Honeywell TB7220 User Manual

TB7220 Ultrastat

Programmable Thermostat

PRODUCT DATA

APPLICATION

The TB7220 Ultrastat Programmable Thermostat is an effortless, seven-day programmable thermostat that provides universal system compatibility, precise comfort control and is easy-to-program.

The TB7220 provides temperature control for gas, oil, electric and heat pumps for up to 2 heat, 2 cool systems.

FEATURES

•Large, clear display with backlight shows the current and set temperature and time—even in the dark.

•Menu-driven programming make setup effortless.

•Beautiful ergonomic design is smart and sophisticated to match your customers’ lifestyle.

•Real-time clock keeps time during power failures and automatically updates to daylight savings.

•“Saving Changes” notification lets you know when the schedule changes have been saved.

•Change reminders let you know when to replace the batteries.

•Holiday Override options allow you to override the program schedule, as desired.

•Speedy same-schedule programming—no need to copy multiple days.

•Armchair programming allows you to remove the thermostat from the wall for programming.

|

Contents |

Application ........................................................................ |

1 |

Specifications ................................................................... |

2 |

Ordering Information ........................................................ |

2 |

Installation ........................................................................ |

4 |

Wiring ............................................................................... |

5 |

Installer Setup .................................................................. |

12 |

Operation .......................................................................... |

17 |

Troubleshooting (Table 10) ............................................... |

22 |

63-2636-03

TB7220 ULTRASTAT PROGRAMMABLE THERMOSTAT

SPECIFICATIONS

Thermostat Description: See Table 1.

Electrical Ratings: See Table 2.

Temperature:

Ratings:

Operating Ambient:

TB7220: 0°F to 120°F (-18°C to 49°C). C7089U, C7189U: 5% to 95%.

Shipping: -30 °F to 150 °F (-34.4°C to 65.6°C). Display Accuracy: ±1°F (±0.5°C).

Setpoint:

Range:

Heating: 40°F to 90°F (4°C to 32°C). Cooling: 50°F to 99°F (10°C to 37°C).

Default Settings: See Table 3.

Humidity Ratings (RH, non-condensing):

TB7220 Thermostat: 5% to 90%.

C7089U, C7189U: 5% to 95%.

Table 1. Thermostat Description.

Feature |

|

|

|

Description |

|

Powering |

|

• |

Battery only |

|

|

methods |

|

• |

24 Vac only |

|

|

|

|

• 24 Vac with battery backup |

|||

System types |

|

• Gas or electric heat with air conditioning |

|||

(up to |

|

• Warm air, hot water, high-efficiency |

|||

2 heat/2 cool) |

|

|

furnaces, and heat pumps |

||

|

|

• |

Heat only |

|

|

|

|

• Heat only with fan |

|

||

|

|

• |

Cool only |

|

|

Changeover |

|

Manual or Auto changeover selectable |

|||

|

|

|

|

|

|

System setting |

|

Heat-Off-Cool-Auto |

|

||

|

|

|

|

|

|

Fan setting |

|

Auto-On |

|

||

|

|

|

|

|

|

|

Table 2. Electrical Ratings |

||||

|

|

|

|

|

|

|

|

|

|

Voltage |

|

Terminal |

|

|

|

(50/60 Hz) |

Running Current |

W (Heating) |

|

|

|

20 - 30 Vac |

0.02 - 1.0A |

|

|

|

|

|

|

Y (Cooling) |

|

|

|

20 - 30 Vac |

0.02 - 1.0A |

|

|

|

|

|

|

G (Fan) |

|

|

|

20 - 30 Vac |

0.02 - 0.60A |

|

|

|

|

|

|

Table 3. Energy-saving Default Program Settings.

