Page 1

XI581 / XI582

BUSWIDE OPERATOR INTERFACE

USER GUIDE

Software License Advisory This document supports software that is proprietary to Honeywell Inc. and/or to

third-party software vendors. Before software delivery, the end user must execute

a software license agreement that governs software use. Software license agreement provisions include limiting use of the software to equipment furnished,

limiting copying, preserving confidentiality, and prohibiting transfer to a third party.

Disclosure, use, or reproduction beyond that permitted in the license agreement is

prohibited.

Copyright © 2009 Honeywell Inc. • All Rights Reserved EN2B-0126GE51 R0309

Page 2

XI581/XI582 BUSWIDE OPERATOR INTERFACE

Trademark Information Echelon, LON, L

LonTalk, LonUsers, LonPoint, Neuron, 3120, 3150, the Echelon logo, the L

logo, and the LonUsers logo are trademarks of Echelon Corporation registered in

the United States and other countries. LonLink, LonResponse, LonSupport, and

LonMaker are trademarks of Echelon Corporation.

ONMARK, LONWORKS, LonBuilder, NodeBuilder, LonManager,

ONMARK

EN2B-0126GE51 R0309 2

Page 3

XI581/XI582 BUSWIDE OPERATOR INTERFACE

CONTENTS

Revision information.................................................................................................................................................................... ii

INTRODUCTION............................................................................................................................................................................ 1

GETTING STARTED...................................................................................................................................................................... 3

EVERYDAY OPERATIONS ......................................................................................................................................................... 16

Manual Organization................................................................................................. 2

Ratings ..................................................................................................................... 3

Connection Options .................................................................................................. 3

Buswide Access Mode ......................................................................................... 6

Screen Displays........................................................................................................ 9

Display Area Description ........................................................................................ 10

Display Window.................................................................................................. 10

Keypad............................................................................................................... 12

Operator Access Levels.......................................................................................... 13

Local and Remote Sign-On and Sign-Off ............................................................... 16

Level 2/3 Password Entry .................................................................................. 17

Logging into a Remote Controller....................................................................... 19

Logging Off from a Remote Controller ............................................................... 21

Controller Sign Off.............................................................................................. 21

Alarm Information ................................................................................................... 22

Viewing Alarm Information ................................................................................. 22

Viewing Buswide Alarms .................................................................................... 23

Enabling/Disabling Buswide Alarm Mode and Alarm Flag ................................. 24

Acknowledging the Buswide Alarm Flag ............................................................ 25

Viewing Point Information ....................................................................................... 26

Reviewing Time Program Schedules...................................................................... 27

Listing Totalizer Status ........................................................................................... 28

Requesting a Trend Log ......................................................................................... 30

Controller Information ............................................................................................. 32

Reading the Controller Clock ............................................................................. 32

Viewing Controller Configuration Data ............................................................... 32

Start-Up and Configuration ....................................................................................................................................................... 35

Hardware Interface Configuration........................................................................... 36

C-Bus ................................................................................................................. 36

LON-Bus ............................................................................................................ 36

B-Port................................................................................................................. 37

Modem and Remote Trend Buffer...................................................................... 37

Configuring the Modem Interface ....................................................................... 38

Enabling/Disabling the Remote Trend Buffer ..................................................... 38

Configuring the Remote Trend Buffer ................................................................ 39

Application Selection .............................................................................................. 42

Requesting a Download ..................................................................................... 43

Data Point Wiring Check......................................................................................... 43

Default Data Points ............................................................................................ 44

Assigning Distributed I/O Modules ..................................................................... 45

ALPHABETIC REFERENCE ....................................................................................................................................................... 49

Data Point Description Function ............................................................................. 49

Point Description Windows................................................................................. 51

Selecting Points by User Address ...................................................................... 55

Selecting Points by Template............................................................................. 56

Selecting Points by Point Type........................................................................... 57

Changing from Manual to Automatic Operation ................................................. 58

Listing Accumulated Runtime............................................................................. 59

Disabling a Point from Trend Log....................................................................... 59

Suppressing Alarm Reporting for a Point ........................................................... 60

Assigning Distributed I/O Modules / Showing Assignments.................................... 62

Flash EPROM and RAM Management ................................................................... 65

Erasing Flash EPROM ....................................................................................... 65

Saving Application Data from RAM to Flash EPROM ........................................ 66

Showing Application Data in Flash EPROM....................................................... 67

i EN2B-0126GE51 R0309

Page 4

CONTENTS XI581/XI582 BUSWIDE OPERATOR INTERFACE

Restoring Application Data from Flash EPROM to RAM.................................... 67

Parameters............................................................................................................. 67

Passwords.............................................................................................................. 68

Remote Communication ......................................................................................... 70

System Clock.......................................................................................................... 71

Template Operations .............................................................................................. 72

Adding a Template............................................................................................. 72

Deleting a Template ........................................................................................... 74

Modifying a Template......................................................................................... 75

Test Options ........................................................................................................... 76

Time Programs ....................................................................................................... 76

Daily Programs .................................................................................................. 77

Switch Points ..................................................................................................... 82

Weekly Programs............................................................................................... 86

Annual Programs ............................................................................................... 88

TODAY Programs .............................................................................................. 90

Special Days ...................................................................................................... 92

Totalizers................................................................................................................ 95

Viewing Bus Devices .............................................................................................. 97

Viewing the Remote Trend Buffer........................................................................... 98

Appendix A: Hardware Set-Up .................................................................................................................................................100

INDEX .........................................................................................................................................................................................103

Revision information

The following pages have been changed from the previous issue of this document:

Page: Change:

97

Explanation of the indication of the time synch master in the “Show All Devices” display by means of an asterisk

has been inserted..

EN2B-0126GE51 R0309 ii

Page 5

INTRODUCTION

XI581/XI582 BUSWIDE OPERATOR INTERFACE

The XI581/XI582 Buswide Operator Interface allows you to view and change basic

information programmed into an Excel controller. The controller information you can

change depends on your security access level and is always restricted to basic

information that controls day-to-day controller operation. To make major database

changes, you must use the XL-Online Operator and Service Software or

Honeywell’s Excel CARE software application programming tool.

Controller models Excel controller models you can directly access include the 50, 100, 500,

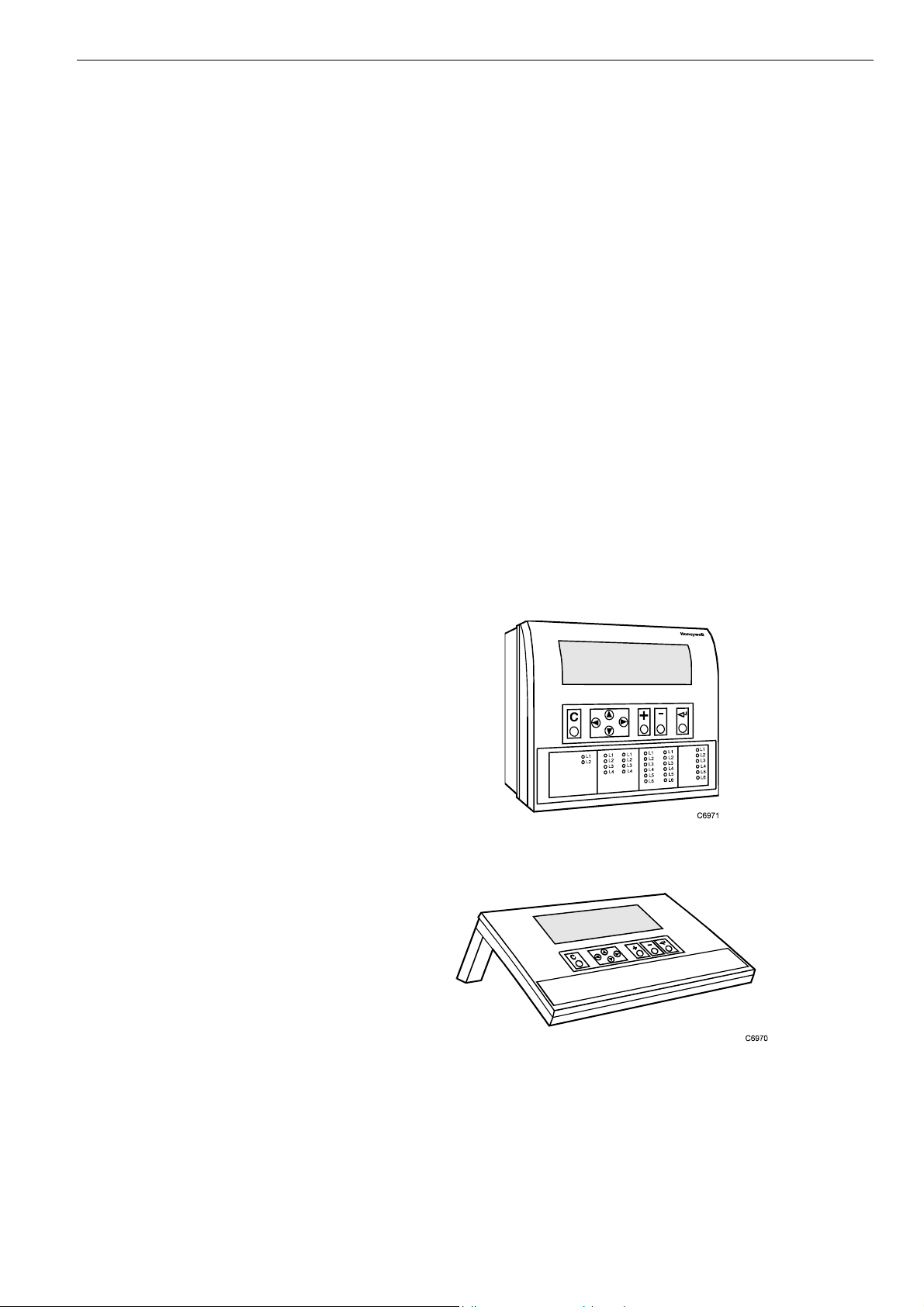

XI581/XI582 differences The XI581 (Fig. 1) and XI582 (Fig. 2) look and operate very much alike. The

500-XCL5010 (with XI582, only), 600, and 800. You can also indirectly access the

following controllers:

• Excel 10 Controllers via XI581/XI582 hookup to an Excel 10 Zone Manager

Controller

• Excel 20 Controllers via XI581/XI582 hookup to an Excel 500 or 600 Controller

In addition, the XI581/XI582 can operate in the buswide access mode, which

permits communication with remote controllers. Remote controllers can be any

Excel controller that connects to the same C-bus as the Excel controller to which

the XI581/XI582 is connected.

NOTE: The Excel controllers must have up-to-date software that includes the

buswide access mode feature. The "GETTING STARTED" section

describes buswide operation and restrictions.

difference is that the XI581 mounts directly on the front of an Excel 500 or 600

Controller, while the XI582 is a desktop unit that you can place up to 50 ft. (15 m)

away from an Excel controller or mount on a wall.

NOTE: Since they cannot be connected to a controller-mounted operator terminal,

the Excel 500-XCL5010 and the Excel 800-XCL8010A are operable only

with the XI582.

