Page 1

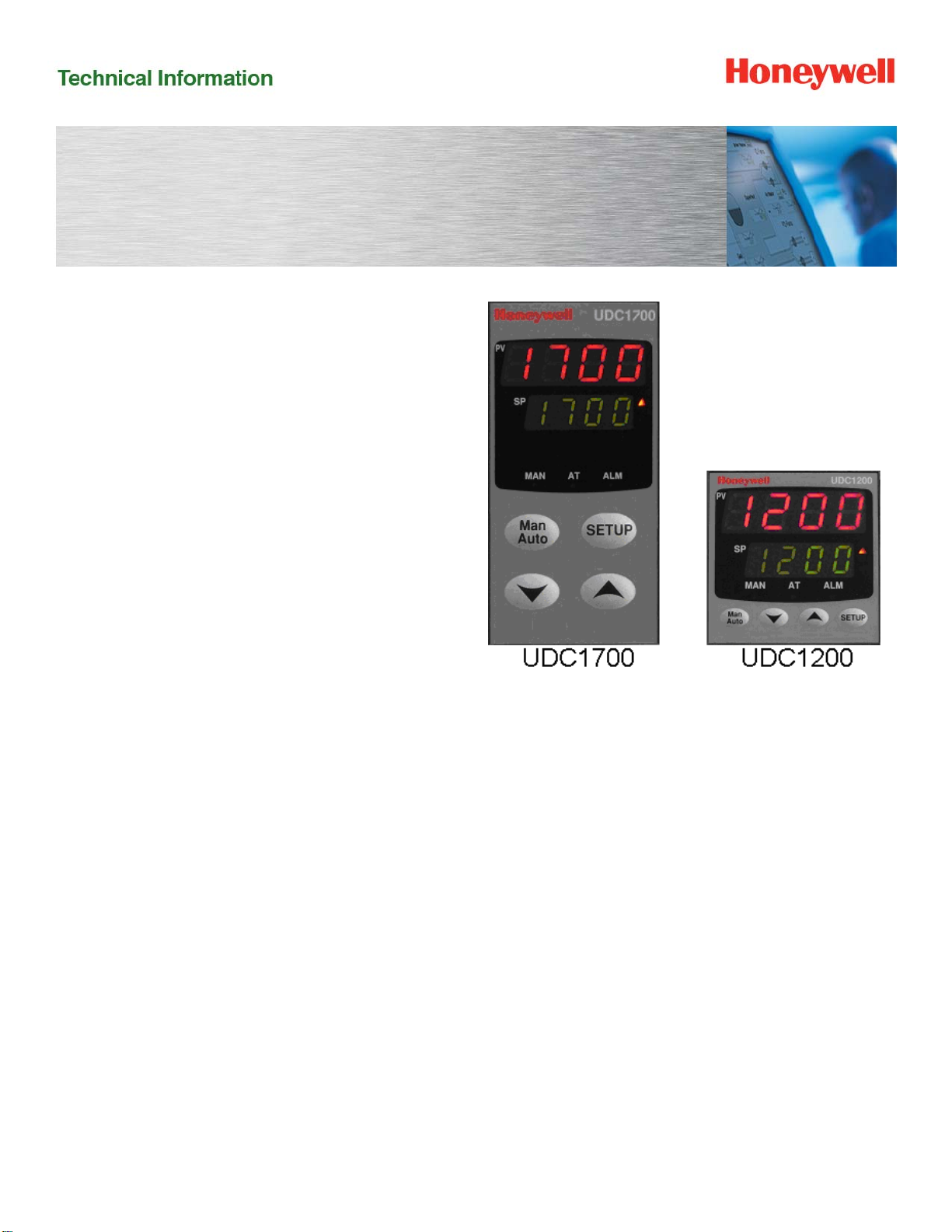

UDC1200 & UDC1700 Universal Digital Controllers

Series Micro-Pro

Specifications

51-52-03-35 June 2011

Overview

The UDC1200 & UDC1700 are microprocessor-based

1/16 DIN and 1/8 DIN controllers, which combine a

high degree of functionality and reliability at low cost.

They are fully dedicated to monitor and control

temperatures, pressures and levels in a wide range of

applications such as environmental chambers,

furnaces, ovens, packaging machines and other

applications in plastics and the food and beverage

industries. The large and easy-to-read dual 4-digit

display and tactile keypad make the UDC1200 and

UDC1700 easy to configure and use. Their

outstanding flexibility enables you to configure any unit

for any application and change it if required.

For the thousands of satisfied UDC1000/1500 users,

the UDC1200/ 1700 controllers are downward

compatible to existing UDC1000/1500 applications

and installations.

