Page 1

UDC 6300 Process Contr oller

T tal P l ant

1

Page 2

UDC 6300 – Compact, Powerful and Easy to Use

The UDC 6300 is Honeywell’s easy-to-use, yet

powerful process controller. From stand-alone control

to a solution fully digitally integrated with Honeywell’s

SCAN 3000 or TDC 3000

the UDC 6300 is suited for a variety of applications.

The UDC 6300 provides all the power you need in

a process controller, yet it’s easy to configure, install

and operate. Designed to handle continuous process

applications, the 6300 provides all the benefits you

expect from a Honeywell LeaderLine controller:

• fast installation and start-up

• application flexibility

• improved process quality and efficiency

• operator confidence

• Honeywell quality and global support.

You get all the power you need: multilingual prompts,

flexible math options, preconfigured algorithms, logic,

and ACCUTUNE™ adaptive tuning. These features and

more make UDC 6300 the easiest-to-use process

controller you’ll find anywhere.

X

distributed control systems,

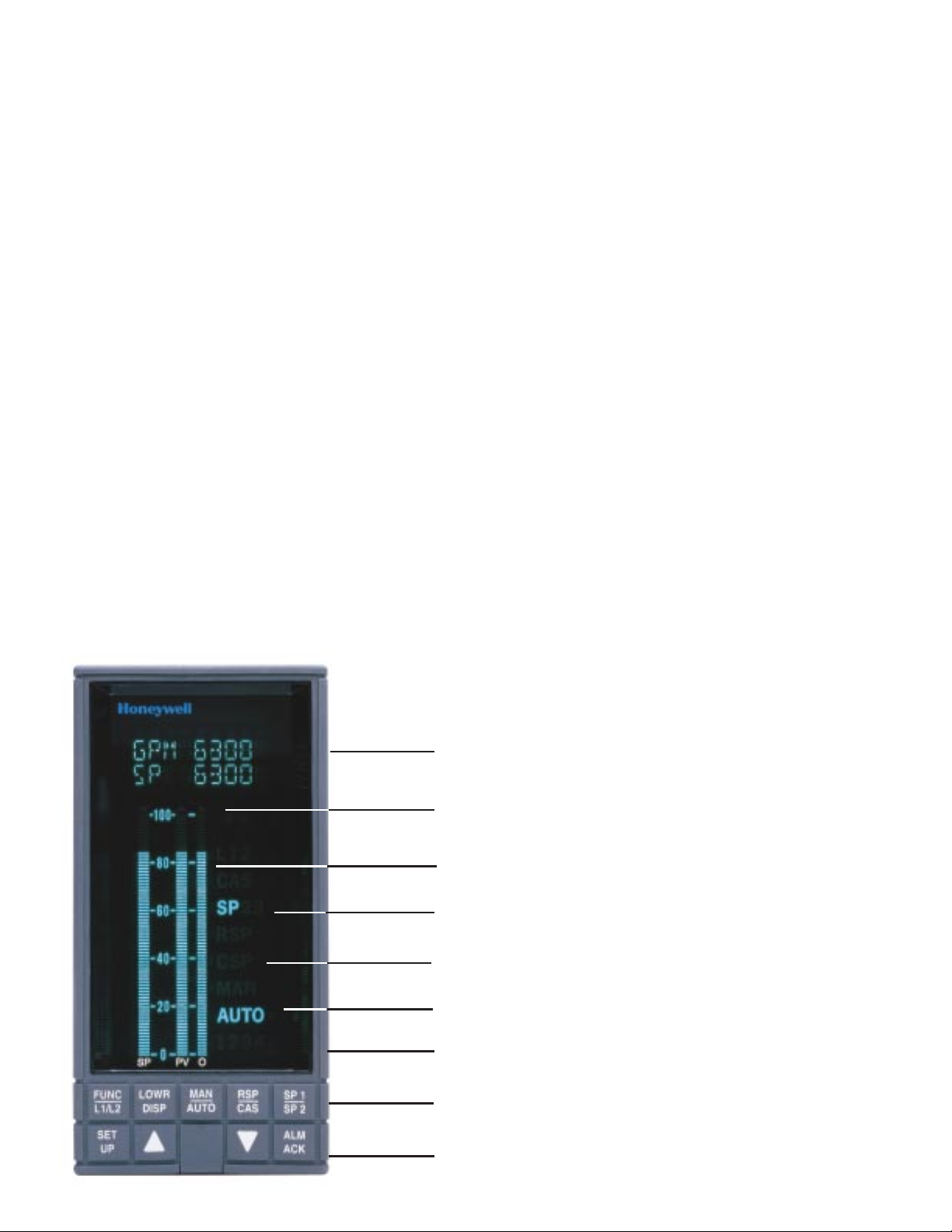

Clear Operator Interface

for Efficient Operation

UDC 6300 features bright displays, and a sealed,

splashproof keyboard for a rugged and informative

operator interface:

