Page 1

32-00015-04

U2-S Model Combination Viewing

WARNING

WARNINGWARNING

AVERTISSEMENT

AVERTISSEMENT

WARNUNG

ATENÇÃO

Head and Signal Processor

USER MANUAL

GENERAL INFORMATION

The Honeywell U2-101xS series model is a viewing head

and signal processor in a single enclosure intended for

use with a burner control system in Industrial Flame

Monitoring applications. There are several options

available (see Table 1 on page 2). Each model includes

one, two, or all three sensors, and can be ordered with

quick disconnect (non-PF Models DIV2,ZN2) or pigtail

external connection method (PF Models DIV1,ZN1).

Each sensor operates independently from another,

allowing adjustment of each sensor.

Read the instructions before use. This control shall be

installed in accordance with the rules in force. Additional

versions of this manual are available online at

https://customer.honeywell.com/enUS/Pages/default.aspx in Canadian French, Portuguese,

and German. Please enter 32-00015 in the search box

and choose Technical Literature from the drop-down

box.

Lire les instructions avant l'utilisation. Cette commande

doit être installée conformément aux lois en vigueur. Des

versions supplémentaires de ce manuel sont disponibles

enligne à https://customer.honeywell.com/enUS/Pages/default.aspx en français du Canada, en

portugais et en allemand. Veuillez inscrire 32-00015 dans

le casier de recherche et choisissez Documentation

technique à partir du menu déroulant.

Lesen Sie vor der Verwendung die Anweisung. Diese

Konsole muss entsprechend den geltenden Vorschriften

installiert werden. Zusätzliche Versionen dieses

Handbuchs sind online unter

https://customer.honeywell.com/enUS/Pages/default.aspx in Frankokanadisch,

Portugiesisch und Deutsch verfügbar. Bitte geben Sie im

Suchfeld 32-00015 ein und wählen Sie Fachliteratur im

Drop-Down Menü aus

IMPORTANT

Flame monitoring systems are safety systems.

Please read this manual carefully and completely

before installation and before attempting adjustments.

Only qualified personnel familiar with Flame

Safety System should carry out installation and

configuration.

U2 is certified to be used in prescribed manner.

Any modification or inappropriate installation or

operation may result in unsafe operation and will

void implied or expressed warranty.

Sensors

The UV tube detector has a peak response at 210 nm.

The IR solid state sensor has a peak response at 1400 nm.

The UV solid state sensor has a peak response at 310 nm.

Cabling Options (Sold Separately)

ASYU2S - Quick Disconnect (non-PF) models molded

connector cable assembly with 50 foot of C22S cable.

Leia as instruções antes de usar. Esse controle tem que

ser instalado de acordo com as normas vigentes. Outras

versões desse manual estão disponíveis online em

https://customer.honeywell.com/enUS/Pages/default.aspx em francês do Canadá, português

e alemão. Insira 32-00015 em cada caixa e selecione

Literatura Técnica na caixa suspensa.

Disposal and Recycling

Waste electrical products should not be disposed

of with general waste. Please recycle where these

facilities exist. Check with your local authority for

recycling advice.

Contents

GENERAL INFORMATION ............................................... 1

SPECIFICATIONS ............................................................ 2

INSTALLATION ................................................................. 3

OPERATION ..................................................................... 6

U2 MENU PARAMETER SETTINGS ................................ 7

TROUBLESHOOTING ...................................................... 10

SAFETY MANUAL ............................................................ 13

Safety Function of the U2-S Model .............................. 14

Proof Test Procedure ................................................... 14

Proof Test Interval ........................................................ 14

Product Decommissioning ........................................... 15

Page 2

U2-S MODEL COMBINATION VIEWING HEAD AND SIGNAL PROCESSOR

WARNING

WARNINGWARNING

WARNING

WARNINGWARNING

ASYU2S-100 - Quick Disconnect (non-PF) models molded

connector cable assembly with 100 foot of C22S cable.

ASYU2S-200 - Quick Disconnect (non-PF) models molded

connector cable assembly with 200 foot of C22S cable.

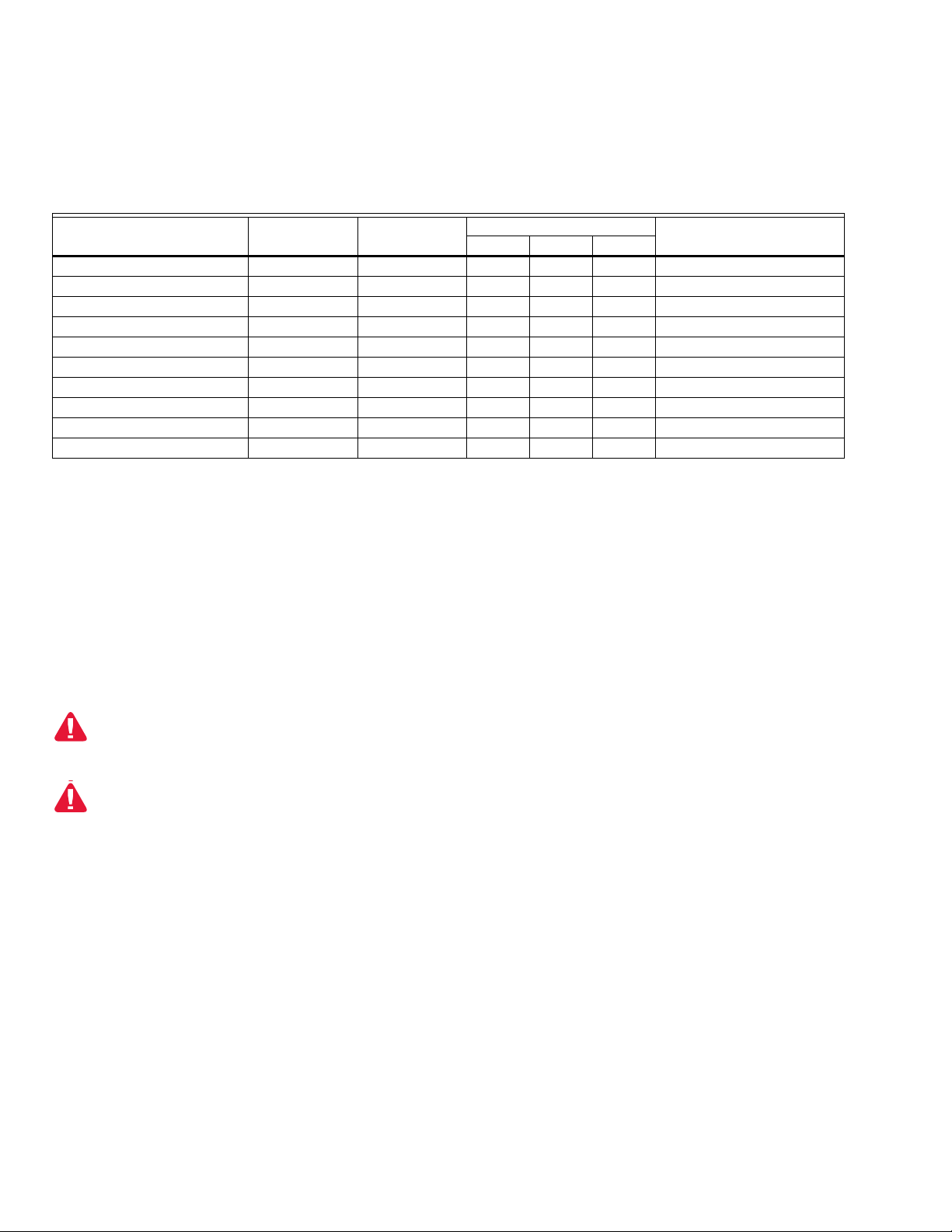

Table 1. Models and Associated Features.

Quick

Model

U2-1010S X X X X All Fuels

U2-1010S-PF X X X X All Fuels

U2-1010S-PF-050* X X X X All Fuels

U2-1010S-PF-100 X X X X All Fuels

U2-1012S X X Oil and Coal

U2-1012S-PF X X Oil and Coal

U2-1016S X X Gas and Light Oils

U2-1016S-PF X X Gas and Light Oils

U2-1018S X X X All Fuels

U2-1018S-PF X X X All Fuels

* The U2-1010S-PF-050 has a 50-ft (15m) pigtail and the U2-1010S-PF-100 has a 100-ft (30m) pigtail.

Connector

Pipe Fit

Connection

SPECIFICATIONS

Input Power Supply: 22-26 VDC, 120 mA max (approxi-

mately 3.5 watts)

Remote Communication: 2 wire RS485 compatible with

Modbus RTU protocol.

Flame And Fault Relay Contact Ratings:

1 A, 30 VDC (Resistive).

Maximum load current of 1A must be de-rated at tem-

peratures higher than 50C ambient according to 1%/C,

or 10mA/C. For example, the maximum current at

70C = 1A – (20C x 10mA) = 0.8A.

Do not apply more than 30VDC to flame relay or

self check relay.

The U2 requires the use of an isolated 24VDC

SELV (Safety Extra Low Voltage) power supply.

User Selectable Analog Output: 0-20 mA and 4-20 mA;

500 Ohm Load Max

File Select Input logic high: 21VDC min

File Select Input logic low: 16VDC max

User Interface: Capacitive TouchWheel with LED Display

Ambient temperature: -40 to 70 ºC (-40 to 158 ºF)

Enclosure: IP66

Weight: 2.8 kg (6.1 lbs)

Physical Dimensions: Diameter: 11.7 cm (4.6 inches)

Length: 15.5 cm (6.1 inches)

Finish: Silicone free powder coated

ASYU2S-300 - Quick Disconnect (non-PF) models molded

connector cable assembly with 300 foot of C22S cable.

C22S - Raw shielded 12 conductor, 22g, ITC, CIC

approved. Order by the foot.

