Page 1

UDA2182

Universal Dual Analyzer

Product Manual

70-82-25-119

January 2009

Honeywell Process Solutions

Page 2

WARRANTY/REMEDY

Honeywell warrants goods of its manufacture as being free of defective materials and faulty

workmanship. Contact your local sales office for warranty information. If warranted goods are

returned to Honeywell during the period of coverage, Honeywell will repair or replace without charge

those items it finds defective. The foregoing is Buyer's sole remedy and is in lieu of all other

warranties, expressed or implied, including those of merchantability and fitness for a particular

purpose. Specifications may change without notice. The information we supply is believed to be

accurate and reliable as of this printing. However, we assume no responsibility for its use.

While we provide application assistance personally, through our literature and the Honeywell web

site, it is up to the customer to determine the suitability of the product in the application.

Notices and Trademarks

Copyright 2008 by Honeywell

Revision 5 January 2009

Honeywell Process Solutions

Honeywell

2500 W. Union Hill Drive

Phoenix, Arizona 85027

UDA2182 is a U.S. registered trademark of Honeywell

Other brand or product names are trademarks of their respective owners.

ii UDA2182 Universal Dual Analyzer Product Manual January 2009

Page 3

About This Document

Abstract

This document provides descriptions and procedures for the Installation, Configuration, Operation, and Troubleshooting of

your UDA2182 Universal Dual Analyzer.

Contacts

World Wide Web

The following lists Honeywell’s World Wide Web sites that will be of interest to our customers.

Honeywell Organization WWW Address (URL)

Corporate http://www.honeywell.com

Honeywell Field Solutions http://www.honeywell.com/ps

Technical tips http://content.honeywell.com/ipc/faq

Telephone

Contact us by telephone at the numbers listed below.

United States and Canada Honeywell 1-800-423-9883 Tech. Support

Organization Phone Number

1-800-525-7439 Service

January 2009 UDA2182 Universal Dual Analyzer Product Manual iii

Page 4

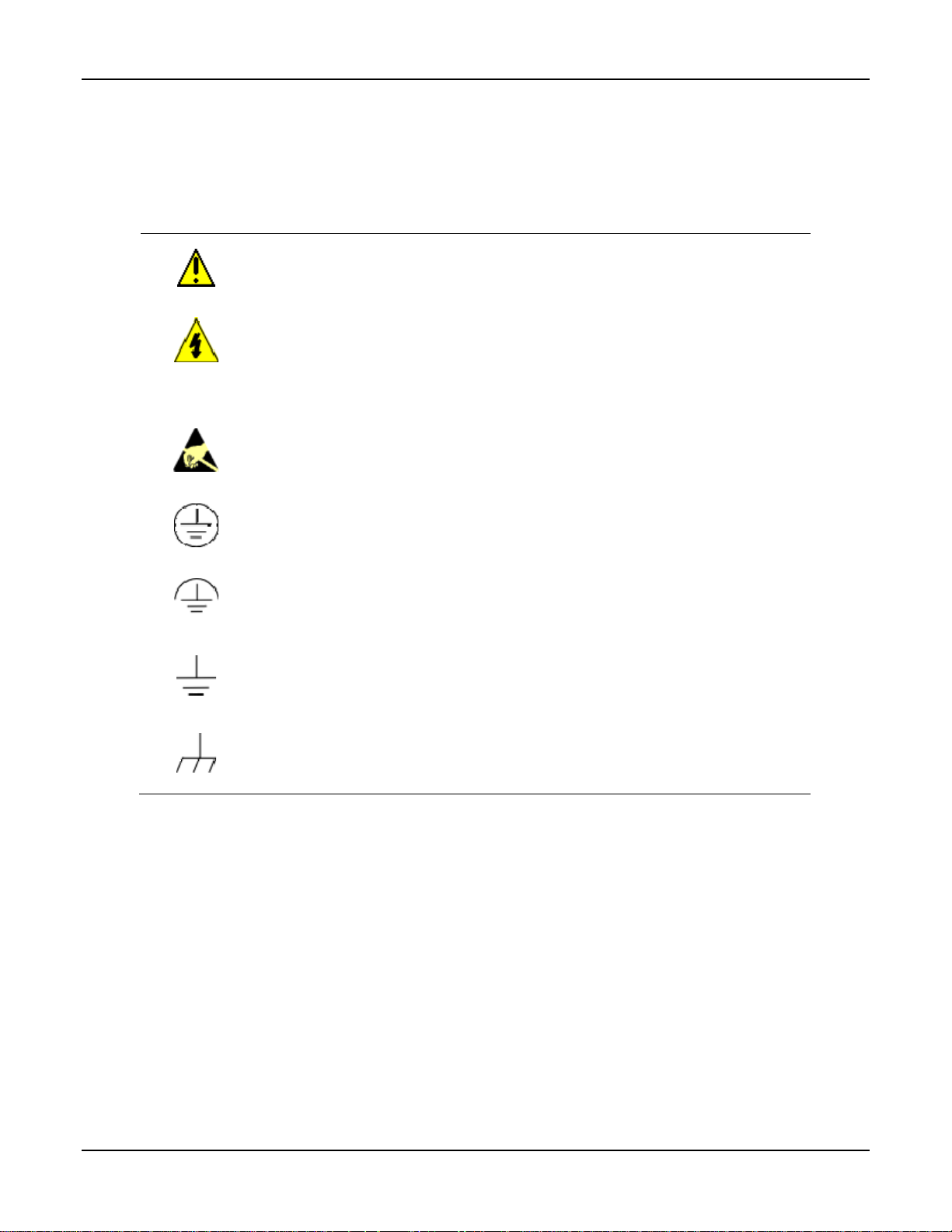

Symbol Definitions

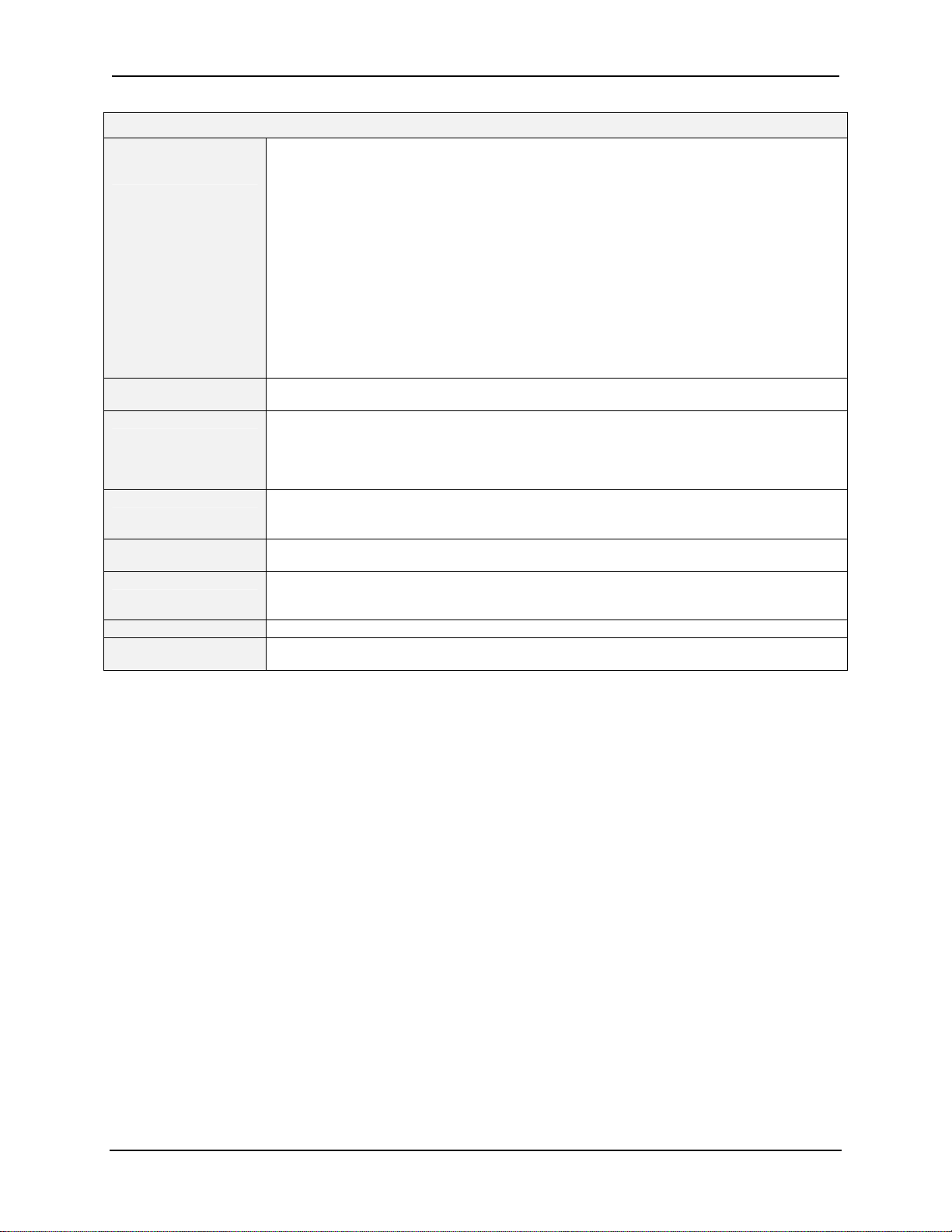

The following table lists those symbols used in this document to denote certain conditions.

Symbol Definition

This CAUTION symbol on the equipment refers you to the Product Manual for

additional information. This symbol appears next to required information in the manual.

WARNING

PERSONAL INJURY: Risk of electrical shock. This symbol warns you of a potential

shock hazard where HAZARDOUS LIVE voltages greater than 30 Vrms, 42.4 Vpeak,

or 60 VDC may be accessible. Failure to comply with these instructions could result in

death or serious injury.

ATTENTION, Electrostatic Discharge (ESD) hazards. Observe precautions for

handling electrostatic sensitive devices

Protective Earth (PE) terminal. Provided for connection of the protective earth (green

or green/yellow) supply system conductor.

Functional earth terminal. Used for non-safety purposes such as noise immunity

improvement. NOTE: This connection shall be bonded to protective earth at the source

of supply in accordance with national local electrical code requirements.

Earth Ground. Functional earth connection. NOTE: This connection shall be bonded to

Protective earth at the source of supply in accordance with national and local electrical

code requirements.

Chassis Ground. Identifies a connection to the chassis or frame of the equipment shall

be bonded to Protective Earth at the source of supply in accordance with national and

local electrical code requirements.

iv UDA2182 Universal Dual Analyzer Product Manual January 2009

Page 5

Contents

1 INTRODUCTION ...................................................................................................1

1.1 Overview.........................................................................................................................................1

1.2 Features...........................................................................................................................................3

2 SPECIFICATIONS.................................................................................................5

2.1 Specifications..................................................................................................................................5

2.2 CE Conformity (Europe).................................................................................................................7

3 UNPACKING, PREPARATION, AND MOUNTING...............................................9

3.1 Overview.........................................................................................................................................9

3.2 Unpacking and Preparing..............................................................................................................10

3.3 Mounting.......................................................................................................................................10

4 POWER WIRING.................................................................................................15

4.1 Overview.......................................................................................................................................15

4.2 General Wiring Practices..............................................................................................................16

4.3 Power Wiring Considerations.......................................................................................................17

4.4 Installing Power Wiring................................................................................................................17

5 OPERATING THE ANALYZER...........................................................................20

5.1 Overview.......................................................................................................................................20

5.2 Analyzer Overview.......................................................................................................................21

5.3 Key Navigation.............................................................................................................................22

5.4 Displays Overview........................................................................................................................23

5.5 Input Displays...............................................................................................................................25

5.6 PID Displays.................................................................................................................................26

5.7 Auto Cycle Displays .....................................................................................................................28

5.7.1 Overview............................................................................................................................ 28

5.7.2 Access to Auto Cycle Displays..........................................................................................28

5.7.3 How it works......................................................................................................................29

5.7.4 Displays..............................................................................................................................29

5.7.5 Hold Active........................................................................................................................30

5.7.6 Probe Transit......................................................................................................................30

5.7.7 Cycle Start Src ...................................................................................................................30

5.7.8 Cycle Interval.....................................................................................................................30

5.7.9 Rinse Cycle Cnt .................................................................................................................30

5.7.10 Rinse Mins......................................................................................................................30

5.7.11 Resume Dly Mins...........................................................................................................30

3/08 UDA2182 Universal Dual Analyzer Product Manual v

Page 6

5.7.12 Manual Starting/Stopping the Auto Cycle .....................................................................31

5.7.13 Auto Cycle Fail ..............................................................................................................32

5.7.14 Conditional Sequencer Steps..........................................................................................32

5.8 Pharma Display............................................................................................................................. 33

5.8.1 Overview............................................................................................................................ 33

5.8.2 How it works......................................................................................................................33

5.8.3 Access to Pharma Display..................................................................................................34