Features

Dual display

Two 4-digit displays with 7 LED segments, each

configurable for:

PV and SP (non adjustable)

PV and SP (adjustable)

PV and Ramping SP

PV only

Easier to configure

Two different configuration levels (Configuration mode

and set-up mode) provide easy access to parameters.

A 4-digit security code prevents unauthorized changes.

Moisture resistant front-face

Meets NEMA 3 / IP65 front-face protection against

dust and water.

Universal input

Accept seven different types of thermocouples, RTDs,

current and voltage linear inputs. All inputs are configurable

as standard.

Universal power supply

The UDC1200 and UDC1700 can operate on any line

voltage from 90 Vac to 264 Vac at 50/60 Hz. A 24/48 Vac/dc

model is available as an option.

Easy upgrade

All the option boards are jumper free and detected

automatically by the instrument.

Easy output selection

All the outputs (including the control output) of the

instrument can be changed to meet the exact

customer’s needs.

Page 2

UDC1200 & UDC1700 Universal Digital Controllers 2

p

Alarm strategy

Two soft alarms for PV, deviation high/low/absolute. A

special loop alarm is also provided to detect faults in

the control loop by continuously analyzing the PV

response to the control output. Alarm inhibit is

available on power up and setpoint switching.

Manual/Automatic mode

Manual control (via bumpless transfer) is enabled by

simply pressing the front-face AUTO/MAN key. The

“SET” LED flashes and the output power is displayed

on the lower display. Output can be adjusted with the

upper and lower keys.

Pre-tuning and self-tuning strategy

Pre-tuning is used to set up the PID parameters close

to the optimum values, which the self-tuning algorithm

uses to subsequently optimize the tuning parameters.

Limit controller

Packaged in 1/16 DIN, the UDC1200 limit controller is

designed to provide a safety shut-off and optional

alarm for use in a wide variety of applications.

Highly secure

A non-volatile memory based on EEPROM technology

ensures data integrity during loss of power supply, with

retention of more than 100 years. A 4-digit security code

prevents unauthorized or accidental change.

Upper display: 4 characters

dedicated to show the PV.

In configuration mode, it shows

the parameter value or selection

Lower display: 4 characters

dedicated in normal operation

mode to display the SP. In

configuration mode, it displays

the

arameter name.

Up to three outputs

The UDC1200 and UDC1700 provide up to three

outputs for time and current proportioning, duplex

mode (heat/cool), PV or SP retransmission, and

alarms.

Setpoint ramp

The current setpoint can ramp to a new-targeted

setpoint by way of a user defined ramp rate.

Dual setpoint

Dual setpoint option is available on the UDC1200 and

UDC1700. The current setpoint is selected by a digital

input. This option is exclusive with UDC1200 limit

model remote alarm reset.

Communication

An optional RS485 communications interface is

available on the UDC1200 and UDC1700. It provides a

link for up to 32 units and a host computer through

ASCII or Modbus RTU protocol at up to 19200 baud.

UDC1700 UDC1200

Selects manual or automatic mode. Becomes

« Reset » on UDC1200 Limit model.

Allows operator mode parameters to be scrolled.

In combination with the «Upper» key, allows

configuration mode or Setup mode to be entered.

Increases setpoint, output or configuration

parameter values.

Decreases setpoint, output or configuration

parameter values.

Page 3

UDC1200 & UDC1700 Universal Digital Controllers 3

Optional Features

The following can be selected via the Model selection

Guide (see page 8):

RS485 ASCII communication

RS485 Modbus RTU communication

Digital Input

Output 2

Output 3

Power Supply 24/48 Vac/dc

Physical Description

The UDC1200 controller is housed in a 110 mm (4.33

inches) deep case with a standard UDC gray bezel. It

can be mounted in a 1/16 DIN panel cutout.

The UDC1700 controller is housed in a 100 mm (3.94

inches) deep case and can be mounted in a 1/8 DIN

panel cutout. By using the pre-assembled mounting

fixture delivered with the unit, you can easily and

securely install the controller into the panel cutout.

Modular plug-in construction allows rapid access and

saves time. All inputs and outputs are connected on

the rear terminal block by screws.

Operator Interface

Four display combinations are offered to the operator.

The upper 4-digit 7-segment display is always

dedicated to monitor the PV. The lower display can

show:

SETPOINT (read only)

SETPOINT (adjustable)

RAMPING setpoint (ramp mode)

BLANK

Universal Inputs

All input types are available on any unit. Selection

among the various types of inputs is made by prompt

configuration. As soon as the Process Variable

reaches the value of the input range limit, the controller

displays a message. A sensor break indication is also

provided. A configurable digital filter is available from

0.5 seconds to 100.0 seconds.

Outputs

Three types of outputs (RELAY, SSR driver or DC linear)

are selectable for three outputs, through the model selection

guide or by adding a plug-in module for outputs 1, 2 and 3.

