Page 1

T8631A,R Communicating

Chronotherm III Thermostats

Application

T8631A,R can be connected to Honeywell's TotalHome

system for external access and control. TotalHome system

devices communicate using HBus, a Honeywell communications protocol.

These thermostats, powered directly from the control

transformer, provide energy saving control for a 24 Vac

conventional heating/cooling or multistage heat pump

heating/cooling system as indicated in Table 1.

As long as AC power is continuously available to the

transformer, the thermostat will be compatible with most

control systems.

The T8631A,R models include a SYSTEM LED near

the top of the thermostat face. The SYSTEM LED lights

when the thermostat is signaling for heating or cooling.

TABLE I—THERMOSTAT MODELS.

Stages Switching

Thermostat Heat Cool System Fan Program

T8631A 1 1 HEAT-OFF-COOL ON-AUTO 5-1-1

T8631R 2 1 EM. HT.-HEAT-OFF-COOL ON-AUTO 5-1-1

Installation

WHEN INSTALLING THIS PRODUCT…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings on the product to make sure the

product is suitable for your application.

3. Installer must be a trained, experienced service technician.

4. After installation is complete, check out product

operation as provided in these instructions.

5. Allow thermostat to warm to room temperature

before operating.

IMPORTANT: After wiring is complete, push excess wire

back into the hole, and plug hole with nonhardening

caulk, putty or insulation to prevent drafts from

affecting thermostat operation.

LOCATION

Install thermostat and subbase about 5 ft [1.5 m] above

the floor in an area with good air circulation at room

temperature.

Do not install the thermostat where it may be affected by:

— drafts or dead spots behind doors, in corners or under

cabinets.

— hot or cold air from ducts.

— radiant heat from sun or appliances.

— concealed pipes and chimneys.

T8631R includes AUX. HT. and EM. HT LEDs near the

bottom center of the subbase. The AUX. HT. LED lights

whenever the thermostat is calling for operation of the

backup or auxiliary heater. Backup (auxiliary) heat is more

expensive to operate than the heat pump and typically is

used only when the heat pump is unable to handle the load.

The EM. HT. LED lights whenever the thermostat system

switch is in the EM. HT. position. The EM.HT. LED may

also light on some systems if the heat pump is malfunctioning. The system switch needs to be moved to EM.HT. on

these heat pumps.

Heat and cool anticipation is fixed in both models; no

adjustment is necessary. T8631A has adjustable cycle rate

for heating; T8631R cycle rate is adjustable only for

auxiliary heat.

— unheated (uncooled) areas behind the thermostat,

such as an outside wall.

WIRING TO HEATING/COOLING SYSTEM

The T8631 requires connection to both sides of the

heating transformer secondary for power.

If Replacing An Existing Thermostat

Turn off power to thermostat at furnace or heat pump.

A two-transformer system may require turning off two

switches or disconnects. Remove any existing wallplate or

subbase from wall. Label each wire with, or write down,

the letter or number on the wiring terminal as the wire is

removed, to avoid miswiring later.

If New Installation

Run cable to a hole at the selected wall location, and

pull about 3 in. [76 mm.] of wire through the opening.

Color-coded, 18-gauge thermostat cable with one conductor for each wiring terminal, excluding H terminals, is

recommended. Good service practice recommends selecting cable with one or two more conductors than the

immediate application requires.

WIRING TO TOTALHOME SYSTEM

The HBus connection requires an unshielded cable with

3 twisted pairs of #22 AWG solid wire. Use Belden #8742,

Alpha #1304 or equivalent wire. Route this cable with the

thermostat cable to the utility room. Do not connect the

HBus cable to the T8631 until the other TotalHome devices

are connected.

J.H . • Rev. 3-93 • © Honeywell Inc. 1993 • Form Number 69-0689—2

Page 2

MOUNTING SUBBASE

The subbase does not require leveling for proper opera-

tion, but only for appearance.

