Page 1

Excel Web

XL1000B/C

HONEYWELL EXCEL 5000 OPEN SYSTEM

INSTALLATION INSTRUCTIONS

TABLE OF CONTENTS

Overview of Hardware.................................................................................................................................................................. 2

Terminal Blocks ....................................................................................................................................................... 3

LonWorks Interface.................................................................................................................................................. 3

Ethernet Interface .................................................................................................................................................... 3

RS232C Serial Interface Ports ................................................................................................................................. 4

CF Port LED, Request Button, and Slot................................................................................................................... 4

USB Interface Downloads ........................................................................................................................................ 4

LEDs and Buttons .................................................................................................................................................... 5

Power Supply LED................................................................................................................................................... 5

Binary Input (terminals 3+4) LED............................................................................................................................. 5

Binary Output (terminals 7+8) LED .......................................................................................................................... 5

Binary Output (terminals 9+10) LED ........................................................................................................................ 5

Ethernet LEDs.......................................................................................................................................................... 5

LEDs L1 and L2 ....................................................................................................................................................... 5

Reset Button ............................................................................................................................................................ 6

Mounting ....................................................................................................................................................................................... 6

Before Installation .................................................................................................................................................... 6

Dimensions .............................................................................................................................................................. 6

Power Supply................................................................................................................................................................................ 7

Wiring....................................................................................................................................................................... 7

Transformer Data..................................................................................................................................................... 7

Lightning Protection ................................................................................................................................................. 7

RIN-APU24 .............................................................................................................................................................. 7

LonWorks Communications........................................................................................................................................................ 8

General Information ................................................................................................................................................. 8

Connecting to the LONWORKS Network .................................................................................................................... 8

Binary Input and Outputs ............................................................................................................................................................ 8

Wiring....................................................................................................................................................................... 8

Binary Input.............................................................................................................................................................. 8

Binary Outputs ......................................................................................................................................................... 9

Engineering, Commissioning...................................................................................................................................................... 9

Required Preparations ............................................................................................................................................. 9

Engineering, Downloading, and Commissioning Procedure..................................................................................... 9

Protocolling ............................................................................................................................................................ 10

Updating Firmware................................................................................................................................................. 10

