Page 1

Proportional Temperature

Remote bulb temperature controllers for ducts,

tanks, boilers, pipes, and other heat exchangers.

These controllers are used with modulating motors

for proportional control of three-wire, low-voltage

valves or damper motors.

T915A-D,F,M,P

Controllers

■ T915M and T915P have spdt switches to control Series

20 motors. T915M controls at high or low end; T915P

controls at low end.

■ Controllers may be used to regulate temperatures of

either air or liquids.

■ All models ambient compensated.

■ Capillary tubing allows remote bulb mounting up to 20 ft

(6.0m) from controller case.

■ Temperature setting scale markings in both Fahrenheit

and Celsius.

■ Steel case with clear plastic cover makes settings readily

visible.

■ Surface mounting using two screws through back of case.

CONTENTS

Specifications .................................................2

Ordering Information.....................................2

Installation .....................................................4

Operation .......................................................6

Settings and Adjustments................................6

1 60-2201—7S. M. • Rev. 10-94 • ©Honeywell Inc. 1994 • Form Number 60-2201—7

Page 2

T915A-D,F,M,P

SPECIFICATIONS • ORDERING INFORMATION

Specifications

MODELS (also refer to Table 1):

T915A: One potentiometer for controlling a modulating

motor. Nonadjustable throttling range.

T915B: Two potentiometers for controlling two mod-

ulating motors in unison or in sequence, factory set for

unison control. Nonadjustable throttling range.

T915C: One potentiometer for controlling a modulating

motor. Adjustable throttling range.

T915D: Two potentiometers for controlling two modu-

lating motors in unison. Adjustable throttling range.

T915F: Two potentiometers for controlling two mod-

ulating motors in sequence. Adjustable deadspot between potentiometers and adjustable throttling range.

