Honeywell TZI 5-15/100, TZI 7-25/20, TZI 7.5-12/100, TZI 7.5-20/33, TGI 5-15/100 Technical Information

...Page 1

Industrial & Commercial Thermal

Ignition transformers TZI, TGI

Technical Information · GB

8 Edition 06.16

• Electrical ignition of gas burners

• Ignition and burner control with a single electrode possible

• TZI 7,520/33R complies with CSA

Page 2

Contents

Ignition transformers TZI, TGI ....................... 1

Contents ............................................2

1 Application ........................................3

1.1 Examples of application ...........................5

1.1.1 Double-electrode operation...........................5

1.1.2 Single-electrode operation............................5

2 Certification .......................................6

3 Function ...........................................7

3.1 Connection diagrams .............................. 7

4 Selection ..........................................8

4.1 Selection table .....................................8

4.1.1 Type code..............................................8

5 Project planning information . . . . . . . . . . . . . . . . . . . . . . 9

5.1 Operation ..........................................9

5.2 Installation .........................................9

5.3 Cable selection ....................................9

5.3.1 Ignition cable ..........................................9

5.4 Reduction of EMC, wiring.........................10

5.5 Single-electrode operation .......................10

5.6 Intermittent operation/Star electrodes...........10

5.7 Duty cycle .........................................11

6 Accessories.......................................12

6.1 High-voltage cable ...............................12

6.2 Radio interference suppressed electrode

adapters ..............................................12

7 Technical data ....................................13

7.1 Dimensions ........................................14

Feedback ...........................................15

Contact.............................................15

TZI, TGI · Edition 06.16 2

= To be continued

▼

Page 3

Application

TZI 5-15/100, T ZI 7-25/20,

TZI 7,5-12/100, TZI 7,5-20/33 TGI

1 Application

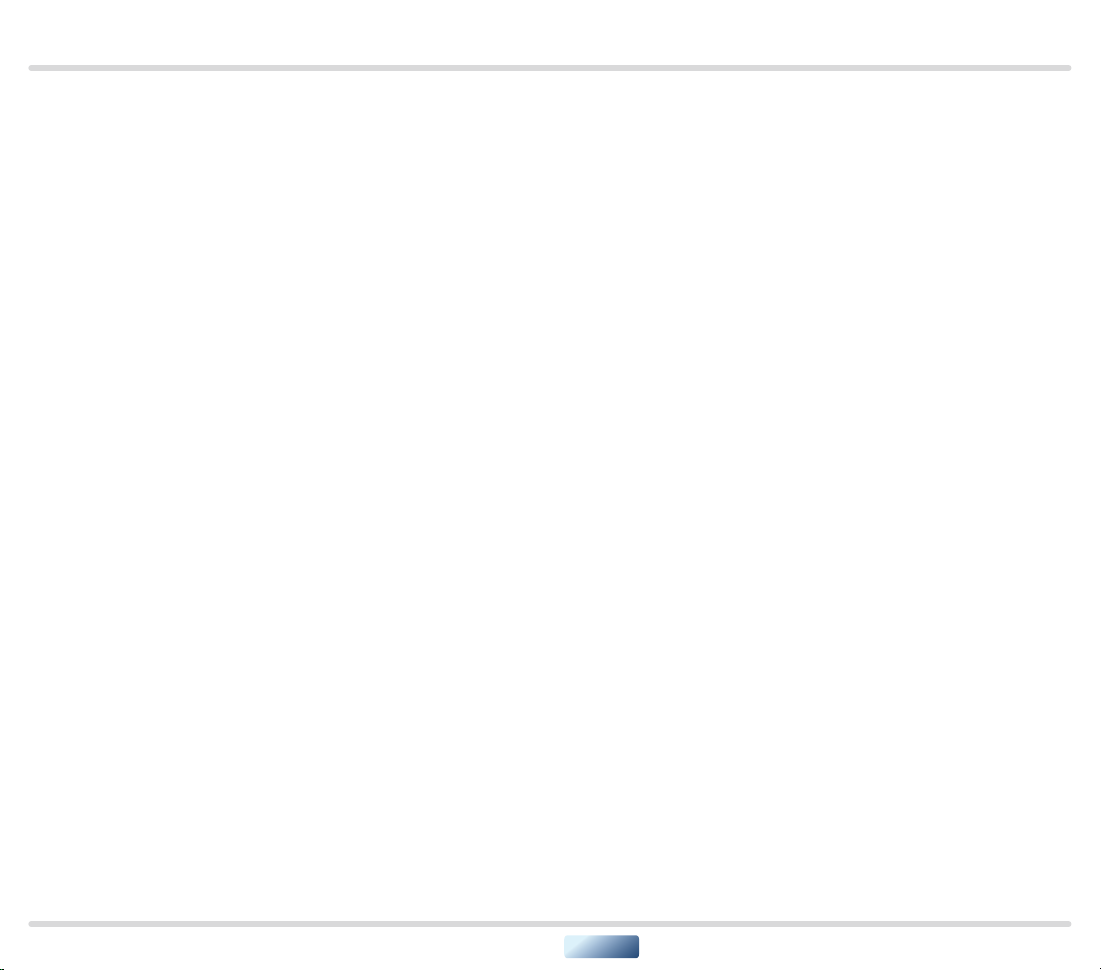

Ignition transformers TZI and TGI are designed for

high-voltage spark ignition of gas burners and gasignited or directly ignited oil burners. The ignition

transformers can also be used on burners with singleelectrode operation; the ignition current and ionization

current flow over a common electrode. The ignition

transformer TZI must be mounted in a housing, e.g. in a

control cabinet. It fulfils the requirements for enclosure

IP 00. Ignition transformer TGI in its die-cast aluminium

housing meets the requirements for enclosure IP 54. It

is suitable for on-site mounting near to the burner.

