Page 1

W8635A

Equipment Interface Module

INSTALLATION INSTRUCTIONS

APPLICATION

The W8635A Equipment Interface Module (EIM) provides 24 Vac control of single or multistage conventional

HVAC equipment when used with a T8635L Microelec-

Table 1. Description.

Model Application Stages Terminals Comments

W8635A Conventional gas, oil

or electric heat

Up to 2 heat/

2 cool

INSTALLATION

tronic Communicating Programmable Thermostat. The

W8635A can be used w ith up to 2 heat/2 cool conventional applications. See Table 1.

1, 2, 3, C, R, Rh, Rc,

G, W1, W2, Y1, Y2

1.

Use with T8635L Communicating

Thermostat

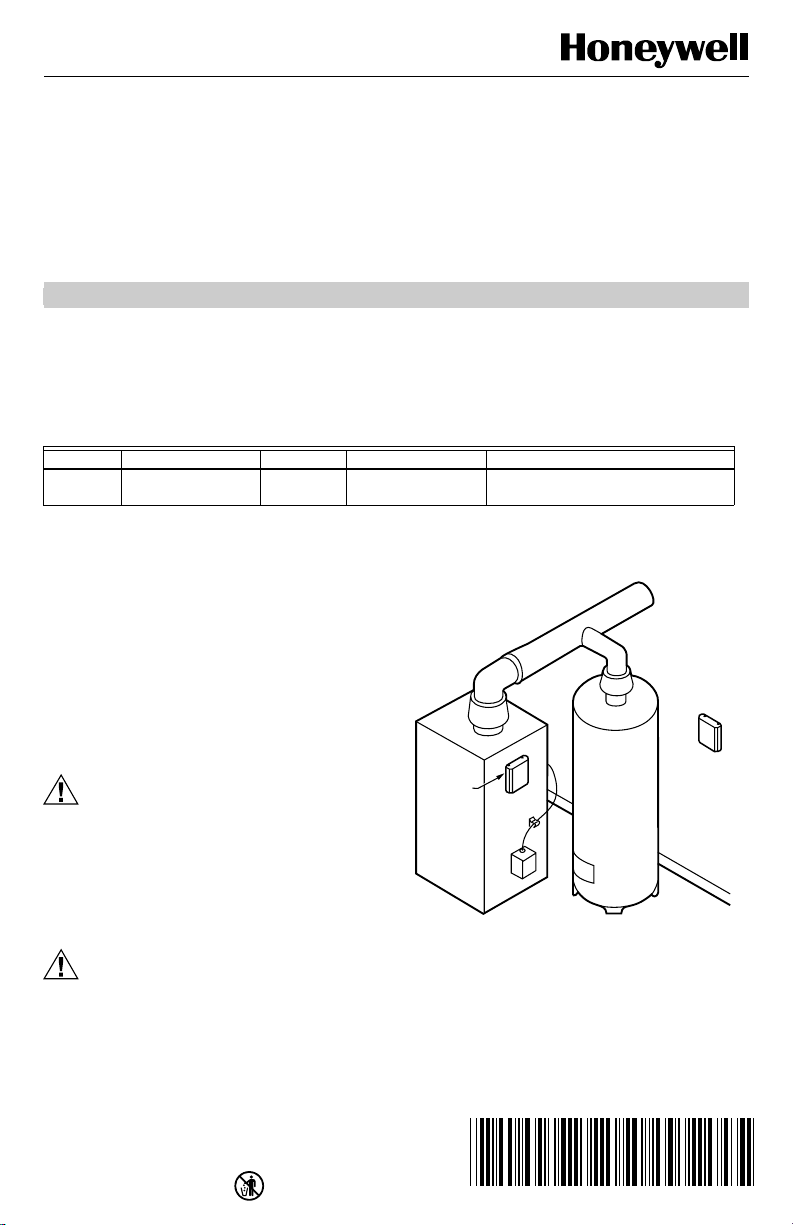

Locate the W8635A in the equipment room near

the HVAC equipment. See Fig. 1.

When Installing this Product…

Read these instructions carefully. Failure to follow

1.

these instructions can damage the product or

cause a hazardous condition.

Check the ratings given in the instructions and on

2.

the product to make sure the product is suitable for

your application.

Installer must be a trained, experienced service

3.

technician.

After completing installation, use these instructions

4.

to check out the product operation.

W8635

CAUTION

Voltage Hazard.

