Page 1

Compact I/O Module

XIO-8AI UNIVERSAL ANALOG INPUT MODULE

LON Interface:

Transceiver: FTT10A free topology.

Neuron: 3150, 64k Flash.

Data format: standard network variables (SNVT).

Transmission rate: 78 kBit/s.

Maximum Length:

line topology 8858 ft. (2700 m) / 64 nodes.

free topology 1640 ft. (500 m) / 64 nodes.

Cabling: twisted pair.

Temperature Ratings:

Operating: 23° F to 131° F (-5° C to +55° C).

Storage: -4° F to +158° F (-20° C to +70° C).

Dimensions (W x H x D):

2.0 x 2.7 x 2.6 in. (30 x 68 x 65 mm).

Weight: 4.4 ounces (126 g).

INSTALLATION INSTRUCTIONS

GENERAL

The Honeywell XI0-8AI Universal LON® Analog Input Module

is a LON module with 8 configurable temperature or voltage

inputs to record temperatures and voltages of passive and

active sensors for example, electrical ventilation and mixing

valves, valve positions etc. The recorded counted

measurands are produced in different formats. Temperature,

resistance, percentage and voltage can be read out

depending on the setting for each input, and bound to other

LonMark

measuring ranges are done by LNS

voltage for active sensors can be provided by the module.

®

devices. The setting of sensor characteristics and

®

-Plugin. The supply

SPECIFICATIONS

Electrical Ratings:

Supply Operating Voltage: 20 to 28 V AC/DC.

Current Consumption: 57 mA (AC) / 30 mA (DC).

Duty cycle: 100%.

Recovery time: 550 ms.

Terminal Blocks:

Supply and Bus: 16 AWG (1.5 mm

(Terminal block and strapping plug included in packing).

Analog Inputs: 14 AWG (2.5 mm

2

).

2

).

Mounting Position: Any.

Mounting: DIN rail per EN 50022.

Input:

Temperature Range: selectable.

NOTE: Temperature input for all sensors is in the range of

40 Ω up to 4 MΩ.

Resolution: 0.2 K.

Error: approximately ± 0.4° F (±0.2° C).

Voltage input: 0 to 10 V DC.

Resolution: 10 mV (0.0 to 100%).

Error: approximately ±100 mV.

Construction Material:

Housing and Terminal Blocks: Polyamide 6.6 V0.

Faceplate: Polycarbonate.

Protective Circuitry:

Operating Voltage: polarity reversal protection.

Protection:

IP40 housing DIN 40050.

IP20 terminal blocks DIN 40050.

Approvals:

UL 916, Standard for Energy Management Equipment.

European Community Mark (CE) Listed.

95-7716—1

Page 2

COMPACT I/O MODULE

SAFETY INSTRUCTIONS

NOTES REGARDING DEVICE DESCRIPTION

These instructions include indications for use and mounting of

the device. In case of questions that cannot be answered with

these instructions, please consult the product supplier or

manufacturer. It is the responsibility of the equipment installer

to ensure that all federal, state and local codes are followed.

SAFETY INSTRUCTIONS

• Keep these Installation Instructions for industrial safety and

the prevention of accidents.

• Only qualified personnel shall do mounting and installation

work with these devices, see section titled “Qualified

Personnel”.

• The information in these instructions must be read and

understood by every person using this device.

QUALIFIED PERSONNEL

Qualified personnel in the sense of these instructions are

persons who are well versed in the use and installation of

such devices and whose professional qualification meets the

requirements of their work.

This includes, for example:

• Qualification to connect the device according to applicable

specifications and regulations, and a qualification to put

this device into operation, to power it down, or to activate it

by respecting the internal directions.

• Knowledge of safety rules.

• Knowledge about application and use of the device within

the equipment system.

BEFORE INSTALLATION

INSTALLATION

CAUTION

Electrical installation and device termination shall

be accomplished by qualified persons only, by

respecting all applicable specifications and

regulations.