5.8.4 Displays..............................................................................................................................34

5.8.5 Pharma Warning and Fail Signal .......................................................................................36

5.9 Cation Calc Display......................................................................................................................37

5.9.1 Overview............................................................................................................................ 37

5.9.2 How it works......................................................................................................................37

5.9.3 pH Calculation from Specific and Cation Conductivity Setup..........................................38

5.9.4 Calibration..........................................................................................................................39

5.9.5 CO2 by Degassed Conductivity..........................................................................................39

5.9.6 Access to Cation Display...................................................................................................39

5.9.7 Troubleshooting.................................................................................................................40

5.10 Status Display............................................................................................................................41

5.11 Event History.............................................................................................................................46

5.12 Process Instrument Explorer Software......................................................................................48

5.13 Modbus Communications..........................................................................................................50

6 CONFIGURATION...............................................................................................51

6.1 Overview.......................................................................................................................................51

6.2 UDA2182 Block Diagram ............................................................................................................52

6.3 Main Setup Menu..........................................................................................................................53

6.4 Basic Configuration Procedure.....................................................................................................55

6.4.1 General Rules for Editing...................................................................................................55

6.5 Analog and Digital Signal Sources...............................................................................................58

6.6 Inputs Configuration.....................................................................................................................63

6.7 Outputs Configuration ..................................................................................................................74

6.8 Relays Configuration....................................................................................................................76

6.9 Alarms Configuration ...................................................................................................................81

6.10 Monitors Configuration.............................................................................................................83

6.11 Math Configuration...................................................................................................................85

6.12 Logic Configuration..................................................................................................................87

6.13 Auxiliary Configuration............................................................................................................89

6.14 PID Control Configuration........................................................................................................92

6.15 Auto Cycling Configuration....................................................................................................100

6.15.1 Overview ......................................................................................................................100

6.15.2 Accessing Auto Cycle Menu........................................................................................100

6.15.3 Auto Cycling Configuration.........................................................................................101

6.15.4 pH Auto Cycling Configuration Example....................................................................103

vi UDA2182 Universal Dual Analyzer Product Manual January 2009

Page 7

6.16 Variables Configuration..........................................................................................................105

6.17 Communication Configuration................................................................................................106

6.18 Maintenance Configuration.....................................................................................................108

7 INPUTS AND OUTPUTS WIRING.....................................................................114

7.1 Overview.....................................................................................................................................114

7.2 General Wiring Practices............................................................................................................115

7.3 Inputs and Outputs......................................................................................................................117

7.4 Direct pH/ORP Input Wiring Diagrams......................................................................................120

7.5 pH Input from External Preamplifier/Cap Adapter Wiring Diagrams........................................126

7.6 Conductivity................................................................................................................................130

7.7 Dissolved Oxygen.......................................................................................................................131

7.8 Communications Card.................................................................................................................133

7.9 Outputs........................................................................................................................................134

7.10 Option Card.............................................................................................................................135

8 INPUT CALIBRATION.......................................................................................136

8.1 Overview.....................................................................................................................................136

8.2 Calibration Menu........................................................................................................................137

8.3 pH/ORP and Conductivity Overview .........................................................................................138

8.4 Recommendations for Successful Measurement and Calibration...............................................139

8.5 pH Calibration.............................................................................................................................140

8.5.1 Introduction......................................................................................................................140

8.5.2 Calibrating pH Electrodes Using Automatic Buffer recognition.....................................141

8.5.3 Buffering Method of Calibrating pH Electrodes..............................................................145

8.5.4 Sample Method of Calibrating pH Electrodes ................................................................. 148

8.5.5 Viewing and resetting pH Offset and (Standardization) pH Slope..................................150

8.6 ORP Calibration..........................................................................................................................151

8.6.1 Introduction......................................................................................................................151

8.6.2 ORP Calibration Using Reference Solution.....................................................................151

8.6.3 ORP Calibration Using Voltage Input .............................................................................154

8.6.4 Viewing and Resetting ORP Offset .................................................................................156

8.7 Conductivity Calibration.............................................................................................................157

8.7.1 Introduction......................................................................................................................157

8.7.2 Entering the Cal Factor for each cell................................................................................157

8.7.3 Determining and Entering the TDS Conversion Factor...................................................157

8.7.4 Determining TDS conversion factor................................................................................158

8.7.5 Performing Calibration Trim............................................................................................159

8.7.6 Resetting Calibration Trim...............................................................................................162

8.7.7 Cation pH Calibration......................................................................................................163

8.7.8 Resetting pH Offset..........................................................................................................165

8.8 Dissolved Oxygen Calibration....................................................................................................166

3/08 UDA2182 Universal Dual Analyzer Product Manual vii

Page 8

9 OUTPUTS CALIBRATION................................................................................178

9.1 Overview.....................................................................................................................................178

9.2 Output Calibration ......................................................................................................................179

10 TEMPERATURE INPUT CALIBRATION ..........................................................185

10.1 Overview.................................................................................................................................185

10.2 Temperature Input Calibration................................................................................................186

11 CALIBRATION HISTORY .................................................................................189

11.1 Overview.................................................................................................................................189

11.2 Clear Calibration History ........................................................................................................190

12 DIAGNOSTICS AND MESSAGES....................................................................191

12.1 Overview.................................................................................................................................191

12.2 System Status Messages..........................................................................................................192

12.3 Calibration Diagnostics...........................................................................................................193

12.4 Auto Cycle Fail Messages.......................................................................................................194

12.5 Pharma Fail Messages.............................................................................................................195

13 ETHERNET AND COMMUNICATIONS ............................................................196

13.1 Overview.................................................................................................................................196

14 ACCESSORIES AND REPLACEMENT PARTS LIST......................................197

14.1 Overview.................................................................................................................................197

14.2 Part Numbers...........................................................................................................................198

15 APPENDICES....................................................................................................199

15.1 Table of Contents ....................................................................................................................199

15.2 Appendix A – Entering Values for Lead Resistance Compensation.......................................200

15.3 Appendix B – Entering Values for Lead Resistance Compensation [Titanium Cells]............202

15.4 Appendix C - Cyanide Waste Treatment.................................................................................204

15.5 Appendix D – Chrome Waste Treatment................................................................................208

15.6 Appendix E – Two-cell Applications......................................................................................212

15.7 Appendix F – Using a Precision Check Resistor (For Conductivity) ....................................216

15.8 Appendix G – Noise Testing, Dissolved Oxygen Application................................................218

15.9 Appendix H – DO Probe and Analyzer Tests .........................................................................219

15.10 Appendix I – Parameters Affecting Dissolved Oxygen Measurement................................222

15.11 Appendix J – Discussion on Chemical Interferences on Measured DO Currents ...............223

15.12 Appendix K – Percent Saturation Readout..........................................................................225

viii UDA2182 Universal Dual Analyzer Product Manual January 2009

Page 9

15.13 Appendix L – Leak Detection in PPB Applications............................................................226

15.14 Appendix M – Procedure for Low Level ppb Dissolved Oxygen Testing ..........................227

15.15 Appendix N – Sample Tap Electrode Mounting Recommendations...................................229

15.16 Appendix O – Auto Clean and Auto Cal Examples ............................................................231

15.17 Appendix P – AutoClean and AutoCal Theory and Piping.................................................234

15.17.1 AutoCal Sequence and Piping......................................................................................235

INDEX..........................................................................................................................239

3/08 UDA2182 Universal Dual Analyzer Product Manual ix

Page 10

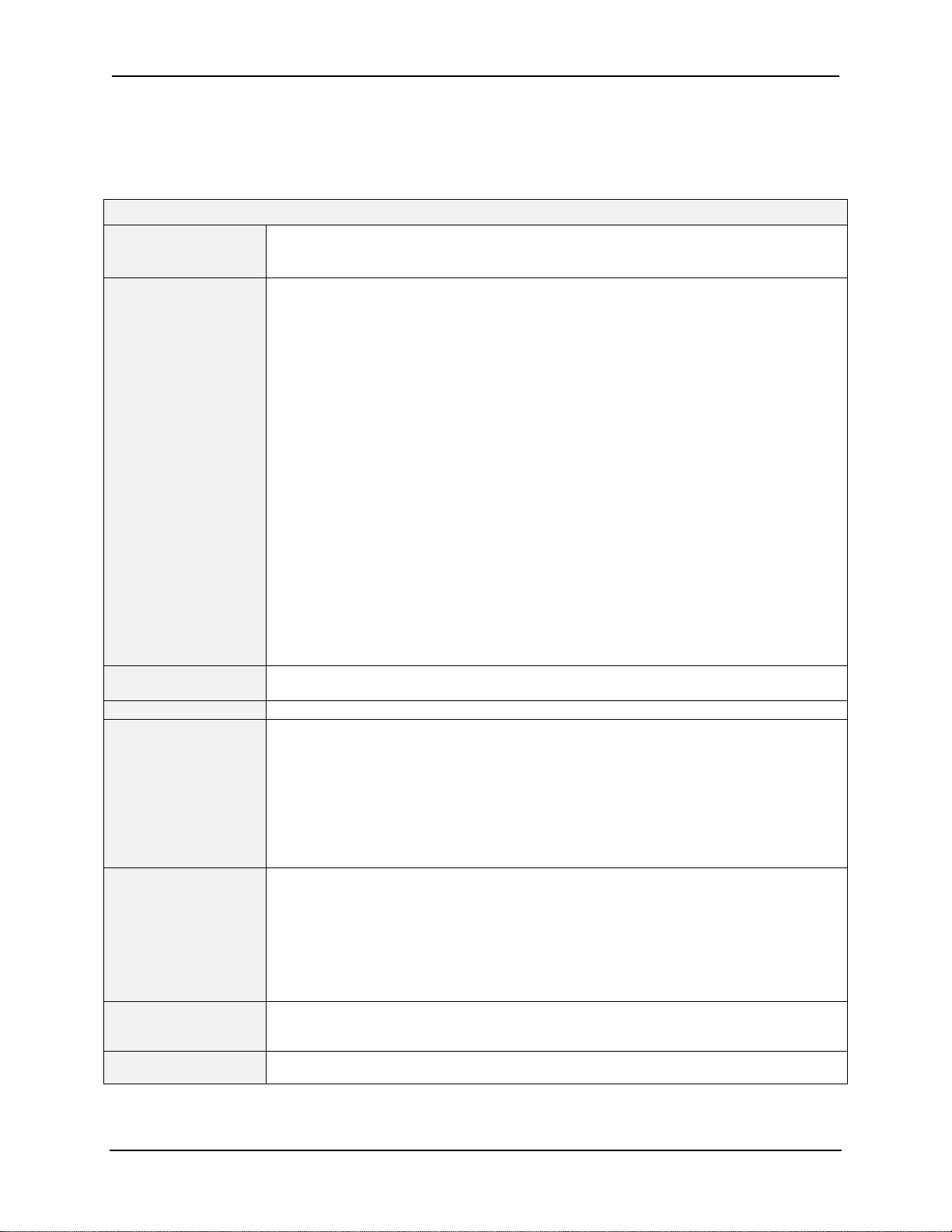

Tables

Table 3-1 Procedure for Unpacking and Preparing the UDA2182 ______________________________ 10

Table 3-2 Panel Mounting Procedure ____________________________________________________ 11

Table 4-1 Procedure for installing AC Power Wiring________________________________________ 17

Table 5-1 Function of Keys____________________________________________________________ 22

Table 5-2 Display Details Functions_____________________________________________________ 24

Table 5-3 Changing PID Parameters on the Display_________________________________________ 27

Table 5-4 Manually Starting/Stopping the Auto Cycle_______________________________________ 31

Table 5-5 Conditional Sequencer Steps for Auto Cycle ______________________________________ 32

Table 5-6 Selecting the Pharma Test on Display ___________________________________________ 35

Table 5-7 Status Display Details________________________________________________________ 41

Table 6-1 Basic Configuration Procedure_________________________________________________ 56

Table 6-2 Signal Sources______________________________________________________________ 58

Table 6-3 Analog Signal Sources _______________________________________________________ 59

Table 6-4 Digital Signal Sources________________________________________________________ 60

Table 6-5 Input Configuration__________________________________________________________ 63

Table 6-6 Outputs Configuration________________________________________________________ 74

Table 6-7 Relays Configuration ________________________________________________________ 77

Table 6-8 Alarms Configuration ________________________________________________________ 82

Table 6-9 Monitors Configuration_______________________________________________________ 83

Table 6-10 Math Configuration_________________________________________________________ 86

Table 6-11 Logic Configuration ________________________________________________________ 88

Table 6-12 Auxiliary Configuration _____________________________________________________ 90

Table 6-13 PID Configuration __________________________________________________________ 94

Table 6-14 PID Tuning _______________________________________________________________ 97

Table 6-15 PID Alarms _______________________________________________________________ 98

Table 6-16 Auto Cycling Configuration _________________________________________________ 101

Table 6-17 Example Auto Cycling Configuration for pH____________________________________ 103