T915M and T915P: One potentiometer and Series 20

contacts for controlling one modulating motor and one

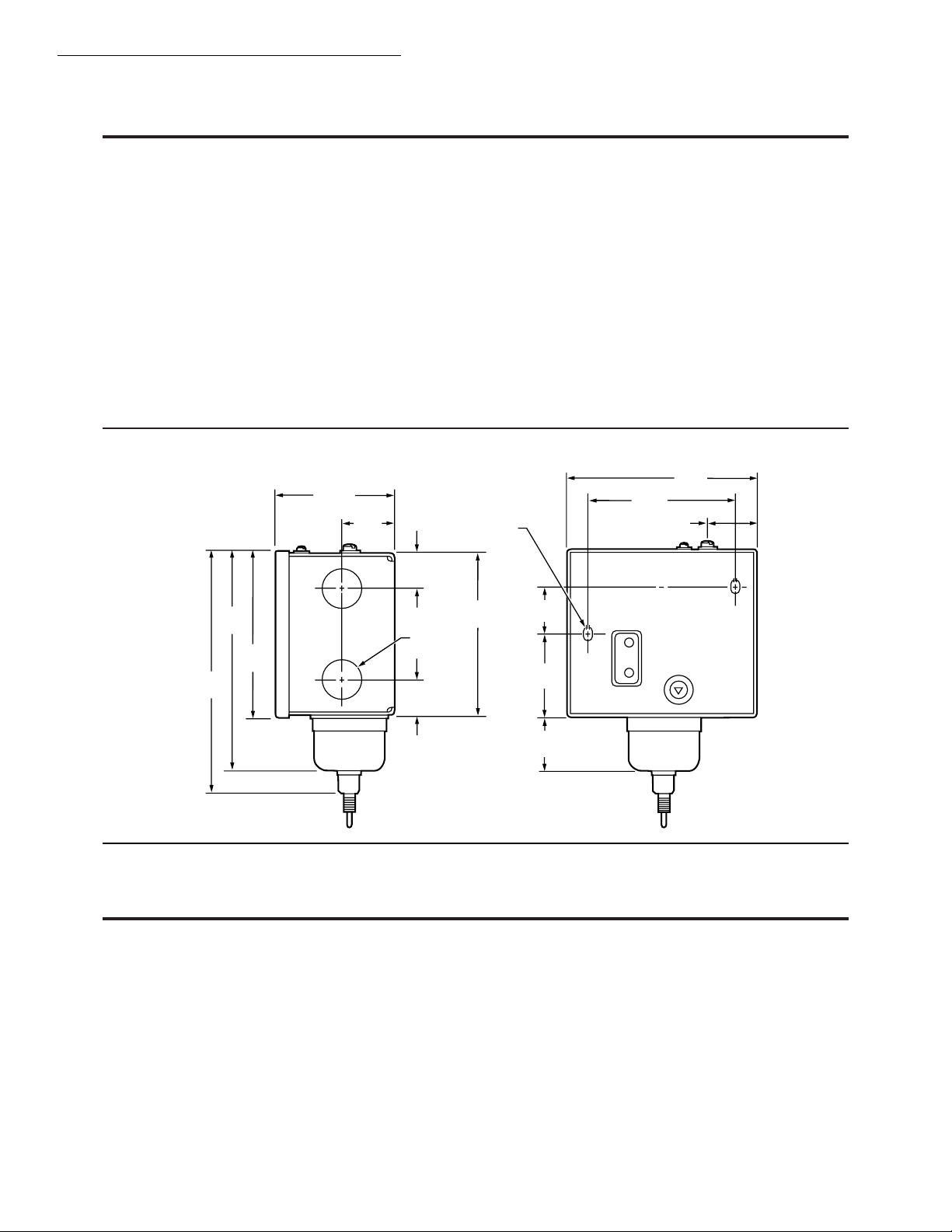

Fig. 1—Mounting dimensions in in. (mm).

2-3/4 (70)

1-1/16

(27)

5-1/32

(128)

3-7/8

(98)

5-1/2

(140)

13/16

(21)

7/8 (22.2) DIA.

13/16

(21)

Series 20 motor or relay in sequence on a temperature

rise. The Series 20 contacts on the T915M operate

above the throttling range and the Series 20 contacts

on the T915P operate below the throttling range. Both

models have nonadjustable throttling ranges and differentials.

BULB HOLDER: Furnished with copper elements.

RANGES: Fahrenheit and Celsius on the same scaleplate.

TEMPERATURE SETTING: Screws on top of controller

provide main and differential adjustment.

ELECTRICAL RATING: Low voltage ac only.

POTENTIOMETER: Standard 135 ohm. Available with

280 ohm potentiometer in some models; see Table 1.

FINISH: Gray enamel.

DIMENSIONS: See Fig. 1.

4-1/2

(114)

3-13/32

MOUNTING HOLE

KNOCKOUTS (2)

3-23/32

(95)

1-3/32

(28)

1-13/16

(46)

(87)

1-5/32

(29)

1-3/16

(30)

M7358

Ordering Information

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the TRADELINE

Catalog or price sheets for complete ordering number, or specify—

1. Order number. 4. Capillary length.

2. Scale range. 5. Accessories, if desired.

3. Bulb size.

If you have additional questions, need further information, or would like to comment on our products or services, please write or phone:

1. Your local Home and Building Control Sales Office (please check the white pages of your phone directory).

2. Home and Building Control Customer Logistics

Honeywell, Inc., 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386 (612) 951-1000

In Canada—Honeywell Limited/Honeywell Limitée, 740 Ellesmere Road, Scarborough, Ontario M1P2V9. International Sales and

Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France, Germany, Japan, Mexico,

Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

®

60-2201—7 2

Page 3

T915A-D,F,M,P

SPECIFICATIONS

ACCESSORIES:

1. 33312B Knurled Knob for finger adjustment of temp-

erature setpoint.