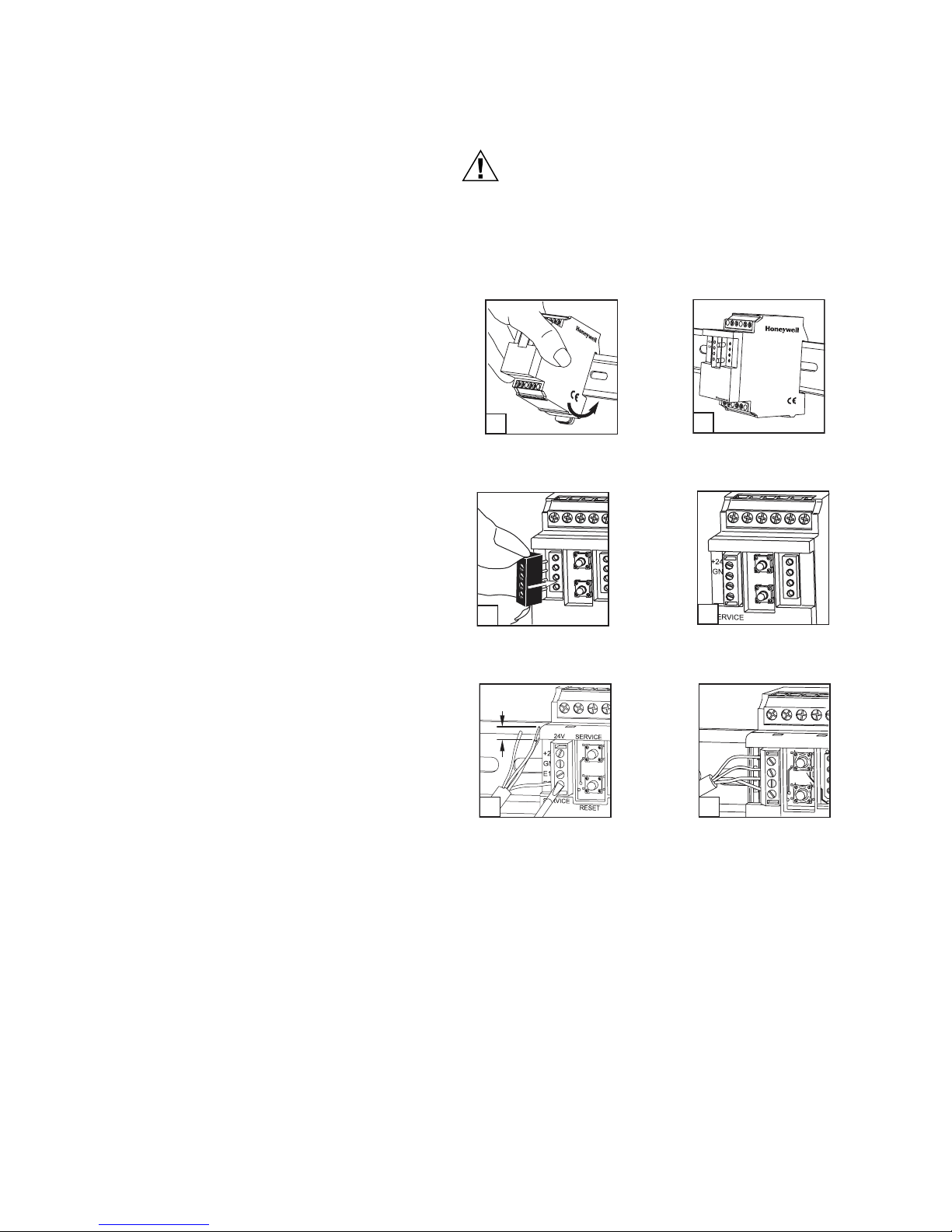

1. Power down the equipment. Mount the module on the

DIN rail.

24V

S

E

R

V

IC

E

24

1b

2b

V

+24V

G

N

D

E1

E1

E2

E2

SE

R

VIC

E

RESET

O

N

M25061

24V

SERVICE

24V

E1

E2

RESET

ON

SERVIC

E

ON

RESET

1a

M25060

2. Plug in the terminal block for bus connection.

24V

SERVICE

SERVICE

2a

3. Prepare the cable for bus connection:

RESET

M25062

+24V

GND

E1

E2

M25063

1. Unpack the XIO-8AI Universal LON Analog Input

Module.

2. Check the equipment and report any damage to a

Honeywell representative.

3. Read all of these instructions and ensure they are

understood.

MOUNTING

Mount the XIO-8AI Universal LON Analog Input Module on

standard DIN rail per DIN EN 50022 (1.35 x 0.3 in. [35 x

7.5 mm]), in junction boxes and/or on distribution panels.

0.2 in.

