Page 1

HONEYWELL EXCEL 5000 OPEN SYSTEM

INSTALLATION AND COMMISSIONING INSTRUCTIONS

CONTENTS

General ............................................................................... 3

LonWorks Communications ........................................... 14

Before Installation ............................................................. 3

Installation ......................................................................... 3

Wiring ................................................................................. 4

XL1000 Series Power Consumption .............................. 5

I/O Modules ................................................................... 5

Description of the XL1000 Controller............................... 7

Overview........................................................................ 7

Terminal Blocks ............................................................. 8

LonWorks Interface........................................................ 8

Ethernet Interface .......................................................... 8

RS232C Serial Interface Ports....................................... 9

Port 1 (Factory Service Interface) ............................ 9

Port 2 (Browser Interface) ........................................ 9

Port 3 (Modem Interface) ......................................... 9

CF Port LED, Request Button, and Slot......................... 9

USB Interface Downloads.............................................. 9

LEDs and Buttons.......................................................... 9

LonWorks Service LED and Service Button ............. 9

Power Supply LED......................................................... 9

Binary Input (terminals 3+4) LED................................... 9

Binary Output (terminals 7+8) LED................................ 9

Binary Output (terminals 9+10) LED............................ 10

Ethernet LEDs ............................................................. 10

Ethernet Link LED .................................................. 10

Ethernet Activity LED ............................................. 10

LEDs L1 and L2 ........................................................... 10

Reset Button ................................................................ 10

Mounting .......................................................................... 10

Before Installation ........................................................ 10

Dimensions .................................................................. 10

DIN Rail Mounting/Dismounting ............................. 11

Wall/Panel Mounting/Dismounting ......................... 11

Swivel Cover Lock.................................................. 11

Power Supply................................................................... 12

Lightning Protection ..................................................... 14

Interfaces and Bus Connections .................................. 14

Technical Data............................................................. 14

System Data........................................................... 14

Binary Input and Outputs................................................ 15

XL1000 Configuration...................................................... 15

Mounting/Dismounting Modules .................................... 18

Description of the I/O Modules ....................................... 21

XL 1000 Series

FOR SMOKE CONTROL

Operational Environment........................................ 14

General Information ..................................................... 14

Connecting to the LONWORKS Network......................... 14

Wiring........................................................................... 15

Binary Input.................................................................. 15

Binary Outputs ............................................................. 15

Hardware Limits...................................................... 15

Protocolling ..................................................................15

Smoke Control Configuration ....................................... 16

Data File Set-Up........................................................... 16

Panel Reset.................................................................. 16

Typical Power Limited Circuit for XL1000 .................... 17

Connecting Single Bus Controller Systems.................. 17

XL1000, I/O Modules on Single Rail....................... 17

XL1000, I/O Modules on Rails in Single Cabinet.... 17

I/O Modules in Separate Rooms............................. 18

LONWORKS Bus Topologies .......................................... 18

Mounting/Dismounting Sockets.................................... 18

Mounting Sockets ................................................... 18

Connecting Sockets................................................ 19

Dismounting Terminal Sockets ............................... 19

Mounting/Dismounting Electronic Modules .................. 20

Mounting Electronic Modules.................................. 20

Dismounting Electronic Modules ............................ 20

Connecting HMIs or Laptops........................................ 20

Connecting Laptops (XW-Online/CARE) ................ 20

Common Features ....................................................... 21

Analog Input Modules .................................................. 22

Types of Analog Input Modules .............................. 22

Features .................................................................22

Terminals................................................................ 22

XFL821AU Connection Examples ..........................23

Analog Output Modules................................................ 24

Types of Analog Output Modules ...........................24

Features .................................................................24

Terminals................................................................ 24

Technical Data........................................................ 24

Copyright © 2008 Honeywell GmbH All Rights Reserved EN1B-0409GE51 R0908A

Page 2

General XL1000

Modules with Manual Overrides..............................25

XFL822AU Connection Example ............................25

Synchronization Behavior of Analog Output Module

Configured as Floating Output ................................25

Binary Input Modules....................................................26

Types of Binary Input Modules................................26

Features..................................................................26

Terminals ................................................................26

Technical Data ........................................................26

Status LEDs............................................................26

XFL823AU Connection Examples...........................27

Relay Output Modules ..................................................28

Types of Relay Output Modules..............................28

Features..................................................................28

Terminals ................................................................28

Permissible Loads...................................................29

Status LEDs with Manual Overrides .......................29

Connection Example...............................................30

Troubleshooting............................................................... 31

Testing Wiring Connections.......................................... 31

I/O Modules Troubleshooting........................................31

Power LED of I/O Modules .....................................32

Service LED of I/O Modules.................................... 32

Trademark Information

Echelon, LON, L

trademarks of Echelon Corporation registered in the United

States and other countries.

ONMARK, LONTALK, LONWORKS, Neuron, are

EN1B-0409GE51 R0908A 2

Page 3

XL1000

WARNING

This equipment generates, uses, and can radiate radio

frequency energy, and if not installed and used in accordance

with the instructions manual, may cause interference to radio

communications. It has been tested and found to comply with

the limits for a Class A computing device pursuant to Subpart

J of Part 15 of FCC Rules, which are designed to provide

reasonable protection against such interference when

operated in a commercial environment. Operation of this

equipment in a residential area is likely to cause interference,

in which case the user, at his own expense, will be required to

take whatever measures may be required to correct the

interference. Any unauthorized modification of this equipment

may result in the revocation of the owner’s authority to

continue its operation.

General

The XL1000 Series is designed to provide heating, ventilating

and air-conditioning control. They can operate either

standalone, or networked to Honeywell central workstations

such as EBI. These controllers can also be used for smoke

control system monitoring and control, for monitor and control

of fire (UL864), and general purpose signaling (UL2017). In

UL2017 applications, the product can be used as a type NM

(Non-Monitored) system. It is also approved for UL916

(Energy Management Equipment.)

The XL1000 Series can be used for smoke control

applications when used in conjunction with a UL-listed fire

alarm control panel (FACP) and UL-listed fire fighters’ smoke

control station (FSCS).

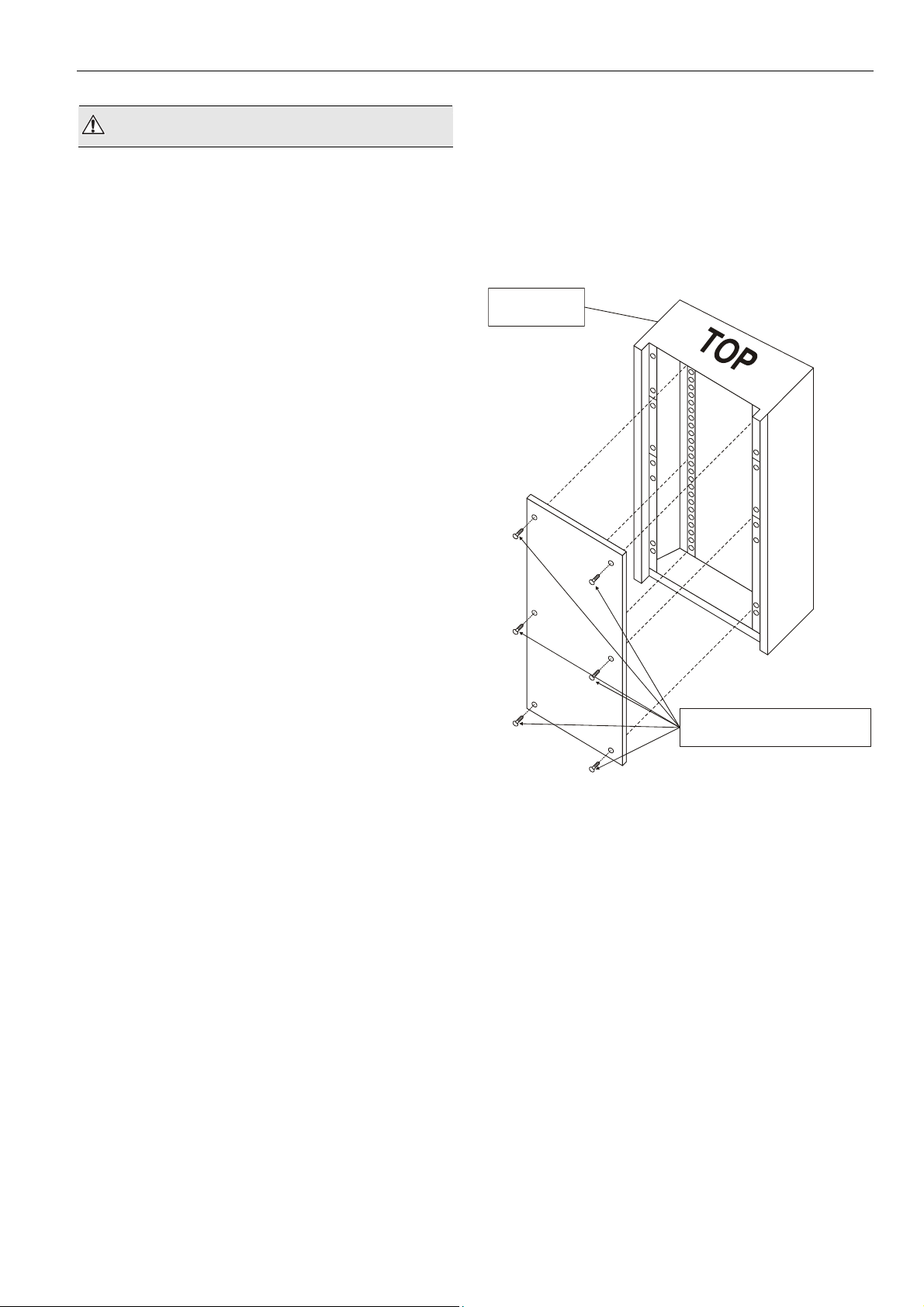

Installation

Mount controller subpanel in cabinet so all labeling is visible.

Secure full-size subpanel in place with six no. 10 x ½-inch

(13 mm) sheet metal screws (not supplied). Secure smaller

subpanel with four no. 10 x ½-inch (13 mm) sheet metal

screws (not supplied).

NOTE: Subpanel must mount flat and should not bulge or

recess anywhere.

FULL-SIZE

CABINET

Before Installation

1. Unpack door and remove the XL1000 from carton. Check

equipment and report any damage to a Honeywell

representative.

2. Verify cabinet is installed correctly.

3. Securely mount the XL1000 to a rigid structural surface

using at least four sets of 1/4 in. (6 mm) mounting

hardware (supplied locally).

NOTE: Anchoring materials must be suitable for the

mounting surface (wood, concrete, steel).

Mounting must comply with all local codes.

4. Obtain correct number and type of sheet metal screws for

subpanel. Installation of a full-size subpanel requires six

no. 10 x ½-inch (13 mm) sheet metal screws (not

supplied). Installation of a smaller subpanel requires four

no. 10 x ½-inch (13 mm) sheet metal screws (not

supplied).

5. Obtain 14505159-001 Tamper Switch per job requirements. Installation of Tamper Switch is optional.

SIX NO. 10 x ½-INCH (13 mm)

SHEET METAL SCREWS

Fig. 1. Mounting controller subpanel in cabinet (full-size

subpanel cabinet shown)

3 EN1B-0409GE51 R0908A

Page 4

Wiring XL1000

Wiring

All wiring to the XL1000 controller is unsupervised, except as

noted.

All circuits are power limited, except for AC power circuits,

relay contacts and other circuits as noted.

All field wiring terminals accept 24 AWG to 14 AWG

(0.25 mm

All wiring must conform to local codes, ordinances, and

regulations. Refer to job drawings for details.