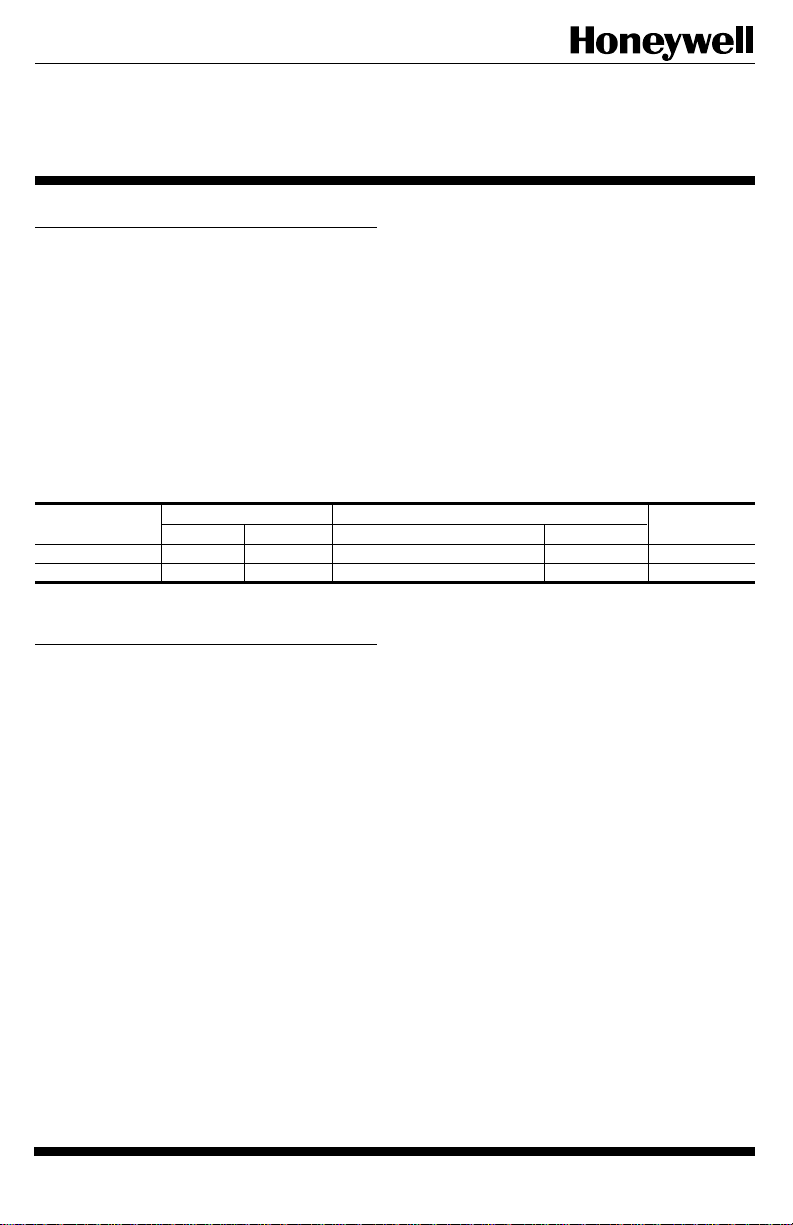

Remove thermostat from subbase. See Fig. 1.

The subbase mounts directly onto the wall with the

screws and anchors included in the package. Use the

subbase as a template, and with a pencil, mark the two

mounting screw positions. See Fig. 2. If drywall construction, plastic anchors must be used; select 3/16 in. bit to

drill holes for anchors. Gently tap anchors into holes until

they are flush with the wall surface. Thread wires through

the center opening of the subbase. Then, mount the subbase

by using two screws provided. Gently tighten screws, level

top surface of subbase and then securely tighten screws.

WIRING

All wiring must comply with local electrical codes and

ordinances.

Fig. 1—Removing thermostat from subbase.