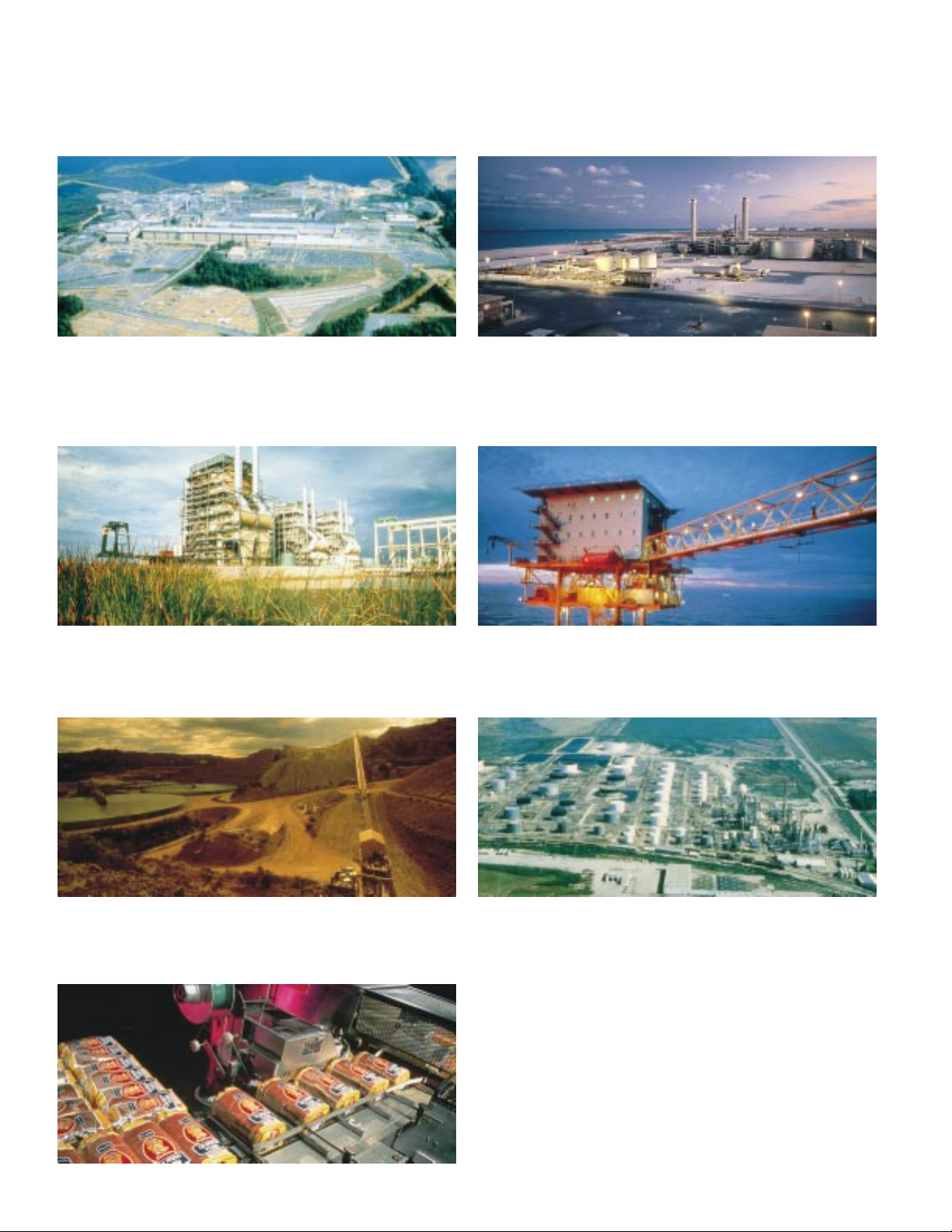

Industry-Specific Experience

At Honeywell, we focus on key industries for which

we supply effective, time-proven industrial automation

solutions. These industries include:

• Hydrocarbon Processing

• Oil and Gas

• Chemicals and Pharmaceuticals

• Pulp and Paper

• Food and Consumer Goods

• Power Generation

• Manufactured Goods

Honeywell’s commitment to these industries is illustrated the world over. For example, our products help:

• refineries produce more than half the world’s supply

of gasoline

• paper mills turn out 40-million metric tons of pulp and

paper each year

• fifteen of the world’s largest chemicals companies

achieve manufacturing competitiveness.

Our market-specific approach gives you the benefit of

practical knowledge of your industry, challenges, and process.

Standard panel mounting – shorter case depth

(72 x144 DIN bezel)

Dual displays show process values, multilingual prompts,

PV tag and ID tag

Display loop one, loop two, or both

Bargraphs display setpoint, process variable and

output values

Three local setpoints, plus remote; or computer setpoint

Display flashes during alarm condition

Manual/automatic control mode indicator

Alarm indicators

Sealed tactile feedback keyboard; security code

prevents tampering

Alarm acknowledge key

2

Page 3

The Best Controller Available for the Process Industries

Honeywell’s UDC 6300 process controller combines reliability and flexibility. The 6300 features traditional

Honeywell quality, and it’s versatile enough to meet a broad range of control needs in a variety of industries and

applications.

Pulp and Paper – Kamyr digester, paper machine,

bleaching, dry stock blending and brown stock washing;

cascade and ratio applications.

