Page 1

UDC3500

Universal Digital Controller

Product Manual

51-52-25-120

September 2006

Industrial Measurement and Control

Page 2

WARRANTY/REMEDY

Honeywell warrants goods of its manufacture as being free of defective materials and faulty

workmanship. Contact your local sales office for warranty information. If warranted goods are

returned to Honeywell during the period of coverage, Honeywell will repair or replace without charge

those items it finds defective. The foregoing is Buyer's sole remedy and is in lieu of all other

warranties, expressed or implied, including those of merchantability and fitness for a

particular purpose. Specifications may change without notice. The information we supply is

believed to be accurate and reliable as of this printing. However, we assume no responsibility for its

use.

While we provide application assistance personally, through our literature and the Honeywell web

site, it is up to the customer to determine the suitability of the product in the application.

Notices and Trademarks

Copyright 2006 by Honeywell

Revision 2

September 2006

Industrial Measurement and Control

Honeywell

1100 Virginia Drive

Fort Washington, PA 19034

UDC3500 is a U.S. registered trademark of Honeywell

Other brand or product names are trademarks of their respective owners.

9/06 UDC3500 Universal Digital Controller Product Manual ii

Page 3

About This Document

Abstract

This document provides descriptions and procedures for the Installation, Configuration, Operation, and Troubleshooting of

your UDC3500 Controller.

Contacts

World Wide Web

The following lists Honeywell’s World Wide Web sites that will be of interest to our customers.

Honeywell Organization WWW Address (URL)

Corporate http://www.honeywell.com

Industrial Measurement and Control http://www.honeywell.com/imc

Telephone

Contact us by telephone at the numbers listed below.

United States and Canada Honeywell 1-800-423-9883 Tech. Support

Organization Phone Number

1-800-525-7439 Service

Web

http://content.honeywell.com/ipc/faq/

9/06 UDC3500 Universal Digital Controller Product Manual iii

Page 4

Symbol Definitions

The following table lists those symbols used in this document to denote certain conditions.

Symbol Definition

This CAUTION symbol on the equipment refers the user to the Product Manual for

additional information. This symbol appears next to required information in the manual.

WARNING

PERSONAL INJURY: Risk of electrical shock. This symbol warns the user of a

potential shock hazard where HAZARDOUS LIVE voltages greater than 30 Vrms, 42.4

Vpeak, or 60 VDC may be accessible. Failure to comply with these instructions

could result in death or serious injury.

ATTENTION, Electrostatic Discharge (ESD) hazards. Observe precautions for

handling electrostatic sensitive devices

Protective Earth (PE) terminal. Provided for connection of the protective earth (green

or green/yellow) supply system conductor.

Functional earth terminal. Used for non-safety purposes such as noise immunity

improvement. NOTE: This connection shall be bonded to protective earth at the source

of supply in accordance with national local electrical code requirements.

Earth Ground. Functional earth connection. NOTE: This connection shall be bonded to

Protective earth at the source of supply in accordance with national and local electrical

code requirements.

Chassis Ground. Identifies a connection to the chassis or frame of the equipment shall

be bonded to Protective Earth at the source of supply in accordance with national and

local electrical code requirements.

9/06 UDC3500 Universal Digital Controller Product Manual iv

Page 5

Contents

1 INTRODUCTION ...................................................................................................1

1.1 Overview.........................................................................................................................................1

1.2 Operator Interface...........................................................................................................................6

1.2.1 Function of Displays and Keys............................................................................................7

1.3 Process Instrument Explorer Software............................................................................................8

1.4 CE Conformity (Europe)...............................................................................................................10

2 INSTALLATION...................................................................................................11

2.1 Overview.......................................................................................................................................11

2.2 Condensed Specifications.............................................................................................................13

2.3 Model Number Interpretation ....................................................................................................... 17

2.4 Control and Alarm Relay Contact Information.............................................................................19

2.5 Mounting.......................................................................................................................................20

2.6 Wiring...........................................................................................................................................22

2.6.1 Electrical Considerations ...................................................................................................22

2.7 Wiring Diagrams...........................................................................................................................24

3 CONFIGURATION...............................................................................................43

3.1 Overview.......................................................................................................................................43

3.2 Configuration Prompt Hierarchy ..................................................................................................45

3.3 Configuration Procedure...............................................................................................................48

3.4 Loop 1 Tuning Set Up Group .......................................................................................................49

3.5 Loop 2 Tuning Set Up Group .......................................................................................................53

3.6 SP Ramp Set Up Group ................................................................................................................56

3.7 Accutune Set Up Group................................................................................................................62

3.8 Algorithm Set Up Group...............................................................................................................67

3.9 Math Set Up Group.......................................................................................................................82

3.10 Logic Gates Set Up Group ........................................................................................................89

3.11 Output Set Up Group.................................................................................................................96

3.12 Input 1 Set Up Group ..............................................................................................................107

3.13 Input 2 Set Up Group ..............................................................................................................111

3.14 Input 3 Set Up Group ..............................................................................................................114

3.15 Input 4 Set Up Group ..............................................................................................................117

3.16 Input 5 Set Up Group ..............................................................................................................120

3.17 Control Set Up Group .............................................................................................................123

3.18 Control 2 Set Up Group ..........................................................................................................132

v UDC3500 Universal Digital Controller Product Manual 9/06

Page 6

3.19 Options Set Up Group.............................................................................................................139

3.20 Communications Set Up Group...............................................................................................150

3.21 Alarms Set Up Group..............................................................................................................154

3.22 Real Time Clock Set Up Group...............................................................................................162

3.23 Maintenance Set Up Group.....................................................................................................163

3.24 Display Set Up Group .............................................................................................................166

3.25 Read Maintenance Set Up Group............................................................................................168

3.26 Time Events Set Up Group .....................................................................................................169

3.27 P.I.E. Tool Ethernet and Email Configuration Screens...........................................................171

3.28 Configuration Record Sheet....................................................................................................174

4 MONITORING AND OPERATING THE CONTROLLER...................................181

4.1 Overview.....................................................................................................................................181

4.2 Operator Interface.......................................................................................................................182

4.3 Entering a Security Code ............................................................................................................182

4.4 Lockout Feature..........................................................................................................................183

4.5 Monitoring Your Controller........................................................................................................185

4.5.1 Annunciators....................................................................................................................185

4.5.2 Viewing the operating parameters....................................................................................186

4.5.3 Diagnostic Messages........................................................................................................187

4.6 Start Up Procedure for Operation ...............................................................................................188

4.7 Control Modes ............................................................................................................................189

4.7.1 Mode Definitions .............................................................................................................189

4.7.2 What happens when you change modes...........................................................................190

4.8 Setpoints......................................................................................................................................190

4.9 Timer...........................................................................................................................................192

4.10 Accutune III.............................................................................................................................193

4.10.1 Tune for Simplex Outputs............................................................................................195

4.10.2 Tune for Duplex (Heat/Cool) .......................................................................................196

4.10.3 Using AUTOMATIC TUNE at start-up for Duplex (Heat/Cool).................................197

4.10.4 Using BLENDED TUNE at start-up for Duplex (Heat/Cool)......................................198

4.10.5 Using MANUAL TUNE at start-up for Duplex (Heat/Cool).......................................199

4.10.6 ACCUTUNE Error Codes............................................................................................200

4.11 Fuzzy Overshoot Suppression.................................................................................................201

4.12 Using Two Sets of Tuning Constants......................................................................................202

4.13 Input Math Algorithms............................................................................................................204

4.14 Logic Gate Operation..............................................................................................................206

