Page 1

T921A,B,E-G Proportional

Control Thermostats

T921 Thermostats provide 3-wire, low voltage

proportional control for Series 90 (135 ohm) valve

motors, damper motors, and balancing relays in

heating or cooling system applications.

■■ T921A ■■ T921B ■■ T921E ■■ T921F ■■ T921G

■ Accessory faceplates available for horizontal mount-

ing of T921A,B,E models.

■ COOL-HEAT changeover switch in the T921B.

■ Night setback mechanism and switch in the T921E.

■ A spdt (single pole double throw) Class 2 auxiliary

switch in the T921F,G, which operates at the low

(T921F) and high (T921G) end of the throttling

range.

■ A bellows element adjusts the potentiometer slider

to regulate motor operation.

■ Various temperature ranges are available.

■ All models are available with a thermometer and a

locking cover.

CONTENTS

Specifications .................................................2

Ordering Information..................................... 2

Installation .....................................................4

Setting and Adjusting .....................................7

Operation .......................................................7

J. D. • Rev. 1-94 • ©Honeywell Inc. 1994 • Form Number 60-2242—2

1 60-2242—2

Page 2

T921A,B,E-G

SPECIFICATIONS • ORDERING INFORMATION

Specifications

TRADELINE® MODELS

TRADELINE® models are selected and packaged to

provide ease of stocking, ease of handling and maximum

replacement value. TRADELINE® model specifications

are the same as those of the standard models except as noted

below.

TRADELINE® MODEL AVAILABLE:

T921A Thermostat for vertical or horizontal mounting.

TEMPERATURE RANGE AND SCALE:

56° to 84° F [13° to 29°].

ADDITIONAL FEATURES:

• TRADELINE® packed with cross-reference label

and special TRADELINE® instructions.

• T6051A may be used in electric heat systems.

• They all include slotted sides and an add-on faceplate

to allow the thermostat to be mounted horizontally.

They also include the 127246A Adapter Plate Assembly for vertical mounting on a horizontal conduit

box or for horizontal mounting on a vertical conduit

box.

STANDARD MODEL

MODELS:

T921A: Heating or cooling applications.

T921B: Is the same as the T921A but includes a cool-

heat changeover switch.

T921E: Includes a switch and heater that provide a night

setback of approximately 10° F [5.5° C].

T921F: Includes an spdt low voltage Class 2 auxiliary

switch that operates at the low end of the throttling

range.

T921G: Includes an spdt low voltage Class 2 auxiliary

switch that operates at the high end of the throttling

range.

SETTING ADJUSTMENT RANGE:

T921A,B,E-G: 56° to 84° F [13° to 29° C].

T921A,B,E-G: 13° to 29° C [56° to 84° F].

T921A: 42° to 75° F [ 5° to 24° C].

T921A,B: 66° to 95° F [19° to 35° C].

THERMOMETER: Bimetal. Scale ranges T921A only:

45° to 75° F [7° to 24° C]. All other models: 60° to 90° F

[16° to 32° C], 15° to 35° C [59° to 95° F]. T921A is also

available with a blank cover and no thermometer.

AUXILIARY SWITCH DIFFERENTIAL:

T921F: 2° F [1° C].

T921G: 1° F [0.5° C].

THROTTLING RANGE:

Fixed.

T921A: 2.5° F [1° C] midscale.

T921B,E: 4° F [2° C].

T921F: 6° F [3° C].

T921G: 5° F [2.5° C].

Variable.

T921A model available with potentiometer for 5° to

6° F [2.5 to 3° C] throttling range.

ELECTRICAL RATINGS:

Voltage: 24 to 30 Vac.

Auxiliary Switch Contact Rating (When Used For Pilot

Duty): 100 VA at 30 Vac.

DIMENSIONS:

Refer to Fig. 1.

ACCESSORIES (ORDER SEPARATELY):

127246A Adapter Plate Assembly for mounting all mod-

els vertically on a horizontal conduit box. (T921

models are shipped with a faceplate for vertical mounting.)