Schedule |

|

|

Setpoints |

|

Period |

Time |

Heat |

|

Cool |

Occ1 |

8:00am |

70°F (21°C) |

|

75°F (24°C) |

|

|

|

|

|

Unocc1 |

10:00pm |

55°F (10°C) |

|

85°F (29.5°C) |

|

|

|

|

|

Occ2 |

— |

— |

|

— |

|

|

|

|

|

Unocc2 |

— |

— |

|

— |

|

|

|

|

|

Cycle Rates (at 50% Load):

Heating: Selectable 1 - 12 cycles per hour.

Cooling: Selectable 1 - 6 cycles per hour.

Interstage Differential:

Droopless control. Once the first stage is running at 90% load, the thermostat energizes the second stage.

Cool Indication: Displays “Cool On” when Cool is activated.

Heat Indication: Displays “Heat On” when Heat is activated.

Auxiliary Heat Indication: Displays “Aux. Heat On” when Auxiliary Heat is activated.

Clock Accuracy: ±1 minute per month.

Finish:

TB7000: Premier White® color.

C7189U Wall Mount Remote Indoor Sensor: Premier White® color.

T7770A Wall Mount Remote Indoor Sensor: Premier White® color.

Batteries:

Two replaceable AA alkaline batteries: Power thermostat when 24 Vac common is not used.

Non-replaceable lithium battery with ten-year life: Under normal conditions holds calendar and time settings.

NOTE: Alkaline batteries keep calendar and time if lithium battery is no longer functional.

Resistance Characteristics of Remote Sensors:

C7089U Outdoor Sensor: 10K ohm NTC. C7189U Remote Indoor Sensor: 10K ohm NTC.

C7772 Flush-Mount Remote Indoor Sensor: 20K ohm NTC. T7770A1006 Wall-Mount Remote Indoor Sensor: 20K ohm

NTC.

T7770A3002 Wall-Mount Remote Indoor Sensor: 10K ohm NTC.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or phone:

1.Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2.Honeywell Customer Care 1985 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Toronto, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France, Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

63-2636—03 |

2 |

Calibration (TB7220, C7089U, C7189U, T7770A):

No field calibration required.

Mounting Means:

TB7220: Direct wall-mount using mounting screws and anchors provided. Fits standard vertical or horizontal 2 in. x 4 in. junction box.

C7089U: Mounts outside of living space with mounting clip and screws provided.

C7189U, T7770A: Mounts directly on the wall using mounting screws and anchors provided. Fits a vertical 2 x 4 in. junction box.

Cover Plate:

32003796-001 Cover Plate is used to cover marks left on the wall by the old thermostat.

Dimensions:

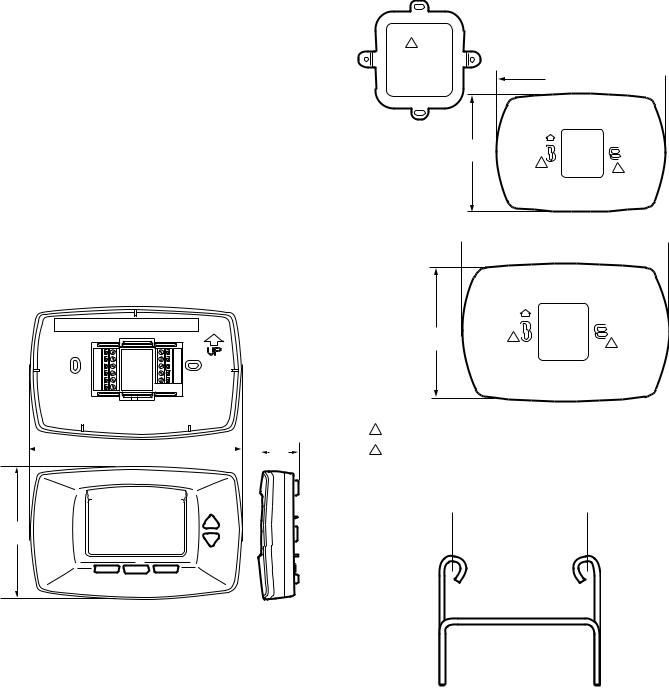

TB7220 Thermostat: See Fig. 1.

