Honeywell TMS 9250 User Manual

TMS 9250 Product User Manual

Rev B

April 2012

© 2012 – Honeywell International Inc. All rights reserved

About This Document

Release Information

Document Name Document

ID

TMS 9250 Product User Manual V 1.1a January

Rev B April 2012

Release

Number

Publication

Date

2012

iii TMS 9250 Product User Manual Rev B

April 2012

© 2012 – Honeywell International Inc. All rights reserved

Indicates a situation which, if not avoided, may result in equipment or work

: Indicates a potentially hazardous situation which, if not avoided,

: Indicates a potentially hazardous situation, which, if not avoided,

L'inobservation de ce symbole risque d'entraîner des blessures graves, voire

additional information. The symbol appears next to required information in the

symbole d'AVERTISSEMENT apparaît sur l’équipement et renvoie

Symbol Definitions

The following table lists those symbols used in this document to denote certain conditions.

Symbol Definition

ATTENTION: Identifies information that requires special consideration.

TIP: Identifies advice or hints for the user, often in terms of performing a task.

REFERENCE - EXTERNAL: Identifies an additional source of information

outside of the booklet.

REFERENCE - INTERNAL: Identifies an additional source of information within

the booklet.

CAUTION

(data) on the system being damaged or lost, or may result in the inability to

properly operate the process.

CAUTION

may result in minor or moderate injury. It may also be used to alert against

unsafe practices.

CAUTION symbol on the equipment refers the user to the product manual for

additional information. The symbol appears next to required information in the

manual.

WARNING

could result in serious injury or death.

AVERTISSEMENT : Indique une situation potentiellement dangereuse.

mortelles."

WARNING symbol on the equipment refers the user to the product manual for

manual.

Ce

l’utilisateur aux informations qui se trouvent dans le manuel du produit. Dans le

manuel, ce symbole apparaît à côté de l’information corr e sp ondan te.

WARNING, Risk of electrical shock: Indicates potential shock hazard where

HAZARDOUS LIVE voltages greater than 30 Vrms, 42.4 Vpeak, or 60 VDC may

be accessible.

AVERTISSEMENT, risque d’électrocution : Indique un risque d'électrocution car

des tensions supérieures à 30 Vrms, 42,4 Vpic ou 60 Vcc, POUVANT ETRE

MORTELLES, sont accessibles.

v TMS 9250 Product User Manual Rev B

April 2012

© 2012 – Honeywell International Inc. All rights reserved

Symbol Definition

ESD HAZARD: Indicates dan ger of an electro-static discharge to which

equipment may be sensitive. Observe precautions for handling electrostatic

sensitive devices.

Protective Earth (PE) terminal: Provided for connection of the protective earth

(green or green/yellow) supply system conductor.

Functional earth terminal: Used for non-safety purposes such as noi se

immunity improvement. NOTE: This connection shall be bonded to Protective

Earth at the source of supply in accordance with national local electrical code

requirements.

Earth Ground: Functional earth connection. NOTE: This connection shall be

bonded to Protective Earth at the source of supply in accordance with national

and local electrical code requirements.

Chassis Ground: Identifies a connection to the chassis or frame of the

equipment shall be bonded to Protective Earth at the source of supply in

accordance with national and local electrical code requirements.

vi TMS 9250 Product User Manual Rev B

April 2012

© 2012 – Honeywell International Inc. All rights reserved

Contents

1. TMS 9250 TORQUE MEASUREMENT SYSTEM ................. 9

1.1 Important General and Safety Warni n g s ............................................... 9

1.2 Certification Information ....................................................................... 11

1.3 In The Box ............................................................................................... 12

1.4 Intended Use .......................................................................................... 14

Torque Sensor ..................................................................................................... 14

Usage Scenario of TMS 9250 .............................................................................. 14

1.5 Installation and Setup ........................................................................... 15

Bolting Information ............................................................................................... 15

Torque Sensor ..................................................................................................... 15

Caliper Coupling Module ..................................................................................... 16

Signal Processing Module ................................................................................... 17

SPM External Connection.................................................................................... 17

SPM Internal Connection ..................................................................................... 18

Powering of Device .............................................................................................. 18

Toolkit Installation ................................................................................................ 18

2. MODES OF OPERATION ................................................... 25

2.1 Normal Mode Operation Detailed Description .................................... 25

Normal Mode Operation ...................................................................................... 25

2.2 Fast Mode Operation Detailed Description ......................................... 26

Fast Mode Operation ........................................................................................... 26

2.3 Analog Output Characteristics ............................................................. 30

3. CALIBRATION ................................................................... 31

3.1 System Calibration Method .................................................................. 31

3.2 Shunt Calibration ................................................................................... 32

3.3 Recalibration .......................................................................................... 32

4. TROUBLESHOOTING ........................................................ 33

4.1 “Power On” Light Not Showing ............................................................ 33

4.2 “Rotor Active” Light Not Showing ....................................................... 33

4.3 SHUNT Calibration Not Operating ........................................................ 34

4.4 No Communication ................................................................................ 34

5. PRODUCT SPECIFICATIONS ........................................... 37

6. APPENDICES ..................................................................... 39

vii TMS 9250 Product User Manual Rev B

April 2012

© 2012 – Honeywell International Inc. All rights reserved

6.1 APPENDIX A ........................................................................................... 39

Principle of Telemetry .......................................................................................... 39

