Honeywell SWW DATASHEET

24 I Flow monitors

SWW series

For monitoring flow of liquid and piped, gaseous media

max. 60 m

shielded cable 4

ASW 454

Technical data of sensor

General

The flow sensor in stainless steel 1.4571 is

suitable for lightly contamina

a

lso aggressive media provided the material is

compatible. Flows in gaseous media can also

be monitored with this sensor

Medium temperature 0…80

Higher medium temperatures (up to 120°C)

may cause a deviat

but cannot damage the sensor.

Temperature compensation up to 80°C

Sensor material

In contact with medium: stainless steel 1.4571

Casting compound: Wepuran (vu 4459/41 sv)

Cable gland: Nickel-plated brass

Max. permitted pressure 20 bar

Process connection G 1/4’’ or G 1/2’’

Connection cable four-core, 2.5 m long

Degree of protection IP 65

ted media, and

.

°C.

ion of the switching point

1.5 mm

x

2

T

he flow in fluids can be monitored reliably with

flow sensors SWF 62 and SWF 62 L and

evaluation unit ASW 454.

T

he sensitivity can be adjusted accurately with

a rough and fine potentiometer. The switching

state is indicated by LED. The sensor element

must be located in the flow.

SWF 62

i

Function

The flow monitors work according to the calorimetric principle. A thermistor is heated up. As heat is

withdrawn by the flowing medium, the thermistor resistance alters. The change in resistance is

evaluated. As the resistance also depends on the temperature of the medium, the difference must be

mined by a second thermistor. The difference is compensated and in this way the switching point

deter

is kept stable. When monitoring high flow rates, rapid temperature fluctuations can trigger switching

operations. Suspended materials adhering to the sensor can have an insulating effect and so affect

the measur

ement result and hence the defined switching point. Therefore it is advisable to remove any

dirt during routine maintenance operations.

Product Summary

Sensors Screw-in thread Sensor length (from thread) Thread length Type

G 1/4 25 mm 23 mm SWF 62

G 1/2

45 mm 18 mm SWF 62 L

Technical data of evaluation unit

Power supply

230

(see Product Summary)

Power consumption approx. 3 VA

Contact load

Relay, single pole

8 A, max. 250 VAC

Ambient temperature 0 - 60

Max.

Flow rate

0.1…3 m/s (liquid media) 1…15 m/s

(gaseous media)

Response time approx. 20 – 60 s

Repetition accuracy

2%, relative to the flow rate at the sensor.

<

Switching hysteresis

Approx. 2% of overall range.

Max.

aluation unit

ev

60 m,

Sensor protection

In case of breaka

sensor wires,

interruption of flo

Type of construction Standard housing N 45

Weight approx. 0.35 kg

VAC/DC

AC or 24

V

C

°

temperature gradient

cable length between sensor and

for shielded cable 1.5 mm

ge or interruption of the

the unit switches off or an

w is signaled.

10 K/min.

2

.