Power Generation – Utility boilers, package boilers,

water treatment, ash and liquid waste handling, metering

pump control.

Fine Chemicals – Steam desuperheaters, batch reactor

cascade control, evaporator control, flow ratio control,

mass flow compensation, and steam and fuel supply

pressure control.

Oil and Gas – Pipeline booster stations, gas plants,

platforms, metering stations, and terminal operations.

Metals – Reheat furnace control for air temperature,

fuel/air ratio, zone, high override, low override; heat

treating and electric furnaces.

Hydrocarbon Processing – Pipeline booster station,

flow ratio, mass flow compensation, pressure, and

evaporator.

Consumer Goods – Tablet coaters, sterilizers, freeze

driers, lyophilizers, and simple cooker and fryer control;

large scale cooking and frying operations, flow ratio,

temperature and pressure, food storage, tobacco dryers,

retorts, evaporator, baking ovens, and crystallizers.

3

Page 4

Addressing Your Needs Today and Tomorrow

The modular design of UDC 6300 saves you money because it allows you to purchase only the power required for

your application. The controller can be easily and economically upgraded if your needs should change tomorrow.

Standard Features

❑ Compact, shallow depth ❑ Selectable scan rate

❑ Feed forward control ❑ Square root, ratio, bias, digital filtering

❑ 3 local setpoints ❑ 4 analog inputs

❑ Remote setpoints ❑ PV Hot Start

❑ 2 sets of tuning constants ❑ Configurable ID tag

❑ Configurable security code ❑ Multilingual prompts

❑ CE Mark compliant ❑ Setpoint ramp rate

❑ Configurable fail-safe output ❑ Configurable output rate limit

❑ Alarm indication and acknowledgement

PV

K

UDC 6300

DP X P

T

FIC

PV RSP

TTPTFT

CV

GAS FLOW

One UDC 6300 provides control plus mass flow compensation.