Outputs Algorithm

The UDC1200 and UDC1700 are available with the

following output algorithms:

Time proportional:

ON/OFF or time proportional with

electromechanical relay SPDT 2 A or SSR driver

(open collector).

Current proportional:

Supply directly proportional current or voltage

signal to the final control elements which require 020 mA, 4 20 mA, 0-10 V or 0-5 V.

Time proportional duplex:

Three duplex modes can be selected, either

ON/OFF duplex, time proportional duplex

(heat/cool with two proportional bands, two cycle

times and deadband) or TPSC.

Current proportional duplex:

In addition to the first current/voltage output, a

second similar output with its own proportional

band is provided.

Current/Time or Time/Current duplex:

Provides a variation of traditional time or current

duplex mode by mixing current and time

proportioning together.

Control Algorithms

Four control algorithms can be set up through the

configuration menu:

On/Off PID

PD + MR TPSC

The TPSC (Three Position Step Control) control algorithm is

dedicated to control valve positioning without slidewire

feedback from the motor shaft.

Page 4

UDC1200 & UDC1700 Universal Digital Controllers 4

Configuration

There are two levels of configuration. The SET-UP

mode allows modification of current parameters such

as tuning parameters, alarm values, setpoint limit,

ramp enable, auto-manual mode enable and autopretune enable.

The CONFIGURATION mode is more oriented to unit

personality: input selection, output 2 and 3 usage,

alarm type, communication address and lockout code.

The operator mode screens are only selectable via the

configuration software only. For instance, the alarm

value screen can be moved from setup mode to

normal operator mode if desired.

Control Mode

Manual or automatic mode with bumpless transfer is

standard feature. In manual mode, the operator can

directly control the output through the two front face

keys (raise and lower keys). The output value is

monitored on the lower display.

Alarms

Outputs 1, 2 and 3 can be used as alarms. Two

electromechanical single pole double throw relays can

activate external equipment when alarm setpoints are

reached. An LED is also activated on the front-face. A

direct or reverse acting alarm output can be

configured. A logical combination of the two alarms:

OR, AND or hysteresis (active when both alarms are

active and inactive when both alarms are inactive) can

be set which associates the two alarms status before

energizing the relay. In order to detect a defective

control loop, the controller can supply special loop

alarm control by continually monitoring the PV

response to output demand. A timer is automatically

set up when any output is on saturation mode. When

the timer reaches twice the reset time with no PV

response, the loop alarm is activated. With this soft

alarm there is no need for a heater circuit breaker,

saving wiring time and costs.

Limit Controller

The UDC1200 1/16 DIN limit controller provides a latched

relay output which is activated when the process parameters

either exceed or fall bellow the desired value, providing a

failsafe cut-off which has to be manually reset before the

process can continue.

The UDC1200 limit controller can be configured to be either

a “high limit” unit where the delay will de-energize when the

PV is above the limit setpoint, or a “low limit”, where the

relay will drop out when the PV falls below the setpoint.

A LED indicator shows when limits have been exceeded,

and when the relay is latched out.

The optional digital input allows a remote reset function.

Remote Setpoint Model

The UDC1700 1/8 DIN "R" model controller has a second

input available that accepts either a linear or potentiometer

input signal as a remote setpoint. The input signals

accepted are field-configurable and are: 0-5 V, 1-5 V, 0-10

V, 2-10 V, 0-20 mA, 4-20 mA (factory set), 0-50 mV, 10-50

mV, 0 100 mV, or 0-2000 ohms. This allows the controller

to act as a "slave" controller accepting a setpoint value from

a 'master' device such as a PLC or setpoint-programming

controller (such as the DCP50, DCP100, DCP300, or

DCP550 series).

The UDC1700R also includes a standard digital input

allowing remote switching between the local setpoint and

the remote setpoint value. Also standard in this model is

"fuzzy" autotune software that minimizes process variable

overshoot when responding to a setpoint change.

PC Software

The UDC1200 & 1700 are supported with PC software

allowing you to quickly configure your device using

configuration wizards, or to perform diagnostics.

Display

Dual, four-digit LED display with decimal point location

configurable up to three places for linear ranges only.

Page 5

UDC1200 & UDC1700 Universal Digital Controllers 5

Specifications (Applies to both UDC1200 and UDC1700)

Technical data

Accuracy 0.1 % of span 1 LSD

Temperature Stability 0.01 % of span per ºC

Input Signal Failure Fail-safe output value: Achieved when burnout is detected.

Input Impedance Voltage impedance: 47 Kohms

Input Sampling Rate Four samples per second

Input Filter Digital filter configurable from front panel

Input Resolution 14 bits approxi m ately, always four times better than display resolution

Input Isolation Universal input isolated at 2500 V from all outputs except SSR and from power supply

Stray Rejection Common mode rejection: > 120 dB at 50/60 Hz

Approvals UL recognized to US & Canadian standards

Control Output Type Type available:

Alarms Maximum number of alarms: 2 soft alarms setpoint + 1 loop alarm

Value depends on configuration.