Can cause electrical shock or equ ip m ent

damage.

Disconnect power before supply before beginning

installation.

POSSIBLE

MOUNTING

LOCATION

W8635

POSSIBLE

MOUNTING

LOCATION

Location

CAUTION

Mounting Location Hazard.

Mounting W8635A inside HVAC equipment

can damage the EIM.

Mount the W8635A only on the outside of HVAC

equipment.

® U.S. Registered Trademark

Copyright © 2000 Honeywell Inc. • • All Rights Reserved

FURNACE OR BOILER

Fig. 1. Selecting W8635A Equipm ent

Interface Module location.

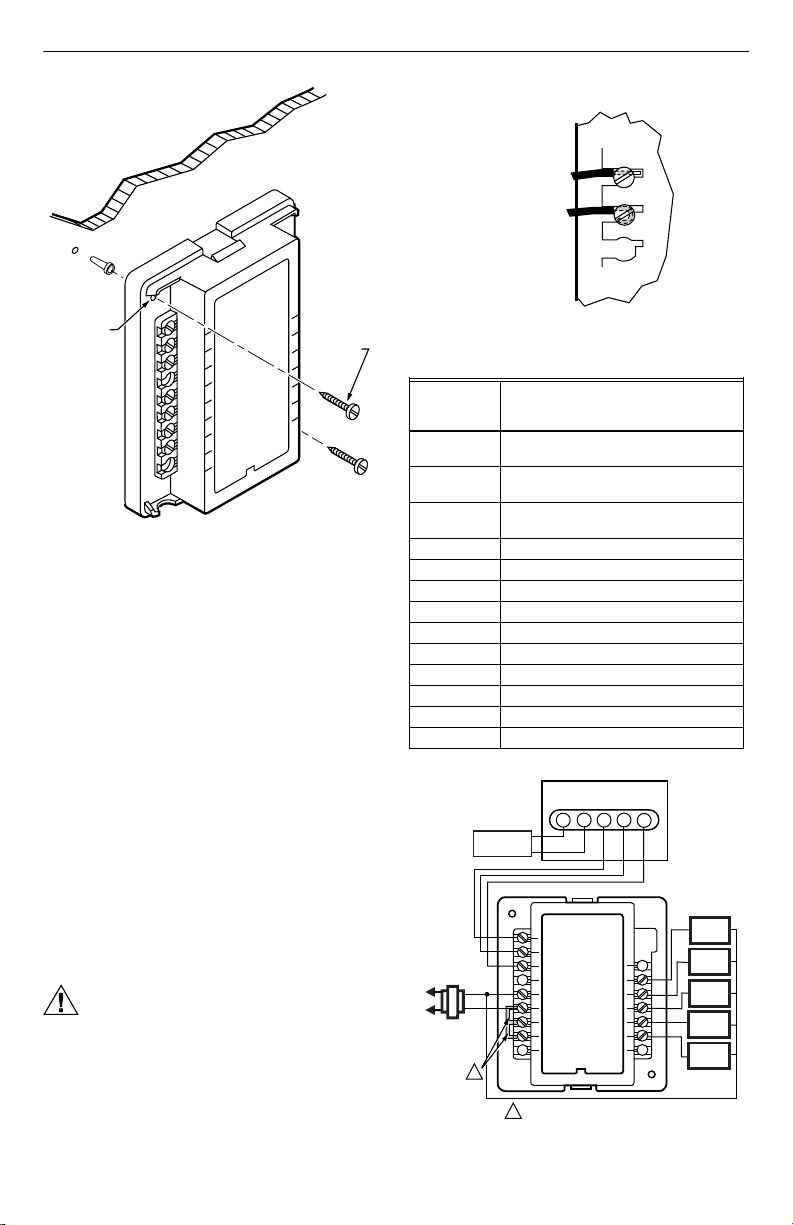

Remove the cover from the W8635A by pulling on

2.

the edge of the module.

Locate the two mounting holes. See Fig. 2.

3.

WATER HEATER

M16637A

69-1339- 2

Page 2

W8635A EQUIPMENT INTERFACE MODULE

FOR WRAPAROUND

CONNECTION—

STRIP 7/16 IN. (11 MM)

FOR STRAIGHT

CONNECTION—

STRIP 5/16 IN. (8 MM)

M16639

W8635

WALL

W8635

MOUNTING

HOLES (2)

Fig. 2. Mounting W8635A

Equipment Interface Modul e.

