26 I Flow monitors

Air flow monitoring

SWL series

Sensor for air ducts, evaluation unit for enclosed mounting

2

3 x 1.5

mm

max. 100 m shielded cable

ASL 453

Technical data of sensor

General

Fast-reacting air flow sensor with movable

flange for installa

t

emperature compensation, suitable for media

with rapid temperature changes.

Medium temperature -20…+100°C

Compensation behavior

(Reaction speed on change in medium

temperature) fast, approx. 0.3 s

Installation depth 35 mm

Sensor tube diameter 10 mm

Sensor tube material nickel-plated brass

Measuring element

Insensitive to moisture (can be cleaned in

water). Sensitive to mechanical deformation

(care must be taken when cleaning with hard

objects).

Degree of protection IP 32

Electrical connection

Terminal strip accessible after removal of

cover. 3-core connection to evaluation unit

tion in air ducts. With

The combination of air flow sensor SLF 3 and

e

valuation unit ASL 453 is suitable for air flow

monitoring in air-conditioning, ventilation and

flow processes must be detected in air or

n

eutral gases. Sensitivity is adjustable over

a wide range.

cooling installations and in any situation where

i

Function

The air flow monitors work according to the calorimetric principle. A thermistor is heated up. As heat

is withdrawn by the flowing air, the thermistor resistance alters. The change in resistance is evaluated.

As the resistance also depends on the temperature of the medium, the difference must be determined

by a second ther

mistor. The difference is compensated and in this way the switching point is kept

stable.

Suspended materials adhering to the sensor can have an insulating effect and so affect the

ement result and hence the defined switching point. Therefore it is advisable to remove any dirt

measur

during routine maintenance operations.

Switch-on bypass

While the plant is being started up (still no airflow present), the output contact is activated and the flow

condition signaled. The time for the switch-on bypass is adjustable from 2-60 s. The start-up or

switch-on bypass starts when the unit is switched on. If an external start button (normally closed

contact) is connected (to the Z-Z terminals), the start-up bypass begins when the (locking) button is

pressed.

Product Summary

Supply voltage

Type

Technical data of evaluation unit

Power supply

230 VAC or 24 VAC/DC

(see Product Summary)

Power consumption approx. 3 VA

Contact load

single pole 8 A, max. 250 VAC

,

Relay

C

Ambient temperature 0 – 60

Flow rate

Adjustable from 0.1 to 20 m/s for gaseous

media

Response time approx. 1 s

Repetition accuracy

relative to the flow rate directly on the

<2%,

sensor.

Switching hysteresis approx. 2% of overall

range

cable length between sensor and

Max.

aluation unit

ev

100 m, for shielded cable 1.5 mm2.

Sensor protection

In case of breaka

sensor wires,

interruption of flow is signaled.

