Honeywell TS8602A, T8602C, TS8602C, T8602B, T8602D Installation Instructions Manual

69-0309-9

T8602A,B,C,D and TS8602A,C

®

Chronotherm

III Fuel Saver Thermostats

INSTALLATION INSTRUCTIONS

APPLICATION

These thermostats provide energy saving control for

24 Vac conventional heating/cooling system or 750 mV

heating and 24 Vac cooling as indicated in Table 1.

Power is supplied for the device by three AA alkaline

batteries (included). This allows the thermostat to be compatible with all control applications.

Cycle rates are adjustable for heating.

The TS8602 current rating in heating is 0.1A at 750 mV.

The current rating on all other models is 1.6A maximum,

up to 30 Vac.

Adaptive Intelligent Recovery™/Conventional Recovery

selection screw is included on the back of the thermostat.

Fan operation switch is included on the back of some

T8602C models to select either independent or direct

thermostat control of the fan in heating.

12/24 hour clock conversion and °C/°F conversion are

available on some models only.

Table 1. Thermostat Models.

Stages Switching

Thermostat Heat Cool System Fan Application

T8602A 1 — — — Gas, oil or electric with independently

T8602B 1 — — ON-AUTO

T8602B 1 — HEAT-OFF —

T8602C 1 1 HEAT-OFF-COOL ON-AUTO

T8602D 1 1 HEAT-OFF-COOL-AUTO ON-AUTO

T8602C 1 1 HEAT-OFF-COOL ON-AUTO Fan operation in heating selectable for

TS8602A 1 — — — Millivolt heating system.

TS8602C

a

Available only in Canada.

a

1 1 HEAT-OFF-COOL ON-AUTO Millivolt heating and 24 Vac cooling

RECYCLING NOTICE

If this control is replacing a control that contains

mercury in a sealed tube, do

control in the trash. Contact your local waste

management authority for instructions regarding

recycling and the proper disposal of your old

control.

If you have any questions, call Honeywell Inc.

at 1-800-468-1502.

INSTALLATION

When Installing This Product…

1 Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2 Check the ratings given on the product to make sure

the product is suitable for your application.

3 Installer must be a trained, experienced service

technician.

4 After installation is complete, check out product

operation as provided in these instructions.

5 Allow thermostat to warm to room temperature

before operating.

controlled fan.

thermostat or independent control; with O

and B terminals for changeover control.

system.

not

place your old

®U.S. Registered Trademark

Copyright © 1995 Honeywell Inc. • • All Rights Reserved

X-XX UL

T8602A,B,C,D AND TS8602A,C Chronotherm

®

III FUEL SAVER THERMOSTATS

CAUTION

Disconnect power supply to prevent electrical

shock or equipment damage.

Location

Install thermostat and wallplate about 5 ft (1.5m) above the

floor in an area with good air circulation at room

temperature.

Do not install the thermostat where it can be affected by:

— drafts or dead spots behind doors, in corners, or

under cabinets.

— hot or cold air from ducts.

— radiant heat from sun or appliances.

— concealed pipes and chimneys.

— unheated (uncooled) areas such as an outside wall,

behind the thermostat.

If Replacing An Existing Thermostat

Turn off power to the thermostat at the furnace or boiler. A

two-transformer system can require turning off two

switches or disconnects. Remove any existing wallplate or

subbase from the wall. Write down the letter or number on

each wiring terminal, as the wire is removed, to avoid

miswiring later.

If New Installation

Run cable to the hole in the selected wall location, and pull

about 3 in. (76 mm) of wire through the opening. Colorcoded, 18 gauge thermostat cable with at least one

conductor for each wiring terminal is recommended.

Push excess wire back into the hole, and plug the hole

with nonhardening caulk, putty or insulation to prevent

drafts from affecting the thermostat operation.

