Page 1

UV100RM TrueUV™ Coil Treatment System

1

2

3

PRODUCT DATA

FEATURES

• Remote mount bulb and ballast allow for flexible

installation in any application.

• 24V ballast does not require electrician to install

additional outlets.

• SnapLamp™ replacement bulb allows for easy

maintenance. No screws needed for bulb replacement.

• Ballast can be set to run continuously or to cycle extending bulb life.

• Shield allows installer to direct UV-C light away from

access panels for safety and onto A/C coil where the

light is needed.

• TrueUV can be installed on exterior surfaces or on

APPLICATION

When installed at the air conditioner coil, TrueUV helps

prevent surface micro-organism contaminants such as mold

from forming on the air conditioning coil and drain pan which

can lower the efficiency of the cooling system and can allow

unwanted odors into the home.

interior surfaces.

• Adjustable mounting bracket allows TrueUV to be

installed in tight locations.

• Exterior mounting requires little clearance, so TrueUV

can be installed in closets and tight spaces.

• Indicator window allows safe viewing of lamp

operation.

• UV-C light kills airborne bacteria and surface mold.

• TrueUV does not produce ozone.

• Five-year limited warranty.

READ THIS FIRST BEFORE TURNING ON POWER

1. Snap in lamp, do not twist.

2. Attach mounting base.

3. Turn ballast to ON or CYCLE.

4. Turn power back on.

IMPORTANT

15 VA minimum needs to be available if connecting to

equipment transformer. If available VA is not known then

AT40A1162 transformer can be used.

M27542

Contents

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Safety Precautions ........................................................... 2

Installation ........................................................................ 3

Wiring ............................................................................... 6

Checkout .......................................................................... 6

Maintenance ..................................................................... 6

Troubleshooting ................................................................ 7

68-0297EFS-05

Page 2

UV100RM TRUEUV™ COIL TREATMENT SYSTEM

SPECIFICATIONS

TRADELINE® Models Available

The UV100RM1 TrueUV Coil Treatment System is ductmounted at the air conditioner coil of an HVAC system. It

helps prevent mold and mildew from forming on the air

conditioner coil and drain pan which can lower the efficiency

of the cooling system and can allow unwanted odors into the

home.

UV100RM1 includes the UC10W1 bulb, handle, base, ballast,

cord connections, adjustable mounting bracket, shield,

indicator window and mounting screws.

UC10W1 Replacement 10 watt UV-C bulb.

Efficiency: UV100RM TrueUV kills up to 99% of mold on

cooling coils.

- Test performed in a test duct showed reduction in Aspergillus-Niger when surface as irradiated at a distance of 18

inches for three hours in still air using new lamps.

Electrical Ratings

Voltage Rating: 24Vac, 50/60 Hz.

Class 2 device 30V, max

Input Current Rating: 750mA

16-11/16 (424)

14-61/64 (380)

Input Power Rating: 18W max, 15W nominal, 15VA

Bulb Rating: 10W, 220mA

Temperature Ratings

Bulb Temperature Range (in moving air): 40 to 170F

Ballast Ambient Temperature Range: 30 to 125F

Shipping Temperature Range: -30 to 150F

Relative Humidity: Up to 95% RH, non-condensing

Switch: CYCLE runs 3 hours on/3 hours off

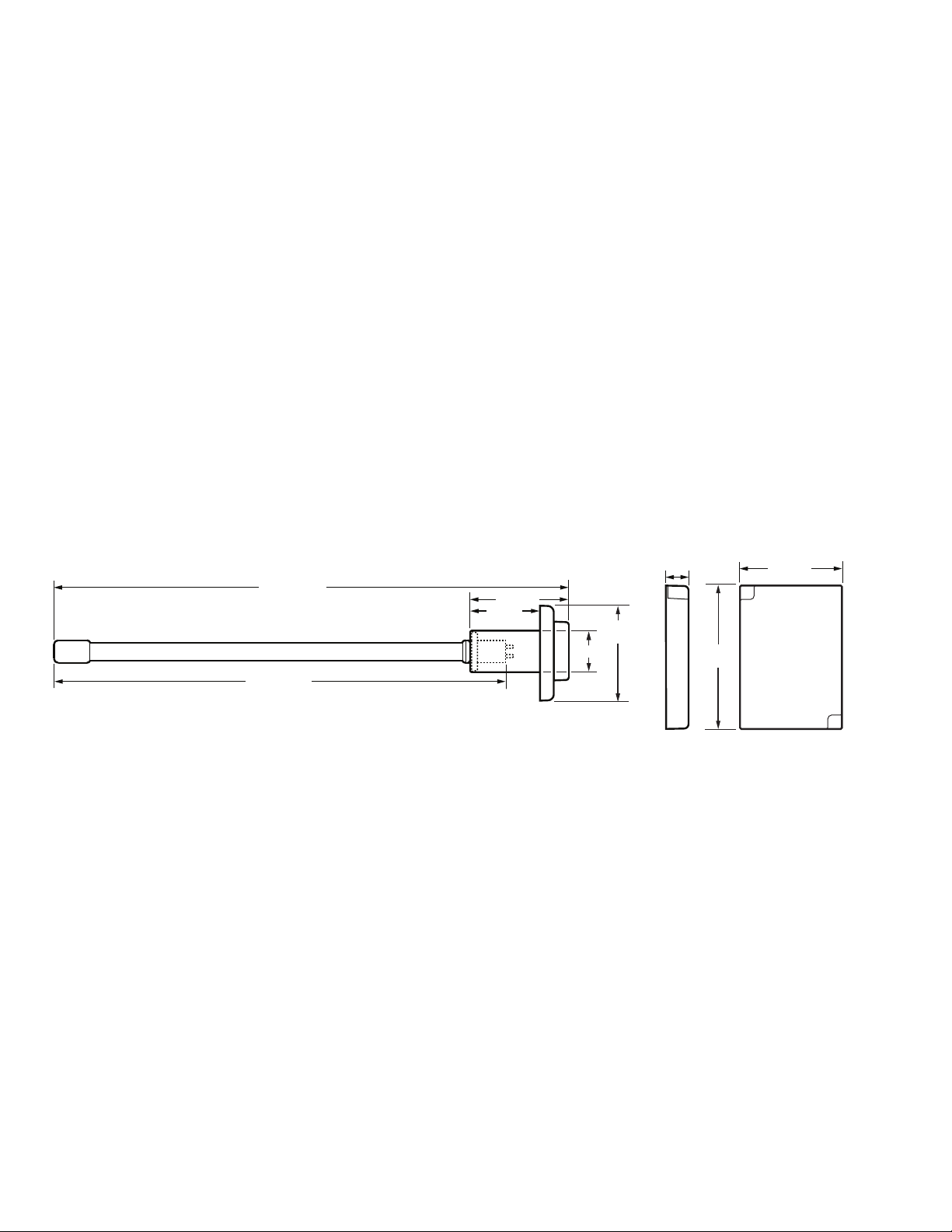

Dimensions: See Fig. 1

Accessories: AT40A1162 NEMA Standard Universal Trans-

former (not included).

Approvals:

Underwriters Laboratories Inc. listed.

Duct-mounted germicidal lamp assembly.

The health aspects associated with the use of this product and

its ability to aid in disinfection of environment air have not

been investigated by UL.

1-11/32

2-3/4 (70)

1-13/16

(47)

1-1/2 (38)

3-5/32

(80)

(34)

4-3/32

(104)

2-3/4 (74)

M27054

M27056

Fig. 1. Dimensions in in. (mm).

