Page 1

Construction

A

The thermostatic mixing valve comprises:

• Housing

• Adjuster knob

• Thermostat

Materials

• Dezincification-resistant brass housing

• Moving parts of high-quality,scale-resistant synthetic

material

• Plastics adjuster knob

• EPDM sealings

• Stainless steel spring

TM50

Thermostatic mixing valve

with scald protection

Product specification sheet

pplication

TM50 thermostatic mixing valves provide control of the water

temperature and are used:

• For centralised control on hot water supply units or for

localised control adjacent to point-use outlets. Or for use

with solar-heated hot water units with dual energy source.

• In heating systems with underfloor heating or for limiting

boiler return temperatures.

Where a system includes a hot water circulation circuit, a

KB191 return flow retarder unit (see accessories) must be

fitted to prevent cold water backfeeding and cooling the

mixed water at the outlets.

Special Features

• Highly sensitive thermal element with good all-round

water temperature sensing, even at low flow rates

• Simple setting of the required water temperature

• Scald protection - the hot water inlet is automatically cut off

if the cold supply fails provided that the hot water inlet

temperature is at least 10 K higher than that of mixed

water setting

• The cold water inlet is automatically cut off if the hot supply

fails

• Inner components are of scale-resistant materials

• Complies with KTW requirements

Range of Application

Flow medium Water

Operating pressure Maximum 10 bar

Maximum pressure

difference between hot

and cold inlet supplies 2.5 bar

Technical Data

Installation orientation As required

Hot water inlet

temperature Maximum 90 °C

Connection sizes G

Setting range 30 °C - 60 °C

Flow rate at 1.0 bar

pressure differential

across valve 25 litres / min

Control accuracy < ± 4 K

3

/4"

