Page 1

T8624C,D (5-1-1 Day

Programming) Chr onotherm

III Fuel Saver Thermostats

The T8624C,D Chronotherm III Programmable Fuel Saver Thermostats provide automatic control of multistage heating/cooling systems and offer users the highest standard of

comfort and convenience available with energy

savings.

■ Different schedules may be selected for week-

days, Saturday and Sunday.

■ Can be programmed in hand (with batteries in-

stalled) or on wall to provide up to four tempera-

ture settings per day.

■ Large digital clock (liquid crystal display) indi-

cates continuous time, day, current period and

room temperature.

■ Adaptive Intelligent Recovery™ brings room tem-

perature to programmed temperature at pro-

grammed time, maximizing comfort and energy

savings.

■ Temperature control program maintains tempera-

ture within 1° F of setpoint.

■ Temporary program override available by using:

— WARMER and COOLER keys.

— SKIP next period key.

— CHANGE to last period key.

■ HOLD TEMP key provided for indefinite pro-

gram override (vacation/holiday).

■ Installer self-test and time delay override save

installation time.

■ SYSTEM light-emitting diode (LED) indicates

system is energized.

■ Models available with automatic or manual heat/

cool changeover.

■ Batteries included provide power to maintain

clock and memory during power failures.

■ Switching subbase with wiring terminals included.

■ Powered directly from control transformer, re-

quiring an extra (24V) wire to thermostat.

■ Fan operation switch to select either independent

or direct thermostat control of fan in heating

included on back of select models.

CONTENTS

Specifications .................................................2

Ordering Information.....................................2

Selection/Application .....................................4

Installation .....................................................5

Checkout.......................................................11

Programming the Thermostat ......................14

Operating the Thermostat ............................18

Troubleshooting ...........................................21

Glossary .......................................................22

®

C.H. • 9-93 • ©Honeywell Inc. 1993 • Form Number 68-0134

1 68-0134

Page 2

T8624C,D

SPECIFICATIONS • ORDERING INFORMATION

Specifications

IMPORTANT: The specifications given in this publi-

cation do not include normal manufacturing tolerances. Therefore, this unit may not exactly match

the listed specifications. Also, this product is tested

under closely controlled conditions, and some minor differences in performance can be expected if

those conditions are changed.

TRADELINE® MODELS

TRADELINE models (see Table 1) are selected and

packaged to provide ease of stocking and handling

and also maximum replacement value.

LIGHT-EMITTING DIODE (LED): SYSTEM LED

lights during thermostat ON cycle.

VOLTAGE RATING: 15 to 30 Vac.

CURRENT RATING: 1.6A maximum total per stage.

OPERATING HUMIDITY RANGE: 5 to 90 percent

relative humidity, noncondensing.

OPERATING AMBIENT TEMPERATURE RANGE:

40° F to 110° F [4° C to 43° C].

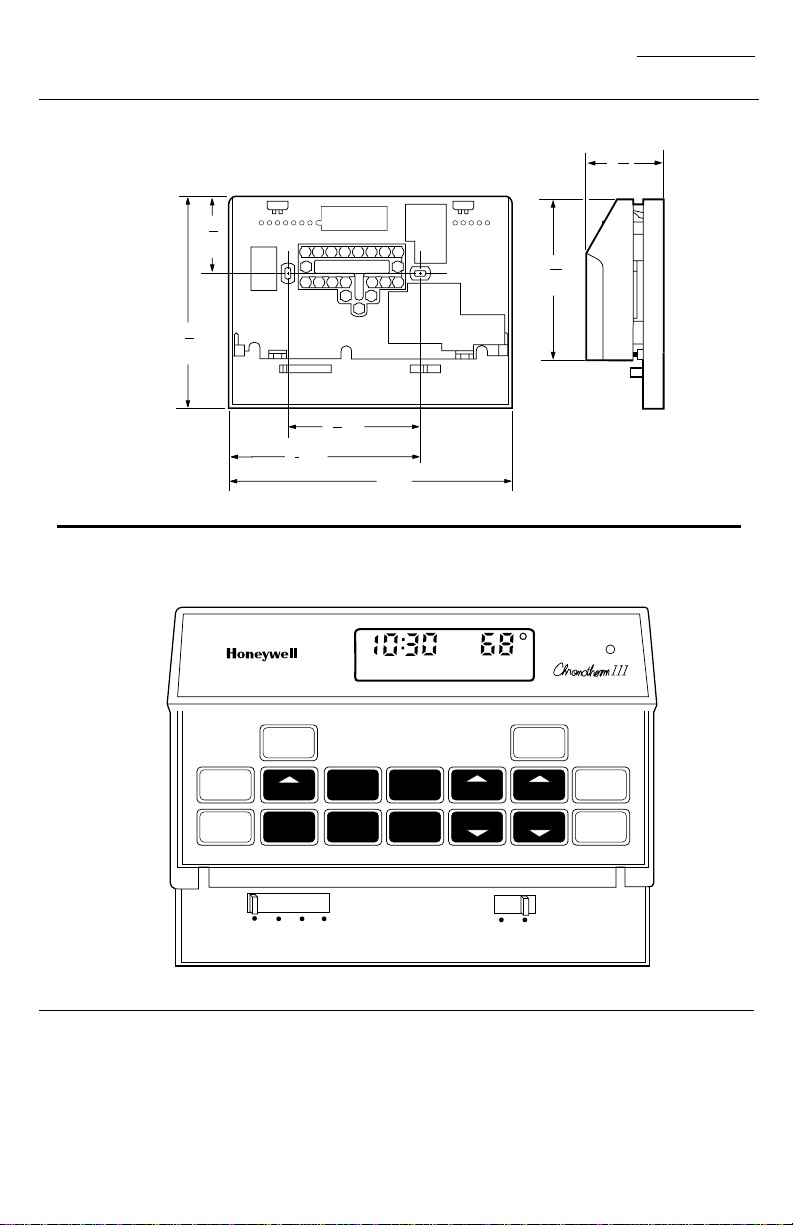

TABLE 1—TRADELINE MODELS.

Thermostat

Model

Number

T8624C 2 1 Auto HEAT-AUTO-COOL-OFF ON-AUTO Multistage

T8624D 2 2 Auto HEAT-AUTO-COOL-OFF ON-AUTO Multistage

T8624D 2 2 Manual HEAT-OFF-COOL ON-AUTO Multistage

Stages Changeover Switching

Heat Cool

Type

SETPOINT RANGE: 45° F to 88° F [7° C to 31° C].

CALIBRATION: Self-calibrating thermostat and

thermometer to ±1° F.

SHIPPING TEMPERATURE: -20° F to +120° F [-29° C

to +49° C].

CYCLES PER HOUR ADJUSTMENT:

Heating: First stage of 2-stage heat models—fixed at

3 cph. Second stage of 2-stage heat models or heat

stage of single-stage heat models—factory-set at

6 cph; field-adjustable to 1,3,6 or 9 cph.

Cooling: Factory-set at 3 cph (not field adjustable);

minimum off-time of five minutes.

FINISH: Beige matte with decorative brushed metal

faceplate or Premier White™.

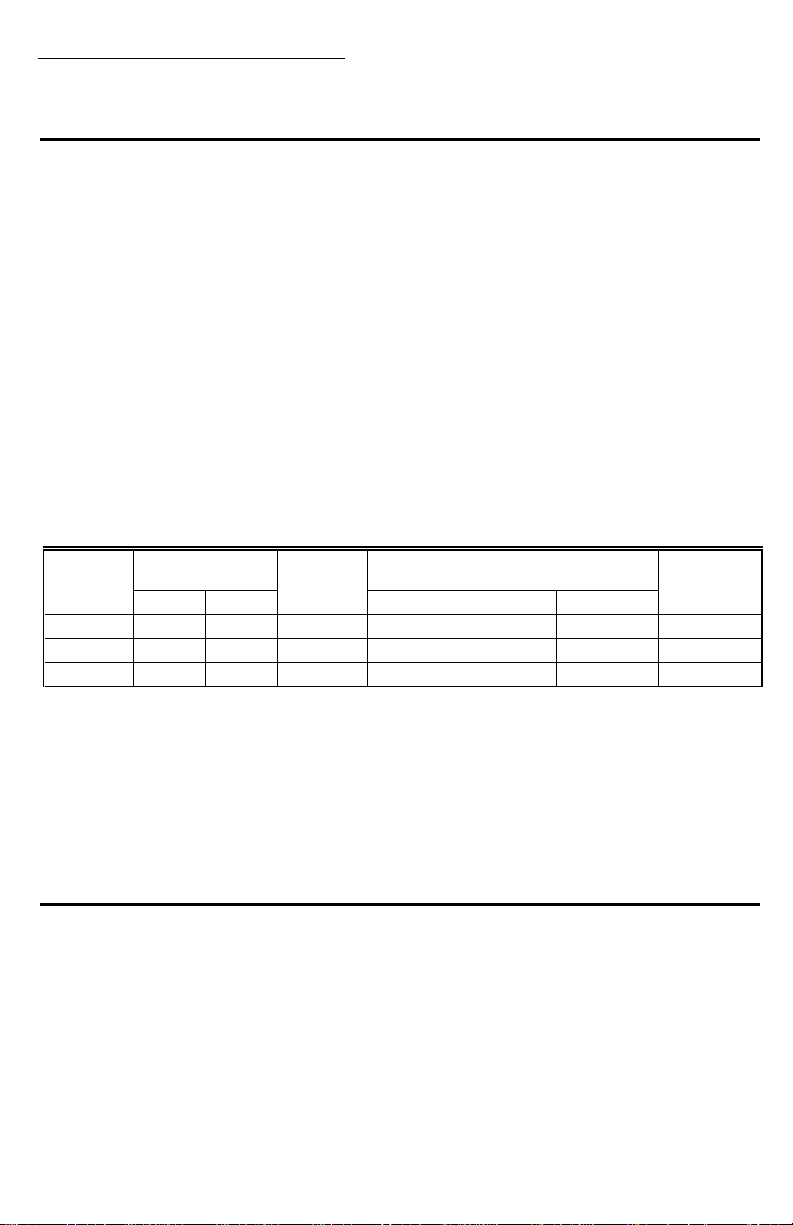

DIMENSIONS: Thermostat (mounted on subbase)—7 in.