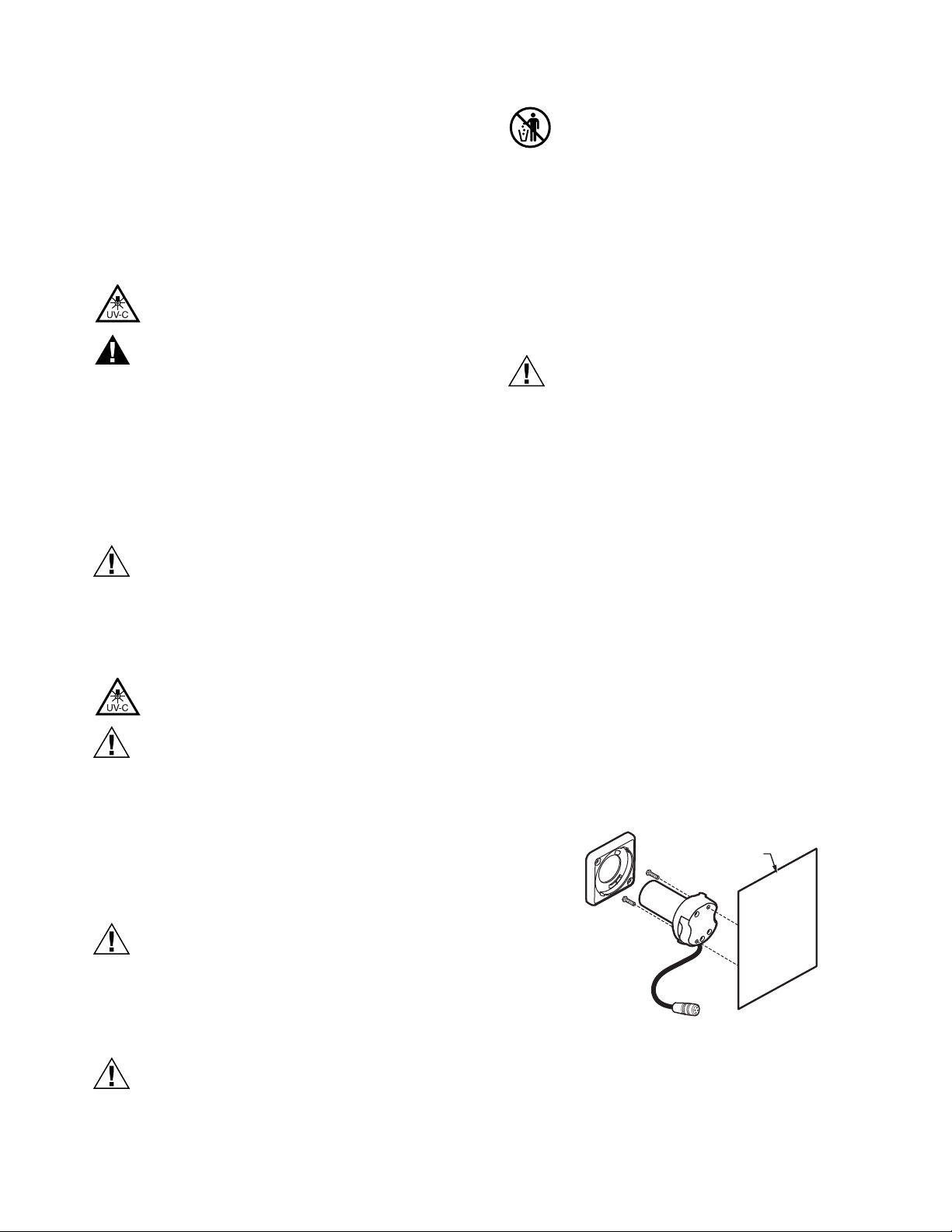

SAFETY PRECAUTIONS

Please read before installing or servicing product.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Toronto, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

68-0297EFS—05 2

Page 3

When installing this product…

WARNING

CAUTION

CAUTION

CAUTION

CAUTION

MERCURY NOTICE

CAUTION

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the rating given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product opera-

tion as provided in these instructions.

UV Light Hazard.

Harmful to bare skin and eyes.

Can cause temporary or permanent loss of vision.

View illumination only through lamp light indicator on

lamp handle.

To prevent exposure to ultraviolet light, disconnect

power to ultraviolet system before servicing any part of

heating and air conditioning system.

Do not mount device in location that allows ultraviolet

light to be seen after installation.

UV100RM TRUEUV™ COIL TREATMENT SYSTEM

This device contains mercury in the sealed ultraviolet

bulb(s). Do not place your used bulb(s) in the trash.

Dispose of properly.

Broken Bulb Cleanup.

Do not use a household vacuum.

Sweep debris into a plastic bag and dispose of

properly.

Contact your local waste management authority for

instructions regarding recycling and the proper disposal

of old bulb(s).

Bulb Burn Hazard.

Harmful to bare skin.

Can cause severe burns.

Disconnect power 15 minutes before removing

ultraviolet bulb(s).

INSTALLATION

Personal Injury Hazard.

Power supply can cause electrical shock.

Disconnect power supply before beginning installation.

Do not open ballast or lamp handle; there are no userserviceable components inside.

Equipment Damage Hazard.

Ultraviolet light can cause color shift or structural

degradation of plastic HVAC materials.

Select mounting location that prevents exposure to

plastic components with unknown resistance to

ultraviolet light. Three feet minimum is recommended

where there is direct exposure between ultraviolet lamp

and plastic-fabricated devices (such as humidifiers and

non-fiberglass media filters).

Sharp Edges Hazard.

Can cause personal injury.

Be careful when inserting ultraviolet device into sheet

metal cutout.

Wear protective gloves when working near sheet metal.

Turn off power to air handler before installation.

Choose a location for duct-mounting the handle that will allow

maximum exposure to the coil, drain pans and internal

surfaces of the air handler. The adjustable mounting bracket

can be used to angle the bulb to fit in tight applications and to

maximize exposure. Ballast can be mounted in the control

panel of the air handler or outside of the duct when mounted in

a weather-protected space. Make sure to mount ballast within

reach of handle so 6-foot cord will reach.

Internal Mounting

For straight mounting, the handle can be mounted right on the

internal surface. Use self-tapping sheet metal screws to mount

the handle in the desired location.

SURFACE OF

AIR HANDLER

M27055

Fig. 2. Direct mount to internal surface.

Breakable Glass Hazard.

Can cause personal injury.

Be careful when inserting bulb(s) into lamp base.

Wear protective gloves when handling bulb(s).

For angled mounting, adjust the mounting bracket to the

desired angle and fix in place with bolt. Use mounting screws

to mount the handle to the bracket. Use self-tapping sheet

metal screws to mount the bracket in the desired location.

3 68-0297EFS—05

Page 4

UV100RM TRUEUV™ COIL TREATMENT SYSTEM

M27062

ADJUSTABLE

BRACKET

SURFACE OF

AIR HANDLER

M27084

Fig. 3. Angled mounting bracket mount to internal surface.

Attach shield to bulb in such a manner as to direct UV-C light

away from access panel for secondary safety to prevent direct

exposure to light.

Mount ballast in chosen location. Drill 3/4-inch hole to run cord

from location of handle to ballast location. Use grommet to seal

hole around cord.

M27079

Fig. 4. Attach shield to bulb.

Fig. 5. Connect cord from handle to ballast location.

Attach base to handle. Base should be used for internal

mounting applications as it activates an internal safety switch

in the handle. Snap bulb into handle.

M27060

Fig. 6. Attach base to handle.

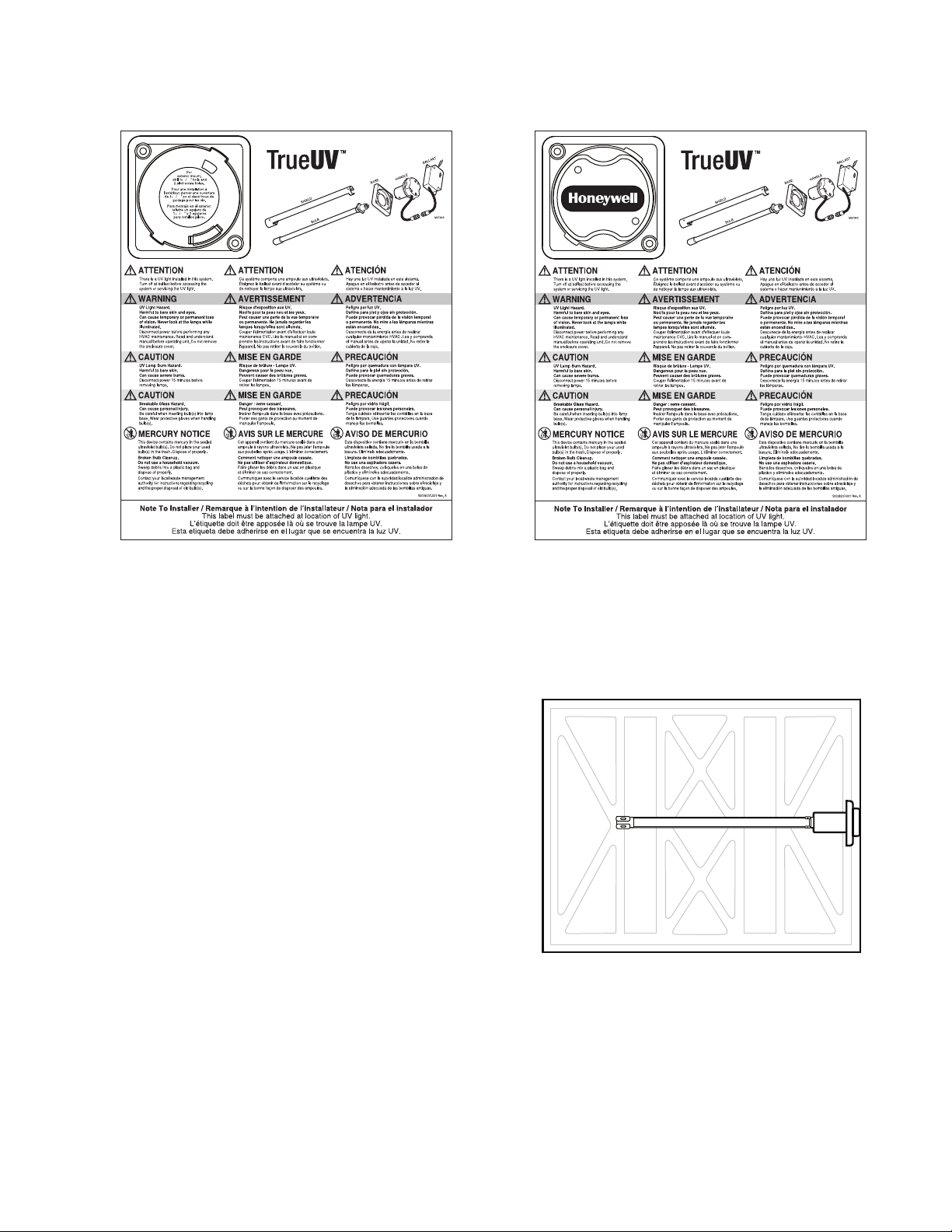

Adhere Safety Precautions/Template sticker outside of the duct

near the access panel or near the location of TrueUV and write

the location of the ballast (switch) on the sticker.