C7089U Outdoor Sensor Mounting Clip: See Fig. 3. C7189U Remote Indoor Sensor: see Fig. 5. T7770A: See Fig. 4.

32003796-001 Cover Plate: See Fig. 2.

THERMOSTAT

AND WALLPLATE

|

|

6 (152) |

|

|

|

1-3/8 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

(35) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3-3/4

(95)

TB7220 ULTRASTAT PROGRAMMABLE THERMOSTAT

1

LEVEL |

LEVEL |

6-7/8 IN. (175 MM)

BRACKET

UP

5 IN.

(127 MM)

2

2

MEDIUM COVER PLATE

8-5/16 IN. (211 MM)

8-5/16 IN. (211 MM)

|

UP |

6 IN. |

2 |

(152 MM) |

2 |

LARGE COVER PLATE

1 BRACKET FOR MOUNTING ON JUNCTION BOX NOT INCLUDED WITH COVER PLATE.

2 USE BOTTOM MOUNTING HOLES.

M13669

Fig. 2. 32003796-001 Cover Plate dimensions in in. (mm).

1-1/2 (38)

1-1/2 (38)

M24100

Fig. 1. TB7220 Thermostat

dimensions in in. (mm).

M4488

Fig. 3. C7089U Outdoor Sensor Mounting Clip dimensions in in. (mm).

3 |

63-2636—03 |

TB7220 ULTRASTAT PROGRAMMABLE THERMOSTAT

KNOCKOUTS FOR

EUROPEAN APPLICATIONS

2-3/8

(60)

STANDARD |

|

|

|

|

UTILITY |

5-1/16 |

|||

CONDUIT |

||||

BOX (2 X 4) |

(128) |

|||

MOUNTING |

|

|

|

|

HOLES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2-3/8 (60) |

|

|

|

|

|

15/16 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

3-3/16 (80) |

|

|

|

(23) |

|

M24101 |

||||

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

||

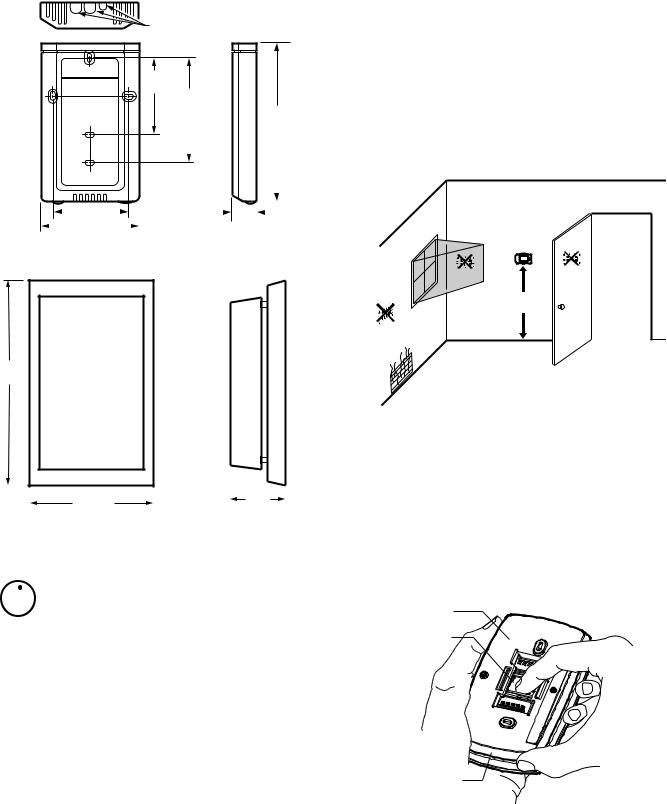

Fig. 4. T7770A dimensions in in. (mm).

