Page 1

HONEYWELL EXCEL 5000 OPEN SYSTEM

INSTALLATION AND COMMISSIONING INSTRUCTIONS

CONTENTS

General ............................................................................... 3

Before Installation ............................................................. 3

Installation ......................................................................... 3

Wiring ................................................................................. 4

XL800 Series Power Consumption ................................ 5

I/O Modules ................................................................... 5

Description of the XCL8010AU Controller Module ......... 7

Overview........................................................................ 7

Interfaces and Bus Connections .................................. 10

Technical Data............................................................. 10

System Data........................................................... 10

Operational Environment ....................................... 10

Smoke Control Configuration....................................... 10

Data File Set-Up .......................................................... 11

Panel Reset ................................................................. 11

Typical Power Limited Circuit for XL800 ...................... 11

Connecting Single Bus Controller Systems ................. 11

XCL8010AU, I/O Modules on Single Rail............... 12

Multiple Rails in Single Cabinet.............................. 12

LonWorks Bus I/O Modules in Separate Rooms .... 12

How to Connect Panel Bus and LONWORKS Bus Mixed

Controller Systems ...................................................... 12

Connecting I/O Modules......................................... 12

Connecting I/O Modules to the XCL8010AU.......... 12

Setting Address of Panel Bus I/O Modules .................. 13

Setting the I/O Bus Switch ........................................... 14

LONWORKS Bus Topologies.......................................... 14

C-Bus Topologies ........................................................ 14

Mounting/Dismounting Modules.................................... 14

Mounting/Dismounting Controller/Sockets ................... 15

Mounting Sockets................................................... 15

Connecting Sockets ............................................... 15

Dismounting Sockets ............................................. 16

Mounting/Dismounting Electronic Modules .................. 16

Mounting Electronic Modules ................................. 16

Dismounting Electronic Modules ............................ 17

Connecting via C-Bus .................................................. 17

Connecting to the Controller................................... 17

Setting the C-Bus Termination Switch.................... 17

Shielding ................................................................ 17

Description of the I/O Modules ....................................... 21

XL 800 Series

FOR SMOKE CONTROL

Connecting HMIs or Laptops........................................ 17

Connecting the XI582 Operator Interface ............... 17

Connecting Laptops (XL-Online/CARE) ................. 18

XCL8010AU Terminals........................................... 18

Features....................................................................... 18

LONWORKS Interface and Terminals ....................... 18

LONWORKS Service LED and Button....................... 18

C-Bus Tx LED and Rx LED ....................................19

Reset Button........................................................... 19

HMI Interface.......................................................... 19

Alarm and Power LEDs ..........................................20

Watchdog Status ....................................................20

Modem Interface..................................................... 20

I/O Bus Switch S2................................................... 20

C-Bus Termination Switch S1................................. 21

Memory .................................................................. 21

Common Features ....................................................... 21

Analog Input Modules .................................................. 22

Types of Analog Input Modules .............................. 22

Features .................................................................22

Terminals................................................................ 22

XFL821AU Connection Examples ..........................23

Analog Output Modules................................................ 24

Types of Analog Output Modules ...........................24

Features .................................................................24

Terminals................................................................ 24

Technical Data........................................................ 24

Modules with Manual Overrides .............................25

XFL822AU Connection Example ............................ 25

Synchronization Behavior of Analog Output Module

Configured as Floating Output................................ 25

Binary Input Modules ................................................... 26

Types of Binary Input Modules ............................... 26

Features .................................................................26

Terminals................................................................ 26

Technical Data........................................................ 26

Status LEDs............................................................ 27

XF823AU Connection Examples ............................ 27

Relay Output Modules.................................................. 28

Types of Relay Output Modules ............................. 28

Features .................................................................28

Terminals................................................................ 28

Permissible Loads .................................................. 29

Status LEDs with Manual Overrides ....................... 29

Connection Examples............................................. 30

Copyright © 2008 Honeywell GmbH All Rights Reserved EN1B-0410GE51 R0908A

Page 2

General Excel 800

Troubleshooting............................................................... 31

Testing Wiring Connections.......................................... 31

Troubleshooting on the XCL8010AU Controller............31

Power LED (green) .................................................31

Alarm LED (red) ......................................................32

LONWORKS Service LED..........................................32

C-Bus Tx and Rx LEDs...........................................33

HMI Tx and Rx LEDs ..............................................33

I/O Modules Troubleshooting........................................34

Power LED of I/O Modules .....................................34

Service LED of I/O Modules.................................... 35

Trademark Information

Echelon, LON, L

trademarks of Echelon Corporation registered in the United

States and other countries.

ONMARK, LONTALK, LONWORKS, Neuron, are

EN1B-0410GE51 R0908A 2

Page 3

Excel 800

WARNING

This equipment generates, uses, and can radiate radio

frequency energy, and if not installed and used in accordance

with the instructions manual, may cause interference to radio

communications. It has been tested and found to comply with

the limits for a Class A computing device pursuant to Subpart

J of Part 15 of FCC Rules, which are designed to provide

reasonable protection against such interference when

operated in a commercial environment. Operation of this

equipment in a residential area is likely to cause interference,

in which case the user, at his own expense, will be required to

take whatever measures may be required to correct the

interference. Any unauthorized modification of this equipment

may result in the revocation of the owner’s authority to

continue its operation.

General

The XL800 Series is designed to provide heating, ventilating

and air-conditioning control. They can operate either

standalone, or networked to Honeywell central workstations

such as EBI. These controllers can also be used for smoke

control system monitoring and control, for monitor and control

of fire (UL864), and general purpose signaling (UL2017). In

UL 2017 applications, the product can be used as a type NM

(Non-Monitored) system. It is also approved for UL916

(Energy Management Equipment.)

The XL800 Series can be used for smoke control applications

when used in conjunction with a UL listed fire alarm control

panel (FACP) and UL listed fire fighters’ smoke control station

(FSCS).

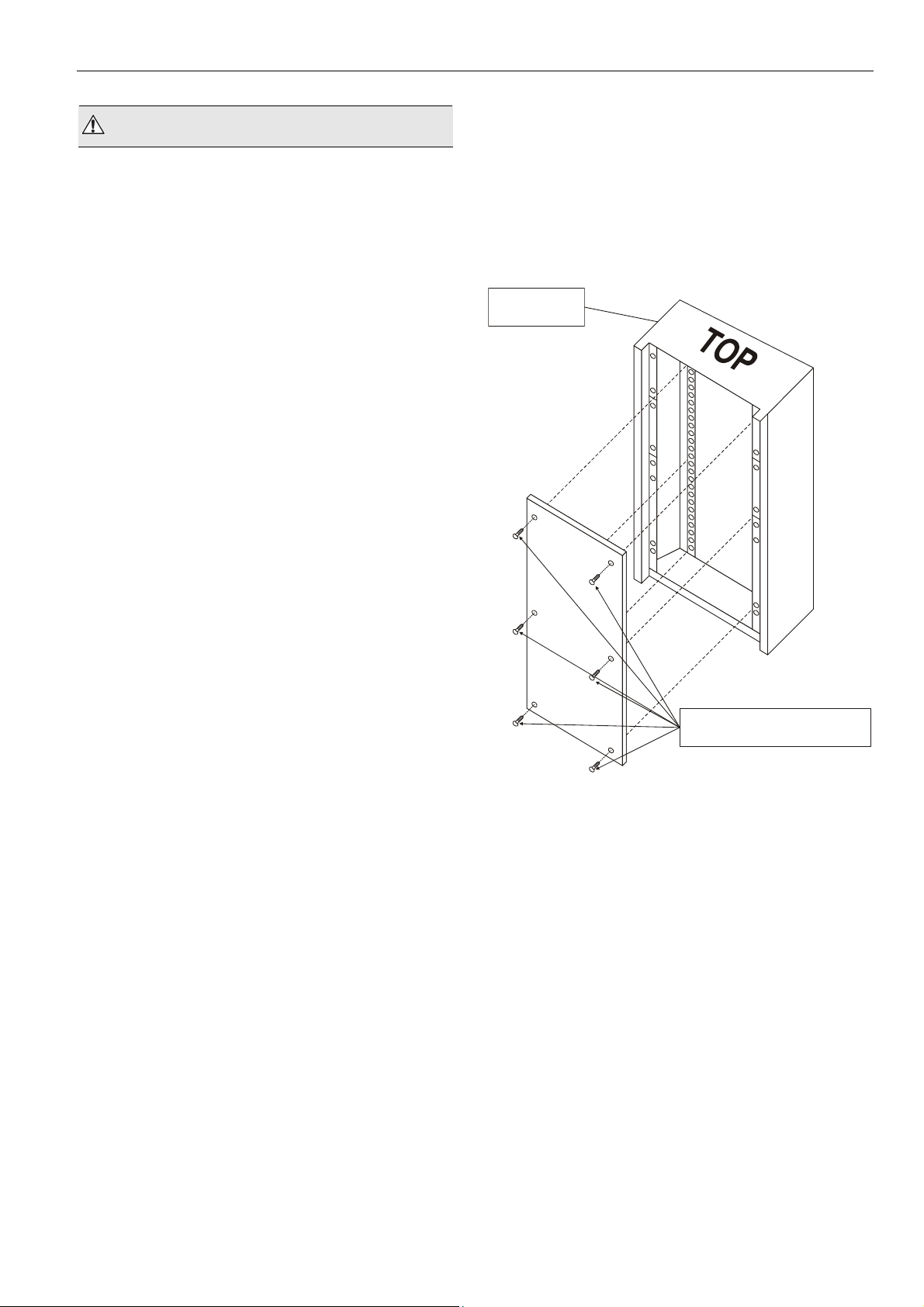

Installation

Mount controller subpanel in cabinet so all labeling is visible.

Secure full-size subpanel in place with six no. 10 x ½-inch

(13 mm) sheet metal screws (not supplied). Secure smaller

subpanel with four no. 10 x ½-inch (13 mm) sheet metal

screws (not supplied).

NOTE: Subpanel must mount flat and should not bulge or

recess anywhere.

FULL-SIZE

CABINET

Before Installation

1. Unpack door and remove the XL800 from carton. Check

equipment and report any damage to a Honeywell

representative.

2. Verify cabinet is installed correctly.

3. Securely mount the XL800 to a rigid structural surface

using at least four sets of 1/4 in. (6 mm) mounting

hardware (supplied locally).

NOTE: Anchoring materials must be suitable for the

mounting surface (wood, concrete, steel).

Mounting must comply with all local codes.

4. Obtain correct number and type of sheet metal screws for

subpanel. Installation of a full-size subpanel requires six

no. 10 x ½-inch (13 mm) sheet metal screws (not

supplied). Installation of a smaller subpanel requires four

no. 10 x ½-inch (13 mm) sheet metal screws (not

supplied).

5. Obtain 14505159-001 Tamper Switch per job

requirements. Installation of Tamper Switch is optional.

SIX NO. 10 x ½-INCH (13 mm)

SHEET METAL SCREWS

Fig. 1. Mounting controller subpanel in cabinet (full-size

subpanel cabinet shown)

3 EN1B-0410GE51 R0908A

Page 4

Wiring Excel 800

Wiring

All wiring to the XL800 controller is unsupervised, except as

noted.

All circuits are power limited, except for AC power circuits,

relay contacts and other circuits as noted.

All field wiring terminals accept 24 AWG to 14 AWG

(0.25 mm

All wiring must conform to local codes, ordinances, and

regulations. Refer to job drawings for details.

Verify that the voltage difference between any conductor and

earth ground does NOT exceed 150 Vac.

1. Connect input/output device wiring, C-Bus transmission

2. Connect line voltage to Terminals H and N of the

3. For Power Modules -001 through -007, leave power to

2

to 2 mm2) conductors except as noted.

wiring (minimum 18 gage [0.8012 sq mm]), LON Bus

transmission wiring, and 14507063 Power Cable to

Controller per job drawings. Fig. 2 and Fig. 3 show typical

controller wiring. Four Power Module models are available

(see Table 2).

14507287 Power Module. Connect a good earth ground to

Terminal G of the Power Module. Fig. 5 through Fig. 7

show typical power wiring.

Power Supply and Controller OFF. Connect 14507063

Power Cable from Controller to Power Module.

WARNING

Risk of electric shock or equipment damage!

► Subpanel and Controller power must remain OFF until

Controller is checked.

4. Install optional Tamper Switch on cabinet per instructions

in the cabinet installation instructions. Wire Tamper

Switch per job drawings.

5. Mount cabinet door.

CAUTION

Risk of electric equipment damage! Excessive static can

burn out equipment.

► Observe proper anti-static material handling practices

when installing or servicing PC parts and related

components.

► Observe proper equipment and body grounding practices.