S

Y

S

T

E

M

HEAT

AUTO

COOL

OFF

F

A

N

O

N

A

U

T

O

AUX. HEAT

M3060

Disconnect power before wiring to prevent electrical

shock or equipment damage.

The shape of the terminal barrier permits insertion of

straight or conventional wraparound wiring connections.

Either method is acceptable.

Refer to Figs. 3-5 for typical hookups of subbase and

thermostat.

NOTE: Keep all wiring restricted to ribbed area surround-

ing terminals to assure thermostat/subbase contact. See

Fig. 6.

Fig. 2—Mounting subbase on wall.

WALL

WIRES THROUGH

WALL OPENING

WALL

ANCHORS

(2)

MOUNTING

HOLES

SUBBASE

SWITCH UP DISCONNECTS THE HBUS.

1

2

FAN CAN BE SET FOR ELECTRIC HEAT OR CONVENTIONAL.

1

HBUS

SWITCH

2

FAN

OPERATIONAL

SWITCH FOR

T8631A ONLY

MOUNTING

SCREWS (2)

M3061

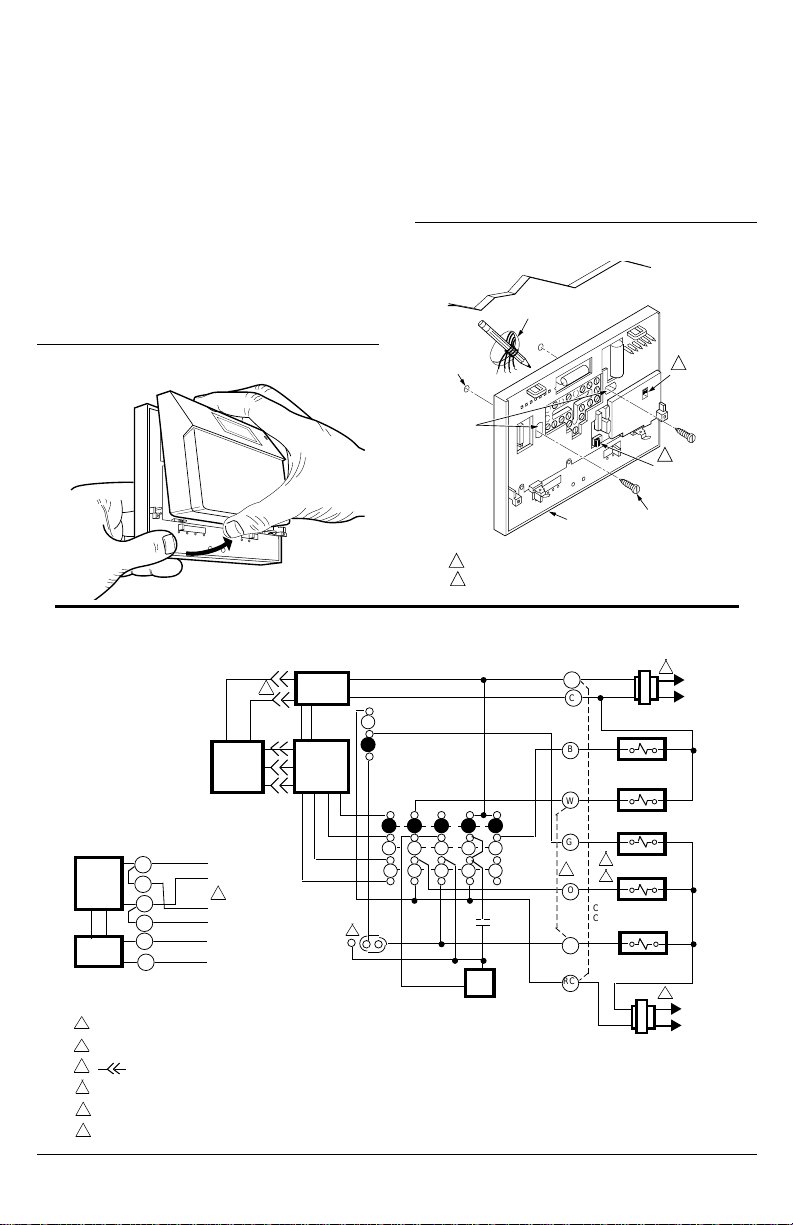

Fig. 3—T8631A 1-stage heat/1-stage cool thermostat with HEAT-OFF-COOL system and ON-AUTO fan

switching.

