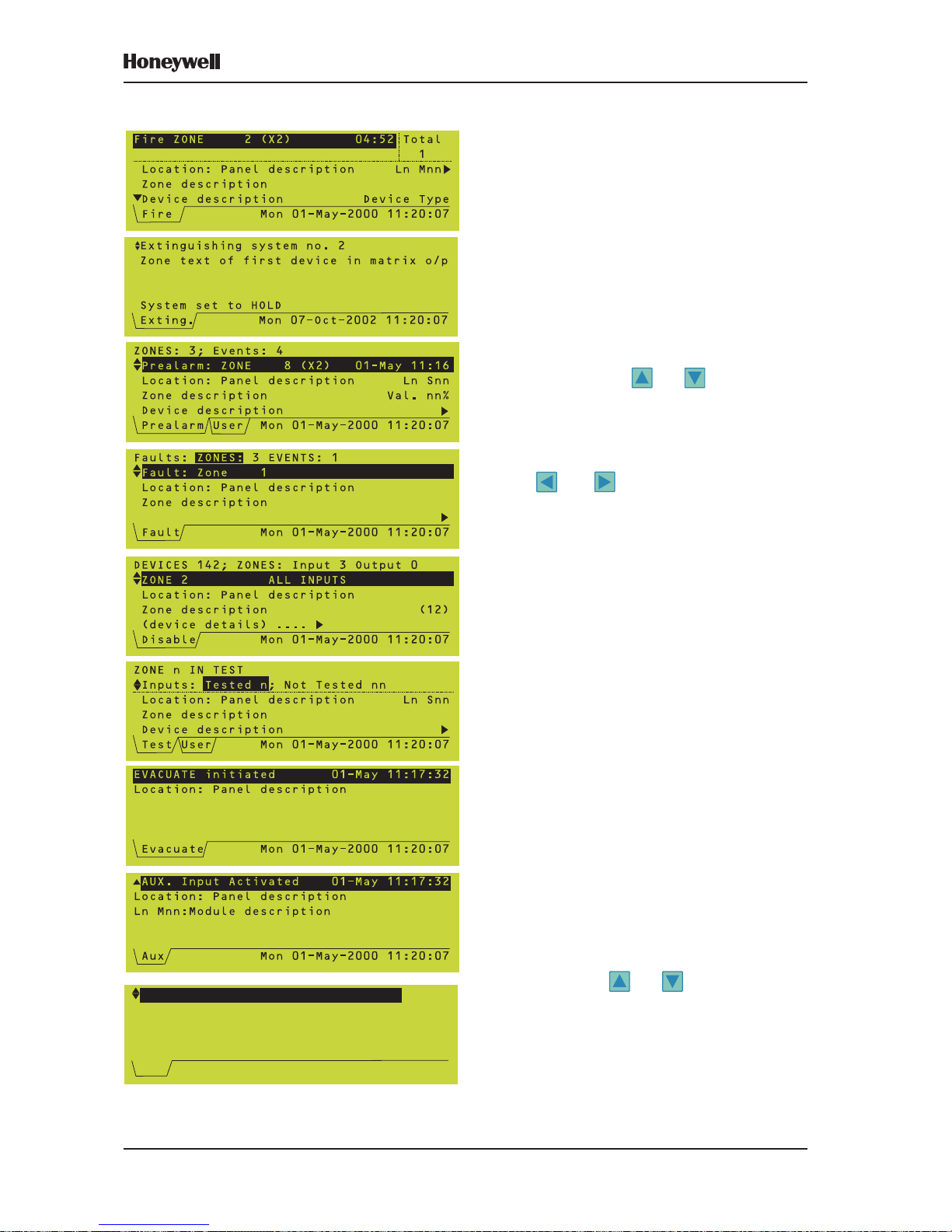

4.3 Event Displays

When a fire alarm, pre-alarm, fault,

disablement, walk test, evacuation, or auxiliary

input activation (if logging is configured)

occurs, an event display replaces the Status:

NORMAL display .

Note: FIRE, FAUL T , DISABLEMENT, or TEST

LEDs illuminate (also ZONE LEDs, if

fitted) as appropriate.

Example event displays are shown at the left.

In general, to move through the displays:

a. If more than one zone is affected by the

event, use the and arrows to scroll

through the zones. For FIRE events these

arrows scroll through device data; ZONES

IN ALARM scrolls through the zones.

b. If more than one device is affected, use the

and arrows to scroll through the

devices and device descriptions.

If a FIRE event occurs and the CHANGE T ABS

pushbutton is used to display other data, the

display area is reformatted so that the top two

lines continue to display fire information.