4.15 Digital Input Option (Remote Switching)...............................................................................208

4.16 Auto/Manual Station ...............................................................................................................213

4.17 Two Loops of Control.............................................................................................................217

4.18 Configuring Two Loops of Control.........................................................................................220

9/06 UDC3500 Universal Digital Controller Product Manual vi

Page 7

4.19 Monitoring Two Loops of Control..........................................................................................221

4.20 Operating Two Loops of Control............................................................................................222

4.21 Alarm Setpoints.......................................................................................................................222

4.22 Three Position Step Control Algorithm...................................................................................225

4.23 Setting a Failsafe Output Value for Restart After a Power Loss.............................................226

4.24 Setting Failsafe Mode..............................................................................................................227

4.25 Carbon Potential, Oxygen and Dewpoint Algorithms.............................................................227

4.26 Healthwatch.............................................................................................................................230

4.27 Setpoint Rate/Ramp/Program Overview.................................................................................230

4.28 Setpoint Rate ...........................................................................................................................231

4.29 Setpoint Ramp.........................................................................................................................231

4.30 Setpoint Ramp/Soak Programming.........................................................................................233

4.31 P.I.E. Tool Maintenance Screens ............................................................................................242

4.32 Configuring your Ethernet Connection...................................................................................252

5 INPUT CALIBRATION.......................................................................................257

5.1 Overview.....................................................................................................................................257

5.2 Minimum and Maximum Range Values.....................................................................................258

5.3 Preliminary Information..............................................................................................................260

5.4 Input Set Up Wiring ....................................................................................................................262

5.4.1 Thermocouple Inputs Using an Ice Bath..........................................................................262

5.4.2 Thermocouple Inputs Using a Thermocouple Source......................................................263

5.4.3 RTD Inputs.......................................................................................................................264

5.4.4 Radiamatic, Millivolts, Volts, Carbon, Oxygen or Thermocouple Differential Inputs....265

5.4.5 0 to 10 Volts or –1 to 1 Volts...........................................................................................267

5.4.6 Milliamperes ....................................................................................................................268

5.4.7 Dual High Level Voltage Inputs......................................................................................269

5.4.8 Dual High Level Milliamperes Inputs..............................................................................270

5.5 Input Calibration Procedure........................................................................................................271

5.6 Restore Input Factory Calibration...............................................................................................273

6 OUTPUT CALIBRATION...................................................................................275

6.1 Overview.....................................................................................................................................275

6.2 First Current Output Calibration.................................................................................................276

6.3 Second Current Output Calibration.............................................................................................278

6.4 Third Current Output Calibration ...............................................................................................280

6.5 Position Proportional and Three Position Step Output Calibration............................................282

6.6 Restore Factory Output Calibration............................................................................................285

7 TROUBLESHOOTING/SERVICE......................................................................287

7.1 Overview.....................................................................................................................................287

vii UDC3500 Universal Digital Controller Product Manual 9/06

Page 8

7.2 Troubleshooting Aids..................................................................................................................288

7.3 Power-up Tests............................................................................................................................290

7.4 Status Tests .................................................................................................................................290

7.5 Background Tests and Diagnostic Messages..............................................................................291

7.6 Controller Failure Symptoms......................................................................................................296

7.7 Troubleshooting Procedures .......................................................................................................297

7.7.1 Procedure #1 – Power ......................................................................................................298

7.7.2 Procedure #2 – Current Outputs.......................................................................................298

7.7.3 Procedure #3 – Position Proportional ..............................................................................300

7.7.4 Procedure #4 – Time Proportional...................................................................................303

7.7.5 Procedure #5 – Current/Time or Time Current/Proportional ...........................................304

7.7.6 Procedure #6 – Alarm Relays ..........................................................................................305

7.7.7 Procedure #7 – Keyboard.................................................................................................306

7.7.8 Procedure #8 – Analog Input ...........................................................................................307

7.7.9 Procedure #9 – RS-485....................................................................................................308

7.7.10 Procedure #10 – Ethernet .............................................................................................310

7.7.11 Procedure #11 – Email .................................................................................................311

7.8 Restoring Factory Configuration ................................................................................................312

7.9 Software Upgrades......................................................................................................................313

8 PARTS LIST......................................................................................................315

8.1 Exploded View............................................................................................................................315

8.2 Removing the chassis..................................................................................................................317

9 MODBUS RTU FUNCTION CODES..................................................................318

9.1 Overview.....................................................................................................................................318

9.2 General Information....................................................................................................................318

9.3 Function Code 20 (14h) - Read Configuration Reference Data..................................................320

9.3.1 Read Configuration Examples .........................................................................................322

9.4 Function Code 21 (15h) - Write Configuration Reference Data.................................................324

9.4.1 Write Configuration Examples ........................................................................................326

10 MODBUS READ, WRITE AND OVERRIDE PARAMETERS PLUS EXCEPTION

CODES........................................................................................................................327

10.1 Overview.................................................................................................................................327

10.2 Reading Control Data..............................................................................................................330

10.3 Read Software Options Status.................................................................................................331

10.4 Miscellaneous Read Onlys......................................................................................................332

10.4.1 Register Addresses for Read Onlys..............................................................................332

10.4.2 SetPoint Program Read Only Information....................................................................332

10.5 Setpoints..................................................................................................................................333

10.6 Using a Computer Setpoint (Overriding Controller Setpoint) ................................................335

9/06 UDC3500 Universal Digital Controller Product Manual viii

Page 9

10.7 Configuration Parameters........................................................................................................338

10.7.1 Tuning Loop 1..............................................................................................................338

10.7.2 Tuning Loop2...............................................................................................................340

10.7.3 SP Ramp/Rate/Program................................................................................................341

10.7.4 Accutune.......................................................................................................................348

10.7.5 Algorithm .....................................................................................................................350

10.7.6 Math..............................................................................................................................355

10.7.7 Logic.............................................................................................................................358

10.7.8 Output Algorithms........................................................................................................362

10.7.9 Input 1...........................................................................................................................364

10.7.10 Input 2...........................................................................................................................366

10.7.11 Input 3...........................................................................................................................368

10.7.12 Input 4...........................................................................................................................370

10.7.13 Input 5...........................................................................................................................372

10.7.14 Control..........................................................................................................................374

10.7.15 Control Loop 2 .............................................................................................................377

10.7.16 Options .........................................................................................................................380

10.7.17 Communications...........................................................................................................384

10.7.18 Alarms ..........................................................................................................................386

10.7.19 Maintenance .................................................................................................................391

10.7.20 Time Event ...................................................................................................................394

10.7.21 Display..........................................................................................................................396

10.7.22 Clock ............................................................................................................................397

10.8 Modbus RTU Exception Codes...............................................................................................398

11 FURTHER INFORMATION................................................................................400

11.1 Modbus RTU Serial Communications ....................................................................................400

11.2 Modbus Messaging on Ethernet TCP/IP.................................................................................400

11.3 How to Apply Digital Instrumentation in Severe Electrical Noise Environments..................400

12 INDEX................................................................................................................401

13 SALES AND SERVICE......................................................................................406

ix UDC3500 Universal Digital Controller Product Manual 9/06

Page 10

Tables

Table 2-1 Condensed Specifications ____________________________________________________ 13

Table 2-2 Control Relay Contact Information _____________________________________________ 19

Table 2-3 Alarm Relay Contact Information ______________________________________________ 19

Table 2-4 Mounting Procedure _________________________________________________________ 21

Table 2-5 Permissible Wiring Bundling__________________________________________________ 23