Table 6-18 Variables Configuration ____________________________________________________ 105

Table 6-19 Communication Configuration _______________________________________________ 106

Table 6-20 Maintenance Configuration__________________________________________________ 108

Table 7-1 Recommended Maximum Wire Size ___________________________________________ 116

Table 7-2 Procedure for installing Input and Output wiring__________________________________ 119

Table 8-1 Standard pH Buffer Values___________________________________________________ 142

Table 8-2 Calibrating pH Electrodes Using Automatic Buffer Recognition______________________ 143

Table 8-3 Procedure for Buffering Method of Calibrating pH Electrodes _______________________ 146

Table 8-4 Procedure for Sample Method of Calibrating pH Electrodes _________________________ 148

Table 8-5 Oxidation-Reduction Potential of Reference Solutions at Specified Temperature________ 152

Table 8-6 Procedure for Calibrating ORP System Using a Reference Solution ___________________ 152

Table 8-7 Procedure for Calibrating ORP Analyzer Using Voltage Input _______________________ 154

Table 8-8 Conductivity of Potassium Chloride Solutions at 25 °C_____________________________ 160

Table 8-9 Procedure for Performing Calibration Trim Using a Reference Solution________________ 160

Table 8-10 Procedure for Sample Method of Calibrating Cation pH ___________________________ 163

Table 8-11 Calibrating a Dissolved Oxygen Probe Using Air Calibration Method ________________ 167

Table 8-12 Calibrating a Dissolved Oxygen Probe Using Sample Calibration Method_____________ 169

Table 8-13 Calibrating the Integral Pressure Sensor________________________________________ 171

Table 8-14 Running a Probe Bias Scan__________________________________________________ 174

Table 9-1 Procedure for Calibrating Analyzer Outputs______________________________________ 181

Table 10-1 Procedure for Calibrating the Temperature Inputs ________________________________ 186

x UDA2182 Universal Dual Analyzer Product Manual January 2009

Page 11

Table 11-1 Cal History items _________________________________________________________ 189

Table 12-1 Status Messages __________________________________________________________ 192

Table 12-2 Probe Calibration Diagnostics________________________________________________ 193

Table 12-3 Auto Cycle Fail Messages___________________________________________________ 194

Table 12-4 Pharma Fail Messages______________________________________________________ 195

Table 14-1 Part Numbers_____________________________________________________________ 198

Table 15-1 Data for Concentration Range Measurements ___________________________________ 217

Table 15-2 Dissolved Oxygen Solubility vs. Temperature ___________________________________ 225

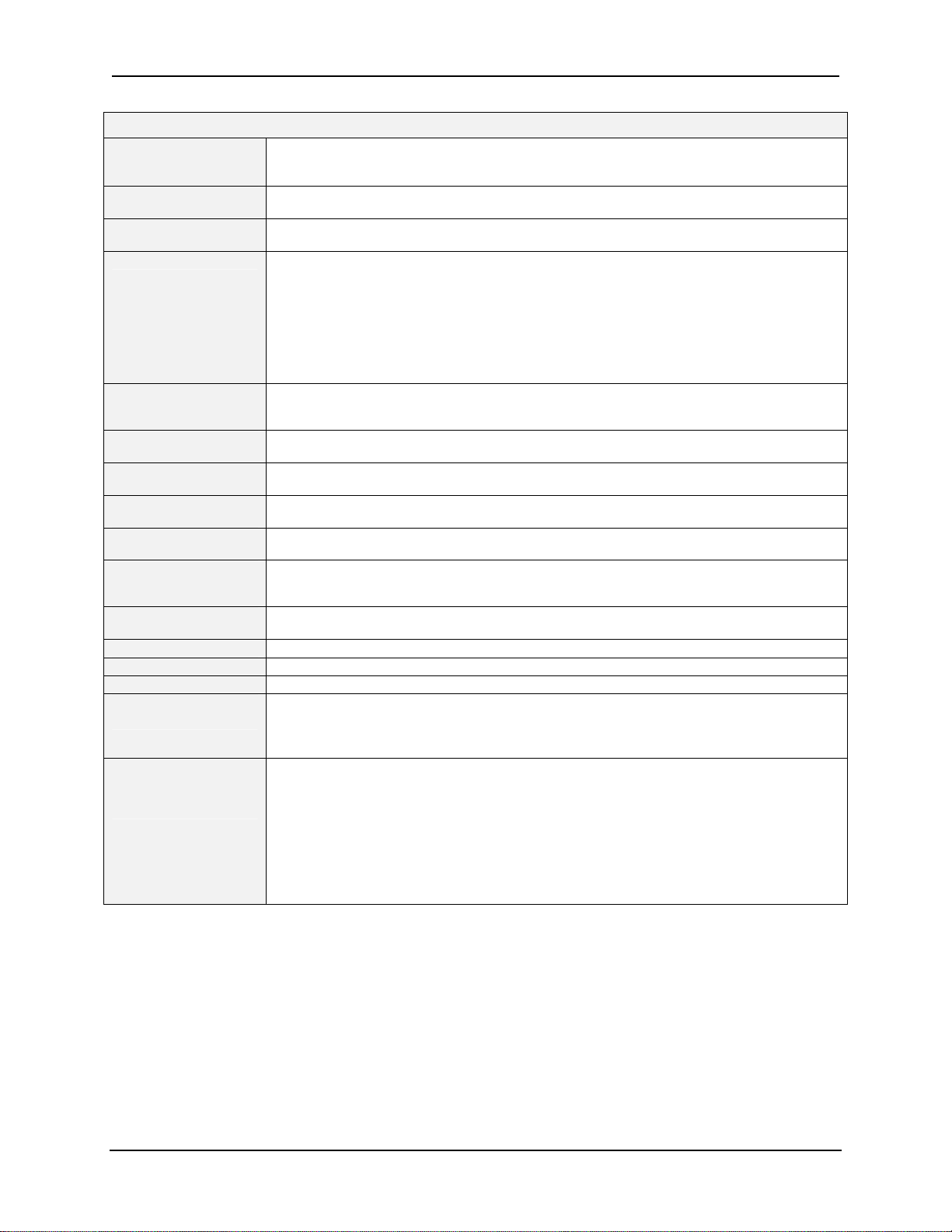

Figures

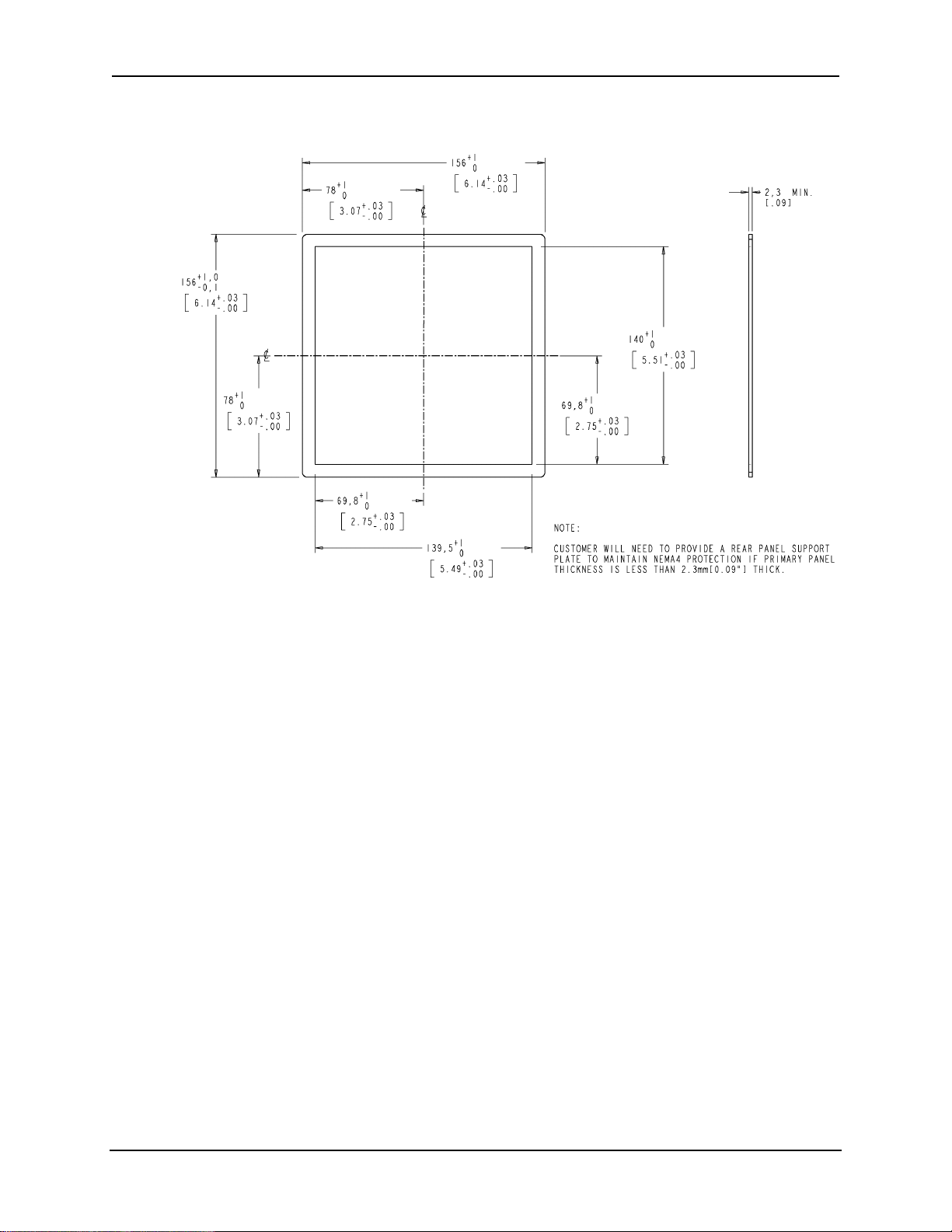

Figure 3-1 Panel Mounting Dimensions (not to scale) _______________________________________ 11

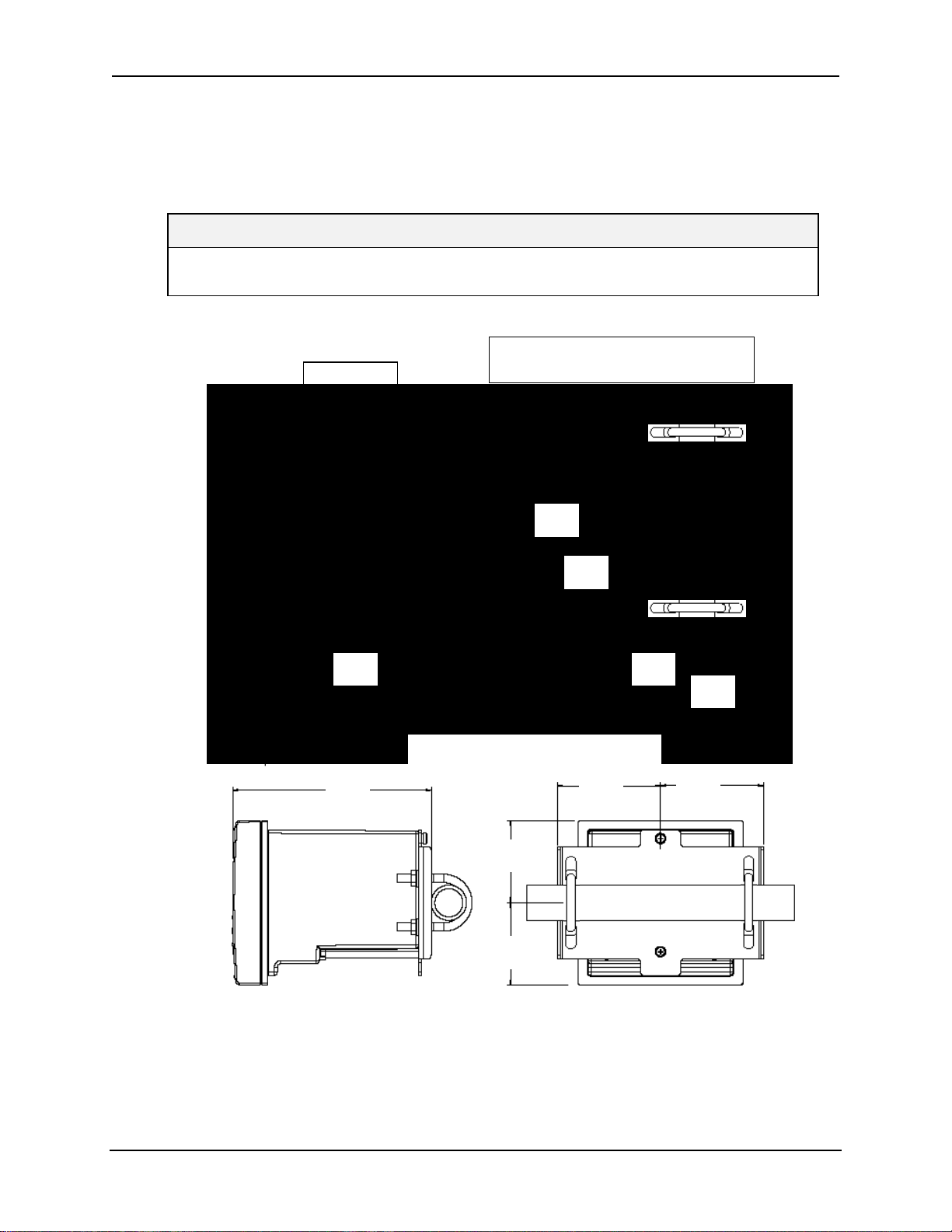

Figure 3-2 Rear Panel Support Plate Dimensions___________________________________________ 12