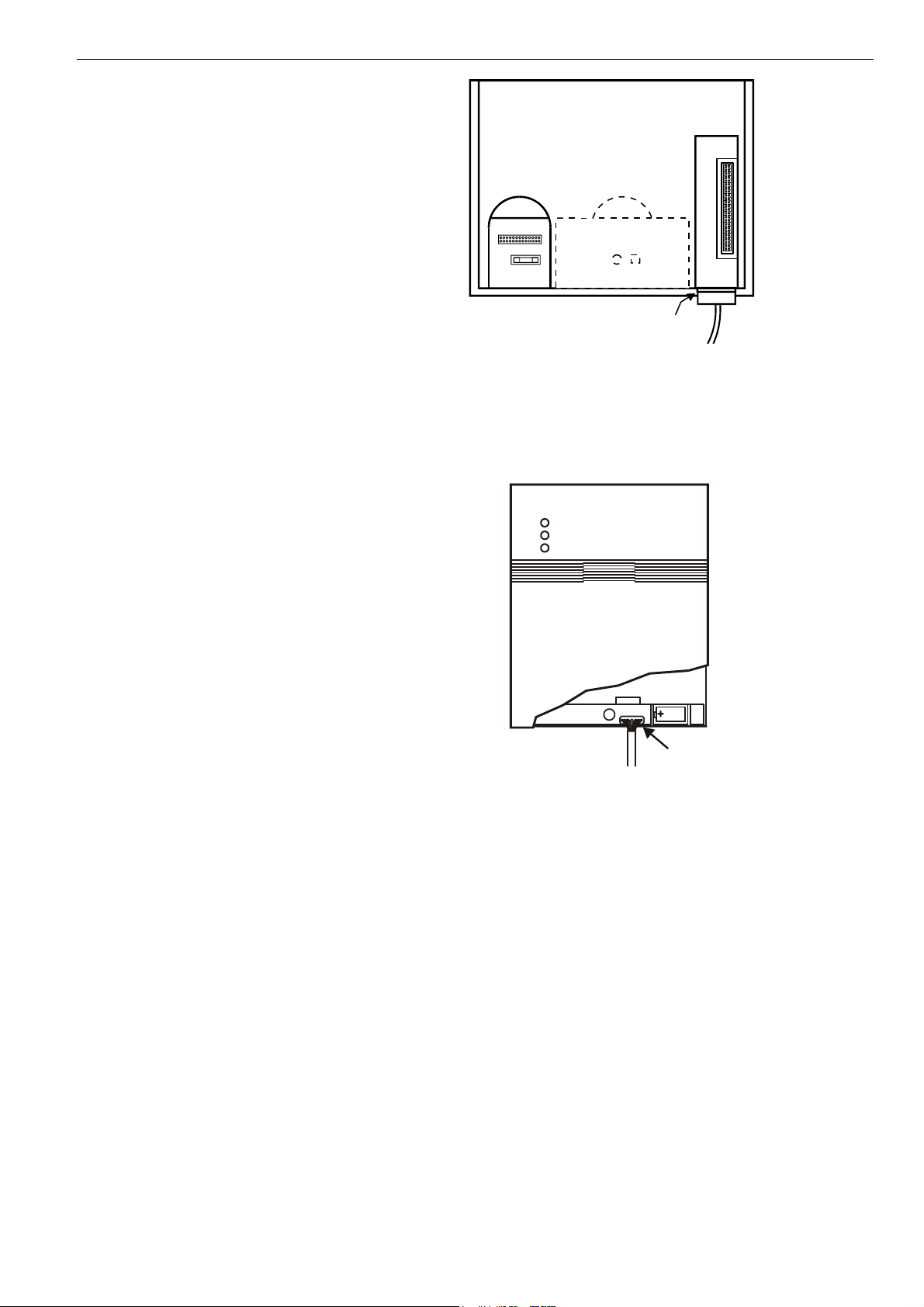

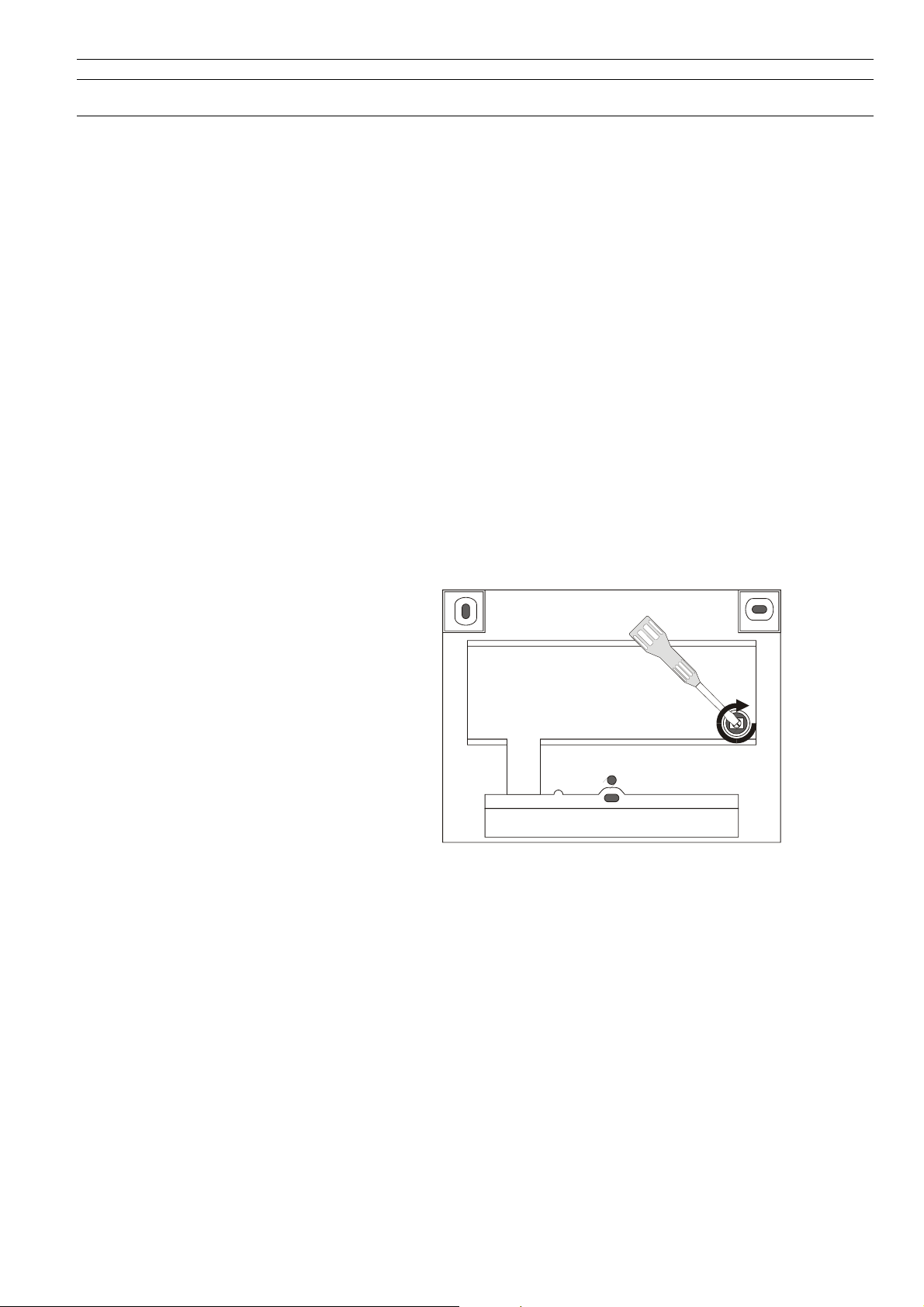

Fig. 1. XI581 Controller-Mounted Operator Terminal

EN2B-0126GE51 R0309 1

Fig. 2. XI582 Desktop Operator Terminal

Page 6

INTRODUCTION XI581/XI582 BUSWIDE OPERATOR INTERFACE

Manual Organization

Purpose This manual explains how to connect and operate the XI581/XI582.

Organization This manual is divided into the following sections, including this introductory section.

The Introduction section briefly describes the XI581/XI582 and highlights

similarities and differences between the two operator terminal models.

The Getting Started section describes:

• XI582 connection to an Excel controller. (The XI581 is mounted directly on an

Excel controller at installation time.)

• Buswide access mode.

• Display area description and keypad operations.

• Password access levels that determine whether you can view and/or modify

information using the XI581/XI582.

The Everyday Operations section explains tasks that you might perform daily or

weekly.

The Alphabetic Reference section explains tasks that you do not perform regularly

or in any particular order. The tasks are arranged alphabetically for easy lookup.

Appendix A: Hardware Setup describes how to route the cable for an XI582 that

does not mount on the wall or an Excel controller.

The Index provides page number references to topics.

EN2B-0126GE51 R0309 2

Page 7

XI581/XI582 BUSWIDE OPERATOR INTERFACE

GETTING STARTED

About this section This section describes:

• Connection options

• Screen display after start-up

• Description of display window and keypad operations

• Password access levels that determine the information you can view and/or

modify

Ratings

Electrical Input Class 2 power supply

Temperature The XI581/XI582 are suitable for use in ambient temperatures of up to 45 °C.

NOTE: The XI582/XI582 must be connected only to Excel 50/100/500/600/800

Controllers.

Connection Options

Connecting the XI581 The XI581 mounts on the front of an Excel 500-XC5010x and Excel 600-XC6010

Connecting the XI582 The XI582 requires the connection and routing of an appropriate cable (see Table

Controller at installation time and requires no further connection. When the

controller is powered, the XI581 is also powered. If the controller is off and then

powered on, the XI581 displays a message about the power failure. Use the Cancel

key (C) to acknowledge the message. The next screen is the main menu. See

"Screen Displays" (page 9) for details.

1). If your XI582 does not already have a connected cable, see Appendix A:

Hardware Setup, and Excel 500 Installation Instructions (EN1R-1047GE51) or Excel

100C Installation Instructions (EN1R-0144GE51) or Excel 800 Installation

Instructions (EN1B-0375GE51) for connection details.

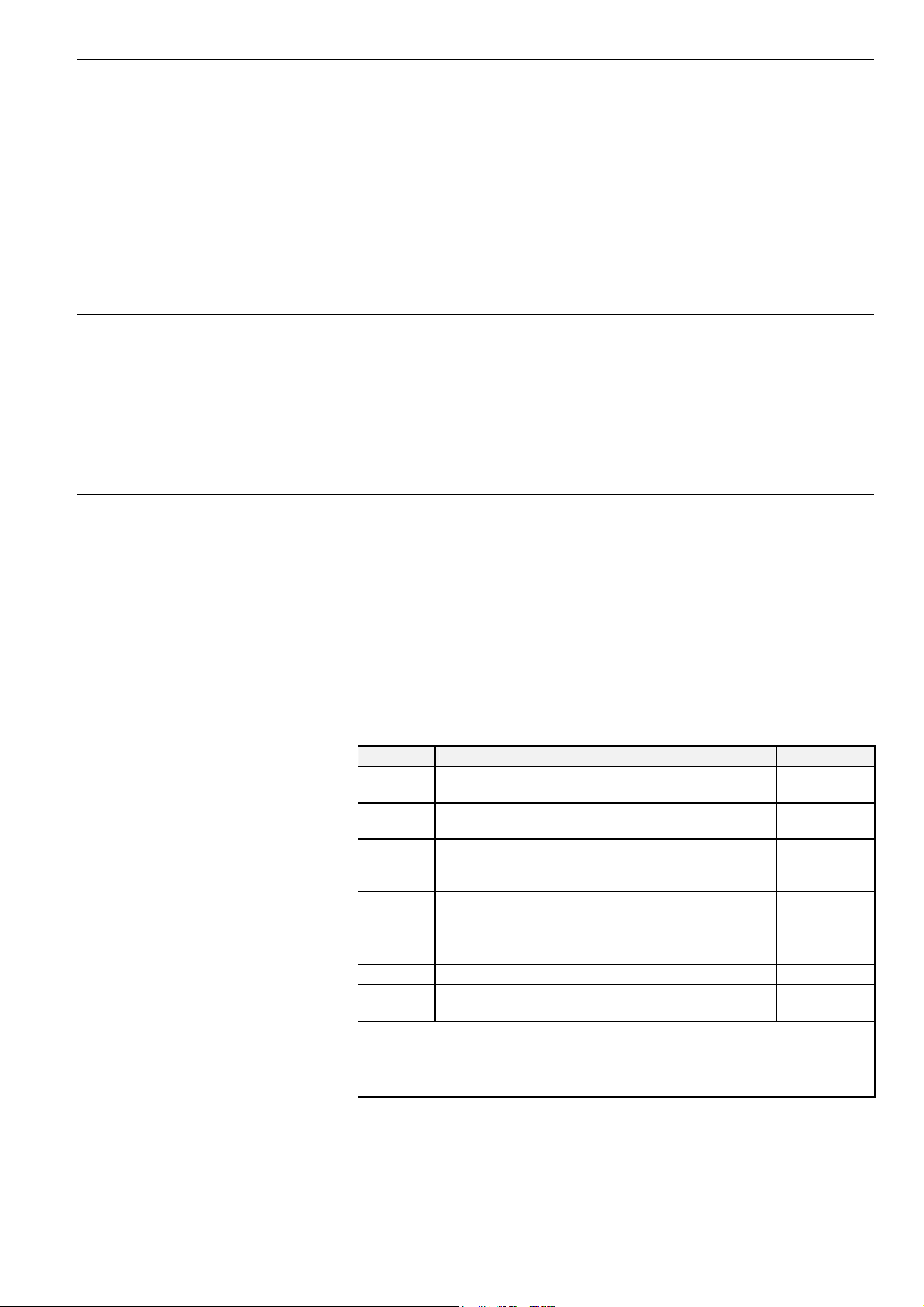

Table 1. Controllers and Compatible Cables

cable controllers length

XW564

XW565

XW582

XW5831

XW584

XW8822 Excel 800 Controller Module (XCL8010A), RJ45 jack 16 ft. (5 m)

XW884

1

Use this cable if the XI582 is to be permanently connected to an Excel 100C.

With the XW582 connected, the cover of the Excel 100C cannot be closed.

2

In lieu of the XW882 cable, it is possible to use an XW582 connected with an

XW586.

Excel 500 (prior to XC5010C CPU), 600;

with strain relief

Excel 500 (prior to XC5010C CPU), 600; without

strain relief

Excel 50, Excel 100C (front connector), Excel 500

(XC5010C CPU, front connector) (XCL5010 CPU,

serial connector)

Excel 100C (rear terminals),Excel 500 (XC5010C

CPU, rear connector)

Adapter cable for XW582 to Excel 100B, 500 (older

CPUs), 600

Adapter cable from XW882 to 9-pin Sub-D front

connector of Excel 50/100C, XC5010C, XCL5010

7 ft. (2.5 m)

16 ft. (5 m)

16 ft. (5 m)

16 ft. (5 m)

6 in. (16 cm)

6 in. (16 cm)

EN2B-0126GE51 R0309 3

Page 8

GETTING STARTED XI581/XI582 BUSWIDE OPERATOR INTERFACE

When the operator terminal has a connected cable, you can move it to any controller and attach it. If the controller has buswide capability, you can leave the XI582

attached to it and then access other controllers on the bus via remote login.

For information about connecting to various controllers, see below. After connection, see "Screen Displays" (page 9) for details on XI582 screen displays.

• Excel 100C Controllers have a RS232 serial port connection at the bottom of the

device as shown in the following diagram. An additional serial port connection is

provided at the terminals on the base of the Excel 100C. A port selector switch is

located on the front to select front or rear port (see below).

IMPORTANT

• Excel 500 and 600 Controllers have the serial port connection at the top of the

It is imperative that the Excel 100C Controller’s port selector switch be

properly set. Thus, after having operated an MMI via the front port, the

switch has to be set back to its left position to reactivate a modem being

connected to the rear terminals. If the switch is set to “front port“, the rear

terminals are deactivated, and vice versa.

controller as shown in the following diagram.