2. 311266D Bulb Holder for mounting sensing bulb in an

3. Immersion well assemblies or pressure fittings—see

appropriate Honeywell specification or TRADELINE

Catalog to order. Wells available in copper and stainless

steel.

air duct (furnished with some models).

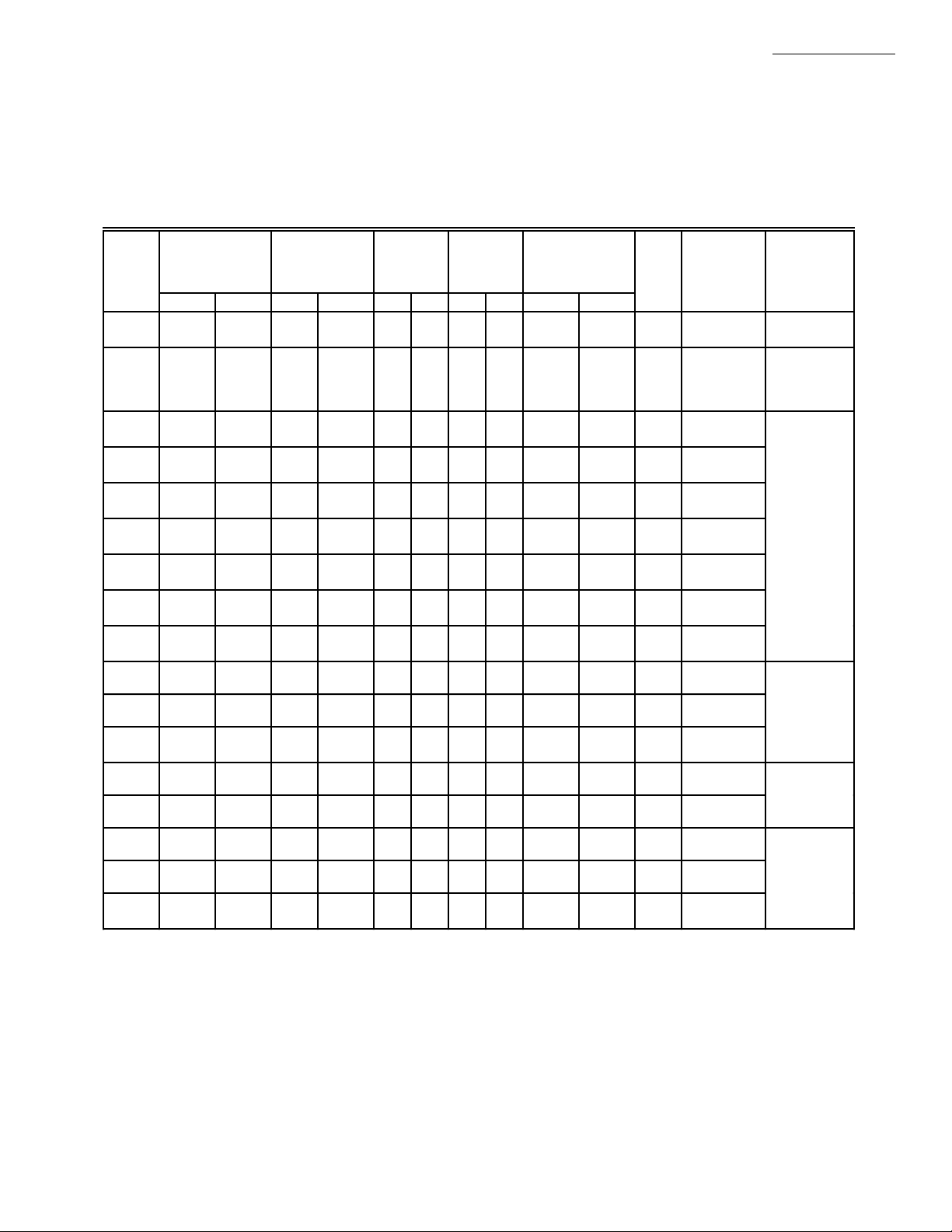

TABLE 1—T915 TEMPERATURE CONTROLLER MODELS.

