Page 1

UDC 2300

UDC 3000

UDC 3300

UDC 5000

UDC 6000

UDC 6300

Universal Digital Controllers

RS422/485 ASCII Communications

Option

Product Manual

51-51-25-35G

5/99

Page 2

Copyright, Notices, and Trademarks

Printed in U.S.A. – © Copyright 1999 by Honeywell Inc.

Rev G, 5/99

While this information is presented in good faith and believed to be accurate,

Honeywell disclaims the implied warranties of merchantability and fitness for a

particular purpose and makes no express warranties except as may be stated in its

written agreement with and for its customer.

In no event is Honeywell liable to anyone for any indirect, special, or consequential

damages. The information and specifications in this document are subject to

change without notice.

This document was prepared using Information Mapping® methodologies and

formatting principles.

UDC 2300, UDC 3000, UDC 3300, UDC 5000, UDC 6000, and UDC 6300 are U.S.

trademarks of Honeywell Inc.

Information Mapping® is a registered trademark of Information Mapping, Inc.

Honeywell

Industrial Automation and Control

Automation College

100 Virginia Drive

Fort Washington, PA 19034

ii RS422/485 ASCII Communications Option Product Manual 5/99

Page 3

About This Publication

The UDC manual for RS422/485 ASCII communications option contains the following sections:

Section 1 – Overview

Section 2 – Installation

Section 3 – Establishing Communications

Section 4 – Read and Write Operations

Section 5 – Reading, Writing, and Overriding Parameters on UDC 3000

Versa-Pro Controllers

Section 6 – Reading, Writing and Overriding Parameters on UDC 5000

Ultra-Pro Controllers

Section 7 – Reading, Writing, and Overriding Parameters on UDC 6000

Process Controllers

Section 8 – Reading, Writing, and Overriding Parameters on UDC 6300

Process Controllers

Section 9 – Reading, Writing, and Overriding Parameters on UDC 3300

Process Controllers

Section 10 – Reading, Writing, and Overriding Parameters on UDC 2300

Process Controllers

Section 11 – Operating the Controller with Communications Option

Section 12 – ASCII Conversion Table

Section 13 – Cable Specifications

Communication between your computer and the UDC Controller is accomplished for one piece of

information (parameter) at a time. Each parameter has an associated identifying code.

The Identifying Code and Format Code will be listed along with information pertaining to that

parameter.

The identifying codes are grouped in the same order as they appear in the controller configuration

prompts.

5/99 RS422/485 ASCII Communications Option Product Manual iii

Page 4

Contents

SECTION 1 – OVERVIEW..................................................................................................1

1.1 Introduction...................................................................................................1

1.2 Message Exchange Protocols ......................................................................2

1.3 Field Upgrade...............................................................................................3

SECTION 2 – INSTALLATION...........................................................................................5

2.1 Introduction...................................................................................................5

2.2 RS232 to RS485 Converters........................................................................6

2.3 Using a Black Box Converter........................................................................7

2.4 Using a Westermo Converter .......................................................................9

2.5 Wiring Diagrams.........................................................................................11

SECTION 3 – ESTABLISHING COMMUNICATIONS AND TESTING ............................15

3.1 Preparing the Controller for Communications.............................................15

3.2 Programming..............................................................................................19

3.3 Message Exchange....................................................................................20

3.4 Request Messages.....................................................................................21

3.5 Response Messages..................................................................................24

3.6 Status Codes..............................................................................................26

3.7 Checksum Protocol (for Data Security) ......................................................28

3.8 Shed ...........................................................................................................34

3.9 Loopback (UDC 2300, UDC 3000, UDC 3300 Only)..................................35

3.10 Recovering from Communications Failures................................................37

SECTION 4 – READ AND WRITE OPERATIONS...........................................................41

4.1 Read Operations.........................................................................................41

4.2 Read Analog Parameters ...........................................................................42

4.3 Read Digital Parameters.............................................................................45

4.4 Write Operations.........................................................................................47

4.5 Write Analog Parameters............................................................................48

4.6 Write Digital Parameters.............................................................................52

SECTION 5 – READ, WRITE AND OVERRIDE PARAMETERS – UDC3000.................55

5.1 UDC 3000 Overview...................................................................................55

5.2 UDC 3000 Reading Control Data ...............................................................57

5.3 UDC 3000 Read Option Status...................................................................58

5.4 UDC 3000 Miscellaneous Read Only’s.......................................................59

5.5 UDC 3000 Setpoints...................................................................................61

5.6 UDC 3000 Using a Computer Setpoint.......................................................62

5.7 UDC 3000 Overriding Input 1 .....................................................................63

5.8 UDC 3000 Canceling the Override.............................................................64

5.9 UDC 3000 Reading or Changing the Output..............................................65

5.10 UDC 3000 Local Setpoint/PID Set Selection /Setpoint Ramp Status.........66

5.11 UDC 3000 Configuration Parameters.........................................................68

SECTION 6 – READ, WRITE AND OVERRIDE PARAMETERS – UDC5000.................85

6.1 Overview.....................................................................................................85

6.2 Reading Control Data.................................................................................88

6.3 Option Status..............................................................................................89

iv RS422/485 ASCII Communications Option Product Manual 5/99

Page 5

6.4 Miscellaneous Read Only’s........................................................................ 90

6.5 Setpoints.................................................................................................... 92

6.6 Using a Computer Setpoint........................................................................ 93

6.7 Overriding the Inputs.................................................................................. 95

6.8 PV, Setpoint, or Input Override Status or Cancellation.............................. 97

6.9 Reading or Changing the Output ............................................................... 98

6.10 Local Setpoint/PID Selection/Setpoint Ramp Status.................................. 99

6.11 Configuration Parameters ........................................................................ 101

SECTION 7 – READ, WRITE AND OVERRIDE PARAMETERS – UDC6000............... 127

7.1 Overview .................................................................................................. 127

7.2 Reading Control Data............................................................................... 130

7.3 Read Options Status................................................................................ 131

7.4 Miscellaneous Read Only’s...................................................................... 132

7.5 Setpoints.................................................................................................. 134

7.6 Using a Computer Setpoint...................................................................... 135

7.7 PV or Setpoint Override Selections.......................................................... 137

7.8 Reading or Changing the Output ............................................................. 138

7.9 Local Setpoint/PID Selection/Setpoint Ramp Status................................ 139

7.10 Configuration Parameters ........................................................................ 142

SECTION 8 – READ, WRITE AND OVERRIDE PARAMETERS – UDC6300............... 177

8.1 Overview .................................................................................................. 177

8.2 Reading Control Data............................................................................... 180

8.3 Read Options Status................................................................................ 181

8.4 Miscellaneous Read Only’s...................................................................... 182

8.5 Setpoints.................................................................................................. 186

8.6 Using a Computer Setpoint...................................................................... 187

8.7 PV or Setpoint Override Selections.......................................................... 189

8.8 Reading or Changing the Output ............................................................. 190

8.9 Local Setpoint/PID Selection/Setpoint Ramp Status................................ 191

8.10 Configuration Parameters ........................................................................ 194

SECTION 9 – READ, WRITE AND OVERRIDE PARAMETERS – UDC3300............... 231

9.1 UDC 3300 Overview ................................................................................ 231

9.2 UDC 3300 Reading Control Data............................................................. 234

9.3 UDC 3300 Read Options Status.............................................................. 235

9.4 UDC 3300 Miscellaneous Read Only’s.................................................... 236

9.5 UDC 3300 Setpoints ................................................................................ 238

9.6 UDC 3300 Using a Computer Setpoint.................................................... 239

9.7 UDC 3300 PV or Setpoint Override Selections........................................ 241

9.8 UDC 3300 Reading or Changing the Output............................................ 242

9.9 UDC 3300 Local Setpoint/PID Selection/Setpoint Ramp Status.............. 243

9.10 UDC 3300 Configuration Parameters ...................................................... 246

SECTION 10 – READ, WRITE AND OVERRIDE PARAMETERS – UDC2300............. 277

10.1 UDC 2300 Overview ................................................................................ 277

10.2 UDC 2300 Reading Control Data............................................................. 280

10.3 UDC 2300 Read Options Status.............................................................. 281

10.4 UDC 2300 Miscellaneous Read Only’s.................................................... 282

10.5 UDC 2300 Setpoints ................................................................................ 284

10.6 UDC 2300 Using a Computer Setpoint.................................................... 285

10.7 UDC 2300 PV or Setpoint Override Selections........................................ 287

10.8 UDC 2300 Reading or Changing the Output............................................ 288

10.9 UDC 2300 Local Setpoint/PID Selection/Setpoint Ramp Status.............. 289

10.10 UDC 2300 Configuration Parameters ...................................................... 292

5/99 RS422/485 ASCII Communications Option Product Manual v

Page 6

SECTION 11 – OPERATING THE CONTROLLER WITH COMMUNICATIONS

OPTION....................................................................................................311

11.1 Operation..................................................................................................311

SECTION 12 – ASCII CONVERSION TABLE................................................................312

12.1 Overview...................................................................................................312

SECTION 13 – CABLE SPECIFICATIONS....................................................................314

13.1 Introduction...............................................................................................314

vi RS422/485 ASCII Communications Option Product Manual 5/99

Page 7

Figures

Figure 2-1 Black Box Converter Wiring Connections .................................................... 8

Figure 2-2 Recommended Switch Settings for Westermo Converter.......................... 10

Figure 2-3 Westermo Converter Wiring Connections.................................................. 10

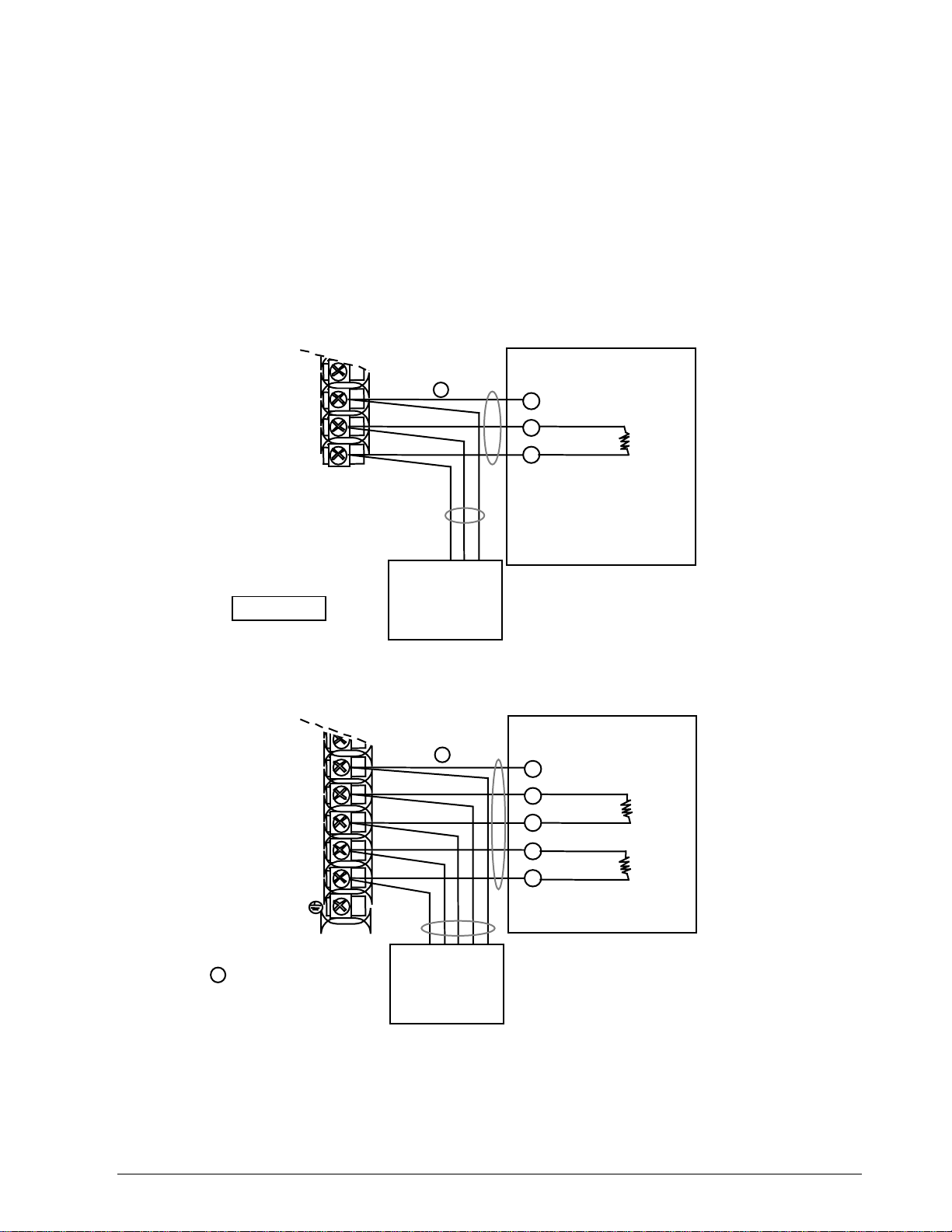

Figure 2-4 UDC3000/3300 Connections ..................................................................... 11

Figure 2-5 UDC6000/6300 Connections ..................................................................... 12

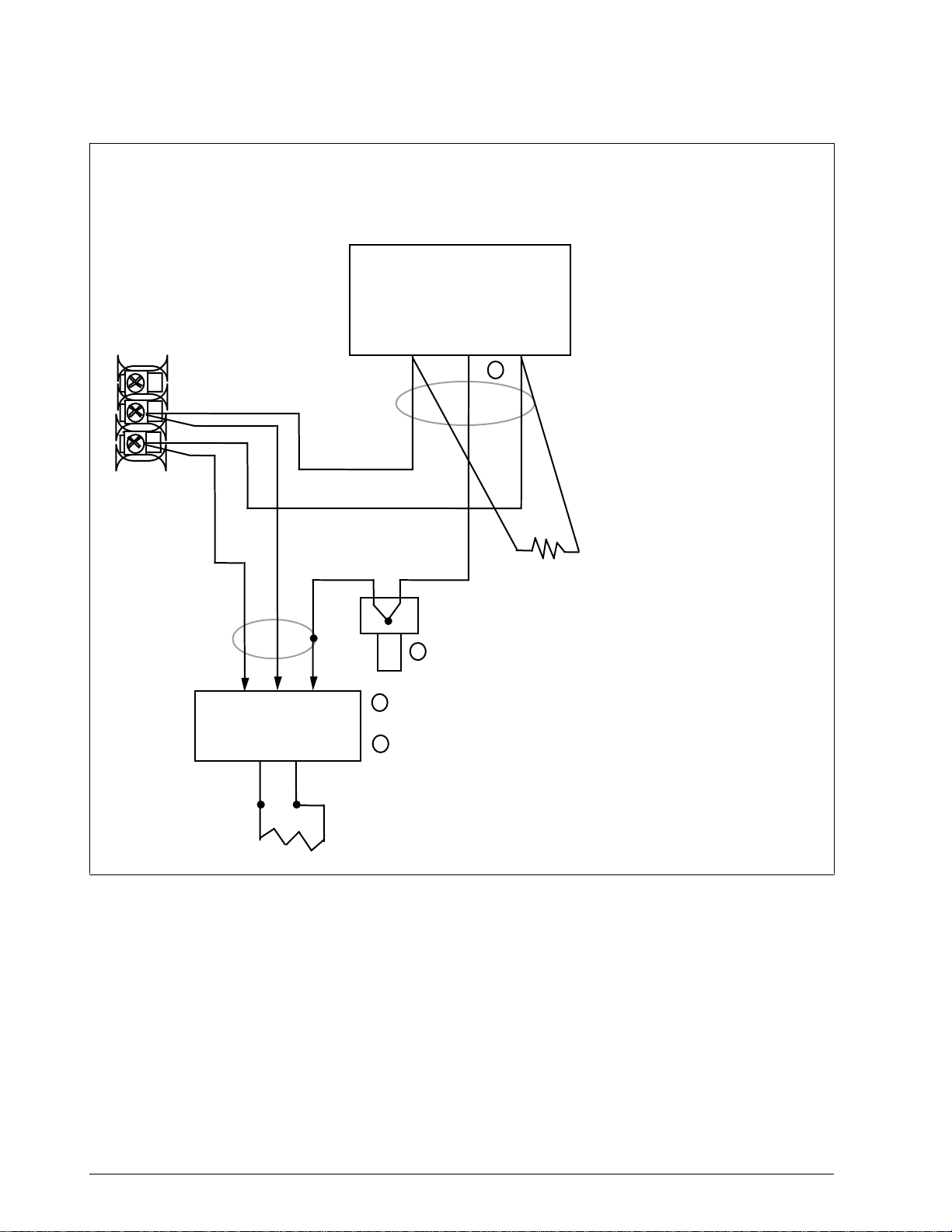

Figure 2-6 Connections (without Digital Input Option)................................................. 13

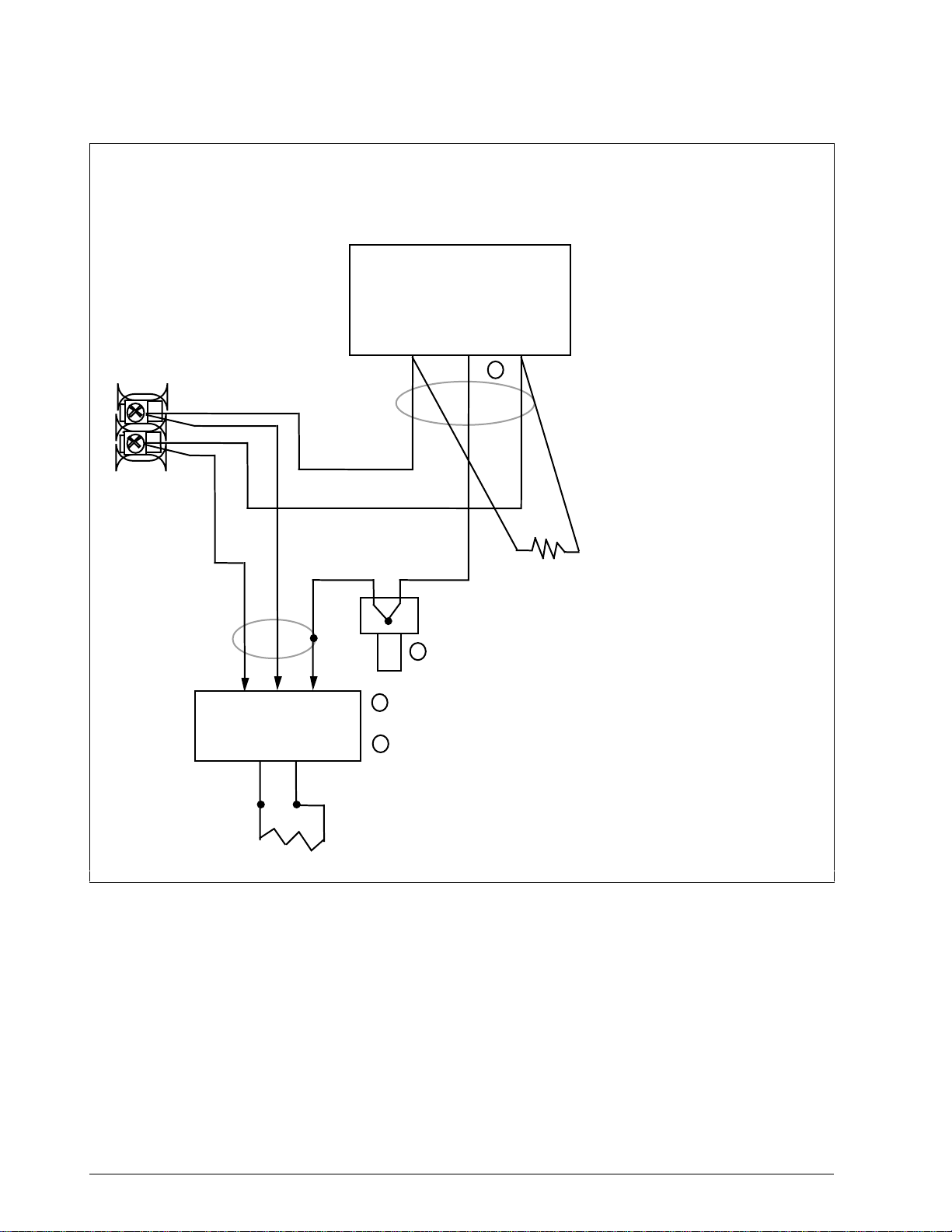

Figure 2-7 UDC2300 Connections .............................................................................. 14