FRONT PORT

ACTIVE

SERIAL

PORT

EXCEL 100C

CONNECTION

PORT

SELECTOR

REAR

TERMINALS

ACTIVE

SERIAL

PORT

REAR TERMINALS FOR

MODEM OR MMI CONNECTION

EXCEL 500/600 CONNECTION

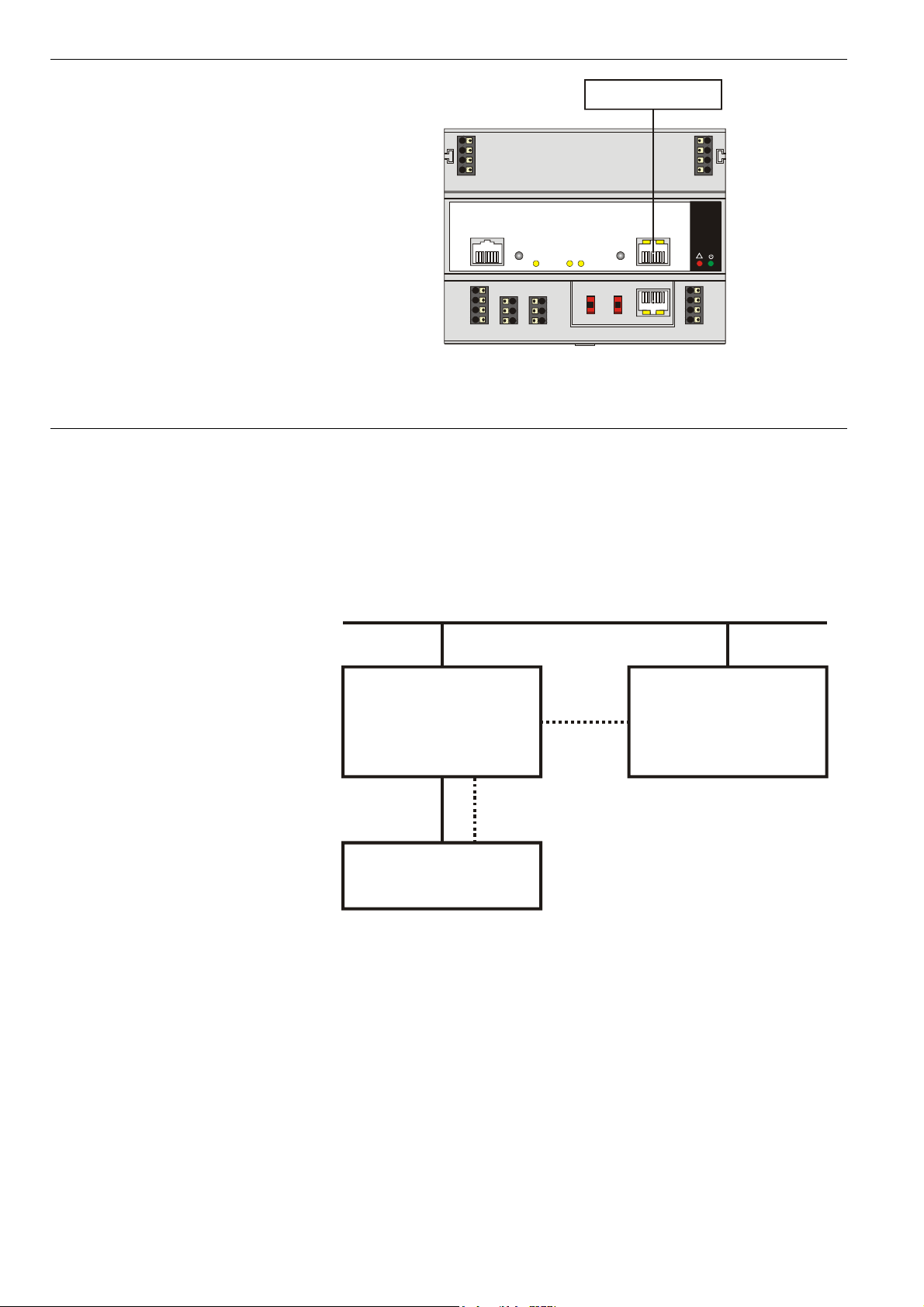

Fig. 3. Excel 100C and Excel 500/600 MMI connection

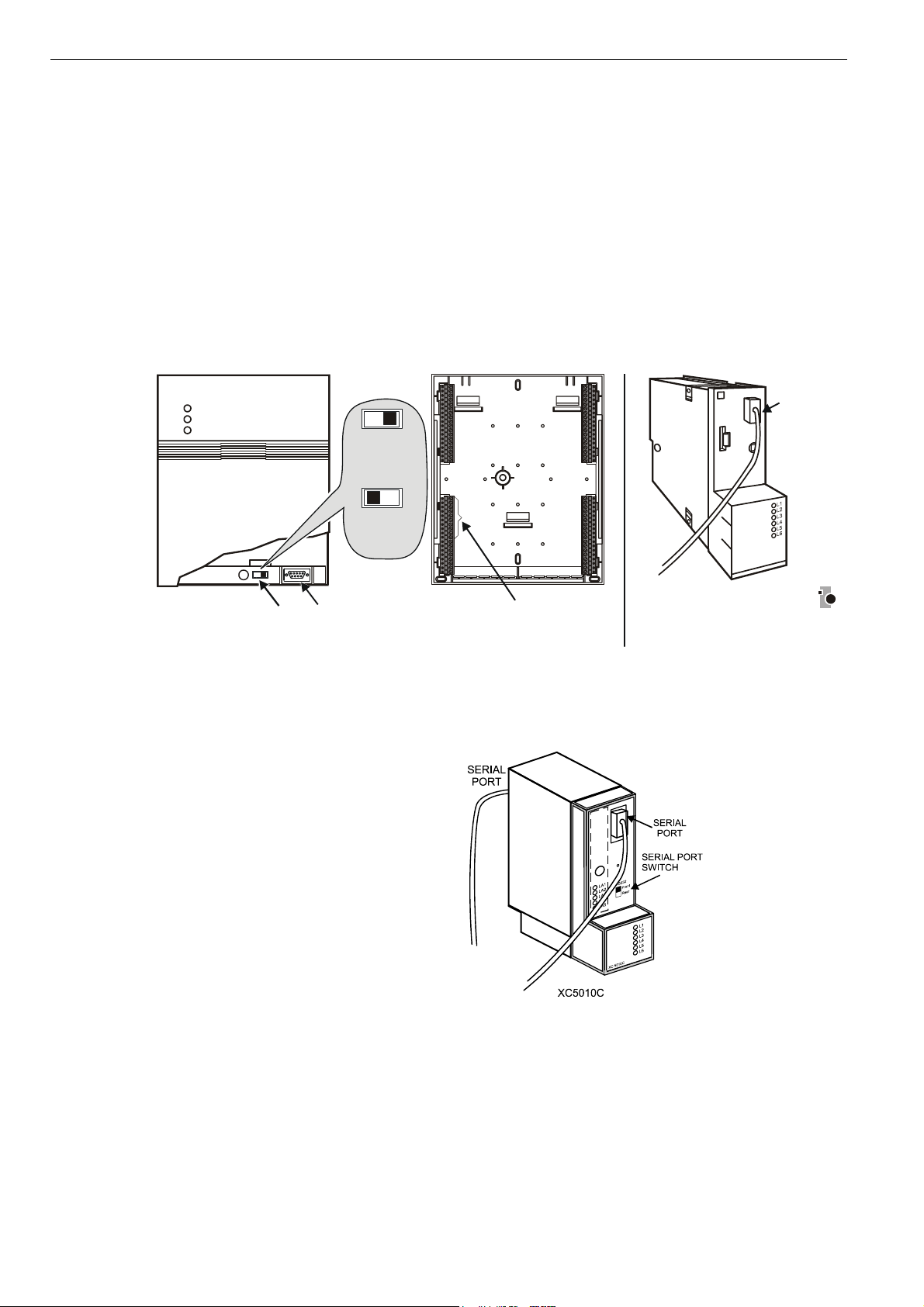

• The XC5010C CPU for Excel 500 has an additional serial port connection at the

terminal block on the back of the unit and a switch on the front to select front or

rear port.

C6982b

Fig. 4. Excel 500-XC5010C MMI connection

• Excel 50 and Excel 500-XCL5010 Controllers require the XW582 cable which

connects to the serial port on the bottom of the device as shown below.

EN2B-0126GE51 R0309 4

Page 9

XI581/XI582 BUSWIDE OPERATOR INTERFACE GETTING STARTED

A

CO

_

EXCEL 50

EXCEL 500-XCL5010

(REAR VIEW)

SERIAL PORT

Fig. 5. Excel 50 and Excel 500-XCL5010 MMI connection

• Excel 10 Zone Manager and Excel 100B Controllers have a serial port connection at the bottom of the device as shown in the following diagram. The

XI581/XI582 reads the data for the Excel 10 Controllers that connect to the Excel

10 Zone Manager.

a

ZM-Con

EXCEL 10

ZONE MANAGER

SERIAL

PORT

ND EXCEL 100B

NNECTION

Fig. 6. Excel 10 Zone Manager and Excel 100B MMI connection

• The Excel 800 Controller Module (XCL8010A) features an RJ45 serial connection

on the front (see Fig. 7) for connection (using the XW882 cable; alternately: the

XW582 together with the XW586) of Human-Machine-Interfaces (HMIs).

5 EN2B-0126GE51 R0309

Page 10

GETTING STARTED XI581/XI582 BUSWIDE OPERATOR INTERFACE

HMI INTERFACE

71 COM a

72 COM b

73 24V

~

74 24V 0

~

LON

87 65 43 21 87 65 43 21

11 1

12 285

13 396

14 410 7

C-Bus

LON

in

C-BUS RESET PC/HMI

C-Bus

out

S1 S2

9.6k

76k

76k

C-Bus

all

mid

end

I/O Bus

Panel

LON

Modem

COM a 75

COM b 76

24V 77

~

24V 0

~ 78

Honeywell

!

87 65 43 21

RxTx

Power/

Alarm

Fig. 7. Excel 800 Controller Module and MMI connection

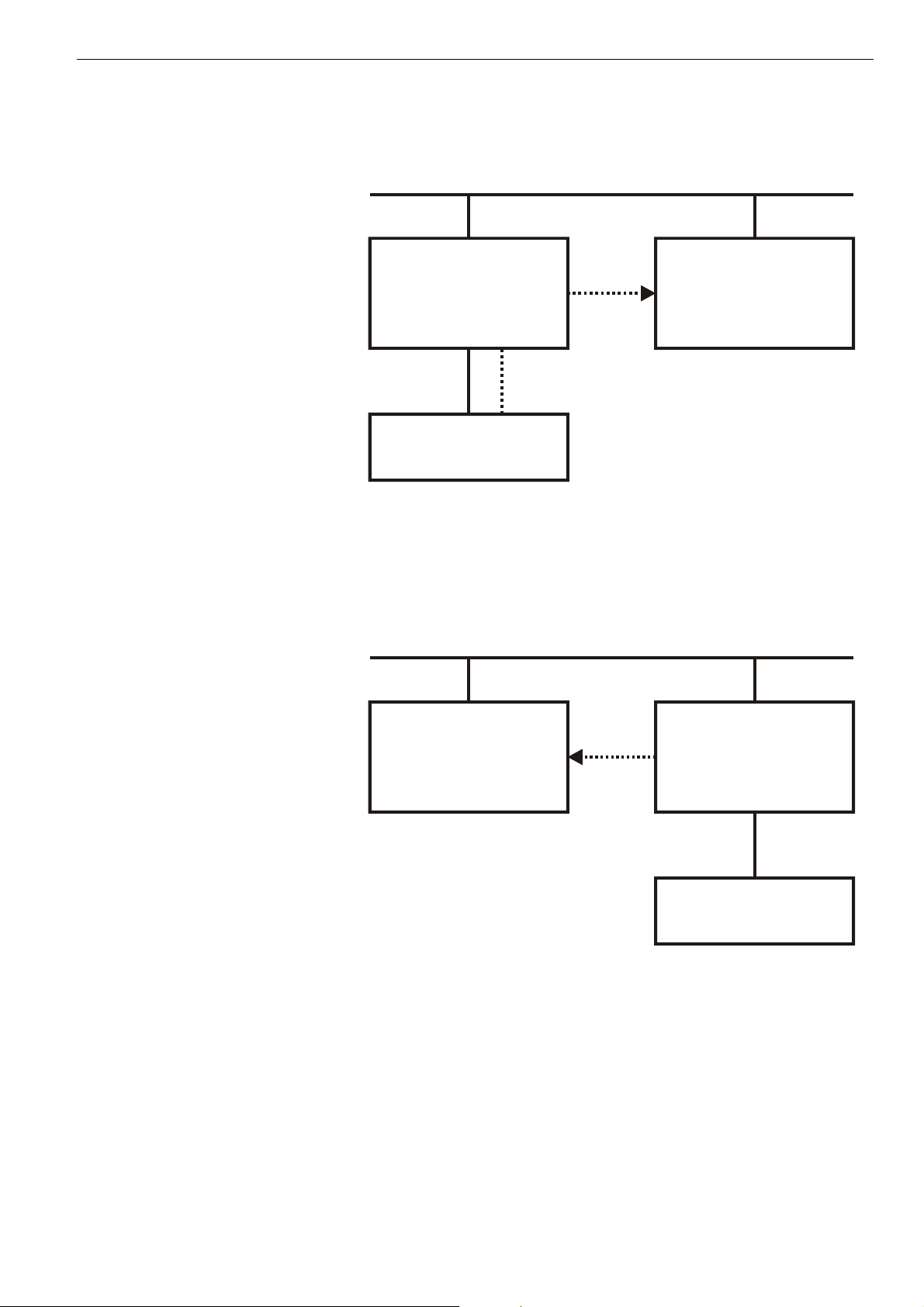

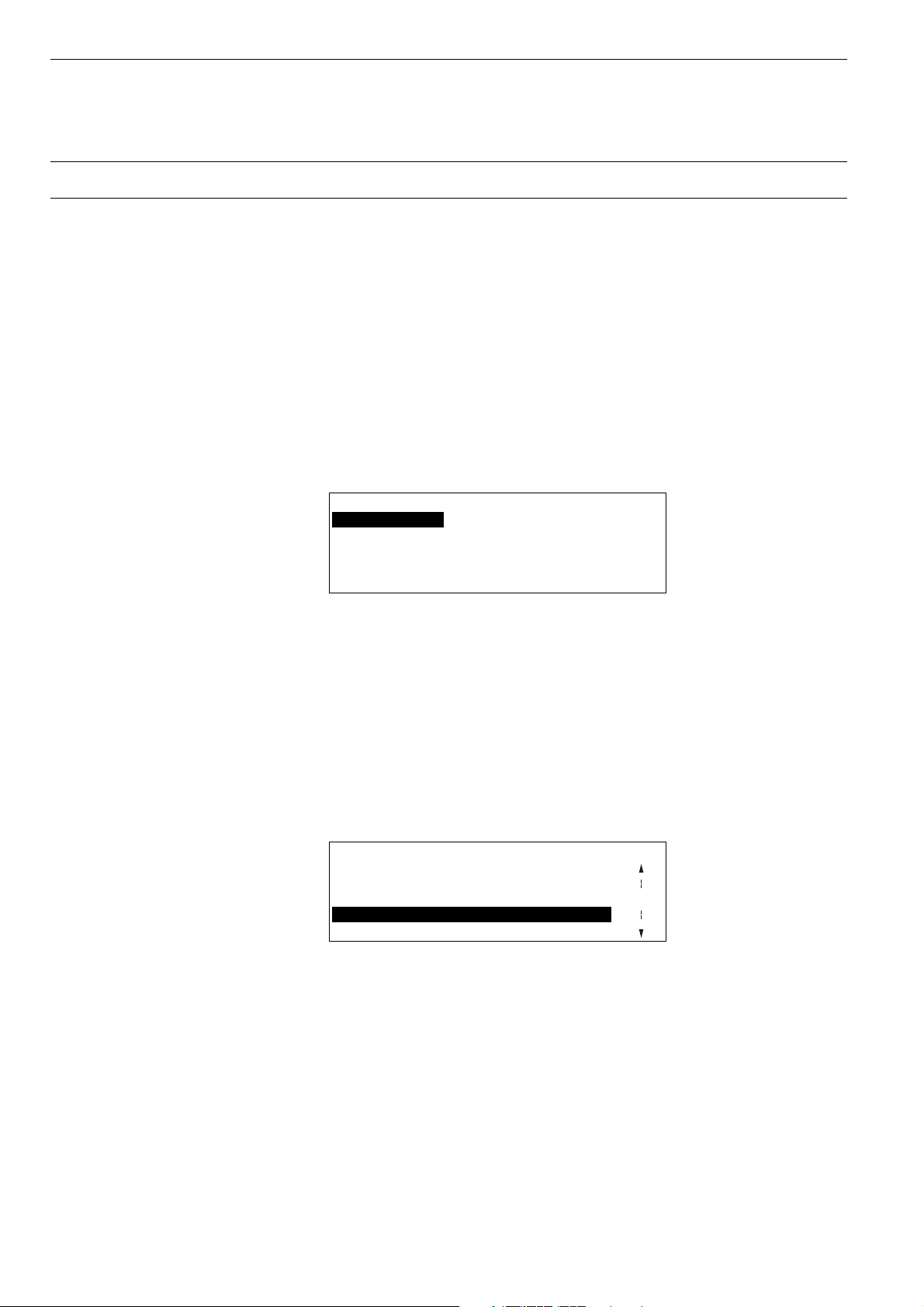

Buswide Access Mode

The buswide access mode allows communication between an XI581/XI582 and an

Excel controller that is not directly connected to the XI581/XI582. Communication

can include reading from and writing to the remote controller as well as receiving

alarm status information.