When mounting the T921A,B,E horizontally, see

Table 1 to order the faceplate with the appropriate

scale. NOTE: Do not mount the T921F,G horizontally.

34297B Thermostat Guard Assembly and 138541A

Mounting Plate.

133722A Thermostat Guard (clear plastic cover).

133723A Thermostat Guard (beige plastic cover).

Ordering Information

When purchasing replacement and modernization products from your TRADELINE® wholesaler or your distributor, refer to the

TRADELINE

1. Model number.

2. Scale range.

3. Accessories, if desired.

If you have additional questions, need further information, or want to comment on our products or services, please write or phone:

1. You local Honeywell Home and Building Control Sales Office (check the white pages of the phone directory).

2. Home And Building Control Customer Satisfaction

60-2242—2 2

®

Catalog or price sheets for complete ordering number or specify—

Honeywell Inc., 1885 Douglas Drive North

Minneapolis, Minnesota 55422 1-800-468-1502

(In Canada—Honeywell Limited/Honeywell Limitee, 740 Ellesmere Road, Scarborough, Ontario M1P 2V9) International Sales

and Service Offices in all Principal Cities of the world. Manufacturing in Australia, Canada, Finland, France, Germany, Japan,

Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

Page 3

T921A,B,E-G

SPECIFICATIONS

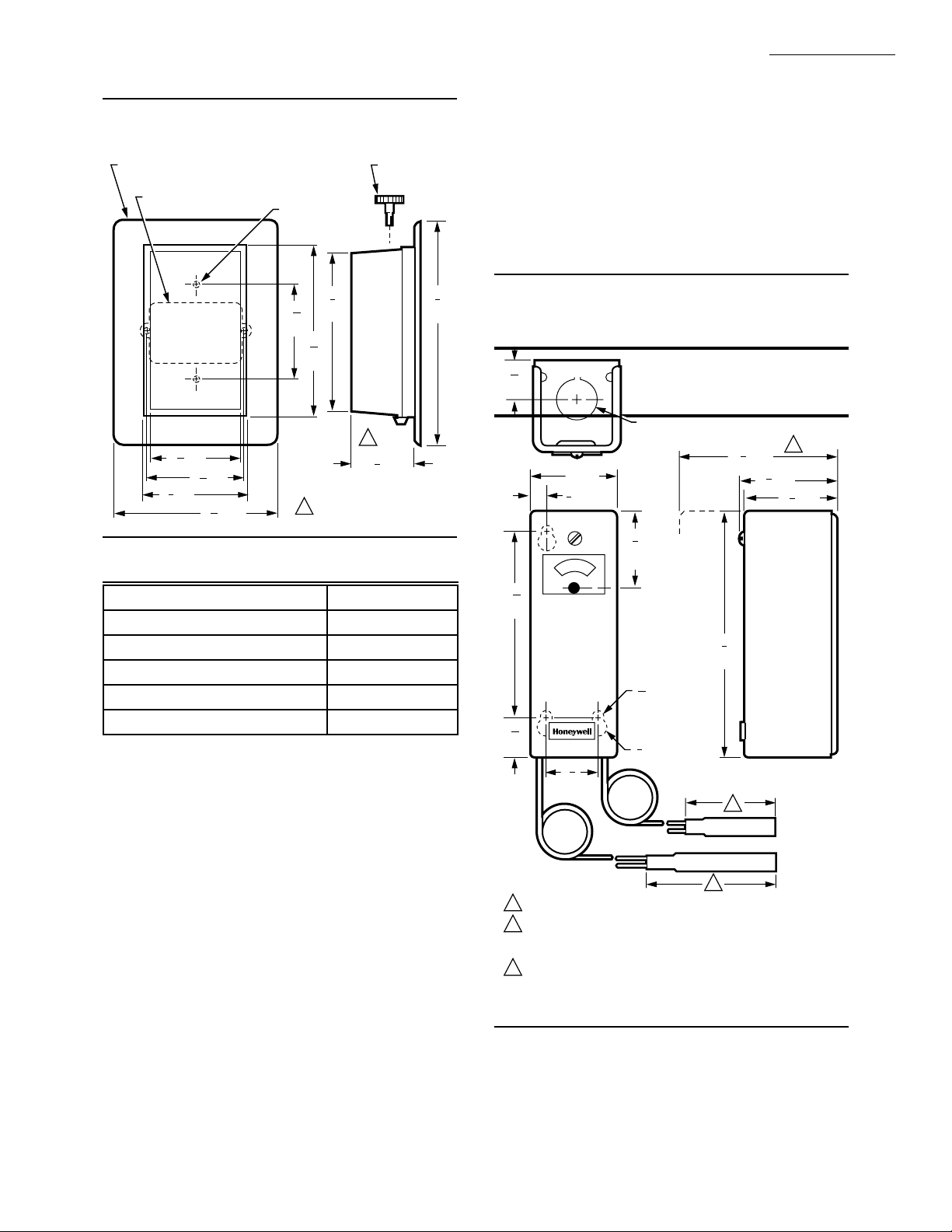

Fig. 1—T921 approximate installation dimensions in in. [mm].

ACCESSORY ADAPTER PLATE (127246A) FOR

MOUNTING ON HORIZONTAL CONDUIT BOX

HORIZONTAL CONDUIT BOX

1

3 [78]

16

5

3 [84]

16

3

3 [86]

8

5

5 [135]

16

FOR VERTICAL

CONDUIT BOX (2)

5

3

16

[84]

11

5

16

[145]

2-11/16 [69] INCHES FOR

1

T921F, G MODELS.

5

[137]

3

8

SETTING

ADJUSTMENT

KNOB