POWER

3

SUPPLY

FAN

SWITCH

STAT

LOGIC

CIRCUIT

H3

TRANSCEIVER

POWER

SUPPLY

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

JUMPER R AND RC FOR SINGLE TRANSFORMER SYSTEM.

2

3

DENOTES THERMOSTAT TO SUBBASE INTERCONNECT.

4

DO NOT CONNECT H BUS WIRES TO THERMOSTAT UNTIL OTHER TotalHome DEVICES ARE CONNECTED.

FAN OPERATION SWITCH (4A) IN ELEC. POSITION, USE ONE SYSTEM TRANSFORMER AND JUMPER R TO RC.

5

FOR SINGLE STAGE HEAT PUMP APPLICATIONS, JUMPER W TO Y FOR SINGLE COMPRESSOR CONTACTOR

6

OPERATION.

BUS IN

H3

H4

H4

H1

H2

BUS OUT

13.7 VDC

+

_

4

BUS

POWER

SUPPLY

SUBBASE

LOGIC/

CONTROL

CIRCUIT

ELEC.

ON

AUTO

SYSTEM

SWITCH

HEAT

OFF

COOL

HEAT/

HIGH

LIMIT

COOL

5

CONV.

R

C

B

HEAT DAMPER OR

CHANGEOVER RELAY

W

G

6

O

COOL DAMPER OR

CHANGEOVER RELAY

Y

RC

1

HEATING SYSTEM

TRANSFORMER

HEAT RELAY

2

FAN RELAY

5

COMPRESSOR

CONTACTOR

1

COOLING

SYSTEM

TRANSFORMER

M3066A

2

L1

(HOT)

L2

L2

L1

(HOT)