68-0297EFS—05 4

Page 5

UV100RM TRUEUV™ COIL TREATMENT SYSTEM

M27080

9 16

9 16

9 16

Fig. 7. Apply Safety Precautions/Template sticker to

outside of duct.

External Mounting

Adhere Safety Precautions/Template sticker in chosen

location. Drill 1-9/16–inch hole for bulb. Mount base using selftapping screws. Snap bulb into handle and twist onto base.

M27081

Fig. 8. Apply Safety Precautions/Template sticker to

chosen location.

Shield can be used to direct UV-C away from susceptible

materials such as media filters.

M27072

Fig. 9. Use shield to protect media filter.

Mount ballast in chosen location. If necessary to penetrate

barrier, drill 3/4-inch hole to run cord. Use grommet to seal hole

around cord. See Fig. 5.

Mount Indicator Window

The indicator window allows you to safely check the operation

of TrueUV. It can also indicate to you when TrueUV has been

turned off and service or maintenance can safely be

5 68-0297EFS—05

Page 6

UV100RM TRUEUV™ COIL TREATMENT SYSTEM

WARNING

M27069

BALLAST

M27061A

24 VAC

GROUND

performed. Choose a location where the indicator window will

show UV operation from the location of maintenance or service

access.

Drill 1/2-inch hole. Snap indicator window into hole.

Place a maintenance warning label next to the indicator

window. Other maintenance warning labels should be placed

at access and service panels where they can be easily seen

during any future maintenance or service.

Fig. 10. Indicator window and label.

WIRING

Ensure power is turned off to the air handler before

proceeding.

Connect the 24V leads of the ballast to the 24VAC transformer.

18 gauge wire can be used to extend leads if necessary. There

is no polarity to TrueUV and either lead can be wired to 24V

hot and common.

Turn ballast switch position to ON or CYCLE.

Check TrueUV operation through indicator window. Do not

attempt to look directly into the duct to see the illuminated

ultraviolet bulb.

Installer should orient the homeowner to the unit by showing

them the blue glow from the indicator window which

indicates the unit is working.

The installer should also emphasize the hazard warnings so

that homeowner knows how to safely inspect and maintain

their system.

MAINTENANCE

UV Light Hazard.

Harmful to bare skin and eyes.

Can cause temporary or permanent loss of vision.

View illumination only through lamp light indicator on

lamp handle.

To prevent exposure to ultraviolet light, disconnect

power to ultraviolet system before servicing any part of

heating and air conditioning system.

Do not mount device in location that allows ultraviolet

light to be seen after installation.

Bulb cleaning is recommended quarterly as routine

maintenance. Keeping dust off the bulb will keep the UV-C

intensity high and maintain the kill rate of TrueUV. Use a damp

cloth to wipe bulb clean.

Bulb should be replaced every year if using the ON position or

every 2 years if using the CYCLE position.

1. Review Safety Precautions regarding UV-C light hazard,

hot bulbs, breakable glass and mercury notice on page 3

before performing any maintenance.

2. Turn power off to HVAC equipment.

3. Turn TrueUV power to OFF position at ballast location.

4. Internal Mount: Reach through access panel and grasp

bulb. Protect your hands from hot light bulb.

External Mount: Twist handle from base.

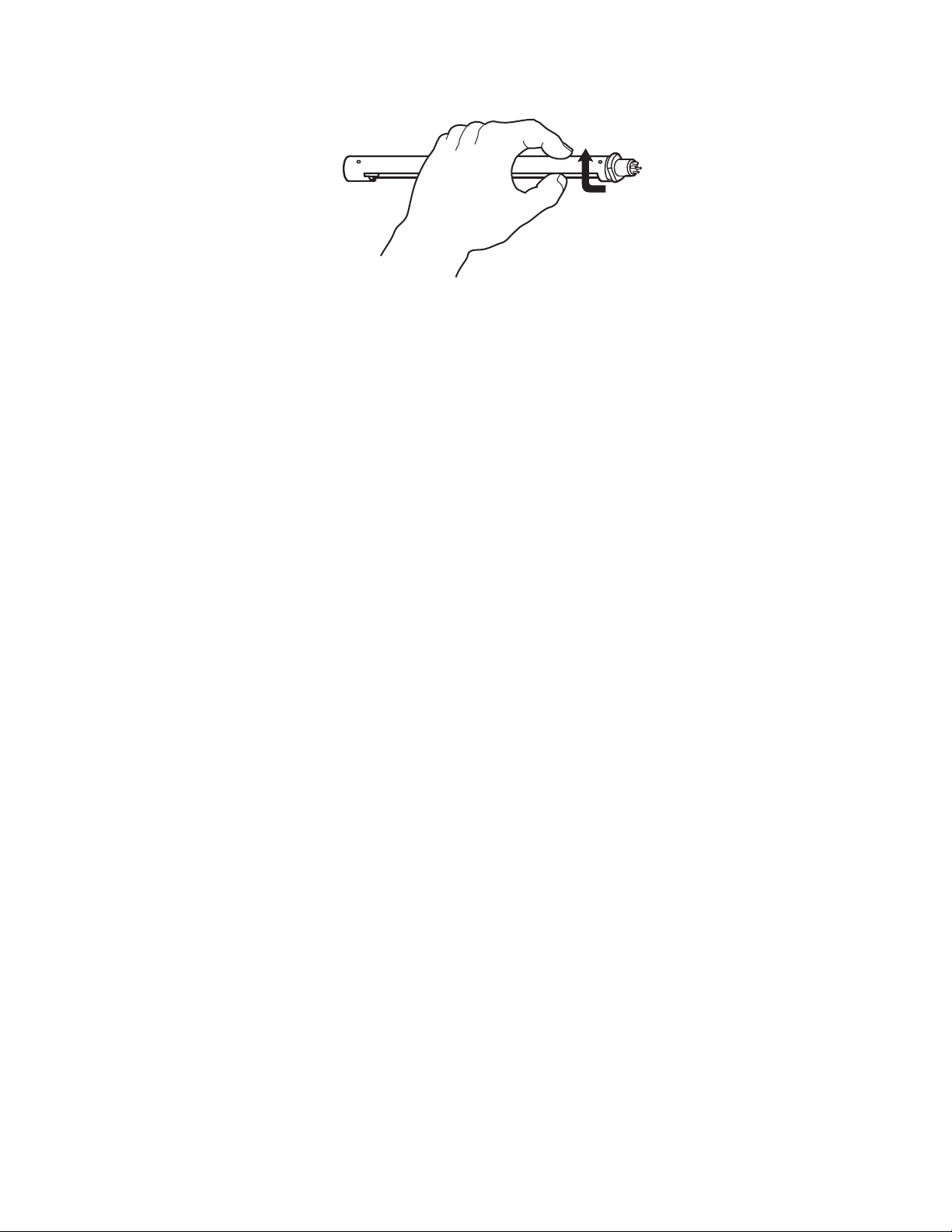

5. Pull bulb straight out of handle to snap loose.

CHECKOUT

Close all access panels and turn power on to HVAC

equipment.

68-0297EFS—05 6

Fig. 11. Wiring diagram.

M27067

Fig. 12. Pull bulb out of handle.

6. If shield is being used, remove shield from old bulb and

attach to new bulb.

Page 7

Fig. 13. Remove shield and reuse.

7. Snap new bulb into handle.

8. Internal Mount: Close all access panels used for

service.

External Mount: Twist handle into base.

9. Turn TrueUV power back to ON or CYCLE position.

10. Turn power back on to HVAC equipment.

TROUBLESHOOTING

TrueUV has no field-serviceable parts.

UV100RM TRUEUV™ COIL TREATMENT SYSTEM

M27068

TrueUV not lighting:

Check TrueUV operation through indicator window. Do not attempt to look directly into the duct to see the illuminated ultraviolet

bulb.