Verify that the voltage difference between any conductor and

earth ground does NOT exceed 150 Vac.

1. Connect input/output device wiring, L

2. Connect line voltage to Terminals H and N of the

3. For Power Modules -001 through -007, leave power to

2

to 2 mm2) conductors except as noted.

ONWORKS Bus

transmission wiring, and 14507063 Power Cable to

Controller per job drawings. Fig. 2 and Fig. 3 show typical

controller wiring. Four Power Module models are available

(see Table 2).

14507287 Power Module. Connect a good earth ground to

Terminal G of the Power Module. Fig. 13 through Fig. 15

show typical power wiring.

Power Supply and Controller OFF. Connect 14507063

Power Cable from Controller to Power Module.

Table 1. Connector terminal specifications

WARNING

Risk of electric shock or equipment damage!

► Subpanel and Controller power must remain OFF until

Controller is checked.

4. Install optional Tamper Switch on cabinet per instructions

in the cabinet installation instructions. Wire Tamper

Switch per job drawings.

5. Mount cabinet door.

CAUTION

Risk of electric equipment damage! Excessive static can

burn out equipment.

► Observe proper anti-static material handling practices

when installing or servicing PC parts and related

components.

► Observe proper equipment and body grounding practices.

► Discharge static electricity from your body before handling

parts.

connector terminal pin signal type

analog input AI input SIGNAL ±12 V ±20 mA 9600 baud 8K ohms

digital input DI input SIGNAL ±10 V ±20 mA -- 15K ohms

analog output AO output(1 SIGNAL ±10 V ±20 mA 9600 baud 8K ohms

digital output DO output(2 AC/DC ±24 VAC/DC ±50 mA -- 10K ohms

totalizer output TI input SIGNAL ±12 V ±12 mA 100 Hz

signal ground GND -- -- -- -- -- --

(1

special application; (2 regulated

model

14507287-001 120 0.5 A 60 24 120 Vac, 10A

14507287-002 120 1.7 A 60 24 24 Vac, 100 VA, 24 Vac, 40 VA 120 Vac, 10A

14507287-003 120 1.7 A 60 24 24 Vac, 100 VA, 24 Vdc, 600 mA 120 Vac, 10A

14507287-007 120 120 A 60 24 -- --

transformer max. input

Vac current draw Hz

input /

output

Table 2. Power module models

(48 VA) controller

voltage

type

VAC output

max.

voltage

max. current

accessory output convenience outlet

max.

frequency

max. line

impedance

EN1B-0409GE51 R0908A 4

Page 5

XL1000 Wiring

XL1000 Series Power Consumption

When selecting the appropriate power supply, the power

consumption of the I/O modules must be taken into account.

Table 3. XL1000 power consumption

model 24 Vac, 60 Hz 24 Vdc

XL1000 with watchdog

load

XL1000 without watchdog

load

XFL821AU 130 mA 80 mA

XFL822AU, XFLR822AU 160 mA 90 mA

XFL823AU 180 mA 130 mA

XFL824AU, XFLR824AU 140 mA 90 mA

max. power consumption

500 mA 500 mA

500 mA 500 mA

I/O Modules

I/O Modules

The XL1000 operates together with L

(dark-gray housings) with communication via L

(FTT10-A, link power compatible) for easy integration and use

with 3rd-party controllers.

Terminal Sockets

The I/O modules are mounted on the appropriate terminal

sockets.

Color Coding

To distinguish modules and components, the following color

coding is used:

Table 4. Color coding of I/O Modules

color part

red All of the user-accessible adjustable

mechanical parts (i.e., bridge connectors and

locking mechanism) and operating controls

(manual overrides, etc.)

dark-gray

ONWORKS I/O modules

L

ONWORKS I/O modules

ONWORKS

5 EN1B-0409GE51 R0908A

Page 6

Wiring XL1000

A

X

X

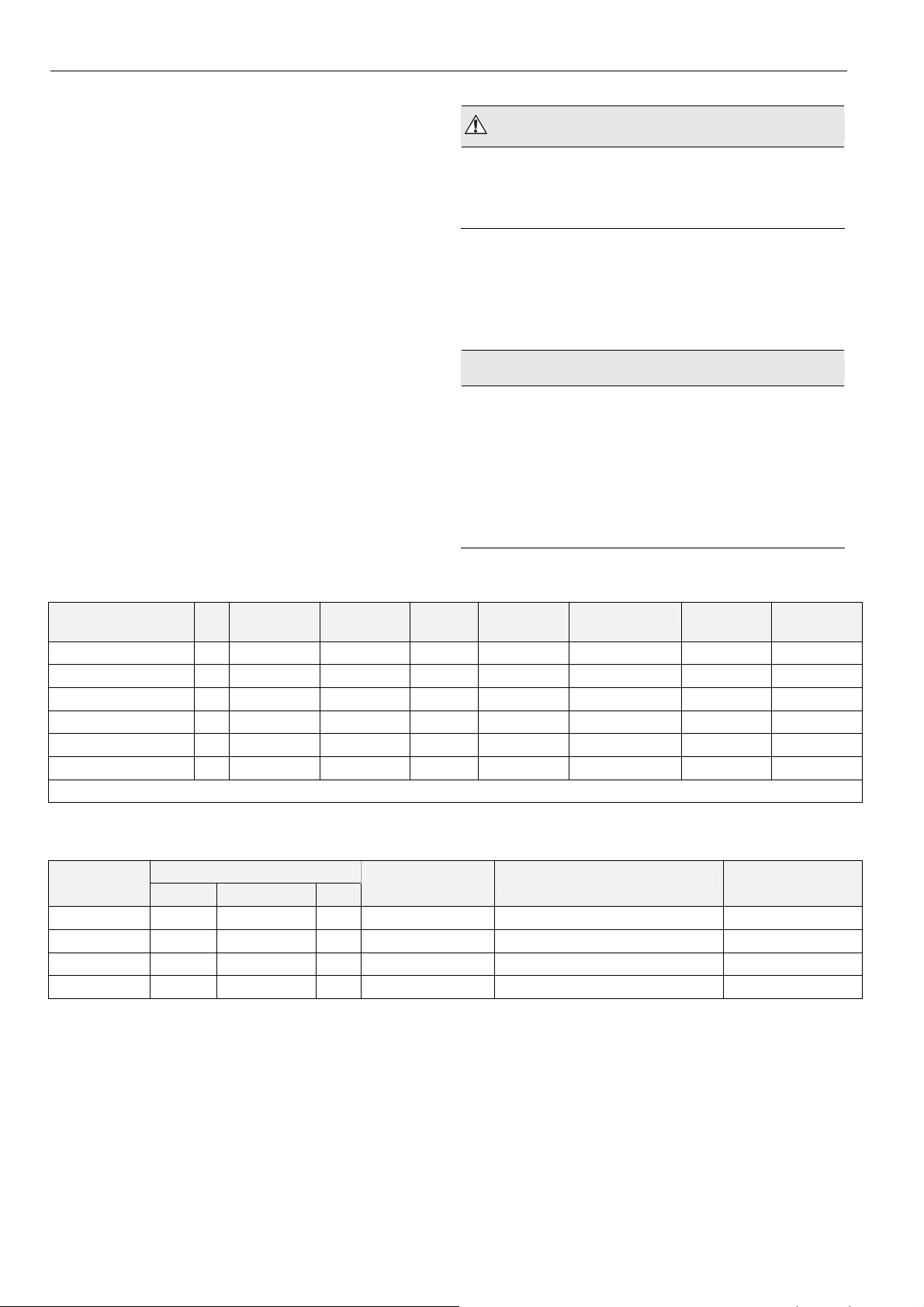

I/O Module Overview

Table 5. Overview of I/O modules and corresponding terminal sockets

LONWORKS I/O

module

XFL821AU Analog Input Module 8 – – –

XFL822AU Analog Output Module – 8 – 8

XFLR822AU Analog Output Module – 8 8 8

XFL823AU Binary Input Module 12 – – 12 XS823

XFL824AU Relay Output Module – 6 2) – 6

XFLR824AU Relay Output Module – 6 2) 6 6

1)

In addition to the power LED and service LED

2)

Changeover outputs

description inputs outputs

ANALOG

INPUT

manual

overrides

NALOG

OUTPUT

status

LEDs 1)

socket scope of delivery

XS821-22

XS824-25

BINARY

INPUT

1 terminal socket,

1 bridge connector

1 swivel label holder

1 terminal socket,

1 bridge connector

1 swivel label holder

1 terminal socket,

1 bridge connector

1 swivel label holder

1 long cross connector

RELAY

OUTPUT

LonWorks

I/O MODULES

LonWorks Bus

FLR822AU

XFL821AU

XS821-22

Fig. 2. Overview of I/O modules and terminal sockets

XFL822AU XFL823AU

S823 XS824-25

XFLR824AU

XFL824AU

EN1B-0409GE51 R0908A

6

Page 7

XL1000 Description of the XL1000 Controller

Description of the XL1000 Controller

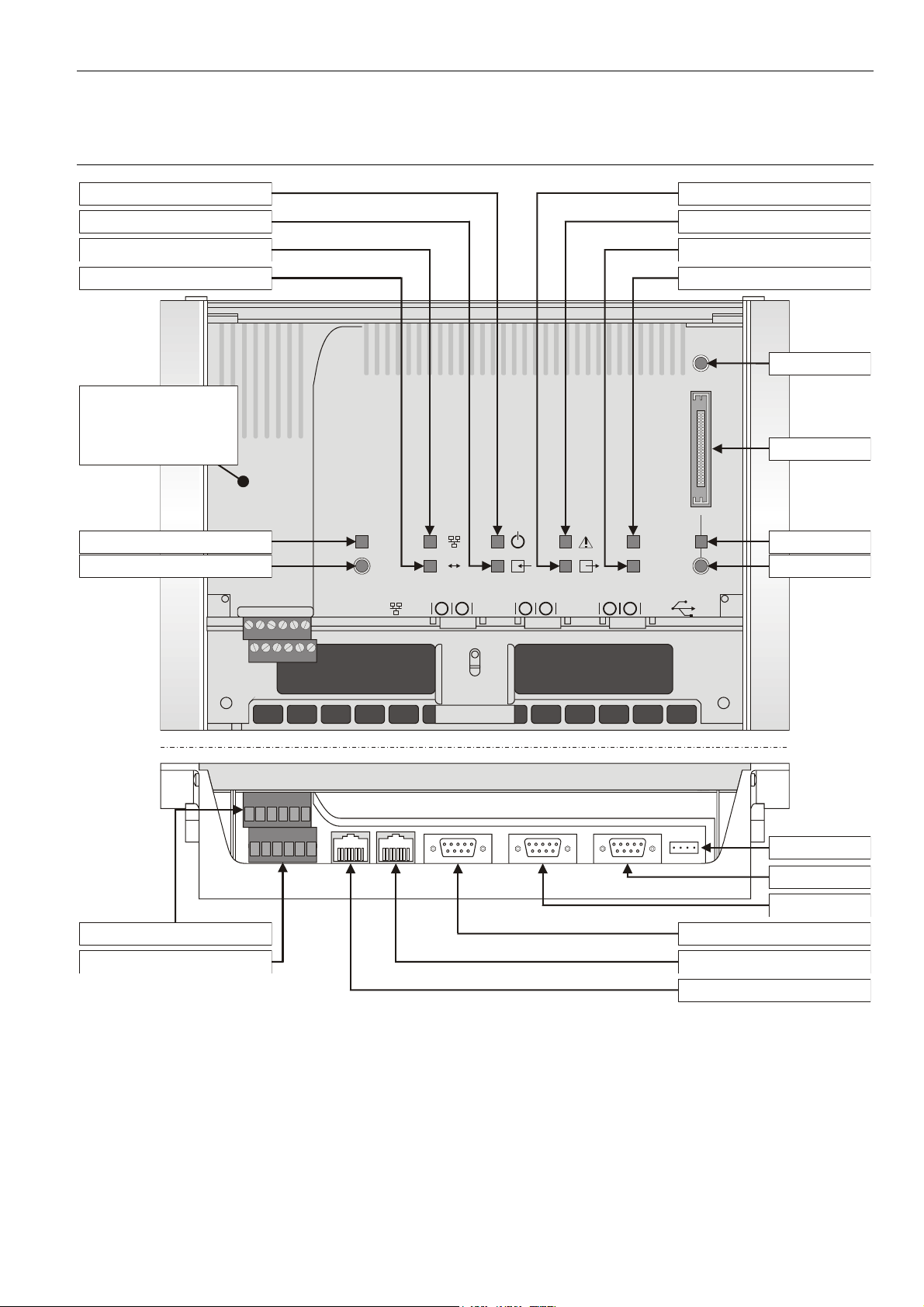

Overview

power supply LED (green)

(LED = power supplied)ON

binary input (terminals 3+4) LED (yellow)

(LED = input closed)ON

Ethernet link LED (yellow)

(LED = Ethernet link is enabled)ON

Ethernet activity LED (yellow)

(LED = Ethernet active)ON

ATTENTION:

Never unscrew and

dismount the inner

metallized cover while

the XL1000 is powered!