Page 3

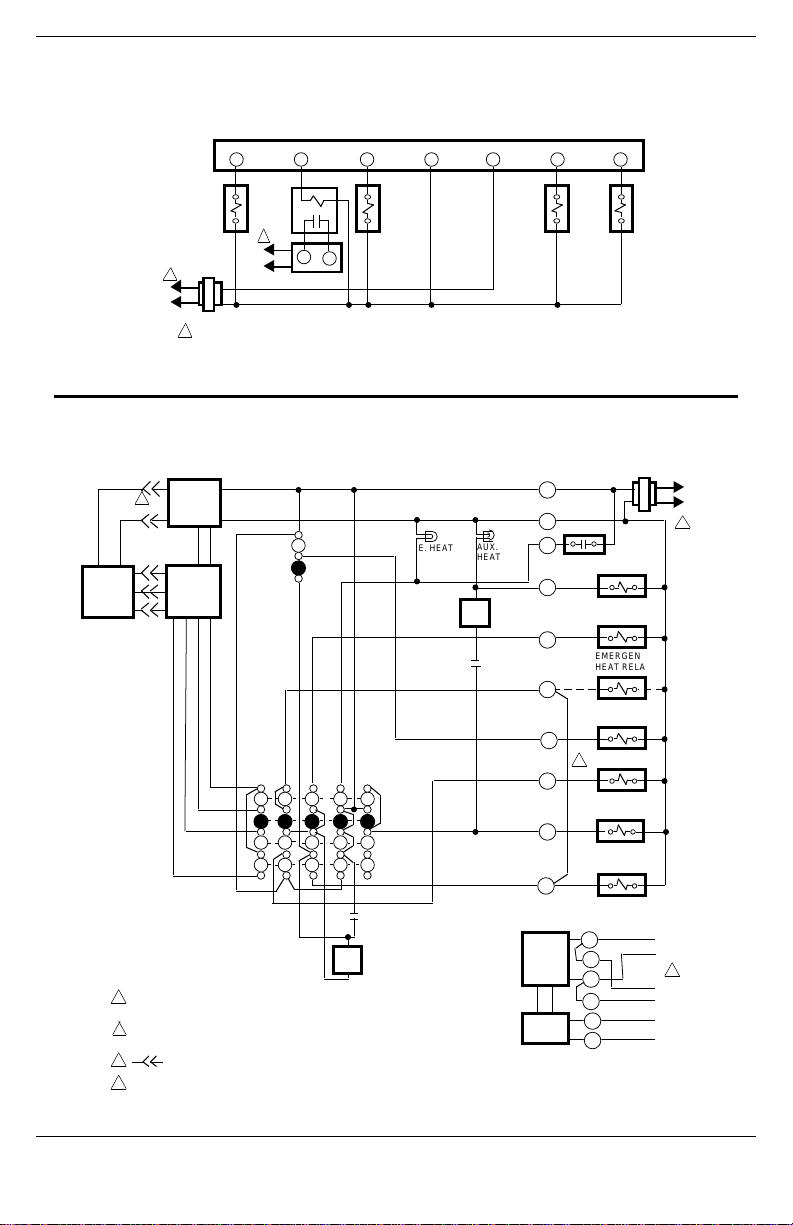

Fig. 4—T8631A 1-stage oil heat/1-stage cool. Oil Primary has its own transformer.

HEATING-COOLING WALLPLATE

O G

1

RELAY

T

T

OIL PRIMARY

COOLING

DAMPER/

COOLING

CHANGEOVER

1

L1

(HOT)

L2

Fig. 5—T8631R 2-stage heat/1-stage cool thermostat with EM. HT.-HEAT-OFF-COOL system and ON-AUTO

fan switching.

L1

(HOT)

L2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

C B

FAN

RELAY

RW

HEATING

DAMPER/

HEATING

CHANGEOVER

AIR

COND.

EQUIP.

Y

M3089

3

POWER

SUPPLY

FAN

STAT

LOGIC

CIRCUIT

SUBBASE

LOGIC/

CONTROL

CIRCUIT

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS

1

REQUIRED.

REMOVE JUMPER ( IF PRESENT) FOR SYSTEM WITH ISOLATED STAGE 1 HEATING

2

AND COOLING CONNECTIONS.

DENOTES THERMOSTAT TO SUBBASE INTERCONNECT.

3

DO NOT CONNECT H BUS WIRES TO THERMOSTAT UNTIL OTHER TotalHome

4

DEVICES ARE CONNECTED.

SWITCH

SYSTEM

SWITCH

ON

AUTO

HIGH

LIMIT

OFF

COOL

HEAT/

COOL 1

E. HEAT

HEAT

E. HEAT

RED

HIGH

LIMIT

AUX.

HEAT

GREEN

HEAT 2

R

C

L

W2

E

W1

G

O

B

Y1

TRANSCEIVER

POWER

SUPPLY

MONITOR

2

H3

H3

H4

H4

H1

H2

TRANSFORMER

AUXILIARY

HEAT RELAY

EMERGENCY

HEAT RELAY

STAGE 1

HEAT RELAY

FAN RELAY

CHANGEOVER

RELAY (COOL)

CHANGEOVER

RELAY (HEAT)

COMPRESSOR

CONTACTOR

BUS IN

BUS OUT

13.7 VDC

+

_

4

BUS

POWER

SUPPLY

M3065A

1

L1

(HOT)

L2

3 69-0689—2

Page 4

Fig. 6—Keep wiring restricted to ribbed area

)

surrounding terminals.