Further details about the event displays and

their operation are given in the XLS80e Series

Operating Manual, 997-474.

Aux T ab

At the end of the list of activated AUX inputs,

the AUX tab displays details of unconfigured

loop devices, should the panel find any during

polling. These are only shown on the panel

local to the devices. If multiple devices are

found, use the and pushbuttons to scroll

through the list of unconfigured devices (and

through the list of activated AUX inputs). In the

example, 1/3 means that ‘L3 S79’ is the first

of a total of three unconfigured devices found

(on all loops).

Note: Modules: the only types that may be

displayed are MON, CTRL and ZMX.

L3 S79 [OPT ] 1/3

Press * for user actions

Aux Tue 27-Jul-2004 11:20:07

Unconfigured Device found on loop

Page 30

23 Honeywell, Issue 9

March 2007

XLS80e Fire Alarm Control Panels

Tech.Alarm: ZONES: 1; Events: 2

Panel 13:Security Office L4 S05

Corridor 13

Ceiling Sensor GAS

Tech.Alarm User 27-Jul-2004 11:20:07

P13 ZONE 31 (x2) 27-Jul 11:20

By default, the panel does not scan for

unconfigured devices when the panel is

completely unconfigured (i.e. no sensors or

modules on any loop), however scanning can

be enabled by the user.

There is an optional, configurable upper limit

on the number of devices to be scanned. When

this number is reached, scanning can be

continued if extended by the user. The default

upper limit is 50 devices.

Press the pushbutton (level 3 access) to

display options to hide or show these devices

for access level 1 or 2 users, and to disable/

enable scanning for unconfigured devices.

a. If there are no devices left to show as a

result of HIDE, the AUX tab disappears

(assuming there are no AUX inputs active).

b. RE-SCAN causes the panel to clear all

indications of unconfigured devices, scan

the loops and then store the list of any

devices still unconfigured. This allows

devices that were present on the loop but

have since been removed to be identified.

The process takes up to about five minutes.

c. DISABLE clears the indicated devices from

the AUX tab and prevents the panel from

detecting further unconfigured devices. To

re-enable the scan, use the Log/Display/

Print menu as described in Section 12.4.

Note: Entry of access level 3 passcode for any

reason (except to display the above

menu from the AUX tab) always results

in SHOW ALL, unless the scan for

unconfigured devices has been

disabled. Any loop device configuration

operation always leads to a RE-SCAN.

If the configured upper limit is reached, the

option to extend the scanning is provided.

Note: The number of devices listed may be

slightly higher than the set limit (because

of synchronisation effects).

The DISABLE option resets the upper limit to

50 (this is the only method or reimposing a

limit if ‘0’, i.e. no limit has been selected).

T ech. Alarm tab

The T ech. Alarm tab is displayed when any Gas

Sensor Interface configured as Technical

Alarm is activated.

Unconfigured Devices Scan Menu

1:

2:HIDE All Unconfigured Devices

3:SHOW All Unconfigured Devices

4:RE-SCAN for Unconfigured Devices

Aux Service Tue 27-Jul-2004 11:20:07

HIDE This Device

Unconfigured Devices Scan Menu

2:HIDE All Unconfigured Devices

3:SHOW All Unconfigured Devices

4:RE-SCAN for Unconfigured Devices

5:

Aux Service Tue 27-Jul-2004 11:20:07

DISABLE Unconfigured Devices Scan

Unconfigured Devices Scan Menu

(50-devices limit reached)

1:

2:HIDE This Device

3:HIDE All Unconfigured Devices

Aux Service Tue 27-Jul-2004 11:20:07

EXTEND Unconfigured Devices limit

es Scan

Set limit to number of unconfigured

devices to be scanned for

(1-1584; 0=no limit): 50

Aux Service Tue 27-Jul-2004 11:20:07

Page 31

24Honeywell, Issue 9

March 2007

XLS80e Fire Alarm Control Panels

Maint Tab

This displays the maintenance status of any

MCS and Acclimate sensors installed on the

loops. If the panel is connected to an XLSnet

network and more than one panel contains

sensors requiring maintenance, an option to

choose the panel is provided.

There are four status messages:

a. Maintenance Urgent. Indicates drift limit

condition and is accompanied by a

SENSOR FAULT fault message.

b. Maintenance Alert. Indicates drift limit or

continuous IR saturation condition.

Maintenance Alert is also displayed in

respect of any Acclimate sensors.

c. 6 months to cell life expiration (MCS4 only).

d. IR light saturation condition (MCS4 only).