4-5/8

(117)

|

|

2-3/4 (70) |

|

1-1/8 |

|

|

|

|

|

||

|

|

|

|

||

|

|

|

|

|

|

|

|

(29) |

|

||

|

|

|

|

||

M24102 |

FRONT VIEW |

|

SIDE VIEW |

||

Fig. 5. C7189U Indoor Sensor dimensions in in. (mm).

MERCURY NOTICE

MERCURY NOTICE

If this control is replacing a control that contains mercury in a sealed tube, do not place your old control in the trash. Dispose of properly.

Contact your local waste management authority for instructions regarding recycling and the proper disposal of an old control.

INSTALLATION

When Installing this Product...

1.Read these instructions carefully. Failure to follow them could damage the product or cause a

hazardous condition.

2.Check ratings given in instructions and on the product to ensure the product is suitable for your application.

3.Installer must be a trained, experienced service technician.

4.After installation is complete, check out product operation as provided in these instructions.

CAUTION

CAUTION

Electrical Shock or Equipment Damage Hazard. Can shock individuals or short equipment circuitry.

Disconnect power supply before installation.

Select Thermostat Location

Select a location for the thermostat about 5 ft (1.5m) above the floor in an area with good air circulation at average temperature. See Fig. 6.

YES NO

|

NO |

NO |

5 FEET |

[1.5 METERS]

M22258

Fig. 6. Select thermostat location.

Do not install the thermostat where it can be affected by:

—Drafts or dead spots behind doors and in corners.

—Hot or cold air from ducts.

—Radiant heat from sun or appliances.

—Concealed pipes and chimneys.

—Unheated (uncooled) areas such as an outside wall behind the thermostat.

Separate Wallplate from Thermostat

1.Separate the wallplate from the thermostat. See Fig. 7.

WALLPLATE

WIRE HOLE

THERMOSTAT

M22267

Fig. 7. Separate wallplate from thermostat.

63-2636—03 |

4 |

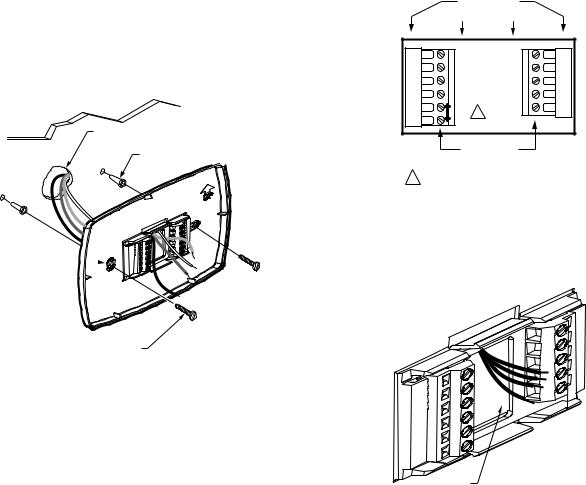

Install Wallplate (See Fig. 8)

Mount the thermostat horizontally on the wall:

1.Pull the wires through the wire hole on the wallplate.

2.Position the wallplate on the wall with the arrow pointing up. Level the wallplate for appearance only.

3.Use a pencil to mark the mounting holes.

4.Remove the wallplate from the wall and drill two 3/16 in. holes in the wall (if drywall) as marked. For firmer material such as plaster, drill two 7/32 in. holes. Tap the wall anchors (provided) into the drilled holes until flush with the wall.

5.Pull the wires through the wire hole on the wallplate and position the wallplate over the wall anchors.

6.Insert the mounting screws into the wall anchors and tighten.

WALL

WIRES THROUGH WALL

AND WIRE SLOT

WALL

ANCHORS (2)

MOUNTING

HOLES

TB7220 ULTRASTAT PROGRAMMABLE THERMOSTAT

NOTES:

—Refer to Table 5 for terminal designation descriptions.

—See Fig. 12 through 21 for wiring diagrams for specific equipment applications.