For example, an XI581/XI582 attached to an Excel 500 Controller can log in to an

Excel 100 Controller connected to the same system bus as the Excel 500

Controller.

C-bus

local

Excel

controller

remote

Excel

controller

buswide

access

XI581 / XI582

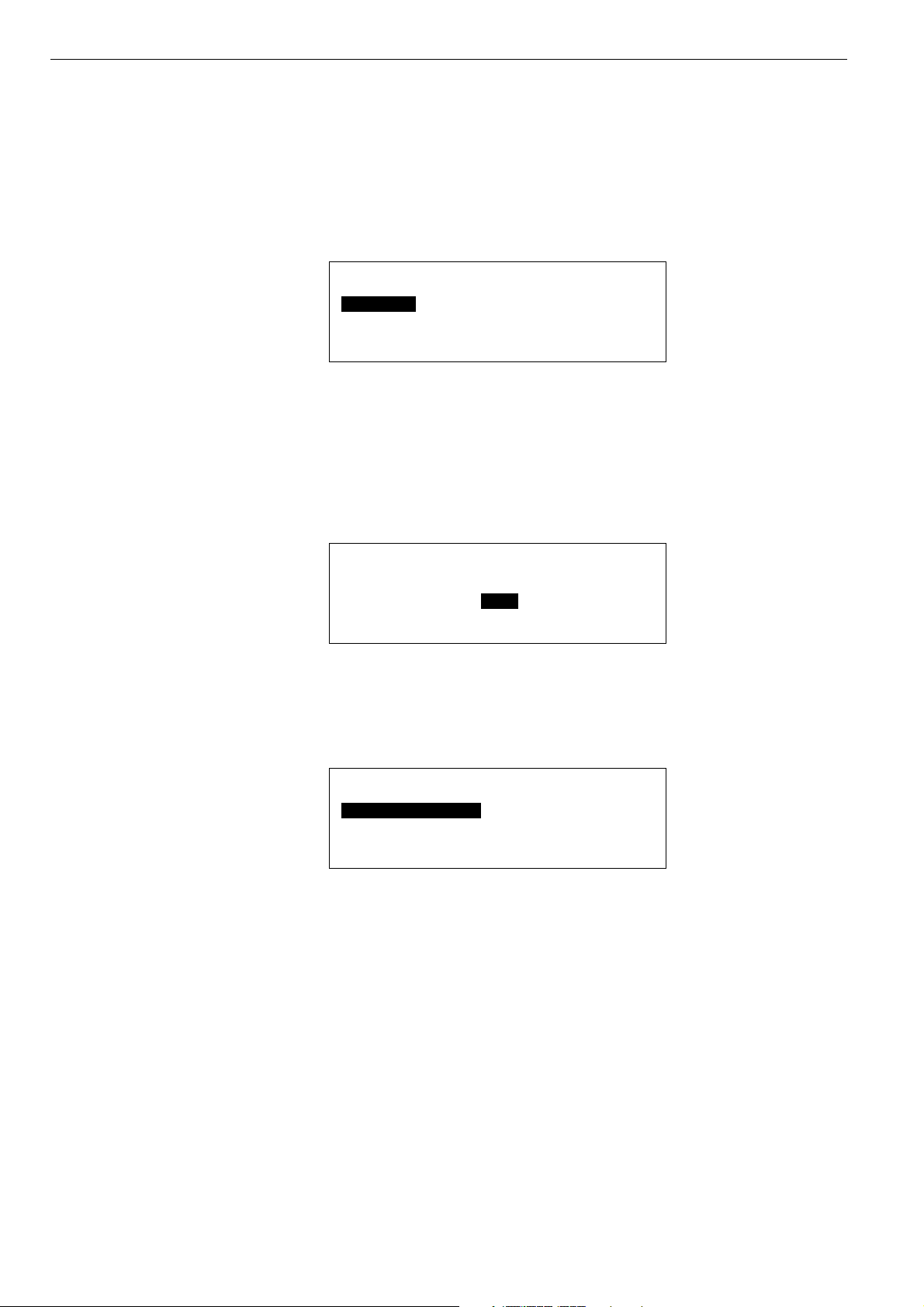

Fig. 8. Buswide access mode

Connection capabilities depend on the version of the controller and whether it has

buswide access mode software. Table 2 specifies the versions capable of the

buswide access mode.

EN2B-0126GE51 R0309 6

Page 11

XI581/XI582 BUSWIDE OPERATOR INTERFACE GETTING STARTED

There are two buswide access modes (active and passive) for controllers that have

this capability.

• With active buswide access, a controller (for example, Controller A) can access

another controller (Controller B) on the same bus if Controller B has at least

passive access.

C-bus

Controller A

active

buswide access

Controller B

active or passive

buswide access

buswide

access

XI581 / XI582

Fig. 9. Active buswide access

• With only passive buswide access mode, a controller (for example, Controller B)

cannot access another controller (Controller A) on the same bus. However, since

Controller B has at least the passive buswide access mode, Controller B can be

accessed by another controller that has the active buswide access mode (in this

case, Controller A).

C-bus

Controller A

active

buswide

X

Controller B

passive buswide

access, only

access

XI581 / XI582

Fig. 10. Passive buswide access

To access a remote controller, you must first log in to the controller. Once you are

logged into the remote controller, operation is almost the same as operating a local

controller. The menu structure used for operation is always that of the remote controller.

7 EN2B-0126GE51 R0309

Page 12

GETTING STARTED XI581/XI582 BUSWIDE OPERATOR INTERFACE

You cannot perform the following tasks while in the buswide access mode:

• Set the controller number.

• Set the communication baud rate.

• Start up a new controller.

Controller versions Some controller models (mainly older versions) do not support buswide functionality

or support passive buswide functionality only after installation of a Firmware

EPROM upgrade kit. Please contact your local branch or affiliate for further

information on EPROM upgrade kits.

Table 2. Buswide Access Capability of Different Devices

device buswide access mode

Excel 50, 100, 500, 600,

800 Controller

Yes, with Firmware EPROM Version Excel

500/600/800 1.03.00 or newer.

1

Version 1.01 cannot support the active access mode.

Excel 20 Controller

Excel 10 Zone Manager

Passive buswide access mode, only.

Excel 10 Zone Manager supports the passive buswide

access mode only with Firmware EPROM Version

1.02.xx or newer3.

XIP100 no

1

Excel 100/500/600 Controllers running under Firmware EPROM Version Excel

500/600 1.2.XX can be upgraded by changing the Firmware EPROM to Version

1.03. The controllers then support full buswide functionality, i.e. passive and active

buswide access. Excel 800 controllers support this with any firmware version,

starting with 3.00.xx.

2

Excel 100/500/600 Controllers running under Firmware EPROM Version Excel 500

Version 1.01 must be equipped with the Excel 1.01 upgrade kit for the buswide

access mode. They then support the passive buswide access mode. However,

Version 1.01 Controllers do not support the active buswide access mode.

3

Excel 800 controllers support this with any firmware version, starting with 3.00.xx.

2

Buswide alarms The XI581/XI582 does not directly report buswide alarms on screen, but you can set

it to an “alarm standby” mode where it listens to the system bus and then reports

the occurrence of a new alarm somewhere on the system bus. In a separate

screen, you can view the contents of the alarm buffer which will tell you where on

the system bus the new alarm has occurred. You can then log in to the appropriate

controller and look in the alarm buffer of the remote controller to find the cause of

the alarm.

To enable the buswide alarm flag, set the XI581/XI582 to Alarm Standby Flag mode

in the 'Buswide Access' screen. To enable receiving of buswide alarms, set the

XI581/XI582 to 'Alarm Standby On'. The "Alarm Information" section describes

these options.

When alarm standby is on and the alarm flag enabled, a screen symbol starts

flashing as soon as a new buswide alarm arrives from somewhere on the system

bus.

NOTE: Local alarms will not show when you are logged in to a remote controller.

The reading of a buswide alarm from an XI581/XI582 is independent of the

XBS/XBS-i/XFI/EBI mechanism for alarm acknowledgment.

Performance Only one buswide XI581/XI582 (local or remote) can be logged onto a controller at

any one time. However, there is no restriction as to the total number of buswide

XI581/XI582 used on the same system bus. When XBS PCs are also on the bus,

there may be up to four XBS PCs on the same bus and one buswide XI581/XI582

that is in remote access at the same time.

All XI581/XI582 are of equal priority, so that whichever device signs on first gains

access to a controller and no other device (local or remote) can sign on to the same

controller during this time.

EN2B-0126GE51 R0309 8

Page 13

XI581/XI582 BUSWIDE OPERATOR INTERFACE GETTING STARTED

Screen Displays

Initial screen displays depend on the status of the controller and its pending alarms.

Powered controller After you plug an XI582 into a powered controller, the main menu appears in the

display window.

An XI581 that is always attached to a controller typically displays the main menu

unless an operator has penetrated to some other menu.

Controller power-on The first display screen that appears after power-on is a message about the power

CPU reset If you press the controller's CPU reset switch, the controller restarts and the

Adjusting contrast The contrast of the display can be adjusted, using a screwdriver, by rotating the

failure. Use the Cancel key (C) to acknowledge the message. The main menu is

displayed.

XI581/XI582 displays the 'title/copyright' screen.

Memory Cleared

If you push the CPU reset switch, everything in the controller is deleted.

Use the CPU reset switch only for servicing.

To reload the controller, follow the download procedure as explained in the Flash

EPROM and RAM Management procedures (in the "ALPHABETIC REFERENCE"

section). If the controller does not have Flash EPROM, use Excel CARE software to

download the controller.

corresponding knob accessible through a hole at the rear of the device. Pressing

any of the eight operating keys activates the backlight. If no entries are made for

approximately ten minutes, the backlight turns itself off automatically until a key is

pressed again.

Operation The rest of this section describes the XI581/XI582 display area and its access

levels. If you are familiar with this information, continue with the sign-on procedure

in the "Local and Remote Sign-On and Sign-Off " section.

9 EN2B-0126GE51 R0309

Page 14

GETTING STARTED XI581/XI582 BUSWIDE OPERATOR INTERFACE

Display Area Description

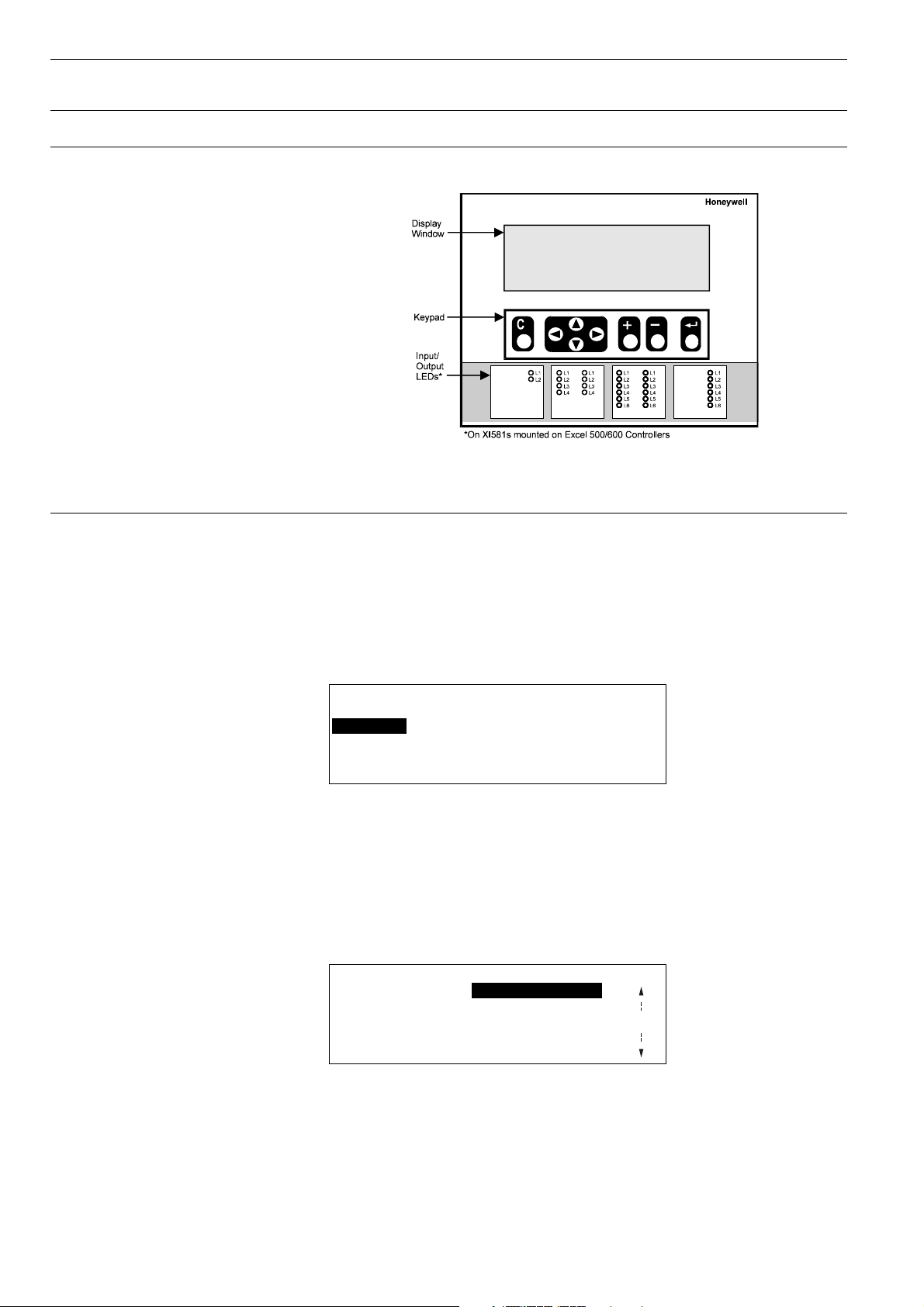

Fig. 11. MMI display area

Display Window

The XI581/XI582 display window is located above the keypad. The window presents

system information, operator entries, and menus of functions that you can perform.