® U.S. Registered Trademark

Copyright © 2009 Honeywell Inc. EN1B-0256GE51 R0609

All Rights Reserved

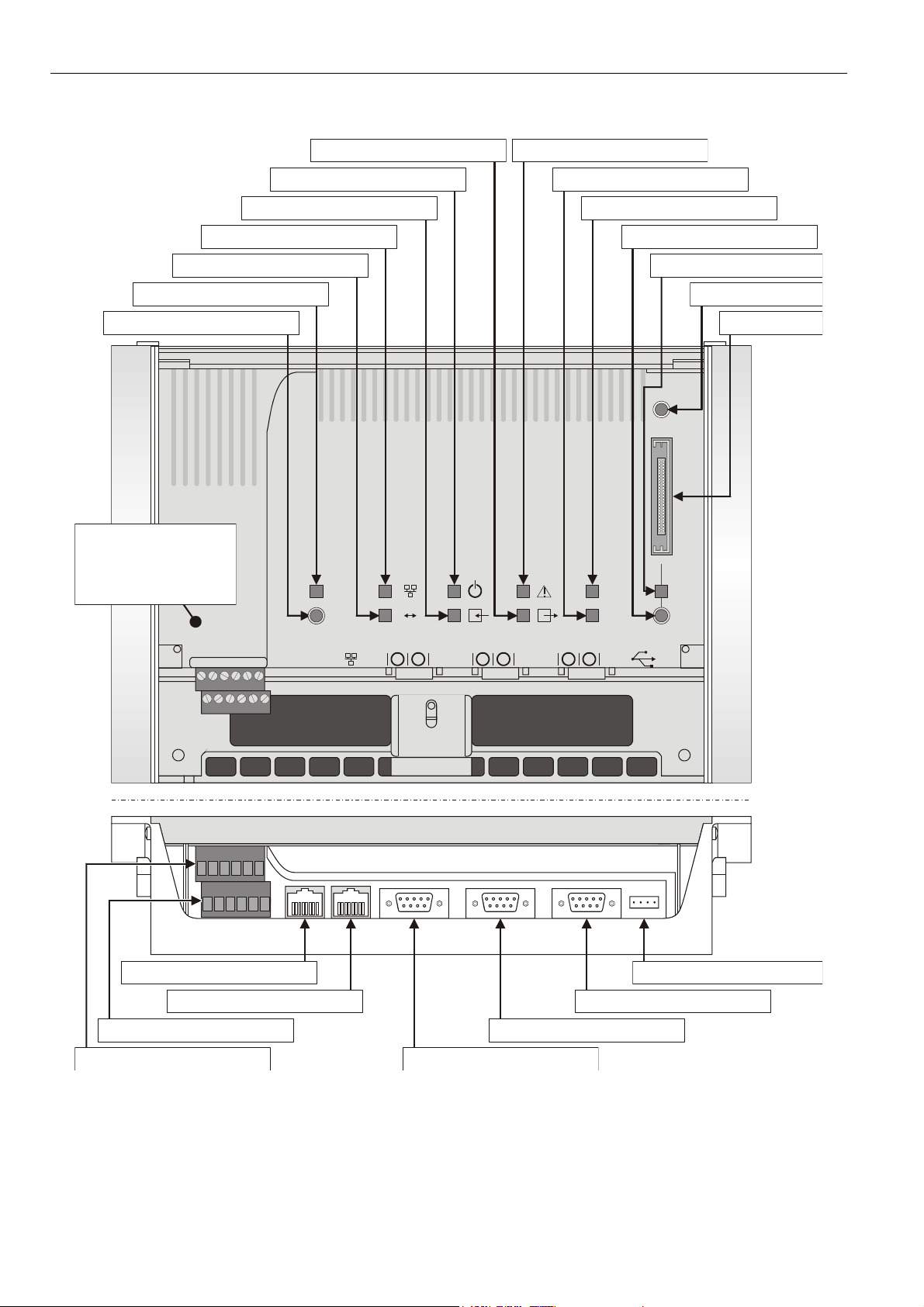

Page 2

EXCEL WEB CONTROLLER – INSTALLATION INSTRUCTIONS

OVERVIEW OF HARDWARE

binary output (terminals 9+10) LED (yellow)

(LED = application has closed contact)ON

power supply LED (green)

(LED = power supplied)ON

binary input (terminals 3+4) LED (yellow)

(LED = input closed)ON

Ethernet link LED (yellow)

(LED = Ethernet link is enabled)ON

Ethernet activity LED (yellow)

(LED = Ethernet active)ON

LonWorks service LED (yellow)

(for meaning of LED behavior, see Table 1)

LonWorks service button

(pushing broadcasts service pin message)

binary output (terminals 7+8) LED (red)

(LED = watchdog has closed contact)ON

LED2 (currently unused)

LED1 (currently unused)

Compact Flash Card (CFC) release button

(push before removing CFC)

(LED = CFC may be removed)OFF

CFC LED (red)

reset button

CFC slot

ATT ENT ION:

Never unscrew and

dismount the inner

metallized cover while

the XL Web is powered!

Danger of short-circuiting!

LonWorks interface (8-position,

unshielded RJ45 connector jack)

lower terminal block (removable)

(terminals 1 thru 6)

upper terminal block (removable)

(terminals 7 thru 12)

LON

LON

71829

10 1112

5

3

6

4

Ethernet interface (8-position,

shielded RJ45 connector jack, CAT5)

Fig. 1. Hardware features (top and front view)

21

RS232C serial interface, port 2

(standard male 9-position sub-D)

RS232C serial interface, port 1

(standard male 9-position sub-D)

L1

CF

L2

3

USB interface

RS232C serial interface, port 3

(standard male 9-position sub-D)