TZI, TGI · Edition 06.16 3

Page 4

Application

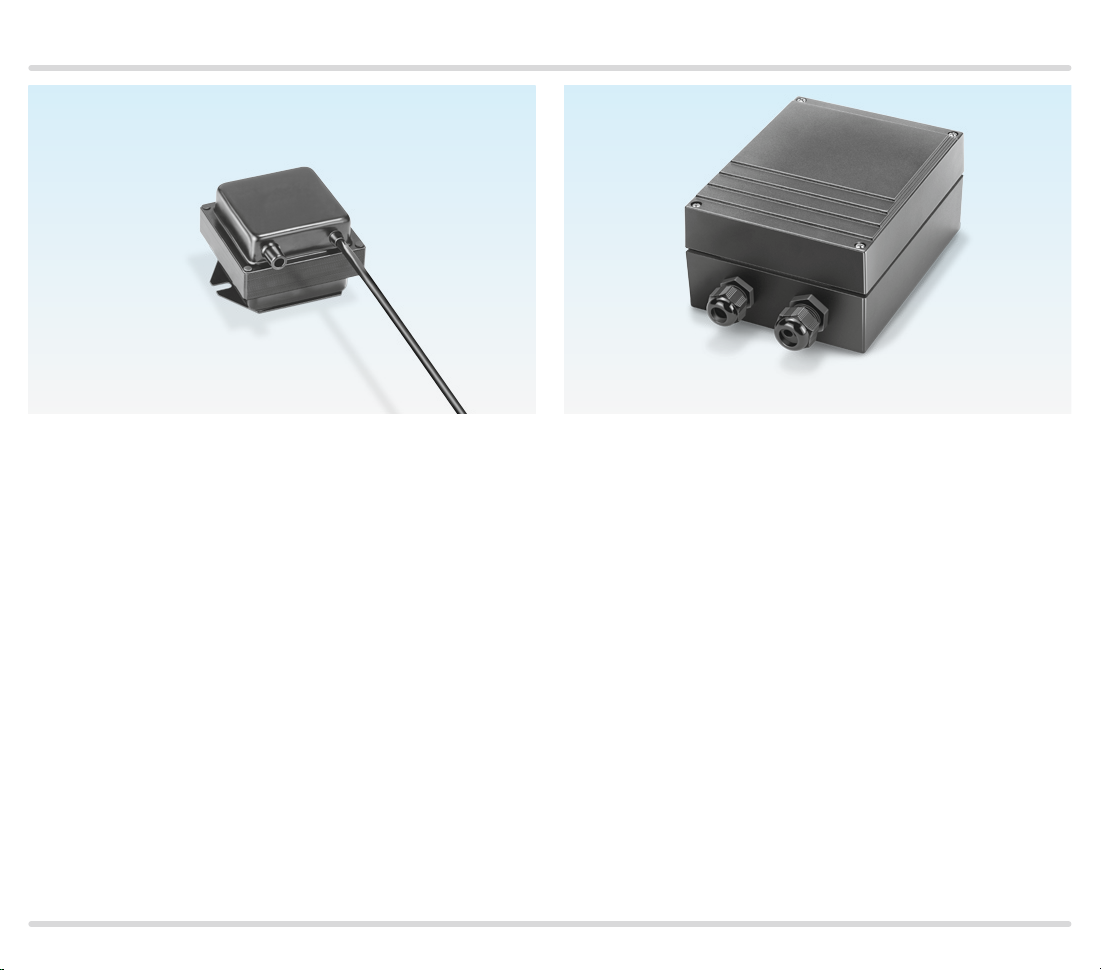

Bogie hearth forging furnace

in the metallurgical industry

Intermittent shuttle kiln

in the ceramics industry

Walking beam furnace

with overhead firing

TZI, TGI · Edition 06.16 4

Page 5

Application

1.1 Examples of application

L1

N

IFD 258

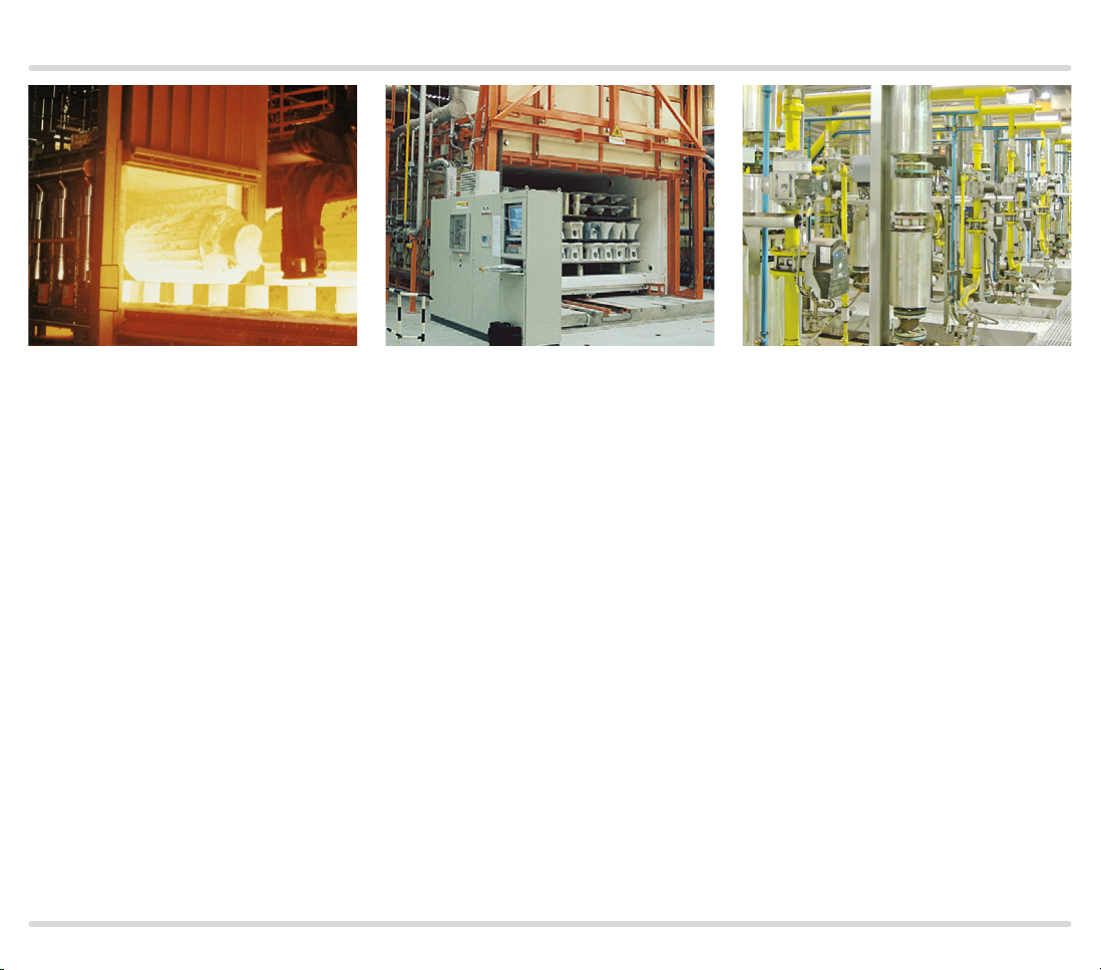

1.1.1 Double-electrode operation

Ignition using ignition electrode

Ignition transformer TGI is supplied with voltage via

VAS

TGI

GIK

BIO/

BIC

the automatic burner control unit IFD 258. The ignition

transformer generates a high voltage. This high voltage

creates ignition sparks between the ignition electrode

and burner ground. After the burner start, a current

flows via the ionization electrode for flame control.

VR..R

1.1.2 Single-electrode operation

Ignition using an ignition and ionization electrode.

L1

N

IFD 258

After burner start, a flame control current flows via the

same electrode that is also used for ignition.

VAS

TGI

GIK

BIO/

BIC

VR..R

TZI, TGI · Edition 06.16 5

Page 6

Certification