Sensor Type

Typical FuelsUVTron IR UVSS

Mounting/Process Connection: 1” NPT female

Pipe Fit Models (PF version): 3/4” NPT

Fuses: Automatically resettable for power source and

Flame Relay.

Maximum furnace back pressure: 35 Kg/Cm2 (500 PSI)

Selectable Flame Failure Response Time (FFRT):

1, 2, 3 seconds, Error= +0.0sec, -0.5sec.

Internal Temperature Indication: Degrees C or F in dis-

play menu of U2, or available at Modbus register

40019.

Self-Checking

Internal electronic self checking is performed once per

second, to verify that system is operating properly. If

self check detects an error, the flame relay, and self

check relays will open, and the device will display "lockout". This lockout may only be cleared by manual entry

reset at the U2 Touchwheel interface.

Approvals:

Quick disconnect type

General

FM, CSA, CE (EN298), and EAC

Hazardous Location

CSA

CLASS I, DIVISION 2, GROUPS A, B, C, D

CLASS II, DIVISION 1, GROUPS E, F, G

CLASS III DIVISION 1 T5

Ex nA nC IIC T5 Gc Ex tb IIIC T85°C Db

CLASS I, ZONE 2, AEx nA nC IIC T5 Gc

ZONE 21 AEx tb IIIC T85°C Db

IECEx SIR 15.0068X Ex nA nC IIC T5 Gc

Ex tb IIIC T85°C Db IP66

SIRA 15ATEX4193X Ex nA nC IIC T5 Gc

Ex tb IIIC T85°C Dc IP66

32-00015—04 2

Page 3

U2-S MODEL COMBINATION VIEWING HEAD AND SIGNAL PROCESSOR

CAUTION

CAUTION

!

CAUTION

CAUTION

!

CAUTION

CAUTION

!

WARNING

WARNINGWARNING

WARNING

WARNINGWARNING

PF version

General

FM, CSA, CE (EN298), and EAC

Hazardous Location

CSA

CLASS I, DIVISION 1, GROUPS A, B, C, D

CLASS II, DIVISION 1, GROUPS E, F, G

CLASS III DIVISION 1 T6

Ex d IIC T6 Gb Ex tb IIIC T85°C Db

CLASS I, ZONE 1, AEx d IIC T5 Gb

ZONE 21 AEx tb IIIC T85°C Db

IECEx SIR 15.0068X Ex db IIC T6 Gb

Ex tb IIIC T85°C Db IP66

SIRA 15ATEX1192X Ex db IIC T6 Gb

Ex tb IIIC T85°C Db IP66

Possible Equipment Damage

The aluminum surface of the U2 may store an

electrostatic charge and become a source of

ignition in applications with a low (<30%) relative

humidity. Cleaning the surface should only be

done with a damp cloth.

Do not expose to acetone, gasoline, hexane, or

ethyl acetate. label is not approved for these

chemicals.

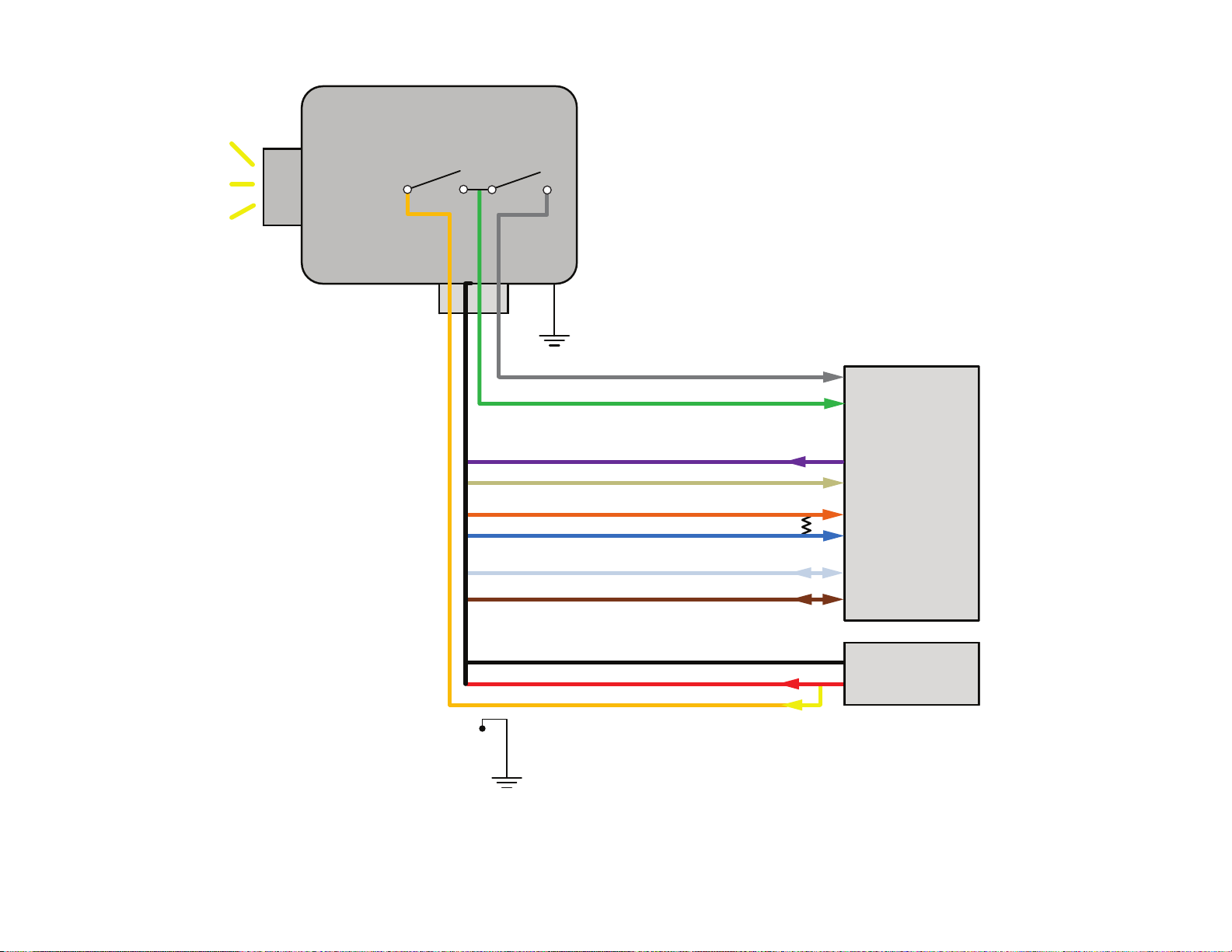

Non-PF/

Color Function Connection

9-Tan File Select Output, 0 or +24V

output. Feedback for system

controlling file input select.

10-White +RS485 Modbus To Modbus +

11-Drain Cable Overall Shield To Earth Ground

12-Brown -RS485 Modbus To Modbus -

*Note - pink wire unused, leave unconnected.

Check wiring before applying power to the

system to make sure it is in accordance with the

wiring chart. Incorrect wiring may result in

unsafe operation or damage to U2.

NOTES:

1. For remote configuration and monitoring, refer

to Honeywell manuals for FlameTool for PC

(32-00001-01) and HMI S7999 Panel (3200003-01).

2. A total of eight parameter files are available.

Files 2 through 7 may be accessed using Flametools, and configured using Modbus register 40093.

To burner control

system. 0V = File

Select Input is low, or

+24V if FileSelect

Input is high.

Wiring

See “Typical Installation Diagram.” on page 12.

Non-PF/

Color Function Connection

1-Red Power Supply +24 VDC

Connect to 22-26 VDC

2-Purple File Select Input, 0 or 1 To control output.

3-Orange mA output (+) To current meter

4-Blue mA output (-) To current meter

5-Black Power Supply Return (-) or 0

VDC

6-Yellow Flame Relay (NO)

(power in)

7-Green Fault Relay (NO) (fault output) To fault monitoring of

8-Grey Flame Relay (NO) (safety

output)

To power supply

positive terminal

>21V input = file 1,

<16V = active file

defined at Modbus

register

40093(default 0).

positive

negative

To Power Supply

negative terminal.

To flame/fault relay

power source

burner control system

To burner control

system

INSTALLATION

See “Typical Installation Diagram.” on page 12.

Installation should be carried out by a qualified engineer

and should meet all local standards and safety

requirements.

Hazardous location installations require the use of

ITC/CIC approved cable installed in cable tray for non-PF

models, and in metal conduit for -PF models. The cable

installation must conform to the latest revision of the

National Electrical Code, or Canadian Electrical Code for

Class I, Division 2 (non-PF models), or for Class I, Division

1 (-PF models).

Approved CLI, DIV1 conduit seal must be installed

at PF model enclosure fitting for CLI, DIV1

hazardous location use.

Non-PF models must be secured as follows: hand-tighten

the connector at viewing head until it can be turned no

more. Continue tightening the connector an additional

180 degrees using pliers, or similar tool. Verify that

connector cannot be loosened by hand.

Over-tightening the connector can damage the

connector or housing.

Damage will void warranty and hazardous location

approvals. Do not exceed 180 degrees of further

rotation after hand tightening!