1. Check that base is twisted into place on handle. Base activates safety switch in handle.

2. Check switch position at ballast. If switch is in CYCLE position, then TrueUV may have cycled off for 3 hours. Temporarily

move switch to ON position to verify

operation.

3. Check for 24V power at ballast.

4. Check cord connectors are securely fastened.

5. Check that bulb is securely inserted in handle.

6. Check to see if bulb has burned out and needs to be replaced.

7 68-0297EFS—05

Page 8

UV100RM TRUEUV™ COIL TREATMENT SYSTEM

PARTS LIST

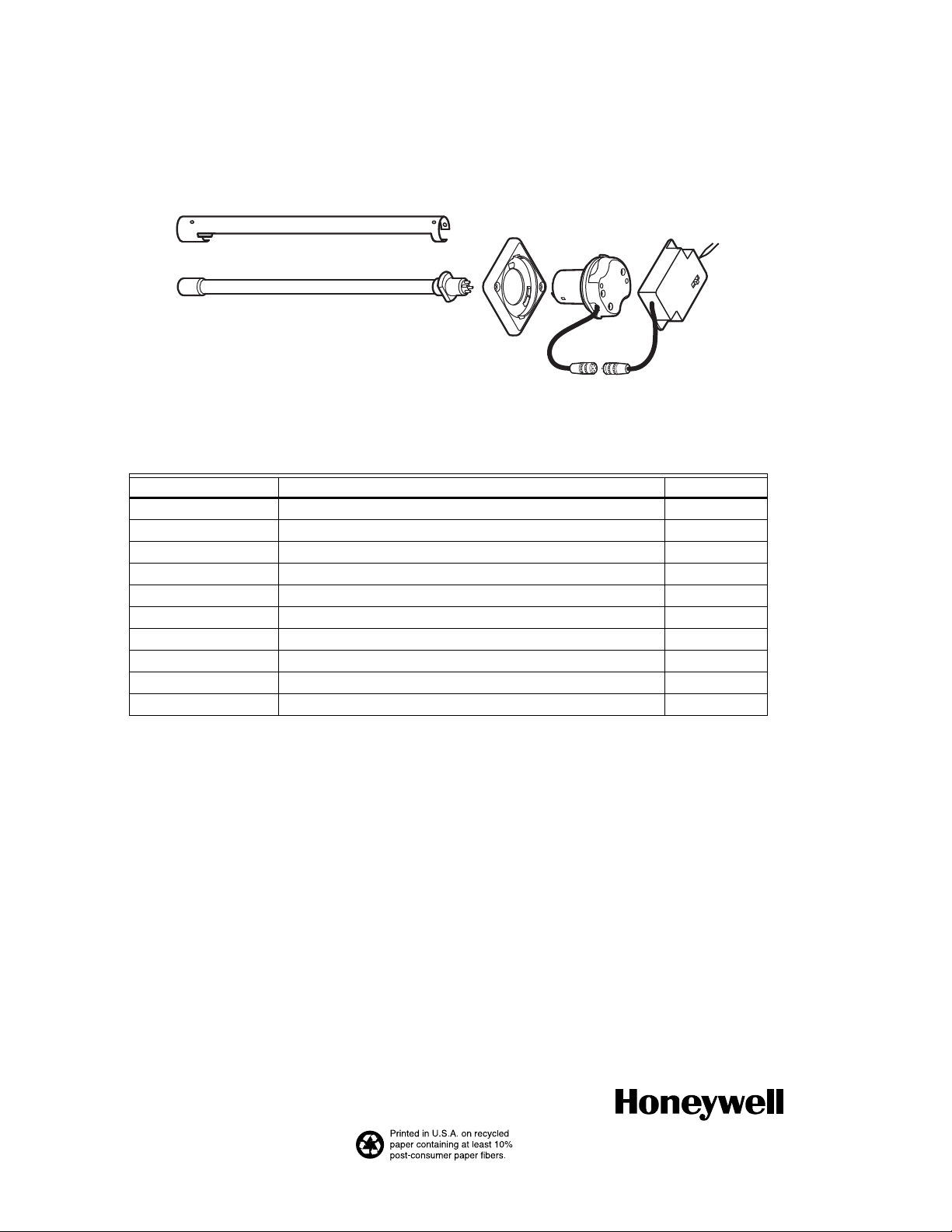

TrueUV parts are shown in Fig. 14.

5. SHIELD

4. BULB

UC10W1

Item Part Name Quantity

1 Ballast 1

2 Handle 1

3Base 1

4Bulb 1

5Shield 1

Not Shown Indicator window 1

Not Shown Mounting bracket (includes two pieces, nut and bolt) 1

Not shown Installation screws for ballast and base. 4

Not shown Installation screws for handle. 2

Not shown Rubber screw caps 4

3. BASE

Fig. 14. TrueUV parts.

Table 1. Parts List.

2. HANDLE

1. BALLAST

M27053

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Toronto, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2008 Honeywell International Inc.

68-0297EFS—05 M.S. Rev. 12-08

Page 9

Système de traitement d'air TrueUV

1

2

3

serpentins UV100RM

CARACTÉRISTIQUES

• Ampoule et ballast montés séparément pour une

grande souplesse d'installation dans toutes les

applications.

• Ballast de 24 V éliminant l'installation de prises

additionnelles par un électricien.

• Ampoule de rechange SnapLamp

Aucun tournevis requis.

• Ballast pouvant fonctionner soit en continu, soit par

cycle pour prolonger la durée de l'ampoule.

• Écran permettant à l'installateur de diriger la lampe

UV-C au bon endroit, c'est-à-dire sur le serpentin de

refroidissement et non pas sur les panneaux d'accès,

APPLICATION

Installée près du serpentin de refroidissement, la lampe

TrueUV empêche les micro-organismes contaminants de

croître à la surface, tels que les moisissures qui se forment

sur le serpentin de refroidissement et dans le bac à

condensats et qui peuvent réduire l'efficacité du système de

refroidissement et dégager des odeurs nauséabondes dans la

maison.

par mesure de sécurité.

• Installation du système TrueUV sur les surfaces

externes ou les surfaces internes.

• Support de montage réglable pour faciliter l'installation

du TrueUV dans les endroits exigus.

• Montage extérieur exigeant peu de dégagement.

Convient particulièrement dans les armoires ou

espaces exigus.

• Hublot permettant de vérifier sans danger si la lampe

fonctionne.

• Ampoule UV-C tuant les bactéries en suspension et

les moisissures sur les surfaces.

• Aucune émission d'ozone.

• Garantie limitée de cinq ans.

MC

pour

NOTICE TECHNIQUE

MC

facile à installer.

VEUILLEZ LIRE CE QUI SUIT AVANT DE METTRE SOUS TENSION

M27542

1. Enclencher la lampe, ne pas la tourner.

2. Fixer la base de montage.

3. Mettre le ballast à ON ou à CYCLE.

4. Mettre sous tension

IMPORTANT

Il faut un minimum 15 VA minimum pour raccorder au

transformateur du matériel. Si le nombre de voltampères (VA)

n'est pas connu, on peut utiliser le transformateur AT40A1162.

Table des matières

Caractéristiques techniques ............................................. 10

Pour commander .............................................................. 10

Consignes de sécurité ...................................................... 10

Installation ........................................................................ 11

Câblage ............................................................................ 14

Vérification ........................................................................ 14

Entretien ........................................................................... 14

Dépannage ....................................................................... 15

Page 10

SYSTÈME DE TRAITEMENT D'AIR TRUEUVMC POUR SERPENTINS UV100RM

CARACTÉRISTIQUES TECHNIQUES

Modèles TRADELINE® offerts

Le système de traitement de serpentin TrueUV UV100RM1

est monté en gaine au serpentin du climatiseur d'un système

CVCA. Elle empêche la formation de moisissures sur le

serpentin de refroidissement et dans le bac à condensats qui

peuvent réduire l'efficacité du système de refroidissement et

dégager des mauvaises odeurs dans la maison.

UV100RM1 : comprend les éléments suivants : ampoule

UC10W1, douille, base, ballast, cordon de raccordement,

support de montage réglable, écran, hublot et vis de montage.

UC10W1 : ampoule de rechange UV-C, 10 watts.

Efficacité : Le UV100RM TrueUV détruit jusqu'à 99 % de la

moisissure sur les serpentins de refroidissement.

- Des tests effectués dans une gaine d'essai ont permis de

constater une réduction des spores Aspergillus Niger sur

une surface irradiée pendant trois heures avec des lampes

neuves, à une distance de 0,45 m (18 po), en air calme.

Caractéristiques électriques nominales

Tension nominale : 24V c.a., 50/60 Hz.