If a sensor returns from a maintenance

condition to its normal state, the display is as

shown opposite.

From the ‘Maint.’ tab, when the status of an

individual sensor is displayed, press the

pushbutton to display a Select Action menu

(the illustrations opposite cover all possible

options - in practice not all options may be

present, see below for details). The options are:

a. Actions on this sensors’s LEDs. The LED

can be set to OFF , 1-second pulsing, or ON

STEADY. This option is always available.

b. DELETE ALL restored sensors from log.

The maintenance status is stored in a log

(capacity 100 records per panel). This

option delete records from the log for all

sensors that are in the ‘Restored from

Maintenance Condition’ state. Available

provided at least one sensor is in this state.

Note: Use the Historic & Data Log Tool

(supplied with the Windows Support

Tool) to access the log.

c. DELETE this sensor from log. Available

only if the current sensor is in the ‘Restored

from Maintenance Condition’ state.

d. DISABLE THIS DEVICE. Always available,

may be ENABLE THIS DEVICE depending

upon disablement status of current sensor.

e. PRINT Sensors in Maint. condition. Always

available.

f. Select another Panel. Displays the Select

Panel option. Only available if the panel is

connected to an XLSnet and more than one

panel contains sensors requiring maintenance.

Select Panel: ( digit )

Panel 1: North-West Building

Panel 2: South Building

Fault Maint. Service 20-Oct 10:15:33

*Panel 3: Secret Laboratory

Recorded on 20-Oct-06 10:05

L1 SO2:upper corridor

Zone 10 MCS4 value 15%

Press * for user actions

Fault Maint. Service 20-Oct 10:15:33

Maintenance Urgent

Recorded on 20-Oct-06 10:05

L1 SO2:upper corridor

Zone 10 MCS4 value 40%

Fault Maint. Service 20-Oct 10:15:33

Restored from Maintenance Condition

L1 S02 Select Action:

1:

2:DELETE ALL restored sensors from log

3:DELETE this sensor from log

4:DISABLE this device

Fault Maint. Service 20-Oct 10:15:33

Actions on this sensor's LEDs

L1 S02 Select Action:

3:DELETE this sensor from log

4:DISABLE this device

5:PRINT Sensors in Maint. Condition

6:

Fault Maint. Service 20-Oct 10:15:33

Select another Panel

Page 32

25 Honeywell, Issue 9

March 2007

XLS80e Fire Alarm Control Panels

4.4 Menu Displays

4.4.1 To Display the User Menu

To display the User Menu when the system

status is Normal, enter the passcode. To use

the Configuration menu and to use some

options on the other menus an access 3 or 3A

passcode must be entered (refer to Section 8

for further details about passcodes).

Note: If event tabs are displayed, CHANGE

TABS first displays these sequentially,

then when the last of these has been

displayed the passcode prompt is

displayed.

Note: An access 2 passcode is also provided,

for use by the operator. If this is entered

the tab is named USER instead of

SERVICE. You can enter the access 3

or 3A passcode at either a prompt for

an access 2 passcode or at a prompt

for an access 3 passcode.

Note: If no further pushbuttons are pressed

the Status: NORMAL display is redisplayed after 2 minutes.

Only the first four options of the User Menu

are displayed at this time. The selected option

is highlighted. Use the and pushbuttons

to scroll through the other options.

Use the pushbutton to return to the S tatus:

NORMAL display .

ACCESS 3 or 3A

PASSCODE,

THEN

(REPEATEDLY)

OR

OR TIMEOUT

Page 33

26Honeywell, Issue 9

March 2007

XLS80e Fire Alarm Control Panels

6

4.4.2 To Navigate Through the Menus

In this example it is desired to display the

Configuration Menu, which is option 6 on the

User Menu.

With the User Menu displayed, press 6 to

go to the Configuration Menu directly .

Alternatively, highlight option 6 on the User

Menu and then select the option as shown

below.

If there are more than 9 items in the menu,

the numeric key highlights a suggested option

but does not select it. 1 alternates between

‘1’ and 10’.

Press the key to exit from the menu.

(REPEATEDLY

UNTIL CURSOR IS

BESIDE OPTION 6)

OR

OR

OR

Page 34

27 Honeywell, Issue 9

March 2007

XLS80e Fire Alarm Control Panels

4.4.3 Menu Structure

Note: ** Requires access 3 passcode. The

menu primarily used in this manual is

the Configuration Menu, therefore its

sub-menus are shown in greater detail

than is the case for the other menus.