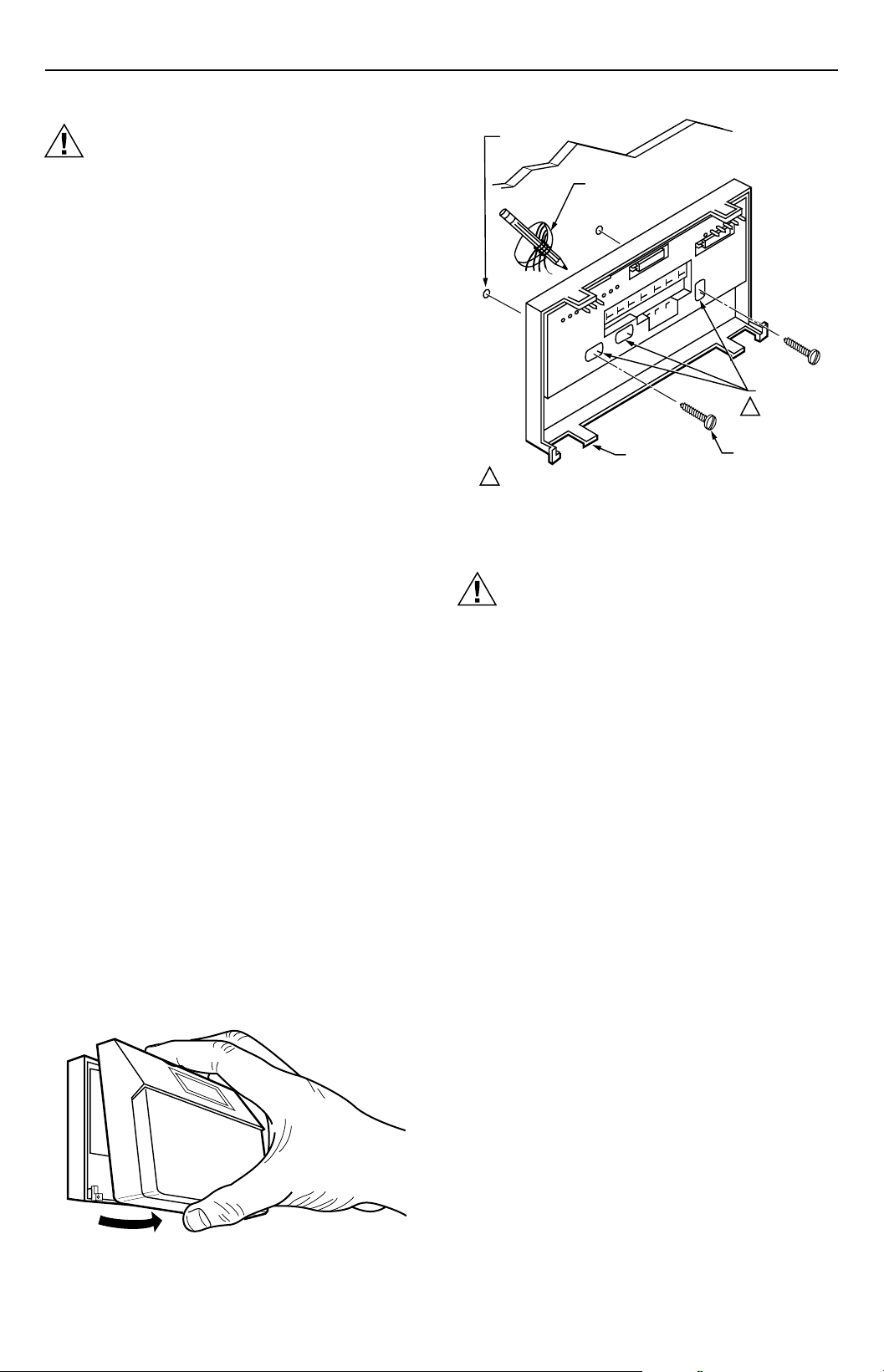

Mounting Wallplate

Remove thermostat from wallplate. See Fig. 1.

The wallplate does not require leveling for operation, but

for appearance only. The wallplate mounts directly onto

the wall with the screws included. Using the wallplate as a

template, with a pencil, mark two (of three) mounting

screw positions on the wallplate that fit the application. See

Fig. 2. Use a 3/16 in. bit to drill holes for the anchors.

Gently tap anchors into the holes until flush with the wall

surface. Thread wires through the center opening of the

wallplate. Mount the wallplate using the two screws

provided. Gently tighten the screws, level the top surface

of the wallplate, and then securely tighten the screws.

WALL

ANCHORS

(2)

WIRES THROUGH

WALL OPENING

USE TWO MOUNTING HOLES THAT

1

BEST FIT APPLICATION.

WALL

WALLPLATE

MOUNTING

HOLES (3)

1

MOUNTING

SCREWS (2)

M2917

Fig. 2. Mounting wallplate on wall.

Wiring

CAUTION

The TS8602A,C can only be used on 750 mV

heating applications. The TS8602A,C will not

function properly on 250 mV, 500 mV or 24 Vac

heating applications.

All wiring must comply with local electrical codes and

ordinances.

Disconnect power before wiring to prevent electrical shock

or equipment damage.