► Discharge static electricity from your body before handling

parts.

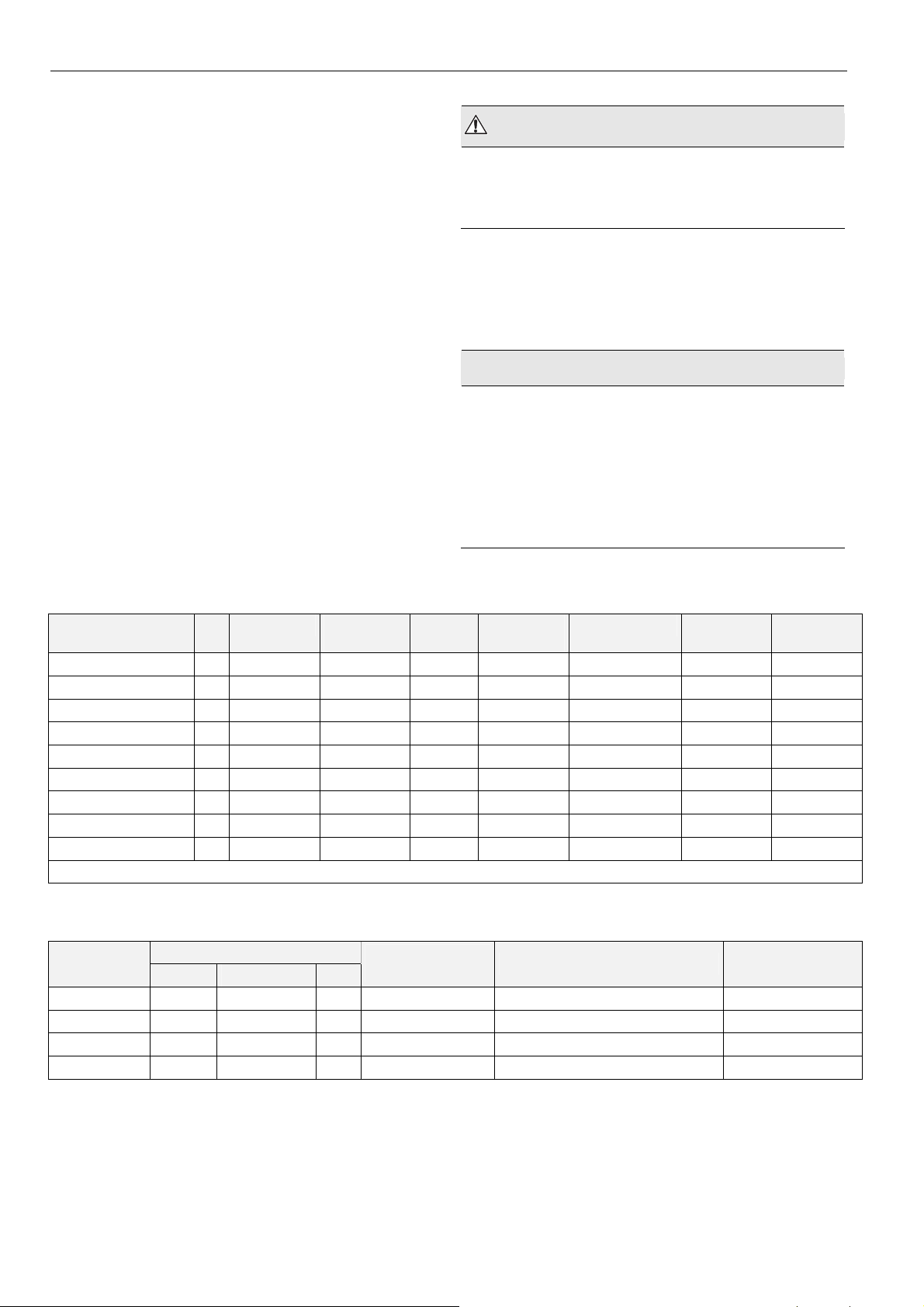

Table 1. Connector terminal specifications

connector terminal pin signal type

analog input AI input SIGNAL ±12 V ±20 mA 9600 baud 8K ohms

digital input DI input SIGNAL ±10 V ±20 mA -- 15K ohms

analog output AO output(1 SIGNAL ±10 V ±20 mA 9600 baud 8K ohms

digital output DO output(2 AC/DC ±24 VAC/DC ±50 mA -- 10K ohms

totalizer output TI input SIGNAL ±12 V ±12 mA 100 Hz

signal ground GND -- -- -- -- -- --

J1 RS-485 (C-BUS)

2 -A input / output SIGNAL ±5 V 1 mA / 180 mA 9600 baud 100 ohms

3S Shield A -- -- -- -- -- --

(1

special application; (2 regulated; (3 supervised

model

14507287-001 120 0.5 A 60 24 120 Vac, 10A

14507287-002 120 1.7 A 60 24 24 Vac, 100 VA, 24 Vac, 40 VA 120 Vac, 10A

14507287-003 120 1.7 A 60 24 24 Vac, 100 VA, 24 Vdc, 600 mA 120 Vac, 10A

14507287-007 120 120 A 60 24 -- --

(3

1 +A input / output SIGNAL ±5 V 1 mA / 180 mA 9600 baud 100 ohms

transformer max. input

Vac current draw Hz

input /

output

Table 2. Power module models

(48 VA) controller

voltage

type

VAC output

max.

voltage

max. current

accessory output convenience outlet

max.

frequency

max. line

impedance

EN1B-0410GE51 R0908A 4

Page 5

Excel 800 Wiring

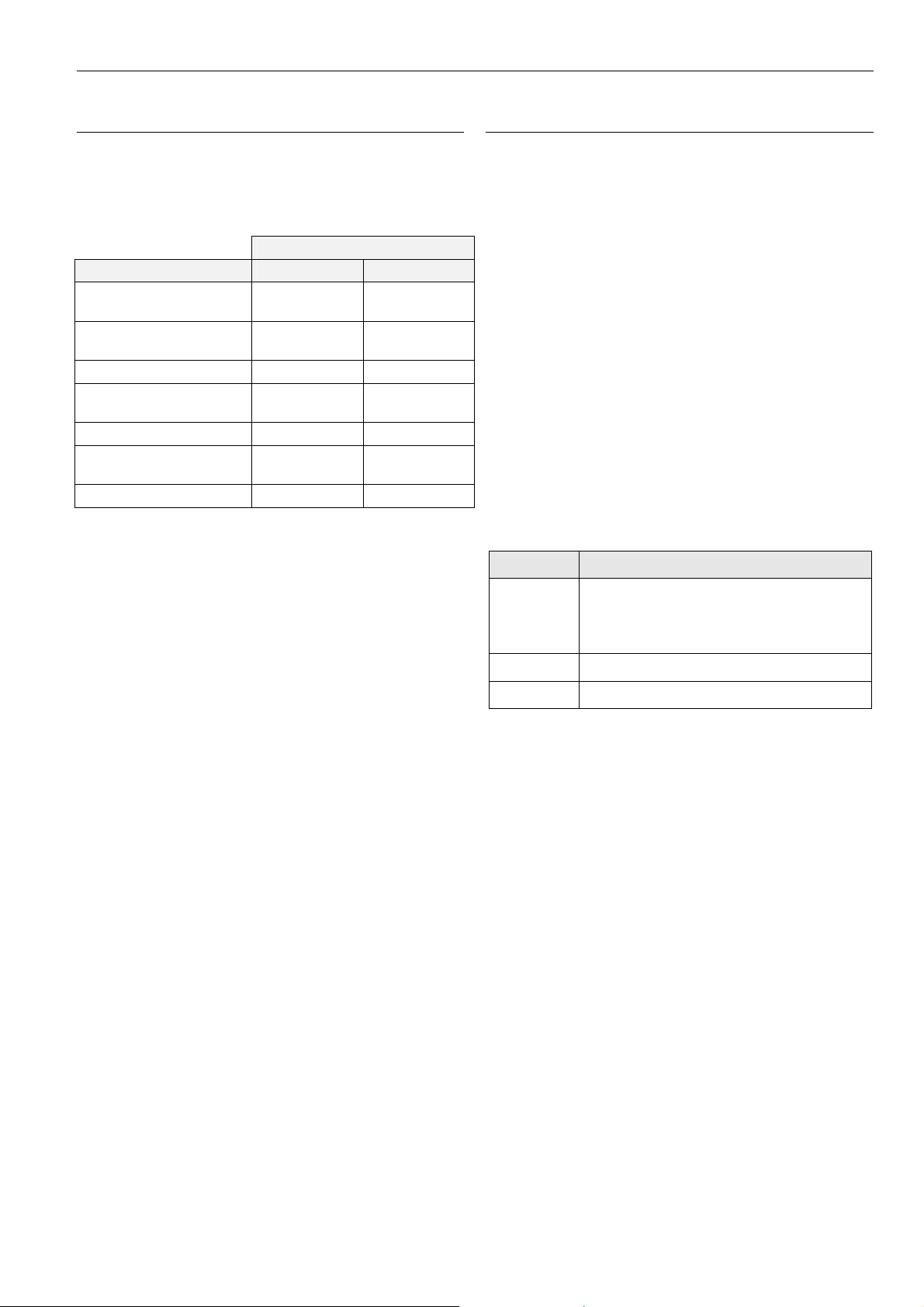

XL800 Series Power Consumption

When selecting the appropriate power supply, the power

consumption of the XL800 modules must be taken into

account.

Table 3. XL800 power consumption

model 24 Vac, 60 Hz 24 Vdc

XCL8010AU with

watchdog load

XCL8010AU without

watchdog load

XF821AU, XFL821AU 130 mA 80 mA

XF822AU, XFR822AU,

XFL822AU, XFLR822AU

XF823AU, XFL823AU 180 mA 130 mA

XF824AU, XFR824AU,

XFL824AU, XFLR824AU

XFR825AU 140 mA 90 mA

max. power consumption

690 mA 640 mA

190 mA 140 mA

160 mA 90 mA

140 mA 90 mA

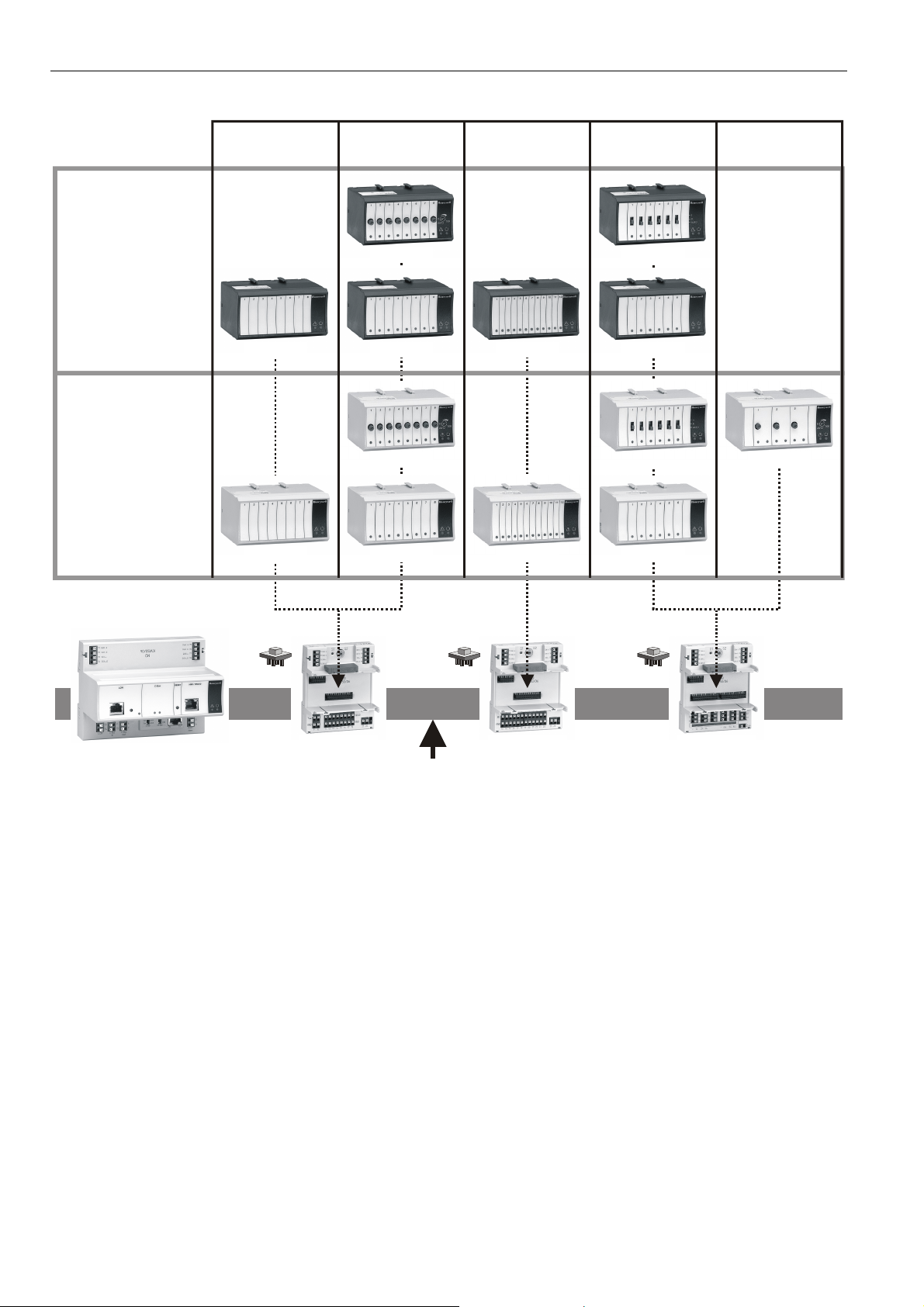

I/O Modules

Variants of I/O Modules

There are two variants of I/O modules:

• Panel Bus I/O modules with communication via Panel Bus

(light-gray housings)

Modules are automatically commissioned (with firmware

download) by the XCL8010AU

• L

ONWORKS Bus I/O modules (dark-gray housings) with

communication via L

compatible) for easy integration and use with 3

controllers

Terminal Sockets

I/O modules are mounted on the appropriate terminal

sockets. Panel Bus I/O modules and L

modules use the same terminal sockets.