EN1B-0256GE51 R0609

2

Page 3

EXCEL WEB CONTROLLER – INSTALLATION INSTRUCTIONS

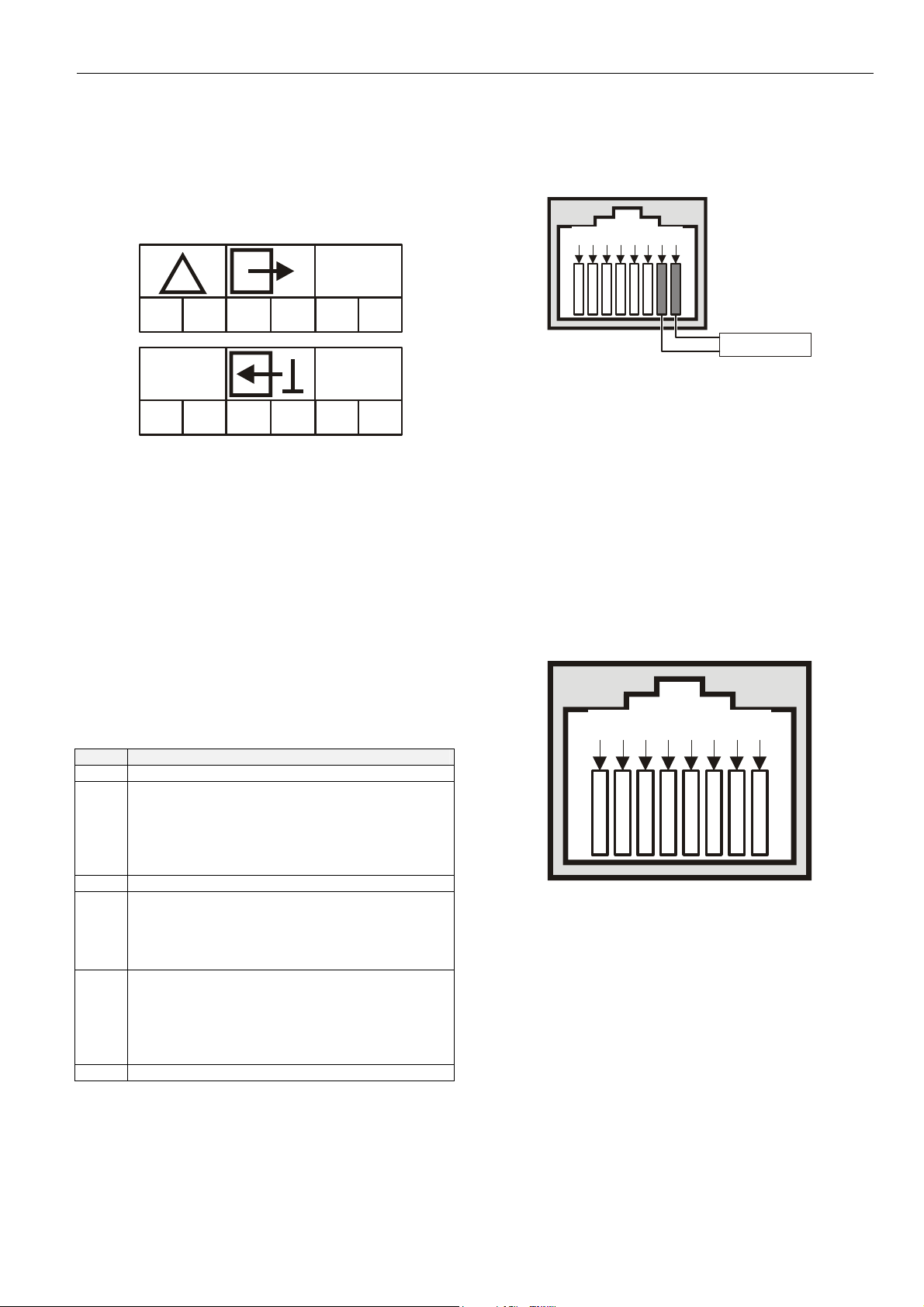

Terminal Blocks

The Excel Web features two rows of removable terminal

blocks (located at the front left-hand side; see Fig. 1 on page

2) for the connection of cables to the two binary outputs and

the binary input as well as for connecting L

power supply. A nearby sticker provides an overview of the

terminal assignment (see Fig. 2).

!

7

8

9310

24V

~ 0

1

2

4

ONWORKS and the

LON

12

11

LON

5

6

24Vac/dc, +/-20%,

10VA, 50/60Hz, IP 20

D-71101 Schoenaich

Made in Germany

CE

Fig. 2. Terminal assignment sticker

Maximum torque for fastening the wiring terminal screws is

0.5 Nm (4.5 lb-in).

Table 1 provides a more-detailed explanation of the terminals

and their functions.

Table 1. Overview of terminals and functions

term. function

1+2 power supply (24 Vac ± 20%, 19.2 to 38 Vdc)

a binary input (normally-open, 36 Vdc; pin 4 is the

signal ground), freely configurable (using CARE 7)

3+4

5+6 LONWORKS

7+8

9+10

11+12 LONWORKS

to read input from either 1) a field device or 2) a

collective alarm input or 3) a 2

controller whose duties it could then assume in the

event of its failure

a binary output / "watchdog relay" (SPDT, normally

closed, 24 Vac, max. 2 A permanent load), permanently configured to write output to an alarm

device (which can then signal that Excel Web is

malfunctioning)

a binary output (potential-free contact, SPST,

normally-open, 24 Vac, max. 2 A permanent load),

freely configurable (using CARE 7) to write output

to either 1) a field device or 2) a 2

controller which could then assume the 1

Web's duties in the event of its failure

nd

Excel Web

nd

Excel Web

st

Excel

LonWorks Interface

The Excel Web is equipped with a LonWorks interface

(specifically: an RJ45 jack) permitting communication on

L

ONWORKS networks.

5

8 7 6

Fig. 3. LonWorks interface (RJ45 jack)

There are two methods of connecting the Excel Web controller to the L

method can be used):

• via terminals 5+6 and 11+12 of the terminal blocks (see

Fig. 1 on page 2); and/or

• via the corresponding jack located to the right of the

terminal blocks (see Fig. 3).

See also section "LonWorks Service LED and Service Button"

on page 5 for details on the corresponding L

LED and one L

ONWORKS networks (both or either connection

ONWORKS service button.

432 1

LonWorks

ONWORKS service

Ethernet Interface

The Excel Web controller is equipped with a 10/100-Mbaud

Ethernet interface (specifically: an RJ45 jack) permitting communication (as per IEEEC 802.3) on BACnet/IP networks.

8 7 6

Fig. 4. Ethernet interface

When thus connected, the user sitting at a platform hosting

EBI can thus e.g. view and edit the time programs, trend

values, etc. of the other devices in the BACnet/IP network.

This Ethernet jack conforms to the specifications of the

following two Ethernet sub-standards:

• 100Base-TX (twisted pair / star wiring; 100 Mbaud

Ethernet based on Manchester signal encoding over

category 5 or better twisted pair cable; max. segment

length = 100 meters) and

• 10Base-T (twisted pair / star wiring; 10 Mbaud Ethernet

based on Manchester signal encoding over category 3 or

better twisted pair cable; max. segment length =

100 meters).

5

432 1

EN1B-0256GE51 R0609

3

Page 4

EXCEL WEB CONTROLLER – INSTALLATION INSTRUCTIONS

RS232C Serial Interface Ports

The Excel Web controller is equipped with three male 9-pin

sub-D jacks into which corresponding female 9-pin sub-D

plugs can be inserted for various different purposes (see

following sub-sections). These ports allow data transmission

rates of 9.6, 19.2, 76.8, or 115.2 kBaud (the default).

Fig. 5. RS232C serial interface

Using CARE 7, the user can configure the specific desired

data transmission rate of each individual RS232C port; it is

thus possible for the three ports to operate simultaneously at

three different rates.

Port 1 (Factory Service Interface)

Port 1 is intended for the connection (as needed) of a platform for the purpose of servicing (in the factory, only) the

Excel Web controller. In this context, "servicing" comprises a

group of different activities including:

• updating portions of the Excel Web controller's Operating

System (namely: LINUX, BACstack, Apache WebServer) and

• diagnostics (Linux, firmware).

Port 2 (Browser Interface)

Port 2 is intended for the connection (as needed, or permanently) of a (portable) platform (which must host an

Internet Explorer-compatible internet browser) for the purpose

of operating the Excel Web controller.