Menu example For example, the following is the first menu (the main menu) that appears. It shows

the controller name, the current time and date, and a list of functions you can select.

The word Password is highlighted (reverse video on the display) because it is the

default selection.

CONTROLLER_07 18:16!

Running 15.12.1994

Password Alarms

Time Programmes Trend Buffer

Data Points System Clock

System Data

The buswide alarm flag (exclamation mark, !, in the top right-hand corner of the

window) indicates that the buswide alarm notification mode is enabled. If it is

blinking, an alarm has occurred. The "Alarm Information" section describes alarm

display and acknowledgment.

Time program window example The following window display appears when you select 'Time Programmes'. It lists

the zones that have time programs and waits for operator selection of a zone. The

scroll bar is on the right-hand side of the window.

Time Programme

Time Program 1

Ventil. Sys

Lighting 1

Heating zone east

Heating zone west

EN2B-0126GE51 R0309 10

Page 15

XI581/XI582 BUSWIDE OPERATOR INTERFACE GETTING STARTED

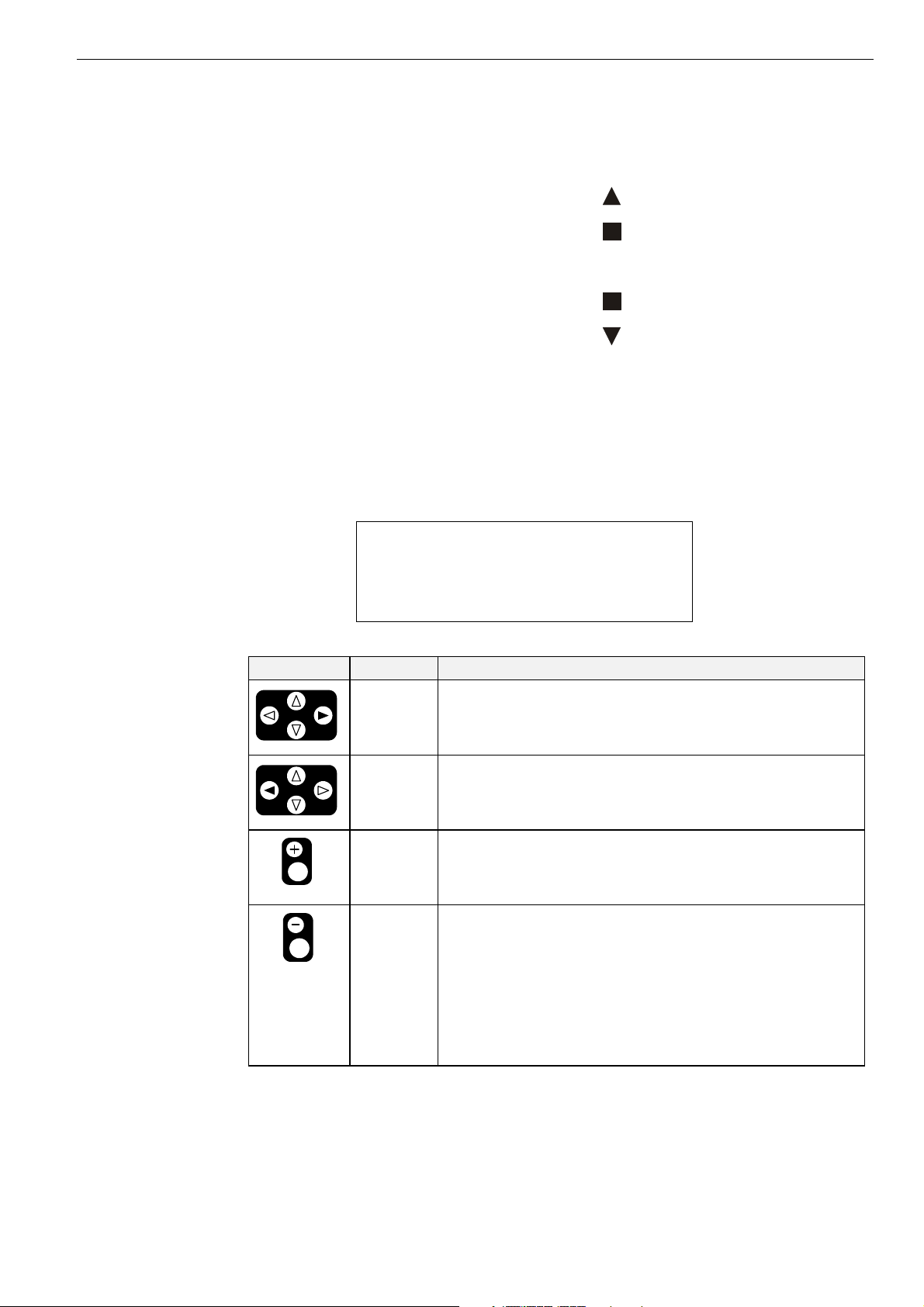

Scroll bar The XI581/XI582 display window can show six lines of information at a time. A scroll

bar appears on the right-hand side of the window as shown in the 'Time

Programme' window example:

1

The scroll bar allows you to quickly move through the items in the list so you can

locate the one you want. The number indicates the number of pages being scrolled

using the right and left arrow keys. Use the following keys to scroll (see Table 3).

NOTE: With an Excel 50 directly connected or accessed via the buswide access

mode, the display varies from that given for an Excel 100/500/600

controller. The left two-thirds show the MMI information of the Excel 50; the

right third shows text equivalents of the four fast-access keys of the Excel

50 (see example below).

AHU PLANT

TUE 21:09 11:55 TIME

to 06:00 20.0 C PARAMETERS

TODAY NEXT ALARM

Table 3. Scroll Key Descriptions

key key name scroll description

right arrow

left arrow

C6985

plus

minus

The next section describes the other keys available on the keypad as well as other

functions for the right arrow, left arrow, plus, and minus keys.

Move forward the selected number of pages. See the plus and

minus key descriptions to select the number of pages. The default

is 1 page.

Move backward the selected number of pages. See the plus and

minus key descriptions to select the number of pages. The default

is 1 page.

Increment the number in the scroll bar by 1 (maximum 9). For

example, select 2 to scroll two pages.

After selecting the number of pages, use the right arrow key to

scroll the pages forward.

Decrement the number in the scroll bar by 1.

After selecting the number of pages, use the right arrow key to

scroll the pages backwards.

If you press the minus key while the number in the scroll bar is 1, a

Less-Than symbol (<) appears. If you then press the left arrow key,

the first page in the list will be displayed.

If you press the minus key again while the Less-Than symbol is in

the scroll bar, a Greater-Than symbol (>) appears. If you then

press the right arrow key, the last page in the list will be displayed.

11 EN2B-0126GE51 R0309

Page 16

GETTING STARTED XI581/XI582 BUSWIDE OPERATOR INTERFACE

Keypad

The XI581/XI582 keypad has eight keys that control all operator entries. The

following table describes the function of each key. Following the table are tips for

moving the cursor around within the display window.

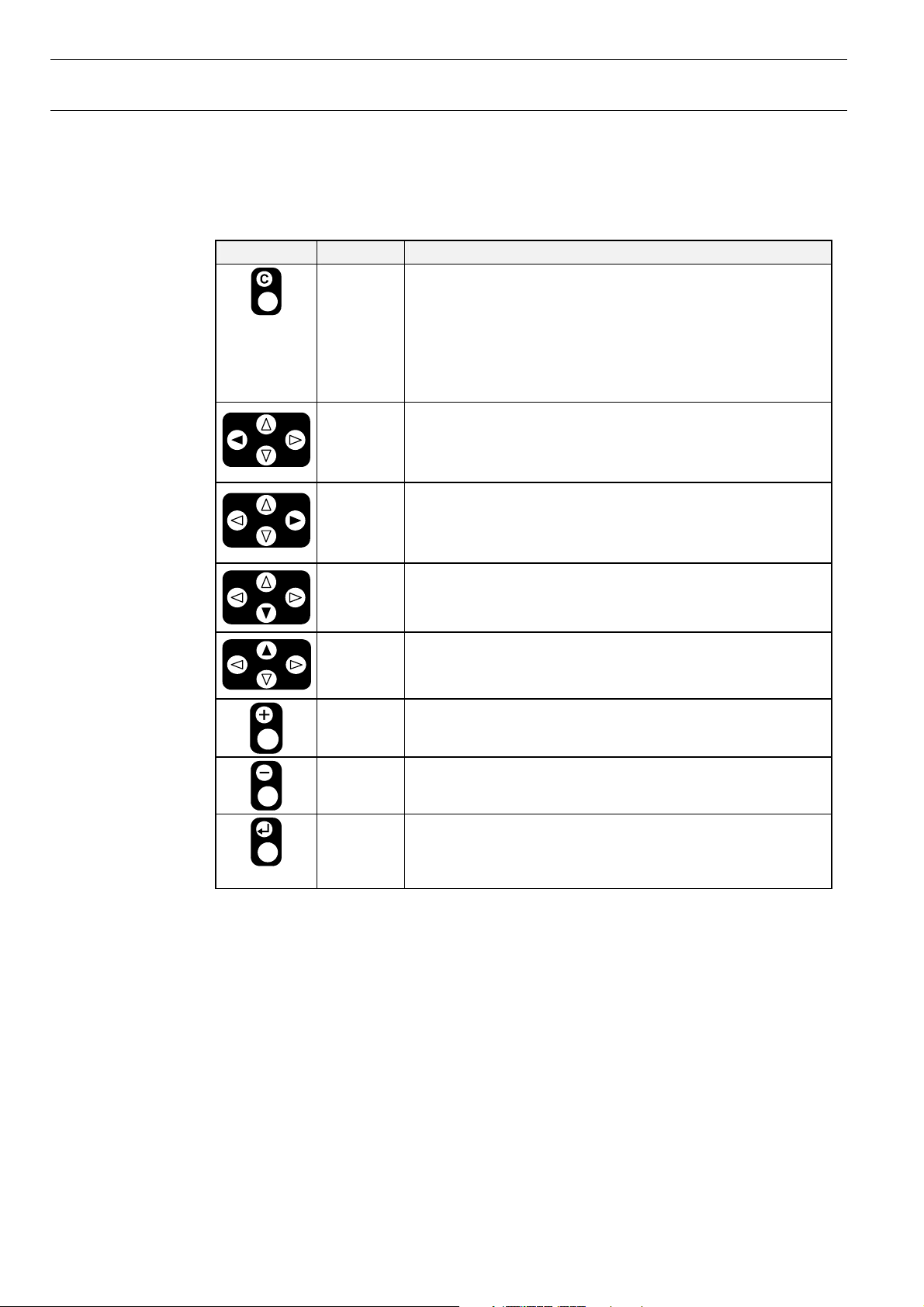

Table 4. Description of Key Functions

key key name description

Cancel

left arrow

C6985

right arrow

down arrow

End the task you are performing and return to a previous display

window.

If you press this key after you modify a field, but before pressing

Enter, ↵, the XI581/XI582 erases any new information you input

and retains the original information.

If you press this key after you modify a field and press Enter, ↵, the

XI581/XI582 retains the new information you input.

Within a menu or a line of items, the left arrow moves the cursor

from one column (or item) to another.

Within a data field, the left arrow moves the cursor to the left one

digit.

Within a menu or a line of items, the right arrow moves the cursor

from one column (or item) to another.

Within a data field, the right arrow moves the cursor to the right one

digit.

Move the cursor to the next field, the next column, or to the next

line in a column.

up arrow

Move the cursor to the previous field, the previous column, or to the

previous line in a column.

plus

Increase the value of a digit by one (for example, from 2 to 3). You

can also use this key to change the condition of a digital point. For

minus

example, press this key to flip a digital point from OFF to ON.

Decrease the value of a digit by one (for example, from 2 to 1). You

can also use this key to change the condition of a digital point. For

Enter

example, press this key to flip a digital point from OFF to ON.

Enter and confirm input values or command choices for the

controller. When you press this key, it allow modification of the

highlighted field. Pressing Enter (

↵) again stores the value in

memory.

Moving between columns To move horizontally between columns in a menu or list, press the down arrow key

until you reach the bottom of the column. When you press the down arrow key

again, the cursor automatically jumps to the first item in the next column.

1

If the cursor is on the first item in the first column, pressing the right arrow key

moves the cursor to the first item in the second column. If the cursor is on the last

item in the second column, pressing the down arrow key moves the cursor to the

first item in the first column.

1

NOTE: In case not all entries are displayed (e.g. no password entered), this may

1

differ slightly.

Modifying a field To change information in a field, first use the arrow keys to move to and highlight

the field. Then press Enter, ↵. After the change is made, Enter (↵) must be pressed

again to confirm the change.

EN2B-0126GE51 R0309 12

Page 17

XI581/XI582 BUSWIDE OPERATOR INTERFACE GETTING STARTED

Moving from field to field Once you begin modifying the digits in a field, you can move from digit to digit within

Point order in lists Points are listed according to hardware type. In other words, all analog points

Display of "****" The string "****" means that no value is available.

that field using the arrow keys.

However, to move to a different field, you must press Enter, ↵, after making your

last change to the field. The field is then highlighted. You can then use the arrow

keys to move to and highlight the next field you wish to modify.

appear first, followed by digital points, and finally totalizer points.