For thermocouple and mV input detected by any lead break: Upscale burnout

For RTD: Burnout detected by any lead break

Current or voltage input: Burnout set by open circuit detection

Current input: 4.7 ohms

All others: 100 Mohms

0.0 (Off), from 0.5 seconds to 100.0 seconds in 0.5 seconds increment

Serial mode rejection: > 500% of span at 50/60 Hz

FM approval on the UDC1200 limit model

Product design to meet CE MARK requirement

Output 1/2/3: DC, Electromechanical relay, SSR drive (open collector)

DC linear output:

0-20 mA, 4-20 mA, 0-5 V, 0-10 V

Accuracy: 0.25 % (250 ohms for mA, 2 Kohms for voltage)

Resolution: 80 bits in 250 ms (10 bits in 1 second typical > 10 bits in > 1 second)

Load impedance: 500 ohms maximum for current output,

500 ohms minimum for voltage output

Isolation: Isolated 2500 V from all other inputs and outputs

Range selection method: Front panel code setting

Temperature stability: 0.01 % / °C

Electromechanical relay: SPDT contact

Resistive load: 2 A at 120 V or 240 V

Life time: > 500000 operations at rated voltage/current

SSR drive/TTL:

Drive capability: SSR > 10 Vdc into 250 ohms minimum

Isolation: Not isolated from input and other SSR output

Alarm inhibit available on power up and setpoint switching

Alarm output: Up to two relays or SSR output on outputs 2 and 3

Types: PV high or low, band, deviation high or low, loop

Combination alarms: Logical “OR”, “AND” or hysteresis of alarms availab le to

individual hardware output

Page 6

UDC1200 & UDC1700 Universal Digital Controllers 6

Loop Control Automatic tuning type: Pre-tune and self-tune

Proportional bands: 0 (inactive), 0.5 % to 999.9 % of input span with 0.1% increments.

Two proportional bands available for duplex mode

Reset: Off or from 1sec. to 99 min 59 sec.

Rate: From 0 sec. to 99 min 59 sec.

Manual reset: from 0 to 100 % of output (single output), from –100 % to 100 % of

output (dual output)

Deadband: 20 of PB1 + PB2

ON/OFF hysteresis: 0.1% to 10.0 % of input span

Auto/manual mode: Front key selectable with bumpless transfer between automatic

and manual mode

Cycle times: Up to two cycle times available for time duplex control

Selection: 0.5, 1, 2, 4, 8, 16, 32, 64, 128, 256, or 512 seconds

Setpoint ramp: From 1 to 9999 engineering units per hour

Retransmission Output Any output can be selected to retransmit the process value or setpoint as a linear

(current or voltage) output

Digital Input (optional) On contact the digital input will switch between SP1/SP2 or Auto/Manual or DC100L

Remote Reset

Communication Interface RS485 – ASCII or Modbus RTU (selectable from the menu)

Baud rate: 1200, 2400, 4800, 9600 or 19200 baud

Link characteristics: 32 drops maximum, ASCII or Modbus protocols, two wires

Mounting Plug-in with pre-assembled mounting fixture

Wiring Connection Screw terminals on the rear of the case (combination head)

Power Consumption 4 W

Physical (UDC1200) Weight: 210 grams maximum

Height: 48 mm / 1.89 in

Width: 48 mm / 1.89 in

Depth: 110 mm / 4.33 in

Cut out: 45 mm x 45 mm / 1.77 in x 1.77 in

Physical (UDC1700) Weight: 250 grams maximum

Height: 96 mm / 3.78 in

Width: 48 mm / 1.89 in

Depth: 100 mm / 3.94 in

Cut out: 45 mm x 92 mm / 1.77 in x 3.62 in

Environmental EMI Susceptibility: Designed to meet EN55101

EMI Emission: Designed to meet EN55022

Safety Considerations: Designed to comply with IEC1010-1as far as applicable

Front Panel Sealing NEMA 3 / IP66

Page 7

UDC1200 & UDC1700 Universal Digital Controllers 7

Input Actuations

Ranges

Thermocouple types °F °C

(Fixed decimal) R

S

J

J

T

T

K

K

L

L

B

C

N

RTD: (3 wires connection)

PT100 (IEC) = 0.00385

(Fixed decimal)

DC linear:

32 – 3198

32 – 3204

-328 – 2192

-199.9 – 999.9

-400 – 752

-199.9 – 752

-400 – 2503

-128.8 – 537.7

32 – 1403

32 – 999.9

211 – 3315

32 – 4208

32 – 2551

-328 – 1472

-199.9 – 999.9

10 – 50 mV

4 – 20 mA

1 – 5 V

2 – 10 V

0 – 1759

0 – 1762

-200 – 1200

-128.8 – 537.7

-250 – 400

-128.8 – 400

-240– 1373

-199.9 – 999.9

0 – 762

0 – 537.7

100 – 1824

0 – 2320

0 – 1399

-199 – 800

-128.8 – 537.7

0 – 50 mV

0 – 20 mA

0 – 5 V

0 – 10 V

Operating Conditions

Ambient Temperature 20 °C 2 °C

Relative Humidity 60-70 % 20-95 % non -condensing

Voltage 90-264 Vac 1 % 90-264 Vac

Frequency 50 Hz 50-60 Hz

Source Resistance < 10 ohms for

Lead resistance for RTD < 0.1 ohm/lead

Reference

Conditions

(68 °F 4 °F)

1000 ohms maximum for

thermocouple

50 ohms per lead maximum

(PT100)

Operative

Limits

0 °C to 55 °C

(32 °F to 131 °F)

thermocouple

balanced

Transportation and

Storage

–20 °C to 80 °C

(–4 °F to 176 °F)

Page 8

UDC1200 & UDC1700 Universal Digital Controllers 8

Sales and Service

For application assistance, current specifications, pricing, or name of the nearest Authorized Distributor, contact one of the offices below.

Asia Pacific Global

Technical Support

Field Instruments

Phone: +65 6580 3156

Fax: +65 6445-3033

Australia

Honeywell Limited

Phone: +(61) 7-3846 1255

FAX: +(61) 7-3840 6481

Toll Free 1300-36-39-36

Toll Free Fax:

1300-36-04-70

China – PRC - Beijing

Honeywell China Inc.

Phone: +(86-10) 84583280

Fax: +(86-10) 8458-4650

China – PRC - Shanghai

Honeywell China Inc.

Phone: (86-21) 5257-4568

Fax: (86-21) 6237-2826

China – PRC - Chengdu

Honeywell China Inc.

Phone: +(86-28) 66135078

Fax: +(86-28) 8678-7061

China – PRC - Xi’an

Honeywell China Ltd Xi’an.

Phone: +(86-29) 88337490

Fax: +(86-29) 8833-7489

China – PRC - Shenzhen-

Honeywell China Inc.

Phone: +(86) 755-25181226

Fax: +(86) 755-2518-1221

Indonesia

PT Honeywell Indonesia

Phone: +(62) 21-535-8833

FAX: +(62) 21-5367 1008

Honeywell Automation

India Ltd.

Honeywell Ltd.

Phone:+(91) 6603-9400

Fax: +(91) 6603-9600

Japan

Honeywell Inc.

Phone: +(81) 3 6730 7197

Fax: +(81) 3 6730 7228

Malaysia

Honeywell Engineering

Sdn Bhd

Phone: +(603) 7958-4788

Fax: +(603) 7958-8922

New Zealand

Honeywell Limited

Phone: +(64-9) 623-5050

Fax: +(64-9) 623-5060

Toll Free (0800) 202-088

Singapore

Honeywell Pte Ltd.

Phone: +(65) 6580 3278

Fax: +(65) 6445-3033

South Korea

Honeywell Korea Co Ltd

Phone: +(822) 799 6114

Fax: +(822) 792 9015

Thailand

Honeywell Systems

(Thailand) Ltd.

Phone: +(662) 693-3099

FAX: +(662) 693-3089

Taiwan R.O.C.

Honeywell Taiwan Ltd.

Phone: +(886-2) 22451000

FAX: +(886-2) 2245-3243

SE Asia Countries

see Honeywell Pte Ltd

(Singapore)

for: Philippines, Pakistan,

Cambodia, Guam, Laos,

Myanmar, Vietnam,

East Timor

SE Asia Countries

see Honeywell

Automation India Ltd for:

Bangladesh

Nepal

Sri Lanka

EUROPE

Austria

Honeywell Austria GmbH

Phone: +43 (316)400123

FAX: +43 (316)40017

Belgium

Honeywell SA/NV

Phone:+32 (0)2728 24 07

FAX: +32 (0)2728 22 45

Bulgaria

Honeywell EOOD

Phone: +(359) 2 40 20

900

FAX: +(359) 2 40 20 990

Czech Republic

Honeywell spol. s.r.o.

Phone:+420 242 442 232

FAX: +420 242 442 131

Denmark

Honeywell A/S

Phone: +(45) 39 55 55 55

FAX: +(45) 39 55 55 58

Finland

Honeywell OY

Phone: +358 (0)20752 2753

FAX: +358 (0) 20752 2751

France

Honeywell SA

Phone: +33 (0)1 60198075

FAX: +33 (0)1 60198201

Germany

Honeywell AG

Phone: +49 (69)8064-299

FAX: +49 (69)806497336

Hungary

Honeywell Kft.