Table 2-6 Single or Cascade Loop Controller – Loop 1 Output Functionality and Restrictions _______ 25

Table 2-7 Dual Loop Controller – Loop 2 Output Functionality and Restrictions __________________ 26

Table 2-8 Terminals for connecting a UDC to a MDI Compliant Hub or Switch utilizing a cross-over cable

______________________________________________________________________________ 39

Table 2-9 Terminals for connecting a UDC directly to a PC utilizing a straight-through cable________ 40

Table 3-1 Configuration Topics ________________________________________________________ 43

Table 3-2 Configuration Prompt Hierarchy _______________________________________________ 45

Table 3-3 Configuration Procedure _____________________________________________________ 48

Table 3-4 TUNING Group Function Prompts _____________________________________________ 49

Table 3-5 TUNING 2 Group Function Prompts____________________________________________ 53

Table 3-6 SPRAMP Group Function Prompts_____________________________________________ 56

Table 3-7 ACCUTUNE Group Function Prompts__________________________________________ 63

Table 3-8 ALGORTHM Group Function Prompts _________________________________________ 67

Table 3-9 MATH Group Function Prompts_______________________________________________ 82

Table 3-10 LOGIC Group Function Prompts ______________________________________________ 89

Table 3-11 OUTPUT Group Function Prompts ____________________________________________ 96

Table 3-12 INPUT 1 Group Function Prompts ___________________________________________ 107

Table 3-13 INPUT 2 Group Function Prompts ___________________________________________ 111

Table 3-14 INPUT 3 Group Function Prompts ___________________________________________ 114

Table 3-15 INPUT 4 Group Function Prompts ___________________________________________ 117

Table 3-16 INPUT 5 Group Function Prompts ___________________________________________ 120

Table 3-17 CONTROL Group Function Prompts__________________________________________ 123

Table 3-18 CONTROL2 Group Function Prompts_________________________________________ 132

Table 3-19 OPTION Group Function Prompts ___________________________________________ 139

Table 3-20 Communications Group Function Prompts _____________________________________ 150

Table 3-21 ALARMS Group Function Prompts __________________________________________ 155

Table 3-22 CLOCK Group Function Prompts ____________________________________________ 162

Table 3-23 MAINTENANCE Group Function Prompts ____________________________________ 163

Table 3-24 DISPLAY Group Function Prompts __________________________________________ 166

Table 3-25 READ MAINTENANCE Group Function Prompts ______________________________ 168

Table 3-26 TIME EVT Group Function Prompts _________________________________________ 169

Table 3-27 Configuration Record Sheet _________________________________________________ 174

Table 4-1 Procedure to Enter a Security Code____________________________________________ 183

Table 4-2 Annunciators _____________________________________________________________ 185

Table 4-3 Lower Display Key Parameter Prompts_________________________________________ 186

Table 4-4 Procedure for Starting Up the Controller________________________________________ 188

Table 4-5 Control Mode Definitions ___________________________________________________ 189

Table 4-6 Changing Control Modes____________________________________________________ 190

Table 4-7 Procedure for Changing the Local Setpoints _____________________________________ 191

Table 4-8 Procedure for Switching Between Setpoints _____________________________________ 191

Table 4-9 Procedure for Starting “TUNE”_______________________________________________ 195

Table 4-10 Procedure for Using AUTOMATIC TUNE at Start-up for Duplex Control ____________ 197

Table 4-11 Procedure for Using BLENDED TUNE at Start-up for Duplex Control _______________ 198

9/06 UDC3500 Universal Digital Controller Product Manual x

Page 11

Table 4-12 Procedure for Using MANUAL TUNE for Heat side of Duplex Control ______________ 199

Table 4-13 Procedure for Using MANUAL TUNE for Cool side of Duplex Control______________ 199

Table 4-14 Procedure for Accessing Accutune Error Codes _________________________________ 200

Table 4-15 Accutune Error Codes _____________________________________________________ 200

Table 4-16 Set Up Procedure _________________________________________________________ 202

Table 4-17 Procedure for Switching PID SETS from the Keyboard ___________________________ 203

Table 4-18 Logic Gates Constraints and Dynamic Operation Status___________________________ 206

Table 4-19 Digital Input Option Action on Contact Closure _________________________________ 208

Table 4-20 Digital Input Combinations “DIG IN1” or “DIG IN2” ____________________________ 211

Table 4-21 Digital Inputs 1 and 2 Combination___________________________________________ 212

Table 4-22 Auto/Manual Station Mode Configuration Procedure_____________________________ 214

Table 4-23 Procedure for selecting Two Loop Algorithm ___________________________________ 220

Table 4-24 Digital Display Indication—Two Loops _______________________________________ 221

Table 4-25 Procedure for Displaying Alarm Setpoints _____________________________________ 223

Table 4-26 Procedure for Displaying TPSC Motor Position _________________________________ 225

Table 4-27 Procedure for Setting a Failsafe Value_________________________________________ 226

Table 4-28 Procedure for Setting a Failsafe Mode_________________________________________ 227

Table 4-29 Running A Setpoint Ramp__________________________________________________ 232

Table 4-30 Program Contents_________________________________________________________ 234

Table 4-31 Run/Monitor Functions ____________________________________________________ 240

Table 5-1 Voltage, Milliamp and Resistance Equivalents for Input Range Values _______________ 258

Table 5-2 Equipment Needed_________________________________________________________ 260

Table 5-3 Set Up Wiring Procedure for Thermocouple Inputs Using an Ice Bath ________________ 262

Table 5-4 Set Up Wiring Procedure for Thermocouple Inputs using a Thermocouple Source _______ 263

Table 5-5 Set Up Wiring Procedure for RTD Inputs _______________________________________ 264

Table 5-6 Set Up Wiring Procedure for Radiamatic, Millivolts, Volts, Carbon, Oxygen or Thermocouple

Differential Inputs (Except 0-10 Volts and –1 to 1 Volts)________________________________ 265

Table 5-7 Procedure to determine calibration voltages for Thermocouple Differential input types other than the

Factory Setting_________________________________________________________________ 266

Table 5-8 Set Up Wiring Procedure for 0 to 10 Volts or –1 to 1 Volts _________________________ 267

Table 5-9 Set Up Wiring Procedure for Milliampere Inputs _________________________________ 268

Table 5-10 Set Up Wiring Procedure for Dual High Level Voltage Inputs______________________ 269

Table 5-11 Set Up Wiring Procedure for Dual High Level Milliampere Inputs __________________ 270

Table 5-12 Input Calibration Procedure _________________________________________________ 271

Table 5-13 Restore Factory Calibration _________________________________________________ 273

Table 6-1 Set Up Wiring Procedure for the First Current Output _____________________________ 276

Table 6-2 First Current Output Calibration Procedure______________________________________ 277

Table 6-3 Set Up Wiring Procedure for the Second Current Output ___________________________ 278

Table 6-4 Second Current Output Calibration Procedure ___________________________________ 279

Table 6-5 Set Up Wiring Procedure for the Third Current Output ____________________________ 280

Table 6-6 Third Current Output Calibration Procedure _____________________________________ 281

Table 6-7 Position Proportional and Three Position Step Output Calibration Procedure ___________ 283

Table 6-8 Restore Factory Calibration __________________________________________________ 285

Table 7-1 Procedure for Identifying the Software Version __________________________________ 289

Table 7-2 Procedure for Displaying the Status Test Results _________________________________ 290

Table 7-3 Background Tests__________________________________________________________ 291