Maximum

Model

Number °F °C °F °C °F °C ft m in. mm Fill

T915A 15 to 90 -9 to +32 3,

T915B 15 to 90 -9 to +32 3,

T915C 15 to 90 -9 to +32 7 to 38 3.9 to

T915C 15 to 90 -9 to +32 7 to 38 3.9 to

T915C 15 to 90 -9 to +32 7 to 38 3.9 to

T915C 15 to 90 -9 to +32 7 to 38 3.9 to

T915C 15 to 90 -9 to +32 7 to 38 3.9 to

T915C 80 to 210 27 to 99 6 to 32 3.3 to

T915C 80 to 120 27 to 99 6 to 32 3.3 to

T915D 15 to 90 -9 to +32 7 to 38 3.9 to

T915D 15 to 90 -9 to +32 7 to 38 3.9 to

T915D 105 to

T915F 15 to 90 -9 to +32 8 to 52 4.4 to

T915F 15 to 90 -9 to +32 8 to 52 4.4 to

T915Me15 to 90 -9 to +32 3,

T915M 105 to

T915Pf15 to 90 -9 to +32 3,

a

Throttling range adjustable except where noted.

b

LTD—Limited-fill elements require that controller, including all of capillary (except bulb and adjacent 4 in. [102 mm] of capillary), be in an ambient

temperature at least 10°F (5.6°C) above bulb temperature. These controllers become inoperative when temperature of controlled air or liquid is above 120°F

(49°C).

HT—High-temperature-fill elements require that controller and all of capillary (except bulb and adjacent 4 in. [102 mm] of capillary) be in an ambient

temperature at least 10°F (5.6°C) below bulb temperature.

CA—Cross ambient.

c

Wiper moves toward W on temperature rise.

d

Factory set for unison control.

e

Spdt contacts operate approximately 1°F (0.6°C) above the throttling range (0.5°F [0.3°C] differential at midscale).

f

Spdt contacts operate approximately 1°F (0.6°C) below the throttling range (0.5°F [0.3°C] differential at midscale).

Scale

Range

40 to 105 9 to 39 5.0 to

220

40 to 105 3,

220

fixed

fixed

fixed

fixed

fixed

Throttle

Range

c

f

c

c

c

a

1.7,

fixed

1.7,

fixed

21.1

21.1

21.1

21.1

21.1

17.8

17.8

21.1

21.1

21.7

28.9

28.9

1.7,

fixed

1.7,

fixed

1.7,

fixed

Bulb

Temp -

erature

200 93 5 1.5 1/2 x 4 13 x 102 LTD 135 1 modulating

c

130 54 5 1.5 11/16 x

f

200 93 11 3.4 1/2 x 4 13 x 102 LTD 135 1 modulating

200 93 20 6.1 1/2 x 4 13 x 102 LTD 135

130 54 5 1.5 11/16 x

130 54 15 4.5 11/16 x 7 17 x 177 CA 135

130 54 5 1.5 11/16 x

230 110 5 1.5 1/2 x 4 13 x 102 HT 135

230 110 20 6.1 1/2 x 4 13 x 102 HT 135

130 54 5 1.5 11/16 x

130

240 116 5 1.5 1/2 x 4 13 x 102 HT 135

130 54 5 1.5 11/16 x

130

130 54 5 1.5 11/16 x

c

240

c

130 54 5 1.5 11/16 x

c

Capillary

(Copper) Size of Bulb

54 20

54 20

116 5

6.1 11/16 x

6.1 11/16 x

1.5 1/2 x 4 13 x 102 HT 135 Series 20 motor

Type

17 x 368 CA 135 2 modulating

14-1/2

17x 368 CA 135

14-1/2

17 x 368 CA 280

14-1/2

17 x 368 CA 135 2 modulating

14-1/2

17 x 445 CA 135 unison

17-1/2

17 x 368 CA 135 2 modulating

14-1/2

17 x 445 CA 135 sequence

17-1/2

17 x 368 CA 135 1 modulating

14-1/2

17 x 368 CA 135

14-1/2

of

Potenti -

ometer

Resistance

b

(ohms) Controls

motor

motors in

unison or

sequence

motor

motors in

motors in

motor and 1

or relay

®

d

3 60-2201—7

Page 4

T915A-D,F,M,P

INSTALLATION

Installation

WHEN INSTALLING THIS PRODUCT…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