1.Select set of terminal identifications that correspond to your system type (conventional or heat pump). See Fig. 9.

HEAT PUMP

CONVENTIONAL

C |

C |

|

W2 |

W1 |

G |

G |

|

Y2 |

Y2 |

Y |

Y |

|

S1 |

|

O/B |

W |

|

S1 |

|

RC |

RC |

S2 |

S2 |

|

R |

R |

1 |

|

|

|

|

|

||

|

|

SCREW |

|

|

|

TERMINALS |

M24015 |

||

1 FACTORY INSTALLED JUMPER.

Fig. 9. Terminal identifications for system type.

2.Loosen screw terminals used for the application.

3.Insert the wires into the terminal block and tighten each screw terminal. See Fig. 10.

M13665

MOUNTING

SCREWS (2)

Fig. 8. Install wallplate.

WIRING

CAUTION

CAUTION

Electrical Shock Hazard.

Can cause electrical shock or equipment damage.

Disconnect power supply before connecting wiring.

IMPORTANT

—All wiring must agree with applicable codes, ordinances and regulations.

—Use 18 gauge thermostat wire. Shielded cable is not required.

M13666

WIRE HOLE

Fig. 10. Insert wires into terminal block.

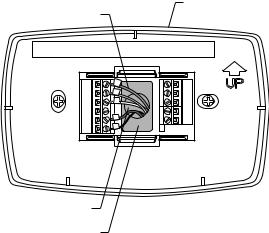

4.Push excess wire back into the wall opening and restrict wires to the shaded area. See Fig. 11.

5.Plug the wall opening with nonflammable insulation to prevent drafts from affecting the thermostat.

5 |

63-2636—03 |

TB7220 ULTRASTAT PROGRAMMABLE THERMOSTAT

WALLPLATE

WIRE

WALL OPENING |

|

SHADED AREA |

M22266 |

Fig. 11. Restrict wires to shaded area of wire hole.

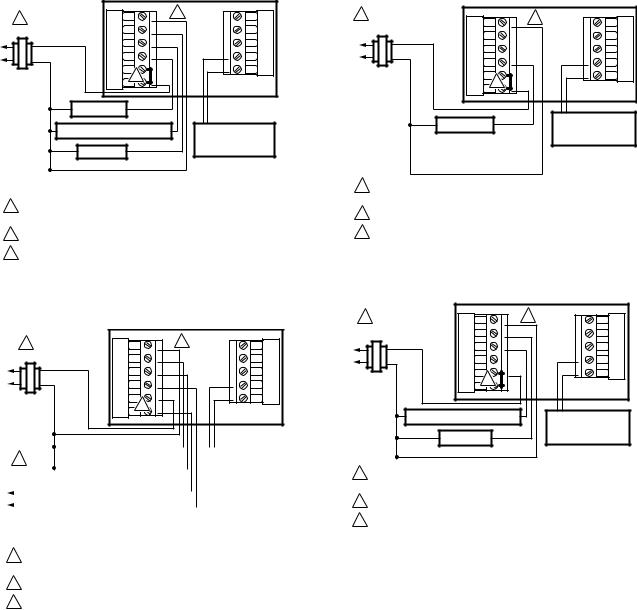

Table 4. Wiring Diagrams.