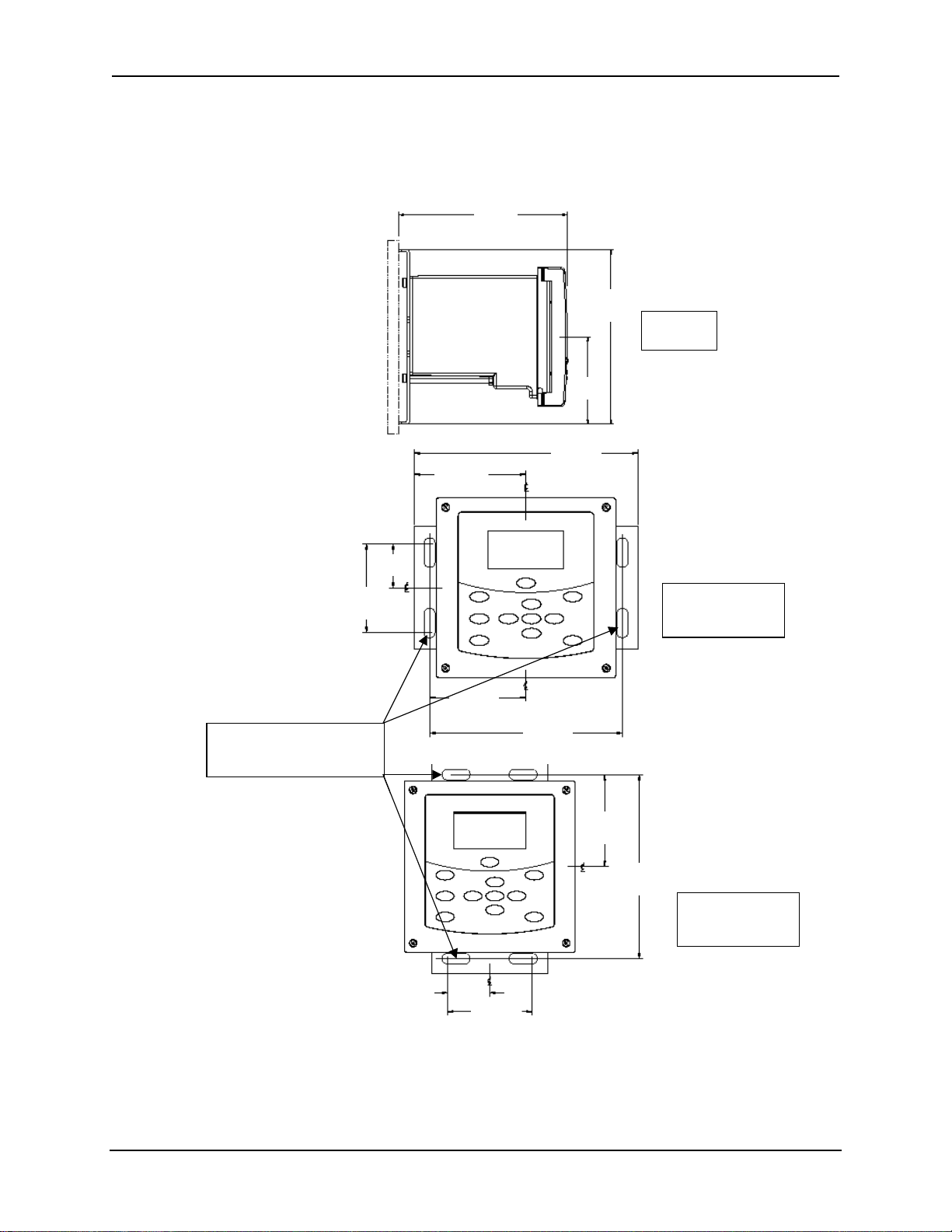

Figure 3-3 Pipe Mounting Dimensions (not to scale) ________________________________________ 13

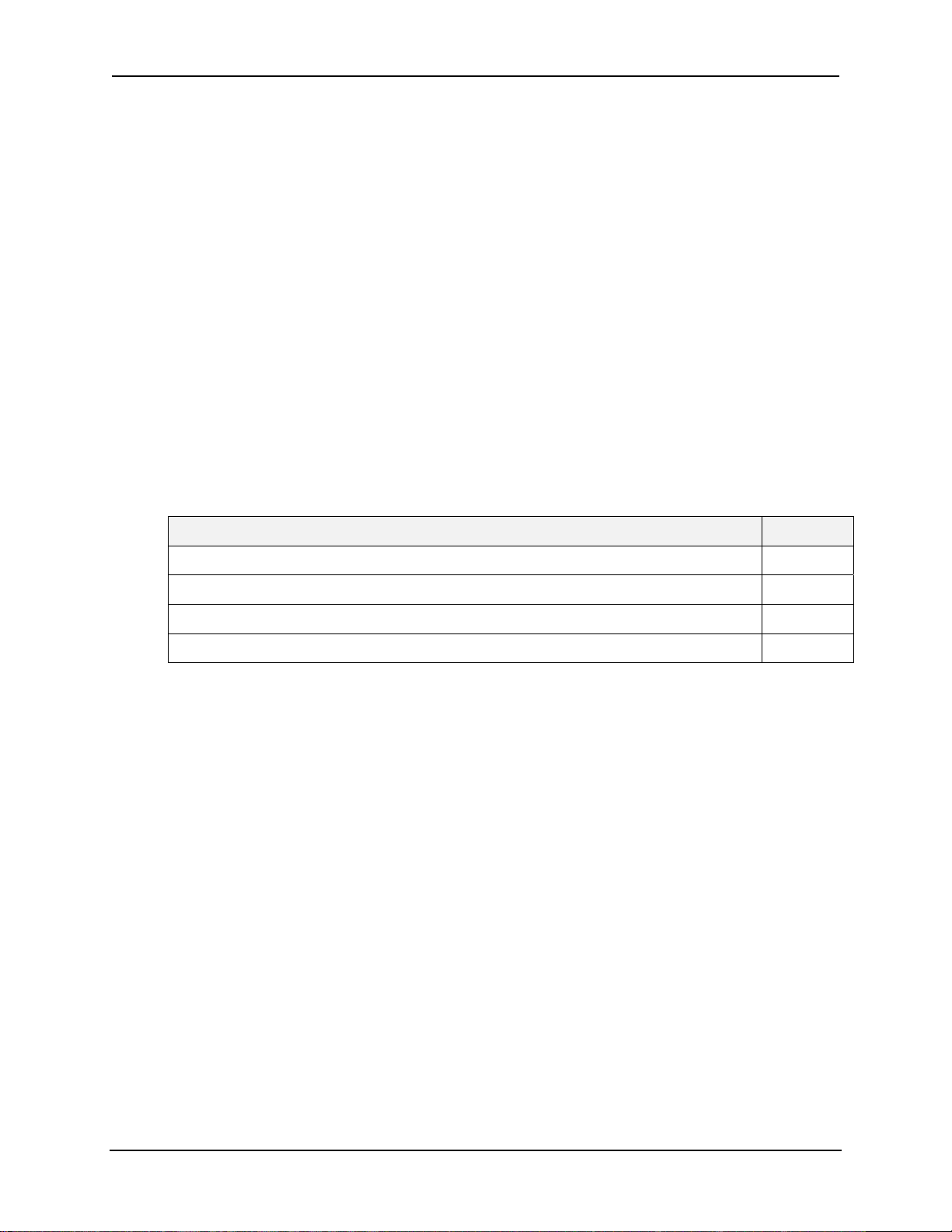

Figure 3-4 Wall Mounting Dimensions (not to scale)________________________________________ 14

Figure 4-1 Power Wiring______________________________________________________________ 19

Figure 5-1 UDA2182 Operator Interface (all display items shown)_____________________________ 21

Figure 5-2 Example – Two Input Display_________________________________________________ 25

Figure 5-3 PID Loop 1 Edit Display screen example ________________________________________ 26

Figure 5-4 Auto Cycle Display screen example ____________________________________________ 28

Figure 5-5 Pharma Display screen example _______________________________________________ 34

Figure 5-6 UDA for Cation and Degassed CO2_____________________________________________ 37

Figure 5-7 Cation Display screen example for pH calculations ________________________________ 39

Figure 5-8 Status Display screen example ________________________________________________ 41

Figure 5-9 Event History Display screen example __________________________________________ 46

Figure 5-10 Alarm Event Display screen example (Read Only)________________________________ 46

Figure 5-11 Screen capture of Process Instrument Explorer running on a Pocket PC_______________ 48

Figure 6-1 UDA2182 Block Diagram____________________________________________________ 52

Figure 7-1 Wiring Terminals and board Location__________________________________________ 118

Figure 7-2 Terminal Designations for Durafet III Electrode__________________________________ 120

Figure 7-3 Terminal Designations for Durafet II Electrode __________________________________ 121

Figure 7-4 Terminal Designations for Meredian II Electrode_________________________________ 122

Figure 7-5 Terminal Designations for Meredian II Electrode with Quick Disconnect______________ 122

Figure 7-6 Terminal Designations for ORP ______________________________________________ 123

Figure 7-7 Terminal Designations for Direct pH/ORP with Quick Disconnect Option_____________ 123

Figure 7-8 Terminal Designations for HPW7000 System____________________________________ 124

Figure 7-9 Terminal Designations for HB Series pH or ORP_________________________________ 125

Figure 7-10 Terminal Designations for Meredian Electrode with External Preamplifier____________ 126

Figure 7-11 Terminal Designations for Durafet II Electrode with External Preamplifier____________ 127

Figure 7-12 Terminal Designations for Durafet II Electrode with Cap Adapter___________________ 128

Figure 7-13 Terminal Designations for Durafet III Electrode with Cap Adapter __________________ 129

Figure 7-14 Terminal Designations for Conductivity with Integral Cable _______________________ 130

Figure 7-15 Terminal Designations for Conductivity Cells with Quick Disconnect _______________ 130

Figure 7-16 Terminal Designations for Dissolved Oxygen with Integral Cable___________________ 131

Figure 7-17 Terminal Designations for Dissolved Oxygen with Quick Disconnect Option _________ 132

Figure 7-18 Terminal Designations for Communications Card _______________________________ 133

Figure 7-19 Terminal Designations for Power, Analog Output, and Relay Output ________________ 134

Figure 7-20 Terminal Designations for Option Board ______________________________________ 135

Figure 8-1 Resetting pH Offset and pH Slope_____________________________________________ 150

3/08 UDA2182 Universal Dual Analyzer Product Manual xi

Page 12

Figure 8-2 Resetting ORP Offset ______________________________________________________ 156

Figure 8-3 Resetting Calibration Trim __________________________________________________ 162

Figure 8-4 Resetting pH Offset ________________________________________________________ 165

Figure 8-5 Display of Probe Bias Test Done in Air ________________________________________ 173

Figure 8-6 Resetting Pressure Offset or Bias Volts_________________________________________ 177

Figure 9-1 Resetting Output 1 Offsets (example) __________________________________________ 184

Figure 10-1 Resetting temperature offset ________________________________________________ 188

Figure 15-1 Example of a Conductivity Loop_____________________________________________ 200

Figure 15-2 Example of a Conductivity Loop_____________________________________________ 202

Figure 15-3 Cyanide Treatment System _________________________________________________ 204

Figure 15-4 First Stage Cyanide Oxidation - Typical Titration Curve __________________________ 205

Figure 15-5 Chrome Treatment System _________________________________________________ 208

Figure 15-6 Chrome Reduction - Typical Titration Curve ___________________________________ 209

Figure 15-7 Suggested ppb Dissolved Oxygen Test Set-up __________________________________ 228

Figure 15-8 Typical Probe Installation __________________________________________________ 229

Figure 15-9 Auto Clean Setup_________________________________________________________ 232

Figure 15-10 Auto Cal Setup__________________________________________________________ 233

Figure 15-11 Automatic Electrode Wash Setup __________________________________________ 235

Figure 15-12 Rinse and One-Point Calibration____________________________________________ 236

Figure 15-13 Two-Point AutoCal Operation______________________________________________ 237

xii UDA2182 Universal Dual Analyzer Product Manual January 2009

Page 13

Introduction

1 Introduction

1.1 Overview

Multi-function instrument

The UDA2182 Universal Dual Analyzer is the next level of dual channel analyzers

providing unprecedented versatility and flexibility.