CAUTION

Disconnect the power supply before connecting

wiring to prevent electrical shock and equipment

damage.

MOUNTING

Locate the bulb where it will sense the average tempera-

ture of the controlled air or liquid.

Mount the case and the bulb of these controllers within

2 ft (0.6m) above or below each other. If the case is more

than 2 ft (0.6m) above or below the bulb, the calibration can

change (Fig. 2). The controller case mounts on a wall or

panel using the two screws through the knockouts on the

rear of the case. Bulb mounts with a bulb holder, pressure

fitting or immersion well assembly.

When running the capillary tubing, avoid kinks by making sure all bends have at least 2 in. (51 mm) radius.

Kinking the tubing renders the controllers inoperable. Leave

any excess tubing coiled under the controller case.

A bulb holder for mounting the bulb in an air duct is

furnished with models having copper elements. If the installation requires a pressure tight fit, use a pressure fitting

(Figs. 3 and 4).

If the bulb is located in an agitated liquid, support it

firmly or protect it with a separable well (Fig. 5). Refer to

the TRADELINE® Catalog for more detailed information

on accessories.

Mount low temperature controller where the case and

the capillary tubing are always warmer than the bulb;

mount high temperature controllers where the case and

capillary tubing are colder than the bulb.

When these instructions are followed, ambient temperature will not affect temperature control point.

Fig. 2—Installation of control and sensing

element.

TANK OR

DUCT WALL

CAPILLARY TUBING

WASTE NUT

BULB

(CAPSULE)

PRESSURE

FITTING

Fig. 3—Assembly of pressure fitting.

1/2 IN. (13mm) PIPE THREAD FOR 1/2 IN. (13mm)CAPSULES

3/4 IN. (19mm) PIPE THREAD FOR 11/16 IN. (17mm) CAPSULES

BOILER PLUG

CAPILLARY TUBING

COMPOSITION DISK

(SLOTTED)

M7357

60-2201—7 4

PACKING NUT

SLOTTED WASHERS

ASSEMBLED IN PAIRS

THUS-

M7354

Page 5

T915A-D,F,M,P

INSTALLATION

Fig. 4—Use of bulb holder for mounting

sensing element in air duct application.

Dimensions in in. (mm).

THERMOMETER

BULB

14

ADJUSTABLE

CONTROLLER BULB

2-1/4 x 2-1/4 (57 x 57) APPROXIMATE

HOLE IN DUCT FOR INATALLATION

3-1/4

(83)

2-3/4

(70)

ACCESS

HOLE

1-5/8

(41)

3-1/4 (83)

1-3/8

(35)

RUBBER GROMET

NO. 8 SHEET METAL

MOUNTING SCREWS (2)

Fig. 5—Use separable well for mounting

sensing bulb in an agitated liquid.

PACKING

NUT

TUBING

COMPOSITION DISK

FITTING (INCLUDING WELL)

SLOTTED BRASS WASHERS (4)

(SLOTS 180 DEGREES APART)

FITTING

MINIMUM INSERTION LENGTH

APPROXIMATELY

4-3/4 IN. (121mm)

BULB

SPRING

CLIPS (2)

M7355

BULB

Fig. 6—Typical heating connections for T915A,C.

For cooling, reverse B and W at motor.

SERIES 90

MOTOR

R

W

B

T915A,C

1

POWER

SUPPLY

R

T

W

T

B

PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQUIRED.