(5 mm)

24V

SERVICE

3a

M25040

3b

a. Remove about 0.75 in. (2 cm) of the plastic cable

sheath.

b. Strip 0.2 in. (5 mm) insulation from each wire. Put a

wire end sleeve to stranded wires.

c. Insert the wire to the respective contact and secure

it by screwing down the contact screw.

d. Wire cross section of the 4 pole terminal block bus/

mains connection:

(1) Maximum 16 AWG (1.5 mm

(2) Maximum 18 AWG (1.0 mm

2

) single wire.

2

) stranded wire.

(3) Wire diameter minimum 28 AWG (0.3 mm) up to

16 AWG (1.4 mm).

M25064

95-7716—1 2

Page 3

COMPACT I/O MODULE

4. Prepare cable for module connections.

0.3 in.

(7 mm)

24V

SERVICE

2

24V

SERVICE

24V

4a

M25041

4b

M25065

a. Strip the wires by 0.3 in. (7 mm). Put a wire end

sleeve on stranded wires.

b. Insert the wire into the respective module contact

and secure it by screwing down the contact screw.

c. Wire cross section of the 4 pole terminal block bus/

mains connection:

(1) Maximum 12 AWG (4.0 mm

(2) Maximum 14 AWG (2.5 mm

2

) single wire.

2

) stranded wire.