3 32-00015—04

Page 4

U2-S MODEL COMBINATION VIEWING HEAD AND SIGNAL PROCESSOR

WARNING

WARNINGWARNING

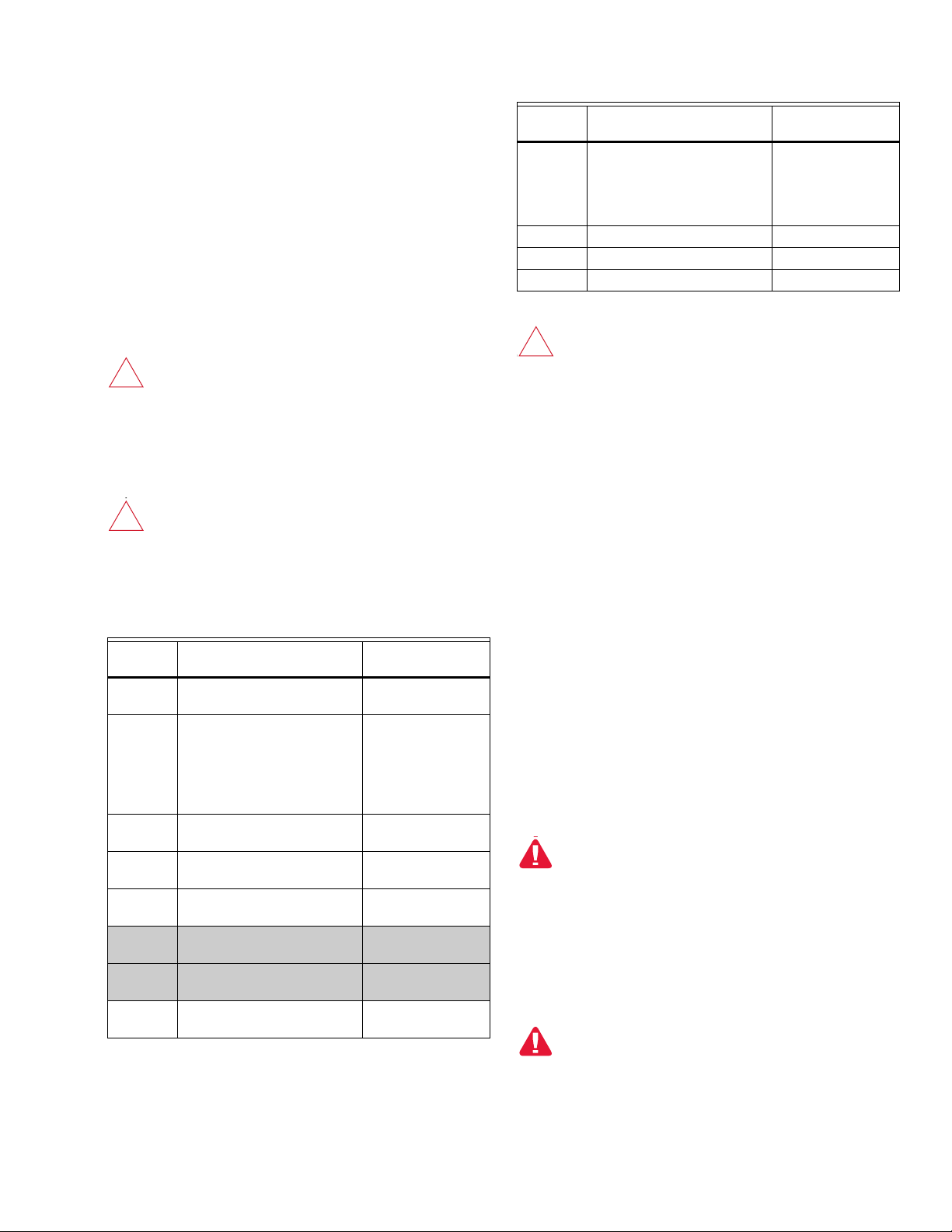

3/4 (19) NPT

CONNECTION

2-29/32 (73)

1(25)

1 (25) NPT

CONNECTION

5-3/32 (130)

4-19/32

(118)

M34431

R-518-CL12-PG

PURGE AIR COUPLER

AND R-518-PT12

INSULATING LOCKING

COUPLER ADAPTER

BURNER FRONT PLATE

OR WINDOWBOX

M33628

1 (25)

NPTF PIPE

FLANGE

(OPTIONAL)

1. Ensure location provides clear view of the flame

under all operating conditions.

EXPLOSION HAZARD

DO NOT DISCONNECT WHILE CIRCUIT IS LIVE

UNLESS AREA IS KNOWN TO BE

NONHAZARDOUS.

Substitution of components may impair suitability

for class i, division 2.

2. If the burner is provided with a pipe mount, use a bell

type reducer to 1" NPT (M).

3. When using purge/cooling air, make sure hoses are

electrically isolated from the Earth to prevent multiple ground loops.

4. Depending upon the application, purge/cooling air

pressure and flow will be different. As it is easier to

The U2-S model viewing port is designed for interface to a

1" NPT (M) fitting. The viewing head can be mounted in

any orientation, any angle, upward or downwards.

It is recommended that earth ground is applied at the

labeled earth ground screw connection on the housing. It

is recommended the drain wire be connected to earth at

power supply.

To reduce noise interference from ignition transformer or

other high voltage sources, make sure all high voltage

cables are in good condition and are at least 300 mm (12")

away from U2 wiring.

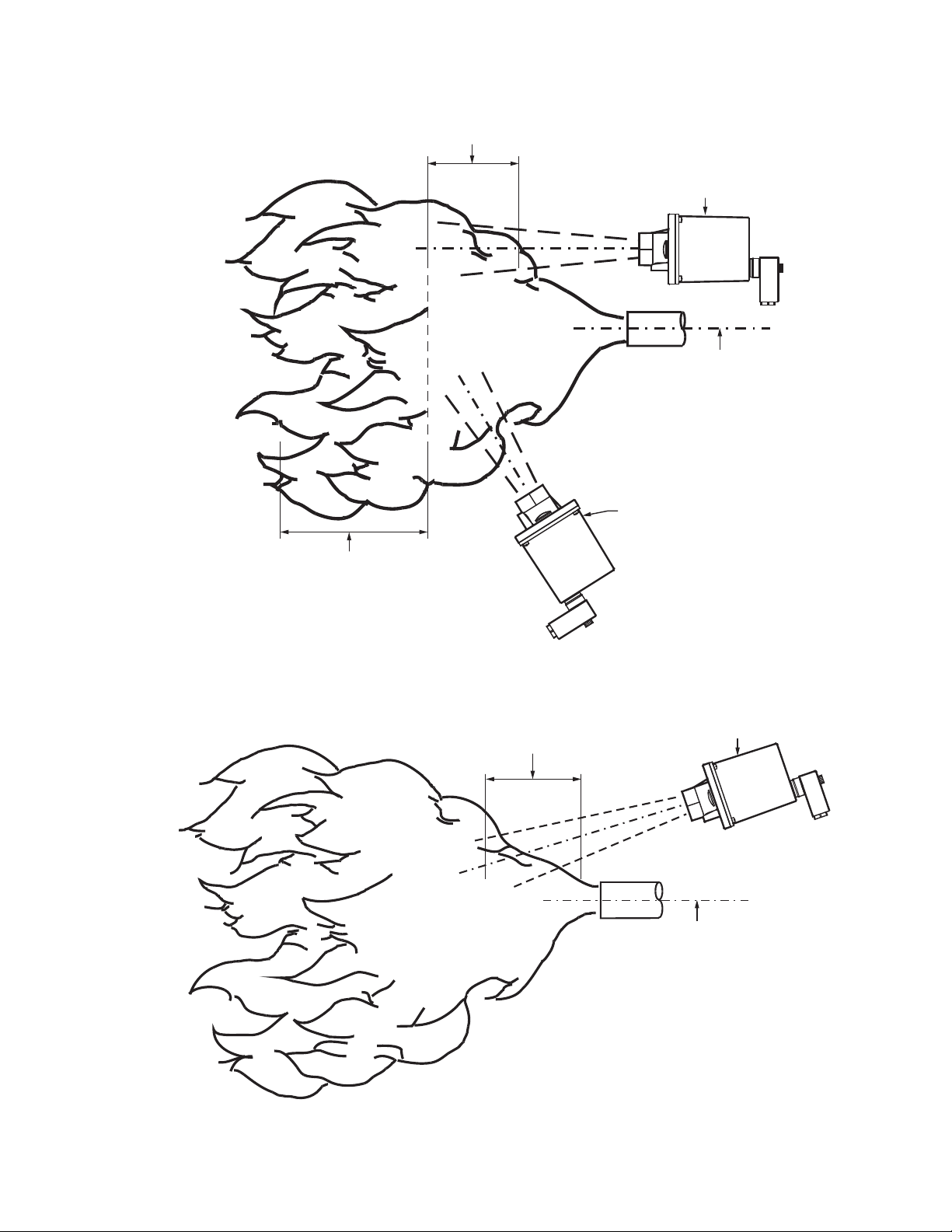

Location/Mounting on Burner

Honeywell can provide mounting accessories such as a

swivel mount, heat/electrical insulator, quick mechanical

measure pressure than flow, ensure that the

entrance to air connection is a minimum of 25 mm

WC (1" wc) above back pressure at all the time, from

minimum to maximum load.