This requires the establishment of a remote connection via

RS232 on the PC, plus a null modem cable (RS232 crossover cable). Because it offers a much higher speed, we

recommend instead using the USB interface.

Port 3 (Modem Interface)

Port 3 is intended for the permanent connection (if needed) of

a modem (e.g. an analog modem, an ISDN adapter, or an

GSM adapter) for the purpose of communicating with other

front-ends (e.g. 3

rd

-party BACnet front-ends) via modem.

CF Port LED, Request Button, and Slot

The Excel Web controller features a slot (type-II socket) into

which type-II Compact Flash Cards (CF cards) − but also

type-I CF cards − can be inserted.

Inserting a CF card allows the Excel Web controller's internal

memory (for storing trend records) to be increased.

CF cards having a variety of storage sizes are available from

wholesale and retailer dealers.

NOTE: Insert the CF card carefully and make sure that it

has the proper orientation (see Fig. 6).

narrow

notch

wide

notch

CF

Fig. 6. Inserting a CF card into the slot

NOTE: Before removing a CF card, always first push the CF

request button and wait (usually just a few seconds)

until the CF LED turns OFF. Violating this rule could

interrupt the transfer of data onto the card.

NOTE: Upon inserting a CF into a running Excel Web, the

CF will be reformatted, if necessary. Specifically: If

the CF already has the format EXT3, it will not be

formatted; otherwise, it will be formatted, and any

data already present on it will be irretrievably lost.

USB Interface Downloads

The Excel Web controller is equipped with a USB port into

which a standard USB type-A connector can be inserted. This

USB interface is the recommended interface for downloading

applications and firmware via CARE 7 and for operating the

Excel Web controller via Internet Browser in parallel to an

Ethernet connection. The following USB host networking

adapter has been approved: BELKIN DIRECT CONNECT

(BELKIN order no.: F5U104 or F5U104G at www.belkin.com

).

12.5 mm

Fig. 7. USB interface

EN1B-0256GE51 R0609

4

Page 5

EXCEL WEB CONTROLLER – INSTALLATION INSTRUCTIONS

Alternatively, either of the following three adapters can also

be used: SMC 2208USB/ETH; SMC 2209USB/ETH; or D-Link

DUB-E100.

See section "Option 1: USB (recommended)" on page 9.

LEDs and Buttons

LonWorks Service LED and Service Button

The Excel Web controller is equipped with a LONWORKS

service LED and a L

marked "LON" (see also Fig. 1 on page 2). They are used for

commissioning the Excel Web controller and for

troubleshooting.

LonWorks Service Button

When the L

ONWORKS service button is pressed, the service

pin message is broadcast on the L

L

ONWORKS tools currently connected to the LONWORKS

network will receive this message.

LonWorks Service LED

The L

ONWORKS service LED can display various behaviors

having different meanings (see Table 2).

ONWORKS service button, together

ONWORKS network, and all

Power Supply LED

The LED marked " " indicates whether or not the Excel

Web controller is currently under power. Specifically, when it

is lit, the controller is under power; when it is dark, the

controller is not under power.

Binary Input (terminals 3+4) LED

The LED marked " " indicates the state of the binary input

(which is a normally-open contact) located at terminals 3 and

4. Specifically, when it is lit, the binary input is closed; when it

is dark, the binary input is open.

Binary Output (terminals 7+8) LED

The LED marked " " indicates the state of the binary output

("watchdog" relay) at terminals 7 and 8 (which is a normally

closed contact). Specifically, when it is lit, the alarm contact is

open; when it is dark, the alarm contact is closed.

For a detailed description of the "watchdog" relay behavior,

see Excel Web User Guide (EN2B-0289GE51).

Binary Output (terminals 9+10) LED

The LED marked " " indicates the state of the binary

output at terminals 9 and 10 (which is a normally-open

contact). Specifically, when it is lit, this means that the

application has closed the relay; when it is dark, the relay is

open.

Table 2. L

1

2

3

4

5

6a

6b

6c

7

8

ONWORKS service LED behaviors / meanings

LED behavior meaning

LED remains OFF after

power-up.

LED is lit continuously after

first power-up.

LED flashes at power-up,

goes OFF, and then is lit continuously.

LED flashes briefly

periodically.

LED repeatedly blinks ON for

1 s and OFF for 1 s.

OFF for approx. 10 s. Afterwards, the service LED turns

ON and remains ON,

indicating completion of the

blanking process.

OFF for approx. 1 s.

Afterwards, the service LED

is lit continuously.

OFF for 1...15 s, depending

on application size and system clock. Afterwards, service LED repeatedly flashes

ON for 1 s and OFF for 1 s.

LED remains OFF after a

short ON duration.

LED flashes ON.

Defective Excel Web hardware

(e.g. power supply problems,

clock problems, or defective

Neuron Chip).

Defective Excel Web hardware.

Neuron chip lacks L

interface program. Remedy: Use

Excelon or LonMaker, set Excel

Web online.

Excel Web probably experiencing

continuous watchdog resets, or

external memory or EEPROM is

corrupt.

Excel Web is unconfigured but

has an application. Remedy:

Commission Excel Web using

CARE 7.

Return Excel Web to factory.

Return Excel Web to factory.

Excel Web is unconfigured but

has an application. Remedy:

Commission Excel Web using

CARE 7.

Excel Web is configured and

running normally.

Excel Web received a WINK

command from L

physical outputs are unaffected.