[178 mm] long, 5-5/16 in. [135 mm] high, 1-3/4 in.

[44 mm] deep. See Fig. 1 for subbase dimensions.

TYPICAL KEYPAD: See Fig. 2.

ACCESSORIES:

TG586A Locking Cover.

TG512 Versaguard™ Universal Thermostat Guard.

System Fan

Application

Ordering Information

When purchasing replacement and modernization products from your TRADELINE® wholesaler or your distributor, refer to the

TRADELINE Catalog or price sheets for complete ordering number, or specify—

1. Model number. 3. System, fan switching desired.

2. Number of heat and cool stages desired. 4. Application.

If you have additional questions, need further information or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Home and Building Control Sales Office (check white pages of your phone directory).

2. Home and Building Control Customer Satisfaction

Honeywell Inc., 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386 (612) 951-1000

In Canada—Honeywell Limited/Honeywell Limitee, 740 Ellesmere Road, Scarborough, Ontario M1P 2V9. International

Sales and Service offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France, Germany,

Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

2

Page 3

Fig. 1—T8624 Subbase mounting dimensions in in. [mm].

13

1

16

[46]

5

5

16

[135]

5

3 [83]

16

3

4 [121]

4

M5181A

7 [179]

Fig. 2—Typical thermostat keypad.

4

[104]

T8624C,D

SPECIFICATIONS

31

1

32

[50]

3

32

SET

PRESENT

DAY/TIME

HOLD

TEMP

PROGRAM

HEAT/COOL

HEAT AUTO

RUN

DAY

SET

COOL

AM

WED

LEAVE

PERIOD

WAKE

SLEEP

OFF

LEAVE

RETURN

HEAT ON

TEMPERATURE

TIME

AHEAD

BACK COOLER

ON AUTO

ROOM

PRESENT

SETTING

WARMER

SYSTEM

SKIP

NEXT

PERIOD

CHANGE

TO LAST

PERIOD

FAN

M2998

3 68-0134

Page 4

T8624C,D

SELECTION/APPLICATION

Selection/Application

The T8624 Thermostat uses the latest microelectronic design and control technology to provide home

and building owners with the highest level of comfort

available and optimal energy savings in a package that is

easy to use and easy to live with.

The following section is a guide to selection and

application of the best thermostat to meet individual

needs.

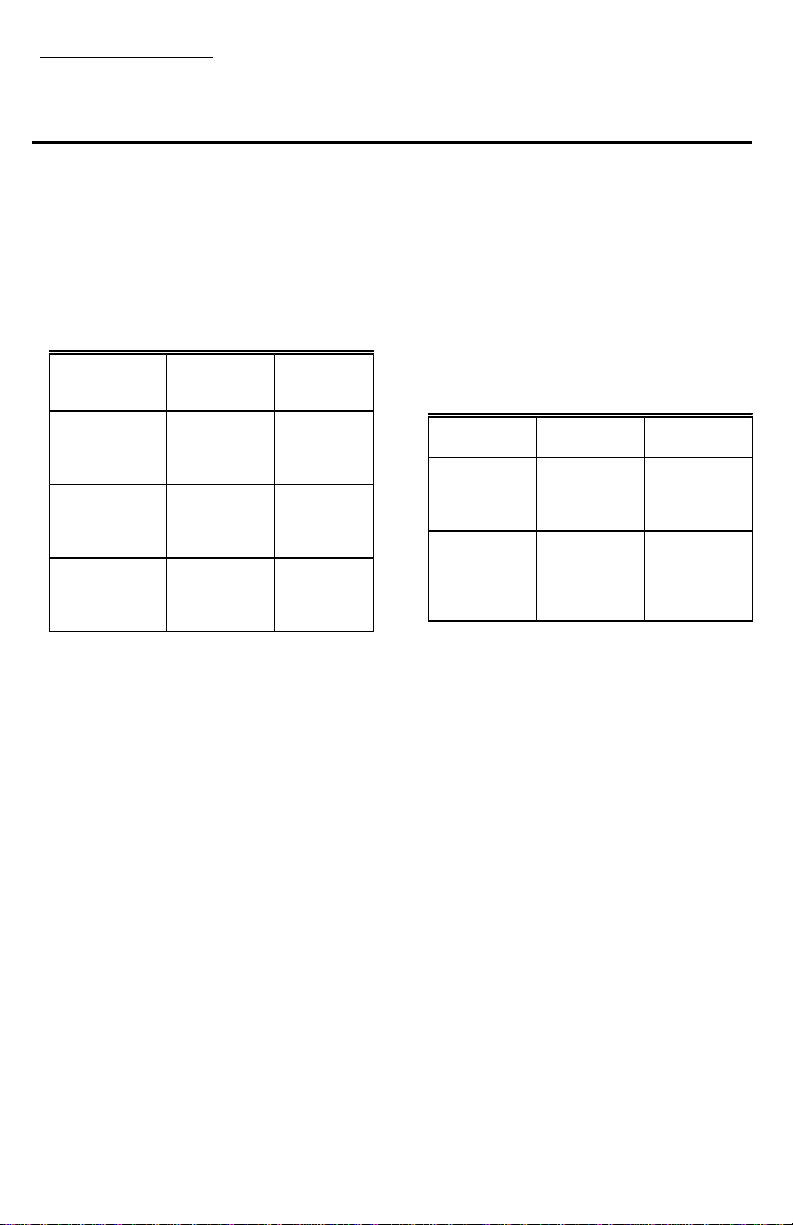

PROGRAMMING

Does the thermostat selected accommodate the

customer’s daily schedule, lifestyle or work schedule?

Device Programming

T8624C,D 5-1-1 (Mon-Fri,

Sat, Sun)

T8621A,C,D 7-day (each

day different)

T8600,01,02,03* 5-1-1 (Mon-Fri,

Sat, Sun)

The choices are:

*Model not currently available to control multistage

equipment.

IF NEW CONSTRUCTION APPLICATION, CONSIDER:

• Equipment type (see manufacturer specifications).

—Staging required.

—System switching required.

—Fan switching required.

• Control wiring—number of conductors required

to operate equipment and thermostat.

IMPORTANT: The T8624 requires an additional con-

ductor to transformer common to provide continuous 24V power for thermostat operation.

IF RETROFIT/REPLACEMENT APPLICATION,

CONSIDER:

• Equipment requirements.

— Staging (heat stages, cool stages).

— System switching (manual: HEAT-OFF-COOL;

automatic: HEAT-AUTO-COOL-OFF). Emergency heat for heat pump application not provided on T8624.

Daily

Temperature

Selection

4 heat and

4 cool

4 heat and

4 cool

4 heat and

4 cool

programmming and the override features that will best

suit the application? The choices are:

SINGLE-STAGE HEAT PUMPS

one option is to use a T8624C or D (see Fig. 8).

ing programmable thermostat. The T8624D is a two-

stage heating, two-stage cooling programmable thermostat. What both thermostats have in common is separate

W1 and W2 (first and second stage heat) terminals. In

both cases, the W1 can be used for changeover in heating.

stage heating and first-stage cooling energized through

the Y terminal), simply jumper Y1 and W1.

cause the compressor to cycle on and off during recovery.

cool are set for hot water systems, the second stage of the

T8624 must be adjusted. Turn the cycle rate adjustment

screws to the hot water setting on both the T8624C and

D to achieve the cycle rate appropriate for heat pumps.

normally closed relay.

stage heat pumps.

— Fan switching; does fan come on automatically

from thermostat on cooling only (typical gas/

oil heating), or on call for cool and heat (typical

electric heat with single speed fan)?

• Existing wiring

— Are there enough conductors to operate the equip-

ment and the thermostat? Can a new cable be

pulled?

IMPORTANT: The T8624 requires an additional con-

ductor to transformer common to provide continuous 24V power for thermostat operation.

SECURITY

Does the thermostat selected provide access to

Access

Free access to

programming

and adjustment/

override.

Restricted

access to

device.

If home/building owner has a single-stage heat pump,

The T8624C is a two-stage heating, one-stage cool-

For single-stage compressor applications (both first-

Note that the recovery algorithm of the T8624 may

Although the cycle rate for the first stages of heat and

If changeover is utilized in the cooling mode, apply a

The above application should be used only on single-

Typical

Application Device

Home or

owner-occupied

commercial

building.

Public

building.

T8624A,C,D

T8624 with

TG512 Locking

Guard or

TG586A

Locking Cover.

4

Page 5

RECYCLING NOTICE

If this control is replacing a control that contains

mercury in a sealed tube, do not place your old control in

the trash. Contact your local waste management authority for instructions regarding recycling and the proper

disposal of your old control.

If you have any questions, call Honeywell Inc. at 1800-468-1502.

COMPATIBILITY

The T8624 Thermostats will replace most heating/

cooling system thermostats. As long as ac power is

continuously available to the transformer, the thermostat

will be compatible with any low-volt control system.