(3) Wire diameter minimum 28 AWG (0.3 mm) up to

10 AWG (2.7 mm).

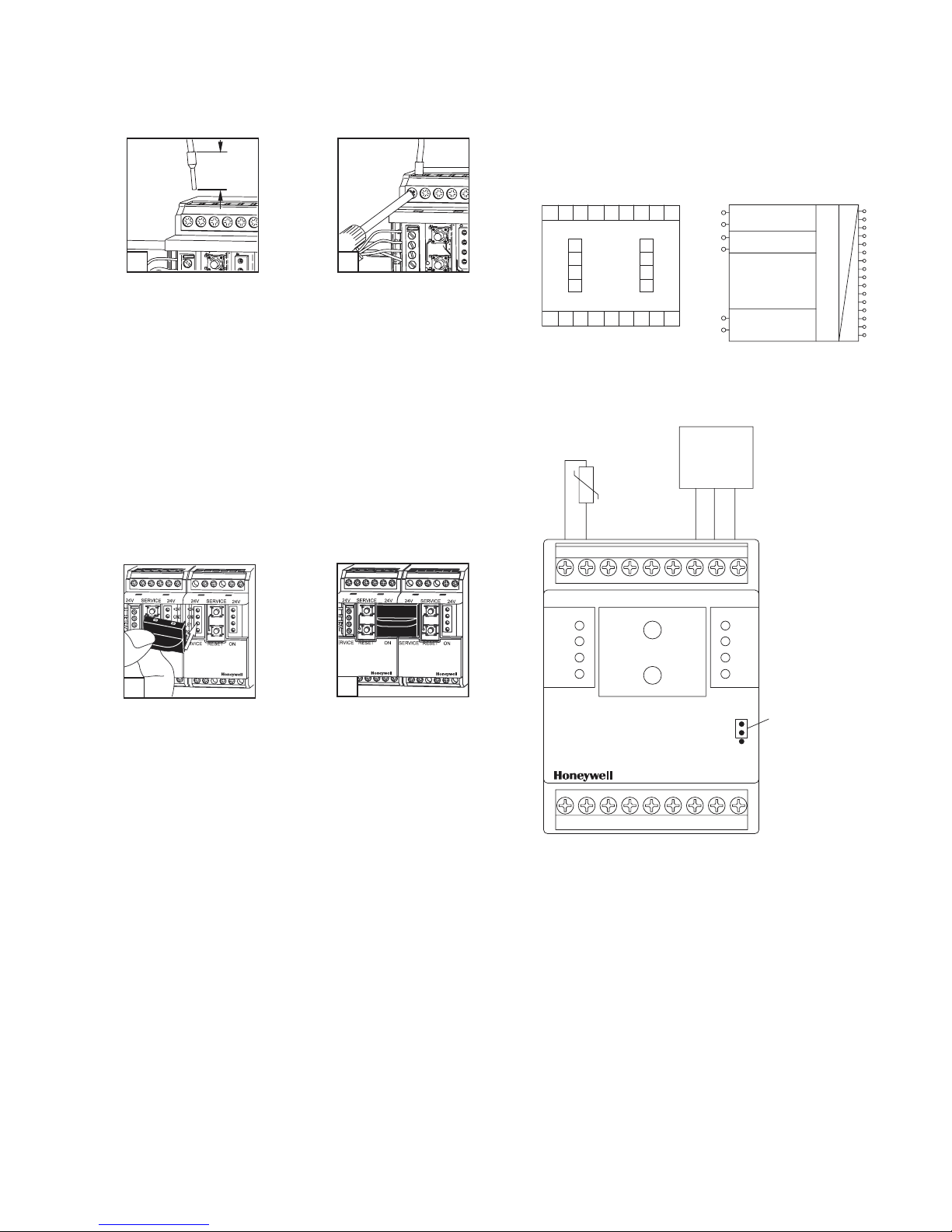

5. The module can be aligned without interspace. Use the

strapping plug to connect bus and supply voltage when

the modules are mounted in series. The modules can

be mounted in series without interspace. The maximum

number of modules connected in series is 15, with each

group needing an external power supply.

TERMINATION

Fig. 1 shows the termination points of the XIO-8AI.

+24V

GND

E1

E2

S

+24V

GND

E-bus 1

E-bus 2

0 - 10V

24V

FTT-10A

Inputs:

voltage 0-10 V

universal

temperature sensor

40 Ohm - 5 MOhm

Outputs:

S

voltage 15 VDC

S

or 24 VAC/DC

active

sensor

GND

Ub

S

C

81CC72CC63CC54CCS

24 V AC/DC

+24V

GND

E1

E2

GND

E-bus 1

E-bus 2

Fig. 1. Termination diagram for XIO-8AI.

passive

sensor

8 C 7 C 6 C 5

8

D

C

7

C

6

C

5

C

4

C

3

Neuron 3150

C

2

C

1

C

A

M25042

5a

+24V

GND

E1

E2

M25066

5b

+24V

GND

E1

E2

M25067

24V

+24V

GND

E1

E2

x10

x1

SERVICE

24V

+24V

GND

E1

E2

ON

XIO-8AI

1

C

2C3C 4

CS

Fig. 2. XIO-8AI Termination example.

Jumper below

the faceplate

M25044

3 95-7716—1

Page 4

COMPACT I/O MODULE

JUMPER POSITIONS

Fig. 3 illustrates the two jumper positions for the voltage

supply of active sensors.

+24V

GND

E1

E2

24V

SERVICE

24V

+24V

GND

E1

E2

Jumper below

SERVICE RESET ON

the faceplate

Jumper in

bottom position

contacts S

= 15 VDC

(factory setting)

+24V

GND

E1

E2

24V 24V

+24V

GND

E1

E2

SERVICE

XIO-8AI

Jumper below

SERVICE RESET ON

the faceplate

Jumper in

top position

contacts S = A1

XIO-8AI

(24V AC/DC)

M25043

Fig. 3. XIO-8AI Jumper positions.

24V 24V

SERVICE

+24V

GND

E1

E2

SERVICE RESET ON

Fig. 4. Front panel diagram of XIO-8AI.

+24V

GND

E-bus 1

E-bus 2

24VAC/DC

1

24V

FTT-10A

Inputs:

Voltage 0-10V

Universal-

Temp. Sensor

40 Ohm - 4 MOhm

Outputs:

S

Voltage 15VDC

S

or 24VAC/DC

XIO-8AI

Analog Input

+24V

GND

E1

E2

XIO-8AI

M25068

D

8

C

7

C

6

C

5

C

4

C

Neuron 3150

3

C

2

C

1

A

C

WIRING

Wiring of the XIO-8AI must be accomplished in accordance

with federal, state, and local requirements. Figures 4 through

6 show sample diagrams of wiring of the XIO-8AI.

95-7716—1 4

02

85267 27076

S

2

S

1 JUMPER IN BOTTOM POSITION (FACTORY DEFAULT),

15 VDC OUTPUT.

2

JUMPER IN TOP POSITION, 24 VDC OUTPUT.

M25069A

Fig. 5. Side panel diagram of XIO-8AI.

Page 5

connectors

8C7C6C5 CS

SERVICE

+24V

GND

E1

E2

SERVICE RESET ON

XIO-8AI

1C2C3C4 CS

Sensor

+10 to +20V

Out

GND

24V 24V

+24V

GND

E1

E2

Fig. 6. Wiring example XIO-8AI with sensor.

Jumper

15V Standard

M25070

COMPACT I/O MODULE

UCPTHyst SNVT_temp_p

Setting of the hysteresis; the output variables nvoHigh and

nvoLow switch over when the hysteresis is expired (factory

setting 2 Kelvin).5; 1. counted measurand = 1.