5. IMPORTANT!

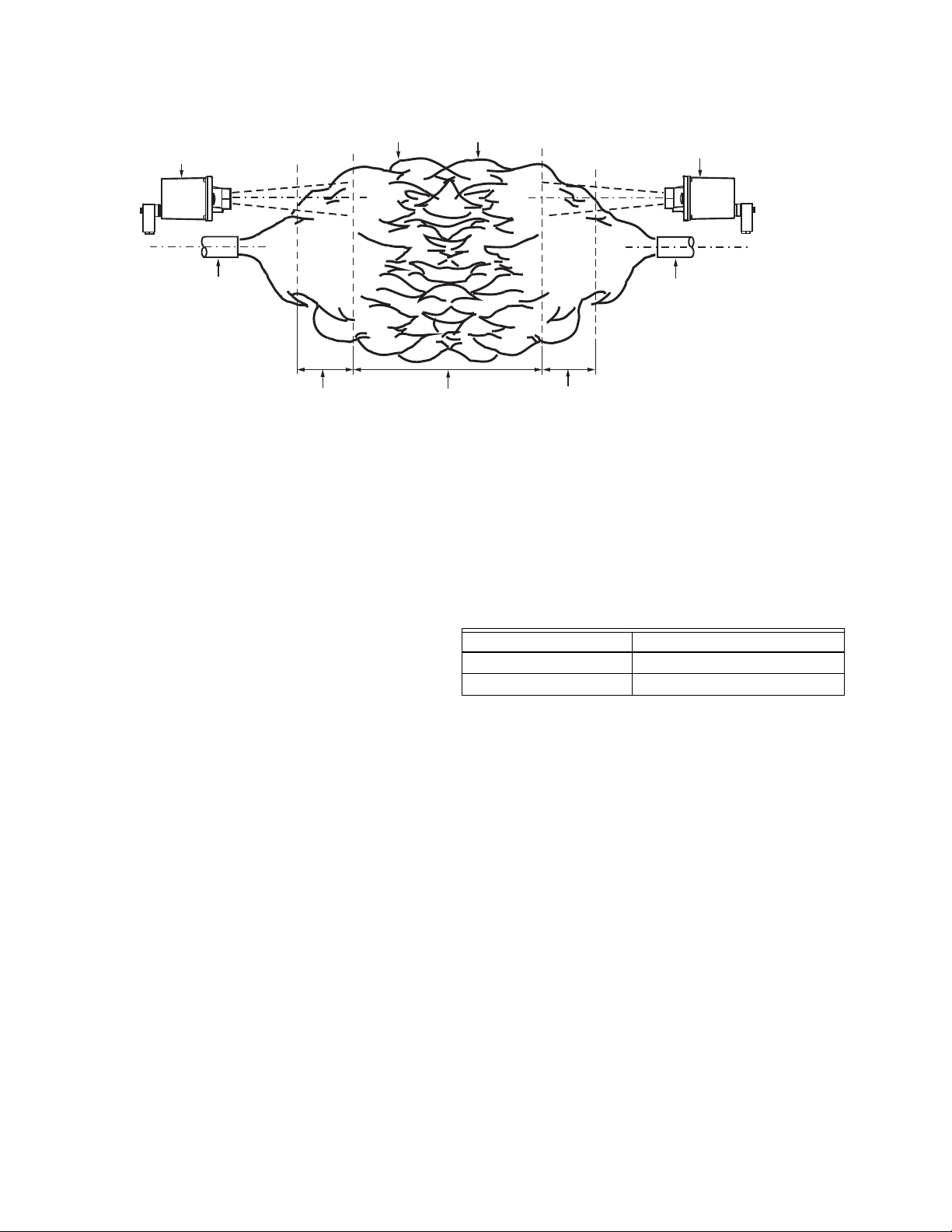

FLAME DISCRIMINATION

In multi-burner applications, it is important to sight

for high frequency, high radiation intensity zone of

the target flame, while sighting the low frequency,

low radiation intensity zone of the background flame

see Fig. 3 for IR, or Fig. 4 for UV for an example. This

allows for filter, gain, and threshold settings to properly discriminate or recognize the target flame while

rejecting background flame.

6. Where practical, use a swivel mount to allow for

adjustments to optimize the flame viewing location.

disconnect, high pressure isolation unit, etc. Check with

your sales representative for your application.

Fig. 1. Dimensional drawings.

32-00015—04 4

Fig. 2. Typical mounting example.

Page 5

U2-S MODEL COMBINATION VIEWING HEAD AND SIGNAL PROCESSOR

UV VIEWING

HEAD SIGHTED

ON UV ZONE

BURNER NOZZLE

CENTERLINE

UV RADIATION

ZONE

M33286B

HIGH FREQUENCY

FLICKER ZONE

DETECTOR IN GOOD

SIGHTING POSITION

(PARALLEL SIGHTING)

BURNER NOZZLE

CENTERLINE

LOW FREQUENCY

FLICKER ZONE

Fig. 3. IR viewing head location.

DETECTOR IN POOR

SIGHTING POSITION

M33285B

Fig. 4. UV viewing head location.

5 32-00015—04

Page 6

U2-S MODEL COMBINATION VIEWING HEAD AND SIGNAL PROCESSOR

VIEWING HEAD

BURNER NOZZLE

NO. 1

NO. 1 FLAME

ENVELOPE

NO. 2 FLAME

ENVELOPE

VIEWING HEAD

BURNER

NOZZLE NO. 2

HIGH FREQUENCY

IR ZONE

LOW FREQUENCY

ZONE (LESS THAN

36HZ)

HIGH FREQUENCY

IR ZONE

M33287B

Fig. 5. Sighting opposed fired burners.

Mounting Accessories

1. Cable assemblies for quick disconnect models are

listed below. All are ITC/CIC approved, and meet

IP67 at connector when properly installed.

• ASYU2S molded connector with 50 foot cable.

• ASYU2S-100 molded connector with 100 foot

cable.

• ASYU2-200 molded connector with 200 foot

cable.

• ASYU2-300 molded connector with 300 foot

cable.

2. Fiber Optic System - The U2 models are compatible

with the Honeywell FASA Glass or Quartz fiber optic

extension. Refer to Honeywell manual 69-2683

3. U2-S supports Modbus protocol. The system can be

monitored using user's hardware and software

and/or Honeywell FlameTool for PC or Honeywell

FlameTool for Panel (S7999). For detail refer to manual 32-00001 and 32-00003.

4. There are several mounting accessories available

from Honeywell. Please check with your sales person

for detail.

a. R-518-PT12 (Ultem Iso PT Adapter)

b. R-518-PT12L (Ultem Iso PT Adapter with lens)

c. R-518-CL12-PG (Purge Air Coupler 1" NPTM &

1/2" NPTF)

d. M-701-2 (Swivel Mount)

e. R-518-CL12-HTG (Locking Coupler).

OPERATION

Available sensors continuously convert flame radiation to

a magnitude displayed on the U2 display. The displayed

value described further as "flamecount" is the sum of all

active sensor readings.

If flame count is greater than the flame on setpoint for

longer than the time delay, a flame on condition is realized

and the flame relay contacts are closed. The flame relay

contacts remain closed until the flame count falls below

the flame off setpoint for longer than the flame failure

response time, at which a flame off condition is realized

and the flame relay contacts are opened. Periodic self

check performs fault detection, and if a fault is detected,

both the flame relay and self check relay contacts are

opened.

While File Input Select is low, file parameters defined at

Modbus register 40093 are used to determine flame relay

state. While file input select is high (+24V), file 1 parameter

settings are used to determine flame relay state.

File Select Output provides feedback to indicate the state

of the file input select. See chart below:

File Input Select Value File Select Output Value

0V 0V

24V 24V

There are several parameter adjustments that permit

configuration of each sensor. .

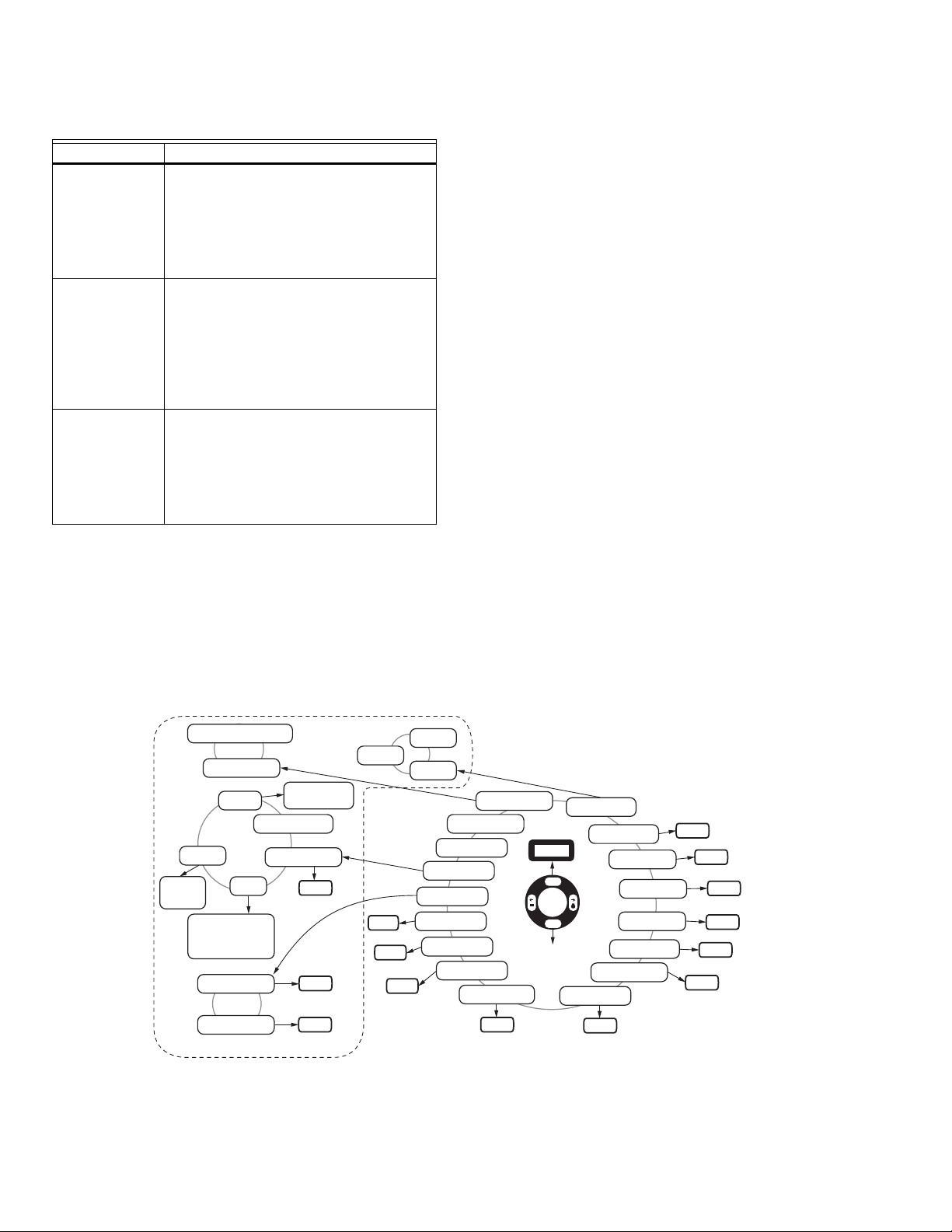

A touch wheel located at the back of the viewing head

provides access to parameters for adjustment and

configuration. The configuration menu is simple and easy

to follow. Full character, 4-digit, scrolling LED displays are

visible in the dark or sunlight. Individual sensor LEDs

(model dependent 1, 2, or 3 total located below the

display) flash to indicate the output of each sensor (green

= UVTron, Blue = SSUV, Red = IR). The upper right green

self-check LED provides indication, and status of the self

check. The upper left red "Flame On" LED provides status

of the flame relay.