Evaluation units Supply voltage Type

230 V AC ASW 454

24 V AC/DC

i

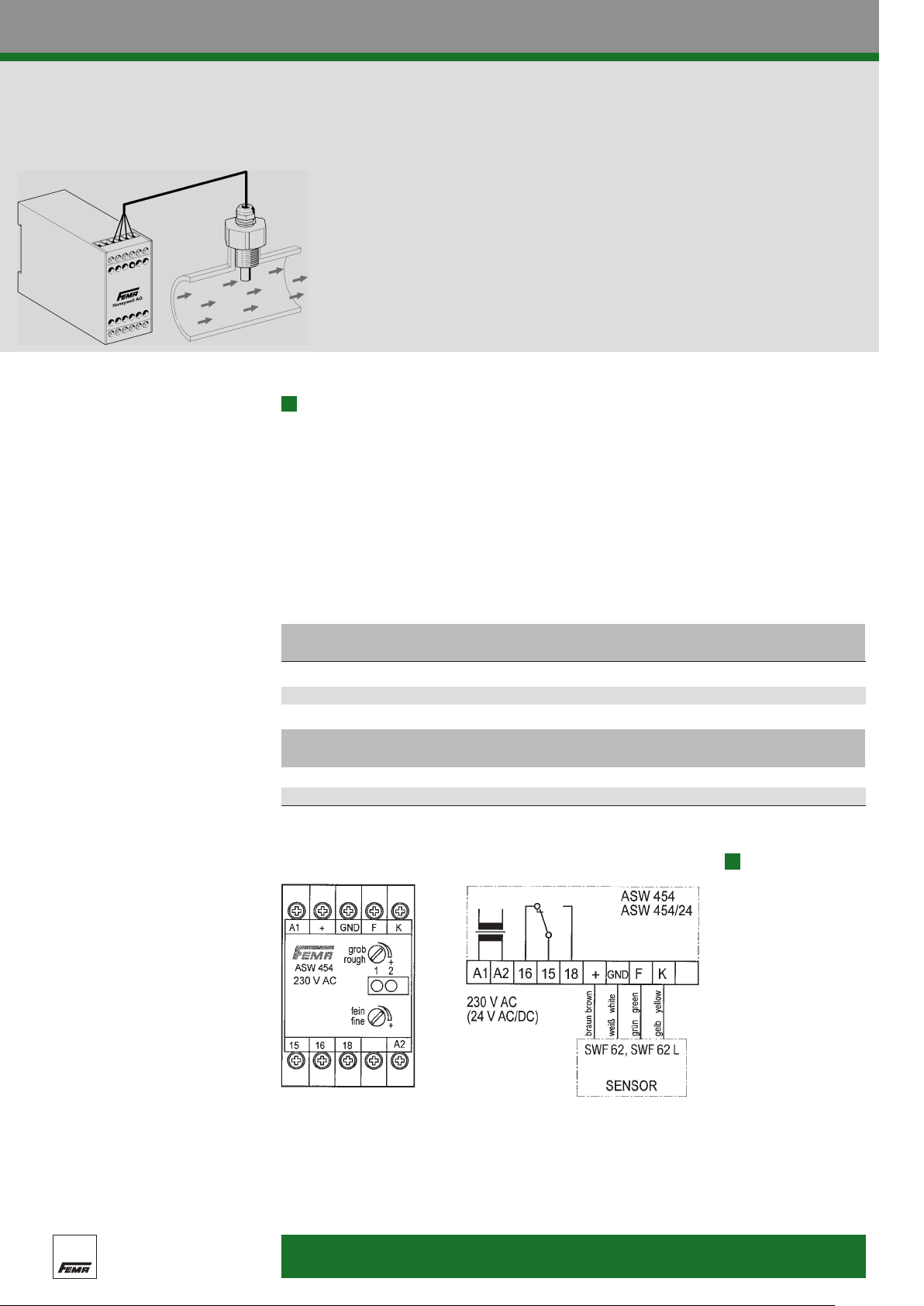

Operator interface Wiring diagram

Adjusting elements

Sensitivity (rough and fine)

In case of malfunction,

a sensor error can be ruled out

by checking the resistances

between the connecting wires

of the sensor

SWF62L must be disconnected

and checked with a suitable

ohmmeter between the

individual connecting wires:

White-bro

White-green approx. 1.0 kOhm

White-yellowapprox. 1.0 kOhm

The terminal voltage of the

evalua

ASW 454/24 can also be

checked with a voltmeter

between the

terminals after disconnecting

the sensor.

14.8 VDC is the correct value.

. Sensor SWF62 or

pprox.

a

wn

tion units

“+” and “Gnd”

(high sensitivity at low flow)

Signal lamps

1 = Flow present

2 = Supply voltage present

ASW 454/24

0.2 kOhm

ASW454 or

s

otection:

ee of pr

Degr

IP 65 (sensor)

IP 32 (evaluation unit)

Loading...

Loading...