Figure 3-1 Message Exchanges.................................................................................. 20

Figure 3-2 Request Message Fields............................................................................ 21

Figure 3-3 Response Message Fields Information...................................................... 24

Figure 3-4 Request Format for Checksum Protocol.................................................... 28

Figure 3-5 Example of Checksum Calculation............................................................. 30

Figure 3-6 Using Checksum Protocol.......................................................................... 31

Figure 3-7 Success Response Message Fields .......................................................... 32

Figure 3-8 Failure Response Message Fields............................................................. 33

Figure 3-9 Lost Messages........................................................................................... 37

Figure 3-10 Timing a Message Exchange and Checking for a Response..................... 38

Figure 4-1 Read Analog Parameter Message Exchange............................................ 44

Figure 4-2 Read Digital Parameter Message Exchange ............................................. 46

Figure 4-3 Write Analog Parameter Message Exchange Example ............................. 51

Figure 4-4 Write Digital Parameter Message Exchange Example............................... 54

Figure 5-1 Option Status Information .......................................................................... 58

Figure 5-2 I.D. Code 250 Indications........................................................................... 67

Figure 5-3 Digital Input Combinations......................................................................... 84

Figure 6-1 Option Status Information .......................................................................... 89

Figure 6-2 I.D. Code 250 Indications......................................................................... 100

Figure 7-1 Option Status Information ........................................................................ 131

Figure 7-2 I.D. Code 250 Indications......................................................................... 140

Figure 7-3 Digital Input Combinations....................................................................... 172

Figure 8-1 Option Status Information ........................................................................ 181

Figure 8-2 I.D. Code 250 Indications......................................................................... 192

Figure 8-3 Digital Input Combinations, Inputs 1 and 2............................................... 225

Figure 9-1 Option Status Information ........................................................................ 235

Figure 9-2 I.D. Code 250 Indications......................................................................... 244

Figure 9-3 Digital Input Combinations, Inputs 1 and 2............................................... 272

Figure 10-1 Option Status Information ........................................................................ 281

Figure 10-2 I.D. Code 250 Indications......................................................................... 290

5/99 RS422/485 ASCII Communications Option Product Manual vii

Page 8

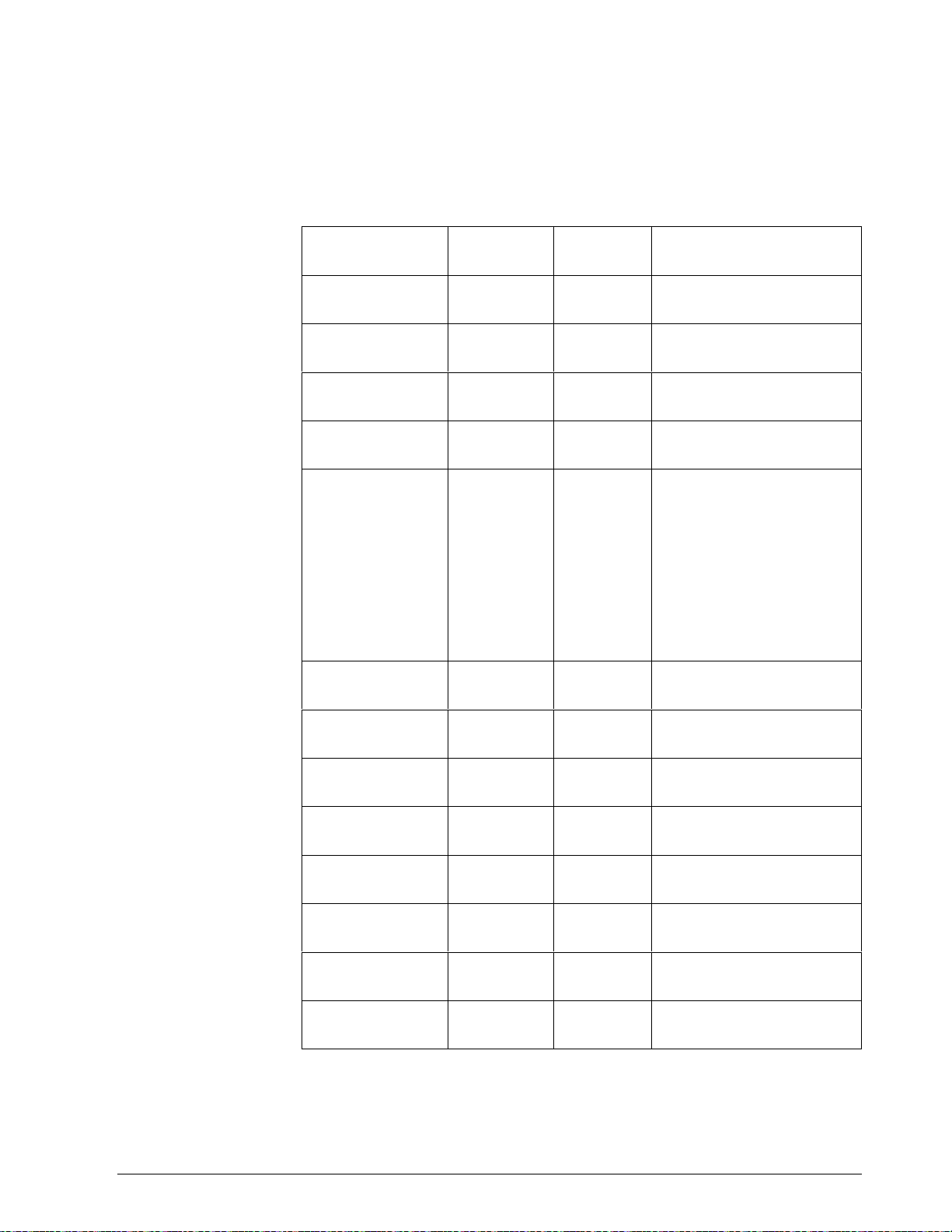

Tables

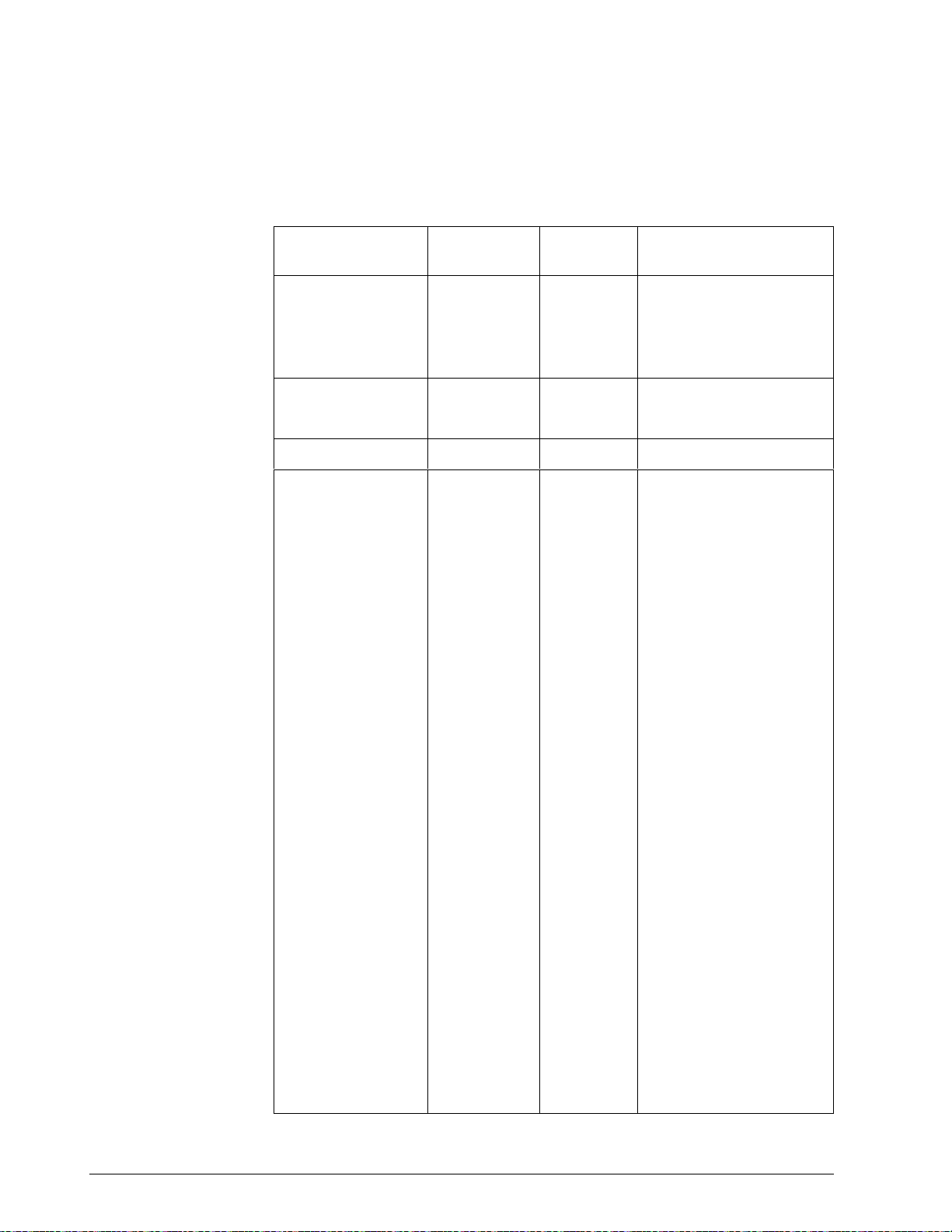

Table 1-1 Rules and Regulations for Configuration Protocol........................................2

Table 1-2 Upgrade PWB Part Numbers........................................................................3

Table 2-1 Converters....................................................................................................6

Table 2-2 Black Box Converter Wiring Connections Procedure ...................................7

Table 2-3 Terminal Connections for Black Box Converters..........................................8

Table 2-4 Westermo Converter Configuration and Wiring Procedure ..........................9

Table 2-5 Terminal Connections for Westermo Converters........................................10

Table 3-1 Communications Parameters .....................................................................15

Table 3-2 Controller Procedure for Communication Parameters................................17

Table 3-3 Programming Statements...........................................................................19

Table 3-4 Request Message Fields Definitions...........................................................22

Table 3-5 Response Message Fields Definitions........................................................25

Table 3-6 Request Message Status Codes................................................................26

Table 3-7 UDC Status Codes .....................................................................................27

Table 3-8 Calculating the Checksum Procedure ........................................................29

Table 3-9 Example of Loopback Request Message ...................................................35

Table 3-10 Example of Loopback Response Message.............................................36

Table 3-11 Programming Example............................................................................36

Table 4-1 Analog Parameter Request Format............................................................42

Table 4-2 Analog Parameter Response Format.........................................................43

Table 4-3 Digital Parameter Request Format.............................................................45

Table 4-4 Digital Parameter Response Format ..........................................................46

Table 4-5 Write Message Exchange Steps.................................................................47

Table 4-6 Write Request Format for Analog I.D. Codes.............................................48

Table 4-7 Busy Response...........................................................................................49

Table 4-8 Ready Requests.........................................................................................49

Table 4-9 Is Ready Response ....................................................................................50

Table 4-10 Write Request Format for Digital I.D. Codes...........................................52

Table 4-11 Busy Response .......................................................................................53

Table 4-12 Ready Request........................................................................................53

Table 4-13 Is Ready Response.................................................................................53

Table 5-1 Control Data Parameters – UDC3000........................................................57

Table 5-2 Option Status..............................................................................................58

Table 5-3 Miscellaneous Read Only’s.........................................................................59

Table 5-4 Error Status Definitions...............................................................................60

Table 5-5 Setpoint Code Selections ...........................................................................61

Table 5-6 Setpoint Associated Parameters ................................................................61

Table 5-7 Computer Setpoint Selection......................................................................62

Table 5-8 Computer Setpoint Associated Parameters................................................62

Table 5-9 Input 1 Override Code ................................................................................63

Table 5-10 Input Override Associated Parameters....................................................63

Table 5-11 PV or Setpoint Override Cancellation......................................................64

Table 5-12 Reading or Changing the Output.............................................................65

Table 5-13 Associated Output Codes........................................................................65

Table 5-14 LSP/PID Set Selection and Setpoint Ramp Status..................................66

Table 5-15 Setup Group-Tuning................................................................................69

Table 5-16 Setup Group-SP Ramp, Rate, or SP Program........................................71

Table 5-17 Setup Group-Adaptive Tune....................................................................74

Table 5-18 Setup Group-Algorithm............................................................................75

Table 5-19 Setup Group-Input 1................................................................................76

Table 5-20 Setup Group-Input 2................................................................................78

Table 5-21 Setup Group-Control ...............................................................................79

viii RS422/485 ASCII Communications Option Product Manual 5/99

Page 9

Table 5-22 Setup Group-Options.............................................................................. 81

Table 5-23 Setup Group-COMRS422....................................................................... 82

Table 5-24 Setup Group-Alarms............................................................................... 83

Table 6-1 Control Data Parameters – UDC5000........................................................ 88

Table 6-2 Option Status ............................................................................................. 89

Table 6-3 Miscellaneous Read Only’s........................................................................ 90

Table 6-4 Error Status Definitions.............................................................................. 91

Table 6-5 Setpoint Code Selections........................................................................... 92

Table 6-6 Setpoint Associated Parameters................................................................ 92

Table 6-7 Computer Setpoint Selections.................................................................... 93

Table 6-8 Computer Setpoint Associated Parameters............................................... 94

Table 6-9 Input Override Codes................................................................................. 95

Table 6-10 Input Override Associated Parameters................................................... 96

Table 6-11 PV, Setpoint , or Input Override Cancellation ......................................... 97

Table 6-12 Reading or Changing the Output............................................................ 98

Table 6-13 Associated Output Codes....................................................................... 98

Table 6-14 I.D. Code 250 Reads .............................................................................. 99

Table 6-15 I.D. Code 250 Writes............................................................................. 100

Table 6-16 Setup Group-Tuning (Loop 1)*.............................................................. 102

Table 6-17 Setup Group-Tuning 2* (Loop 2)........................................................... 103

Table 6-18 Setup Group-Setpoint Ramp/Program.................................................. 104

Table 6-19 Setpoint Program Ramp and Soak Identifying Codes for Each Segment106

Table 6-20 Setup Group-Autotune/Adaptive Tune.................................................. 107

Table 6-21 Setup Group-Algorithm......................................................................... 109

Table 6-22 Setup Group-Output Algorithm ............................................................. 112

Table 6-23 Setup Group-Input 1 (Loop 1 Address only) ......................................... 113

Table 6-24 Setup Group-Input 2 (Loop 1 Address only) ......................................... 115

Table 6-25 Setup Group-Input 3 (Loop 1 Address only) ......................................... 118

Table 6-26 Setup Groups-Control and Control 2 .................................................... 120

Table 6-27 Setup Group-Options............................................................................ 122

Table 6-28 Setup Group-Communications.............................................................. 123

Table 6-29 Setup Group-Alarms............................................................................. 124

Table 6-30 Setup Groups-Display........................................................................... 126

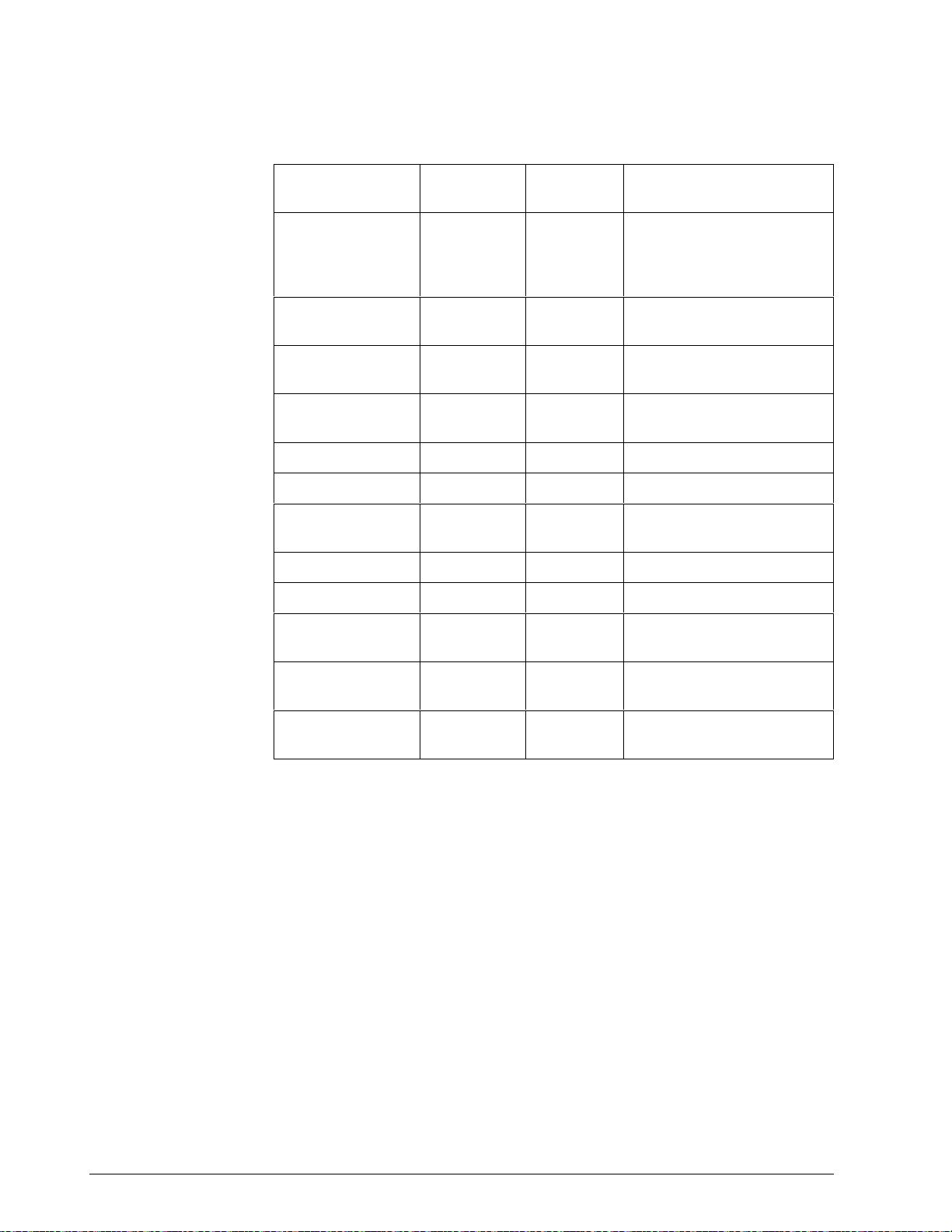

Table 7-1 Control Data Parameters – UDC6000...................................................... 130

Table 7-2 Option Status ........................................................................................... 131

Table 7-3 Miscellaneous Read Only’s...................................................................... 132

Table 7-4 Error Status Definitions............................................................................ 133

Table 7-5 Setpoint Code Selections......................................................................... 134

Table 7-6 Setpoint Associated Parameters.............................................................. 134

Table 7-7 Computer Setpoint Selection.................................................................... 135

Table 7-8 Computer Setpoint Associated Parameters............................................. 136

Table 7-9 PV or Setpoint Override Selections.......................................................... 137

Table 7-10 Reading or Changing the Output.......................................................... 138

Table 7-11 Associated Output Codes..................................................................... 138

Table 7-12 I.D. Code 250 Reads ............................................................................ 139

Table 7-13 I.D. Code 250 Writes............................................................................. 141

Table 7-14 Setup Group-Tuning (Loop 1)*.............................................................. 143

Table 7-15 Setup Group-Tuning 2* (Loop 2)........................................................... 145

Table 7-16 Setup Group-Setpoint Ramp/Rate........................................................ 147

Table 7-17 Setup Group-Adaptive Tune................................................................. 148