FOR STRAIGHT

INSERTION –

STRIP 5/16 in. [8 mm]

FOR WRAPAROUND –

RESTRICT

WIRING TO

THIS AREA

FRONT VIEW OF

TERMINAL AREA

WIRING TO BE BELOW

THIS SURFACE

CROSS-SECTIONAL VIEW OF

TERMINAL AREA

STRIP 7/16 in. [11 mm]

TOP SURFACE

OF SUBBASE

M3062

Fig. 7—T8631R cycle rate adjustment.

1A

1B

2A

2B

DISPLAY TEMPERATURE

M3063A

NOT USED

o

C

2B

IN

o

F

2B

OUT

AUXILIARY HEAT

CYCLE RATE

NORMAL

FASTER

1B

OUT

1 TURN

(FACTORY

SETTING)

IN

Fig. 8—T8631A cycle rate adjustment.

1B

1A

2B

2A

The room air temperature will normally vary slightly

from the comfort temperature setting with the cycling of

the heat pump, auxiliary heater, furnace or air conditioner.

The cycle rate of the T8631R Thermostat is factory-set for

heat pumps. The heat pump compressor cycle rate can not

be adjusted. The auxiliary heat cycle rate can be adjusted

by turning the cycle rate adjustment screw located on the

back of the thermostat. See Fig. 7.

T8631A has a factory-set cycle rate of six cycles per

hour in heating and three cycles per hour in cooling. For

high efficiency furnaces, it can be necessary to change the

cycle rate to the hot water setting. Cooling cycle rate is not

adjustable, but heating can be adjusted by turning one or

both 1A and 1B screws on the back of the thermostat. See

Fig. 8 for adjustments. The screw should only be backed

out about one-half turn, or be turned in until tight.

ADAPTIVE INTELLIGENT RECOVERY™/CONVENTIONAL RECOVERY CONVERSION

The T8631A and T8631R are factory-set for Adaptive

Intelligent Recovery™, but the T8631A can be converted

to Conventional Recovery by using the screw 2A on the

back of the thermostat as indicated in Fig. 8.

With the Adaptive Intelligent Recovery setting, the

room will reach the comfort temperature at the exact time

programmed into the thermostat. The control temperature

will increase gradually and turn the equipment on and off

several times to reach the comfort temperature slowly and

on time.

With Conventional Recovery, the start time should be

programmed to be earlier than the desired comfort time. It

may require some trial and error to arrive at the best starting

time. A ■ will appear on the display when using Conven-

tional Recovery.

TEMPERATURE CONVERSION

The display readout can be converted between °C and

°F using screw 2B. See Figs. 7 and 8.

HBUS SWITCH

The subbase has a switch that you can move t o discon nect

the thermostat from the external control device. See Fig. 2.

INSTALLING BATTERIES

Three AAA alkaline batteries are provided as backup to

prevent program loss in event of power outage. Batteries

are included with thermostat. Install batteries in back of

thermostat. See Fig. 9.

Without battery backup, the program will remain about

20 seconds in event of power loss.

RECOVERY OPTION

ADAPTIVE

CONVENTIONAL

DISPLAY TEMPERATURE

a

SOME HIGH EFFICIENCY FURNACES OPERATE BETTER IF ADJUSTED

TO HOT WATER SETTING.

2A

2A

o

2B

IN

C

o

2B

OUT

F

IN

OUT

HEAT

CYCLE RATE

SYSTEM

GRAVITY

AIR/WATER

HOT

WATER

GAS/OIL

WARM AIR

ELECTRIC

WARM AIR

1A

OUT

1 TURN

a

IN

IN

(FACTORY SETTING)

OUT

1 TURN

1B

OUT

1 TURN

OUT

1 TURN

IN

IN

M3064A

CYCLE RATE ADJUSTMENT

NOTE: MOST APPLICATIONS WILL NOT REQUIRE

A CHANGE IN CYCLE RATE.

Fig. 9—Battery placement.

M3058

4

BATTERY PLACEMENT

(NOTE CORRECT PLUS

AND MINUS DIRECTION

Page 5

Fig. 10—Mounting the thermostat on subbase.