Color Coding

To distinguish modules and components, the following color

coding is used:

Table 4. Color coding of Excel 800 Modules

color part

ONWORKS (FTT10-A, link power

ONWORKS Bus I/O

rd

-party

red All of the user-accessible adjustable

mechanical parts (i.e., bridge connectors and

locking mechanism) and operating controls

(manual overrides, etc.)

light-gray

dark-gray

Panel Bus I/O modules

ONWORKS Bus I/O modules

L

5 EN1B-0410GE51 R0908A

Page 6

Wiring Excel 800

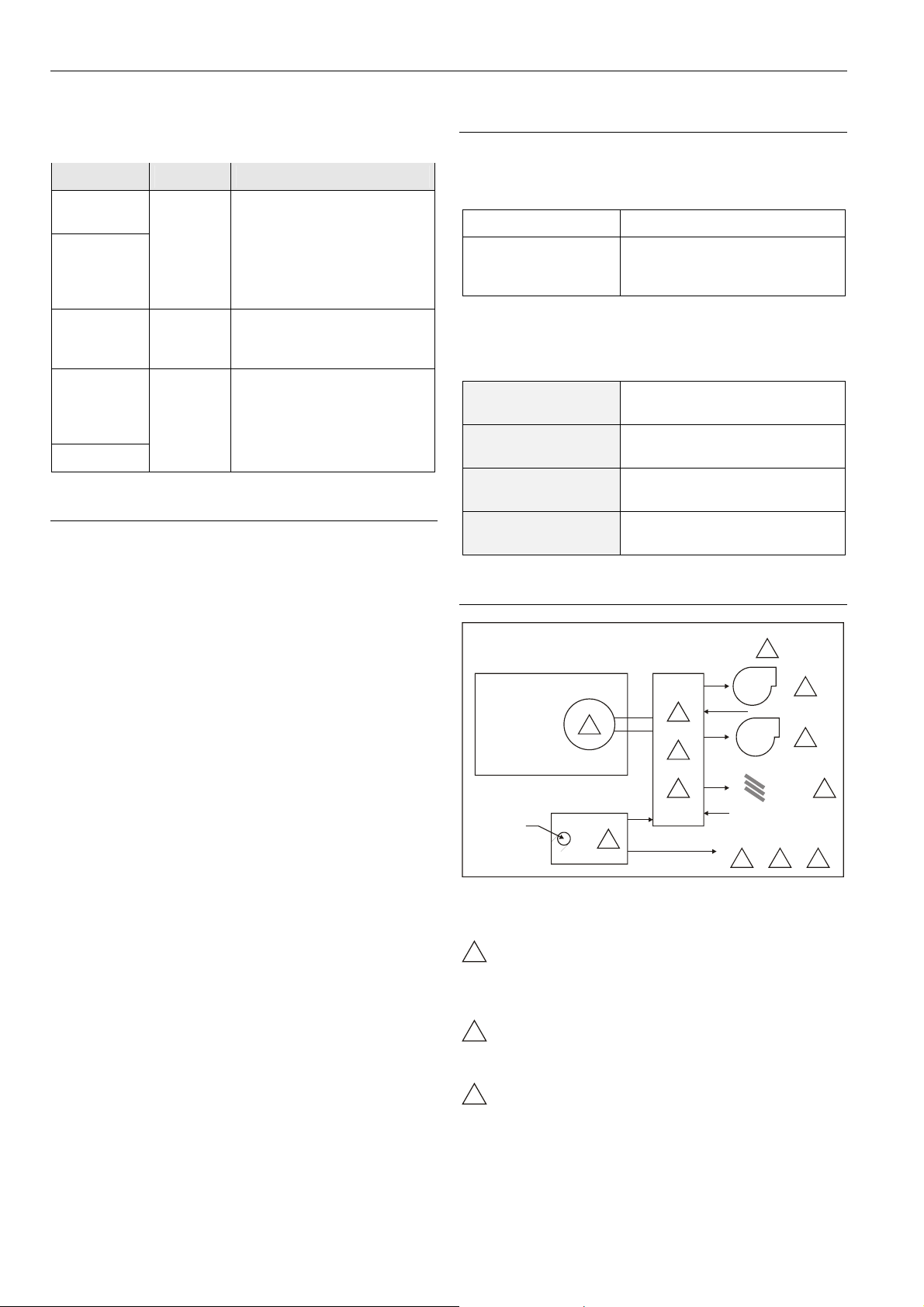

X

X

X

X

LonWorks

BUS

MODULES

PANEL

BUS

MODULES

ANALOG

INPUT

XFL821AU

XF821AU

ANALOG

OUTPUT

XFLR822AU

XFL822AU XFL823AU

XFR822AU

XF822AU XF823AU

BINARY

INPUT

RELAY

OUTPUT

FLR824AU

FL824AU

XFR824AU

F824AU

FLOATING

OUTPUT

XFR825AU

XCL8010AU

CONTROLLER MODULE

XS821-22

S823 XS824-25

LonWorks or Panel Bus

Fig. 2. Overview of I/O modules and terminal sockets

EN1B-0410GE51 R0908A

6

Page 7

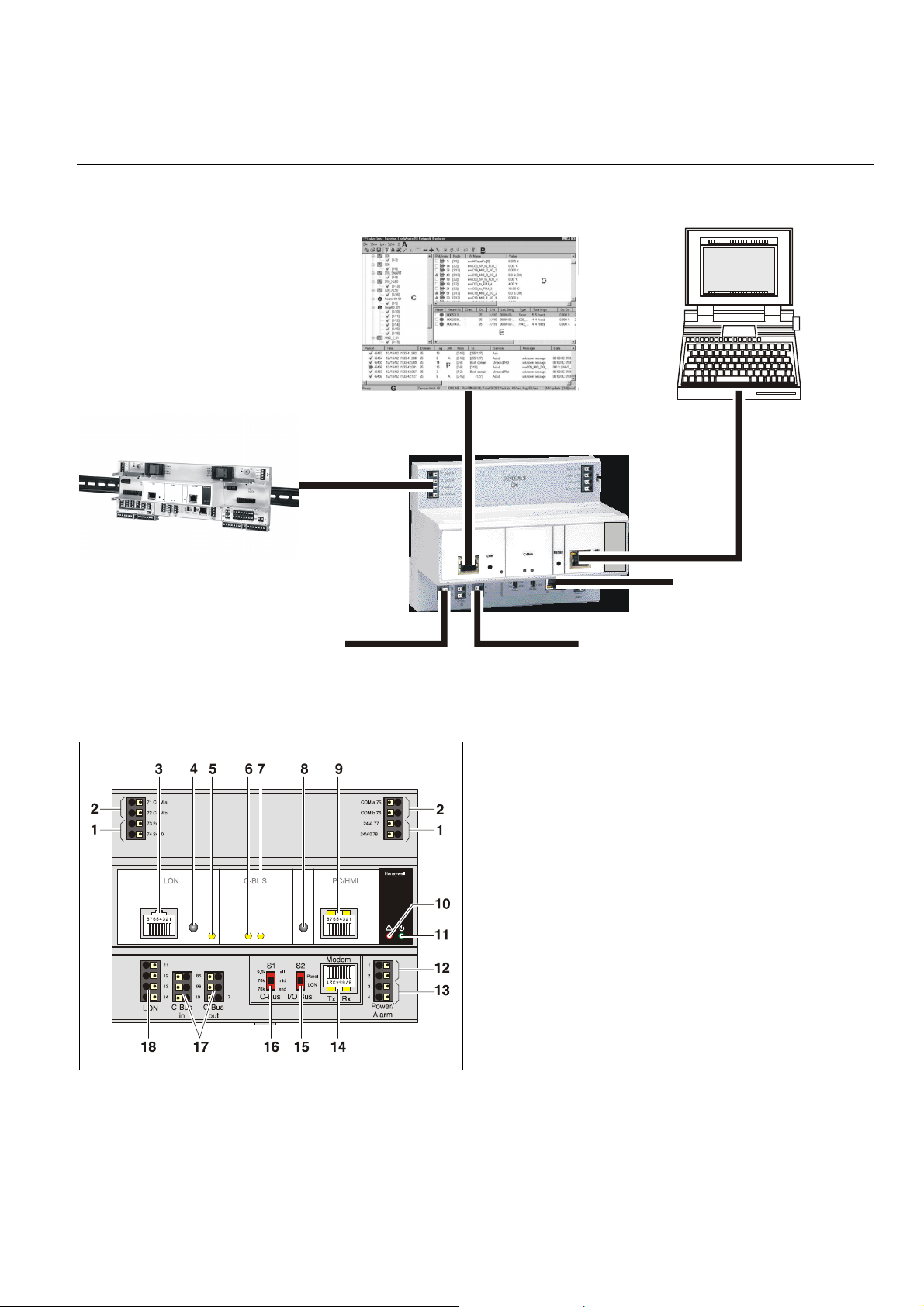

Excel 800 Description of the XCL8010AU Controller Module

Description of the XCL8010AU Controller Module

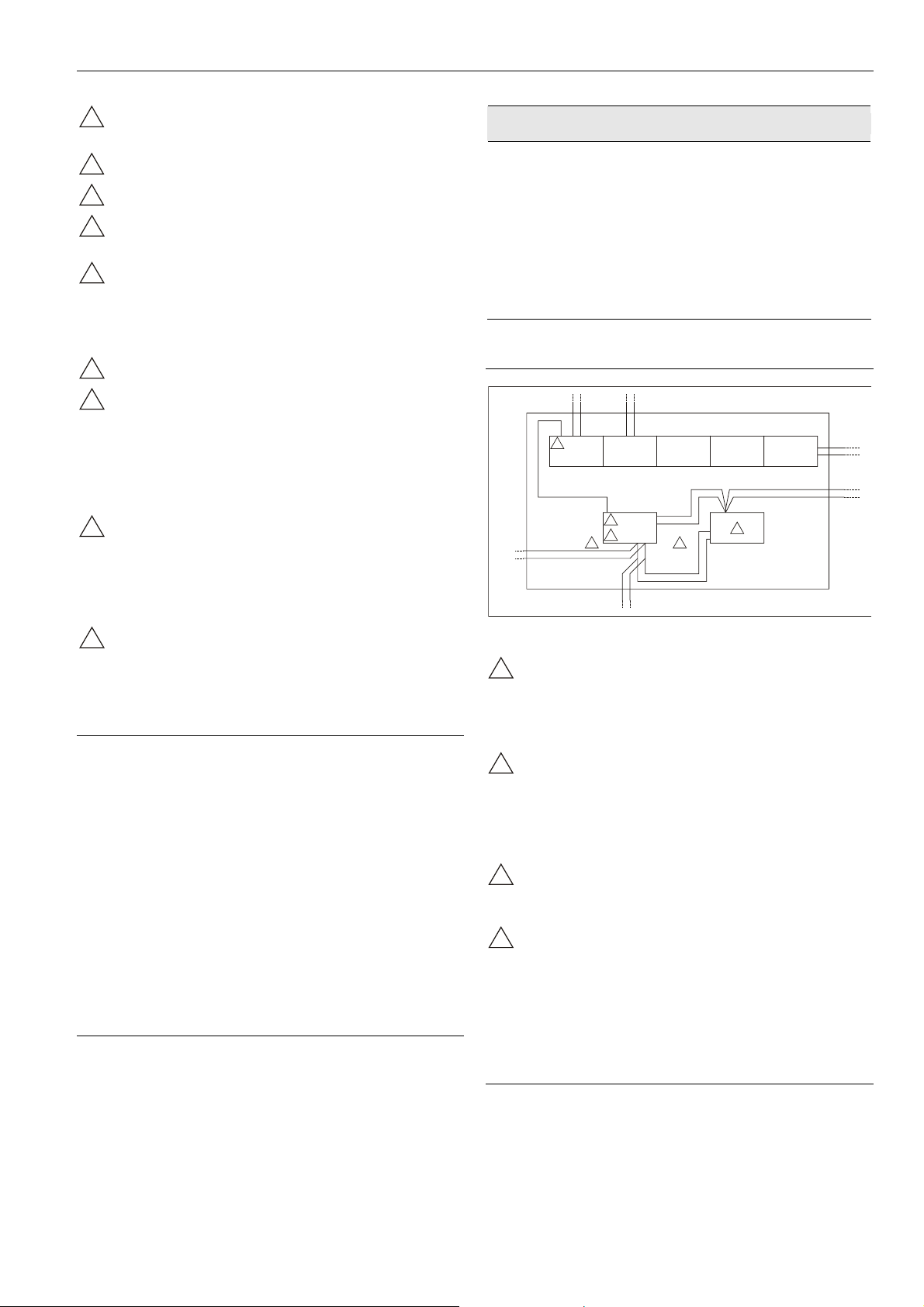

Overview

I/O MODULES

LonWorks BUS C-BUS

EXCELON

Fig. 3. Connections to the XCL8010AU Controller

PC or HMI

NO CONNECTION

Fig. 4. XCL8010AU

Controller Module front details

Legend

1 Power supply for I/O modules

2 I/O Bus communication terminals

3 L

ONWORKS interface

4 LONWORKS service button

5 L

ONWORKS service LED

6 C-Bus Tx LED

7 C-Bus Rx LED

8 Reset button

9 HMI interface (for field use, only)

10 Alarm LED

11 Power LED

12 Power supply terminals

13 Alarm/watchdog outputs

14 NO CONNECTION

15 S2 I/O Bus switch

16 S1 C-Bus termination switch

17 C-Bus terminals

18 L

ONWORKS terminals

7 EN1B-0410GE51 R0908A

Page 8

Description of the XCL8010AU Controller Module Excel 800

24 VAC CONTROLLER

CONNECTOR TO

XL800 CONTROLLER

J5

POWER SWITCH

MAIN LINE VOLTAGE

120 VAC, 60 HZ

TERMINAL MUST BE

CONNECTED TO A GOOD

EARTH GROUND.

14507063-002 POWER CABLE

(incl. with 14507287 power modules

14507287-001 through -003, only.)

CONNECTORS ARE KEYED TO

PREVENT MISALIGNMENT.

CONVENIENCE OUTLET

(UNFILTERED, UNSWITCHED)

-001 = 120 VAC, 10 AMP

““

G

BRN

GRN

BLK

120 VAC, 60 HZ

LINE INPUT

CONTROLLER

POWER

*

ON

H

N

OFF

G

CONTROLLER

SUPPLY

24VAC

48VA

~

G

““

G MUST BE

WIRED TO EARTH GROUND

* 14507287-001 POWER TERMINALS LABELED H-N-G.

2 AMP

F1

MUST BE WIRED

TO EARTH GROUND

UNSWITCHED

UNFILTERED

120 VAC

FUSE F1 (2 AMPS) PART NUMBERS ARE AS FOLLOWS:

–HONEYWELL PART NO. 14000485-007

(AVAILABLE FROM HONEYWELL BRANCH LOCATIONS, ONLY)

–BUSSMAN PART NO. AGC-2

–LITTLEFUSE PART NO. 312002

Fig. 5. Typical 14507287-001 Power Module wiring

CONNECTOR TO

XL800 CONTROLLER

J5

24 VAC CONTROLLER

POWER SWITCH

MAIN LINE VOLTAGE

120 VAC, 60 HZ

TERMINAL MUST BE

CONNECTED TO A GOOD

EARTH GROUND.

14507063-002 POWER CABLE

(incl. with 14507287 power modules

14507287-001 through -003, only.)

CONNECTORS ARE KEYED TO

PREVENT MISALIGNMENT.

CONVENIENCE OUTLET

(UNFILTERED, UNSWITCHED)

-002 AND -003 = 10 AMP

““

G

BRN

GRN

BLK

Fig. 6. Typical 14507287-002, -003 Power Module wiring

120 VAC, 60 HZ

LINE INPUT

““

G MUST BE

WIRED TO EARTH GROUND

* 14507287-001 POWER TERMINALS LABELED H-N-G.

POWER MODULE

14507287-001 THROUGH -003

14507287-002 AND -003

14507287-002 AND -003

CONTROLLER

POWER

*

ON ON

H

N

OFF OFF

G

CONTROLLER

SUPPLY

24VAC

48VA

FUSE NO.

F1

F2

F3

TO EARTH GROUND

~

G

-002 MODEL, ONLY. 2 AMP MAX.

FUSE RATING

2 AMPS

5 AMPS

2 AMPS

2 AMP 5 AMP

F1 F2

2 AMP

MUST BE WIRED

24 VAC ACCESSORY POWER

FOR 14507287-003 (24VDC)

FOR 14507287-002 (24VAC)

UNSWITCHED

UNFILTERED 120 VAC

HONEYWELL PART NO.

14000485-007

14507374-001

14000485-007

F3

120 VAC, 60 HZ

LINE INPUT

24VAC ACCESSORY

POWER -002 AND -003

MODELS (4 AMP MAX.)

~

BRN

BUSSMAN PART NO.

AGC-2

GMA 5AMP

AGC-2

GRY GRY

BRN

BRNRED

GRYGRY

LITTLEFUSE PART NO.

312002

235005

312002

EN1B-0410GE51 R0908A

8

Page 9

Excel 800 Description of the XCL8010AU Controller Module

CONTROLLER TRANSFORMER

CONTROLLER

SUPPLY 24 VAC

48 VA

G

~

70

71

72

BRN

BLK

3

GRN

1

4

H

N

G

BLK

WHT

GRN

24 V 50 VA

14507351-001

429P156A

E1A 1052 XXXX

COM 120 V

1

2

MAIN LINE (120 VAC, 60 Hz)

TERMINAL “G” MUST BE

CONNECTED TO A GOOD

EARTH GROUND.

MECHANICALLY SECURED TO SUBPANEL WITH MOUNTING SCREW

1

Fig. 7. Typical 14507287-007 Power Module wiring

I/O Module Overview

Table 5. Overview of I/O modules

1

Panel Bus

module

XF821AU XFL821AU Analog Input Module 8 – – –

XF822AU XFL822AU Analog Output Module – 8 – 8 status LEDs

XFR822AU XFLR822AU Analog Output Module – 8 8 manual overrides 8 status LEDs

XF823AU XFL823AU Binary Input Module 12 – – 12 status LEDs

XF824AU XFL824AU Relay Output Module – 6 2) – 6 status LEDs

XFR824AU XFLR824AU Relay Output Module – 6 2) 6 manual overrides 6 status LEDs

XFR825AU – Floating Output Module – 3 3 manual overrides 3 pairs of status LEDs