Danger of short-circuiting!

LonWorks service LED (yellow)

(for meaning of LED behavior, see Table 1)

LonWorks service button

(pushing broadcasts service pin message)

LON

LON

binary output (terminals 9+10) LED (yellow)

(LED = application has closed contact)ON

binary output (terminals 7+8) LED (red)

(LED = watchdog has closed contact)ON

LED2 (currently unused)

LED1 (currently unused)

reset button

NO CONNECTION

L1

CF

L2

21

3

NOT USED

NOT USED

71829

10

11 12

5

6

3

upper terminal block (removable)

(terminals 7 thru 12)

lower terminal block (removable)

(terminals 1 thru 6)

4

RS232C serial interface, port 1

(standard male 9-position sub-D)

Ethernet interface (8-position,

shielded RJ45 connector jack, CAT5)

LonWorks interface (8-position,

unshielded RJ45 connector jack)

USB interface

NO CONNECTION

NO CONNECTION

Fig. 3. Connections to the XL1000 Controller

7 EN1B-0409GE51 R0908A

Page 8

Description of the XL1000 Controller XL1000

Terminal Blocks

The XL1000 features two rows of removable terminal blocks

(located at the front left-hand side; see Fig. 3) for the connection of cables to the two binary outputs and the binary

input as well as for connecting L

supply. A nearby sticker provides an overview of the terminal

assignment (see Fig. 4).

!

7

8

24V

~ 0

1

2

Fig. 4. Terminal assignment sticker

Maximum torque for fastening the wiring terminal screws is

0.5 Nm (4.5 lb-in).

Table 6 provides a more-detailed explanation of the terminals

and their functions.

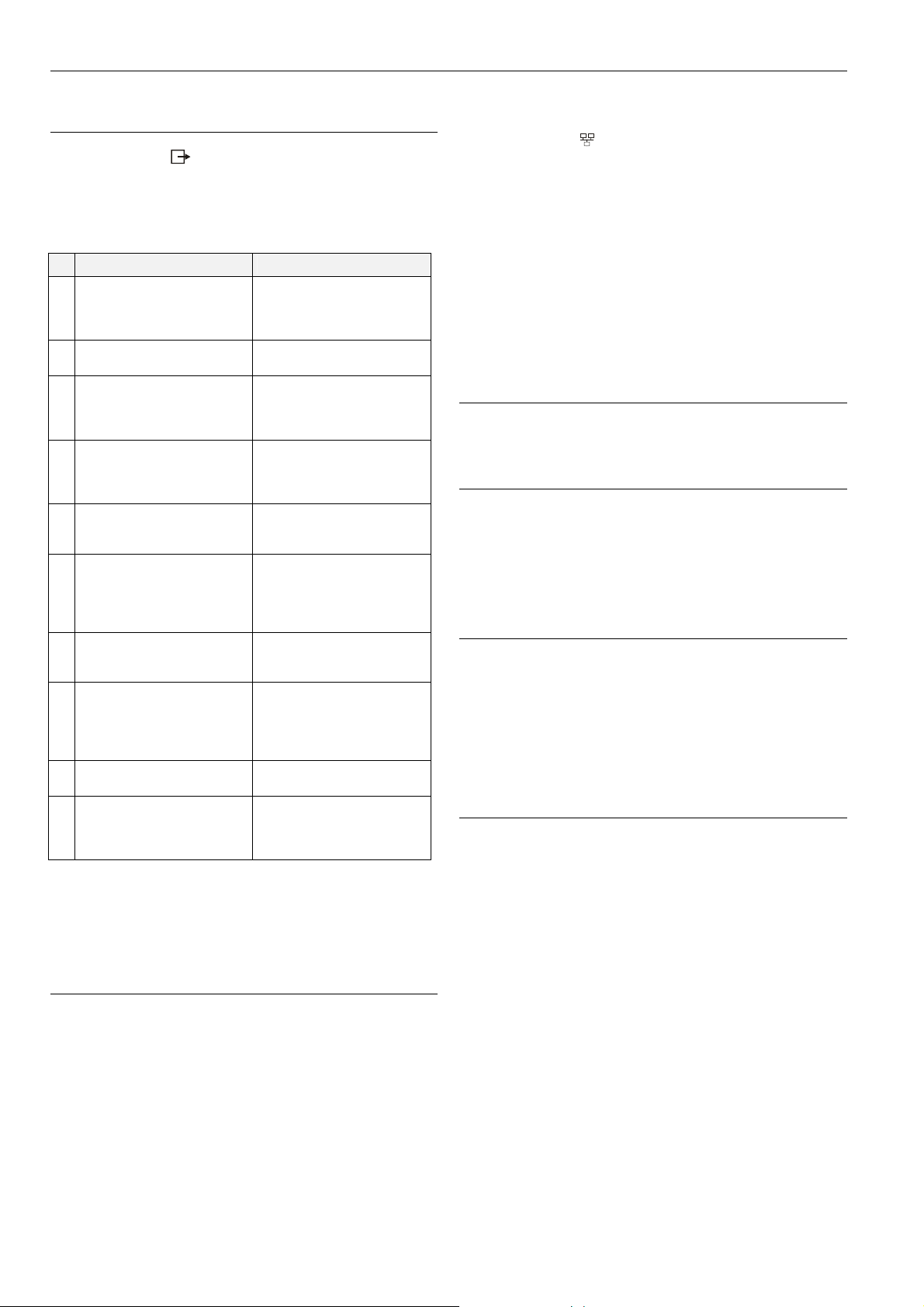

Table 6. Overview of terminals and functions

term. function

1+2 power supply (24 Vac)

a binary input (normally-open, 36 Vdc; pin 4 is the

signal ground), freely configurable (using CARE 7)

3+4

5+6 LONWORKS

7+8

9+10

11+12 LONWORKS

to read input from either 1) a field device or 2) a

collective alarm input or 3) a 2nd XL1000 whose

duties it could then assume in the event of its failure

a binary output / "watchdog relay" (SPDT, normally

closed, 24 Vac, max. 2 A permanent load), permanently configured to output to an alarm device

(which can then signal that XL1000 is

malfunctioning)

a binary output (potential-free contact, SPST,

normally-open, 24 Vac, max. 2 A permanent load),

configurable (using CARE) to output to either 1) a

field device or 2) a 2

assume the 1

failure

st

XL1000’s duties in the event of its

ONWORKS and the power

LON

9310

11

LON

5

4

nd

XL1000 which could then

12

6

LonWorks Interface

The XL1000 is equipped with a LONWORKS interface (specifically: an RJ45 jack) for communication on L

networks.

5

8 7 6

Fig. 5. LonWorks interface (RJ45 jack)

There are two methods of connecting the XL1000 to the

LONWORKS network (both or either connection method can be

used):

• via terminals 5+6 and 11+12 of the terminal blocks (see

Fig. 3); and/or

• via the corresponding jack located to the right of the

terminal blocks (see Fig. 5).

See also section "LonWorks Service LED and Service Button"

on page 9 for details on the corresponding L

LED and one L

ONWORKS service button.

432 1

ONWORKS

LonWorks

ONWORKS service

Ethernet Interface

The XL1000 is equipped with a 10/100-Mbaud Ethernet

interface (specifically: an RJ45 jack) permitting communication (as per IEEEC 802.3) on BACnet/IP networks.

8 7 6

Fig. 6. Ethernet interface

When thus connected, the user sitting at a platform hosting

EBI can thus e.g. view and edit the time programs, trend

values, etc. of the other devices in the BACnet/IP network.

This Ethernet jack conforms to the specifications of the

following two Ethernet sub-standards:

• 100Base-TX (twisted pair / star wiring; 100 Mbaud

Ethernet based on Manchester signal encoding over

category 5 or better twisted pair cable; max. segment

length = 100 meters) and

5

432 1

EN1B-0409GE51 R0908A

8

Page 9

XL1000 Description of the XL1000 Controller

• 10Base-T (twisted pair / star wiring; 10 Mbaud Ethernet

based on Manchester signal encoding over category 3 or

better twisted pair cable; max. segment length =

100 meters).