*** Requires access 3A passcode.

+Only available if a PRN-ID printer is

configured.

^Only available if at least one SMART

sensor is configured on the loops.

STATUS: NORMAL

DISABLE/ENABLE

INDIVIDUAL DEVICE

ALARM OUTPUTS

BY ZONE

LOG/DISPLAY/

PRINT MENU

LOG/DISPLAY

DEVICE DATA

PRINT DEVICE

DATA

SET CLOCK

DISPLAY/PRINT

EVENT LOG

USER MENU

ALARM INPUTS

BY ZONE

TEST

ZONE WALK TEST

CONTROL OUTPUT/

SOUNDER TEST **

DAILY/WEEKLY AUTO

TEST NOW

LAMP TEST

PRINTER

CONTROL +

VIEW ALARM

COUNT

DISPLAY BAD

POLL LOG ***

A

DISPLAY ACTIVE

C. MATRIX RULES **

UNCONFIGURED

DEVICES **

MCS SENSORS

COMMISSIONING ^

Page 35

28Honeywell, Issue 9

March 2007

XLS80e Fire Alarm Control Panels

Note: If access level 2 is entered by use of the keyswitch, no decision has been

made by the user to enter a specific access level passcode. In this case

the ‘CONFIGURATION’ menu option is replaced by ‘ENTER LEVEL 3

PASSCODE’. When a level 3 passcode is entered, the User Menu is redisplayed so that the level 3 user can select any of the menus available at

access level 2 (to access their level 3 options, see Section 12), in addition

to the ‘CONFIGURA TION’ menu.

SET LANGUAGE

CONFIGURE

INDIVIDUAL DEVICE

AMEND DEVICE

CONFIGURATION

MANUALLY

CONFIGURATION **

LOOP DEVICE

CONFIGURATION

ZONE TEXT EDITOR

CONTROL MATRIX

CONFIGURATION

PANEL TEXT EDITOR

PANEL SETTINGS ***

A

CONFIGURE GROUP

OF DEVICES

LEARN DEVICES

ON LOOPS

REVIEW/EDIT

CONTROL MATRIX

PRINT CONTROL

MATRIX

NETWORK

CONFIGURATION

MASTER/SLAVE

CONFIGURATION

XLSnet NETWORK

CONFIGURATION

STAND ALONE

CONFIGURATION

REPEATERS ONLY

CONFIGURATION

PRINT NETWORK

CONFIGURATION

PASSCODE

CHANGE

INTERNAL BUZZER

OPTIONS

SENSOR/MODULE

LEDs

PULSING SOUNDER

MODES

AUTOMATIC TEST

OPTIONS

LOOP OPTIONS

ACCESS LEVEL FOR

MUTE BUZZER

RELAY CIRCUITS

'SILENCE' OPTION

LCD BACKLIGHT 'ON'

DURATION

ISOLATED RS232

PORT SETUP

REMOTE FIRE

OUTPUT OPTIONS

EXTINGUISHING SYS

COMMON OPTIONS

NUMBER OF LOOPS

ON PANEL

WALK TEST

OPTIONS

DISABLEMENT

OPTIONS

PANEL FUNCTIONS

UNLATCHED NONALARM I/P LOGGING

MAINS/PSU FAULT

DELAYS

BLANK LINES IN

PRINTED EVENTS

DIAGNOSTIC RS232

PORT SETUP

DAY/NIGHT MODES

CONFIGURATION

ALARM

COINCIDENCE

VIRTUAL OUTPUT

POINT

VIRTUAL POINT

CONFIGURATION

VIRTUAL INPUT

POINT

EXTINGUISHING SYS

COMMON OPTIONS

NETWORK

SETTINGS

THERMAL ALARM

VERIFICATION TIME

Page 36

29

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

5 Loop Device Configuration

You can configure loop devices:

a. Individually (Section 5.1).

b. As a group (Section 5.2).

c. As a system (Section 5.3), learning the

loops either automatically or with manual

intervention.

5.1 Configure Individual Device

5.1.1 Select a Device

1 From the Loop Device Configuration menu,

select the Configure Individual Device

option.

2 Select the number of the loop to which the

device is physically wired (‘n’ is the highest

loop number on the panel, e.g. 4, 6 or 8).

3 Select whether the device is a sensor or

module (both have device numbers in the

range 1-99, so this selection determines the

meaning of the device number).

NUMERIC KEYS,

THEN

SEE NEXT PAGE

Page 37

30

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

4 In this example SENSOR was chosen. The

procedure for choosing a MODULE is the

same. Enter the device number. Leading

zeros are optional.