LT

REFLUX

CV1CV2

TT

DISTILLATE

PV1 PV2

TIC LIC

UDC 6300

Distillation column reflux control two loops in one UDC 6300.

FT

FUEL

FT

AIR

Metered fuel/air ratio.

STEAMFLOW

STEAM

DRUM

LT

FE

IN 2

PID

R/B

LOOP 2

INTERNAL

CASCADE

FEEDWATER FLOW

IN 3

FEEDFORWARD

IN 1

PID

LOOP 1

M FE

UDC

6300

Boiler drum level control – cascade plus feedforward.

FURNACE

❑ ACCUTUNE adaptive tuning

❑ Transmitter power

❑ Output override

❑ Second current output

❑ Communications interface

❑ Direct TC or RTD input

❑ Dual-loop control/Internal cascade

Additional Features

❑ Math functions

– Input/output characterization

– Deadtime

– Totalization

– Gain scheduling

– 5 logic blocks

❑ Digital inputs and outputs

❑ Pulse inputs

4

Page 5

UDC 6300 Is Easy To Configure From the Keyboard...

• Add/subtract

• Weighted average

• Multiply/divide

• High-low select

• Feed forward

• Flow compensation

• Totalization

• Square root

• Gain scheduling

• 8-segment input/output characterizers (2)

• Polynomial equation input characterization

• Dead time

• 5 logic blocks

Pre-engineered control functions are

enabled via straightforward prompts in

English, German or French.

Or From Your PC...

Honeywell’s LeaderLine PC Software

offers a cost-effective and efficient means to

monitor, archive, and configure Honeywell’s

LeaderLine controllers and recorders using a

Windows*-based personal computer. On-line

or off-line device configuration allows the

operator to change configuration parameters

from pull-down menus. The familiar environment and the on-line help utility allow

even first-time users to quickly configure

UDC controllers for their application.

Converter

Up to 16 addresses

ALM

DI

RSP

OUT

FUNCTION

SET UP

%

SETPOINT

LOWER

MANUAL

SELECT

DISPLAY

AUTO

RUN

HOLD

UDC 3000

RS232

ALARM

MANUAL

PAPER

RECORD

COMM

MEMORY

1

2

3

4

5

6

7

DPR 3000

ASCII RS 422/485

6PQR

5MNO

4JKL

3GHI

2DEF

1ABC

MANUAL

DISPLAY

PRINT

ENTER

+ _CONF

CHANNEL

8

9

10

11

12

13

14

0°%

RECORD

ACK

ACK ALL

29

22

30

15

23

31

16

24

32

17

25

18

26

19

27

20

28

21

100

80

60

SP

40

SP

20

AUTO

0

LOWR

MAN

RSP

SP 1

FUNC

DISP

AUTO

CAS

SP 2

L1/L2

ALM

SET

ACK

UP

UDC 6300

3 DPR100 C

1

2

3

DPR 100

5

Page 6

UDC 6300 Makes

the Connection

UDC 6300 gives you the option of digitally integrating to Honeywell’s PC-based SCAN 3000 system or

TDC 3000

the functionality needed for your process.

SCAN 3000 Supports Connection

to UDC 6300

SCAN 3000, a scalable, supervisory system, offers a

powerful, cost-effective solution for a variety of applications. SCAN’s client/server architecture operates on

Windows NT. UDC 6300 can be configured directly from

the SCAN 3000 graphical user interface, or locally, via

X

distributed control system, depending on

R485

the control panel. Controller configurations can be copied

between the controllers and modified for reuse – saving

you time and effort.

The low cost RS485 multidrop serial link allows SCAN

to communicate directly with up to 15 UDC devices per

serial line, and up to a maximum of 100 UDC controllers.

SCAN uses an optimized scanning algorithm to enhance

the dialog speed with the controllers.