Table 7-4 Controller Failure Symptoms_________________________________________________ 296

Table 7-5 Troubleshooting Power Failure Symptoms ______________________________________ 298

Table 7-6 Troubleshooting Current Output Failure ________________________________________ 298

Table 7-7 Troubleshooting Position Proportional Output Failure _____________________________ 300

xi UDC3500 Universal Digital Controller Product Manual 9/06

Page 12

Table 7-8 Troubleshooting Time Proportional Output Failure _______________________________ 303

Table 7-9 Troubleshooting Current/Time or Time/Current Proportional Output Failure ___________ 304

Table 7-10 Troubleshooting Alarm Relay Output Failure ___________________________________ 305

Table 7-11 Troubleshooting a Keyboard Failure __________________________________________ 306

Table 7-12 Troubleshooting an Analog Input Failure ______________________________________ 307

Table 7-13 Troubleshooting a RS-485 Communications Failure______________________________ 308

Table 7-14 Troubleshooting an Ethernet Communications Failure ____________________________ 310

Table 7-15 Troubleshooting an Email Failure ____________________________________________ 311

Table 7-16 Restoring Factory Configuration _____________________________________________ 312

Table 7-17 Software Upgrades________________________________________________________ 313

Table 8-1 Parts Identification_________________________________________________________ 316

Table 8-2 Parts Not Shown___________________________________________________________ 316

Table 8-3 Software Upgrades (see Section 7.9)___________________________________________ 317

Table 9-1 Integer Parameter Type _____________________________________________________ 319

Table 9-2 Floating Point Parameter Type________________________________________________ 319

Table 9-3 Register Parameter ID Address Format for Function Code 20 _______________________ 321

Table 9-4 Register Parameter ID Address Format for Function Code 21 _______________________ 325

Table 10-1 Control Data Parameters ___________________________________________________ 330

Table 10-2 Option Status ____________________________________________________________ 331

Table 10-3 Miscellaneous Read Onlys__________________________________________________ 332

Table 10-4 SetPoint Program Read Only Information______________________________________ 332

Table 10-5 Setpoint Code Selections ___________________________________________________ 333

Table 10-6 Setpoint Associated Parameters______________________________________________ 334

Table 10-7 Computer Setpoint Selection ________________________________________________ 335

Table 10-8 Computer Setpoint Associated Parameters for Loop 1 ____________________________ 336

Table 10-9 Computer Setpoint Associated Parameters for Loop2_____________________________ 337

Table 10-10 Set-up Group – Tuning Loop 1 _____________________________________________ 338

Table 10-11 Set-up Group – Tuning Loop 2______________________________________________ 340

Table 10-12 Set-up Group – Setpoint Ramp/Rate _________________________________________ 341

Table 10-13 Set-up Group – Adaptive Tune _____________________________________________ 348

Table 10-14 Set-up Group – Algorithm _________________________________________________ 350

Table 10-15 Set-up Group – Math _____________________________________________________ 355

Table 10-16 Set-up Group – Logic_____________________________________________________ 358

Table 10-17 Set-up Group – Output Algorithms __________________________________________ 362

Table 10-18 Set-up Group – Input 1____________________________________________________ 364

Table 10-19 Set-up Group – Input 2____________________________________________________ 366

Table 10-20 Set-up Group – Input 3____________________________________________________ 368

Table 10-21 Set-up Group – Input 4____________________________________________________ 370

Table 10-22 Set-up Group – Input 5____________________________________________________ 372

Table 10-23 Set-up Group – Control ___________________________________________________ 374

Table 10-24 Set-up Group – Control2 __________________________________________________ 377

Table 10-25 Set-up Group – Options ___________________________________________________ 380

Table 10-26 Set-up Group – Communications____________________________________________ 384

Table 10-27 Set-up Group – Alarms ___________________________________________________ 386

Table 10-28 Set-up Group – Maintenance _______________________________________________ 391

Table 10-29 Set-up Group – Time Event________________________________________________ 394

Table 10-30 Set-up Group – Display ___________________________________________________ 396

Table 10-31 Set-up Group – Clock ____________________________________________________ 397

Table 10-32 Modbus RTU Data Layer Status Exception Codes ______________________________ 399

9/06 UDC3500 Universal Digital Controller Product Manual xii

Page 13

Figures

Figure 1-1 UDC3500 Operator Interface __________________________________________________ 6

Figure 1-2 Screen capture of Process Instrument Explorer running on a Pocket PC_________________ 8

Figure 1-3 Depiction of infrared communications ___________________________________________ 9

Figure 2-1 Model Number Interpretation_________________________________________________ 18

Figure 2-2 Mounting Dimensions (not to scale)____________________________________________ 20

Figure 2-3 Mounting Methods _________________________________________________________ 21

Figure 2-4 Composite Wiring Diagram___________________________________________________ 27

Figure 2-5 Mains Power Supply ________________________________________________________ 28

Figure 2-6 Input 1 Connections_________________________________________________________ 29

Figure 2-7 Input 2 Connections_________________________________________________________ 30

Figure 2-8 Input 3 Connections_________________________________________________________ 31

Figure 2-9 HLAI Inputs 2 and 4 Connections______________________________________________ 32

Figure 2-10 HLAI Inputs 3 and 5 Connections_____________________________________________ 33

Figure 2-11 Optional Analog Input Jumper Positions________________________________________ 33

Figure 2-12 First Current Output________________________________________________________ 34

Figure 2-13 Second Current Output _____________________________________________________ 34

Figure 2-14 Output #2 – Electromechanical Relay Output____________________________________ 35

Figure 2-15 Output #2 – Solid State Relay Output __________________________________________ 35

Figure 2-16 Output #2 – Open Collector Output- Third ______________________________________ 36

Figure 2-17 Output #2 – Third Current Output_____________________________________________ 36

Figure 2-18 Output #2 – Dual Relay Output for Time Duplex_________________________________ 37

Figure 2-19 Output #2 – Dual Relay Output for Position Proportional or Three Position Step Control _ 37

Figure 2-20 RS-422/485 Communications Option Connections________________________________ 38

Figure 2-21 Ethernet Communications Option with Adaptor Board_____________________________ 38

Figure 2-22 Ethernet Communications Option without Adaptor Board __________________________ 39

Figure 2-23 Digital Inputs_____________________________________________________________ 40

Figure 2-24 Optional Electromechanical Relay Outputs______________________________________ 41

Figure 2-25 Transmitter Power for 4-20 mA — 2 wire Transmitter Using Open Collector Output_____ 41

Figure 2-26 Transmitter Power for 4-20 mA — 2 Wire Transmitter Using Second Current Output ____ 42

Figure 3-1 Mass Flow Example ________________________________________________________ 80

Figure 3-2 Example of Eight Segment Characterizer________________________________________ 88

Figure 3-3 Ethernet Configuration Screen _______________________________________________ 171

Figure 3-4 Email Configuration Screen _________________________________________________ 172

Figure 4-1 Operator Interface_________________________________________________________ 182

Figure 4-2 Auto/Manual Station_______________________________________________________ 213

Figure 4-3 Functional Overview Block Diagram of a Single Loop (Loop #1) or Dual Loop Controller (Loop #1

and Loop #2) __________________________________________________________________ 218

Figure 4-4 Functional Overview Block Diagram of Internal Cascade Controller _________________ 219

Figure 4-5 Hi/Lo Override Selector ____________________________________________________ 220

Figure 4-6 Carbon Potential Control ___________________________________________________ 229

Figure 4-7 Ramp/Soak Profile Example_________________________________________________ 237