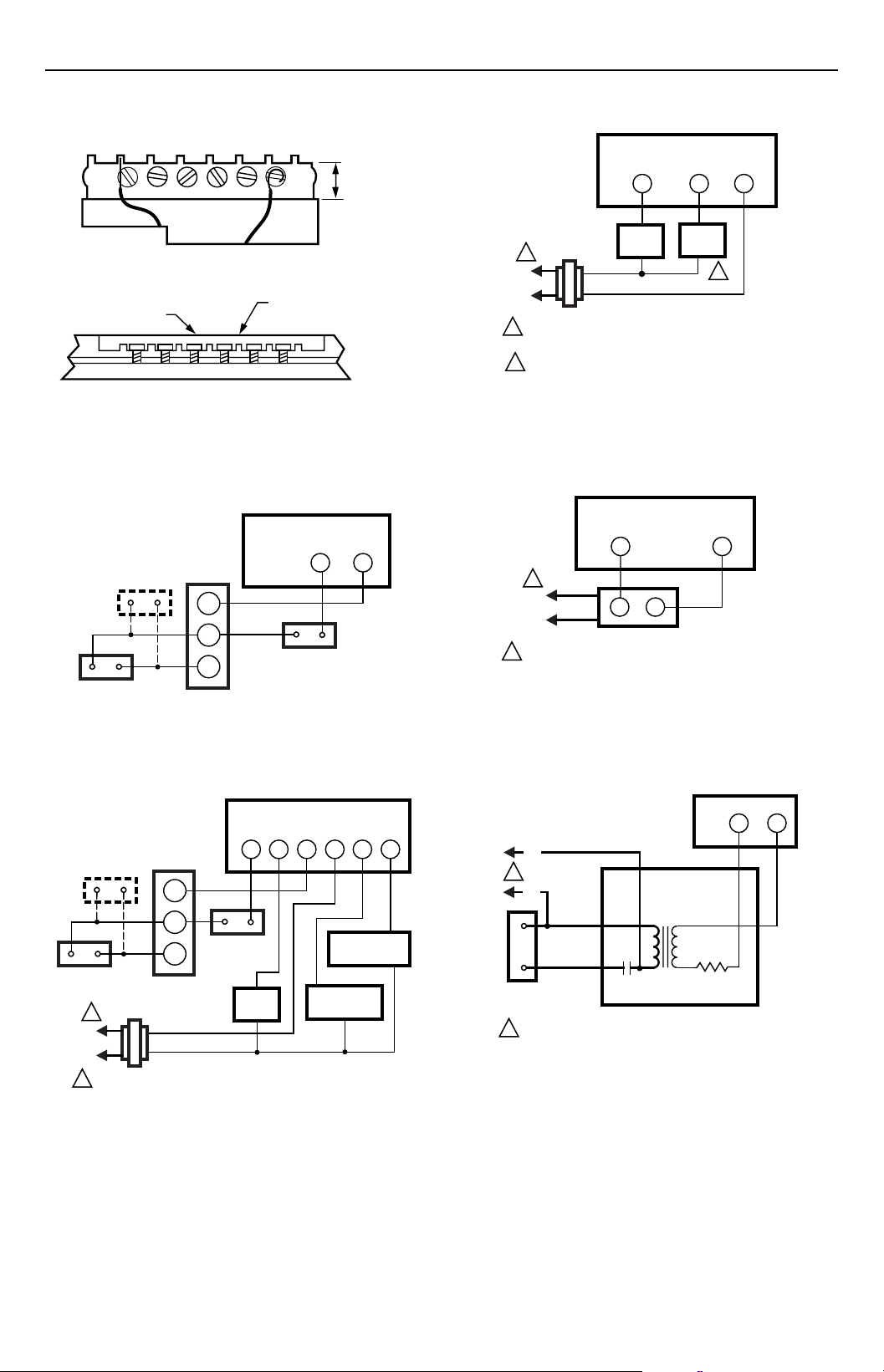

The shape of the terminal barrier permits insertion of

straight or conventional wraparound wiring connections.

Either method is acceptable.

Refer to Fig. 4 through 15 for typical wallplate and

thermostat hookups.

NOTE: • Keep all wiring restricted to the ribbed area

surrounding the terminals (Fig. 3) to assure

thermostat/wallplate contact.

• For single transformer applications, jumper

terminals R and RC for proper operation.

M2918

Fig. 1. Removing thermostat from wallplate.

69-0309—9 2

T8602A,B,C,D AND TS8602A,C Chronotherm

®

III FUEL SAVER THERMOSTATS

FOR STRAIGHT

INSERTION –

STRIP 5/16 in. (8 mm)

FOR WRAPAROUND –

STRIP 7/16 in. (11 mm)

RESTRICT

WIRING TO

THIS AREA

FRONT VIEW OF

TERMINAL AREA

WIRING TO BE BELOW

THIS SURFACE

TOP SURFACE

OF SUBBASE

CROSS-SECTIONAL VIEW OF

TERMINAL AREA

M2927

Fig. 3. Keep wiring restricted to the ribbed area

surrounding terminals.

MILLIVOLT HEATING-ONLY

WALLPLATE

PILOTSTAT

CONTROL

(IF USED)

MILLIVOLTAGE

GENERATOR

TH

TH/

PP

PP

MILLIVOLTAGE

GAS CONTROL

W

R

LIMIT

CONTROL

M2931

Fig. 4. TS8602 in typical millivoltage heating circuit.

HEATING-ONLY WALLPLATE

W

GAS

1

L2

L1

(HOT)

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

2

MODELS WITH ON-AUTO FAN SWITCH.

VALVE

G

FAN

RELAY

R

2

M2928

Fig. 6. T8602A,B heating-only circuit in a continuous

pilot gas system.

HEATING-ONLY WALLPLATE

W

1

L1

(HOT)

L2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

T

T

OIL PRIMARY

R

M2929

Fig. 7. T8602A,B heating-only circuit in an oil system.

MILLIVOLT HEATING-24Vac

COOLING WALLPLATE

PILOTSTAT

CONTROL

(IF USED)

TH

TH/

PP

LIMIT

PP

CONTROL

MILLIVOLTAGE

GENERATOR

1

L1

(HOT)

L2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

MILLIVOLTAGE

GAS CONTROL

FAN

RELAY

G

W

R

Y O

RC

CHANGEOVER

RELAY

COOLING

CONTACTOR

M2942

Fig. 5. TS8602C in typical millivoltage heating and

24 Vac cooling circuit.

HEATING ONLY WALLPLATE

R

W

BLACK

L1

(HOT)

1

L2

BLUE

RED

RESISTANCE

HEATER

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

BIMETAL

SWITCH

SWITCH

HEATER

RED

WHITE

R841C

M2923

Fig. 8. T8602A,B heating-only circuit in an electric

baseboard or ceiling cable system.

69-0309—93

T8602A,B,C,D AND TS8602A,C Chronotherm

®

III FUEL SAVER THERMOSTATS

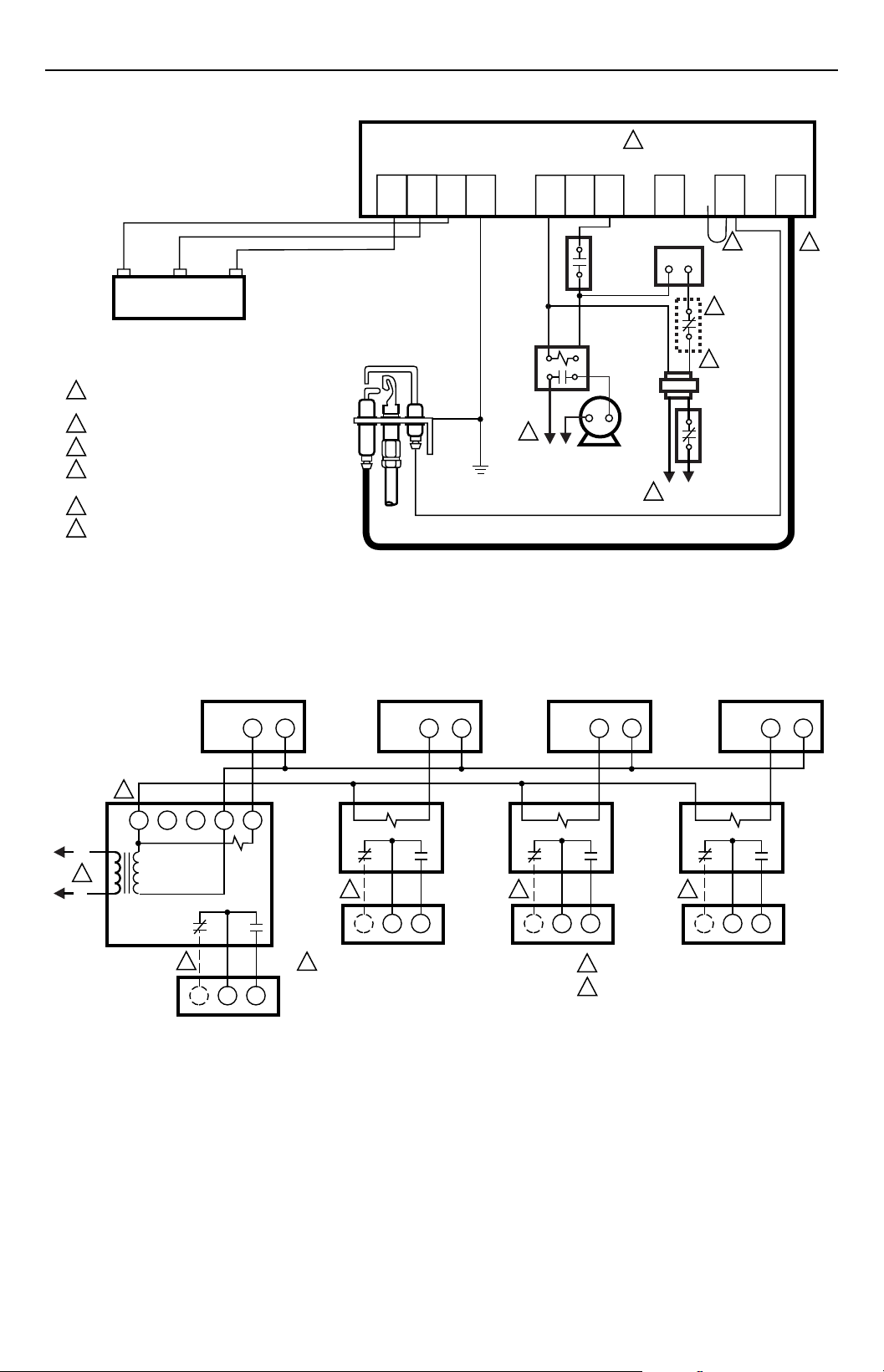

MV

DUAL VALVE COMBINATION

GAS CONTROL

POWER SUPPLY. PROVIDE DISCONNECT MEANS

1

AND OVERLOAD PROTECTION AS REQUIRED.

2

ALTERNATE LIMIT CONTROLLER LOCATION.

3

MAXIMUM CABLE LENGTH 3 FT (0.9M ).

4

CONTROLS IN 24V CIRCUIT MUST NOT BE

GROUND LEG TO TRANSFORMER.

5

LEAVE VENT DAMPER PLUG CONNECTED.

6

REMOVE JUMPER AND CONNECT SENSE

TERMINAL ON TWO ROD APPLICATION ONLY.

MV/PV

VR8345

MV

IGNITER

MV

MV/PV

PILOT GAS

SUPPLY

PV

SENSOR

GND

(BURNER)

PILOT

BURNER

GROUND

24V

GND

1

L1

(HOT)

CONTROLLER

S8610U

24V

L2

COMBUSTION

AIR BLOWER

MOTOR

5

TH-W

AIR

PROVING

SWITCH

COMBUSTION

AIR BLOWER

RELAY

VENT

DAMPER

PLUG

WR

L2

1

THERMOSTAT

4

LIMIT

CONTROLLER

L1

(HOT)

Fig. 9. T8602A,B heating-only circuit in a Honeywell Intermittent Pilot Gas Burner Ignition System.

SENSE

6

2

SPARK

3

M8600

L2

1

L1

(HOT)

2

R8239A1052

C

ZONE 1

VALVE OR

DAMPER

MOTOR

ZONE 1

HEATING ONLY WALLPLATE

W

RG

Y

W

3

R

ZONE 2

VALVE OR

DAMPER

MOTOR

ZONE 2

HEATING ONLY WALLPLATE

R

W

R8222B1067 R8222B1067

3 3 3

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

ZONE 3

VALVE OR

DAMPER

MOTOR

ZONE 3

HEATING ONLY WALLPLATE

2

3

ZONE 4

HEATING ONLY WALLPLATE

R

W

R8222B1067

ZONE 4

VALVE OR

DAMPER

MOTOR

USE ONE R8239 FOR EVERY FOUR ZONES.

USE FOR 3-WIRE ZONE VALVE OR DAMPER.

W

M2921

R

Fig. 10. T8602A,B circuit for controlling incompatible or three-wire zone valves or dampers. Heating or cooling

equipment is operated by an end switch on the zone valve or motor, or by a thermostat in a master zone.

69-0309—9 4

Loading...

Loading...