6.2 APPENDIX B ........................................................................................... 39

Manual Supplement for TMS 9250 SPM Remote SHUNT CAL Option ............... 39

Overview .............................................................................................................. 39

Setup ................................................................................................................... 39

6.3 APPENDIX C ........................................................................................... 40

Filter Operation General Description ................................................................... 40

Filter Operation Detailed Description ................................................................... 40

Filter Settling Time ............................................................................................... 41

Example............................................................................................................... 42

Sample Charts ..................................................................................................... 44

6.4 APPENDIX D ........................................................................................... 46

Conversion Table ................................................................................................ 46

6.5 APPENDIX E ........................................................................................... 50

Power Supply Positioning and Cleaning .............................................................. 50

6.6 APPENDIX F ............................................................................................ 51

SPM cable connections ....................................................................................... 51

6.7 APPENDIX G ........................................................................................... 58

Manual Supplement for TMS 9250 SPM SQUAREWAVE output Option ............ 58

Overview.............................................................................................................. 58

Setup ................................................................................................................... 58

viii TMS 9250 Product User Manual Rev B

April 2012

© 2012 – Honeywell International Inc. All rights reserved

1. TMS 9250 Torque Measurement System

Complete installation, operation, and maintenance information is

Failure to comply with these instructions could result in death or

Les informations complètes d'installation, d'utilisation et d'entretien

Failure to comply with these instructions could result in serious

sitifs d’arrêt

d’urgence ou de sécurité, ni dans aucune autre application où la

défaillance du produit pourrait entraîner des personnels blessures

SPM and CCM shall be connected to equipment providing low

voltage (not more than 33Vac rms / 46.7V peak or 70Vdc total)

1. TMS 9250 Torque Measurement System

1.1 Important General and Safety Warnings

Before you work on any electronic equ ipment, review and follow the safety guidelines to hel p

protect the system from potential damage and to ensure personal safety.

WARNING

MISUSE OF DOCUMENTATION

•

provided in the instructions supplied with each product.

•

serious injury.

AVERTISSEMENT

MAUVAIS USAGE DE LA DOCUMENTATION

•

sont fournies avec les instructions ac compagnant chaque produit.

• L'inobservation de ces instructions risque d'entraîner des blessures

graves, voire mortelles.

008-0738-00

WARNING

PERSONAL INJURY

• DO NOT USE these products as safety or emergency stop devices

or in any other application where failure of the product could result

in personal injury.

•

injury or death.

AVERTISSEMENT

PERSONNELS BL E SSU RES CORPORELL E S

• NE PAS UTILISER ces produits en tant que dispo

corporelles.

• L'inobservation de ces instructions risque d'entraîner des blessures

graves, voire mortelles.

CAUTION

• For continued protection from electrical shock, all connectors on the

double insulated (SELV) sources of supply.

• When you are adjusting the CCM to align with the torque sensor,

you must lock out power to the prime mover and ensure that you

are trained prior to accessing these areas of the installation.

Rev B TMS 9250 Product User Manual 9

April 2012

© 2012 – Honeywell International Inc. All rights reserved

1. TMS 9250 Torque Measurement System

The SPM is intended only for connection to the specific power

The system was evaluated for use with a specific SELV power

ther power supply with this system may result in

The CCM is intended only for connection to the SPM with cables

This equipment provides only low voltage double insulated signal

Due to the multitude of variations possible for connection of the

guarding for the end application to meet provisions of the

Directive and RTTE Directives and is not evaluated to the

machinery directive for the reasons stated. Therefore, you must

ensure the compliance of this equipment with the provisions of the

will normally

mandate the need for additional guarding at the mechanical

Place the power supply of the system in a place where you can

008-0738-00

CAUTION

•

supply shipped with the system.

•

supply of limited energy output that affords electrical fire and shock

hazard protection.

• The use of ano

electrical shock or fire hazards or non-compliance of certification

standards.

•

provided by the manufacturer.

• Refer to the APPENDIX F for connecting cables to the SPM.

•

I/O for connection to other equipment.

ATTENTION:

• The product shall be in “POWER ON” condition for minimum period

of 30-45 minutes for meeting the product output specifications and

emission standards.

ATTENTION:

• Ensure that the interface cables are shielded before connecting to

•

• The equipment is evaluated only with respect to the Low Voltage

TIP

•

the product.

torque sensor to the load and prime mover, you must increase the

machinery directive.

machinery directive in the end application. This

coupling points to the torque sensor.

easily unplug the power cords.

10 TMS 9250 Product User Manual Rev B

April 2012

© 2012 – Honeywell International Inc. All rights reserved

1.2 Certification Information

FCC statement: (1) this device may not cause harmful interference,

and (2) this device must accept any interference received, including

exempt RSS standard(s). Operation is subject to the following two

conditions: (1) this device may not cause interference, and (2) this

Canada applicables aux appareils radio exempts de licence.

accepter tout brouillage radioélectrique subi, même si le brouillage est

Certification

FCC ID: XJLTMS9250FCC

IC ID: 9832A-TMS9250IC

interference that may cause undesired operation.

IC statement: This device complies with Industry Canada license-

device must accept any interference, including interference that may

cause undesired operation of the device.

déclaration IC : Le présent appareil est conforme aux CNR d’Industrie

L’exploitation est autorisée aux deux conditions suivantes: (1) l’appareil

ne doit pas produire de brouillage, et (2) l’utilisateur de l’appareil doit

1. TMS 9250 Torque Measurement System

008-0738-00

susceptible d’en compromettre le fonctionnement.