The UDA2182 can accept single or dual inputs from Honeywell Direct pH, pH from

preamp, ORP (Oxidation Reduction Potential), Contacting Conductivity and Dissolved

Oxygen sensors. Measurements for Dual channel units can be arranged in any

combination of measurement.

User interface

“Process Information at a Glance” is a unique feature of the UDA2182 graphical

backlit LCD.

Two PV values with corresponding UOM (unit of measure), temperature, alarm state,

scales, and limits, tagging, and status messages can be displayed simultaneously.

Ten dedicated keys provide direct access to Setup configuration menus and sub-menus

and Calibration.

Easy to configure

Menu-driven configuration of the UDA2182 is intuitive, fast and easy. A Setup menu is

provided for every configuration task. You will be permitted to configure only those

parameters relevant to your application and supported by the Analyzer model you

purchased.

In fact, Setup configuration screens will contain only prompts and menu choices that

apply to your application.

Multi-language prompts guide the operator step-by-step through the configuration

process assuring quick and accurate entry of all configurable parameters. Nine languages

are available via configuration: English, French, German, Spanish, Italian, Russian,

Turkish, Polish and Czech.

Inputs

Analytical measurements of Direct pH, pH from preamp, ORP, Conductivity and

Dissolved Oxygen (ppm or ppb) can all be done in one analyzer. The unit can be used as

a single input or dual input instrument – you decide what measurements are included.

The input boards are factory calibrated and easily replaced. Addition of additional relays

or an analog output is done with a single board. The “Mix –n- Match” design reduces

inventory and increases flexibility. You can purchase a basic unit and then add input and

output boards as needed.

January 2009 UDA2182 Universal Dual Analyzer Product Manual 1

Page 14

Introduction

Outputs

Two standard Analog outputs 0 –20 or 4–20 mAdc, 750 ohms maximum, isolated from

inputs, ground, and each other, and independently assignable to any parameters and

ranges Proportional to user-set output range(s) of selected parameter(s).

One optional Analog output 0 –20 or 4–20 mAdc, 750 ohms maximum, isolated from

inputs, ground, and each other, and independently assignable to any parameters and

ranges.

Relays

Two 4A SPDT alarm/control relays are standard; with an additional two 4A relays

available as an option.

Infrared Communications

The infrared connection provides a non-intrusive wireless connection with the instrument

and maintains its weather tight integrity when combined with the optional PIE (Process

Instrument Explorer).

No need to get access to the back of the analyzer to communicate with the instrument, no

need to take your screw driver to wire the communication cable, no wiring mistake

possible. You can now duplicate an instrument’s configuration, upload or download a

new configuration in a matter of seconds, just by pointing your Pocket PC in the direction

of the instrument.

Communications Card (Optional)

The Communication card provides one Serial Port and one Ethernet Port.

Serial port provides

RS422/RS485 multi-drop

Modbus RTU protocol to read signals and read/write variables

Ethernet port provides:

Multi-language web pages to monitor readings, alarms, statuses, events

Multi-language web pages to setup Ethernet port settings

Multi-language email to send alarm status changes

Modbus TCP protocol to read signals and read/write variables

Both ports can communicate to a PIE tool

2 UDA2182 Universal Dual Analyzer Product Manual January 2009

Page 15

Introduction

1.2 Features

Standard and solution temperature compensation

Measured pH temperature is compensated in one of two ways. Electrode temperature

sensitivity is automatically compensated to display the correct pH value at temperature.

In addition, displayed pH can be optionally normalized to a solution temperature of 25°C

as determined by the current Solution Temperature Coefficient, which is expressed in

units of pH/°C with precision to the hundredths decimal place. The parameter “Solu

Temp Coeff” allows the selection of Pure Water, Ammonia, Phosphate, Morpholine, and

Custom or None (User Entry).

Measured Conductivity and Resistivity can optionally be temperature compensated to

25°C for a specific solution type. TDS and concentration are always measured based on a

specific solution type. The cell constant and measurement type determines which solution

types are available for selection.

Dissolved Oxygen accurately measures the concentration of dissolved oxygen in water.

The Analyzer energizes the probe and receives dissolved oxygen and temperature signals.

Optional salinity compensation is provided. The Analyzer provides for Air or Sample

calibration with ambient temperature and atmospheric pressure compensation.

Calculated pH

High purity water pH can be calculated from Specific and Cation conductivities to be

used as a check on in-line high purity water pH measurements.

Automatic buffer recognition

“Buffer Group” types NIST/USP, USA, or Europe determines the set of standard pH

buffer values to be used for Zero and Slope calibration by automatic buffer recognition.

Each of the available Buffer Groups is a set of 5 or 6 pH buffer standards.

Solution Temperature Compensation

For high purity water measurement you can select pre-set compensations or configure

custom values.

USP26 Alarm Capabilities

Relays can be configured to alarm on conductivity values as determined by the USP26

standards.

Computed Variables

The availability of calculated variables in the list of available sources for alarms, math

and control and for status display is determined by similarity of units of measure between

the two input boards. For example with Dual Conductivity, %Rejection/Passage,

Difference, or Ratio can be displayed and assigned to the outputs or alarms.

CO2 concentration in ppm can be calculated from de-gassed conductivity measurement.

January 2009 UDA2182 Universal Dual Analyzer Product Manual 3

Page 16

Introduction

Password protection

Keyboard security protects configuration and calibration data. A password (up to four

digits) can be configured. If the security feature is enabled, the password will be required

to access configuration and calibration software functions.

Auto Clean/Auto Cal

Built-in real time clock is used to set-up versatile cycles that can be used to initiate

automatic sensor cleaning and then calibration.

Diagnostic/Failsafe Outputs

Continuous diagnostic routines detect failure modes, trigger a failsafe output value and

identify the failure to minimize troubleshooting time. The UDA2182 Analyzer performs

extensive self-diagnostics as a background task during normal operation. If a problem is

detected, a message is displayed on the Message stripe to alert the operator. In addition,

the operator can initiate keypad and display tests using Maintenance Menu functions.

High Noise Immunity

The analyzer is designed to provide reliable, error-free performance in industrial

environments that often affect highly noise-sensitive digital equipment.

Watertight corrosion-resistant case

CSA Type 4X (NEMA 4X) rated enclosure permits use in applications where it may be

subjected to moisture, dust, or hose-down conditions. The UDA2182 is designed for

panel, pipe or wall mounting.

4 UDA2182 Universal Dual Analyzer Product Manual January 2009

Page 17

Specifications

2 Specifications

2.1 Specifications

UDA2182 Universal Dual Analyzer

Display Graphical LCD with white LED Backlight

Viewing Area: 66.8 mm (W) X 35.5 mm (H)

Dot Pixels: 128 (W) X 64 (H)

Display Ranges pH:

Keypad 10 Button Membrane Switch w/Directional Functionality

Case Material GE Valox® 357 (un-reinforced thermoplastic polyester)

Performances (Under

reference operating

conditions)

Operating Conditions Ambient Temperature

Standard Analog Output Two 0-20 mAdc or 4-20 mAdc, 750 ohms max., isolated from inputs, ground, and each other,

Optional Analog Output One 0-20 mAdc or 4-20 mAdc, 750 ohms max., isolated from inputs, ground, and each other.

0-14 pH

Temperature: -10 to 110°C (14 to 230°F)

ORP:

-1600 to +1600 mV

Conductivity:

0.01 Cell: 0-2 uS/cm displayable to 200 uS/cm; 0-0.2 mS/cm;

0-2,000 ppb TDS; 0-200 ppm TDS

0.1 Cell: 0-20 uS/cm displayable to 2000 uS/cm; 0-2 mS/cm,

0-2,000 ppb TDS; 0-2,000 ppm TDS,

1.0 Cell: 0-200 uS/cm displayable to 20,000 uS/cm; 0-20 mS/cm;

0-200 ppm TDS; 0-20 ppt TDS

10 Cell: 0-2,000 uS/cm displayable to 99999 uS/cm; 0-200 mS/cm;

0-2,000 ppm TDS; 0-200 ppt TDS

25 Cell: 0-20,000 uS/cm displayable to 99999 uS/cm; 0-500 mS/cm;

0-10% Concentration displayable to 20%

50 Cell: 0-20,000 uS/cm displayable to 99999 uS/cm; 0-1,000 mS/cm;

0-20% Concentration

Temperature: 0 to + 140°C (32 to 284°F)

Dissolved Oxygen:

0 - 20 ppm

0 –200 ppb, displayable to 20000 ppb

0 – 100% saturation, displayable to 200% saturation

Temperature: 2 – 60°C (35.6 – 104°F), must not freeze

UV/Solvent/Abrasion Resistant

Accuracy: 0.5% of reading

Output Accuracy: +/- 0.01 mA

Drift: Negligible

Repeatability: 0.05%

Temperature Accuracy:

pH and Conductivity Thermistor: +/- 0.1°C from –10 to 100° C, +/- 1.0° C from 101° to 140° C

pH 1000 ohm RTD: +/- 0.4° C

D.O. Thermistor: +/- 0.1° C from 0 to 60° C

Reference Operating Conditions: 25 +/- 1° C; 10-40% RH; 120 or 240 Vac

Operating: 0 to 60°C (32 to 140°F)

Storage: -30 to 70°C (-22 to 158°F)

RH: 5 to 90% max. Non-condensing up to 40°C (104°F). For higher temperatures the RH specification

is derated to maintain constant moisture content

Vibration:

5-15 Hz disp 8 mm pk to pk

15-200 Hz accel 2 G

Independently field-assignable to any parameters and ranges.

Proportional to user-set output range(s) of selected parameter(s),

Independently field-assignable to any parameters and ranges

January 2009 UDA2182 Universal Dual Analyzer Product Manual 5

Page 18

Specifications

UDA2182 Universal Dual Analyzer

Control Loop/Outputs Control Loops: 2 standard (one for each PV); current, pulse frequency, or time proportional

Control Loop Types: PID (optional), Duplex (optional), On/Off (standard)

Auto-tuning: Accutune II, fuzzy logic overshoot suppression, applicable to both PID loops

Standard Alarm/ Control

Relays

Optional Additional

Alarm/Control Relays

Alarm/Control Settings Alarm/on-off control delay: 0-100 seconds.

Remote Preamplifier Input

Option

pH Temperature

Compensation

Calculated pH from

Differential Conductivity

Auto Buffer Recognition

(pH)

Conductivity

Compensations

Dissolved Oxygen

Measurement

Auto Clean/ Auto Cal

Function

Event History Screen Event history screen stores 256 events with a description of the event and a Date/time stamp.

Calibration History Screen Calibration history screen stores information on 128 calibration events with a date/time stamp.

Power Requirements 90 -264 Vac, 47-63 Hz, 15 VA. Memory retained by E2PROM when power is off.

Wireless Interface

RS422/RS485 Modbus

RTU Slave

Communications Interface

(Optional)

Two SPDT (Form “C”) Relays

Resistive Load Rating: 4A, 120/240 Vac

Two SPDT (Form “C”) Relays

Resistive Load Rating: 4A, 120/240 Vac

Alarm/on-off control deadbands: individually set, from 1 count to full scale for pH, ORP, and

temperature.

On/off cycle period: 0 to 1000 seconds.

On/off percent “on” time: 0 to 100%, 1% resolution.

Set point and proportional band limit ranges: ±19.99 pH, ±1999 mV, -10 to 130°C, 1 count resolution.

DAT cycle period: 1 to 1999 seconds.

PFT maximum frequency: 1 to 200 pulses/minute.

PFT pulse width: 50 ms, compatible with electronic pulse-type metering pumps.

Optional input card to accept input signal from Honeywell digital preamplifiers:

Meridian II – 31075707 and 31022283

Durafet – 31079288 and Cap Adapter cables

Conventional compensation for changing electrode output (Nernst response), plus selectable solution

temperature compensation for high-purity water.

User selectable when unit has two Conductivity inputs. Used when ammonia or amine is the water

treatment chemical.

User Selectable

Available Buffer Series: NIST/USP, US, and Euro

NaCl, HCl, H

Max flowrate (probe): 950 ml/min with flow chamber; no dependence on stirring or flowrate

Atmospheric pressure: 500-800 mm Hg with internal sensor, for calibration

Calibration with either Air or Sample

Real time clock is used to set-up cycles to initiate a cleaning and calibration sequence. Cycle Set-up is

user configurable.

Type: Infrared (IR)

Length of Link: 0 –1 M, 0 –15° Offset

Baud Rate: 9600

Data Format: Modbus Protocol

Baud Rate: 2400, 4800, 9600, 19200, 38400, 57600, or 115200 selectable

Data Format:: IEEE floating point and 32-bit integer. Word swap configurable.