Table 7-18 Setup Group-Algorithm......................................................................... 149

Table 7-19 Setup Group-Advanced Math ............................................................... 154

Table 7-20 Setup Group-Output Algorithm ............................................................. 159

Table 7-21 Setup Group-Input 1 (Loop 1 Address only) ......................................... 160

Table 7-22 Setup Group-Input 2 (Loop 1 Address only) ......................................... 161

Table 7-23 Setup Group-Input 3 (Loop 1 Address only) ......................................... 162

Table 7-24 Setup Group-Input 4 (Loop 1 Address only) ......................................... 163

5/99 RS422/485 ASCII Communications Option Product Manual ix

Page 10

Table 7-25 Setup Group-Input 5 (Loop 1 Address only)..........................................164

Table 7-26 Setup Group-Control and Control 2.......................................................166

Table 7-27 Setup Groups-Options...........................................................................169

Table 7-28 Setup Group-Communications..............................................................173

Table 7-29 Setup Group-Alarms (Loop 1 Address only)..........................................174

Table 7-30 Setup Group-Display.............................................................................175

Table 8-1 Control Data Parameters – UDC6300......................................................180

Table 8-2 Option Status............................................................................................181

Table 8-3 Miscellaneous Read Only’s.......................................................................182

Table 8-4 Error Status Definitions.............................................................................185

Table 8-5 Setpoint Code Selections .........................................................................186

Table 8-6 Setpoint Associated Parameters ..............................................................186

Table 8-7 Computer Setpoint Selection....................................................................187

Table 8-8 Computer Setpoint Associated Parameters..............................................188

Table 8-9 PV or Setpoint Override Selections..........................................................189

Table 8-10 Reading or Changing the Output...........................................................190

Table 8-11 Associated Output Codes......................................................................190

Table 8-12 I.D. Code 250 Reads.............................................................................191

Table 8-13 I.D. Code 250 Writes.............................................................................193

Table 8-14 Setup Group-Tuning (Loop 1)*..............................................................195

Table 8-15 Setup Group-Tuning 2* (Loop 2)...........................................................197

Table 8-16 Setup Group-Setpoint Ramp/Rate ........................................................199

Table 8-17 Setup Group-Adaptive Tune..................................................................200

Table 8-18 Setup Group-Algorithm..........................................................................201

Table 8-19 Setup Group-Advanced Math................................................................207

Table 8-20 Setup Group-Output Algorithm..............................................................212

Table 8-21 Setup Group-Input 1 (Loop 1 Address only)..........................................213

Table 8-22 Setup Group-Input 2 (Loop 1 Address only)..........................................214

Table 8-23 Setup Group-Input 3 (Loop 1 Address only)..........................................215

Table 8-24 Setup Group-Input 4 (Loop 1 Address only)..........................................216

Table 8-25 Setup Group-Input 5 (Loop 1 Address only)..........................................217

Table 8-26 Setup Group-Control and Control 2.......................................................219

Table 8-27 Setup Groups-Options...........................................................................222

Table 8-28 Setup Group-Communications..............................................................227

Table 8-29 Setup Group-Alarms (Loop 1 Address only)..........................................228

Table 8-30 Setup Group-Display.............................................................................230

Table 9-1 Control Data Parameters – UDC3300......................................................234

Table 9-2 Option Status............................................................................................235

Table 9-3 Miscellaneous Read Only’s.......................................................................236

Table 9-4 Error Status Definitions.............................................................................237

Table 9-5 Setpoint Code Selections .........................................................................238

Table 9-6 Setpoint Associated Parameters ..............................................................238

Table 9-7 Computer Setpoint Selection....................................................................239

Table 9-8 Computer Setpoint Associated Parameters..............................................240

Table 9-9 PV or Setpoint Override Selections..........................................................241

Table 9-10 Reading or Changing the Output...........................................................242

Table 9-11 Associated Output Codes......................................................................242

Table 9-12 LSP/PID Set Selection and Setpoint Ramp Status................................243

Table 9-13 I.D. Code 250 Writes.............................................................................245

Table 9-14 Setup Group-Tuning (Loop 1)*..............................................................247

Table 9-15 Setup Group-Tuning 2* (Loop 2)...........................................................249

Table 9-16 Setup Group-Setpoint Ramp/Rate ........................................................251

Table 9-17 Setup Group-Adaptive Tune..................................................................254

Table 9-18 Setup Group-Algorithm..........................................................................255

Table 9-19 Setup Group-Output Algorithm..............................................................260

Table 9-20 Setup Group-Input 1 (Loop 1 Address only)..........................................261

Table 9-21 Setup Group-Input 2 (Loop 1 Address only)..........................................263

Table 9-22 Setup Group-Input 3 (Loop 1 Address only)..........................................265

x RS422/485 ASCII Communications Option Product Manual 5/99

Page 11

Table 9-23 Setup Group-Control and Control 2...................................................... 266

Table 9-24 Setup Groups-Options.......................................................................... 269

Table 9-25 Setup Group-Communications.............................................................. 273

Table 9-26 Setup Group-Alarms (Loop 1 Address only)......................................... 274

Table 9-27 Setup Group-Display............................................................................. 276

Table 10-1 Control Data Parameters – UDC2300 .................................................. 280

Table 10-2 Option Status........................................................................................ 281

Table 10-3 Miscellaneous Read Only’s................................................................... 282

Table 10-4 Error Status Definitions......................................................................... 283

Table 10-5 Setpoint Code Selections...................................................................... 284

Table 10-6 Setpoint Associated Parameters........................................................... 284

Table 10-7 Computer Setpoint Selection................................................................ 285

Table 10-8 Computer Setpoint Associated Parameters.......................................... 286

Table 10-9 PV or Setpoint Override Selections ...................................................... 287

Table 10-10 Reading or Changing the Output.......................................................... 288

Table 10-11 Associated Output Codes..................................................................... 288

Table 10-12 LSP/PID Set Selection and Setpoint Ramp Status............................... 289

Table 10-13 I.D. Code 250 Writes............................................................................. 291

Table 10-14 Setup Group-Timer............................................................................... 293

Table 10-15 Setup Group-Tuning ............................................................................. 293

Table 10-16 Setup Group-Setpoint Ramp/Rate........................................................ 295

Table 10-17 Setup Group-Adaptive Tune................................................................. 298

Table 10-18 Setup Group-Algorithm......................................................................... 299

Table 10-19 Setup Group-Input 1 ............................................................................. 300

Table 10-20 Setup Group-Input 2 ............................................................................. 304

Table 10-21 Setup Group-Control............................................................................. 306

Table 10-22 Setup Group-Communications.............................................................. 308

Table 10-23 Setup Group-Alarms............................................................................. 309

Table 11-1 Emergency Manual Procedure ............................................................. 311

Table 12-1 ASCII Character Codes ........................................................................ 312

Table 12-2 Hexadecimal to Binary.......................................................................... 313

Table 13-1 Cable Specifications.............................................................................. 314

5/99 RS422/485 ASCII Communications Option Product Manual xi

Page 12

Parameters

ADDRESS 2.................................................................... Communication Address (Loop 2)

ADDRESS....................................................................... Communication Address (Loop 1)

BAUD RATE................................................................................... Baud Rate (bits/second)

COM STATE........................................................................................Communication State

CSP BIAS..................................................................................Commun. SP Bias (Loop 1)

CSP RATIO..............................................................................Commun. SP Ratio (Loop 1)

CSP2 BIAS................................................................................Commun. SP Bias (Loop 2)

CSP2 RATIO............................................................................Commun. SP Ratio (Loop 2)

DUPLEX....................................................................................................Duplex Operation

PARITY.........................................................................................................................Parity

SHED MODE..........................................................Controller Shed Mode and Output Level

SHED SP............................................................................................. Shed Setpoint Recall

SHED TIME..........................................................................................................Shed Time

TX DELAY............................................................................................. Transmission Delay

UNITS..................................................................................................Communication Units