2 Certification

Ignition transformers TZI and TGI are built for applications pursuant to the Machinery Directive 2006/42/EC.

TZI 7,520/33R

Complies with Canadian Standards Association

CSA C22.2 No. 131962.

TZI, TGI · Edition 06.16 6

Page 7

Function

3 Function

Z

I

H

br

gn/ye

bk

bl

L1

N

3.1 Connection diagrams

Ignition: double-electrode operation

Burner control unit

H

br

gn/ye

∅ 7 mm (0.275")

H

Legend

H High-voltage connection

br Connection cable brown

bk Connection cable black

bl Connection cable blue

gn/ye Connection cable green/yellow

bk

bl

Ignition: single-electrode operation

Single-electrode operation is possible only in conjunction with suitable automatic burner control units. The

L1

N

switchover between ignition and monitoring is performed by the automatic burner control unit.

High-voltage connection

Cut end of high-voltage cable is inserted into the

shroud and screwed onto the wood screw (H).

TZI, TGI · Edition 06.16 7

Page 8

Selection

4 Selection

4.1 Selection table

R W

T ZI 5-1 5/100

T ZI 7-25 /20

T ZI 7,5 -12 /1 00

TZI 7,5-20/33

TG I 5 -15/ 100

TGI 7-25/20

TGI 7,5 -12/1 00

TGI 7,5-20/33

Order example

TZI 5-15/100W

= standard, = available

4.1.1 Ty pe c ode

Code Description

TZI

TGI

5

7

7,5

-12

-15

-20

-25

/20

/33

/100

R

W

Ignition transformer

Ignition transformer, enclosed

High voltage: 5 kV

7 kV

7.5 k V

Output current: 12 mA at 50 Hz (9 mA at 60 Hz)

15 mA at 50 Hz (11 mA at 60 Hz)

20 mA at 50 Hz (15 mA at 60 Hz)

25 mA at 50 Hz (18 mA at 60 Hz)

Duty cycle: 20%

33%

100%

Mains voltage: 115 V

230 V

TZI, TGI · Edition 06.16 8

Page 9

Project planning information

5 Project planning information

5.1 Operation

The ignition transformers are suitable only for applica-

tions for igniting gas burners and gas-ignited or directly

ignited oil burners. An automatic burner control unit

with integrated fuse (max. 4 A) must be provided to

activate the ignition transformers. Do not operate the

transformers when no ignition sparks are created (distance between spark electrode and burner ground = 2 ±

0.5 mm). The duty cycle and the ambient temperature

must not exceed the permissible limits.