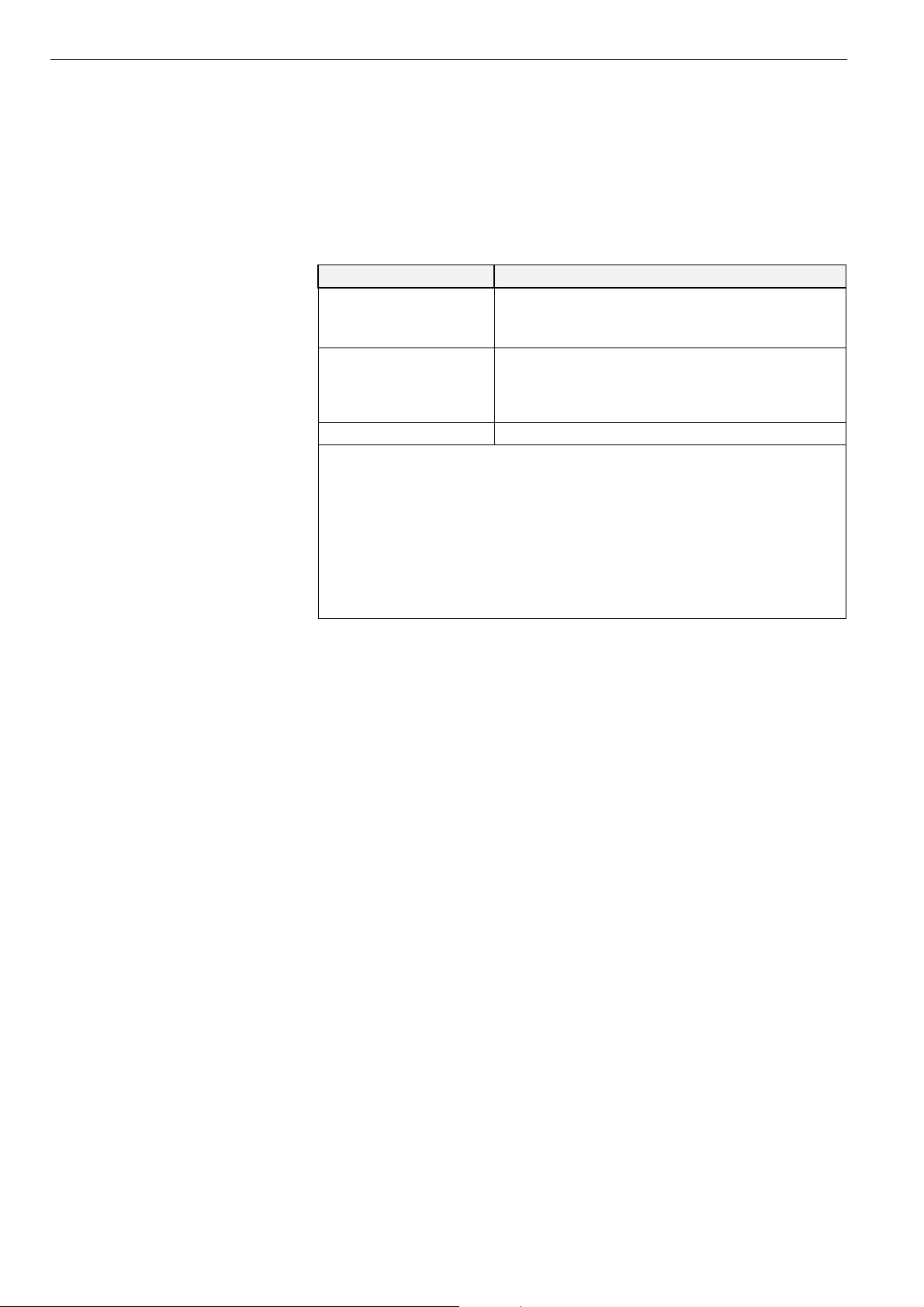

Operator Access Levels

There are three access levels that control operator access to XI581/XI582

information. The access levels determine the information an operator can view and

which tasks an operator can perform.

Access level 1 Access level 1 is available to all operators and does not require a password. At level

1, you can view some, but not all, of the information programmed into the controller.

You cannot modify any data. Specifically, access level 1 allows you to view the

following:

• Time program information

• Point descriptions

• System clock

• Trend log

• Alarm information

• Buswide information

Passwords To operate at level 2 or 3, an operator must enter a password. Passwords are four

numerical characters and are controlled by the site administrator. The "Level 2/3

Password Entry" section explains how to enter your password.

Access level 2 Access level 2 allows you to view all information accessible to level-1 operators. In

Access level 3 Access level 3 allows you to perform all tasks accessible to level-1 and level-2

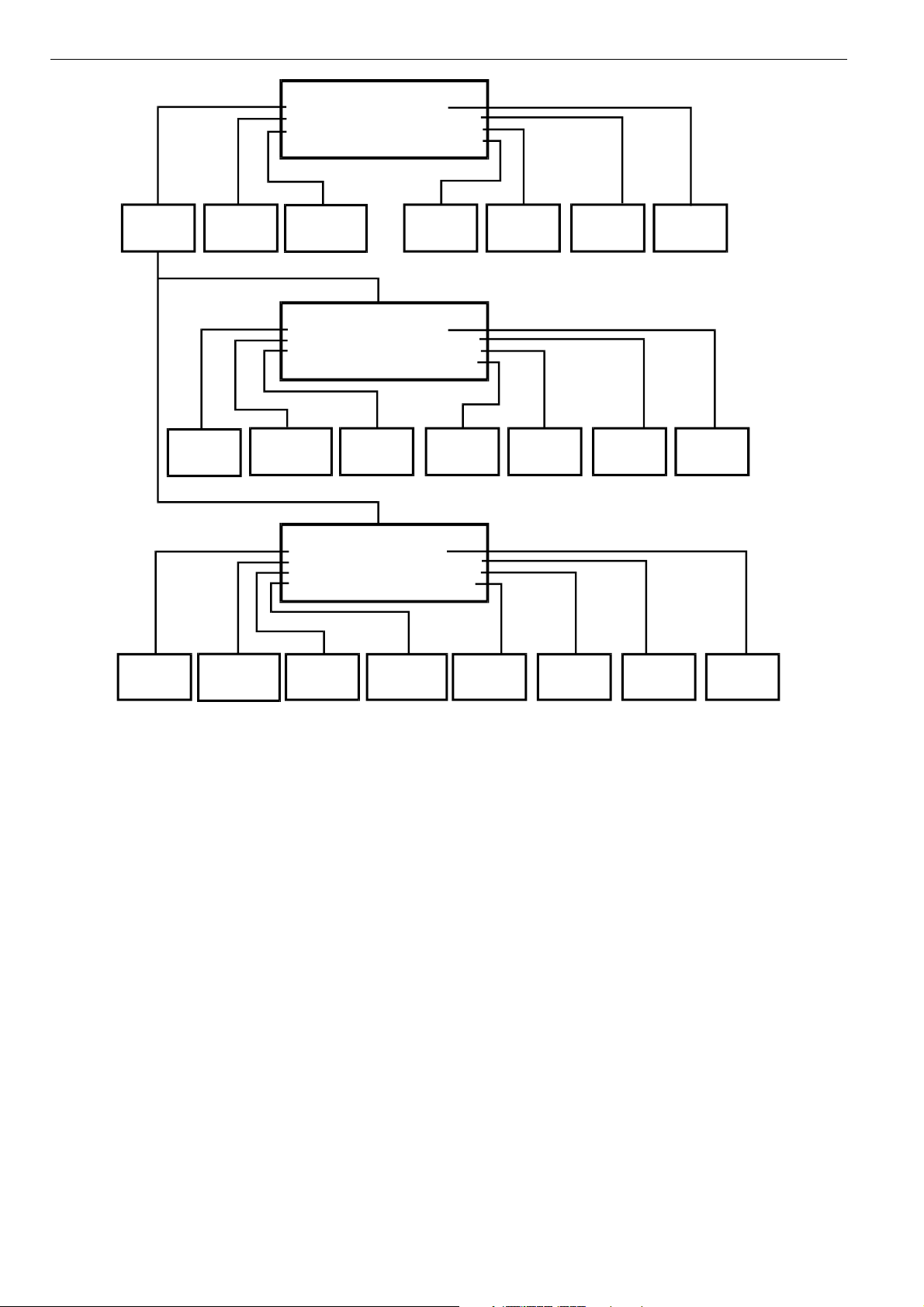

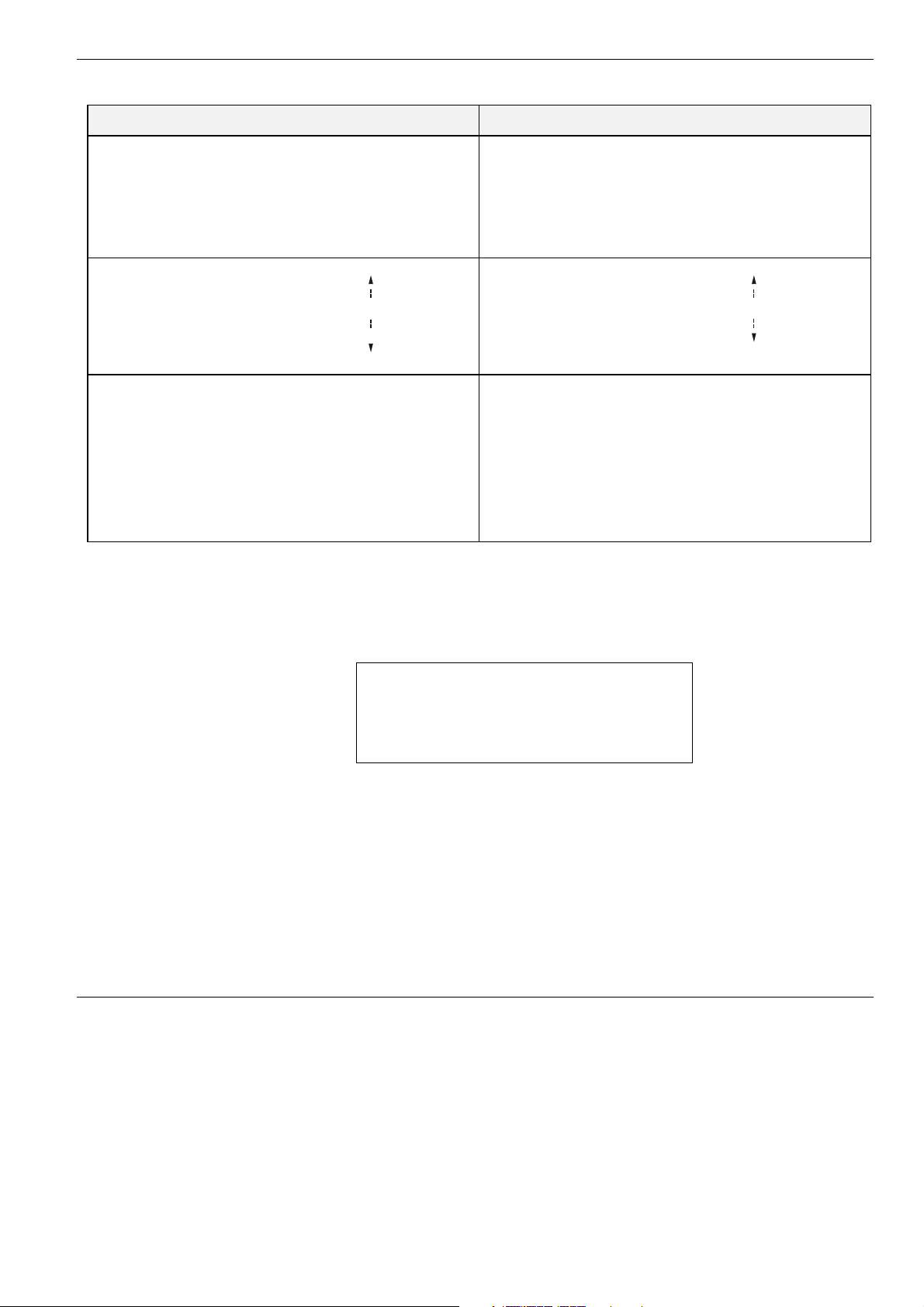

Access level chart The following chart summarizes the functions available at each access level.

addition, you can modify time programs, set the system clock, and view totalizer

information. You can also view and modify information in other controllers on the

same system bus.

operators. In addition, you can:

• Modify point descriptions

• Reset totalizers

• Modify parameters

• Change setpoints

This access level should be reserved for only those users who are responsible and

competent in HVAC engineering, such as a commissioning engineer. This is to

avoid incorrect operation of the plant. This access level is required for setting the

access levels of the other users.

13 EN2B-0126GE51 R0309

Page 18

GETTING STARTED XI581/XI582 BUSWIDE OPERATOR INTERFACE

A

S

OM

ENTER

PASSWORD

PROGRAM

MODIFY

TIME

PROGRAM

VIEW

TIME

DATA POINT

DESCRIPTION

CONTROLLER_01

PASSWORD

TIME PROGRAM

DATA POINTS

VIEW

DATA POINT

DESCRIPTION

CONTROLLER_01

TIME PROGRAM

DATA POINTS

TOTALIZERS

VIEW

CONTROLLER_01

TIME PROGRAM

DATA POINTS

TOTALIZERS

PAR AMET ERS

ALARMS

TREND BUFFER

SYSTEM CLOCK

SYSTEM DATA

ALARMS

TREND BUFFER

SYSTEM CLOCK

SYSTEM DATA

VIEW

TOTALIZERS

ALARMS

TREND BUFFER

SYSTEM CLOCK

SYSTEM DATA

VIEW

SYSTEM

DATA

VIEW BUSWIDE

DATA

VIEW

SYSTEM

DATA

BUSWIDE ACCESS

FLASH EPROM

VIEW

SYSTEM

CLOCK

SET

SYSTEM

CLOCK

CCESS LEVEL 1

LOWEST ACCESS

VIEW

TREND

LOG

ACCESS LEVEL 2

VIEW

TREND

LOG

ACCESS LEVEL 3

HIGHEST ACCESS

VIEW

ALARMS

VIEW

ALARMS

MODIFY

TIME

PROGRAM

MODIFY

DATA POINT

DESCRIPTION

RESET

TOTALIZERS

MODIFY

PARAMETERS

MODIFY

SYSTEM

DATA

BUSWIDE ACCESS

H EPR

FLA

SET

SYSTEM

CLOCK

VIEW

TREND

LOG

Fig. 12. Operator access level and corresponding functions of XI581/XI582

VIEW

ALARMS

C6992-2

EN2B-0126GE51 R0309 14

Page 19

XI581/XI582 BUSWIDE OPERATOR INTERFACE GETTING STARTED

15 EN2B-0126GE51 R0309

Page 20

XI581/XI582 BUSWIDE OPERATOR INTERFACE

EVERYDAY OPERATIONS

About this section This section details steps for common everyday procedures. The procedures are

grouped by common functions as follows.

Local and Remote Sign-on and Sign-off

• Level-2 and level-3 password entry

• Logging into a remote controller

• Logging off from a remote controller

• Signing off from a controller (local or remote)

• Alarm Information

• Viewing alarm information

• Viewing buswide alarms

• Enabling/disabling the buswide alarm mode and alarm flag

• Acknowledging the buswide alarm flag

Viewing point information

Reviewing time program schedules

Requesting a trend log in tabular or graphic format

Listing status of totalizer points

Controller information

• Reading controller date and time

• Viewing controller configuration data

All these procedures, except listing totalizer status, are level-1 operator tasks. The

totalizer function is a level-2 or level-3 operator task.

Any procedures requiring access to a remote controller require log-in to that controller.

Point vs. data point Note that XI581/XI582 refers to points as “data points”. This document uses the

term “point” except when the expression “data point” appears in XI581/XI582 screen

displays. EXCEL 5000™ literature generally uses the term “points”. The terms have

the same meaning.

See also ⇒ the "ALPHABETIC REFERENCE" section (page 49) for other procedures that you

may use less frequently.

Local and Remote Sign-On and Sign-Off

Because the XI581/XI582 is powered whenever the controller it is connected to is

powered, there is no “sign-on” and “sign-off” as for other types of operator terminals.