IMPORTANT: The T8624 requires an additional con-

ductor to transformer common to provide continuous 24V power for thermostat operation.

WHEN INSTALLING THIS PRODUCT…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given on the product to make

sure the product is suitable for your application.

3. Installer must be a trained, experienced service

technician.

4. Allow thermostat to warm to room temperature

before operating.

5. After installation is complete, check out product

operation as provided in these instructions.

T8624C,D

INSTALLATION

Installation

or disconnects. Remove any existing wallplate or subbase from wall. To avoid miswiring later, label each

wire color with the letter or number on the wiring terminal as the wire is removed.

NEW INSTALLATION

Run cable to a hole at the selected wall location for the

thermostat, and pull about 3 in. [76 mm] of wire through

the opening. Color-coded, 18-gauge thermostat cable with

at least one conductor for each wiring terminal is recommended. Good service practice recommends selecting

cable with one or two more conductors than the immediate application requires.

MOUNTING SUBBASE

IMPORTANT: Before mounting, set the system switch

to the OFF position.

NOTE: The subbase does not require leveling for proper

operation, but only for appearance.

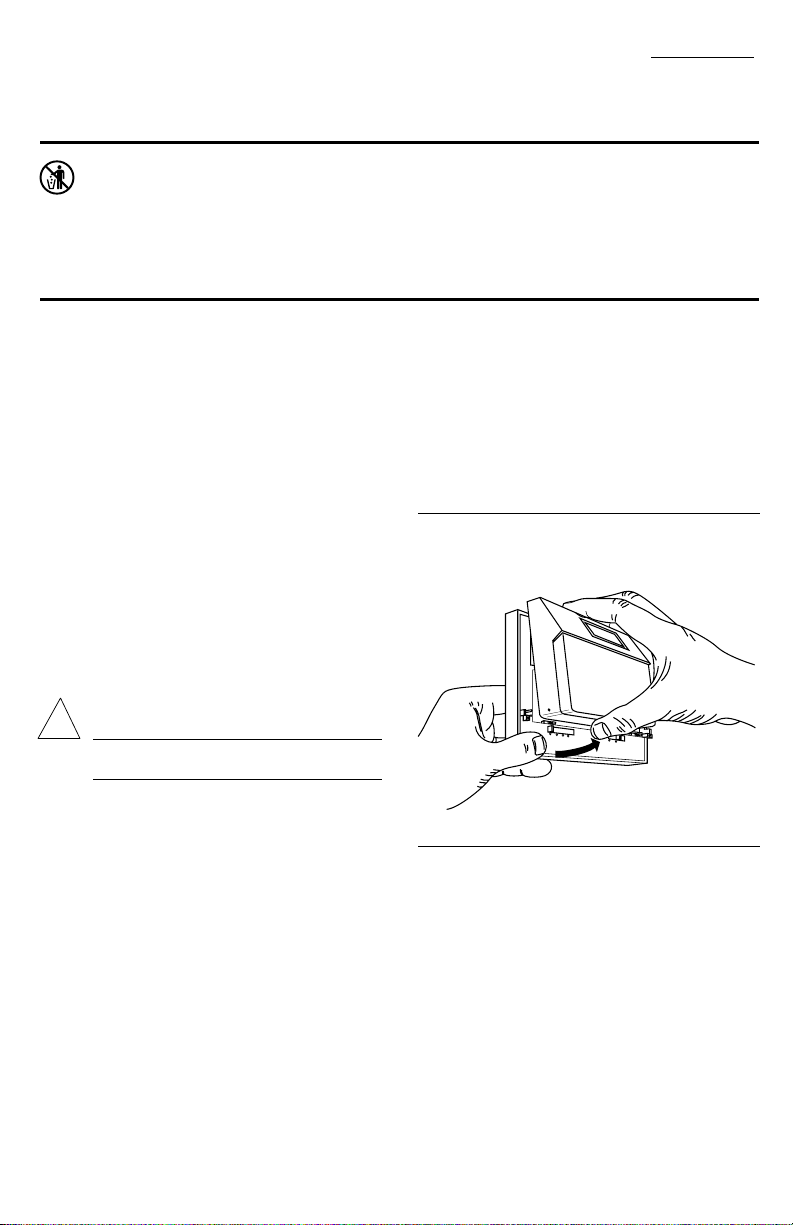

Fig. 3—Removing thermostat from subbase.

CAUTION

!

Disconnect power supply to prevent electrical

shock or equipment damage.

LOCATION

Install thermostat and subbase about 5 ft [1.5m] above

the floor in an area with good air circulation at room

temperature.

Do not install thermostat where it may be affected by:

— drafts or dead spots behind doors, in corners or

under cabinets.

— hot or cold air from ducts.

— radiant heat from sun or appliances.

— concealed pipes and chimneys.

— unheated (uncooled) areas such as an outside wall

behind the thermostat.

REPLACING AN EXISTING THERMOSTAT

Turn off thermostat power at furnace or boiler. A twotransformer system may require turning off two switches

H

E

A

T

A

U

T

O

C

O

O

L

O

F

F

F

A

N

O

N

A

U

T

O

M 844

Remove thermostat from subbase (Fig. 3).

Mount the subbase directly onto the wall with the

screws and anchors included. If drywall construction,

use plastic anchors. Use the subbase as a template, and

with a pencil, mark the two mounting screw positions

(Fig. 4). Use

3/16 in. bit to drill holes for anchors. Gently tap anchors

into holes until they are flush with the wall surface.

Thread wires through the center opening of the subbase.

Then mount the subbase using the two screws provided.

Gently tighten the screws, level the top surface of the

subbase, and securely tighten the screws.

5 68-0134

Page 6

T8624C,D

INSTALLATION

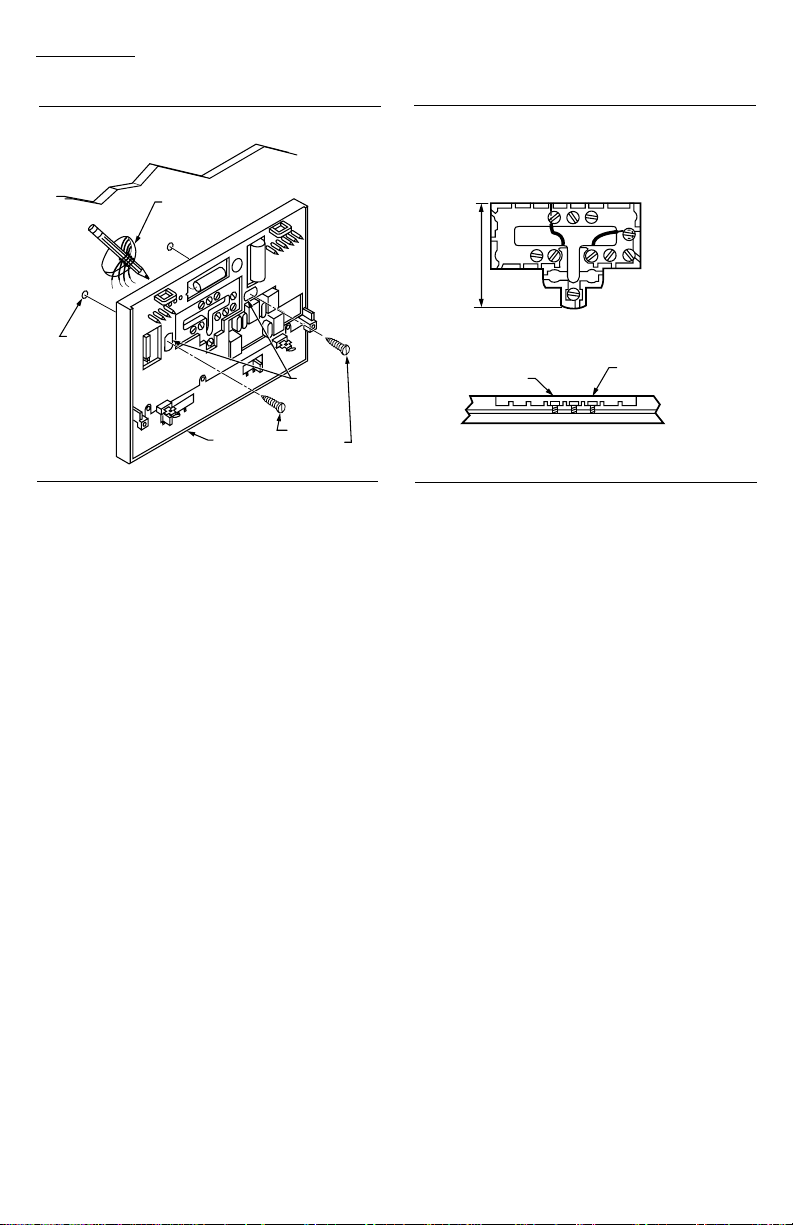

Fig. 4—Mounting subbase on wall.

WALL

WIRES THROUGH

WALL OPENING

WALL

ANCHORS

(2)

MOUNTING

HOLES

SUBBASE

MOUNTING

SCREWS (2)

M846

WIRING

All wiring must comply with local electrical codes

and ordinances.

Disconnect power before wiring to prevent electrical

shock or equipment damage.

The shape of the terminal barrier permits insertion of

straight or conventional wraparound wiring connections.

Either method is acceptable.

Push excess wire back into the hole, and plug the hole

with nonhardening caulk, putty or insulation to prevent

drafts from affecting thermostat operation.

NOTE: Restrict wiring to the recessed area surrounding

the terminals (Fig. 5) to assure thermostat/subbase

contact.

Refer to Figs. 6-8 for typical hookups of subbase and

thermostat.