5.2 Installation

Installation position for TZI and TGI: install with the

connections facing down. Position the ignition trans-

former right next to the burner (recommended ignition

cable length: max. 5 m, recommended < 1 m).

TZI

The length of the mains cable is approx. 410 mm.

Fix the ignition transformer in a housing or control

cabinet.

5.3 Cable selection

Use mains cable suitable for the type of operation and

complying with local regulations.

Install an equipotential bond (4 mm

local regulations) between burner and ignition transformer.

TGI

The TGI housing has two A/F 27 cable glands with dou-

ble seal inserts for two cables up to 7 mm in diameter. A

seal insert for 10 to 14 mm is enclosed and can be used

in the A/F 27 cable gland, see page 14 (Dimensions).

5.3.1 Ignition cable

Use unscreened high-voltage cable for the ignition cable, see page 12 (Accessories). The ignition capacity

is lower when using a screened ignition cable.

Ignition cable length:

Recommended < 1 m, max. 5 m. The longer the ignition

cable, the lower the ignition capacity.

Use radio interference suppressed terminal boots only

on the burner (with 1 kΩ resistor), see page 12 (Accessories).

2

, compliant with

TZI, TGI · Edition 06.16 9

Page 10

Project planning information

5.4 Reduction of EMC, wiring

Avoid external electrical interference.

Lay cables individually and, if possible, not in a metal

conduit.

Do not lay UV/ionization cable and ignition cables to-

gether and lay them as far apart as possible.

Screw the ignition cable securely into the high-voltage

connection on the ignition transformer and run to the

burner by the shortest possible route, see page 7

(High-voltage connection).

Use radio interference suppressed terminal boots only

on the burner (with 1 kΩ resistor), see page 12 (Accessories).

5.5 Single-electrode operation

Single-electrode operation is possible only in conjunction with suitable automatic burner control units.

For single-electrode operation, wire an equipotential

bond between the burner and the automatic burner

control unit, see page 7 (Ignition: single-electrode

operation). Ensure that the wiring has been done correctly, otherwise the connected units will be damaged.

5.6 Intermittent operation/Star electrodes

We recommend using 7.5 kV ignition transformers for

On/Off intermittent operation or when using burners

with star electrodes.

TZI, TGI · Edition 06.16 10

Page 11

Project planning information

100

Duty cycle [%]

Duty cycle [%] × 180 s

20 [%] × 180 s

5.7 Duty cycle

The duty cycle indicates for how long the ignition transformer can be switched on within 180 s, without it be-

ing overloaded.

80

60

40

20

0

-20 0 20 40 60

Ambient temperature [°C]

For ignition transformers, the duty cycle is dependent

on the ambient temperature.

TZI/TGI duty cycle in % – see page 13 (Technical

data).

Converting the duty cycle into seconds:

Example

Ignition transformer TZI 725/20W with a duty cycle of

20% for an ambient temperature of 20 to +35°C.

Duty cycle =

100%

= 36 s

In an ambient temperature of 20 to +35°C, this results

in a maximum duty cycle of 36 s within 180 s for the

ignition transformer.

For an automatic burner control unit with an ignition

time t

= 6 s, for example, the resultant timing cycle is a

Z

maximum of 2 ignitions per minute.

0 60 120 180

Legend

tZ = 6 s

t [s]

Duty cycle [s] =

TZI, TGI · Edition 06.16 11

100%

Page 12

Accessories

6 Accessories

6.1 High-voltage cable

FZLSi 1/7 50°C (58°F) to 180°C (356°F),

Order No. 04250410,

FZLK 1/7 5°C (23°F) to 80°C (176°F),

Order No. 04250409.

6.2 Radio interference suppressed electrode adapters

Plug cap, 4 mm (0.16 inch), interference-suppressed,

Order No. 04115308.

Straight adapter, 4 mm (0.16 inch), interference-suppressed,

Order No. 04115307.

Straight adapter, 6 mm (0.2 inch), interference-suppressed,

Order No. 04115306.