Classe 2, appareil 30 V, max

Courant d'entrée : 750 mA

16-11/16 (424)

14-61/64 (380)

Puissance d'entrée : maximale 18 W, nominale 15 W, 15 VA

Puissance nominale de l'ampoule : 10 W, 220 mA

Température nominale

Température de l'ampoule (air en circulation) : 5 ºC à 77 ºC

Température ambiante du ballast : -1 ºC à 52 ºC

Température d'expédition : -34 ºC à 66 ºC

Humidité relative : Jusqu'à 95 %, sans condensation

Interrupteur : Cycle de fonctionnement - 3 h en marche/3 h à

l'arrêt

Encombrement : Voir la Fig. 1

Accessoires : Transformateur universel standard NEMA

AT40A1162 (non compris).

Homologations :

Répertorié Underwriters Laboratories Inc.

Ensemble de lampe germicide à montage en gaine.

Les aspects de santé liés à l'utilisation de ce produit et à sa

capacité d'aider à la désinfection de l'air ambiant n'ont pas été

évalués par les laboratoires UL.

1-11/32

2-3/4 (70)

1-13/16

(47)

1-1/2 (38)

3-5/32

(80)

(34)

4-3/32

(104)

2-3/4 (74)

M27054

M27056

Fig. 1. Encombrement en po (mm).

CONSIGNES DE SÉCURITÉ

Il est important de lire les consignes de sécurité ci-après avant

d'installer le produit ou d'en faire l'entretien.

POUR COMMANDER

Au moment d'acheter des produits de modernisation ou de remplacement auprès de votre grossiste ou distributeur

TRADELINE®, consultez le catalogue TRADELINE® ou les tarifs pour obtenir le numéro de pièce.

Prière d'adresser toute question additionnelle, demande d'information ou commentaires sur les produits et services par écrit ou

par téléphone :

1. Au bureau des ventes de produits de régulation et d'automatisation Honeywell de votre localité (consulter les pages

blanches de l'annuaire téléphonique).

2. À Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

Au Canada : Honeywell Limited-Honeywell Limitée, 35 Dynamic Drive, Toronto (Ontario) M1V 4Z9. Points de vente et de service

dans toutes les grandes villes du monde. Usines en Allemagne, en Australie, au Canada, en Espagne, aux États-Unis, en

Finlande, en France, au Japon, au Mexique, aux Pays-Bas, au Royaume-Uni et à Taiwan.

68-0297EFS—05 10

Page 11

SYSTÈME DE TRAITEMENT D'AIR TRUEUVMC POUR SERPENTINS UV100RM

AVERTISSEMENT

MISE EN GARDE

MISE EN GARDE

MISE EN GARDE

MISE EN GARDE

AVIS SUR LE MERCURE

MISE EN GARDE

Avant d'installer ce produit…

1. Lire attentivement les présentes instructions. Le fait de

ne pas les suivre risque d'endommager le produit ou de

constituer un danger.

2. Vérifier les caractéristiques spécifiées dans les instruc-

tions ou indiquées sur le produit pour s'assurer que le

produit convient à l'application prévue.

3. L'installeur doit être un technicien d'expérience ayant

reçu une formation pertinente.

4.

Une fois l'installation terminée, vérifier le fonctionnement

du produit comme indiqué aux présentes instructions.

Risque d'exposition aux UV.

Nocifs pour la peau nue et les yeux.

Peut causer une perte de la vue temporaire ou

permanente.

Regarder la lampe allumée par le hublot seulement.

Pour empêcher l'exposition aux rayons UV, couper

l'alimentation avant d'effectuer toute maintenance du

CVCA.

Ne pas installer l'appareil dans un endroit permettant

de voir la lampe UV une fois l'installation terminée.

Peut provoquer des blessures.

Risque de choc électrique.

Couper l'alimentation électrique avant de commencer

l'installation. Ne pas ouvrir le ballast ou la douille de la

lampe; aucun élément à l'intérieur ne peut être réparé

par l'utilisateur.

Danger : verre cassant.

Peut provoquer des blessures.

Insérer l'ampoule dans la base avec précautions.

Porter des gants de protection au moment de

manipuler l'ampoule.

Cet appareil contient du mercure scellé dans l'ampoule

à rayons ultraviolets. Ne pas jeter l'ampoule aux

poubelles après usage. L'éliminer correctement.

Comment nettoyer une ampoule cassée.

Ne pas utiliser d'aspirateur domestique.

Faire glisser les débris dans un sac en plastique et

éliminer ce sac correctement.

Communiquer avec le service local de cueillette des

déchets pour obtenir de l'information sur le recyclage

ou sur la bonne façon de disposer des ampoules.

Risque de brûlure - Lampe UV.

Dangereux pour la peau nue.

Peut causer des brûlures graves.

Couper l'alimentation 15 minutes avant de retirer les

lampes.

INSTALLATION

Couper l'alimentation de l'appareil de traitement d'air avant de

commencer l'installation.

Peut causer des dommages matériels.

Les rayons UV peuvent abîmer les matériaux en

plastique du CVCA ou en changer la couleur.

Choisir un endroit de montage où les éléments en

plastique dont la résistance aux UV est inconnue ne

seront pas exposés à ces rayons. Il est recommandé

d'installer la lampe à une distance minimale de un

mètre (trois pieds) d'appareils ou dispositifs en

plastique (p. ex. des humidificateurs et des filtres, sauf

ceux en fibre de verre).

Danger : arêtes coupantes.

Peut provoquer des blessures.

Insérer avec précautions l'ampoule dans l'ouverture

découpée dans la tôle de la gaine.

Porter des gants de protection pour effectuer des

travaux près de tôle.

Choisir un endroit pour monter une douille en gaine qui

permettra d'avoir une irradiation maximale du serpentin, des

bacs de condensats et des surfaces internes du système de

traitement d'air. Utiliser le support de montage réglable pour

installer la lumière à l'angle voulu dans les endroits exigus afin

de maximiser l'exposition. Le ballast se monte dans le tableau

de commande de l'appareil de traitement d'air, ou à l'extérieur

de la gaine dans le cas d'une installation dans un endroit

protégé contre les intempéries. S'assurer d'installer le ballast

près de la douille pour pouvoir le raccorder avec le cordon de

2 mètres (6 pieds).

Montage interne

Dans le cas de montage droit, la douille peut être installée

directement sur la surface interne. Utiliser des vis à tôle

autotaraudeuses pour monter la douille à l'endroit désiré.

11 68-0297EFS—05

Page 12

SYSTÈME DE TRAITEMENT D'AIR TRUEUVMC POUR SERPENTINS UV100RM

MF27055

SURFACE DE L’APPAREIL

DE TRAITEMENT D’AIR

MF27084

SURFACE DE L’APPAREIL DE

TRAITEMENT D’AIR

SUPPORT

RÉGLABLE

Fig. 2. Montage direct sur une surface interne.

Dans le cas de montage à angle, ajuster le support de

montage selon l'angle désiré, puis le fixer à l'aide d'un boulon.

Monter la douille sur le support à l'aide des vis de montage.

Monter le support à l'endroit voulu à l'aide des vis à métal

autotaraudeuses.

Fig. 3. Montage à angle sur la surface interne au moyen du

support de montage.

Installer l'écran sur l'ampoule de manière à ne pas diriger la

lampe UV-C sur le panneau d'accès par mesure de sécurité

supplémentaire et de manière à éviter toute exposition aux

rayons UV.

M27062

Fig. 4. Installation de l'écran sur l'ampoule.

Monter le ballast à l'endroit déterminé. Percer un trou de

19 mm (3/4 po) pour amener le cordon de la douille au ballast.

Utiliser une rondelle pour boucher le trou autour du cordon.

M27079

68-0297EFS—05 12

Fig. 5. Raccordement du cordon de la douille au ballast.

Fixer la base sur la douille. La base doit être utilisée dans le

cas de montage interne car elle actionne un interrupteur de

sécurité dans la douille. Encliqueter l'ampoule sur la douille.

Page 13

SYSTÈME DE TRAITEMENT D'AIR TRUEUVMC POUR SERPENTINS UV100RM

M27080

9 16

9 16

9 16

M27060

Fig. 6. Montage de la base sur la douille.

Coller les autocollants de sécurité et de gabarit à l'extérieur de

la gaine près du panneau d'accès ou près du TrueUV. Indiquer

sur l'autocollant l'endroit où est le ballast (interrupteur).

Fig. 7. Pose des autocollants de sécurité et de gabarit sur

la surface extérieure de la gaine.

Montage externe

Coller les autocollants de sécurité et de gabarit à l'endroit

choisi. Percer un trou de 39 mm (1-9/16 po) pour l'ampoule.

Fixer la base à l'aide des vis autotaraudeuses. Encliqueter

l'ampoule sur la douille et insérer celle-ci sur la base en la

tournant.

M27081

Fig. 8. Pose des autocollants de sécurité et de gabarit à

l'endroit choisi.

L'écran peut servir à protéger les matériaux sensibles aux

UV-C comme ceux des filtres.

M27072

Fig. 9. Protection du filtre à l'aide de l'écran.