ADJUSTING CYCLE RATE

To customize the thermostat cycling performance to

various types of heating equipment, cycle rate adjustment screws are provided on the back of the thermostat

to provide optimum room temperature control.

NOTE: Most applications will not require a change in

cycle rate.

The room air temperature will normally vary slightly

from the comfort temperature setting with the cycling of

the furnace or air conditioner.

The heating cycle rate of this thermostat is factory-set

for gas/oil warm air heating. The cooling cycle rate is

factory-set and cannot be adjusted. The heating cycle

rate can be adjusted by turning one or both cycle rate

adjustment screws located on the back of the thermostat.

Fig. 5—Restrict wiring to recessed area

surrounding terminals.

FOR STRAIGHT

INSERTION –

STRIP 5/16 in. [8 mm]

FOR WRAPAROUND –

RESTRICT

WIRING TO

THIS AREA

FRONT VIEW OF

TERMINAL AREA

WIRING TO BE BELOW

THIS SURFACE

CROSS-SECTIONAL VIEW OF

TERMINAL AREA

STRIP 7/16 in. [11 mm]

TOP SURFACE

OF SUBBASE

M 847

In multistage heat systems, the cycle rate adjustment

applies to the highest stage of heat only. Screws should

be backed out about one-half to one turn, or be turned in

until tight. See Fig. 9.

TIME/TEMPERATURE CONVERSION

(SOME MODELS)

The display readout may be converted between 12

and 24 hour clock or °C and °F using screws 2A and 2B

as indicated in Fig. 9.

FAN OPERATION OPTION SWITCH

(SELECT MODELS ONLY)

Select models include a fan operation option switch

on the subbase that is visible before the thermostat is

mounted on the subbase. The switch should be in electric

heat position for electric heating systems that do not

have independent fan control.

INSTALLING BATTERIES

Three AAA alkaline batteries are included to provide

backup to prevent program loss in case of power outage.

Install batteries in back of thermostat as shown in Fig.

10.

Without battery backup, the program will remain

about 30 seconds in event of power loss.

IMPORTANT: When batteries are first installed, the

display will flash 1:00 PM and 32°. The temperature will stay at 32

°

F until the thermostat is

powered from the system wiring.

When the batteries are low, the display will flash

REPL BAT. Homeowner will have 20-30 seconds to

install new batteries after removing old batteries from

back of thermostat. After 20-30 seconds, it will be necessary to reprogram. REPL BAT indication will disap-

6

Page 7

T8624C,D

INSTALLATION

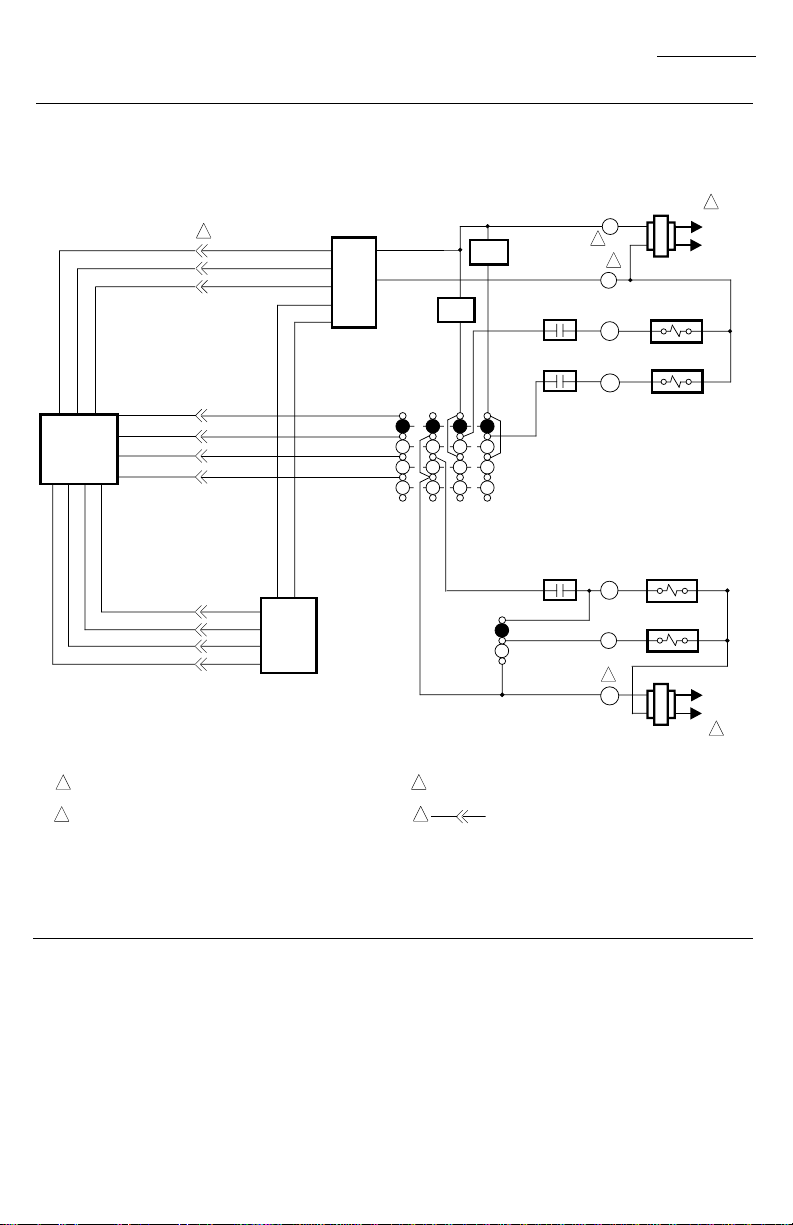

Fig. 6—T8624C 2-stage heat/1-stage cool thermostat with HEAT-AUTO-COOL-OFF system and AUTO-ON

fan switching.

HEATING

TRANSFORMER

R

2

3

C

W1

W2

Y1

G

2

RC

HEAT RELAY 1

HEAT RELAY 2

COOLING

CONTACTOR

FAN RELAY

COOLING

TRANSFORMER

THERMOSTAT

LOGIC CIRCUIT

4

POWER

SUPPLY

SYSTEM

SWITCH

SUBBASE

LOGIC/

CONTROL

CIRCUIT

HIGH

LIMIT

HIGH

LIMIT

FAN

SWITCH

HEAT 1

HEAT 2

HEAT

AUTO

COOL

OFF

COOL

AUTO

ON

1

L1

(HOT)

L2

L1

(HOT)

L2

1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

2

FOR SINGLE TRANSFORMER SYSTEM JUMPER R AND RC.

3

NOMINAL 24 Vac POWER MUST BE PRESENT BETWEEN R AND C FOR

THERMOSTAT OPERATION.

4

DENOTES THERMOSTAT TO SUBBASE INTERCONNECTION.

M5233

7 68-0134

Page 8

T8624C,D

INSTALLATION

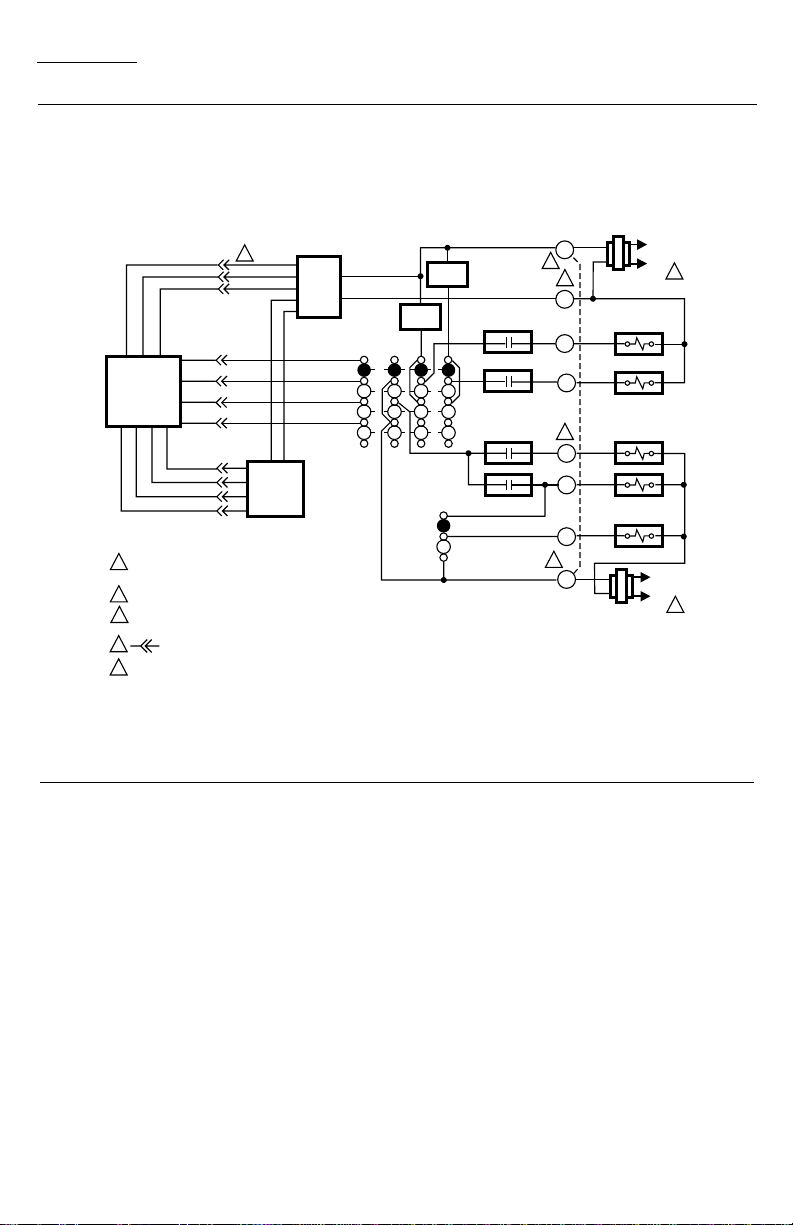

Fig. 7—T8624D 2-stage heat/2-stage cool thermostat with HEAT-AUTO-COOL-OFF system and AUTO-ON

fan switching.