|

Wallplate Terminal |

Wiring Diagram |

System Type |

Identifications |

Figure |

Standard Heat/Cool |

Conventional |

12, 13 |

|

|

|

Heat Only |

Conventional |

14 |

|

|

|

Cool only |

Conventional |

15 |

|

|

|

Standard Multistage |

Conventional |

16, 17 |

up to 2 Heat/2 Cool |

|

|

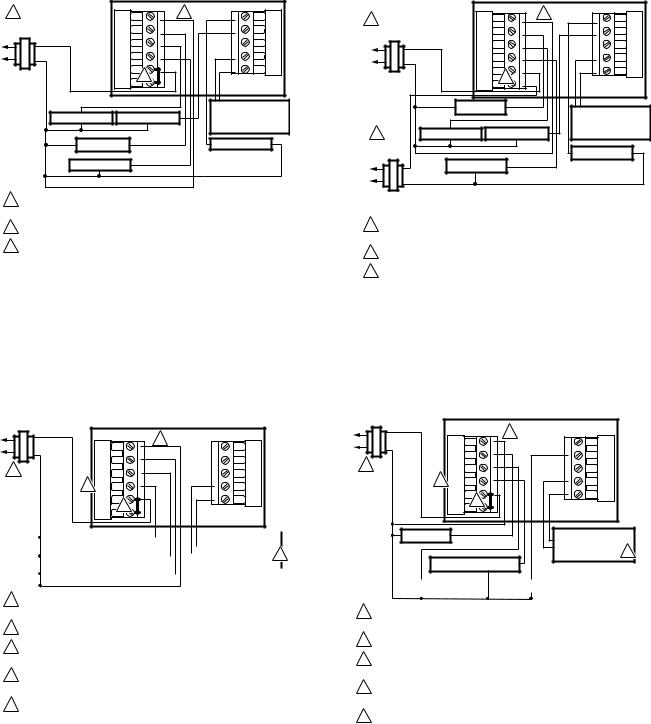

Heat Pump |

Heat Pump |

18, 19 |

(No Auxiliary Heat) |

|

|

Heat Pump |

Heat Pump |

20, 21 |

(with Auxiliary Heat) |

|

|

Multiple T7770A |

— |

26, 27, 28 |

Sensors |

|

|

Multiple C7189U |

— |

29 |

Sensors |

|

|

Table 5. Terminal Designation Descriptions.

Terminal |

|

Designation |

Description |

Rc |

Power for cooling—connect to secondary side |

(see Note 1) |

of cooling system transformer. |

R |

Power for heating—connect to secondary side |

(see Note 1) |

of heating system transformer. |

Y |

Compressor output. |

|

|

C |

Common wire from secondary side of cooling |

(see Note 2) |

system transformer. |

W |

Heat relay. |

|

|

G |

Fan relay. |

|

|

W2 |

Second stage heat relay. |

|

|

Y2 |

Second stage cooling. |

|

|

O/B |

Changeover valve for heat pumps. |

(see Note 3) |

|

S1 |

Optional outdoor or indoor remote sensor. |

(See Note 5) |

|

S2 |

Optional outdoor or indoor remote sensor. |

(See Note 5) |

|

NOTES:

1.When used in a single-transformer system, leave metal jumper wire in place between Rc and R. If used on a two-transformer system, remove metal jumper wire between Rc and R.

2.Common wire is optional when thermostat is used with batteries. When using separate transformers for heating and cooling, the common must come from the cooling transformer.

3.If thermostat is configured for a heat pump in the Installer Setup, configure changeover valve for cool (O-factory setting) or heat (B).

63-2636—03 |

6 |

Conventional System Wiring |

|

||||

L1 |

1 |

|

C |

3 |

W2 |

|

G |

|

Y2 |

||

(HOT) |

|

|

|||

|

|

|

Y |

|

S1 |

|

24 VAC |

|

W |

|

|

L2 |

|

2 |

RC |

|

S2 |

|

|

R |

|

|

|

|

|

|

|

|

|

|

|

HEAT RELAY |

|

|

|

|

COMPRESSOR CONTACTOR |

|

OUTDOOR/INDOOR |

||

|

|

|

|

|

TEMPERATURE |

|

|

FAN RELAY |

|

|

SENSOR |

1POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

2FACTORY INSTALLED JUMPER.

3WHEN USING BATTERIES, THE 24V COMMON CONNECTION

IS OPTIONAL. |

M24016 |

Fig. 12. Typical wiring of single transformer 1H/1C system.