Monter le ballast à l'endroit déterminé. S'il y a lieu, percer un

trou de 19 mm (3/4 po) dans la paroi pour passer le cordon.

Utiliser une rondelle pour boucher le trou autour du cordon.

Voir la Fig. 5.

13 68-0297EFS—05

Page 14

SYSTÈME DE TRAITEMENT D'AIR TRUEUVMC POUR SERPENTINS UV100RM

AVERTISSEMENT

M27069

Montage du hublot

Le hublot permet de vérifier sans danger le fonctionnement du

système TrueUV. Il permet également de savoir s'il est éteint et

si l'entretien et le nettoyage peuvent être effectués en toute

sécurité. Installer le hublot à un endroit permettant l'accès

pour l'entretien ou le nettoyage et permettant de voir si la

lampe est allumée ou éteinte.

Percer un trou de 13 mm (½ po). Encliqueter le hublot sur le

trou.

Installer un autocollant de sécurité concernant l'entretien à

côté du hublot. Les autres autocollants de sécurité doivent être

installés sur les panneaux d'accès et d'entretien, de façon à

être bien visibles au cours de l'entretien.

Fig. 10. Hublot et autocollant.

CÂBLAGE

VÉRIFICATION

Fermer tous les panneaux d'accès et rétablir l'alimentation

du système de CVCA.

Tourner l'interrupteur du ballast à ON ou à CYCLE.

Vérifier le fonctionnement du TrueUV par le hublot. Ne

jamais regarder directement dans la gaine, pour vérifier si

l'ampoule UV est allumée.

L'installateur doit expliquer à l'utilisateur comment voir par

le hublot la lueur bleue qui indique que l'appareil est en

marche.

L'installateur doit aussi donner à l'utilisateur les consignes

de sécurité de manière qu'il puisse faire l'inspection et

l'entretien du système en toute sécurité.

ENTRETIEN

Risque d'exposition aux UV.

Nocifs pour la peau nue et les yeux.

Peu causer une perte de la vue temporaire ou

permanente.

Regarder la lampe allumée par le hublot seulement.

Pour empêcher l'exposition aux rayons UV, couper

l'alimentation avant d'effectuer toute maintenance du

CVCA.

Ne pas installer l'appareil dans un endroit permettant

de voir la lampe UV une fois l'installation terminée.

Il est recommandé de nettoyer l'ampoule tous les trois mois. Si

l'ampoule est propre, l'intensité d'éclairage sera élevée et le

TrueUV détruira efficacement les bactéries. Utiliser un chiffon

humide pour nettoyer l'ampoule.

S'assurer que l'alimentation de l'appareil de traitement d'air est

coupée avant de commencer le câblage.

Raccorder les conducteurs 24 V du ballast au transformateur

24 V c.a. S'il y a lieu, utiliser du fil de calibre 18 comme

prolongateur. Il n'y a pas de polarité sur le TrueUV; n'importe

quelle borne peut être raccordée au fil sous tension 24 V et au

fil commun.

BALLAST

24 V c.a.

MISE À LA TERRE

Fig. 11. Schéma de câblage.

68-0297EFS—05 14

MF27061A

L'ampoule devrait être remplacée une fois par année si le

système est réglé à la position ON, ou tous les deux ans s'il est

réglé à la position CYCLE.

1. Relire les consignes de sécurité concernant les

ampoules UV-C, les ampoules chaudes, le verre

cassable et le mercure avant de faire le nettoyage ou

l'entretien. Voir page 11.

2. Couper l'alimentation du système de CVCA.

3. Couper l'alimentation du TrueUV sur le ballast.

4. Montage interne : Par le panneau d'accès, saisir

l'ampoule. Prendre garde de se brûler les mains sur

l'ampoule chaude.

Montage externe : Tourner la douille dans la base.

5. Tirer l'ampoule droit vers soi pour la dégager de la

douille.

Page 15

SYSTÈME DE TRAITEMENT D'AIR TRUEUVMC POUR SERPENTINS UV100RM

M27067

Fig. 12. Dégagement de l'ampoule de la douille.

6. S'il y a un écran sur l'ancienne ampoule, l'enlever et

l'installer sur la nouvelle.

DÉPANNAGE

M27068

Fig. 13. Enlèvement de l'écran pour réutilisation.

7. Encliqueter la nouvelle ampoule dans la douille.

8. Montage interne: Fermer tous les panneaux d'accès

utilisés pour l'entretien.

Montage externe: Tourner la douille dans la base.

9. Remettre le TrueUV à la position ON ou à la position

CYCLE selon le cas.

10. Rétablir l'alimentation du système de CVCA.

Aucune pièce du TrueUV ne peut être réparée.

Le TrueUV n'allume pas :

Vérifier le fonctionnement du TrueUV par le hublot. Ne jamais regarder directement dans la gaine pour vérifier si l'ampoule UV est

allumée.

1. Vérifier si la base est bien fixée dans la douille. La base actionne l'interrupteur de sécurité dans la douille.

2. Vérifier la position de l'interrupteur à l'endroit où est installé le ballast. Si l'interrupteur est réglé à CYCLE, il peut être arrêté

pendant 3 heures. Mettre temporairement l'interrupteur à ON pour vérifier le fonctionnement.

3. Vérifier si l'alimentation au ballast est de 24 V.

4. Vérifier si les connecteurs du cordon sont bien fixés.

5. Vérifier si l'ampoule est bien insérée dans la douille.

6. Vérifier si l'ampoule est grillée et doit être remplacée.

15 68-0297EFS—05

Page 16

SYSTÈME DE TRAITEMENT D'AIR TRUEUVMC POUR SERPENTINS UV100RM

PIÈCES

Les pièces du TrueUV sont illustrées à la Fig. 14.

5. ÉCRAN

3. BASE

4. AMPOULE

UC10W1

Fig. 14. Pièces du TrueUV.

Tableau 1. Pièces.

Article Pièce Quantité

1 Ballast 1

2 Douille 1

3Base 1

4Ampoule 1

5 Écran 1

Non illustré Hublot 1

Non illustré Support de montage (comprend deux pièces, boulon et

écrou)

Non illustré Vis d'installation du ballast et de la base 4

Non illustré Vis d'installation de la douille 2

Non illustré Capuchon de vis en caoutchouc 4

2. DOUILLE

1. BALLAST

MF27053

1

Solutions de régulation et d’automatisation

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35, Dynamic Drive

Golden Valley, MN 55422 Toronto (Ontario) M1V 4Z9

customer.honeywell.com

® Marque de commerce déposée aux É.-U.

© 2008 Honeywell International Inc. Tous droits réservés

68-0297EFS—05 M.S. Rev. 12-08

Page 17

Sistema de tratamiento de serpentín

1

2

3

TrueUV™ UV100RM

INFORMACIÓN DEL PRODUCTO

CARACTERÍSTICAS

• La bombilla de montaje remoto y el balastro permiten

una instalación flexible en cualquier aplicación.

• El balastro de 24V permite que el electricista no tenga

que instalar salidas adicionales.

• Las bombillas de reemplazo SnapLamp™ facilitan el

mantenimiento. No hacen falta tornillos para el

reemplazo de la bombilla.

• El balastro puede configurarse para que funcione

continuamente o en ciclo - prolongando la vida de la

bombilla.

• El protector permite al instalador apartar la luz UV-C de

los paneles de acceso como medida de seguridad y

APLICACIÓN

Cuando se instala en el serpentín del aire acondicionado,

TrueUV ayuda a evitar la formación de microorganismos

contaminantes tales como el moho en la superficie del

serpentín del aire acondicionado y en la bandeja de drenaje,

los cuales pueden disminuir la eficacia del sistema de

enfriamiento y permitir la incorporación de olores no

deseados en la vivienda.

dirigirla hacia el serpentín A/C donde se necesita la

luz.

• TrueUV puede instalarse en superficies exteriores o

interiores.

• El soporte de montaje ajustable permite que TrueUV

pueda instalarse en lugares con poco espacio.

• El montaje exterior no necesita de mucho espacio, de

modo que TrueUV puede instalarse en armarios y

lugares estrechos.

• La ventanilla indicadora permite observar el

funcionamiento de la lámpara de forma segura.

• La luz UV-C mata las bacterias del aire y el moho de la

superficie.

• TrueUV no produce ozono.

• Garantía limitada de cinco años.

LEA ESTO PRIMERO ANTES DE ACTIVAR EL SUMINISTRO ELÉCTRICO

M27542

1. Coloque la bombilla a presión, no gire.

2. Fije la base de montaje.

3. Gire el balastro a ON (encendido) o CYCLE (ciclo)

4. Active nuevamente el suministro eléctrico.

IMPORTANTE

Necesita un mínimo disponible de 15 VA si se conecta al

transformador del equipo. Si el VA se desconoce entonces

puede utilizar el transformador AT40A1162.