Temp_1- 8 Objects

nvoTemp_1 - 8

SNVT_temp

nvoTempp_1 - 8

SNVT_temp_p

nvoPercent_1 - 8

SNVT_lev_percent

nvoVoltage_1 - 8

SNVT_volt_f

nvoResistance_1 - 8

SNVT_res_f

nvoHigh_1 - 8

SNVT_switch

SOFTWARE DESCRIPTION

The Node Object monitors and controls the functions of the

different objects in the device. It supports the basic functions

Object-Status and Object-Request required by LonMark.

Refer to Fig. 7 for a basic illustration of Node Objects. The

following objects are monitored by the Node Object.

nviRequest NVT_obj_request

nvoStatus SNVT_obj_status

nvoFileDirectory SNVT_address

Node Object

nviRequest

SNVT_obj_request

SCPTmaxSendTime

UCPTHyst

Fig. 7. XIO-8AI Node Object.

SCPTmaxSendTime SNVT_time_sec

All output variables described below will be issued at the

latest at the end of the preset period even without status

change.

Time settings: 0 timer function off-state

6553,8 s (factory setting 60 s)

nvoStatus

SNVT_obj_status

nvoFileDirectory

SNVT_address

M25045

nvoLow_1 - 8

SNVT_switch

UCPTTemp_Offset

UCPTSensor_tab

UCPTTempMax

UCPTTempMin

UCPTHighT

UCPTLowT

SCPTinvrtOut

SCPTminSendTime

SCPTminDeltaTemp

M25046

Fig. 8. XIO-8AI Temp Objects.

nvoTemp_1...8 SNVT_temp

The output variable supplies a value with format ° C

depending on the input signal of 0 to 10.0 V and the settings in

UCPTTempHigh and UCPTTempLow and/or the resistance of

the selected temperature sensor.

nvoTemp_1...8 SNVT_temp_p

See Temp_1...8 but with 0.01° C format.

nvoPercent_1...8 SNVT_lev_percent

The output variable supplies a value with format 0 to 100.0%

for voltage measurements depending on the input signal of 0

to 10.0 Volt.

nvoVoltage_1...8 SNVT_volt_f

The output variable supplies a value with format 0 to 10.0 Volt

for voltage measurements depending on the input voltage.

nvoResistance_1...8 SNVT_res_f

The output variable supplies a value with format Ohm

depending on the input signal of 40 Ohm to 4 MOhm.

5 95-7716—1

Page 6

COMPACT I/O MODULE

nvoHigh_1...8 SNVT_switch

When exceeding the temperature set in UCPTHighT the

output variable changes from 0,0 0 to 100,0 1. When underrunning the temperature set in UCPTHighT plus the hysteresis

set in UCPTHyst the output variable changes from 100,01 to

0,0 0.

UCPTSensor_tab

Temperature

° F (° C) Resistance Sensor Name

nvoLow_1...8 SNVT_switch

When under-running the temperature set in UCPTLowT the

output variable changes from 0,0 0 to 100,0 1. When

exceeding the temperature set in UCPTLowT plus the

hysteresis in UCPTHyst the output variable changes from

100,0 1 to 0,0 0.

UCPTTemp_Offset SNVT_temp

The respective measurand can be readjusted in steps of 0.1 K.

ST_ON

(Resistance)

ST_OFF

(Voltage)

Factory setting: NTC20k in the range-22° F to 266° F (-30° C to +130° C).

UCPTTempMax SNVT_temp Werk:

UCPTHighT SNVT_temp Werk:

+ 302° F (+150° C)

UCPTTempMin SNVT_temp Werk:

UCPTLowT SNVT_temp Werk:

- 58° F (-50° C)

The temperature output variables are calculated during

voltage measurings according to a 0 to 10 Volt input signal

Setting of the thresholds nvoHigh and nviLow to make the

switch variables switch over.

and the here selected range.

SCPTinvrtOut SNVT_lev_disc

Inverting the values at nvoHigh or nvoLow.

®

, LonMark®, LNS® and Echelon® are registered trademarks of Echelon Corporation.

LON

+212° F (+100° C)

-14° F (-10° C)

95-7716—1 6

Page 7

COMPACT I/O MODULE

7 95-7716—1

Page 8

COMPACT I/O MODULE

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your use or modification to, the

literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and against any liability, cost, or damages, including

attorneys’ fees, arising out of, or resulting from, any modification to the literature by you.

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2006 Honeywell International Inc.

95-7716—1 C.H. Rev. 02-06

Loading...

Loading...