EMC

Safety

Product meets EMC/EMI requirement as per following standards:

• Class B FCC § 15.225(a)

• Class B FCC § 15.225(d)

• Class B FCC § 15.207

• IC RSS-Gen Issue3

• IC RSS-210 Issue 8

• ETSI EN 300 330-1 V1.7.1 and ETSI EN 300 330-2 V1.5.1

• ETSI EN 301 489-1 V1.8.1 and ETSI EN 301 489-3 V1.4.1

Product is meeting safety requirement as per following standard

• EN 60950-1: 2006 + A11:2006 and IEC 60950-1: 2005 (second edition)

• EN 61010-1: 2001 (second edition) and IEC 61010-1: 2001(second edition)

Rev B TMS 9250 Product User Manual 11

April 2012

© 2012 – Honeywell International Inc. All rights reserved

1. TMS 9250 Torque Measurement System

008-0738-00

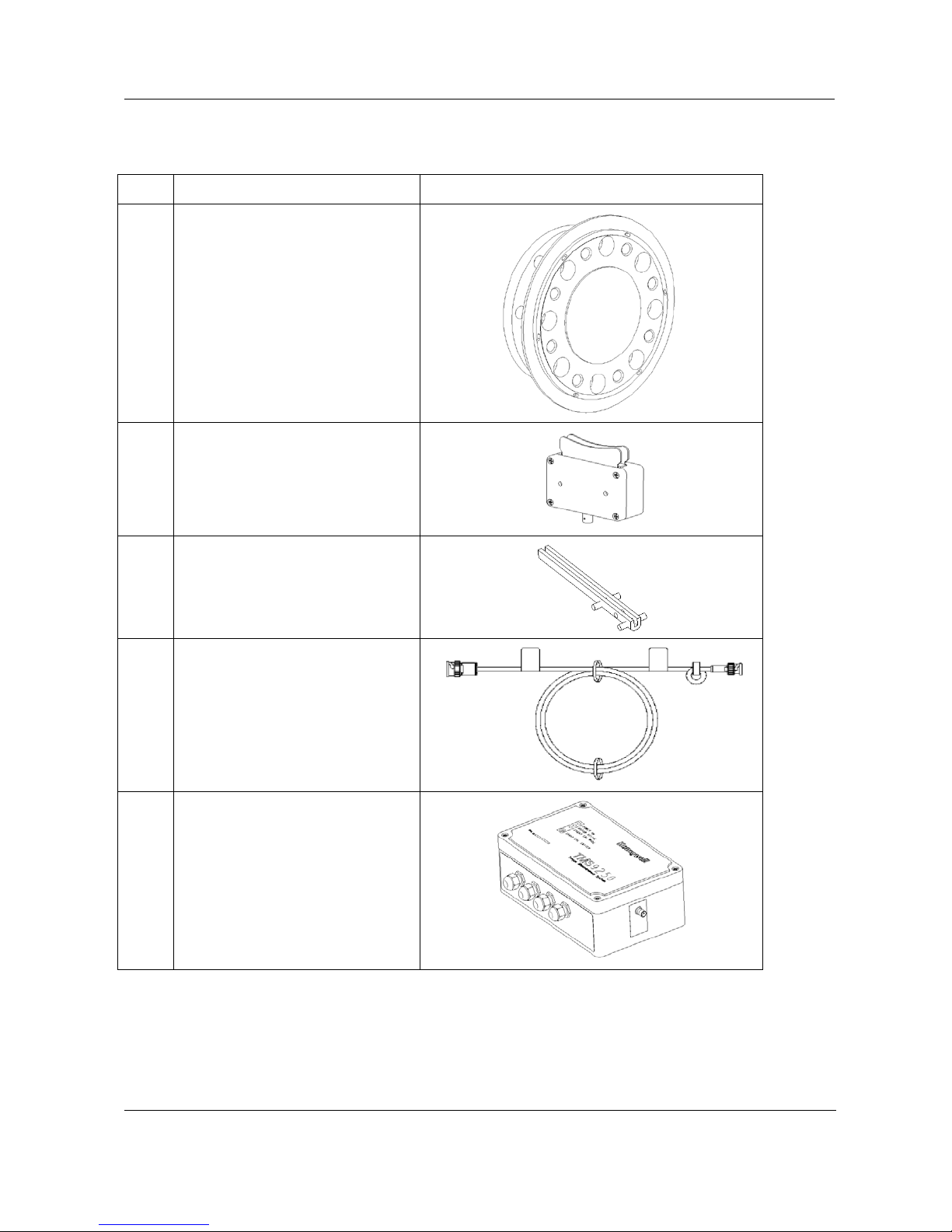

1.3 In The Box

Sl no. Description Part

1 Rotor

2 Caliper Coupling Module (CCM)

3 Alignment Tool / Setting Gauge

4 RF Tri-Axial Cable

5 Signal Processing Module (SPM)

12 TMS 9250 Product User Manual Rev B

April 2012

© 2012 – Honeywell International Inc. All rights reserved

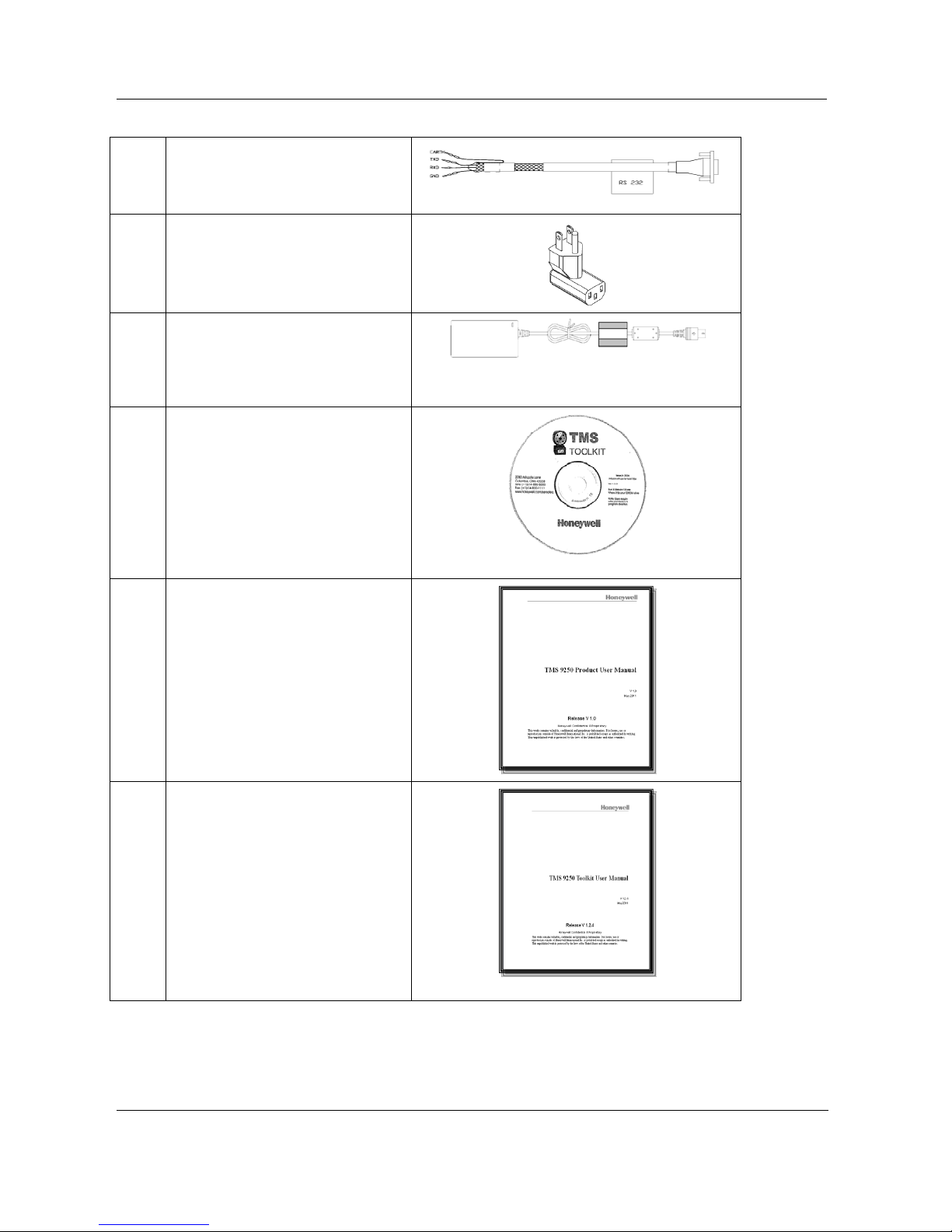

6 RS232 Interface Cable

(Communication cable)