4

POWER

SUPPLY

THERMOSTAT

LOGIC

CIRCUIT

SUBBASE

LOGIC/

CONTROL

CIRCUIT

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

FOR SINGLE TRANSFORMER SYSTEM, JUMPER R AND RC.

2

NOMINAL 24 Vac POWER MUST BE PRESENT BETWEEN

3

R AND C FOR THERMOSTAT OPERATION.

DENOTES THERMOSTAT TO SUBBASE INTERCONNECTION.

4

AVAILABLE ON T8624D MODELS ONLY.

5

HEAT

AUTO

COOL

OFF

SYSTEM

SWITCH

HIGH

LIMIT

FAN

SWITCH

AUTO

R

HEAT 1

HEAT 2

COOL 2

COOL 1

2

W1

2

3

C

W2

5

Y2

Y1

G

RC

COOLING

TRANSFORMER

HIGH

LIMIT

ON

L1

(HOT)

L2

HEATING

TRANSFORMER

HEAT RELAY 1

HEAT RELAY 2

COOLING

CONTACTOR 2

COOLING

CONTACTOR 1

FAN RELAY

L1

(HOT)

L2

M3765

1

1

8

Page 9

T8624C,D

INSTALLATION

Fig. 8—T8624D 2-stage heat/2-stage cool thermostat with HEAT-OFF-COOL system and AUTO-ON fan

switching; auto fan on heat and cool; convertible to auto fan on cool only.

L1

(HOT)

1

HEATING

TRANSFORMER

HEAT 1

HEAT 2

COOL 2

R

4

C

W1

W2

B

HEATING DAMPER OR

CHANGEOVER RELAY

COOLING DAMPER OR

CHANGEOVER RELAY

O

Y2

Y1

G

RC

COOLING

TRANSFORMER

STAGE 1

HEAT RELAY

STAGE 2

HEAT RELAY

STAGE 2

COOLING RELAY

STAGE 1

COOLING RELAY

FAN RELAY

3

1

5

THERMOSTAT

LOGIC CIRCUIT

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

FOR GAS OR OIL APPLICATIONS OR ELECTRIC HEAT APPLICATIONS

2

WHERE THE FAN OPERATION IS CONTROLLED INDEPENDENTLY OF

THE THERMOSTAT (AUTO FAN OPERATES WITH Y1 ONLY), TWO

TRANSFORMERS MAY BE USED. SET SWITCH TO NONELECTRIC

POSITION.

SUBBASE

LOGIC/

CONTROL

CIRCUIT

POWER

SUPPLY

3

ELECTRIC

NON-ELECTRIC

2

HEAT

OFF

COOL

FOR ELECTRIC HEAT APPLICATIONS (AUTO FAN OPERATES WITH W1

3

AND Y1), USE ONLY ONE TRANSFORMER; JUMPER R AND RC. SET

SWITCH TO ELECTRIC POSITION.

NOMINAL 24 VAC POWER MUST BE PRESENT BETWEEN R AND C FOR

4

THERMOSTAT OPERATION.

5

HIGH

LIMIT

FAN

OPERATION

SWITCH

SYSTEM

SWITCH

FAN

SWITCH

AUTO

ON

HIGH

LIMIT

COOL 1

DENOTES THERMOSTAT TO SUBBASE INTERCONNECTION.

L1

(HOT)

L2

L2

M1016D

9 68-0134

Page 10

T8624C,D

INSTALLATION

Fig. 9—Cycle rate adjustment.

1A

1B

1

2A 2B

CYCLES

SYSTEM

1A

1B

OUT 1/2

GRAVITY

AIR/WATER

HOT

WATER

GAS/OIL

WARM AIR

ELECTRIC

WARM AIR

1 SCREWS 2A, 2B AVAILABLE ON SOME MODELS ONLY.

OUT 1/2

TO 1 TURN

TO 1 TURN

OUT 1/2

TO 1 TURN

IN IN

(FACTORY SETTING)

OUT 1/2

IN

TO 1 TURN

IN

PER HOUR

1

3

6

9

TIME/TEMP

DISPLAY

24 HR

12 HR

o

C

o

F

2A

IN

OUT 1/2

TO 1 TURN

2B

IN

OUT 1/2

TO 1 TURN

M311A

pear when thermostat is mounted back on the subbase.

IMPORTANT: For proper thermostat operation, al-

ways replace dead batteries with new alkaline

batteries. We recommend Energizer® batteries.

If batteries are completely dead, the display will go

blank when the thermostat is removed from the subbase.

Fig. 10—Battery placement.

POWER OUTAGES

Backup batteries will hold the programming and keep

the display on during most power outages. Once the

power is restored, the system will resume normal operation.

After replacing the batteries, reprogramming will be necessary.

BATTERY PLACEMENT

(NOTE CORRECT PLUS

AND MINUS DIRECTION)

M 372A

If the display goes off when power is lost, either the

backup batteries need to be replaced or are not installed.

When power is restored, the display will flash 1:00 PM

as a reminder to reprogram.

MOUNTING THE THERMOSTAT

With system switch set to OFF, hang the thermostat

on the tabs at the top of the subbase (Fig. 11A). Swing

down and press on lower edge until thermostat snaps in

place (Fig. 11B). Open cover and tighten the captive

mounting screws (Fig. 11C).

SETTING DAY AND TIME

Restore 24V power to the thermostat. When power is

applied to the thermostat, the display will read 1:00 PM

and room temperature. It will go off for a few seconds,

then begin to flash on and off. Set present day and time.

SET

PRESENT

Press .

DAY/TIME

Press to set the current day. Each press of

the DAY key advances the display one day.

DAY

Press TIME or to set the current time.

AHEAD

BACK

If the display will not come on:

— Check the mounting of the thermostat to the sub-

base. If loose or misaligned, remove thermostat

and reinstall on the subbase, making sure it is

firmly attached.

— Check to see that heat or cool system power is on.

— Check voltage between R and C; it should be 24 to

30 Vac.

10

Page 11

Fig. 11—Mounting thermostat on subbase.

T8624C,D

INSTALLATION • CHECKOUT

A.

N

A

F

O

T

U

A

N

O

F

F

O

L

O

O

C

O

T

U

A

T

A

E

H

C.

P

R

D

A

H

T

HEATING

Move the system switch to HEAT and the fan switch

to AUTO. Press WARMER key until the setting is about

10° F [6° C] above room temperature. Heating should

start (both stages if multistage), and the fan should run

(may be a short delay on forced air systems). Press

COOLER key until the setting is about 10° F [6° C]

below room temperature. The heating equipment should

shut off, followed by the fan.

NOTE: On an AUTO changeover thermostat, the cool-

ing temperature must be set at least 3° F [2° C] above

the heating temperature, or display will flash.

COOLING

CAUTION

!

Do not operate cooling if outdoor temperature

is below 50° F [10° C]. Refer to manufacturer

recommendations.

N

O

M

N

R

TU

E

R

R

U

N

P

R

O

G

R

A

M

P

E

R

IO

D

S

E

T

E

S

E

N

T

W

A

K

E

L

E

A

V

E

D

A

Y

Y

/T

IM

E

O

L

D

S

E

T

S

L

E

E

P

R

E

T

U

R

E

M

P

N

H

E

A

T

/

C

O

O

L

B.

PM

MON

RETURN

HEAT ON

SYSTEM

M

P

N

O

T

A

E

H

T

E

M

P

E

R

A

T

U

R

E

P

R

E

S

E

N

T

S

E

T

T

IN

G

T

I

M

E

S

K

IP

N

E

X

T

A

H

E

A

D

W

A

R

M

E

R

P

E

R

IO

D

C

H

A

N

G

E

B

A

C

K

C

O

O

L

E

R

T

O

L

A

S

T

P

E

R

I

O

D

Checkout

Move the system switch to COOL and the fan switch

to AUTO. Press COOLER key until the setting is about

10° F [6° C] below room temperature. The cooling

equipment and fan should start (both stages if multistage). Press WARMER key until the setting is about

10° F [6° C] above room temperature. The cooling

equipment and fan equipment should stop.

NOTE: On an AUTO changeover thermostat, the heat-

ing temperature must be set at least 3° F [2° C] below

the cooling temperature, or display will flash.

FAN

Move the system switch to OFF, and the fan switch to

ON. The fan should run continuously. When the fan

switch is in the AUTO position, the fan operates directly

with the thermostat call for cooling and also with the

SYSTEM

A

U

T

O

M3764

NOTE: When cooling setting is changed, thermostat

will wait up to five minutes before turning on the

cooling equipment. This delay is to protect the compressor.