xii RS422/485 ASCII Communications Option Product Manual 5/99

Page 13

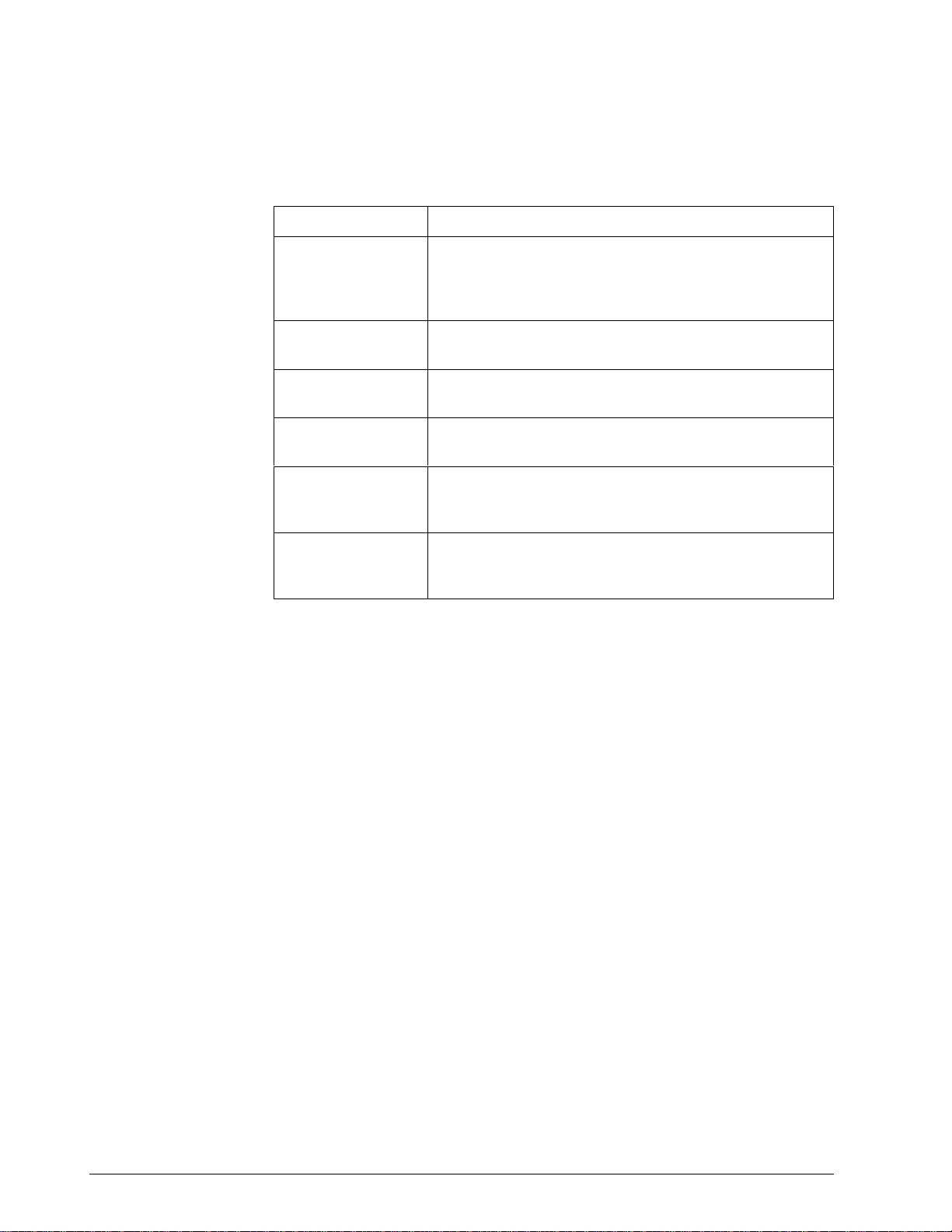

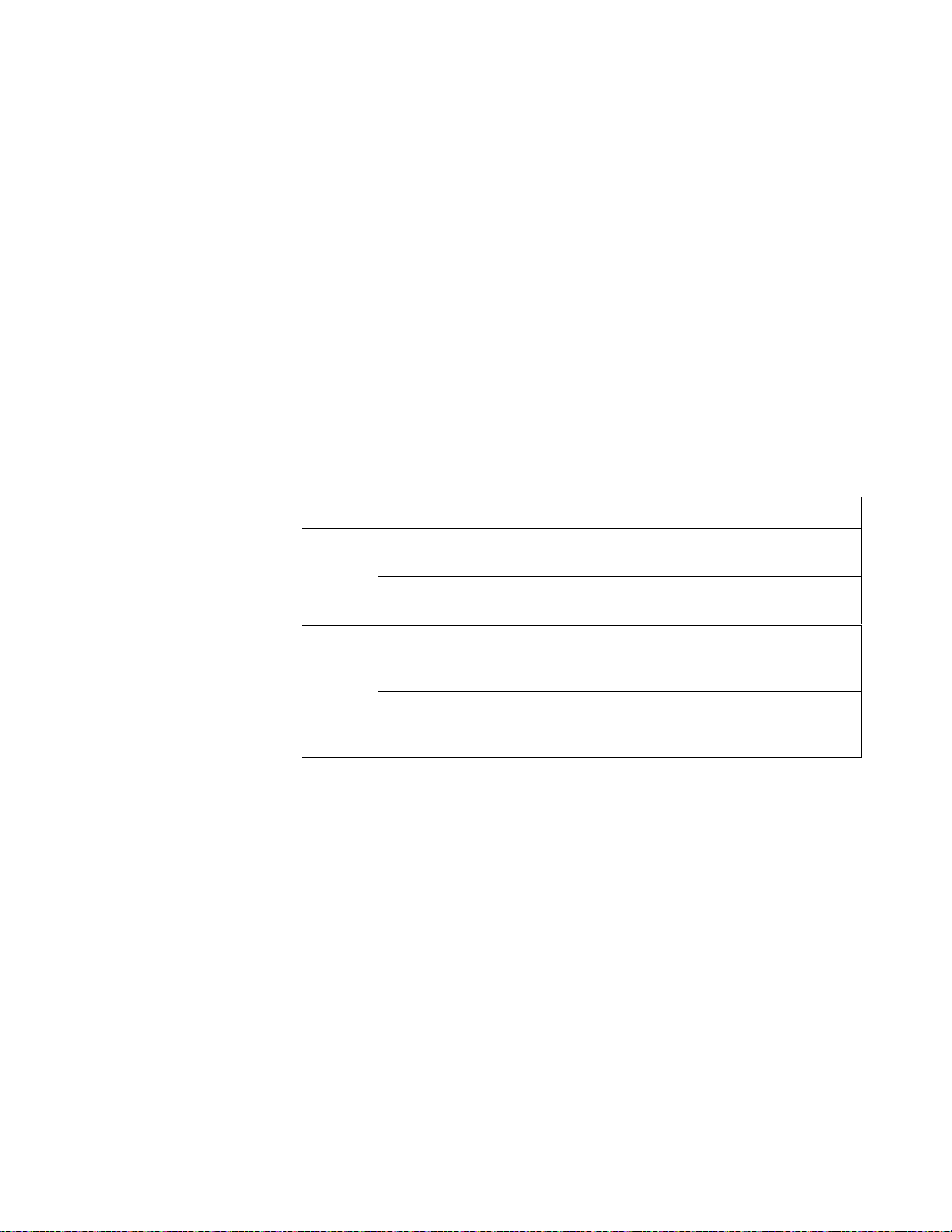

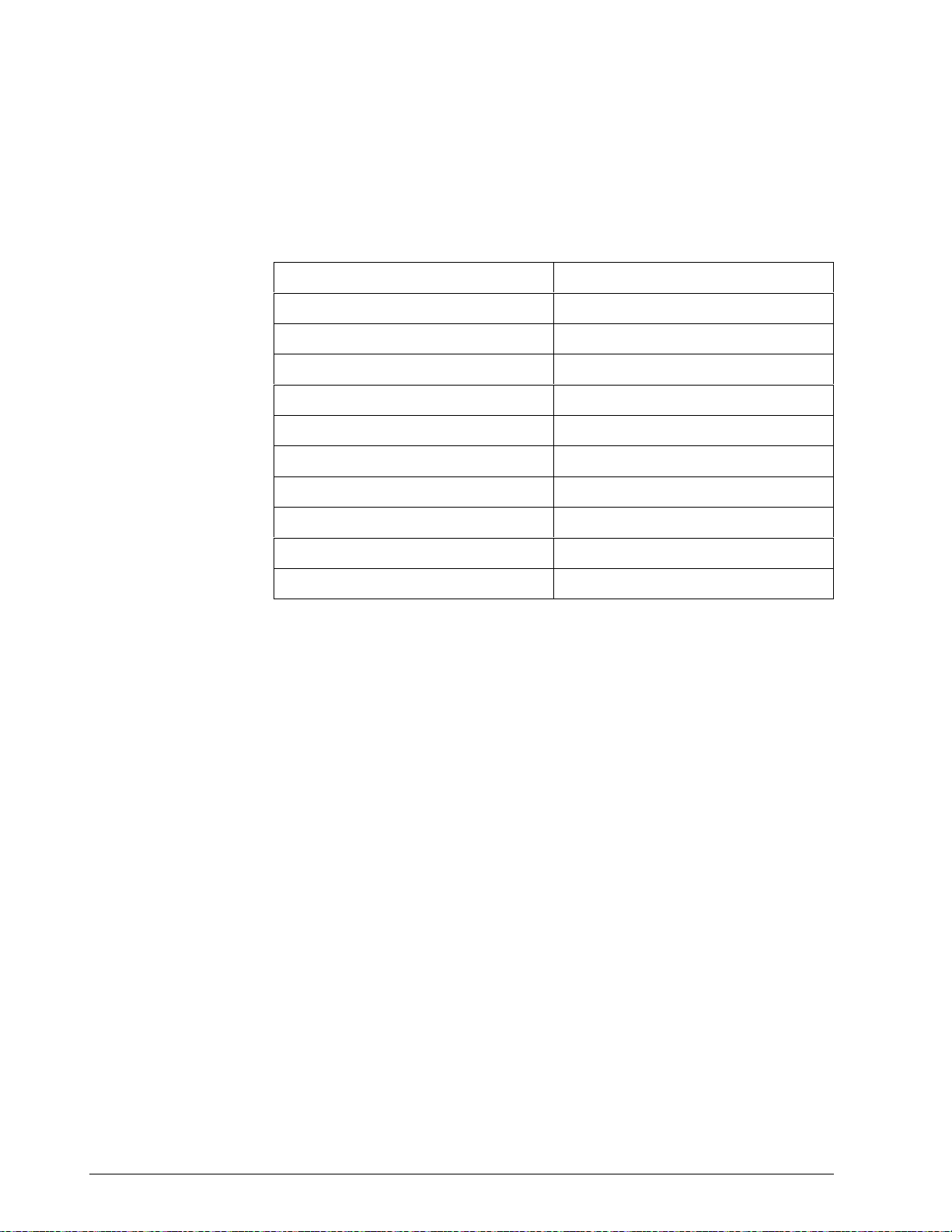

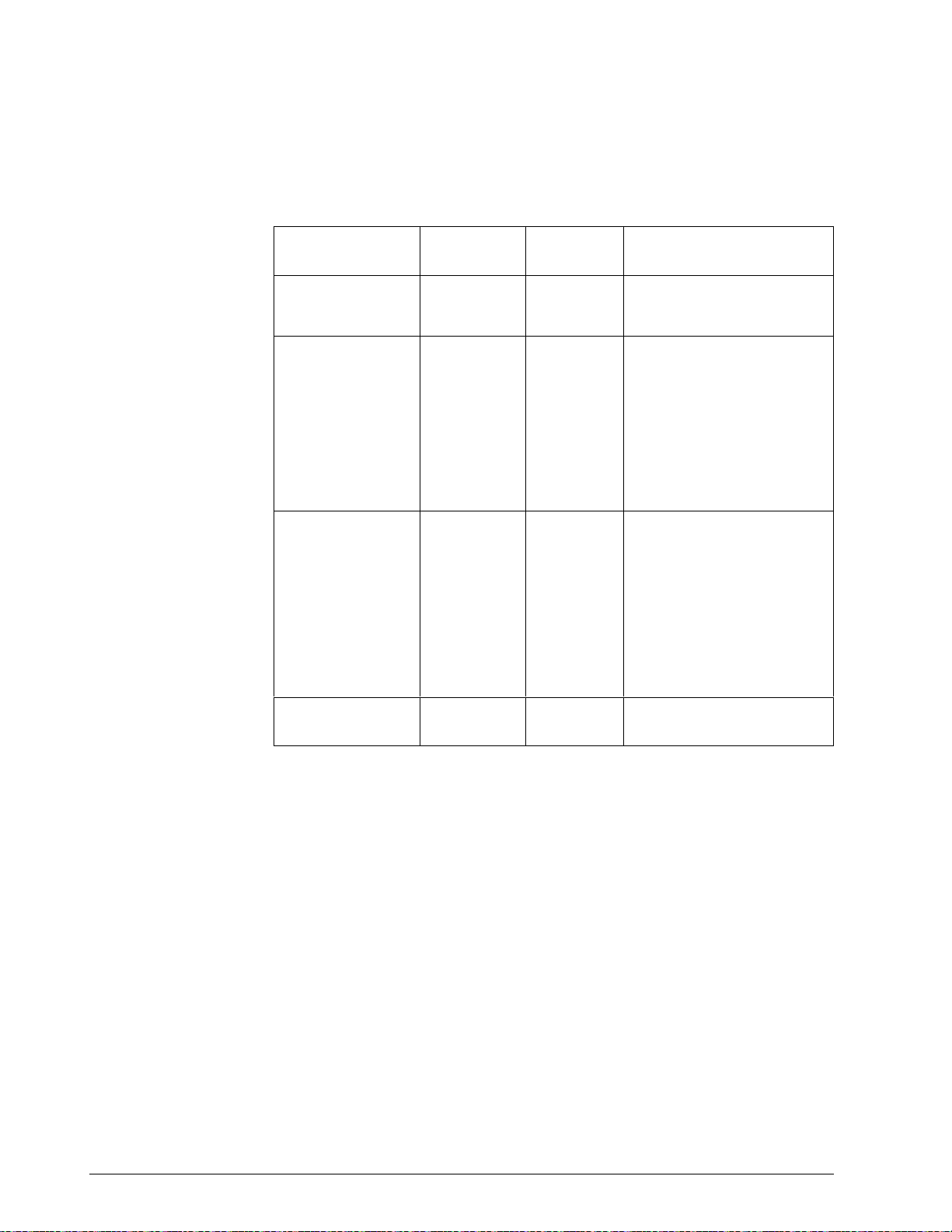

References

Publication

Title

UDC 3000 Controller Product Manual

UDC 3000 Limit Controller Product Manual

UDC 5000 Controller Product Manual

UDC 6000 Controller Product Manual

UDC 6300 Controller Product Manual

UDC 6300 Indicator Product Manual

UDC 3300 Controller Product Manual

UDC 3300 Limit Controller Product Manual

UDC 2300 Controller Product Manual

Publication

Number

51-52-25-07

51-52-25-09

51-51-25-17

51-52-25-32

51-52-25-45

51-52-25-46

51-52-25-55

51-52-25-56

51-52-25-73

5/99 RS422/485 ASCII Communications Option Product Manual xiii

Page 14

xiv RS422/485 ASCII Communications Option Product Manual 5/99

Page 15

1.1 Introduction

Section 1 – Overview

The communications

option

Monitor or slave mode

Message exchanges

The RS422/485 Communications Option on the UDC Controller provides

a serial multi-drop link whereby up to fifteen UDC controllers connect

directly to a host computer.

The UDC controller can be placed in monitor or slave by the host

computer. When monitored, the controller will send Configuration,

Tuning, and Operating parameters to the host computer. When in slave,

the controller will be switched through the communications interface

board to "Slave" operation. This means that the computer can write

configuration or tuning information into any controller on the link

including overriding of PV, the setpoint, and output.

The computer and the controllers talk to each other through a series of

message exchanges. There are two RS422/485 message exchange

protocols: Configuration or Loopback.

5/99 RS422/485 ASCII Communications Option Product Manual 1

Page 16

1.2 Message Exchange Protocols

Configuration

protocol

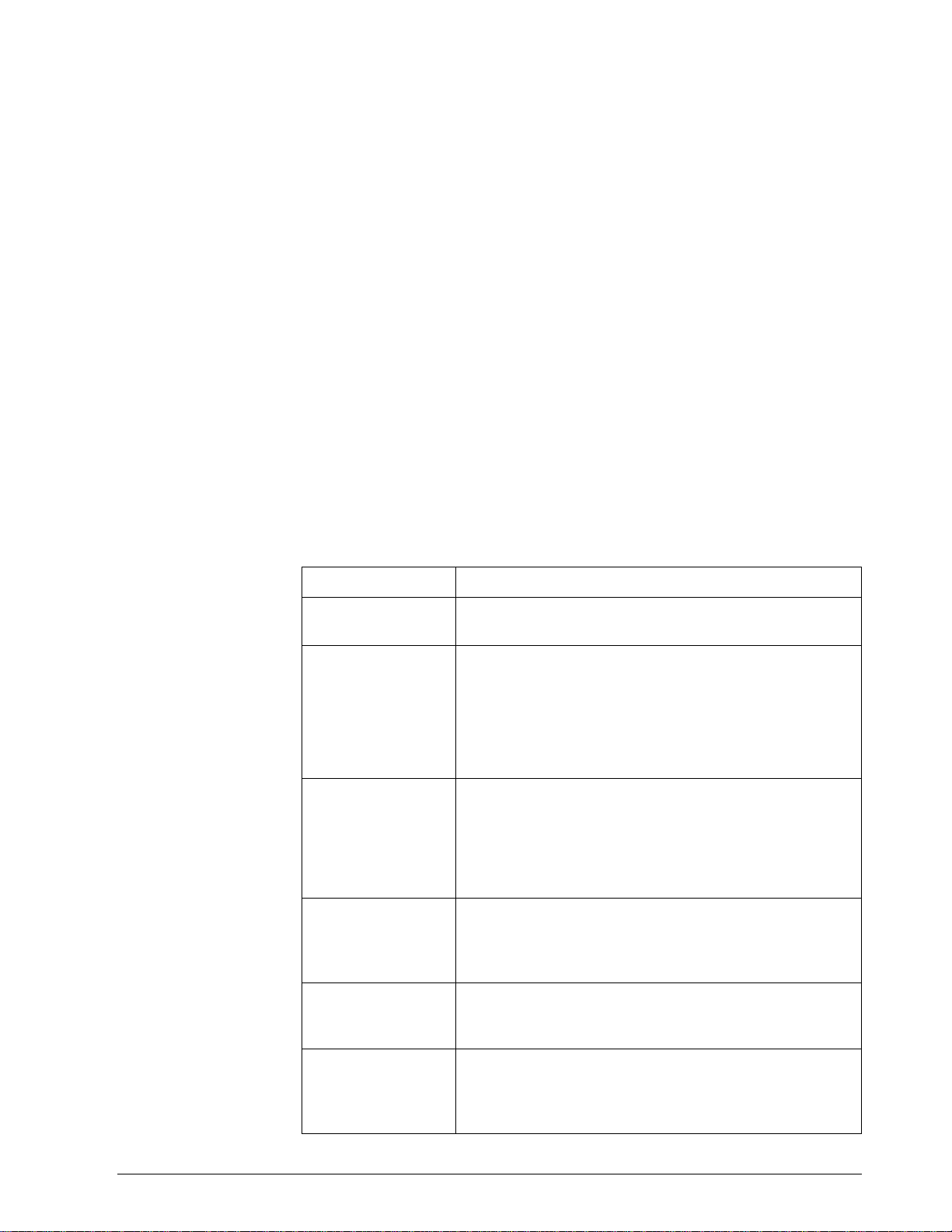

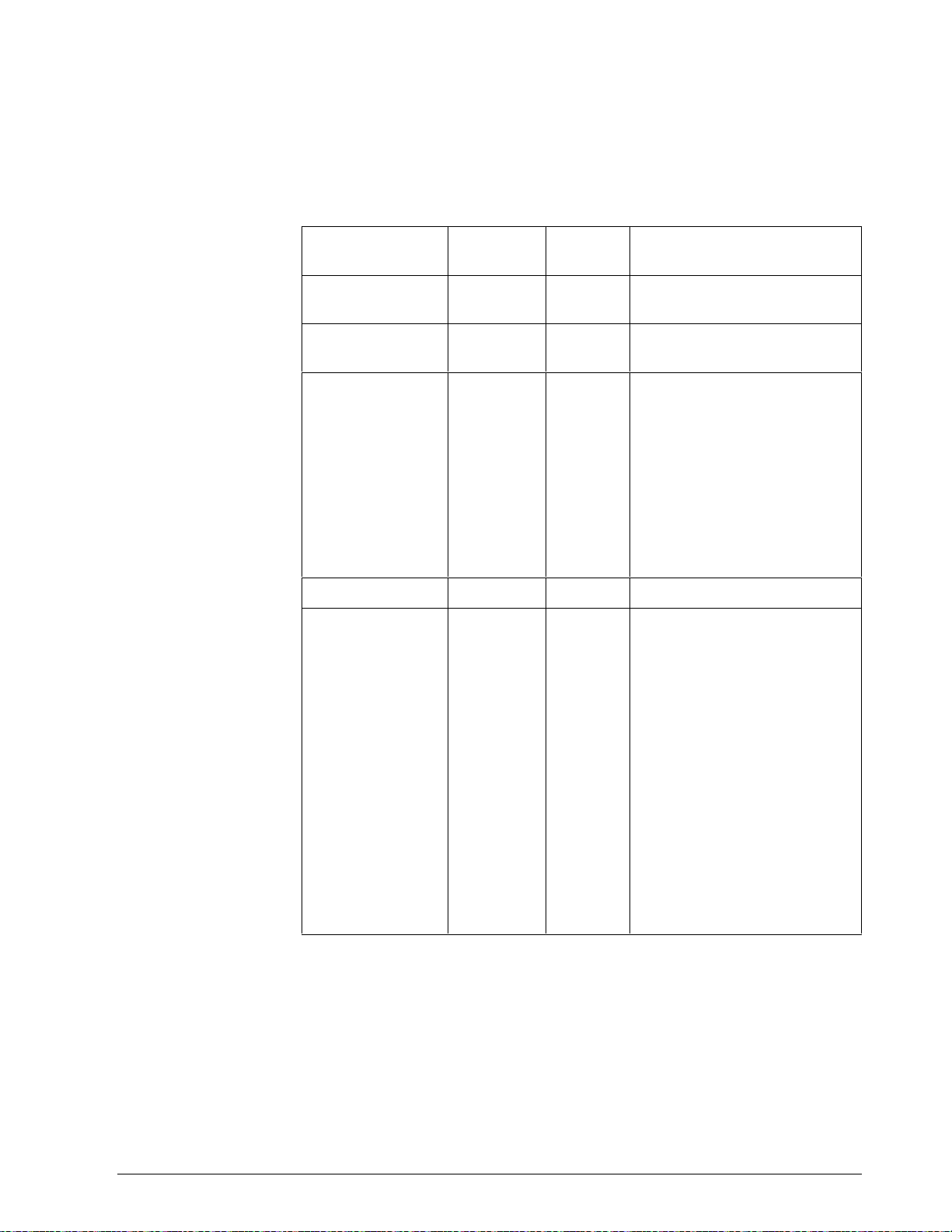

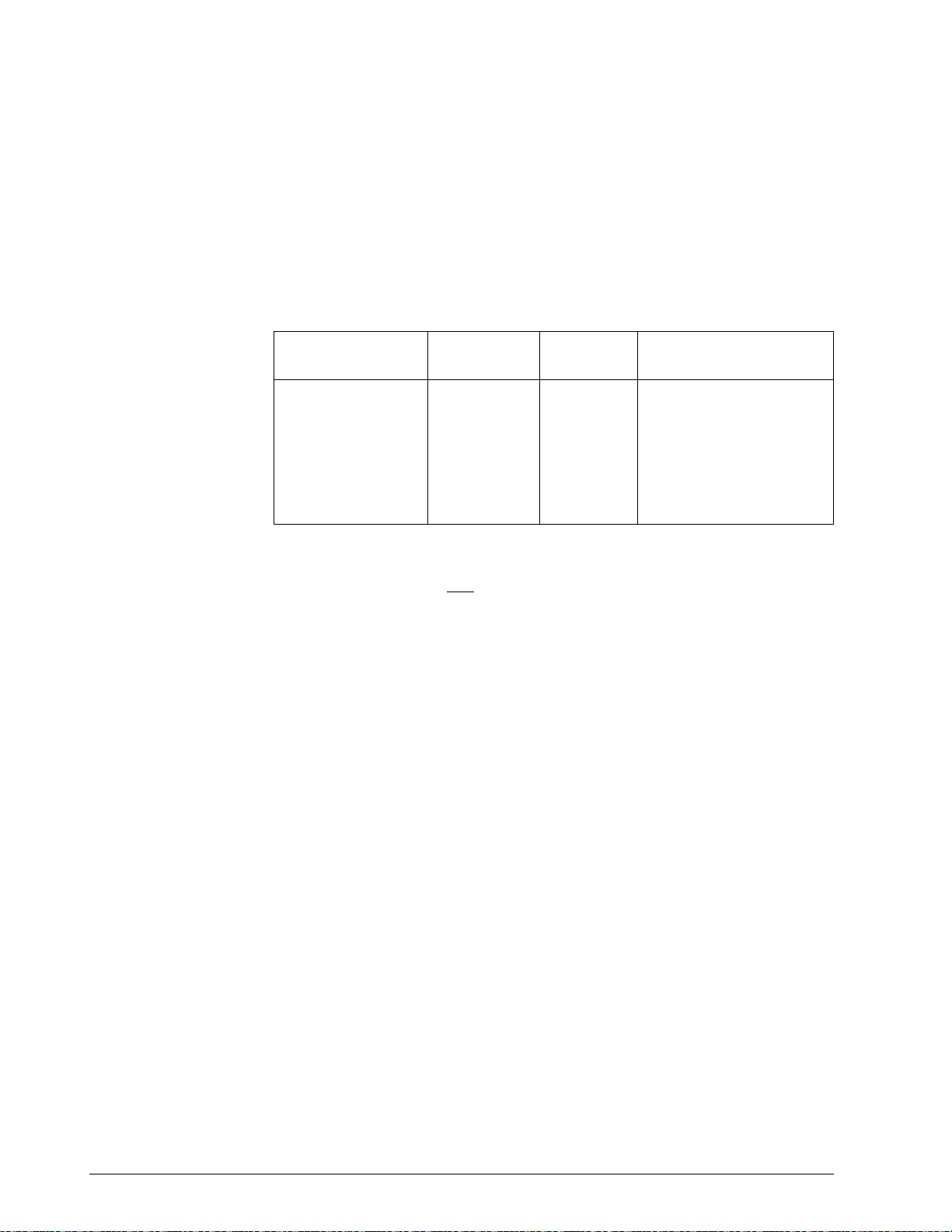

Table 1-1 lists the rules and regulations of configuration protocol.

Table 1-1 Rules and Regulations for Configuration Protocol

Protocol Rule

Data Type

Transactions

Read Read transactions can be performed in either UDC state:

Write Write transactions can only be performed in the Slave

Busy Following any Write message, a Busy indication is

Ready A Ready transaction is required as the next message

Transaction Limits In a Write transaction, only single items are permitted to

The configuration protocol permits reading or writing of

data type transactions such as PV, SP, or Output, as well

as configuration type transactions such as Tuning,

Algorithm selections, etc.

Monitor or Slave.

mode.

returned.

request to determine if the information received was

correct.

be written, however, for Read transactions, single or

multi-item parameters may be requested.

Loopback

Checksum

Controller Address

Keyboard

Configuration

Loopback protocol is also provided for link tests. With this message

exchange you can test the Communications link between your computer

and the controllers on the link. The host computer sends a series of ASCII

characters to the desired device, and the device returns the characters it

received to the host computer.

There is an optional transaction called "Checksum" which is used to

increase security on the RS422/485 link. Used with any message

exchange, it enables both your computer and controller to detect messages

that have been interrupted by line noise.

Each controller will have its own specific address. If you have a 2 loop

controller, there will be a specific address for each loop.

Address, Baud Rate, and Parity are keyboard selectable as well as Shed

Time, Shed Mode, and Output Level.

2 RS422/485 ASCII Communications Option Product Manual 5/99

Page 17

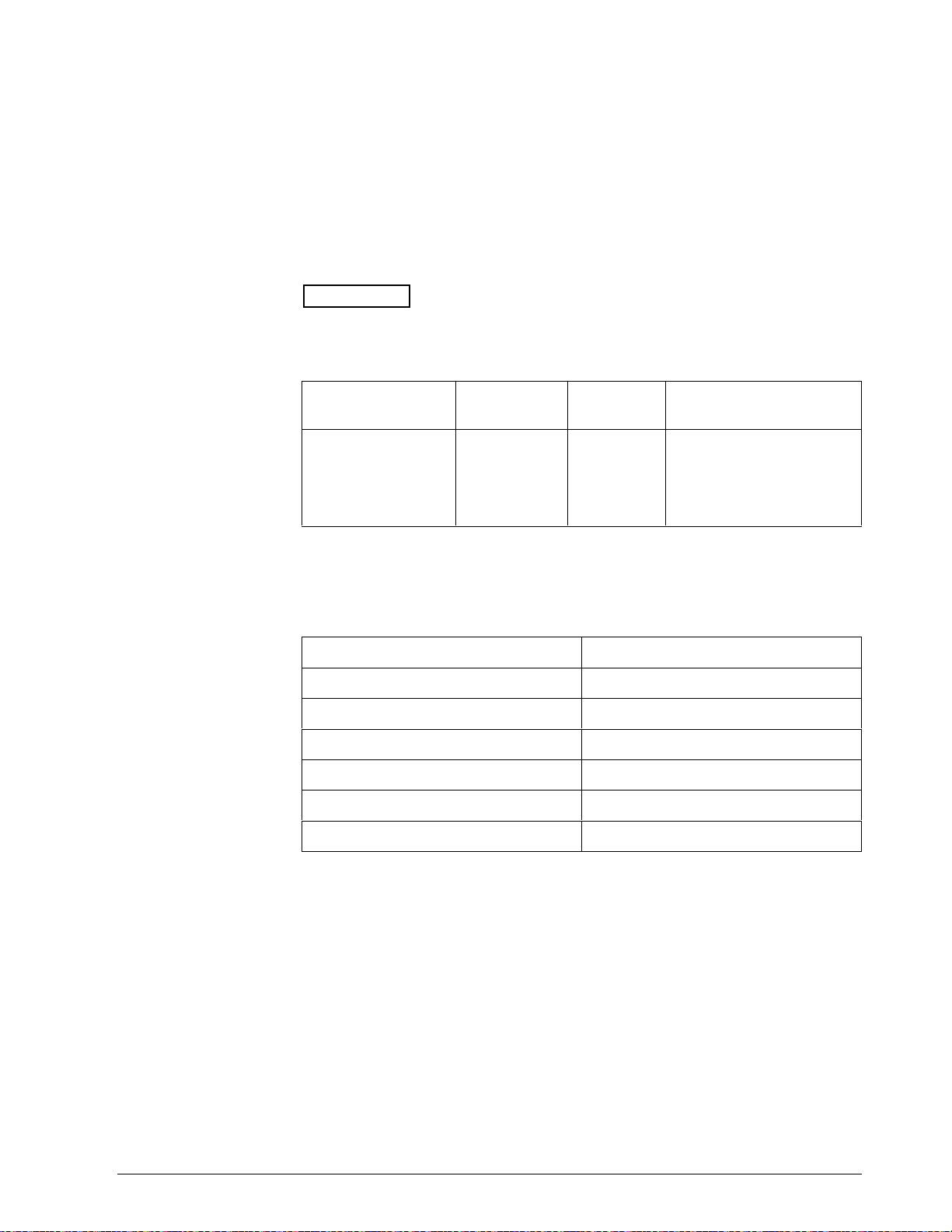

1.3 Field Upgrade

Adding the

communications

option

ATTENTION

RS422/485 Communications Option can be added in the field by installing

the proper RS422/485 Printed Wiring Board Assembly.