Phone: +36-1-451 4300

FAX: +36-1-451 4343

Italy

Honeywell S.p.A.

Phone:+390292146307

FAX: +39 0292146377

The Netherlands

Honeywell B.V.

Phone: +31 (0) 20 5656200

FAX: +31 (0) 20 5656210

Norway

Honeywell A/S

Phone: (45) 39 55 55 55

Poland

Honeywell Sp. zo.o

Phone: +48-22-6060900

FAX: +48-22-6060901

Portugal

Honeywell Portugal Lda

Phone: +351 21 424 5000

FAX: +351 21 424 50 99

Romania

Honeywell Bucharest

Phone: +40 (0) 21 2316437

FAX: +40 (0) 21 2316439

Russian Federation (RF),

Honeywell Field Solutions

Kievskaya str., 7,

Moscow 121059, Russia

Phone +7 (495) 796 98 60

Fax +7 (495) 797 99 64

Slovak Republic

Honeywell s.r.o.

Phone: +421-2-58247 410

FAX: +421-2-58247 415

Spain

Honeywell S.A.

Phone: +34 (0)91313 61 00

FAX: +34 (0)91313 61 30

Sweden

Honeywell AB

Phone: +(46) 8 775 55 00

FAX: +(46) 8 775 56 00

Switzerland

Honeywell AG

Phone: +41 18552448

FAX: +(41) 1 855 24 45

Turkey

Honeywell Turkey A.S.

Phone: +90 216 578 71 00

FAX: +90 216 575 66 35

Ukraine

Honeywell

Tel: +380-44-201 44 74

Fax: +380-44-201-44-75

United Kingdom

Honeywell Control Systems

Ltd.

Phone: +44 (0)1344 655251

FAX: +44 (0) 1344 655554

MIDDLE EAST

Abu Dhabi U A E

Middle East Headquarters

Honeywell Middle East Ltd.

Phone: +971 2 4041246

FAX: +971 2 4432536

Sultanate of Oman

Honeywell & Co Oman LLC

Phone: +968 24 701153/

Ext.33

FAX +968 24 787351

Saudia Arabia

Honeywell Turki Arabia Ltd

Jubail Office

Phone: +966-3-341-0140

Fax: +966-3-341-0216

Honeywell - ATCO

Dammam Office

Phone: 0096638304584

Fax: 0096638338059

Kuwait

Honeywell Kuwait KSC

Phone: +965 242 1327 to 30

Fax: +965 242 8315

And

Phone: +965 326

2934/1821Fax: +965 326

1714

AFRICA

Mediterranean & African

Distributors

Honeywell SpA

Phone: +39 (02) 250 10 604

FAX: +39 (02) 250 10 659

South Africa (Republic of)

and sub saharan

Honeywell Southern Africa

Honeywell S.A. Pty. Ltd.

Phone: +27 11 6958000

FAX +27 118051504

NORTH AMERICA

Canada

Honeywell LTD

Phone: 1-800-737-3360

FAX: 1-800-565-4130

USA

Honeywell Process

Solutions,

Phone: 1-800-423-9883

Or 1-800-343-0228

Email: ask-

ssc@honeywell.com

SOUTH AMERICA

Argentina

Honeywell S.A.I.C.

Phone: +(54-11) 4383-3637

FAX: +(54-11) 4325-6470

Brazil

Honeywell do Brasil & Cia

Phone: +(55-11) 7266-1900

FAX: +(55-11) 7266-1905

Chile

Honeywell Chile, S.A.

Phone: +(56-2) 233-0688

FAX: +(56-2) 231-6679

Mexico

Honeywell S.A. de C.V.

Phone: +(52) 55 5259-1966

FAX: +(52) 55 5570-2985

Puerto Rico

Honeywell Inc.

Phone: +(809) 792-7075

FAX: +(809) 792-0053

Trinidad

Honeywell Inc.

Phone: +(868) 624-3964

FAX: +(868) 624-3969

Venezuela

Honeywell CA

Phone: +(58-2) 238-0211

FAX: +(58-2) 238-3391

Page 9

UDC1200 & UDC1700 Universal Digital Controllers 9

r

R

Model Selection Guides are subject to change and are inserted into the specifications as guidance only.

Prior to specifying or ordering a model check for the latest revision Model Selection Guide s which are published at:

http://hpsweb.honeywell.com/Cultures/en-US/Products/Instrumentation/ProductModelSelectionGuides/default.htm

Model Selection Guide

51-51-16U-78

Issue 13

Page 1 of 3

UDC1200 MICRO-PRO

Model Selection Guide

Un iver sa l Digital Con trolle

Instructions

Select the desired key number. T he ar r ow to the right marks the selections available.