11 68-0134

Page 12

T8624C,D

CHECKOUT

REPL

AM

BAT

This

Key

CHANGE

TO LAST

PERIOD

SKIP

NEXT

PERIOD

PRESENT

SETTING

PRESENT

SETTING

PM

Look For This Response

Key

Down Key Released

07 Blank

15 Blank

15 1st stage cooling,

SUN MON TUE WED THU FRI SAT COOL ON HEAT ON

WAKE LEAVE RETURN SLEEP TEMPORARY

System Press

Switch

Position

OFF 03 Blank

COOL or

AUTO

(with fan in

AUTO) 15 2nd stage cooling

PRESENT

SETTING

PRESENT

SETTING

PRESENT

SETTING

15 2nd stage cooling

15 1st stage cooling,

SET

PT

M410C

RUN

PROGRAM

fan and SYSTEM

LED on.

also on.

off.

fan and SYSTEM

LED off.

NOTE: If single-stage cooling system, press key twice

instead of four times; once to turn on cooling, fan

and SYSTEM LED, second time to turn off.

(continued)

System Press

Switch

Position

OFF 06 Blank

(CHECK

EACH

This

Key

WARMER

COOLER

AHEAD

LEAVE

RETURN

WAKE

Look For This Response

Key

Down Key Released

02 Blank

05 Blank

BACK

04 Blank

01 Blank

00 Blank

12 See note A

A

POSITION)

OFF 08 Blank

SLEEP

13 Microprocessor

mask no. and

revision no.

09 Blank

14 Blank

14 1st stage heating

and SYSTEM

LED on.

14 2nd stage heating

also on.

14 2nd stage heating

off.

14 1st stage heating

and SYSTEM

HEAT or

AUTO

DAY

SET

HEAT/COOL

SET

PRESENT

DAY/TIME

SET

PRESENT

DAY/TIME

1

SET

PRESENT

DAY/TIME

SET

PRESENT

DAY/TIME

SET

PRESENT

DAY/TIME

LED off.

NOTE: If single-stage heating system, press key twice

instead of four times; once to turn on heating and

SYSTEM LED, second time to turn off.

OFF 10 Blank

HOLD

TEMP

RUN

PROGRAM

11 Normal operating

display.

END SELF-TEST

12

Page 13

T8624C,D

CHECKOUT

Cycle Rate Setting (cph at 50% on

time for stage 1 on 1-heat models,

First Digit

stage 2 on 2-heat models)

01

13

29

36

Third

Digit

Manual or Auto

Changeover

System Switch

Position

0 Manual HEAT or OFF

1 Auto HEAT or OFF

3 Auto AUTO

4 Manual COOL

5 Auto COOL

Second

Digit

Stages of

Heat Cool

021

122

211

312

402

510

620

M5734

Fourth

Digit Degrees

Clock

(hrs)

System Switch

Position

0 F 12 COOL, AUTO

or OFF

1 F 24 COOL, AUTO

or OFF

2 F 12 HEAT

3 F 24 HEAT

4 C 12 COOL, AUTO

or OFF

5 C 24 COOL, AUTO

or OFF

6 C 12 HEAT

7 C 24 HEAT

13 68-0134

Page 14

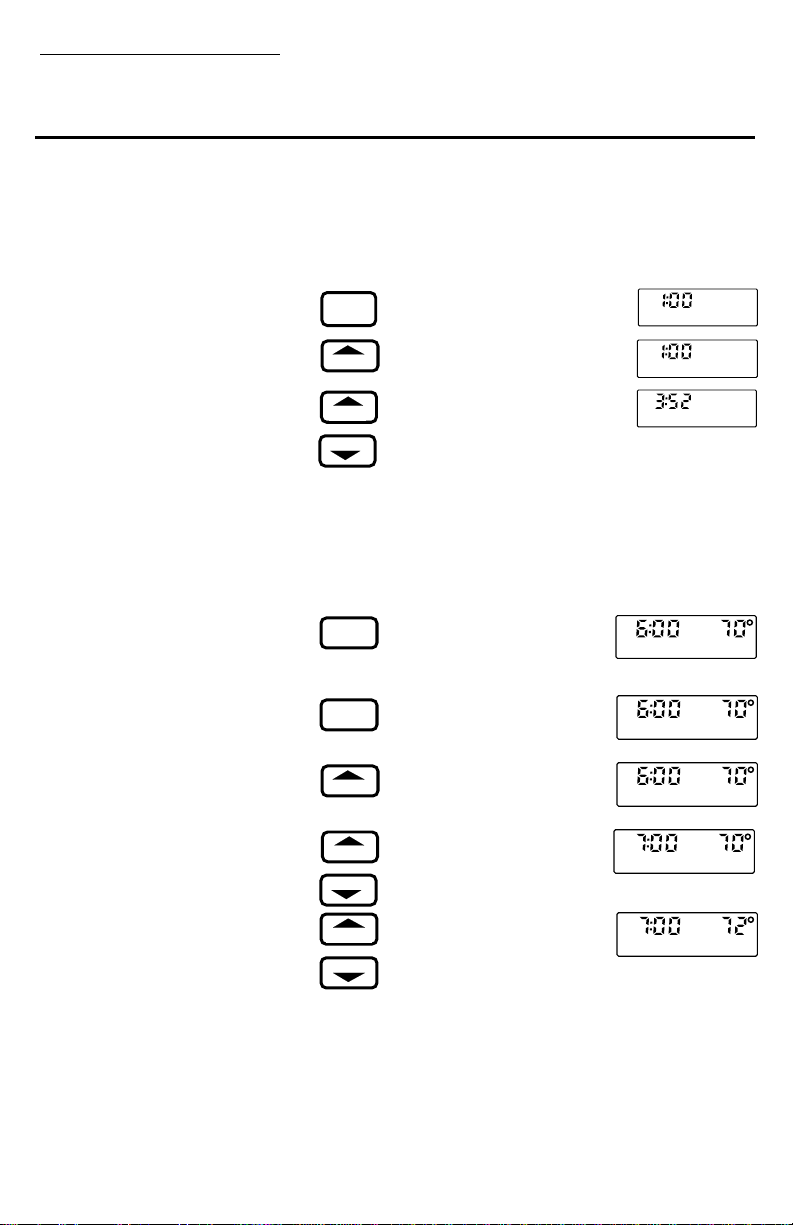

MON

PM

M5015

TUE

M5016

PM

T8624C,D

PROGRAMMING THE THERMOSTAT

Programming the Thermostat

IMPORTANT: With Adaptive Intelligent Recovery™,

program the times for when the homeowner wants

the home comfortable. The thermostat will decide

how early to begin the temperature changes.

STEP 1

SET THE CURRENT DAY AND

TIME

This thermostat can be programmed either

on the wall or in hand. SEE PAGE 5 TO

SET

PRESENT

DAY/TIME

DAY

FIND OUT HOW TO REMOVE THE

THERMOSTAT FROM THE SUBBASE.

Always press the keys with fingertip or

similar blunt tool. Sharp instruments like a

AHEAD

BACK

pen or pencil point can damage the keyboard.

NOTE: Check the glossary, page 22, for

STEP 2

SET THE PROGRAM SCHEDULE

AND HEATING TEMPERATURES

WAKE

Before Beginning…

The schedule form on page 22 provides the

homeowner an opportunity to plan the

schedule.

SET

HEAT/COOL

Now…

Start by programming the WAKE time

and temperature for weekdays.

DAY

The thermostat requires a program for

WAKE. You can program LEAVE, RETURN and SLEEP or not, as desired.

AHEAD

BACK

NOTE: Some models will show 32° F instead of the

current temperature, indicating the thermostat is operating on backup batteries until the thermostat is

mounted on the wallplate and the system is powered.

definitions of unfamiliar

words.

Press and release. The display

shows 1:00 PM MON.

Press and hold until the current

day appears in the display.

Press and hold until the current

PM

TUE

M5017

time appears in the display. Be

sure AM or PM appears as desired.

Press and release. Note that

the display shows WAKE and

the preprogrammed time and

temperature.

If the display reads COOL,

press and release to switch to

HEAT.

If display reads SAT or SUN,

press and hold until MON

TUE WED THU FRI appears.

Press and hold until the display shows the desired starting time.

WAKE

WAKE

WAKE

WAKE

AM

MON TUE WED THU FRI ON HEAT

M5018

AM

MON TUE WED THU FRI ON HEAT

M5018

AM

MON TUE WED THU FRI ON HEAT

M5018

AM

MON TUE WED THU FRI ON HEAT

M5019

SET

PT

SET

PT

SET

PT

SET

PT

WARMER

COOLER

Press and hold until the display shows the desired temperature.

WAKE

AM

MON TUE WED THU FRI ON HEAT

M5020

SET

PT

If the display starts to blink while holding down TEMPERATURE WARMER or COOLER, the setting limit

has been reached. If the thermostat can switch automatically between heating and cooling, the heating temperature must be at least three degrees below the air conditioning temperature. For example, if the cooling setting

14

Page 15

T8624C,D

PROGRAMMING THE THERMOSTAT

is 75° F, the maximum heating setting is

72° F.

Program the LEAVE time and temperature, if desired.

NOTE: The LEAVE, RETURN or SLEEP

program may be canceled by holding

down the period key until the time and

Press and hold until the display shows the

desired temperature.

Program the RETURN time and temperature, if desired.

LEAVE

AHEAD

BACK

WARMER

COOLER

RETURN

AHEAD

BACK

WARMER

COOLER

SLEEP

AHEAD

BACK

WARMER

COOLER

temperature disappear from

the display.

MON TUE WED THU FRI ON HEAT

LEAVE

Press and release. The display

shows LEAVE, but no time

or temperature.

AM

MON TUE WED THU FRI ON HEAT

LEAVE

Press and hold until the display shows the desired starting time.

AM

MON TUE WED THU FRI ON HEAT

LEAVE

Press and release. The display

shows RETURN, but no time

or temperature.

Press and hold until the display shows the desired starting time.