1

1

2 [57]

4

7

[194]

M9107

TABLE 1—ACCESSORY FACEPLATE.

Scale Part No.

56° to 84° F [13° to 29° C] 135135A

13° to 29° C [56° to 84° F] 135135B

42° to 75° F [5° to 24° C] 135135C

66° to 95° F [19° to 35° C] 135135D

56° to 84° F [13° to 29° C] 135135C

a

Blank faceplate.

a

REPLACEMENT PART:

130224 Locking Cover Knob.

OPTIONAL SPECIFICATION (USING THE T991B):

Alternate proportional control similar to the T921A, but

uses an outdoor temperature, automatic control point

reset.

T991B with 3-1/2: 1 reset and 50° to 120° F [10° to

49° C] temperature setting scale (when the outdoor

bulb is at 60° F [16° C]).

DIMENSIONS:

Refer to Fig. 2.

ACCESSORIES:

Compression fittings, immersion wells: Refer to the

appropriate specification or the TRADELINE® Catalog.

314439 Mounting Clips: For mounting a capillary tub-

ing (averaging element) in a duct.

7640HX Averaging Element Mounting Kit: For mount-

ing in existing installations where access to the duct

is impractical.

Q615A Enclosure: To protect the device when mounted

outside; splash proof.

801534 Calibration Wrench.

107324A Bulb Holder: For mounting the bulb in a duct.

34886A Outdoor Bulb Shield: To protect the outdoor

bulb mounting.

5

8

Fig. 2—T991B approximate installation

dimensions in in. [mm].

15

16

[24]

KNOCKOUT FOR 1/2 INCH

CONDUIT (BOTH ENDS)

1

4 [108]

4

2 [51]

3

[10]

8

3

1

4

[45]

3

4

16

[106]

5

[143]

7

[6]

32

DIAMETER (3)

15

16

[24]

1

1

4

[32]

1

OUTDOOR BULB SIZE VARIES INVERSELY WITH THE RESET RATIO.

2

INDOOR BULB LENGTH AND DIAMETER IS 4-1/2 [114] INCH BY

1/2 [13] INCH EXCEPT FOR THE AVERAGING ELEMENT WHICH IS

1/8 [3] INCH DIAMETER BY 12 FT. [3 M] LONG.

3

CLEARANCE NECESSARY TO REMOVE COVER.