L1 1 |

|

C |

3 |

W2 |

(HOT) |

|

G |

|

Y2 |

24 VAC |

|

Y |

|

S1 |

|

W |

|

||

L2 |

|

|

||

|

RC |

|

S2 |

|

COOLING |

2 |

|

||

R |

|

|

||

TRANSFORMER |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

FAN RELAY |

|

|

|

|

|

|

|

||

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OUTDOOR/INDOOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TEMPERATURE |

||

L1 |

|

COMPRESSOR CONTACTOR |

|

|

|

|

|

||||||||||

|

|

|

|

|

|

SENSOR |

|||||||||||

(HOT) |

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

24 VAC |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

HEAT RELAY |

|

|

|

|||||||||

L2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

HEATING |

|

|

|

|

|

|

|

|

|

|

|

|

||||

TRANSFORMER |

|

|

|

|

|

|

|

|

|

|

|

|

|||||

1POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

2REMOVE FACTORY INSTALLED JUMPER.

3WHEN USING BATTERIES, THE 24V COMMON CONNECTION IS OPTIONAL. WHEN USED, THE COMMON MUST CONNECT

TO THE COOLING TRANSFORMER SECONDARY. |

M24017 |

Fig. 13. Typical hookup of dual transformer 1H/1C system.

TB7220 ULTRASTAT PROGRAMMABLE THERMOSTAT

1 |

|

|

C |

3 |

W2 |

L1 |

|

|

|||

(HOT) |

|

|

G |

|

Y2 |

L2 |

24 VAC |

|

Y |

|

S1 |

|

W |

|

|||

|

|

|

|

||

|

|

2 |

RC |

|

S2 |

|

|

R |

|

|

|

|

|

|

|

|

|

|

|

HEAT RELAY |

|

|

OUTDOOR/INDOOR |

|

|

|

|

TEMPERATURE |

|

|

|

|

|

|

|

|

|

|

|

|

SENSOR |

1POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

2FACTORY INSTALLED JUMPER.

3WHEN USING BATTERIES, THE 24V COMMON CONNECTION IS

OPTIONAL. |

M24018 |

Fig. 14. Typical hookup of heat-only system.

1 |

|

C |

3 |

W2 |

L1 |

|

G |

|

Y2 |

(HOT) |

|

|

||

|

Y |

|

|

|

|

|

|

S1 |

|

24 VAC |

|

W |

|

|

L2 |

2 |

RC |

|

S2 |

|

R |

|

|

|

|

|

|

|

|

COMPRESSOR CONTACTOR |

|

OUTDOOR/INDOOR |

||

|

|

|

|

TEMPERATURE |

|

FAN RELAY |

|

|

SENSOR |

1POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

2FACTORY INSTALLED JUMPER.

3WHEN USING BATTERIES, THE 24V COMMON CONNECTION

IS OPTIONAL. |

M24019 |

|

Fig. 15. Typical hookup of cool-only system.

7 |

63-2636—03 |

TB7220 ULTRASTAT PROGRAMMABLE THERMOSTAT

1 |

|

C |

3 |

W2 |

L1 |

|

G |

|

Y2 |

(HOT) |

|

|

||

|

|

Y |

|

S1 |

24 VAC |

|

W |

|

|

L2 |

2 |

RC |

|

S2 |

|

R |

|

|

|

|

|

|

|

|

|

|

|

|

OUTDOOR/INDOOR |

COOL RELAY 1 |

COOL RELAY 2 |

|

TEMPERATURE |

|

|

|

|

|

SENSOR |

FAN RELAY |

|

|

HEAT RELAY 2 |

|

HEAT RELAY 1 |

|

|

|

|

1POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

2FACTORY INSTALLED JUMPER.

3WHEN USING BATTERIES, THE 24V COMMON CONNECTION

IS OPTIONAL. |

M24020 |

Fig. 16. Typical hookup of single transformer multistage system (up to 2H/2C).