Position the W8635A on the wall or on the cold air

4.

return.

Level the W8635A for appearance only; the device

5.

functions properly even when not level.

Use a pencil to mark the position of the mounting

6.

holes on the wall or cold air return.

Remove the W8635A from the wall or cold air

7.

return and drill 3/ 1 6 in . ho l e s in th e wall (if drywall)

where marked. For firmer materials such as plaster

or wood, drill 7/32 in. holes.

When mounting on the cold air return, drill a pilot

8.

hole where marked.

Gently tap the anchors (provided) into the holes

9.

until flush with the w all.

Reposition the W8635A over the holes.

10.

Loosely insert the screws into the holes and tighten

11.

each screw.

WIRING

All wiring must comply with local electrical code s and

ordinances. See Fig. 4 through 6 wiring diagrams for

specific equipment applications. Refer to Table 2 for

terminal designations.

CAUTION

Voltage Hazard.

Can cause electrical shock or equ ip m ent

damage.

Disconnect power before beginning installation.

Loosen the terminal screws on the W8635A and

1.

connect the system wires. See Fig.3.

Securely tighten each terminal screw.

2.

1

2

3

C

R

R

H

R

C

G

W

W

Y1

Y2

1

2

MOUNTING

SCREWS (2)

M16636

Fig. 3. Wiring the W8635A terminals.

Table 2. Terminal Designations.

W8635A

Terminal

Designations Function

1 To Communicating Thermostat

Terminal 1

2 To Communicating Thermostat

Terminal 2

3 To Communicating Thermostat

Terminal 3

R 24 Vac System Transformer

Rh 24 Vac Heating Transformer

Rc 24 Vac Cooling Transformer

C 24 Vac Transformer Common

GFan Relay

W1 Stage 1 Heat Relay

W2 Stage 2 Heat Relay

Y1 Stage 1 Cool Relay

Y2 Stage 2 Cool Relay

Green LED Indicates Data Communication

T8635L

OT

OT

W8635A

1

2

3

C

R

R

H

R

C

1

FACTORY INSTALLER JUMPERS.

1

G

W1

W2

Y1

Y2

L2

L1

(HOT)

SYSTEM

TRANSFORMER

C7089B

OUTDOOR

TEMPERATURE

SENSOR

1

Fig. 4. 2H/2C single transformer.

69-1339—22

2

3

FAN

RELAY

HEAT 1

RELAY

HEAT 2

RELAY

COOL 1

RELAY

COOL 2

RELAY

M13429

Page 3

W8635A EQUIPMEN T INTERFACE MODULE

T8635L

3

OT

FAN

RELAY

HEAT 1

RELAY

HEAT 2

RELAY

COOL 1

RELAY

COOL 2

RELAY

L1

(HOT)

L2

SYSTEM

TRANSFORMER

C7089B

OUTDOOR

TEMPERATURE

SENSOR

1

1

T8635L

OT

OT

W8635A

1

2

3

C

R

R

H

R

C

FACTORY INSTALLER JUMPERS.

2

1

G

W1

W2

Y1

Y2

Fig. 5. Three zone configuration.

WIRE NUT

M13378

Fig. 6. Using wire nut to pigtail a connection when

three or more wires are terminated at one terminal.

Discovery Mode

Discovery mode begins when the T8635L Thermost at

and W8635 EIM are first installed and power is

connected:

— The W8635 EIM transmits i nformation to the T8635L

Thermostat that indicates the maximum number of

stages that are enabled and the type of EIM

connected.

— The thermostat receives informati on from the W8635

and then sets the cycle rates and equipment types

automatically.

Stage Configuration

The W8635A automatically configures the T8635L for

two stages of heat and two stages of cool. If using the

W8635A and the T8635L on a one heat/one cool

application, set Installer Setup No. 5 and 8 to 1 when

configuring the T8635L Communicati ng Thermostat.

For configuration combinations, see Table 3.

T8635L

OT

2

1

3

546Z

213X

546Z

213X

546Z

213X

TROL-A-TEMP

MODEL AOBD

ZONE DAMPER

OT

W8703A

1

OT

OPEN

CLOSE

OPEN

CLOSE

OPEN

CLOSE

OPTIONAL

TROL-A-TEMP

MODEL ARD-PC

OR MODEL ZD

2

3

ZONE AZONE B

TR1

TR2

COM

ZONE C

1

2

3

Table 3. Stage Combinations.