3

[10]

8

DIAMETER

2

1

2 [57]

4

5

8

1

3

1

2 [57]

8

M9108

3 60-2242—2

Page 4

T921A,B,E-G

INSTALLATION

!

WHEN INSTALLING THIS PRODUCT…

1. Installer must be a trained, experienced service tech-

nician.

2. All wiring must comply with applicable electrical

codes, ordinances and regulations.

3. Do not exceed the ratings listed on the device name-

plate.

4. After the installation is complete, conduct a thorough

checkout of the product operation.

LOCATION

Locate the thermostat about 5 feet [1.5m] above the

floor in an area with good air circulation at average room

temperature.

Do not mount the thermostat where it can be affected by:

— drafts, or dead spots behind doors and in corners.

— hot or cold air from ducts.

— radiant heat from the sun or appliances.

— concealed pipes and chimneys.

— unheated (uncooled) areas such as an outside wall

behind the thermostat.

CAUTION

Disconnect power supply before installation to

prevent electrical shock and equipment damage.

Installation

ADD FACEPLATES FOR HORIZONTAL

MOUNTING (T921A,B,E ONLY)

T921 models are shipped with a faceplate for vertical

mounting. When mounting the T921A,B,E horizontally,

see Table 2 to order the faceplate with the appropriate scale.

NOTE: Do not mount the T921F,G horizontally.

TABLE 2—ACCESSORY FACEPLATE

Scale Part No.

56° to 84° F [13° to 29° C] 135135A

13° to 29° C [56° to 84° F] 135135B

42° to 75° F [5° to 24° C] 135135C

66° to 95° F [19° to 35° C] 135135D

56° to 84° F [13° to 29° C] 135135C

a

Blank faceplate.

Affix the accessory faceplate when mounting the

T921A,B,E models horizontally with contemporary covers. Peel the backing strip from the faceplate and place it

lightly over the vertical faceplate. Align the edges and

corners and make sure the scales align with the markings.

Press firmly over the entire surface. Do not attempt to

reapply once the faceplate has been mounted.

a

MOUNTING

1. Disconnect power supply before installation to pre-

vent electrical shock and equipment damage.

2. Loosen the locking screw at the bottom of the case

with an Allen wrench.

3. Lift off the thermostat cover.

4. Remove the mounting screws that secure the thermo-

stat to the backplate and remove the backplate.

5. Fasten the backplate to the conduit box (see Fig. 3).

Use the 127246A Adapter Plate Assembly (ordered separately) to mount the thermostat vertically on the horizontal

conduit box; or to mount the thermostat horizontally on the

vertical conduit box (see Fig. 4).

NOTE: When an accessory adapter plate is used, fasten the

adapter plate to the conduit box with the two screws

provided. Then fasten the backplate to the adapter plate.

6. Make all electrical connections to the terminals on

the back of the thermostat before mounting the instrument

on the backplate. Refer to the Wiring section.

7. Mount the thermostat on the backplate with the mounting screws.

8. After performing the checkout tests, replace the thermostat cover and tighten the locking screw.

Fig. 3—Vertical mounting of T921A,B,E-G

Thermostats on vertical conduit box.

T921A,B,E Thermostats can also be mounted

horizontally on horizontal conduit box using

add-on faceplate. (Do not mount T921F,G

horizontally.)

NOTE: ACCESSORY FACEPLATE FOR USE WHEN

THE THERMOSTAT IS MOUNTED HORIZONTALLY.

PEEL OFF BACKING AND APPLY OVER VERTICAL

FACEPLATE AFTER MOUNTING IS COMPLETE.

CONDUIT

BACKPLATE

LOCKING

SCREW

BOX

80

70

60

60 70 80 90

HONEYWELL

MOUNTING

SCREWS

COVER

M9037

60-2242—2 4

Page 5

T921A,B,E-G

INSTALLATION

Fig. 4—Vertical mounting of T921A,B,E-G

Thermostats on horizontal conduit box.

T921A,B,E Thermostats can also be mounted

horizontally on vertical conduit box using

add-on faceplate. (Do not mount T921F,G

horizontally.)