Heat Pump System Wiring |

|

||

L1 |

|

|

|

(HOT) |

|

|

|

24 VAC |

C |

3 |

W1 |

|

|||

L2 |

G |

|

Y2 |

1 |

Y |

|

|

4 |

O/B |

|

S1 |

|

RC |

2 |

S2 |

|

R |

|

|

|

|

|

|

|

|

CHANGEOVER VALVE |

|

|

|

|

|

|

OUTDOOR/INDOOR |

||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

TEMPERATURE |

5 |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

COMPRESSOR CONTACTOR |

|

|

|

|

|

|

||||||

|

|

|

|||||||||||

|

|

|

|

|

|

|

SENSOR |

||||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

FAN RELAY |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||||

1POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

2FACTORY INSTALLED JUMPER.

3WHEN USING BATTERIES, THE 24V COMMON CONNECTION IS OPTIONAL.

4"O/B" TERMINAL SET TO CONTROL AS EITHER "O" OR "B" IN THE INSTALLER SETUP.

5OPTIONAL OUTDOOR OR INDOOR REMOTE SENSOR. WIRES MUST HAVE A CABLE SEPARATE FROM THE

THERMOSTAT CABLE. |

M24021 |

Fig. 18. Typical hookup of single-stage heat pump with no auxiliary heat (1H/1C).

1 |

|

|

C 3 |

W2 |

L1 |

|

|

G |

Y2 |

(HOT) |

|

|

Y |

|

|

|

|

S1 |

|

24 VAC |

|

W |

||

L2 |

|

2 |

RC |

S2 |

COOLING |

|

R |

|

|

TRANSFORMER |

|

|

|

|

|

|

|

|

|

|

FAN RELAY |

|

OUTDOOR/INDOOR |

|

|

|

|

|

|

|

|

|

|

TEMPERATURE |

1 |

COOL RELAY 1 |

COOL RELAY 2 |

SENSOR |

|

L1 |

|

|

|

HEAT RELAY 2 |

(HOT) |

|

|

|

|

|

HEAT RELAY 1 |

|

|

|

24 VAC |

|

|

|

|

L2 |

|

|

|

|

HEATING |

|

|

|

|

TRANSFORMER |

|

|

|

|

1POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

2REMOVE FACTORY INSTALLED JUMPER.

3WHEN USING BATTERIES, THE 24V COMMON CONNECTION IS OPTIONAL. WHEN USED, THE COMMON MUST CONNECT

TO THE COOLING TRANSFORMER SECONDARY. |

M24022 |

Fig. 17. Typical hookup of dual transformer multistage system (up to 2H/2C).

L1 |

|

|

|

|

(HOT) |

|

|

|

|

24 VAC |

C |

3 |

W1 |

|

|

|

|||

L2 |

G |

|

Y2 |

|

1 |

Y |

|

|

|

4 |

O/B |

|

S1 |

|

|

RC |

2 |

S2 |

|

|

R |

|

|

|

|

|

|

|

|

FAN RELAY |

|

|

OUTDOOR/INDOOR |

|

|

|

|

TEMPERATURE |

5 |

CHANGEOVER VALVE |

SENSOR |

|||

|

|

|||

COMPRESSOR 1 |

|

COMPRESSOR 2 |

|

|

|

|

|

1POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

2FACTORY INSTALLED JUMPER.

3WHEN USING BATTERIES, THE 24V COMMON CONNECTION IS OPTIONAL.

4"O/B" TERMINAL SET TO CONTROL AS EITHER "O" OR "B" IN THE INSTALLER SETUP.

5OPTIONAL OUTDOOR OR INDOOR REMOTE SENSOR. WIRES MUST HAVE A CABLE SEPARATE FROM THE

THERMOSTAT CABLE. |

M24023 |

Fig. 19. Typical hookup of multistage heat pump with no auxiliary heat (2H/2C).

63-2636—03 |

8 |

Loading...

Loading...