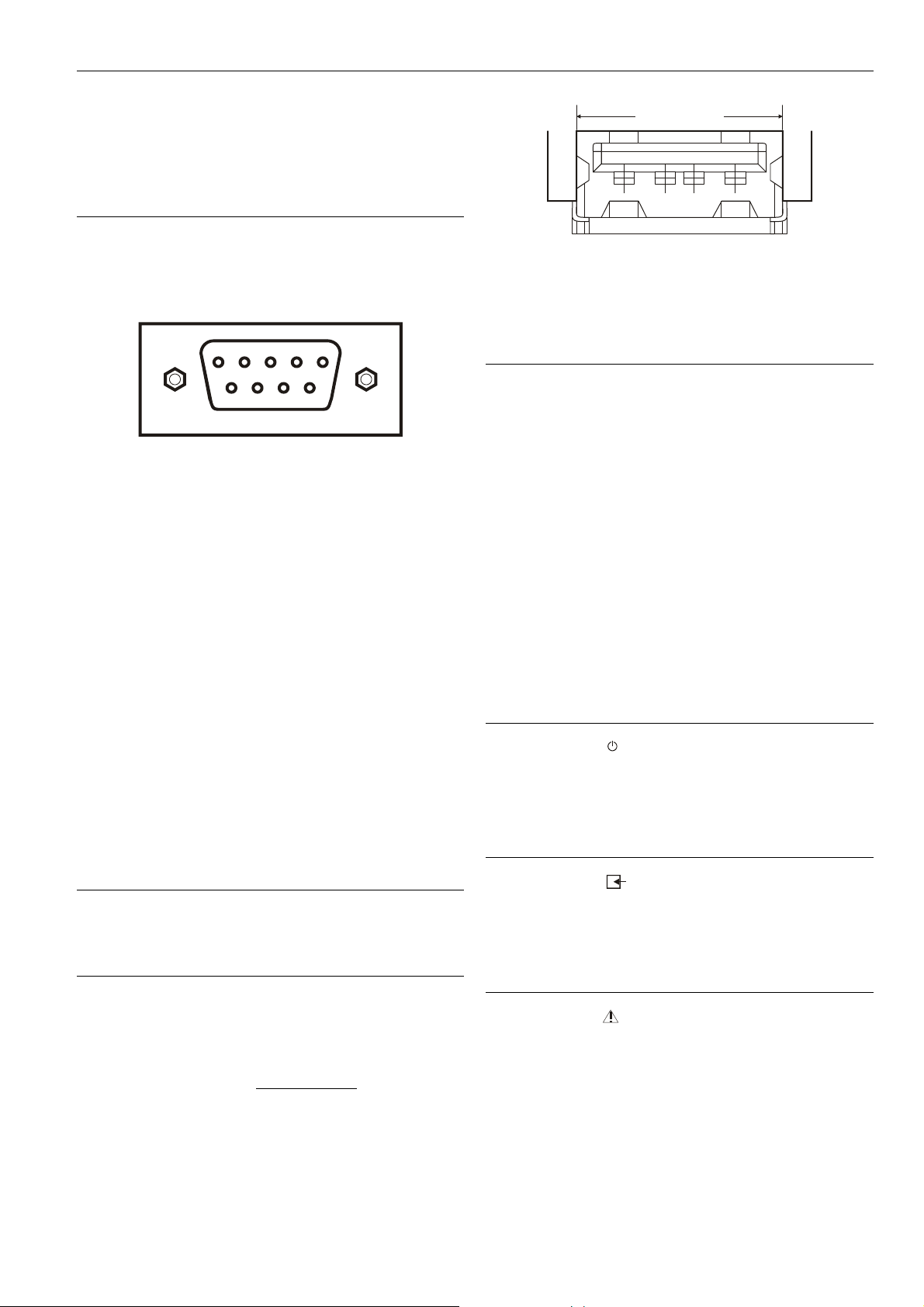

RS232C Serial Interface Ports

The XL1000 is equipped with three male 9-pin sub-D jacks

into which corresponding female 9-pin sub-D plugs can be

inserted for various different purposes (see following subsections). These ports allow data transmission rates of 9.6,

19.2, 76.8, or 115.2 kBaud (the default).

Fig. 7. RS232C serial interface

The user can configure the specific desired data transmission

rate of each individual RS232C port; it is thus possible for the

three ports to operate simultaneously at three different rates.

Port 1 (Factory Service Interface)

Port 1 is intended for the connection (as needed) of a platform for the purpose of servicing (in the factory, only) the

XL1000. In this context, "servicing" comprises a group of

different activities including:

• updating portions of the XL1000’s Operating System

(namely: LINUX, BACstack, Apache Web-Server) and

• diagnostics (Linux, firmware).

Port 2 (Browser Interface)

NO CONNECTION.

Port 3 (Modem Interface)

NO CONNECTION.

12.5 mm

Fig. 8. USB interface

Alternatively, either of the following two adapters can also be

used: SMC 2208USB/ETH and SMC 2209USB/ETH.

LEDs and Buttons

LonWorks Service LED and Service Button

The XL1000 is equipped with a LONWORKS service LED and a

L

ONWORKS service button, together marked "LON" (see Fig.

3). They are used for commissioning the XL1000 and for

troubleshooting.

LonWorks Service Button

When the L

pin message is broadcast on the L

ONWORKS tools currently connected to the LONWORKS

L

network will receive this message.

LonWorks Service LED

The L

having different meanings (see Table 7).

ONWORKS service button is pressed, the service

ONWORKS network, and all

ONWORKS service LED can display various behaviors

Power Supply LED

The LED marked " " indicates whether or not the XL1000 is

currently under power. Specifically, when it is lit, the XL1000

is under power; when it is dark, the XL1000 is not under

power.

Binary Input (terminals 3+4) LED

CF Port LED, Request Button, and Slot

NO CONNECTION.

USB Interface Downloads

The LED marked " " indicates the state of the binary input

(which is a normally-open contact) located at terminals 3 and

4. Specifically, when it is lit, the binary input is closed; when it

is dark, the binary input is open.

Binary Output (terminals 7+8) LED

The XL1000 is equipped with a USB port into which a

standard USB type-A connector can be inserted. This USB

interface is the recommended interface for downloading

applications. The following USB host networking adapter has

been approved: BELKIN DIRECT CONNECT (BELKIN order

no.: F5U104 or F5U104G at www.belkin.com

9 EN1B-0409GE51 R0908A

).

The LED marked " " indicates the state of the binary output

("watchdog" relay) at terminals 7 and 8 (which is a normally

closed contact). Specifically, when it is lit, the alarm contact is

open; when it is dark, the alarm contact is closed.

Page 10

Mounting XL1000

Binary Output (terminals 9+10) LED

The LED marked " " indicates the state of the binary output at terminals 9 and 10 (which is a normally-open contact).

Specifically, when it is lit, this means that the application has

closed the relay; when it is dark, the relay is open.

Table 7. L

LED remains OFF after

1

power-up.

LED is lit continuously after

2

first power-up.

LED flashes at power-up,

3

goes OFF, and then is lit continuously.

LED flashes briefly

4

periodically.

LED repeatedly blinks ON for

5

1 s and OFF for 1 s.

OFF for approx. 10 s. Afterwards, the service LED turns

6a

ON and remains ON,

indicating completion of the

blanking process.

OFF for approx. 1 s. After-

6b

wards, the service LED is lit

continuously.

OFF for 1 ─ 15 s, depending

on application size and system

6c

clock. Afterwards, service LED

repeatedly flashes ON for 1 s

and OFF for 1 s.

LED remains OFF after a

7

short ON duration.

8 LED flashes ON.

ONWORKS service LED behaviors / meanings

LED behavior meaning

Defective XL1000 hardware

(e.g. power supply problems,

clock problems, or defective

Neuron Chip).

Defective XL1000 hardware.

Neuron chip lacks L

interface program. Remedy:

Use Excelon or LonMaker, set

XL1000 online.

XL1000 probably experiencing

continuous watchdog resets,

or external memory or

EEPROM is corrupt.

XL1000 is unconfigured but

has an application. Remedy:

Commission XL1000.

Return XL1000 to factory.

Return XL1000 to factory.

XL1000 is unconfigured but

has an application. Remedy:

Commission XL1000.

XL1000 is configured and

running normally.

XL1000 received a WINK

command from L

other physical outputs are

unaffected.

ONWORKS

ONWORKS;

In case of a problem, check if the L

ONWORKS service LED's

behavior is changed by resetting the XL1000 using the reset

button. Please contact Honeywell if this does not solve the

problem.

Ethernet LEDs

The XL1000 is equipped with two Ethernet LEDs (see Fig. 3).

Ethernet Link LED

The LED marked " " indicates the Ethernet link's status.

Specifically, it is lit whenever an Ethernet jack has been

inserted into the corresponding port and the software has

established the Ethernet link. It is dark when the link has been

disabled.

Ethernet Activity LED

The LED marked " ↔ " indicates whether or not the Ethernet

link is currently active. Specifically, when it flashes, this

means that signals are being transmitted / received on the

Ethernet network; when it is dark, no messages are being

transmitted/received.

LEDs L1 and L2

At present, these LED's are not in use.

Reset Button

The reset button can be pressed only using a long, thin tool

(e.g. a screwdriver). Pressing it reboots the XL1000’s

operating system and restarts the application.

Mounting

Before Installation

IMPORTANT

To allow the evaporation of any condensation resulting

from low shipping / storage temperatures, keep the

controller at room temperature for at least 24 h before

applying power.

In order to meet the criteria for CE certification, the XL1000

must be mounted inside an electrical panel.

Dimensions

The XL1000 has the following dimensions (W x L x H):

278 x 190 x 61 mm. Its housing conforms to IP20. Its pollution

degree (2) makes it suitable for use in residential controls,

commercial controls, in a clean environment, or non-safety

controls for installation on or in appliances.

The XL1000 is suitable for mounting on a standard rail (DIN

EN 50022-35 x 7,5) for installation in appropriately-sized

wiring cabinets. Allow sufficient clearance (approx. 30 mm) to

access the interfaces and to open the swivel cover (see Fig.

9).

EN1B-0409GE51 R0908A

10

Page 11

XL1000 Mounting

1

41.

5

0.3

36.

5

Allow 30 mm clearance

for opening swivel cover.

step

1

LON

Allow 30 mm

clearance for

accessing interfaces.

+/-

12

LON

278

4.4 +/- 0.3

220 +/- 0.3

321

Fig. 9. Dimensions (in mm)

DIN Rail Mounting/Dismounting

17 mm

CF

190

100 mm

0.6

60.6

step

2

step

plate

3

step

4

fastening

Fig. 11. Mounting the XL1000 onto two DIN rails

5 +/- 0.3

Wall/Panel Mounting/Dismounting

The XL1000 can be mounted on walls or in panels in any

desired orientation. However, mounting the XL1000 upside

down on ceilings should be avoided, insofar as the swivel

cover would then swing open.

4.4 +/- 0.3

36.5141.5 +/- 0.3

(center-to-center distance = 100 +3 mm)

slots for DIN rails

fastening

plate

Fig. 10. Housing base (view from below)

The XL1000 can be mounted onto DIN rails as follows (refer

also to Fig. 11):

1. Hang the upper slot onto the upper DIN rail.

2. Swing the unit down until it is flush with the lower DIN

rail.

3. Slide the fastening plate and corresponding screw in the

oval hole up against and behind the bottom edge of the

lower DIN rail and screw it firmly into place.

4. If necessary, the swivel cover can be locked by inserting

a small string lock, lead seal, or screw into either one of

the two openings provided.

The unit is dismounted by loosening the fastening plate and

lifting the unit out of place.

190

12

29 29

220 +/- 0.3

278

Fig. 12. Drilling template (view from above)

Swivel Cover Lock

The swivel cover can be locked by inserting a small string

lock, lead seal, or screw into either one of the two openings

provided (see Fig. 11).

5 +/- 0.3

11 EN1B-0409GE51 R0908A

Page 12

Power Supply XL1000

Power Supply

Power is supplied via terminals 1 and 2 of the lower removable terminal plug. The removable terminal plug permits

individual XL1000 controllers to be disconnected from the

power supply without disturbing the operation of other devices

powered by the same source.

24 VAC CONTROLLER

CONNECTOR TO

XL1000 CONTROLLER

J5

POWER SWITCH

MAIN LINE VOLTAGE

120 VAC, 60 HZ

TERMINAL MUST BE

CONNECTED TO A GOOD

EARTH GROUND.

14507063-002 POWER CABLE

(incl. with 14507287 power modules

14507287-001 through -003, only.)

CONNECTORS ARE KEYED TO

PREVENT MISALIGNMENT.

CONVENIENCE OUTLET

(UNFILTERED, UNSWITCHED)

-001 = 120 VAC, 10 AMP

““

G

BRN

GRN

BLK

Fig. 13. Typical 14507287-001 Power Module wiring

120 VAC, 60 HZ

LINE INPUT

““

G MUST BE

WIRED TO EARTH GROUND

* 14507287-001 POWER TERMINALS LABELED H-N-G.

NOTE: Do not reverse the polarity of the power connection

cables, and avoid ground loops (i.e. avoid

connecting one field device to several controllers) as

this may result in short-circuiting.