NOTE: ACCESSORY FACEPLATE FOR USE WHEN THE THERMOSTAT

IS MOUNTED HORIZONTALLY. PEEL OFF BACKING AND APPLY

OVER VERTICAL FACEPLATE AFTER MOUNTING IS COMPLETE.

CONDUIT

BOX

127246A

ACCESSORY

ADAPTER

PLATE

M9036

60 70 80 90

HONEYWELL

BACKPLATE

MOUNTING

SCREWS

80

70

60

LOCKING

COVER

SCREW

WIRING

Be sure all wiring must complies with applicable electri-

cal codes, ordinances and regulations.

Do not exceed the following electrical ratings:

Voltage: 24 to 30 Vac.

Auxiliary Switch Contact Ratings: 100 VA at 30

Vac.

Make all electrical connections to the terminals on the

back of the thermostat before mounting the instrument onto

the conduit box. Terminal locations for all models are

shown in Fig. 5. Note the difference in terminal designations for the auxiliary switch on the T921F and G. The H

(Heater) terminal on the T921E is a black leadwire.

Typical wiring diagrams are shown in Figs. 6 through

10. Wire the T921 color-to-color when the modulating

motor must drive the valve or damper open on temperature

fall (heating application). When opposite motor action is

required, reverse the B and W connections. Refer to the

appropriate instructions when wiring the 2-position actuator (Figs. 9 and 10).

Fig. 5—Terminals on back of thermostats.

TOPTOP

B

W

R

(BLACK)

T921A, B

TOP

RBW

B

W

R

H (HEATER)

AUXILIARY

SWITCH

TERMINALS

T921E

TOP

T921GT921F

Fig. 6—Typical wiring diagram for T921A.

SERIES 90

1

L1

(HOT)

L2

TRANSFORMER

MODULATING

MOTOR

B

T

W

T

R

2

T921A

B

W

R

B

W

R

B

W

R

RBW

M9038

B

W

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

2

INTERCHANGE B AND W CONNECTIONS TO REVERSE

DIRECTION OF MOTOR TRAVEL.

M5989

5 60-2242—2

Page 6

T921A,B,E-G

INSTALLATION • SETTING AND ADJUSTING

Fig. 7—Typical wiring diagram for T921B.

SERIES 90

MODULATING

1

L1

(HOT)

L2

TRANSFORMER

1

2

MOTOR

T

T

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

INTERCHANGE B AND W CONNECTIONS TO REVERSE

DIRECTION OF MOTOR TRAVEL.

2

B

W

R

T921B

B

SUMMER-

COOL

W

R

Fig. 8—Typical wiring diagram for T921E.

1

L1

(HOT)

L2

TRANSFORMER

1

2

TIMER SWITCH

(OPTIONAL)

H

R

T

W

T

B

SERIES 90

MODULATING

MOTOR

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

H TERMINAL IS A BLACK LEADWIRE.

R

W

B

HEATER

T921E

2

WINTER-HEAT

M5992

NIGHT

SETBACK

SWITCH

B

W

M5988A

Fig. 9—Typical wiring diagram for T921F.

SERIES 90

1

L1

(HOT)

L2

TRANSFORMER

2-POSITION

ACTUATOR

1

2

3

MODULATING

MOTOR

B

T

T

CLASS 2 POWER SUPPLY.

INTERCHANGE B AND W CONNECTIONS TO REVERSE

DIRECTION OF MOTOR TRAVEL.

USE FOR CLASS 2 CIRCUITS. MAKES R TO B ON

TEMPERATURE FALL BELOW THROTTLING RANGE:

2˚ F [1˚ C] DIFFERENTIAL. SEE FIG. 10.

2

W

R

T921F

B

W

R

R

B

W

AUXILIARY

SWITCH

Fig. 10—Typical wiring diagram for T921G.

SERIES 90

1

L1

(HOT)

L2

TRANSFORMER

2-POSITION

ACTUATOR

1

2

3

MODULATING

MOTOR

B

T

T

CLASS 2 POWER SUPPLY.