Typically, when you plug an XI582 into a powered controller, the main menu will be

displayed and you can begin selecting level-1 functions. Alternatively, you can enter

a password to obtain access to level-2 or level-3 functions.

The following are descriptions of the types of screen displays that occur depending

on the status of the controller (powered or reset) and its alarms.

Powered controller When you plug an XI582 into a powered controller, the main menu appears in the

display window.

A XI581 that is always attached to a controller typically displays the main menu

unless an operator has penetrated to some other menu. You can press Cancel (C)

repeatedly until the main menu is displayed.

EN2B-0126GE51 R0308 16

Page 21

XI581/XI582 BUSWIDE OPERATOR INTERFACE EVERYDAY OPERATIONS

Main menu (access level 1)

CONTROLLER_01 18:16!

Running 15.12.1994

Password Alarms

Time Programmes Trend Buffer

Data Points System Clock

System Data

Level 1 operators Level-1 operators do not have to enter a password.

Level 2 & 3 operators Level-2 and level-3 operators must enter a password to perform level-2 and level-3

Controller power-on The first display screen that appears after power-on is a message about the power

Procedures This section describes the following procedures:

operations. See "Level 2/3 Password Entry" (page 17) for details.

failure. Use the Cancel key (C) to acknowledge the message. The main menu will

be displayed.

• Level 2/3 password entry to enter a password if level-2 or level-3 functions are

required

• Logging into a remote controller to gain access to a controller that is not directly

connected to the XI581/XI582

• Logging off from a remote controller to disconnect from a remote controller that

you previously logged into

• Signing off from a controller (local or remote) to return to the level-1 main menu.

Level 2/3 Password Entry

Purpose To sign on to an XI581/XI582 connected to a controller.

Procedure 1. After the XI581/XI582 is connected to a controller, the main menu automatically

appears in the display window unless the controller is reset and needs to be

downloaded. If the controller needs to be downloaded, the 'title/copyright' screen

will be displayed.

NOTE: If the main menu does not appear, press Cancel (C) until it does.

RESULT: The main menu appears and lists information that level-1, -2, and -3

operators can view. The word Password is highlighted as the default

selection.

Level-2 and -3 operators 2.

Level-2 and level-3 operators do not have to enter a password to perform a

level-1 task. However, to perform a level-2 or level-3 task, you must enter a

password using the 'Password' function. Press Enter (↵) to select the 'Password'

function.

NOTE: If the 'Password' function is not highlighted, use the arrow keys to

move to and highlight the item and then press Enter (↵).

RESULT: XI581/XI582 asks for your password. The display window shows four

asterisks where you enter your password.

Please enter your Password:

****

17 EN2B-0126GE51 R0309

Page 22

EVERYDAY OPERATIONS XI581/XI582 BUSWIDE OPERATOR INTERFACE

Password entry 3. Press Enter (↵) to select the password field (four asterisks).

— The display window shows a 5 as the first, left-most digit of the password

field.

— If the first digit of your password is higher than 5, press the plus key (or the

up arrow key) until the first digit of your password is correct.

— If the first digit of your password is lower than 5, press the minus key (or the

down arrow key) until the first digit of your password is correct.

— Use the right arrow key to move the cursor to the second digit. Notice that

the first digit becomes an asterisk again to maintain password privacy.

Repeat this procedure until you have correctly input all digits in the password

field.

If you incorrectly input a digit, press Cancel (C) to start over again with the first,

left-most digit.

Once the password is input, press Enter (↵) to complete password entry. If the

password is incorrect, software re-prompts for password entry.

RESULT: If you correctly enter a password, the word Next will be displayed.

For level-3 operators, the word 'Change' will also be displayed to

allow you to change the password. See the "Passwords" section for

the procedure to change a password.

Please enter your Password:

****

Change Next

Press Enter (↵) to select Next.

Main menu for access level 2

CONTROLLER_01 18:16

Running 15.12.1994

Time Programmes Alarms

Data Points Trend Buffer

Totalizers System Clock

System Data

Main menu for access level 3

CONTROLLER_01 18:16

Running 15.12.1994

Time Programmes Alarms

Data Points Trend Buffer

Totalizers System Clock

Parameters System Data

RESULT: The display window shows the main menu appropriate for the pass-

word you entered.

NOTE: The main menu for access level 2 shows three items ('Time

Programmes', 'Data Points', and 'Totalizers') in the left column, while

the main menu for access level 3 shows four items ('Time

Programmes', 'Data Points', 'Totalizers', and 'Parameters').

5. Select desired function. The rest of this manual contains procedure for each of

EN2B-0126GE51 R0309 18

the functions.

Page 23

XI581/XI582 BUSWIDE OPERATOR INTERFACE EVERYDAY OPERATIONS

Logging into a Remote Controller

Purpose To initiate communication with a remote controller.

Performance Only one buswide XI581/XI582 (local or remote) can be logged onto a controller at

Procedure 1. Sign on to the XI581/XI582 at the desired user level (1, 2, or 3). See section

any one time. However, there is no restriction as to the total number of buswide

XI581/XI582 used on the same system bus. When XBS PCs are also on the bus,

there may be up to four XBS PCs on the same bus and one buswide XI581/XI582

that is in remote access at the same time.

All XI581/XI582 Operator Terminals are of equal priority, so that whichever device

signs on first gains access to a controller and no other device (local or remote) can

sign on to the same controller during this time.

"Level 2/3 Password Entry" (page 17) if you do not know how.

2. At the main menu, use the arrow keys to move to and highlight System Data.

Then press Enter (↵) to complete the selection.

RESULT: The display window shows system data, including the 'Buswide

Access' option. In the following example, note that the local controller

is CONTROLLER_01.

System Data

System Info

HW-Interface Config.

Flash EPROM

Buswide Access

NOTE: The 'Flash EPROM' item will be displayed only if you signed on as a

level-3 operator.

3. Use the arrow keys to move to and highlight Buswide Access. Then press

Enter (↵) to complete the selection.

RESULT: The display window lists the buswide access options you can choose.

Buswide Access

CONTROLLER_01

Remote Login Alarm Standby On

Logoff Alarm Standby Flag

Show All DevicesAlarm Standby Off

The option 'Logoff' appears below 'Remote Login' only if you have

already logged in on the remote controller (i.e. a connection has been

established). 'Logoff' can be used to sever the connection to the

remote controller. See section "Logging Off from a Remote

Controller" (page 21) for details.

4. Press Enter (↵) to select Remote Login (highlighted default).

RESULT: The display window lists all devices available for log-in. Controller

name and number are shown for each device.

Remote Login

CONTROLLER_07 7

CONTROLLER_09 9

1

19 EN2B-0126GE51 R0309

Page 24

EVERYDAY OPERATIONS XI581/XI582 BUSWIDE OPERATOR INTERFACE

5. Use the arrow keys to move to and highlight the name of the desired controller.

Press Enter (↵) to complete the selection.

RESULT: After about 5 seconds, the level-1 main menu of the selected con-

troller will be displayed unless there is a pending alarm. If an alarm is

pending in the remote controller, the alarm will be displayed instead

of the menu. Press Cancel (C) and log in again to see the remote

controller’s main menu.

The following example shows the result of selecting

CONTROLLER_07.

CONTROLLER_07 18:16!

Running 15.12.1994

Password Alarms

Time Programmes Trend Buffer

Data Points System Clock

System Data

Excel 20 and Excel 50 Controllers

6. Press Enter (↵) to select Password.

The operator interface for Excel 20 and Excel 50 Controllers has only four

lines and varies considerably from the screens in this manual. If you log

into a remote Excel 20 or Excel 50 Controller, see the appropriate

Controller User Guide for operator interface description and details.

RESULT: The 'Password' screen will be displayed.

Please enter your Password:

****

Change Next

7. Press Enter (↵) to have the same access level as the local controller. To have a

higher access level, type in your password and press Enter (↵).

RESULT: The main menu of the selected controller will be displayed. The

following example shows level-3 access for CONTROLLER_07.

CONTROLLER_07 18:16

Running 15.12.1994

Time Programmes Alarms

Data Points Trend Buffer

Totalizers System Clock

Parameters System Data

⇒ If the selected device is already being accessed (locally or remotely), the

Buswide alarm flag If the buswide alarm flag was enabled on the local controller, the flag disappears

log-in fails and the system displays the message “Device logged”. Try again

when the device is available.

8. Perform listed tasks as desired just as for a local controller. Log off from the

remote controller when finished (see section "Logging Off from a Remote

Controller", page 21, for details).

after log-in to the remote controller. Set it for the remote controller again to reestablish it, if desired. See section "Alarm Information" (page 22) for procedures.

EN2B-0126GE51 R0309 20

Page 25

XI581/XI582 BUSWIDE OPERATOR INTERFACE EVERYDAY OPERATIONS

Logging Off from a Remote Controller

Purpose To disconnect from a remote controller.

Procedure 1. From the remote controller’s main menu, use the arrow keys to move to and

highlight System Data. Then press Enter (↵) to complete the selection.

RESULT: The display window shows system data, including the 'Buswide

Access' option.

System Data

System Info

HW-Interface Config.

Flash EPROM

Buswide Access

NOTE: The 'Flash EPROM' item will be displayed only if you signed on as a

level-3 operator.

2. Use the arrow keys to move to and highlight Buswide Access. Then press

Enter (↵) to complete the selection.

RESULT: The display window lists the buswide access options you can choose

for remote CONTROLLER_07.

Buswide Access

CONTROLLER_07

Remote Login

Logoff

Show All Devices

3. Use the arrow keys to move to and highlight Logoff. Then press Enter (↵) to

complete the selection.

RESULT: Software logs off CONTROLLER_07 and displays the 'Remote Login'

menu screen to allow you to log in to another controller.

Remote Login

CONTROLLER_07 7

CONTROLLER_09 9

1

4. Select a remote controller to log into or press Cancel (C) to return to the

'Buswide Access' screen for the local controller.

Controller Sign Off

Purpose When you have finished using the XI581/XI582 Operator Terminal to access either

a remote or local controller, sign off so no one else can access the controller at the

same level that you accessed.

Sign-off To sign off, press Cancel (C) until the main menu appears with Password high-

lighted.

21 EN2B-0126GE51 R0309

Page 26

EVERYDAY OPERATIONS XI581/XI582 BUSWIDE OPERATOR INTERFACE

Main menu

CONTROLLER_01 18:16!

Running 15.12.1994

Password Alarms

Time Programmes Trend Buffer

Data Points System Clock

System Data

Auto sign-off If you are signed on to the XI581/XI582 and do not press any keys for 10 minutes,

the operator terminal automatically signs you off.

Alarm Information

This section describes how to view alarm information from the local controller as

well as buswide alarms. For buswide alarms, the section describes how to set the

buswide alarm mode and acknowledge the buswide alarm flag.

Viewing Alarm Information

Purpose To view selected alarm information, including the last 99 alarms, the controller has

generated and stored in memory, all current alarms (critical and non-critical), current

critical alarms, current non-critical alarms, and buswide alarms. All operators can

perform this task.

Select "Alarms" 1. At the main menu, use the arrow keys to move to and highlight the Alarms

option. Press Enter (↵) to complete the selection.

RESULT: The 'View Alarms' screen displays options for viewing alarm

information.

View Alarms

Alarm Buffer

All Points in Alarm

Critical Points in Alarm

Non Critical Points in Alarm

Buswide Alarms

Select desired option 2. Use the arrow keys to move to and highlight the desired option:

EN2B-0126GE51 R0309 22

Page 27

XI581/XI582 BUSWIDE OPERATOR INTERFACE EVERYDAY OPERATIONS

Table 5. Alarm Buffer Options and Alarm Type Options

alarm buffer option alarm type options

Alarm Buffer is highlighted by default when the 'Alarms'

screen is displayed.

Press Enter (↵) to select Alarm buffer.

RESULT: The display window lists all alarms in controller

memory.

Alarm Buffer

19.07.93 16:35 Exhaust_fan

19.07.93 06:26 Cafe_room_temp

18.07.93 23:57 Window_contact_17 1

18.07.93 16:07 Conf_room_temp

17.07.93 20:17 Htg._zone_pump_1

First column—The date the controller generated the alarm.

The date appears in Date.Month.Year (DD.MM.YY)

notation where DD=1-31, MM=1-12, and YY=the last

two digits of the year.

Second column—The time the controller generated the alarm.

The time appears in 24-hour (HH.MM) notation where

HH=00-23 and MM=00-59.

Third column—The user address of the point in alarm.

Press the arrow keys to move to and highlight the desired

option (All Points in Alarm, Critical Points in Alarm, Non

Critical Points in Alarm, or Buswide Alarms). Then press

Enter (↵) to complete the selection.

RESULT: The display window lists points (all, critical, or

non critical) currently in alarm.

All Points in Alarm:

Exhaust_fan

Cafe_room_temp

Window_contact_17 1

Conf_room_temp

Htg._zone_pump_1

NOTE: Alarm memory can contain 99 entries. All alarms

may not be able to appear in the display window at

the same time. To view alarms that do not display,

press the right arrow key to display the next page.

For other scroll bar functions, see the scroll bar

description in the "GETTING STARTED" section.

Select the desired alarm 3. Use the arrow keys to move to and highlight the specific alarm you want to view.

Then press Enter (↵) to complete the selection.

RESULT: The display window shows detailed information about the selected

alarm.

Alarm Buffer

19.07.93 12:03:31

Cafe_room_temp

Alarm Back

CPU not available with

C-Button

Second line Date and time the controller generated the alarm.

Third line User address of the alarm point.

Fourth line State or value of the point at the time the alarm was

generated. If you selected an analog point, this line displays a

value such as a temperature. If you selected a digital point,

this line displays a status such as OFF or ON.

Fifth line Alarm text.

4. Press Cancel (C) to return to the list of alarms.

Viewing Buswide Alarms

Purpose To view new critical and non-critical alarms that occurred on controllers other than

the local controller. You can also view the alarm buffer of a remote controller.

Access level All users can perform this task.

23 EN2B-0126GE51 R0309

Page 28

EVERYDAY OPERATIONS XI581/XI582 BUSWIDE OPERATOR INTERFACE

Requirement To enable viewing of buswide alarms, see section "Enabling/Disabling Buswide

Procedure 1. At the main menu, use the arrow keys to move to and highlight Alarms. Then

Alarm Mode and Alarm Flag" (page 24).

press Enter (↵) to complete the selection.

RESULT: The 'View Alarms' screen will be displayed.

View Alarms

Alarm Buffer

All Points in Alarm

Critical Points in Alarm

Non Critical Points in Alarm

Buswide Alarms

2. Use the arrow keys to move to and highlight Buswide Access. Then press

Enter (↵) to complete the selection.