TZI, TGI · Edition 06.16 12

Page 13

Technical data

7 Technical data

Type Input Output Duty cycle** Enclosure Weight

V AC Hz* A* V mA* % kg

TZI 5-15/100W 230 50 (60) 0.45 (0.35) 5000 15 (11) 100 IP 00 1.5

T ZI 7-25 /20 W 230 50 (60) 1.1 (0.8) 7000 25 (18) 20 IP 00 1.5

TZI 7,5-12/100W 230 50 (60) 0.6 (0.45) 7500 12 (9) 100 IP 00 2

TZI 7,5-20/33W 230 50 (60) 0.9 (0.7 ) 7500 20 (15) 33 IP 00 2

TZI 5-15/20R 115 50 (60) 1 (0.7) 5000 15 (11) 20 IP 00 0.9

T ZI 5-1 5/100R 115 50 (60) 0.9 (0.7 ) 5000 15 (11) 100 IP 00 1.5

T ZI 7-25 /20 R 115 50 (60) 2.2 (1.6) 7000 25 (18) 20 IP 00 1.5

T ZI 7,5 -12 /1 00 R 115 50 (60) 1.2 (0.9) 750 0 12 (9) 100 IP 00 2

TZI 7,5-20/33R 115 50 (60) 1.8 (1.35) 7500 20 (15) 33 IP 00 2

TGI 5-15/100W 230 50 (60) 0.45 (0.35) 5000 15 (11) 100 IP 54 3

TGI 7-25/20W 230 50 (60) 1.1 (0.8) 7000 25 (18) 20 IP 54 3

TGI 7,5-12/100W 230 50 (60) 0.6 (0.45) 75 00 12 (9) 100 IP 54 3.5

TGI 7,5-20/33W 230 50 (60) 0.9 (0.7 ) 7500 20 (15) 33 IP 54 3.5

TG I 5 -15/ 100 R 115 50 (60) 0.9 (0.7) 5000 15 (11) 100 IP 54 3

TGI 7-25/20R 115 50 (60) 2.2 (1.6) 7000 25 (18) 20 IP 54 3

TGI 7,5 -12/1 00 R 115 50 (60) 1.2 (0.9) 7500 12 (9) 100 IP 54 3.5

TGI 7,5-20/33R 115 50 (60) 1.8 (1.35) 7500 20 (15) 33 IP 54 3.5

* Values in brackets apply to 60 Hz.

** For temperatures between -20 and +35°C.

Converting the duty cycle into seconds, see page 11

(Duty cycle).

Ambient temperature:

20 to +60°C.

TZI, TGI · Edition 06.16 13

Page 14

Technical data

7.1 Dimensions

TZI

Length of connection cable: approx. 410 mm

73

92

7

69

74

86

73

92

7

TZI 5-15/100, T ZI 7-25/20 TZI 7,5-12/100, TZI 7,5-20/33

TGI

TGI

95

180

103

∅ 5.0

M20 (A/F 27)

M20 (A/F 24)

140

165

92

99

110

TZI, TGI · Edition 06.16 14

Page 15

Feedback

Kromschröder AG

Michael Rehkamp

m.rehkamp@kromschroeder.com

Osnabrüc

k

Feedback

Finally, we are offering you the opportunity to assess this “Technical Information (TI)” and to give us your opinion,

so that we can improve our documents further and suit them to your needs.

Clarity

Found information quickly

Searched for a long time

Didn’t find information

What is missing?

Comprehension

Coherent

Too complicated

No answer

Scope

Too lit tle

Sufficient

Too wide

No answer

No answer

Use

To get to know the product

To choose a product

Planning

To look for information

Remarks

Contact

Contact

Elster GmbH

Postfach 2809 · 49018 Osnabrück

Strotheweg 1 · 49504 Lotte (Büren)

Germany

Tel +49 541 12140

Fax +49 541 1214370

info@kromschroeder.com

ww w.kromschroeder.com

TZI, TGI · Edition 06.16

Navigation

I can find my way around

I got “lost”

No answer

The current addresses of our international agents

are available on the Internet:

ww w.kromschroeder.de/Weltweit.20.0.html?&L=1

We reserve the right to make technical

modifications in the interests of progress.

Copyright © 2016 Elster GmbH

All rights reser ved.

My scope of functions

Technical department

Sales

No answer

03250846

Loading...

Loading...