1)

In addition to the power LED and service LED

2)

Changeover outputs

9 EN1B-0410GE51 R0908A

LONWORKS

Bus module

description inputs outputs manual controls LEDs 1)

Page 10

Description of the XCL8010AU Controller Module Excel 800

X

1

2

3

Corresponding Terminal Sockets

Table 6. I/O modules and corresponding terminal sockets

I/O module socket scope of delivery

XF821AU,

XFL821AU

XF822AU,

XS821-22

1 terminal socket,

1 bridge connector

1 swivel label holder

XFL822AU,

XFLR822AU,

XFR822AU

XF823AU,

XFL823AU

XF824AU,

XFL824AU,

XFLR824AU,

XFR824AU

XS823

XS824-25

1 terminal socket,

1 bridge connector

1 swivel label holder

1 terminal socket,

1 bridge connector

1 swivel label holder

1 long cross connector

XFR825AU

Interfaces and Bus Connections

The Excel 800 System can be connected to the following

devices and systems:

Panel Bus

• For communication with up to 16 Panel Bus I/O modules

• Polarity-insensitive

LonWorks Bus

• For communication with other L

within the building

• FTT10, link power compatible

• Polarity-insensitive

C-Bus

• For communication with other controllers

HMI

• For connecting an operator interface, e.g., XI582 or a

laptop, e.g., for CARE

Modem

• NO CONNECTION

ONWORKS Bus devices

Technical Data

System Data

Table 7. System data

Operating voltage 24 VAC/DC, 60 Hz

Power consumption

Max. 3.57 A

(1 XCL8010AU Controller

+ 16 I/O modules)

Operational Environment

Table 8. Operational environment

ambient operating

temperature

ambient operating

humidity

ambient storage

temperature

ambient storage

humidity

0 ─ 49 °C (32 ─ 122 °F)

5 ─ 93 % rel. humidity

(non-condensing)

–20 ─ +70 °C (–4 ─ +158 °F)

5 ─ 95 % rel. humidity

(non-condensing)

Smoke Control Configuration

SMOKE CONTROL CONFIGURATION

L800

AO

UL-LISTED

FIRE ALARM

CONTROL UNIT

14505068

AUDIBLE

ANNUNCIATOR

8

FIREFIGHTERS’

SMOKE CONTROL

PAN EL (F SCS)

1

Fig. 8. Typical smoke control configuration

NOTES:

Locate and configure per NFPA 92A, Section 3-4.3.4.

UL-listed annunciator / FSCS panel switches have a

minimum rating of 24 V, 1/10 Amp, and lamps / LEDs

have a rating of 24 V, limited to 50 mA.

Locate so as to minimize control wiring and piping.

Avoid running wires or piping through areas that have

a high fire risk.

11

AO

12

AO

2 3

STATUS CONTROL

9

SUPPLY

FAN

AIRFLOW SENSOR

EXHAUST

FAN

DAMPER

VERIFICATION

6 7

10

4

5

EN1B-0410GE51 R0908A

Locate per UL 555S.

10

Page 11

Excel 800 Description of the XCL8010AU Controller Module

4

5

6

7

8

9

3

4

Locate separate from and below all building exhaust

fans and upstream of any prevailing winds.

Exhaust to outside of building.

Locate airflow differential switch.

Locate UL-listed damper pressure / position indicator

per damper installation instructions.

Smoke control must be initiated by a listed fire alarm

control unit or in zone automatic alarm devices and not

devices located outside of the smoke control zone.

Interconnecting wiring must be within 20 ft. (6 meters)

and in conduit.

Refer to NFPA 92A.

10

Verify that the AC voltage source connected to the

inside of the main line voltage terminal block is from a

UL-1481 listed uninterruptible power supply. The main

line voltage terminal block maximum current draw is

0.5 A. For 220/240 VAC (60 Hz) applications, verify

that no potential between any conductor and the earth

ground exceeds 150 VAC.

11

All external LONWORKS bus field wiring must be limited

to 4000 ft. (1200 meters) and be terminated to

14506944-001 transient protector (35 V, 290 mA max.)

except C-Bus field wiring communicating at 1 MHZ,

which uses 14502412-014 transient protector (19 V,

500 mA).

12

Panel Bus wiring must be in the same enclosure or

less than 20 ft. to adjacent enclosure. No protection is

required.

Data File Set-Up

Generate the engineering data file for the XL800 Series

Controllers. This data file has a mix of hardware points for the

necessary inputs and outputs to control fans, dampers, and

other equipment. In addition to the inputs and outputs, a

custom control program is written to control the outputs per

the sequence. The XL800 controllers can reset the program

once the data from the operator interface indicates a normal

condition for the dedicated smoke control equipment. Wire

conditions must be programmed to provide annunciation of

trouble conditions.

Also required for a dedicated application for the XL800, is a

weekly time program to test control points, fans, and dampers

by exercising the equipment and verifying feedback

automatically during low building activity periods.

Panel Reset

When in Smoke Control Mode, panel reset is accomplished

by resetting the initiating panel contact circuit or by the

separate initiating/reset switch on the FSCS panel.

CAUTION

Risk of electric equipment damage!

► Failure to use listed/approved replacement parts can

damage product, degrade operation and result in loss of

safety function.