FUSE F1 (2 AMPS) PART NUMBERS ARE AS FOLLOWS:

2 AMP

CONTROLLER

POWER

*

ON

H

N

OFF

G

CONTROLLER

SUPPLY

24VAC

48VA

~

G

MUST BE WIRED

TO EARTH GROUND

UNSWITCHED

UNFILTERED

120 VAC

–HONEYWELL PART NO. 14000485-007

(AVAILABLE FROM HONEYWELL BRANCH LOCATIONS, ONLY)

F1

–BUSSMAN PART NO. AGC-2

–LITTLEFUSE PART NO. 312002

CONNECTOR TO

XL1000 CONTROLLER

J5

24 VAC CONTROLLER

POWER SWITCH

MAIN LINE VOLTAGE

120 VAC, 60 HZ

TERMINAL MUST BE

CONNECTED TO A GOOD

EARTH GROUND.

14507063-002 POWER CABLE

(incl. with 14507287 power modules

14507287-001 through -003, only.)

CONNECTORS ARE KEYED TO

PREVENT MISALIGNMENT.

CONVENIENCE OUTLET

(UNFILTERED, UNSWITCHED)

-002 AND -003 = 10 AMP

G

““

BRN

GRN

BLK

Fig. 14. Typical 14507287-002, -003 Power Module wiring

120 VAC, 60 HZ

LINE INPUT

““

G MUST BE

WIRED TO EARTH GROUND

* 14507287-001 POWER TERMINALS LABELED H-N-G.

POWER MODULE

14507287-001 THROUGH -003

14507287-002 AND -003

14507287-002 AND -003

CONTROLLER

POWER

*

ON ON

H

N

OFF OFF

G

CONTROLLER

SUPPLY

24VAC

48VA

FUSE NO.

F1

F2

F3

TO EARTH GROUND

~

G

-002 MODEL, ONLY. 2 AMP MAX.

FUSE RATING

2 AMPS

5 AMPS

2 AMPS

2 AMP

F1 F2

MUST BE WIRED

24 VAC ACCESSORY POWER

FOR 14507287-003 (24VDC)

FOR 14507287-002 (24VAC)

UNFILTERED 120 VAC

HONEYWELL PART NO.

14000485-007

14507374-001

14000485-007

5 AMP

2 AMP

F3

UNSWITCHED

120 VAC, 60 HZ

LINE INPUT

24VAC ACCESSORY

POWER -002 AND -003

MODELS (4 AMP MAX.)

~

BRN

BUSSMAN PART NO.

AGC-2

GMA 5AMP

AGC-2

GRY GRY

BRN

BRNRED

GRYGRY

LITTLEFUSE PART NO.

312002

235005

312002

EN1B-0409GE51 R0908A

12

Page 13

XL1000 Power Supply

CONTROLLER TRANSFORMER

CONTROLLER

SUPPLY 24 VAC

48 VA

G

~

70

71

72

BRN

BLK

3

GRN

1

4

H

N

G

MAIN LINE (120 VAC, 60 Hz)

TERMINAL “G” MUST BE

CONNECTED TO A GOOD

EARTH GROUND.

MECHANICALLY SECURED TO SUBPANEL WITH MOUNTING SCREW

1

Fig. 15. Typical 14507287-007 Power Module wiring

BLK

WHT

GRN

24 V 50 VA

14507351-001

429P156A

E1A 1052 XXXX

COM 120 V

1

2

1

13 EN1B-0409GE51 R0908A

Page 14

LonWorks Communications XL1000

Lightning Protection

LONWORKS: 14502412-014

Ethernet: 14507678-004

Interfaces and Bus Connections

The XL1000 System can be connected to the following

devices and systems:

LonWorks Bus

• For communication with other LONWORKS Bus devices

within the building

• FTT10, link power compatible

• Polarity-insensitive

Technical Data

System Data

Table 8. System data

operating voltage

power

consumption

NOTE: The max. permitted number of LonWorks I/O

modules depends upon the type of modules used.

In the case, e.g., of XL800 Binary Input Modules, a

maximum of 21 may be used.

Operational Environment

Table 9. Operational environment

ambient operating

temperature

ambient operating

humidity

ambient storage

temperature

ambient storage

humidity

24 VAC/DC, 60 Hz

max. 7 A

(one XL1000 + 40 I/O modules)

0 ─ 49 °C (32 ─ 122 °F)

5 ─ 93 % relative humidity

(non-condensing)

–20 ─ 70 °C (–4 ─ +158 °F)

5 ─ 95 % relative humidity

(non-condensing)

LonWorks Communications

General Information

The XL1000 is equipped with a free-topology transceiver

(FTT10A or FT-X1) for communication (at a data transmission

rate of 78 Kbaud) on LONWORKS® networks (using the

LonTalk protocol).

The L

ONWORKS network is insensitive to polarity, eliminating

the possibility of installation errors due to miswiring.

Different network configurations (daisy-chain, loop, and star

configurations, or any combination thereof) are possible (see

also Excel 50/500 L

Description, EN0B-0270GE51).

Connecting to the LONWORKS Network

IMPORTANT

Do not bundle wires carrying field device signals or

ONWORKS communications together with high-voltage

L

power supply or relay cables. Specifically, maintain a

min. separation of 3 inches (76 mm) between such

cables. Local wiring codes may take precedence over

this recommendation.

IMPORTANT

Try to avoid installing in areas of high electromagnetic

noise (EMI).

XL1000 XL1000

Fig. 16. Connection to L

termination module (here: daisy-chain network

The XL1000 can be connected to the LONWORKS network via

terminals 5+6 and 11+12 of the removable terminal plug or

via the LONWORKS jack (see also section "LonWorks

Interface" on page 8).

This permits individual XL1000 controllers to be connected /

disconnected from the L

the operation of other devices.

Depending upon the chosen network configuration, one or

two terminations may be required.

Two different L

• L

ONWORKS termination module, order no.: 209541B

ONWORKS connection / termination module

• L

(mountable on DIN rails and in fuse boxes),

order no.: XAL-Term

ONWORKS Mechanisms Interface

11 11

12 12

55

66

termination

module

ONWORKS network and

configuration)

ONWORKS network without disturbing

ONWORKS termination modules are available:

EN1B-0409GE51 R0908A

14

Page 15

XL1000 Binary Input and Outputs

X

X

The binary input is protected against miswiring. Specifically, it

is protected against voltages of up to 29 Vac; when miswired,

the XL1000 is unable to detect a valid input signal.

l

l

e

w

removable screw-type

3-pole terminal block

y

e

n

o

H

m

r

e

T

-

L

A

X

4

3

L

L

O

O

N

N

shield shield

plug-in

jumper

34

LON

Termination

FTT/LPT Bus

FTT/LPT Free

Park Position

5

1

06

Binary Outputs

The XL1000 is equipped with two binary outputs.

Hardware Limits

• A min. current of 50 mA is required to ensure a reliable

contact.

• The binary outputs are designed for a max. continuous

current of 2 A.

• Switching voltage = 24 Vac, 60 Hz

Fig. 17. L

ONWORKS connection and termination module

Protocolling

Binary Input and Outputs

Wiring

When wiring the two binary outputs and the binary input, use

a min. size of 20 AWG (0.5 mm

(2.5 mm

2

). The max. length of all cables is 400 m.

Binary Input

The XL1000's binary input (a normally-open contact) is not

electrically isolated. It is suitable for connection with /

signalling via 24 Vdc voltage or external resistor or dry

contact.

2

) and a maximum of 14 AWG

In the context of the XL1000, "protocolling" means creating a

log of the values or states of the data-points which have

been assigned to this particular XL1000. Using the

browser interface, the user must place the corresponding

data-points into "trend." If, at some later point in time, i.e. after

lengthy operation, a protocol of the XL1000's history is

desired, the corresponding trend data can be generated,

viewed, and downloaded (in CSV format) via the browser

interface. For the storage of larger amounts of trend data

(more than 64,000 trend entries – corresponding to approx.

2 MB), a CF card (see section "CF Port LED, Request Button,

and Slot") can be used.

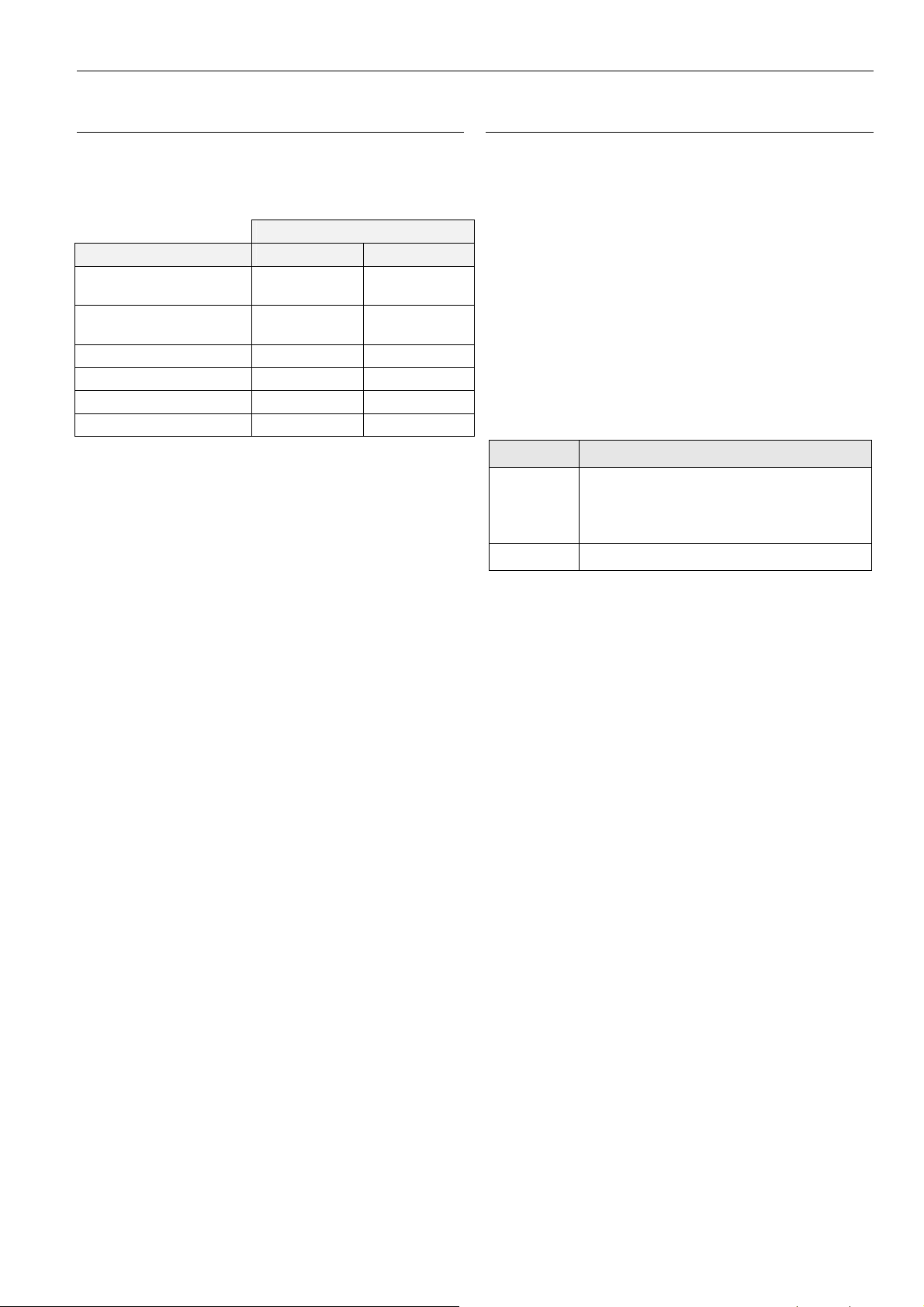

XL1000 Configuration

1

14507287-001,

-002, -003, -007

POWER SUPPLY

120 VAC

60 Hz

XL1000C500U

(XL WEB)

ETHERNET

LON

14502412-014

LIGHTNING

PROTECTOR

14502412-014

LIGHTNING

PROTECTOR

6 5

14507678-004

DITEK SURGE

SUPPRESSOR

ANALOG INPUT ANALOG OUTPUT ANALOG OUTPUT DIGITAL INPUT DIGITAL OUTPUT DIGITAL OUTPUT

2

14506944-01

TOTAL EQUALIZER

PROTECTOR

XFL821AU XFL822AU

14506944-01

TOTAL EQUALIZER

PROTECTOR

14506944-01

TOTAL EQUALIZER

PROTECTOR

FLR822AU XFL823AU XFL824AU

14506944-01

TOTAL EQUALIZER

PROTECTOR

TOTAL EQUALIZER

14506944-01

PROTECTOR

3 4

14507678-004

DITEK SURGE

SUPPRESSOR

14507719-001

BLACK BOX HUB

120 VAC

60 Hz

14507678-004

DITEK SURGE

SUPPRESSOR

14507678-004

DITEK SURGE

SUPPRESSOR

EBI

(R310)

Fig. 18. XL1000 configuration

14506944-01

TOTAL EQUALIZER

PROTECTOR

FLR824AU

120 VAC

60 Hz

15 EN1B-0409GE51 R0908A

Page 16

XL1000 Configuration XL1000

3

4

5

6

1

2

3

4

5

6

7

8

9

1

Power supply output power

Locate per UL555S.