ONWORKS

ONWORKS; other

In case of a problem, check if the L

ONWORKS service LED's

behavior is changed by resetting the Excel Web controller

using the reset button. Please contact Honeywell if this does

not solve the problem.

Ethernet LEDs

The Excel Web controller is equipped with two Ethernet LEDs

(see also Fig. 1 on page 2).

Ethernet Link LED

The LED marked " " indicates the Ethernet link's status.

Specifically, it is lit whenever an Ethernet jack has been

inserted into the corresponding port and the software has

established the Ethernet link. It is dark when the link has been

disabled.

Ethernet Activity LED

The LED marked " ↔ " indicates whether or not the Ethernet

link is currently active. Specifically, when it flashes, this

means that signals are being transmitted / received on the

Ethernet network; when it is dark, no messages are being

transmitted/received.

LEDs L1 and L2

At present, these LED's are not in use.

EN1B-0256GE51 R0609

5

Page 6

EXCEL WEB CONTROLLER – INSTALLATION INSTRUCTIONS

141.5 +

.

3

36.

5

Reset Button

The reset button can be pressed only using a long, thin tool

(e.g. a screwdriver). Pressing it reboots the Excel Web

controller's operating system and restarts the application.

MOUNTING

Before Installation

IMPORTANT

To allow the evaporation of any condensation resulting

from low shipping / storage temperatures, keep the

controller at room temperature for at least 24 h before

applying power.

US requirement, only: This device must be installed in

a UL-listed enclosure offering adequate space to

maintain the segregation of line voltage field wiring

and Class 2 field wiring.

In order to meet the criteria for CE certification, the XL1000

controller must be mounted inside an electrical panel.

Dimensions

Allow 30 mm clearance

for opening swivel cover.

LON

LON

Allow 30 mm

clearance for

accessing interfaces.

CF

321

278

4.4 +/- 0.3

190

0.6

60.6

DIN Rail Mounting/Dismounting

17 mm

(center-to-center distance = 100 +3 mm)

Fig. 9. Housing base (view from below)

The Excel Web controller can be mounted onto DIN rails as

follows (refer also to Fig. 10):

1. Hang the upper slot onto the upper DIN rail.

2. Swing the unit down until it is flush with the lower DIN rail.

3. Slide the fastening plate and corresponding screw in the

oval hole up against and behind the bottom edge of the

lower DIN rail and screw it firmly into place.

4. If necessary, the swivel cover can be locked by inserting

a small string lock, lead seal, or screw into either one of

the two openings provided.

The unit is dismounted by loosening the fastening plate and

lifting the unit out of place.

slots for DIN rails

fastening

plate

/- 0

12

220 +/- 0.3

5 +/- 0.3

Fig. 8. Dimensions (in mm)

The Excel Web has the following dimensions (W x L x H):

278 x 190 x 61 mm. Its housing conforms to IP20. Its pollution

degree (2) makes it suitable for use in residential controls,

commercial controls, in a clean environment, or non-safety

controls for installation on or in appliances.

The Excel Web is suitable for mounting on a standard rail

(DIN EN 50022-35 x 7,5), on walls or in panels, as well as for

installation in appropriately-sized wiring cabinets or fuse

boxes. Allow sufficient clearance (approx. 30 mm) to access

the interfaces and to open the swivel cover (see Fig. 8).

step

1

100 mm

fastening

plate

step

step

2

3

step

4

Fig. 10. Mounting the Excel Web on to two DIN rails

Wall/Panel Mounting/Dismounting

The Excel Web controller can be mounted on walls or in

panels in any desired orientation. However, mounting the

Excel Web controller upside down on ceilings should be

avoided, insofar as the swivel cover would then swing open.

EN1B-0256GE51 R0609

6

Page 7

EXCEL WEB CONTROLLER – INSTALLATION INSTRUCTIONS

4.4 +/- 0.3

36.5

190

141.5 +/- 0.3

12

29 29

Fig. 11. Drilling template (view from above)

220 +/- 0.3

278

Swivel Cover Lock

The swivel cover can be locked by inserting a small string

lock, lead seal, or screw into either one of the two openings

provided (see Fig. 10).

POWER SUPPLY

Wiring

NOTE: All wiring must comply with applicable electrical

standards and ordinances. Refer to job or manufacturers’ drawings for details. Local wiring guidelines (e.g. VDE 0100) may take precedence over

recommendations provided in these installation

instructions.

• Power supply: 24 Vac [±20%], 50 or 60 Hz, or

24...38 Vdc, galvanically isolated;

• Power consumption = max. 10 VA (USB unloaded);

• Excel Web® and 24 Vac field devices can obtain their

power from the same transformer;

• Several Excel Web controllers can share a single

common transformer. In this case, you must ensure that

terminal 1 of each of the Excel Web controllers is

connected to 24 V and terminal 2 is connected to the

minus pole (optionally, terminal 2 can additionally be

connected to the earth) (see also Fig. 12).

• The power supply LED (see section "Power Supply LED"

on page 5) indicates whether power is being supplied.

• In the event you wish to connect one of the 24 Vac pins

to the earth ground, connect it via terminal 2 of the lower

removable terminal plug (see also Fig. 12).

Table 3. Cable sizing (use only copper cables)

cross-sectional area

type of signal

24 Vac power

supply

low-voltage*

*0...10 V sensors, totalizers, binary inputs, 0...10 V signals

for actuators, etc.