Press and hold until the display shows the desired tem-

MON TUE WED THU FRI ON HEAT

RETURN

PM

MON TUE WED THU FRI ON HEAT

RETURN

PM

MON TUE WED THU FRI ON HEAT

RETURN

perature.

Program the SLEEP time and temperature, if desired.

Press and release. The display shows SLEEP and the

PM

MON TUE WED THU FRI ON HEAT

SLEEP

pre-programmed time and

temperature.

Press and hold until the dis-

PM

MON TUE WED THU FRI ON HEAT

SLEEP

play shows the desired starting time.

PM

MON TUE WED THU FRI ON HEAT

SLEEP

M5021

M5022

M5023

M5024

M5025

M5026

M5027

M5060

M5028

SET

PT

SET

PT

SET

PT

SET

PT

SET

PT

SET

PT

SET

PT

SET

PT

SET

PT

Press and hold until the display shows the

desired temperature.

to set the time and the WARMER/COOLER

keys to set the temperature.

DAY

Set the SATURDAY schedule. Use the same procedure

as for weekdays.

WAKE

Press and release until SAT ap-

LEAVE

pears on the display.

SLEEP

Press WAKE, LEAVE, RE-

RETURN

TURN or SLEEP to select the

AHEAD

BACK

time period.

WARMER

COOLER

Use the AHEAD/BACK keys

DAY

Set the SUNDAY schedule.

Use the same procedure as for

weekdays.

SUN ON HEAT

15 68-0134

PM

SLEEP

PM

SLEEP

SAT ON HEAT

M5029

M5030

SET

PT

SET

PT

Page 16

T8624C,D

SUN COOL

WAKE

AM

SET

PT

M5032

MON TUE WED THU FRI COOL

WAKE

AM

SET

PT

M5033

SUN ON HEAT

WAKE

AM

SET

PT

M5031

MON TUE WED THU FRI COOL

LEAVE

AM

SET

PT

M5035

PROGRAMMING THE THERMOSTAT

If cooling temperatures are not being programmed, skip Step 3 and press the RUN

PROGRAM key.

STEP 3

SET THE COOLING TEMPERATURES

The program times are the same for both

heating and cooling. Only the cooling temperatures need to be programmed if the

thermostat has already been programmed

for heating. To set times as the cooling

temperatures are programmed, use the TIME

AHEAD and BACK keys as described in

Step 2. If the times are changed for cooling,

they are also being changed for heating.

mum cooling setting is

73° F. If a lower cooling temperature is

WAKE

Press and hold until SUN ap-

LEAVE

pears on the display.

SLEEP

Press WAKE, LEAVE, RE-

RETURN

TURN or SLEEP to select

AHEAD WARMER

BACK

the time period.

COOLER

Use the AHEAD/BACK keys

to set the time and the

WARMER/COOLER keys to set the temperature.

This completes setting the program schedule and heating temperatures. To set air conditioning, go to Step 3.

WAKE

First program the WAKE temperature for weekdays.

Press and release. The display shows WAKE and the

SET

HEAT/COOL

time and temperature programmed for heating.

Press and release so COOL

shows on the display, along

DAY

with the preprogrammed cooling temperature.

If display reads SAT or SUN,

WARMER

COOLER

press and hold until MON

TUE WED THU FRI appears.

Press and hold until the dis-

MON TUE WED THU FRI COOL

WAKE

play shows the desired temperature.

If the display blinks while holding down TEMPERA-

TURE WARMER or COOLER, the setting limit has

been reached. If the thermostat can switch automatically

between heating and cooling, the cooling temperature

must be at least three degrees higher than the corresponding heating temperature. For example, if the heating setting is 70° F, the mini-

LEAVE

desired, the heating temperature first must be lowered accordingly.

Program the LEAVE temperature, if desired.

WARMER

COOLER

Press and release. The display

MON TUE WED THU FRI COOL

AM

AM

LEAVE

M5034

M5036

SET

PT

SET

PT

shows LEAVE, the time programmed for

heating, and

78° F.

RETURN

Press and hold until the display shows the desired temperature.

16

PM

MON TUE WED THU FRI COOL

RETURN

M5037

SET

PT

Page 17

T8624C,D

PROGRAMMING THE THERMOSTAT

Press and release. The display shows RETURN, the time programmed for heating,

ture, if desired.

Press and release.

pears on the display.

Press WAKE, LEAVE, RETURN or SLEEP

WARMER

COOLER

SLEEP

WARMER

COOLER

DAY

WAKE

SLEEP

WARMER

COOLER

DAY

WAKE

SLEEP

WARMER

COOLER

RUN

PROGRAM

Program the RETURN temperature, if

desired.

MON TUE WED THU FRI COOL

RETURN

and

78° F.

MON TUE WED THU FRI COOL

Press and hold until the

display shows the desired temperature.

MON TUE WED THU FRI COOL

Program the SLEEP tempera-

Press and hold until the display shows the desired temperature.

Set the cooling temperatures

for the SATURDAY schedule.

LEAVE

RETURN

Use the same procedure as for

weekdays.

Press and hold until SAT ap-

to select the time period.

Use the WARMER/COOLER

SUN COOL

LEAVE

keys to set the temperature.

Set the cooling temperatures for

RETURN

the SUNDAY schedule. Use the

same procedure as for weekdays.

Press and hold until SUN appears on the display.

Press WAKE, LEAVE, RETURN or SLEEP to select the

time period.

TUE

LEAVE

SAT COOL

M5038

M5039

M5040

M5041

M5042

M5043

SET

PT

SET

PT

SET

PT

SET

PT

SET

PT

SET

PT

PM

PM

SLEEP

PM

SLEEP

PM

SLEEP

PM

SLEEP

PM

17 68-0134

Page 18

T8624C,D

M3762

HEAT OFFCOOLAUTO

PROGRAMMING THE THERMOSTAT • OPERATING THE THERMOSTAT

Use the WARMER/COOLER keys to set the temperature.

You have completed programming the cooling temperatures.

Press and release to start the program.

Go to Step 4.

STEP 4

cleaning.

SET THE SYSTEM AND FAN

SWITCHES ON THE SUBBASE.

FAN

AUTOON

Depending on thermostat model,

some of the switch positions shown

may not be available on the thermostat. Note the positions provided

on the subbase, then set the

switch(es) as desired.

ON

FAN

AUTO

M3763

First set the fan switch.

FAN ON: The fan runs continuously. Use for improved

air circulation during special occasions or for more efficient electronic air

FAN AUTO: Normal setting

for most homes. The fan goes

on and off with the air conditioner in summer. In winter, the

COOL

AUTOHEAT OFF

fan on most

systems starts a few minutes

after the furnace comes on. It

stops a few minutes after the

HEAT OFF

AUTO

COOL

furnace goes off. The fan starts

and stops with the furnace in

some electric heat systems and

with the compressor in heat

pump systems.

HEAT OFFCOOLAUTO

Then set the system switch.

HEAT: The thermostat controls

your heating system.

AUTO (select models only): The thermostat controls

OFF: Both the heating and cooling systems are off.

This completes the programming of the thermostat.

either your heating or cooling system, depending on

room temperature.

COOL: The thermostat controls your cooling system.

Operating the Thermostat

If the thermostat is removed from the wall to program, replace it following the procedure on page 5.

TEMPORARILY CHANGING THE PROGRAM

These features allow the program to be customized for

those times when someone comes home early, or stays

up late, or plans to be out for the evening.

To keep the current temperature through the

next program period:

SKIP

NEXT

PERIOD

Press and release. The name

of the period to be skipped

will flash in the display until

the next regularly scheduled

period starts.

To go back to the temperature of the previous program period:

CHANGE

TO LAST

PERIOD

Press and release. The display will show the name of

the previous period and flash

TEMPORARY until the next

regularly scheduled period starts.

18

PM

TUE

LEAVE RETURN

PM

TUE

WAKE TEMPORARY

M5044

M5045

Page 19

T8624C,D

OPERATING THE THERMOSTAT

To temporarily raise or lower the temperature for the current period only:

PERMANENTLY CHANGING THE

PROGRAM

If the schedule changes or a different temperature is desired, any setting can be updated without affecting other program settings.

WARMER

COOLER

PRESENT

SETTING

RUN

PROGRAM

WAKE

SLEEP

DAY

AHEAD

BACK

RUN

PROGRAM

Press and hold until the desired temperature is reached.

The display will flash TEMPORARY until the next programmed time period starts.

With the system switch at the

AUTO position, press and

hold down the key to alternate between heating and cooling temperature settings for

temporary override.

Press and release to cancel

any of the temporary settings.

Press and release the desired

period key.

Press and hold until the desired

day schedule shows on the display.

Press and hold the Time or Temperature keys until the display

shows the desired new program.

Press and release to return to

normal operation.

TUE

LEAVE

LEAVE

RETURN

WARMER

COOLER

ON HEAT

TEMPORARY

M5046

PM

M5047

MANUALLY OPERATING THE

THERMOSTAT

This feature is particularly useful when on

vacation or other extended absences. It does

not cancel the program.

HOLD

TEMP

WARMER

COOLER

PRESENT

SETTING

RUN

PROGRAM

Press and release.

Press and hold to change the

temperature setting. After a

few seconds, the display will

ON HEAT

M5048

ON HEAT

M5049

show the current temperature.

Press and release to check the

temperature setting.

ON HEAT

M5050

Press and hold down to alternate between heating and

cooling temperature settings.

Press and release to cancel

hold.

PM

TUE

LEAVE

M5051

19 68-0134

SET

PT

SET

PT

SET

PT

Page 20

T8624C,D

OPERATING THE THERMOSTAT

NOTE: Moving the system switch also can-

cels hold.