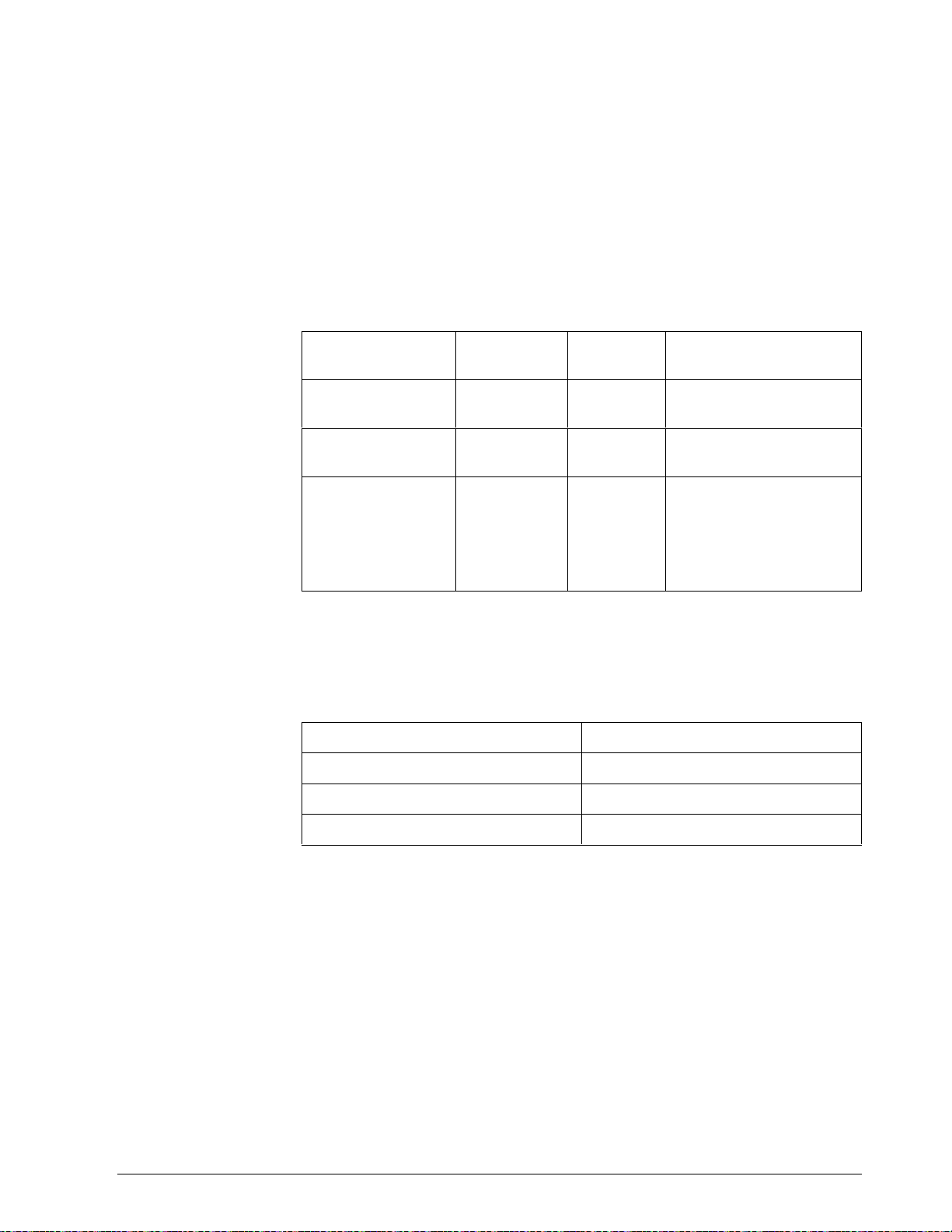

Table 1-2 lists the part numbers required to add the RS422/485

Communication option Printed Wiring Board to the UDC controllers.

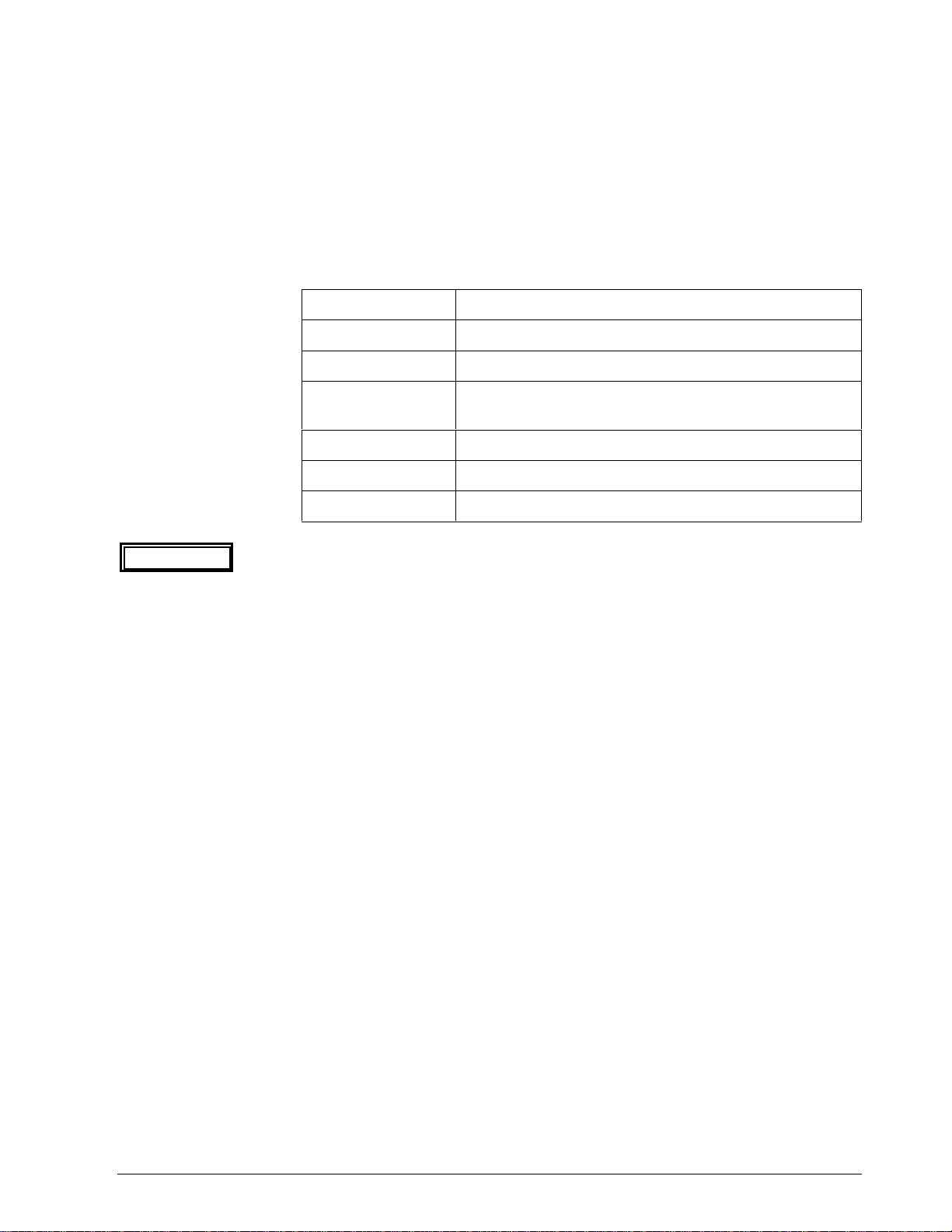

Table 1-2 Upgrade PWB Part Numbers

Model Upgrade PWB Part Numbers

UDC 2300 Part Number 51309831-501

UDC 3000 Part Number 30756693-501

UDC 3300 Part Number 30756693-501 or

Part Number 30756687-502 (Aux Out/RS-485)

UDC 5000 Part Number 30755865-502

UDC 6000 Part Number 30755865-501

UDC 6300 Part Number 30755865-504

Early version UDC 5000 with 28-pin PROM cannot be upgraded to

RS422/485 unless the PROM socket has 32-pin receptacles.

5/99 RS422/485 ASCII Communications Option Product Manual 3

Page 18

4 RS422/485 ASCII Communications Option Product Manual 5/99

Page 19

2.1 Introduction

Section 2 – Installation

General

Electrical noise

protection

What’s in this section

The Installation section (Section 2) of the UDC Product Manual contains

information and drawings required to mount and wire the controller. Refer

to the Controller Product Manual for appropriate information regarding

the basic installation requirements.

When installing and wiring the controller, follow the practices that

conform to all local codes and ordinances. In addition, be aware of the

precautions you should take to avoid electrical noise.

Electrical noise is unwanted electrical signals that provide undesirable

effects. Digital equipment is especially sensitive to the effects of electrical

noise. The controller has built-in circuits to reduce the effects of this

noise.

For information concerning further reduction of electrical noise, refer to

"How to Apply Digital Instrumentation in Severe Electrical Noise

Environments" – in the UDC Controller Product Manual or Honeywell

Document 51-52-05-01.

This section contains the following information:

Topic See Page

2.1 Introduction

General

Electrical Noise Protection

5

5

5

2.2 RS232 to RS485 Converters 6

2.3 Using a Black Box Converter

Wiring the Black Box converter and the link

Wiring connections

Link devices terminal connections

2.4 Using a Westermo Converter

Wiring the Westermo converter and the link

Configuring the Westermo converter and the link

Wiring connections

Link devices terminal connections

2.5 Wiring Diagrams 11

7

7

8

8

9

9

10

10

10

5/99 RS422/485 ASCII Communications Option Product Manual 5

Page 20

2.2 RS232 to RS485 Converters

Overview

Converters

Up to 16 devices on an RS485 link can be connected to your computer by

installing a Black Box or Westermo RS232 to RS485 converter between

the RS232 port on your computer and the devices on the RS485 link.

These devices include:

• UDC2300, UDC3000, UDC 5000, UDC3300, UDC6000, or

UDC6300 Controllers with an RS485 Communications Option

Table 2-1 lists the specific information needed to procure either of these

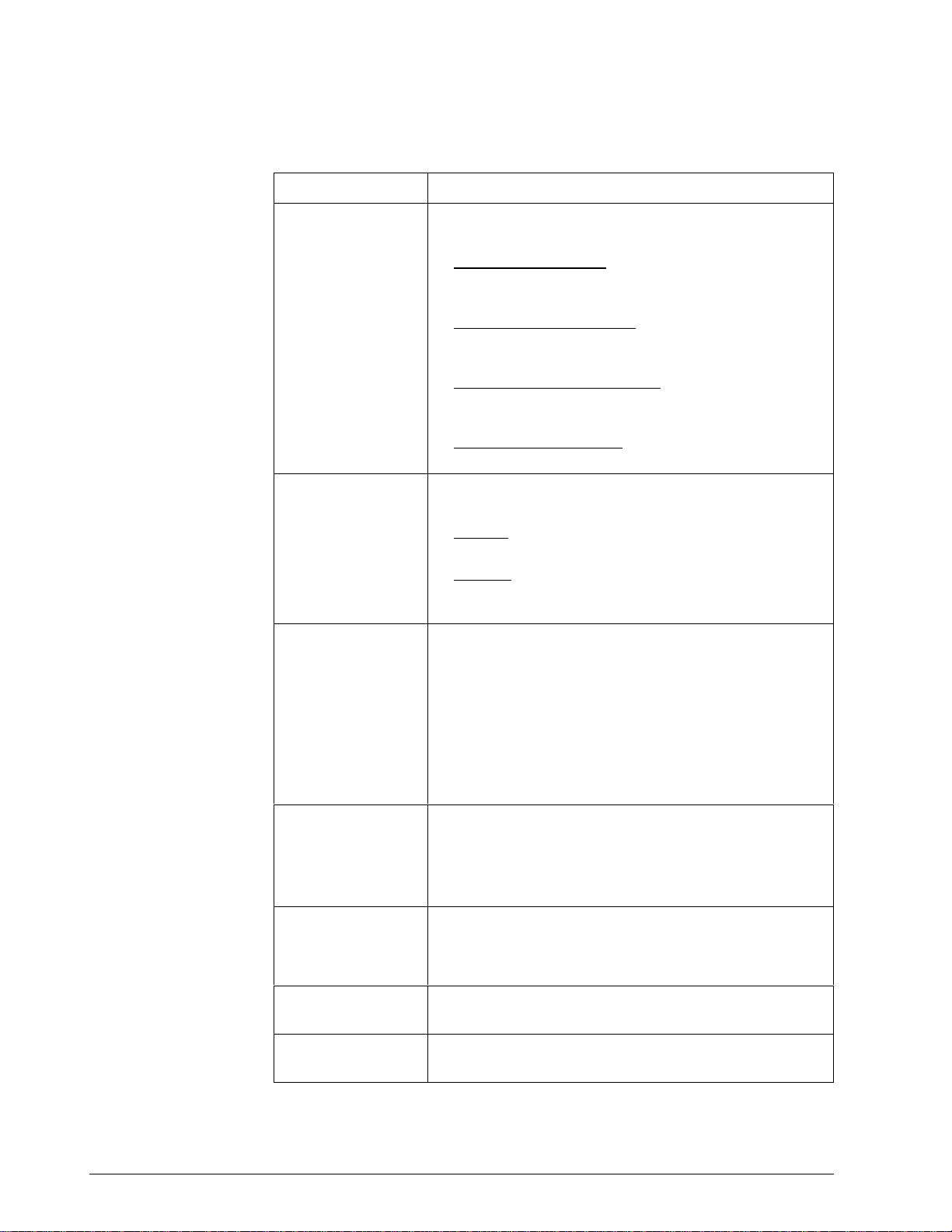

converters.

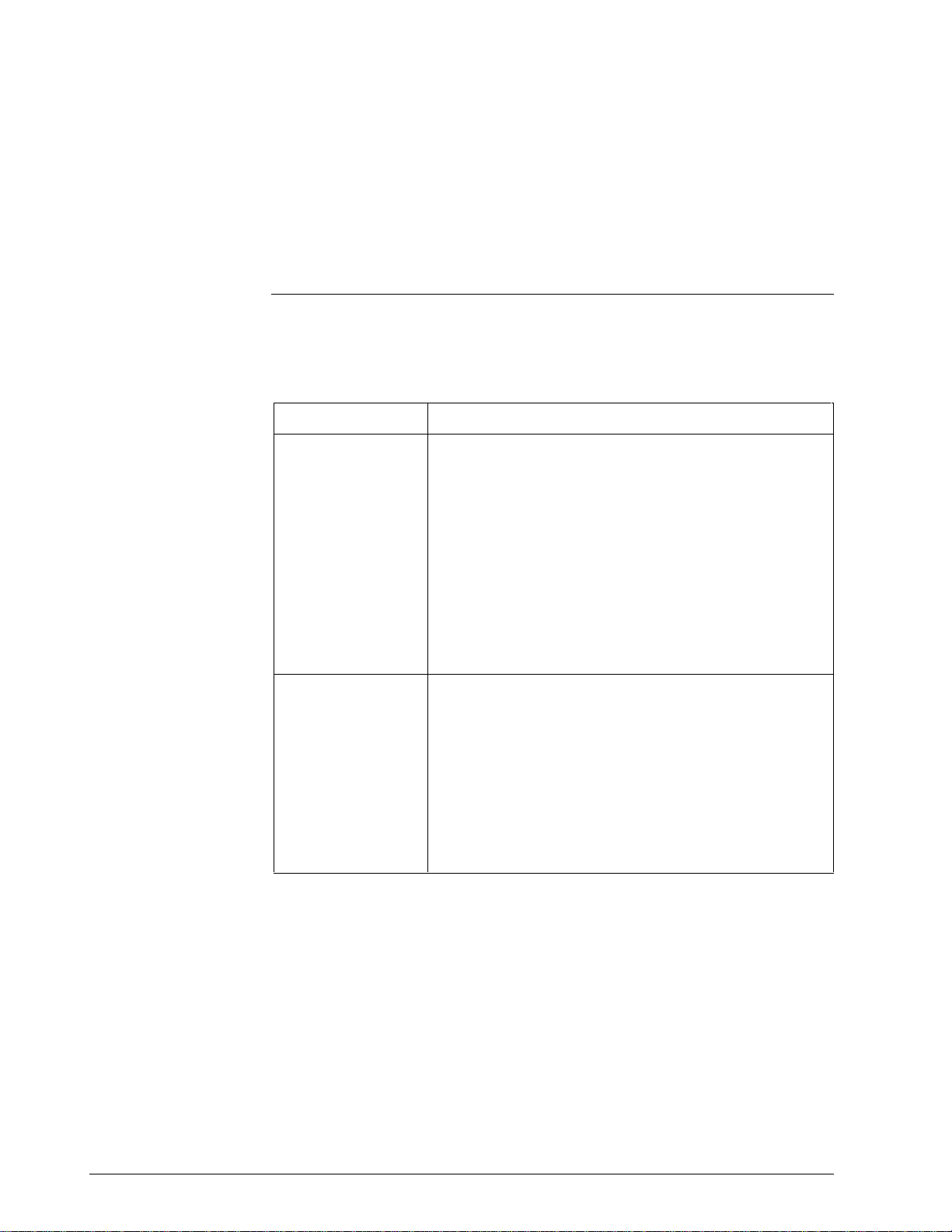

Table 2-1 Converters

Arrangement Description

Black Box

Converter

Using the RS232 port and a Black Box RS232 to RS485

converter installed between the RS232 port and the first

device on the link.

This converter is available from . . .

Black Box Corp

Pittsburgh PA..

Westermo

Converter

(Europe)

Model

IC109A - Stand alone RS232 to RS485/422 converter

with opto-isolation

Using the RS232 port and a Westermo RS232 to RS485

converter installed between the RS232 port and the first

device on the link.

The Westermo converter can be ordered from a

Honeywell sales office, Part Number 46210088-001.

A 2 meter shielded cable with Female/Male DB9/DB25

connectors for use between the PC communication port

and the Westermo box is also available,

Part Number 46210061-002

6 RS422/485 ASCII Communications Option Product Manual 5/99

Page 21

2.3 Using a Black Box Converter

Wiring the Black Box

converter and the link

Figure 2-1 shows the wiring diagram and terminal connections for wiring

the RS232 to RS485 Black Box converter.

Follow the procedure in Table 2-2 to wire the Black Box converter.

Table 2-3 shows the terminal designation for the devices on the link.

Table 2-2 Black Box Converter Wiring Connections Procedure

Step Action

1 Install an appropriate Serial Communication Connector between the

Computer serial port and the RS232 input connector of the Black Box

converter.

interfacing signals.

2 Connect one wire to terminal 2 (–).

3 Connect other wire to terminal 1 (+).

4 Connect a 120 ohm resistor across 1 and 2.

5 Set the jumpers on the Black Box converter Printed Circuit Board as

follows:

See the Black Box data sheet for the required

JUMPER SETTING

XW1A DCE

W8 B-C (2-wire)

W15 B-C (Data Enabled)

W5 A-B (RTS/CTS delay - normal)

W9 C (0 msec)

W17 C (2 msec)

W16 B (0.1 msec)

S1 OUT (Normal)

S2 ON (RS485 Receiver Terminated)

S3 ON (Line Bias On)

6 Create a chain of up to 16 devices by connecting them with shielded

twisted pair wiring (Belden 9271 Twinax or equivalent) to a maximum

total length of 4000 feet(1250 meters).

(See Section 12—Cable Specifications.)