NOTE: The number of LEDs are model dependent.

The touch wheel is designed like an iPod™ to allow for slow

or fast changes by moving a finger slower or faster around

the back glass. Alternatively, the user may tap ← (-) or →

(+) to make changes. Swirl finger at touchwheel > 360

degrees and release to enter the menu. Tap

ENTER/STORE to store selected data. Tap BACK to return

to the previous menu. Exiting all of the menus will display

the current flame count.

NOTE: Only the pertinent menu will be displayed. For

example, for UVtron only sensor (U2-1016S and

U2-1016S-PF), only UVTron gain will be displayed. UVSS and IR gain will not be visible.

32-00015—04 6

Page 7

U2-S MODEL COMBINATION VIEWING HEAD AND SIGNAL PROCESSOR

CAUTION

CAUTION

!

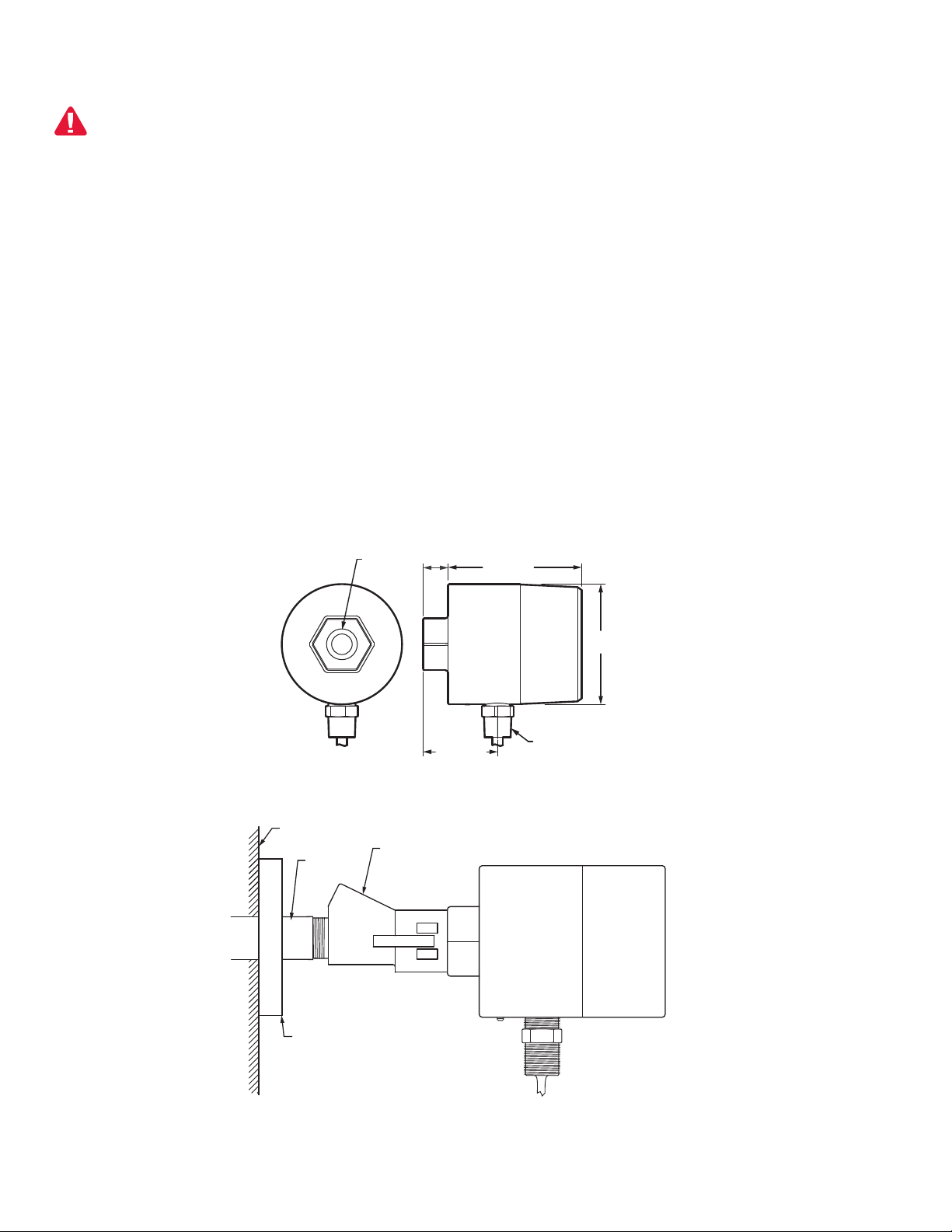

Display, as seen by the user, is shown in BOLD RED in the list

below as it appears in sequence.

U2 MENU PARAMETER SETTINGS

If the display shows "9999" while in operation, it

indicates flamecount has exceeded maximum

range of device. Reduce appropriate sensor

gain(s) so that Flame count is about 1.5 to 3

times Flame OFF threshold settings. If

unsuccessful, orificing or increased sight pipe

length may be required.

Gain UVTron

GTXX - Displays the current UVTRON tube sensor gain

(adjustable 0-99). The default value is 32.

Gain SSUV

GÛXX - Displays the current solid state UV sensor gain

(adjustable 0-99). The default value is 75. Adjusting the

gain too high may result in lockout due to saturation of the

sensor.

Flicker Filter Setting for SSUV

FÛ0X - Displays the current solid state UV flicker filter

setting (adjustable 0-9). The default value is 3.

Gain IR

GIXX - Displays the current IR sensor gain (adjustable 0-

99). The default value is 75. Adjusting the gain too high

may result in lockout due to saturation of the sensor.

Flicker Filter Setting for IR

FI0X - Displays the current IR sensor flicker filter setting

(adjustable 0-9). The default value is 3.

Flicker settings indicated below apply to SSUV and IR.

These are high pass filter setting:

Setting HZ Setting HZ Setting HZ

0 9 4 52 8 215

1 16 5 75 9 300

2246 100

3337 155

Gain MA OUT

GMXX - Displays the current multiplier for analog output

(adjustable 0-99). The default value is 30, and will result in

approximately 12mA analog out at 1700 flamecount, and

20mA at 3425 counts. The ma gain setting allows for

scaling of the analog output value proportional to the

flamecount at full load. For example, increasing the gain,

increases the analog output for a given flamecount.

Adjusting the MA gain does not alter gain settings of

UVTron, SSUV, or IR. After completing flame setpoint

configuration, adjustment to the MA gain may be used to

set MA output at full system load.

Flame On Threshold Setting

Displays the current Flame On threshold settings. It is

important to note that flame count must reach this

threshold in order for the flame relay to energize. After the

flame relay is energized, the flame count may drop below

Flame ON threshold but must remain above Flame Off

threshold (refer to FFRT below). Range is 51- 3425 flame

count.

NOTE: The Flame ON threshold setting must be 1 digit

above Flame OFF setting.

Flame OFF Threshold Setting

Displays the current Flame OFF threshold settings. Flame

count must remain above Flame Off threshold setting

otherwise flame relay will be de-energized after Flame

Failure response time has expired. Range is 50- 3424

flame count.

NOTE: The Flame Off threshold setting must be 1 digit

below Flame On setting.

Flame Failure Response Time (FFRT)

RT0X - Displays the current Flame Failure response time in

seconds. Flamecount must remain above Flame Off

threshold setting otherwise the flame relay will be deenergized after Flame failure response time has expired.

FFRT selection is 1, 2 or 3 seconds. Default setting is 1

second.

IMPORTANT

The FFRT must be set to 1 second, to meet requirements defined in European Standard EN298,

unless the application standard allows for longer

response time. Care must be used to ensure that

the overall response time of the system is acceptable for safe operation.

Flame On Time Delay

TD0X - Displays the current Flame On time delay in

seconds. The flame relay will be energized after the

flamecount has remained above the flame ON threshold,

and the time delay has elapsed. This feature is useful in

applications where flames from other sources are

temporarily present in target area, such as grate fired

boilers. Selection is 0,1, 2 or 3.

NOTE: The time delay also reduces Trial for Ignition by

the set time. Default setting is 3 seconds.

File Selection

*F0X - The U2 is able to store up to 8 different file

(configurations) (file0 - file7). Files are used to store

device settings for different fuels or applications.

Parameters that are stored in each file include Flame On

Setpoint, Flame Off Setpoint, Flame Failure Response

Time, Time Delay, UVT Gain, SSUV Gain, IR Gain, SSUV

Filter, IR Filter, mA gain, and Panel timeout.

Modifying file parameters

Press ENTER at menu location FILE, and select file

number using the touchwheel. Press enter when desired

file number is reached. The 4 digit display will flash

7 32-00015—04

Page 8

U2-S MODEL COMBINATION VIEWING HEAD AND SIGNAL PROCESSOR

WARNING

WARNINGWARNING

WARNING

WARNINGWARNING

decimal points to indicate file other that 0 is being

modified. Change menu parameters as desired.

IMPORTANT! Menu selections will only affect the currently

selected file.