Figure 4-8 Program Record Sheet _____________________________________________________ 238

Figure 4-9 Loop Data Maintenance Screen ______________________________________________ 242

Figure 4-10 Alarm Details Maintenance Screen __________________________________________ 243

Figure 4-11 Status Data Maintenance Screen_____________________________________________ 245

Figure 4-12 Diagnostic History Maintenance Screen_______________________________________ 246

Figure 4-13 Ethernet Status Maintenance Screen__________________________________________ 247

Figure 4-14 Healthwatch Data Maintenance Screen _______________________________________ 248

xiii UDC3500 Universal Digital Controller Product Manual 9/06

Page 14

Figure 4-15 Healthwatch Data Reset Screen _____________________________________________ 249

Figure 4-16 Totalizer Maintenance Screen ______________________________________________ 250

Figure 4-17 Real Time Clock Maintenance Screen ________________________________________ 251

Figure 4-18 IR Communications Address _______________________________________________ 252

Figure 4-19 Configuration Upload in Progress ___________________________________________ 253

Figure 4-20 Ethernet Communications Address __________________________________________ 255

Figure 4-21 Configuration Upload in Progress ___________________________________________ 256

Figure 5-1 Input Wiring Terminals ____________________________________________________ 260

Figure 5-2 Wiring Connections for Thermocouple Inputs Using an Ice Bath ____________________ 262

Figure 5-3 Wiring Connections for Thermocouple Inputs Using a Thermocouple Source __________ 263

Figure 5-4 Wiring Connections for RTD (Resistance Thermometer Device) ____________________ 264

Figure 5-5 Wiring Connections for Radiamatic, Millivolts, Volts, Carbon, Oxygen or

Thermocouple Differential Inputs (Except 0-10 Volts and –1 to 1 Volts)____________________ 265

Figure 5-6 Wiring Connections for 0 to 10 Volts or –1 to 1 Volts_____________________________ 267

Figure 5-7 Wiring Connections for Milliampere Inputs_____________________________________ 268

Figure 5-8 Wiring Connections for Dual High Level Voltage Inputs __________________________ 269

Figure 5-9 Wiring Connections for Dual High Level Milliampere Inputs_______________________ 270

Figure 6-1 Wiring Connections for Calibrating the First Current Output _______________________ 276

Figure 6-2 Wiring Connections for Calibrating the Second Current Output _____________________ 278

Figure 6-3 Wiring Connections for Calibrating Third Current Output _________________________ 280

Figure 8-1 UDC3500 Exploded View __________________________________________________ 315

Figure 10-1 Software Option Status Information__________________________________________ 331

9/06 UDC3500 Universal Digital Controller Product Manual xiv

Page 15

1.1 Overview

Function

The UDC3500 is a microprocessor-based stand-alone controller. It combines a high

degree of functionality and operating simplicity in a 1/4 DIN size controller. This

instrument is an ideal controller for regulating temperature and other process variables in

numerous heating and cooling applications, as well as in metal working, food,

pharmaceuticals, semiconductor, testing and environmental work.

The UDC3500 monitors and controls temperatures and other variables in applications

such as environmental chambers, plastic processing machines, furnaces and ovens, and

packaging machinery.

Features

Introduction

1 Introduction

• 3 Universal Analog Inputs (can be configured to act as one Universal and four High

Level)

• ± 0.10% Analog Input Accuracy (can be Field Calibrated to ± 0.05%)

• 16-bit Analog Input resolution typical

• Fast scanning rate (166ms)

• Up to 7 Analog and Digital Outputs

• 4 Digital Inputs

• Two Math Functions, two Characterizers, one Polynomial equation and one

Totalizer available

• Two Independent Loops or Cascade Loop

• Ethernet TCP/IP with Email or RS-485 Modbus communication

• Infrared PC & Pocket PC configuration

• NEMA4X and IP66 front face protection

• Multilanguage prompts

• ¼ DIN Size

• Easily Field Upgradeable

Easy to read displays

Bright, dual displays with multi-language prompts (in English, French, German, Spanish,

or Italian) make the operator interface easy to read, understand, and operate. Simple

keystrokes let you set operating parameters that meet your process control needs.

9/06 UDC3500 Universal Digital Controller Product Manual 1

Page 16

Introduction

Analog Inputs

The UDC3500 has three universal analog inputs with a typical accuracy of ±0.10% of

full-scale input and a typical resolution of 16 bits. These can be configured to act as one

Universal and four High Level Inputs for a total of five analog inputs. All analog inputs

are sampled six times per second (every 166 ms).

The Process Variable input can be one of the various thermocouple, RTD, Radiamatic or

linear actuations. Linear actuations have thermocouple, RTD, and Radiamatic transmitter

characterization capability as a standard feature. Linear actuations also have square root

capability.

The optional second and third inputs are isolated from each other and all other inputs and

outputs and accept the same actuations as input one. Input 3 provides the Slidewire input

for Position Proportional control. These optional inputs can each be split into two high

level inputs. The fourth input is enabled by first configuring Input 2 as a 20 mA or 5 Vdc

type (high level) input and moving a jumper on the Second Optional Input Board. Input 4

will then be available as a high level input. The fifth input is enabled by first configuring

Input 3 as a 20 mA or 5 Vdc type (high level) and moving a jumper on the Third Optional

Input Board. Input 5 will then be available as a high level input.

All actuations and characterizations are keyboard configurable. Cold junction

compensation is provided for thermocouple type inputs. Upscale, downscale or failsafe

sensor break protection is keyboard configurable. A configurable digital filter of 0 to 120

seconds provides input signal damping.

Thermocouple Health—In addition to the standard configurable upscale, downscale or

failsafe output burnout selections, the condition of the thermocouple can be monitored to

determine if it is good, failing or in danger of imminent failure.

Math Functions

Algorithm—Two pre-configured algorithms are available for easy implementation. This

includes the capability of using a Ratio and Bias with any input. You can select from the

following menu:

Feedforward Summer—Uses any input, followed by a Ratio/Bias calculation, summed

directly with the computed PID output value to provide a resultant output to the final

control element (standard feature).

Weighted Average —Computes the weighted average of a PV or SP for the control

algorithm from two inputs (standard feature).

Feedforward Multiplier—Uses any input, multiplied by the calculated PID output to

provide a resultant output, which is sent to the final control element (standard feature).

Summer/Subtractor—Will add or subtract inputs with the result used as the derived PV.

Multiplier/Divider—Uses the analog inputs to calculate a derived PV. It is available

with or without Square Root.

Input High/Low Select—Specifies the PV input as the higher or lower of two inputs.

2 UDC3500 Universal Digital Controller Product Manual 9/06

Page 17

8 Segment Characterizers—Two characterizers are available that can be applied to any

Analog Input, to Loop 1 Output or to Loop 2 Output. The Characterizers can be

combined to produce a single 16-segment characterizer.

Totalizer—Calculates and displays the total flow volume as measured by any of the

analog inputs or as derived by either Math algorithm. Displayed value is eight digits with

a configurable scaling factor. The totalizer value may be reset.

Combinational Inputs—Inputs can be combined for use with Relative Humidity, %

Oxygen, Carbon Potential, Dewpoint or Math Algorithms. This controller can accept

carbon probes from Cambridge, Marathon Monitors, Corning, A.A.A.C, Barber

Coleman, MacDhui, Bricesco or Furnace Controls.

Polynomial Curve Characterizer—A fifth order polynomial equation can be used on

any one of the analog inputs.