Length of Link:

2000 ft (600 m) max. with Belden 9271 Twinax Cable and 120 ohm termination resistors

4000 ft (1200 m) max. with Belden 8227 Twinax Cable and 100 ohm termination resistors

Link Characteristics: Two-wire (half-duplex), multi-drop Modbus RTU protocol, 15 drops maximum or

up to 31 drops for shorter link length.

Modbus RTU slave: Provides monitoring of inputs outputs, statuses, alarms, and variables. Provides

writing of variables for remotely modifying parameter settings.

, PO4, NaOH, NH3, C4H9C, Pure Water, Custom (User Selectable)

2SO4

6 UDA2182 Universal Dual Analyzer Product Manual January 2009

Page 19

Specifications

UDA2182 Universal Dual Analyzer

Ethernet TCP/IP

Communications Interface

(Optional)

Safety Compliance UL/CSA General Purpose

CE Compliance CE Conformity (Europe): CE Mark on all models signifies compliance to EMC Directive 84/336/EEC

Case Dimensions 156 mm X 156 mm X 150 mm (6.14” X 6.14” X 5.91”)

Enclosure Rating CSA Type 4X (NEMA 4X) rated enclosure

Installation Ratings Installation Category (Overvoltage Category): Category II

Weight Approx 3 lbs (6.6kg)

Mounting Panel mounting-hardware supplied.

Type: 10 or 100 BaseT; auto-speed and auto-polarity sensing

Length of Link: 330 ft. (100 m) maximum. Use Shielded twisted-pair, Category 5 (STP CAT5) Ethernet

cable.

Link Characteristics: Four-wire plus shield, single drop, five hops maximum

IP Address: IP Address is 192.168.1.254 as shipped from the factory

Recommended network configuration: Use Switch rather than Hub in order to maximize UDA Ethernet

performance

Configuration: Ethernet parameters are configured via the front-panel or web pages.

Modbus TCP/IP: Five simultaneous socket connections provide monitoring of inputs outputs, statuses,

alarms, and variables. Provides writing of variables for remotely modifying parameter settings.

Modbus TCP/IP Data Format: IEEE floating point and 32-bit integer. Word swap configurable.

Web server: multiple client support

Multi-language Web pages: monitoring inputs, outputs, statuses, alarms, and events

Multi-language Email: Alarm notification to eight email addresses. These must be configured using

web pages signed in as the administrator.

DHCP: ( Dynamic Host Configuration Protocol) selectable via web page or front-panel

FM/CSA Approval for Class I, Div 2; Groups A, B, C and D. T4, T

and LVD Directive 73/23/EEC.

EMC Classification: Group 1, Class A, ISM Equipment

Method of Assessment: Technical File (EN61010-1; EN 61326)

Declaration of Conformity: 51453667

Panel cutout: 138.5 mm X 138.5 mm (5.45” X 5.45”)

Panel thickness: 1.52 mm (0.06”) min, 9.5 mm (0.38”) max

FM Class 1, Div 2

Pollution Degree: 2

Altitude: 2000 m

Optional Wall and 1” to 2” pipe mounting. Select option appropriate in Model Number.

=60°C

a

2.2 CE Conformity (Europe)

This product is in conformity with the protection requirements of the following European

Council Directives: 73/23/EEC, the Low Voltage Directive, and 89/336/EEC, the EMC

Directive. Conformity of this product with any other “CE Mark” Directive(s) shall not be

assumed.

Product Classification: Class I: Permanently connected, panel-mounted Industrial

Control Equipment with protective earthing (grounding) (EN61010-1).

Enclosure Rating: The front panel of the analyzer is rated at NEMA4X when properly

installed.

Installation Category (Overvoltage Category): Category II (EN61010-1)

Pollution Degree: Pollution Degree 2: Normally non-conductive pollution with

occasional conductivity caused by condensation. (Ref. IEC 664-1)

EMC Classification: Group 1, Class A, ISM Equipment (EN61326, emissions), Industrial

Equipment (EN61326, immunity)

Method of EMC Assessment: Technical File (TF)

January 2009 UDA2182 Universal Dual Analyzer Product Manual 7

Page 20

Specifications

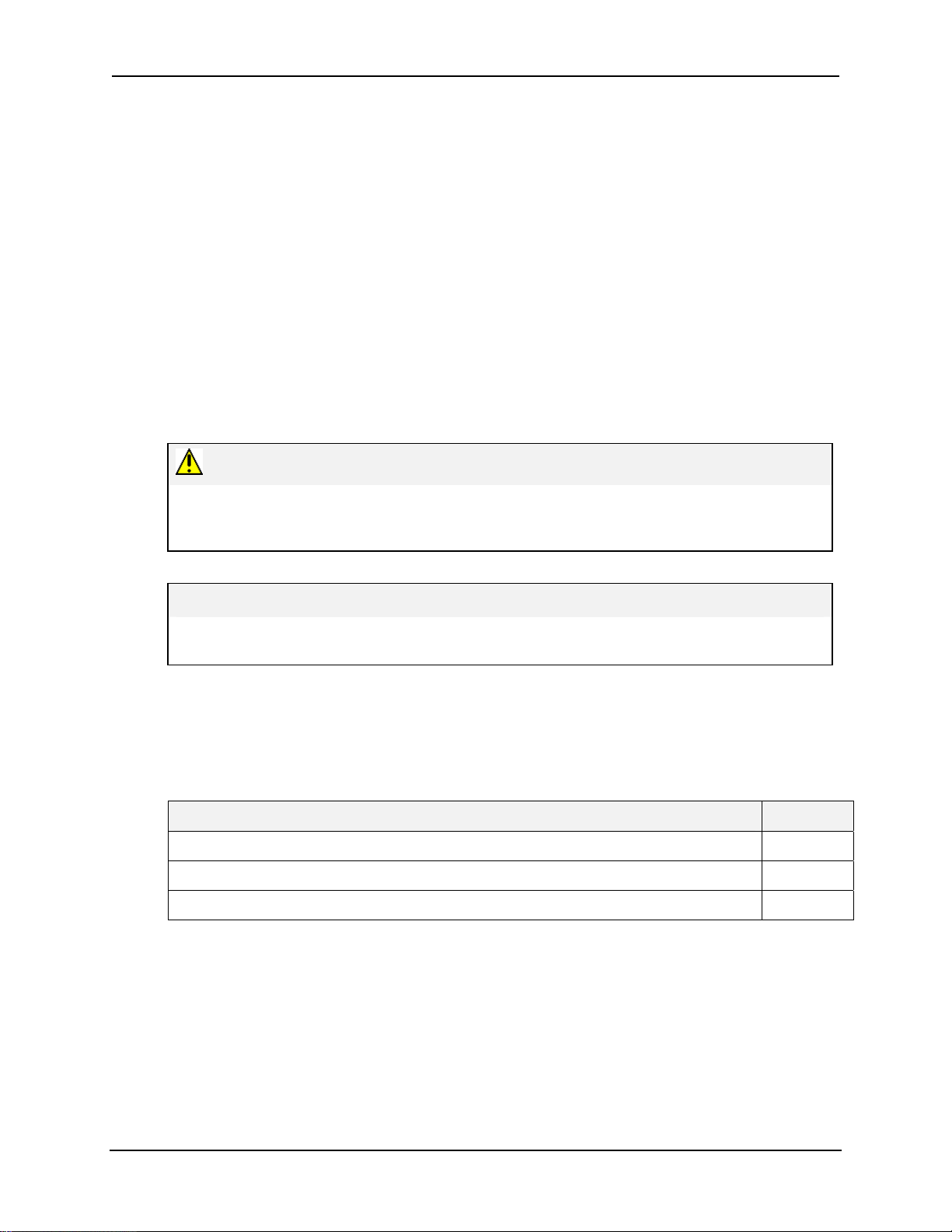

ATTENTION

The emission limits of EN61326 are designed to provide reasonable protection against harmful interference

when this equipment is operated in an industrial environment. Operation of this equipment in a residential

area may cause harmful interference. This equipment generates, uses, and can radiate radio frequency

energy and may cause interference to radio and television reception when the equipment is used closer

than 30 meters (98 feet) to the antenna (e). In special cases, when highly susceptible apparatus is used in

close proximity, you may have to employ additional mitigating measures to further reduce the

electromagnetic emissions of this equipment.

WARNING

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the

equipment may be impaired.

8 UDA2182 Universal Dual Analyzer Product Manual January 2009

Page 21

Unpacking

3 Unpacking, Preparation, and Mounting

3.1 Overview

Introduction

This section contains instructions for unpacking, preparing, and mounting the Analyzer.

Instructions for wiring are provided in Section 4 (power wiring) and Section 7 (input

wiring). Software configuration is described in Section 6.

The UDA2182 Analyzer can be panel, wall, or pipe mounted.

Each unit has (4) 22.22mm [.87"] dia. holes on the bottom of the unit for lead wires and

conduit fittings. The user supplies the conduit fittings.

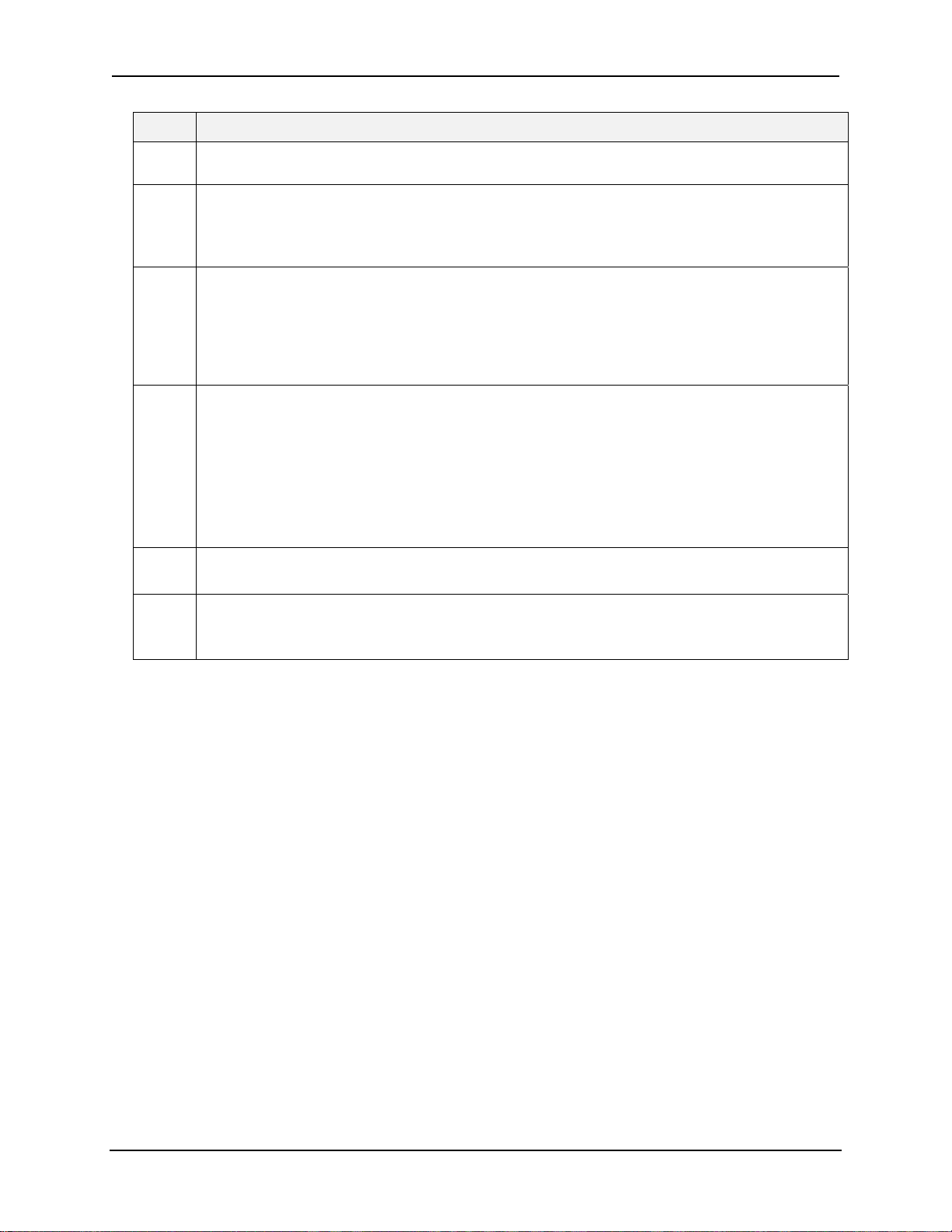

CAUTION

To avoid damage to the case when connecting to a rigid metallic conduit system, the

conduit hub must be connected to the conduit before the hub is connected to the

enclosure

ATTENTION

When installing the unit, you must select appropriate watertight fittings to insure

watertight integrity.

What’s in this section?

The topics in this section are listed below.