CANCELING THE PROGRAM

SETTINGS

The thermostat requires time and temperature settings in the WAKE period, but any of

the others can be canceled. Weekday, Satur-

normal operation.

CHECKING THE PROGRAM TIMES

AND TEMPERATURES

normal operation.

SLEEP

LEAVE

RETURN

RUN

PROGRAM

WAKE

SLEEP

LEAVE

RETURN

DAY

RUN

PROGRAM

day and Sunday settings are

canceled separately.

Press and hold the desired pe-

MON TUE WED THU FRI ON HEAT

LEAVE

M5052

riod key until the time and temperature clear from the

display (about three seconds).

PM

MON

Press and release to return to

RETURN

M5053

Check all the stored settings without affecting the permanent program.

Press and release the desired

period key. The start time and

PM

MON TUE WED THU FRI ON HEAT

SLEEP

M5054

temperature setting will appear on the display.

Press and release to display

the next daily time and temperature for that period.

Press and release to return to

PM

SAT ON HEAT

SLEEP

MON

RETURN

M5055

PM

M5056

SET

PT

SET

PT

CHECKING THE CURRENT

TEMPERATURE SETTING

Press a single key to compare current room

temperature to the current temperature setting at any time.

PRESENT

SETTING

PRESENT

SETTING

Press and release. The display will show the current

temperature setting for several seconds, then revert to the room temperature.

To check the heating and cooling settings with the system switch at the AUTO position, press and hold down

to alternate between the heating and cooling settings.

During recovery from energy savings, the setting displayed will not match the programmed setting. This is

because the thermostat gradually changes the temperature setting during recovery to provide most efficient use

of the heating or cooling equipment.

20

ON HEAT

M5057

SET

PT

Page 21

SYMPTOM POSSIBLE CAUSE ACTION

ROOM TEMPERATURE DISPLAY

˚

F.

IS 32

FURNACE OR AIR CONDITIONER

WON'T OPERATE.

PARTIAL DISPLAY INOPERATIVE THERMOSTAT REPLACE THERMOSTAT.

PRESENT SETTING APPEARS

INACCURATE.

CANNOT TEMPORARILY OVERRIDE

BOTH HEATING AND COOLING

SETTINGS IN AUTO MODE.

THERMOSTAT TEMPERATURE NEEDS

TO BE ADJUSTED ON A REGULAR

BASIS.

PROGRAM IS LOST DUE TO POWER

OUTAGE OR DISPLAY GOES BLANK

WHEN POWER IS TURNED OFF.

DISPLAY FLASHES WHILE

PROGRAMMING.

DISPLAY FLASHES DURING

OPERATION.

NO ac POWER TO THERMOSTAT

NO ac POWER TO THERMOSTAT

THERMOSTAT INOPERATIVE CONDUCT SELF-TEST; SEE CHECKOUT.

PRESENT SETTING TOO LOW/HIGH

SYSTEM SWITCH ON THERMOSTAT

IN WRONG POSITION.

MINIMUM-OFF TIMES IN THERMOSTAT

IN OPERATION ON COOLING

INCORRECT WIRING CHECK CIRCUIT DIAGRAM.

FURNACE OR AIR CONDITIONER

INOPERATIVE

THERMOSTAT MOUNTED

INCORRECTLY ON BASE.

THERMOSTAT IS IN RECOVERY

MODE.

NOT USING PRESENT SETTING KEY.

WARMER/COOLER KEYS BEING

USED TO ADJUST TEMPERATURE

BATTERIES ARE INCORRECTLY

INSTALLED.

BATTERIES ARE DEAD.

IMPROPER PROGRAM SEQUENCE

AUTOMATIC THERMOSTAT HEATING

OR COOLING TEMPERATURE CAN

NOT BE SET CLOSER THAN 3 F.

PROGRAMMING HAS BEEN LOST

BECAUSE OF A POWER OUTAGE.

O

CHECK POWER TO FURNACE OR AIR CONDITIONER.

–ON-OFF SWITCH

–FUSE OR CIRCUIT BREAKER

–LOOSE 24V CONNECTION

–AT THERMOSTAT

–AT FURNACE /AIR CONDITIONER

–INCORRECT WIRING

–CHECK WIRING DIAGRAM

CHECK POWER TO FURNACE OR AIR CONDITIONER.

–ON-OFF SWITCH

–FUSE OR CIRCUIT BREAKER

–LOOSE 24V CONNECTION

–AT THERMOSTAT

–AT FURNACE /AIR CONDITIONER

–INCORRECT WIRING

–CHECK WIRING DIAGRAM

ADJUST TEMPERATURE BY PUSHING WARMER/

COOLER KEYS.

RESET THERMOSTAT SYSTEM SWITCH.

WAIT 5 -10 MIN. OR USE SELF-TEST IN THERMOSTAT.

SEE CHECKOUT.

CONSULT FURNACE OR AIR CONDITIONER

INSTRUCTIONS.

CHECK THAT HEAT OR COOL SYSTEM POWER IS ON.NO POWER TO THERMOSTATNO DISPLAY

SEE INSTALLATION INSTRUCTIONS FOR CORRECT

MOUNTING.

• NORMAL OPERATION THERMOSTAT TURNS ON

HEATING/COOLING EARLY TO MEET TEMPERATURE

SETTING AT PROGRAMMED TIMES.

• RECOVERY CAN BE ENDED BY PUSHING WARMER/

COOLER KEYS.

PRESS AND HOLD DOWN PRESENT SETTING KEY TO

ALTERNATE BETWEEN HEATING AND COOLING SETTINGS.

REPROGRAM THERMOSTAT TO MAKE PERMANENT

CHANGE IN PROGRAM. WARMER/COOLER KEYS ARE

TEMPORARY UNLESS PERIOD KEY IS PRESSED FIRST.

REMOVE AND REPLACE PER MARKINGS ON THERMOSTAT.

REPLACE BATTERIES.

CHECK PROGRAMMING INSTRUCTIONS FOR CORRECT

PROGRAM SEQUENCE.

SET HEATING AND COOLING TEMPERATURES 3 F OR

MORE APART.

REPROGRAM ACCORDING PROGRAMMING INSTRUCTIONS

(MAKE SURE BATTERIES ARE INSTALLED).

T8624C,D

TROUBLESHOOTING

O

M5234A

21 68-0134

Page 22

T8624C,D

GLOSSARY

Recovery

The time when the thermostat operates the heating or

air conditioning equipment to return the home from the

energy saving temperature to the comfort temperature.

Troubleshooting

Glossary

Comfort temperature

The temperature desired when active and occupying

the home.

Energy-saving temperature

The lower (heating) or higher (cooling) temperature

that allows savings on heating and cooling costs when

asleep or away. Also called the setback (heating) or

Period Time

WAKE 6:00 AM 70° F78° F

LEAVE ——— No program ————

RETURN ——— No program ————

SLEEP 10:00 PM 60° F78° F

setup (cooling) temperature.

Period key

One of the four keys—WAKE, LEAVE, RETURN or

SLEEP—to check or program the start time and

temperatue for a time period.

Preprogrammed schedule

This is the schedule programmed into the thermostat

at the factory. It sets a night program that provides

energy savings when homeowner sets no program, or if

personal program is lost for any reason. The program,

which is the same for all days of the week, is:

Program

The times and temperatures homeowner sets to define

the comfort and energy saving periods for each day

schedule.

home.

RETURN—The time period that the house is at a comfortable temperature for family activities in the evening before

bedtime.

SLEEP—The time period that the temperature can be set back (winter) or set up (summer) for energy savings

because the family is sleeping. It can be set to start at the family’s normal bedtime. Often the SLEEP program is set

only for the heating season so family members can sleep cool in the cooling season.

Weekday program schedule

The schedule of WAKE, LEAVE, RETURN and SLEEP period start times and temperatures programmed to run

Monday through Friday.

Start

Temperature

Heating Cooling

The thermostat starts the recovery period early so the

home will be at the comfort setting by the time the

homeowner has chosen.

Saturday program schedule

The schedule of WAKE, LEAVE, RETURN and

SLEEP period start times and temperatures programmed

to run on Saturdays.

Setback

Reducing the temperature in the home for a set period

in heating for energy savings. The lower temperature is

the energy saving temperature.

Setup

Raising the temperature in the home for a set period

in cooling for energy savings. The higher temperature is

the energy saving temperature.

Setpoint

The thermostat temperature setting the homeowner

selects. The thermostat turns the heating or cooling

equipment on and off to maintain this temperature at the

thermostat location until another temperature setting

(setpoint) goes into effect.

Sunday program schedule

The schedule of WAKE, LEAVE, RETURN and

SLEEP period start times and temperatures programmed

to run on Sundays.

SYSTEM light

This light glows whenever the thermostat is calling

for heating or air conditioning.

Time period

One of four program periods: WAKE, LEAVE, RETURN and SLEEP available with the thermostat. One

period begins when the previous program period ends:

WAKE—The time period that the house is at a com-

fortable temperature while the family gets up and gets

ready to leave for work or school. This is the only

period that must contain a time and temperature.

LEAVE—The time period that the temperature can

be set back (winter) or set up (summer) for energy

savings because the family is usually away from

22

Page 23

23 68-0134

Page 24

Home and Building Control Home and Building Control

Honeywell Inc. Honeywell Limited—Honeywell Limitée

1985 Douglas Drive North 740 Ellesmere Road

Golden Valley, MN 55422 Scarborough, Ontario

M1P 2V9

Printed in U.S.A.

Loading...

Loading...