Logic Gates—Five Logic Gates configurable as OR, NOR, AND, NAND, XOR, XNOR,

or COMPARATOR. Each Gate has two inputs and one output. The Gates may be linked

together to perform more complex functions.

Digital Inputs

Introduction

Four isolated digital inputs are provided for remote dry contact closure to select one of 25

actions. Also, two of these digital inputs can allow one of six additional selections to be

combined with one of the above selections.

Outputs

Output Types - The UDC3500 may have up to seven of the following outputs:

Alarms

Up to four electromechanical alarm relays are available to activate external equipment

when preset alarm setpoints are reached. Each of the four alarms can be set to monitor

two independent setpoints. Each alarm setpoint can be either high or low alarm. The

alarm type can be selected to be either of the inputs, the Process Variable, Deviation,

Output, Shed from communications, PV rate of change, or to alarm on manual mode

activation or a Current Output Open failure. It can also be used as an On or Off event at

the beginning or end of a Ramp/Soak segment. An individual alarm hysteresis setting is

provided for each relay and these are configurable from 0 to 100% of range.

• Current Outputs (4-20 or 0-20 mA)

• Electromechanical Relays (5 amps)

• Solid State Relay (1 amp)

• Dual Electromechanical Relays (2 amps)

• Open Collector Output (+30 VDC @ 20 mA)

• Alarms can be configured as latching or non-latching.

9/06 UDC3500 Universal Digital Controller Product Manual 3

Page 18

Introduction

• Alarm blocking is also available which allows start-up without alarm energized

until after it first reaches the operating region.

• PV rate of change alarm.

• Loop break alarm.

• Timer output reset.

• Diagnostic Alarm

Communications

A communications link is provided between the UDC3500 and a host computer or PLC

via the RS422/485 Modbus® RTU or Ethernet TCP/IP * communications option. An

infrared communication link is also available allowing a non-intrusive configuration of

the instrument.

Miscellaneous Features

Auxiliary Output * (optional)—All of the three current outputs can function as Auxiliary

Outputs which can be scaled from 4-20 ma for 0 to 100% for any range. These can be

configured to represent any analog input, PV, active Setpoint, Local SP1, Deviation, or

the Control Output for either control loop.

Transmitter Power—This feature provides up to 30 volts dc to power a 2-wire transmitter (requires the use of open collector output selection or one of the current outputs).

Four Local and one Remote Setpoints—Can be configured to provide four Local and

one Remote Setpoints, which are selectable either via the keyboard or by Digital Input.

Universal Switching Power—Operates on any line voltage from 90 to 264 Vac 50/60 Hz

without jumpers. 24 Vac/dc instrument power is available as an option.

Timer—This standard feature provides a configurable time period of 0 to 99 hours, 59

minutes or units of minutes and seconds. It can be started via the keyboard, alarm 2, or by

a digital input. The timer output is Alarm 1, which energizes at the end of the Timer

Period. Alarm 1 can be automatically reset. The Timer Period can be changed between

each batch. Status is shown on the lower display.

Healthwatch—Consists of three timers and three counters, which can each be assigned to

track UDC3500 controller functions. Selected Maintenance & Diagnostic data can be

accessed from the front panel or via communications. Alarms can be configured to

activate when a desired threshold is reached. A security code is required to perform

resetting of any of the above listed counter or timer functions.

Real Time Clock—An optional battery-backed clock feature that allows the user to

perform such things as starting an SP Program on a specific date and time.

Auto/Manual Station Plus Back-up Control—A UDC3500 can act as both an

Auto/Manual Station PLUS as a back-up PID Controller, should the primary loop

controller fail. Since the PID control is sometimes implemented via a PLC, this feature

provides a very cost-effective way to insure the process does not have to shutdown or

4 UDC3500 Universal Digital Controller Product Manual 9/06

Page 19

Introduction

remain in manual mode if the PLC should fail. Switching from the Auto/Manual Station

to the back-up control mode is accomplished using the Digital Input option.

Moisture Protection—The NEMA4X and IP66 rated front face permits use in

applications where it may be subjected to moisture, dust, or hose-down conditions. UL

and CSA approved as Type 4 protection.

Setpoint Ramp/Soak Programming (Optional)—Enables you to program and store ten

Ramp and ten Soak segments (total of twenty segments) for setpoint programming. Run

or Hold of program is keyboard or remote digital switch selectable.

Setpoint Rate—Lets you define a ramp rate to be applied to any local setpoint change. A

separate upscale or downscale rate is configurable. A single setpoint ramp is also

available as an alternative.

Output Rate Limiter—A maximum output rate may be configured for both the upscale

and the downscale output directions.

CE Mark—Conformity with 73/23/EEC, Low Voltage Directive and 89/336/EEC, the

EMC Directive as a standard feature.

Approval Body Options—CSA certification and UL listing are available as an option.

Four Sets of Tuning Constants—Four sets of PID parameters can be configured for each

loop and automatically or keyboard selected.

Data Security—Five levels of keyboard security protect tuning, configuration, and

calibration data, accessed by a configurable 4-digit code. Nonvolatile EEPROM memory

assures data integrity during loss of power.

Diagnostic/Failsafe Outputs—Continuous diagnostic routines detect failure modes,

trigger a failsafe output value and identify the failure to minimize troubleshooting time.

High Noise Immunity—The controller is designed to provide reliable, error-free

performance in industrial environments that often affect highly noise-sensitive digital

equipment.

Accutune III™ —This standard feature provides a truly plug and play tuning algorithm,

which will, at the touch of a button or through a digital input, accurately identify and tune

any process including those with deadtime and integrating processes. This speeds up and

simplifies start-up plus allows retuning at any setpoint. The algorithm used is an

TM

improved version of the Accutune II

algorithm found on earlier controllers. Two

possibilities are now offered when tuning your process: Fast Tune and Slow Tune.

Fast Tune will tune the process in such a way that the temp is reached faster, a

slight overshoot will be allowed.

Slowtune will minimize overshoot, but it will take more time for the process

temperature to reach the target setpoint.

Heat/Cool (Duplex Tune) will automatically tune both the heating and cooling

sides of the process.

9/06 UDC3500 Universal Digital Controller Product Manual 5

Page 20

Introduction

Fuzzy Logic—This standard feature uses fuzzy logic to suppress process variable

overshoot due to SP changes or externally induced process disturbances. It

operates independently from Accutune III™ tuning. It does not change the PID

constants, but temporarily modifies the internal controller response to suppress

overshoot. This allows more aggressive tuning to co-exist with smooth PV

response. It can be enabled or disabled depending on the application or the control

criteria.

* The Second Current Output option is mutually exclusive with the Ethernet

Communications option.