3.1 Overview 9

3.2 Unpacking and Preparing 10

3.3 Mounting 10

Topic See Page

January 2009 UDA2182 Universal Dual Analyzer Product Manual 9

Page 22

Unpacking

3.2 Unpacking and Preparing

Procedure

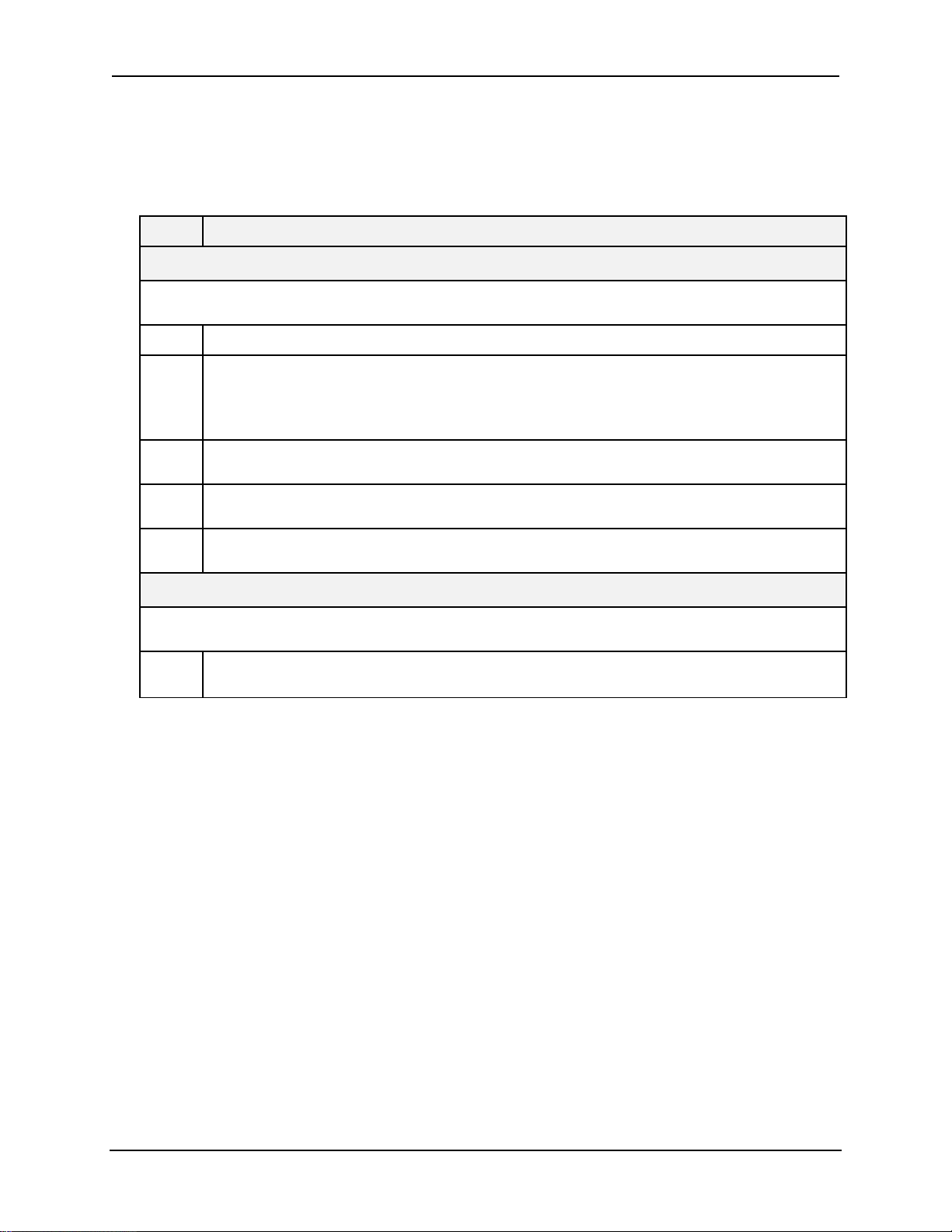

Table 3-1 Procedure for Unpacking and Preparing the UDA2182

Step Action

ATTENTION

For prolonged storage or for shipment, the instrument should be kept in its shipping container.

Do not remove shipping clamps or covers. Store in a suitable environment only (see specifications in Section 2).

Carefully remove the instrument from the shipping container.

1

Compare the contents of the shipping container with the packing list.

2

• Notify the carrier and Honeywell immediately if there is equipment damage or shortage.

• Do not return goods without contacting Honeywell in advance.

Remove any shipping ties or packing material. Follow the instructions on any attached tags, and then

3

remove such tags.

All UDA2182 Analyzers are calibrated and tested at the factory prior to shipment. Examine the model

4

number on the nameplate to verify that the instrument has the correct optional features.

Select an installation location that meets the specifications in Section 2. The UDA2182 can be panel-

5

, wall-, or pipe-mounted (see Section 3.3).

ATTENTION

Pipe mounting is not recommended if the pipe is subject to severe vibration. Excessive vibration may affect

system performance.

If extremely hot or cold objects are near the installation location, provide radiant heat shielding for the

6

instrument.

3.3 Mounting

Introduction

The Analyzer can be mounted on either a vertical or tilted panel or can be pipe or wall

mounted (option) using the mounting kit supplied. Overall dimensions and panel cutout

requirements for mounting the analyzer are shown in Figure 3-1. Pipe mounting is

shown in Figure 3-3. Wall Mounting is shown in Figure 3-4.

For Sample Tap Electrode Mounting recommendations, See Section 15.15 – page 229.

The analyzer’s mounting enclosure must be grounded according to CSA standard C22.2

No. 0.4 or Factory Mutual Class No. 3820 paragraph 6.1.5.

Before mounting the analyzer, refer to the nameplate on the outside of the case and make

a note of the model number. It will help later when selecting the proper wiring

configuration.

10 UDA2182 Universal Dual Analyzer Product Manual January 2009

Page 23

Unpacking

Panel Mounting Dimensions

+1

+1

+1

138

138

138

-0

-0

-0

+.04

+.04

+.04

[5.43]

[5.43]

[5.43]

-0

-0

-0

+1

+1

+1

138

138

138

-0

-0

Panel Cutout

Panel Cutout

Customer will need to provide a rear panel support

Customer will need to provide a rear panel support

plate to maintain NEMA4 protection if primary

plate to maintain NEMA4 protection if primary

panel thickness is less that 2.3mm [0.09”] thick

panel thickness is less that 2.3mm [0.09”] thick

156

156

[6.14]

[6.14]

33.5

33.5

[1.32]

[1.32]

-0

+.04

+.04

+.04

[5.43]

[5.43]

[5.43]

-0

-0

-0

CUSTOMER PANEL

CUSTOMER PANEL

1.6[.06] to 6.35 MAX[0.25]

1.6[.06] to 6.35 MAX[0.25]

152

152

[5.98]

[5.98]

Figure 3-1 Panel Mounting Dimensions (not to scale)

Panel Mounting Procedure

Table 3-2 Panel Mounting Procedure

Step Action

Mark and cut out the analyzer hole in the panel according to the dimension information

1

in Figure 3-1.

Orient the case properly and slide it through the panel hole from the front.

2

Customer will need to provide a rear panel support plate to maintain NEMA4

protection if primary panel thickness is less that 2.3mm [0.09”] thick –

See Figure 3-2.

Remove the mounting kit from the shipping container and clamp the edges of the

3

cutout between the case flange and the supplied U-bracket that is fastened to the rear

of the case using (2) M5 X 16mm long screws and (2) M5 lock washers supplied.

156

156

[6.14]

[6.14]

(4) 22.22[.87] holes for

(4) 22.22[.87] holes for

lead wires and conduit fittings

lead wires and conduit fittings

(conduit fittings supplied by user)

(conduit fittings supplied by user)

January 2009 UDA2182 Universal Dual Analyzer Product Manual 11

Page 24

Unpacking

Rear Panel Support Plate Dimensions

Figure 3-2 Rear Panel Support Plate Dimensions

12 UDA2182 Universal Dual Analyzer Product Manual January 2009

Page 25

Unpacking

Pipe Mounting

The analyzer can be mounted vertically or horizontally on a pipe. Use the bracket and

hardware supplied in the mounting kit.

Select 1 inch or 2 inch U-Bolts.

ATTENTION

Pipe mounting is not recommended if the pipe is subject to severe vibration. Excessive

vibration may affect system performance.

M5 X 10mm long screw with M5 lock washer (2 places)

M5 X 10mm long screw with M5 lock washer (2 places)

Note orientation of hole and slot in mounting bracket.

Note orientation of hole and slot in mounting bracket.

Hole is to be in the upper position.

M8 Nut

M8 Nut

M8 Lock Washer

M8 Lock Washer

M8 Flat Washer

M8 Flat Washer

Hole is to be in the upper position.

195.1

195.1

[7.68]

[7.68]

Do not over

Do not over

tighten fasteners

tighten fasteners

4.5Nm (40 Lb-in) of

4.5Nm (40 Lb-in) of

torque max.

torque max.

188.1

188.1

[7.40]

[7.40]

188.1

188.1

[7.40]

[7.40]

97.5

97.5

[3.84]

[3.84]

77.4

77.4

[3.05]

[3.05]

1 or 2 inch Vertical Rear Pipe Mounting

1 or 2 inch Vertical Rear Pipe Mounting

97.5

97.5

[3.84]

[3.84]

78

78

[3.07]

[3.07]

78

78

[3.07]

[3.07]

1 or 2 inch Horizontal Rear Pipe Mounting

1 or 2 inch Horizontal Rear Pipe Mounting

97.5

97.5

[3.84]

[3.84]

156

156

[6.14]

[6.14]

Figure 3-3 Pipe Mounting Dimensions (not to scale)

January 2009 UDA2182 Universal Dual Analyzer Product Manual 13

Page 26

Unpacking

Wall Mounting Dimensions

The analyzer can be mounted on a wall. Use the bracket and hardware supplied in the

mounting kit.

188.1

188.1

[7.40]

[7.40]

195.06

195.06

[7.680]

38.5

38.5

[1.51]

[1.51]

97.5

97.5

[3.84]

[3.84]

195.1

195.1

[7.68]

[7.68]

83.9

83.9

[3.30]

[3.30]

97.53

97.53

[3.840]

[3.840]

195.1

195.1

[7.68]

[7.68]

[7.680]

Left hand

Left hand

Side View

Side View

77

77

[3.03]

[3.03]

Four slots in bracket for

Four slots in bracket for

6.0mm [1/4 “] dia mounting

6.0mm [1/4 “] dia mounting

bolts supplied by customer

bolts supplied by customer

38.5

38.5

[1.52]

[1.52]

83.9

83.9

[3.30]

[3.30]

77

77

[3.03]

[3.03]

167.6

167.6

[6.60]

[6.60]

83.9

83.9

[3.30]

[3.30]

167.8

167.8

[6.61]

[6.61]

Front View

Front View

Mounting Bracket

Mounting Bracket

Horizontal

Horizontal

Front View

Front View

Mounting Bracket

Mounting Bracket

Vertical

Vertical

Figure 3-4 Wall Mounting Dimensions (not to scale)

14 UDA2182 Universal Dual Analyzer Product Manual January 2009

Page 27

Power Wiring

4 Power Wiring

4.1 Overview

Introduction

This section contains instructions for installing ac power wiring for the Analyzer, in

preparation for performing configuration setup as described in Section 6.

We recommend that you wait to install input and output wiring (See Section 7) until after

Configuration Setup. During configuration the software will determine for you, which

relay to use for each feature.

What’s in this section?

The topics in this section are listed below.

Topic See Page

4.1 Overview 15

4.2 General Wiring Practices 16

4.3 Power Wiring Considerations 17

4.4 Installing Power Wiring 17

January 2009 UDA2182 Universal Dual Analyzer Product Manual 15

Page 28

Power Wiring

4.2 General Wiring Practices

WARNING

Safety precaution

Qualified personnel should perform wiring only.

WARNING

A disconnect switch must be installed to break all current

carrying conductors. Turn off power before working on

conductors. Failure to observe this precaution may result in

serious personal injury.

WARNING

An external disconnect switch is required for any hazardous

voltage connections to the relay outputs.

Avoid damage to components

ATTENTION

This equipment contains devices that can be damaged by electrostatic discharge (ESD). As

solid-state technology advances and as solid-state devices get smaller and smaller, they

become more and more sensitive to ESD. The damage incurred may not cause the device to

fail completely, but may cause early failure. Therefore, it is imperative that assemblies

containing static sensitive devices be carried in conductive plastic bags. When adjusting or

performing any work on such assemblies, grounded workstations and wrist straps must be

used. If soldering irons are used, they must also be grounded.

A grounded workstation is any conductive or metallic surface connected to an earth ground,

such as a water pipe, with a 1/2 to 1 megohm resistor in series with the ground connection. The

purpose of the resistor is to current limit an electrostatic discharge and to prevent any shock

hazard to the operator. The steps indicated above must be followed to prevent damage and/or

degradation, which may be induced by ESD, to static sensitive devices.