SCAN 3000 system offers the advantages and features

of a distributed control system in a stand-alone or networked design. Implemented through configuration, not

programming, the system provides numerous standard,

configurable elements to support quick start-up and easy

operation.

Native LCN Window

GuideCRUDE DISTILLATION TOWER

292.

Advice

55

Current CRUDE

Messages

SPQC

100.

1860

BRENT

Messages

10

10

Supervisory

Alarms

30.1 18.8

COT TEMP

351.

Crude

141.

51

Unit #2

60

PRODUCTION DATA

11

FEED

3200

19.0

30.4

690.

61

45

61

11

BBL HR

107.

Residue

292

Fuel/Gas

1869

Naphta

ASSOCIATED DISPLAYS

Kerosene

CRUDE

PROFIT

PRODUCT

Alarms

CHANGE

DATA

DATA

Gasoil

PLANT OR

PROGRAM

SUMMARY

Residue

DATA

DATA

GROUP

Station

352

689

106

ALM

DI

100

80

60

SP

40

SP

20

AUTO

0

LOWR

MAN

RSP

SP 1

FUNC

DISP

AUTO

CAS

SP 2

L1/L2

ALM

SET

ACK

UP

RSP

OUT

FUNCTION

SET UP

UDC 3000

%

SETPOINT

LOWER

MANUAL

SELECT

DISPLAY

AUTO

RUN

HOLD

S9000

Controller

UDC 6300

Seamless Digital Integration

to Honeywell’s TDC 3000

The evolution of UDC 6300 continues as the only

process controller with the capability to digitally integrate

to Honeywell’s TDC 3000

single-window access via the Universal Station to all

UDC 6300 operating and data base parameters, alarms

and diagnostics. UDC 6300 gives you a logical, straightforward migration path from your UDC 6300 single loop

stand-alone controllers to a fully integrated solution.

All this and it’s easy to use. Honeywell provides a

full set of Universal Station displays for UDC 6300 that

give the operator unlimited access to process and configuration data. In addition, digital integration provides

other advantages, including fast speed for very high

speed loop processing applications, and automatic/

manual station capability for Process Manager/Advanced

Process Manager.

X

X

. Digital integration provides

Ethernet

!

Local Operators

Panel

6

Page 7

PV

PV

Illustration of 3Illustration of 3

Illustration of 3

Typical ProblemsTypical Problems

Typical Problems

Resolved byResolved by

Resolved by

ACCUTUNEACCUTUNE

ACCUTUNE

SP VALUE

SP VALUE

Start-Up Mode

Start-Up Mode

Prevents Overshoot

Prevents Overshoot

Automatic Loop Tuning

Maintains Precise Control

ACCUTUNE, Honeywell’s innovative adaptive

tuning feature is a powerful rules-based expert system

that automatically tunes the controller for peak operating efficiency. ACCUTUNE lines-out your process

quickly and adjusts PID parameters as required.

When enabled, ACCUTUNE continuously monitors

your process, adjusting the PID constants when necessary

to maintain optimum controller response. Your process

runs closer to specified setpoints – helping your company

produce higher quality products with greater yields,

saving valuable raw materials, and reducing energy costs.

A few simple keystrokes is all it takes to put

ACCUTUNE to work for you; detailed process knowledge is not required. Two tuning criteria selections,

“normal” or “fast”, are available to match the controllers

response to the control strategy.

Detects and Adapts

Detects and Adapts

to Disturbances

to Disturbances

Adapts to Process

Adapts to Process

Dynamics

Dynamics

Time

Time

The LeaderLine Commitment

UDC 6300 Process Controller is a member of

Honeywell’s proven LeaderLine family of controllers and

recorders. All LeaderLine instruments are engineered

to offer maximum performance for minimum investment.

To qualify as a member of the LeaderLine, a controller

or recorder must:

• Offer the best price/performance ratio of any instrument

in its class.

• Be priced below all competitive instruments in its class.