1.2 Operator Interface

Figure 1-1 UDC3500 Operator Interface

6 UDC3500 Universal Digital Controller Product Manual 9/06

Page 21

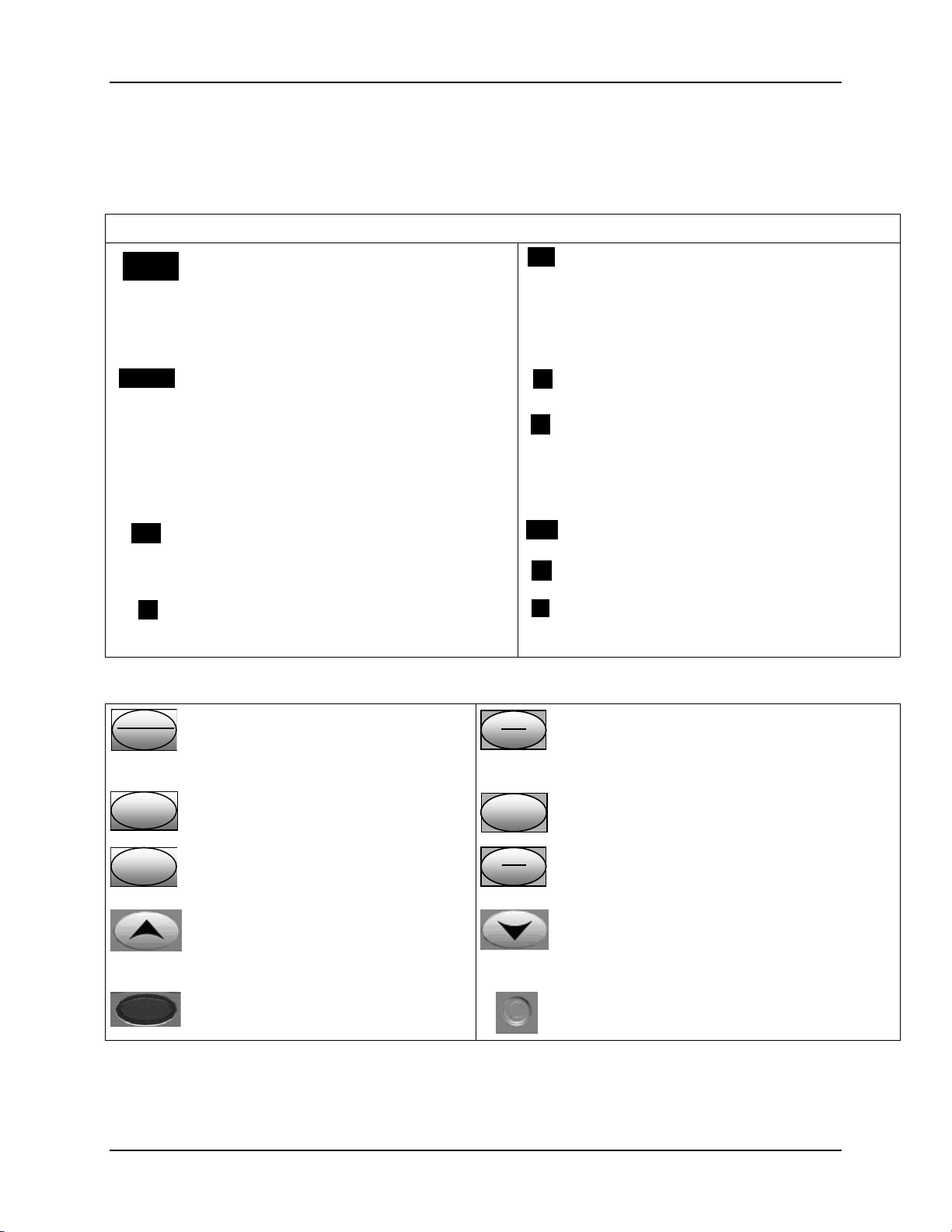

1.2.1 Function of Displays and Keys

Table 1-1 Function of Displays and Keys

Display Indicators

Introduction

3200

3500

SP 3500

SP

ALMALM

3200

DIDI

Upper display with 4 larger digits shows

Process Variable value (normal operation)

and special annunciator features. During

Configuration, the upper display provides

guidance for the operator through prompts (7

– characters)

During normal operation, the lower display

shows key-selected operating parameters

such as Output, Setpoints, Inputs, Deviation,

active Tuning Parameter Set, Timer Status, or

minutes remaining in a setpoint ramp (4

digits). During configuration, the lower display

provides guidance for the operator through

prompts (8-characters).

Indicates Alarm 1 and/or Alarm 2 conditions

exist.

Indicates Digital Input 1 and/or 2 on.

Keys and Functions

Indicates Control Relay 1 and/or 2 on.

OUT

FF

Or

Indicates either degrees Fahrenheit or

Centigrade.

CC

MAN

Or

Indicates either Manual or Auto mode.

AA

Indicates Local Setpoint #1. Also, a bar is

SPSP

lighted when the setpoint being used is shown

on the lower display.

Func

Loop 1/2

Selects functions within each

configuration group. Switches between

Loop Displays for Two Loop and

Man

Man

Man

Auto

Auto

Auto

Selects Manual or Auto mode.

Cascade units.

SetupSetup

Lower

Lower

Lower

Display

Display

Display

Scrolls through the configuration

groups.

Returns Controller to normal display

from Set Up mode. Toggles various

operating parameters for display.

Increases setpoint or output value.

Increases the configuration values or

changes functions in Configuration

mode groups.

Infrared transceiver

SP

SP

SP

Select

Select

Select

Run

Run

Run

Hold

Hold

Hold

Hold key down to cycle through configured

setpoints.

Enables Run/Hold of the SP Ramp or Program

plus Timer start.

Decreases setpoint or output value. Decreases

the configuration values or changes functions in

Configuration mode groups.

NEMA4X and IP66 screw attachment (each

corner)

9/06 UDC3500 Universal Digital Controller Product Manual 7

Page 22

Introduction

1.3 Process Instrument Explorer Software

Overview

Process Instrument Explorer (P.I.E.) lets you configure your instrument on a

desktop/laptop or Pocket PC. For details see Process Instrument Explorer Manual #5152-25-131.

Features

• Create configurations with intuitive software program running on a Pocket PC, a

Desktop or a laptop computer.

• Create/edit configurations live, just connect software to the controller via a

communications port.

• Create/edit configurations offline and download to controller later via a

communications port.

• Communication types available on every UDC3500:

Infrared (standard)

RS 485 (optional)

Ethernet (optional)

• Same port types on UDC2500 and UDC3200 allow interconnectivity.

• This software is available in English, Spanish, Italian, German and French.

Figure 1-2 Screen capture of Process Instrument Explorer

running on a Pocket PC

8 UDC3500 Universal Digital Controller Product Manual 9/06

Page 23

Infrared communications

The infrared connection provides a non-intrusive wireless connection with the instrument

and maintains NEMA4X AND IP66 integrity.

No need to get access to the back of the controller to communicate with the instrument,

no need to take your screw driver to wire the communication cable, no wiring mistake

possible. You can now duplicate an instrument’s configuration, upload or download a

new configuration in a matter of seconds, just by pointing your Pocket PC in the direction

of the instrument.

It takes just a few seconds to upload a configuration from an instrument. You can then

save the configuration file onto your PC or pocket PC for review, modification or

archiving. Furthermore, this software also gives you important maintenance information

on the controller: instantly, get information on the current operating parameters, digital

inputs and alarm status, identify internal or analog input problems.

Question: What if I have several controllers on the same panel? How can I be sure I am

communicating with the correct one?

Answer: The infrared port of the controller is normally “off”. You activate the infrared

port by pressing any controller’s key. You can now communicate. After 4 minutes, the

port will be shut down again. Each controller may also be assigned a different

communications address.

Introduction

Figure 1-3 Depiction of infrared communications

9/06 UDC3500 Universal Digital Controller Product Manual 9

Page 24

Introduction

1.4 CE Conformity (Europe)

This product is in conformity with the protection requirements of the following European

Council Directives: 73/23/EEC, the Low Voltage Directive, and 89/336/EEC, the EMC

Directive. Conformity of this product with any other “CE Mark” Directive(s) shall not be

assumed.

Product Classification: Class I: Permanently connected, panel-mounted Industrial

Control Equipment with protective earthing (grounding) (EN61010-1).