REFER TO TABLE 2-3 FOR TERMINAL DESIGNATIONS OF THE

DEVICES ON THE LINK

5/99 RS422/485 ASCII Communications Option Product Manual 7

Page 22

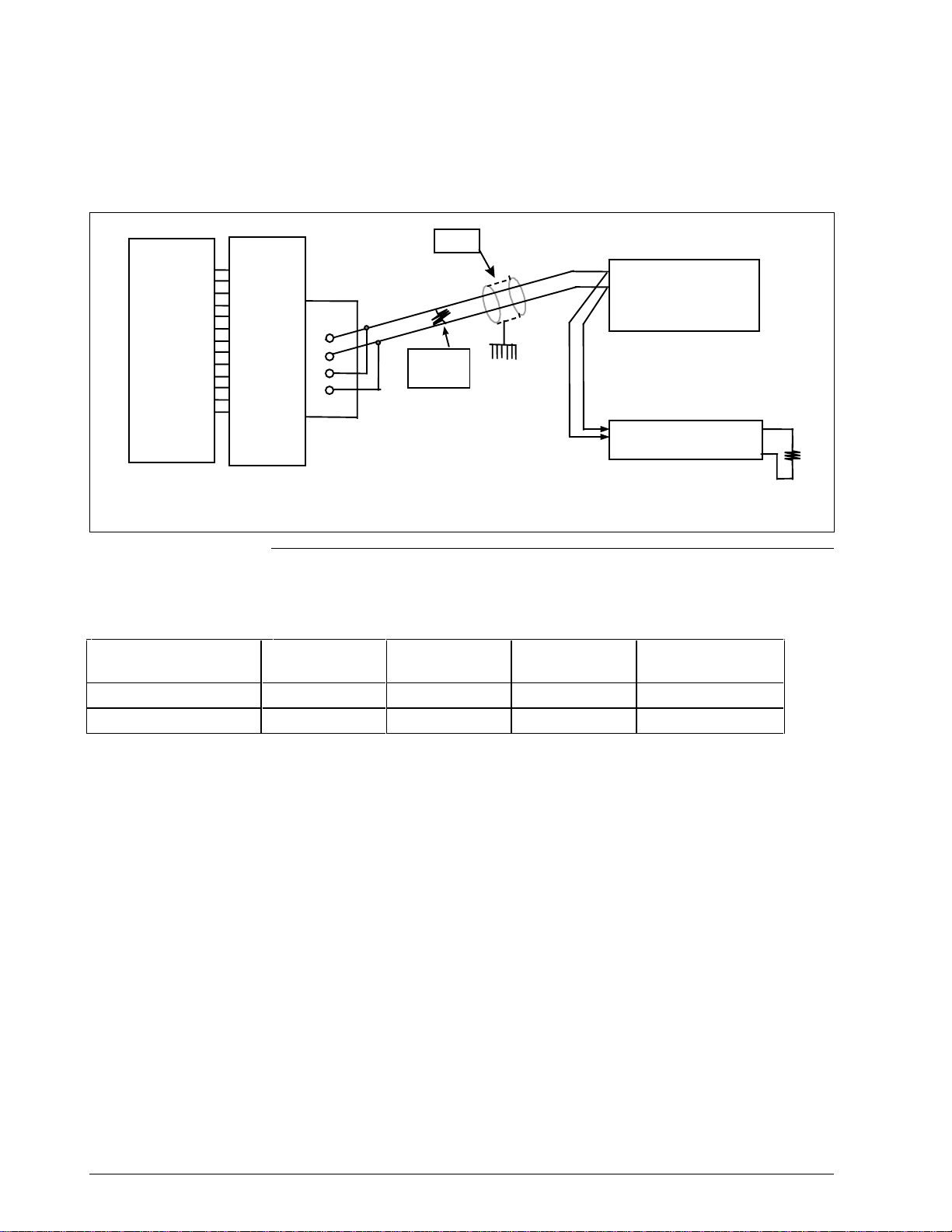

2.3 Using a Black Box Converter, Continued

Black Box wiring

connections

Figure 2-1 shows the wiring for the Black Box converter and the devices

on the link.

Figure 2-1 Black Box Converter Wiring Connections

Shield

Computer

RS232

output

Black Box

Converter

1

2

3

4

120 Ohm

Resistor

+

–

1ST Device

on Link

To other devices on link

Maximum 16 addresses

120 ohm resistor between A and B

on last device on link

22937A

Link devices terminal

connections

Table 2-3 lists the terminal connections between the Black Box converter and the

devices on the communication link.

Table 2-3 Terminal Connections for Black Box Converters

BLACK BOX UDC3000

2 152311 14

1 142212 13

UDC3300

UDC6000

UDC6300

UDC5000 UDC2300

8 RS422/485 ASCII Communications Option Product Manual 5/99

Page 23

2.4 Using a Westermo Converter

Wiring the Westermo

converter and the link

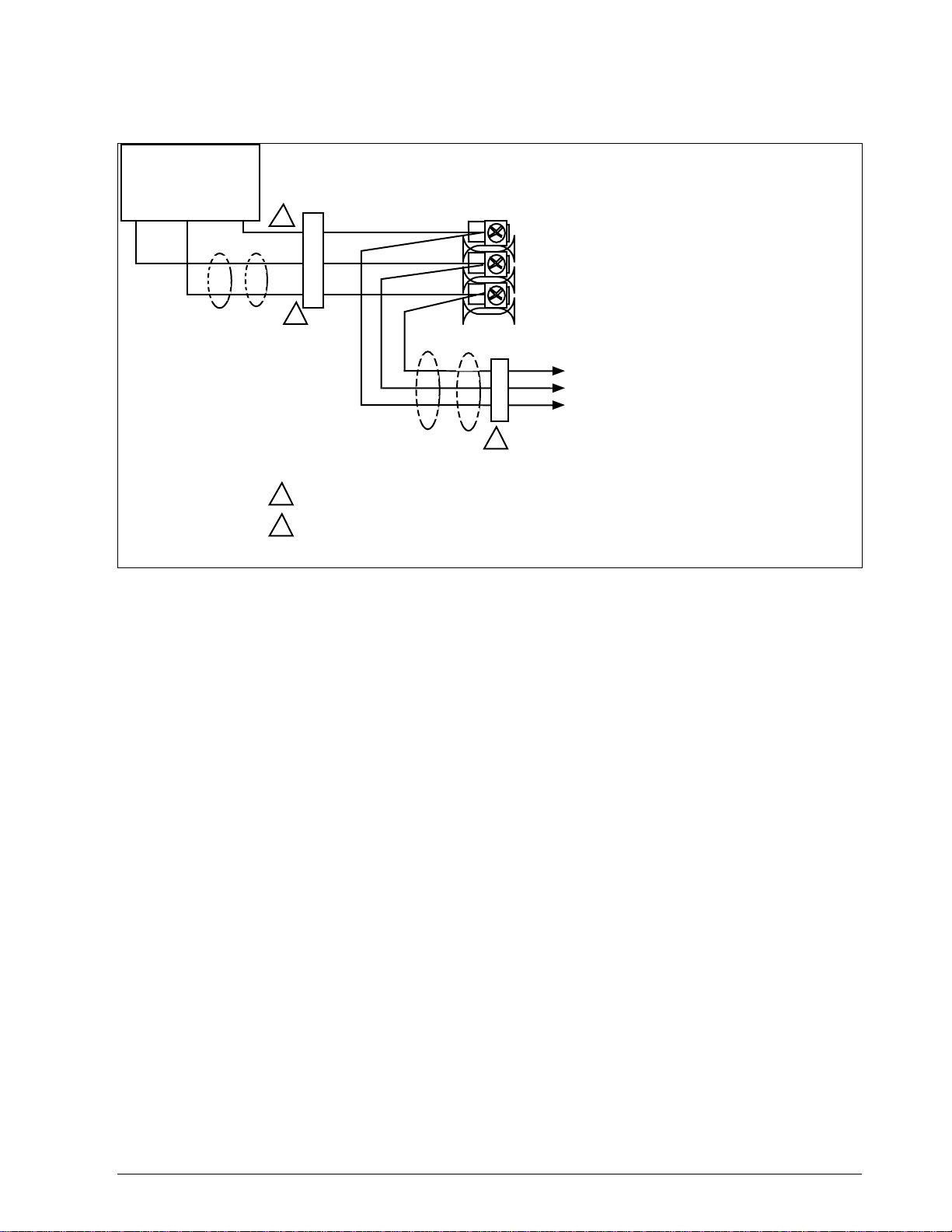

Figure 2-2 shows the recommended switch setting for the WESTERMO

converter.

Figure 2-3 shows the wiring diagram and terminal connections for wiring

the RS485 Westermo converter.

Follow the procedure in Table 2-4 to configure and wire the Westermo

converter.

Table 2-5 shows the terminal designation for the devices on the link.

Table 2-4 Westermo Converter Configuration and Wiring Procedure

Step Action

1 Install an appropriate Serial Communication Connector between the

Computer serial port and the RS232 input connector of the Westermo

converter. See the Westermo data sheet for the required interfacing

signals.

2 Configure the switch settings on the Westermo converter as shown in

Figure 2-6.

3 Connect the shield to terminal 5. See Figure 2-3.

4 Connect one wire to terminal 3 (–).

5 Connect other wire to terminal 4 (+).

6 Connect a 120 ohm resistor across terminals 3 and 4.

7 Create a chain of up to 16 Devices by connecting them with shielded

twisted pair wiring (Belden 9271 Twinax or equivalent) to a maximum

total length of 4000 feet(1250 meters).

(See Section 13—Cable Specifications.)

REFER TO TABLE 2-5 FOR TERMINAL DESIGNATIONS OF THE

DEVICES ON THE LINK

5/99 RS422/485 ASCII Communications Option Product Manual 9

Page 24

2.4 Using a Westermo Converter, Continued

Configuring the

WESTERMO

Figure 2-2 shows the recommended switch settings for the WESTERMO

converter.

Converter

Figure 2-2 Recommended Switch Settings for Westermo Converter

S1 S3 S2

Westermo wiring

connections

ON

230

OFF

12345

Power

Supply

Figure 2-3 shows the wiring for the Westermo converter and the devices

on the link.

2

34

1

Line Connection

5

6

Figure 2-3 Westermo Converter Wiring Connections

ON

1

OFF

V 24/RS-232-C

23456

CONNECTION

22933

Computer

RS232

output

Link devices terminal

connections

Westermo

Converter

5

4

3

2

1

Twisted pair shield – connect shield

wire with supplied crimp connector

120 Ohm

Resistor

Shield

Table 2-5 shows the terminal connections between the Westermo

converter and the devices on the communication link.

Table 2-5 Terminal Connections for Westermo Converters;

Westermo

Line Connections

3 15112314

4 14122213

UDC 3000

UDC 3300

UDC 5000 UDC 6000

UDC 6300

+

–

1ST Device

on Link

To other devices on link

Maximum 16 addresses

120 ohm resistor between A and B

on last device on link

22937

UDC 2300

10 RS422/485 ASCII Communications Option Product Manual 5/99

Page 25

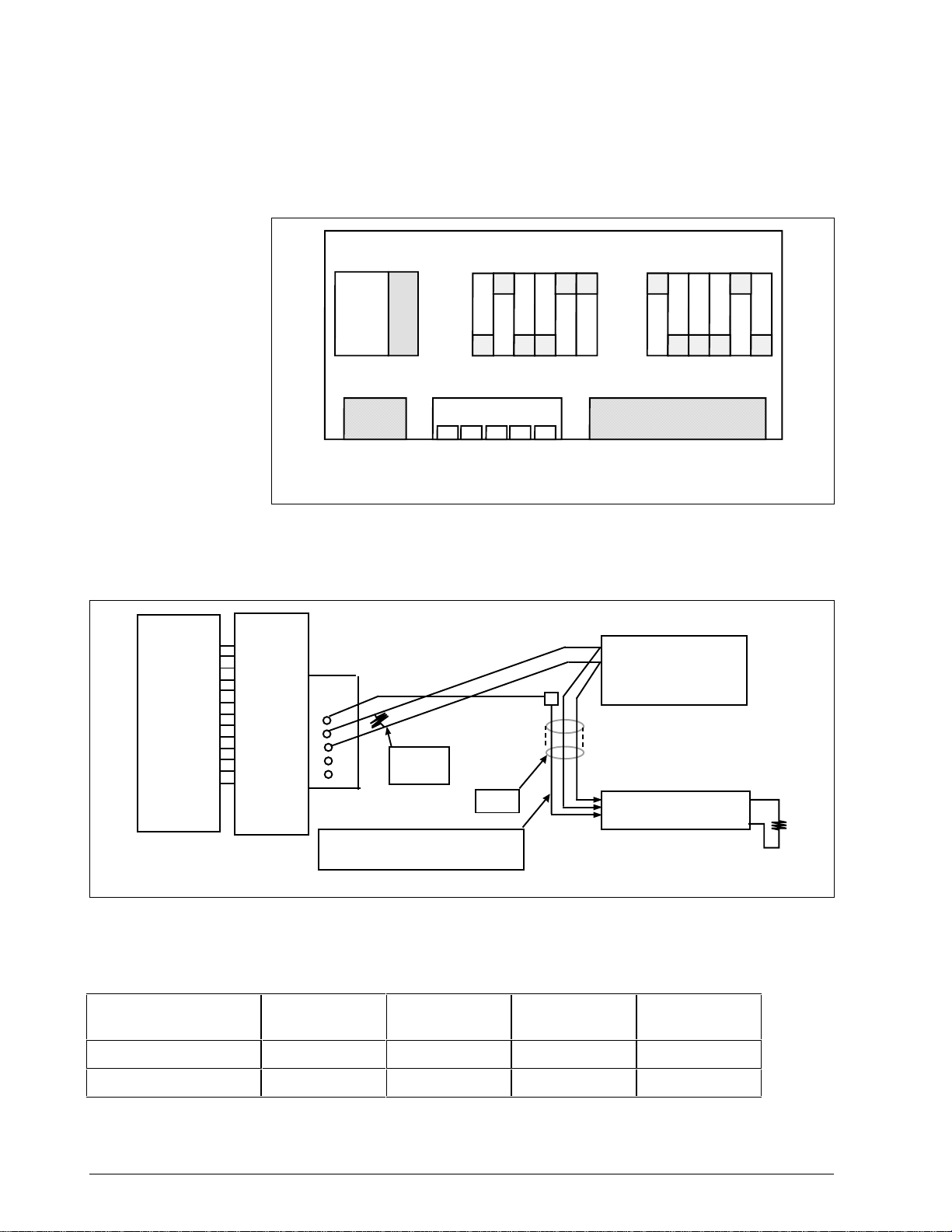

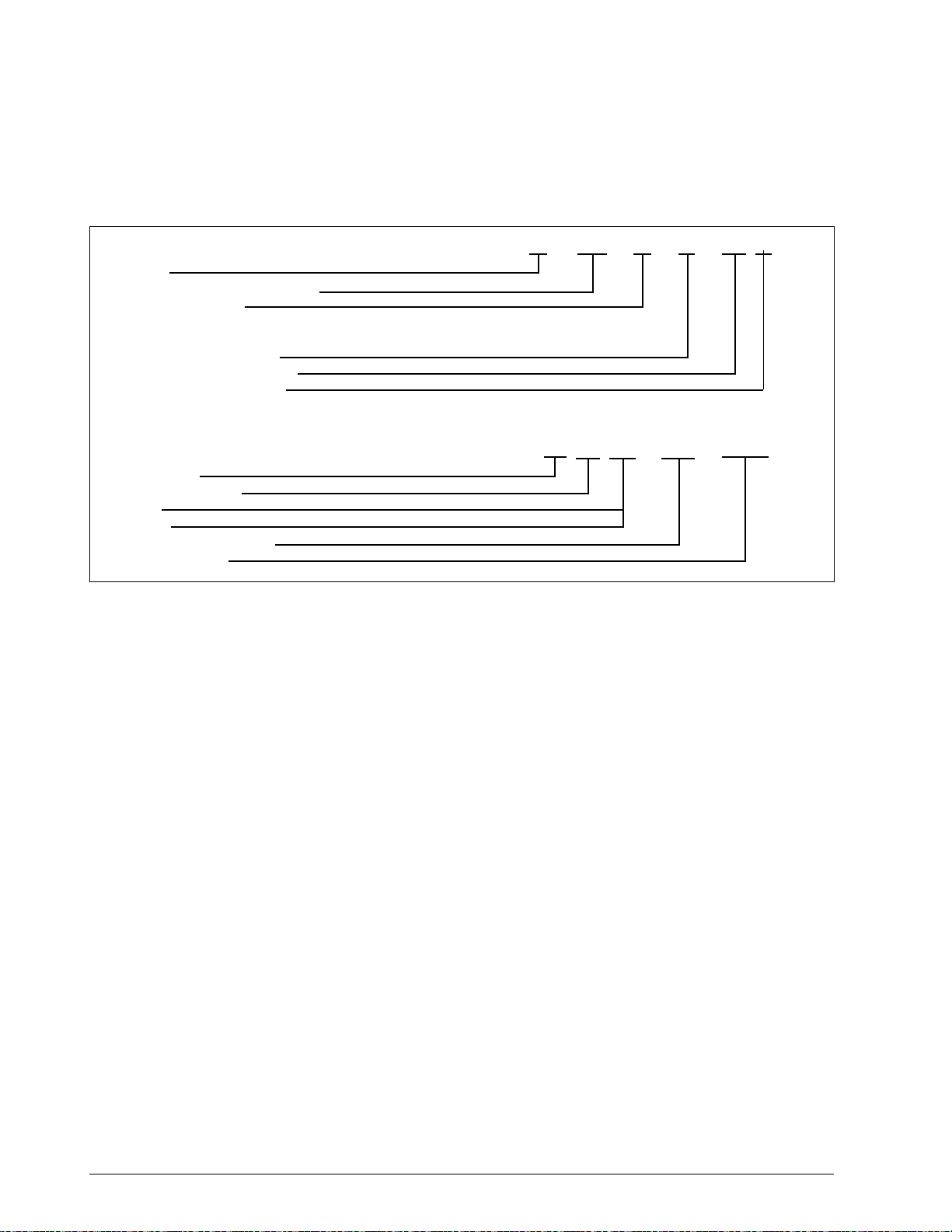

2.5 Wiring Diagrams

Communications option

connections

Figure 2-4: UDC3000 and UDC3300

Figure 2-5: UDC6000 and UDC6300

Figure 2-6: UDC5000

Figure 2-7: UDC 2300

Figure 2-4 UDC3000/3300 Connections

RS422/485

HALF DUPLEX

12

13

14

15

CAUTION

Do not mix half and

full duplex wiring.