H

T

A

E

H

.

X

U

A

.

T

H

.

M

E

N

A

F

O

T

U

A

N

O

F

F

O

L

O

O

C

O

T

U

A

T

A

E

C.

R

U

N

P

R

O

G

R

A

M

S

E

T

P

R

E

S

E

N

T

D

A

Y

D

A

Y

/

T

I

M

E

H

O

L

D

S

E

T

T

E

M

P

H

E

A

T

/

C

O

O

L

A.

SYSTEM

M

P

MON

HEAT ON

RETURN

T

E

M

P

E

R

A

T

U

R

E

P

R

E

S

E

N

T

S

E

T

T

I

N

G

T

I

M

E

S

K

I

P

N

E

X

L

E

A

V

E

W

A

K

E

S

L

E

E

P

R

E

T

U

R

N

T

A

H

E

A

D

W

A

R

M

E

R

P

E

R

I

O

D

C

H

A

N

G

E

B

A

C

K

C

O

O

L

E

R

T

O

L

A

S

T

P

E

R

I

O

D

B.

RETURN

SYSTEM

PM

MON

HEAT ON

A

U

T

O

M3059

When the batteries are low, the display will flash REPL

BAT. REPL BAT indication will disappear when thermostat is mounted back on the powered subbase with fresh

batteries. This may take up to 15 minutes to occur.

If batteries are completely dead, the display will go

blank when the thermostat is removed from subbase.

MOUNTING THE THERMOSTAT

With system switch set to OFF, hang the thermostat on

the tabs at the top of the subbase. See Fig. 10A. Swing

down and press on lower edge until thermostat snaps into

place. See Fig. 10B. Open cover and tighten the captive

mounting screws. See Fig. 10C.

SETTING DAY AND TIME

NOTE: Thermostat must be mounted on powered subbase

to program.

Restore 24V power to the thermostat. When power is

applied to the thermostat, the display will read 1:00 PM and

32° for a minute or less, followed by 1:00 PM and room

temperature. It will go off for a few seconds, then begin to

flash on and off. Set present day and time.

SET

PRESENT

Press .

DAY/TIME

Press to set the current day. Each press of

DAY

the DAY key advances the display one day.

Press TIME or to set the current time.

AHEAD

BACK

If the display will not come on:

— check mounting of thermostat to subbase. If loose

or misaligned, remove thermostat and reinstall on

the subbase, making sure it is firmly attached.

— check to see that system power is on.

— check to see that voltage between R and C is 20 to

30 Vac.

Checkout

CAUTION

!

During cold weather, some heat pumps will require that crankcase heater be energized several

hours before operating heat pump. Refer to

manufacturer’s recommendations.

HEATING

Move the system switch to HEAT and the fan switch to

AUTO. Press WARMER key until the setting is about

10° F [6° C] above room temperature. Heating should start

and the fan should run (there may be a delay of 5-10

minutes before heat turns on). Press COOLER key until the

setting is about 10° F [6° C] below room temperature. The

heating equipment and fan should shut off. The fan will run

a short time after equipment shuts off with T8631A unless

fan operation switch set for electric.

COOLING

CAUTION

!

Do not operate cooling if outdoor temperature is

below 50° F [10° C]. Refer to manufacturer’s

recommendations.

NOTE: When cooling setting is changed, thermostat can

wait up to five minutes before turning on the cooling

equipment. This delay is to protect the compressor.

5 69-0689—2

Page 6

Move the system switch to COOL and the fan switch to

AUTO. Press COOLER key until the setting is about

10° F [6° C] below room temperature. The cooling equipment and fan should start. Press WARMER key until the

setting is about 10° F [6° C] above room temperature. The

cooling equipment and fan should stop.

FAN

Move the system switch to OFF, and the fan switch to

ON. The fan should run continuously. When the fan switch

is in the AUTO position, fan cycles with the heating or

cooling system.