Wiring for immunity compliance

In applications where either the power, input or output wiring are subject to

electromagnetic disturbances, shielding techniques will be required. Grounded metal

conduit with conductive conduit fittings is recommended.

Connect the AC mains through a fused disconnect switch.

Conform to code

Instrument wiring should conform to regulations of the National Electrical Code.

16 UDA2182 Universal Dual Analyzer Product Manual January 2009

Page 29

Power Wiring

4.3 Power Wiring Considerations

Recommended wire size

Observe all applicable electrical codes when making power connections. Unless locally

applicable codes dictate otherwise, use 14-gauge (2.081 mm

including protective earth.

Power supply voltage and frequency within specs

The power supply voltage and frequency must be within the limits stated in the

specifications in Section 2.

4.4 Installing Power Wiring

Procedure

WARNING

Turn power off at mains before installing AC Power Wiring.

Do not remove boards with power ON.

WARNING

The ground terminal must be connected to a reliable earth

ground for proper operation and to comply with OSHA and

other safety codes. If metal conduit is used, connect a bonding

wire between conduits. Do not rely upon the conductive coating

of the instrument case to provide this connection. Failure to

observe this precaution may result in serious personal injury.

2

) wire for ac power,

CAUTION

To avoid damage to the case when connecting to a rigid metallic conduit system, the

conduit hub must be connected to the conduit before the hub is connected to the

enclosure

Table 4-1 Procedure for installing AC Power Wiring

Step Action

Check the tag on the outside of the case to be sure that the voltage rating of the unit

1

matches the input voltage at your site.

ATTENTION

The Unit may be damaged if you apply power with the wrong voltage.

2 With Power off, open the case:

• Loosen the four captive screws on the front of the bezel.

• Grasp the bezel on the right side. Lift the bezel gently and swing the bezel open to the left.

Refer to Figure 7-1 for the location of the printed wiring board retainer. Loosen the two

3

January 2009 UDA2182 Universal Dual Analyzer Product Manual 17

Page 30

Power Wiring

Step Action

screws that hold the retainer and slide the retainer to the left until the retainer tabs

disengage from the terminal boards.

Refer to Figure 7-1 for the location of the Power Supply/Analog Output/Relay Output board.

4

Insert a screwdriver into the hole in the middle of the terminal board and pull out gently.

Slide the board half way out. There is a notch in the terminal board into which you can slide

the retainer tabs and hold the board in place while wiring.

Install a fused disconnect switch in the power line that will be connected to the Analyzer.

5

•If a 230/240 Vac line is to be connected, use a 0.15 amp fuse.

•If a 110/120 Vac line is to be connected, use a 0.30 amp fuse.

Fuse must be a Time-Delay or Slo-Blo type.

Each unit has (4) 22.22mm [.87"] dia. holes on the bottom of the unit for lead wires and

6

conduit fittings. Conduit fittings to be supplied by the user.

Feed the power wiring through the wiring port on the bottom of the case. Connect the power

wiring to terminals L1 and L2/N as shown in Figure 4-1. Connect the Green safety ground

wire to the grounding stud on the case.

Attention: Terminal 1 must be connected to the ground stud on the grounding bar using

a #14 AWG UL/CSA-approved wire.

Slide the retainer to the left then slide the terminal board back into place. Slide retainer to

7

engage the tabs and tighten the screws.

Close the Bezel and secure four captive screws to a torque value of .20 Nm (1.5 Lb-in).

8

Power up the unit.

Do not apply power until the bezel is closed.

18 UDA2182 Universal Dual Analyzer Product Manual January 2009

Page 31

Power Wiring

13

13

13

Analog Output 1 (+)

Analog Output 1 (+)

Analog Output 1 (+)

Analog Output 1 (+)

Analog Output 1 (–)

Analog Output 1 (–)

Analog Output 1 (–)

Analog Output 1 (–)

Analog Output 2 (+)

Analog Output 2 (+)

Analog Output 2 (+)

Analog Output 2 (+)

Analog Output 2 (–)

Analog Output 2 (–)

Analog Output 2 (–)

Analog Output 2 (–)

Relay Output 1 (N.O. )

Relay Output 1 (N.O. )

Relay Output 1 (N.O. )

Relay Output 1 (N.O. )

Relay Output 1 (COM)

Relay Output 1 (COM)

Relay Output 1 (COM)

Relay Output 1 (COM)

Relay Output 1 (N.C.)

Relay Output 1 (N.C.)

Relay Output 1 (N.C.)

Relay Output 1 (N.C.)

Relay Output 2 (N.O.)

Relay Output 2 (N.O.)

Relay Output 2 (N.O.)

Relay Output 2 (N.O.)

Relay Output 2 (COM)

Relay Output 2 (COM)

Relay Output 2 (COM)

Relay Output 2 (COM)

Relay Output 2 (N.C.)

Relay Output 2 (N.C.)

Relay Output 2 (N.C.)

Relay Output 2 (N.C.)

AC Hot L1

AC Hot L1

AC Hot L1

AC Hot L1

AC N L2

AC N L2

AC N L2

AC N L2

13

12

12

12

12

11

11

10

10

10

10

9

9

9

9

8

8

8

8

7

7

7

7

6

6

6

6

5

5

5

5

4

4

4

4

Case Earth Ground

Case Earth Ground

Case Earth Ground

Case Earth Ground

1

1

1

1

Grounding Stud

Grounding Stud

Grounding Stud

Grounding Stud

on Case

on Case

on Case

on Case

Figure 4-1 Power Wiring

January 2009 UDA2182 Universal Dual Analyzer Product Manual 19

Page 32

Operating the Analyzer

5 Operating the Analyzer

5.1 Overview

Introduction

This section contains instructions for operating the Analyzer.

What’s in this section?

The topics in this section are listed below.

Topic See Page

5.1 Overview 20

5.2 Analyzer Overview 21

5.3 Key Navigation 22

5.4 Displays Overview 23

5.5 Input Displays 25

5.6 PID Displays 26

5.7 Auto Cycle Displays 28

5.8 Pharma Display 33

5.10 Status Display 41

5.11 Event History 46

5.12 Process Instrument Explorer Software 48

20 UDA2182 Universal Dual Analyzer Product Manual January 2009

Page 33

Operating the Analyzer

5.2 Analyzer Overview

The UDA2182 Universal Dual Analyzer is the next level of dual channel analyzers

providing unprecedented versatility and flexibility.

The analyzer can accept single or dual inputs from Honeywell Direct pH, pH from

preamp, ORP (Oxidation Reduction Potential), Contacting Conductivity and Dissolved

Oxygen sensors.

Measurement for Dual channel units can be arranged in any combination of

measurement.

A Communications card provides one Serial Port (RS485) and one Ethernet Port.

Figure 5-1 UDA2182 Operator Interface (all display items shown)

January 2009 UDA2182 Universal Dual Analyzer Product Manual 21

Page 34

Operating the Analyzer

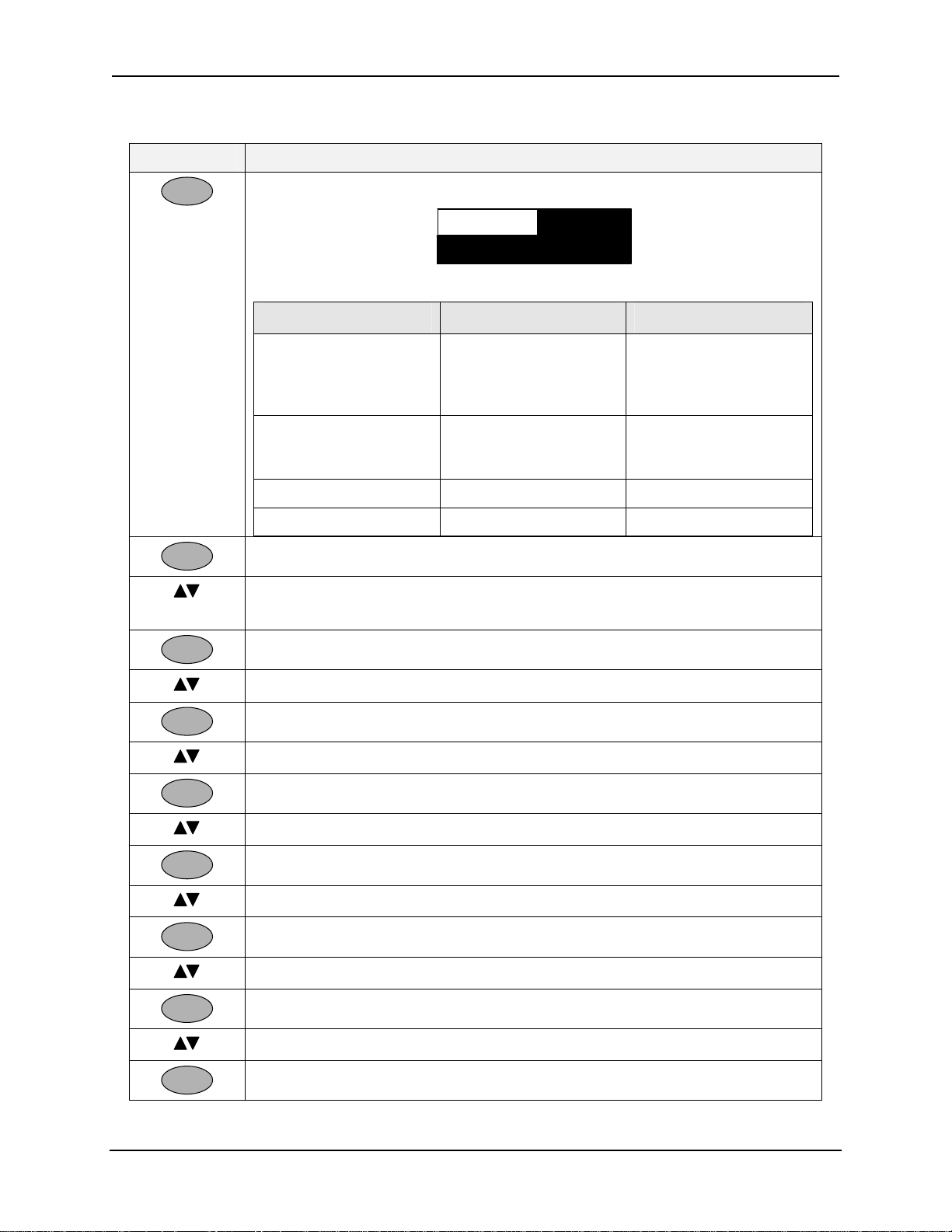

5.3 Key Navigation

Table 5-1 shows each key on the operator interface and defines its function.

Table 5-1 Function of Keys

Key Function

• When process values are on display: Use DISPLAY to cycle between PV

Displays, PID Loop Displays, Auto Cycle Displays, Pharma Displays, Cation

Display

Display, Status Displays and an Event History Display.

• In Setup mode, calibration mode, or calibration edit mode, use DISPLAY to

abort current mode and return to the last accessed online display.

• Engages hold of analog and digital values at their current values and any

relays assigned to alarm events or control are deactivated.

Hold

Setup

Exit

Calibrate

or

ATTENTION:

• Selects the configuration main menu when online, in calibration mode, or at a

calibration submenu.

• In configuration menu, exits submenu to parent menu. If at configuration main

menu, selects current online display.

• In configuration edit mode, aborts editing of current parameter.

• When online, acknowledges current alarm event to stop the flashing of the

relay indicator and status message area.

• Selects the calibration main screen when online, in configuration mode or at

another calibration screen.

• When a Setup configuration menu or configuration edit screen is on display:

Use Up/Down keys to highlight a different item.

• In configuration edit mode, either selects the parameter character or

numerical digit to change or selects an enumerated parameter value:

Use Up/Down key to increment the value of the digit at the cursor.

Increases/decreases the selected parameter value.

• When in display mode, use up/down keys to adjust the contrast on the screen.

This takes precedence over the FAILSAFE function.

• In configuration edit mode, selects the character or digit to change.

or

Enter

22 UDA2182 Universal Dual Analyzer Product Manual January 2009

• In calibration mode, selects the next or previous calibration screen.

• In display mode, selects a single or dual display on a unit with dual input.

• In configuration menu, selects edit mode for selected parameter.

• In configuration edit mode, saves edited parameter selection or value.

• In calibration mode, selects parameters to reset and the next calibration

screen.

Page 35

Operating the Analyzer

5.4 Displays Overview

Viewing the Displays

To view display screens, push the

screens which show the current status of pH/ORP, Conductivity, or Dissolved Oxygen

Concentration. There are displays for PID, Auto Cycle, and Pharma. It also lets you view a Status

Display and an Event History Display.

Displays Shown

One Input - When only one input board is installed, the online screen displays one PV and its

units in a larger font size (Section 5.5).

Two Inputs - When two input boards are installed, the online screen displays two PVs and its

units in a smaller font size. Press