SHD

TX+/RX+

TX–/RX–

To Other

Communication

Instruments

(maximum 15)

Master

1

SHD

TX+/RX+

120 Ohm

TX–/RX–

Do not run these

lines in the same

conduit as AC power

120 Ohm Resistor

on Last Leg

Resistor

12

13

14

15

16

17

Use shielded twisted pair cables

1

(Belden 9271 Twinax or equivalent)

RS422/485

FULL DUPLEX

SHD

RX+

RX–

TX+

TX–

Communication

1

To Other

Instruments

(maximum 15)

Master

SHD

TX+

TX–

RX+

RX–

Do not run these

lines in the same

conduit as AC power

120 Ohm Resistor

on Last Leg

120 Ohm

Resistor

120 Ohm

Resistor

24169A

5/99 RS422/485 ASCII Communications Option Product Manual 11

Page 26

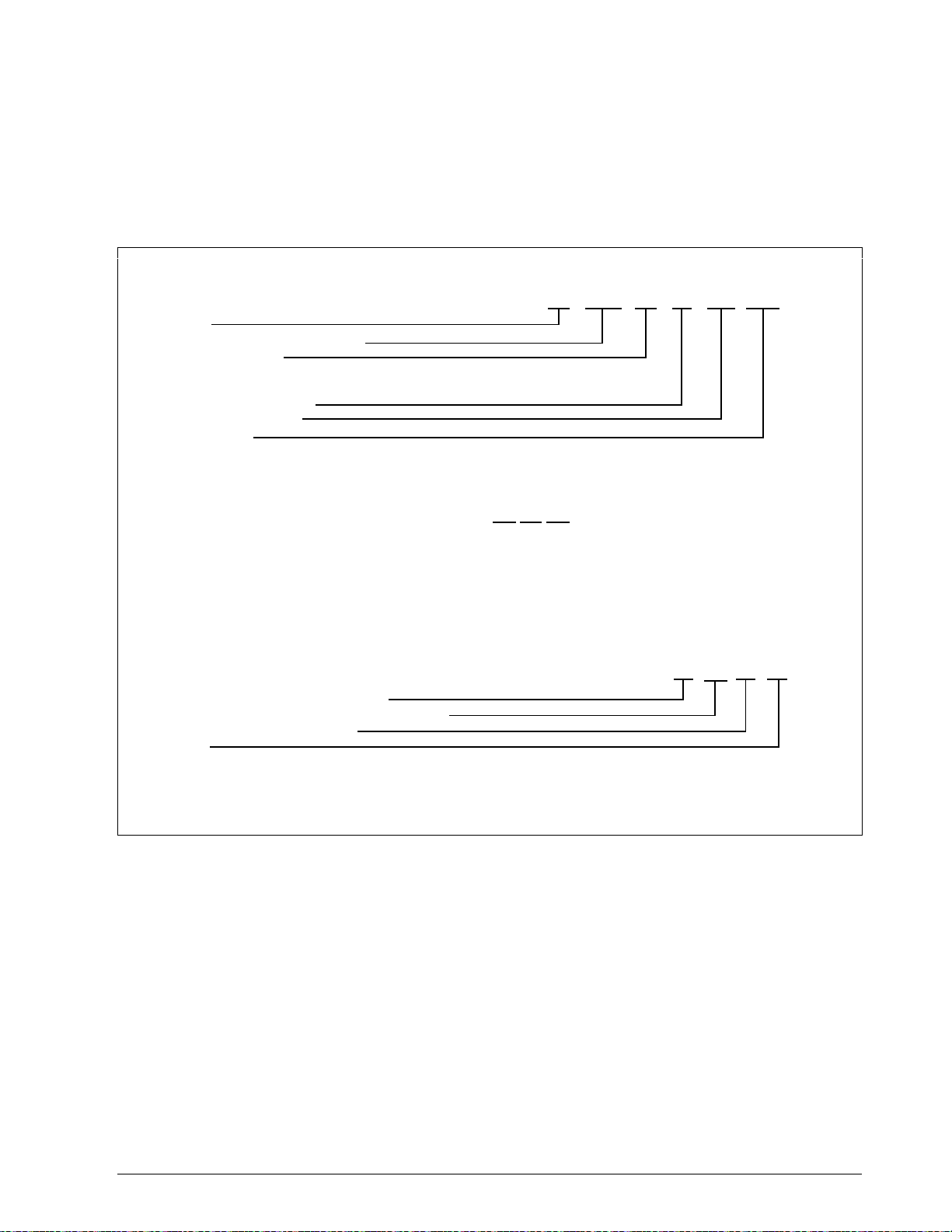

2.5 Wiring Diagrams, Continued

Figure 2-5 UDC6000/6300 Connections

COMMUNICAT ION MASTER

(A) (RTN) (B)

D+

SHLD

21

22

23

D+

D–

D–

2

TO OTHER

COMMUNICATION

CONTROLLERS

D+D–

120 OHMS ON LAST LEG

120 OHMS

1

Connect shield wires together with Honeywell

1

supplied crimp part number 30755381-001

2

Do not run these lines in the same conduit as AC power.

21758A.ppt

12 RS422/485 ASCII Communications Option Product Manual 5/99

Page 27

2.5 Wiring Diagrams, Continued

Figure 2-6 UDC5000 Connections (without Digital Input Option)

Communication

Master

D+ SHLD D-

1

11

12

13

2

Optional Communicati on

To Other

Communication

Controllers

4

Do not run these lines in the same conduit as AC power

1

Required for CE Mark Compliance - Kit supplied Part Number

2

51197612-508 contains 8 Ferrite filters

22330A.ppt

5/99 RS422/485 ASCII Communications Option Product Manual 13

Page 28

2.5 Wiring Diagrams, Continued

Figure 2-7 UDC2300 Connections

COMMUNICAT ION MASTER

(A) (RTN) (B)

D+

SHLD

D–

2

13

14

D+

D–

TO OTHER

COMMUNICATION

CONTROLLERS

120 OHMS

1

Connect shield wires together with Honeywell

1

supplied crimp part number 30755381-001

2

Do not run these lines in the same conduit as AC power.

D+D–

120 OHMS ON LAST LEG

21758B.ppt

14 RS422/485 ASCII Communications Option Product Manual 5/99

Page 29

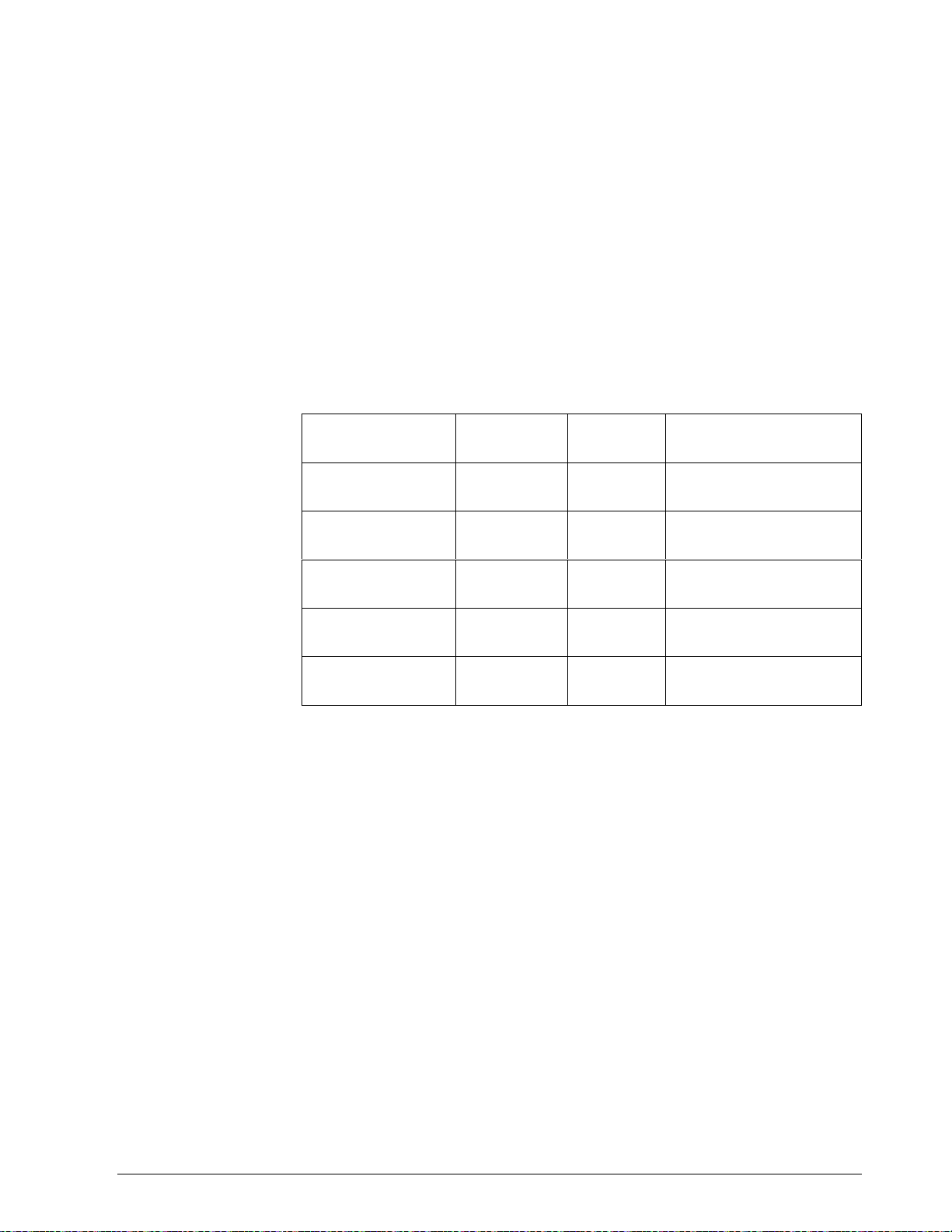

Section 3 – Establishing Communications and Testing

3.1 Preparing the Controller for Communications

Introduction

Synchronization

Configurable

parameters

Each controller on the RS422/485 Communications link must be

configured at the controller level for certain parameters before

communications between the Host and the Controller can be

accomplished.

Before you attempt to exchange messages between your computer and the

controllers on the RS422/485 link, you must set up the controller for the

same form of data transmission that the host computer’s RS422/485

interface uses. This is called Synchronization.

You must match the controller Baud Rate and Parity with that of your

computer.

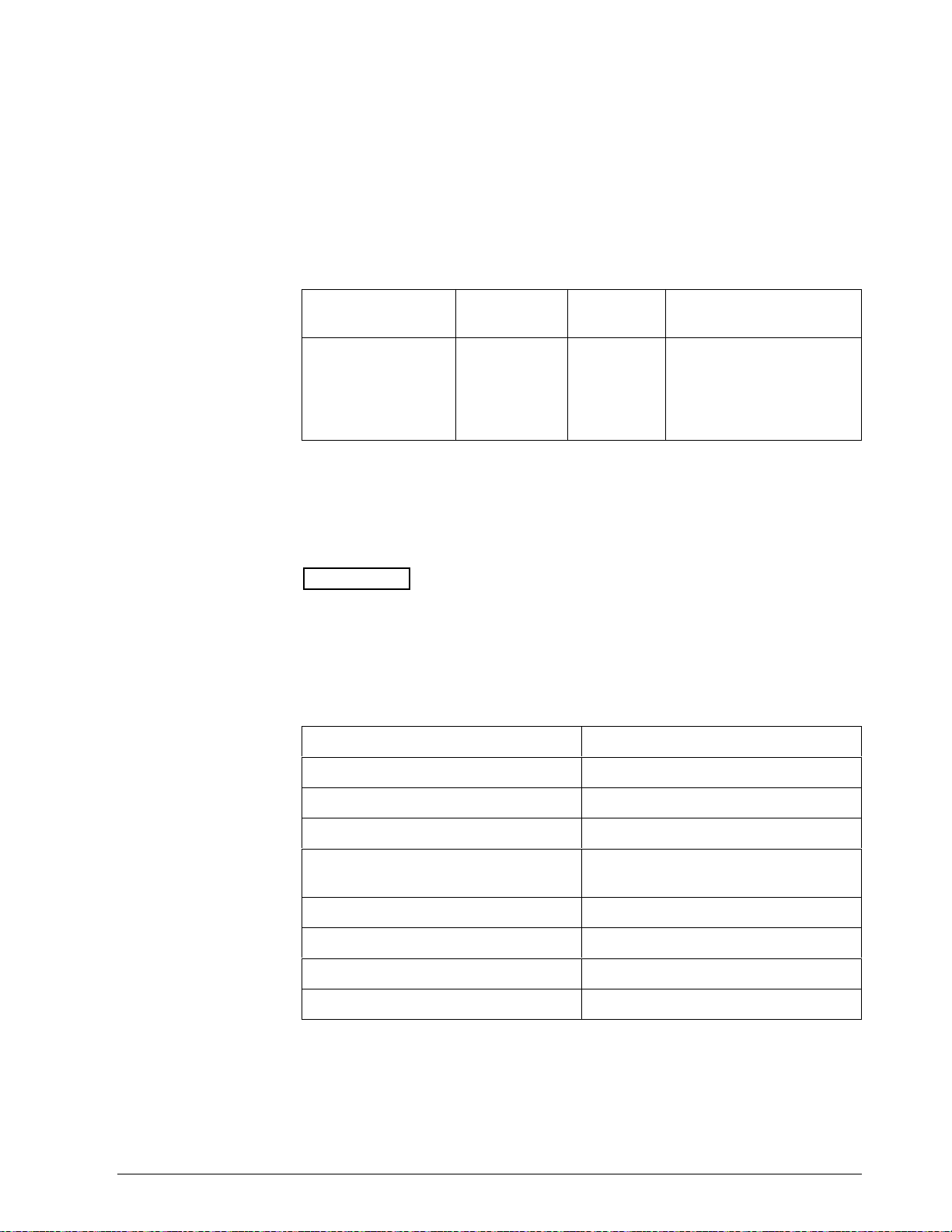

Table 3-1 is a list of parameters that should be configured, their

definitions, range of settings or selections, the procedure for entering the

information into the controller is found in Table 3-2.

Table 3-1 Communications Parameters

Parameter Definition

Communications

State

Enables or disables the Communication function in the

controller.

Communications

Address

Shed Term used to describe a point in time when the controller,

Shed Time The number selected will represent how many sample

Duplex Selection made for transmission type. Two-wire

TX Delay Configurable response delay timer allows you to force the

This is a number that is assigned to a controller (limited

to 15 controllers) that will be used during

communications. This number will be its address on the

link (address 0-99).

If your controller has two loops, each loop must have its

own individual address (i.e. Loop 1, #6; Loop 2, #7).

which had been working as a slave, reverts to an

independent, stand alone controller using its own inputs,

configuration data and control mode. Shed will happen

when a controller is in slave, the shed is not zero, and the

communication stops.

periods will elapse before the controller sheds from

computer control. Each period equals 1/3 second. 0 = No

shed.

transmission is half duplex. Four-wire transmission is full

duplex.

UDC to delay its response for a time period of from 1 to

500 milliseconds. Compatible with the host system

hardware/software.

5/99 RS422/485 ASCII Communications Option Product Manual 15

Page 30

3.1 Preparing the Controller for Communications, Continued

Parameters,

continued

Table 3-1 Communications Parameters, Continued

Parameter Definition

Shed Controller

Mode and Output

Level

Shed Setpoint

Recall

This selection determines the mode of local control

whenever the controller is SHED from the slave mode.

• Last Mode and Output – The controller will return to

the same mode (Manual or Automatic) and Output

level that it was in before shed.

• Manual Mode, Last Output – The controller will return

to manual mode and the last output level it was in

before shed.

• Manual Mode, Failsafe Output – The controller will

return to manual mode at the output level selected at

ID code 40 – Failsafe Output Value.

• Shed to Automatic Mode – The controller will return to

automatic mode.

This selection determines what setpoint will be used if the

controller is shed from the communications link.

• TO LSP – The controller will use the last local setpoint

stored.

• TO CSP – The controller will store the last computer

setpoint and use it at the Local Setpoint (LSP1, LSP2,

or LSP3, whichever is in use).

Parity Transmitting each ASCII character requires 8 bits:

• 7 bits for the character code

• 1 bit (the eighth) for Parity, which may represent either

ODD or EVEN parity.

Thus, the controller can accommodate your computer's

choice of parity (odd or even) and perform parity checks

on your computer's data transmission. The controller will

return STATUS CODE 04 if it detects incorrect parity.

Baud Rate This is the transmission speed in bits per second. In

order to communicate properly, the controller must be set

to the same Baud Rate as your computer. The Baud

Rate selections are: 300, 600, 1200, 2400, 4800, 9600,

or 19,200.

Communication

Units

Communications

Setpoint Ratio

Communications

Setpoint Bias

This selection determines how the controller values are

expressed during communications:

Percent of span or Engineering units.

Ratio value for computer setpoint. The range is from

-20.00 to +20.00.

Bias value for computer setpoint. The range is from

-999 to 9999.

16 RS422/485 ASCII Communications Option Product Manual 5/99

Page 31

3.1 Preparing the Controller for Communications, Continued

Procedure

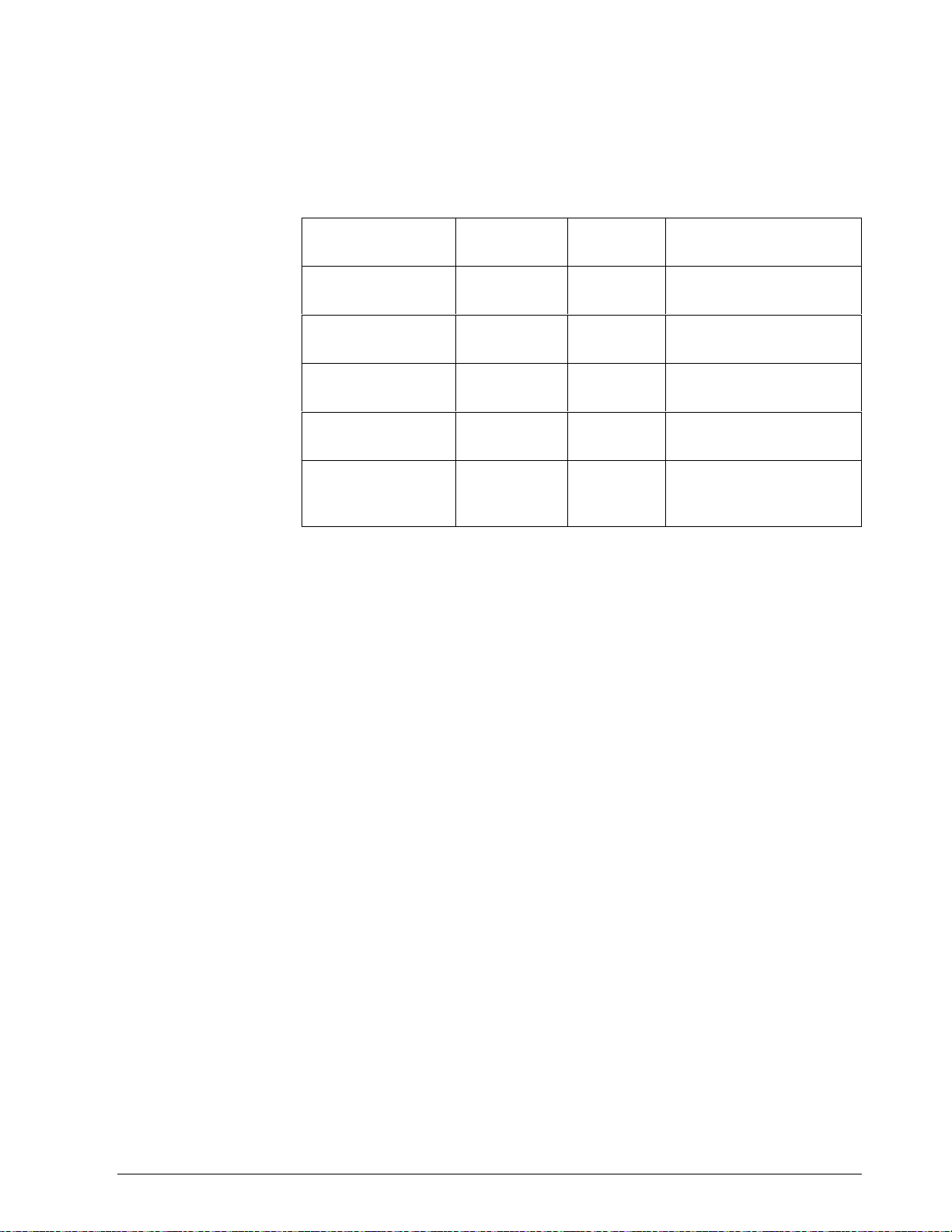

The procedure in Table 3-2 tells you what keys to press on the controller

keyboard, the upper and lower display indications, and the range of

settings available to you.

Not all prompts may be available for your particular controller.

Use ▲▼ to make adjustments to the range of setting or selection.