In this example the device is an optical sensor

(type OPT); all other values use ‘n’ to represent

a numeric value and ‘a’ or a description to

represent alphabetic characters.

The and pushbuttons step through the

parameters that can be edited for the currentlydisplayed device. Press the pushbutton to

edit the currently-highlighted parameter. The

following sections describe the options

available for each parameter for a sensor, and

then the differences applicable to a control

module.

Note: The and pushbuttons step

through the various devices on the

system (all loops).

If the device has not been configured, the

display is as shown.

FROM PREVIOUS P AGE

NUMERIC KEYS,

THEN

REPEATED

USE OF

FURTHER

USE OF

Page 38

31

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

5.1.2 Change Device Configuration Sensors

The following can be altered for sensors:

a. The device type.

b. The zone or cell in which the device is

placed.

c. The device location text. Note that the zone

text is displayed but cannot be edited here

(it is edited in the Zone Text Editor, see

Section 6.3).

d. Sensitivity levels (see Section 13 for

recommendations).

e. Verification delay times. See Section 13 for

recommendations.

f. Priority option.

g. Time-of-day sensitivity changes.

5.1.2.1 Edit Device Type

Select the required TYPE. If no sensor exists

at the entered number, its type is NONE.

Available types are:

Type Description Physical Type

NONE Deleted - no sensor

exists at this address

HEAT Thermal sensor TC808

ION IONisation sensor TC807

OPT Photo sensor TC806

MULT Photo/Thermal sensor TC840

LASR Photo ‘Laser’ sensor TC846

GAS Gas Sensor Interface

MCS4 Optical/thermal/infra-red/

carbon monoxide

If you change a device type, the other settings

(except zone, cell and device text) revert to

default.

Gas Sensor Interface

Interface IIG1 requires three consecutive

sensor addresses; the lowest is shown as type

GAS and the other two as NONE. Interface IIG4

requires up to twelve consecutive addresses

(depending upon how many of four possible

interfaces are configured at the device), the first,

fourth, seventh and tenth are type GAS and the

others NONE. The following then applies:

i Attempts to change the type at the

addresses shown as ‘NONE’ display the

message ‘This address is not available:

GAS sensor occupying one of the previous

two addresses.’.

ii Type GAS cannot be configured at an

address if either or both of the next two

addresses are already occupied (the

message ‘PLEASE DELETE next two

higher-addressed sensors before installing

GAS sensor at this address.’ is displayed).

TO

MAKE

SELECTION

GAS SENSOR INTERFACE:

This device produces a Technical

Alarm by default, but can be

configured as a Fire Alarm by the

configuration option shown below. The Control

Matrix groups Technical Alarms with Fire Alarms.

Device Configuration - Loop 3 Sensor 8

Type GAS Zone 203 Cell 0

Zone <Storage area >

Loc. <First IIG4 >

=select *=edit =next device =finish

TECHNICAL ALARM device:

Device Configuration - Loop 3 Sensor 8

1:Normal Alarm Input

2:TECHNICAL ALARM device

Set device type - Loop n Sensor nn

6:OPTICAL 'LASER' SENSOR (TC846)

7:GAS Sensor Inteface (IIG1/IIG4)

8: (MCS4)

4:PHOTO (OPT) SENSOR (TC806)

5:PHOTO/THERMAL (MULT) SENSOR (TC840)

Multi Criteria 4 Sensor

Page 39

32

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

5.1.2.2 Edit Device Zone or Cell

Zone Number

Enter the zone number within the displayed

range. RANGE! is displayed if the entered

number is out of range. For details of zone

ranges, refer to Section 14.1.2. The ‘Internal

Zone no.’ is only displayed if network zones

are used, also in this case an error message

is displayed if you try to configure more than

255 zones on a panel.

Reference Number

If network zones are used, a maximum of 99

devices can be placed in the zone. Each device

is identified by a reference number in the range

1 to 99 (i.e. maximum of 99 devices in a zone).

When a device’s zone number is configured

the device is automatically given the first

available reference number by default.

To change this default, either enter one of the

unused reference numbers from the display,

or a reference number that is already used by

a device. If the latter is chosen, the option to

swap the number for that device with one of

the unused numbers is provided automatically

(see below). If the swap is not accepted then

the entered number is rejected.

Cell Number

Devices can optionally be placed in a cell in

addition to a zone. Certain Control Matrix

functions can be set to apply to the cell rather

than the zone.

Enter the cell number in the range 1 to 255, or

select 0 if the device is not to be placed in a

cell.