INTERCHANGE B AND W CONNECTIONS TO REVERSE

DIRECTION OF MOTOR TRAVEL.

USE FOR CLASS 2 CIRCUITS. MAKES R TO B ON

TEMPERATURE RISE ABOVE THROTTLING RANGE:

1˚ F [0.5˚ C] DIFFERENTIAL. SEE FIG. 11.

2

W

R

T921G

B

W

R

W

B

R

3

AUXILIARY

SWITCH

B

W

3

M5993

B

W

M5996

TEMPERATURE SETTING

Adjust all T921 models at the top of the thermostat for

vertically mounted models and on the left side for horizontally mounted models using the setting adjustment knob or

an Allen wrench (see Fig. 11). The device is shipped with

the temperature setting indicator at the center of the temperature range. Without removing the cover, turn the setting adjustment knob or use an Allen wrench so the indicator is at the desired average room temperature.

60-2242—2 6

Setting and Adjusting

ADDITIONAL FEATURES:

T921B SUMMER-WINTER CHANGEOVER

The T921B includes a summer-winter changeover switch.

It is labeled COOL-HEAT. For horizontally mounted

models, this switch is located on the left side of the

thermostat. For vertically mounted models, it is located on the top of the thermostat (see Fig. 11).

T921E NIGHT SETBACK

The T921E includes a manual night setback switch

located on the top of the thermostat (see Fig. 11).

Page 7

T921A,B,E-G

SETTING AND ADJUSTING • OPERATION

This switch energizes a heater that offsets the thermostat approximately 10° F [6° C], lowering the

temperature for night operation. Leave this switch in

the OFF position for normal operation; turn it to the

ON position for lower night time temperature.

CALIBRATION

IMPORTANT: Do not recalibrate unless the thermostat

continues to be out-of-adjustment after several hours

of operation.

T921 Thermostats are calibrated at the factory so when

the room temperature matches the setpoint temperature, the

wiper is at the center of the active potentiometer winding.

If the thermostat is out of calibration, proceed as follows

(see Fig. 11):

1. Remove the thermostat cover.

2. Turn the thermostat setting adjustment knob or an

Allen wrench until the valve or damper motor is at midpoint.

3. Loosen the indicator lock screw and move the indicator to room temperature. Tighten the lock screw.

4. Replace the thermostat cover. Recheck the calibration and repeat the procedure if necessary.

Fig. 11—Internal view of vertically mounted

T921 (horizontally mounted model is similar).

POTENTIOMETER

WIPER

1

80

70

60

SUMMER-WINTER (COOL-HEAT) CHANGEOVER SWITCH ON

1

T921B ONLY; NIGHT SETBACK SWITCH ON T921E ONLY.

SETTING

ADJUSTMENT KNOB

TEMPERATURE

SETTING

INDICATOR

INDICATOR

LOCK SCREW

BELLOWS

M9039

In the T921, a vapor-filled bellows moves the potentiometer wiper by expanding or contracting in proportion to

temperature changes. As the wiper moves, the appropriate

motor winding is energized, opening or closing the valve or

damper to compensate for the temperature change in the

controlled area.

Operation of the auxiliary switch in the T921F,G is

shown in Figs. 12 and 13.

See Table 3 for the throttling range of each thermostat.

The T921F Auxiliary Switch makes R-W at the low end of

the throttling range on temperature rise and makes R-B at

2° F [1° C] below the low end of the throttling range on

temperature fall.

The T921G Auxiliary Switch makes R-W at the high

end of the throttling range on temperature fall and R-B at

1° F [0.5° C] above the high end of the throttling range on

temperature rise.

TABLE 3—THERMOSTAT THROTTLING RANGES

Model Throttling Range

T921A 2.5° F [1.5° C] midscale

T921B 2.5° F [1.5° C] midscale

T921E 4° F [2° C]

T921F 6° F [4° C]

T921G 5° F [3° C]

Operation

Fig. 12—T921F auxiliary switch operation.