7 Plug Top

8 Power Adapter

9 Software Installation CD

1. TMS 9250 Torque Measurement System

008-0738-00

10 Product User Manual

11 Toolkit Software Manual

Rev B TMS 9250 Product User Manual 13

April 2012

© 2012 – Honeywell International Inc. All rights reserved

1. TMS 9250 Torque Measurement System

008-0738-00

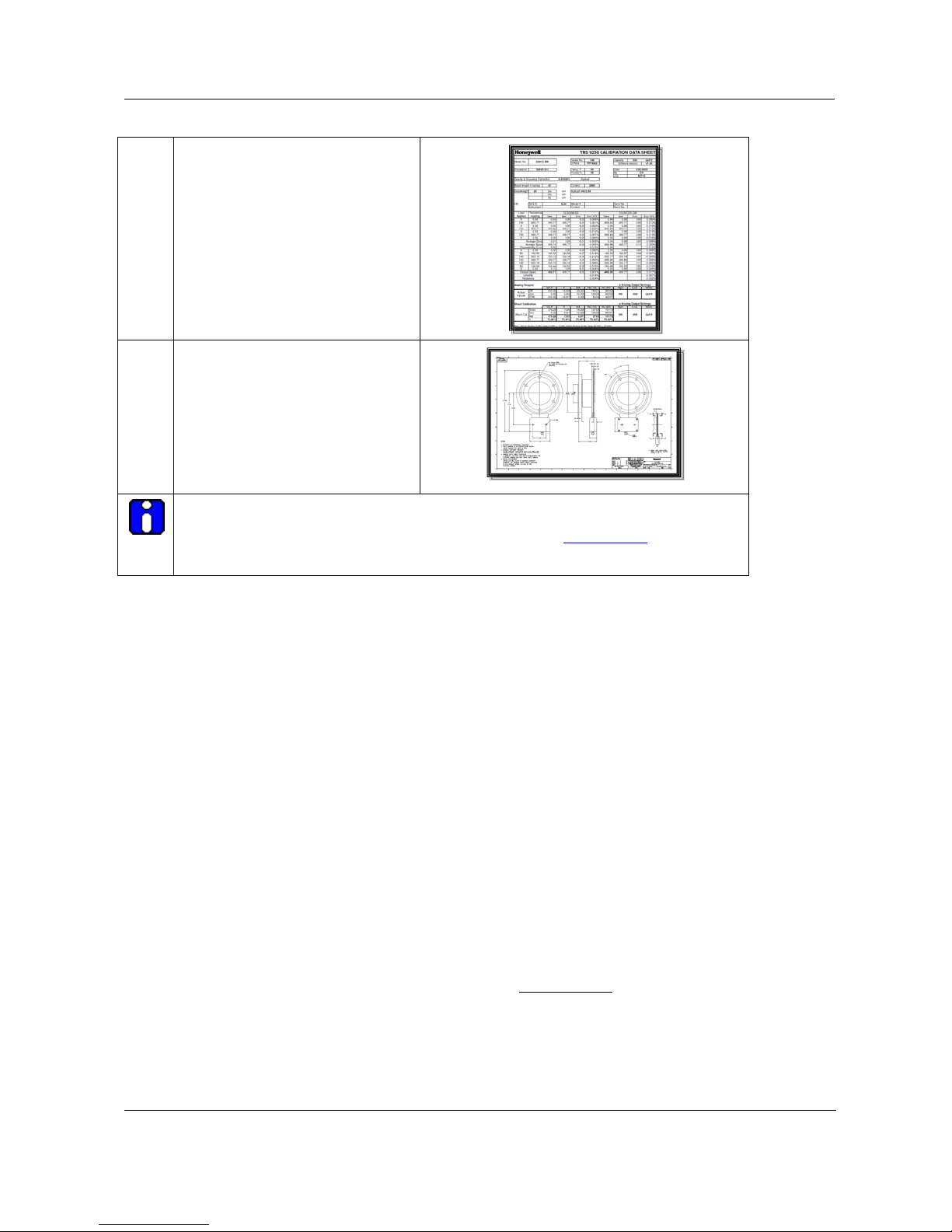

12 Calibration Sheet

13 Outline Dimension Drawings (ODD)

Note:

• RS232 Interface cable connection is mentioned in

• P ictures shown above are for representation only, not to actual scale.

APPENDIX F step 5.

1.4 Intended Use

Torque Sensor

Honeywell Torque Sensors are dedicated structures that perform in a predictable and

repeatable manner wh en torque f orces are a pplied. This torque f orce is tr anslated i nto a sig nal

voltage by the resistance change of strain gages, which are attached to the torque sensor

structure. The change in r esistance indic ates the degr ee of deformat ion, and in t urn, the torque

force on the structure.

The strain gages are connec ted in a four arm Wheats tone bri dge conf igurati on whic h acts as an

adding and subtracting ele ctrical network and allows compensati on for temperature effects as

well as cancellation of signals caused by extraneous loading.

When the torque sens or is rotati ng, a means m ust be prov ided to trans fer an excitat ion voltage

to the rotational el ement from a stationary s urface, and also to transfer the torque signal from

the rotational element bac k to the stationary surface. This is acc omplished through the use of

digital telemetry.

Usage Scenario of TMS 9250

This product is used in controlled environment, not intended for outdoor use and designed

typically for dynamometer test laboratories.

Refer to the cleaning instructions provided in the

APPENDIX E.