Heat Stages Cool Stages

10

20

01

02

11

22

Cycle Rate

The thermostat automatically sets the cycle rate based

on the information it received during Discovery M ode.

See Table 4.

To change the default cycle rate settings:

— enter T8635L Thermostat Installer Setup and select

the desired cycle rate settings for each stage. (All

stages can be set bet ween 1 and 12 cph.)

Table 4. Default Cycle Rate Settings.

st

1

W8635A

Equipment

Interface

Module

Stage

Heat

2nd

Stage

Heat

6 cph 6 cph 3 cph 3 cph

1st

Stage

Cool

Electric Heat Setting

When using the W8635A on an electric heat application,

set the T8635L Thermostat Installer Setup No. 4 to 1.

This instructs the W8635A EIM to energize the fan with

any call for heat.

L1

(HOT)

L2

EXTERNAL

40 VA

TRANSFORMER

M13430A

2nd

Stage

Cool

3 69-1339—2

Page 4

W8635A EQUIPMENT INTERFACE MODULE

Flash COM OK LED Description

LED blinks rapidly

mitting information on the communications bus.

LED blinks once

acknowledged a message.

LED on constantly

device.

LED off constantly

device is not functioning properly and there is no

LED activity at least once a minute. Check wiring to

communications bus terminals 1, 2 and 3.

NOTE: It is normal for LED to blink continuously dur-

ing startup and discovery.

LED blinks continuously

if device is not functioning properly and there is a

continuous series of LED blinks. Check wiring to

communications bus terminals 1, 2 and 3.

—indicates device is currently trans-

—indicates device received and

—indicates device failure. Replace

—indicates a wiring probl em if

—indicates a wiring problem

CAUTION

Equipment Damage Hazard.

Minimum compressor off-tim e is bypassed

during Installer System Test.

Do not allow compressor rapid cycling (on and

off).

Observe compressor protection period.

To start the Installer System Test:

Press and hold the T8635L Thermostat increase

1.

and decrease ▼ keys at the same time until 10

▲

appears. All display segments display before the

10 appears. See Fig. 7 and 8.

Set Program

Hold for

Em Ht

Aux Ht

Mon

TueWedThuFriSatSun

Wake

System Fan

Heat

Em

INSTALLER SYSTEM TEST

Use the Installer System Test to check the thermostat

and W8635A EIM operation for each thermostat in the

system. Table 5 lists the available system tests.

Table 5. Installer System Tests.

Test Number System Test Description

10-12 Heating stages can be turned on and

30-32 Cooling stages can be turned on and

40-42 Fan and damper test

70-74 Thermostat information including date

Heating Equipment Sys te m Test

Cooling Equipment Sy stem Test

off in sequence

off in sequence

60 Keyboard keys test

code and software versions are

displayed.

Fig. 8. Installer Test Number display.

Refer to Table 6 for Installer System Test option.

2.

Table 6. Installer System Test Options.

Key to Press Test Number Description

10 Enter Heating Equipment system test.

▲

▲

▼

▼

11 First Stage Heat turns on.

12 Second Stage Heat turns on.

11 Second Stage Heat turns off.

10 First Stage Heat turns off.

30 Enter Cooling Equipment system test.

▲

▲

▼

▼

31 First Stage Cool turns on.

32 Second Stage Cool turns on.

31 Second Stage Cool turns off.

30 First Stage Cool turns off.

Temporary Setting Enrg

Set Day/Time

Start Time

AM

PM

Heat

Cool

Filter

Recovery

LeaveReturnSleep

Off Auto

Cool

In

Wait

DST

Auto

Fig. 7. LCD segments display.

TEST NUMBER

Room

%Humid

Outdoor

Repl Batt

Auto

On

M10345A

Sav

M10257A

69-1339—24

Page 5

W8635A EQUIPMEN T INTERFACE MODULE

Table 6. Installer System Test Options. (Continued)

Key to Press Test Number Description

Fan and Damper Test (Damper Test available only when using W8703A)

40 Enter Fan and Damper test.

▲

▲

▼

▼

41 Fan turns on; damper for this zone opens.

42 Damper closes for this zone (if not already closed); fan stays on.

41 Damper opens for this zone.

40 Fan turns off.

Key Operation Test

60 Enter Key Operation test.

Press any key to test if the key is functional. Each time a key is pressed, a different num ber is disp lay ed. This

indicates the key is functioning properly . Pressing enters the next test .