Type of construction Standard housing N 45

Weight approx. 0.35 kg

ge or interruption of the

the unit s

°

witches off or an

Sensor

–

SLF 3

Evaluation unit 230 VAC ASL 453

24 V AC/DC ASL 453/24

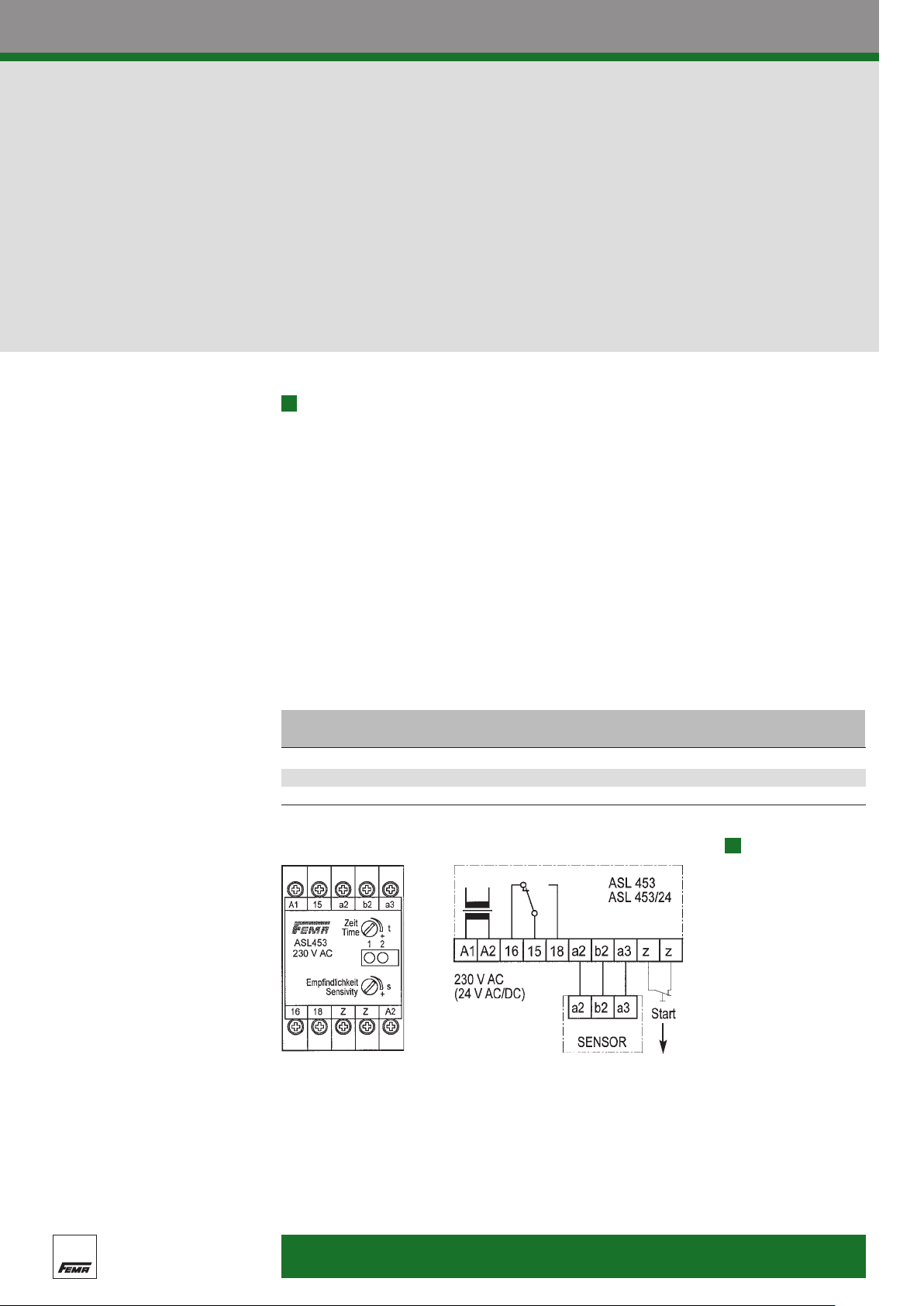

Operator interface Wiring diagram

with

locking

button

Adjusting elements

s = sensitivity

t

= time for switch-on bypass

(high sensitivity at low flow)

Signal lamps

1 = Flow present or switch-on bypass active

2

= supply voltage pr

esent

i

In case of malfunction,

a sensor error can be ruled out

by checking the resistances

between the connecting wires.

Sensor SLF 3 must be

disconnected and checked with

a suitable ohmmeter between

the individual connecting wires:

Black-brownapprox. 8.2 kOhm

Black-blue approx. 8.2 kOhm

Brown-blue approx. 18 kOhm

The terminal volta

evaluation units ASW454 or

ASW 454/24 can also be

checked with a voltmeter

between the “a2” and “a3”

terminals after disconnecting

the sensor.

31.4 VDC is the correct value.

ge of

s

Degree of protection:

IP 32 (sensor)

IP 65 (evaluation unit)

Loading...

Loading...