24 VAC, 60 Hz, 48 VA (-001, -002, -003, and -007)

24 VAC, 60 Hz, 100 VA (-002 and -003, only)

24 VAC, 60 Hz, 40 VA (-002, only)

Locate separate from and below all building exhaust

fans and upstream of any prevailing winds.

24 VDC, 60 Hz, 0.6 A (-003, only)

Exhaust to outside of building.

2

LONWORKS wire distance

1200 m (approx. 4000 ft.)

Locate airflow differential switch.

24 ohm total line resistance

47 microfarad capacitance

Locate UL-listed damper pressure / position indicator

per damper installation instructions.

XFL822AU / XFLR822AU

8 analog outputs

10 V, 1 mA each

XFL824AU / XFLR824AU

6 digital outputs

4 A max. per output (relay current)

12 A max. per module

W7761A2010/U

W7751D2016/U

W7751F2011/U

W7751B2010

W7751H2025

separately listed S4804, Vol. 3

Ethernet line load

pin 1 – 10 ohm

pin 2 – 10 ohm

pin 3 – 10 ohm

pin 6 – 10 ohm

Smoke Control Configuration

Smoke control must be initiated by a listed fire alarm

control unit or in zone automatic alarm devices and not

devices located outside of the smoke control zone.

Interconnecting wiring must be within 20 ft. (6 meters)

and in conduit.

Refer to NFPA 92A.

10

Verify that the AC voltage source connected to the

inside of the main line voltage terminal block is from a

UL-1481 listed uninterruptible power supply. The main

line voltage terminal block maximum current draw is

0.5 A. For 220/240 VAC (60 Hz) applications, verify

that no potential between any conductor and the earth

ground exceeds 150 VAC.

11

All external LONWORKS bus field wiring must be limited

to 4000 ft. (1200 meters) and be terminated to

14506944-001 transient protector (35 V, 290 mA

max.).

Data File Set-Up

SMOKE CONTROL CONFIGURATION

9

SUPPLY

FAN

AIRFLOW SENSOR

EXHAUST

FAN

DAMPER

VERIFICATION

6 7

10

UL-LISTED

FIRE ALARM

CONTROL UNIT

14505068

AUDIBLE

ANNUNCIATOR

XL1000

8

FIREFIGHTERS’

SMOKE CONTROL

PAN EL (F SCS)

1

AO

11

AO

AO

2 3

STATUS CONTROL

Fig. 19. Typical smoke control configuration

NOTES:

Locate and configure per NFPA 92A, Section 3-4.3.4.

UL-listed annunciator / FSCS panel switches have a

minimum rating of 24V, 1/10 Amp, and lamps / LEDs

have a rating of 24 V, limited to 50 mA.

Locate so as to minimize control wiring and piping.

Avoid running wires or piping through areas that have

a high fire risk.

Generate the engineering data file for the XL1000 Series

Controllers. This data file has a mix of hardware points for the

necessary inputs and outputs to control fans, dampers, and

other equipment. In addition to the inputs and outputs, a

4

custom control program is written to control the outputs per

the sequence. The XL1000 controllers can reset the program

once the data from the operator interface indicates a normal

5

condition for the dedicated smoke control equipment. Wire

conditions must be programmed to provide annunciation of

trouble conditions.

Also required for a dedicated application for the XL1000, is a

weekly time program to test control points, fans, and dampers

by exercising the equipment and verifying feedback

automatically during low building activity periods.

Panel Reset

When in Smoke Control Mode, panel reset is accomplished

by resetting the initiating panel contact circuit or by the

separate initiating/reset switch on the FSCS panel.

EN1B-0409GE51 R0908A

16

Page 17

XL1000 XL1000 Configuration

3

4

CAUTION

Risk of electric equipment damage!

► Failure to use listed/approved replacement parts can

damage product, degrade operation and result in loss of

safety function.

► This product must be installed and operated within its

environmental, mechanical, and electrical specifications as

contained in this document.

► When servicing, use only listed/approved replacement

parts ordered directly from the manufacturer.

Typical Power Limited Circuit for XL1000

POWER

LIMITED

2

CPU

1 1

NON-POWER

LIMITED

Fig. 20. Typical power-limited circuit for XL1000

1

14507287-001 through -003 power module accessory

24 VAC output (rated 2A) must be wired in accordance

with NFPA 70, Article 725 when routed within the

cabinet or adjacent cabinets and also for external field

wiring.

2

14507287-001, -002, -003, and -007 control power

module 24 VAC output is inherently power-limited.

Thus, all sourced power from the XL1000 controller is

power-limited. All field wiring from these controllers

meet NFPA 70, Article 725 power limited Class II

requirements.

ANALOG INPUT

MODULE

CONTROL

24VAC

2

3

NON-POWER

POWER

LIMITED

LIMITED

ACCESSORY

ANALOG OUTPUT

MODULE

24VAC

DIGITAL INPUT

MODULE

POWER LIMITED

24VAC

2

DIGITAL OUTPUT

MODULE

NON-POWER

LIMITED

NON-POWER

LIMITED

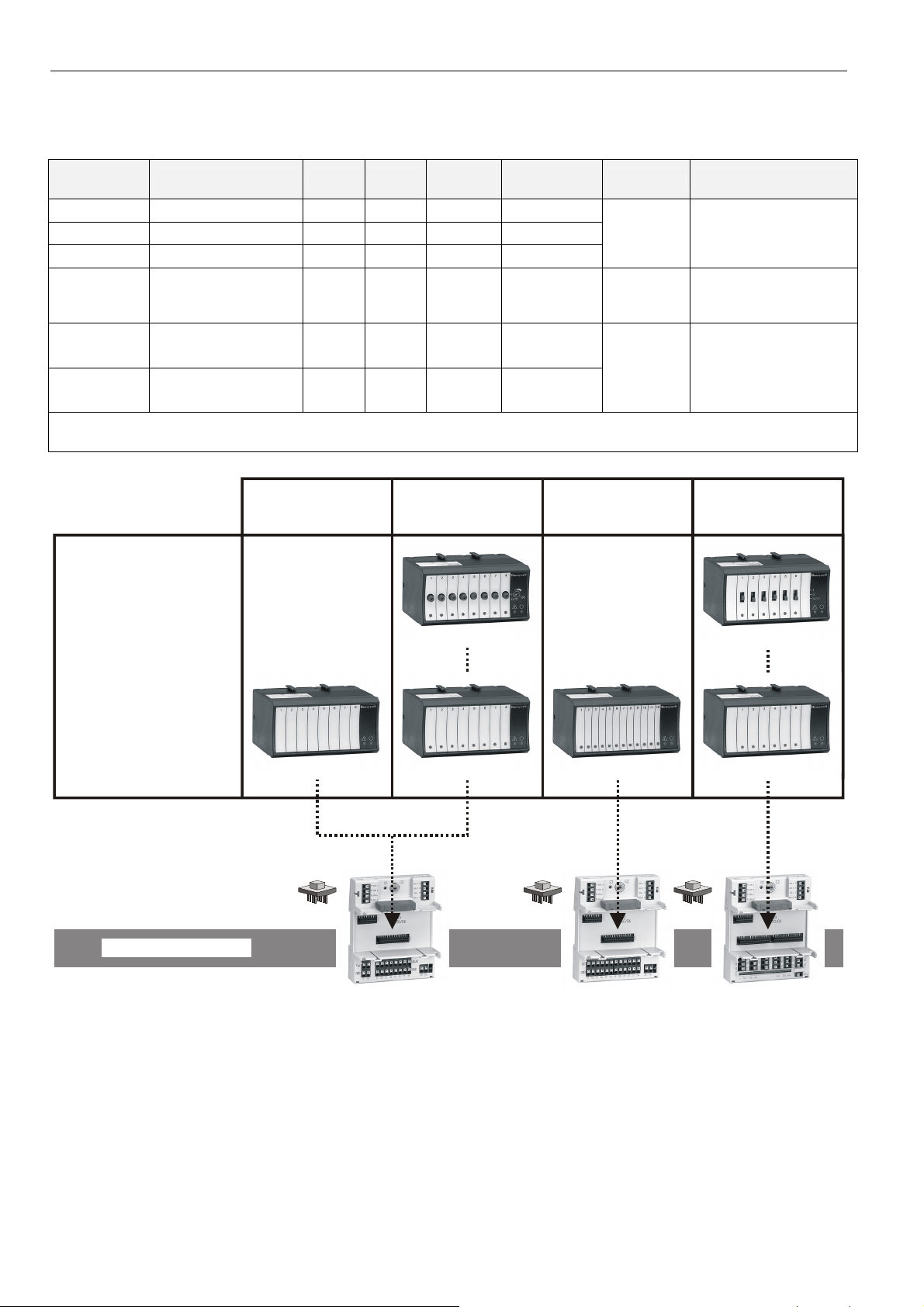

Connecting Single Bus Controller Systems

This section describes how to connect a controller system

which uses L

XL1000, I/O Modules on Single Rail

► Connect XL1000 and I/O modules using the bridge

connectors.

This provides power supply and communication connection.

No further wiring is necessary.

XL1000, I/O Modules on Rails in Single Cabinet

The multiple rails of a controller system are connected in

series.

► Connect the rail ends as follows:

– Power supply

via power supply terminals 73, 74 or 77, 78

– Communication

via communication terminals 71, 72 or 75, 76

ONWORKS I/O modules, only.

71

LonWorks

72

I/O MODULE

73

74

71

72

73

LonWorks

I/O MODULE

LonWorks

I/O MODULE

74

71

72

I/O MODULE

73

74

71

72

73

LonWorks

LonWorks

I/O MODULE

75

5

6

XL1000

1

11

12

2

76

74

LonWorks

I/O MODULE

71

LonWorks

72

I/O MODULE

75

76

77

78

75

76

77

78

If a separate auxiliary power-limited 24 VAC power

source is required, use a control power module

(14507287-001 or -007 control supply).