M ak e one select ion eac h from Tables I through VI II using the column below the proper arr ow.

Key N umber I II III IV V VI VIIVIII

DC _ _ _ _ -_-_-_-_-_-_-_-_

KEY NUMBE

1/16 DI N Controller: RTD or Linear mV

48x4 8mm Thermocouple

Input Type

(Field Selec table) Linear Voltage

TABLE I

Output 1

Description

Linear mA

Limit Controller - FM Approv ed

TPS C Controller (Ther mocouple F ac tory S et)

Relay 1

SSR Dr iver 2

Linear: 0 - 10 Volts 3

Linear: 0 - 20 mA 4

Linear: 0 - 5 Volts 5

Linear: 4- 20mA 7

Selection Availability

DC1201

DC1202

DC1203

DC1204

DC120L

DC120T

TABLE II

Output 2

TABLE III

Output 3

TABLE IV

Communications No Selection 0

None 0

Relay 1

SSR Dr iver 2

Linear: 0 - 10 Volts 3

Linear: 0 - 20 ma 4

Linear: 0 - 5 Volts 5

Linear: 4- 20mA 7

Dual Relay B oar d 9

None 0

Relay 1

SSR Dr iver 2

Linear: 4- 20mA 7

Transmitter P ower S upply (24Vdc) 8

RS485 ASCII S er ial Communication 1

Digital Input (SP1/SP2 Selection or Auto/Manual 2

Select ion or DC100L Remote Reset)

RS485 MODBUS Communication 3

Basic Remote Setpoint 4

Page 10

UDC1200 & UDC1700 Universal Digital Controllers 10

Availability

DC120_

TABLE V

Power Supply Power Supply 90 to 264 Vac 1

Power S upply 24 to 48 Vac/dc 2

TABLE VI

Manuals English (51-52-25-123)

(Single sheet Frenc h (51-52-25-123- FR) 1

Concise manuals German (51-52-25-123-GE) 2

for UDC1200) It alian (51-52-25- 123- IT) 3

Spanish (51-52-25-123-SP) 4

TABLE VII

Packaging Individual Carton 0

Bulk P ac k of 10 identical models 1

Bulk P ac k of 50 identical models 2

Bulk Pac k of 100 identical models 3

TABLE VIII

Specials

UDC1200 sty l e overlay 0

Special Instrument (Consult Factory) S

UDC1200 MICRO-PRO

Universal Digital Controller

Selection 1 2 3 4 L T

Supplemental

Accessori es & Kits

0

Des cr ip tion

Option Slot 1

Relay module 51453391-501

10 Vdc SSR Driver module 51453391-502

Linear (mA/V d c ) module 51453391-504

Option Slot 2 & 3

Relay module 51453391-506

10 Vdc SSR Driver module 51453391-507

Linear (mA/V d c ) module 51453391-509

Dual Relay B oard ( S lot 2 only) 51453391-510

24V dc t r ansmitter module (Slot 3 only) 51453391-511

Option Slot A

RS485 communication module 51453391-512

Digital Input module 51453391-513

Basic Remote Set p oint module 51453391- 515

Others

PC Software (inc ludes th e c able) 51453391-514

Produc t Manual ( 8 1/2 x 11) English 51-52-25-122

French 51-52-25-122-FR

UDC1000/1200 Fixing str ap 46189016-501

UDC1500/1700 Fixing str ap 46189017-501

UDC1000/1200 Rep lac ement c ase 46189018-501

UDC1500/1700 Rep lac ement c ase 46189019-501

DIN Rail Adaptor Kit 46189025-501

Part Number

Page 11

UDC1200 & UDC1700 Universal Digital Controllers 11

s

V

_

_-_-_-_-_-_-_-_

Model Selection Guides are subject to change and are inserted into the specifications as guidance only.

Prior to specifying or ordering a model check for the latest revision Model Selection Guide s which are published at:

http://hpsweb.honeywell.com/Cultures/en-US/Products/Instrumentation/ProductModelSelectionGuides/default.htm

Model Selection Guide

51-51-16U-85

Issue 8

Page 1 of 3

UDC1700 MICRO-PRO

Model Selection Guide

Un i versal D igital Controller

Instruction

Select the desired key number. The ar r ow t o the right marks the selections available.

M ak e one select ion eac h from Tables I through VII I using the column below the pr oper ar r ow.