NUMERIC

KEYS, THEN

NUMERIC

KEYS, THEN

Page 40

33

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

5.1.2.3 Edit Device Location Text

Edit the text description which is used for the

various tab displays (e.g. fire, fault) and for

printing at the printer. Section 6 describes how

to use the text editor.

5.1.2.4 Edit Sensitivity level and Fault

Supervision

The alarm and pre-alarm sensitivities can be

configured.

The Gas Sensor Interface Alarm, Pre-alarm

and Fault levels are all editable values in the

range 4 to 20mA instead of pre-set levels.

Details are given in Section 5.1.3.3.

Alarm

The illustration shows the alarm sensitivity

selected for edit. Up to 9 pre-set levels are

available for each sensor (except

Photo/Thermal (MULT) and MCS); for all

sensor types (except MULT and MCS) the

default setting is L5. L1 is most sensitive and

L9 is least sensitive. Refer to Section 13 for

recommendations.

Details of MULTI sensor sensitivity are given

in Section 5.1.3.

Further information about MCS sensors

sensitivity is given in Section 5.1.3.2.

ALARM

Page 41

34

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

Pre-alarm

Again the default setting is 5 for all types of

sensor except Photo/Thermal (MULT) and

MCS. The alarm and pre-alarm ranges do not

overlap, except for MUL T and MCS for which

the alarm must be set lower than the pre-alarm

for pre-alarm supervision to work (set it equal

or higher if pre-alarm supervision is not

required). For other sensor types the pre-alarm

sensitivity range includes ‘0’ which selects no

pre-alarm supervision.

Note: The ALARM and PRE-ALARM values

are upper thresholds, i.e. an alarm

occurs if the sensor reading equals or

exceeds the threshold.

The option to Lock the Pre-alarm level is then

provided:

a. If NO (default) is chosen and Time-of-Day

is used to vary the alarm sensitivity

(Section 5.1.2.7), Pre-alarm sensitivity

changes with Time-of-Day by the same

amount that is set for Alarm. Also, for MUL TI/

MCS sensors, Pre-alarm is ignored at those

times when Thermal-only mode L6 is in

operation for Alarms as a result of a Control

Matrix rule or Time-of-Day.

b. If YES is chosen, the Pre-alarm sensitivity

remains fixed at the selected level. Also,

for MULTI/MCS sensors, Pre-alarm is no

longer ignored at those times when

Thermal-only mode is in operation for

Alarms. A ‘#’ symbol is displayed beside the

Pre-alarm value.

Fault

To comply with EN54-2: 8.3, fault supervision

is always set to ON.

Device Configuration - Loop 1 Sensor 30

LOCK Pre-alarm level against Time-of-Day

Variation etc.:

1

2:YES

:NO

PRE-ALARM

Page 42

35

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

5.1.2.5 Edit Verification Delay

Set the verification delay within the displayed

range. RANGE! is displayed if the entered

number is out of range. Refer to Section 13

for recommended verification delays.

Alarm verification display is shown on the left.

The Fault verification display has the same

layout.

5.1.2.6 Edit Priority Option

Set the priority polling ON of OFF. When ON

the device will scan at intervals of less than

one second.

A maximum of 43 devices per loop may be

designated as priority; however, to obtain the

1-second scan interval do not designate more

than 21 devices per loop as priority (as more

devices are assigned priority scan status, the

scan rate becomes slower for the remaining

devices).

5.1.2.7 Time of Day

The sensitivity can be varied at different times

of day .

Refer to Section 9 for details of time-of-day

programming.

Note: If the device’s alarm sensitivity is

changed, the time of day variation is

cancelled automatically to prevent it

going out of range.

NUMERIC

KEYS, THEN

Page 43

36

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

5.1.2.8 LED Blink Options

Select whether the device’s LEDs follow the

panel setting (Section 11.2) or are set to blink

or not (non-blink).

5.1.2.9 LED Also Controls

Select the required option:

a. NONE. There are no additional controls.

b. SOUNDER. For use with B601BH base

with integral sounder; the sounder will be

silenced by operation of the panel’s

SILENCE/RESOUND (to silence) or

RESET pushbuttons.

c. Non-Sil. Control. Used when auxiliary

equipment is driven in parallel with the

sensor LED. Control of this auxiliary

equipment is then independent of the

SILENCE/RESOUND pushbutton - it is only

switched off by operating the RESET

pushbutton.

5.1.2.10 End the Editing Session

When all the changes have been made, press

to confirm them. The panel then uses the

changed parameters.