Especificaciones .............................................................. 18

Información Para Pedidos ................................................ 18

Precauciones de Seguridad ............................................. 18

Instalación ........................................................................ 19

Cableado .......................................................................... 22

Verificación ....................................................................... 22

Mantenimiento .................................................................. 22

Localización Y Solución De Problemas ........................... 23

Contenido

Page 18

SISTEMA DE TRATAMIENTO DE SERPENTÍN TRUEUV™ UV100RM

ESPECIFICACIONES

Modelos TRADELINE® disponibles

El sistema de tratamiento de serpentín TrueUV UV100RM1

va montado en el conducto en el serpentín del aire

acondicionado de un sistema HVAC. Ayuda a evitar la

formación de moho y hongos en el serpentín del aire

acondicionado y en la bandeja de drenaje, los cuales pueden

disminuir la eficacia del sistema de enfriamiento y permitir la

incorporación de olores no deseados en la vivienda.

UV100RM1 incluye la bombilla UC10W1, mango, base,

balastro, conexiones del cable, soporte de montaje ajustable,

protector, ventanilla indicadora y tornillos para montaje.

Bombilla de reemplazo UV-C de 10 vatios UC10W1.

Eficacia: UV100RM TrueUV mata hasta el 99% de los hon-

gos en los serpentines de enfriamiento.

- El examen realizado en un conducto de prueba mostró la

disminución de Aspergillus-Niger cuando la superficie se

irradia a una distancia de 45,7 cm durante tres horas con

aire en calma utilizando lámparas nuevas.

Clasificación eléctrica

Clasificación de voltaje: 24 Vac, 50/60 Hz.

Clase 2 dispositivo 30V, máx

Clasificación de corriente de entrada: 750mA

16-11/16 (424)

14-61/64 (380)

Clasificación de potencia de entrada: 18W máx,

15W nominal, 15VA

Clasificación de la bombilla: 10W, 220mA

Clasificación de temperatura

Rango de temperatura de la bombilla (con aire en mov-

imiento): 5ºC a 77ºC

Rango de temperatura ambiente del balastro: -1ºC a 52ºC

Rango de temperatura de embarque: -34ºC a 66ºC

Humedad relativa: Hasta 95% RH, sin condensación

Interruptor: El CICLO está activo 3 horas/apagado 3 horas

Dimensiones: Ver Fig. 1

Accesorios: Transformador universal estándar NEMA

AT40A1162 (no se incluye).

Aprobaciones:

Clasificación de Underwriters Laboratories Inc.

Ensamble de bombilla germicida para montaje en conducto.

Los aspectos de salud relacionados con el uso de este

producto y su capacidad para ayudar en la desinfección del

aire ambiental no han sido investigados por UL.

1-11/32

2-3/4 (70)

1-13/16

(47)

1-1/2 (38)

3-5/32

(80)

(34)

4-3/32

(104)

2-3/4 (74)

M27054

M27056

Fig. 1. Dimensiones en pulgadas (mm).

PRECAUCIONES DE SEGURIDAD

Por favor lea antes de instalar o brindar servicio al producto.

INFORMACIÓN PARA PEDIDOS

Cuando compre productos de reemplazo y modernización a su mayorista o distribuidor de TRADELINE®, refiérase al catálogo o

listas de precios de TRADELINE® para tener el número de pedido completo, o especifique:

1. Número del modelo

2. Voltaje.

Si tiene preguntas adicionales, si necesita más información, o si quisiera dar sus comentarios sobre nuestros productos o

servicios, escriba o llame a:

1. Su oficina de ventas local de Automatización y control desenlace (consulte las páginas blancas de su directorio telefónico)

2. Honeywell Customer Care

1885 Douglas Drive North

Golden Valley, MN 55422-4386

En Canadá : Honeywell Limited/Honeywell Limitée, 35 Dynamic Dr., Toronto, Ontario, M1V 4Z9. Oficinas internacionales de

ventas y servico en todas las principales ciudades de mundo. Manufactura en Australia, Canadá, Finlandia, Francia, Alemania,

Japón, México, los Países Bajos, España, Taiwán, Reino Unido, EE.

68-0297EFS—05 18

Page 19

Al instalar este producto…

ADVERTENCIA

PRECAUCIÓN

PRECAUCIÓN

PRECAUCIÓN

PRECAUCIÓN

NOTIFICACIÓN SOBRE EL MERCURIO

PRECAUCIÓN

1. Lea detenidamente estas instrucciones. De no seguirlas

se podría dañar el producto o provocar una situación

peligrosa.

2. Verifique los valores nominales del producto y en las

instrucciones, para asegurarse de que el producto sea

adecuado para su aplicación.

3. El instalador debe ser un técnico de servicio capacitado

y experimentado.

4. Después de terminar la instalación, verifique el funciona-

miento del producto tal como se indica en estas instrucciones.

Riesgo de luz UV.

Dañino para la piel y los ojos sin protección.

Puede ocasionar pérdida de la visión temporal o

permanente

Mire hacia la luz únicamente a través del indicador de

luz de la lámpara en el mango de la lámpara.

Para evitar la exposición a la luz ultravioleta,

desconecte la energía al sistema ultravioleta antes de

dar servicio a cualquier parte del sistema de

calefacción y aire acondicionado.

No monte el dispositivo en un lugar que permita la

observación de la luz ultravioleta después de la

instalación.

Riesgo de lesiones personales.

El suministro eléctrico puede ocasionar descarga

eléctrica.

Desconecte el suministro de electricidad antes de

comenzar la instalación. No abra el balastro o el

mango de la lámpara; contiene componentes a los

cuales el usuario no puede darle servicio.

SISTEMA DE TRATAMIENTO DE SERPENTÍN TRUEUV™ UV100RM

Riesgo de bordes afilados.

Puede ocasionar lesiones personales.

Tenga cuidado al insertar el dispositivo ultravioleta en

el corte efectuado a una lámina de metal.

Utilice guantes protectores cuando trabaje cerca de

una lámina de metal.

Riesgo de rotura de vidrio.

Puede ocasionar lesiones personales.

Tenga cuidado cuando inserte la(s) bombilla(s) en la

base de la lámpara.

Utilice guantes protectores cuando manipule la(s)

bombilla(s).

Este dispositivo contiene mercurio en la(s) bombilla(s)

ultravioleta sellada(s). No coloque la(s) bombilla(s)

usada(s) en la basura. Deséchelas adecuadamente.

Limpieza de una bombilla rota.

No utilice una aspiradora doméstica.

Barra los desechos hacia una bolsa plástica y

deséchela adecuadamente.

Contacte la oficina de manejo de desechos de su

localidad en relación a la forma de reciclar o desechar

adecuadamente la(s) bombilla(s) vieja(s).

Riesgo de quemadura con la bombilla.

Dañina a la piel sin protección.

Puede ocasionar quemaduras graves.

Desconecte la electricidad 15 minutos antes de retirar

la(s) bombilla(s) ultravioleta.

Riesgo de daño al equipo.

La luz ultravioleta puede ocasionar cambio de

color o degradación estructural de los materiales

plásticos del HVAC.

Elija una ubicación para el montaje que evite la

exposición a los componentes plásticos cuya

resistencia a la luz ultravioleta sea desconocida. Se

recomienda una separación mínima de 91,4 cm donde

haya exposición directa entre la lámpara ultravioleta y

los dispositivos de fabricación plástica (tales como los

humidificadores y filtros de material que no sea de fibra

de vidrio).

INSTALACIÓN

Desconecte el suministro de energía al controlador de aire

antes de la instalación.

Elija una ubicación para montar el mango en el conducto que

permita la máxima exposición al serpentín, bandejas de

drenaje y superficies internas del controlador de aire. El

soporte de montaje ajustable puede utilizarse para facilitar la

colocación de la bombilla en espacios reducidos y para

maximizar la exposición. El balastro puede montarse en el

panel de control del controlador de aire o fuera del conducto

cuando se monte en un espacio protegido de la intemperie.

Cuide de montar el balastro dentro del alcance del mango de

modo que el cable de 1,8 m sea suficiente.

Montaje interno

Para montaje recto, el mango puede montarse directamente

en la superficie interna. Utilice tornillos autoperforantes para

lámina de metal para montar el mango en la ubicación

deseada.

19 68-0297EFS—05

Page 20

SISTEMA DE TRATAMIENTO DE SERPENTÍN TRUEUV™ UV100RM

MS27055

SUPERFICIE DEL

CONTROLADOR DE AIRE

MS27084

SUPERFICIE DEL

CONTROLADOR

DE AIRE

SOPORTE

AJUSTABLE

Fig. 2. Montaje directo a la superficie interna.

Para montaje en ángulo, ajuste el soporte de montaje al

ángulo deseado y fije en su lugar con un perno. Utilice los

tornillos de montaje para montar el mango al soporte. Utilice

tornillos autoperforantes para lámina de metal para montar el

soporte en la ubicación deseada.

Fig. 3. Ensamble del soporte de montaje en ángulo a la

superficie interna.