Key Number I II III IV V VI VII

_ _ _ _ _ -

KEY NUMBER Selection Availability

1/8 DIN Controller:

48x96mm RTD or Linear mV DC1701

Input Type

(Field S elec table) Linear mA DC1703

TABLE I

Output 1

Description

Thermocouple DC1702

Linear Voltage DC1704

TP S C Controller * DC170T

Remote Set poin t, Fuzz y Logic, Digital Input * DC170R

* fac tory set for thermocouple input

Relay 1

SSR Dr iver 2

Linear 0 t o 10 Volts 3

Linear 0 to 20 ma 4

Linear 0 to 5 Volts 5

Linear 4 to 20 mA 7

III

TABLE II

Output 2

TABLE III

Output 3

None 0

Relay 1

SSR Dr iver 2

Linear 0 t o 10 Volts 3

Linear 0 to 20 ma 4

Linear 0 to 5 Volts 5

Linear 4 to 20 mA 7

Dual Relay Board 9

None 0

Relay 1

SSR Dr iver 2

Linear 0 t o 10 Volts 3

Linear 0 to 20 ma 4

Linear 0 to 5 Volts 5

Linear 4 to 20 mA 7

Tr ansmitter P ower S upply (24Vdc) 8

Dual Relay Board 9

Page 12

UDC1200 & UDC1700 Universal Digital Controllers 12

Model Selection Guide (continued)

DC170 _ Availability

TABLE IV

Selection 1 2 3 4 T R

No Selec tion 0

Option 1 RS485 ASCII Serial Communication 1

Digital Input (SP1/SP2 Selection) 2

RS485 MODB US Communication 3

Basic Remote Setpoint 4

TABLE V

Option 2 Power S upply 90 t o 264 Vac 1

Power S uppl y 24 to 48 Vac/ dc 2

TABLE VI

Manuals English (51-52-25-123) 0

(Singl e sheet Frenc h (51-52- 25- 123- FR) 1

Concise manuals Ger man (51-52-25-123- GE) 2

for UDC1200) Italian (51-52-25-123- IT) 3

Spanish (51-52-25-123-SP) 4

TABLE VII

Pack agi ng I ndividual Carton 0

Bulk Pack of 10 identical models 1

Bulk Pack of 50 identical models 2

TABLE VIII

Special None 0

Special I nstrument (Consult F ac t or y) S

Page 13

UDC1200 & UDC1700 Universal Digital Controllers 13

t

UDC1700 MICRO-PRO

Universal Digital Controller

Descr iption

Option Slot 1

Relay module 51453391-501

10 Vdc SSR Dr iver module 51453391-502

Linear (mA/Vdc) module 51453391-504

Option Slot 2 & 3

Relay module 51453391-506

10 Vdc SSR Dr iver module 51453391-507

Linear (mA/Vdc) module 51453391-509

Dual Relay B oar d 51453391-510

24V dc transmitt er module (Slot 3 only) 51453391-511

Option Slot A

RS485 communication module 51453391-512

Digita l I n put module 51453391-513

Basic Remote Se tpoint module 51453391-515

Supplemental

Accessories & Ki t s

Part Num ber

Option Slot B

Full r e mote Setpoint module (to upgrade a DC1700 t o a DC17 0R) 51 453391-516

Others

PC Software ( i nc ludes t he c a ble) 51453391-514

Produc t M anual ( 8 1/2 x 11) English 51-52- 25- 122

French 51-52-25-122-FR

UDC1000/ 1200 Fix ing str ap 46189016-501

UDC1500/ 1700 Fix ing str ap 46189017-501

UDC1000/ 1200 R eplac ement c ase 46189018-501

UDC1500/ 1700 R eplac ement c ase 46189019-501

DIN Rail Adaptor K i

46189025-501

Page 14

UDC1200 & UDC1700 Universal Digital Controllers 14

Warranty/Remedy

Honeywell warrants goods of its manufacture as being free of defective materials and faulty workmanship. Contact your local

sales office for warranty information. If warranted goods are returned to Honeywell during the peri od of coverage, Honeywell

will repair or replace without charge those items it finds defective. The foregoing is Buyer's sole remedy and is in lieu of all

other warranties, expressed or implied, including those of merchantability and fitness for a particular purpose.

Specifications may change without notice. The information we supply is believed to be accurate and reliable as of this

printing. However, we assume no responsibility for its use.

While we provide application assistance personally, throug h our literature and the Honeywell web site, it is up to the

customer to determine the suitability of the product in the application.

Specifications are subject to change without notice.

For More Information

Learn more about how Honeywell’s UDC1200/1700

Micro-Pro Series can monitor and control

temperatures, pressures and levels in a wide

range of applications visit our website

www.honeywell.com/ps/hfs

or contact your

Honeywell account manager.

Honeywell Process Solutions

1860 W. Rose Garden Lane

Phoenix, Arizona 85027

Tel: 1-800-423-9883 or 1-800-343-0228

www.honeywell.com/ps

51-52-03-35

June 2011

© 2011 Honeywell International Inc.

Loading...

Loading...