► This product must be installed and operated within its

environmental, mechanical, and electrical specifications as

contained in this document.

► When servicing, use only listed/approved replacement

parts ordered directly from the manufacturer.

Typical Power Limited Circuit for XL800

POWER

LIMITED

2

CPU

1 1

NON-POWER

LIMITED

Fig. 9. Typical power-limited circuit for XL800

1

14507287-001 through -003 power module accessory

24 VAC output (rated 2A) must be wired in accordance

with NFPA 70, Article 725 when routed within the

cabinet or adjacent cabinets and also for external field

wiring.

2

14507287-001, -002, -003, and -007 control power

module 24 VAC output is inherently power-limited.

Thus, all sourced power from the XL800 controller is

power-limited. All field wiring from these controllers

meet NFPA 70, Article 725 power limited Class II

requirements.

If a separate auxiliary power-limited 24 VAC power

source is required, use a control power module

(14507287-001 or -007 control supply).

Devices must be installed in areas as shown. All cable

must be routed as shown. All internal power-limited

wiring must be separated by ¼ inch (6 mm) or barrier

from non-power-limited wire. Excess wiring must be

cut, trimmed, and dressed properly to ensure that

proper clearances are maintained.

LIMITED

ANALOG INPUT

MODULE

CONTROL

24VAC

2

3

NON-POWER

POWER

ACCESSORY

LIMITED

ANALOG OUTPUT

MODULE

24VAC

DIGITAL INPUT

MODULE

POWER LIMITED

24VAC

2

DIGITAL OUTPUT

MODULE

NON-POWER

LIMITED

NON-POWER

LIMITED

Connecting Single Bus Controller Systems

This section describes how to connect a controller system

which uses Panel Bus I/O modules, only or L

I/O modules, only.

ONWORKS Bus

11 EN1B-0410GE51 R0908A

Page 12

Description of the XCL8010AU Controller Module Excel 800

XCL8010AU, I/O Modules on Single Rail

► Connect XCL8010AU Controller Module and I/O modules

using the bridge connectors.

This provides power supply and communication connection.

No further wiring is necessary.

ROOM 1

71

LonWorks

72

I/O MODULE

73

74

XCL8010AU

1 2

LonWorks

I/O MODULE

75

76

77

78

Multiple Rails in Single Cabinet

The multiple rails of a controller system are connected in

series.

► Connect the rail ends as follows:

– Power supply

via power supply terminals 73, 74 or 77, 78

– Communication

via communication terminals 71, 72 or 75, 76

71

72

I/O MODULE

73

74

ROOM 2

I/O MODULE

73

74

LonWorks

LonWorks

I/O MODULE

LonWorks

I/O MODULE

75

76

77

78

71

72

I/O MODULE

73

74

71

72

I/O MODULE

73

74

71

72

I/O MODULE

73

74

I/O MODULE

XCL8010AU

1 2

I/O MODULE

I/O MODULE

75

76

77

78

75

76

77

78

Fig. 10. Wiring the power supply and the communication

lines to the I/O modules

LonWorks Bus I/O Modules in Separate Rooms

In this scenario, only communication lines must be connected

between the rooms.

► Connect the last module of room 1 to the first module of

room 2:

– via communication terminals 71, 72 or 75, 76

Fig. 11. Wiring the L

ONWORKS Bus I/O modules in

separate rooms

Maximum Cable Length

Max. cable length: 1200 meters (4000 ft), supervised.

How to Connect Panel Bus and LONWORKS

Bus Mixed Controller Systems

Connecting I/O Modules

For connecting the I/O modules with each other, proceed as

described for single-bus controller systems.

Connecting I/O Modules to the XCL8010AU

Panel Bus I/O Modules

► Connect communication terminals 71 ─ 74 or 75 ─ 78 of

Panel Bus I/O modules to communication terminals 71 ─

74 or 75 ─ 78 of the XCL8010AU Controller Module using

either

– Bridge connectors

for flush mounting on a single DIN rail or

– Cables

for separate mounting, e.g., on multiple rails, separate

cabinets, etc.

L

ONWORKS Bus I/O Modules

► Connect communication terminals 71 ─ 74 or 75 ─ 78 of

L

ONWORKS Bus I/O modules to LONWORKS terminals 11 ─

14 of the XCL8010AU using cables.

EN1B-0410GE51 R0908A

12

Page 13

Excel 800 Description of the XCL8010AU Controller Module

Panel Bus modules

71

72

73

74

LonWorks Bus modules

71

72

73

74

71

72

73

74

Panel Bus modules

75

76

77

78

75

76

77

78

71

72

XCL8010AU

73

74

11 1

12 2

13 3

14 4

Fig. 12. Mixed bus system – correct wiring

75

76

77

78 78

71

72

73

74

LonWorks Bus modulesPanel Bus modules

75 75

76 76

77 77

78

71

72

XCL8010AU

73

74

75

76

77

78 78

71

72

73

74

75

76

77

11 1

12 2

13 3

14 4

Fig. 13. Mixed bus system – incorrect wiring

Setting Address of Panel Bus I/O Modules

Each Panel Bus I/O module is assigned its own unique

address. For the sake of clarity for maintenance personnel, it

is recommended that you address the Panel Bus I/O modules

in ascending order 0 through F.

Table 9. HEX switch settings and addresses

HEX switch

address

HEX switch

address

0 1 2 3 4 5 6 7

01 02 03 04 05 06 07 08

8 9 A B C D E F

09 10 11 12 13 14 15 16

► Use the rotary HEX switch to set the address to the one

already defined during engineering.

13 EN1B-0410GE51 R0908A

Page 14

Mounting/Dismounting Modules Excel 800

LONWORKS Bus Topologies

4

4

LOCK

Fig. 14. HEX switch location

NOTE: If the HEX switch setting is changed, the Panel

Bus I/O module will revert to its default

configuration. With L

the HEX switch is without function.

ONWORKS Bus I/O modules,

Setting the I/O Bus Switch

► Set the I/O Bus switch S2 of the XCL8010AU Controller

Module depending on the modules connected to terminals

71 ─ 78 and the desired communication as follows:

Table 10. I/O Bus switch settings

communication S2 setting terminals

LONWORKS Bus

only

Panel Bus and

L

ONWORKS Bus

LON 71 ─ 74 L

75 ─ 78

11 ─ 14

Panel 71 ─ 74 Panel Bus

75 ─ 78 Panel Bus

11 ─ 14 L

ONWORKS Bus

LONWORKS Bus

LONWORKS Bus

ONWORKS Bus

The LONWORKS Bus is a 78-kilobit serial link that uses

transformer isolation so that the bus wiring does not have a

polarity. I.e. it is not important which of the two LONWORKS

Bus terminals are connected to each wire of the twisted pair.

The L

ONWORKS Bus does not need to be shielded on the

controller module side.

The LONWORKS Bus can be wired in daisy chain, star, loop or

any combination thereof as long as the maximum wire length

requirements are met.

Configuration

The recommended configuration is a daisy chain with two bus

terminations. This layout allows for max. L

lengths, and its simple structure presents the least number of

possible problems, particularly when adding on to an existing

bus.

ONWORKS Bus

C-Bus Topologies

Via the C-Bus up to 30 C-Bus devices (e.g., controllers, etc.)

can communicate with one another and a PC central. The CBus must be connected via the individual controllers (open

ring).

NOTE: Star connection is not allowed because

uncontrollable line reflections may occur.

Mounting/Dismounting Modules

WARNING

Risk of electric shock or equipment damage!

► Do not touch any live parts in the cabinet.

► Disconnect the power supply before you start to install the

Excel 800 System.

More than one disconnect switch may be required to deenergize the system.

► Do not reconnect the power supply until you have

completed the installation.

Fig. 15. S2 I/O Bus switch

EN1B-0410GE51 R0908A

NOTE: The terminal socket of each I/O module can be

mounted and wired before inserting and locking

the corresponding electronic module.

14

Page 15

Excel 800 Mounting/Dismounting Modules

Mounting/Dismounting Controller/Sockets

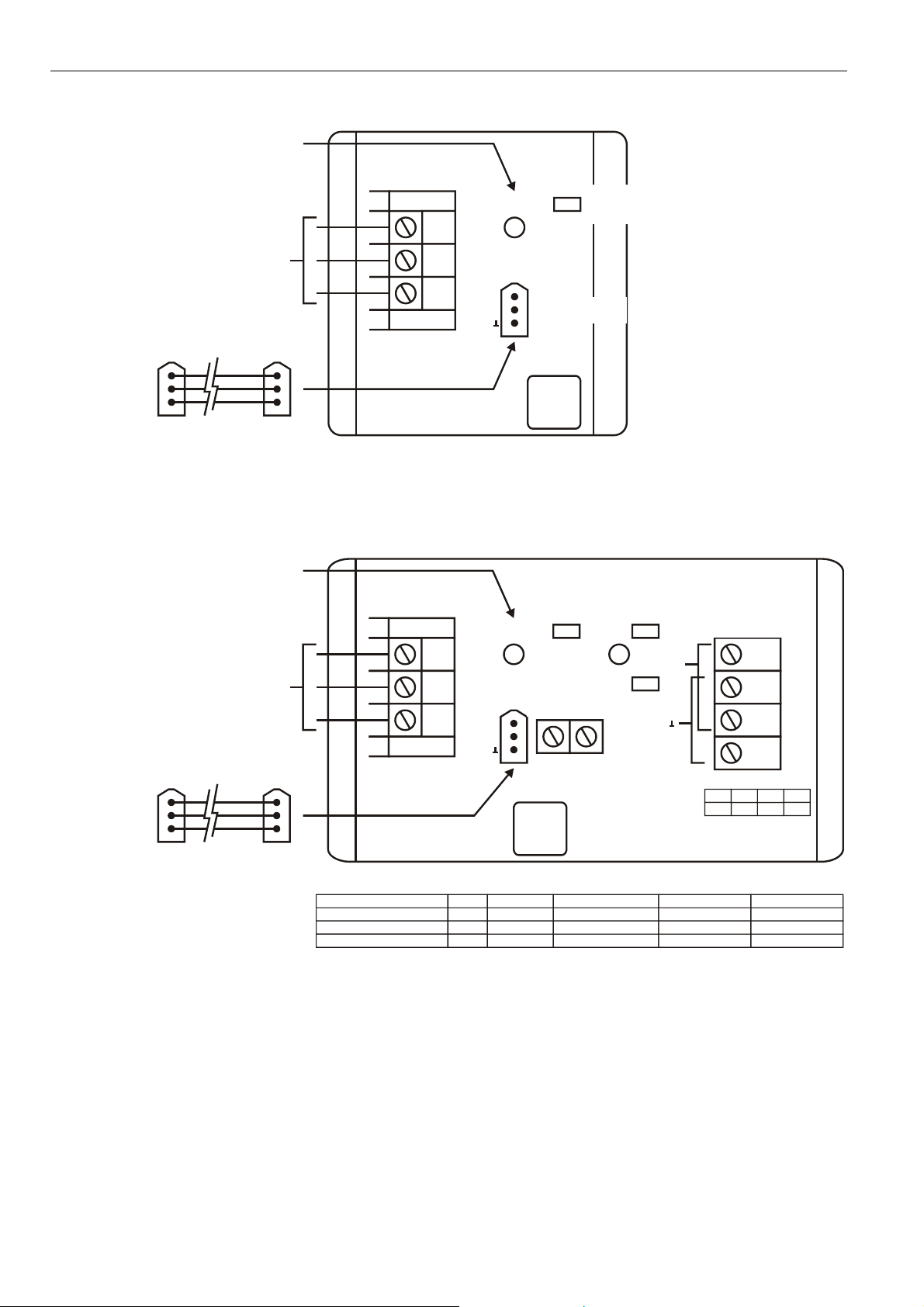

Mounting Sockets

NOTE: When using both Panel Bus and LONWORKS Bus

I/O modules in an Excel 800 System, group both

Panel Bus modules (light-gray) and L

Bus I/O modules (dark-gray), e.g., on different

rails. Up to 10 Panel Bus I/O modules can be

mounted to one side of the XCL8010AU. In total,

up to 16 Panel Bus I/O modules can be mounted

to one controller. The XCL8010AU Controller

Module is mounted on the DIN rail in the same way

as a terminal socket.

ONWORKS

Panel

BUS I/O

max. 10

Panel

BUS I/O

XCL8010AU

max. 16

BUS I/O

Panel

LonWorks

Panel

BUS

BUS I/O

I/O

max. 10

Fig. 16. Max. number of Panel Bus I/O modules

LonWorks

BUS I/O

NOTE: MAX. OF 16 DIGITAL INPUT MODULES MAY BE USED.