NOTE: The U2 touch wheel interface allows access to all

eight files for configuration; however, the active

file cannot be changed at the U2 interface. It can

only be changed at the "File Select" wired input or

through Modbus communication. Only two files,

"0" and "1", may be automatically activated by

changing the voltage input to the "File Select"

wire (purple). When the file select line is power

grounded, the file selection = "0", when connected

to 24 VDC File select #1 is automatically activated.

NOTE: File selection for "0" may be changed, by modify-

ing the modbus register location 40093. Default

value is 0, and may be changed to 0 through 7.

When using file select input (purple) to control

parameter selection for different fuels, control

system must monitor file select output (tan) to

confirm U2S is using the correct file parameters. If

only one file parameter is used, set file 0 and file 1

settings to identical values, and connect file input

select to ground.

Panel Lock and Time Out.

Tapping the ENTER/STORE button when PANEL appears

on the menu screen will provide access to two sub-menus.

Panel Lock

The Panel Lock sub-menu enables a security feature that

locks the U2 interface preventing any parameter

modifications.

A factory default 4-digit access code is required to enable

panel lock. This code is only available from the factory.

Once enabled, the same code will be required to modify

parameters from the touch-wheel interface. Any attempt

to make changes will generate the message, "Panel

Locked Enter Code". The display will show "Bad" upon

entry of an incorrect access code. Additionally, a user may

select a unique lock code through Modbus, this procedure

is only available from the factory.

If the password is forgotten or lost, the user must contact

the factory for assistance with unlocking the panel.

Panel Timeout

The Time Out sub-menu allows for adjustment to a

secondary safety feature that locks the U2 interface

preventing accidental parameter modifications. This

setting may be adjusted from 0-9999 minutes. After this

time expires, with no touchwheel activity, any attempt to

access the menu will generate the message, "KEY

DISABLED ENTER 1234", simply enter "1234" as

prompted by the display. The Panel Time Out is by default

10 minutes, and is disabled with a setting of 0.

Communication

The U2-S products support 2 wire Modbus RTU

communication as slave devices. Default address is 0, and

must be changed prior to use. The communications

submenus allow adjustment of settings. See

communications sub menus, and Fig. 1 for details. Default

communication settings are:

— 9600 baud

— 8 data bits

—no parity

—1 stop bit

Note that some registers are read only.

Do not write to registers not defined in the list

below.

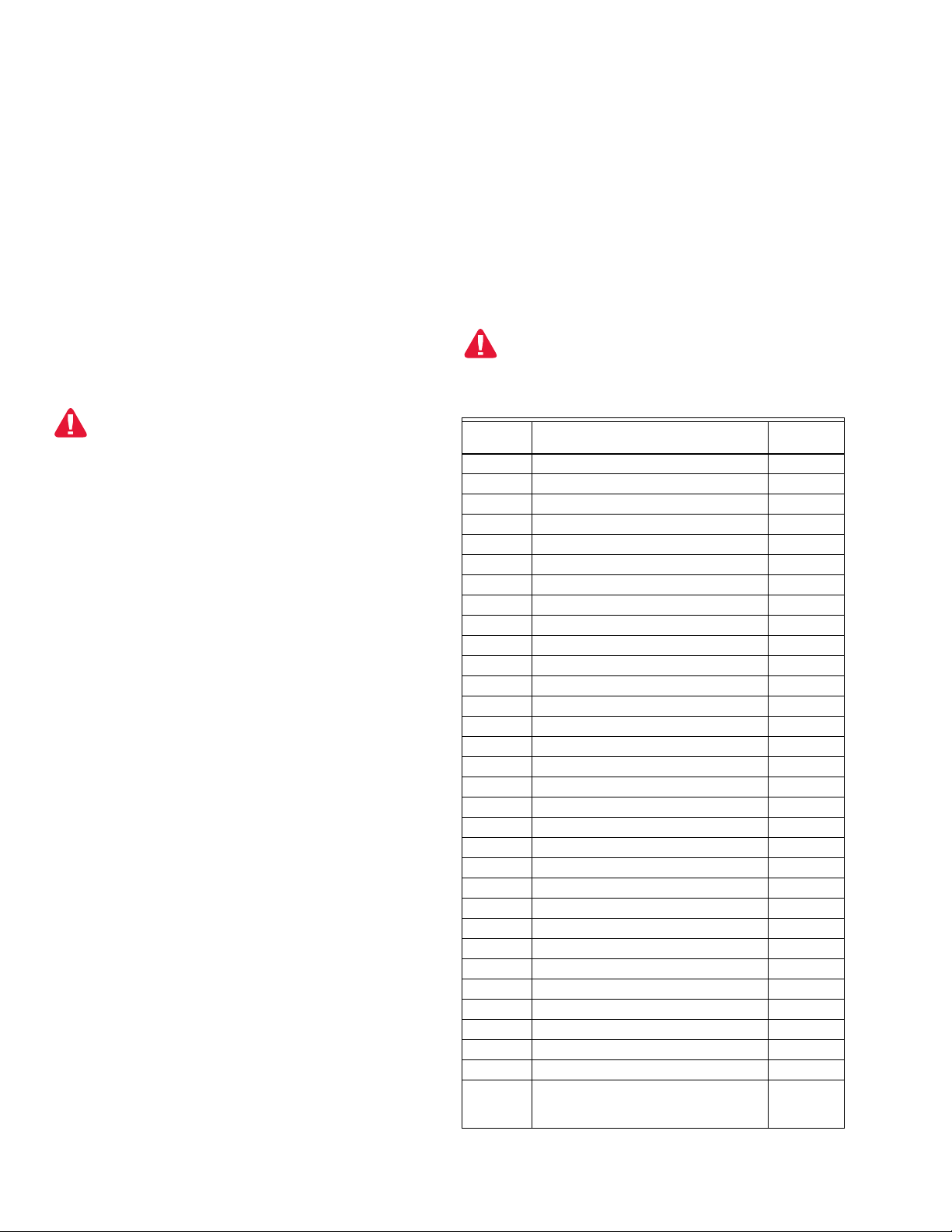

Register

Address Register Description

40001 FLAMECOUNT R

40003 FLAME ON SETPOINT(50-3425) R/W

40005 FLAME OFF SETPOINT(51-3425) R/W

40007 MA GAIN(0-99) R/W

40011 IR FILTER(0-9) R/W

40012 UVTUBE GAIN(0-99) R/W

40015 SSUV FILTER(0-9) R/W

40016 SSUV GAIN(0-99) R/W

40019 TEMPERATURE R

40021 TIMEDELAY(0-3) R/W

40022 FFRT(1-3) R/W

40085 BAUD(24-1152) R/W

40086 PARITY(0-2) R/W

40087 COMM ADDRESS(0-247) R/W

40089 KEY TIMEOUT(0-9999) R/W

40092 NUMFILES(1-8) R/W

40093 ACTIVE FILE(0-7) R/W

40095 UVTUBE FLAMECOUNT R

40096 IR FL AMECOUNT R

40097 SSUV FLAMECOUNT R

401x0 FLAMEON SETPOINT x = file 0-7 R/W

401x1 FLAMEOFF SETPOINT x = file 0-7 R/W

401x2 FFRT x = file 0-7 R/W

401x3 TIMEDELAY x = file 0-7 R/W

401x4 UVTGAIN x = file 0-7 R/W

401x5 UVSSGAIN x= file 0-7 R/W

401x6 UVSSFILT x = file 0-7 R/W

401x7 IRFILT x = file 0-7 R/W

401x8 IRGAIN x = file 0-7 R/W

401x9 MA GAIN x = file 0-7 R/W

40182 MODBUSLOCK R/W

40000 -

40300

Other registers unlisted in this

range are special use. DO NOT

WRITE.

Read

Write

NA

32-00015—04 8

Page 9

U2-S MODEL COMBINATION VIEWING HEAD AND SIGNAL PROCESSOR

WARNING

WARNINGWARNING

Address

For applications with many flamescanners on single

modbus loop, it is recommended to start with address 11

for burner #1, 21 for burner #2 and so on.

Baud

Speed of Modbus communications (2400, 4800, 9600,

19200). The default baud is 9600.

Parity

Select Modbus checking method (NONE, ODD, or EVEN).

The default parity is NONE.

RS485

Sets Modbus registers to either READ ONLY or read and

writable (WRITE OK). Default is "Read and Write".

IMPORTANT!

Modbus registers should be set to read only

through the menu, or locked using modbus register 40182 after system commissioning to prevent

unintended writes to critical parameters. Modbus

register lock requires code from factory, contact

your sales representative for details.

0-20 mA OR 4-20 mA

Sets the current output to either 0-20mA or 4-20mA. The

4-20mA output is the default setting.

Auto Gain

NOTE: Auto Gain and Auto Filter only adjust solid state

UV, and IR sensors. It will not adjust UV tube gain,

and is non-functional in U2-1016 or U2-1016-PF

models.

This menu selection automatically sets the gain for the

SSUV and IR sensors necessary to generate a total flame

count of approximately 1200. Desired sensors must be

turned on (gain of at least 1) before auto gain is selected.

Auto Filter

This menu selection automatically sets the optimum filter

for the SSUV and IR sensors. It should only be performed

after the AUTO GAIN routine.

NOTE: While using the Auto Gain and Auto Filter modes,

the system will be adjusting to the firing conditions at the time of implementation. This condition should be carefully selected to ensure

discrimination through complete load changes

from minimum to maximum and from cold

burner/boiler startup to hot burner/boiler startup.

Default

Tapping will access the file default and factory default sub

menus.

File Default

Selecting file default will reset the currently selected file

parameters to default values (See File Selection).

Factory Default

Selecting factory default will reset all file parameters to

default values, along with additional settings of panel lock

code, baud rate, communications address, file selection

register, and number of active files allowed.

Temperature

This menu displays the U2 internal temperature, software

version, and device hours. Tapping ENTER will bring the

user into the submenu that will allow changes between

displaying Celsius or Fahrenheit, display the software

version, or display the number of hours the unit has been

in operation.