THEN

Device Configuration - Loop n Sensor nn

Type OPT Zone nn Cell n

Zone <(no zone text defined) >

Loc. <Device text description >

LED BLINK MODE

=select *=edit =next device =finish

Follow Panel Setting

Device Configuration - Loop n Sensor nn

LED BLINK MODE

1:

2:Always BLINK

3:Always NON-BLINK

Follow Panel Setting

Device Configuration - Loop 1 Sensor 1

Type OPT Zone 20 Cell 0

Zone <Corridor >

Loc. <Ceiling >

LED also controls:

=select *=edit =next device =finish

NONE

Device Configuration - Loop 1 Sensor 1

LED also controls:

1:

2:SOUNDER

3:Non-Sil.CONTROL

NONE

Page 44

37

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

5.1.3 MULTI, MCS & GAS Sensor

Interface Sensitivities

5.1.3.1 Photo/Thermal (MULT) Sensors

Device type MULT applies to the

TC840ME.

ACCLIMATE, has a Thermal-Only mode, i.e.

a mode in which the sensor does not respond

to smoke.

Sensitivity (including Acclimate)

When configuring the Alarm and Pre-alarm

sensitivity for MULT sensors, there are five

sensitivity levels plus Pre-alarm disable (L0) and

(for Acclimate only) the Thermal-Only mode:

Sensitivity MULT Sensor

Levels Default Settings

L1 (Most)

L2 For Pre-alarm Threshold

L3

L4

L5 (Least) For Alarm Threshold

L6 Thermal-Only mode (Acclimate)

For Pre-alarm to operate, the Pre-alarm

Threshold MUST be set at least one level

below the Alarm Threshold. In Thermal-Only

mode (L6), Pre-alarm applies to both smoke

and heat, unless L6 is linked to Time-of-Day

or Day Mode with Lock Pre-alarm monitoring

not set, in which case there is NO Pre-alarm

in L6 mode.

Thermal Mode by Zone (Acclimate only)

All Acclimate sensors in a zone or range of

zones and configured as described below can

be set to their Thermal-Only mode by the

Control Matrix. To configure an Acclimate

sensor for this action, set its device

configuration option ‘Thermal Mode by Zone’

to ‘Yes’. Only those Acclimate sensors so

configured will be included in the Control Matrix

output. The default for this option is ‘No’.

ILLUSTRATION SHOWS ACCLIMA TE CONFIGURED

IN THERMAL-ONLY MODE FOR ALARM.

NORMALLY ACCLIMATE WILL BE CONFIGURED

AT L5 FOR ALARM, AND THE THERMAL-ONLY MODE

WILL BE INVOKED VIA A TIME-OF-DAY PROGRAM

OR VIA THE DAY MODE PUSHBUTTON. SEE

SECTION 9.4.

THERMAL MODE BY ZONE OPTION IS ONLY

DISPLA YED FOR MULTI SENSORS AND IS ONLY

APPLICABLE FOR ACCLIMATE DEVICES. AN

ACCLIMATE SENSOR SET TO ‘YES’ WILL BE

INCLUDED IN ANY CONTROL MATRIX ENTRY

FOR WHICH THE INPUT IS NON-FIRE OR TRUE

AND THE OUTPUT ‘SET TO THERMAL-ONLY

MODE’ INCLUDES THE SENSOR’S ZONE

NUMBER. SEE SECTION 7.6.2.6.

Software version 4.33 and above:

Default Alarm thr eshold is L5 for

newly installed multi-criteria sensors

(was L3 on previous versions; if

software is upgraded to 4.33, existing

devices retain this default).

Pre-Alarm threshold value MUST

be LOWER than the Alarm

threshold value to be effective.

Device Configuration - Loop n Sensor nn

Alarm Sensitivity level (1-6):

(1 = most sensitive, 5 = least)

(6 = Thermal-only mode; default = 5)

6

Page 45

38

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

5.1.3.2 MCS Sensors

The system supports Multi-criteria (MCS)

sensors.

The MCS4 sensor has the capability for carbon

monoxide, photoelectronic (optical), infra-red

and thermal detection.

This sensor has a thermal-only mode as

described on the previous page for Acclimate.

The Alarm and Pre-alarm levels and defaults are

as described for Acclimate, and the verification

delays are the same as for a MUL TI sensor .

5.1.3.3 GAS Sensor Interface

The analogue level output from the Gas

Sensor Interface IIG1 or IIG4 is a current in

the range 4 to 20mA. The Alarm, Pre-alarm

and Fault thresholds are editable within this

range. Use the and pushbuttons to toggle

between the Pre-alarm and Fault parameters.