14 TMS 9250 Product User Manual Rev B

April 2012

© 2012 – Honeywell International Inc. All rights reserved

1.5 Installation and Setup

sunpower

SPM

CCM

Power

Supply

Belden Tri-axial RF cable

Plug Top

DC Cable

To SPM

RS 232 Cable For

Computer Interface

Analog V/mA

Output

Frequency

Output

Rotor

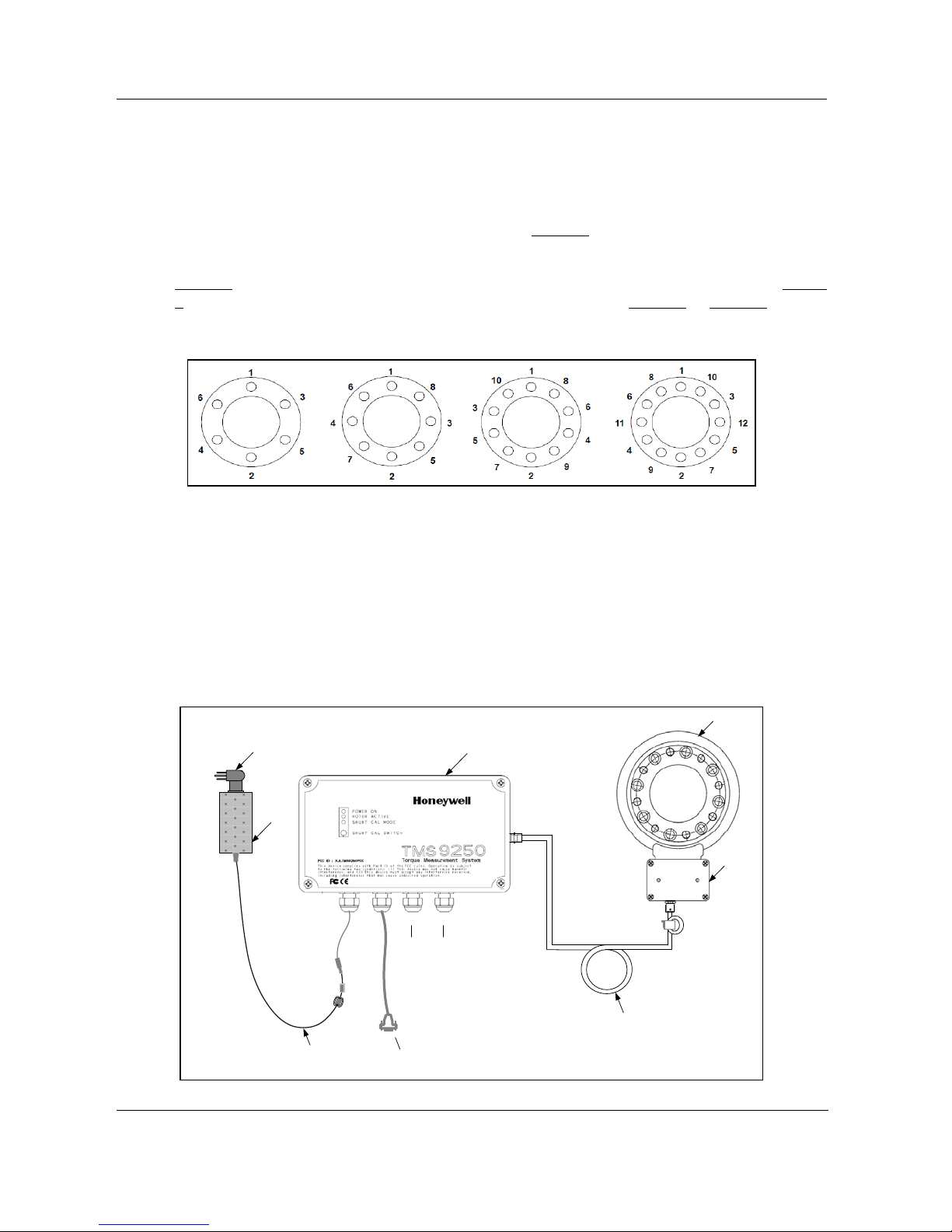

Bolting Information

Tighten all bolts, in incremental steps, to the bolt manufacturer’s rated torque specification.

Use the respective sequence illustration shown in

the sensor requires. This bolting sequence applies to both bolt circles of the to rque sensor.