Fig. 17. Max. number of L

max. 10

LonWorks

BUS I/O

XCL8010AU

max. 20

ONWORKS Bus I/O modules with

LonWorks

BUS I/O

LonWorks

LonWorks

BUS

BUS I/O

I/O

max. 10

power supply via XCL8010AU

► Angle the terminal socket at the upper edge of the DIN rail

until it snaps in.

► Swing the terminal socket down and apply gentle force

until it snaps into position with an audible "click".

► Position XCL8010AU Controller Module and terminal

sockets flush with one another along the rail.

► If desired, mount stoppers at the ends of the rail to prevent

sliding.

Fig. 18. Mounting terminal sockets

NOTE: Take care to not bend the Omega clamp, which

serves to establish the electrical contact with the

DIN rail and which located on the back of the

terminal socket.

Connecting Sockets

Controller and terminal sockets on the same DIN rail can be

connected mechanically and electrically with bridge

connectors.

Controller and terminal sockets on different DIN rails must be

connected using cables.

NOTICE

Risk of malfunction!

► Wire Panel Bus I/O modules and LONWORKS Bus

I/O modules separately.

► When using both Panel Bus and LONWORKS Bus

I/O modules in an Excel 800 System, L

I/O modules must be connected to the XCL8010AU

Controller Module via LON terminals 11 ─ 14.

Position the bridge connector on terminals 71 ─ 74 of the

right hand terminal socket or XCL8010AU Controller Module

and on terminals 75 ─ 78 of the left hand terminal socket or

XCL8010AU Controller Module. Then press the bridge

connector down.

ONWORKS Bus

15 EN1B-0410GE51 R0908A

Page 16

Mounting/Dismounting Modules Excel 800

Fig. 21. Releasing latch

Fig. 19. Connecting terminal sockets with bridge

connector

Mounting/Dismounting Electronic Modules

NOTE: Bridge connectors transmit both communication

signals and power supply between modules.

Removing bridge connectors will interrupt the

transmission of both communication signals and

power supply between the modules.

Dismounting Sockets

Disconnecting Sockets

Release all bridge connectors before removing the

XCL8010AU Controller Module and/or the terminal sockets

from the DIN rail.

► Press down at the same time both the gray side wings next

to the red button and then pull the bridge connector out of

the module.

Mounting Electronic Modules

NOTE: Electronic modules can be removed from the

socket or inserted into the sockets without

switching off the power supply. The behavior of

connected field devices must be taken into

consideration.

► Make sure that terminal socket und I/O module match.

► Make sure that the red locking mechanism is in the open,

i.e., left, position.

► Gently push the electronic module onto the terminal socket

until snug.

Fig. 20. Releasing bridge connectors

Dismounting Controller/Terminal Sockets

► Insert a screwdriver into the latch on the underside of the

module and lever the red latch 2–3 mm downwards. The

module can then be swung away from the rail.

EN1B-0410GE51 R0908A

► Lock the red locking mechanism by sliding it to the right.

16

Fig. 22. Inserting the electronic module

Page 17

Excel 800 Mounting/Dismounting Modules

Setting the C-Bus Termination Switch

► Set the C-Bus termination switch S1 appropriately.

Fig. 23. Locking the electronic module

NOTE: The red locking mechanism will not close if the

electronic module is not properly mounted.

Dismounting Electronic Modules

NOTE: Electronic modules can be removed from the

socket or inserted into the sockets without

switching off the power supply. The behavior of

connected field devices must be taken into

consideration.

► Open the red locking mechanism by sliding it to the left

and then gently pull the electronic module out of the

terminal socket.

Table 11. XCL8010AU

switch setting

9.6k all

76k mid Up to 76800 baud without bus termination

76k end Up to 76800 baud with bus termination

Shielding

In principle, data transmitting cables should be shielded in

case of RFI.

► On the controller side, connect the shield to terminals 7

and 10.

► On the side of the device, connect the shield to the

respective terminals.

Do not connect it to the cabinet ground or any other

ground points.

Fig. 25. C-Bus termination switch S1

C-Bus termination switch settings

S1

Up to 9600 baud (default setting)

baud rate

Connecting HMIs or Laptops

Fig. 24. Dismounting the electronic module

Connecting via C-Bus

Via C-Bus, an XCL8010AU Controller Module can be

connected to other controller systems to form a network.

Connecting to the Controller

► Connect the C-Bus to the XCL8010AU Controller Module

as follows:

– Input to C-Bus terminals 8 and 9

– Output to C-Bus terminals 5 and 6

– Do not connect the C-Bus to the cabinet earth or any

other earth ground points

17 EN1B-0410GE51 R0908A

Laptops or HMIs, e.g., XI582, can either be connected via the

HMI interface of the XCL8010AU Controller Module or via the

L

ONWORKS interface.

Connecting the XI582 Operator Interface

► Connect the XI582AH Operator Interface to the HMI

interface or L

Controller Module by means of

– the XW882 cable or

– the XW582 cable connected with an XW586 cable.

ONWORKS interface of the XCL8010AU

Page 18

Mounting/Dismounting Modules Excel 800

Connecting Laptops (XL-Online/CARE)

► Connect a laptop (on which e.g., XL-Online or CARE has

been installed) to the HMI interface or L

of the XCL8010AU

Controller Module by means of

ONWORKS interface

– the XW885 cable or

– the XW585 cable connected with an XW586 Cable.

XCL8010AU Terminals

COM

71

A

COM

72

B

24

73

V~

24

74

V~ 0

87 6543 21

LON

11

1

12

13

14

LON

LON

LON

2

1

2

8 5

C+ C+

9 6

C- C-

SHIELD SHIELD

10 7

*Watch Dog

Fig. 26. Terminal assignment and internal connections of

the XCL8010AU Controller Module

Table 12. Description of XCL8010AU terminals

ter-

minal

71, 75 COM a

72, 76 COM b

signal comment

2-wire communication bus

(LON/Panel Bus)

2-wire communication bus

(LON/Panel Bus)

73, 77 24 V~ Power supply for I/O modules

74, 78 24 V~0 Power supply for I/O modules

1 24 V~ Power supply from transformer

2 24 V~0 Power supply from transformer

3 24 V~0 Alarm/watchdog output

4 NC Alarm/watchdog output

5, 8 C+ C-Bus

6, 9 C- C-Bus

7, 10 Shield C-Bus shield

11, 12 LON LONWORKS IN

13, 14 LON LONWORKS OUT

Relay

COM

75

A

COM

76

B

24

77

V~

24

78

V~0

24

1

V~

24

2

V~0

24

3

V~0

NC

4

*

Features

LONWORKS Interface and Terminals

The XCL8010AU Controller Module features

• An RJ45 socket serving as an interface

to connect laptops or HMIs to the L

• LONWORKS terminals 11, 12, 13, and 14

to connect L

ONWORKS devices to the XCL8010AU Controller or other

L

L

ONWORKS controllers.

ONWORKS Bus I/O modules or other

Fig. 27. L

ONWORKS interface and LONWORKS terminals

LONWORKS Interface Signals on RJ45 Socket

Table 13. Signals of L

pin signal type

1 Connection to LONWORKS Bus

2 Connection to LONWORKS Bus

3 ─ 8 Not used

LONWORKS Service LED and Button

The XCL8010AU Controller Module is equipped with a

L

ONWORKS service button and corresponding LONWORKS

Service LED (status: yellow/OFF).

Fig. 28. L

ONWORKS service button (1) and service LED (2)

ONWORKS Bus

ONWORKS interface

LON

1

2

EN1B-0410GE51 R0908A

See also section "Troubleshooting" on page 31.

18

Page 19

Excel 800 Mounting/Dismounting Modules

C-Bus Tx LED and Rx LED

The XCL8010AU Controller Module is equipped with a Tx

LED (status: yellow/OFF) and an Rx LED (status:

yellow/OFF).

C-Bus

1

2

Fig. 29. C-Bus Tx LED (1) and Rx LED (2)

C-Bus LEDs

Table 14. Controller C-Bus LEDs

Tx (1)

flickering

Rx (2)

flickering

The controller is sending data onto the

C-Bus

The controller is receiving data from the

C-Bus

Reset Button

The XCL8010AU Controller Module is equipped with a reset

button.

RESET

1

Fig. 30. Reset button (1)

Pushing the reset button (1), e.g. using a paperclip, will cause

the XCL8010AU

NOTE: In the event of a reset, all non-volatile memory

Controller Module to reset.

contents are permanently deleted, though the

clock will not be set to zero. In order to avoid

problems, we therefore recommend that you

always save your application changes (e.g., time

program changes) to FLASH memory.

HMI Interface

The XCL8010AU Controller Module is equipped with an HMI

Interface for the connection of HMIs, e.g., XI582 Operator

Interface or a laptop (with XL-Online/CARE).

Fig. 31. HMI interface, Tx LED (1) and Rx LED (2)

HMI interface LEDs on RJ45 socket

Table 15. HMI interface LEDs

Tx (1)

flickering

Rx (2)

flickering

HMI interface Signals on RJ45 socket

1 -

2 Receive

3 Transmit

4 -

5 Signal ground

6 -

7 5 V

8 -

The controller is transmitting data to the HMI

The controller is receiving data from the HMI

Table 16. Signals of the HMI interface

pin signal type

NOTICE

Equipment damage!

► If earth grounding is required, make sure that only terminal

2 is connected to earth ground. Terminal 1 must not be

connected to earth ground. See also Appendix 1.

19 EN1B-0410GE51 R0908A

Page 20

Mounting/Dismounting Modules Excel 800

Alarm and Power LEDs

The XCL8010AU Controller Module is equipped with an alarm

LED and a power LED.

Fig. 32. Alarm LED (1) and power LED (2)

Alarm LED (1, red)

Table 17. Controller alarm LED

Off

On

Flashing The watchdog alarm output has not yet been

Power LED (2, green)

On

Flashing One or more of the internal voltage supplies

Goes out

briefly

Normal operation

Watchdog alarm output is powered

• The controller has encountered a hardware

problem

• The application has a fault

• The controller has been powered up without

an application or the operator has manually

stopped the application.

In this case, the LED will light up 13 minutes

after power-up without application

powered, although the controller has

encountered a problem.

The controller performs a warm start.

If problem persists, the LED will become lit

constantly, see above.

See section "Troubleshooting" on page 31.

Table 18. Controller power LED

Normal operation

are outside of the permissible ranges.

The controller stops operation.

► Check wiring or see section

"Troubleshooting" on page 31.

• The operator has activated the reset

button

• The controller is performing a warm start

Watchdog Status

Table 19. Watchdog status (terminal 4)

status signal on terminal 4

Failure (= alarm) 24 V

Normal operation 0 V

Modem Interface

NO CONNECTION.

I/O Bus Switch S2

The XCL8010AU Controller Module features a 2-position I/O

Bus switch S2.

I/O Bus switch S2 must be set in accordance with the kind of

I/O modules connected to communication terminals 71, 72

and 75, 76 of the XCL8010AU Controller Module.

Terminals 71, 72 and 75, 76 must be all connected either to

Panel Bus I/O modules or to L

The default setting is Panel.

Fig. 33. I/O Bus switch S2

Table 20. I/O Bus switch settings

communication S2 setting

LONWORKS Bus only LON

Panel Bus and LONWORKS Bus

ONWORKS BUS modules connected to

L

terminals 11 ─ 14 of the XCL8010AU

Controller Module

Panel Bus connected to terminals 71, 72 or

75, 76 of the XCL8010AU Controller

Module

ONWORKS Bus I/O modules.

Panel

Panel

EN1B-0410GE51 R0908A

20

Page 21

Excel 800 Description of the I/O Modules

C-Bus Termination Switch S1

The XCL8010AU Controller Module features a 3-position CBus termination switch S1.

This switch must be set in accordance with the given C-Bus

configuration.

Fig. 34. C-Bus termination switch

Table 21. XCL8010AU

switch setting

S1

9.6k all

76k mid Up to 76800 baud without bus termination

76k end

Up to 9600 baud (default setting)

Up to 76800 baud with bus termination

controller at the end of the C-Bus

C-Bus termination switch S1

settings

baud rate

Description of the I/O Modules

Common Features

Switches Located on the Terminal Socket

Table 23. Terminal socket switches

feature function

Service button

S1

Hex switch S2

LEDs Located on the I/O Module

feature function

Service LED

(yellow)

Power LED

(green)

For the location of these elements, see figures of the

respective modules.

• LED test, see section "Troubleshooting"

on page 31

• L

ONWORKS service button functionality

for L

ONWORKS Bus I/O modules

• Module addressing for Panel Bus

I/O modules

Table 24. LEDs on I/O module

• Service information, see section

"Troubleshooting" on page 31

• Information on power supply, see section

"Troubleshooting" on page 31

Memory

Table 22. XCL8010AU memory

memory size usage

SRAM 512 KB

Flash 2 MB

EPROM 128 KB For bootstrap loader

NOTE: The XCL8010AU

contain a battery. RAM (data and realtime

clocktime) is buffered for 3 days by a super

capacitor.