Enclosure Rating: This controller must be panel-mounted with the rear terminals

enclosed within the panel. The front panel of the controller is rated at NEMA4X and IP66

when properly installed.

Installation Category (Overvoltage Category): Category II (EN61010-1)

Pollution Degree: Pollution Degree 2: Normally non-conductive pollution with

occasional conductivity caused by condensation. (Ref. IEC 664-1)

EMC Classification: Group 1, Class A, ISM Equipment (EN61326, emissions), Industrial

Equipment (EN61326, immunity)

Method of EMC Assessment: Technical File (TF)

Declaration of Conformity: 51453681

Deviation from the installation conditions specified in this manual, and the special

conditions for CE conformity in Subsection 2.1, may invalidate this product’s conformity

with the Low Voltage and EMC Directives.

ATTENTION

The emission limits of EN61326 are designed to provide reasonable protection

against harmful interference when this equipment is operated in an industrial

environment. Operation of this equipment in a residential area may cause harmful

interference. This equipment generates, uses, and can radiate radio frequency

energy and may cause interference to radio and television reception when the

equipment is used closer than 30 meters (98 feet) to the antenna(e). In special

cases, when highly susceptible apparatus is used in close proximity, the user may

have to employ additional mitigating measures to further reduce the

electromagnetic emissions of this equipment.

WARNING

If this equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.

10 UDC3500 Universal Digital Controller Product Manual 9/06

Page 25

2.1 Overview

Introduction

Installation of the UDC3500 consists of mounting and wiring the controller according to

the instructions given in this section. Read the pre-installation information, check the

model number interpretation (Subsection 2.3) and become familiar with your model

selections, then proceed with installation.

What’s in this section?

The following topics are covered in this section.

2.1 Overview 11

Installation

2 Installation

TOPIC See Page

2.2 Condensed Specifications 13

2.3 Model Number Interpretation 17

2.4 Control and Alarm Relay Contact Information 19

2.5 Mounting 20

2.6 Wiring 22

2.7 Wiring Diagrams

Figure 2-4 Composite Wiring Diagram

Figure 2-5 Mains Power Supply

Figure 2-6 Input 1 Connections

Figure 2-7 Input 2 Connections

Figure 2-8 Input 3 Connections

Figure 2-9 HLAI Inputs 2 and 4

Figure 2-10 HLAI Inputs 3 and 5

Figure 2-11 Optional Analog Input Jumper Positions

Figure 2-12 First Current Output

Figure 2-13 Second Current Output

Figure 2-14 Output #2 – Electromechanical Relay Output

Figure 2-15 Output #2 – Solid State Relay Output

Figure 2-16 Output #2 – Open Collector Output

Figure 2-17 Output #2 – Third Current Output

Figure 2-18 Output #2 – Dual Relay Output for Time Duplex

Figure 2-19 Output #2 – Dual Relay Output for Position

Proportional or Three Position Step Control

Figure 2-20 RS-422/485 Communications Option

27

28

29

30

31

32

33

33

34

34

35

35

36

36

37

37

38

39

9/06 UDC3500 Universal Digital Controller Product Manual 11

Page 26

Installation

Figure 2-22 Ethernet Communications Option

Figure 2-23 Digital Inputs

Figure 2-24 Optional Electromechanical Relay Outputs

Figure 2-25 Transmitter Power for 4-20 mA — 2 wire

Transmitter Using Open Collector Output

Figure 2-26 Transmitter Power for 4-20 mA — 2 Wire

Transmitter Using Second Current Output

40

41

41

42

12 UDC3500 Universal Digital Controller Product Manual 9/06

Page 27

Pre-installation Information

If the controller has not been removed from its shipping carton, inspect the carton for

damage then remove the controller.

• Inspect the unit for any obvious shipping damage and report any damage due to

transit to the carrier.

• Make sure a bag containing mounting hardware is included in the carton with the

controller.

• Check that the model number shown on the inside of the case agrees with what you

have ordered.

2.2 Condensed Specifications

Honeywell recommends that you review and adhere to the operating limits listed in Table

2-1 when you install your controller.

Table 2-1 Condensed Specifications

Analog Inputs

Analog Input Signal

Failure Operation

Stray Rejection Common Mode

Digital Inputs (Four)

(Optional)

Up to three Universal analog inputs. These can easily be configured to operate as 2

Universal and 2 High Level or as 1 Universal and 4 High Level inputs.

Accuracy:

± 0.10% of full scale typical (± 1 digit for display)

Can be field calibrated to ± 0.05% of full scale typical

16-bit resolution typical

Sampling Rate: All inputs are sampled six times per second

Temperature Stability: ± 0.0075% of Full Scale span / ˚C change—typical

Input Impedance:

0-20 and 4-20 Milliampere Inputs: 250 ohms

0-10 Volt and –1 to +1 Volt Input: 200K ohms

All Others: 10 megohms

Maximum Lead Wire Resistance:

Thermocouples: 50 ohms/leg

100 ohm, 200 ohm, 500 ohm and 1000 ohm RTD: 100 ohms/leg

100 ohm Low RTD: 10 ohms/leg

Slidewire Input for Position Proportional Control (Input 3 only):

100 ohm to 1000 ohm resistive slidewire types

Herculine

Burnout Selections: Upscale, Downscale, Failsafe or None

Thermocouple Health: Good, Failing, Failure Imminent or Failed

Failsafe Output Level: Configurable 0-100% of Output range

AC (50 or 60 Hz): 120 dB (with maximum source impedance of 100 ohms) or ± 1 LSB (least

significant bit) whichever is greater with line voltage applied.

DC: 120 dB (with maximum source impedance of 100 ohms) or a ±1 LSB whichever is

greater with 120 Vdc applied.

DC (to 1 KHz): 80 dB (with maximum source of impedance of 100 ohms) or ±1 LSB

whichever is greater with 50 Vac applied.

Normal Mode

AC (50 or 60 Hz): 60 dB (with 100 % span peak-to-peak maximum)

+30 Vdc source for external dry contacts or isolated solid-state contacts. Digital Inputs are

isolated from line power, earth ground, analog inputs and all outputs.

©

Models 10260 and 11280 Slidewire Emulation

Installation

Specifications

9/06 UDC3500 Universal Digital Controller Product Manual 13

Page 28

Installation

Current and Auxiliary

Outputs

Output 2 Options

Three Relay Board

(Optional)

Specifications

Up to three Milliamp Outputs. These outputs provide a 0 to 21 mA current output into a

negative or positive grounded load or into a non-grounded load. Current outputs are isolated

from each other, line power, earth ground and all inputs. Outputs can easily be configured

via the keyboard to be 0 to 20 mA or 4 to 20 mA without field calibration and for either direct

or reverse action when used as a control output.

Any current output not being used as a control output can be used in an Auxiliary Output

mode. Auxiliary Outputs can be configured to represent any Analog Input, PV, Setpoint,

Deviation, or Control Output. The range of an Auxiliary Output can be scaled per the range

of the selected variable and can be set anywhere between 0 to 21 mA.

Resolution: 14 bits over 0 to 21 mA

Accuracy: 0.05% of full scale

Temperature Stability: 0.01% F.S./°C typical

Load Resistance: 0 to 1000 ohms

The First Current Output is a standard feature and is present on all instruments. The Second

Current Output is an option and is mutually exclusive with Ethernet Communications. The

Third Current Output is an option and is mutually exclusive with the other Output 2 Options

listed directly below.

Output 2 is a socket which may be populated with any one of the following output types:

Electromechanical Relay