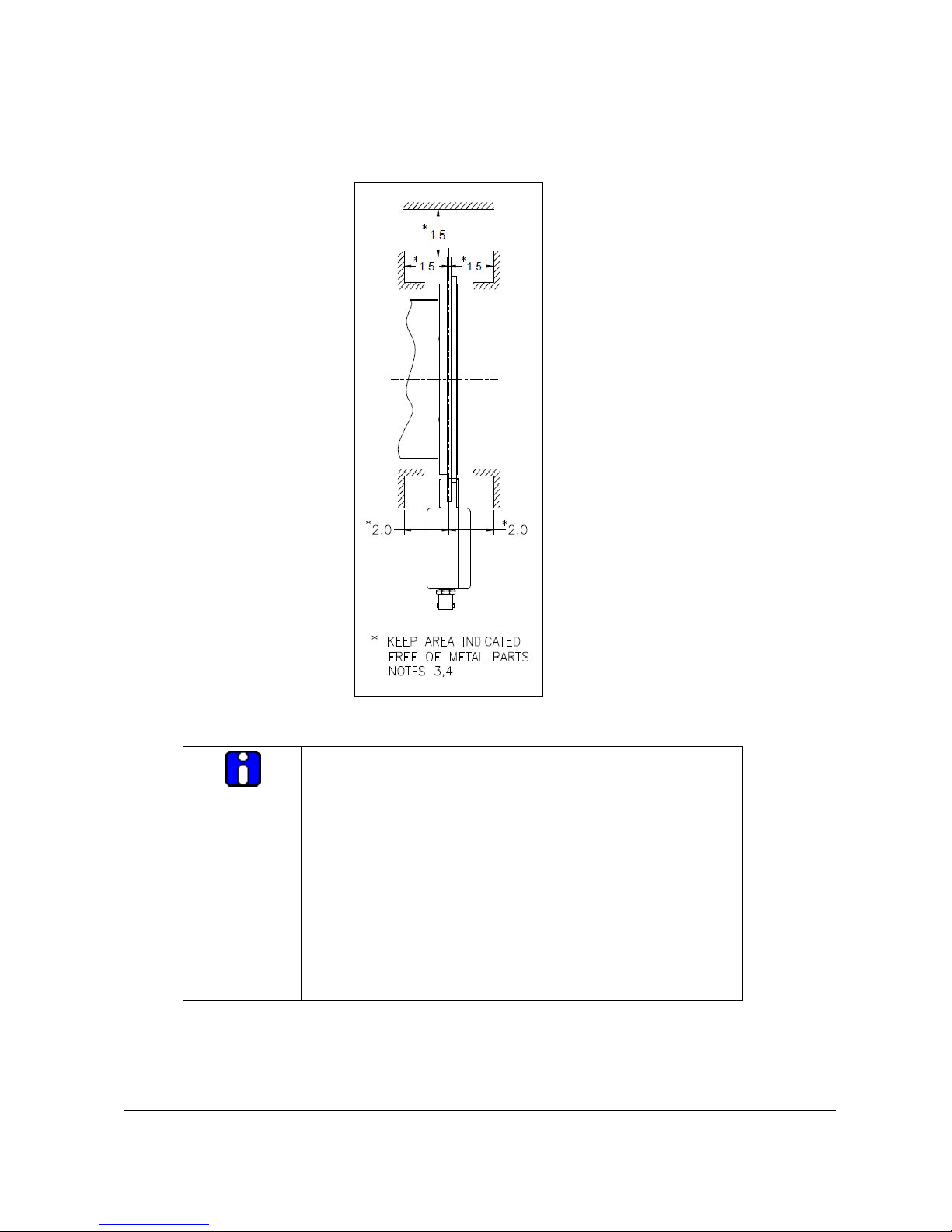

Typical connection schematic of the product for any torque measurement is as shown in

Figure 2. General gu idelines shall be c onsidered for moun ting the sensor as shown in Figure

3. Outlin e dimension d etails for standar d models ar e indicated in Figure 4 to Figure 9; contact

factory for other configurations.

Figure 1: Bolting Pattern for Flange Model

1. TMS 9250 Torque Measurement System

008-0738-00

Figure 1 depending on the number of bolts

Torque Sensor

Honeywell's TMS 9250 series torque sensors may be operated horizontally, vertically, or at

any angle in between, provi ded the load is ap plied t hrough t he load ing ax is. Al l torque s ensors

in this series have bolt patterns that mate directly to standard DIN compa nion flanges. When

mounted, one of the flanges should be mated to a good quality double flex coupling or a

driveshaft arrangement that incorporates universal joints at each end. This is designed to

compensate for angular and parallel misalignment. Avoid applications that place extraneous

loads on the torque sensor.

Rev B TMS 9250 Product User Manual 15

April 2012

© 2012 – Honeywell International Inc. All rights reserved

1. TMS 9250 Torque Measurement System

and 2.0 inches

008-0738-00

Figure 2: Complete Setup Connection Representation

Figure 3: General Precautions to be Considered for Rotor and CCM Installation

Note:

1. Pilot diameters in accordance with ANSI B4.1 (ANSI

standards for limits and fits)

2. Mating driveline components shall be more than 1.5

inches around the rotating antenna

around CCM.

3. Minimum s afety shield clearance of 1.5 inches shall be

provided between the rotating antenna and test stand

safety shields.

4. Signal loss will occur if maximum component diameter

or minimum safety shield clearance is not maintained

more than 2.0 inches around CCM.

Caliper Coupling Module

The caliper coupling module must be firmly mounted to a non-rotating support structure. It

must be aligned with the annular printed circuit board antenna so that the air ga p between the

16 TMS 9250 Product User Manual Rev B

April 2012

© 2012 – Honeywell International Inc. All rights reserved

caliper and the antenna is approximately equa l on both sides. Care should be taken to avoid

any items touching one another, and consideration should be given to the effects of

vibration as well as the free play in any driveshaft sliding joints.

To assist in the process of aligning the caliper and the antenna, a simp le plastic alignment tool

is provided with each system. The tool is used to hold the required clearance between the

caliper and the antenna while the ca liper fixing b olts are bein g tightened, and then is removed

before the sensor is rotated.

The tolerances for end-float (axial) are i.e. +/- 3/16 in. (+/- 3.5 mm) and for run out (radial) are

+/- 1/16 in. (+/- 1.0 mm). For installations where run-out cannot be controlled within the

specified tolerance, the secondary coupling position can be used. This is achieved by

placing the edge of the caliper in close proximity to the edge of the antenna. In this position,

the run-out tolerance can b e at least doubled, at the expense of a reduced signa l t o noise r a ti o

caused by the higher incidence of data drop outs. The axial tolerance is limited by the

distance between the caliper sections.

The caliper can also be mounted such that only one side is in prox imity to the antenna, if

the mounting arrangement does not allow for placing of the antenna between the two sides of

the caliper.

Successful positioning of the caliper can be confirmed by the quality test of the TMS Toolkit

returning >97% result. Th e pr ocedure t o run t he qual ity is explain ed in Toolkit manual su pplie d

with product.

The length of the RF cable connection between the caliper coupling module and the signal

processing module is critical to sy stem performance (due to ref lections and standing waves).

You must use tri-axial cable only of length 14.6 meters (47 ft. 11 in.) supplied with the

product.

Signal Processing Module

The receiver is mounted remote ly with the tri-axial ca ble being the only connection between it

and the caliper coupling module. The receiver has holes provided for permanent mounting.

Customer shall request appropriate certified drawings from Ho neywell before making fixtures

for mounting in racks.

When deciding where to locate the signal processing module, consideration should be given to

the type of output that will be used. If t he analog voltage or current out put is to be used,

then the signal process ing module should be mounted in an area of low electrical noise,

and the connection between the module and the dat a acquisition equipment should be as

short as possible made up of double sc r eened twisted pair cable. If the frequency output or th e

digital output is to be used, then the signal processing module can be mounted in the

electrically noisy area prov i ded that good quality dual screened twisted pair cables are used.