Fig. 7—Typical connections for T915B,D and F.

POWER

SUPPLY

SERIES 90

MOTOR

1

R

W

B

R

T

W

T

B

PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

R

W

B

T915B,D,F

R

W

B

SERIES 90

MOTOR

T

T

POWER

SUPPLY

M7362

M7364

1

TUBING

SPRING CLIP

INSERTION LENGTH

APPROXIMATELY

3-3/8 IN. (86mm)

M7356

WIRING

Disconnect the power supply before connecting wiring

to prevent electrical shock and equipment damage. All

wiring must agree with local codes, ordinances, and regulations.

There are two 7/8 in. knockouts for 1/2 in. conduit on the

right side of the case. When wiring, refer to the instructions

packed with the motor or valve and the following typical

wiring hookups (Fig. 6 through 8). Refer to Fig. 9 for

internal schematics of T915 controllers.

NOTE: Connect B models, which control two motors or

valves in sequence on a temperature rise, so that the first

motor or valve to operate is connected to the front poten-

tiometer terminals (Fig. 7). Connect F models when used

in the above application so that the first operator is

connected to the rear potentiometer.

Fig. 8—Typical connections for T915M and P.

POWER

SUPPLY

SERIES 90

MOTOR

1

R

SERIES 20

TERMINALS

R

T

W

T

B

PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

W

B

R

W

B

T915M,P

R

W

B

SERIES 20

DEVICE

SERIES 90

TERMINALS

T

T

1

POWER

SUPPLY

M7363

5 60-2201—7

Page 6

T915A-D,F,M,P

INSTALLATION • OPERATION • SETTINGS AND ADJUSTMENTS

Fig. 9—Internal schematics of T915 temperature controllers.

BACK

POTENTIOMETER

R

W

B

T915A,C

FRONT

POTENTIOMETER

T915B,D,F T915M,P

Temperature changes at the remote sensing bulb cause a

pressure change within the bulb and capillary of the T915

Proportional Temperature Controller. This pressure change

is transmitted to the bellows inside the controller case that

operate the potentiometer wiper. Proportional control of a

valve or damper is obtained.

R

W

B

R

W

B

SERIES 20

CONTACTS

BACK

POTENTIOMETER

R

W

B

R

W

B

M7361

Operation

Operation of T915M and P models is the same except

that at the high or low end of the proportioning range

(depending on the model), an spdt switch is used to operate

a Series 20 system component.

Settings and Adjustments

TEMPERATURE SETTING

Set the main scale setting at the desired temperature on

all models except C,D, and F; set those models so the main

scale indicator is at the low end of the desired proportioning

range.

The T915B is factory set for simultaneous operation and

is adjustable to full sequence. Depending on the setting, the

first operator may complete its full cycle or any portion

before the second operator starts.

Adjustable proportional ranges (differentials) on

T915C,D, and F are additive to the main scale setting. The

T915D is designed for simultaneous operation and has no

sequence adjustment. The T915F is factory set for sequence operation and has a deadspot equal to about onethird of the proportional range. This deadspot cannot be

increased, but it can be set to zero or to a partial overlap.

The T915M and P have one potentiometer and a set of

Series 20 contacts for controlling one Series 90 operator

and a Series 20 motor or relay in sequence.

The T915M contacts operate above the proportioning

range about 1°F (0.6°C); the T915P contacts operate below the proportioning range. Both models have nonadjustable proportional ranges (Series 90) and differentials (Series 20).

Turn the adjustment screw (Fig. 10) until the indicator is

opposite the desired mark on the scaleplate.

Fig. 10—Internal view of T915F (see Specifications for differences between models).