Self Check Lockout Codes

During self check if an error is detected, the flame relay

and self check relay will be de-energized, and the U2 will

display the message "Lockout". The lockout error code may

be viewed at this point by pressing ENTER at touchwheel.

The lockout error code is displayed. Next, pressing enter

resets the device and normal operation is attempted.

Before clearing the lockout, user must ensure that

system is safe for continued operation. Below are

lockout code definition and recommended actions

for each code.

Table 2. Lockout Codes.

Lockou

t Code Failure Cause Action

1 SSUV SENSOR SSUV sensor failure. Adjust gain or apply

0, 2, 3, 4,

9, 10, 11,

12, 15

4, 7 MEMORY ERROR Clear Lockout. Parameter settings may

5 UV TUBE SENSOR UVtube sensor failure. Device must be

6 UVTUBE SENSOR

8 IR SENSOR IR Sensor failure. Adjust gain or apply

14 RELAY DRIVE

16 POWER FAILURE Clear Lockout. Verify power source is

INTERNAL ERROR Clear Lockout. Verify all parameter

SUPPLY

FAILURE

orifice to lower flamecount. If failure

persists, replace device.

settings, all sensor operation, correct

relay operation, and overall device

operation before continuing. If error

persists device must be replaced.

be defaulted or corrupted. Verify all

parameter settings and device operation

before continuing. If error persists device

must be replaced.

replaced.

UVtube sensor supply failure. Device

must be replaced.

orifice to lower flamecount. If failure

persists, replace device.

Relay drive failure, device must be

replaced.

correctly set before continuing (24V

@120ma). If error persists device must

be replaced.

9 32-00015—04

Page 10

U2-S MODEL COMBINATION VIEWING HEAD AND SIGNAL PROCESSOR

M35420

GT32

GU32

FU09

GI32

FI04

GM32

0800

0600

RT01

TD03

*F01

A000

FILE DEFAULT

0000

0000

PANEL LOCK

TIME OUT MIN

FACTORY DEFAULT

RS485

PARITY

HOURS

4 SUB MENUS

LAST MENU

HELPHELP

°F OR °C

VERSION

ADDRESS

-

DEFAULT

127 °F

GAIN TUBE UV

-

GAIN SS UV

-

FILTER SS UV

-

GAIN IR

-

FILTER IR

-

GAIN MA OUT

-

FLAME ON

-

FLAME OFF

-

FFRT

-

TIME DELAY

-

FILE

PANEL

COMMS

AUTO GAIN

AUTO FILTER0

-

>20 OR 4->20

READ ONLY

WRITE ONLY

NONE

ODD

EVEN

2400

9600

38400

115200

4800

19200

57600

BAUD

3425

ENTER

STORE

BACK

TROUBLESHOOTING

Symptoms Remedies

No Display 1. Check 24 VDC power connections and

level at red and black wires.

2. Turn off power completely for 10-20 seconds to allow for internal thermal fuse to

reset.

3. Check ambient temperature is below 70C

(158F)

Display ON but

flame relay contact

not closing when

flame recognized

Lack of

communication on

Modbus

Important Information

1. When connected to an approved Burner control Sys-

tem, additional EMC tests are not required.

2. All external connection should not exceed 30 VDC. If

higher voltage operation is required, approved interposing relay should be used.

3. The U2 must be powered using a isolated 24VDC

SELV (Safety Extra Low Voltage) power supply.

Check wiring as follows:

1. Continuity between common (green) wire

and yellow (this should be closed when

power is applied -Self Check Relay)

2. If 1 above shows continuity, repeat test

with green and grey wire (Flame relay).

Make sure flame LED shows Flame relay

is energized.

A unique address must be used for each loop.

Address "0" disables communication. Check

communication settings in menu.

If using a converter, make sure the dip switches

are set correctly. For further troubleshooting,

check vendor information for the converter

used.

Maintenance

There are no user replaceable parts in U2.

Depending upon the application, periodic cleaning of the

lens may be necessary. Usually, the pressurized front of

the lens prevents dirt and debris from depositing on the

lens. Make sure positive pressure is maintained under all

firing conditions.

User Interface

Interface Techniques:

TAP: Press a finger on a button and remove.

SCROLL: Press a finger on the glass and move the finger

in circles (twirl).

RAMP: Hold a finger on the + or - button.

Two button interface (BACK and ENTER). Everything else

can be done by scrolling.

Interface Modes:

FLAME DISPLAY: Tap BACK (may require more than on

tap).

HELP: Tap + or - (from display).

LAST MENU: Tap ENTER, move through menu with taps or

scrolls.

ADJUST MODE: Tap ENTER from adjustable menu item,

change value using any technique.

NO YES MODE: Change to YES and tap STORE.

NOTE: If a sensor is not available in your model, then no menu item will exist for sensor setting. See Table 1, “Models

32-00015—04 10

and Associated Features.,” on page 2 to determine which sensors are active in your U2 model.

Fig. 6. User interface menu overview.

Page 11

U2-S MODEL COMBINATION VIEWING HEAD AND SIGNAL PROCESSOR

WARNING

WARNINGWARNING

WARNING

WARNINGWARNING

U2-S Flame Threshold Setup

Desired target burner flamecount during normal

operation is 1200 to 2000 counts.

Using multiple sensors is useful for monitoring different

fuels, pilot/main flame monitoring, or for a high level of

discrimination. See feature chart on page 2 for application

sensors.

Positioning of flame scanner, along with gain and

filter settings must result in a background

radiation flamecount that is less than the flame off

setpoint! (Example: If target flame is extinguished,

but background flame(s) are still present,

flamecount must fall below flame off setpoint).

Recommended Ideal Flame On and Flame Off threshold

settings:

1. Adjust available sensor filters to 0, and gain of each

sensor so that flamecount under normal operation is

approximately 1500 to 2000 counts total when viewing target flame under normal firing rate.

2. Take a reading of the Flame On and Flame OFF

flamecount values at minimum firing rate and Maximum firing rate:

f. Target burner Flame ON flame count at lowest

firing rate = AL

g. Target burner Flame Off, flame count at lowest

firing rate = BL

h. Target burner Flame ON flame count at highest

firing rate = AH

i. Target burner Flame Off, flame count at highest

firing rate = BH

j. Select AL if AL < AH, otherwise use AH value.

Let us call this value = X

k. Select BH if BH < BL otherwise use BL value.

Let us all call this value =Y

3. Use X, Y, along with formulas below to arrive at new

Flame ON, and Flame OFF thresholds.

Flame ON set point = 0.75X + 0.25Y

Flame OFF set point = 0.25X + 0.75Y

4. Using new values for Flame On and Flame Off

threshold, calculate FLAME ON/Flame OFF ratio.

The ratio of 1.5 or higher is desirable. Adjust flame

ON and flame OFF thresholds to calculated values in

step 3.

5. Extinguish target flame while maximum background

radiation is present. Observe flamecount, and

increase filter setting(s) of sensor(s) to decrease

total flamecount present from background radiation. The resulting background radiation flamecount

should be adjusted to minimum. Verify that resulting

flamecount falls below the flame off setpoint. If not,

continue adjusting gain and filter settings, or adjust

target flame sighting.

After setup is complete, installer must test for

background flame radiation below flame off

setpoint when target flame is extinguished over all

conditions. Failure to verify this may result in

unsafe operation.

6. When filtering settings are complete, operate system

once again with all flames present over minimum

and maximum load, and verify proper flame threshold operation. If no further adjustment is necessary,

threshold setup is complete. If gain or filter adjustments are necessary, repeat step 5 to confirm background radiation below flame OFF setpoint as any

adjustments will affect both the target and background radiations.

11 32-00015—04

Page 12

32-00015—04 12

(GREY) FLAME SIGNAL OUTPUT 30VDC 1A MAX

(GREEN) FAULT SIGNAL OUTPUT 30VDC 1A MAX

(YELLOW) FLAME SIGNAL INPUT 30VDC 1A MAX

(PURPLE) FILE SELECT INPUT 30VDC MAX

(TAN) FILE SELECT OUTPUT 24VDC 10ma MAX

(ORANGE) mA OUPUT + 500Ω MAX

(BLUE) mA OUPUT - 500Ω MAX

(WHITE) RS485+

(BROWN) RS485-

(RED) +24V INPUT 120mA MAX

(BLACK) POWER SUPPLY

MCR35492

SCREW

TO EARTH

GROUND

CABLE DRAIN

TO EARTH

GROUND

FLAME

RELAY

SELF

CHECK

RELAY

U2-101xS

FLAMESCANNER

BURNER

CONTROL

SYSTEM

500Ω

MAX

24VDC SELV

POWER SUPPLY

U2-S MODEL COMBINATION VIEWING HEAD AND SIGNAL PROCESSOR

Fig. 7. Typical Installation Diagram.

Page 13

U2-S MODEL COMBINATION VIEWING HEAD AND SIGNAL PROCESSOR

SAFETY MANUAL

U2-S Model Product Declaration

FIT FOR USE IN A LOW DEMAND SAFETY APPLICATION

Models:U2-1010S, U2-1012S, U2-1016S, U2-1018S, U2-1010S-PF, U2-1012S-PF, U2-1016S-PF, U2-1018S-PF

Models SIL HFT SFF PFD

U2-1010S/U2-1010S-PF 3 0 >99%

U2-1012S/U2-1012S-PF 3 0 >99%

U2-1016S/U2-1016S-PF 3 0 >99%

U2-1018S/U2-1018S-PF 3 0 >99%

1.20 x10

1.16x10

1.15x10

1.16x10

-4

-4

-4

-4

λ

S

1.23x10

1.64x10

1.06x10

1.16x10

-5

-6

-5

-5

λ

DD

3.34x10

1.77x10

1.74x10

1.77x10

-7

-9

-9

-9

λ

DU

5.38x10

5.32x10

5.27x10

5.32x10

-9

-9

-9

-9

System Architecture 1oo1

MTTR 8 hours

Proof Test Interval 5 years

Fit for use in SIL 3 environment

Definitions

Term Definition

Dangerous Failure Failure which has the potential to put the safety-related system in a hazardous state

Safety-Related System A system that implements the required safety functions required to achieve or maintain a

Safety Function Defined function, which is performed by a safety-related system with the aim of achieving

Proof Test Periodic test performed to detect failures in a safety-related system so that, if necessary, the

MTTR (Mean Time To

Restoration)

λ

sd

λ

su

λ

dd

λ

du

HFT Hardware Fault Tolerance

System Architecture Specific configuration of hardware and software elements in a system.