RESULT: The display window lists all devices available for log-in. Controller

name and number as well as alarm status information list for each

device. The number of the controller appears below 'No'. An 'x'

appears below an alarm header (Critical or Non Critical) to indicate

the presence of an alarm.

Buswide Alarms

Name No Crit Non Crit

CONTROLLER_07 7 x

CONTROLLER_09 9 x x 1

3. Press the arrow keys to move to and highlight the desired controller. Then press

Enter (↵) to complete the selection.

RESULT: You are now logged into the alarm buffer of the selected remote

controller.

4. View the alarm buffer using the same procedure as for a local controller. See

section "Viewing Alarm Information" (page 22) for details if you do not know

how. When you are through reading the buffer, log off the remote controller

(press Cancel repeatedly).

RESULT: Software removes the controller number character from the alarm

buffer to indicate that the alarm(s) were viewed.

Enabling/Disabling Buswide Alarm Mode and Alarm Flag

Purpose To set up XI581/XI582 so that it displays the alarm flag, !, when new buswide

alarms occur.

Access level All users can perform this task.

Procedure 1. At the main menu, use the arrow keys to move to and highlight System Data.

Then press Enter (↵) to complete the selection.

RESULT: The display window show system data, including the 'Buswide

Access' option.

EN2B-0126GE51 R0309 24

Page 29

XI581/XI582 BUSWIDE OPERATOR INTERFACE EVERYDAY OPERATIONS

System Data

System Info

HW-Interface Config.

Flash EPROM

Buswide Access

2. Use the arrow keys to move to and highlight Buswide Access. Then press

Enter (↵) to complete the selection.

RESULT: The display window lists the buswide access options you can choose.

Buswide Access

CONTROLLER_03

Remote Login Alarm Standby On

Alarm Standby Flag

Show All DevicesAlarm Standby Off

3. Use the arrow keys to move to and highlight Alarm Standby On. Then press

Enter (↵) to complete the selection.

RESULT: Software enables buswide alarm mode to enable receiving of

buswide alarms into the buffer (the "Viewing Buswide Alarms" section

describes the procedure).

The 'Buswide Access' screen remains on display.

4. Use the arrow keys to move to and highlight Alarm Standby Flag. Then press

Enter (↵) to complete the selection.

RESULT: The system is set to place the buswide alarm flag, !, in the top right-

hand corner of most other windows.

The 'Buswide Access' screen remains on display.

5. Press Cancel (C) to exit this screen and return to the main menu.

Alarm standby flag example The following level-3 menu shows the exclamation mark, !, in the upper right-hand

corner of the screen.

CONTROLLER_01 18:16!

Running 15.12.1994

Time Programmes Alarms

Data Points Trend Buffer

Totalizers System Clock

Parameters System Data

When an alarm occurs, the flag starts blinking.

Disable buswide alarm notification To disable alarm reporting, follow Steps 1 and 2 in the previous procedure. In Step

3, highlight Alarm Standby Off and press Enter (↵) to complete the selection. The

system removes the flag from all display windows.

Acknowledging the Buswide Alarm Flag

Purpose To notify the system that you saw the notification of a new buswide alarm (blinking

Procedure Use the arrow keys to move to and highlight the alarm flag. Then press Enter (↵) to

exclamation mark, !, in the top right-hand corner of any display window).

complete the selection.

RESULT: The flag stops blinking but remains on display.

25 EN2B-0126GE51 R0309

Page 30

EVERYDAY OPERATIONS XI581/XI582 BUSWIDE OPERATOR INTERFACE

The flag remains as long as buswide alarm notification is enabled.

See section "Enabling/Disabling Buswide Alarm Mode and Alarm

Flag" (page 24) for details.

Viewing Point Information

Purpose To display point information for selected points.

⇒ This procedure details only how to select points by their user addresses and

The "Data Point Description Function" section describes these procedures in

Access level All users can perform this task.

Procedure 1. At the main menu, use the arrow keys to move to and highlight Data Points.

how to display their associated point attributes. There are other options on

the 'Data Points' screen that provide functions to modify point information

and to select points by type or template. If there are many user addresses, it

may be easier to select points by type or template.

detail.

Press Enter (↵) to complete the selection.

RESULT: The display window lists options for viewing point information. User

Address is highlighted by default.

Data Points

User Address Suppress Alarm

Manual Operation Add Template

Accumul. Runtime Delete Template

Type Selection Modify Template

Points in Trend Template Search

NOTE: The 'Add Template', 'Delete Template', and 'Modify Template' items

2. Press Enter (↵) to select User Address.

⇒ The other options on the 'Data Points' screen provide functions to modify

RESULT: The display window lists points (by user address) that you can view.

do not display for level-1 operators, and 'Template Search' appears

only if there are defined templates. If there are no defined templates,

only the 'Add Template' item will be displayed for higher-level

operators so they can define templates.

point information and to select points by type or template. The "Data Point

Description Function" section describes these procedures in detail.

Example:

User Address

Exhaust_fan 1

Hall_main_lights On

Main_water_meter 000 m3 1

Conf_room_temp 23 °C

Select the desired point 3. Use the arrow keys to move to and highlight the point you wish to view. Then

press Enter (↵) to complete the selection.

RESULT: The display window shows detailed information about the selected

point in a series of windows. Most points require three windows to

fully display their attributes. The following example shows the first

window for a digital point.

NOTE: Additional user-defined text for the point may appear on the second

line.

EN2B-0126GE51 R0309 26

Page 31

XI581/XI582 BUSWIDE OPERATOR INTERFACE EVERYDAY OPERATIONS

Htg_zone_pump_1

Status : ON

Operating Mode: AUTO

Trend Logging : OFF

Back Next

To move forward to the next page, highlight Next and press Enter

(↵). To move backward a page, press Cancel (C). To return to the

previous menu, highlight Back, and press Enter (↵).

Second window example:

Htg_zone_pump_1

Technical Address : 010205

Accumulated Runtime : 12736 h

Service Interval : 500 h

Hours Since Serviced: 398 h

Back Next

Third window example:

Htg_zone_pump_1

Last Changed : 15:36 07.06.1993

Cycle Count : 656

Suppress Alarm : NO

Back

The information (or “attributes”) appearing in a point description varies

depending on the type of point you selected (digital, analog, or totalizer). For

more information on the different point descriptions and their attributes, see

section "Data Point Description Function" (page 49).

4. Use the arrow keys to move to and highlight Back and press Enter (↵) to return

to the list of points (by user address). When you are finished, repeatedly press

Cancel (C) to return to the main menu.

See also ⇒ Section "Data Point Description Function" (page 49) for attribute information;

section "Selecting Points by Template" (page 56) for details on the Template search

function;

section "Selecting Points by Point Type" (page 57) for details on the Type search

function.

NOTE: In the case of Excel 800 controllers, the sensor offset cannot be

accessed via the XI581/2; rather, XL-Online must be used, instead.

Reviewing Time Program Schedules

Purpose To display time program equipment start/stop schedules. For an overview of time

Select "Time programmes" 1. At the main menu, use the arrow keys to move to and highlight Time

programs (daily programs, weekly programs, annual programs, the TODAY

program, and the special days program), see section "Time Programs" (page 76).

Programmes. Press Enter (↵) to complete the selection.

RESULT: The 'Time Programme' screen lists available time programs.

27 EN2B-0126GE51 R0309

Page 32

EVERYDAY OPERATIONS XI581/XI582 BUSWIDE OPERATOR INTERFACE

Time Programme

Time Program 1

Ventil. Sys

Lighting 1

Heating zone east

Heating zone west

NOTE: All time programs may not be able to appear in the display window at

the same time.

Select the desired time program 2. Use the arrow keys to move to and highlight the desired time program. Then

press Enter (↵) to complete the selection.

RESULT: The top line of the window displays the selected time program. The

remaining lines display the types of time programs.

Time Programme Time Program 1

Today

Daily Programme

Weekly Programme

Annual Programme

Special Days

Select the desired type of time program 3. Use the arrow keys to move to and highlight the desired type of time program

(such as TODAY) and then press Enter (↵) to complete the selection.

TODAY

Program Lists TODAY program start/stop times.

Daily

Programme Shows a menu to view data, prompts for selection of the

desired daily program, and then displays associated switching

point data.

Weekly

Programme Lists the daily program assigned to each day of the week.

Annual

Programme Prompts for starting date and then displays the daily program

assigned to each day of the year.

Special Days Shows a menu to view data and then lists the daily program

assigned to special days (holidays) of the year.

For more information on the types of time programs, see section "Time

Programs" (page 76).

RESULT: The top line of the display window shows the selected time program.

The remaining lines list time program information or show another

menu depending on the type of time program selected.

4. When you are finished, repeatedly press Cancel (C) to step backwards and

return to the main menu.

Listing Totalizer Status

Purpose To view totalizer information for points.

Access level You must have access level 2 or 3 to perform this task.

Select "Totalizers" 1. At the main menu, use the arrow keys to move to and highlight Totalizers.

EN2B-0126GE51 R0309 28

Press Enter (↵) to complete the selection.

Page 33

XI581/XI582 BUSWIDE OPERATOR INTERFACE EVERYDAY OPERATIONS

RESULT: The display window shows two options for listing totalizer data.

Totalizers

Service Interval

All Totalizers

Service interval Displays a list of digital points and the number of hours.

All Totalizers Displays a list of totalizer points and the value of the units

assigned to them.

Select the desired type of totalizer 2. Use the arrow keys to move to and highlight the type of totalizer you want to

view. Then press Enter (↵) to complete the selection.

RESULT: The display window lists totalizer points.

Service Interval h

Supply_fan 1267s

Exhaust_fan 1257n

Burner 4761

Htg._zone_pump 736n

Cafe._hood 123t

NOTES:

1. All totalizer points may not be able to appear in the display window at

the same time.

2. The appearance of the 'Totalizer' screen differs slightly from that of

the 'Service interval' screen, although they operate the same.

Select the desired totalizer 3. Use the arrow keys to move to and highlight the specific totalizer you want to

view. Press Enter (↵) to complete the selection.

RESULT: The display window shows detailed information about the selected

totalizer.

Service Interval : 1000 h

Supply fan : 1267 h

Reset : Yes/NO

Back

Service interval Number of hours a point can run before the controller

generates a maintenance alarm.

User Address

(Supply fan) Number of hours the point has run since it was last serviced.

The name of this field reflects the name of the totalizer point

you selected.

Reset Zero the totalizer point after service.

NOTE: Additional user-defined text for the point may appear on the second

line.

The "Totalizers" section has more details on totalizer options.

4. When you are finished, repeatedly press Cancel (C) to return to the main menu.

29 EN2B-0126GE51 R0309

Page 34

EVERYDAY OPERATIONS XI581/XI582 BUSWIDE OPERATOR INTERFACE

Requesting a Trend Log

Purpose To request a trend log for a point and view the information in a table or in a graph.

All users can perform this task.

Select "Trend Buffer" 1. At the main menu, use the arrow keys to move to and highlight Trend Buffer.

Press Enter (↵) to complete the selection.

RESULT: The display window lists two options for viewing a trend log.

Trend Buffer

Table

Graph

Select the desired trend log format 2. Choose the desired option for viewing a trend log.

— Table is highlighted by default. Press Enter (↵) to complete the selection.

— Use the arrow keys to move to and highlight Graph. Then press Enter (↵) to

complete the selection.

RESULT: The display window lists points whose activity is recorded in the trend

buffer.

Trend Buffer

Ventilation system

Lighting

Heating zone east 1

Heating zone west

Heating zone north

NOTES:

1. The controller can collect and save trend log data for up to 20 points. The controller’s trend log memory (buffer) can save the latest 200 point change-ofstates. In the case of analog points, a value is saved when the point changes a

specified amount. In the case of digital points and totalizer points, each change

of status is saved.

2. All trend log points may not be able to appear in the display window at the same

time.

Select the desired trend log point 3. Use the arrow keys to move to and highlight the point whose trend log you want

to view. Then press Enter (↵) to complete the selection.

EN2B-0126GE51 R0309 30

Page 35

XI581/XI582 BUSWIDE OPERATOR INTERFACE EVERYDAY OPERATIONS

A

A

Table 6. Trend Log in Tabular and Graph Format

Trend Log in Tabular Format Trend Log in Graph Format

RESULT: The display window shows the trend

RESULT: The display window shows a graph.

log for the selected point in a tabular

format.

Trend Buffer Exhaust_fan

16.07.93 17:45 Switched off

16.07.93 08:30 Switched on

15.07.93 18:30 Switched off 1

15.07.93 13:30 Switched on

15.07.93 12:00 Switched off

26.6

%

18.9

s

n

1

n

t

LARM 19.02.1993 16:40:00

C6993

First column—The date that the point's condition

or value changed. The date appears in

Date.Month.Year (DD.MM.YY) notation

where DD=1-31, MM=1-12, and YY=the

last two digits of the year.

Second column—The time that the point's con-

dition or value changed. The time appears

in 24-hour (HH.MM) notation where

HH=00-23 and MM=00-59.

Third column—A description of the change that

took place.

Maneuver the graph using the following keys:

Key Graph Function

plus Zooms in on graph.

minus Zooms out on graph.

left or right

arrow keys Scrolls graph left or right.

Enter (↵) Switches the trend log from a

graph format to a tabular format.

You can add an additional point to the trend log

graph as long as the two points are different point

types. For example, the first point is an analog

point and the second point is a digital point.

With the graph of the first trend point displayed,

press Cancel (C) to switch back to the list of points

whose activity is recorded in a trend log.

Press the up and down arrow keys to highlight the

additional point whose trend log you want to view.

Then press Enter (↵) to complete the selection.

RESULT: The display window shows the trend

log for the selected points in a graph

format.

26.6

%

18.9

LARM 19.02.1993 16:40:00

C6994

4. Press Cancel (C) to return to the trend log point list. When you are finished,

repeatedly press Cancel (C) to step backwards and to return to the main menu.

31 EN2B-0126GE51 R0309

Page 36

EVERYDAY OPERATIONS XI581/XI582 BUSWIDE OPERATOR INTERFACE

Controller Information

Reading the Controller Clock

Purpose To read the controller date and time and the starting/ending daylight savings times.

Select "System Clock" 1. At the main menu, use the arrow keys to move to and highlight System Clock.

All users can perform this task.

Press Enter (↵) to complete the selection.

RESULT: The display window lists two options for viewing controller clock

information.

System Clock

Date / Time

Daylight Savings

Select the desired clock option 2. Select Date / Time to view controller clock or select Daylight Savings to view

daylight savings time dates as follows:

Table 7. Daylight Savings Time

Date/time Daylight savings time

Date / Time is highlighted by default. Press Enter

(↵) to complete the selection.

RESULT: The display window shows the

current date and time.

Use the arrow keys to move to and highlight