Subject to change 33 EN0H-1326GE23 R0304

Page 2

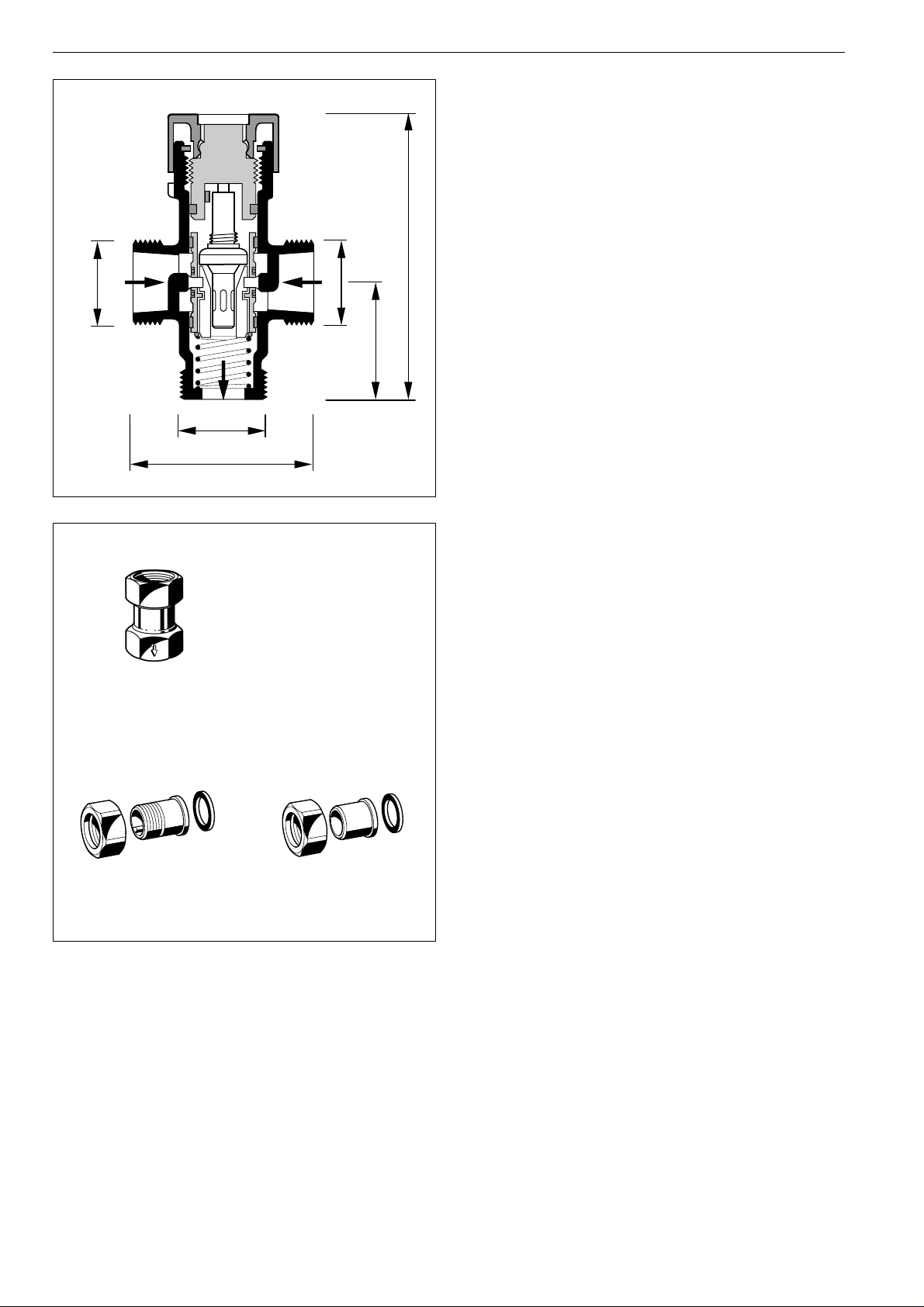

TM50 Thermostatic mixing valve

A

G 3/4

G 3/4

57

Method of Operation

a) As a mixing valve for hot water supply and heating systems:

The highly sensitive thermal element located in the outlet of the

valve controls a plug which regulates the flow proportions of cold

and hot water in relation to the mixed hot water setting selected.

Soft seatings are fitted to both hot and cold water inlets.

They provide:

• A positive hot inlet shutoff if the cold water supply is

interrupted, provided that the hot water inlet temperature is

at least 10 K higher than that of the mixed water setting.

approx. 93

G 3/4

• The cold water supply is cut off if the hot water supply is

interrupted.

b) As a diverter valve on central heating systems:

37

For this application flow through the valve is in the reverse direction compared with its use as a hot water mixing valve. The inlet

water passes around the sensing element and regulates the control piston so that for temperatures above the set value the water

is returned to the heating circuit and for temperatures lower than

the set value the water is diverted to the boiler.

Options

TM50-1/2E = with male connection G

3

/4"

KB191

VST06-A VST06-B

ccessories

KB191 Return flow-retarder unit

for fitting to systems which include a hot water

circulation circuit - to prevent cold water backfeeding and cooling the mixed water at the outlets.

Operating pressure: Maximum 10 bar

Operating temperature: Maximum 90 °C

Installation orientation: Arrow pointing in flow

direction

VST06 Connection set

With threaded or solder connections

A = Threaded male connections

B = Solder connections

EN0H-1326GE23 R0304 34 Subject to change

Page 3

Installation Examples

r

r

r

r

a) Mixing valve in hot water supply systems

TM50 Thermostatic mixing valve

KB191

Central control of wate

temperature

Zone control of wate

temperature

a) Mixing valve in central heating systems

Heating circuit at boile

Underfloor heating

temperature

Installation Guidelines

• Install so that the valve is not strained or twisted

• Fit a return flow-retarder unit where the hot water supply

system includes a circulation circuit

• Observe the flow direction arrow when fitting a KB191

return flow-retarder unit

• To prevent the growth of legionella, DVGW-W551 and

W552 specify that the water volume in the pipework

between the mixer valve and the furthest take-off point

should not exceed 3 litres. This corresponds to a maximum

length of 10 metres for

3

/4" (20 mm) pipework and

17 metres for 1/2" (15 mm)

Maintenance

No specific maintenance is necessary under normal operating

conditions. However, all moving parts which may be subject

to wear can be exchanged.

Central control of wate

temperature in solar heated,

dual-energy-source systems

b) Diverter valve in central heating systems

Limiting of boiler return

temperature

Typical Applications

TM50 thermostatic mixing valves can be used within the

limits of their specification for the control of hot water supply

or central heating systems.

Some typical applications are:

a) Hot water supply systems:

• Single and multiple-occupancy households

• Retirement homes

• Children's nurseries

• Schools

• Hotels

• Commercial kitchens

• For industrial applications with control either from a

central location or adjacent to point-of-use outlets

b) Central heating systems:

• As a mixing valve for underfloor heating systems

• As a diverter valve for limitation of boiler return

temperatures

Subject to change 35 EN0H-1326GE23 R0304

Page 4

TM50 Thermostatic mixing valve

Automation and Control Products

Honeywell GmbH Phone: (49) 6261 810

Hardhofweg Fax: (49) 6261 81309

D-74821 Mosbach braukmann@honeywell.com http://europe.hbc.honeywell.com

EN0H-1326GE23 R0304 36 Subject to change

Loading...

Loading...