For controller application,

modem trend and firmware

RACL application: 128 KB

Total application: 192 KB

Firmware (1 MB) and application

(1 MB) storage

Controller Module does not

21 EN1B-0410GE51 R0908A

Page 22

Description of the I/O Modules Excel 800

Analog Input Modules

Types of Analog Input Modules

Table 25. Excel 800 Analog Input Modules

type description housing

XF821 Panel Bus Analog Input Module light-gray

L

XFL821

ONWORKS Bus Analog Input

Module

XS821-822 terminal socket light-gray

Features

• 8 analog inputs

• Sensor-break and short-circuit detection, see section

"Troubleshooting" on page 31.

Fig. 35. XF821AU Analog Input Module with terminal

socket

Legend

1 Service button S1

2 Hex switch S2

3 Service LED

4 Power LED

Functionality of service LED and power LED: see Table 42

and following.

dark-gray

Terminals

COM

71

A

COM

72 76

B

24

73 77

V~

24

74

V~0

AI8

AI7

AI6

AI5

AI4

AI3

AI2

V

AUXVAUX

22

21

GND9GND

10

Fig. 36. Terminal assignment and internal connections of

Table 26. Description of Analog Input Module terminals

ter-

minal

71, 75 COM a

72, 76 COM b

73, 77 24 V~ Power supply

74, 78 24 V~0 Power supply

1 ─ 8 AI1 ─ AI8 Analog inputs 1 ─ 8

9 ─ 18 GND

21, 22

25, 26

NOTE: Shield connection to be used for shielded I/O

AI1

8

7

6

5

4

3

2

1

GND11GND GNDGND GND GND GND GND

18171615141312

Analog Input Modules

signal comment

2-wire communication bus

(LON/Panel Bus)

2-wire communication bus

(LON/Panel Bus)

Ground. All grounds are connected

internally to each other

Auxiliary voltage signal (used e.g. for

10 VDC /

5 mA

supplying setpoint potentiometers).

Connections to these terminals

must be made in the same room.

Shield connection (functional earth),

internally connected to the DIN rail

cables only. It is not allowed to connect a

ONWORKS shield.

L

COM

A

COM

B

24

V~

24

V~0

25 26

75

78

EN1B-0410GE51 R0908A

22

Page 23

Excel 800 Description of the I/O Modules

XFL821AU Connection Examples

400 OHM

25

18

1

SHIELD SHIELD

1

2

0(4) to 20 mA

0(4) to 20 mA (VIA EXTERNAL

500 OHM RESISTOR).

5

14

10 1

11 12 2

25 25

22

SHIELD SHIELD

VMP Pt1000 NTC20kW

Fig. 37. XFL821AU Analog Input Module

2

12

1

2

0 to 10 V

0 TO 10 VDC

3

13

25

23 EN1B-0410GE51 R0908A

Page 24

Description of the I/O Modules Excel 800

Analog Output Modules

Types of Analog Output Modules

Table 27. Excel 800 Analog Output Modules

type description housing

XF822

XFR822

XFL822

XFLR822

XS821-22 terminal socket light-gray

Panel Bus Analog Output

Module

Panel Bus Analog Output

Module with manual overrides

L

ONWORKS Bus Analog Output

Module

L

ONWORKS Bus Analog Output

Module with manual overrides

Features

• 8 analog outputs;

can also be configured per output as binary outputs

(0 ─ 10 V, 2 ─ 10 V, ON/OFF, or floating)

• Corresponding output status LEDs (red)

• XFR822AU/XFLR822AU: 8 manual overrides, see figure

below

Fig. 38. XF822AU Analog Output Module with terminal

socket

light-gray

light-gray

dark-gray

dark-gray

Terminals

Fig. 39. Terminal assignment and internal connections of

the Analog Output Modules

Table 28. Description of the Analog Output Module

terminals

ter-

minal

71, 75 COM a

72, 76 COM b

73, 77 24 V~ Power supply

74, 78 24 V~0 Power supply

1 ─ 8 AO1 ─ AO8 Analog outputs 1 ─ 8

9 ─ 18 GND

21, 22 N.C. Do not use!

25, 26

NOTE: Shield connection to be used for shielded I/O

signal comment

2-wire communication bus

(LON/Panel Bus)

2-wire communication bus

(LON/Panel Bus)

Ground. All grounds are connected

internally to each other

Shield connection (functional earth),

internally connected to the DIN rail

cables only. It is not allowed to connect a

L

ONWORKS shield.

Technical Data

Output status LEDs behavior

Table 29. Analog Output Module status LED behavior

Legend

1 Service button S1

2 Hex switch S2

3 Manual overrides

4 Output LEDs

5 Service LED

6 Power LED

Functionality of service LED and power LED: see Table 42

and following.

EN1B-0410GE51 R0908A

automatic mode brightness follows the

commanded output signal

override mode

24

flashes

Page 25

Excel 800 Description of the I/O Modules

X

Modules with Manual Overrides

The XFR822AU/XFLR822AU Analog Output Modules are

equipped with manual overrides: one rotary knob for each

analog output.

The manual overrides can be set manually to either "auto" or

"0 ─ 110%".

NOTICE

Damage to the electronic module!

► Do not use a tool to adjust the rotary knobs.

► Do not use excessive force. Adjust only by hand.

XFL822AU Connection Example

LN

24V

14507287

POWER

MODULE

This updating (synchronization) is performed:

• If the calculated position of the actuator

< lower synchronization threshold (2 %)

= synchronization towards 0 %

• If the calculated position of the actuator

> upper synchronization threshold (98 %)

= synchronization towards 100 %

• Following any power-up or any reset

~

XFL822AU

11

1

738

Umax = 11 VDC

Imax = 1 mA, -1 mA

SL511

GND SIGNAL 24VAC

M

Fig. 40. XFL822AU Analog Output Module

Synchronization Behavior of Analog Output Module

Configured as Floating Output

In order to regularly update the real actuator position with the

calculated position and thus ensure that the actuator

definitely reaches its end position, a synchronization process

is performed by the Analog Output Module.

During the synchronization process, the Analog Output

Module will continue running for the configured runtime once

it reaches the calculated end position.

25 EN1B-0410GE51 R0908A

Page 26

Description of the I/O Modules Excel 800

Binary Input Modules

Types of Binary Input Modules

Table 30. Excel 800 Binary Input Modules

type description housing

XF823 Panel Bus Binary Input Module light-gray

L

XFL823

ONWORKS Bus Binary Input

Module

XS823 terminal socket light-gray

Features

• 12 binary inputs

• 12 configurable status LEDs (green/red, yellow/OFF)

• Binary inputs can be used as

– Static digital inputs as dry-contacts

Fig. 41. XF823AU Binary Input Module with terminal

socket

Legend

1 Service button S1

2 Hex switch S2

3 Input LEDs

4 Service LED

5 Power LED

Functionality of service LED and power LED: see Table 42

and following.

dark-gray

Terminals

COM

71

A

COM

72 76

B

24

73 77

V~

24

74

V~0

BI12

BI11

BI10

BI9

BI8

BI7

BI6

BI5

BI4

BI3

BI2

BI1

12

11

10

9

8

7

6

5

4

3

2

1

GND13GND GNDGND GND GND GNDGND GND GNDGND GND

2423222120191817161514

Fig. 42. Terminal assignment and internal connections of

Binary Input Modules

Table 31. Description of Binary Input Module terminals

ter-

minal

71, 75 COM a

72, 76 COM b

signal comment

2-wire communication bus (LON/Panel

Bus)

2-wire communication bus (LON/Panel

Bus)

73, 77 24 V~ Power supply

74, 78 24 V~0 Power supply

1 ─ 12 BI1 ─ BI12 Binary inputs 1 ─ 12

13 ─

24

25, 26

GND

Ground. All grounds are connected

internally to each other.

Shield connection (functional earth),

internally connected to the DIN rail.

NOTE: Shield connection to be used for shielded I/O

cables only. It is not allowed to connect a

L

ONWORKS shield.

COM

A

COM

B

24

V~

24

V~0

25 26

75

78

Technical Data

Table 32. Technical data for of Binary Input Modules

input type

current rating (closed

input)

open contact voltage

dry-contact

2 mA

16 ─ 22 VDC

EN1B-0410GE51 R0908A

26

Page 27

Excel 800 Description of the I/O Modules

Status LEDs

The status LEDs can be configured individually for use as

either alarm LEDs (red/green) or as status LEDs (yellow/OFF

[default]).

Given a state of "logical ON," the LED will be lit (yellow or

red).

XF823AU Connection Examples

25

13

SHIELD

1

2

5 TO 24V

2 1

MIN.

25 MS

3 15

MIN.

25 MS

CONTACT SUITABLE FOR

LO W V OLTA GE (G OL D) .

1

PROTECTED SWITCHING

2

UP TO 40 VDC / 24 VAC.

21

14

5 TO 24

VDC

1

~ 120V

PT1000 NTC20kW

Fig. 43. XFL823AU Binary Input Module

27 EN1B-0410GE51 R0908A

Page 28

Description of the I/O Modules Excel 800

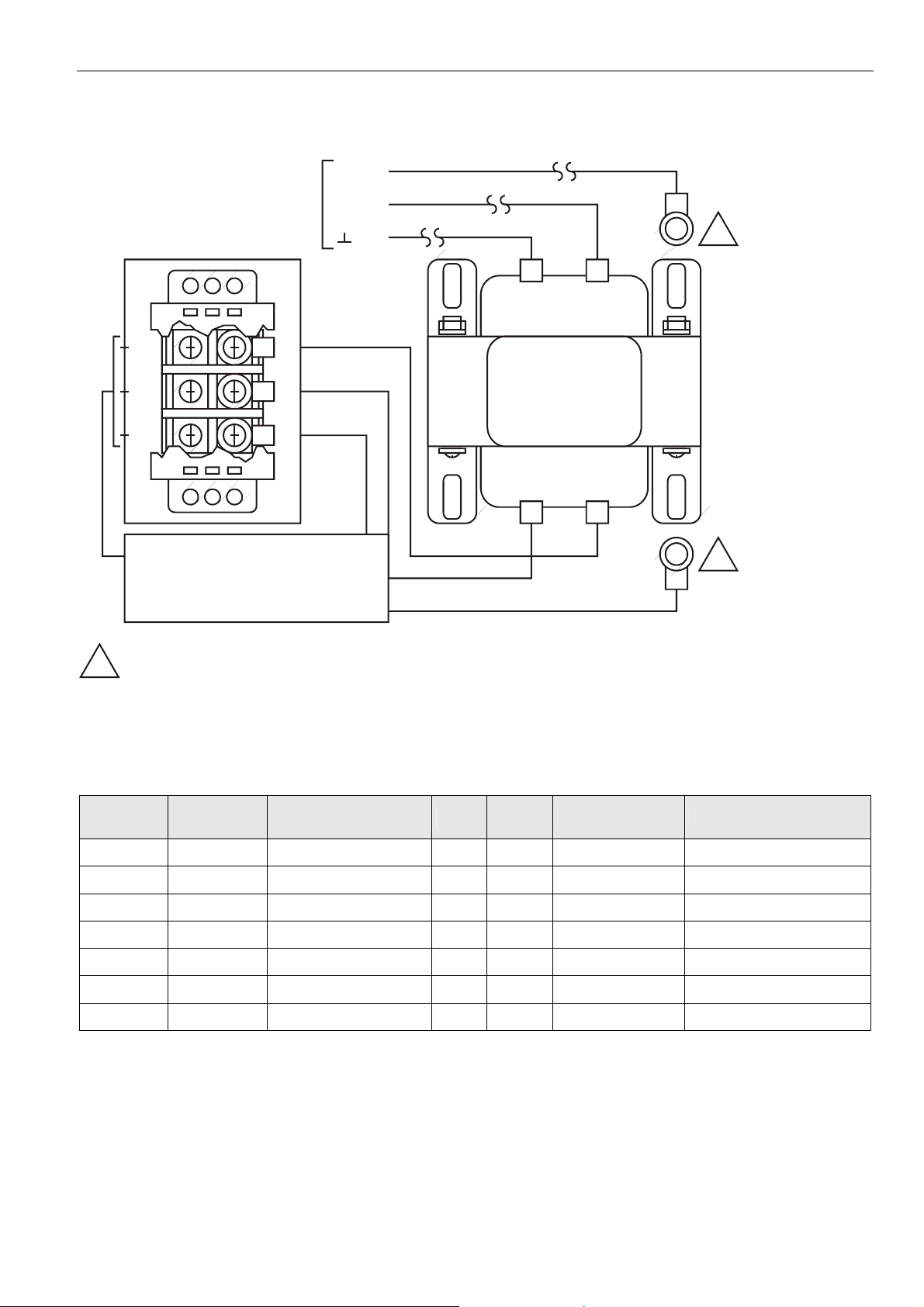

Relay Output Modules

Types of Relay Output Modules

Table 33. Excel 800 Relay Output Modules

type description housing

XF824 Panel Bus Relay Output Module light-gray

XFR824

Panel Bus Relay Output Module

with manual overrides

L

XFL824

ONWORKS Bus Relay Output

Module

L

XFLR824

ONWORKS Bus Relay Output

Module with manual overrides

XS824-25

terminal socket; can be fitted

with long (red) cross connector

(incl. in scope of the delivery)