Fig. 21. Wiring power supply and communication lines to

Devices must be installed in areas as shown. All cable

must be routed as shown. All internal power-limited

wiring must be separated by ¼ inch (6 mm) or barrier

the I/O modules

from non-power-limited wire. Excess wiring must be

cut, trimmed, and dressed properly to ensure that

proper clearances are maintained.

17 EN1B-0409GE51 R0908A

Page 18

Mounting/Dismounting Modules XL1000

I/O Modules in Separate Rooms

In this scenario, only communication lines must be connected

between the rooms.

► Connect the last module of room 1 to the first module of

room 2: via communication terminals 71, 72 or 75, 76

ROOM 1

71

72

I/O MODULE

73

74

LonWorks

75

76

77

78

5

6 12

XL1000

1

2

71

11

LonWorks

72

I/O MODULE

73

74

75

76

ROOM 2

LonWorks

I/O MODULE

73

74

Fig. 22. Wiring L

LonWorks

I/O MODULE

ONWORKS I/O modules in separate rooms

LonWorks

I/O MODULE

Maximum Cable Length

Max. cable length: 1200 meters (4000 ft), supervised.

75

76

77

78

LONWORKS Bus Topologies

The LONWORKS Bus is a 78-kilobit serial link that uses

transformer isolation so that the bus wiring does not have a

polarity. I.e. it is not important which of the two L

Bus terminals are connected to each wire of the twisted pair.

The LONWORKS Bus can be wired in daisy chain, star, loop or

any combination thereof as long as the maximum wire length

requirements are met.

Configuration

The recommended configuration is a daisy chain with two bus

terminations. This layout allows for max. L

lengths, and its simple structure presents the least number of

possible problems, particularly when adding on to an existing

bus.

ONWORKS

ONWORKS Bus

Mounting/Dismounting Modules

WARNING

Risk of electric shock or equipment damage!

► Do not touch any live parts in the cabinet.

► Disconnect the power supply before you start to install the

controller system.

More than one disconnect switch may be required to deenergize the system.

► Do not reconnect the power supply until you have

completed the installation.

NOTE: The terminal socket of each I/O module can be

mounted and wired before inserting and locking

the corresponding electronic module.

Mounting/Dismounting Sockets

Mounting Sockets

LonWorks

I/O Module

Fig. 23. Max. number of L

LonWorks

I/O Module

max. no.: approx. 40

(depending upon mix)

XL1000

LonWorks

I/O Module

ONWORKS I/O modules

NOTE: The max. permitted number of LonWorks I/O

modules depends upon the type of modules used.

In the case, e.g., of XL800 Binary Input Modules, a

maximum of 21 may be used.

► Angle the terminal socket at the upper edge of the DIN rail

until it snaps in.

► Swing the terminal socket down and apply gentle force

until it snaps into position with an audible "click".

► Position terminal sockets flush with one another along the

rail.

► If desired, mount stoppers at the ends of the rail to prevent

sliding.

LonWorks

LonWorks

BUS

I/O Module

I/O

EN1B-0409GE51 R0908A

18

Page 19

XL1000 Mounting/Dismounting Modules

Fig. 25. Connecting terminal sockets with bridge

connector

NOTE: Bridge connectors transmit both communication

Fig. 24. Mounting terminal sockets

Connecting Sockets

Terminal sockets on the same DIN rail can be connected

mechanically and electrically with bridge connectors.

The XL1000 and terminal sockets must be connected using

cables.

NOTICE

Risk of malfunction!

► LONWORKS I/O modules must be connected to the XL1000

via LON terminals 5 and 6 and/or 11 and 12.

Dismounting Terminal Sockets

Disconnecting Terminal Sockets

Release all bridge connectors before removing the terminal

sockets from the DIN rail.

► Press down at the same time both the gray side wings next

to the red button and then pull the bridge connector out of

the terminal socket.

signals and power supply between I/O modules.

Removing bridge connectors will interrupt the

transmission of both communication signals and

power supply between the I/O modules.

Position the bridge connector on terminals 71 ─ 74 of the

right-hand terminal socket and on terminals 75 ─ 78 of the

left-hand terminal socket. Then press the bridge connector

down.

Fig. 26. Releasing bridge connectors

Dismounting Terminal Sockets

► Insert a screwdriver into the latch on the underside of the

terminal socket and lever the red latch 2–3 mm downwards. The terminal socket can then be swung away from

the rail.

19 EN1B-0409GE51 R0908A

Page 20

Mounting/Dismounting Modules XL1000

Fig. 27. Releasing latch

Mounting/Dismounting Electronic Modules

Mounting Electronic Modules

NOTE: Electronic modules can be removed from the

terminal socket or inserted into the terminal

sockets without switching off the power supply.

The behavior of connected field devices must be

taken into consideration.

► Make sure that terminal socket und I/O module match.

► Make sure that the red locking mechanism is in the open,

i.e., left-hand, position.

► Gently push the electronic module onto the terminal socket

until snug.

Fig. 29. Locking the electronic module

NOTE: The red locking mechanism will not close if the

electronic module is not properly mounted.

Dismounting Electronic Modules

NOTE: Electronic modules can be removed from the

terminal socket or inserted into the terminal

sockets without switching off the power supply.

The behavior of connected field devices must be

taken into consideration.

► Open the red locking mechanism by sliding it to the left

and then gently pull the electronic module out of the

terminal socket.

Fig. 28. Inserting the electronic module

► Lock the red locking mechanism by sliding it to the right.

EN1B-0409GE51 R0908A

Fig. 30. Dismounting the electronic module

Connecting HMIs or Laptops

Laptops or HMIs (e.g., XI882) can be connected via the

XL1000’s Ethernet interface (see section “Ethernet Interface”

on page 8) or its USB interface (see section “USB Interface

Downloads” on page 9).

Connecting Laptops (XW-Online/CARE)

► Connect a laptop (on which e.g., XW-Online or CARE has

been installed) to the XL1000’s Ethernet interface (see

section “Ethernet Interface” on page 8) or its USB interface

(see section “USB Interface Downloads” on page 9).

20

Page 21

XL1000 Description of the I/O Modules

Description of the I/O Modules

Common Features

Switches Located on the Terminal Socket

Table 10. Terminal socket switches

feature function

Service button

S1

Hex switch S2

LEDs Located on the I/O Module

feature function

Service LED

(yellow)

Power LED

(green)

For the location of these elements, see figures of the

respective modules.

• LED test, see section "Troubleshooting"

on page 31

• L

ONWORKS service button functionality

for L

ONWORKS I/O modules

• No function.

Table 11. LEDs on I/O module

• Service information, see section

"Troubleshooting" on page 31

• Information on power supply, see

section "Troubleshooting" on page 31

21 EN1B-0409GE51 R0908A

Page 22

Description of the I/O Modules XL1000

Analog Input Modules

Types of Analog Input Modules

Table 12. XL800 Analog Input Modules

type description housing

XFL821 LONWORKS Analog Input Module dark-gray

XS821-822 terminal socket light-gray

Features

• 8 analog inputs

• Sensor-break and short-circuit detection, see section

"Troubleshooting" on page 31.

1

2

3

4

Fig. 31. XFL821AU Analog Input Module with terminal

socket

Legend

1 Service button S1

2 Hex switch S2 (no function)

3 Service LED

4 Power LED

Functionality of service LED and power LED: see Table 24

and following.

Terminals

COM

71

A

COM

72 76

B

24

73 77

V~

24

74

V~0

AI8

AI7

AI6

AI5

AI4

AI3

AI2

V

AUXVAUX

21

GND9GND

Fig. 32. Terminal assignment and internal connections of

Table 13. Description of Analog Input Module terminals

ter-

minal

71, 75 COM a 2-wire LONWORKS communication bus

72, 76 COM b 2-wire LONWORKS communication bus

73, 77 24 V~ Power supply

74, 78 24 V~0 Power supply

1 ─ 8 AI1 ─ AI8 Analog inputs 1 ─ 8

9 ─ 18 GND

21, 22

25, 26

NOTE: Shield connection to be used for shielded I/O

AI1

8

7

6

5

4

3

2

22

10

1

GND11GND GNDGND GND GND GND GND

18171615141312

Analog Input Modules

signal comment

Ground. All grounds are connected

internally to each other

Auxiliary voltage signal (used e.g. for

10 VDC /

5 mA

supplying setpoint potentiometers).

Connections to these terminals

must be made in the same room.

Shield connection (functional earth),

internally connected to the DIN rail

cables only. It is not allowed to connect a

ONWORKS shield.

L

COM

A

COM

B

24

V~

24

V~0

25 26

75

78

EN1B-0409GE51 R0908A

22

Page 23

XL1000 Description of the I/O Modules

XFL821AU Connection Examples

400 OHM

25

18

1

SHIELD SHIELD

1

2

0(4) to 20 mA

0(4) to 20 mA (VIA EXTERNAL

500 OHM RESISTOR).

5

14

10 1

11 12 2

25 25

22

SHIELD SHIELD

2

1

0 to 10 V

0 TO 10 VDC

3

12

2

13

25

VMP Pt1000 NTC20kW

Fig. 33. XFL821AU Analog Input Module, connection to

field devices

23 EN1B-0409GE51 R0908A

Page 24

Description of the I/O Modules XL1000

Analog Output Modules

Types of Analog Output Modules

Table 14. XL800 Analog Output modules

type description housing

L

XFL822

XFLR822

XS821-22 terminal socket light-gray

ONWORKS Analog Output

Module

L

ONWORKS Analog Output

Module with manual overrides

Features

• 8 analog outputs;

can also be configured per output as binary outputs

(0 ─ 10 V, 2 ─ 10 V, ON/OFF, or floating)

• Corresponding output status LEDs (red)

• XFLR822AU: 8 manual overrides

1

2

3

4

Fig. 34. XFLR822AU Analog Output Module with terminal

socket

Legend

1 Service button S1

2 Hex switch S2 (no function)

3 Manual overrides

4 Output LEDs

5 Service LED

6 Power LED

dark-gray

dark-gray

5

6

Functionality of service LED and power LED: see Table 24

and following.

Terminals

Fig. 35. Terminal assignment and internal connections of

the Analog Output Modules

Table 15. Description of Analog Output Module terminals

ter-

minal

71, 75 COM a 2-wire LONWORKS communication bus

72, 76 COM b 2-wire LONWORKS communication bus

73, 77 24 V~ Power supply

74, 78 24 V~0 Power supply

1 ─ 8 AO1 ─ AO8 Analog outputs 1 ─ 8

9 ─ 18 GND

21, 22 N.C. Do not use!

25, 26

NOTE: Shield connection to be used for shielded I/O

Technical Data

Table 16. Analog Output Module status LED behavior

automatic mode brightness follows the

override mode

signal comment

Ground. All grounds are connected

internally to each other

Shield connection (functional earth),

internally connected to the DIN rail

cables only. It is not allowed to connect a

L

ONWORKS shield.

commanded output signal

flashes

EN1B-0409GE51 R0908A

24

Page 25

XL1000 Description of the I/O Modules

X

Modules with Manual Overrides

The XFLR822AU Analog Output Modules are equipped with

manual overrides: one rotary knob for each analog output.

The manual overrides can be set manually to either "auto" or

"0 ─ 110%".

NOTICE

Damage to the electronic module!

► Do not use a tool to adjust the rotary knobs.

► Do not use excessive force. Adjust only by hand.