TEMPERATURE

SETTING

INDICATOR

DIFFERENTIAL

(PROPORTIONAL

RANGE) SETTING

INDICATOR

TEMPERATURE

ADJUSTMENT SCREW

PROPORTIONAL RANGE

ADJUSTMENT SCREW

BELLOWS HOUSING

POTENTIOMETER

COIL(S)

SLIDING CONTACTS

WIRING TERMINALS

DEADSPOT

(ECCENTRIC)

ADJUSTMENT

SCREW

OPERATING LEVER

M7360

60-2201—7 6

Page 7

T915A-D,F,M,P

SETTINGS AND ADJUSTMENTS

PROPORTIONAL RANGE (Differential) SETTING

Refer to proportional range curve, Fig. 11.

1. If this graph covers the scale and proportional ranges

of your controller, refer to the graph and read as follows:

a. Locate the horizontal line that represents the desired

main scale temperature setting of the controller.

b. Locate the vertical line that represents the desired

proportional range setting.

c. Determine the point at which the lines intersect.

d. The relation of this point to the proportional range

setting curves, labeled at the top of the graph, deter-

mine the proportional range indicator setting. Thus, if

the point lies between curve A and curve B, turn the

proportional range adjustment screw (Fig. 10) until

the proportional range indicator is between A and B on

the scaleplate.

2. If the controller model being installed is not covered

by this graph, use a trial and error method:

a. Refer to the graph in Fig. 11.

b. Select a tentative setting by following steps 1.a through

1.d.

c. Run a test to determine the direction for further adjust-

ment.

NOTE: Too narrow a proportional range may make the sy-

stem unstable. Increase the range to stabilize the system,

remembering that increasing the proportional range also

increases offset (control point rise at very light load and

drop at very heavy load).

Fig. 11—Proportional range curve for T915

with 15°F to 90°F (minus 9°C to plus 32°C)

scale range.

PROPORTIONAL RANGE SETTING

F

C

MIN A

B

90

30

80

CDEF

ADJUSTMENT OF SEQUENCE

OPERATION (T915B)

1. For simultaneous operation, no adjustment is required.

2. (On a temperature rise, the front wiper sweeps a

portion of the active windings of its potentiometer before the

back wiper enters the active windings of its potentiometer.)

For operation with partial overlap of wiper travel, turn the

eccentric screw to the left an amount proportional to the

desired overlap of wiper travel. For example, if on a temperature rise, the back wiper is to enter its active windings after

the front wiper has swept one-half of its active windings, turn

the eccentric screw to the left one-half as far as it will go.

3. (On a temperature rise, the front wiper leaves the

active windings of its potentiometer as the back wiper

enters the active windings of its potentiometer.) For sequence operation, turn the eccentric screw to the left as far

as it will go.

4. For sequence operation with a deadspot equal to

one-third of the overall proportioning range, no adjustment is required.

5. For sequence operation without deadspot or with a

deadspot of less than one-third of the overall proportioning, turn the eccentric screw to the left. Turning the

eccentric screw three-fourths of its full travel to the left

will reduce the deadspot to zero. Turning the eccentric

screw less than three-fourths of its full travel will reduce

the deadspot proportionally.

6. (Front wiper enters the active windings of its potentiometer before the back wiper leaves the active windings

of its potentiometer.) For operation with partial overlap of

wiper travel, turn the eccentric screw to the left as far as it

will go.

70

20

60

50

10

40

0

30

MAIN SCALE SETTING – DEGREES

20

15

–10

01020304050

051015 20 25

PROPORTIONAL RANGE – DEGREES

F

C

M7365

7 60-2201—7

Page 8

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your use or

modification to, the literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and against any liability,

cost, or damages, including attorneys’ fees, arising out of, or resulting from, any modification to the literature by you.

Home and Building Control Home and Building Control Helping You Control Your World

Honeywell Inc. Honeywell Limited—Honeywell Limitée

1985 Douglas Drive North 740 Ellesmere Road

Golden Valley, MN 55422 Scarborough, Ontario

M1P 2V9

60-2201—7 8

Printed in U.S.A.

QUALITY IS KEY

Loading...

Loading...