TEMPERATURE

+3˚ F

[+1.5˚ C]

SETPOINT

TEMPERATURE

-3˚ F

[-1.5˚ C]

R-W MAKES

TEMPERATURE

RISE

2˚ F [1˚ C]

DIFFERENTIAL

THROTTING

RANGE (6˚ F [4˚ C])

TEMPERATURE

FALL

R-B MAKES

M5990

7 60-2242—2

Page 8

T921A,B,E-G

OPERATION␣

Fig. 13—T921G auxiliary switch operation.

TEMPERATURE

TEMPERATURE

+2.5˚ F

[+1.5˚ C]

SETPOINT

TEMPERATURE

-2.5˚ F

[-1.5˚ C]

FALL

R-W MAKES

1˚ F [0.5˚ C]

DIFFERENTIAL

THROTTING

RANGE (5˚ F [3˚ C])

R-B MAKES

TEMPERATURE

RISE

M5991

CHECKOUT

After the thermostat is wired and mounted, check to be

sure the thermostat and controlled equipment are functioning properly. Before proceeding, allow from one to three

hours for the system to stabilize.

T921A

1. Set the temperature setting indicator to room temperature by using the setting adjustment knob, or an Allen

wrench (see Fig. 11). The valve or damper motor should be

at midpoint.

2. Move the setpoint 5° F [3° C] below room temperature. In a heating application, the valve or damper should

close; in a cooling application, the valve or damper should

open. If the valve or damper is driven in the opposite

direction, interchange the wires at the B and W terminals.

NOTE: If a proportional action limit control is used, the

motor may not move the damper or valve all the way

closed or open. Check the limit action after interchanging the wiring.

3. Move the setpoint 5° F [3° C] above room temperature. In a heating application, the valve or damper should

open; in a cooling application, the valve or damper should

close.

4. If the valve or damper responds properly to the

thermostat, move the setpoint to the desired temperature.

T921B

1. Place the changeover switch (see Fig. 11) in the

HEAT position and follow steps 1 through 3 of the T921A

procedure.

2. Move the switch to the COOL position and repeat

steps 1 through 3 of the T921A procedure.

3. If the valve or damper responds properly to the

thermostat, move the setpoint to the desired temperature.

T921E

1. Place the night setback switch (see Fig. 11) in the

OFF position and follow steps 1 through 3 of the T921A

procedure.

2. Move the setpoint 5° F [3° C] above room temperature; the valve or damper should open.

3. Move the night setback switch to the ON position; as

the heater in the thermostat warms up, the valve or damper

should be driven toward the closed position. Allow 30

minutes for the heater and bellows to warm up.

4. If the valve or damper responds properly to the

thermostat, move the setpoint to the desired temperature.

T921F

1. Follow steps 1 through 3 of the T921A procedure.

2. Move the setpoint at least 10° F [6° C] above room

temperature. The auxiliary switch should be make R-B and

the valve or damper should be open (for heating application). Lower the setpoint gradually; the auxiliary switch

should make R-W before the setting indicator reaches room

temperature. As the setting indicator moves below room

temperature, the valve or damper should be driven closed.

3. If the valve or damper responds properly to the

thermostat, move the setpoint to the desired temperature.

T921G

1. Follow steps 1 through 3 of the T921A procedure.

2. Move the setpoint at least 6° F [4° C] below room

temperature. The auxiliary switch should be made R-B and

the valve or damper should be closed (for heating application). Raise the setpoint gradually; the auxiliary switch

should make R-W before the setting indicator reaches room

temperature. As the setting indicator moves above room

temperature, the valve or damper should open.

4. If the valve or damper responds properly to the

thermostat, move the setpoint to the desired temperature.

Home and Building Control Home and Building Control Helping You Control Your World

Honeywell Inc. Honeywell Limited—Honeywell Limitée

1985 Douglas Drive North 740 Ellesmere Road

Golden Valley, MN 55422 Scarborough, Ontario

M1P 2V9

60-2242—2 8

Printed in U.S.A.

QUALITY IS KEY

Loading...

Loading...