XFL822AU Connection Example

LN

24V

14507287

POWER

MODULE

This updating (synchronization) is performed:

• If the calculated position of the actuator

< lower synchronization threshold (2 %)

= synchronization towards 0 %

• If the calculated position of the actuator

> upper synchronization threshold (98 %)

= synchronization towards 100 %

• Following any power-up or any reset

~

XFL822AU

11

1

738

Umax = 11 VDC

Imax = 1 mA, -1 mA

SL511

GND SIGNAL 24VAC

M

Fig. 36. XFL822AU Analog Output Module, connection to

field devices

Synchronization Behavior of Analog Output Module

Configured as Floating Output

In order to regularly update the real actuator position with the

calculated position and thus ensure that the actuator

definitely reaches its end position, a synchronization process

is performed by the Analog Output Module.

During the synchronization process, the Analog Output

Module will continue running for the configured runtime once

it reaches the calculated end position.

25 EN1B-0409GE51 R0908A

Page 26

Description of the I/O Modules XL1000

Binary Input Modules

Types of Binary Input Modules

Table 17. XL800 Binary Input Modules

type description housing

XFL823 LONWORKS Binary Input Module dark-gray

XS823 terminal socket light-gray

Features

• 12 binary inputs

• 12 configurable status LEDs (green/red, yellow/OFF)

• Binary inputs can be used as static digital inputs (dry-

contacts)

1

2

3

4

5

Terminals

COM

71

A

COM

72 76

B

24

73 77

V~

24

74

V~0

BI12

BI11

BI10

BI9

BI8

BI7

BI6

BI5

BI4

BI3

BI2

BI1

12

11

10

9

8

7

6

5

4

3

2

1

GND13GND GNDGND GND GND GNDGND GND GNDGND GND

2423222120191817161514

Fig. 38. Terminal assignment and internal connections of

Binary Input Modules

Table 18. Description of Binary Input Module terminals

ter-

minal

signal comment

71, 75 COM a 2-wire LONWORKS communication bus

72, 76 COM b 2-wire LONWORKS communication bus

73, 77 24 V~ Power supply

74, 78 24 V~0 Power supply

1 ─ 12 BI1 ─ BI12 Binary inputs 1 ─ 12

13 ─

24

25, 26

GND

Ground. All grounds are connected

internally to each other.

Shield connection (functional earth),

internally connected to the DIN rail.

NOTE: Shield connection to be used for shielded I/O

cables only. It is not allowed to connect a

L

ONWORKS shield.

COM

A

COM

B

24

V~

24

V~0

25 26

75

78

Technical Data

Fig. 37. XFL823AU Binary Input Module with terminal

socket

Legend

1 Service button S1

2 Hex switch S2 (no function)

3 Input LEDs

4 Service LED

5 Power LED

Functionality of service LED and power LED: see Table 24

and following.

EN1B-0409GE51 R0908A

Table 19. Technical data for of Binary Input Modules

input type

current rating (closed input)

open contact voltage

dry-contact

2 mA

16 ─ 22 VDC

Status LEDs

The status LEDs can be configured individually for use as

either alarm LEDs (red/green) or as status LEDs (yellow/OFF

[default]).

Given a state of "logical ON," the LED will be lit (yellow or

red).

26

Page 27

XL1000 Description of the I/O Modules

XFL823AU Connection Examples

25

13

SHIELD

1

2

5 TO 24V

2 1

MIN.

25 MS

5 TO 24

VDC

3 15

MIN.

25 MS

CONTACT SUITABLE FOR

LO W V OLTA GE (G OL D) .

1

PROTECTED SWITCHING

2

UP TO 40 VDC / 24 VAC.

21

14

1

~ 120V

PT1000 NTC20kW

Fig. 39. XFL823AU Binary Input Module, connection to

field devices

27 EN1B-0409GE51 R0908A

Page 28

Description of the I/O Modules XL1000

Relay Output Modules

Types of Relay Output Modules

Table 20. XL800 Relay Output Modules

type description housing

XFL824 LONWORKS Relay Output Module dark-gray

L

XFLR824

ONWORKS Relay Output Module

with manual overrides

XS824-25

terminal socket; can be fitted

with long (red) cross connector

(incl. in scope of the delivery)

Features

• 6 relays (changeover contacts), arranged in two blocks

• XFLR824AU: 6 manual overrides

• Low and line voltage allowed, see WARNING.

1

2

dark-gray

light-gray

Terminals

COM

71 75

A

COM

72 76

B

24

73 77

V~

24

74

V~ 0

NO

NC

COM

CON

11

12

13

14

Relay block 1

NO

21

NC

22

COM

23

CON

24

Cross connector (can be removed, as desired)

NO

31 41 51 61

NC

32

COM

33 43 53 63

CON

34 44 54 64

NO

NC

COM

CON

42

Relay block 2

NO

NC

52 62

COM

CON

Fig. 41. Terminal assignment and internal connections of

Relay Output Modules

NO

NC

COM

CON

COM

A

COM

B

24

V~

24

V~0

78

25

3

4

5

6

Fig. 40. XFLR824AU Relay Output Module with terminal

socket

Legend

1 Service button S1

2 Hex switch S2 (no function)

3 Manual overrides

4 Status LEDs

5 Service LED

6 Power LED

Functionality of service LED and power LED: see Table 24

and following.

EN1B-0409GE51 R0908A

28

Page 29

XL1000 Description of the I/O Modules

Table 21. Description of Relay Output Module terminals

terminal signal comment

11

12

13

14

21

22

23

24

31

32

33

34

41

42

43

44

51

52

53

54

61

62

63

64

COM a

COM b

24 V~

24 V~0

REL1 N.O.

REL1 N.C.

R1 COM

R1 COM

REL2 N.O.

REL2 N.C.

R2 COM

R2 COM

REL3 N.O.

REL3 N.C.

R3 COM

R3 COM

REL4 N.O.

REL4 N.C.

R4 COM

R4 COM

REL5 N.O.

REL5 N.C.

R5 COM

R5 COM

REL6 N.O.

REL6 N.C.

R6 COM

R6 COM

2-wire LONWORKS communication bus

2-wire LONWORKS communication bus

Power supply

Power supply

Relay 1 N.O. contact

Relay 1 N.C. contact

relay 1 common contact

For connection of relay 1 common via

cross connector*

Relay 2 N.O. contact

Relay 2 N.C. contact

Relay 2 common contact

For connection of relay 2 common via

cross connector*

Relay 3 N.O. contact

Relay 3 N.C. contact

Relay 3 common contact

For connection of relay 3 common via

cross connector*

Relay 4 N.O. contact

Relay 4 N.C. contact

Relay 4 common contact

For connection of relay 4 common via

cross connector*

Relay 5 N.O. contact

Relay 5 N.C. contact

Relay 5 common contact

For connection of relay 5 common via

cross connector*

Relay 6 N.O. contact

Relay 6 N.C. contact

Relay 6 common contact

For connection of relay 6 common via

cross connector*

Shield connection (functional earth),

internally connected to the DIN rail

71, 75

72, 76

73, 77

74, 78

RELAY BLOCK 1

RELAY BLOCK 2

25

* Do not connect by wire!

Permissible Loads

Table 22. Permissible loads of Relay Output Modules

max. load

per relay output

module (total)

(common)

24 VAC, 60 Hz

12 A

24 VDC

12 A resistive, 12 A, 0.6 PF

per normally open

contact (common)

24 VAC, 60 Hz

4 A

24 VDC

4 A resistive, 4 A, 0.6 PF

per normally

closed contact

(common)

24 VAC, 2 A, 60 Hz

24 VDC

4 A resistive, 4 A, 0.6 PF

Status LEDs with Manual Overrides

5

12

4

3

6

Fig. 42. Manual overrides (toggle switches)

The XFLR824AU Relay Output Modules are equipped with

six manual overrides: one for each relay output. These toggle

switches can manually be set to either "auto" or "0" or "1".

Table 23. Relay Output Module status LED behavior

mode LED

automatic mode, state

ON ON OFF

N.O.*

(direct)

“logical ON”

automatic mode, state

OFF OFF ON

“logical OFF”

override mode (setting “0”) flashes OFF ON

override mode (setting “1”) flashes ON OFF

*As configured during engineering.

Honeywell

--1

--0

--AUTO

!

N.C.*

(reverse)

29 EN1B-0409GE51 R0908A

Page 30

XL1000

Connection Example

14507287 SERIES

POWER MODULE

COM

71 71

A

COM

72 72

B

24

73 7377

V

~

24

74 74

V

~

0

NO

NC

COM

CON

11

12

13

14

NO

NC

COM

CON

21

22

23

24

NO

NC

COM

CON

31

32

33

34

NO

NC

COM

CON

41

42

43

44

NO

NC

COM

CON

51

52

53

54

NO

NC

COM

CON

COM

A

COM

B

24

V

24

V

61

62

63

64

75

76

~

78

~

0

25

1 2

Fig. 43. XFL824AU connection example

COM

A

COM

B

24

V

~

24

V

~

0

M

EN1B-0409GE51 R0908A

30

Page 31

XL1000 Troubleshooting

Troubleshooting

Testing Wiring Connections

The push-in terminals feature small holes (1 mm in diameter)

which can be used to measure the signals.

► Insert a probe (1) as shown in Fig. 44.

Fig. 44. Testing wiring connections

I/O Modules Troubleshooting

► Check if the power supply voltage level is OK and that

there is no high voltage (> 24 VAC or > 40 VDC)

connected to the inputs/outputs of the XFL821AU,

XFL822AU, XFLR822AU, and XFL823AU I/O modules.

► Replace the problem LONWORKS I/O module with another

module of the same kind.

– If the problem persists, this is an indication that the

problem is caused by the application or incorrect wiring.

– If the problem is solved, this is an indication that the

L

ONWORKS I/O module was defective.

For troubleshooting purposes on all L

the following features can be used:

• Power LED

• Service LED

• Service button

In addition, a module-specific troubleshooting may be

necessary.

ONWORKS I/O modules,

31 EN1B-0409GE51 R0908A

Page 32

XL1000

Power LED of I/O Modules

Table 24. Power LED of LonWorks I/O modules

case power LED meaning remedy

1 ON

2 OFF

3 flashing continuously

LONWORKS I/O module is powered

No power

If the LONWORKS I/O module’s service LED is

likewise flashing, the L

ONWORKS I/O module is

No action necessary

► Check power supply

► Wait until rebooting (firmware

download) has been completed

in the boot mode

Service LED of I/O Modules

Table 25. Service LED of LonWorks I/O modules

case Service LED meaning remedy

LED remains OFF after

1

power-up

LED is lit continuously after

2

first power-up

LED flashes at power up,

3

goes OFF, and then is lit

continuously

LED repeatedly blinks

4

ON for 1 sec and

OFF for 1 sec

LED remains OFF after a

5

short ON duration

LED flashes continuously in

6

following pattern:

4 x ON/OFF followed by

pause

LED flashes continuously in

7

following pattern:

5 x ON/OFF followed by

pause

LED flashes continuously in

8

following pattern:

6 x ON/OFF followed by

pause

LED flashes continuously in

9

following pattern:

7 x ON/OFF followed by

pause

If the power LED is also OFF, then

– Defective device hardware

– Possible power supply problems, clock

problems, defective processor

Defective hardware

ONWORKS I/O module lacks application

L

ONWORKS I/O module is unconfigured, but has

L

an application

ONWORKS I/O module is configured and

L

running normally

Sensor failure of Analog Input Module

(this behavior can occur only if the appropriate

NV has been bound)

ONWORKS I/O Module has received the wink

L

command from network, physical outputs are

unaffected

Boot loader problem or hardware defect

Communications failure

► Replace hardware

► Replace hardware

► Download application

► Set module to configured mode

No action necessary

► Check sensor or connection

► Check sensor configuration

No action necessary

► Replace hardware

► Check bus wiring

► Check heartbeat

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Ecublens, Route du Bois 37, Switzerland by its Authorized Representative: