Page 1

(7-Day Programming)

Chr onotherm III™

Heat Pump Thermostats

The T8611M Chronotherm III Programmable

Thermostat provides automatic control of multistage heat pump systems and offers users the

highest standard of comfort and convenience

available with energy savings.

T8611M

■ Full seven-day program capability; different sched-

ules may be selected for every day.

■ Can be programmed in hand (with batteries in-

stalled) or on the wall to provide up to four tem-

perature periods per day.

■ Large digital clock (liquid crystal display) indi-

cates continuous time-of-day, day-of-week, cur-

rent period and room temperature.

■ Adaptive Intelligent Recovery™ brings room tem-

perature to programmed temperature at program-

med time, maximizing comfort and energy sav-

ings.

■ Temperature control program maintains tempera-

ture within 1° F of setpoint.

■ Temporary program override available by using—

—WARMER and COOLER keys.

—SKIP next period key.

—CHANGE to last period key.

■ HOLD TEMP key provided for indefinite program

override (vacation/holiday).

■ Installer self-test with time delay override saves

installation time.

■ SYSTEM light-emitting diode (LED) on thermo-

stat indicates system is energized.

■ AUX. HT., EM. HT., CHECK LEDs available on

select models.

■ Automatic heat/cool changeover.

■ Batteries included provide power to maintain clock

and memory during power failures.

■ Switching subbase with wiring terminals included.

■ Powered directly from control transformer.

■ Model available with separate sensor for remote

CONTENTS

Specifications ................................................. 2

Ordering Information..................................... 2

Selection/Application ..................................... 5

Installation ................................................... 12

Checkout....................................................... 18

Programming The Thermostat ..................... 20

Operating The Thermostat ........................... 25

Operation ..................................................... 27

Troubleshooting ........................................... 29

Glossary ....................................................... 30

Table of Contents ......................................... 32

temperature sensing.

1 68-0076—1

C. H. • Rev. 10-92 • ©Honeywell Inc. 1992 • Form Number 68-0076—1

Page 2

T8611M

SPECIFICATIONS • ORDERING INFORMATION

TRADELINE MODELS

TRADELINE models are selected and packaged to

provide ease of stocking and handling and also maximum

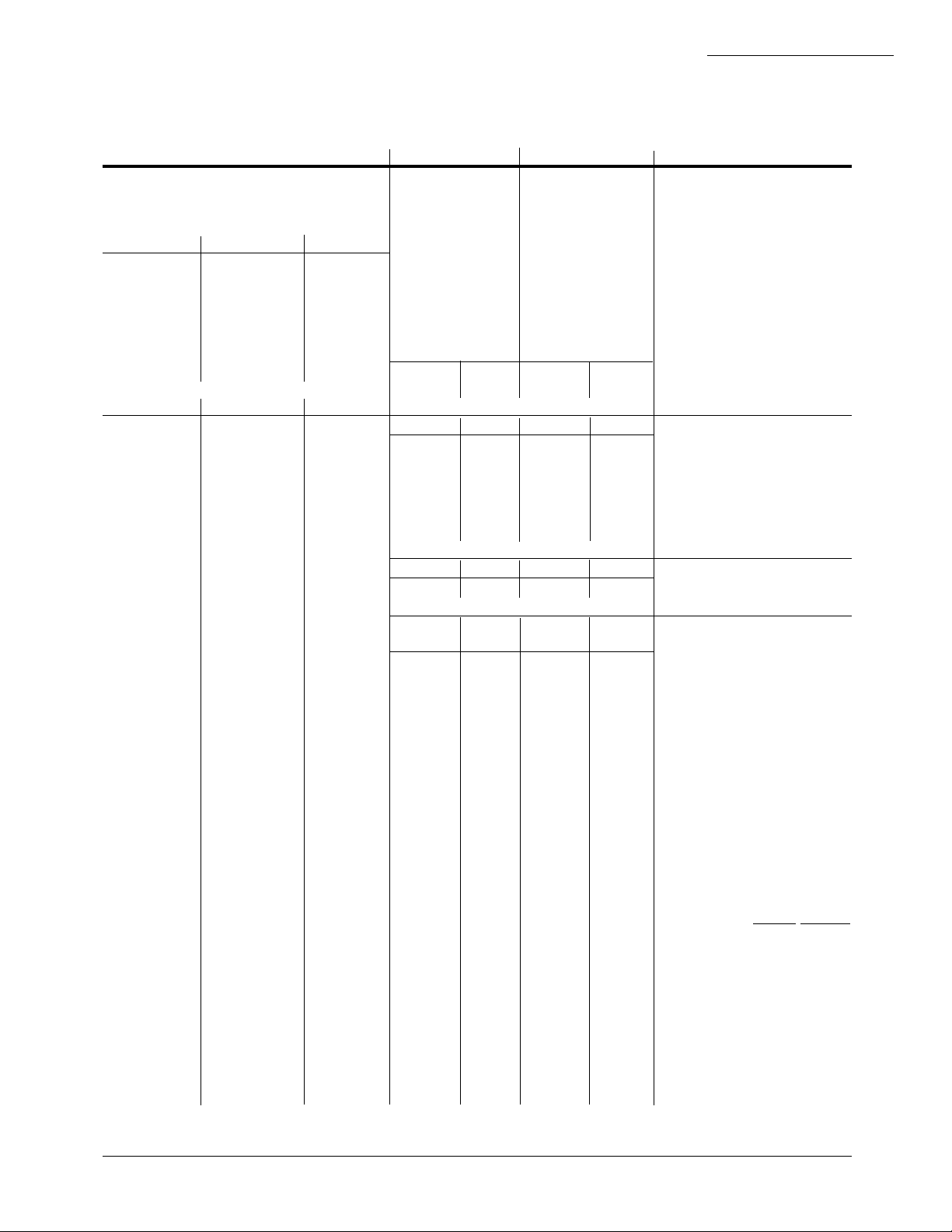

TABLE 1—TRADELINE MODELS AVAILABLE.

Stages Changeover Switching

Thermostat Heat Cool Type System Fan Application Program

T8611M* 3 2 Automatic EM. HT.-HEAT-OFF- ON-AUTO Heat Pump 7-Day

AUTO-COOL

*Model available with separate sensor for remote temperature sensing.

Specif ications

replacement value.

TRADELINE models available are listed in Table 1.

LIGHT-EMITTING DIODES (LEDs):

SYSTEM LED (yellow) on thermostat lights during

thermostat heating and cooling ON cycles.

EM.HT. LED (red) on subbase lights when system

switch is in EM.HT. On some systems, light may

indicate need to switch to EM.HT. because of heat

pump problem.

AUX. HT. LED (green) on subbase lights when ther-

mostat is calling for operation of auxiliary heat.

CHECK LED (yellow) on subbase lights when an

equipment or system problem needs to be checked.

Consult heat pump literature to determine meaning.

VOLTAGE RATING: 15 to 30 Vac.

CURRENT RATING: 1.6A maximum, total per stage.

OPERATING HUMIDITY RANGE: 5 to 90 percent rela-

tive humidity, noncondensing.

OPERATING AMBIENT TEMPERATURE RANGE:

40° F to 110° F [4° C to 43° C].

SET POINT RANGE: 45° F to 88° F [7° C to 31° C].

CALIBRATION: Self-calibrating thermostat and thermo-

meter to ±1° F.

SHIPPING TEMPERATURE: -20° F to +120° F [-29° C

to +49° C].

CYCLES PER HOUR ADJUSTMENT:

Auxiliary heating—factory-set at 3 cph (adjustable to

6 cph for special systems); minimum off-time of five

minutes.

Nonauxiliary heating and cooling—factory-set (not

field adjustable); minimum off-time of five minutes.

FINISH: Beige matte with decorative brushed metal face-

plate.

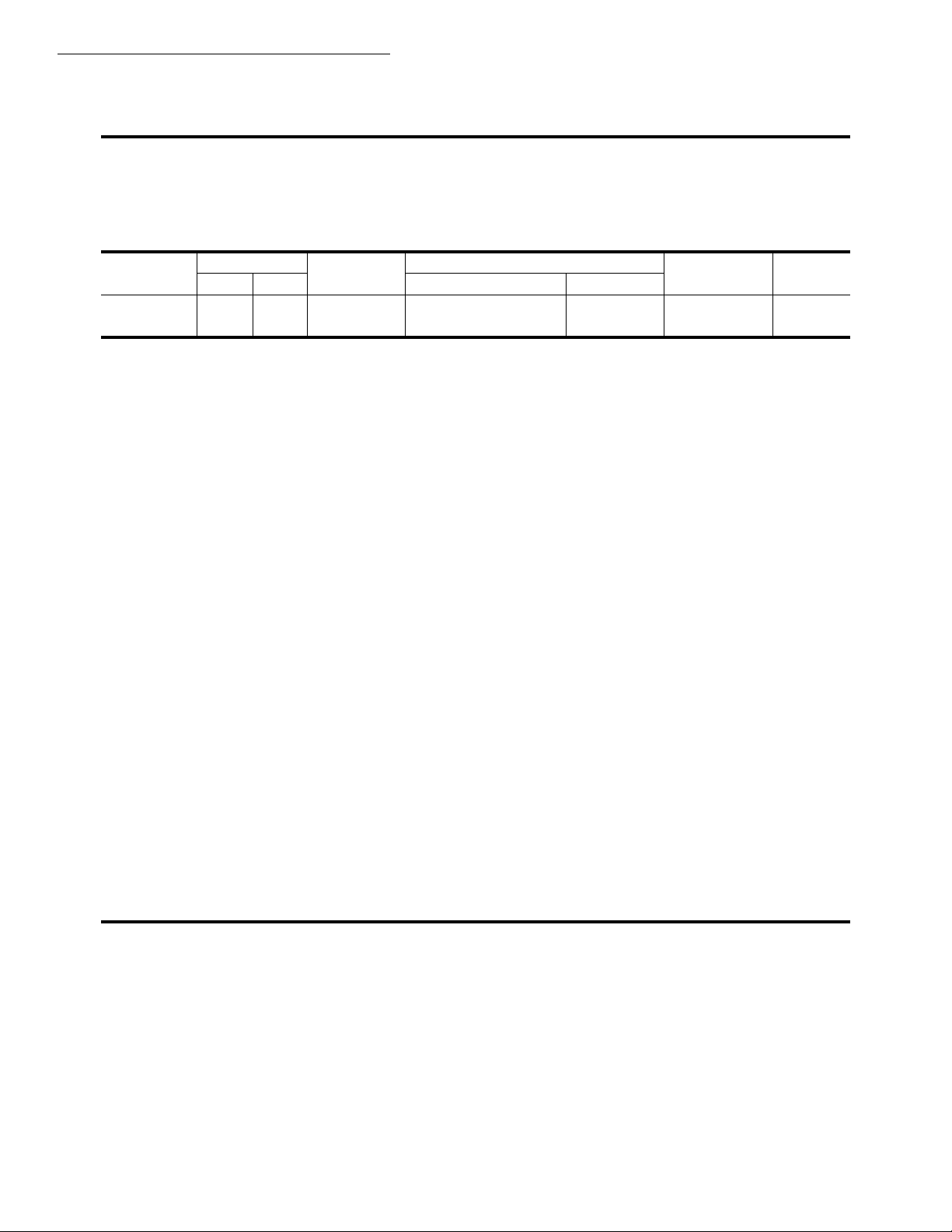

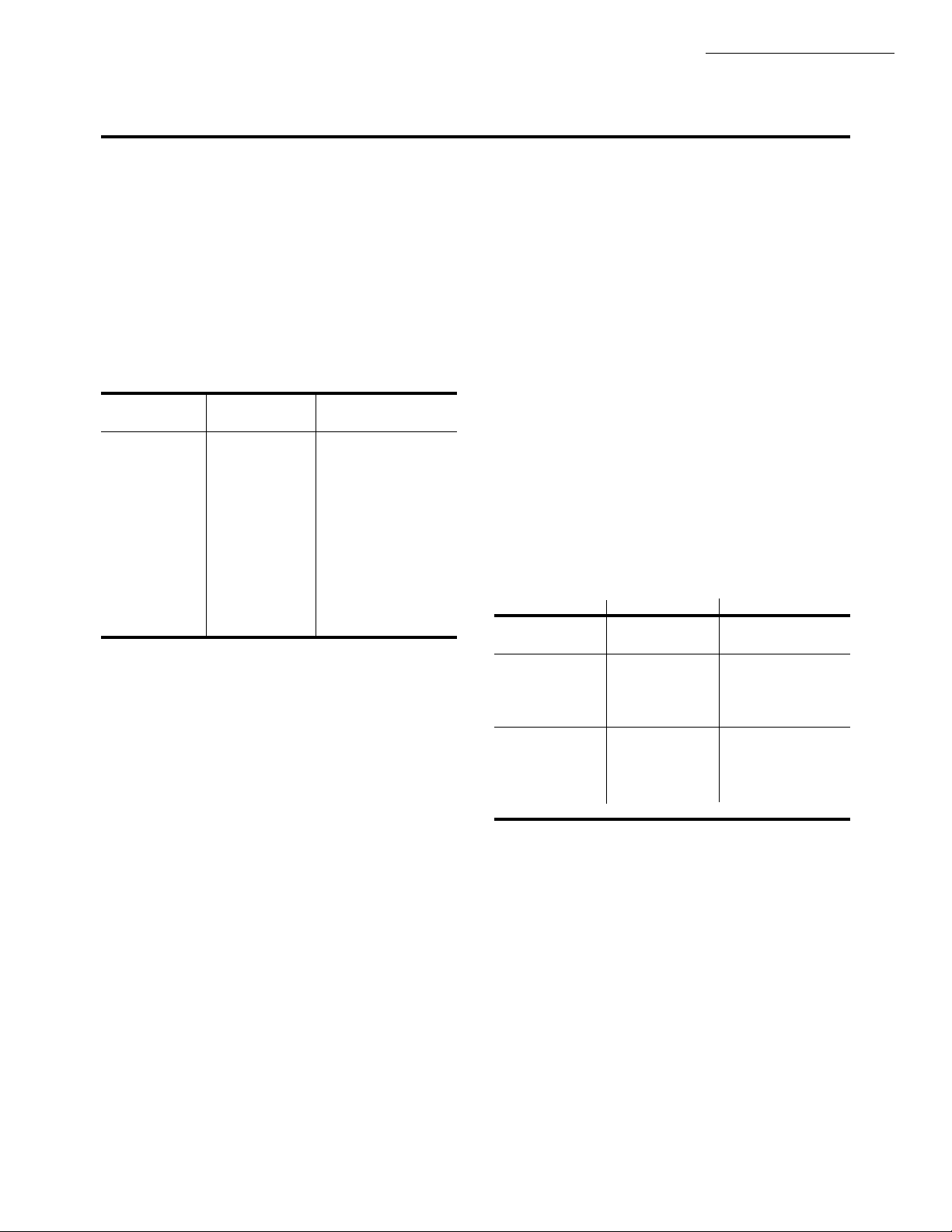

DIMENSIONS: Thermostat (mounted on subbase)—7 in.

[178 mm] long, 5-5/16 in. [135 mm] high, 1-3/4 in.

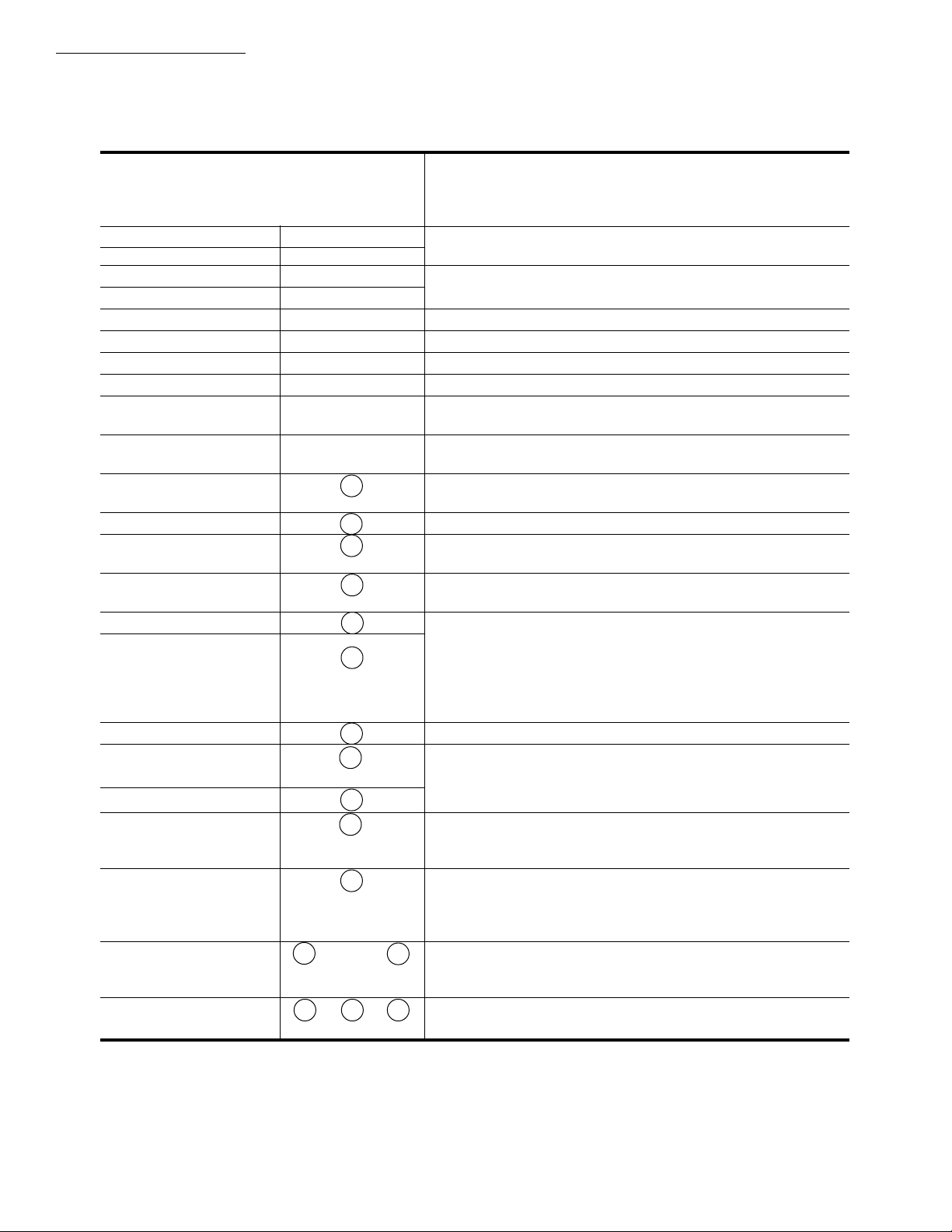

[44 mm] deep. See Fig. 1 for subbase dimensions. See

Fig. 2 for remote sensor dimensions.

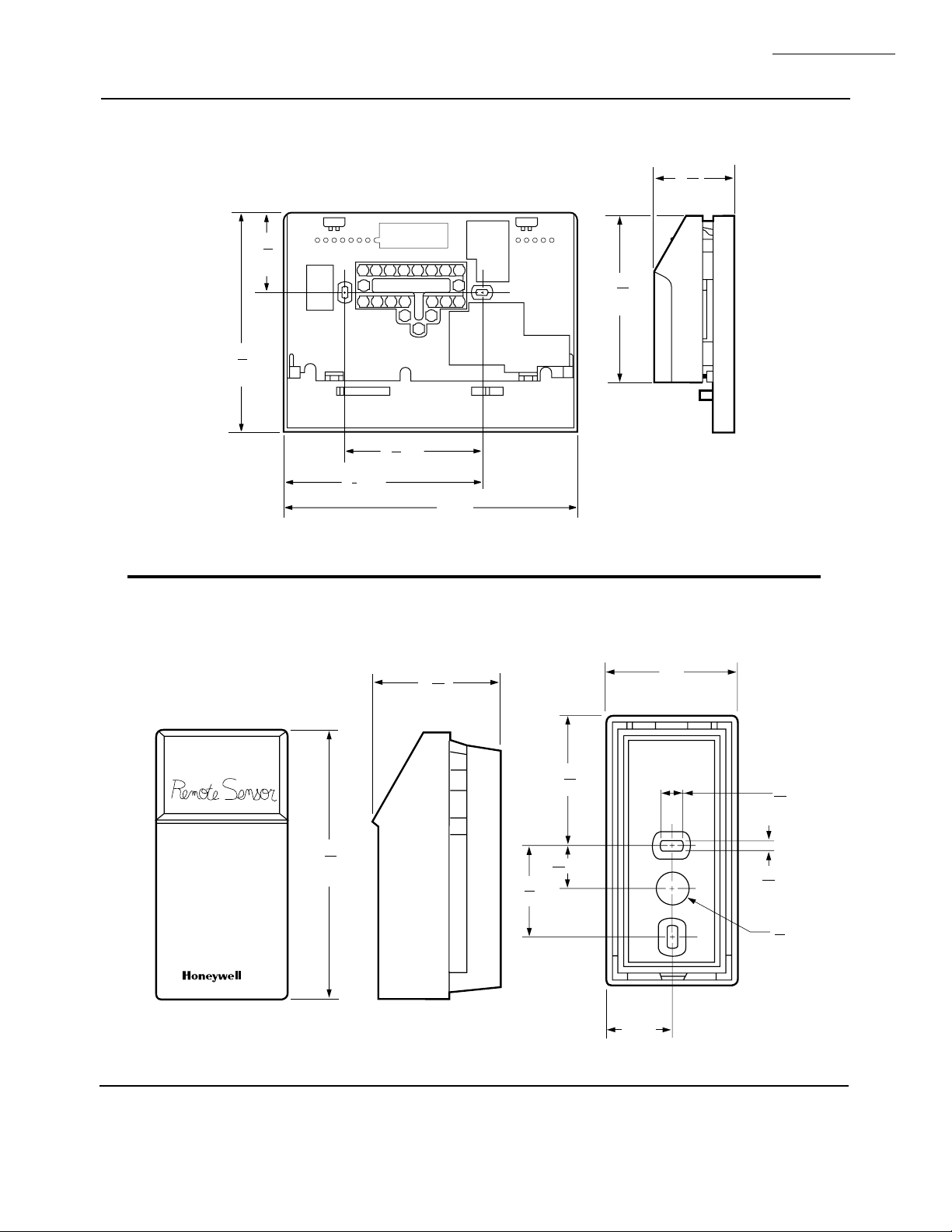

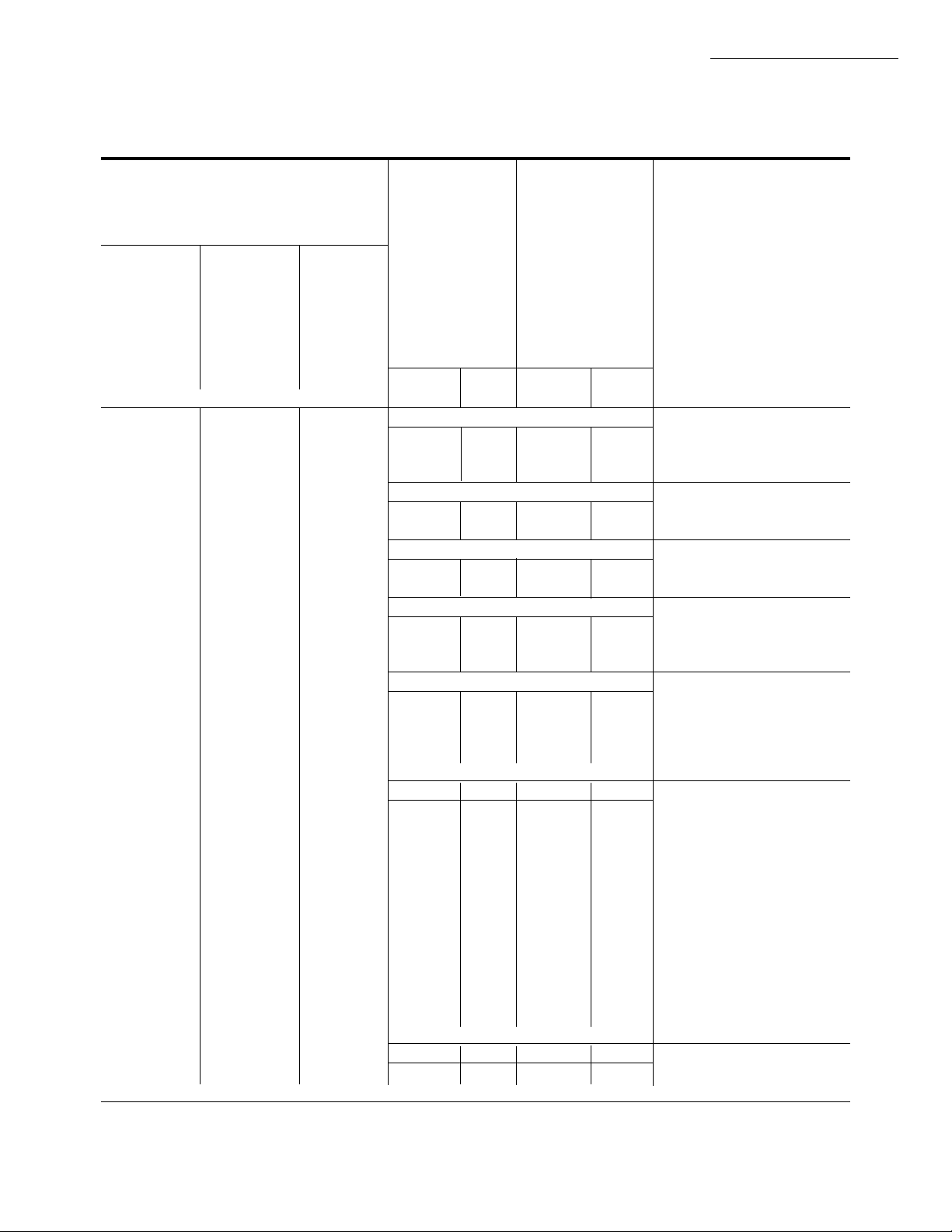

TYPICAL KEYPAD: See Fig. 3.

REPLACEMENT PARTS:

202905AA Remote Temperature Sensor.

220529 Replacement Door.

AAA alkaline batteries, available locally.

ACCESSORIES:

193121A Cover Plate Assembly. Includes cover plate,

adapter ring and screws; 6-9/10 in. x 4-3/4 in. [175

mm x 121 mm]. Covers marks left by old thermostat.

Allows mounting on vertical or horizontal outlet

box.

TG512 Universal Thermostat Guards. Includes clear or

opaque plastic or metal cover, ring base, opaque

plastic wallplate, tumbler lock with two keys.

TG586A Locking Cover.

Ordering Inf ormation

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE Catalog or price sheets for complete ordering number, or specify—

1. Model number. 3. Remote temperature sensing, if desired.

2. Number of heat and cool stages desired.

If you have additional questions, need further information or would like to comment on our products or services, please write or phone:

1. Your local Honeywell Home and Building Control Sales Office (check white pages of your phone directory).

2. Home and Building Control Customer Satisfaction

Honeywell inc., 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386 (612) 951-1000

In Canada—Honeywell Limited/Honeywell Limitée 740 Ellesmere Road, Scarborough, Ontario M1P 2V9. International sales

and service offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France, Germany, Japan,

Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

2

Page 3

Fig. 1—T8611 Subbase mounting dimensions in in. [mm].

13

1

16

[46]

5

5

16

[135]

5

3 [83]

16

3

4 [121]

4

M5181A

7 [179]

4

[104]

T8611M

SPECIFICATIONS

31

1

32

[50]

3

32

Fig. 2—202905AA Remote Sensor dimensions in in. [mm].

FRONT

4

[104]

3

32

SIDE

1

[50]

31

32

BACK

2

[51]

31

[50]

1

32

41

[16]

64

3

1

[35]

8

[25]

1

19

[8]

64

9

[4]

64

1

DIA.

2

[13]

M5244

3 68-0076—1

Page 4

T8611M

SPECIFICATIONS

Fig. 3—Typical thermostat keypad.

SET

PRESENT

DAY/TIME

HOLD

TEMP

PROGRAM

HEAT/COOL

HEAT OFF

RUN

DAY

SET

COOL

PERIOD

CANCEL

PERIOD

MIDDAY

COPY

FROM

COPY

WED

TO

AM

TIME

AHEAD

BACK COOLER

ROOM

HEAT ON

TEMPERATURE

PRESENT

SETTING

WARMER

FAN

ON AUTO

SYSTEM

SKIP

NEXT

PERIOD

CHANGE

TO LAST

PERIOD

M5360

4

Page 5

T8611M

SELECTION/APPLICATION

Selection/A pplication

The T8611 Thermostat uses the latest microelectronic

design and control technology to provide home and building owners with the highest level of comfort available and

optimal energy savings in a package that is easy to use and

easy to live with.

The following section is a guide to selection and application of the best thermostat to meet individual customer

needs.

PROGRAMMING

Does the thermostat selected accommodate the

customer’s daily schedule, lifestyle or work schedule?

Refer to choices below.

TRADELINE Daily Temperature

Device Programming Selection

T8611G,R* Weekday, 4 heat and

Sat, Sun. 4 cool

T8611M 7-day 4 heat and

(each day 4 cool

different)

IF RETROFIT/REPLACEMENT APPLICATION,

CONSIDER

• equipment requirements

— system switching (manual: EM. HT.-HEAT-OFF-

COOL, automatic: EM. HT.-HEAT-OFF-AUTOCOOL).

— unique heat pump functions of emergency or

supplemental heat, changeover on heat or cool,

and status indication.

— Table 3 lists typical applications by manufac-

turer.

• existing wiring

— Are there enough conductors to operate the equip-

ment and the thermostat? Can a new cable be

pulled?

• existing thermostat

— Table 3 is a guide for replacing popular Honeywell

standard nonprogrammable thermostats with a

T8611.

SECURITY

Does the thermostat selected provide access to programming and the override features that will best suit the

application? Refer to choices below.

*Specifications form 68-0057 for information.

IF NEW CONSTRUCTION APPLICATION,

CONSIDER

• equipment type (see manufacturer’s specifications)

— system switching required

— status indication provided

• control wiring—number of conductors required to

operate equipment and thermostat.

IMPORTANT: The T8611 requires a conductor to trans-

former common to provide continuous 24V power

for thermostat operation. This feature is commonly

specified and provided by equipment manufacturer.

Typical

Access Application Device

Free access to Home or T8611

programming owner-occupied

and adjustment/ commercial

override. building.

Restricted Public building. T8611 with TG512

access to Locking Cover;

device. T8611 with remote

temperature

sensing.

5 68-0076—1

Page 6

T8611M

SELECTION/APPLICATION

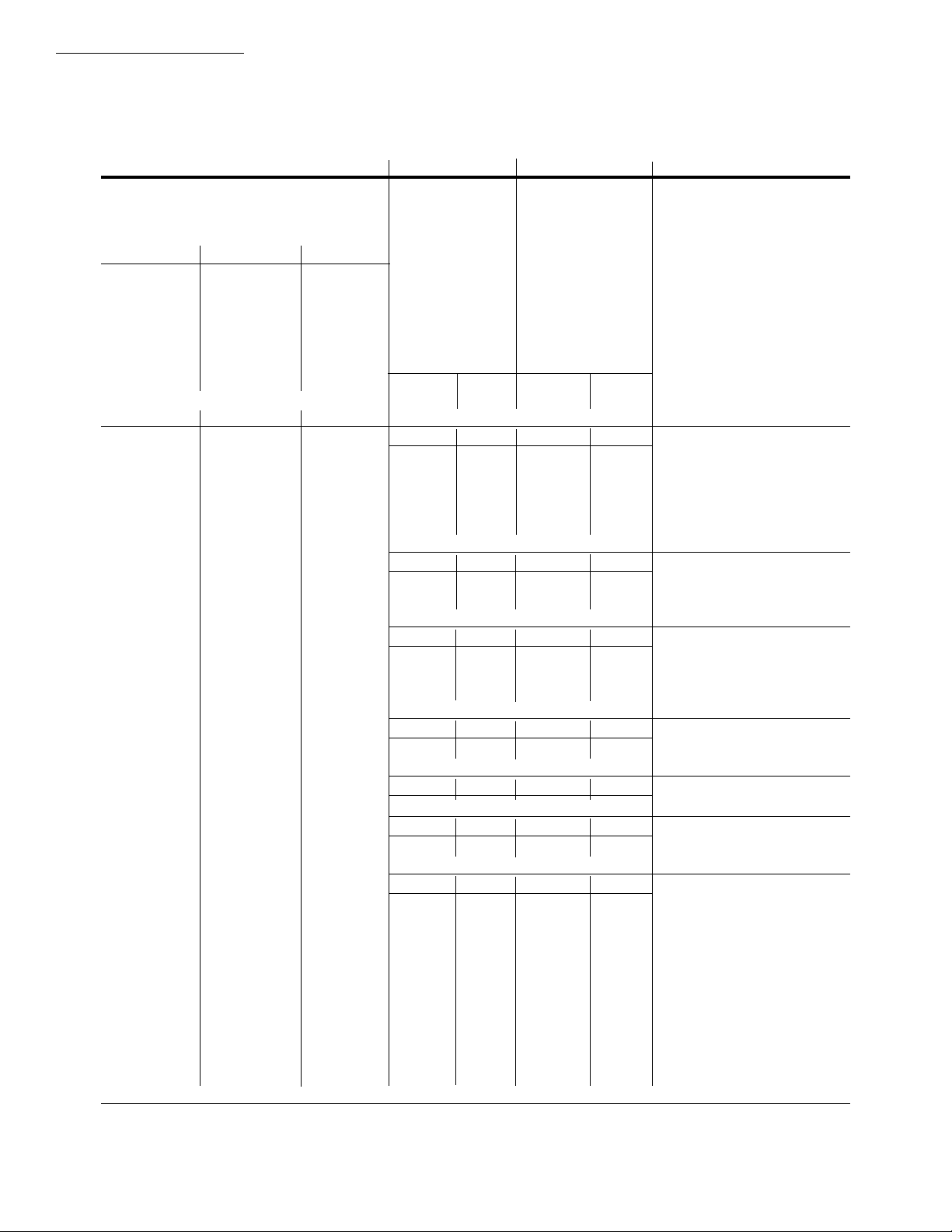

Table 2 lists features and wiring terminal functions of the TRADELINE T8611M thermostat.

TABLE 2—T8611M FEATURES AND TERMINALS.

T8611M

FEATURES

COMMENTS

Heating Stages 3 May be applied to 2-stage heat pump systems; see wiring

Cooling Stages 2 diagrams Figs. 6 and 7.

Changeover Auto

Programming 7-day

SYSTEM LED Yes Lights on call for heat or cool.

EM. HEAT LED (red) Yes Lights continuously in EM. HEAT mode.

AUX. HEAT LED (green) Yes Lights during call for final auxiliary heat stage.

CHECK LED (yellow) Yes Field wired option; indicates equipment malfunction.

Remote Temperature Yes Available on T8611M7040 only. (202905A Remote Sensor

Sensing included).

WIRING TERMINAL

FUNCTION

24 Vac Common C Must be connected to control transformer to operate

thermostat.

24 Vac Power R

Compressor, Stage 1 Y

heat and cool.

Compressor,

Stage 2 cool unconnected.

Second Stage Heat

Auxiliary (Resistive) second stage is compressorized, connect stage 2 to W2;

Third Stage Heat

Fan G

Changeover Heat Mode B O/B changeover terminals are energized continuously

Changeover Cool Mode O

System Monitor, L Energizes EM. HEAT LED when externally powered.

continuously energized

in EM. HEAT mode.

Emergency Heat E

energized on call for

stage 1 heat in

EM. HEAT mode

Check LED terminals

to indicate equipment

malfunction

Remote Temperature

Sensing 202905A Remote Sensor for proper thermostat operation.

Y2

W2

W3

X1 X2

S1 S2 S3

If applying T8611M to 1-stage cooling system, leave Y2

If applying T8611M to 2-stage heat systems in which the

leave W3 unconnected.

If 2-stage heat system in which the second stage is auxillary

(electric resistive), connect auxiliary stage to W3; leave

W2 unconnected.

following first call for cool or heat, respectively.

See wiring diagrams for hookup alternatives.

Available on T8611M7040 only. Must be connected to

6

Page 7

SELECTION/APPLICATION

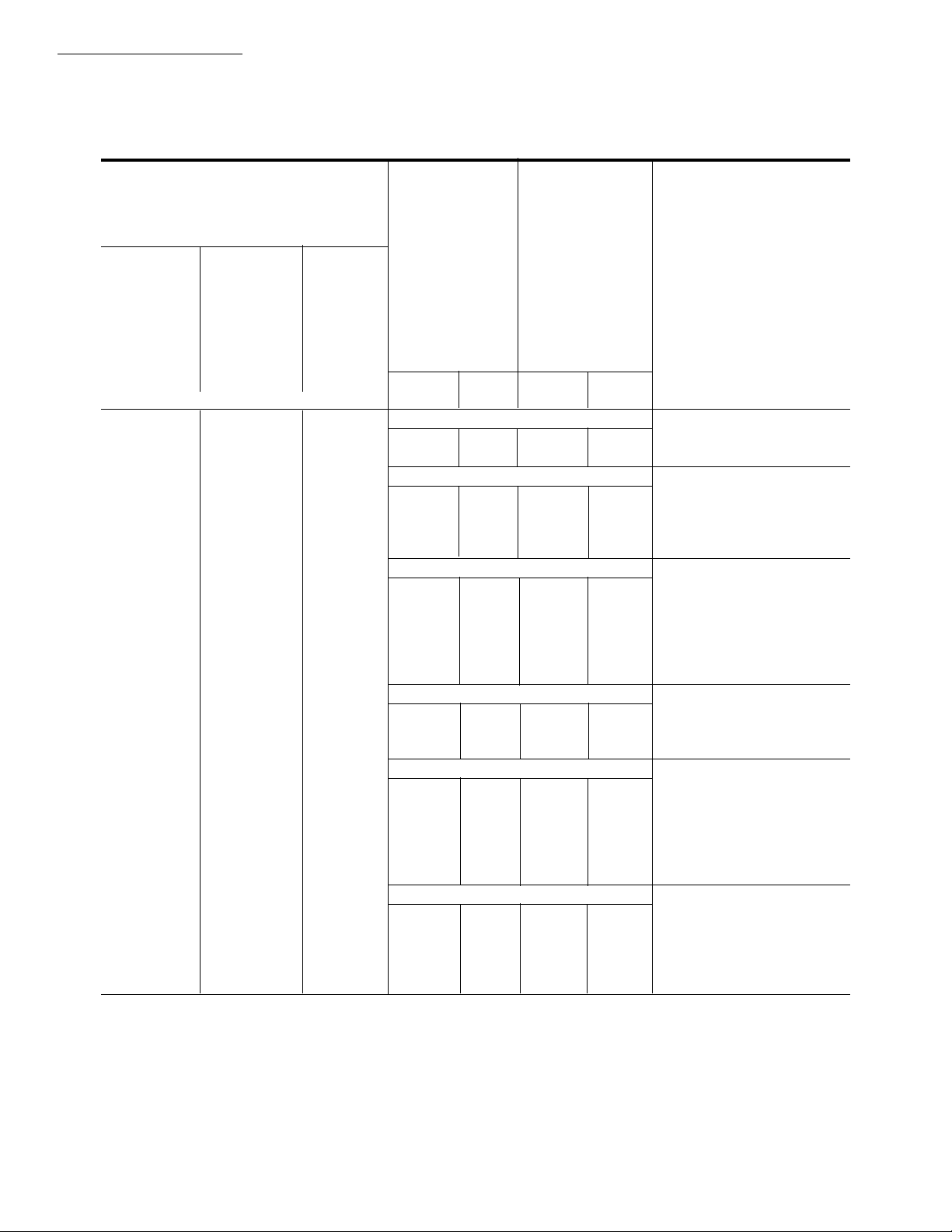

TABLE 3—T8611 GUIDE FOR REPLACING POPULAR T874 AND T872 THERMOSTATS,

BY EQUIPMENT MANUFACTURER.

(NOTE: Also see form 70-6627, Heat Pump Thermostat Cross Reference Guide, for wiring hookup illustrations.)

Thermostat (Subbase Included)

Auto Manual

Changeover Changeover

Weekday, Weekday,

Sat, Sun Sat, Sun Auto

T8611G1004 T8611R1000 Changeover

T8611G1012 (°C)T8611R1042 (°C) 7-day

T8611G1103 T8611R1141 T8611M7008

(Premier White) (Premier White) T8611M7040cThermostat Subbase Thermostat Subbase

(also see form 68-0057, Specifications) T874 Q674 T872 Q672 Comments

Amana

• D1009 F1022 D1003 F1026 Separate first stage

• D1017 D1011 heat/cool terminals W1, Y1.

• D1165 D1300

Arco/Comfort Maker

••

a

• na na na na Check LED optional;

X = X1, jump X2 to C.

Arco/Friedrich

••

a

• na na na na Changeover on heat,

check LED optional.

Bard

••

a

• N1024 F1261 N1036 F1299 Changeover on heat (typical),

• • • R1129 L1181 R1146 L1185 check LED optional, equipment

terminal W1 to thermostat B.

Bryant, Day-Night, Payne

b

•

••

••

changeover

••

a,b

•

a

a

a

b

•

G1451 F1113bG1166 F1125 Check LED optional; F = X1,

• G1261 F1253 jump X2 to C. Note: P terminal

• J1010 L1371 G1174 available on manual

• R1335 L1405 (T8611R) models only.

Carrier

••

a

• G1055 J1035 G1075 J1054 Check LED optional (typical)

• • • G1071 L1041 G1158 L1052

• • • G1121 L1397 G1182

• • • P1005 G1273

• • • G1307

• • • G1257 L1169

• • • J1002 L1371

• • • J1028 L1074

• D1074 F1059 Multistage heat pump

• F1030

• F1063

• E1114 No Supl. Ht. function

• E1042 No Supl. Ht. function

• D1264 L1116 Multistage heat pump

Command Aire

• • • H1005 C1041 H1009 C1086 No AUX. HEAT or EM.

• • • G1352 C1066 HEAT required; Y1 = 0

a

No CHECK LED.

b

Dual transformer requires conversion to single transformer.

c

Model includes separate sensor for remote temperature sensing.

(continued)

T8611M

7 68-0076—1

Page 8

T8611M

SELECTION/APPLICATION

TABLE 3—T8611 GUIDE FOR REPLACING POPULAR T874 AND T872 THERMOSTATS,

BY EQUIPMENT MANUFACTURER (Continued).

(NOTE: Also see form 70-6627, Heat Pump Thermostat Cross Reference Guide, for wiring hookup illustrations.)

Thermostat (Subbase Included)

Auto Manual

Changeover Changeover

Weekday, Weekday,

Sat, Sun Sat, Sun Auto

T8611G1004 T8611R1000 Changeover

T8611G1012 (°C)T8611R1042 (°C) 7-day

T8611G1103 T8611R1141 T8611M7008

(Premier White) (Premier White) T8611M7040cThermostat Subbase Thermostat Subbase

(also see form 68-0057, Specifications) T874 Q674 T872 Q672 Comments

Coleman

••

a

• R1368 L1421 na na Late models optional check

LED. Z = X2, jump X1 and C,

K = L.

• • • na na na na Earlier T.H.E. models with

reverse-acting EM. HT.

require relay isolation.

Crispaire/Marvair

• • • G1089 F1162 G1208 F1166

F1204 F1323

• • • R1111 L1215 R1156 L1094

Fedders/Airtemp/Climatrol

a

•

a

•

a

•

C1398 L1090 C1509 L1102 Separate first stage heat/cool

C1406 C1517 terminals required; check LED

C1414 C1541 optional; equipment terminal

K to thermostat E.

Florida Heat Pump

••

a

• na na na na Optional check LED;

X = X1, jump X2 to C.

Heatwave/Southwest Mfg.

• • • G1105 F1170 G1232 F1224

Heil Quaker/Whirlpool/Tempstar

• • • R1137 L1132 R1172 L1193 Equipment terminal B

to thermostat C.

Honeywell

• A-D (typ.) F1006 A-D (typ.) F1000 Separate first stage

• F1022 F1026 heat/cool terminals.

• F1048 F1042

• C1000 F1089 C1004 F1075

• • C1018 C1038

• • C1117 C1350 °C

• • C1240 C1566 °C

• • • G1246 F1212 G1224 F1208 TRADELINE

• • • G1444 G1000 F1018

• • • G1018 °C

• • • G1212 F1238 G1083 F1158

• • • G1139

a

No CHECK LED.

b

Dual transformer requires conversion to single transformer.

c

Model includes separate sensor for remote temperature sensing.

(continued)

8

Page 9

T8611M

SELECTION/APPLICATION

TABLE 3—T8611 GUIDE FOR REPLACING POPULAR T874 AND T872 THERMOSTATS,

BY EQUIPMENT MANUFACTURER (Continued).

(NOTE: Also see form 70-6627, Heat Pump Thermostat Cross Reference Guide, for wiring hookup illustrations.)

Thermostat (Subbase Included)

Auto Manual

Changeover Changeover

Weekday, Weekday,

Sat, Sun Sat, Sun Auto

T8611G1004 T8611R1000 Changeover

T8611G1012 (° C)T8611R1042 (° C) 7-day

T8611G1103 T8611R1141 T8611M7008

(Premier White) (Premier White) T8611M7040cThermostat Subbase Thermostat Subbase

(also see form 68-0057, Specifications) T874 Q674 T872 Q672 Comments

Honeywell (continued)

• • • N1016 F1220 N1002 F1133 Changeover on heat; equip-

• • • N1040 F1261 N1028 F1216 ment terminal C to thermostat

• • • R1004 B1042 R1008 B1046 Y, W1 to B, K to E.

• • • B1109 R1057 L1037

• • • R1152 L1207 R1198 L1227

• • • R1285 L1157

• • • R1350 L1181

Janitrol/Tappan

• • • G1147 F1139 G1109 F1117 Equipment terminal C to

thermostat C.

Lennox NOTE: Rewire for single 75

VA

transformer if two-transformer

system.

• • • G1014 F1113 G1026 F1067

• • • G1022 E1148 G1125 E1019 °C

• • • G1162 G1091 DoD specs—use guard.

• • • G1154 F1105 G1323 L1201

• • • R1024 B1160

• • • R1040 B1202

• • • R1178 L1355

• • • L1165

• • • C1148 L1165

• D1207 L1199 Two-speed unit; optional check

• L1389 LED; thermistor A not used.

Ter- minal Conversion

Guide:

Lennox Standard

Transformer

Common X C

Transformer

Power VR (in) R

V (out)

Compressor M Y

M2 Y2

Aux. Heating Y W2

Fan F G

Changeover R O

System Monitor L L,X1,X2

Em.Heat (cycling) E E

Thermistor A T (not

required)

a

No CHECK LED.

b

Dual transformer requires conversion to single transformer.

c

Model includes separate sensor for remote temperature sensing.

9 68-0076—1

(continued)

Page 10

T8611M

SELECTION/APPLICATION

TABLE 3—T8611 GUIDE FOR REPLACING POPULAR T874 AND T872 THERMOSTATS,

BY EQUIPMENT MANUFACTURER (Continued).

(NOTE: Also see form 70-6627, Heat Pump Thermostat Cross Reference Guide, for wiring hookup illustrations.)

Thermostat (Subbase Included)

Auto Manual

Changeover Changeover

Weekday, Weekday,

Sat, Sun Sat, Sun Auto

T8611G1004 T8611R1000 Changeover

T8611G1012 (° C)T8611R1042 (° C) 7-day

T8611G1103 T8611R1141 T8611M7008

(Premier White) (Premier White) T8611M7040cThermostat Subbase Thermostat Subbase

(also see form 68-0057, Specifications) T874 Q674 T872 Q672 Comments

Luxaire

• • • G (Borg F1188 G1315 F1281

Warner)

Magic Chef

• na na na na Earlier PB series, separate first

••

a

• na na na na Late PE series, optional check

stage heat/cool.

LED; X1 = X1, jump X2 to R.

Rheem/Ruud

• • • G1097 F1238 G1133 F1158

• • • G1238 G1141 L1157

• • • R1081 L1045

• • • G1220 R1107 L1136

• • • R1079

• • • R1095

Square D/Sun Dial

a

•

C1224 F1071 C1525 F1182 Separate first stage heat/cool

required; optional check LED;

X = X1, jump X2 to R.

Trane/General Electric

••

a

• G1204 J1043 G1059 J1039 Optional check LED; F = X1,

jump X2 to C; T not used;

equipment terminal B to thermostat C, R to R, Y to Y (Y1 +

W1), W to W2, G to G, 0 to 0,

X2 to E.

Weather King

• • • na na G1265 F1265 Optional check LED; X = X1,

jump X2 to R; equipment terminal C to thermostat C, W1

to Y (W1 + Y1), E to W2,

Y1 to 0.

a

No CHECK LED.

b

Dual transformer requires conversion to single transformer.

c

Model includes separate sensor for remote temperature sensing.

(continued)

10

Page 11

SELECTION/APPLICATION

TABLE 3—T8611 GUIDE FOR REPLACING POPULAR T874 AND T872 THERMOSTATS,

BY EQUIPMENT MANUFACTURER (Continued).

(NOTE: Also see form 70-6627, Heat Pump Thermostat Cross Reference Guide, for wiring hookup illustrations.)

Thermostat (Subbase Included)

Auto Manual

Changeover Changeover

Weekday, Weekday,

Sat, Sun Sat, Sun Auto

T8611G1004 T8611R1000 Changeover

T8611G1012 (° C)T8611R1042 (° C) 7-day

T8611G1103 T8611R1141 T8611M7008

(Premier White) (Premier White) T8611M7040cThermostat Subbase Thermostat Subbase

(also see form 68-0057, Specifications) T874 Q674 T872 Q672 Comments

Wesco/Addison

• • • G1287 F1253 Equipment terminal C1 to thermostat C, W1 to Y (W1 + Y1),

• • • R1012 B1109 R1016 B1103 Y1 to 0. Common to thermostat

• • • G1265 F1265 direct from control transformer.

• • • G1281

Westinghouse

• • • G1048 F1121 G1034 F1141

• • • F1246 F1091

• • • F1279 F1257

• • • J1019 J1013

• • • J1050 J1062

• • • R1103 L1108 R1149 L1110

• • • L1173 L1128

• • • L1151

• na na na na Separate first stage heat/cool

ter- minals required.

• D1108 L1223 G1356 L1219 2-speed heat pump; optional

check LED; L = X1, jump

X2 to C.

White Rodgers

• • • na na na na 1F58-910/S28 series.

Williamson

• • • R1236 L1348 na na

• • • N1008 F1196 na na Changeover on heat; W1 = B.

York/Borg Warner

••

a

• G1170 J1027 G1042 J1021 Optional check LED; X = X1,

• • • G1295 F1311 G1299 L1177 jump X2 to C; equipment ter-

• • • G1345 L1363 G1331 D1077 minal B to thermostat C,

• • • G1402 D1032 G1364 W to W2, H to B, T not re-

quired.

• • • G1410 G1398

• • • G1428

• • • G1436

• • • R1046 L1017 R1032 L1011

• • • R1169 L1330

• • • R1251 L1272

Zone Aire

• • • N1040 F1261 Changeover on heat;

• • • R1350 L1181 W1 = B.

a

No CHECK LED.

b

Dual transformer requires conversion to single transformer.

c

Model includes separate sensor for remote temperature sensing.

11 68-0076—1

T8611M

Page 12

T8611M

INSTALLATION

Installation

COMPATIBILITY

The T8611 Thermostats will replace most heat pump

system thermostats. As long as ac power is continuously

available to the thermostat, the thermostat will be compatible with almost any low-volt control system.

WHEN INSTALLING THIS PRODUCT…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given on the product to make sure

the product is suitable for your application.

3. Installer must be a trained, experienced service technician.

4. Allow thermostat to warm to room temperature

before operating.

5. After installation is complete, check out product

operation as provided in these instructions.

CAUTION

!

Disconnect power supply to prevent electrical

shock or equipment damage.

LOCATION

Thermostat with Integral Sensor

Install thermostat and subbase about 5 ft. [1.5 m] above

the floor in an area with good air circulation at room

temperature.

Do not install the thermostat where it may be affected

by—

— drafts or dead spots behind doors, in corners or under

cabinets.

— hot or cold air from ducts.

— radiant heat from sun or appliances.

— concealed pipes and chimneys.

— unheated (uncooled) areas behind the thermostat,

such as an outside wall.

This thermostat requires a single transformer. A twotransformer system may require turning off two switches

or disconnects, and rewiring to run the thermostat from a

single transformer. Make sure the transformer has adequate power (VA) for the heating/cooling control system.

Add current ratings of the system components (such as

auxiliary heat relay, changeover relay, fan relay). Multiply

this total by 24V to determine transformer VA required.

Remove any existing wallplate or subbase from wall.

Label or write down each wire color with the letter or

number on the wiring terminal as the wire is removed to

avoid miswiring later.

IF NEW INSTALLATION

Run cable to a hole at the selected wall location for

thermostat and remote sensor, and pull about 3 in. [76 mm]

of wire through the opening. Color-coded, 18-gauge thermostat cable with at least one conductor for each wiring

terminal is recommended. Good service practice recommends selecting cable with one or two more conductors

than the immediate application requires.

If using thermostat model with remote temperature

sensing, run 3-wire, 18-gauge thermostat cable from the

thermostat location to the sensor location (200 ft. [61 m]

maximum). Route cable away from sources of electrical

noise.

MOUNTING SUBBASE

IMPORTANT: Set the subbase system switch in the OFF

position before mounting.

The subbase does not require leveling for operation, but

for appearance only.

Remove thermostat from subbase (Fig. 4).

Thermostat with Remote-Mounted Sensor

Install thermostat in an area that is accessible for setting

and adjusting the temperature and settings.

Install remote temperature sensor in an area with good

air circulation at average temperature.

Do not install the sensor where it may be affected by—

— drafts or dead spots behind doors, in corners, or

under cabinets.

— hot or cold air from ducts.

— radiant heat from sun or appliances.

— concealed pipes and chimneys.

— unheated (uncooled) areas behind the sensor, such

as an outside wall.

IF REPLACING AN EXISTING THERMOSTAT

Turn thermostat power off at furnace or heat pump.

12

Page 13

Fig. 4—Removing thermostat from subbase.

REMOTE SENSOR

COVER

REMOTE

SENSOR BASE

WALL

MOUNTING HOLES

WIRING

HOLE

M1549B

WALL

ANCHORS (2)

MOUNTING

SCREWS (2)

WIRES

THROUGH

WALL

OPENING

The subbase mounts directly onto the wall with the

screws and anchors included. Instead, the subbase can be

mounted on a vertical or horizontal outlet box. If you must

mount the subbase on a vertical outlet box, order 193121A

Adapter Assembly. The assembly includes an adapter

ring, two screws and a cover plate to cover marks on the

wall. Install the ring and cover plate on the vertical outlet

box as instructed.

Use the subbase as a template, and with a pencil, mark

the two mounting screw positions (Fig. 5).

If drywall construction, plastic anchors must be used;

use 3/16 in. bit to drill holes for anchors. Gently tap

anchors into holes until they are flush with the wall

surface.

Thread wires through the center opening of the sub-

base.

T8611M

INSTALLATION

Use a 3/16 in. bit to drill the required holes. Gently tap

anchors into holes until they are flush with the wall

surface. Thread wires through the opening in the base.

Mount remote sensor base using the screws provided. See

Fig. 6. Make sure base looks level before tightening

screws.

Fig. 6—Mounting remote sensor base on wall.

Mount the subbase using two screws provided. Gently

tighten screws, level top surface of subbase, and securely

tighten screws.

Fig. 5—Mounting subbase on wall.

MOUNTING REMOTE TEMPERATURE SENSOR

(IF APPLICABLE)

The remote sensor mounts directly on the wall with

screws and anchors included. Remove cover from remote

sensor (Fig. 6). Use the remote sensor base as a template,

and with a pencil, mark holes for mounting screws.

WIRING

All wiring must comply with local electrical codes and

ordinances.

Disconnect power before wiring to prevent electrical

shock or equipment damage.

The shape of the terminal barrier permits insertion of

straight or conventional wraparound wiring connections.

Either method is acceptable.

Push excess wire back into the hole, and plug hole with

nonhardening caulk, putty or insulation to prevent drafts

from affecting operation of thermostat and remote sensor,

if applicable.

Refer to Figs. 8-10 for typical hookups of subbase and

thermostat.

After wiring remote sensor, replace cover.

NOTE: Restrict all wiring to recessed area surrounding

13 68-0076—1

Page 14

T8611M

INSTALLATION

terminals (Fig. 7) to assure thermostat/subbase contact.

7

POWER

SUPPLY

FAN

SWITCH

ON

AUTO

THERMOSTAT

LOGIC

CIRCUIT

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

POSSIBLE CHECK LED CIRCUITS:

2

X2

CHECK

LED

(YELLOW)

SWITCH TO R (POWER) SIDE OF

SYSTEM TRANSFORMER

3

SOME OLDER HEAT PUMP THERMOSTATS USE X FOR COMMON TERMINAL.

NOMINAL 24 Vac POWER MUST BE PRESENT BETWEEN R AND C TERMINALS FOR THERMOSTAT OPERATION.

4

RECOMMENDED INTERCONNECT CABLE: 18-GAUGE THERMOSTAT CABLE, 200 ft. [61 m] MAXIMUM LENGTH. ROUTE INTERCONNECT

5

CABLE AWAY FROM SOURCES OF ELECTRICAL NOISE.

APPLICABLE ONLY ON MODEL WITH REMOTE SENSOR.

6

7

FAULT DETECTION

SWITCH

X1

DENOTES THERMOSTAT TO SUBBASE INTERCONNECT.

SUBBASE

LOGIC/

CONTROL

CIRCUIT

EM. HT.

HEAT

OFF

AUTO

COOL

TO R

TO C

SYSTEM

SWITCH

HEAT 1

HIGH

LIMIT

S1

S2

S3

5

CHECK

LED

(YELLOW)

SWITCH TO C (COMMON) SIDE

OF SYSTEM TRANSFORMER

S1

S2

S3

202905 REMOTE

SENSOR

X2

FAULT DETECTION

SWITCH

X1

HIGH

LIMIT

EM. HEAT

LED (RED)

COOL 1

6

TO R

CHECK

LED

TO C

(YELLOW)

SWITCH IN SECONDARY OF

SEPARATE TRANSFORMER

HEAT 3

X2

SWITCHING

DEVICE

X1

4

AUX. HEAT

LED (GRN)

W3

W2

HEAT 2

G

C.O.

C.O.

Y2

COOL 2

X2

CHECK LED

(YELLOW)

X1

24 Vac

R

3

C

MONITOR

L

AUXILIARY

HEAT RELAY

STAGE 2

HEAT RELAY

EMERGENCY

HEAT RELAY

E

FAN RELAY

CHANGEOVER

RELAY (COOL)

O

CHANGEOVER

RELAY (HEAT)

B

STAGE 1 COMPRESSOR

CONTACTOR

Y

STAGE 2 COMPRESSOR

CONTACTOR

2

L1

(HOT)

1

L2

M1017D

1

L1

(HOT)

L2

14

Page 15

Fig. 7—Restrict wiring to recessed area surrounding terminals.

T8611M

INSTALLATION

THERMOSTAT

LOGIC

CIRCUIT

6

POWER

SUPPLY

SUBBASE

LOGIC/

CONTROL

CIRCUIT

EM. HT.

HEAT

OFF

AUTO

COOL

HEAT 1

HIGH

LIMIT

FAN

SWITCH

SYSTEM

SWITCH

ON

AUTO

HIGH

LIMIT

COOL 1

EM. HEAT

LED (RED)

HEAT 3

HEAT 2

C.O.

C.O.

COOL 2

R

4

3

C

AUX. HEAT

LED (GRN)

L

W3

W2

E

G

O

B

Y

STAGE 2 COMPRESSOR

CONTACTOR

Y2

MONITOR

EMERGENCY

HEAT RELAY

CHANGEOVER

RELAY (COOL)

CHANGEOVER

RELAY (HEAT)

STAGE 1 COMPRESSOR

CONTACTOR

STAGE 2

HEAT RELAY

FAN RELAY

1

L1

(HOT)

L2

S1

S2

S3

5

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

2

POSSIBLE CHECK LED CIRCUITS:

X2

CHECK

LED

(YELLOW)

SWITCH TO R (POWER) SIDE OF

SYSTEM TRANSFORMER

3

SOME OLDER HEAT PUMP THERMOSTATS USE X FOR COMMON TERMINAL.

4

NOMINAL 24 Vac POWER MUST BE PRESENT BETWEEN R AND C TERMINALS FOR THERMOSTAT OPERATION.

5

RECOMMENDED INTERCONNECT CABLE: 18-GAUGE THERMOSTAT CABLE, 200 ft. [61 m] MAXIMUM LENGTH. ROUTE

INTERCONNECT CABLE AWAY FROM SOURCES OF ELECTRICAL NOISE.

6

7

APPLICABLE ONLY ON MODEL WITH REMOTE SENSOR.

FAULT DETECTION

SWITCH

X1

DENOTES THERMOSTAT TO SUBBASE INTERCONNECT.

TO R

TO C

SWITCH TO C (COMMON) SIDE

OF SYSTEM TRANSFORMER

S1

S2

S3

202905 REMOTE

SENSOR

X2

CHECK

LED

(YELLOW)

FAULT DETECTION

SWITCH

X1

7

TO R

TO C

CHECK

LED

(YELLOW)

SWITCH IN SECONDARY OF

SEPARATE TRANSFORMER

X2

X1

X2

CHECK LED

(YELLOW)

X1

SWITCHING

DEVICE

24 Vac

2

L1

(HOT)

1

L2

M1018D

15 68-0076—1

Page 16

T8611M

INSTALLATION

Fig. 8—T8611M Thermostat with EM.HT.-HEAT-OFF-AUTO-COOL system and ON-AUTO fan switching;

EM.HT., CHECK, and AUX. HT. LEDS. Applied to 3-stage heat/2-stage cool system.

Fig. 9—T8611M Thermostat with EM.HT.-HEAT-OFF-AUTO-COOL system and ON-AUTO fan switching,

THERMOSTAT

LOGIC

CIRCUIT

7

POWER

SUPPLY

SUBBASE

LOGIC/

CONTROL

CIRCUIT

EM. HT.

HEAT

OFF

AUTO

COOL

HEAT 1

HIGH

LIMIT

FAN

SWITCH

ON

AUTO

SYSTEM

SWITCH

HIGH

LIMIT

EM. HEAT

LED (RED)

COOL 1

HEAT 3

HEAT 2

AUX. HEAT

LED (GRN)

C.O.

C.O.

COOL 2

R

4

3

C

MONITOR

L

AUXILIARY

HEAT RELAY

W3

W2

E

G

O

B

STAGE 1 COMPRESSOR

CONTACTOR

Y

Y2

EMERGENCY

HEAT RELAY

FAN RELAY

CHANGEOVER

RELAY (COOL)

CHANGEOVER

RELAY (HEAT)

1

L1

(HOT)

L2

2

S1

S2

S3

5

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

POSSIBLE CHECK LED CIRCUITS:

2

X2

CHECK

LED

(YELLOW)

SWITCH TO R (POWER) SIDE OF

SYSTEM TRANSFORMER

SOME OLDER HEAT PUMP THERMOSTATS USE X FOR COMMON TERMINAL.

3

NOMINAL 24 Vac POWER MUST BE PRESENT BETWEEN R AND C TERMINALS FOR THERMOSTAT OPERATION.

4

RECOMMENDED INTERCONNECT CABLE: 18-GAUGE THERMOSTAT CABLE, 200 ft. [61 m] MAXIMUM LENGTH. ROUTE

5

INTERCONNECT CABLE AWAY FROM SOURCES OF ELECTRICAL NOISE.

6

APPLICABLE ONLY ON MODEL WITH REMOTE SENSOR.

7

FAULT DETECTION

SWITCH

X1

DENOTES THERMOSTAT TO SUBBASE INTERCONNECT.

TO R

TO C

S1

S2

S3

202905 REMOTE

SENSOR

CHECK

LED

(YELLOW)

SWITCH TO C (COMMON) SIDE

OF SYSTEM TRANSFORMER

6

X2

FAULT DETECTION

SWITCH

X1

TO R

TO C

CHECK

LED

(YELLOW)

SWITCH IN SECONDARY OF

SEPARATE TRANSFORMER

X2

CHECK LED

(YELLOW)

X1

X2

SWITCHING

DEVICE

X1

24 Vac

L1

(HOT)

1

L2

M1019D

16

Page 17

T8611M

INSTALLATION

EM.HT. and CHECK LEDs. Applies to 2-stage

heat/2-stage cool system in which both heating

stages are compressorized.

Fig.10—T8611M Thermostat with EM.HT.-HEATOFF-AUTO-COOL system and ON-AUTO fan

switching; EM.HT., CHECK, and AUX. HT. LEDs.

Applied to 2-stage heat/1-stage cool system.

ADJUSTING CYCLE RATE

To customize the thermostat last heating stage cycling

performance to various types of auxiliary heating equipment, a cycle rate adjustment screw is provided on the back

of the thermostat to provide optimum savings and occupant

comfort.

NOTE: MOST APPLICATIONS WILL NOT REQUIRE

A CHANGE IN CYCLE RATE.

The room air temperature normally will vary slightly

from the comfort temperature setting with the cycling of

the heat pump or auxiliary heater.

Fig. 11—Cycle rate adjustment.

The Stage 1 cycle rate of this thermostat is factory-set

for heat pumps and cannot be adjusted. The auxiliary heat

cycle rate can be adjusted by turning the cycle rate adjustment screw on the back of the thermostat. See Fig. 11.

Increasing the cycle rate will reduce room temperature

swings when auxiliary heat is being used.

INSTALLING BATTERIES

Three AAA alkaline batteries are included to provide

backup to prevent program loss in case of power outage.

Install batteries in back of thermostat as shown in Fig. 12.

Without battery backup, the program will remain about

20 seconds in event of power loss.

IMPORTANT: When batteries are first installed, the

display will flash 1:00 PM and 32°. After a brief

delay, the display will flash 1:00 PM and room

temperature.

When the batteries are low, the display will flash REPL

BAT. Homeowner will have 20-30 seconds to install new

batteries after removing old batteries from back of thermostat. After 20-30 seconds, it will be necessary to reprogram. REPL BAT indication will disappear within 5-10

minutes when thermostat is remounted on the powered

subbase.

Fig. 12—Battery placement.

IMPORTANT: For proper thermostat operation, always

replace dead batteries with new alkaline batteries.

If batteries are completely dead, the display will go

blank when the thermostat is removed from subbase. After

replacing the batteries, reprogramming will be necessary.

POWER OUTAGES

Backup batteries will hold the programming and keep

the display on during most power outages. Once the power

is restored, the system will resume normal operation.

If the display goes off when power is lost, either the

backup batteries need to be replaced or are not installed.

When power is restored, the display will flash 1:00 PM to

remind you to reprogram.

MOUNTING THE THERMOSTAT

With system switch set to OFF, hang the thermostat on

the tabs at the top of the subbase (Fig. 13A). Swing down

SET

PRESENT

DAY/TIME

and press on lower edge until thermostat snaps in place

(Fig. 13B). Open cover and tighten the captive mounting

DAY

screws (Fig. 13C).

BACK

SETTING DAY AND TIME

AHEAD

Restore 24V power to the thermostat. Set present day

and time.

Press .

Press to set the current day. (Each press of the

DAY key advances the display one day.)

Press TIME or to set the current time.

If the display will not come on—

— check mounting of thermostat to subbase. If loose or

misaligned, remove thermostat and reinstall on the

17 68-0076—1

subbase, making sure it is firmly attached.

— check to see that batteries are installed properly.

Page 18

T8611M

INSTALLATION • CHECKOUT

Fig. 13—Mounting thermostat on subbase.

CAUTION

!

During cold weather, some heat pumps will require that crankcase heater be energized several

hours before operating heat pump. Refer to

manufacturer’s recommendations.

HEATING

NOTE: When heating setting is changed, thermostat will

wait up to 5 minutes before turning on the heating

equipment. This delay protects the compressor.

Move the system switch to HEAT and the fan switch to

AUTO. Press WARMER key until the setting is about 10°

F [6° C] above room temperature. Heating should start and

the fan should run (there may be a delay of 5-10 minutes

before heat turns on). Press COOLER key until the setting

is about 10° F [6° C] below room temperature. The heating

equipment should shut off, followed by the fan.

NOTE: On an AUTO changeover thermostat, the cooling

temperature must be set at least 3° F [2° C] above the

heating temperature, or display will flash.

Checkout

COOLING

CAUTION

!

Do not operate cooling if outdoor temperature is

below 50° F [10° C]. Refer to manufacturer’s

recommendations.

NOTE: When cooling setting is changed, thermostat will

wait up to five minutes before turning on the cooling

equipment. This delay protects the compressor.

Move the system switch to COOL and the fan switch to

AUTO. Press COOLER key until the setting is about 10°

F [6° C] below room temperature. The cooling equipment

and fan should start. Press WARMER key until the setting

is about 10° F [6° C] above room temperature. The cooling

equipment and fan should stop.

NOTE: On an AUTO changeover thermostat, the heating

temperature must be set at least 3° F [2° C] below the

cooling temperature, or display will flash.

18

Page 19

T8611M

CHECKOUT

FAN

Move the system switch to OFF, and the fan switch to

ON. The fan should run continuously. When the fan switch

is in the AUTO position, fan cycles with the heating or

cooling system.

INSTALLER SELF-TEST (OPTIONAL)

IMPORTANT:

• Thermostat must have ac power to perform self-test.

• Five-minute time delay on compressor does not

function during self-test.

Perform the following test as a check of all thermostat

functions. If thermostat does not respond as indicated,

thermostat and subbase must be replaced.

1. Press AHEAD and BACK keys at the same time.

While holding keys down, all segments of the display

should be on (see Fig. 14).

Fig. 14—All segments on display.

REPL

MON

SUN

MORNING

TUE WED THU FRI SAT TEMPORARY

MIDDAY EVENING NIGHT COOL ON HEAT ON

AM

PM

BAT

SET

PT

ROOM

OUTDOOR

M 525A

2. Set system switch to OFF. Press and release AHEAD,

BACK, and PRESENT SETTING keys at the same time to

enter self-test.

3. Press each key as listed below, and look for responses listed as key is held down and released. Keys may

be pressed in any order except RUN PROGRAM should

be pressed last because it ends self-test.

System Press Look For This Response

Switch This Key

Position Key Down Key Released

OFF 03 Blank

COOL or 15 1st stage cooling, fan and

(with fan 15 2nd stage cooling also on.

in AUTO)

OFF 06 Blank

(CHECK 12 See note A .

EACH )

CHANGE

TO LAST

PERIOD

SKIP

NEXT

PERIOD

PRESENT

SETTING

PRESENT

SETTING

AUTO SYSTEM LED on.

PRESENT

SETTING

PRESENT

SETTING

PRESENT

SETTING

WARMER

COOLER

AHEAD

BACK

COPY

FROM

COPY

TO

PERIOD

07 Blank

15 Blank

15 2nd stage cooling off.

15 1st stage cooling, fan and

SYSTEM LED on.

02 Blank

05 Blank

04 Blank

01 Control microprocessor

mask no. and revision no.

00 Blank

POSITION)

OFF 08 Blank

CANCEL

PERIOD

13 Interface microprocessor

DAY

no.

HEAT or 14 1st stage heating, fan

AUTO and SYSTEM LED on.

(with fan 14 2nd stage heating also on.

in auto)

OFF 10 Blank

SET

HEAT/COOL

SET

PRESENT

DAY/TIME

SET

PRESENT

DAY/TIME

SET

PRESENT

DAY/TIME

SET

PRESENT

DAY/TIME

SET

PRESENT

DAY/TIME

SET

PRESENT

DAY/TIME

SET

PRESENT

DAY/TIME

HOLD

TEMP

RUN

PROGRAM

09 Blank

14 Blank

14 3rd stage heating and AUX.

14 3rd stage heating and AUX.

14 2nd stage heating also off.

14 1st stage heating, fan and

11 Normal operating display

mask no. and revision

HT. LED also on.

HT. LED off.

SYSTEM LED also off.

A HEAT displayed when system switch is in HEAT, COOL

when in COOL, HEAT and COOL when in AUTO, neither

when in OFF. Also, a four-digit code is displayed. Explanation for each digit is following.

19 68-0076—1

Page 20

T8611M

CHECKOUT • PROGRAMMING THE THERMOSTAT

First Digit Degrees Clock (Hrs.)

0F12

1F24

2C12

3C24

Second Digit System Switch Position

0 EM. HT., HEAT or OFF

1 AUTO

2 COOL

Third System Switch Sensor

Digit Position Location

0 COOL, AUTO or OFF Local

1 HEAT or EM.HT. Local

4 COOL, AUTO or COOL Remote

5 HEAT or EM. HT. Remote

M5346

Nominal Cycle Rate

Fourth (cph at 50% load

Digit for 3rd stage heat)

46

53

STEP 1

SETTING THE CURRENT DAY

AND TIME

This thermostat can be programmed

either on the wall or in the hand. See

page 12 to remove the thermostat from

the subbase.

Always press the keys with fingertip or

similar blunt tool. Sharp instruments

like a pen or pencil point can damage

the keyboard.

NOTE: Check the glossary, page 30,

for definitions of unfamiliar words.

STEP 2

SETTING THE PROGRAM

TIMES AND TEMPERATURES

FOR ONE DAY

Choose a day to program first. Monday

is used in the examples. Start by programming the MORNING time and

temperatures. The thermostat requires

a MORNING program every day. Set

additional programs as desired.

Programming The Ther mostat

SET

PRESENT

DAY/TIME

DAY

TIME

AHEAD

BACK

PERIOD

SET

HEAT/COOL

DAY

Press and release. The display shows

1:00 PM Mon.

Press and hold until the current day appears in the display.

Press and hold until the current time appears in the display. Be sure AM or PM

appears as desired.

This completes setting the current day and

time. Go on to Step 2.

Press and release. Note that the display

shows MORNING and the preprogrammed

time and temperature.

If the display reads COOL, press and release to switch to HEAT.

Press and hold until MONDAY (or the

desired day) appears in the display.

MON

MON

MORNING

MON

MORNING

MON

MORNING

TUE

TUE

PM

PM

PM

AM

AM

AM

M2701

M2702

M2703

HEAT

M2704

HEAT

M2704

HEAT

M2704

SET

PT

SET

PT

SET

PT

20

Page 21

T8611M

PROGRAMMING THE THERMOSTAT

Program the MIDDAY time and heating temperature if desired.

AHEAD

BACK

WARMER

COOLER

PERIOD

AHEAD

BACK

Press and hold until the display shows the

time that the temperature should be at the

comfort setting.

Press and hold until the display shows the

desired heating temperature.

If the display flashes while holding down

TEMPERATURE WARMER or

COOLER, the setting limit has been

reached. If thermostat is an auto changeover

model, the heating temperature must be at

least 3 degrees below the air conditioning

temperature. For example, if the cooling

setting is 75° F, the maximum heating setting is 72° F. To set a higher heating temperature, first raise the cooling setting.

Press and release. The display shows MIDDAY, but no time or temperature.

Press and hold until the display shows the

time to start the energy saving period.

AM

MON

MORNING

AM

MON

MORNING

MON

MIDDAY

AM

MON

MIDDAY HEAT

HEAT

M2705

HEAT

M2706

HEAT

M2708

SET

PT

SET

PT

SET

PT

SET

PT

NOTE: It is possible to cancel any

period showing on the display except MORNING by pushing the

CANCEL PERIOD key. To move

to the next period while programming, simply press the PERIOD

key again.

Program the EVENING time and temperature, if desired.

WARMER

COOLER

PERIOD

AHEAD

BACK

WARMER

COOLER

Press and hold until the display shows the

desired temperature.

Press and release. The display shows

EVENING, but no time or temperature.

Press and hold until the display shows the

time the temperature should be at the comfort setting.

Press and hold until the display shows the

desired heating temperature.

AM

MON

MIDDAY HEAT

MON

EVENING

PM

MON

EVENING HEAT

PM

MON

EVENING HEAT

M2709

HEAT

M2711

M2712

SET

PT

SET

PT

SET

PT

SET

PT

21 68-0076—1

Page 22

T8611M

PROGRAMMING THE THERMOSTAT

Program the NIGHT time and temperature, if desired.

PERIOD

AHEAD

BACK

WARMER

COOLER

Press and release. The display shows

NIGHT and the preprogrammed time and

temp-erature.

Press and hold until the display shows the

time to start the energy saving period.

Press and hold until the display shows the

desired heating temperature.

MON

MON

MON

PM

NIGHT HEAT

PM

NIGHT HEAT

PM

NIGHT HEAT

M2713

M2714

M2715

SET

PT

SET

PT

SET

PT

Set the cooling temperatures for all the

periods programmed. The program

times are the same for both heating and

cooling. Only the cooling temperatures

need to be programmed if programming has been completed for heating.

If you change program times for cooling, you are also changing the times for

SET

HEAT/COOL

WARMER

COOLER

PERIOD

WARMER

COOLER

PERIOD

heating.

Press and release. The display shows

COOL, the preprogrammed cooling temperature and the programmed start time for

NIGHT.

Press and hold until the display shows the

desired cooling temperature for NIGHT.

If the display blinks while holding down

TEMPERATURE WARMER or

COOLER, the setting limit has been

reached. If thermostat can switch automatically between heating and cooling, the

heating temperature must be at least 3 degrees F below the air conditioning temperature. For example, if the heating setting is 72° F, the minimum cooling setting

is 75° F. To set the cooling temperature

lower, first lower the heating setting.

Press and release. The display shows the

preprogrammed cooling temperature and

the programmed start time for MORNING.

Press and hold until the display shows the

desired cooling temperature for MORNING.

MON

MON

MON

MORNING

MON

MORNING

MON

MIDDAY COOL

PM

NIGHT COOL

PM

NIGHT COOL

AM

AM

AM

COOL

COOL

M2716

M2717

M2718

M2719

M2720

SET

PT

SET

PT

SET

PT

SET

PT

SET

PT

WARMER

COOLER

PERIOD

WARMER

COOLER

Press and release. The display shows the

preprogrammed cooling temperature and

the programmed start time for MIDDAY.

Press and hold until the display shows the

desired cooling temperature for MIDDAY.

Press and release. The display shows the

preprogrammed cooling temperature and

the programmed start time for EVENING.

Press and hold until the display shows the

desired cooling temperature for EVENING.

22

This completes the program schedule for

one day. Go to Step 3 to copy this program

AM

MON

MIDDAY COOL

PM

MON

EVENING COOL

PM

MON

EVENING COOL

M2721

M2722

M2723

SET

PT

SET

PT

ROOM

SET

PT

ROOM

Page 23

T8611M

PROGRAMMING THE THERMOSTAT

STEP 3

COPYING THE PROGRAM TO

THE DESIRED DAYS

It is possible to copy the program for

one day to any other day or combination of days. The new program will

replace any program already set in the

day selected.

PERIOD

DAY

COPY

FROM

COPY

TO

DAY

COPY

TO

If necessary, press and release to enter the

programming mode.

Press and hold until the day containing the

program to be copied shows in the display.

Press and release. The day to be copied will

show, and the next day will flash, in the

display.

Press and release to copy the program into

the day that is flashing in the display. Note

that the next day now starts to flash.

Press and release if it is not desired to copy

into the day that is flashing. Note that the

next day now starts to flash.

Press and release the COPY TO key again

to select the day that is flashing, or the

DAY key to bypass it.

Continue until all desired days are showing

in the display and are not flashing.

If an error is made in copying, start over by

pressing COPY TO key repeatedly until all

days are shown (not flashing); press COPY

TO key once more.

MON

MON

MON

MON

MON

MON

TUE

TUE WED

WED

WED THU

TUE

MIDDAY

PM

NIGHT HEAT

PM

NIGHT HEAT

PM

M2724

M2724

M2725

M2726

M2727

M2728

M2729

SET

PT

SET

PT

STEP 4

SETTING THE SCHEDULES

AND TEMPERATURES FOR

THE REMAINING DAYS

Use the procedures described in Steps

2 and 3 and summarized in this step to

program the remaining days.

RUN

PROGRAM

PERIOD

DAY

SET

HEAT/COOL

AHEAD

BACK

PERIOD

Press and release to copy the program into

all the days selected.

Press and release to enter the programming

mode.

Press and hold until the day desired to

program shows on the display.

If COOL shows on the display, press and

release to switch to HEAT.

Use the AHEAD/BACK keys to set the

time and the WARMER/COOLER keys to

set the heating temperature.

Press and release the PERIOD key to step

through the remaining time periods. Use the

AHEAD/BACK keys to set the time and the

WARMER/COOLER keys to set the heating temperature for each time period.

AM

TUE

MIDDAY HEAT

FRI

MIDDAY HEAT

FRI

MIDDAY HEAT

WARMER

COOLER

AHEAD

BACK

WARMER

COOLER

M2730

M2731

M2731

SET

PT

SET

PT

SET

PT

23 68-0076—1

Page 24

T8611M

PROGRAMMING THE THERMOSTAT

SET

HEAT/COOL

PERIOD

COPY

FROM

COPY

TO

DAY

COPY

TO

RUN

PROGRAM

Press and release so COOL shows on the

display.

Press and release the PERIOD key to step

through the time periods, and use the

WARMER/COOLER keys to set the

cooling temperature for each period.

This completes the time and temperature

program for another day. Copy it into

additional days if desired.

Press and release COPY FROM to enter

the copy mode. The next day flashes on

the display.

Press and release the COPY TO key to

select the day that is flashing, or the DAY

key to bypass it.

Continue, using the COPY TO key to

bring up the next day, followed by COPY

TO to select, or DAY to bypass the DAY,

until all desired days are selected.

Press and release RUN PROGRAM to

complete the copy.

Repeat Step 4 as needed until all days are

programmed.

AM

MORNING

WARMER

COOLER

SUN FRI

COPY

DAY

PM

TUE

MIDDAY

FRI

FRI SAT

TO

COOL

M2732

M2733

M2734

M2735

SET

PT

STEP 5

SETTING THE SYSTEM AND

FAN SWITCHES ON THE

SUBBASE.

Depending on thermostat model, some

of the switch positions shown may not

be available. Note the positions provided on subbase, then set the switch(es)

as desired.

First set the fan switch.

Then set the system switch.

FAN ON: The fan runs continuously.

Use for improved air circulation during

special occasions or for more efficient

electronic air cleaning.

FAN AUTO: Normal setting for most

homes and businesses. The fan starts and

stops with the compressor in heat pump

systems when the system switch is set to

HEAT, AUTO or COOL. When system

switch is set to EM. HT., the fan operates

with the auxiliary heat (on some models).

EM. HT: The thermostat controls only

the backup heat. The heat pump is off.

HEAT: The thermostat controls the heating system.

OFF: Both the heating and cooling systems are off.

AUTO

ON

AUTO

ON

EM. HT. HEAT OFF

EM. HT. HEAT OFF

EM. HT. HEAT OFF

AUTO

AUTO

AUTO

FAN

M2757

FAN

M2758

COOL

COOL

M2754

M2752

COOL

M2753

24

Page 25

T8611M

PROGRAMMING THE THERMOSTAT • OPERATING THE THERMOSTAT

Then set the system switch. (continued)

Now, read on to learn about the operating flexibility that makes this thermostat THE SMART CHOICE.

TEMPORARILY CHANGING

THE PROGRAM

These features allow customizing the

program for those times when someone comes home early, is working late

or planning to be out for the evening.

AUTO (select models only): The thermostat controls either the heating or cooling system, depending on room temperature.

EM. HT. HEAT OFF

AUTO

COOL

M2755

COOL: The thermostat controls the cool-

COOL

ing system.

EM. HT. HEAT OFF

AUTO

M2756

This completes the programming of the

thermostat.

If thermostat was removed from the wall

to program, replace it following the procedure on page 20.

Operating The Thermostat

Changes made with these keys are active for one program period and then

are canceled.

To keep the current temperature

through the next program period:

SKIP

NEXT

PERIOD

Press and release. The name of the period

to be skipped will flash in the display

until the start time of the skipped period.

During the skipped period, the display

will flash “temporary” to show that the

programmed temperature for this period

is not being used.

To go back to the temperature of the

previous program period:

CHANGE

TO LAST

PERIOD

Press and release. The display will show

the name of the previous period and flash

“temporary” until the next regularly

scheduled period starts.

IMPORTANT: The CHANGE feature will be operable the day after the thermostat has been

programmed and operating. The thermostat requires this time to learn the programmed

schedule.

To temporarily raise or lower the temperature for the current period only:

WARMER

Press and hold until the desired temperature is reached. The display will flash

“tem-porary” until the next programmed

COOLER

time period starts.

PM

TUE

MIDDAY EVENING

PM

TUE TEMPORARY

MORNING

M2736

M2737

TEMPORARY

HEAT

M2738

SET

PT

SET

PT

SET

PT

To change back:

RUN

PROGRAM

Press and release to cancel any of the

temporary settings.

TUE

MIDDAY

25 68-0076—1

PM

M2739

Page 26

T8611M

OPERATING THE THERMOSTAT

REPROGRAMMING THE

THERMOSTAT

If schedule changes or a different temperature is desired, update any setting

without affecting the rest of the program.

PERIOD

DAY

Press and hold until the desired time period

shows on the display.

Press and hold until the desired schedule

day shows on the display.

Copy the new program into other days,

if desired. When copying a program, all

the times and temperatures for that day

HOLDING A TEMPERATURE

FOR EXTENDED ABSENCE

This feature is particularly useful when

going on vacation or other extended

absence. It does not cancel the pro-

AHEAD

BACK

COPY

FROM

RUN

PROGRAM

HOLD

TEMP

WARMER

COOLER

PRESENT

SETTING

RUN

PROGRAM

Press and hold the Time or Temperature

keys until the display shows the desired

new program.

are copied.

Press and release. The next day will flash

on the display. Press COPY TO to copy

into, or DAY to bypass, the day. Continue

until the program has been copied into all

desired days.

Press and release to return to normal operation.

gram.

Press and release.

Press and hold to change the temperature

setting. After a few seconds, the display

will show the current temperature.

Press and release to check the temperature

setting.

TUE

MIDDAY

WARMER

COOLER

COPY

TO

DAY

PM

HEAT

M2740

HEAT

M2741

HEAT

M2742

M2743

SET

PT

SET

PT

SET

PT

Press and release to cancel manual control.

CANCELING PROGRAM

SETTINGS

The thermostat requires time and temperature settings in the MORNING time

period for each day, but any of the

Both the heating and cooling temperatures will be canceled.

Use the copy function to cancel the

program from other days, but remem-

PERIOD

DAY

CANCEL

PERIOD

RUN

PROGRAM

others can be canceled. Each time period

for each day must be canceled separately.

Press and hold until the desired time period

shows on the display.

Press and hold until the desired day shows

on the display.

Press and release to cancel the time and

temperature settings for that time period.

ber: all the programs will be copied, not

just the cancellation.

26

MON

WED

WED

WED

EVENING HEAT

PM

NIGHT HEAT

PM

NIGHT HEAT

NIGHT HEAT

PM

M2744

M2745

M2746

M2747

SET

PT

SET

PT

SET

PT

Page 27

T8611M

OPERATING THE THERMOSTAT • OPERATION

Press and release to return to normal

operation.

CHECKING THE PROGRAM

TIMES AND TEMPERATURES

If desired, check all the stored settings

tion.

CHECKING THE CURRENT

TEMPERATURE SETTING

Press a single key to compare actual

room temperature to the setting at any

PERIOD

DAY

RUN

PROGRAM

PRESENT

SETTING

without affecting the permanent program.

Press and hold until the desired period shows

on the display. The start time and temperature setting will appear on the display.

Press and release to display the next day

time and temperature for that period.

Press and release to return to normal opera-

time.

Press and release. The display will show

the current temperature setting for several

seconds, then revert to the room temperature.

During recovery from energy savings, the

setting displayed will not match the programmed setting. This is because the thermostat gradually changes the temperature

setting during recovery to provide maximum comfort combined with most efficient use of the heating or cooling equipment.

Operation

PM

FRI

NIGHT HEAT

PM

NIGHT HEAT

PM

FRI

EVENING

SAT

M2748

M2749

M2750

HEAT

M2751

SET

PT

SET

PT

SET

PT

SET

PT

The T8611M Thermostat provides automatic control of

multistage heat pump systems with up to three stages of

heat and up to two stages of cool. The first heat stage is the

heat pump and the last stage is electric, gas, or oil auxiliary

heat. T8611M provides automatic changeover from heat

to cool or cool to heat.

ADAPTIVE INTELLIGENT RECOVERY™

OPERATION

Adaptive Intelligent Recovery™ is the Honeywell trademark for the way the T8611 controls the heating and

cooling equipment during recovery from an energy savings setting to a comfort setting. During recovery, the

control point changes gradually rather than jumping from

the energy savings setting to the comfort setting all at once.

This provides additional energy savings.

When Adaptive Intelligent Recovery™ is used in the

heating mode, the control point raises gradually, maximizing the use of the more economical heat pump to bring the

sensed temperature to the desired comfort setpoint. This

minimizes the use of the typically more expensive auxiliary heat.

In both heating and cooling, the thermostat monitors

recovery each day and adjusts the next day recovery start

time. This ensures that the building is at the desired

temperature at the programmed time, regardless of the

outdoor temperature. Recovery time varies depending on

the weather conditions and the building heating/cooling

system.

The advantages are:

• The comfort setting is achieved at the programmed

time and maintained regardless of weather conditions; occupants come home and wake up to comfort.

• Drafts from low temperature discharge air are minimized during occupied periods.

• The thermostat automatically uses the more economical heat pump as the primary heat source during heat mode recovery, avoiding the use of the

expensive auxiliary heat.

• Comfort and energy savings can be achieved in both

heating and cooling.

• Reduces heat pump compressor cycling, extending

equipment life.

Use of Outdoor Thermostats

Because Adaptive Intelligent Recovery™ calls for auxiliary heat only when it is truly needed, it eliminates the

need for outdoor thermostat(s). If an outdoor thermostat is

used with T8611 and it is set close to the balance point, the

recovery time from energy savings will be prolonged

because the outdoor thermostat will prevent operation of

27 68-0076—1

Page 28

T8611M

OPERATION

the auxiliary heat even when the T8611 is calling for it.

(Balance point is the outdoor temperature below which the

heat pump must call on auxiliary heat to help handle the

load.) The resulting unnecessarily long recovery times

reduce building energy savings.

When Adaptive Intelligent Recovery™ Is Used

Adaptive Intelligent Recovery™ is used during recovery from energy savings. It is bypassed when the setpoint

is changed, and when the CHANGE TO LAST PERIOD,

SKIP NEXT PERIOD or HOLD TEMP key is pressed. If

Adaptive Intelligent Recovery™ is bypassed, the system

operates the stages of equipment like a conventional thermostat.

WHAT TO EXPECT DURING RECOVERY

FROM ENERGY SAVINGS IN HEATING

The T8611 controls the heating equipment based on the

indoor sensed temperature, which is a combination of air

temperature and wall temperature.

In Mild Weather

When the outdoor temperature is mild, say 50°F [10°

C], the recovery from energy savings will be handled

completely by the heat pump, without using the more

costly auxiliary heat. The heat pump starts only after the

control point has risen above the sensed temperature and

is locked on until the comfort setpoint is reached. During

the comfort period, the heat pump will cycle on and off as

needed to maintain the sensed temperature within +/-1° F

of the setpoint. During energy savings periods, the T8611

will call the heat pump on only if the sensed temperature

falls below the control point.

In Moderate Weather

When outdoor temperature is below the balance point

of the heat pump, the heat pump will run continuously

during the recovery period and the auxiliary heat will cycle

as necessary. During the comfort period, the heat pump

runs continuously and auxiliary heat cycles until the next

energy savings period begins. During energy savings, the

heat pump cycles on only when the sensed temperature

falls below the control point. Under these conditions,

auxiliary heat is typically not needed during the energy

savings period.

In Severe Weather

When the outdoor temperature is severe, say 0° F [-18°

C], the heat pump is on continuously and auxiliary heat

cycles even during the energy savings period. When recovery from energy savings begins, the heat pump will

stay on and auxiliary heat will cycle. During recovery, the

auxiliary heat ON times will be long, and the OFF times

will be short. The ON times will shorten as the control

point approaches the comfort setpoint. During the comfort

period, the heat pump is on continuously and auxiliary heat

cycles until the next energy savings period. When energy

saving begins, the heat pump cycles off until the sensed

temperature falls below the control point. Although the

heat pump comes on when the sensed temperature falls

below the control point, the sensed temperature may lag 2°

or 3° F below the control point because of the time required

to warm up the walls and furniture. Auxiliary heat will

cycle as necessary during the energy savings period.

THERMAL PERFORMANCE WITH T8611

During severe weather, the T8611 actually controls

closer to the setpoint than a conventional thermostat. This

is because the heat anticipator is replaced by two electronic control strategies—cycling by heat anticipation and

proportional plus integral control.

Electronic cycling by heat anticipation acts like a traditional heat anticipator, except that never needs adjustment

for various control circuit load currents. It cycles the heat

pump off slightly before the room temperature reaches the

setpoint to keep heat remaining in the ductwork from

overheating the room.

In severe weather, a conventional thermostat with a

heat anticipator tends to turn off the thermostat too soon,

so the effective control point is somewhat below the

setpoint. In very cold weather, the difference between

setpoint and effective control point may be 5° or 6° F [2°

or 3° C] with a conventional thermostat. This phenomenon

is called droop.

Proportional plus integral action eliminates droop by

adjusting the on-time of the stage that is cycling longer or

shorter until the control point matches the setpoint. The

T8611 controls space temperature within one degree of

setpoint, when the temperature has stabilized after an

energy savings period.

This zero droop performance of the T8611 provides

improved occupant comfort and energy savings. Occupants do not need to continually adjust thermostat setting

to maintain desired temperature, even during severe

weather.

MINIMUM-OFF TIMING

A minimum-off timer in the T8611 ensures that the

compressor will not come on again for at least five minutes

after it turns off. The minimum-off timer is triggered when

the compressor goes off, or when the system switch is

moved. If the compressor turns off when the setpoint is

changed or the CHANGE TO LAST PERIOD key is

pressed, then the minimum-off timer is triggered. The

minimum-off timer operates during the first stage of both

heating and cooling.

28

Page 29

TROUBLESHOOTING

Troubleshooting

Start the system by setting the thermostat and observing system response. If problem occurs, establish symptom and use

the following troubleshooting chart to check for possible cause and action.

SYMPTOM POSSIBLE CAUSE ACTION

HEAT PUMP OR AUXILIARY HEAT

WON'T OPERATE

NO ac POWER TO THERMOSTAT

THERMOSTA T INO P E RAT IVE CONDUCT SELF - TEST; SEE CHE CK OUT.

CHECK POWER TO HEAT PUMP OR

AUXILIARY HEATING SYSTEM

–ON-OFF SWITCH

–FUSE OR CIRCUIT BREAKER

–LOOS E 24 V CONNECTION

-AT THERMOSTAT

-AT HEAT PUMP OR AUXILIAR Y HEATI NG SYSTEM

–INCORR E CT WI RING

-CHECK WIRING DI A GRAM

T8611M

PAR TIAL DISPLAY

NO DISPLAY

PRESENT SETTING APPEARS

INACCURATE

ROOM T EMPERATURE DISPLAY

APPEARS INACCURATE

PRESENT SETTING TOO LOW/HIGH

SYSTEM SWITCH ON THERMOSTAT IN

WRONG POSITION

MINIMUM-OFF TIMES IN THERMOSTAT IN

OPERATION ON COOLING OR HEATING

INCORR E CT WI RING CHECK CIRCUIT DIAGRA M .

HEAT PUMP OR AUXILIARY HEAT SYSTEM

INOPERATIVE

INOPERATI VE T HER MO STAT

NO POWER T O T HER MO STAT

THERMOSTAT IN SELF-TEST MODE PRESS RUN PROGR AM KEY T W I CE.

THERMOSTAT MOUNTED INCORR ECTLY

ON BASE

THERMOSTAT IS IN RECOVERY MO DE

THERMOSTAT HAS SEPARATE REMOTEMOUNT E D SENSOR

ADJUST TEMPER AT UR E BY PUSHING WARMER / COO LER

KEYS.

R ESE T THERMOSTAT SYST EM SWIT CH.

WAIT 5-10 MIN. OR USE SELF-TEST IN THERMOSTAT.

SEE CHECKOUT.

CONSULT HEAT PUMP/AUXILIARY HEAT SYSTEM

INSTRUCTIONS.

REPLACE THERMOSTAT.

CHECK THAT HEAT OR COOL SYSTEM POWER IS ON.

SEE INSTALLATION INS TRUCTIONS FOR CORRECT

MOUNTING.

•

NORMAL OPERATION THERMOSTAT TURNS ON

HEATING/COOLING EAR LY TO MEET T EMPERATURE

SETTING AT PROGRAMMED TIMES.

•

RECOVERY CAN BE ENDED BY PUSHING

WARMER / COO LER KEYS.

•

THERMOSTAT IS CONTROLLED BY TEMPERATUR E SENSED

AT REMOTE SENS OR LOCATION.

•

CHECK TEMPERATURE AT R EMO T E SENSOR LOCATION.

•

MAKE SURE WIRING FROM THERMO STAT LOCATION TO

REMOTE SENSOR LOCATION IS IN GOOD CONDITION.

ROOM T EMPERATURE IS NOT WHAT

IS EXPECTED ON WEEKENDS

THERMOSTAT TEMPER AT UR E

NEEDS TO BE ADJUSTED ON A

REGULAR BASIS

PROGRAM IS LOST DUE TO POWER

OUTAGE OR DISPLAY GOES BLANK

WHEN POWER IS TURNED OFF

DISPLAY FLASHES WHILE

PROGRAMMING

DISPLAY F LA SHES DURING

OPERATION

THERMOSTAT NOT PR O G RAMMED FOR

WEEKENDS

WARMER / COO LER KEYS BEING USED

TO ADJUST TEMPERATURE

BATTERI ES ARE INCOR RECTLY INSTALLED REMO VE AND REPLACE PER MARKINGS ON THERMOSTAT.

BATTERI ES ARE DEAD REPLACE BATTERI ES.

IMPROPER PROG RAM SEQUENCE

AUTOMATIC CHANGEOVER THER MO STAT

HEATING OR COO LING T EMPERATURES

CAN NOT BE SET CLOSER THAN 3°F

PROGRAMMING HAS BEEN LOST BECAUSE OF

A POWER OUTAGE

REPRO G RAM FOR W EEKENDS PER INSTRUCTIONS.

REPRO G RAM THERMOSTAT TO MAKE PERMANENT