EXTERNAL ACCESS AND CONTROL

A triangle ▲ symbol is displayed on the lower right

corner of the LCD when the T8631 setting has been

adjusted through the TotalHome system. See Fig. 11.

INSTALLER SELF-TEST (OPTIONAL)

NOTE: Thermostat must have AC power to perform

self-test.

Perform the following test as a check of all thermostat

functions. If thermostat does not respond as indicated,

thermostat must be replaced.

1. Press AHEAD and BACK keys at the same time.

While holding keys down, all segments of the display

should be on. See Fig. 11.

2. Set system switch to OFF. Press AHEAD and BACK

and PRESENT SETTING keys at the same time to enter

self-test.

Fig. 11—All segments on display.

REPL

AM

BAT

SUN MON TUE WED THU FRI SAT COOL ON HEAT ON

WAKE LEAVE RETURN SLEEP TEMPORARY

PM

SET

PT

M410C

3. Press each key as listed below, and look for re-

sponses listed as key is held down and released.

Look For This Response

Press This Key Key Down Key Released

PRESENT SETTING 15 see note

following

SKIP NEXT PERIOD 07 blank

CHANGE TO LAST 03 blank

PERIOD

COOLER 02 blank

WARMER 06 serial number

transmitted

on HBus

BACK 04 blank

AHEAD 05 blank

RETURN 00 blank

LEAVE 01 control micro-

processor mask

number and

revision number

SLEEP 08 blank

WAKE 12 see note

following

SET HEAT/COOL 09 blank

DAY 13 interface

micro-

processor

mask number

and revision

number

HOLD TEMP 10 blank

SET PRESENT 14 see note

DAY/TIME following

RUN PROGRAM 11 normal operat-

ing display

NOTES:

a

If the system switch is in COOL, the following sequence will occur:

a

b

c

6

Page 7

CAUTION

!

Do NOT operate cooling if outdoor temperature

is below 50° F [10° C]. Refer to manufacturer’s

recommendations.

First press—cooling system and SYSTEM LED on.

Second press—cooling system and SYSTEM LED off.

b

A four-digit code number will appear when the key is

released. The four digits of the code represent the

following options:

Third System Switch

Digit Position

0 OFF

1 COOL

2 HEAT

4 EM.HT.

c

If the system switch is in HEAT, the following sequence will occur:

Fourth Digit: Not used.

First T8631A T8631R

Digit CPH CPH

01 3

23 3

49 6

66 6

Second Recovery

Digit Model Degrees Type

0 T8631R F A.I.R.

1 T8631R C A.I.R.

2 T8631A F Conventional

3 T8631A C Conventional

4 T8631R F A.I.R.

5 T8631R C A.I.R.

6 T8631A F A.I.R.

7 T8631A C A.I.R.

a

Adaptive Intelligent Recovery™

CAUTION

!

Do NOT operate heating until heat pump warmup

procedure is followed. Refer to manufacturer’s

recommendations.

T8631A:

First press—1st stage heating and SYSTEM LED on.

Second press—heating and SYSTEM LED off.

a

a

a

a

a

a

T8631R:

First press—1st stage heating and SYSTEM LED on.

Second press—2nd stage heating also on.

Third press—2nd stage heating off.

Fourth press—1st stage heating and SYSTEM LED off.

(If system switch is in EM. HT., operation is as above,

except 1st stage heating is locked out.)

REFER TO OWNER’S MANUAL FOR PROGRAMMING INSTRUCTIONS AND HOMEOWNER

TROUBLESHOOTING.

This equipment is a Class B digital apparatus which complies with Canadian Radio Interference Regulations, CRC c. 1374.

7 69-0689—2

Page 8

Home and Building Control Home and Building Control

Honeywell Inc. Honeywell Limited—Honeywell Limitée

1985 Douglas Drive North 740 Ellesmere Road

Golden Valley, Minnesota 55422 Scarborough, Ontario

Printed in Taiwan R.O.C.

M1P 2V9

Loading...

Loading...