≤ 300 ft

(100 m)

16 AWG

(1.5 mm

14 – 18 AWG (2.5 – 0.75 mm2)

2

)

≤ 550 ft

(170 m)

14 AWG

(2.5 mm2)

≤ 1300 ft

(400 m)

-

Power is supplied via terminals 1 and 2 of the lower removable terminal plug. The removable terminal plug permits

individual Excel Web controllers to be disconnected from the

power supply without disturbing the operation of other devices

powered by the same source.

NOTE: Do not reverse the polarity of the power connection

cables, and avoid ground loops (i.e. avoid

connecting one field device to several controllers) as

this may result in short-circuiting.

5 +/- 0.3

Transformer Data

Table 4. 1450 series transformers data

part #

1450 7287

-001 120 Vac 24 Vac, 50 VA

-002 120 Vac

-003 120 Vac

-004 240/220 Vac 24 Vac, 50 VA

-005 240/220 Vac

-006 240/220 Vac

Table 5. Overview of CRT Series AC/DC current

transformer max. AC current max. DC current

CRT 2 2 A 0.5 A = 500 mA

CRT 6 6 A 1.3 A = 1300 mA

CRT 12 12 A 2.5 A = 2500 mA

primary side secondary side

2 x 24 Vac, 40 VA, and

100 VA from separate

transformer

24 Vac, 100 VA, and 24 Vdc,

600 mA

2 x 24 Vac, 40 VA, and

100 VA from separate

transformer

24 Vac, 100 VA, and 24 Vdc,

600 mA

primary

voltage

24 V~

1

24 Vac

(-)

transformer

2

optional

Fig. 12. Connection of Excel Web

Lightning Protection

Please contact your local Honeywell representative for

information on lightning protection.

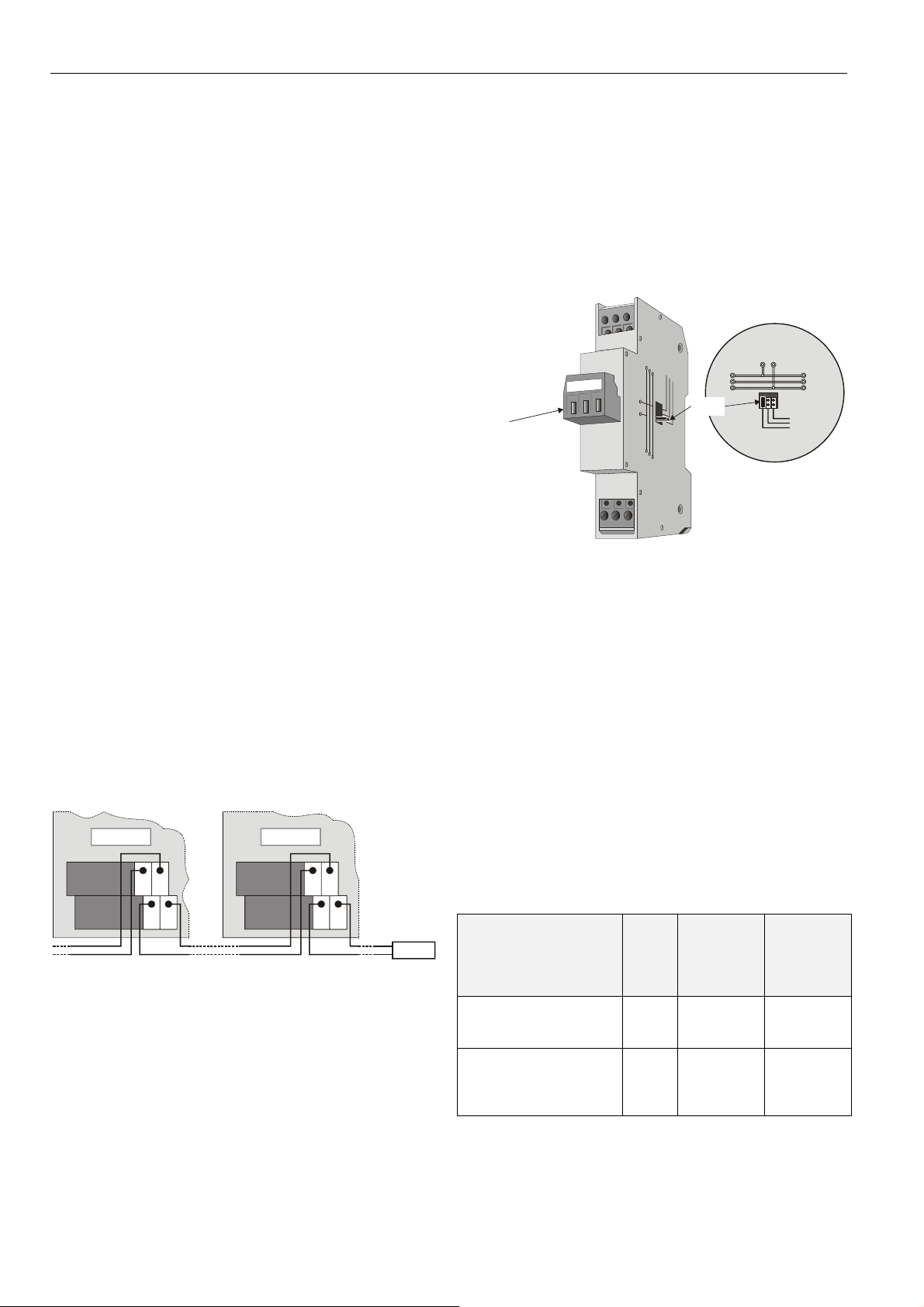

RIN-APU24

The RIN-APU24 Uninterruptable Power Supply can be

directly wired to an Excel Web.