Thermostat Information

70 Enter Thermostat Information mode.

▲

▲

▲

▲

71 Production date code is displayed. The fir st two large digits are

the month and the third digit is the last digit of the year (exam pl e:

031 = March 2001).

72 Software identification code is displayed.

73 Software revision number is displayed.

74 EEPROM identification code is displayed.

Exit Installer Test Mode

Run

Program

Thermostat returns to normal operating mode.

TROUBLESHOOTING GUIDE

Refer to Table 7 for troubleshooting informat ion .

Table 7. Troubleshooting Guide.

Symptom Possible Cause Action

Display does not come

on at thermostat.

“1 COM”, “2 COM” or

“3 COM” is displayed.

System Switch setting

displays “off only.”

Thermostat is not being powered. Check if the therm ost at is mounted and latched on the

Thermostat is unable to

communicate with the W8635A.

During Discovery Mode, the

thermostat did not correctly set

the number of heat or cool stages.

wallplate; if not:

—mount and latch the thermostat on the wallplate.

Check if the circuit breaker is tripped; if it is:

—reset the circuit breaker.

Check if the fuse is blown; if it is:

—replace the fuse.

Check if the power switch at the equipment is in the Off

position; if it is:

—set to the On p o s ition.

Check for 24 Vac on terminals 2 and 3:

—replace any broken wires.

If 24 Vac is present on terminals 2 and 3:

replace the thermostat.

Check the connection to terminal 1 at the thermostat

and W8635A EIM:

—replace any broken wires.

cycle power.

Manually run Discovery Mode; see Installer Setup.

manually configure heat and/or cool stages

(Installer Setup 5 and 8).

5 69-1339—2

Page 6

W8635A EQUIPMENT INTERFACE MODULE

Table 7. Troubleshooting Guide. (Contin ued)

Symptom Possible Cause Action

Heating does not come

on. System on indicator

( = heat) displays.

Cooling does not come

on. System on indicator

( = cool) displays.

“wait” is displaye d and

the call for Cool has not

started.

nd

2

stage heat or cool

does not energize.

Fan does not come on

with a call for electric

heat.

Communication is not being

completed.

Heat load at W8635A is not

connected correctly.

Communication is not being

completed.

Cool load at W8635A is not

connected correctly.

Compressor protection is in

effect.

Stage configuration not set

correctly to match the number of

selected stages.

Cool load at W8635A is not

connected correctly.

Electric heat setting is not

configured.

Fan load at W8635A is not

connected correctly.

End and repeat the call for heat. Check the Flas h COM

OK LED on the W8635A EIM while the call is being

made.

If the Flash COM OK LED does not blink:

check communication Bus wiring.

If the Flash COM OK LED blinks:

check that 24 Vac is present at W1 terminal.

If 24 Vac is not present:

check R to Rh connection.

If the connection is good:

replace the W8635A EIM.

End and repeat the call for cool. Check the Flash COM

OK LED on the W8635A EIM while the call is being

made.

If the Flash COM OK LED does not blink:

check communication bus wiring.

If the Flash COM OK LED blinks:

check that 24 Vac is present at Y1 terminal.

If 24 Vac is not present:

check R to Rh to Rc jumper connection.

If the R to Rh to Rc connection is good:

replace the W8635A EIM.

Compressor protection can be set from 0 to 5 minutes

to prevent compressor damage due to rapid cycling.

Wait until the compressor protection period expires.

To bypass compressor protection during the installat ion

phase, see the Installer System Test section.

Set the Stage configuration in Ins tal ler Setup for two

stages or heat and/or two stages of cool.

Check that 24 Vac is present at Y2 or W2 terminal. If

24 Vac is not present, all connections are good and the

thermostat is correctly configured, replace W8635A EIM.

Set Installer Setup No. 4 to 1 for electric heat.

Check that 24 Vac is present at G terminal. If 24 Vac is

not present, all connections are good and the thermostat

is configured, replace the W8635A EIM.

Home and Building Control Home and Building Control

Honeywell Inc. Honeywell Limited-Honeywell Limitée

Honeywell Plaza 155 Gordon Baker Road

P.O. Box 524 North York, Ontario

Minneapolis, MN 55408-0524 M2H 3N7

69-1339—2 G.H. Rev. 6-00 www.honeywell.com

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

Loading...

Loading...