Fije el protector a la bombilla de forma que aparte la luz directa

UV-C del panel de acceso como medida secundaria de

seguridad para evitar la exposición directa a la luz.

M27062

Fig. 4. Fije el protector a la bombilla.

Monte el balastro en la ubicación elegida. Perfore un agujero

de 1,9 cm para pasar el cable desde el mango al balastro.

Utilice una arandela aislante para sellar el agujero alrededor

del cable.

68-0297EFS—05 20

M27079

Fig. 5. Conecte el cable desde el mango hasta el balastro.

Fije la base al mango. La base deberá utilizarse para

aplicaciones de montaje interno ya que activa un interruptor

interno de seguridad en el mango. Coloque la bombilla a

presión en el mango.

Page 21

M27060

M27080

9 16

9 16

9 16

Fig. 6. Fije la base al mango.

Pegue la etiqueta de Medidas de Seguridad/Plantilla en la

parte de afuera del conducto cerca del panel de acceso o

cerca de la ubicación de TrueUV y escriba la ubicación del

balastro (interruptor) en la etiqueta.

SISTEMA DE TRATAMIENTO DE SERPENTÍN TRUEUV™ UV100RM

Fig. 7. Aplique la etiqueta de las Medidas de Seguridad/

Plantilla a la parte de afuera del conducto.

Montaje externo

Pegue la etiqueta de Medidas de Seguridad/Plantilla en la

ubicación elegida. Taladre un agujero de 4 cm para la

bombilla. Monte la base utilizando tornillos autoperforantes.

Coloque la bombilla a presión en el mango y enrosque en la

base.

M27081

Fig. 8. Aplique la etiqueta de las Medidas de Seguridad/

Plantilla en el sitio elegido.

El protector puede utilizarse para apartar los UV-C de los

materiales susceptibles tales como los filtros de material.

M27072

Fig. 9. Utilice el protector para resguardar el filtro de

material.

Monte el balastro en la ubicación elegida. Si fuese necesario

para penetrar la barrera, perfore un agujero de 1,9 cm para

pasar el cable. Utilice una arandela aislante para sellar el

agujero alrededor del cable. Ver Fig. 5.

21 68-0297EFS—05

Page 22

SISTEMA DE TRATAMIENTO DE SERPENTÍN TRUEUV™ UV100RM

ADVERTENCIA

M27069

BALASTRO

MS27061A

24 VAC

TIERRA

Montaje de la ventanilla indicadora

La ventanilla indicadora le permite verificar de manera segura

el funcionamiento de TrueUV. También puede indicarle cuando

se ha apagado TrueUV y sea posible efectuar servicio o

mantenimiento de forma segura. Elija una ubicación donde la

ventanilla indicadora le muestre el funcionamiento UV desde la

ubicación de mantenimiento o acceso para servicio.

Taladre un agujero de 1,3 cm. Coloque a presión la ventanilla

indicadora en el agujero.

Coloque una etiqueta de advertencia de mantenimiento al lado

de la ventanilla indicadora. Deben colocarse otras etiquetas de

advertencia de mantenimiento en los paneles de acceso y

servicio donde pueden ser vistas fácilmente durante cualquier

futuro mantenimiento o servicio.

Fig. 10. Ventanilla indicadora y etiqueta.

CABLEADO

Verifique que se haya desconectado la energía al controlador

de aire antes de proceder.

Conecte los conductores de 24V del balastro al transformador

de 24VAC. Puede utilizarse cable calibre 18 para prolongar los

conductores si fuese necesario. TrueUV no tiene polaridad y

cualquier conductor puede cablearse al activo de 24V y el

común.

VERIFICACIÓN

Cierre todos los paneles de acceso y conecte la energía del

equipo de HVAC.

Gire la posición del interruptor del balastro a ON

(encendido) o CYCLE (ciclo).

Verifique el funcionamiento de TrueUV a través de la

ventanilla indicadora. No intente mirar directamente en el

conducto para ver la bombilla ultravioleta iluminada.

El instalador debe orientar al propietario sobre la unidad

mostrándole el resplandor azul de la ventanilla indicadora,

lo cual indica que la unidad está trabajando.

El instalador también deberá enfatizar las advertencias de

los riesgos de modo que el propietario conozca como

inspeccionar y mantener de manera segura el sistema.

MANTENIMIENTO

Riesgo de luz UV.

Dañino para la piel y los ojos sin protección.

Puede ocasionar pérdida de la visión temporal o

permanente

Mire hacia la luz únicamente a través del indicador de

luz de la lámpara en el mango de la lámpara.

Para evitar la exposición a la luz ultravioleta,

desconecte la energía al sistema ultravioleta antes de

dar servicio a cualquier parte del sistema de

calefacción y aire acondicionado.

No monte el dispositivo en un lugar que permita la

observación de la luz ultravioleta después de la

instalación.

Se recomienda la limpieza de la bombilla trimestralmente

como mantenimiento de rutina. Conservar la bombilla sin polvo

mantendrá alta la intensidad de los UV-C y la proporción de

eliminación de microorganismos por parte de TrueUV. Utilice

un paño húmedo para limpiar la bombilla.

La bombilla debe cambiarse todos los años si se utiliza en la

posición ON (encendido) o cada 2 años si se usa en la

posición CYCLE (ciclo).

1. Repase las Precauciones de Seguridad relacionadas

con los riesgos de la luz UV-C, bombillas calientes, vidrio rompible y aviso sobre mercurio en la página 19

antes de efectuar mantenimiento.

2. Desconecte el suministro de energía al equipo HVAC.

3. Desconecte la energía de TrueUV en el balastro.

4. Montaje interno: Meta la mano a través del panel de

acceso y agarre la bombilla. Proteja sus manos de la

bombilla caliente.

Montaje externo: Gire el mango por la base.

5. Hale la bombilla derecho hacia afuera del mango para

extraerla a presión.

Fig. 11. Diagrama de cableado.

68-0297EFS—05 22

Page 23

SISTEMA DE TRATAMIENTO DE SERPENTÍN TRUEUV™ UV100RM

M27067

Fig. 12. Extraiga la bombilla del mango.

6. Si utiliza un protector, retírelo de la bombilla vieja y fíjelo

a la nueva.

7. Coloque la bombilla a presión en el mango.

8. Montaje interno: Cierre todos los paneles de acceso

9. Vuelva a conectar el suministro de energía de TrueUV

10. Conecte de nuevo el suministro de energía al equipo

LOCALIZACIÓN Y SOLUCIÓN DE PROBLEMAS

M27068

Fig. 13. Retire el protector y reutilice.

utilizados para servicio.

Montaje externo: Gire el mango en la base.

en la posición ON (encendido) o CYCLE (ciclo).

HVAC.

TrueUV no tiene partes a las cuales se les pueda proporcionar servicio en el lugar.

TrueUV no se ilumina:

Verifique el funcionamiento de TrueUV a través de la ventanilla indicadora. No intente mirar directamente en el conducto para ver

la bombilla ultravioleta iluminada.

1. Verifique que la base esté enroscada en su lugar en el mango. La base activa el interruptor de seguridad en el mango.

2. Revise la posición del interruptor en el balastro. Si el interruptor está en la posición CYCLE (ciclo), entonces TrueUV puede

haber cerrado el ciclo durante 3 horas. Mueva el interruptor temporalmente a la posición ON (encendido) para verificar el

funcionamiento.

3. Verifique la potencia de 24V en el balastro.

4. Revise que los conectores de cables estén firmemente asegurados.

5. Revise que la bombilla esté insertada de forma segura en el mango.

6. Verifique si la bombilla se ha quemado y necesita reemplazo.

23 68-0297EFS—05

Page 24

SISTEMA DE TRATAMIENTO DE SERPENTÍN TRUEUV™ UV100RM

LISTA DE PARTES

Las partes de TrueUV se ilustran en la Fig. 14.

5. PROTECTOR

4. BOMBILLA

UC10W1

Fig. 14. Partes de TrueUV.

Tabla 1. Lista de partes.

Artículo Nombre de la parte Cantidad

1Balastro 1

2 Mango 1

3Base 1

4 Bombilla 1

5 Protector 1

No se ilustra Ventanilla indicadora 1

No se ilustra Soporte de montaje (incluye dos piezas, tuerca y perno) 1

No se ilustra Tornillos de instalación para el balastro y la base. 4

No se ilustra Tornillos de instalación para el mango. 2

No se ilustra Capuchones de goma para tornillos 4

3. BASE

2. MANGO

1. BALASTRO

MS27053

Automatización y control desenlace

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35, Dynamic Drive

Golden Valley, MN 55422 Toronto, Ontario M1V 4Z9

customer.honeywell.com

® Marca Registrada en los E.U.A

(C) 2008 Honeywell International Inc. todos Los Derechos Reservados

68-0297EFS—05 M.S. Rev. 12-08

Loading...

Loading...