See RIN-APU24 Uninterruptable Power Supply – Mounting

Instructions (EN0B-0382GE51) for a detailed wiring diagram.

EN1B-0256GE51 R0609

7

Page 8

EXCEL WEB CONTROLLER – INSTALLATION INSTRUCTIONS

LONWORKS COMMUNICATIONS

General Information

The Excel Web controller is equipped with a free-topology

transceiver (FTT10A or FT-X1) for communication (at a data

transmission rate of 78 Kbaud) on L

(using the LonTalk protocol).

The L

ONWORKS network is insensitive to polarity, eliminating

the possibility of installation errors due to miswiring.

Different network configurations (daisy-chain, loop, and star

configurations, or any combination thereof) are possible (see

also Excel 50/500 L

ONWORKS Mechanisms Interface

Description, EN0B-0270GE51).

Connecting to the LONWORKS Network

IMPORTANT

Do not bundle wires carrying field device signals or

L

ONWORKS communications together with high-voltage

power supply or relay cables. Specifically, maintain a

min. separation of 3 inches (76 mm) between such

cables. Local wiring codes may take precedence over

this recommendation.

IMPORTANT

Try to avoid installing in areas of high electromagnetic

noise (EMI).

Cable Types

The unit must be wired to the L

• level IV 22 AWG (Belden part number 9D220150)

or

• plenum-rated level IV 22 AWG (Belden part number

9H2201504) non-shielded, twisted-pair, solid-conductor

wire.

When possible, use Honeywell AK3781, AK3782, AK3791, or

AK3792 cable (US part numbers). See Excel 50/5000

L

ONWORKS Mechanisms, EN0B-0270GE51, for details,

including maximum lengths.

Use wire with a minimum size of 20 AWG (0.5 mm

maximum size of 14 AWG (2.5 mm

XL Web XL Web

12 12

11 11

55

66

Fig. 13. Connection to L

termination module (here: daisy-chain network

configuration)

The Excel Web controller can be connected to the L

network via terminals 5+6 and 11+12 of the removable

terminal plug or via the L

"LonWorks Interface" on page 3).

ONWORKS jack (see also section

ONWORKS® networks

ONWORKS network using either

2

2

).

ONWORKS network and

) and a

termination

module

ONWORKS

This permits individual Excel Web controllers to be connected

/ disconnected from the L

ONWORKS network without disturbing

the operation of other devices.

Depending upon the chosen network configuration, one or two

terminations may be required.

Two different L

• L

ONWORKS termination module, order no.: 209541B

• L

ONWORKS connection / termination module

ONWORKS termination modules are available:

(mountable on DIN rails and in fuse boxes),

order no.: XAL-Term

l

l

e

w

removable screw-type

3-pole terminal block

Fig. 14. L

ONWORKS connection and termination module

y

e

n

o

H

m

r

e

T

-

L

A

X

4

3

L

L

O

O

N

N

shield shield

plug-in

jumper

34

1

06

Termination

BINARY INPUT AND OUTPUTS

Wiring

When wiring the two binary outputs and the binary input, use

a min. size of 20 AWG (0.5 mm

(2.5 mm

2

). The max. length of all cables is 400 m.

Two wires with a total thickness of 14 AWG can be twisted

together and connected using a wire nut (include a pigtail with

this wire group and attach the pigtail to the individual terminal

block). Deviations from this rule can result in improper

electrical contact. Local wiring codes may take precedence

over this recommendation.

Binary Input

The Excel Web controller's binary input (a normally-open

contact) is not galvanically isolated. It is suitable for connection with / signalling via 0...36 Vdc voltage or external

resistor or dry contact.

Table 6. Binary input specifications

purpose assigned to

binary input by user using

CARE 7

high-level detection (i.e.

detection that binary input

has opened)

low-level detection (i.e.

detection that binary input

has closed)

2

) and a maximum of 14 AWG

at

resistance at

binary con-

tact (ext.

resistor or

dry contact)

> 10 kΩ or

open input

< 400 kΩ or

when binary

input shorted

voltage

binary

input

3.8 to

36 Vdc

0 to 0.8

Vdc

voltage at

open terminals = 5 V

current from

shorted

terminals =

2 mA

5

LON

FTT/LPT Bus

FTT/LPT Free

Park Position

info

EN1B-0256GE51 R0609

8

Page 9

EXCEL WEB CONTROLLER – INSTALLATION INSTRUCTIONS

The binary input is protected against miswiring. Specifically, it

is protected against voltages of up to 29 Vac; when miswired,

the Excel Web controller is unable to detect a valid input

signal.

Binary Outputs

The Excel Web controller is equipped with two binary outputs.

Hardware Limits

• A min. current of 50 mA is required to ensure a reliable

contact.

• The binary outputs are designed for a max. continuous

current of 2 A.

• Switching voltage = 24 Vac ± 20%.

NOTE: If inductive components are to be connected to the

binary outputs and if these binary outputs switch

more often than once every two minutes, these

components must be prevented from causing

harmful interference to radio or television reception

(conformance with EN 45014).

ENGINEERING, COMMISSIONING

Please refer also to CARE 7 User Guide (Product Literature

No.: EN2B-0182GE51) for more information.