The thresholds are selected for editing in the

same manner as for other devices, but the edit

procedure is different:

1 Enter the new value in tenths of milliamps.

All digits must be entered including the one

after the decimal point, even if it is zero.

2 The decimal point is not displayed during

the entry. It is redisplayed when the

pushbutton is pressed.

See the example at left, in which the Alarm

Sensitivity is changed from 12.0mA to 13.5mA.

Device Configuration - Loop 3 Sensor 5

Alarm Sensitivity level (4-20mA):

(Please type in units of 0.1mA):

12.0

Device Configuration - Loop 3 Sensor 5

Alarm Sensitivity level (4-20mA):

(Please type in units of 0.1mA):

135

Device Configuration - Loop 3 Sensor 5

Alarm Sensitivity level (4-20mA):

(Please type in units of 0.1mA):

13.5 Confirm ( /X)?

Device Configuration - Loop 3 Sensor 8

Type GAS Zone 203 Cell 0

Zone <Storage area >

Loc. <First IIG4 >

Sensitivity: Alarm=12.0mA Pre= mA

=select *=edit =next device =finish

10.0

Device Configuration - Loop 3 Sensor 8

Type GAS Zone 203 Cell 0

Zone <Storage area >

Loc. <First IIG4 >

Sensitivity: Alarm=12.0mA Fault= mA

=select *=edit =next device =finish

4.0

Page 46

39

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

5.1.4 Change Device Configuration Modules

The following can be altered for modules:

a. The device type.

b. The zone or cell in which the device is

placed.

c. The device location text. Note that the zone

text is displayed but cannot be edited here

(it is edited in the Zone Text Editor, see

Section 6.3).

d. Module supervision options (see

Section 13 for recommendations).

e. Verification delay times. See Section 13 for

recommendations.

f. Priority options.

g. Silence and Pulse options.

5.1.4.1 Edit Device Type

Select the required TYPE. If no module exists

at the entered number, its type is NONE.

Available types are:

Type Description Physical Type

NONE Deleted - no module

exists at this address

MCP Manual Call Point MMX

BELL Bell/sounder circuit or

loop-powered sounder CMX

CTRL (generalised)

Control Function CMX

MON (generalised)

MONitoring function MMX

SPRK Sprinkler Monitor ASPR Aspirator Interface AUX. Auxiliary Module

ZMX Low cost version of CDI ZMX

CDI Conventional

Detector Interface CDI

LBM Loop Booster Module LBM

Note: While sensor types are Physical device

types (they are determined by the

sensor hardware and must be selected

so as to match the actual sensor

installed at that address), module types

are Logical device types. These refer

to one of the physical module types as

shown in the table above.

TO

MAKE

SELECTION

Set device type - Loop n Module nn

1:

2:MCP MANUAL CALL POINT

3:BELL/SOUNDER

4:CONTROL MODULE

5:MONITOR MODULE

DELETE

Set device type - Loop n Module nn

6:SPRINKLER MODULE

7:ASPIRATOR INTERFACE

8:AUX INPUT

9:ZMX ZONE MONITOR

10:CDI ZONE MONITOR

Set device type - Loop n Module nn

7:ASPIRATOR INTERFACE

8:AUX INPUT

9:ZMX ZONE MONITOR

10:CDI ZONE MONITOR

11:LBM LOOP BOOSTER MODULE

Page 47

40

XLS80e Fire Alarm Control Panels

Honeywell, Issue 9

March 2007

Auxiliary Modules

Any Input (MMX) module can be defined as

logical type AUXILIAR Y.

T o make use of several special Control Matrix

facilities, certain input modules must be

defined as logical type AUXILIARY. Auxiliary

modules:

a. Cannot generate an ALARM of FIRE,

b. Are not included in Zone operations,

c. Must be referred to individually (not by

zone) in Control Matrix records,

d. Generate non-latching Control Matrix

output operation,

e. Are treated in the usual way, if faulty,

f. Cannot have a delayed output.

It is essential that the correct type of

Module is used.

Loop Boosters

Only the following parameters can be

edited:zone, cell and (network zones)

reference numbers, location text, short-circuit

supervision option (default ON), fault

verification delay, priority polling and LED blink

mode. The following cannot be edited: alarm

supervision option (always OFF), open-circuit

supervision option (always ON) and alarm

verification delay.

5.1.4.2 Edit Device Zone or Cell

The procedure for modules is identical to that

described for sensors (Section 5.1.2.2).

5.1.4.3 Edit Device Location Text

The procedure for modules is identical to that

described for sensors (Section 5.1.2.3).