Features

• 6 relays (changeover contacts), arranged in two blocks

• XFLR824AU, XFR824AU: 6 manual overrides

• Low and line voltage allowed, see WARNING.

light-gray

dark-gray

dark-gray

light-gray

Terminals

COM

71 75

A

COM

72 76

B

24

73 77

V~

24

74

V~ 0

NO

NC

COM

CON

Relay block 1

11

12

13

14

NO

NC

COM

CON

NO

21

22

23

24

31 41 51 61

NC

32

COM

33 43 53 63

CON

34 44 54 64

Cross connector (can be removed, as desired)

NO

NC

COM

CON

42

Relay block 2

NO

NC

52 62

COM

CON

Fig. 45. Terminal assignment and internal connections of

Relay Output Modules

NO

NC

COM

CON

COM

A

COM

B

24

V~

24

V~0

78

25

Fig. 44. XF824AU Relay Output Module with terminal

socket

Legend

1 Service button S1

2 Hex switch S2

3 Manual overrides

4 Status LEDs

5 Service LED

6 Power LED

Functionality of service LED and power LED: see Table 42

and following.

EN1B-0410GE51 R0908A

28

Page 29

Excel 800 Description of the I/O Modules

Table 34. Description of Relay Output Module terminals

terminal signal comment

2-wire communication bus

(LON/Panel Bus)

2-wire communication bus

(LON/Panel Bus)

Power supply

Power supply

Relay 1 N.O. contact

Relay 1 N.C. contact

relay 1 common contact

For connection of relay 1 common via

cross connector*

Relay 2 N.O. contact

Relay 2 N.C. contact

Relay 2 common contact

For connection of relay 2 common via

cross connector*

Relay 3 N.O. contact

Relay 3 N.C. contact

Relay 3 common contact

For connection of relay 3 common via

cross connector*

Relay 4 N.O. contact

Relay 4 N.C. contact

Relay 4 common contact

For connection of relay 4 common via

cross connector*

Relay 5 N.O. contact

Relay 5 N.C. contact

Relay 5 common contact

For connection of relay 5 common via

cross connector*

Relay 6 N.O. contact

Relay 6 N.C. contact

Relay 6 common contact

For connection of relay 6 common via

cross connector*

Shield connection (functional earth),

internally connected to the DIN rail

11

12

13

14

21

22

23

24

31

32

33

34

41

42

43

44

51

52

53

54

61

62

63

64

COM a

COM b

24 V~

24 V~0

REL1 N.O.

REL1 N.C.

R1 COM

R1 COM

REL2 N.O.

REL2 N.C.

R2 COM

R2 COM

REL3 N.O.

REL3 N.C.

R3 COM

R3 COM

REL4 N.O.

REL4 N.C.

R4 COM

R4 COM

REL5 N.O.

REL5 N.C.

R5 COM

R5 COM

REL6 N.O.

REL6 N.C.

R6 COM

R6 COM

71, 75

72, 76

73, 77

74, 78

RELAY BLOCK 1

RELAY BLOCK 2

25

* Do not connect by wire!

Permissible Loads

Table 35. Permissible loads of Relay Output Modules

max. load

per relay output

module (total)

(common)

24 VAC, 60 Hz

12 A

24 VDC

12 A resistive, 12 A, 0.6 PF

per normally open

contact (common)

24 VAC, 60 Hz

4 A

24 VDC

4 A resistive, 4 A, 0.6 PF

per normally

closed contact

(common)

24 VAC, 2 A, 60 Hz

24 VDC

4 A resistive, 4 A, 0.6 PF

Status LEDs with Manual Overrides

5

12

4

3

6

Fig. 46. Manual overrides (toggle switches)

The XFR824AU and XFLR824AU Relay Output Modules are

equipped with six manual overrides: one for each relay

output. These toggle switches can manually be set to either

"auto" or "0" or "1".

Table 36. Relay Output Module status LED behavior

mode LED

automatic mode, state

ON ON OFF

N.O.*

(direct)

“logical ON”

automatic mode, state

OFF OFF ON

“logical OFF”

override mode (setting “0”) flashes OFF ON

override mode (setting “1”) flashes ON OFF

*As configured during engineering.

Honeywell

--1

--0

--AUTO

!

N.C.*

(reverse)

29 EN1B-0410GE51 R0908A

Page 30

Description of the I/O Modules Excel 800

Connection Examples

14507287 SERIES

POWER MODULE

COM

71 71

A

COM

72 72

B

24

73 7377

V

~

24

74 74

V

~

0

NO

NC

COM

CON

12

13

14

11

NO

NC

COM

CON

22

23

24

21

NO

NC

COM

CON

31

32

33

34

NO

NC

COM

CON

41

42

43

44

NO

NC

COM

CON

51

52

53

54

NO

NC

COM

CON

COM

COM

24

V

24

V

61

62

63

64

75

A

76

B

~

78

~

0

25

1 2

Fig. 47. XF824AU connection example

COM

A

COM

B

24

V

~

24

V

~

0

M

14507287 SERIES

POWER MODULE

COM

71 71

A

COM

72 72

B

24

73 7377

V

~

24

74 74

V

~

0

NO

NC

COM

CON

12

13

14

11

NO

NC

COM

CON

22

23

24

21

NO

NC

COM

CON

31

32

33

34

NO

NC

COM

CON

41

42

43

44

NO

NC

COM

CON

51

52

53

54

NO

NC

COM

CON

COM

COM

24

V

24

V

61

62

63

64

75

A

76

B

~

78

~

0

25

123

M

Fig. 48. XFR825AU connection example

COM

A

COM

B

24

V

24

V

~

~

0

EN1B-0410GE51 R0908A

30

Page 31

Excel 800 Troubleshooting

Troubleshooting

Testing Wiring Connections

The push-in terminals feature small holes (1 mm in diameter)

which can be used to measure the signals.

► Insert a probe (1) as shown on the right.

Fig. 49. Testing wiring connections

Troubleshooting on the XCL8010AU Controller

The following LEDs of the XCL8010AU Controller can be used for troubleshooting purposes:

• Power LED (green)

• Alarm LED (red)

• L

ONWORKS service LED

• C-Bus Tx and Rx LEDs

• HMI Tx and Rx LEDs

Power LED (green)

Table 37. XCL8010AU power LED

case power LED meaning remedy

1 ON

2 Flashing

3 Goes out briefly

Normal operation No action necessary

One or more of the internal voltage supplies

are outside of the permissible ranges. The

controller stops operation.

• The operator has activated the reset button

• The controller is performing a warm start

► Check power

► Check wiring

► If problem persists, replace hardware

No action necessary

31 EN1B-0410GE51 R0908A

Page 32

Excel 800

Alarm LED (red)

Table 38. XCL8010AU alarm LED

case alarm LED meaning remedy

1 OFF

2 ON

Normal operation No action necessary

Watchdog alarm output is powered

– The controller has encountered a

hardware problem

- or -

– The application has a fault

- or -

– The controller has been powered up

without an application or the operator

has manually stopped the application,

e.g., using XL-Online.

In this case, the LED will light up

13 minutes after power-up without

application

3 Flashing Although the controller has encountered a

problem, the watchdog alarm output has not

yet been powered.

If problem persists, the LED will become lit

constantly, see case #2.

The controller performs a warm start.

LONWORKS Service LED

► Try powering down and then

powering up the XCL8010AU.

► If problem persists, check and – if

necessary – reload the application.

► If problem still persists, replace

hardware

If it happens only once, the controller

has performed a restart

If, however, it happens multiple times,

then there is an application or hardware

problem (see case #2)

Fig. 50. Flashing pattern of the L

ONWORKS service LED

ONWORKS service LED of the XCL8010AU Controller Module displays the following flashing patterns indicating possible

The L

failure modes:

EN1B-0410GE51 R0908A

32

Page 33

Excel 800 Troubleshooting

Table 39. XCL8010AU L

ONWORKS service LED

case When can it occur? meaning remedy

1

2

3

4

Anytime

Power up of controller

Power up of controller

Power up / reset

Node is configured and running normally

Bad node hardware

Bad node hardware

Node lacks application.

May be caused by neuron chip firmware when

a mismatch occurs on application checksum

No action necessary

► Replace hardware

► Replace hardware

► Using EXCELON, set module to

“configured online”

► If problem persists, the MIP software

on LW interface has been erased due

to wrong setting performed using

ECHELON tool:

Replace hardware

5

Anytime

Watchdog timer resets occurring.

► Download firmware

Possible corrupt EEPROM and bootstrap

mode

6

Anytime

Node is unconfigured but has an application

► Proceed with commissioning

C-Bus Tx and Rx LEDs

Table 40. XCL8010AU C-Bus Tx and Rx LEDs

case C-Bus LEDs meaning remedy

1

Both LEDs are flashing

2

Both LEDs are OFF

3 Both LEDs are flashing

synchronously

If the C-bus is functioning properly, then the

XCL8010AU is functioning properly

If the C-bus is not functioning properly, then

the termination can be wrong

No C-bus communication

No C-bus communication

No action necessary

► Check C-bus termination switch S1

(location: see Fig. 4 on page 7)

► Check C-bus settings

► Check C-bus wiring

HMI Tx and Rx LEDs

Table 41. XCL8010AU HMI Tx and Rx LEDs

case HMI LEDs meaning remedy

1

2

Both LEDs are flashing

Both LEDs are OFF

33 EN1B-0410GE51 R0908A

If the HMI Interface is functioning properly,

then the XCL8010AU is functioning properly

No HMI Interface communication

No action necessary

► Check HMI Interface connection and

proper earthing of connected

hardware

Page 34

Excel 800

I/O Modules Troubleshooting

► Check if the power supply voltage level is OK and that there is no high voltage (> 24 VAC or > 40 VDC) connected to the

inputs/outputs of the XF821AU, XFL821AU, XF822AU, XFL822AU, XFR822AU, XFLR822AU, XF823AU, and XFL823AU I/O

modules.

► Replace the problem I/O module with another module of the same kind.

– If the problem persists, this is an indication that the problem is caused by the application or incorrect wiring.

– If the problem is solved, this is an indication that the I/O module was defective.

For troubleshooting purposes on all I/O modules the following features can be used:

• Power LED

• Service LED

• Service button

In addition, a module-specific troubleshooting may be necessary.

Power LED of I/O Modules

Table 42. Power LED of I/O modules

case power LED meaning remedy

1 ON

2 OFF

3 Flashing continuously

I/O module is powered

No power

If the I/O module’s service LED is likewise

flashing, the I/O module is in the boot mode

No action necessary

► Check power supply

► Wait until rebooting (firmware

download) has been completed

EN1B-0410GE51 R0908A

34

Page 35

Excel 800 Troubleshooting

Service LED of I/O Modules

Table 43. Service LED of I/O modules

case Service LED meaning remedy

1

2

3

4

5

6

7

8

9

10

LED remains OFF after

power-up

LED is lit continuously after

first power-up

Alternating flash between

service LED and power LED

LED flashes at power up,

goes OFF, and then is lit

continuously

LED repeatedly blinks

ON for 1 sec and

OFF for 1 sec

LED remains OFF after a

short ON duration

LED flashes continuously in

following pattern:

4 x ON/OFF followed by

pause

LED flashes continuously in

following pattern:

5 x ON/OFF followed by

pause

LED flashes continuously in

following pattern:

6 x ON/OFF followed by

pause

LED flashes continuously in

following pattern:

7 x ON/OFF followed by

pause

If the power LED is also OFF, then

– Defective device hardware

– Possible power supply problems, clock

problems, defective processor

ONWORKS Bus I/O modules:

• L

– Defective hardware

• Panel Bus I/O modules:

– I/O module has not yet been configured

by XCL8010AU

– Boot loader is active

– Failure during last firmware download

– Checksum error