Required Preparations

In order to access (with a laptop or PC) the Excel Web via

Ethernet/IP for the first time, you may employ any one of the

following three options:

Option 1: USB (recommended)

This USB interface is the recommended interface for

downloading applications and firmware via CARE 7. The

following USB host networking adapter has been approved:

BELKIN DIRECT CONNECT (BELKIN order no.: F5U104 or

F5U104G at www.belkin.com

For access via USB, the Excel Web has a permanent default

IP address 192.168.252.20 and Network Mask

255.255.255.0. Your PC's IP address must match the Excel

Web controller's default IP address subnet: We recommend

using 192.168.252.21 and Network Mask 255.255.255.0.

Option 2: Dedicated Ethernet Interface

For access via Ethernet, the Excel Web has a permanent

default IP address 192.168.253.20 and Network Mask

255.255.255.0. Your PC's IP address must match the Excel

Web controller's default IP address subnet: We recommend

using 192.168.253.21 and Network Mask 255.255.255.0.

If the laptop or PC with which you wish to access the Excel

Web via Ethernet/IP is not already equipped with an

integrated Ethernet Card, or if you want to leave the IP

settings of the integrated network card unchanged, buy and

install (into your laptop or PC) an external Ethernet network

card, e.g. Devolo MicroLink LAN USB Network Adapter

(typical retail price: €30).

Option 3: Standard Ethernet Interface

For access via Ethernet, the Excel Web has a permanent

default IP address 192.168.253.20 and Network Mask

255.255.255.0. Your PC's IP address must match the Excel

).

Web controller's default IP address subnet: We recommend

using 192.168.253.21 and Network Mask 255.255.255.0.

Change the (factory-set) configuration of the integrated

Ethernet card so as to match the Excel Web IP address and

IP subnet.

When using this default address, you must ensure that you

have only one powered-up Excel Web controller on your

Ethernet; otherwise, communication will fail because all Excel

Web controllers have the same permanent default IP

address. Alternatively, you can use an Ethernet cross-over

cable between your PC and the Excel Web controller rather

than having your PC and the Excel Web controller both

connected to a LAN. In any case, your PC's IP address must

match the Excel Web controller's default IP address subnet.

We recommend using 192.168.253.21 and Network Mask

255.255.255.0.

NOTE: In order to (subsequently) operate on your standard

Ethernet network (again), you will have to change

the configuration back to the previous settings.

Engineering, Downloading, and

Commissioning Procedure

1. The user must first create (on a Windows-compatible

platform, using CARE 7) the application data for the Excel

Web controller. Before downloading the application, it can

be tested using the simulator (called "LIVE CARE

OFFLINE").

2. The user then downloads (from the Windows-compatible

platform) the application data (created in step 1) into the

Excel Web controller (typically via the USB interface).

After the very first set-up, the Excel Web controller gets

the final IP address which you assigned offline during the

engineering process using CARE. You can use this final

IP address for further application / firmware downloads

provided all of the Excel Web controllers are powered up.

3. Typically, testing and debugging (using the LIVE CARE

functionality of CARE 7) is then performed (in a simulated

environment, i.e. with the Excel Web controller connected

to a test board).

4. The Excel Web is then physically installed in the wall,

wiring cabinet, etc. In the course of doing this, the Excel

Web controller's terminal blocks are wired and the

corresponding RJ45 jacks are inserted into its L

interface and the Ethernet interface. If desired (i.e. if the

Excel Web controller is to later communicate by modem,

too), the corresponding jack can be inserted into the

corresponding RS232C interface (namely: Port 3).

ONWORKS

EN1B-0256GE51 R0609

9

Page 10

EXCEL WEB CONTROLLER – INSTALLATION INSTRUCTIONS

5. The user must now commission the Excel Web and the

field devices to which it is connected via L

ONWORKS (i.e.

their NV's must be bound and configured). This is performed with the same platform hosting CARE 7 as in step

3, via any L

11+12 or via the RJ45 L

ONWORKS access (e.g. terminals 5+6 and

ONWORKS jack).

6. Typically, the user again tests and debugs the Excel Web

controller – this time in its actual working environment.

Testing and debugging is again performed using the LIVE

CARE functionality of CARE 7. Optionally, testing can be

performed using an Internet browser on a laptop or PC

with 800x600 resolution or higher. The tester/debugger

can now perform audio-visual checking to see if the field

devices are responding as predicted/desired.

7. Engineering, installation, and commissioning are now

complete. The corresponding jack can now be removed

from the USB port. The Excel Web controller begins

operation.

Protocolling

In the context of the Excel Web controller, "protocolling"

means creating a log of the values or states of the data-points

which have been assigned to this particular Excel Web

controller. Using the browser interface, the user must place

the corresponding data-points into "trend." If, at some later

point in time, i.e. after lengthy operation, a protocol of the

Excel Web controller's history is desired, the corresponding

trend data can be generated, viewed, and downloaded (in

CSV format) via the browser interface. For the storage of

larger amounts of trend data (more than 64,000 trend entries

– corresponding to approx. 2 MB), a CF card (see section "CF

Port LED, Request Button, and Slot") can be used.

Updating Firmware

If, at some later point in time, i.e. after the release of a new

version of the firmware, the user wishes to download the new

firmware into the Excel Web, this can be done using CARE 7

(via either USB or Ethernet) or using EBI (via Ethernet).

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Rolle, Z.A. La Pièce 16, Switzerland by its Authorized Representative:

Automation and Control Solutions

Honeywell GmbH

Böblinger Strasse 17

71101 Schönaich, Germany

Phone: (49) 7031 63701

Fax: (49) 7031 637493

http://ecc.emea.honeywell.com

Subject to change without notice. Printed in Germany

EN1B-0256GE51 R0609

Loading...

Loading...