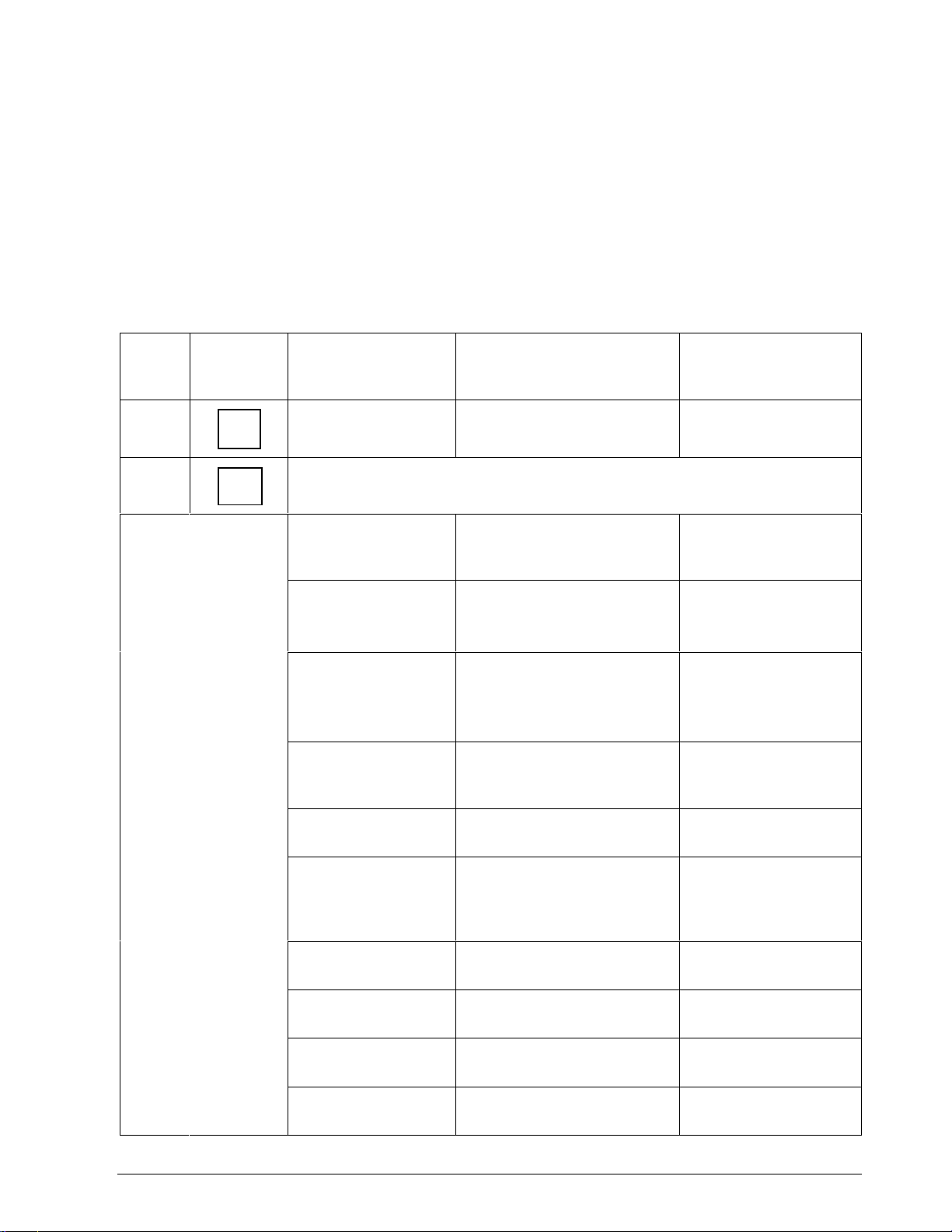

Table 3-2 Controller Procedure for Communication Parameters

Step Press Lower Display Upper Display

Range of Setting

or Selection

1

2

SET

UP

FUNC

COMMUN

successive presses of the [FUNCTION] key will sequentially display all the

functions and their values or selections.

COM STATE DISABLE

DMCS

RS422

ADDRESS 01 to 99*

* Address 00 disconnects it from the

link

Parameter Description

Communication State

Communication Address

(Loop 1)

ADDRESS 2 01 to 99* (must be different

from Loop 1)

* Address 00 disconnects it from the

link

SHED TIME 0 to 255

Sample periods

0 = No Shed will occur

PARITY ODD

EVEN

BAUD RATE 300 4800

600 9600

1200 19200

2400

SHED MODE LAST FAILSAFE

TO MAN TO AUTO

SHED SP TO LSP

TO CSP

DUPLEX HALF

FULL

TX DELAY 1 to 500 milliseconds Transmission Delay

Communication Address

(Loop 2)

Shed Time

Parity

Baud Rate (bits/second)

Controller Shed Mode

and Output Level

Shed Setpoint Recall

Duplex Transmission

Type

Timer

5/99 RS422/485 ASCII Communications Option Product Manual 17

Page 32

3.1 Preparing the Controller for Communications, Continued

Procedure, continued

Table 3-2 Controller Procedure for Communication Parameters, Continued

Step Press Lower Display Upper Display

Range of Setting

or Selection

UNITS PERCENT

ENG UNITS

CSP RATIO –20.00 to +20.00 Commun. SP Ratio

CSP BIAS –999 to +9999 Commun. SP Bias

CSP2 RATIO –20.00 to +20.00 Commun. SP Ratio

CSP2 BIAS –20.00 to +20.00 Commun. SP Bias

3

LOWR

DISP

TO RETURN TO

NORMAL CONTROL

Parameter Description

Communication Units

(Loop 1)

(Loop 1)

(Loop 2)

(Loop 2)

18 RS422/485 ASCII Communications Option Product Manual 5/99

Page 33

3.2 Programming Your Computer

Introduction

Request

Response

Example

To program your computer for communication with the various

controllers on the link, you write input and output statements to send and

receive ASCII character strings to and from the controller. (See ASCII and

Hexadecimal conversion table in Section 12.) You treat the controller like

any I/O device.

To send a request, you program your computer to output the appropriate

character string to the controller.

To get a response, you program your computer to input the expected

character string from the controller.

The following programming statements show how you would output a

request message and read the resulting response. This example is written

in Fortran and uses the following assignments:

• I/O Channel 5 for your computer's RS422/485 Transmit Data Line.

• I/O Channel 6 for your computer's RS422/485 Receive Data Line.

• I/O Channel 7 for your computer's printer or terminal.

Table 3-3 lists the programming statements for this example.

Table 3-3 Programming Statements

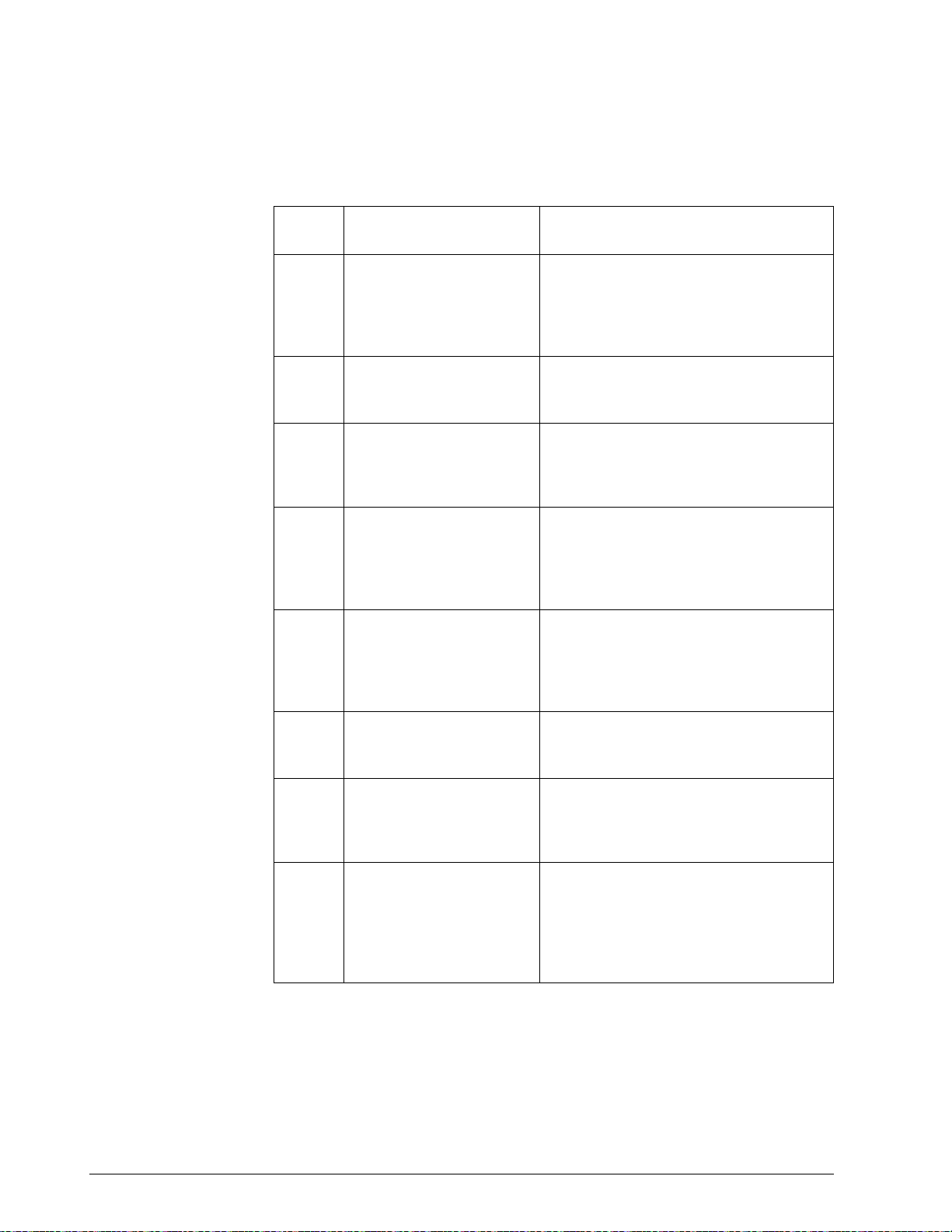

Step Statement Action

Sending the

Request

Getting the

Response

Displaying

the

Response

10 Write (5,20)

20 Format (“XXXXXXX”)

30 Read (6,40) Reply

40 Format (12)

50 Write (7,60) Reply

60 Format (12)

Writing the character string the

character string XXXXXXX to I/O

channel 5 which transmits the

character string XXXXXXX to the

controller.

Reading the character string at I/O

Channel 6 which receives data

from the controller into reply.

Writing the contents of Reply to I/O

Channel 7, a printer or terminal.

5/99 RS422/485 ASCII Communications Option Product Manual 19

Page 34

3.3 Message Exchange

What is a message

exchange?

Your computer communicates with the UDC controllers using the

RS422/485 link. Each communication takes place as a message exchange:

Your computer sends a request message (ASCII characters), and then

waits for the resulting response from the controller involved (ASCII

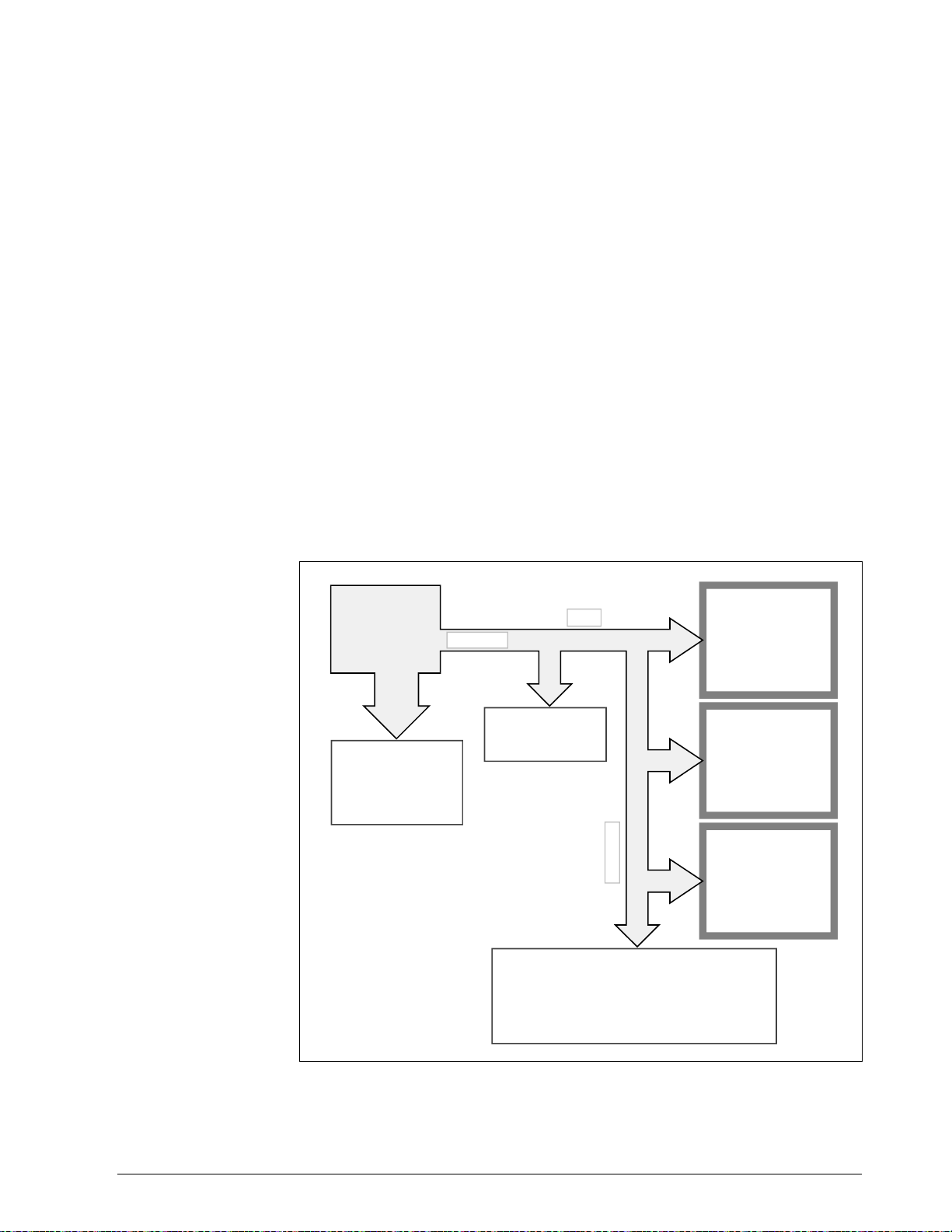

characters). Figure 3-1 shows how this occurs.

Figure 3-1 Message Exchanges

Read request

Host

Host

Response

Write request

Busy

Ready

Status of Last

Transaction

UDC

UDC

23092

Sending requests

Your computer is the host, it initiates a message exchange. The UDC

controllers are respond-only devices.

When you send a Read request, the UDC responds with the data

requested. If you write configuration or override data into a UDC, the

UDC responds with a Busy message (0082xx). The host should send a

Ready message at which time the UDC will respond with a status of the

write transaction. Communication with a single UDC should not be faster

than 1/3 second.

Until the UDC completes processing of the data, any subsequent valid

message received is answered with a busy response.

20 RS422/485 ASCII Communications Option Product Manual 5/99

Page 35

3.4 Request Messages

What is a request

message?

Your computer queries a controller and indicates the communication

function, or operation, that the controller should perform by sending a

request message. Request messages are composed of standard fields,

separated by commas. Each field contains a certain kind of information,

which you must enter in order to have a valid request message.

Request message

fields

Figure 3-2 shows the request message fields and the selections that may be

entered into each field. Table 3-4 lists these selections and their

definitions.

Figure 3-2 Request Message Fields

,,,, ,

Station

Address

A two digit device

address – 01 to 99

NOTE: Two loop

controllers will have an

address assigned to

each loop. Specify the

specific address for the

loop with which you

want to communicate.

Comma

Delimiter

required to separate fields

Protocol Field

4204 –

selects checksum

protocol

0204 –

ignores checksum

UDC Status (hexadecimal)—see matrix below

– REQUEST –

=

Single Byte Decimal – unsigned (digital configuration list) – for

11

Parameter codes 128 to 255

=

Single Byte Decimal – unsigned (extended

41

list) – for Parameter codes 128 to 158 in extended configuration

Oxford Floating Point (analog configuration list) – for Parameter

=

18

codes 001 to 125

Oxford Floating Point (extended

=

48

Parameter codes 001 to 021 in extended configuration

ASCII Text (Loopback only)

=

DD

ASCII Text (Analog configuration list for parameter

=

I D

I D Code #103 - Totalizer value (UDC6300, UDC 3300 only)

Data Type Field

CR LF

Checksum Field

HH=2-digit Hex

representing

Data Field

READ – Item no. only

WRITE – Item no., value

READY – 000

LOOPBACK – ASCII text

analog configuration list) – for

calculated checksum

digital configuration

UDC State and Mode

0 = Slave, Manual

2 = Slave, Toggle between LSP/RSP*

4 = Slave, Automatic

6 = Slave, No Change

E = Monitor, No Change

Change from RSP to LSP or LSP to RSP

*

READ only in Monitor Mode

**

READ and WRITE in Control Mode

Used after WRITE to verify data transaction

***

Protocol Class and Operation Code

4 = Configuration, Read**

5 = Configuration, Write**

6 = Configuration, Ready*** (only E6)

8 = Loopback (only E8)

P

r

o

t

o

c

Mode

SLAVE

MAN

SLAVE

TOGGLE

SLAVE

AUTO

SLAVE

NO CHNG

MON

NO CHNG

CONF

o

l

READ

00000100 00000101 00000110

04 05 06 X

00100100 00100101 00100110

24 25 26 X

01000100 01000101 01000110

44 45 46 X

01100100 01100101 01100110

64 65 66 68

11100100 11100110

CONF

WRITE

E4 X E6 E8

CONF

READY

LOOP

BACK

23083

5/99 RS422/485 ASCII Communications Option Product Manual 21

Page 36

3.4 Request Messages, Continued

Request message

field selections

Table 3-4 is a list of selections for the request message fields and their

definitions.

Table 3-4 Request Message Fields Definitions

Selection Definition

Station Address A two digit device address – from 01 to 99 – that

identifies the specific controller you are addressing. You

must assign a unique station address to each controller

on the link.

For a 2 Loop controller, two distinct addresses must be

configured. One address is used to designate Loop 1;

and one is used to designate Loop 2. Either address may

be used for transactions which are loop independent.

See "Preparing the Controller for Communications" in this

manual. A UDC will not respond to address 0 since the

address results in a disconnect.

Protocol Field A four digit number that selects whether or not you are

going to use a Checksum Protocol (for increased data

security) with your message exchange.

• 4204 selects Checksum Protocol

– see “Checksum Protocol”

UDC State and

Mode

Protocol Class and

Operation Code

• 0204 ignores Checksum Protocol

Any sequence utilizing other than 4 or 0 in the first digit

results in an error with an error message returned.

A hexadecimal number that determines what state you

want the UDC to be in (monitor or slave) and the mode of

operation desired (manual or automatic). You can also

change the controller setpoint from Local setpoint to

Remote setpoint or vice-versa.

ATTENTION

mode will not be indicated in the response until the next

transaction.

A hexadecimal number that allows you to do a Loopback

or do a READ, WRITE, or READY transaction.

Any change made in UDC State or Control

22 RS422/485 ASCII Communications Option Product Manual 5/99

Page 37

3.4 Request Messages, Continued

Request message

field selections,

continued

Table 3-4 Request Message Fields Definitions, Continued

Selection Definition

Data Type Field A two digit number that specifies the format, or data type,

of each of the parameters that can be accessed in the

UDC controller.

11 = Single Byte Decimal (unsigned) – used with

configuration protocol for digital parameter code

numbers 128 through 255.

41 = Single Byte Decimal (unsigned) – used with

configuration protocol of extended digital

parameter code numbers.

18 = Floating Point Format – used with configuration

protocol for analog parameters code numbers 001

through 125.

48 = Floating Point Format – used with configuration

protocol for extended analog parameter code

numbers.

DD = ASCII Text – Used with loopback protocol only.

I D = ASCII Text – Used with configuration protocol for

Analog Parameters ID Code #103 |

(UDC 6300, UDC 3300 only)

Data Field The data in this field is determined by the type of request:

• READ – three digit parameter code which identifies a

particular parameter for which you want to know the

value or selection.

• WRITE – three digit parameter code, which identifies a

particular parameter you want to change, a comma (,),

and the value or selection you want to enter.

• READY – three zero's (000) – used in conjunction with

a write request. Sent after a write request to verify that

the information transmitted was received.

• LOOPBACK – ASCII Text

Checksum Field

(Optional)

Carriage

Return/Line Feed

This field is a one byte hexadecimal value (two ASCII

characters) representing the binary sum, ignoring carries,

generated by adding the ASCII code for each character

in the message exchange, up to but not including the

checksum and the CR and LF characters.

• No Characters = No Checksum

• HH = two digit hexadecimal number representing the

calculated checksum

Terminates a message. The message will not be

exchanged unless used in this order (CR LF).

5/99 RS422/485 ASCII Communications Option Product Manual 23

Page 38

3.5 Response Messages

What is a response

message?

The response message tells your computer the present status of the

operation initiated by the request message. Response messages are

composed of standard fields, separated by commas.

Response message

fields

Each field contains a certain kind of information. Figure 3-3 indicates the

response message fields and lists the information that could be returned in

each field.

Figure 3-3 Response Message Fields Information

– RESPONSE –

,,

Request Message Status Code

00 =

Request message received successfully

01 =