PFD

(Average

AVG

Probability of Failure on

Demand)

FIT (Failures in Time) A unit of measurement representing one failure per billion hours. 1,000,000,000 hours is

safe state and is intended to achieve on its own or with other systems the necessary safety

integrity for the required safety functions.

or maintaining a safe state for the plant, in respect of a specified hazardous event.

system can be restored to an “as new” condition or as close as practical to this condition.

The average duration required for restoration of operations after a failure.

Rate of safe detectable failures per one billion hours.

For example, if λ

= 3000, then it is estimated that there will be about 3000 safe detectable

sd

failures during every one billion hours of operation.

For λ

= 3000, this is about one safe detectable failure every 38 years.

sd

Rate of safe undetectable failures per one billion hours.

Rate of dangerous detectable failures per one billion hours.

Rate of dangerous undetectable failures per one billion hours.

Average Probability of Failure on Demand.

approximately 114,155.25 years.

13 32-00015—04

Page 14

U2-S MODEL COMBINATION VIEWING HEAD AND SIGNAL PROCESSOR

Safety Function of the U2-S Model

The safety function of the U2-S signal processor consists

of a Flame Relay which comprises its safety function and

behaves as follows:

The Flame Relay (Normally Open)

• The Flame Relay will be energized when the product is

powered and a flame on condition is detected for longer

than the time delay value.

• The Flame Relay will be de-energized when the product

is powered, a flame off condition is detected, and the

FFRT (Flame Failure Response Time) has elapsed.

• The Flame Relay will be de-energized when the product

is powered and detects a fault condition.

• The Flame Relay will be de-energized when power to

the product is off.

All U2-S signal processor models contain a Self Check

Relay designed to be energized during normal operation

and de-energized during power off, or detection of a fault.

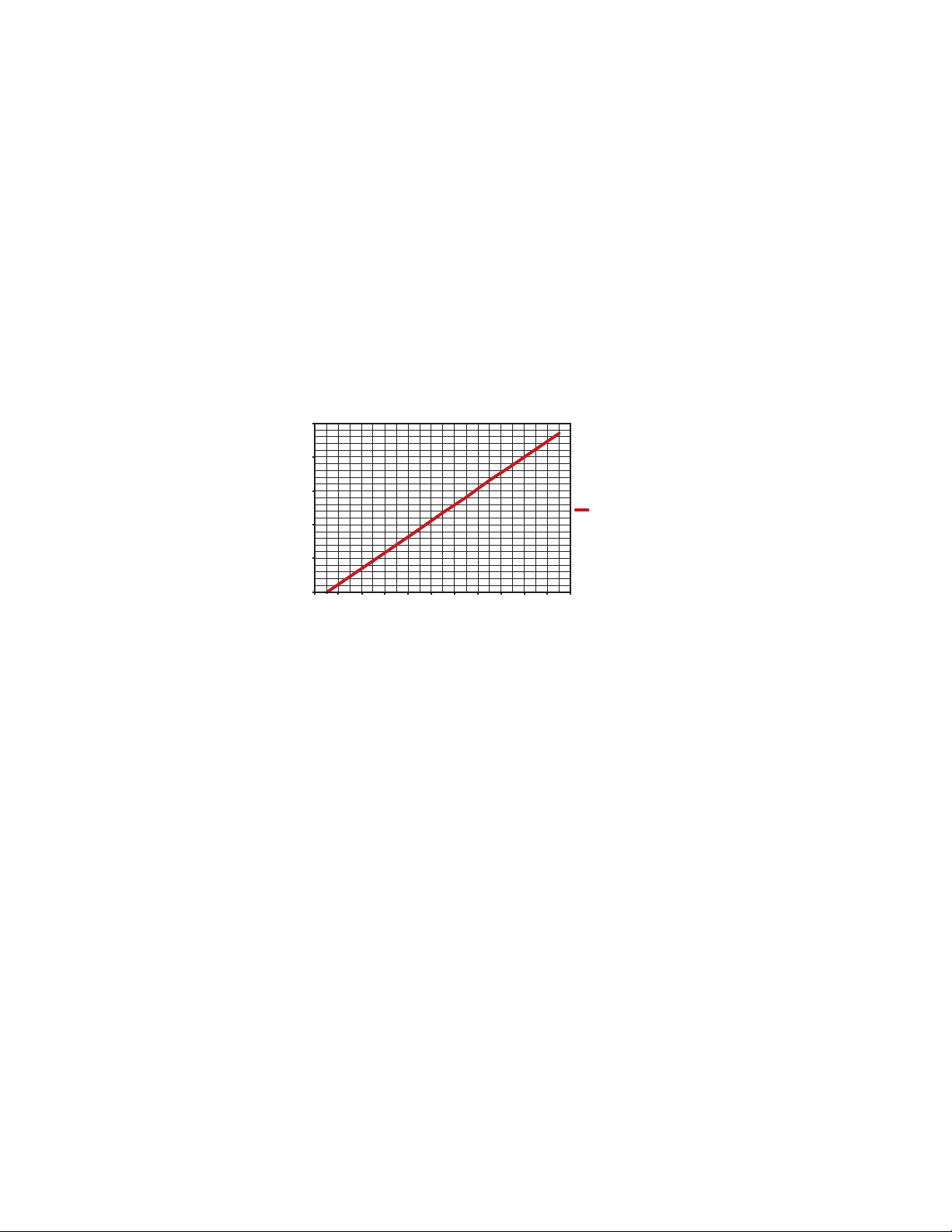

Proof Test Interval

The Proof test must be conducted every 1 to 5 years. This

range is given to allow for the test to be performed during

the normally scheduled burner shutdown period. It is the

responsibility of the user to perform the proof test in the

specified time frame.

The following chart for the U2-1010S shown for example,

presents the dependence of the PFD

interval. The PFD

increases.

on the proof test

increases as the proof test interval

AVG

AVG

2.53E-04

2.03E-04

1.53E-04

1.03E-04

5.27E-05

2.71E-06

U2-1010S TIME IN YEARS VS PFDavg

012345678910

Fig. 8. 1010S PFD

Proof Test Procedure

EQUIPMENT REQUIRED

• Powered Uniscan 2S signal processor

• Multimeter capable of voltage measurements < 50V,

and resistance measurements 1 Ohm to 1MOhm. Fluke

87 or similar.

• 24V DC Power supply < 500mA

• Light source* capable of generating a flame on

condition for all sensors.

* Use an incandescent bulb for IR sensor, deep UV light for

solid state UV and UV tube sensors. If none of these are

available a flame may be used. Note that IR, and SSUV

sensors require flickering light source.

Setup

1. Set power supply to OFF. Connect U2-S model to

power supply as described in manual.

2. While performing the proof test, disconnect or disregard the signal processor so that any outputs due to

testing do not affect the overall safety system and

potentially cause a hazardous situation.

3. Record all previously entered user programmable

settings so that they may be restored after the proof

test.

PFDavg

MCR35675

over time.

AVG

Tests

1. Ensure that power is completely removed form the

U2-S. Measure resistance between yellow and green

wires and verify that self check relay contact is open

circuit ( >1MOhm ). Measure between green and

gray, and verify flame relay contact is open circuit (>

1MOhm).

2. Reapply power to the signal processor and, using a

multimeter, ensure closure of the self check relay by

measuring continuity * between the yellow and

green wires.

* Less than ~5ohm / 50foot cable

3. Use a light source to generate a flame on condition

and, using a multimeter, ensure closure of the flame

relay by measuring continuity between the green

and gray wires.

4. Remove any light source to generate a flame off condition and, using a multimeter measure resistance

between green and gray wires, and verify flame relay

contacts are open ( > 1MOhm), after the FFRT

(Flame Failure Response Time) has elapsed.

5. Measure the current draw of the U2 and ensure it is

less than 120 mA.

6. Change FFRT settings of the signal processor and

store the changed setting. Remove power to the signal processor for 10 seconds. Restore power to the

signal processor and ensure the stored value has

remained unchanged.

32-00015—04 14

Page 15

U2-S MODEL COMBINATION VIEWING HEAD AND SIGNAL PROCESSOR

7. Use your light source to generate flamecounts of

between 1200 and 2000 in the signal processor.

Note the flamecount.

a. Increase the gain and store the setting. Confirm

the flamecount increased.

b. Decrease the gain and store the setting. Confirm

the flamecount decreased.

8. Restore all original settings as recorded in setup and

reconnect the signal processor to the safety system.

Product Decommissioning

When required, decommissioning of the U2-S

flamescanner should be performed in accordance with

requirements of the overall safety system.

15 32-00015—04

Page 16

U2-S MODEL COMBINATION VIEWING HEAD AND SIGNAL PROCESSOR

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422-3992

www.honeywell.com

United States

Maxon, A Honeywell Company

201 East 18th Street

P.O. Box 2068

Muncie, IN 47307-0068

Tel: 765.284.3304

Fax: 765.286.8394

Europe

Maxon International bvba

Luchthavenlaan 16

1800 Vilvoorde

Belgium

® U.S. Registered Trademark

© 2016 Honeywell International Inc.

32-00015—04 M.S. Rev. 05-16

Printed in United States

Loading...

Loading...