SPM External Connection

Refer to

APPENDIX F for SPM IO box connections.

1. TMS 9250 Torque Measurement System

008-0738-00

Rev B TMS 9250 Product User Manual 17

April 2012

© 2012 – Honeywell International Inc. All rights reserved

1. TMS 9250 Torque Measurement System

J5 are interchangeable but

connector J6 is neither interchangeable with J4 nor J5. Do not

008-0738-00

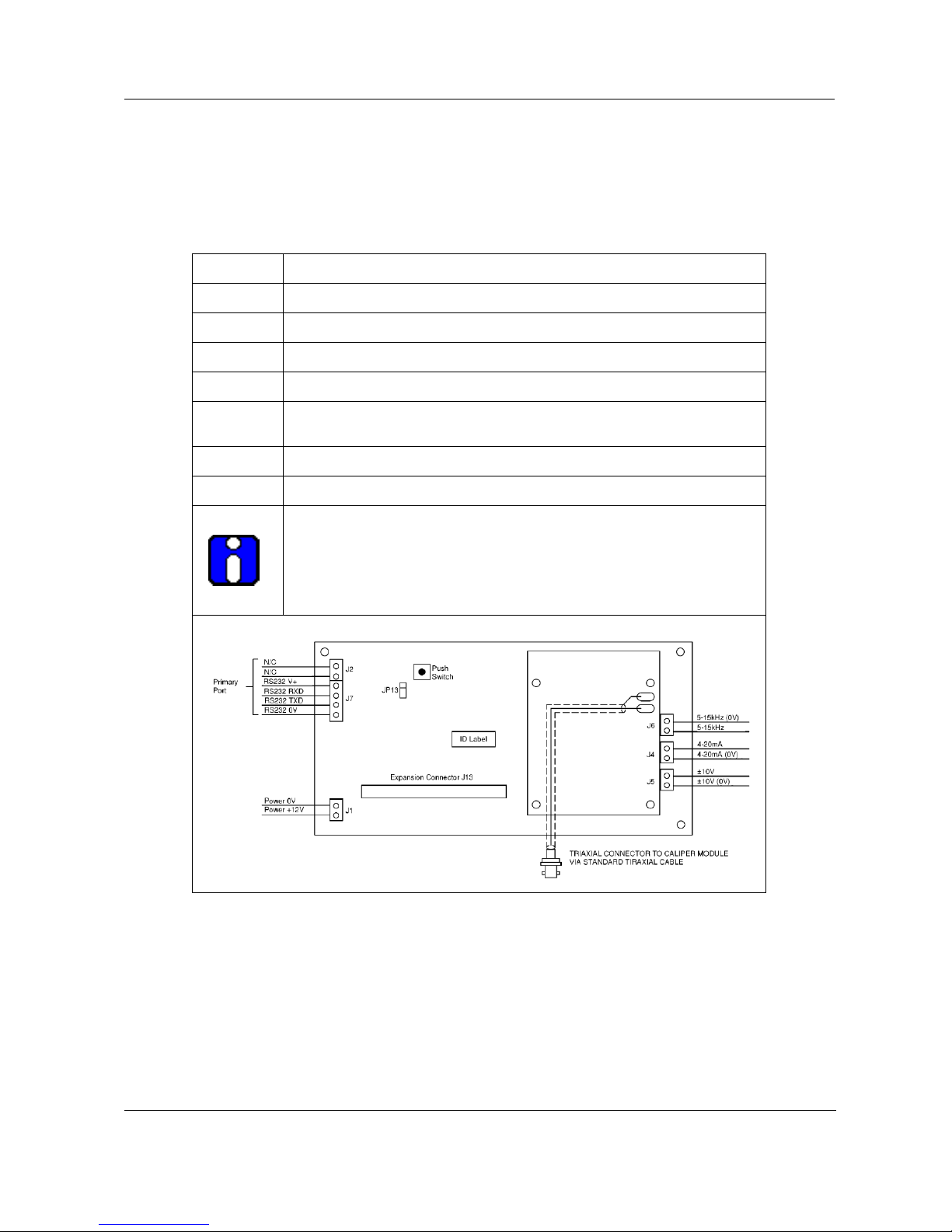

SPM Internal Connection

The following table provides detail of internal connection for the SPM. Honeywe ll does not

recommend that the user change these settings/ connections until/unless assisted by the

factory. Table and pin connection details are listed as follows:

Connector Function

J1 DC Power 12 V

J4 Current loop output

J5 Voltage output

J6 Frequency output

J7

J13 Expansion port

JP1 Primary RS232 default select

Primary RS232 port

NOTE: THIS IS THE DEFAULT COMMUNICATIONS PORT

ATTENTION:

SPM shall be configured for either voltage or current output from

factory hence connectors J4 and

attempt to interchange frequency output to any other output.

Powering of Device

After all the connections are completed, the system s hould be powered and al lowed to warmup for 30-45 minutes, in order to get stable outputs from the SPM.

Toolkit Installation

After all the mechanic al and electrical se tup is completed, s oftware should b e installed on the

computer as detailed in the Toolkit Software Manual supplied with the product.

18 TMS 9250 Product User Manual Rev B

April 2012

© 2012 – Honeywell International Inc. All rights reserved

Loading...

Loading...