• Feature Honeywell quality, assured by a two-year

warranty program, a toll-free “Help” program, and a

customer support network second to none.

• Provide functionality targeted to market segments so

customers never need to buy more capability than

they need.

• Include comprehensive, easy-to-follow product

manuals.

Find out how UDC 6300 can improve your application. Call 1-800-288-7491 or contact your Honeywell

account manager or distributor.

7

Page 8

Condensed Specifications (some features are optional)

4 Analog Inputs

– 1 to 5 Vdc, 4-20mA or 10 to 50 mA

– Isolated from all other inputs and outputs

Universal Input — isolated

– Thermocouple – Millivolts or Volts

– RTD – Pulse

1 or 2 Current Outputs

– 4-20mA dc

– Isolated

4 Universal Digital Inputs /Outputs

– Open-collector outputs or digital inputs

– Externally powered

2 Digital Inputs

– User configurable

– Isolated

Math Functions

– summer – input/output

– weighted average characterization

– multiplier/divider – logic

– hi/lo select – totalization

Dimensions:

millimeters

inches

NOTES:

1. Drawing is not to scale

2. No minimum horizontal

spacing is defined.

3. Controller may be

mounted at any angle

or tilt.

33

1.22

max

2.83

panel cutout

Standard)

68

2.68

(DIN

+0.7

+0.027

-0

-0

144

5.67

72

233

9.19

max

138

5.43

+1.0

+0.039

-0

-0

Serial Communications Link

– RS485 TDC 3000 Integration – DMCS

– RS422/485 — 15 drops

Transmitter Power

– 24Vdc

±

2V

– 50mA dc for one or two transmitters

Accuracy

– ±0.01% of span for linear inputs

– ±0.02% of span typical for T/C and RTD inputs

Temperature Stability

– ±0.005% per F° typical

Pulse Input

– Range: 1Hz to 25K Hz

Power Consumption

– 20 VA maximum

Splashproof faceplate

Power Requirements

– 24Vdc, 120 Vac or 240 Vac

CE Mark Compliant

– Full conformity with CE directives

Rear Terminal Cover

1.00

25

Max. Panel

thickness

For complete product specifications please request

document 51-52-03-13.

Specifications are subject to change without notice.

™ACCUTUNE is a U.S. trademark of Honeywell, Inc.

*All other brand and product names are trademarks of their respective owners.

Industrial Automation and Control

Honeywell Inc.

http://www.iac.honeywell.com

U.S.A.: Honeywell Industrial Automation and Control, 16404 North Black Canyon Hwy., Phoenix, AZ 85053

Canada: The Honeywell Centre, 155 Gordon Baker Rd., North York, Ontario M2H 3N7

Latin America: Honeywell Inc., 480 Sawgrass Corporate Parkway, Suite 200, Sunrise, Florida 33325

Japan: Industrial Operations Tokyo, 4-28-1 Nishi-Rokugo Ohtu-ku, Tokyo 144, Japan

Asia: Honeywell Asia Pacific Inc., Room 3213-3225, Sun Hung Kai Centre, No. 30 Harbour Road, Wanchai, Hong Kong

Pacific Division: Honeywell Pty Ltd., 5 Thomas Holt Drive, North Ryde NSW Australia 2113

Northern Europe and Southern Africa: Honeywell Ltd., Honeywell House, Arlington Business Park, Bracknell, RG 12 1EB, U.K.

Central Europe: Honeywell A.G., Kaiserleistraße 39, 63067 Offenbach, Germany

Western and Southern Europe: Honeywell S.A., Avenue de Schiphol 3, 1140 Brussels, Belgium

Eastern Europe: Honeywell Praha, s.r.o., Budejovicka 1, 140 00 Prague 4, Czech Republic

Middle East: Honeywell Middle East Ltd., Khalifa Street, Sheikh Faisal Building, Abu Dhabi, U.A.E.

51-51-58-18 (7.5M) 10/98

©Honeywell Inc. Printed in U.S.A.

8

Recycled Paper

Loading...

Loading...